Journal of the Association for Petroleum and Explosives Administration

Opinions expressed in this Journal are not necessarily the views of the Association

Opinions expressed in this Journal are not necessarily the views of the Association

This column is frequently used to draw attention to the many problems of road tankers delivering petrol to petrol filling stations, and has long campaigned for action by the HSE and Industry.

Esso Petroleum during 1988 completed one of the most comprehensive exercises in safety training on petrol deliveries to the fore-court ever seen in the Industry.

All their licensees, operators and dealers were invited to safety seminars involving deliveries, and local petroleum officers were often involved. In addition a comprehensive booklet was produced to give further guidance to the operators staff.

The high profile Esso placed on this subject is recognised the increased awareness of their operators will do much to increase public safety. Well done.

New regulations governing the transport of explosives, due to become law in July, might have prevented the death of a fireman and injury to more than 50 people recently.

A Ford Cargo owned by ICI subsidiary Nobel Explosives caught fire and exploded in Peterborough. The 800 kg load of detonators, fuseheads and nitroglycerine-based commercial explosives was destined for firework makers and quarries.

The Fire Brigade is angry that under current law the 1875 Explosives Act and its 1924 amendment such vehicles are not required to carry warning labels.

New rules, the Road Traffic (Carriage of Explosives) Regulations, already have ministerial approval, and pressure is being brought in Westminster to speed their progress through Parliament.

The regulations will bring the transport of explosives into line with other types of dangerous goods: vehicles will have to be clearly labelled; drivers will have to be trained; and written instructions on the nature of explosive loads will have to be carried in the cab.

The present law lays down detailed requirements for the construction and equipment of vehicles carrying explosives, but the only restriction on the load is that there is a maximum limit of five tonnes. Operators feared that marked loads would alert criminals.

MPs are now calling for further changes to the law to include compulsory notification of routes to the police and stricter limits on the amount of explosive material which can be carried in one vehicle.

(Source: Motor Transport, 29th March 1989)

T?ere .is an error on page 12 Licensing Authorities. The Licensmg Authority for Buckinghamshire should read:-

The harmonization work involved identifying differences between ADR and British legislation, evaluating the safety principles, and considering how best ADR be incorporated into British legislation so as to s1mphfy compliance and enforcement.

Health and Safety Executive working groups are consider classification, packaging and labelling and. report to the HSC by mid-1989. Revisions to ex1stmg regulations will subsequently be drafted.

This action follows a report, Transport of Dangerous Goods and Waste Final Report from the Commission, by the Commission of the European Community (CEC) m June 1987. The CEC also indicated that it would make proposals to the Council of Ministers for four directives on various aspects of the transport of dangerous substances. These covered the acceptance by Member States of vehicles conforming to ADR, the training of drivers and transport managers, and the enforcement of regulations.

On the 22nd February 1989 I received a call-out from Mrs Jones of Park House. She reported a strong smell of petrol in the downstairs toilet.

On the 9th March while in the area I called at Park House and spoke to Mr Jones' mother and father. I enquired whether they were still getting a smell of petrol from the toilet, they said they were not, but were able to throw some light on the cause of the petroleum smell of the 22nd February 1989.

Park House is semi-detached, Mr and Mrs Jones' next door neighbours are Mr and Mrs Maloney. Mr Maloney carries out car repairs from these premises. In the Maloney's garden is a well which is situated close to the house, so close in fact that Mr Maloney has built a kitchen extension halfway across the well opening. The old well has been with rubble and general rubbish including the believe petrol cans or old oil cans that at one time contamed petrol.

When, on the 22nd February 1989 I had spoken to Mr Maloney he could offer no explanation for the smell of petrol next door, however, on the following Saturday the 25th February, he could smell petrol in his property, he could also hear the sound of running water.

Mr Maloney called a plumber who discovered that there was a significant leak from the main water supply to the Maloney's home, this water had filled the well and contaminated water was causing the smell in the Jones and Maloney's home.

The Health and Safety Commission (HSCJ have outlined a programme of harmonizing British legislation on the transpo_rt of dangerous substances by road with that of the rest of the European Community, based on the ADR (European Agreement concerning the International Carriage of Dangerous Goods by Road).

The UK regulations being considered are the: Dangerous Suhstance.1· (Com·eyance hv Road in Road and Tank Container.1· J Regulatir;n.1· 1981. Conveyance provisions of the Classification. Packaging and f,ahe!ling nf Dangerous Suhstw1ce.1. Regulations 1984. Road Tmfti1· !Carriage of' Oangemus Suhstances in P11clwge.1 etc i Reg1ilatio11.1

These regulations are often referred to as the 'Road Tanker Regu Iat ions·. the 'CPL Regulations' or the ·Packaged Goods Regulations·

The mains water supply leak has now been repaired. Mr Jones has repaired the outer wall of his toilet and the water level of the well has dissipated. At present there is no smell of petroleum at Park House.

Three railway cars carrying 120 tonnes of indusu:ial explosives blew up at a railway station. The massive explosion resulted in the deaths of eighty people with 700 injured. Railcars and automobiles were hurled through the air and the blast left a crater 28 m deep and 58 m wide. The explosion completely destroyed 150 houses and damaged a further 250. Preliminary investigations showed that there were no violations of regulations and the cargo was handled and carried in accordance with instructions. The locomotive was in good repair. It was thought that very hot weather may have caused the explosion.

