• '•

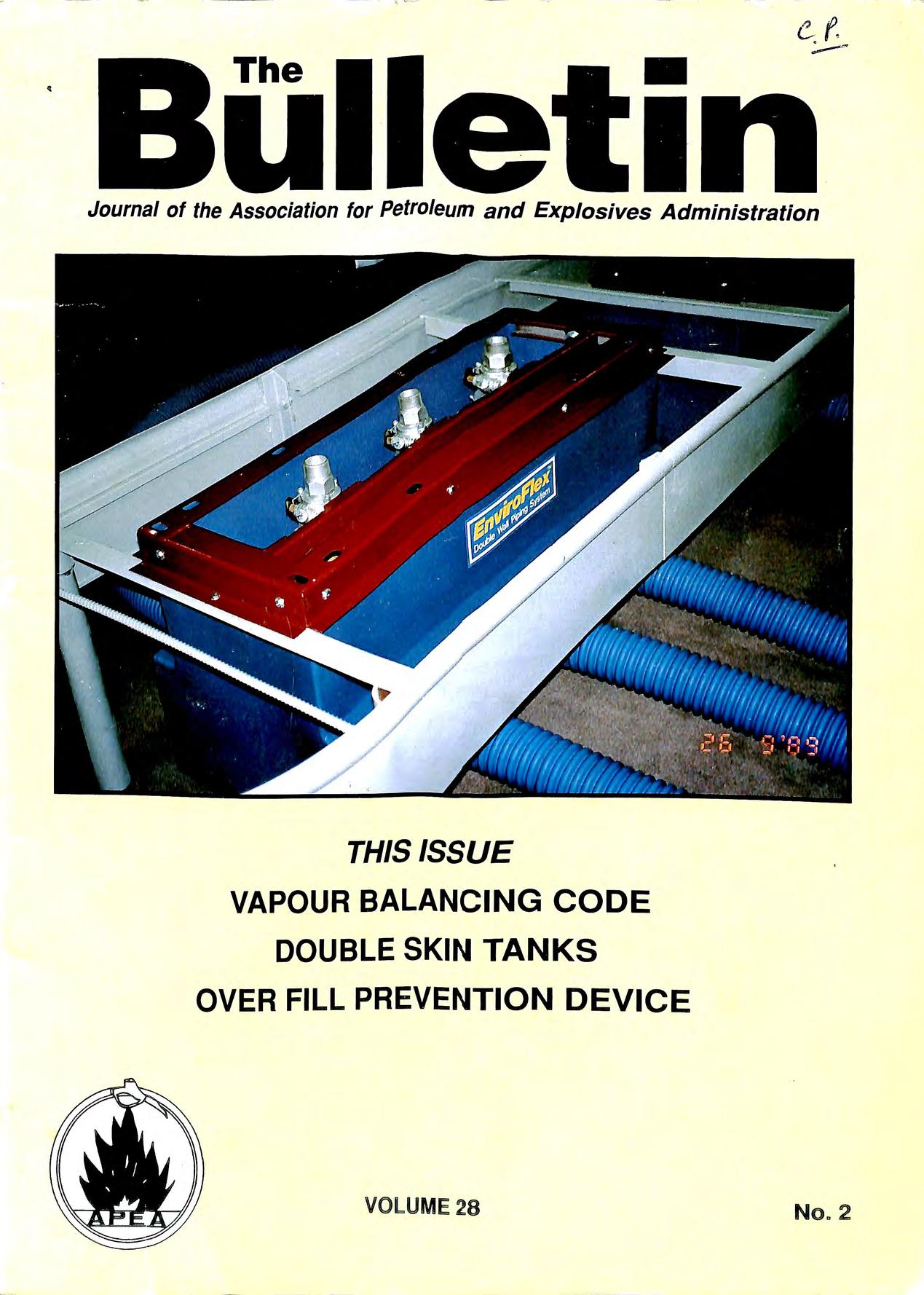

THIS ISSUE VAPOUR BALANCING CODE DOUBLE SKIN TANKS OVER FILL PREVENTION DEVICE VOLUME 28 No. 2

Journal of the Association for Petroleum and Explosives Administration

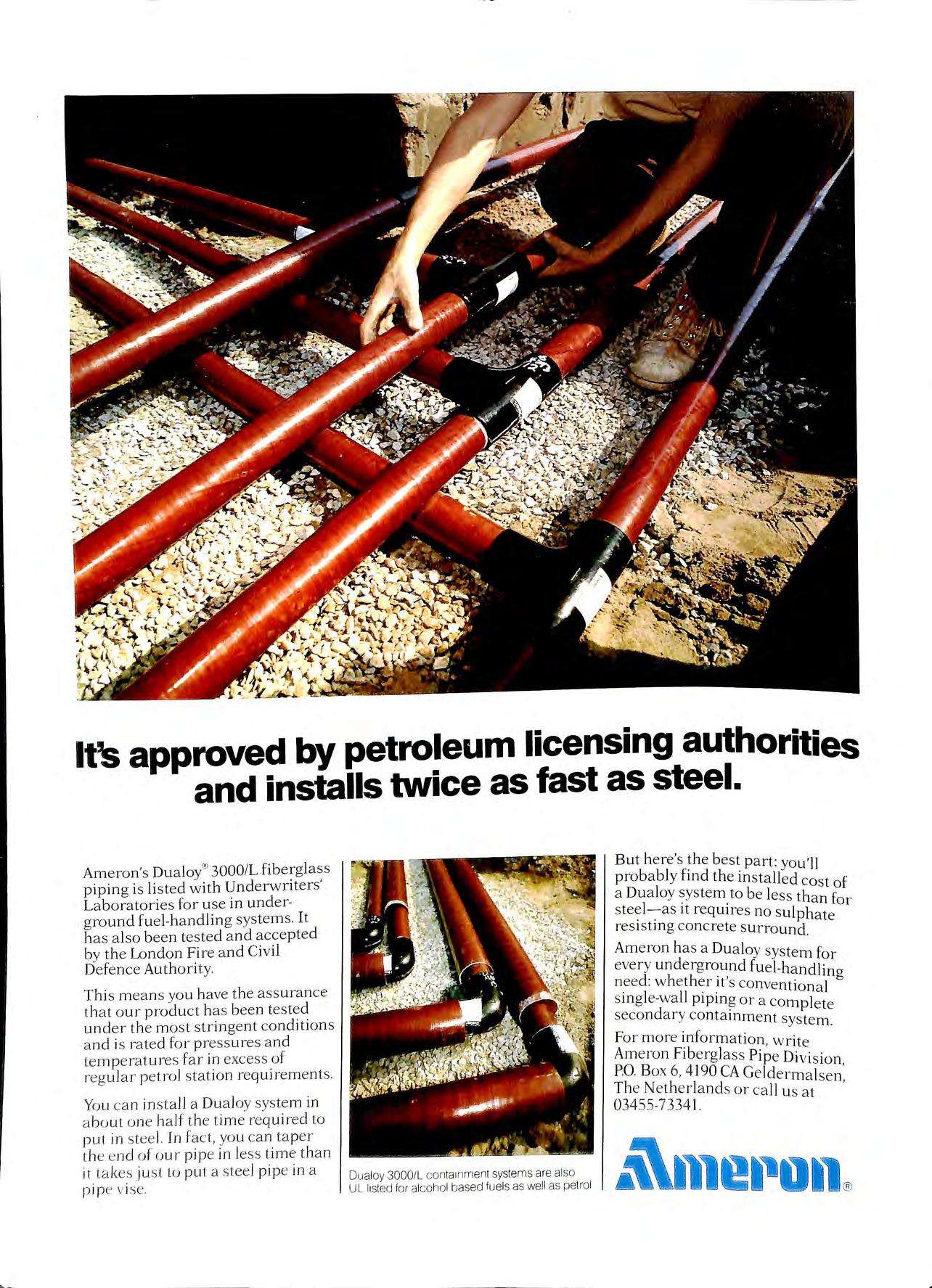

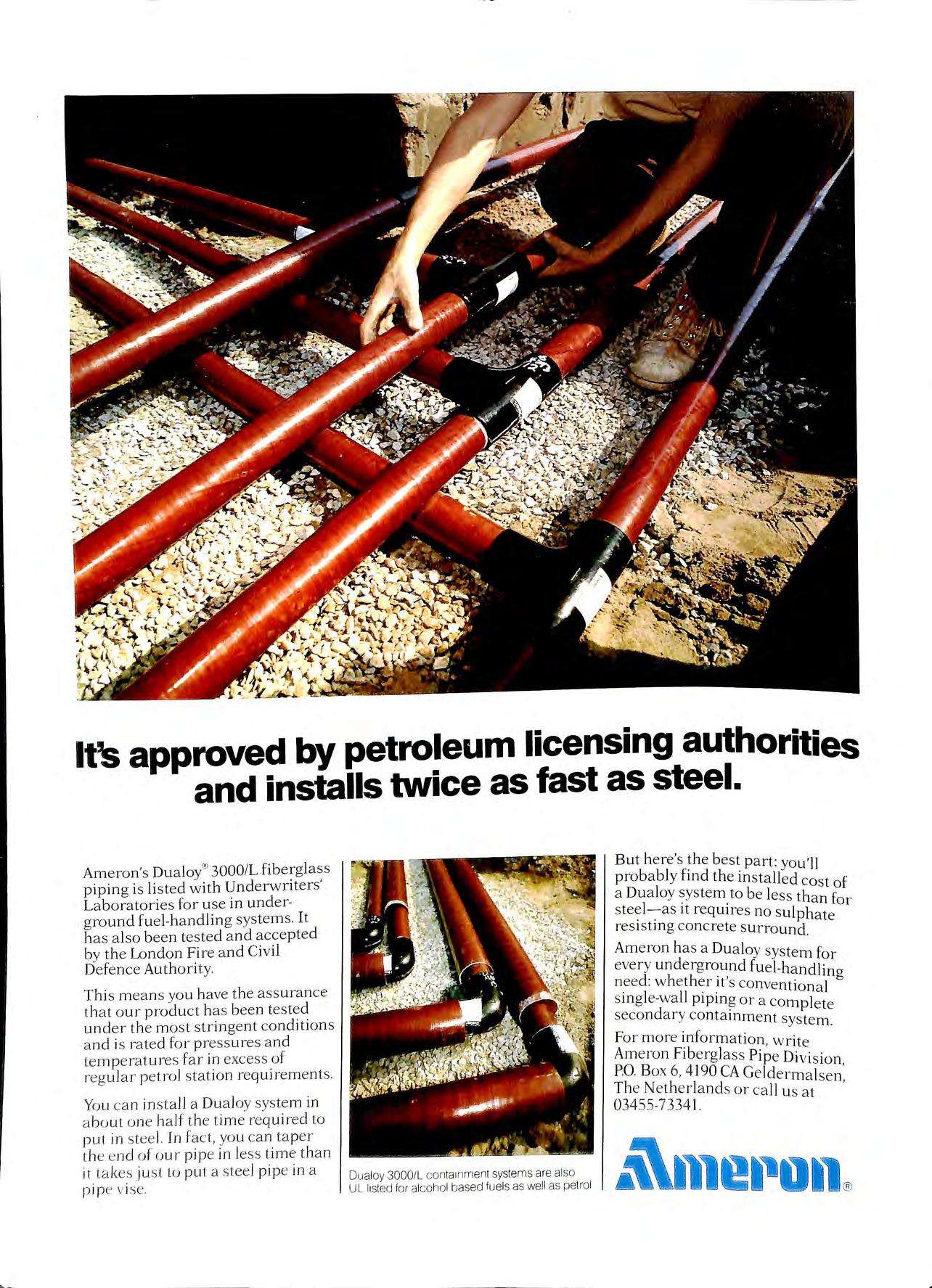

Ameron's Dualoy®3000/L fiberglass piping is listed with Underwriters ' Lab ora tories for use in und e rground fuel-handling systems. It h as also been tested and accepted by th e London Fire and Civil Defence Authority.

Thi s m ea n s you have the a ss u ra n ce th a t o ur product ha s b ee n te s ted und er th e mo s t stringent co nditions a nd is rat e d for pressure s a nd te mp e ra ture s far in excess o f reg ul a r p e trol s tation re quirem e nt s.

