THE BULLETIN

Journal of the Association for Pe'tro./eum and Explosives Administration

VOLUME 25 No 2

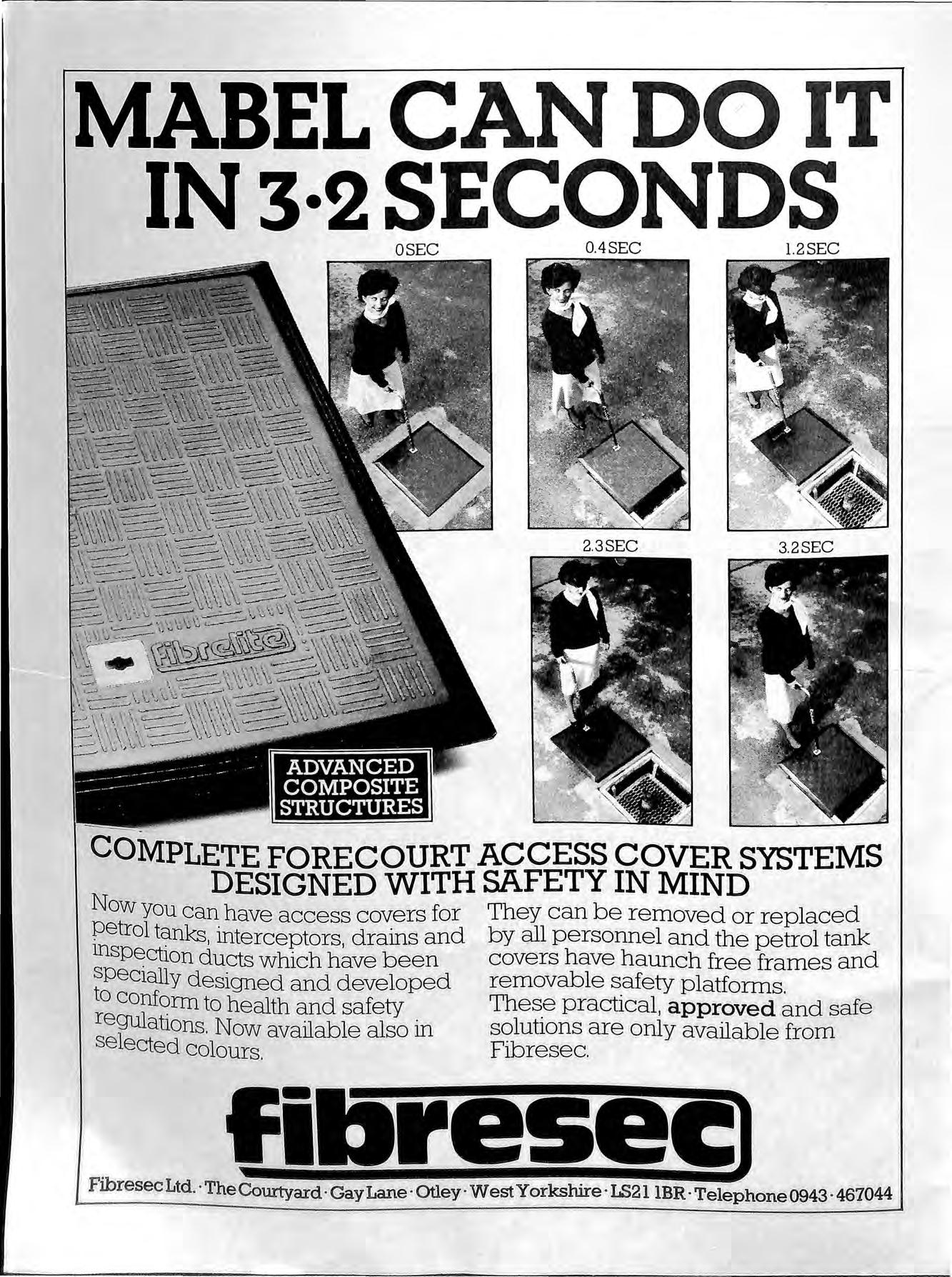

MABEL CAN DO IT IN 3·2 SECONDS OSEC ADVANCED COMPOSITE STRUCTURES 0.4 SEC ..,....,....."....., 2,3SEC COMPLETE FORECOURT ACCESS COVER SYSTEMS DESIGNED WITH SAFETY IN MIND Now you can have access oovers for They can be removed or replaced petrol interceptors, drains and by all personnel and the petrol tank ducts which have been covers have haunch free frames and speCIally designed and developed removable safety platforms. to to health and safety Thes,e practical, approved and safe reFattons . Now available also in solutIons are only available from se ected colours. Fibresec. Fibre sec Ltd.' The Courtyard ' Gay Lane ' Otley ' West Yorkshire' LS211BR· Telephone 0943 . 467044

Rapid Response Units on call 24 hours a day for Land or Water Borne incidents . 24 HOUR EMERGENCY TEL: 01-8051856 ... DEWCO 'PROTECTING THE ENVIRONMENT' FOR DETAILS OF THIS AND OTHER OIL RELATED SERVICES: Contact: Sales and Marketing Department, DEWCO SERVICES UMITED HERTFORD ROAD, ENFIELD WASH, MIDDLESEX, TELEPHONE: 01-804 1095

MANGAN BROS. LTD. Building Contractors 402 Seven Sisters Road, London N4 2LU (REGISTERED OFFICE) Telephone: 01 800 4651 Specialists in Petrol Filling Stations D. S. Leggett (Electrical) Limited" ELECTRICAL CONTRACTORS NICEIC APPROVED 181 VICTORIA ROAD, NEW BARN ET, HERTS. Telephone: 01 =441 3958 SPECIALISTS IN PETROL STATIONS -

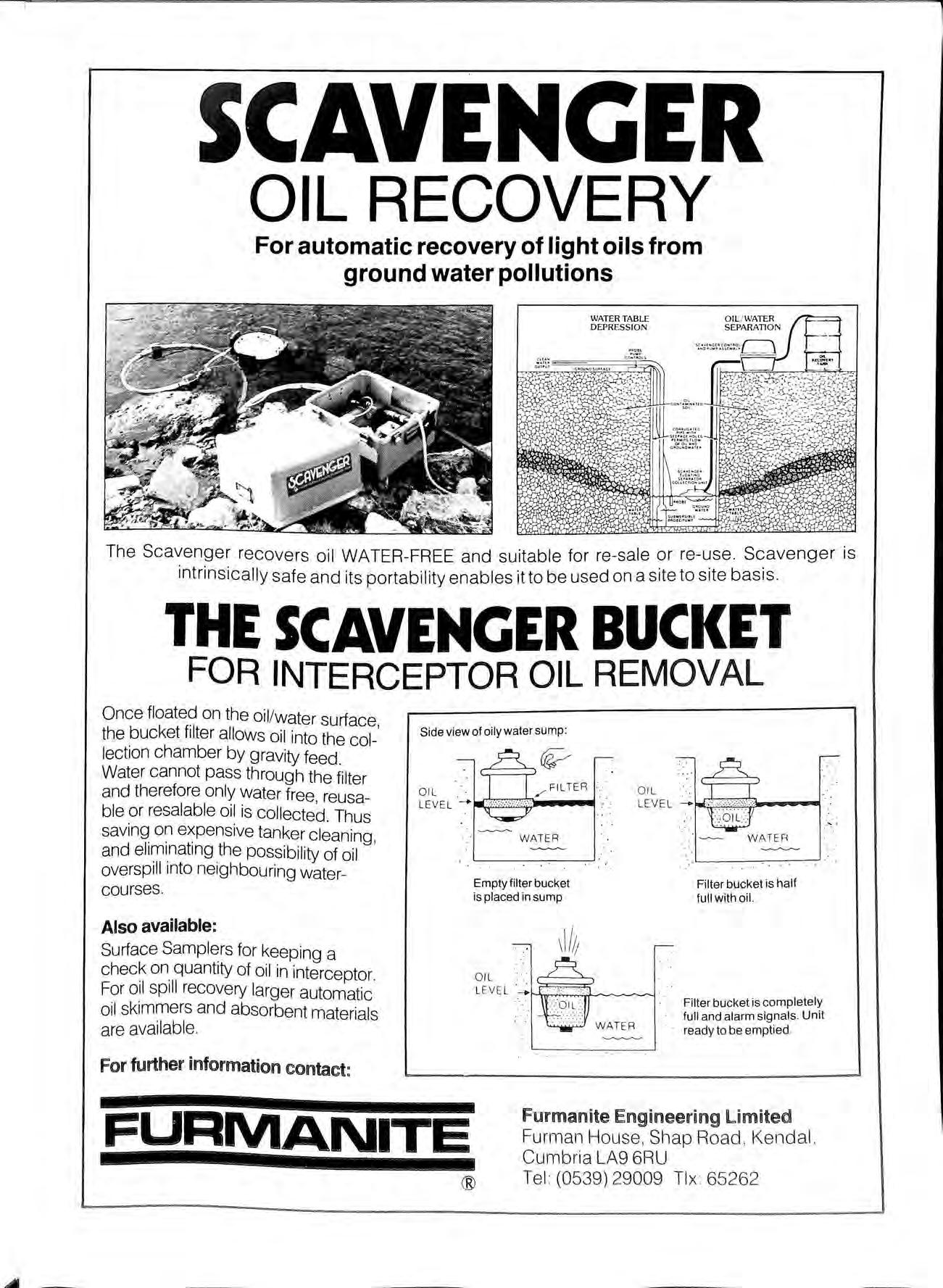

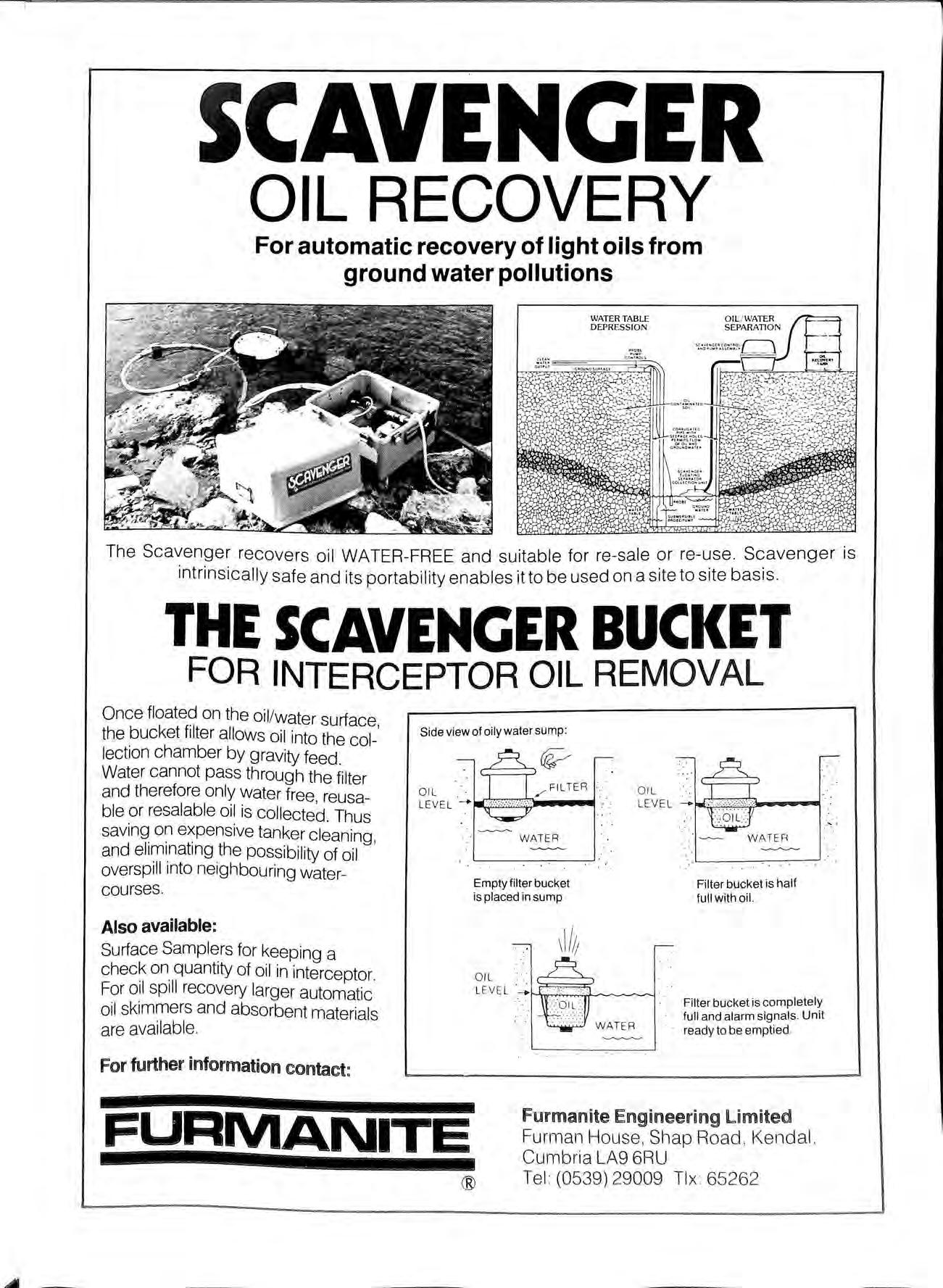

Once on the oil / water surface , the bucket filter allows oil into the collection chamber by gravity feed . Water cannot pass through the filter and therefore only water free, reusable or resalable oil is collected. Thus saving on tanker cleaning, and .the possibility of oil overspill Into neighbouring watercourses.

Also available:

Surface Samplers for keeping a check on. quantity of oil in interceptor. For 011 spill recovery larger automatic oil skimmers and absorbent materials are available.

For furt her informati on contact:

ENCiER OIL RECOVERY For automatic recovery of light oils from ground water pollutions

The Scavenger recovers oil WATER-FREE and suitable for re-sale or re-use. Scavenger is intrinsically safe and its portability enables it to be used on a site to site basis. THE SCAVENGER BUCKET FOR INTERCEPTOR OIL REMOVAL

WATER

TABlE DEPRESSION

Side view of oily water sump: OIL LE VE L WA T ER Empty filter bucket is placed in sump Filter bucket is half full with oil. Filter bucket is completely full and ala r m signals Unit ready to b e emptied FURMANITE Furman ite Eng ineer ing li m ited Fu rm a n House , Sh ap Road , K en da l , Cum br ia LA 9 6RU ® T e l : (0 539 ) 2 900 9 T l x 65262

W. LAMB LTD. THE PREMIER PUMP AND TANK COMPANY Forecourt and Commercial - Above and Below Ground Supply - Test - Exchange - Service - Instal Product Transfer De-Watering Removal Purchase Tank Demolition Removal Safety Filling Large Stocks of New and Second hand Petrol and Diesel Pumps, Tanks and Accessories DAYBROOK STREET, SHERWOOD, NOTTINGHAM 0602 621511 + 608084 TRINITY WORKS, BOURNE END LANE, HEMEL HEMPSTEAD 0442772296 Telephone 021-236 0347 w. J. FINCH (Installations) Ltd. Steaming out and de-gassing petrol tanks; issuing gas free certificates Complete petrol and fuel oil bulk storage tank installations Petrol and fuel oil tank cleaning service Pressure testing tanks and pipe work Heaton House, Camden St., Binningham BI 3BZ -

Work has progressed in recent years in the Health & Safety Executive on draft guidance to replace the Home Office Code of Principles of Construction for Petrol Filling Stations. It was their stated intention that this would take the form of an approved code of practice to supplement a new set of Flammable Liquid Regulations to replace the Petroleum Acts. In 1985 doubts were expressed on the need for new Regulations and following discussions in the Health & Safety Commission and the Commission Advisory Committee on Dangerous Substances it was decided that the current petroleum licensing system will remain for the foreseeable future. The Health & Safety Executive are now changing the proposed code of practice into a replacement for the out dated Home Office Code. It is understood that a draft may be out for comment later this year.

HUMBERSIDE BRANCH

The Bulletin ISSN 0263 4597 VOLUME, 25 Number 2 MAY 1987 £3.00 (Free to Members)

by the Association

and Explosives

the

Contents TALKING POINT NOTES & NEWS PROSECUTIONS LETTERS TO EDITOR NEW MEMBERS JOINTING COMPOUNDS P.T.F.E. THREAD SEAL TAPE CARRIAGE BY ROAD OF DANGEROUS SUBSTANCES IN PACKAGES ELECTRICAL NIGHTMARE

Published

for Petroleum

Administration Opinions expressed in this Journal are not necessarily the views of

Association

R. G. Kitching Humberside County Council,

EASTERN BRANCH

F. C. Rason

20 21 22 24 23 21 26 28 32

Point

Honorary Secretary: Mr. B. D. Taylor, Cambridgeshire County Council,

Talking

SOUTHERN BRANCH M. Cox Normond Instruments Ltd., MIDLAND BRANCH Derek Hopkins Warwickshire County Council,

Honorary Editor: Mr. J. A. J. Thompson,

LEAKING PETROL LINES MAKE NATIONAL HEADLINES

Reports have been received that some recently built petrol filling stations have been leaking petrol from suction line joints made with Litharge and Glycerine a jointing compound traditionally used in the Industry with success for many years. It would appear on the few sites where problems have occured that the product was having a scouring effect and "washing" away the compound from the joints.