County Fire & Rescue Officer Buckinghamshire Fire & Rescue ServiceA 59 million litre tank exploded at this petrol supply plant killing two people and seriously injuring sixteen others. Over ten thousand people were forced to evacuate their homes as two other storage tanks became involved. The explosion was thought to have occurred during the filling of the large tank. There was spillage of petrol which flowed to an area where soldering was being carried out. The spillage was ignited and flashed back to the large tank. Three hundred firemen assisted by the armed forces fought the blaze for 20 hours before it was extinguished using dry chemicals.

This Guidance Note has been prepared by the Institute of Petroleum Marketing Conveyance Panel and is complementary to the Institute's Code of Practice for Road Tank Vehicles Equipped for Bottom Loading and Vapour Recovery.

Amendments to the Guidance Note will be issued by the Institute as considered necessary and users are invited to send comments or suggestions for improvement to the Secretary, Marketing Conveyance Panel, Institute of Petroleum, 6 I New Cavendish Street, London WI M 8AR

Although it is believed that adoption of the recommendations of this Guidance Note will help to reduce the risk of an incident, the Institute of Petroleum cannot accept any responsibility, of whatever kind, for damage or alleged damage arising, or otherwise occurring as a result of applying the guidance contained in this document.

AVAILABLE ONLY FROM:

The Institute of Petroleum PRICE: £7.00 (UK and Europe) £10.00 (Overseas)

This Code of Practice describes a system for use m _t e storage and handling of petroleum products ondl 1 II mainstream re me refinery process plants. t covers a . . F I h"ch are covered by the Products except A v1at1on ue s. w 1 · !S4? "Airport American Petroleum Institute Bulletm ·f· · " 4th Ed1t1on Equipment Marking for Fuel Ident1 1cat1on · April I 986, and Solvents for which separate stand'.lfds exist. R . I b . . o·11s 'ire given. No ecommendat10ns for u ncatmg · ' recommendation is made for LPGs at this time.

This Code describes a standard method of identifying according to the products handled in. order to assist in the prevention of accidental mixmg and contamination of product.

!he risk of such mixing occurs at product transfer durmg the loading and unloading of road tankers. The principal. purpose of this Code is to identify equipment at these pomts, although it is intended to apply to all product storage and handling systems.

Brand names alone are insufficient to identify adequately the individual product grades since similar names are frequently used for dissimilar products by different marketing companies.

Products and grades of product are identified by a combination of colour and symbol or shape. Provision is made for the inclusion of brand-names but these are subsidiary to the colour/symbol system. As an exception, the use of the word "unleaded" to identify all grades of unleaded gasoline is a requirement of the system.

The product identification system may be apphed to equipment by means of: self-adhesive tape paint stencils labels or signs in suitable material plastic or metal tags of the same shape as the appropnate symbol colouring of flexible hoses used m such apphcat10ns as the bottom-loading of vehicles or vapour-return lines other suitable means

All personnel who handle be trained in and familiar with the product 1dent1ficat10n system. An illustrated colour card is available from the Institute of Petroleum and an example is included with this Code. AVAILABLE

will be in existence shortly. However we can't leave it all to the long suffering committee members, we need your support and assistance to carry it forward. Names a_nd addresses of the committee members and Branch Secretaries are published in the bulletin so please contact them.

My second aim is the promotion of UK standards. As you are aware the first part of BS7 I 17 was recently published and will be followed (shortly we hope) by parts two and three. This is the first time we have had a British Standard covering pumps and dispensers for liquid fuels and it means we have a unifollll set of rules that everyone can work to. With 1992 only three years away we must now try to get these standards adopted in Europe so that we can avoid further changes in only a few years. Formulating the standards was the first step but we will have a much better chance of getting them adopted if the UK can show that v:e are (a) using them and (b) they actually work. To do this, all parts of the industry, from the manufacturers to the regulatory authorities, need to adopt BS7 I 17 at the first possible opportunity . The APEA will be providing further guidance and working with the other parties to promote Standards but we ned feedback from you about the benefits and the problems that the Standards provide.

Please let us have your views!

C. G. Knight

At the AGM on 11.4.89 I wa s elected as Chairman of your organi sation A s I said at the meeting , in echoing our outgomg chairman 's word s , it is indeed a privilege and an honour to be able to serve the APEA in this capacity after s uch a s hort period of member s hip.