You ca n in s tall a Dualoy sys t e m in a bo ut o n e half the tim e req uire d to put in s t ee l In fa c t, yo u c an ta p er th e e nd o f o ur pip e in less time t han i t ta kes ju s t to put a s teel pip e in a p i p e v1se.

Ou al oy 3000/L c ontai nment syste ms are also UL listed for alcohol based fue ls as well as petrol

But here's the best part: you'l l probably fmd t h e installed cost of a Dualoy system to be less th f I · an or stee -as 1t requ i res no su lph · ate res1st111g concrete s u rround .

Ameron has a Du a loy system for eve ry underground fue l ha dl. d . h h . , - n mg n.ee . w e t er 1t s conventi I I II ona s m g e wa p1p111g or a co rn I d seco n a r y co ntamment syst e m.

For more i.nformation, wr it e Ameron F1berg lass Pipe Division, PO. Box 6, 4 190 CA Geldei ma l Th N h c se n , e e t er lands or cal l u s at 03455-73341.

It's approved by petroleum licensing authorities and installs twice as fast as steel.

C p INSTALLATIONS LTD. (Established 1968) Specialists in Petroleum Pipework Installations New and existing Tanks and Lines tested Modifications to existing Installations And all work associated with Forecourt Pipework 39 BROOK ROAD, RAYLEIGH WEIR INDUSTRIAL ESTATE RAYLEIGH, ESSEX SS6 7XN Tel: RAYLEIGH (0268) 781184 I 781859 (24 hrs ans.) PHONE: 071-739 9538 FAX: 071-729 6108 TUBEFLOW LTD SPECIALISTS IN PETROL PUMP, TANK AND PIPEWORK INSTALLATIONS AND ASSOCIATED WORKS APPROVED CONTRACTORS TO THE PETROLEUM INDUSTRY AND LOCAL GOVERNMENT AUTHORITIES 29 TEMPLE STREET, LONDON E2 6QQ MEMBER A.P.E.A.

W. LAMB LTD. THE PREMIER PUMP AND TANK COMPANY Forecourt and Commercial - Above and Below Ground Supply Test - Exchange - Service - lnstal Product Transfer De-Watering - Removal - Purchase Tank Demolition Removal Safety Filling Large Stocks of New and Secondhand Petrol and Diesel Pumps, Tanks and Accessories DAYBROOK STREET, SHERWOOD, NOTTINGHAM 0602 621511 + 608084 TRINITY WORKS, BOURNE END LANE, HEMEL HEMPSTEAD 0442 872296 Telephone 021-236 0347 W. J. FINCH (Installations) Ltd. Steaming out and de-gassing petrol tanks; issuing gas free certificates Complete petrol and fuel oil bulk storage tank installations Petrol and fuel oil tank cleaning service Pressure testing tanks and pipe work Heaton House, Camden St., Birmingham BI 3BZ

BARNES & KERR CONSTRUCTION PETROL SERVICE STATION SPECIALISTS Unit 2, Block 3, Strutherhill Industrial Estate LARKHALL ML9 2PA Pump Installations Tanks/Pipework Self Service Equipment Canopies All Building Works Electrical Work NICEIC Drainage/Civil Works Degassing/Pressure Testing For a competitive quotation and the best attention at all times CALL 0698 887950/1 FAX: 0698 887951 We cover Scotland/North of England 1obn Uigfull & <!Co. lltb. FIRST HANGINGS BLABY ROAD ENDERBY LEICESTER LE9 SAQ Telephone (0533) 862287 Fora Comprehensive service for liquid fuel & LPG installations Consu/Jancy, design, installation, maintenance & decommissioning certificates Site surveys LPG vessel 5 & 10 year inspections MEMBER APEA, LPGITA DESIGN FUELLED B EXPERIENC Personal attention in d esign & development for the petroleum retail industry • Principal with over 25 years experience • Proj ect Management specialists • Progress ive & innovative outlook • Consultants for stat utory & planning re quir e ments •C omprehensive or tailor e d service to suit PLANACOURT Planacourt Lirnited PO. Bo:-,: 27 BilleiicJ\ ' Essc:--,: CMll '.2ES 0277 630868

C·S·STANSFIELD MECHANICAL SPECIALISTS IN FORECOURT PETROLEUM INSTALLATIONS SERVICES Unit 10 Boundary Road Industrial Estate Sturmer, Haverhill Suffolk, CB9 7YH Tel: 0440 712505 Fax: 0440 712506 BELHAN CONSTRUCTION CO LTD Building Contractors (Est 1970) Comprehensive Development and Maintenance Servi c e s By Petrol Station Sp ec ial is t s 58 St. A n d rew s Road Shoebury ness Essex SS3 9JJ Tel: 0702 295197

MANGAN BROS. LTD. Building Contractors 402 Seven Sisters Road, London N4 2LU (REGISTERED OFFICE) Telephone: 01 800 4651 Specialists in Petrol Filling Stations D. S. Leggett (Electrical) Limited ELECTRICAL CONTRACTORS NICEIC APPROVED 181 VICTORIA ROAD, NEW BARNET, HEATS. 01-441 3958 SPECIALISTS IN PETROL STATIONS

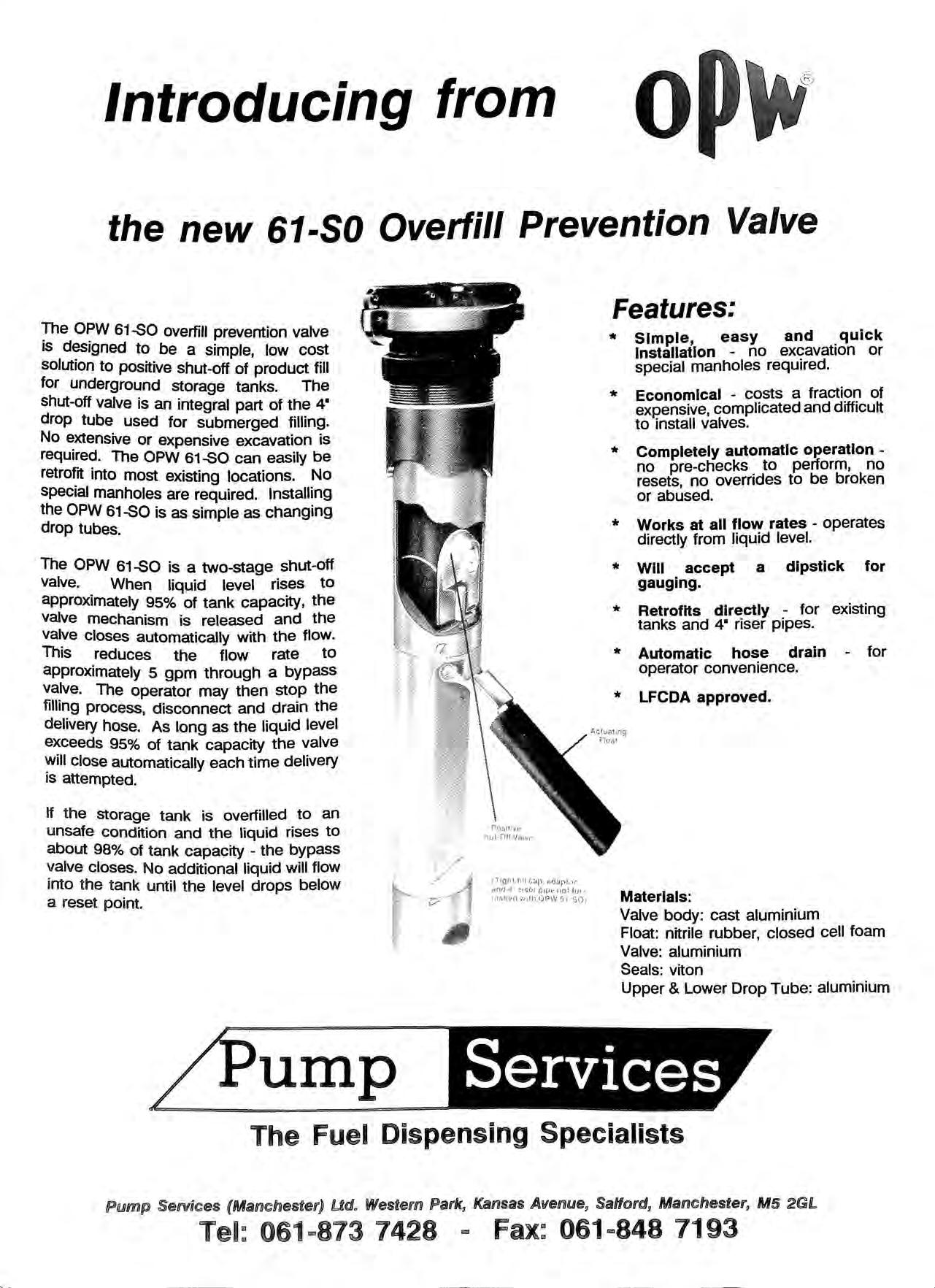

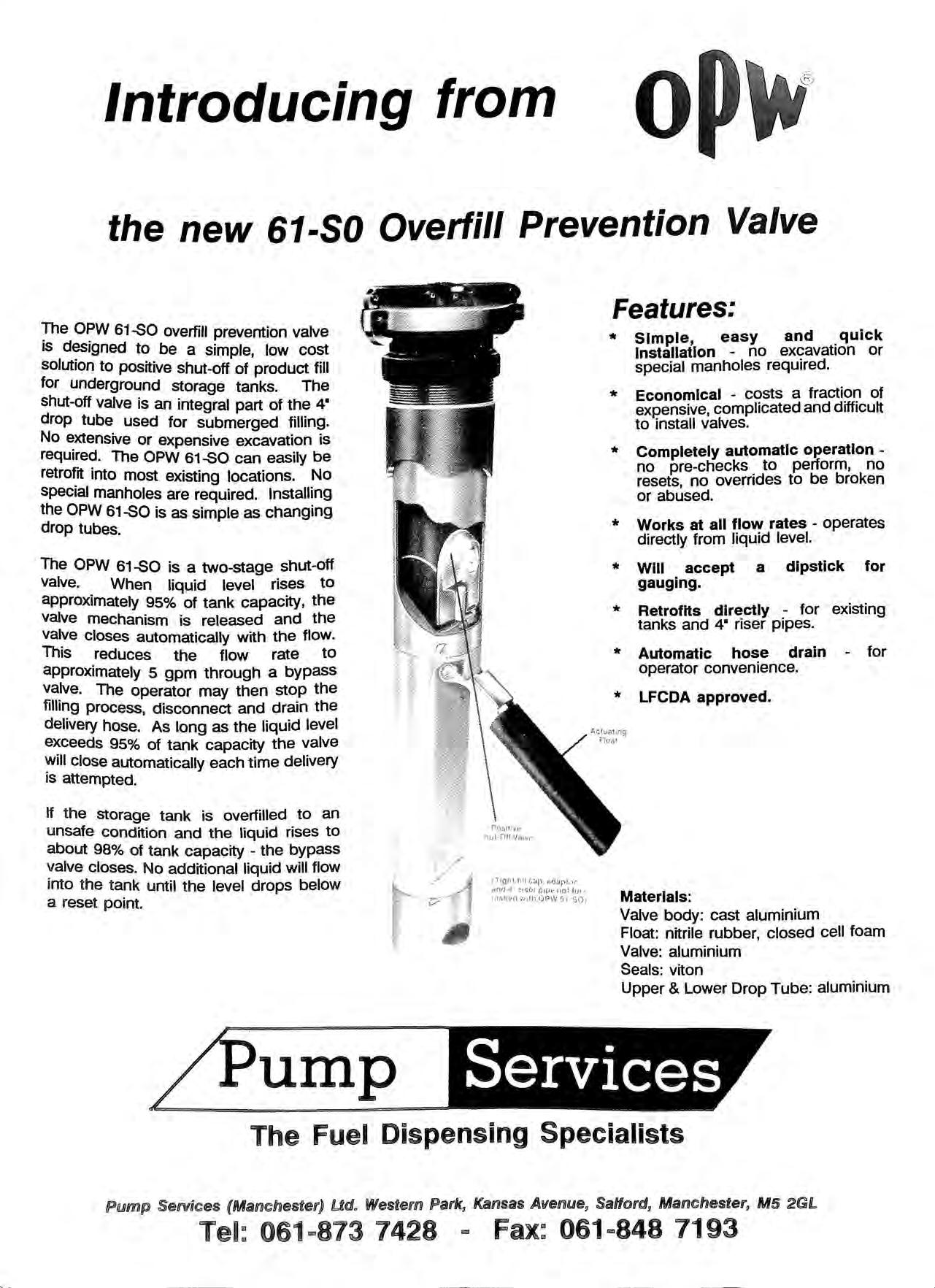

Introducing from the new 61-SO Overfill Prevention Valve

Features:

!he 61-SO overfill prevention valve is to be a simple, low cost solution to positive shut-off of product fill for underground storage tanks. The shut-off valve is an integral part of the 4" drop tube used for submerged filling. No extensive or expensive excavation is required. The OPW 61-SO can easily be retrofit into most existing locations. No special manholes are required. Installing the OPW 61-SO is as simple as changing drop tubes.