These incidents are very isolated in comparison with the large number of sites built each year by the Industry, but nevertherless disturbing for both the Oil Industry and Petroleum Licensing Authorities alike.

While investigations are being carried out, some sections of the Industry are turning to the use of P.T.F.E. tape or Heldite as an alternative.

Stories appearing in the National Press were to potentially leaking tanks on all filling stations and It is clear that there is no evidence to support this. At the time of press three newly constructed sites had bad failures of pipework joints, these were two separate Oil Companies and also involved two dIfferent pipe installations companies. There appears to. be .no common denominator on these sites, and inveStIgatIOn is continuing to see if the Oxygenates which are replacing lead in the fuel could have a longer term effect on such joints.

PETROLEUM CONSOLIDATION ACT

Under section 20 of the Petroleum Consolidation Act the DTI has responsibility for the initial testing of Abel FJashpoint apparatus and for the subsequent retesting at intervals not exceeding ten years. Authorities using this apparatus should when necessary contact the National Weights and Measures Laboratory at their new address. AGM

At the AGM at Dunstable a well attended meeting of over 100 members voted in the following officers:-

CHAIRMAN: A. Levett

VICE CHAIRMAN: R. Kitching

HON. SECRETARY: B. Taylor

HON. TREASURER: R. lones

HON. EDITOR l.A.l. THOMPSON

MEMBERSHIP SECRETARY: B. Thompson

ADVERTISING SECRETARY: l. Luke

Two excellent speakers after the formal meeting were Lt Col M.l. Harris R.A.O.C. and Mr. P.l. Edgington B.P. International.

Underground Pipework jointing compounds

- Shell filling stations

by Shell UK Oil Retail Engineering Unit

Following recent press and trade journal reports on defective jointing materials we would like to inform Licencing Authorities, Fire Authorities and to advise the Industry of the facts pertaining to Shell sites.

Earlier this year we had problems with the pipework installation at two of our recently developed Traveller Check sites, Southend and Harlow. The third suspected site which had been quoted in Edinburgh has been tested and was found to be sound.

The problem at the two sites appeared to be a breakdown .of the litharge jointing compound. In of th.e P?sslble consequences which could have anse.n we mstIgated an immediate investigation of thIS problem, through the Shell Research Centre.

We suspended all pipework installations for a week. the complexitites of the research tests, over 150 mdlVldual tests are being carried out, it was that the result would not be available for some whIle. We th.erefore sought advice for a suitable replacement matenal. PTFE tape which is known to be inert was recommended and this was used as a jointing material for installations currently underway. In most cases this proved to he totally satisfactory. However there is no

the level of skill and care required to effect thIS Jomt IS much higher than that When using litharge or one of the set jOinting compounds.

We have carned out mechanical and hydraulic rig tests .and these proved that litharge, PTFE tape and Heldlte correctly applied are all suitable jointing materials. The interim report from our Research Centre these results. Litharge correctly mixed and IS not affected by gasoline or any of the additives m our brand. We have also inspected and tested plpework from our older sites and these have proved to be sound.

We therefore propose to revert to litharge all underground pipework joints on future installatIOns. Where PTFE tape joints have been made and tested as being satisfactory they will remain.

Our research into this problem will continue we are determined to establish the cause of these faIlures S? we are better equipped to meet the challenge of the hIghest standards of safety in our network in the future.

We hope that this will clarify the situation and would like to thank those Petroleum Authorities that have cooperated with us during the period of our investigations.

notes

& news

•

21

LOW LEAD GASOLINE an Institute of Petroleum Comment.

Statements widely circulating in the press wrongly attribute to the Institute of Petroleum the view that closures of newly-constructed service stations had been caused 'apparently because low lead petrol has melted the modernjointing compound', and that this compound had been introduced some ten years ago 'when it was found that older type compounds being used abroad could not withstand the corrosive effect of petrol'.

Neither statement is subscribed to by the Institute, as they exaggerate what appears to be a very limited problem which we understand is now under investigation by the Companies concerned. Statements that deteriorating pipe work under petrol forecourts may soon force the shutdown of thousands of filling stations throughout the country are alarmist hyperbole.

Litharge/glycerning jointing material has given widespread satisfactory service both before and after the change to low lead gasoline in January 1986 and scattered evidence of leakage in the past at sites on the Continent has been attributed not to low lead gasoline but to too much oxygenate, in the form of methanol in the blend at those retail outlets.

The need to limit the proportions of methanol in gasoline because of its potentially aggressive effect on a number of materials of construction used both in gasoline distribution, and in the components and finishes wide us.e by the automotive industry, has re.sulted m.the maximum content of 3 vol percent being stIpulated m the EEC Oxygenate Directive.

Though safely within such a proportion in many Eurorean cou?t.nes, It has not yet been the practice for the direct additIon of methanol to have been made in the U.K. It should be noted that the EEC Directive permits the addition to gasoline of large proportions of less polar oxygenate than methanol such as MTBE with no adverse effects being reported. '

lEE WORK .ON THE 16th EDITION

The Re?ulatlO!ls Committee of the Institution of Electncal Engmeers IS to begin a review of the 15th Edition of Regulations for Electrical Installations in preparatIon for the publication of the 16th Edition 1990. At some nine years will have elapsed smce the pubhcatIon of the 15th Edition and because of subsequent international work, the 15th Edition has been subjected to several amendments and a futher substantial amendment is planned for later in 1987.

It is intended that the 16th Edition will maintain the principles and adopted for the 15th and will incorporate work. The opportunity w!1I be to Issue a senes of lEE publications dealing With speCIfIc aspects of the Regulations. Some of the and notes to RegUlations, together With additIOnal explanatory material will be included in these publications.

In addition, an on-site will be produced to serve as a ready source of reference for thos engaged in practical work on smaller installations and the Associatio.n of Supervisory and Executive Engineers, the Electncal Contractors Associations, the Electrical Ele.ctronic and Plumbing Trade Umon. and the NatIOnal Inspection Council for Electncal Contracting will be consulted in its ThIS guide will not preclude the necessIty to refer to the Regulations themseleves for detailed re4uirements.

The programme for a new edition is of necessity somewhat long term and the lEE wishes to emphasise that the 16th Edition will not be published before 1990. Accordingly, the 15th Edition will remain in use for at least three years.

PROSECUTIONS

On 11 June 1986 an Inspector stopped on a garage forecourt in Peterborough when he saw a delivery of petrol taking place.

It was found that no one was keeping a watch on the tanker connections or the underground tank filling points.

The Inspector noticed that petrol was leaking from the air separator on one of the pumps and also from the hose connection to the fill pipe of one of the storage tanks. The tank was obviously full with the delivery still taking place.

The garage manager and the tanker driver were both in the kiosk where they could see the tanker but not the connections to either the tanker or the tank.

Appropriate action was taken to terminate the delivery and a potentially serious situation was prevented. The garage manager blamed the overfill on a faulty contents gauge which he said had not been working correctly for some time.

The manager was prosecuted under Regulation 20(1) and Paragraph 6 of Schedule 4 of the Dangerous Substances (Conveyance by Road in Road Tankers and Tank Containers) Regulations 1981 for failing to secure that no petroleum spirit overflowed from the storage tank and also Paragraph 8 of Schedule 4 of the Regulations for failing to keep a constant watch during the whole time of delivery into a petroleum storage tank.

He pleaded guilty on both charges and was fined £25 on each with £30 costs.

It it interesting to note that Paragraph 10 of the Regulations refers to the person attending the vehicle 'shall keep a constant watch on the carrying tank from which petroleum spirit is being delivered'.

We did not prosecute the driver because he was keeping a watch on the carrying tank, from the kiosk, although he could not see the hose connections. A point where the law needs amending.

PETROL PUMP GOES UP IN SMOKE

An elderly lady driver started a fire when she accidentally knocked over a petrol pump as she drove into a Berkshire garage.

The 75 year-old driver, bumped into the pump, knocking it off a concrete island as she went to fill up her car.

Sparks flew out of the pump as it fell to the ground and set light to the contents of a rubbish bin nearbv.

Flames leapt more than 10 feet into the air as tl;ey spread around the pump.

Garage staff switched off all the pumps and customers dived for cover including the elderly driver, and her passenger.

A fire engine rushed to the scene and soon had the blaze under control.

Police escorted the distressed lad\ home. The\ described the blaze as potentiallv leth<;I. .

A spokesman for the garage said Accidents do happen and it was clearly just that ....

SPARK FROM PLUG MAY HAVE CAUSED FATAL GARAGE BLAST

A poorly connected plug on an electric lamp was the most likely cause of an explosion in which motor mechanic Christopher Myhill suffered fatal injuries, an inquest was recently informed.

And, the inquest was told, the lamp was of a kmd Mr. Myhill should never have used for the job he was doing.

Mr. Myhill was engulfed in flames by the blast which happened as he tried to trace the fault on the petrol gauge of a car on December 22nd last year.

He sustained 93 per cent burns and subsequently died in the burns unit of Stoke Mandeville Hospital.

Mr. Royce Keers, an electrical inspector from the Health and Safety Executive, told the inquest at Aylesbury that the lamp, cable, plug and he examined at the garage after the blaze were "not sUItable for use in garage pits where petrol is being drained."

Mr. Keers stated: "Petrol vapour is a highl.y inflammable material and where electrical apparatus IS used it has to be specially constructed."

There were many specifications regarding electncal appliances used where petrol vapour might be present, he said.

Mr. Keets added that the lamp used by Mr. was "in very poor condition." It was plugged mto a socket in the wall of the inspection pit and where the cable joined the plug one terminal was loose and the other was connected by only a very few strands.

Simply moving the lamp would have been to produce a spark and ignite the petrol fumes, saId Mr. Keers.

The inquest also heard that Mr. Myhill's decis.ion to place the car above the inspection pit while workmg on the fuel tank went against the policy of the garage

On the day of the explosion Mr. Myhill was workmg on a Vauxhall Nova with a faulty petrol guage, helped by a young trainee mechanic, Jeffrey New.

Mr. New told the inquest that he and Mr. Myhill had siphoned petrol out of the car into a plastic container. They were trying to trace the fault when Mr. New was called out of the workshop to serve a customer on the forecourt.

After a few minutes, Mr. New heard what he described as a "whoosh" and he returned to the building to see Mr. Myhill appear from the driver's side of the car, near the fuel tank.

"He was on fire. He was just screaming," said Mr. New.

He ran to alert Roy Newell who was in his house next door. Mr Newell used a fire extinguished to put out the flames on Mr. Myhill's body and the two men dragged him outside. He was still concious as he lay on the forecourt, said Mr. New.

Mr. Myhill was rushed to Reading's Royal Berkshire Hospital, then to Stoke Mandeville where he died that evening.

Pathologist Or. loan Rivett described the cause of death as "very extensive, severe burns."

The Vauxhall Nova was gutted and the garage severely damaged in the fire which followed the blast.

Station officer Geoffrey Kershaw. who was in charge of the fire-fighting operation. told the inquest that when he later inspected the workshop he found the charred

remains of a plastic petrol container inside the inspection pit.

The remains of a plug from a lamp were stIll m the socket in the wall of the pit, and there was a very strong smell of petrol.

Mr. Kershaw said he found the lamp lying on the floor of the workshop, about a metre away the rear of the car. He "immediately suspected" that It may have been the cause of the fire.

"It's my experience that lamps of this kind are very often faulty or damaged," he said.

Mr. Kershaw added that Mr. Myhill was certainly standing outside the inspection pit at the tIme of the explosion. .

"It would have been an explosion rather tha? a There would be no time to react to this sort of inclden t.

Electrical inspector Royce Keers said he It probably that Mr. Myhill had carried the can contammg petrol down into the pit and placed it under the tank to catch any remaining drops of fuel.

"It's my opinion that he probably had some petrol on his clothing he must have got this from the container into the pit. I was amazed to hear how qUlckly he was engulfed," said Mr. Keers.

He also stated that just a small percentage of pe.tro! vapour in air was enough to create an incendIary mixutre.

need half a pint of petrol to fill a pi.t with In this case you had a pit WIth no ventllatlOn, Just a box containing vapour."

A jury of six men and four women returned a verdict of misadventure.

New

following

J. Gill t

Board D. Bell, P. A. Clark, Humberside County Council, W. Cunningham. Fuel Management Systems.

Members The Association welcomes the

new members

Industry Training

To many members, the organisation and management of the Association may seem something of a mystery. Who is this body called 'the Council'? Throughout the years this group meets to deal with the business of the Association, although the principal officers handle much of the day to day matters. This year, 1986-87, the Council have met four times. At each A.G.M. the officers of the Association are elected. At the time of writing they are the Chairman, Vice-Chairman, Immediate Past Chairman, Honorary Secretary, Honorary Treasurer, and Editor of the Bulletin, In addition, four other members are elected to Council, and representatives appointed by the Branches are entitled to attend and vote. The Council may appoint committees to handle special maters and co-opt extra people to assist; in fact the Seminar is organised in this way.

With many and varying views, meetings take all day. I have listed below some of the issues recorded in the minutes of the meetings.

1. The bulletin will be 25 years old this year and it is hoped the publish a special insert. This will probably contain reprints of early material, in particular a series of articles by 'OUo·.

2. The effect of the Safety Signs Reglations have been the subject of requests for information by members. In particular are text only signs covered. The answer is no.

3. Late payment by some advertisers. exhibitors and members creates accounting difficulties, please note.

4. The Council has had joint talks with the I. P. These talks are I?roving valuable and subjects of concern on both Sides have been aired.

5. considerable effort, the 'Can Store Code' was published. Sales have gone well.

6. The Association is represented on B.S.I. Technical Committee .PLC/6, construction of petrol pumps.

7. It was decided to establish a sub-committee to review for tank testing. Shortly after this decIsion was taken it was found that LACOTS intended to carry out a similar exercise. After an initial joint discussion it was decided to proceed with a joint working party consisting of A.P.E.A. representatives. LA rOTS adviser and a member of the I.T.S.A. This has no met once and a framework for doing the job decided.

8. The Seminar took shape. grew. proved every bit as successful as hoped. then notes for improvements next year were made in readiness.

9. A new fea.ture ?n the scene were the two large logos provided tor special occasions such as the A.G.M.

10. A proposal to purchase A.P.E.A. cuftlinks was turned down.

11. The Bulletin was a regular feature for discussion. the whole Council agree about its importance and are looking for ways to improve it.

12. The Council are watching the activities of the embryo Branch interest and hope it will be successful. Indeed the activities of all branches are valued.

Letters to the Editor

Dear Sir,

There has been much discussion recently on the merits of various designs of drainage interceptors for petrol filling stations.

Although convinced that the by-pass type of interceptor is NOT suitable as a petrol interceptor, I am not so convinced regarding the necessity for each chamber of a conventional three chamber petrol interceptor to be a separate unit, rather than a compartment of a larger unit, albeit designed and functioning in the same way.

Any information that you or any readers may be able to supply would be much appreciated.

Yours faithfully,

R. Jones

EDITORIAL NOTE

While in theory this is correct a number of units with baffles or weirs have collapsed during operation or cleaning and the intergrity of the interceptor has suffered. It has been found that if built of sufficient strength to stand up to test there should be no problem.

Dear Sir,

I write to ask. when does Ordinary Portland Cement become Sulphate Resisting?

When it contains PFA. PBFS, POZA. or CHEZA or so I am told.

To the unknowing all these abreviations could be what the Chancellor uses when he delivers his Budget speech to describe a new kind of tax. but to operatives within the Industry these are becoming apparent. When ordering concrete to cover lines or tanks to provide sulphate resisting qualities. The dilema arrives when the concrete arrives on site with a ticket stating OP/PFS or OP/PBFS and not SR when refering to cement type. I am led to believe that sulphate resisting cement is becoming difficult to obtain in certain areas of the UK. We have been refused use of OP/PF A by petroleum officers in some areas and had to ship concrete in from another county using a SR type.

It would seem that the problem is that the seller of the concrete must state what the type of cement he uses under the Trades Description Acts and he is unable to use the term sulphate resisting to describe its properties.

The time is ripe when we and the petroleum officers should be sufficientlv briefed on this.

P. Oglesby Contractor

Editorial Note

The Bulletin will attempt to get a paper published nn this subject later this year.

--

COUNCIL

THE

19 PLASHET GROVE, LONDON. E6 1 AD

I Adencon Draughting Services Ltd.

Specialists in the preparation of drawings for petrol filling service station redevelopments, alterations and tank or equipment installations and obtaining all necessary statutory authority approvals (Le. planning building regulation approval, petroleum officer approval etc.) MEMBER A.P.E.A. PHONE 01-739 9538 TUBEFLOW L TO and SOUTHERN PUMP SERVICES IlWE COVER LONDON" CONTRACTORS TO THE PETROLEUM INDUSTRY AND lOCAL GOVERNMENT AUTHORiTIES SUPPLY, INSTALLATION AND OF FUEL PUMPS, TANKS AND ANCilLARY PIPEWORK ETC. TEMPLE STREET, LONDON E2 6QQ

Telephone: 01-472 6627/8

PTFE Thread Seal Tape

by K.J. Taylor - TBA Industrial Products Ltd.