Ma ny of you may be a s king yourselve s who your new chairman is My name is Knight , I' m 34 years old , married · h · . , wn a 2 year old daughter. I'm the Managmg Director of Permex Ltd , fluid handling engineers, and a director of El fl L a ex td , s uppl 1ers of no zzle s and component s _tlie pump indu s try. B y tr a inin g I'm a phy s ici st with a pa1t1 cular intere s t in e ng ine e ring

Thi s ye a r, o ur fir s t full ye ar as a company limited by g uar '1ntee · · c , p1 o m1 s es to be ex c itin g There is a lot of chan ge g o in g o n in th e indu s try parti c ularl y with the Lead-free ca mpai g n, and thi s me an s a lo t o f wo rk for all c oncerned. M y aim s as C h a in11an are t wo fold: M y fir s t is to · d · · · co ntrnu e Ro el Kit c hin gs campai g n to exp a n th e m e mb e rs hip a nd to in c re a se me mber s involv e me nt with t h e A P EA. A n o rg a ni s ati o n lik e o urs is ci e pe ncl e nt o n it s m e mb e rs bo th to s upp o rt it s e ffort s a nd to kee p o th e r awa re of th e d eve lo pm e nt s . Yo ur co mmittee ha s rna n a g e d l o res ta rt br a nc h m ee tin g s in th e Eas te rn are a a nd <1L t1 ve 111 th e So wh e rn an d Micil a nd s are as to ge t th ese g o in g ag a in A S c o tti s h br a nc h a ncl a No rth e rn Ire la ncl bra nc h

The Association welcomes the following new membersPaul William Gunn Russell Henry Parker tRobert Michael Conlin Francis Gilleece Mr Colin Reid Trevor Martin BSc (Hons), BA, MIAS Alexander Ross Micrelec pie R. C. Lively David Mawer