The OPW 61-SO is a two-stage shut-off valve. When liquid level rises to approximately 95% of tank capacity, the valve mechanism is released and the valve closes automatically with the flow. This reduces the flow rate to approximately 5 gpm through a bypass va_lve. The operator may then stop the filling process, disconnect and drain the delivery hose. As long as the liquid level exceeds 95% of tank capacity the valve close automatically each time delivery 1s attempted.

If t he storage tank is overfilled to an u nsafe condition and the liquid rises to about 98% of tank capacity - the bypass closes No additional liquid will flow into t he t ank u ntil t he level drops below a reset point.

* Simple, easy and quick Installation no excavation or special manholes required.

* Economical costs a traction of expensive, complicated and difficult to install valves.

* Completely automatic operation no pre-checks to perform, no resets, no overrides to be broken or abused.

* Works at all flow rates operates directly from liquid level.

* Will accept a dipstick for gauging.

* Retrofits directly - for existing tanks and 4• riser pipes.

* Automatic hose drain for operator convenience.

* LFCDA approved.

Valve body: cast aluminium

Float: nitrile rubber, closed cell foam

Valve: aluminium Seals: viton

Upper & Lower Drop Tube: aluminium

ump h u t-O H

Ac t uat!ng f" it.ld !

Materials:

Services The Fue l Di s pen s ing Specialist s Pl!imp Services (Manchester) Ud. Western Park, Kansas Avenue, Safford, M anchester, M 5 2GL 061 "'873 7428 la Fax: 06 1..,848 71 93

Petroleum licensing authorities are having a continual battle with cowboy installers of hand operated car jet washes on petrol fillinostations. Operators with a view to increasing their revenue entering agreements with jet wash installers who instal machines free of charge for a share in the income generated by the machine.

The installers have obtained no approval from petroleum licensing authorities who with over enthusiastic marketing techniques are informing potential customers that they fully comply.

Car wash machines break down the action of petrol interceptors on the filling station and allow petrol etc to enter sewers and rivers. Their installation must be separately drained with their own interceptor and silt trap and. wil! usual.ly. involve major drainage alterations. Another nsk 1s the. mdescnmmate placing of these machines on the forecourt. machines have turned up under vents. by fill pipes and road tanker stands.

Oil companies and licensees should make sure that petroleum licensing authorities have approval before allowing work to commence on these mstallat10ns.

BRANCH

HUMBERSIDE BRANCH

The Bulletin

by the Association for Petroleum and Explosives Administration

28 Number2 MAY 1990 A company Limited by Guarantee registered in England

2261660 Reg. Office: Stoughton House, Harborough Road,

Leicester LE2 4LP £4.00 (Free to Members) ISSN

4597 Contents TALKING POINT NOTES & NEWS DOUBLE SKIN TANKS PROSECUTIONS TANKER BLAZE NEW MEMBERS VAPOUR BALANCING CODE OVERFILL PREVENTION DEVICE

J.

R.

Mr.

D.

20 21 23 25 27 28 30 33

Point

Published

VOLUME,

No.

Oadby,

0263

Horsburgh EASTERN BRANCH

G. Green Honorary Secretary:

B.

Taylor.

Opinions expressed in this Journal are not necessarily the views of the Association Talking

SOUTHERN

M.Cox Normand Instruments Ltd., MIDLAND BRANCH Mr. L. Lloyd CMS Ltd.

Honorary Editor: Mr. J. A. J. Thompson.

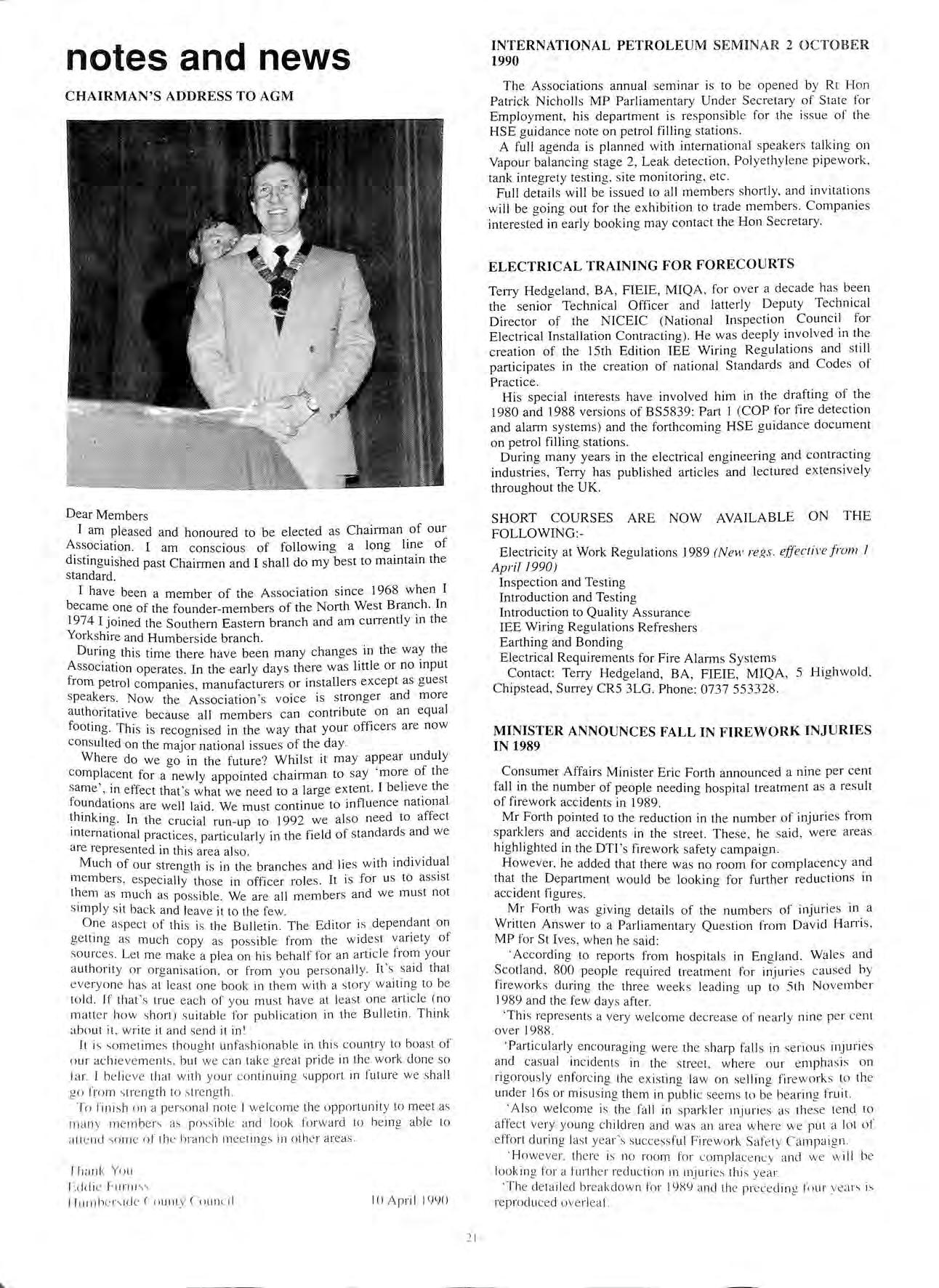

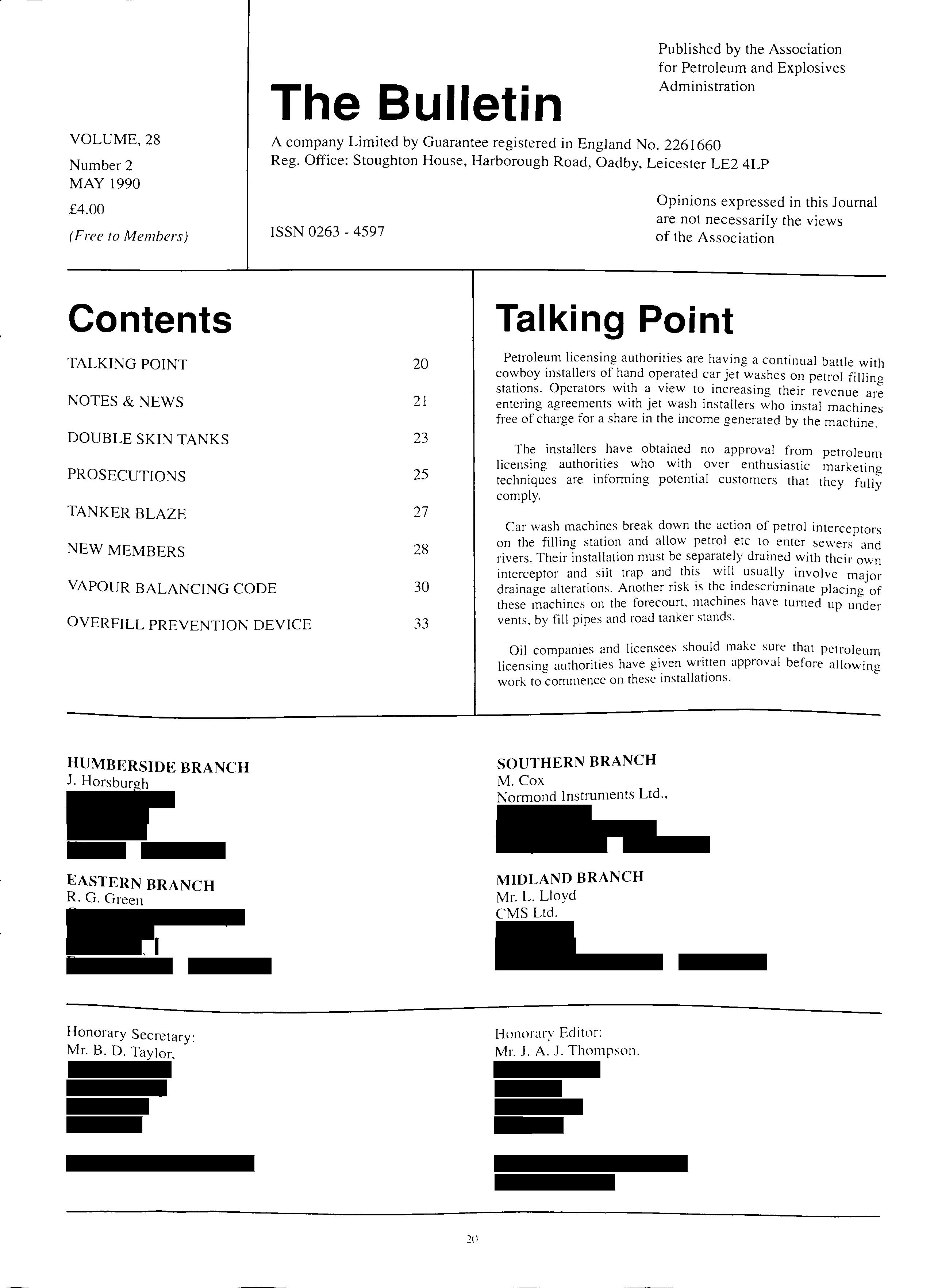

Dear Members

I am plea se d and honoured to be elected as Chairman of our A ssoc ia tion. I am conscious of following a long !me o f di stingui s hed past Chairmen and I s hall do my best to maintain th e standard.