The Material

PTFE is the recognised and recommended abbreviation for polytetrafluoroethylene, (CF) in chemical notation. It is a plastic in relatively cOIhmon general use but, unlike many, it is less well recognised under its chemical name than under one of the various trade names- e.g. Fluon, Teflon, Soreflon, Hostaflon, Algoflon.

Discovered in 1938 and with the first pilot plants built during World War II, PTFE was first produced commercially in 1946 although the scale remained small until about 1950. Today the production rate of this exceptional engineering material is over 20,000 tonnes per annum, with over 5% and perhaps as much as 10% of the output being converted to tape for the sealing of threaded joints.

PTFE has an outstanding combination of properties, of which its virtually total chemical inertness, excellent electrical properties, low coefficient of friction and the retention of these over a wide temperature range are probably those which are most exploited. The claim that PTFE is completely inert chemically is often made but is not literally correct. However it is attacked only by such highly aggressive chemicals as the molten alkali metals e.g. sodium or potassium or (slowly) by fluorine gas so that for all practical purposes the claim may be accepted. Equally important, no chemical is known which will dissolve, or even swell, PTFE over its operating temperature range, which extends to 250°C (480°F). This makes it the ideal material for use in the petroleum and chemical industries.

The Product

More the heading should be plural, since a number of ?Ifferent qualities of thread seal tape are currently .. choice of which grade to use in a aphcatlOn may not be immediately obvious .IS III relatively simple and for this purpose It IS mstruchve to consider the background to the present range both from a technical and hIstorical vIewpoint.

Thread Seal Tape of the highest quality is 99.95% PTFE. The 0.05% remainder comprises a residue of the lubricant which is during the tape production and/or the solvent, whIch m Some processes is used to "degrease" the tape.

The present British Standard, BS.4375:1968, allows the content to be as high as 1% and this composItIOn IS for very many purposes. However, for certam critical applications, most particularly where high oxygen concentrations are present. or perhaps where there is contact with potable water, lubncant levels below 0.1 % are essential.

Density

Whatever the lubricant content, PTFE tape can be produced to a bulk density anywhere in the range 0.3-1.). Ongmally all tapes had the maximum density of I.) but.. as soon as the first lower-density tapes become avaIlal?le. these rapidly predominated. These products were found to be equallv effective sealants. to be easier to wrap and less costly to produce. By today's

standards they are of medium density i.e. generally in the range 0.8-1.2.

In turn the medium density tapes have lost ground to the low density version, which most usually are manufactured to be in the 0.4-0.6 range. The major factor in this change is that of cost reduction. Although there is some further technical gain in that these tapes are preferred for narrow bore pipes and/or fine threads, they perform less well in heavy duty work. But they remain easy to wrap and, crucially, they still perform well in the overwhelming majority of applications at a lower price.

Thickness and mass/unit area

Almost all tape sold in the U.K. at the present time is 0.075mm (0.003') thick. In some countries O.lmm has been officially specified for some time for use on gas lines and, for more demanding applications, the use of even thicker tapes is becoming necessary. Conversely, in the continuing drive for economy, thinner tapes are beginning to appear in many countries abroad. It is pertinent to consider these developments in more detail, particularly with regard to the quantity of tape to be used.

An essential feature with any joint sealant is that the correct quantity ("not too little, not too much") should be applied. Where pastes are used the quantity is traditionally achieved by using too much and disposing of the excess. The excess is squeezed simultaneously to the outside and to the inside of the pipe. The excess on the outside is easily removed but that on the inside (and its effects on the pipe contents) is, of necessity, ignored. In addition to the waste and contamination problems arising from this procedure, the packing/paste ratio may vary between relatively wide limits to the detriment of performance.

A strong advantage of PTFE tape has been that a controlled quantity is simply and regularly applied. It has been a feature further to the advantage of low density tapes that a single wrap provides a small but often adequate quantity of sealant; and, if more tape is required, multiple wrapping is a simple procedure for increasing the dose in small increments.

As already noted, almost all the tapes available in the U.K. are 0.075 mm thick. However, if a range of thickness becomes available it becomes apparent that one aspect of simplicity is at risk. Confusion in this area needs to be avoided and fortunately this is easily achieved by considering neither density nor thickness alone but by combining these two in the much more meaningful parameter of mass/unit area. Using this approach, the majority of tapes currently available in the U.K. fall into the ranges 30-45 (95%) and I 115 (5%).

Interestingly. at least some of the thinner tapes available abroad are being manufactured at densities which bring them into the band. which suggests this may represent the optimum in economy/ performance. At the other end of the scale. it is ,dread\ dear that to meet the most stringent requirements next section) tapes in the region of 2011g/m' are required.

Specifications

All tapes of U.K. manufacture and some imported tapes conform to BS.4375:1968. This standard is adequate for all general plumbing applications and also for higher pressure work with certain limits.

For work with gas, the standard set down in British Gas publication IMl16 is more appropriate and is satisfactory for pipe diameters up to at least 50mm (2') although tape to BS.4375 is allowed on some installations up to 15mm "Work on joint sizes above 50 mm confirms that the tape to the IMl16 standard (e.g. the Permanite GT grade sold by TBA Industrial Products Ltd.) is very much perferred", and "Detailed information on joint couplings up to 100mm (4') is now available from TBA".

Where tape is to be used in the presence of high concentrations of oxygen, it is essential that the residual lubricant content is below the safe working limit. At present the standards for this are set by the major oxygen suppliers and are met by all the U.K. producers of tape. The tape manufacturers are actively collaborating to achieve a new and published standard, which will include a safe limit automatically. It must be emphasised that compliance with BS.4375 in its present form is not sufficient.

No standards directly related to LPG have been set down but appropriate tests do exist within BS.5292: 1980 and are thus incorporated automatically into the IMl16 standard. These tests are also included in the new British Standard currrently being drafted.

Summary

PTFE tape is used extensively and increasingly for sealing threaded joinst because:it is universally applicable (all pipe materials and virtually all contained fluids); joints are ready for immediate use; joints are easily dismantled after long use; it does not contaminate the pipe contents; it is clean and simple to apply; it operates over a wide temperature (at least -20°C to 250°C).

On an international basis, variety of standards (or lack of them) could lead to confusion but within the U. K. the position is relatively simple and promises to become even more so. At present the basic questions and answers are:-

1. Is the tape to be used in the presence of oxygen? If so, check that the quality (i.e. lubricant content) is satisfactory.

2. Is the tape to be used on large pipes and/or with gas and/or at high pressures and/or extremes of temperature cycling? If so, tape to IM/16 is to be preferred.

3. Is economy the primary consideration? If so, tape t? BS.4375 .will be satisfactory for most domestic and bght duty mdustrial work. If in doubt check with your supplier. * *TBA Industrial Products I '11 SEALING MATERI . a so. \VI always be pleased to advice. ALS DIVISION PO BOX 40. ROCHDALE 0L12 7EQ Telephone: (0706) 47422.

C P_I_NS_TA_LL_AT_IO_N_S (Established 1968) Specialists in Petroleum Pipework Installations New and existing Tanks and Lines tested Modifications to existing Installations And all work associated with Forecourt Pipework 39 BROOK ROAD, RAYLEIGH WEIR INDUSTRIAL ESTATE RAYLEIGH, ESSEX SS6 7XN RAYLEIGH (0268) 781184/ 781859 (24 hrs ans.) 27

The Carriage by Road of Dangerous Substances in Packages

M G Sewell, BSc DIC CEng MIChemE, Hazardous Substances Division, Health and Safety Executive, London

INTRODUCTION

1. For nearly 60 years control of the carriage by road of dangero}ls substances (excl uding radioactive substances and explosives) has been by regulations made under the Petroleum (Consolidation) Act 1928 (the "1928 Act"). This situation has rapidly changed over the last five years, and all but those relating to gas cylinders have now been revoked. Even these are likely to be revoked later this year.

2. Following the making of the Health and Safety at Work etc. Act 1974 (the "HSW Act") and the setting up of the Health and Safety Commission (the "HSC"), it was decided that a single comprehensive set of regulations should be drafted covering the classification, packaging, labelling and carriage by road of all dangerous substances. A first Consultative Document was published in 1979, but it was subsequently decided to produce three sets of regulations covering:-

(a) the carriage of dangerous substances in road tankers and tank containers:

(b) the classification, packaging and labelling of dangerous substances; and (c) the carriage of dangerous substances in packages.

3. All three sets of regulations have now been made and they comprise the Dangerous Substances (Conveyance by Road in Road Tankers Containers) Regulations 1981 (the "Road Tanker Regulations"), the Classification, Packaging and Labelling of Dangerous Substances Regulations 1984 (the "CPL Regulations") and the Traffic (Carriage of Dangerous Substances III Packages etc.) Regulations 1986 (the "Packaged Goods Regulations"). This last set of regulations forms the basis of this paper.

4. Before dealing with the specific details of the Packaged Goods Regulations, it will be appropriate to mention the power in the HSW Act for the HSC to approve Codes of Practice. Most health and safety legislation is now written in general terms with detailed guidance provided in Approved Codes of Practice ("ACOPs:'). It should.b.e noted that although failure to comply With any provIsion of an ACOP is not in itself an offence, that failure may be used in criminal proceedings as evidence that a person has contravened a regulation to which the provision relates. In sllch a case it would be to. that person to satisfy the Court that he had complIed With the regulation in some other way.

5. Because of criticisms received on the first Consultative Document referred to above. it was to. carry out a wide range of consultation on the detail of the Packaged Guods Regulations. It was not. therefore. until March. 19X4. a Consultative Document (Ref. I ) containing the draft Regulations. a

draft Approved List and two draft ACOPs one on classification and the other on operational matters was published. Most people who commented on these drafts believed that the proposed Regulations should be directly linked to and co-ordinated with the CPL Regulations and the Road Tanker Regulations, and this had now been done. The Packaged Goods Regulations were laid before Parliament on 27 November, 1986, and came into force, with one exception, on 6 April, 1987.

APPLICATION

6. The application of the Regulations is linked to the classification system used by the CPL Regulations so that a separate Approved List of dangerous substances and a separate ACOP on the classification of dangerous substances are not required. In order that this could be done, an amendment to the CPLApproved List (Ref.2), so that Packing Groups could be included, was necessary. Revision No. 1 to the CPL Approved List was published in October, 1986, and the classification, Packing and Labelling of Dangerous Substances (Amendment) Regulations 1986 were subsequently made to bring this Revision into effect for the purpose of the CPL Regulations.

7. Unlike the Road Tanker Regulations and the CPL Regulations, the Packaged Goods Regulations do not control the carriage of all dangerous substances, but only those which present the greatest hazard. Under the United Nations Recommendations (Ref.3) substances are classified into Packing Groups I, II and III according to their hazard, and the Packaged Goods Regulations only control those substances in Packing Groups I and 11, plus a few other specific groups of substances to which, in the main, Packing Groups have not been allocated. These other groups comprise flammable gases, toxic gases, organic peroxides, asbestos, asbestos waste and other hazardous wastes.

8. As there is no separate Approved List of dangerous substances for the Packaged Goods Regulations, the Regulations refer directly to the CPL Approved List and to those substances listed in Part I of the List as dangerous for conveyance by road. Substances subject to the CPL Regulations but not listed, such as proprietory mixtures, may still be subject to the Packaged Goods just as they are to the CPL Regulations. A consignor of an unlisted substance will have to identify its properties and classify it in accordance with the CPL Regulations. If necessary. he will have to allocate it to Paeking Group I or Il with the help of Schedule I to the Packaged Goods Regulations. The link between the det'initions l)j' 'dangerous substances' used in the Road Tankn Regulations, the C'PL Regulations and the Packaged Goods Regulations means that the work necessary to identify the properties of these substances does not have to be repeated to satisfy each set of rl'gulatiolls

SCOPE

9. The Packaged Goods Regulations only apply to the substances referred to in para. 7 according to the quantity being carried as follows:-

(a) any quantity in bulk, ie, not in a road or tank container, but possibly in a tipper vehIcle or skip;

(b) any quantity of an organic peroxide or reactive flammable solid which has a self-acceleratmg decomposition temperature ("SADT") of 50°C or below or where it is required to be conveyed below a specified temperature;

(c) in receptables with a capacity of 5L or more where the substance is an organic peroxide (not subject to sub-para. (b) above), a flammable or toxic gas, asbestos or asbestos waste, certain other hazardous wastes and any other substance allocated to Packing Group I; and (d) in receptacles with a capacity of 200L or more where the substance is allocated to Packing Group II.

RELATIONSHIP BETWEEN CONSIGNOR AND VEHICLE OPERATOR

10. 'Consignor' is used and defined similarly in both the CPL and the Packaged Goods Regulations. In the latter, 'Consignor' and 'vehicle operator' have responsibilities although, in many situations, Will be one and the same person. For example, If an employer manufacturers or stores a substance and he uses his own drivers and vehicles to deliver it to his customers, then he is both 'consignor' and 'vehicle operator'. Similarly, if a sends his own driver and vehicle to a supplier to collect dangerous substances, then he is taking on the both 'consignor' and 'vehicle operator'. The 'supplier of a dangerous substance who has a duty to ensure that it is properly packaged and labelled as required by the CPL Regulations has no duties under the Packaged Goods Regulations.

EXCEPTIONS

11. There are a number of exceptions to the Regulations which will be familiar to those who deal with the Road Tanker Regulations. These include the carriage ?f substances on vehicles which are engaged III international transport operations which are in accord international conventions, eg, ADR (Ref.4). There IS a further exception for those vehicles which are only on public roads in order to allow their operators to move dangerous substances from one part to another part of their premises in the near vicinity, eg, fork-lift trUcks vehicles on a public road or the transfer between different parts of a farm.

.cepted IS the carriage of an LPG cylinder when It IS used as part of equipment to be carried in a vehicle, such a tar boiler or oxy-propane burning gear. This also permits the carriage of a single spare for use with such equipment as long as the concerned operates using only a single cylInder fhe handling and use of such cylinders and equipment remains suhject to the general provisions of the HSW Act

GUIDANCE DOCUMENTS AND VIDEO

12. The details that follows are only a brief summary of the requirements of the Packaged Goods Regulations. Practical guidance on the operational provisions of the Regulations are given in an ACOP (Ref.5), whilst further details on the application of the Regulations, the need for vehicle placarding and other provisions are contained in a Guide (Ref.6).

13. The HSE has produced a short video cassette to publicise the introduction of the Regulations (Ref. 7). The cassette outlines the requirements of the Regulations and also emphasises the links with the CPL Regulations and the Road Tanker Regulations. It will serve as an excellent introduction to formal training courses or seminars, and is aimed both at those with duties under the Regulations and those employed by local authorities and the emergency services who will be helped by them if accidents occur. The video cassette is available from CFL Vision and copies may be purchased at a cost of £20 or hired at a cost of £10 per week.

INFORMATION TO BE PROVIDED BY THE CONSIGNOR.

14. Separate duties are laid on the consignors of dangerous substances and on the vehicle operators Their obligations are complementary. but qUite diStInct, and there will have to be effective liaison them. Firstly, the Regulations .the consignor of a dangerous substance to provide suffiCient and. accurate information about the consignment to the operator to enable him to comply with th.e of the Regulations that are h.IS resp.onslblhty. This information will normally be III wntIng, but, in certain circumstances, may be provided verbally. The provision of such information by a is in line with his obligations under the CPL RegulatIOns to label packages of substances classified as for by road. Secondly, the RegulatIOns prohll;Ht the carriage of dangerous substances by a vehicle operator until he has obtained from the consignor the relevant information which enables him to comply with his obligations.

INFORMA TION TO BE CARRIED BY THE DRIVER.

The Regulations duty upon vehicle operators to ensure that theIr dnvers receive information in writing which:-

(a) identifies the dangerous substance( s); (b) describes the dangers that can arise; and (c) specifies the action which the driver should take in the event of an emergency.

In addition. the driver has a duty to keep this information on the vehicle and for it to be available at all times when the substance to which it relates is being carried. In order that the emergency services are ?ot misled, a driver must ensure that any informatl.on regarding any dangerous substance not being car:l ed has been removed from his vehicle or is stored III a

CASSETTE

1

securely closed container. The information in writing can be in any form as long as it contains the necessary details. Many vehicle operators and drivers are likely to comply with this requirement by carrying the internationally accepted Transport Emergency Cards CTremcards') (Ref. 7) for the substance(s) concerned.

16. This Regulation will also be satisfied if the relevant information is carried in the form of readily available and easily seen labels on the packages or receptacles concerned, or on both package labels and accompanying written statements so long as they comply with the comprehensive requirements of Regulations 9 (2) and 9 (3) of the CPL Regulations or the de rogations permitted from those Regulations by Regulation 10. Such labels and the accompanying statements, which consignors are obliged to provide under the CPL Regulations for packages containing 250L or more of dangerous substances, contain all the information required.

CONSTRUCTION OF VEHICLES.

17. The Regulations place a duty on the operator of any vehicle used to carry dangerous substances to ensure that the vehicle andlor any freight container in which the substances are carried is properly designed, constructed, maintained and is suitable for the purpose for which it is used. For the vast majority of journeys subject to these Regulations specialised vehicles are not required.