By The Editor

By The Editor

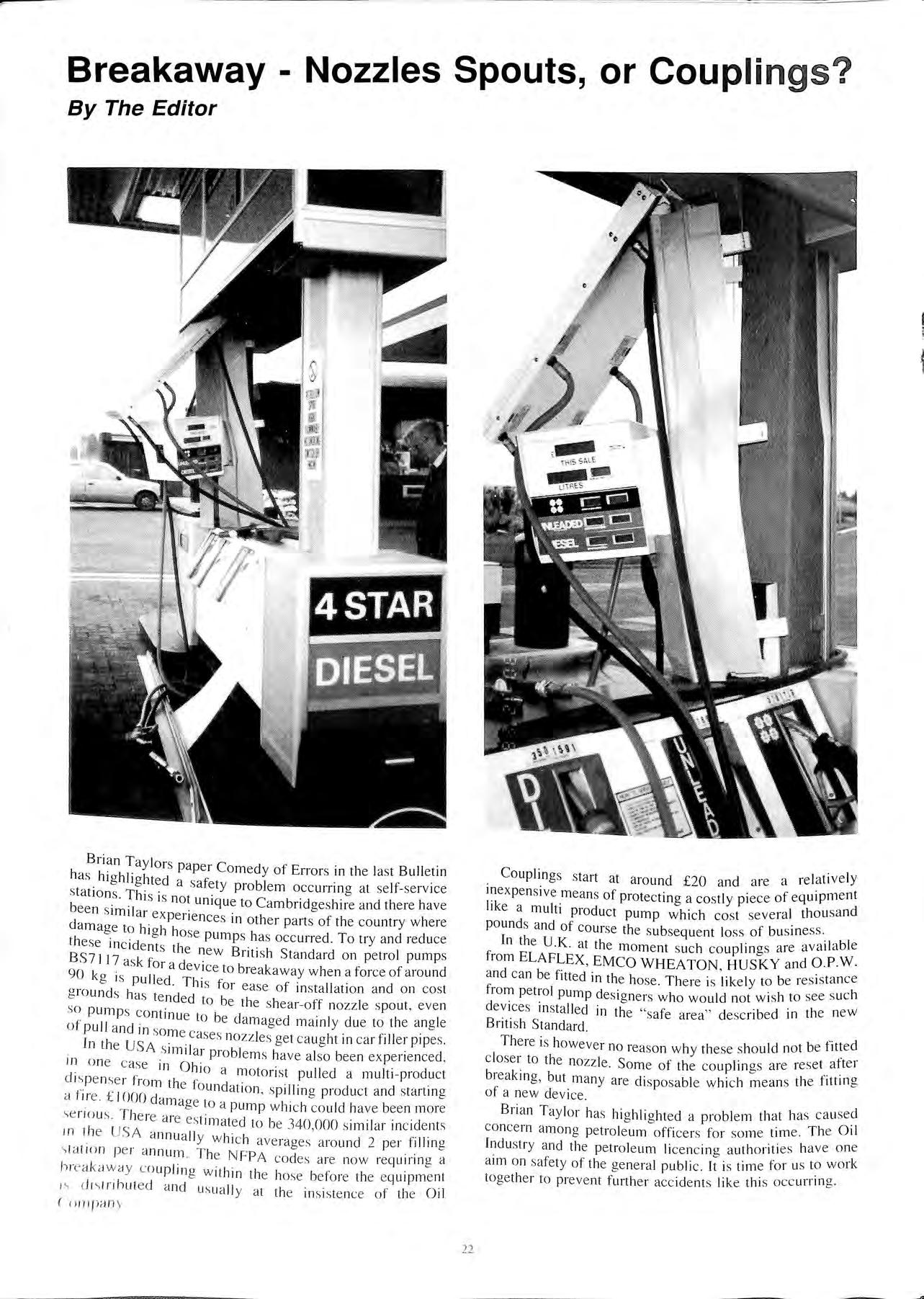

Brian Taylors pap e r Comedy of Errors in th e las t Bull e tin ha s hi g hlight ed a safety problem occurrina at se lf-service sta tion_s Thi s is not uniqu e to Ca mbrid ges hi;e and there hav e been s imilar ex perience s in other pai1 s of the country where damage to hi g h ho se pump s ha s occ urred. To tr y and reduce the se lll c 1d e nt s th e new British Standard on pe trol pumps BS7 I l 7 ask for a device to breakaway w hen a force of aro und 90 kg is pull ed. Thi s fo r ease of in stallation and on cost g rounds ha s tended to be th e s hear -o ff nozz le s pout , eve n so pump s co ntinu e lo be damaged ma inl y due to th e angle of pull a nd 111 so m e cases nozzle s get ca ug ht in car fill er pipes. . In the USA s imil a r problems ha ve a lso been ex pe ri e nced , lll one case in O hi o a moto ri s t pulled a multi -p roduct from the fo und at ion . sp illi ng produ c t and sta rtin g a tire. f IOOO da ma ge to a pump which co uld hav e been more se riou s. There are es tim ated to be 340 ,000 s imil ar in c id e nt s in rh e USA ann ua ll y w hi c h averages around 2 per fi llin g -., 1a t1on pe r ann um. T he NF PA co des are now requiring a h re akaway co uplin g w ithin th e hose before th e equipment I '> cJ1 .., 1rihu1 e d a nd usu a ll y al the in s is tence of the Oi l ( (impan)

Couplings start at aro und £20 and are a rel ative ly ' . t 111expen s1ve mean s of protecting a costly pi ece of equipmen like a multi product pump which cost se veral thousand pound s and of course th e s ub sequent lo ss of bu s ine ss

In the U.K. at the moment s uch couplings are availab le from ELAFLEX, EMCO WHEATON, HUSKY and 0.P.W. and can be fitted in the ho se. There is likely to be res istanc e from petrol pump des ign e rs who would not wish to see such devices in stall ed in th e "sa fe area " de sc ribed in th e new Br iti sh Standard.

There is howeve r no rea so n why the se s hould not be fitted _ closer to th e no zz le. Some of the coup !in gs are re se t __ aftei breakin g, but man y are disposab le w hi c h mean s the fittin g of a new dev ice

Brian Ta y lo r ha s hi g hli g ht ed a probl em that ha s ca used co nc e rn among petro le um officer s fo r so me tim e. The Oil Indu st ry and the petroleum li ce nc in g author iti es have one aim on safety of the ge nera l pub li c It is time for us to work together to prevent furth e r acc ident s lik e this occ urrin g.

I am writing to you with a query which may be suitable for inclusion in the Bulletin, in the hope that it may bring some replies or discussions from other members.

Following an incident at a petrol filling station in this County where a spillage resulted in spirit escaping from the forecourt and flowing down a sloping street in a town, this Authority is reviewing its policy on petrol interceptors. All retail sites will be required to 'have interceptors within the next few years, with priority being given to sites where there is a paiticular hazard, such as being on a gradient.

In common with a number of other licencing authorities, we require interceptors which are sufficiently large to contain the contents of the largest compartment of a road tanker.

The drainage channels on a forecourt which feed the interceptor appear to be of two types, as shown in the photographs. The Safticurb type is of concrete section with a 2" slot in the top, whilst the second is of U-Section with the open top covered by cast-iron grilles.

In the case of a large spillage, I am led to wonder how well these would cope with the flow of spirit. It would appear that the iron-grille type may have advantages, particularly on a sloping site, and I would welcome the comments of anyone who has any experience on this.

Yours sincerely, C. Day Divisional Trading Standards Officer

It has come to the attention of several members in The Eastern Branch that Architects are confused with the varying licensing requirements for car parks of different Local Authorities. Most Di s trict Councils Planning Authorities now insist on the provision of parking facilities on all new office and residential development s With the price of land bemg at a premium most car parking facilities are now bemg built below ground, basement or sub-basement.

Bearing the above _in mind, it wa s proposed and agreed at the last A.P E.A. Eastern Branch Meeting to set up a working party to investigate the licensing for car parks. I would be most grateful if any member from any other branches who has any information which may help the "working paity" to contact me:

Robin Gre en , Secretary Eastern Branch ,Dear Editor.

Unleaded Petrol and the recent waiver given by NWML.

I notice that the National Weights and Measures Laboratory have given a waiver for 12 months on the use of blender pumps to be converted to provide two grades of petrol, leaded and unleaded from the same nozzle.

In the area I am responsible for there are numerous US air force bases, and the personnel drive cars which can only be used with the small unleaded nozzle. There have been several incidents of spillages and problems created by members of the public trying to fill cars where the nozzle will not fit. The problem has produced a flourish of nozzle spout extensions (see photographs). I will no doubt be informed that this does not conform to the British Standard BS7!17.

I am sure that I have not the only area of the country where this happens, and a number of cars coming from Europe on holiday with catalytic convertors will also be affected. Is there not a case therefore for the NWML to contact the APEA to discuss these important safety points before making decisions which is causing safety problems in this area of the country.

Yours faithfully

Rod Jones Suffolk County Council

Dear Editor. A.P.E.A.

Ref: LETTER FROM CHIEF FIRE OFFICER J. A. ROBINSON.