I hav e b ee n a member of the Association since 1968 when I bec a me one of the founder-member s of th e North We s t Branch In 1974 I joine d the Southern Ea s te rn branch and am currently in th e York s hire a nd Humber s ide branch

Durin g thi s tim e there ha ve been m a n y changes in the way th e A ss ociation operates. In the earl y day s th e re wa s little or no input from pe trol companies , manufacture rs or in s ta llers except as g ues t s p ea ker s Now the As soc iati o n ' s vo ice is s tronger and mor e aut h or it a tiv e because all m e mb e rs can contribute on an equal footing. Thi s is recogni se d in th e way that your officers a re now co n s ult e d on the major national iss ues of th e day.

Wh e re do we go in the future ? Whil s t it may appear unduly c omplacent for a newly appointed c h a irman to say ' more of th e s ame', in e ffect th a t's w hat we ne ed to a large extent. I b e li e ve th e foundation s a re we ll laid W e mu s t co ntinu e to influence national thinkin g In th e crucial run up to 1992 we also ne e d to affect mt e rn a ti o nal practic es , parti c ul a rl y in th e fi e ld of s ta ndard s and we a re re prese nt e d in thi s area al so.

Much of o ur s tre n g th is in th e bran ches and li es w ith indi v idual m e mb e rs , e s p ec ially th ose in office r role s It is for u s to assis t th e m as mu c h a s po ss ibl e . We a r e a ll m e mb e rs and we mu s t not s impl y s it ba c k and le ave it t o th e few.

One a s p ec t of thi s is the Bulletin. Th e E dit o r is dependant on ge ttin g as much copy as p oss ibl e from th e wide s t vari e ty of s o urces. Le t m e mak e a pl ea o n hi s be h a lf fo r an article fr om yo ur a uth o rit y o r orga ni s ati o n , o r from yo u p e rs o n a ll y. It ' s sa id th a t e ve ry o ne h a s a t least o ne b ook in th e m w ith a s t o r y wa itin g to b e to ld. l f th a t s t ru e e ac h of yo u mu s t h a ve at leas t one a rti c le (n o ma t te r how s h o rt ) s uita b le for p ubli c a ti o n in th e Bull e tin Think a bout it w r ite it a nd s e nd it in ' lt is s o m e tim e s thou g ht un fa s hi o n ab le in t hi s c o untry t o bo a s t o f o ur a c hi e ve m e nt s c an t ak e g re at prid e in th e wo rk don e so f'a r I be li eve th a t w ith y o ur c on tinuin g s u pport in fu tur e we s h a ll g o from s tr e ng th to s tr e ng th .

To f ini s h o n a p e rso n a l no te I w e lcom e th e o pportunit y to me e t a s man y m e mb e rs a s po ss ib le and look fo r wa rd to be in g a bl e to <:1 1t c n d 'i Om e o r th e bran c h m ee ting s in o th e r a re as.

f ha 11 k Yo u 1-: dd ic F urni s \

Hu 111 h c r, 1d e Co unt y C oun c i l 10 A pr il 1990

The Association s annual se minar is to be op e ne d b y Rr Hon Patrick Nicholl s MP Parliam e nt ary Under Se c re tar y of Sta te fo r Emplo y ment , his d e partm e nt is res pon s ible for th e iss ue of th e HSE guidance note on p e trol filling s tation s

A full agenda is plann ed w ith int e rnational s peak e rs ta lkin g o n Vapour balancin g stage 2, L eak detection, Pol yet hyl e ne pipework , tank integrety testin g, site monitorin g etc.

Full details will b e iss u ed to all members shortly, and invit a ti o n s will be going out for the e xhibition to trade member s. Compa ni es intere s ted in early booking m ay contact the Hon S ec reta ry.

ELECTRICAL TRAINING FOR FORECOURTS

Te rry Hedgeland , BA , FIEIE , MIQA , for ov e r a decad e ha s b ee n th e senior Techni ca l Officer and latterly Deput y Tec hmc a l Director of the NICEIC (National In s pection Council for Electrical Installation Contracting). He was deeply in vo lv e d in th e creation of the 15th Edition IEE Wiring Regulation s and s till participates in the creat ion of national Standards and Codes of Practice.

Hi s special interest s have involved him in the drafting of the 198 0 and 1988 version s of BS5839: Part 1 ( COP for fire detection and alarm systems) and th e forthcoming HSE guidance document on petrol filling s tation s

During man y years in th e e lec trical engineerin g and contractmg indu s trie s, Terry ha s publi s hed articles and lectured exten s iv e ly throughout the UK

SHORT COURSES ARE NOW AVAILABLE ON THE FOLLOWING:-

Electricity at Work Regulations 1989 (New regs. effec tiv e from I April 1990)

In s pection and Te stin g

Introduction and Te s ting

Introduction to Quality A ss uran ce

IEE Wiring Re g ulation s Re fre s h e rs

Earthing and Bondin g

Electrical Requirement s for Fire Alarm s System s

Contact: Terry H e d ge la nd , BA , FIEIE, MIQA , 5 Hi g h wo ld , Chipstead, Surre y CR5 3LG. Phone: 0737 55332 8

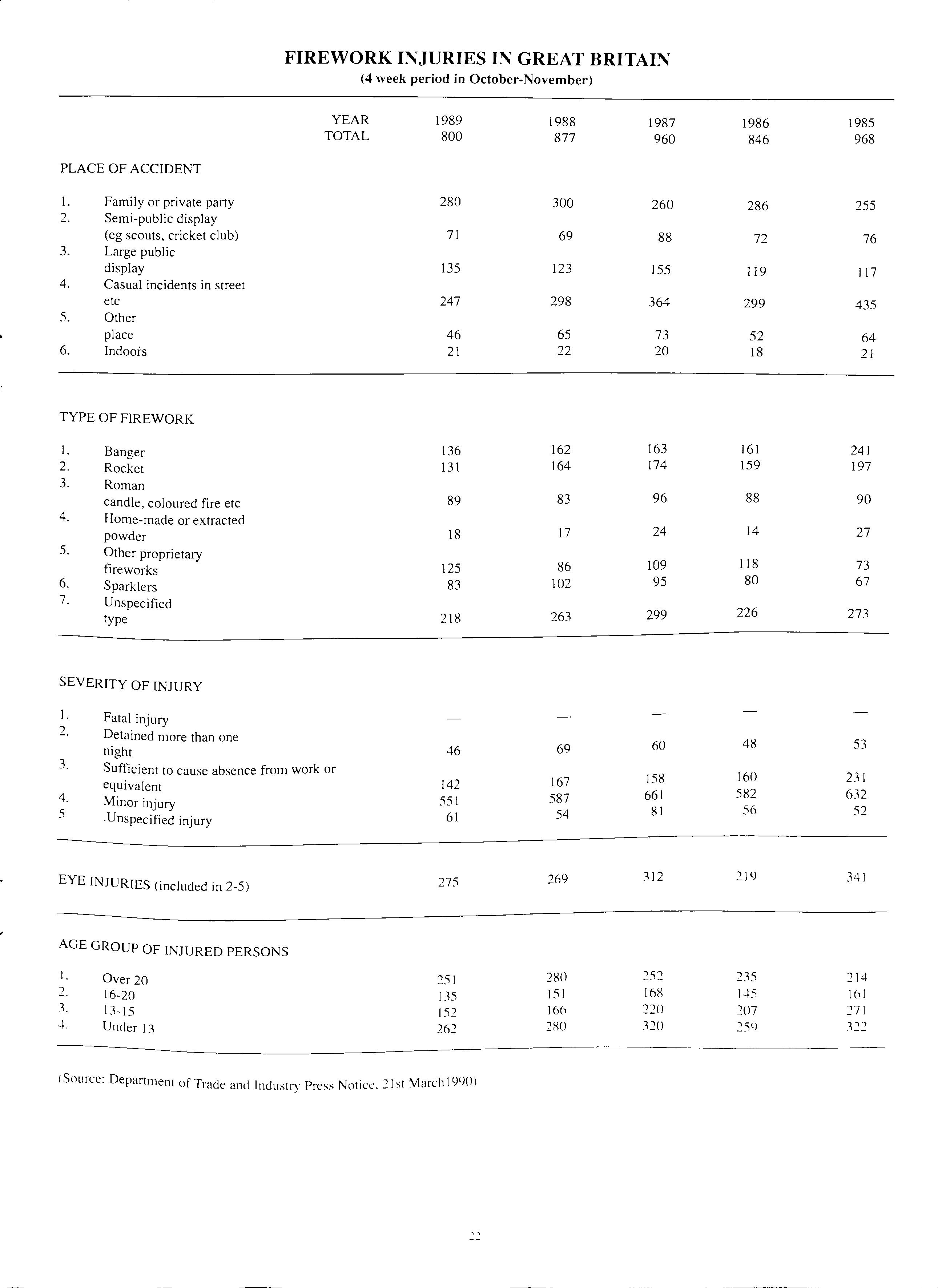

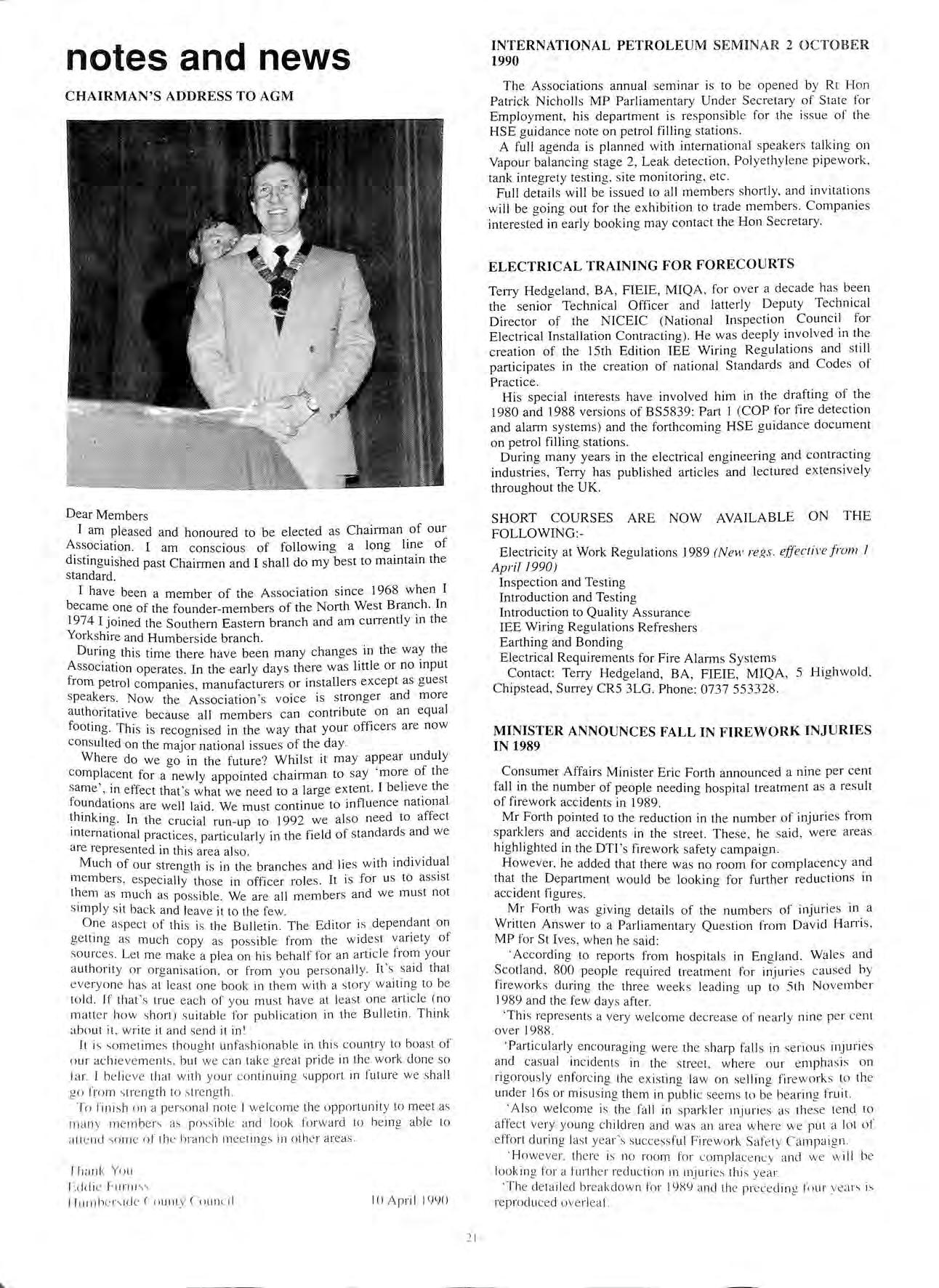

MINISTER ANNOUNCES FALL IN FIREWORK INJURIES IN 1989

Consumer Affair s Mini s te r Eric Forth announced a nin e per cent fall in the number of peopl e n ee din g ho s pital treatm e nt as a res ult of fir ew ork accident s in 1989.