LOADING, UNLOADING AND STOW AGE

18. The Regulations contain general wide-ranging obligations as a consequence of the fact that accidents involving dangerous substances commonly occur during loading or unloading, or, more commonly, are due to the manner in which the dangerous substances are stowed on the vehicles. The requirements recognise, that a number of people, as well as the vehicle operator, have responsibilities and that all have a part to play to ensure safety. As the Regulations cover a wide range of vehicles and a large number of different operations, the controls provide for a measure of flexibility. For example, the Regulations will not prohibit, under all circumstances, the carriage of substances considered to be chemically incompatible in the same vehicle. The ACOP on the operational provisions gives obvious examples of incompatible substances which should at least be adequately segregated.

PRECAUTIONS AGAINST FIRE AND EXPLOSION

19. The requirement here is the same as that under the Road Tanker Regulations and places a duty on all those concerned with the carriage of the dangerous substance, eg, persons involved in loading and unloading the vehicle in addition to the driver. Such precautions would include maintaining the vehicle so as to prevent engine, wheel or tyre fires and ensuring that no ignition sources are in the vicinity during loading and unloading of flammable substances. All vehicles should carry at least a small fire extinguisher in the cab, and where flammable substances are carried it will be appropriate to carry in addition a larger extinguisher in order to fight any fire as a result of a small spillage of the flammable substance.

DRIVER TRAINING

20. Vehicle operators are obliged to provide adequate instruction and training for drivers of vehicles which are subject to the Regulations. In addition, the operators of vehicles whose drivers carry loads of 3,000 kg or more of dangerous substances within the scope of the Regulations will be required to maintain a record of such training. This effectively means that the level of training will depend on the quantities of dangerous substances carried. Those who regularly carry more than 3,000kg will be expected to attend a formal training course of, say, two days duration such as the HAZPAK courses arranged under the auspices of the RHAlCIAI RTITB/NA WDC/PFT consortium, whereas those drivers who only occasionally carry small quantities of dangerous substances might only need a few hours inhouse training. This Regulation will not come into force until 6 April, 1988, in order to give vehicle operators a chance to organise the necessary training.

SUPERVISION OF VEHICLES.

21. The driver of any vehicle in which 3,000 kg or more of dangerous substances are being carried in a manner subject to the Regulations is required to supervise it when not being driven or to park it in a safe place. In choosing a safe place the driver will need to consider factors such as the nature of his load, the security of the vehicle, the time of his proposed absence and the risk of interference with his vehicle at the chosen parking place. The ACOP on operational provisions gives guidance as to a safe place.

LABELLING OF VEHICLES

22. The Regulations require the operator of any vehicle in which 500kg or more of dangerous substances are being carried in a manner subject to these Regulations to display 2 orange plates (similar to those required under ADR) on the vehicle. One of these plates must be mounted at the front of the vehicle and the other at the rear. When displayed, the plates must be kept clean and free from obstruction. Whereas they must be removed or covered up when all the dangerous substances have been removed, the Regulations permit the plates to remain on the vehicle if the load falls below 500 kg during a journey. This derogation has been included because many journeys involve off-loading and picking up en route, and exact quantities of dangerous substances on board are sometimes difficult to estimate. The Regulations also contain a derogation for a 'slip trailer' left on a customer's premises for him to unload. Such a trailer will not need to have an orange plate affixed to its front after the motive unit has been removed.

23. The purpose of these orange plates is to inform the emergency services, in the event of an accident. that the vehicle is carrying a significant quantity of dangerous substances and that it must be approached with extra caution. Because manv consignments of dangerous substances are carried ilS part a mixed load containing a number of substances. it has not been practicable to impose a svstem of vehicle labelling which can always identify the 'different classes of which may be on This is especially true ut' those journeys where the load is as part loads are off-loaded and replaced at inter\als.

I

EFFECT OF CPL AND PACKAGED GOODS REGULATIONS ON THE CARRIAGE OF PETROLEUM-SPIRIT.

24. With the Revocation o f the Petroleum-Spirit (C onv ey ance by Road) Regulation s 195 7 and the lat e r amendments, there are no longer any special r e quirements relating to the con s truction or cap a city of receptacles used to carry the petroleum-spirit. The CPL Regul a tio ns only require that they b e properly design e d a nd co n st ructed and th a t they a r e compatible with th e s ub s t a nc e being carried An ACOP (Ref.9) gives guid a nc e on the factors which s hould b e taken into acco unt when designing s uch a receptacle. The lab e llin g for co nv eya nce of such r ece ptacl es/pac kages must now be in accordance with th e C PL R eg ulations , although th ese sp ec ific requirement s d o not apply where the p a ck age contains 1L or le ss of petroleum-spirit.

25. As mo s t , if not a ll , substances falling within the d efi niti o n of petroleum- spirit (as given in the 192 8 Act) a r e P acki n g Group II substances, the Packaged R eg ul a ti o n s will only apply when th e petroleum- s pmt is in rec e pt acles with a capacity of 200L or more . Th ere is no lo nge r a n y requirement for a spec ia ll y ve hicl e to be used for th e carr iage of petroleum- spm t -o nl y that it must be s uit ab le for the purpo se (see par a. 17).

REFERENCES

1. Proposals for D ange r o u s S u bs t a nc es (Co nv eya n ce by Road in Packages etc.) R egu l a ti o n s. Consultative Document. 1984. HSE

2. Information App r oved fo r th e Classification , Packag in g a nd Labelling of Dangerous Substances fo r S u ppy and Co n veya n ce by Ro a d. A uth o ri sed a nd Approved List. 1984 HMSO. Revision No. 1. 1986 HMSO.

3. Tra n spo rt of Dan gerous Goods. R eco mmend at ion s prepa r e d by th e United Nat ions Commi tt ee of Experts o n t h e Tra n s port of D a n gero us Goods. Fo urth R evised E diti o n. 1986 U nit ed Nat io ns

4. European Agreement concern in g the int e rnational carriage of dangerou s goo d s by road (A DR ). 1985 Ed iti o n. HMSO.

5. Ope r at io n a l Provis ions of th e Road Tr a ffic (Carriage of Dangerous S ub sta nces in Package s etc.) Regu lat ions 1986 A ppro ved Code of Prac tic e

6. A G uid e to th e Road Traff ice (Carriag e of Dangerous S ub s tanc es in Packages etc .) Re gu la ti o n s 1986. HS(R) 24. 19 87. HMSO

Danger Co nt ained. Video Casse tt e. 19 86 CFL Cha lfont Grove , Ga r ard s Cross , Buck s , SL9

CEFTC Tre mca r ds Refe rence Ed iti o n J 979. , em lca l Industries Associat io n L imited. S upplement to h e Reference Ed iti o n. 1982 .

G ro u p T ex ts 1980.

9. Packaging of D angerou s S ub sta nc es for C o n vey an ce by Road (O R ' . ' e VISlon I). A pplO ve d CO de o f Pra c tic e 19 87. HMSO.

Pe rs onal attention in des ign & deve lopm e nt for th e petroleum retail industry

Principal with ove r 25 yea rs ex pe ri e nc e

Proj ec t Manag e me nt specialists

Progressive & inn ova ti ve outl oo k

Co nsultants for sta tut ory & planning requir e me nts

Co mpr e he nsive or tailored serv ic e to suit

Planaco urt Lim ited Po. Box 27 Bill ericay Essex CM ll 2E S

3 1

DESIGN FUELLED B EXPERIENC

•

•

PLANACOURT

•

•

•

027744016

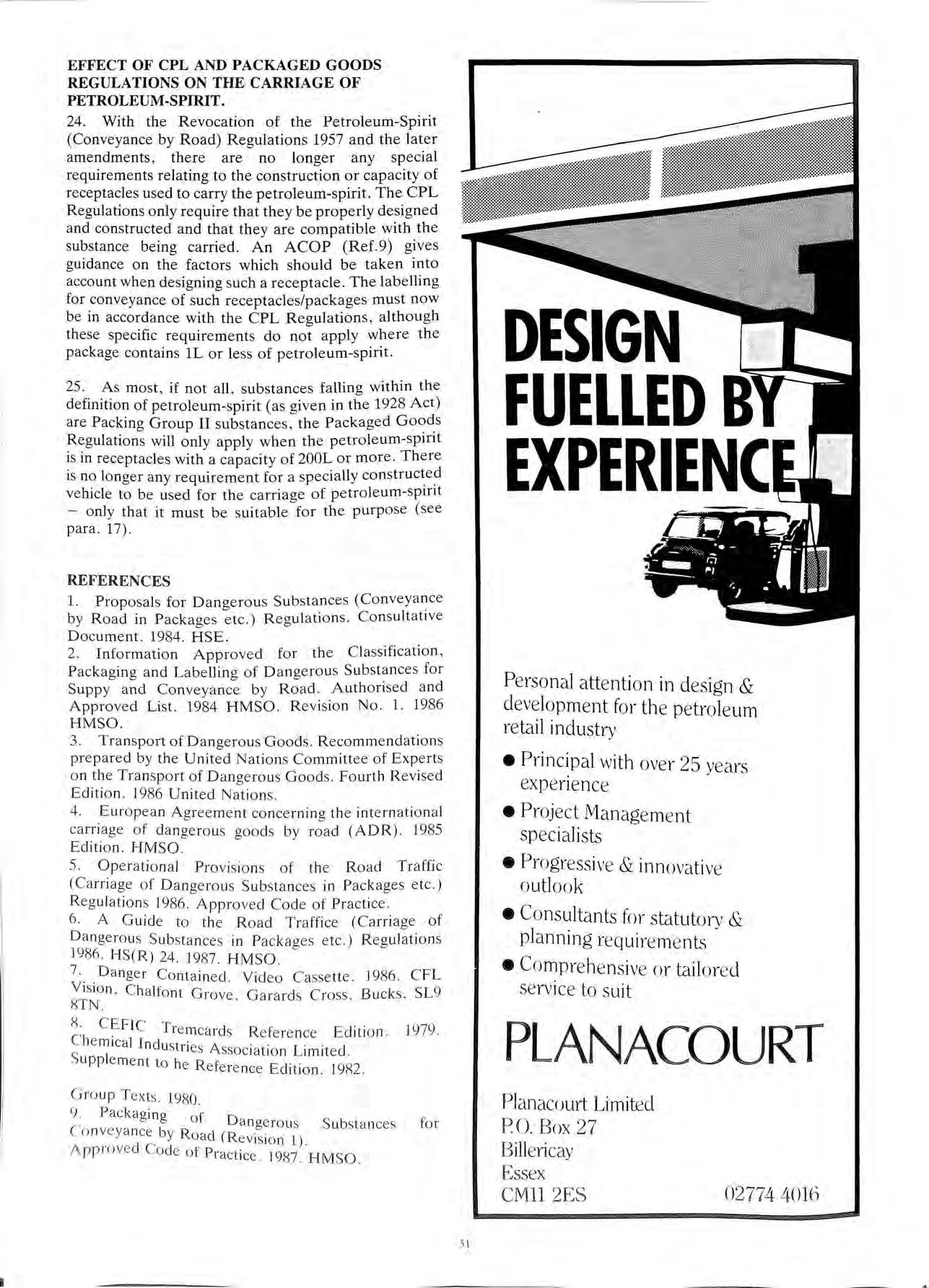

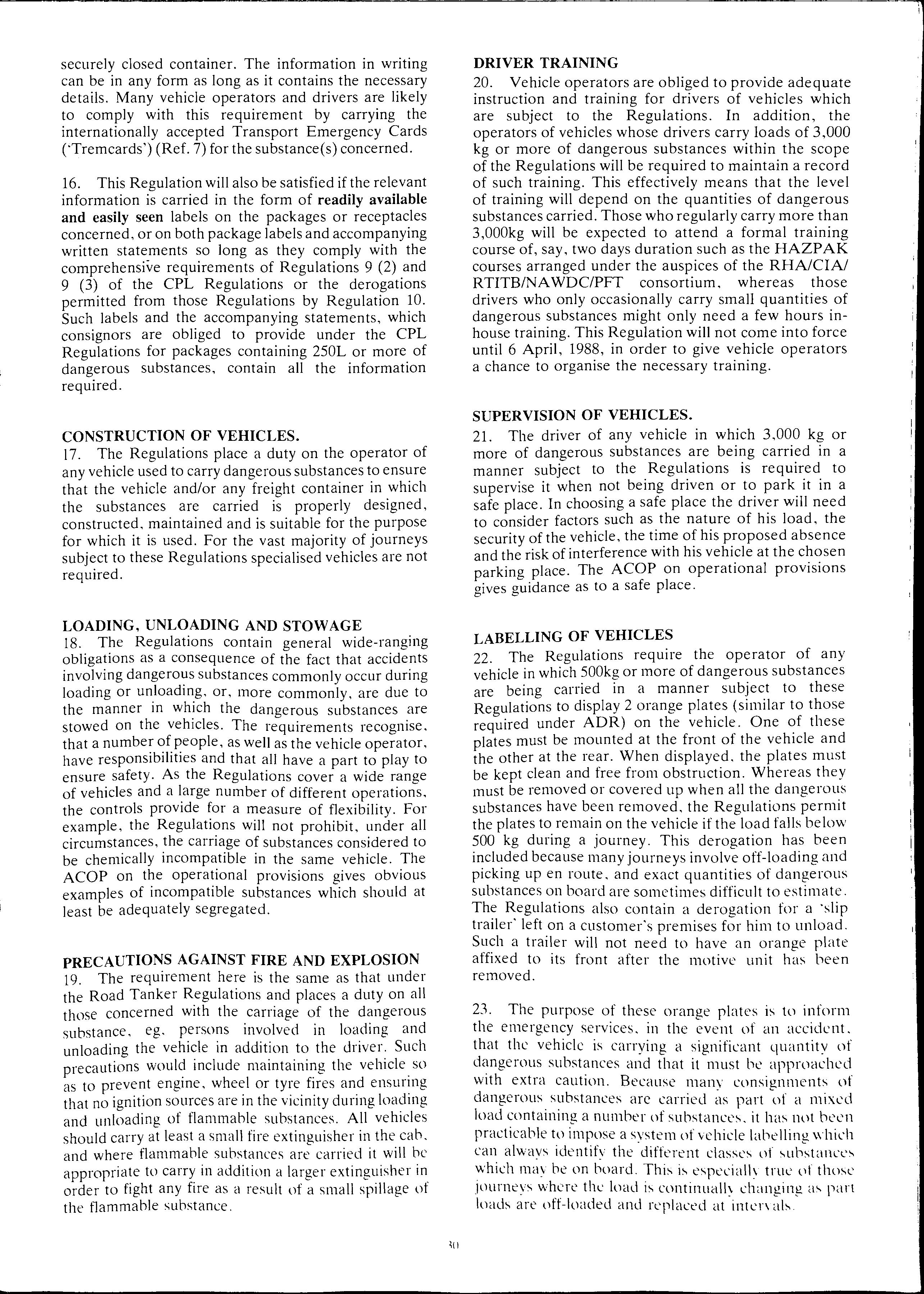

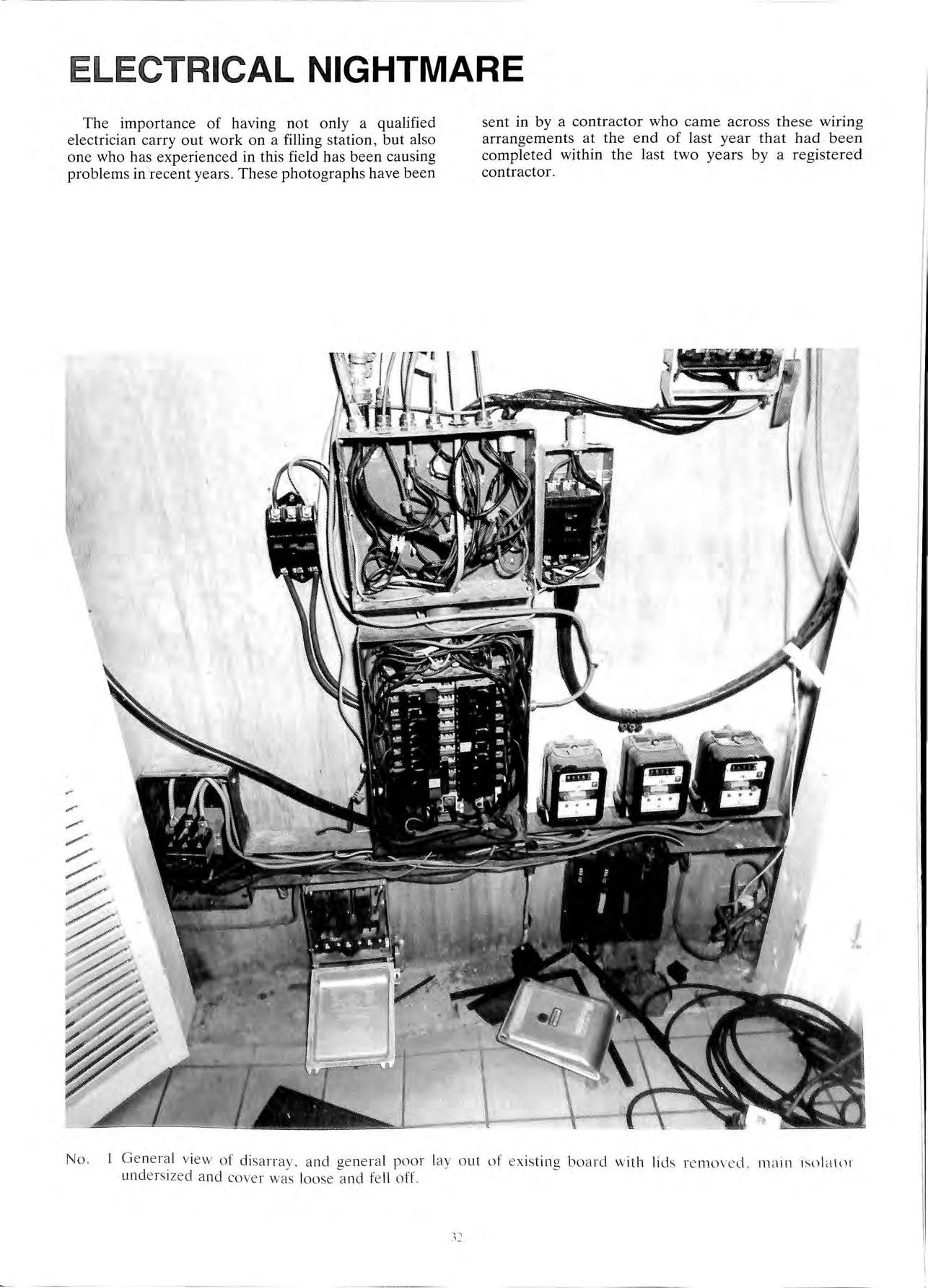

ELECTRICAL NIGHTMARE

The importance of having not only a qualified electrician carry out work on a filling station , but also one who has experienced in this field has been causing problems in recent years. These photographs have been

sent in by a contractor who came across these wiring arrangements at the end of last year that had been completed within the last two years by a registered contractor.