Volume 27 Issue No. 1.

fillThe proble.m which Mr Robinson has raised concerning pipes which have worked loose and dropped into the tank, has happened many times , usually on tank s with a d1rect fill and metal diprod s .

When an operator takes a tank dip, they quite often bend the di prod slightly to see the reading , at the same time turning the rod mto the light. Thi s ha s the effect of digging the end of the rod mto the aluminium internal fill & screwing it out.

Mo st tank lids have a threaded bo ss welded into them , with a Fill Pipe sc rewed in from the top , and an internal fill screwed Ill from the bottom. With this kind of in s tallation , the los s of an internal fill us ually means the lid ha s to be taken off to replace it. However , it is now po ss ible to buy an adaptor with an internal fill fixed to it which can be inserted from the top without lid removal and the need to Re-pre ss ure te s t the tank.

On Monday, 27th February, 1989 a 2 ,000 gallon underground petrol tank which had been installed pr ior to 1974 , exploded whilst being made -s afe at Chatteris, Cambridgeshire

The incident which occurred at about 2.1 Spm did not cause any injury to persons working on the site.

The full facts of this incident cannot be reported due to being investigated by the Health and Safe ty.

The exposure of the tank revealed that it was of a square construction with internal metal braces for support and wa s installed within a brick chamber back-filled with sand.

The resultant explosion burst an underground water main to the premises and it was thought that a 12" gas main may also have been damaged.

The Gas Board were asked to attend and whilst the gas engineers were working , one was struck by a passing heavy goods vehicle. The engineer was taken to hospital and was seriously ill with head injuries.

The accompanying two photos show the tank both in the ground and above ground after being exposed .

There have been numerous stories in the press and on television recently alleging that unleaded petrol is more difficult to extinguish than leaded. The stories appear to stem from an extinguisher manufacturer who claimed that standard foam would not deal effectively with the high alcohol content of unleaded petrol. There have even been claims that BCF is not effective. This indicates that different free radicals are released during an unleaded petrol fire than during a leaded fire. I have now witnessed and carried out a number of tests on both leaded and unleaded petrol tray fires to BS 5423: 1987. The extinguishing media has included protein foam, high-ex foam, AFFF and dry powder. With each, there was no discernible difference in a comparative test between leaded and unleaded petrol fires; there were, of course, differences between the extinguishing times and effectiveness of the extinguishing media used. In some tests the unleaded fire was extinguished quicker than the leaded not what one had been led to believe.

It is worth considering the two types of petrol and their chemical compositions.