Mr Forth pointe d to th e reduction in the number of injuri es from s parkl e rs and accident s in th e s treet. The se , he s aid, were a reas hi g hlighted in the DTI ' s fir ewo rk s afety campaign.

Ho weve r, he added th a t th e re was no room for complacency and th a t the Departm e nt would b e loo king for furth e r red u c tion s in accident figure s

Mr Forth wa s g ivin g d e tail s of the number s of injuri es in _ a Written An swe r to a P a rliam e nt a ry Question from David H a rn s MP for St Ive s, when h e sa id:

' Ac c ording to re p o rt s fr o m h osp ital s in En g land W a les and Sco tland , 800 p eop le require d tr ea tm e nt for injuri e s ca u s e d b y fir ewo rk s durin g th e three week s lea din g up to 5th N ove mb e r 1989 a nd th e few d ay s afte r.

' Thi s re presen ts a ve ry we lco m e d ec rea se of nea rl y nin e p e r ce nt ove r 1988.

' Pa rti c ularl y e n co ur ag in g we re th e s harp fall s in se riou s injuri es and cas ua l in c id e n ts in th e s tr ee t , w h e re o ur e mph a s is on rigorou s ly e n fo rc in g th e ex is ting law on se llin g fir ew ork s t o th e und e r I 6 s o r mi s us in g th em in publi c see m s to be h ea rin g fruit.

' A ls o wel co m e is th e fall in s parkl e r in1uri es a s th e se te nd to affec t ve ry yo un g c hildr e n and was a n ar ea w h e re w e put a lo t of effo rt durin g las t ye a r ' s s ucce ss f u l F i rewo rk Sa fe t y Ca mp a ig n

How e ve r. th e re is n o room fo r c o m p lac e n c y and we w i 11 b e look in g for a furth e r re du ct io n in injuri e;, thi s ye ar

' Th e d e ta il e d br ea kd o w n for 1989 a nd th e p re c e din g fo ur ye ar s 1 ' re pro d uce d o ve r lea f.

notes and news CHAIRMAN'S ADDRESS TO AGM

2 1

PETROLEUM SEMINA R 2 O C TOBE R

INTERNATIONAL

1990

FIREWORK INJURIES IN GREAT BRITAIN (4 week period in October-November)

YEAR 1989 1988 1987 1986 1985 TOTAL 800 877 960 846 968

PLACE OF ACCIDENT

I. Family or private party 280 300 260 286 255 2. Semi-public display (eg scouts, cricket club) 71 69 88 72 76 3. Large public display 135 123 155 119 117 4. Casual incidents in street etc 247 298 364 299 435 5. Other place 46 65 73 52 64 6. Indoors 21 22 20 18 21

TYPE OF FIREWORK

I. Banger 136 162 163 161 241 2. Rocket 131 164 174 159 197 3. Roman candle, coloured fire etc 89 83 96 88 90 4. Home-made or extracted powder 18 17 24 14 27 5. Other proprietary fireworks 125 86 109 118 73 6. Sparklers 83 102 95 80 67 7. Unspecified 226 263 299 273 type 218

SEVERITY OF INJURY

I. Fatal injury 2. Detained more than one 48 53 night 46 69 60 3. Sufficient to cause absence from work or 160 231 equivalent 142 167 158 587 661 582 632 4. Minor injury 551 5 61 54 81 56 52 .Unspecified injury

EYE INJURIES (included in 2-5) 275 269 312 219 341

AGE GROUP OF INJURED PERSONS

l. Over 20 251 280 252 235 214 2. 16-20 135 151 168 145 161 3. 13-15 152 166 220 207 271 4. Under 13 262 280 320 25lJ 322 (Source: Department of Tracie and Inc!ustry Press Notice. 21 st March I lJlJ())

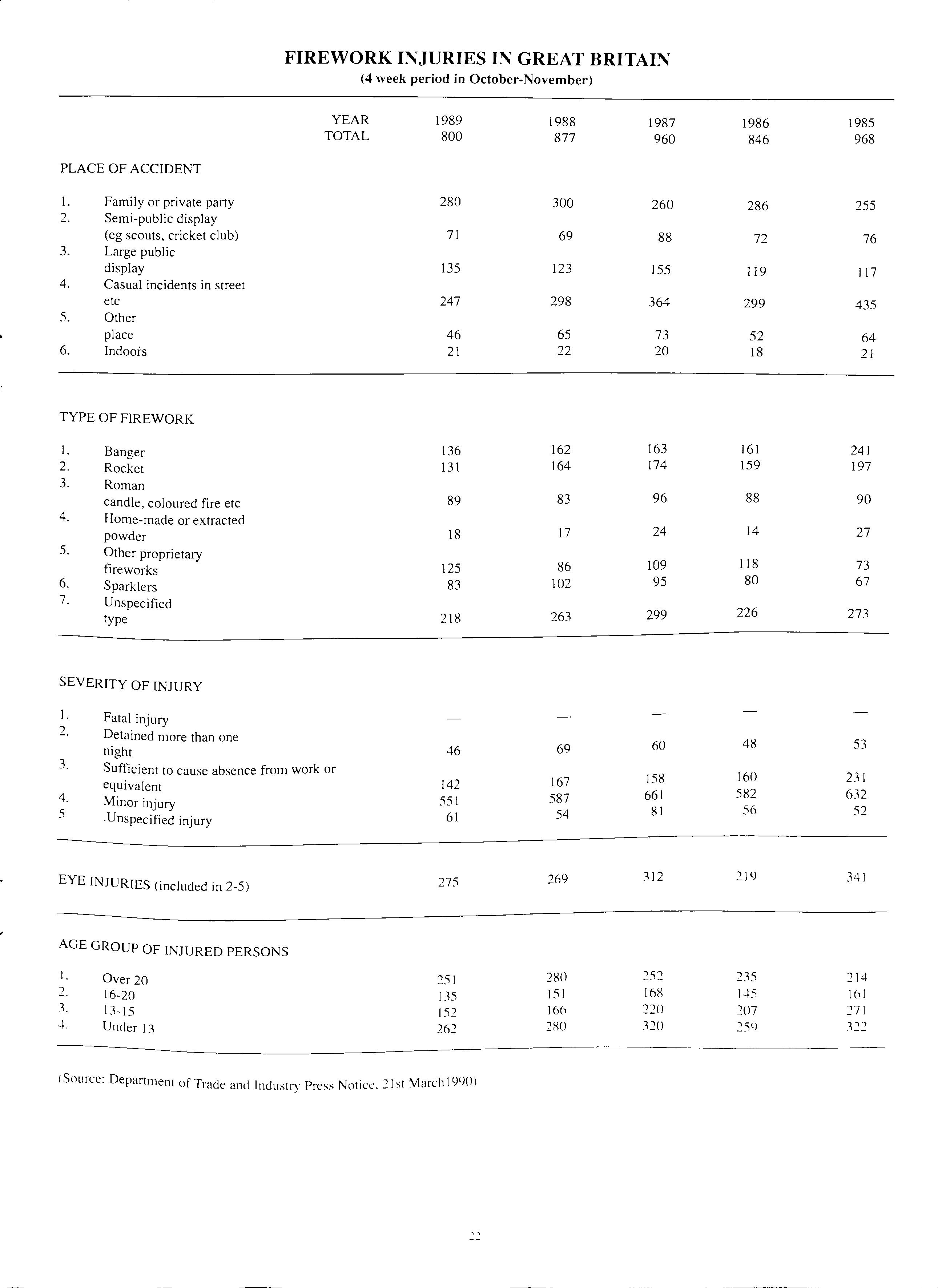

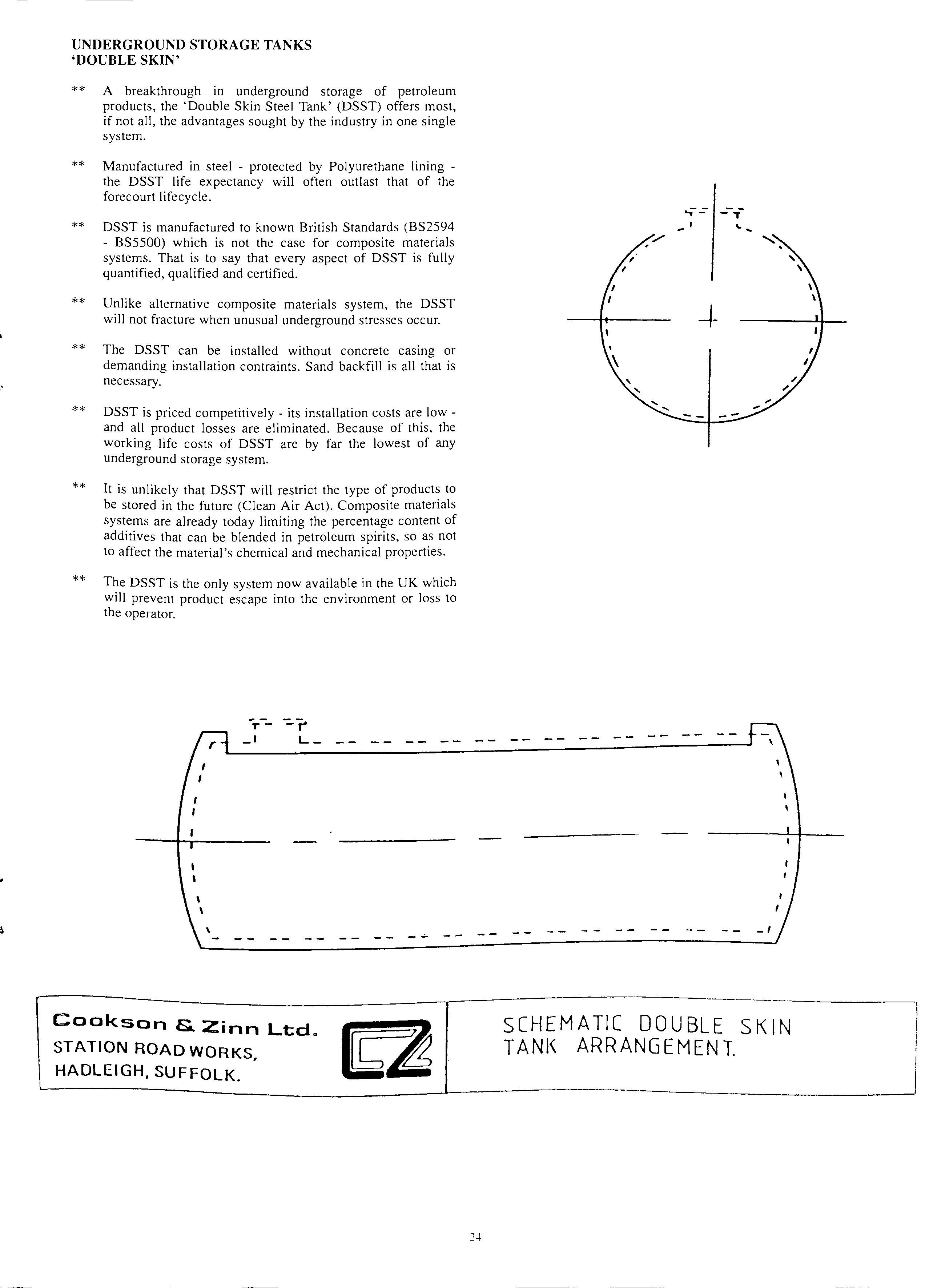

Double Skin Steel Tanks

JOHN BOUDRY, COOKSON & ZINN

Cookson and Zinn have, for many years, been a leading manufacturer of storage tanks in the UK.