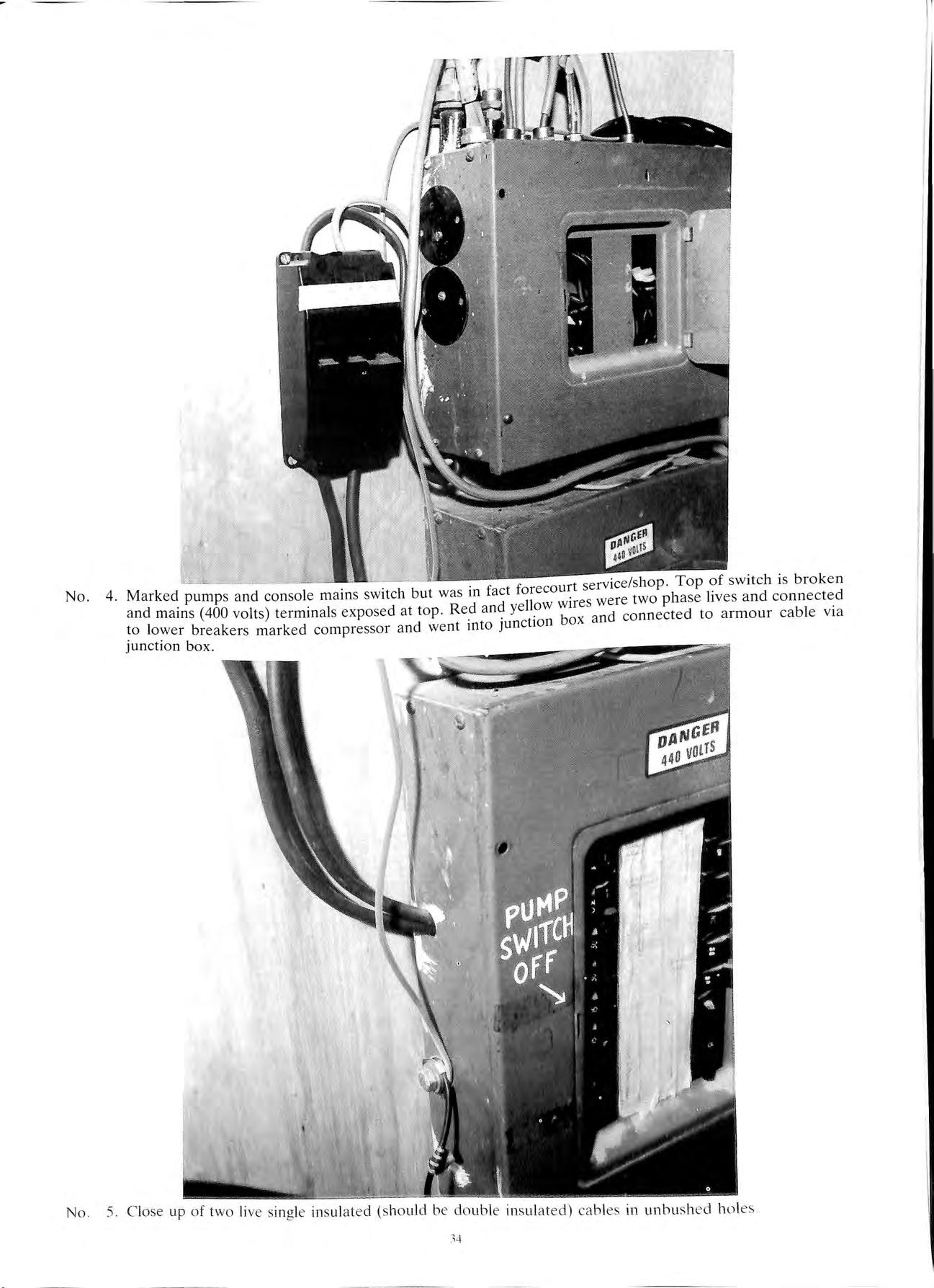

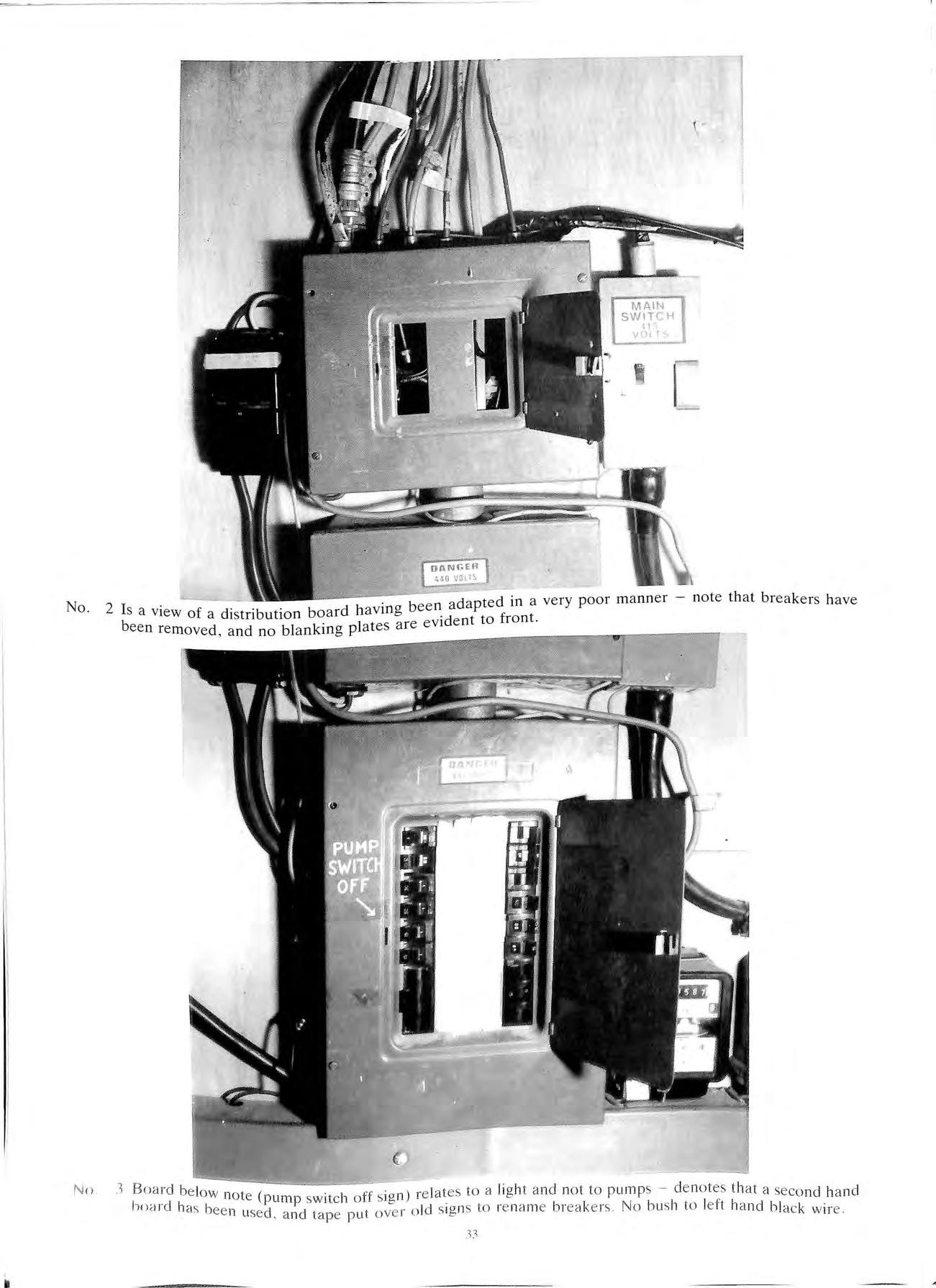

No. Ge n e ral v iew of di sa rr ay. a nd ge ner a l p oo r layo ut of ex is tin g b oard w i t h lid s r e mo ve d m a in iSll l a\l)1 un ders Ize d and cove r was loose a nd fe ll off.