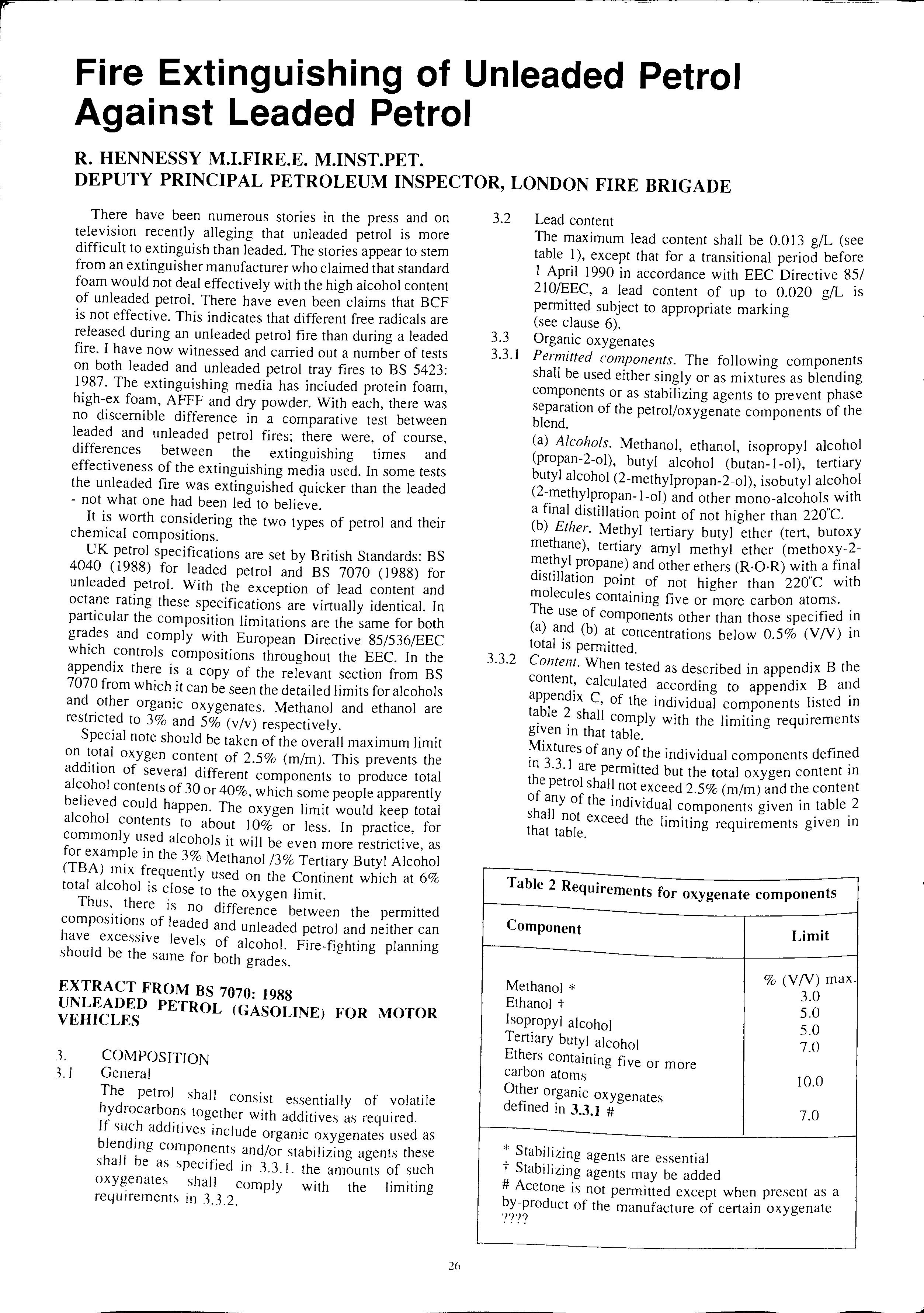

UK petrol specifications are set by British Standards: BS 4040 (1988) for leaded petrol and BS 7070 (1988) for unleaded petrol. With the exception of lead content and octane rating these specifications are virtually identical. In particular the composition limitations are the same for both grades and comply with European Directive 85/536/EEC which controls compositions throughout the EEC. In the appendix there is a copy of the relevant section from BS 7070 from which it can be seen the detailed limits for alcohols and other organic oxygenates. Methanol and ethanol are restricted to 3% and 5% (v/v) respectively.

Special note should be taken of the overall maximum limit on total oxygen content of 2.5% (m/m). This prevents the addition of several different components to produce total alcohol contents of 30 or 40%, which some people apparently believed could happen. The oxygen limit would keep total alcohol contents to about I 0% or Jess. In practice, for commonly used alcohols it will be even more restrictive, as for example in the 3% Methanol /3% Tertiary Butyl Alcohol (TBA) mix frequently used on the Continent which at 6% total alcohol is close to the oxygen limit.

Thus._ . there is no difference between the permitted of leaded and unleaded petrol and neither can have excessive levels of alcohol. Fire-fighting planning should be the same for both grades.

EXTRACT FROM BS 7070: 1988

The petrol shall consist essentially of volatile hydrocarbons together with additives as required. If suc.h additives include organic oxygenates used as blending components and/or stabilizing agents these shall be as specified in 3.3.1. the amounts of such oxygenates shall comply with the limiting reyuirements in 3.3.2.

3.2 3.3 3.3.I

The maximum lead content shall be 0.013 g/L (see table I), except that for a transitional period before I April 1990 in accordance with EEC Directive 85/ 21 O/EEC, a lead content of up to 0.020 g/L is pennitted subject to appropriate marking (see clause 6).

Permitted components. The following components shall be used either singly or as mixtures as blending components or as stabilizing agents to prevent phase separation of the petrol/oxygenate components of the blend.

(a) Alcohols. Methanol, ethanol, isopropyl alcohol (propan-2-ol), butyl alcohol (butan-1-ol), tertiary butyl alcohol (2-methylpropan-2-ol), isobutyl alcohol (2-methylpropan-1-ol) and other mono-alcohols with a final distillation point of not higher than 220"C.

(b) Ether. Methyl tertiary butyl ether (tert, butoxy methane), tertiary amyl methyl ether (methoxy-2methyl propane) and other ethers (R·O·R) with a final distillation point of not higher than 220"C with molecules containing five or more carbon atoms. The use of components other than those specified in (a) and (b) at concentrations below 0.5% (VN) in total is pennitted.

3.3.2

Content. When tested as described in appendix B the content: calculated according to appendix B appendix C, of the individual components listed m shall comply with the limiting requirements given m that table.

of any of the individual components m 3.3.1 are permitted but the total oxygen content m the petrol shall not exceed 2.5% (m/m) and the content of any of the individual components given in table. 2 shall not exceed the limiting requirements given m that table.

The specifications discussed above set the upper limits of oxygenate components and hence establish the basis for fire-fighting planning. However, it is worth noting that at the present time there is no use of alcohols in UK petrol blending nor of any intention to make significant use of them in the future. Only low levels of other oxygenates (e.g. the ethers MTBE and TAME) are being used, in both leaded and unleaded petrol, and fires containing these materials do not add to the difficulty of extinguishment.

Alcohols, being hydroscopic, are not likely to be preferred in the UK because water present in our coastal distribution systems tends to be absorbed by the alcohol and to put the gasoline off specification.

It is acknowledged that if large quantities of alcohol blendstocks were permitted they would render a petrol fire more difficult to extinguish. However, for alcohol contents up to I 0% the difference is not significant.

Oxygenates have been widely used in other countries. In particular, Germany has had 3% Methanol /3% TBA blends for several years. They use fluoroprotein foam with no problems and no change in application rates.

It is therefore hoped that the above clarifies and redresses some of the unfounded stories being publicised at the moment. I would stress that when carrying out any scientific test, attention to repeatability, consistency and exclusion of experimental anomalies must be ensured for the tests to be valid.