As a company we have made in excess of 10,000 underground steel tanks and I feel that it is our responsibility to support the efforts of the Engineers from the Oil Companies and all members of the APEA in defining the storage system of the future.

Having researched the product by contacting and visiting manufacturers and users alike, both in the U.S. and the Continent, the product we now propose is, therefore, a well known tried and tested one.

What I found during my research was that, fundamentally, both the and the Continent had eventually arrived at the same solution, but by two different methods. This is why today we have double skin steel tanks in Europe and double skin steel and G.R.P. tanks in the U.S.

The process of evaluation in the U.S. was slow and, indeed, it is only very recently that some States tacitly decided to insist that all tanks should be double skin, especially if made with G.R.P. However, it is during this process of evaluation that substantial research was made which provides us today with the necessary background information to ensure that the decision we take in the U.K. is the most suitable.

I have heard it said over the last few months that 'We are lagging other countries' 'We are trying to re-invent the wheel' We can't make our minds up'. I don't believe this to be the case at all. I believe that we are cautious as an industry, and rightly so.

Until today, one of the alternatives was the one offered by G.R.P. The. more the industry looks into the product, the more it is that its shortcomings outweigh its advantages.

First we have the problem of complicated and difficult not to say onerous installation procedures.

Secondly, we have the problem of poor resistance to structural stresses and its implications.

In February 1989 a law suit in Texas against an operator whose tanks ruptured, brought to light previously confidential information concerning the thickness of tank shells of fibreglass tanks. An independent testing firm had concluded, in two separate studies, that many G.R.P. tanks were not structurally stable because of wall thickness insufficiencies and, thus, unable to withstand some underground stresses.

A creep-to-collapse analysis was performed to a service life of 30 years, resulting in a recommended increase of thickness design factor to 2.77 inch. The Operator heeded the study and is currently making its G.R.P. tanks 25% 35% thicker.

Another G.R.P. fracture at an Unocal service station in Columb.us, Ohio, cost the company in excess of one million dollars Just to recover the product Jost in this case 7000g. The leak having occurred on January !Oth last year, the petrol station was still closed in July the product having seeped far and wide.

Today most, if not all, of the G.R.P. tanks supplied in the U.S. are double skin.

G.R.P. tanks are marketed as being corrosion proof not structurally fail safe and, therefore, the reluctance of the industry to invest in such a product is understandable, especially in view of the American experience. So why does the industry need an alternative to existing storage methods? After all. the steel tank encased in concrete has served its purpose successfully for over 30 years.

The considerations are twofold.

The first is financial. Possible product loss forecourt downtime installation costs.

The second. and possibly the more important one. is the ·Environment". Any product escape in the environment could ueatc -.uhstantial prohlcms and danger. In town centres we have a m;u.t· of tuhe tunnels hank vaults underground car parks deep cellars and sewerage systems. In the country we have water suppl1e'> rivers wildlife.

Not only could an escape have disasterous consequences to the environment but the cost of product recovery and clean up operation, not to mention possible consequential claims, could be astronomical.

I believe that the solution we should adopt must ensurue that:

The storage system life will equal that of the forecourt lifecycle.

The storage system can be easily removed and possibly re-used if need be.

The storage systems integrity can be monitored 24 hours a day.

The storage system working life cost is kept to a viable level.

The storage system will be capable of taking any additives that might be used in petroleum spirit blends in the future.

Double skin steel tanks, together with adequate surface lining and monitoring equipment, is the solution which we must adopt.

By adopting unilaterally double skin steel tanks as the storage system of the future, the Oil Companies will not only work with a product which can be properly designed qualified and quantified, but they will also have access to several sources of supply readily available in the U.K.

Double and triple compartment tanks will still be available and future design developments on tanks to forecourt connecting systems will be more easily absorbed.

TANK PROTECTION

An effective coating extensively used on the Continent by all major Oil Companies today the 'Polystac 5207' is proving to be very successful. It is totally waterproof and offers substantial protection against possible chemical and electrical underground attack or contamination.

This coating can be applied under normal, uncontrolled, conditions by either brush or spray. As it does not contain solvents, it is atmosphere and personnel friendly. As well as offering a comprehensive barrier against electrical and chemical contamination, it also possesses excellent mechanical properties.

FAILSAFE DETECTION

Contrary to what one might think product inventory and detection equipment are not the main methods by which leaks are The environment has probably been badly affected by the time a leak is detected, as in 68% of all cases sight and smell represent the only method of detection.

. I that it is imperative that detection of leaks ought to be immediate, so as to prevent all possible product escape in the environment and therefore eliminate product loss.

Double skin steel tanks offer the protection required and allow for 1mmed1ate detection in case of containment malfunction.

The cavity between the skins can be monitored by a very effective and low cost system.

To that effect, the tank manufacturer can fill the cavity between the skins at the factory with a mix of 2/3 water J/3 anti-freeze and seal the system after pressure test. A sensor connected to the alarm box located in the forecourt operator's office monitors the level of the product in the cavity. A variation in the level will indicate that a malfunction has occurred and the tank can be immediately isola.ted and rendered safe no product having escaped rn the environment or been lost to the operator.

The design proposed by Cookson and Zinn Limited is already adopted by most of the Oil Companies throughout the continental E.E.C. It is practical economical and gives all involved in the mdustry the comfort of knowing that their product and the environment are totally protected.

Petroleum spirit in double skin steel tanks is in safe keeping for many years to come.

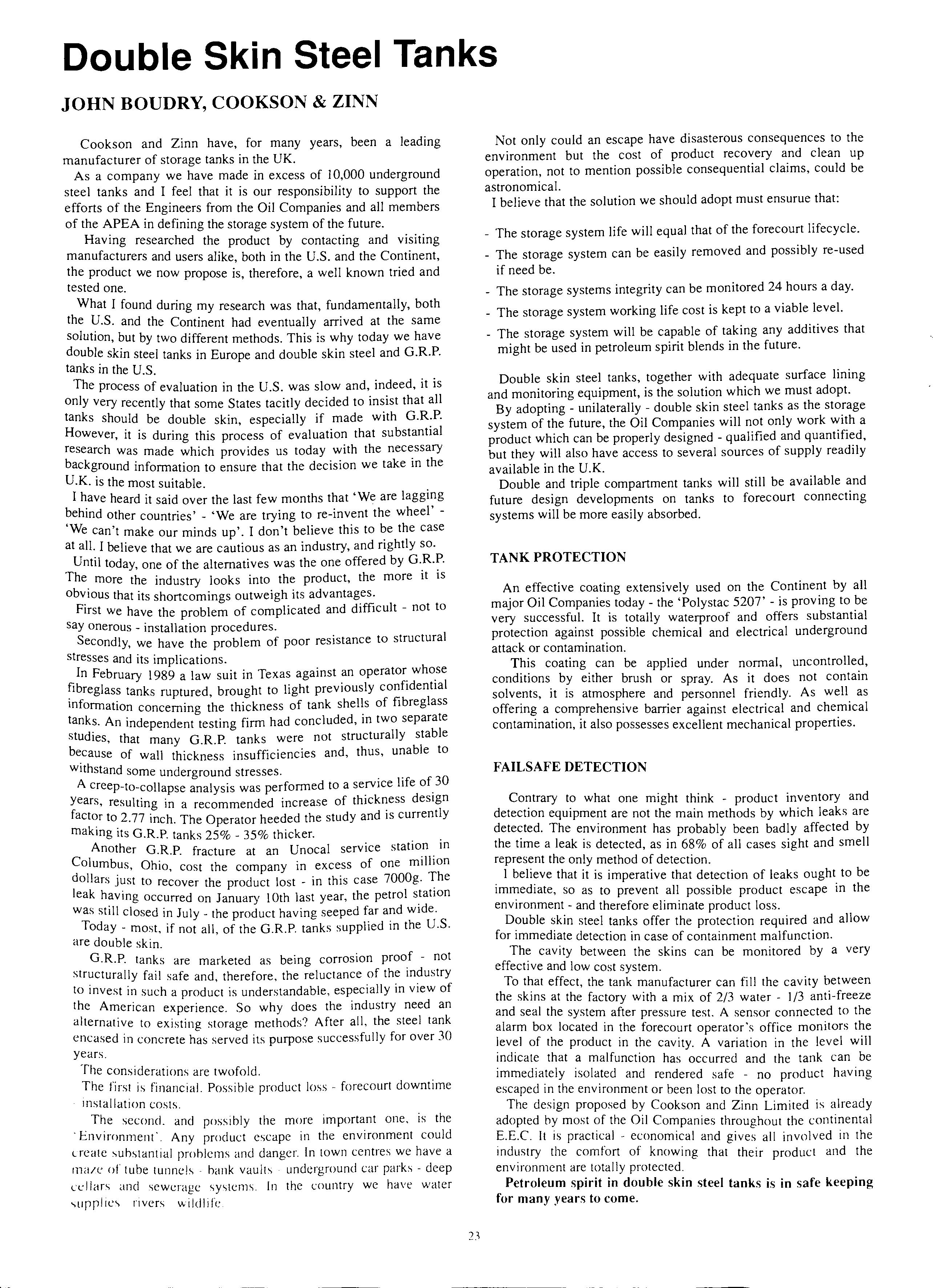

A breakthrough in underground storage of petroleum products, the 'Double Skin Steel Tank' (DSST) offers most, if not all, the advantages sought by the industry in one single system.

Manufactured in steel protected by Polyurethane lining the DSST life expectancy will often outlast that of the forecourt lifecycle.

DSST is manufactured to known British Standards (BS2594 BS5500) which is not the case for composite materials systems. That is to say that every aspect of DSST is fully quantified, qualified and certified.

Unlike alternative composite materials system, the DSST will not fracture when unusual underground stresses occur.

The DSST can be installed without concrete casing or demanding installation contraints. Sand backfill is all that is necessary.

DSST is priced competitively its installation costs are low and all product losses are eliminated. Because of this, the working life costs of DSST are by far the lowest of any underground storage system.

It is unlikely that DSST will restrict the type of products to be stored in the future (Clean Air Act). Composite materials systems are already today limiting the percentage content of additives that can be blended in petroleum spirits, so as not to affect the material's chemical and mechanical properties.

The DSST is the only system now available in the UK which will prevent product escape into the environment or loss to the operator.

Cookson & Zinn Ltd. STATION ROAD WORKS, HADLEIGH, SUFFOLK.

SCHEMATIC DOUBLE SKIN TANI\ ARRANGEMENT.

UNDERGROUND STORAGE

'DOUBLE SKIN' ** ** ** ** ** ** **

TANKS

**

-- -- -- --

-_,

Prosecutions

SHELL FINED £1 MILLION

In the first major prosecution by the National Rivers Authority, Shell UK has been fined £1 million for polluting the Mersey. On 19 August last year, a l 2in bore pipeline, running between the Tranmere Oil Jetty and the refinery at Stanlow, fractured where it crosses the foreshore at Bromborough and allowed the escape of at least 30,000 gallons crude oil.

The fine, the highest ever in a river pollution incident, was imposed by Mr Justice Mars-Jones at Liverpool Crown Court at the end of February. The judge concluded that the fracture was the result of su?stantial corrosion of the steel pipe, and did not accept defence claims that no human error was involved.

He added that the defendants had enormous resources and could pay any fine, even of several million pounds, without being deeply affected.

Shel_I, who pleaded guilty, have confirmed that bitumen product10n at Stanlow realised a profit of £4.7 million in 1989, but tha_t the spil_lage had cost £ 1.4 million in operational losses and claims by third parties during the clean-up.

The leak had remained undetected for almost an hour and Shell's m_onitoring system was criticised by the judge. The National Rivers Authority was not informed of the disaster for a further two and then by Mersey Fire Brigade rather than Shell, by which time there was a JO-mile slick on the Mersey. Attempts to flush the pipeline with water, against the wishes of two rep_resentatives of Wirral Borough Council and the senior police officer on the scene, served only to increase the amount of oil which leaked.