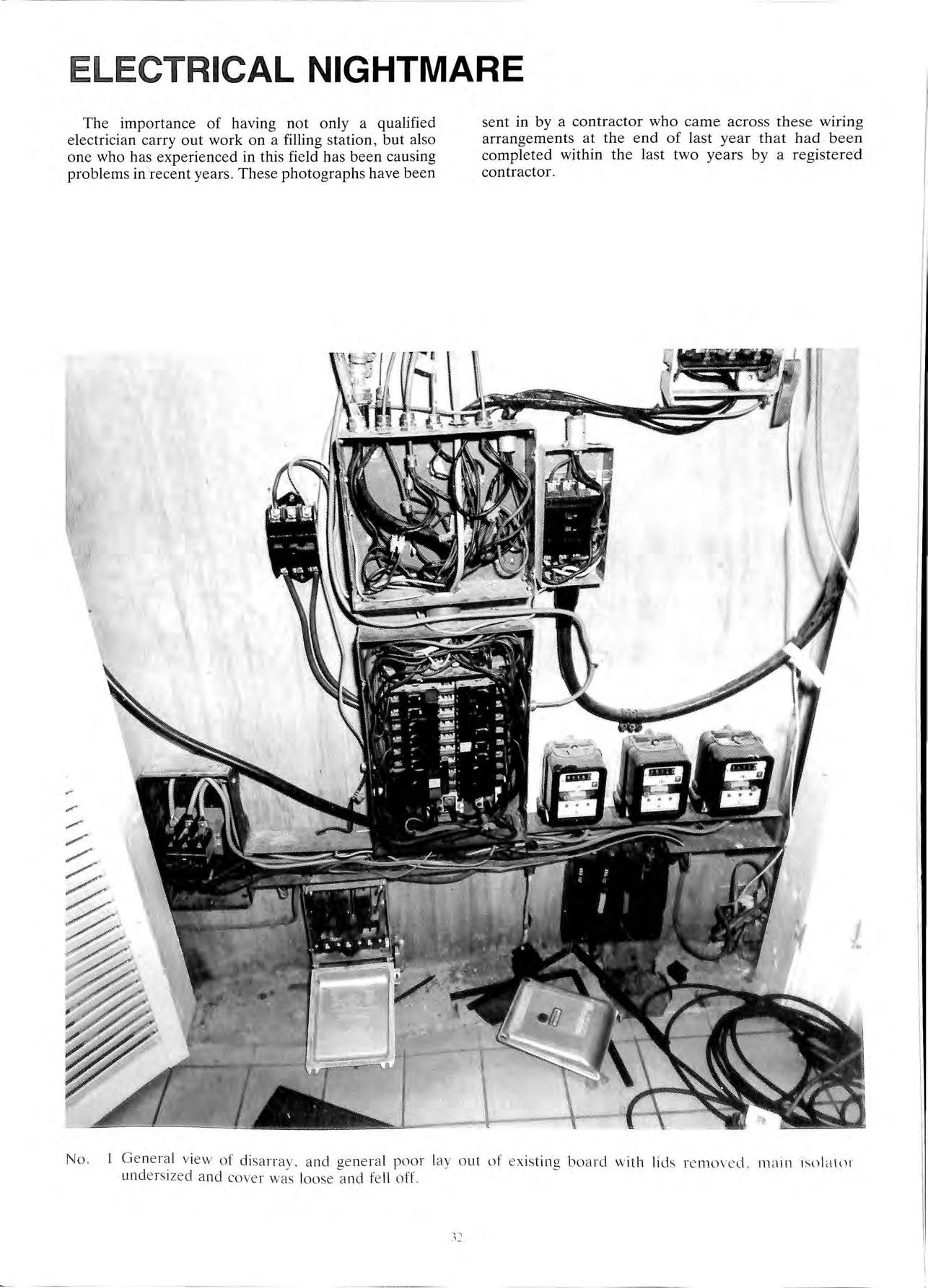

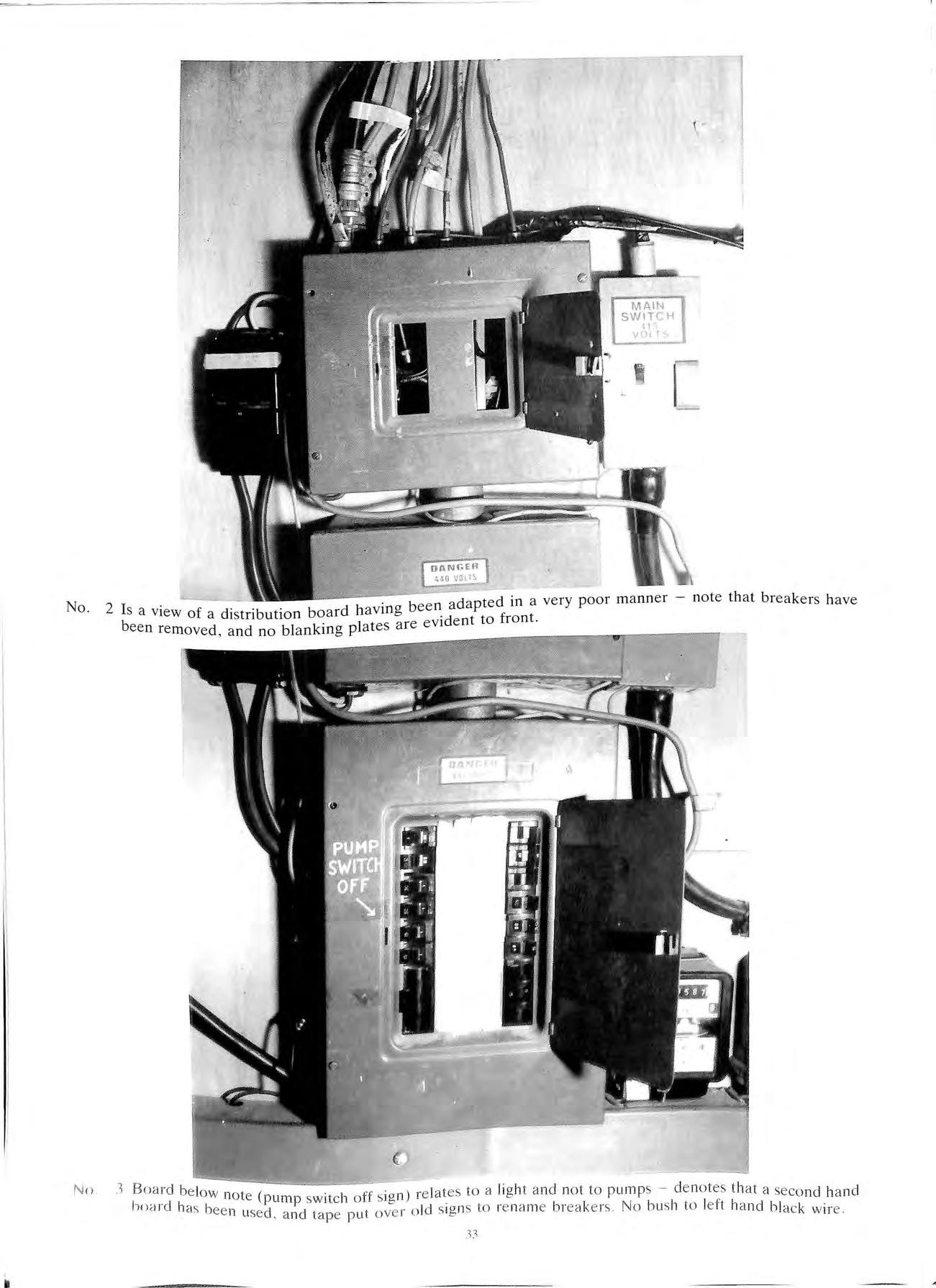

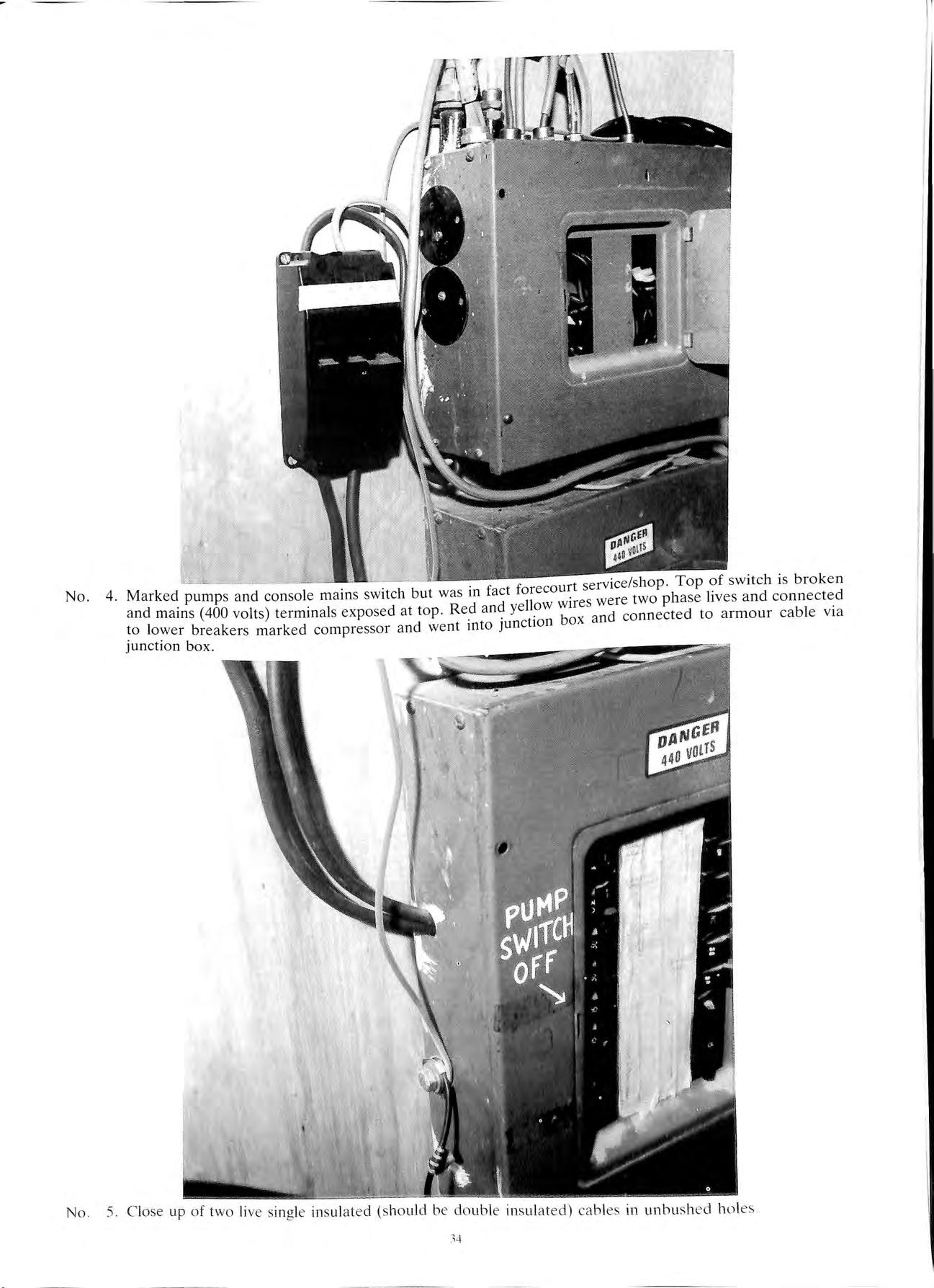

No. No , 11 MAIN SWITCH 11 vGt T-... I l I 2 Is a distribution bo a rd having b ee n adapted in a very poor manner note that bre a kers hav e be e n removed , and no blanking plates are evident to front. J Board be low I ' h hoard h as b n o t e ( pump s WIt c h o ff s Ig n) r e lat es to a Ig t a nd n o t t o pump s d e n o t es t h at a seco nd h and ee n use d , a nd ta p e p ut over o ld s Ig n s to l e n a m e br ea k e rs No bu s h to le ft hand bl a k ,c wir e.

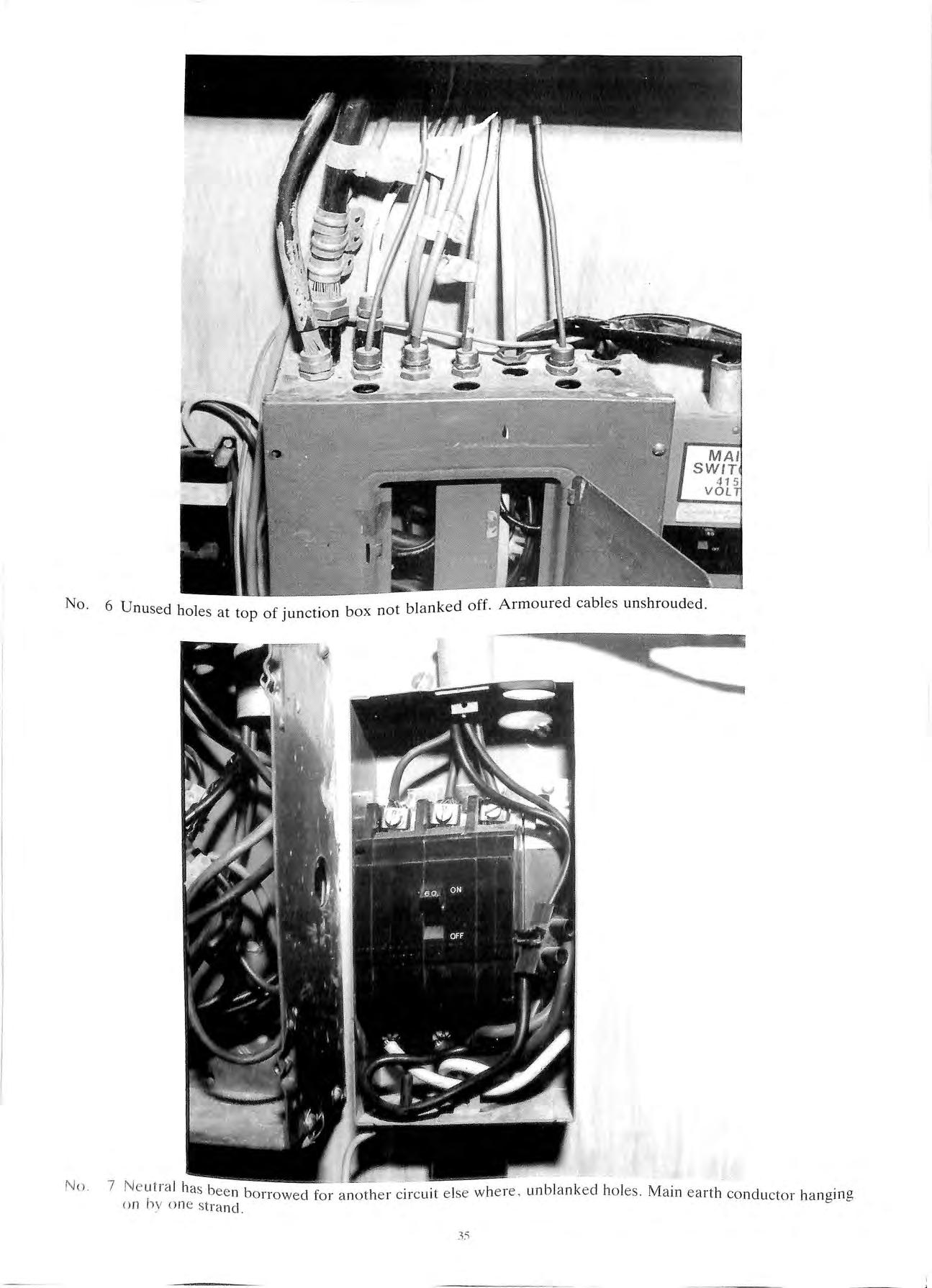

No. 5. C lose up o f t wo li ve s in g le in s ul a t e d ( s h o uld b e d o ubl e in s ul a t e d) ca bl es in unbu s h e d hol es

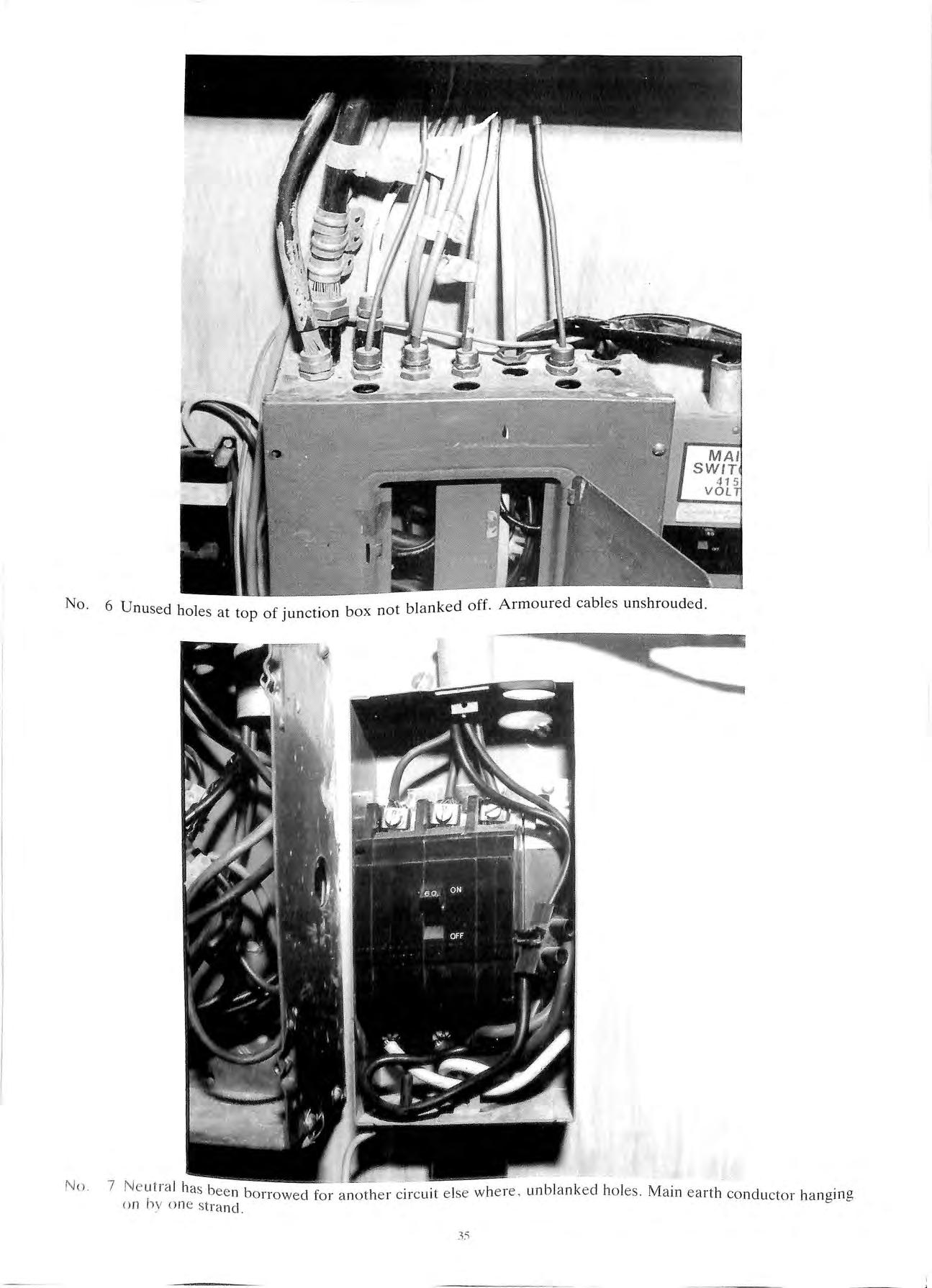

No. 4. Marked pumps and console main's switch but was in fact forecourt service/shop. Top of switch is brok e n and mains (400 volts) terminals exposed at top. Red and yellow wires were two phase lives and connected lo:-v er breakers marked compressor and went into junction box and connected to armour cable vi a Junctton box.

No. No. 6 Unused h If '

ot blanked

o es at top 0 JunctIon ox n 7 Ne utral ha s b ee n borrowed for e lse wh e r e , unblank e d h o les Main e arth conductor hanging o n h y o n e stra nd .

b

off. Armoured cables unshrouded.

Loose locknuts on armoured cables and Pyros to top of junction box This would effect earth continuity. Would constitute no earth to pump installation. (HIGHLY DANGEROUS) No. 9 Unbushed entry hole to bottom of box. Phase barrier missing. Note left h a nd fuse carrier missing and lower connection has fuse wire st ill attached No. 10 Ev id e nc e of ex pl os io n a nd po wd e r burn a nd ca rb o n (pha se t o ph ase ex plos io n) No . 12 Unbushed hole to top of lower mains switch f No. 13 F las h m a rk t o in sid e of m a in s cov e r of di str ibu t io n b oa rd r ef : No 10

No.

comprehensive safety and vessel servicing which Includes all aspects of work. : Nitrogen Inert Foam Inerting • Gas freeing using variouS Nitrogen purging techniques • Leak testing by all modern techniques Hot Work modifications, and repairs, to Lloyds/A.S.M.E. : Bottoming, Cleaning, Removal, Slurry Filling Mothballing • Resin, or Glass Reinforced, Spirit, Solvent, and Chemical Resistant • LiningS, engineered to Lloyds inspectorate of shipping approval. Abras ion to S.A.3, Protective Coatings, and Cathodic Protection. Please Ph exp' one (we charge no extra for our knowledge, insurance or enence) TELEX aMEWS 28 COMMERCIAL ROAD GUILDFORD GU1 4SU 59535 INTCOM G FAX 0483 571162 • LONDON / SOUTH EAST AREAS 01-549 6517 • SOUTHE GU iLD RN / CENTRA L AREAS &TECHN IC Al ENQUiRiES • FORD (0483) 222307 SOUTH • WEST AREA (0822) 2753 1 DAY.2 HOUR EMERGENCY CAll OUT (All AREAS) IRD (0483) 222301

Front end tn","ltn'" vehicles for the economic hand/ingof compactab/e wastes. A/so static compactors installed and serviced. FIFTY YEARS OF SERVICE PROGRESS AND EXPERIENCE A modern fleet of tankers for dealing with general and special industrial effluents. Established services for domestic and farm cesspits and gully cleaning Skip services for the professional builder and DI Yenthusiast. wide specialist Tank Cleaning Service. Jetting services for , garages and industrial commercial ;/ A 'Hotline' emergency se r vice for t he 'ou t of hours ' unexpected crises IS WHAT YOU GET WITH CLEANSING SERVICE GROUP HEAD OFFICE GRA NGE ROAD BOTLEY SOUTHA MPTO N 8032GD BOTlEY 2232 Ri NG WOOD 2008 BRISTOl552286 NEWBURY 45357 OXFORD 61150 EVESHA M 2620 STONEHOUSE 6116 SEVENOAKS 453175 M A R 2 6 A