To summarise, therefore, it should be noted that:-

1. There are no differences in the British Standard composition specifications for unleaded and leaded petrols.

2. The total oxygen limit would restrict any alcohol content to about 10% and in practice normally less.

3. At the present time, no alcohols are being used in UK petrol blends and ethers are only being used at low levels.

4. Ordinary protein foams are not recommended for petrol fires. Oil experts normally recommend fluoroprotein or AFFF foams for petrols, including those with up to 10% oxygenates. Alcohol-resistant foams should be considered for blend components and other stocks with high oxygenate levels.

5. With the current application rate of fluoroprotein foam there are no significant differences between the firefighting characteristics of UK petrols without oxygenates and those containing up to the permitted levels.

6. Dry powder extinguishers are very effective for fires on petrol station forecourts.

7. No extra extinguisher requirements should be attached to the marketing of unleaded petrol.

However, during all the debate about leaded and unleaded, we should not lose sight of the fact that any petrol fire can be difficult to extinguish. Petrol is a highly flammable liquid and we as Petroleum Officers, together with industry, must try to ensure that the likelihood of fire is minimised.

Minutes of the Yorkshire and Humberside Branch of the Association for Petroleum and Explosives Administration Held on 20th April 1989 at the Red Hart, Blyth, Nottinghamshire

Mr Clive Sweeting, Chairman, extended a cordial greeting to 38 members and guests, to the Spring and Annual General Meeting of the Branch.

Following the welcome a presentation of a tankard, suitably engraved, was made to Mr.· Rodney Kitching as a token of appreciation for his sterling work as secretary of the branch for the past 11 years.

The minutes of the meeting held on I 8th October 1988 were read and agreed as a true record and signed by the Chairman. There were no matters arising.

Apologies were received from nine members.

The Treasurer reported that expenditure over the last year had been £124.20 and the balance of the current account stood at £149.10.

There having been no opposing nominations the existing officers were re-elected as follows:

Clive Sweeting as Chairman

Colin Horsburgh as Secretary

Eric Dean as Treasurer

Mr Chris Knight the National Chairman addressed the meeting and spoke of his aims during his year of office. He

wished to continue the drive on branches and said that there had been a re-start of the Eastern Branch and that moves in relation to the Southern and Midland branches were taking place. He was hopeful of the Scottish and Northern Ireland branches starting up.

Chris continued with reference to B.S. 7117 -a British Standard covering the design, installation and maintenance of petrol pumps. In conclusion he answered various questions pertinent to this field.

A presentation of fibre glass pipework was given by Richard Graham of Ameron, assisted by David Osborne of the company. The presentation included videos of the installation of the pipework and also tank installation.

The business meeting was concluded at 12.45 p.m. after a vote of thanks for the morning presentation had been given by David Bucknall.

The afternoon presentation was by Paddy Watson of Whessoe Systems and Controls Limited. He gave a description of the company's operations and an outline of the origins of the company. This was followed by a description of the Whessoe Whesstation Fuel Gauging System and members were able to make a close examination of the equipment.

After questions a vote of thanks was given by Maurice Scott.

The meeting was closed by the Chairman at 3.30 p.m. Chairman

NITROGEN INERT FOAM. THE QUICK INEXPENSIVE 100% SAFE WAY OF INERTING WITH NO PROBLEMS ASSOCIATED WITH WATER SUPPLY AND TANKERING AWAY ETC. OR OTHER COSTLY TIME CONSUMING AND SOMETIMES NON-EFFECTIVE METHODS.

SUB-LICENCES are at the moment being considered to enable Companies to operate this patented process with simple automatic equipment from their own small vans. EXAMPLE: It takes only a few minutes and one cylinder of Nitrogen to totally FOAM inert a 1500 gallon compartment, and so on. The sub-licences, officially registered at the UK Patent Office, will include full training being given in these procedures and other associated ANALYTICAL and NITROGEN services that may be required on the Forecourt, during the Contractors routine day to day work. Training may be undertaken on the Contractors own sites to save staff 'down time' and is simple and non-time consuming. Demonstrations can be arranged on our own glass panelled petroleum vessel.

NITROGEN INERT FOAM is suitable for 'MOTHBALLING' during periods of shutdown or 100% inerting for EXTENDED CLOSURES. After Foam filUng the vessel is sealed off and remains inert with Oxygen content at ZERO, no problems of re-distribution of improperly purged gases, or corrosion etc. as with water fill methods exist.

NITROGEN INERT FOAM may be used in most situations for MANHOLE MODIFICATION with product in situ, or if preferred the product may be lifted and quick and simple FOAM inerting may be earned out, before the work is undertaken.

NITROGEN INERT FOAM provides quick and inexpensive inerting prior to manhole removal and slurry filling.

NITROGEN INERT FOAM is highly suitable for inerting prior to excavation, and the excavated vessel may be loaded and safely transported foam filled for disposal if the demolition is not undertaken, Foam filled, in safety on site. Foam filled vessels are unaffected by 'Pecker' Perforation or porosity as are water filled vessels and any spirit leakage can be simply blanketed with this process.