An estimated 300 sea-birds died, with a further 3,000 badly olled. Many were saved by heroic volunteer effort. More than of foreshore was despoiled by a three-mile band of crude oil which, by a fortuitous combination of strong onshore winds and an unusually high tide, was stranded beyond the reach of subsequent tides and could be shovelled away.

Dr Chris Harpley, General Manager of the NRA in the North West, believes that the fine reflects the level of public interest in the environment today. He is most concerned that such a spillage happen again, given that there are hundreds of miles of similar pipeline throughout Britain. He believes that common sense tells us the pipeline must have become corroded over a period of years and hopes that the case will act as an effective deterrent, so that even the largest organisations will want to look carefully at their inspection and maintenance procedures.

ELECTRICAL CERTIFICATE

False Statement leads to fine

S June 1989 a Petroleum Officer with Warwickshire Trading c\andards investigated claims by Mackelectric Ltd, l Re_dhill hose, Wellesbourne, Warwickshire that they held membership of t Contractors Association.

ese claims were made on two electrical certificates completed mgecember 1.987 and February 1988 for different filling stations.

n 3rd Apnl 1990 Mackelectric pleaded guilty to two charges under Section 14( I ){a) of the Trade Descriptions Act 1968 of claiming membership. They were fined £800 in total plus <-125.75 costs.

The offences came to light when the poor standard of the installation at one site was noticed.

SHELL TANKER DRIVER CAUSES 600 LITRE SPILL

. A petrol station manager and a tanker driver were each fined t I()() m1 January I 7th after an incident involving a spillage of 600 I 1t res of petrol.

Michael William Mills of Stanningley Road. Armley. Leeds. manager of Thorpe Service Station in Richardshaw Lane. Pudsey. ''.nd Jack Binns of Ncpshaw Lane. Morley. a tanker driver with Shell. hoth admitted offences contrary to the Health and Safety at Work Act 1974 and thl' Dangerous Suh..,tance'> Rcgulatiom. ·(hey were cach ordered to pay £83.7'i costs.

Proserntor Mr Michael Barne'" Clerk to West Yorkshire Fire and 1vi! Defence Authority. told Otley Magistrates· Court that (100 /111''' 1 >! pelr<>I had heen -.pillecl on to the station forecourt and 11, ·;11h\ marl during a delivery 111 September_ causing a potentiallv 1111.dli" dangerou-, '-.llU<1l1011. The r"acl had to he closed hy .A. i11/<' flr<·l1)'lllt'r' ",\<,·illt-cJ <IV.ii\ ill<' Jl<'ll'!il

TEXACO FIRM FINED AGAIN BY WEST SUSSEX

Two major incidents within 11 days resulted in Star Service Stations Ltd being fined £5000 with £146 costs.

Investigations by West Sussex Trading Standards Officers revealed the following offences:-

At their premises in London Road, Crawley, 011 the 9th June last year, a leaking suction line was the cause of a 2000 litre loss within a month. An old suction line was mistakenly used to connect the new pump to a tank. Petrol was found in manholes, electrical ducting, and foul sewers in the highway.

Eleven days later, at the companies site in Balcombe Road, Crawley, hundreds of litres flooded onto the forecourt when an untrained 'competent person' saw in a delivery. The manager of the site has since resigned but the attendant concerned stated that he was often left in charge and that pumps overflowed regularly. Following the incident the manager made him sign a backdated training document.

Both sites were closed to the public whilst emergency mopping up procedures were carried out.

Four Charges were brought against the company, two in respect of the London Road site for (a), failing to notify the Licensing Authority of a suspected leak, and (b), failing without delay to take all practical steps to remedy a suspected leak; and in respect of the Balcombe Road site for (c), failing to ensure a competent person was in charge of the storage tank before delivery, and (d) having no provision maintained to prevent the outflow of petroleum-spirit from the place of storage.

Charges (a) & (b) = 2 x £1000, charges (c) & (d) = 2 x £1500.

TEENAGER DIES IN GARAGE FIRE OWNERS FINED FOR INADEQUATE SAFETY PRECAUTIONS

Paisley Sheriff AKF Hunter fined two partners, John Graham and John Wallace, trading as Canal Garage, Johnstone, £750 each for offences under the Highly Flammable Liquids and Liquefied Petroleum Gases Regulations 1972 and the Health and Safety at Work etc Act 1974, at a hearing last December.

Teenager Jason Reid was helping a mechanic to drain petrol from a vehicle when his overalls became soaked with it and he splashed some into his eyes. He went upstairs to bathe his eyes and was trapped there when a fire broke out below. Despite efforts by his workmates, and later by firemen, the young man could not be rescued and died in the blaze.

A spark from a welding torch had ignited petrol vapour and caused the blaze which led to Jason's death. Sheriff Hunter told the accused that 'it was crazy to have welding going on when you were try mg to empty a petrol tank'.

The specific offences were described to the Court by Depute Fiscal, Jim Bris?ane. The first, relating to a failure to take all reasonably practicable steps to contain and safely drain off any spilt highly flammable liquid, was taken under Regulations 3 and 8 of the Highly Flammable Liquids and Liquefied Petroleum Gases Regulations 1972.

T.he second, relating to the use of welding equipment likely to 1grnte the va.pours from petrol. was taken under regulations 3 and 9 of the Highly Flammable Liquids and Liquefied Petroleum Gases Regulations 1972.

The third, relating to the general safety of the employees at the garage was taken under Section 2 of the Health and Safety at Work etc Act 1974 and covered the failure to make the system of work safe: failure to use and handle substances safely viz: highly flammable liquids; and failure to provide such information. 1nstruct1on. tra111mg and supervision as was necessary. so far as practicable to ensure the safety of employees.

Each .partner (both of whom pleaded guilty) was fined ±:2)0 on each of the three charges. They were further admoni.shed bv the Sheriff for using the premises as a place of work without being in force a valid Fire Certificate issued hy the Fire Authority. A lawyer for the partners said they had been in business for over twenty years and had heen responsible employers durinµ that penod.

·The accident occurred in spite of their traininl! and att1tuLk. said the partners· lawyer. ·1t was an accident tha1 w;, 1nL·onccivahlc to them. Thn could nol hclieVL' th<1t Jlt'ln>I vap" 111 1111111.t 1r<11l'I a-, rar ;1s 11 did ·

Assistant Divisional Officer John Johnson of West Yorkshire Fire Service had discovered that the correct procedures had not been followed when the delivery had been made.

It is remarkable that the amount of petrol used and handled in the course of our daily lives does not produce far more incidents than it actually does. I am not surprised that even garage proprietors had not conceived that petrol vapour could be the insidious fartravelling hazard that it is. This accident is an object lesson to all who handle flammable liquids. Many, even at ambient temperatures to be found in the average workshop are heavierthan-air and will linger, especially in drains, vehicle pits and other low lying places.

Once any petrol or similar liquid is spilt there should be a drill to ensure that it is collected, mopped up or dispersed safely, and that only after a suitable period for good through ventilation to purge the suspected area of all its contamination should work be allowed to continue there. Until the go-ahead is given by someone competent to judge (if necessary by the use of testing instruments) there should be very great care that no source of ignition is present where it could initiate an explosion and repeat this dreadful tragedy which occurred in Johnstone recently.

One BA crew on the first floor located fire immediately above the fire on the ground floor but as the jet was opened up the fire escalated, spread across the building and threatened to surround them.

They retreated to half way and attacked the fire again but the extremely rapid spread through the shelved stock forced them to retreat to their entry point.

MAKE PUMPS 12

At 0018 hours the Divisional Officer took over command of the incident and sent a further assistance message to Fire Control 'makes pump 12'. Half of the first floor was now well alight and at approximately 0020 hours the BA crews were withdrawn from the building because of rapidly deteriorating conditions.

The first of the aerial appliances was brought into use and the external attack stepped up utilising ladders and BA men with branches, on both sides of the building.

FIREWORKS PROVIDE

AN ADDED

HAZARD IN MAJOR WAREHOUSE FIRE

Large stocks of fireworks, provided firefighters with an early Guy Fawkes night display at a major 25 pump warehouse fire in the West Midlands.

The blaze, estimated to have caused 2 million pounds of damage, broke out at 2305 hours on Sunday 22 October 1989, at the 100 year old Soho Pool Warehouse in the centre of Birmingham.

Soho Pool Warehouse was used as a fancy goods and general cash and carry and was situated with its front elevation to Princip Street. It was a traditionally constructed Victorian building of 4 floors and basement approximately 60 x 20 metres. The walls were of brick containing metal windows of small pane traditional design. The floors were constructed of open timber joists and boards supported on cast iron columns on all floors except first floor which is part brick arch.

The roof was boarded and felted timber with a concrete 'skim'. The floors of the main warehouse were not compartmented and were totally open to the four external walls. An office block and staircase was situated at the left of and at 90 degrees to the frontage. A similar wing to the right of the frontage was compulsorily purchased in 1987 and demolished. The accesses to this wing were bricked up. The floors served by a further staircase at the other end of the building were provided with one half hour fire resisting doors. A further timber accommodation staircase linked all floors.

The building was provided with a manual fire alann system, a hosereel, on first, second and third floors, supported throughout with hand held extinguishers.

A fire certificate, under Section 29 of the Offices, Shops and Railway Premises Act 1963 was issued by the Fire Authority in 1975. Apart from one lay out amendment in 1983 the building had remained unchanged, a registration for the keeping of fireworks was also held.

The contents of the building were contained in racks which line the perimeter of the floors and provided gangways within the floor area. An extremely high fire loading was present. The staircases were of complicated design and relied on the staff to usher patrons out in the event of emergency.

FIRST ATTENDANCE

The first attendance of 3 pumping appliances and a Turntable ladder were mobilised with a Station Officer in charge. On arrival the storage area. total smoke logging of building using 4 x BA. 3 x BA checking first and second floor for fire spread. ventilation not taking place at present. incident known to i11\'olve firework stock·. Good progress was being made on the fire with all crews fully committed when a report was received that fire had penetrated the first floor.

At 0023 hours a request for an additional aerial appliance was made, immediately available water supplies were insufficient and as the adjacent canal was empty a request to the Water Board to increase mains pressure was passed. This request could not be complied with as the mains in use were gravity fed.

Water supplies were increased by means of a 5 pump relay from Fire Service Headquarters and a 2 pump relay from the canal. Three ground monitors were brought into use at the rear of the building to overcome the difficulty of access created by a large glass canopy and concern of instability of the building and falling debris. At 0152 hours a total of four aerial appliances was requested and these were deployed two at the front and two at the rear. The fire had now spread to all floors and extreme difficulty was experienced in delivering water to any great effect: At 0254 hours a further informative message was passed from the Deputy Chief Fire Officer, 'The building as previously described fire now involving second, third and fourth floors and the roof, three aerial appliances in use at the front of the building, .aerial appliances plus two ground monitors at the rear of the bmldmg, nine jets are in use, all BA have been withdrawn.'

FIRE SURROUND

The 'fire surrounded' message was passed at 0323 hours with the 'stop message' stating -a four storey building approximately 50m x 30m used as fancy goods and general warehouse. all floors and roof severely damaged by fire. fourteen jets. three ground monitors, five aerial appliances. ten BA sets and 2 x three pump water relays are in use, being passed at 0355 hours. During the fire two firefighters received hospital treatment for minor injuries. At the time of writing the cause of the fire is still being investigated.

Road Petrol Tanker Fire, Union Road, Oldbury: 22 Nov 1989

by ADO Mike Conolley

It is not every day that a petrol tanker is involved in a major fire on the highway. It is probably unique that such an incident should occur without causing personal injury.

At approximately 0922 hours on Wednesday 22 November a road tanker carrying 23,400 litres of 4 star unleaded petrol left Gulf Oil's largest UK distribution terminal sited in Union Road, Oldbury, West Midlands.

Less than one minute later a collision occurred between the tanker and a 38 ton articulated tri-axle tipper lorry carrying metal swarf. The force of the impact overturned the trailer unit and completely ruptured the front compartment of the tanker releasing 3,400 litres of petrol almost instantaneously.

Miraculously both drivers managed to dismount and get clear from their respective vehicles, the tanker driver also alerting members of the public, before the petroleum vapours explosively ignited in a fireball.