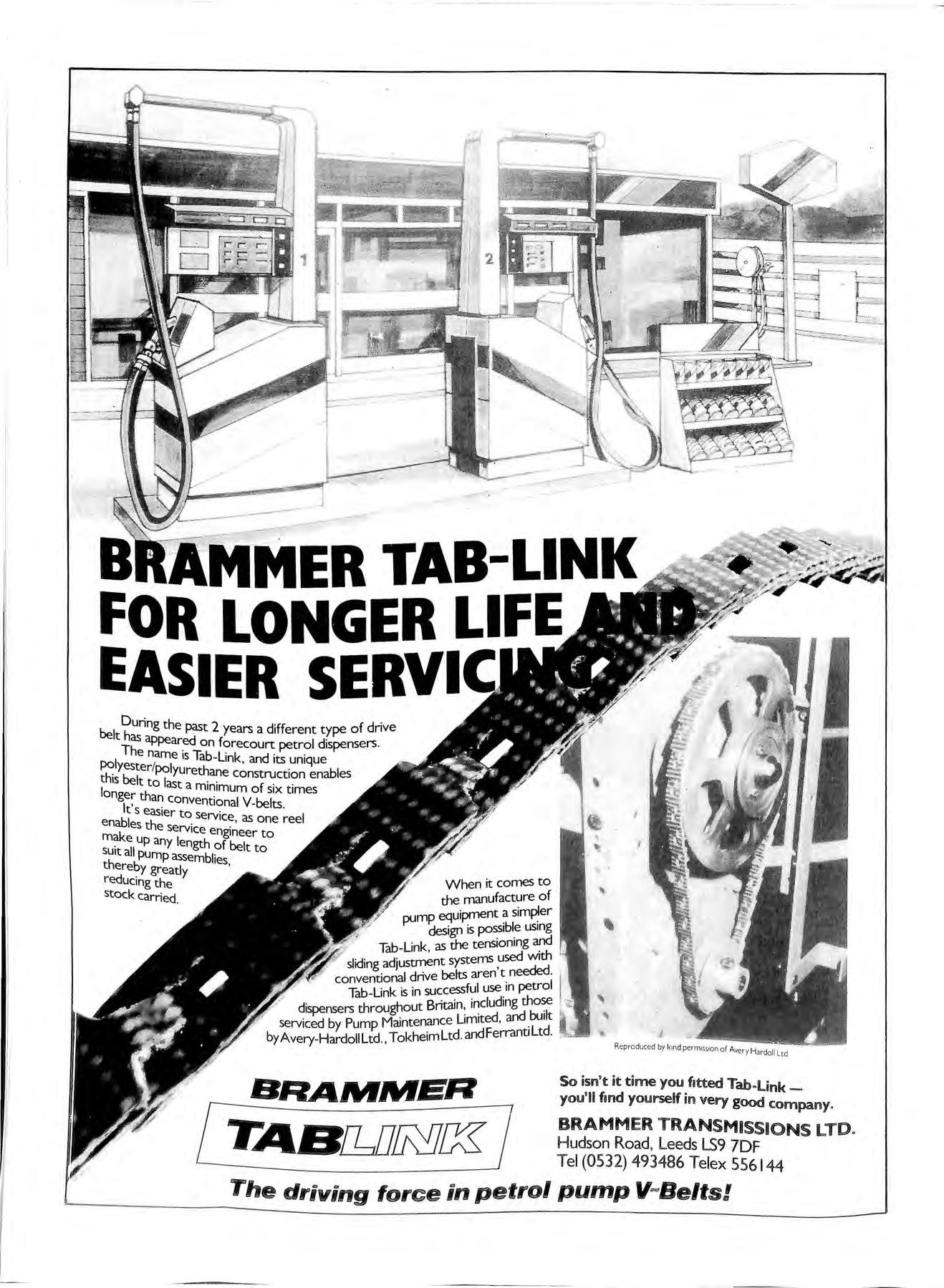

DUring the 2' belt h past years a different type of dnve appeared on forecourt petrol dispensers. pol e name IS Tab Link and its unique yester/pol h ' this belt to I yuret construction enables longer th ast a of six times I , an Conventional V-belts t s easier to enables th . service, as one reel make e service engineer to suit all up any length of belt to pump assemblies thereby greatly , redUcing the stock carried.

LONGER

B MER TAB-LINK FOR

LIFE EASIER SERVI

BRANlItIIER [ TAB!YJ!iYli% I So it time you fitted Tab-link _ you 11 fmd yourself in very good company BRAMMER TRANSMISSIONS LTD. Hu dson Road, Leeds LS9 7DF Te l (0 532) 49 3486 Telex 556 144 The driving force in petrol pump V=Belts!

When it comes to the manufacture of pump equipment design is poSSible USIng Tab-Link , as the tensioning sliding adjustment systems ,used with conventional drive belts aren t needed. Tab-Link is in successful use in petrol dispensers throughout including those serviced by Pump Maintenance Limited , and bUilt by Avery-HardoIlLtd., TokheimLtd and Ferrantl Ltd.

r Now you dispense, meter or transfer uSing our unique portable battery operated pump which delivers up to 10 GPM • 12 and 24 volt D.e. pumps • Mechanical and Electronic digital flow meter Pump Services (U.K.) Ltd. Western Park , Kansas Avenue Salford, Manchester MS 2GL. Tel : 061-873 7428 Telex: 667834 THE FUEL DISPENSING SPECIALISTS Jfobn gigfuII &: ([0. Jitb. FIRST HANGINGS· BLABY ROAD ENDERBY LEICESTER· LE9 5AQ Telephone: Leicester 862287 (STD 0533) For a Comprehensive service for Liquid Fuel & LPG installations Consultancy, design , installation, maintenance & decomlnissioning Gas-free certificates Site surveys LPG vessel 5 & 10 year inspections MEMBER A,P,E.A, LP,G,LT,A,

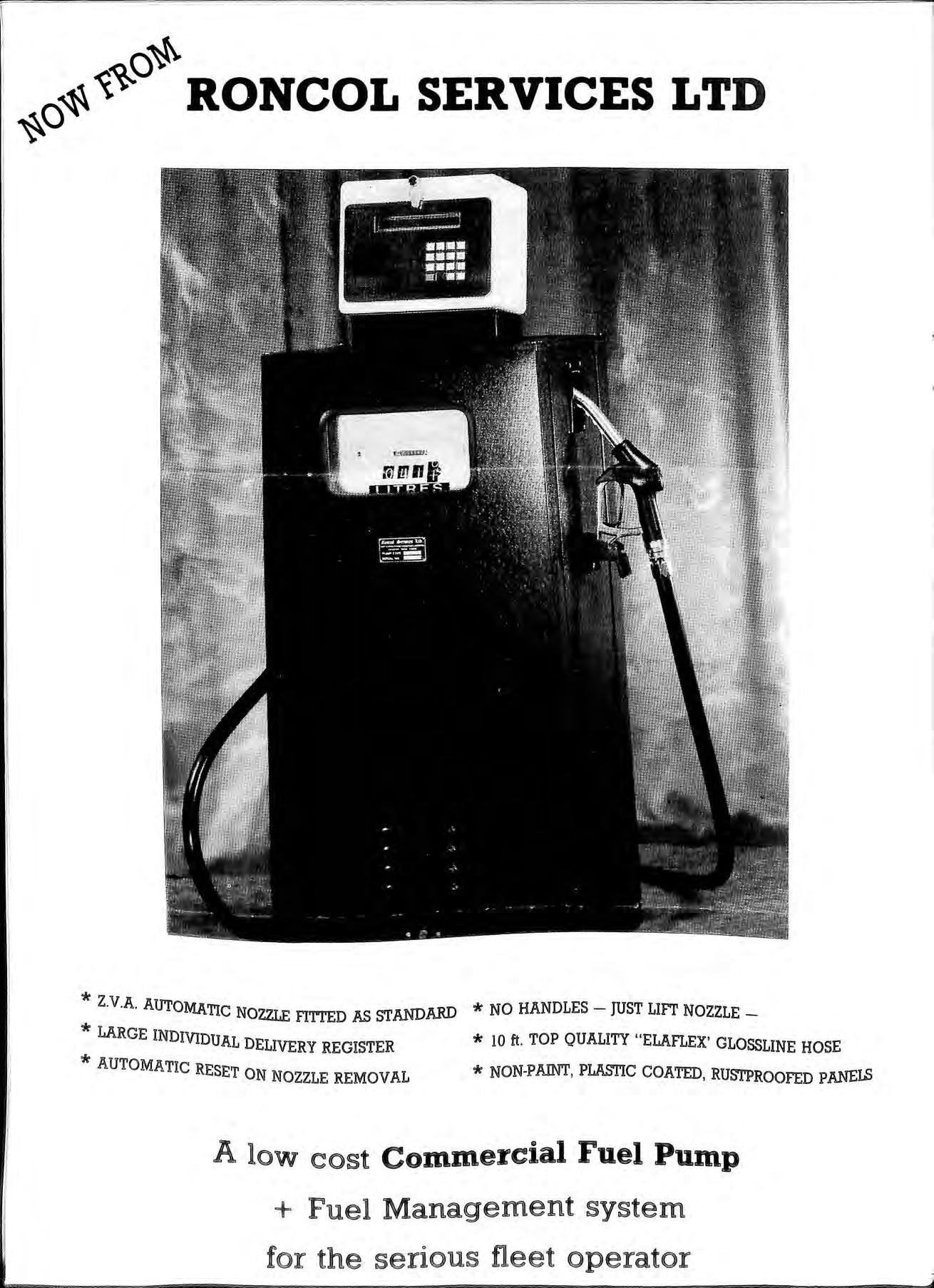

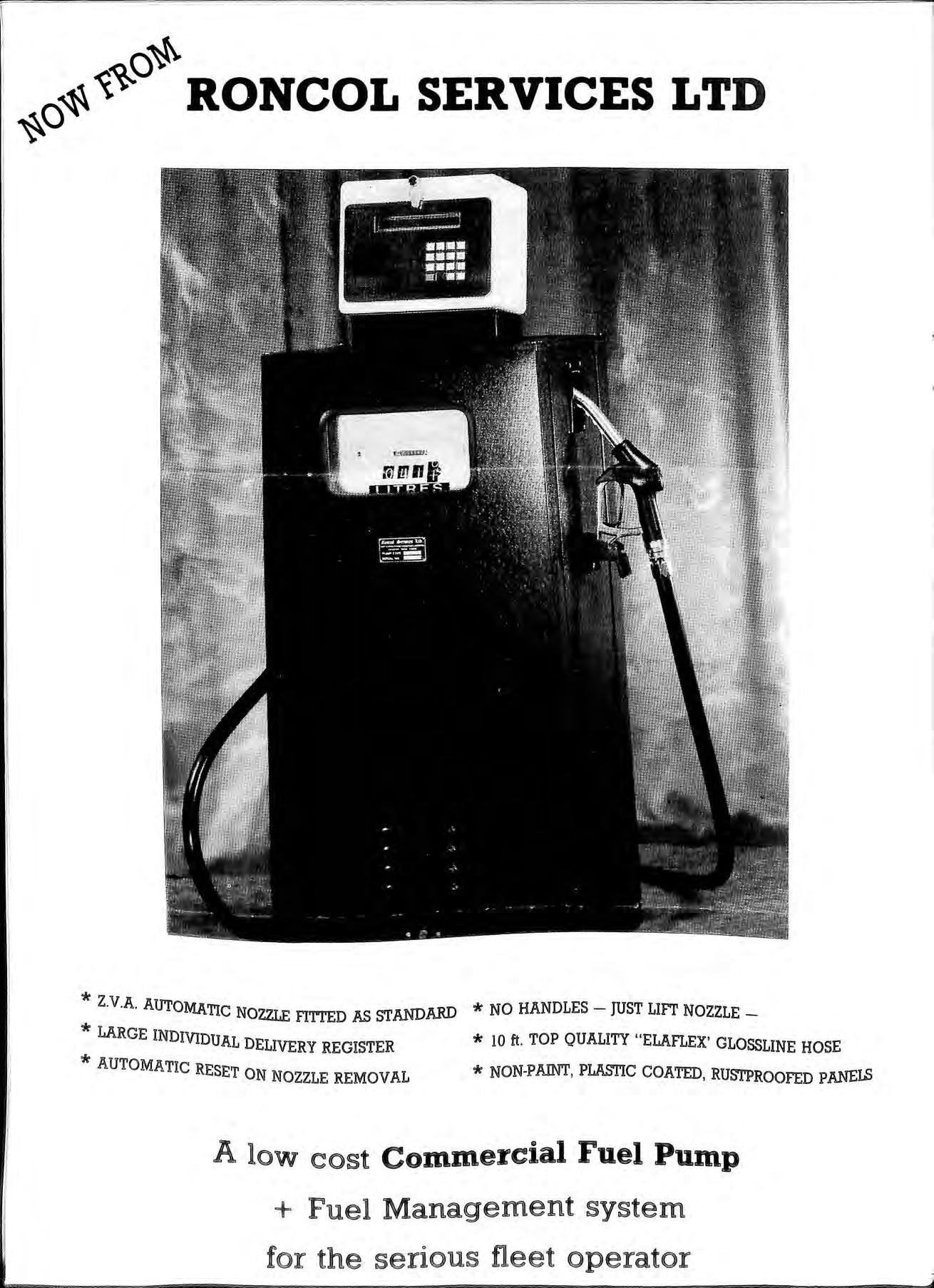

RONCOL SERVICES LTD * Z.V.A. AUTOMATIC NOZZLE FITTED AS STANDARD * NO HANDLES JUST LIFT NOZZLE* LARGE INDIVI DUAL DELIVERY REGISTER * 10 ft. TOP QUALITY "ELAFLEX' GLOSSLINE HOSE * AUTOMATIC RE SET ON NOZZLE REMOVAL * NON-PAINT , PLASTIC COATED, RUSTPROOFED pANELS A low cost Commercial Fuel Pump + Fuel Management system for the serious fleet operator