NITROGEN INERT FOAM gives 100% safety during Demolition, and as a VAPOUR PLUG allows alterations to be carried out on pipework that has held product, in complete safety, in close to hazardous areas.

We also undertake all other Nitrogen and Hi-tech service associated with the Petroleum and Chemical Industries.

GAS FREEING using inert foam or other nitrogen purging techniques.

LEAK TESTING by Helium trace and other modern techniques. HOT WORK modifications and repairs to Lloyds and ASME. BOTTOMING and CLEANING, REMOVAL or SLURRY FIWNG.

'MOTHBALLING'.

FILLED or glass reinforced, spirit or solvent resistant linings, engineered to Lloyds lnspecto t Of Shipping approval. ra e under totally inert or Water Filled conditions, and GRIT ABRASION t S using NITROaBRADE @)equipment, under totally inert Constant Purge situations. 0 .A.3

We/beck House High Street Guildford Surrey GU1 3JF Tel : Guildford (0483) 3822

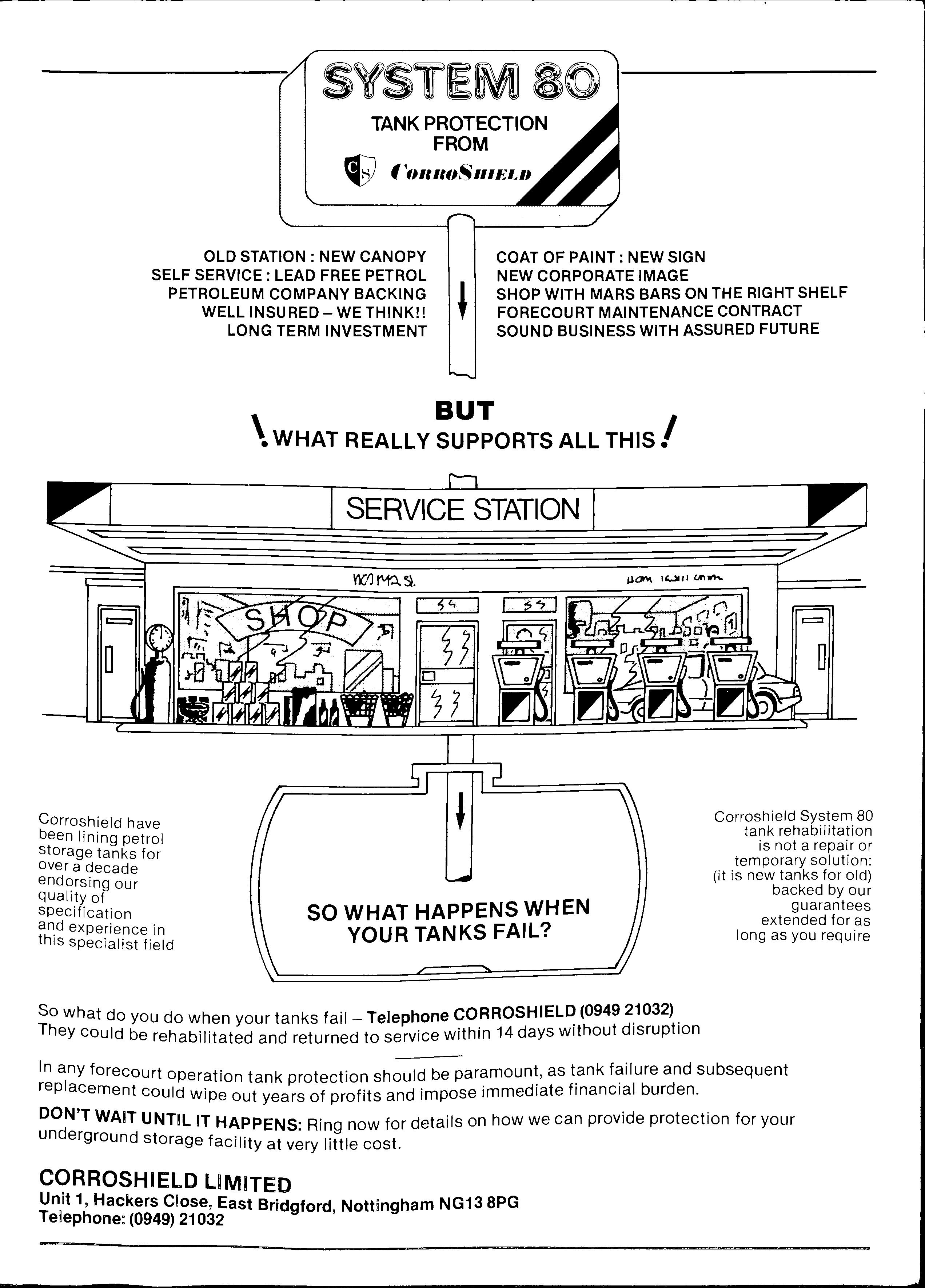

Corroshield have been lining petrol storage tanks for over a decade endorsing our quality of specification experience in this specialist field

Corroshield

solution: (it is

COMMERCE HOUSE, THE MALTINGS, STATION ROAD, SAWBRIDGEWORTH, HERTS. CM21 9JX Telephone: 0279 723448