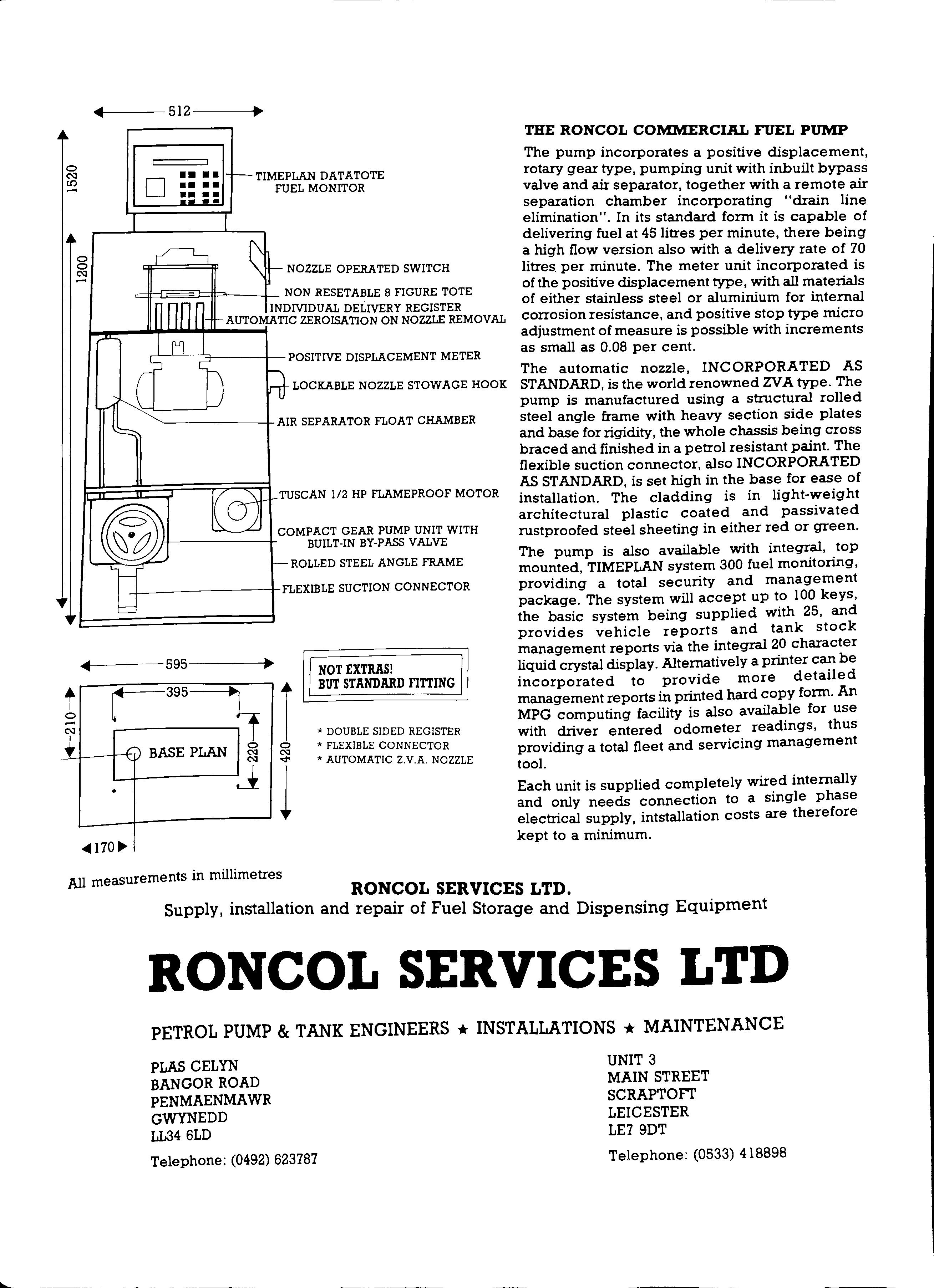

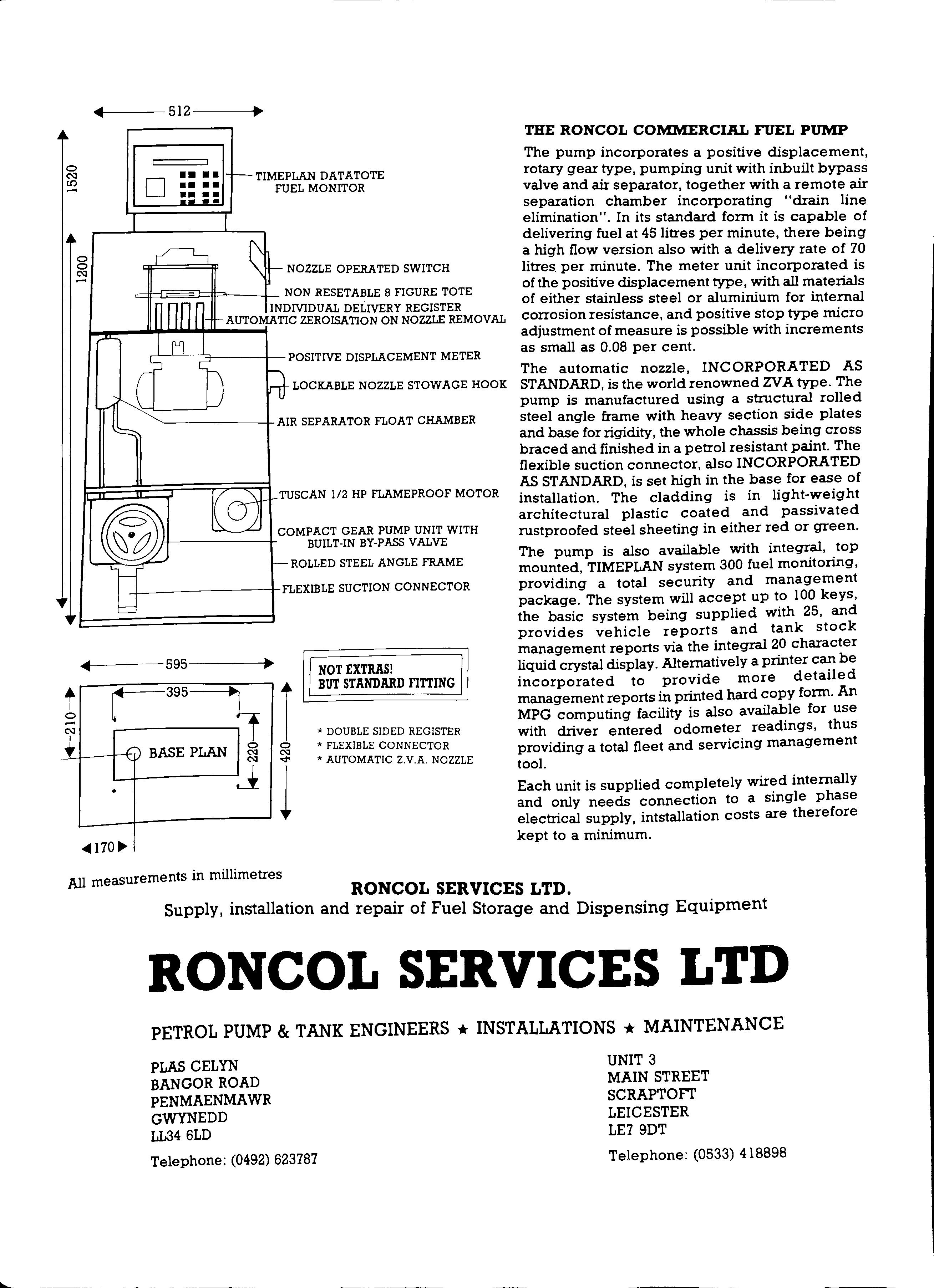

TIMEPLAN DATATOTE FUEL MONITOR NOZZLE OPERATED SWITCH NON RESETABLE 8 FIGURE TOTE INDMDUAL DELIVERY REGISTER TIC ZEROISATION ON NOZZLE REMOVAL POSITIVE DISPLACEMENT METER

THE RONCOL COMMERCIAL FUEL PUMP

The pump incorporates a positive displacement, rotary gear type, pumping unit with inbuilt bypass valve and air separator, together with a remote air separation chamber incorporating "drain line elimination". In its standard form it is capable of delivering fuel at 45 litres per minute, there being a high flow version also with a delivery rate of 70 litres. per minute. The meter unit incorporated is of the positive displacement type, with all materials of either stainless steel or aluminium for internal corrosion resistance, and positive stop type micro adjustment of measure is possible with increments as small as 0.08 per cent. TUSCAN 1/2 HP FLAMEPROOF MOTOR

The automatic nozzle, INCORPORATED AS STANDARD, is the world renowned ZVA type. The pump is manufactured using a structural rolled steel angle frame with heavy section side plates and base for rigidity, the whole chassis being cross braced and finished in a petrol resistant paint. The flexible suction connector, also INCORPORATED AS STANDARD, is set high in the base for ease of installation. The cladding is in light-weight architectural plastic coated and passivated rustproofed steel sheeting in either red or green.

The pump is also available with integral, top mounted, TIMEPLAN system 300 fuel monitoring, providing a total security and management package. The system will accept up to 100 keys, the basic system being supplied with 25, and provides vehicle reports and tank stock management reports via the integral 20 character liquid crystal display. Alternatively a printer can be incorporated to provide more detailed management reports in printed hard copy form. An MPG computing facility is also available for use with driver entered odometer readings, thus providing a total fleet and servicing management tool.

Each unit is supplied completely wired internally and only needs connection to a single phase electrical supply, intstallation costs are therefore kept to a minimum.

o c:-;J too o c:-;Jo •••• •••• •••• •

"-------l- AIR

LOCKABLE NOZZLE STOWAGE HOOK

SEPARATOR FLOAT CHAMBER

t 0COMPACT GEAR PUMP UNIT WITH 1+_____ .1- BUILT-IN BY-PASS VALVE ROLLED STEEL ANGLE FRAME --+--_------t-FLEXIBLE SUCTION CONNECTOR BASE PLAN 0 c:-;J "- c:-;J r NOT EXTRAS! I r I BUT STANDARD nTl'ING * DOUBLE SIDED REGISTER * FLEXIBLE CONNECTOR * AUTOMATIC Z.V.A. NOZZLE . 1

All measurements in millimetres RONCOL SERVICES LTD. Supply, installation and repair of Fuel Storage and Dispensing Equipment RONCOL SERVICES LTD PETROL PUMP & TANK ENGINEERS * INSTALLATIONS * MAINTENANCE PLAS CELYN BANGOR ROAD PENMAENMAWR GWYNEDD 11346LD Telephone: (0492) 623787 UNIT 3 MAIN STREET SCRAPTOFT LEICESTER LE79DT Telephone: (0533) 418898

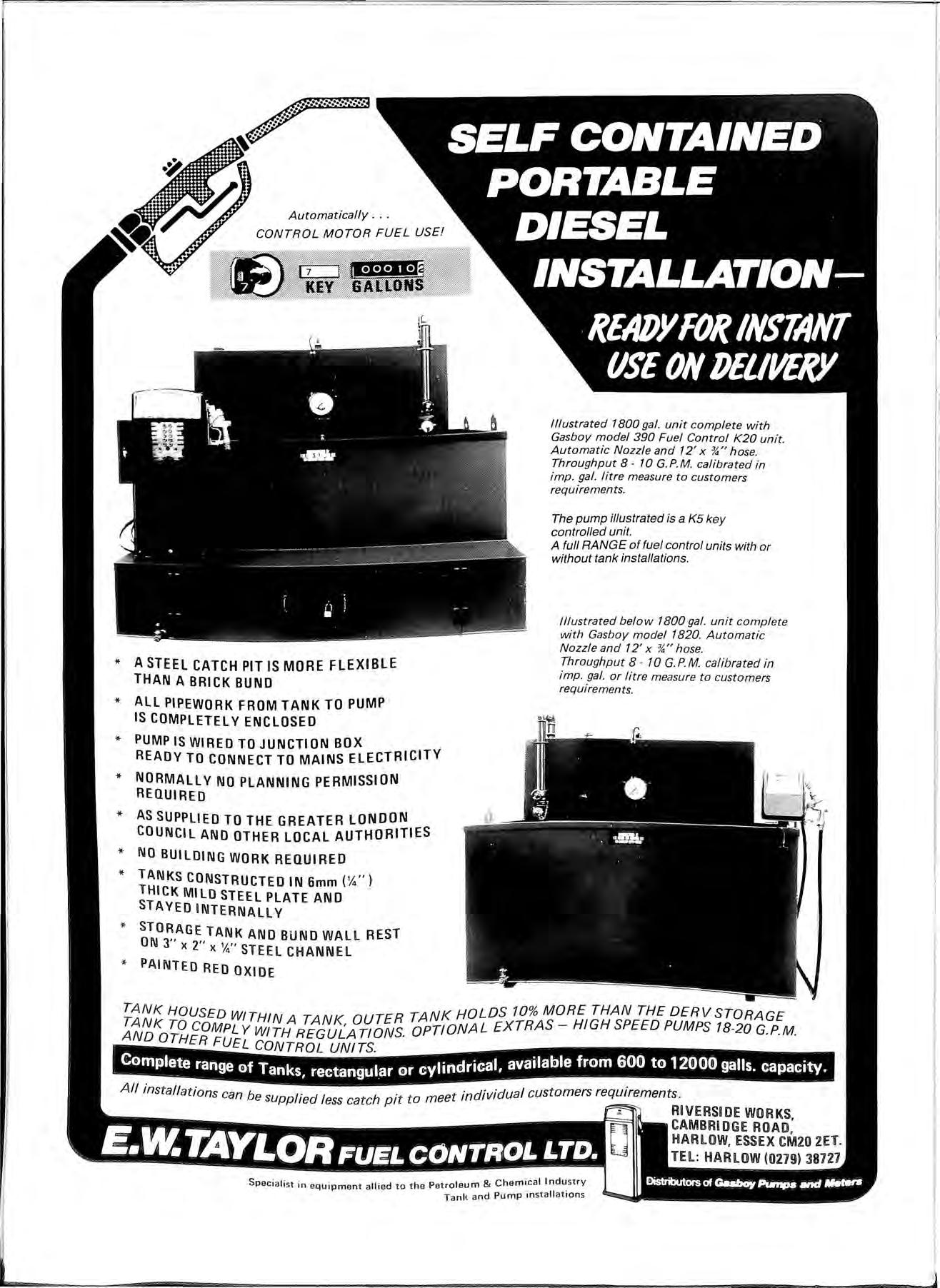

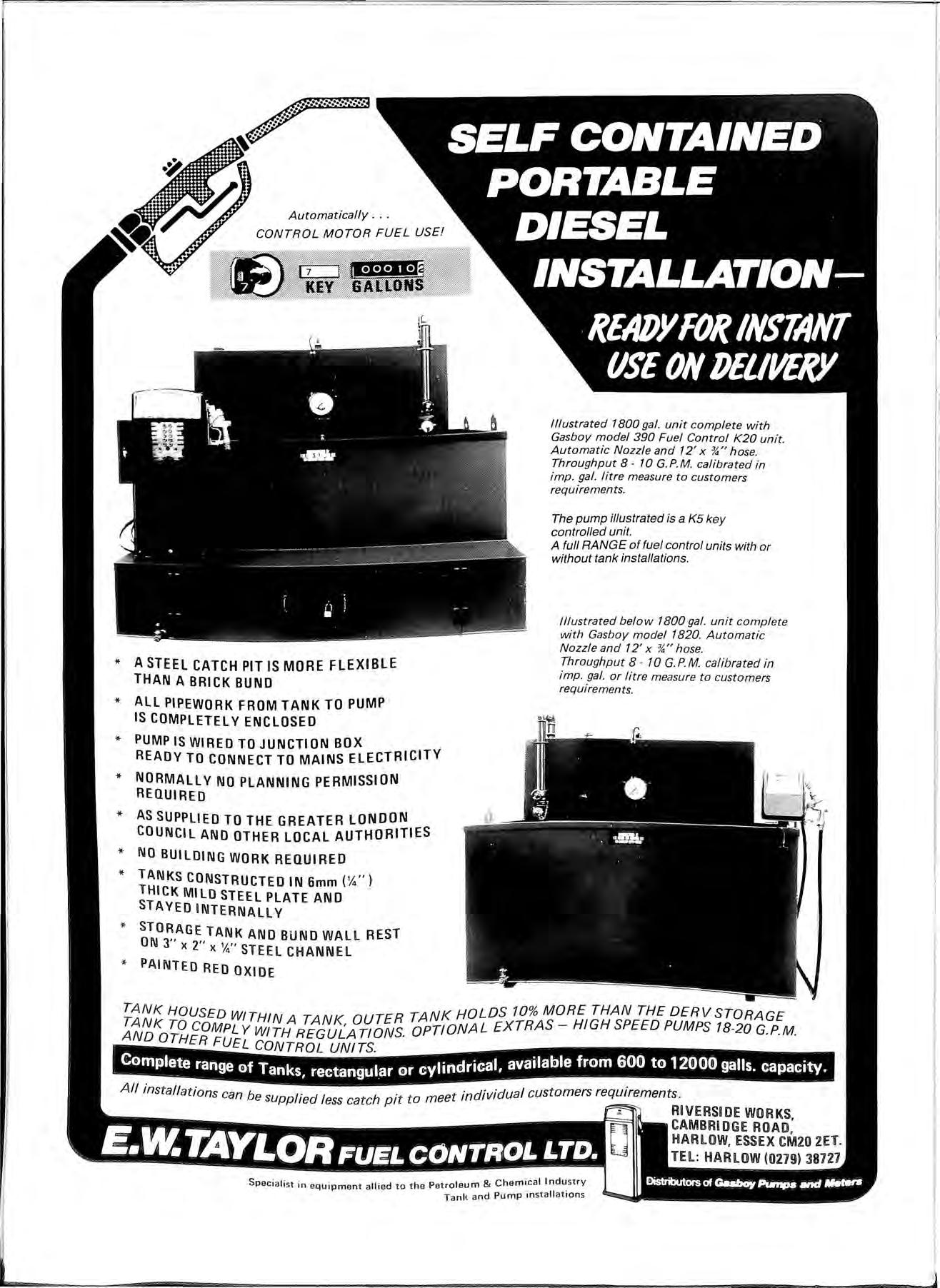

I l * A STEEL CATCH PIT IS MORE flEXIBLE THAN A BRICK BUND * ALL PIPEWORK FROM TANK TO PUMP IS COMPLETEL Y ENCLOSED * PUMP IS WIRED TO JUNCTION BOX READY TO CONNECT TO MAINS ELECTRICITY * NORMALLY NO PLANNING PERMISSION REQUIRED * AS SUPPLIED TO THE GREATER LONDON COUNCIL AND OTHER LOCAL AUTHORITIES * NO BUILDING WORK REQUIRED * TANKS CONSTRUCTED IN 6mm (Yo") THICK MILD STEEL PLATE AND STAYED INTERNALLY * STORAGE TANK AND BUND WALL REST ON 3" x 2" x Yo" STEEL CHANNEL * PAINTED RED OXIDE Illustrated 1800 gal unit complete with Gasboy model 390 Fuel Control K20 unit. Automatic Nozzle and 12' x hose Throughput 8 10 G P. M. calibrated in imp gal litr e measure to customers requirements

pump illustrated is a K5 key controlled unit. A full RANGE of fuel control units with or without tank installations.

below 1800 gal. unit complete with Gasboy model 1820. Automatic N ozzl e and 12' x %," hose.

ghput 8 10 G. P M. ca librated in imp. gal. or litre measure to customers requirements TANK HOUSED WITHIN A TANK OUTER TANK HOLDS 10 % MORE THAN THE DERV STORAGE COMPL Y WITH REGULA TlONS. OPTIONAL EXTRAS HIGH SPEED PUMPS 18 20 G P.M. THER FUEL CONTROL UNITS Complete range of Tanks, rectangular or cylindrical, available from 600 to 12000 galls. capacity. A ll Installatlons can be supplied less catch pit to meet individual customers reqUirements. RIVERSiDE WORKS CAMBRIDGE ROAD' HARLOW, ESSEX CM20 2ET. TH : HARLOW (0279) 38727 Specialist i n e quipment allied to the Petroleum & Chem ic a l I ndust ry Tank a nd Pump installations

The

Illustrated

Throu

LAFON SAFETY FILLING LIMITERS

For above or underground tank storage of petrol and diesel, gravity or pump fed.

With forecourt safety in mind, the Lafon Filling Limiters ensure no overfills , no pollution or environmental damage.

With deliveries out of hours no errors in filling can take place .

Full protection against product overfills, damage and pollution costs.

The LAFON Filling Limiters require no maintenance, are used internationally, and do not rely on extraneous products such as electricity.

-on (Forecourt Safety at its Best) I.F.L. Ltd. 160 Abb ey Stre et , Der by D E3 3SS T el : 0332 36 9 6 14 Tel ex: 3 77 106

(IFL)

EASTERN COUNTIES TANK CLEANERS LTD. St. Margarets Wharf STANSTED ABBOTTS, Ware, Herts. 5, Brinell Way, Hal1reys Industrial Est. GREAT YARMOUTH, Norfolk. TANK CLEANING, GENERAL CLEANING and 24 HOUR EMERGENCY OIL SPILLAGE ANTI-POLLUTION SERVICE TANKS Oil . Spirit . Chemical . Pharmaceutical· Water· Petrol Aviation Fuel . Tank Painting · Tank Removal Descaling of Pressure or Condensate Tanks Pressure testing of Tanks and Pipes Interceptor Pit clearance · Oil spillages Also rehabilitation of below ground Service Station Tanks. Waste Oil Collection and Recycling. Telephone: Ware (0920) 870343 Telex: 817535 Gt. Yarmouth (0493) 602848 Telex: 975422 EASTE RN COUNTIES TANK CL£AN£RS Published by the Association for Petroleum and Explosives Administration and Printed by Miro Press, Bury St. Edmunds.