MANY CALLS

The first of many calls received by the West Midlands Fire Service came from the Gulf Oil Terminal at 0924 hours and the pre-determined attendance of 3 pump rescue ladders, hydraulic platform, foam unit and accident support unit were dispatched to the terminal address, with a Station Officer in charge.

The pall of smoke was seen by the approaching wh? mwardly prepared themselves for a major incident the _011 terminal. However, when the first appliances turned mto Umon Road at 0928 hours and started to climb the incline toward the terminal, they were confronted by a wall of flame engulfing the roadway before them.

At the centre of the fire could be seen what appeared to be a road tanker. To the left side on the roadway, a mini car was totally involved in flame and a roadside diner caravan was beginning to bum.

To the right, window frames in an adjacent office building were smouldering, the glazing was missing. The roadway and pavements could be seen to be giving off vapours.

MAKEPUMPS8

Immediate firefighting commenced with 2 main jets, bystanders gave the Station Officer sufficient information to indicate that all persons in the immediate vicinity were accounted for. At 0931 _the Station Officer made pumps 8 and then alm?st immediately after, a second fireball explosion occurred, which released large amounts of heat and fuel. Burning fuel flowed down over 150 metres of roadway past and under where the appliances had been parked.

The demountable foam unit in attendance was brought into full operation within 2 minutes of its arrival and the original main jets we.re converted to FB5X foam branches fed directly from the foam unit by dedicated hose, hosereels and utilising maric valves.

The Deputy Divisional Commander attended at 0939 hours followed closely by the Divisional Commander.

At 0948 hours the Divisional Commander sent an informative message stating 'one 4000 gallon road tanker and a private motor car were totally involved in fire, radiated heat was affecting 2 buildings and a portacabin. 3 FBSX foam branches and 2 main jets lll use

Principal Officers informed at Headquarters some 9 miles away could clearly see the rising column of smoke.

Shortly after the informative message was sent crews penetrated past the road tanker. both along the roadway and hy use of a I L'im ladder over a fence into an adjoining yard. almost '11llU ltw1cously.

fht:v were confronted with the 38 ton overturned lorry and an cxteri;;tl -.toragt: area containing drum resins. flammable liquids

and fibre glass mould patterns adjacent to a further factory building all of which were involved in fire.

MAKE PUMPS 15

At 0953 hours a further assistance message was sent from the Divisional Commander making pumps 15 and foam units 2.

Crews worked well under ardous conditions and substantial progress was made in subduing the main area of fire involving the road tanker, car, roadside cafe (portacabin) adjacent building. At this time 4 foam branches, 4 main jets and 4 BA were in use.

The Assistant Chief Officer who attended took charge at 1030 hours. Excellent progress had been made fighting both areas of fire and a Fire Surrounded message was passed at 1034 hours.

HELICOPTER

Chief Officer Fuller attended the incident shortly afterwards and through liaison with the Senior Police Officer present was able to make an aerial assessment of the scene using West Midlands Police Helicopter, a facility that has been used on a number of occasions previously.

All apparent fires were extinguished by 1100 hours with cooling jets remaining on the tanker.

The 'Stop' message was sent at ll15 hours and following liaison with Gulf Oil, arrangements were made

POLLUTION OF THE ENVIRONMENT

During the initial stages of firefight operations it became obvious that pollution control would play a major role in the overall incident. An Assistant Divisional Officer undertook the task of coordinating effective measures and liaison with the Severn Trent Water Authority and National Rivers Authority. Considerable amounts of petroleum and foam compound had entered the storm drainage system from the roadway and through early liaison with Severn Trent it was established that the storm drainage system discharged directly into an open water course (the River Tame) and did not enter the foul drainage system.

Representatives of the National Rivers Authority were contacted at an early stage and attended the incident. The information given to them of the resultant pollution from the incident enabled an early warning to be given to 2 major users of the river water downstream from the incident.

The Officers of both Authorities were appreciative of the early involvement in the incident and the quality of information that was supplied to them.

Measures taken to mitigate the effects of pollution involved the use of 3 major pumps to wash the roadway and storm drainage system, to aerate the river water and to increase the river flow using in total 6 open ended hose lines and 2 main jets.

NO INJURIES

In the aftermath of the incident, everyone who was involved was amazed that despite an RTA which overturned a lorry. the fireball that consumed these vehicles and enveloped a much greater area, including a storage yard of resins, flammable liquids and fibreglass mouldings, 3 other buildings. the roadside cafe and some 18 vehicles in total not one person received any injuries!! The potential for the incident was obvious to all who attended.

It was also noted and appreciated by the Senior Officers and fire crews attending that Ambulances stood by throughout the incident. even though they were involved in an industrial dispute. All were thankful that their expertise was on this occasion not required to be put to the test.

The incident was finally closed the following day at 1918 hours.

27

New Members

The Association welcomes the following new members

James A. A. Gray

Trevor Mason Purfleet Commercials Ltd

Ian Keith Farmer Esso Petroleum Co Ltd

Clive D. Hale Gilbarco Ltd Installation Division

CR Richardson (Contractors) Ltd

T. F. Hocking Ledbury Welding & Eng. Ltd

U

Michael Carl Bryan Kuwait Petroleum (GB) Ltd

P. S. Doughty Allied Tanks & Fabrications Ltd

Harry A. G. Birch G. W. Birch & Sons

Mr. Gary Donovan BP Oil UK Ltd

Mr Andrew Mortimer

Esso Petroleum

Richard Stephen Strachan London Fire & Civil Defense Authority

Catherine Connelly Strathclyde Regional Council

Peter O'Nion D. J. Duncan Ltd Building Contractors

W. R. G. Musgrave Cleveland County Fire Brigade Daniel Clifford Reynolds Pump & Pipework Services

T. R. Ambridge Trading Standards Dept Southend-Borough Council

R V. J. Smart Trading Standards Department Southend Borough Council A. F. Chandler Veeder Root Ltd

Thomas Henry Cole Esso Petroleum Co Ltd

Miss Victoria Lee Gordon White and Hood

2H

Michael Robert Finlayson Highland Regional Council

R. J. & N. J. Williams Limited

Mr Rodney J Williams

Stephen Hall WeldemLtd

Mike Marczynski Tank-Clean Ltd Alec Southcott Isle of Wight County Council (Fire Authority)

OHR E. J. Thompson J Sainsbury pie W. & J. Risbridger Ltd

David Orpwood Normand Instruments Ltd

M. Nicholas Esso Petroleum Co Ltd

Glynn Watson Murray Murray Pumps Complete Forecourt

Keith John Monday Gulf Oil (Great Britain) Ltd

E

Allan B. Matthews ARIBA Chartered Architects

r

Melvin John Chambers

Kuwait Petroleum (GB) Ltd

Peter Carr Shell UK Oil

John Brierley Brown & Tawse Limited

David A. Payten (Architectural & Building Consultant)

G. F. King Esq Taylor Fuel Control

Trading Standards Department Surrey County Council

Mr. R. Wells Kuwait Petroleum (GB) Ltd

Paul Clarke and Partners Ltd

Jonathan Funnell Nash and Partners Ltd

Timothy Anscombe Nash and Partners Ltd

Leon ()"Dell

N;1sh and Panncrs Lid

Mr S. P. White, Dir Pool & Pump Ltd

Philip A. Monger Petrol Retailers Association

J. M. Sullivan Burmah Petroleum Fuels Ltd

Mr Graham Biggs Autovend Ltd

John Ackerley Fuelmasters M. W. Dodd Micrelec Group pie

Navinchandra Shah

Mr. S. Nathwani Klargester Environmental Engineering Limited

Desmond Kavanagh Pump Services Ltd

Mr Colin Boyd Jones West Midlands Fire Service S. A. Horsley Cambs CC

H.B.S. Pumps (Northern) Ltd Mr. N. D. Hall Hall Architects

Wyndham Carey G.C.S. Garage Consultancy Services Ltd

Andrew Gardiner Brown & Tawse Limited

Martin Gafinowitz Normond Instruments

J.M. Searle A. E. Finch & Co Ltd

E. Day DOC Builders Ltd

J. D. Chandler (Senior Fire Prevention Officer) Shropshire Fire & Rescue Service

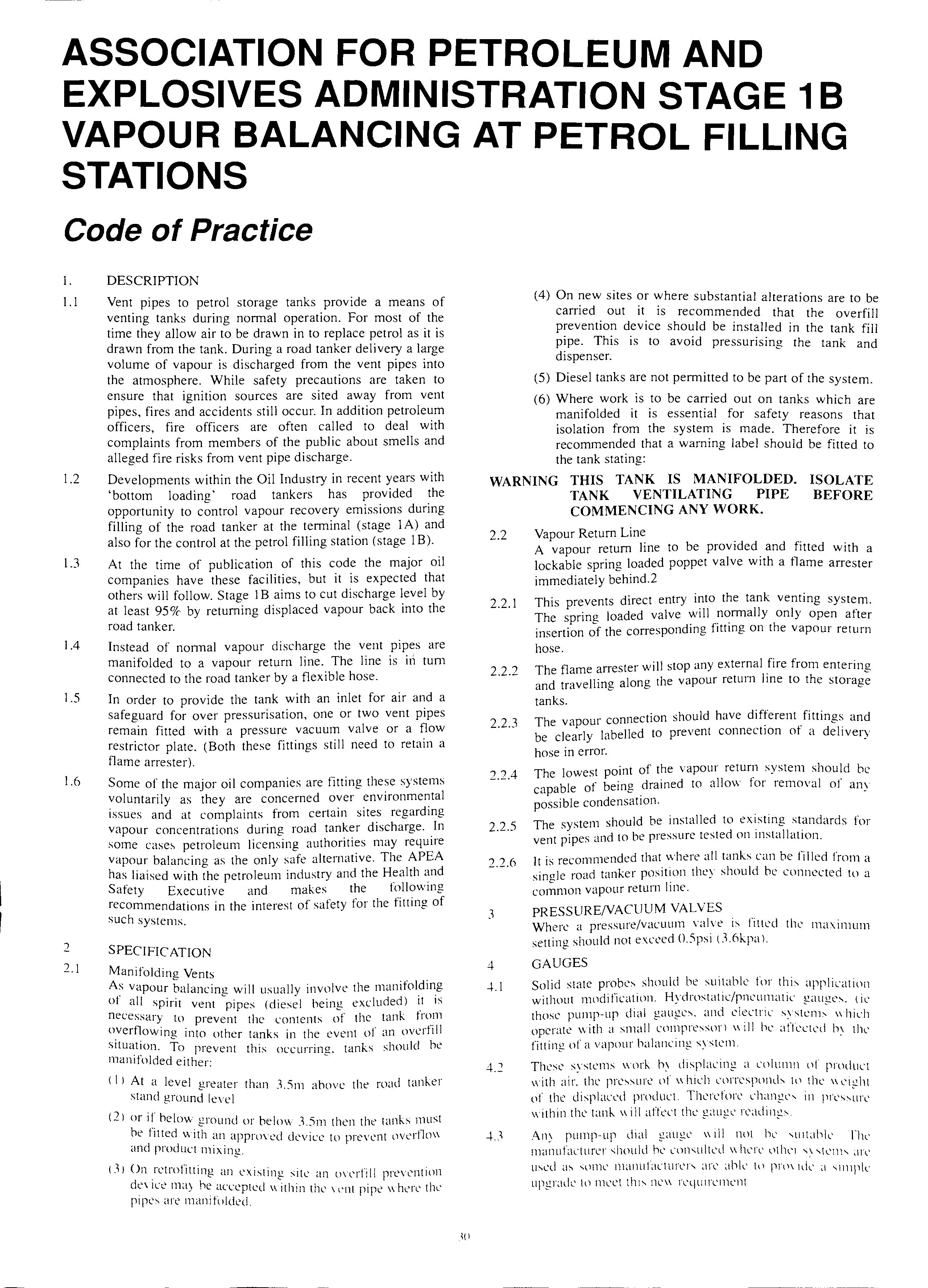

FOR

AND EXPLOSIVES ADMINISTRATION STAGE 1 B

VAPOUR BALANCING AT PETROL FILLING STATIONS

Code of Practice

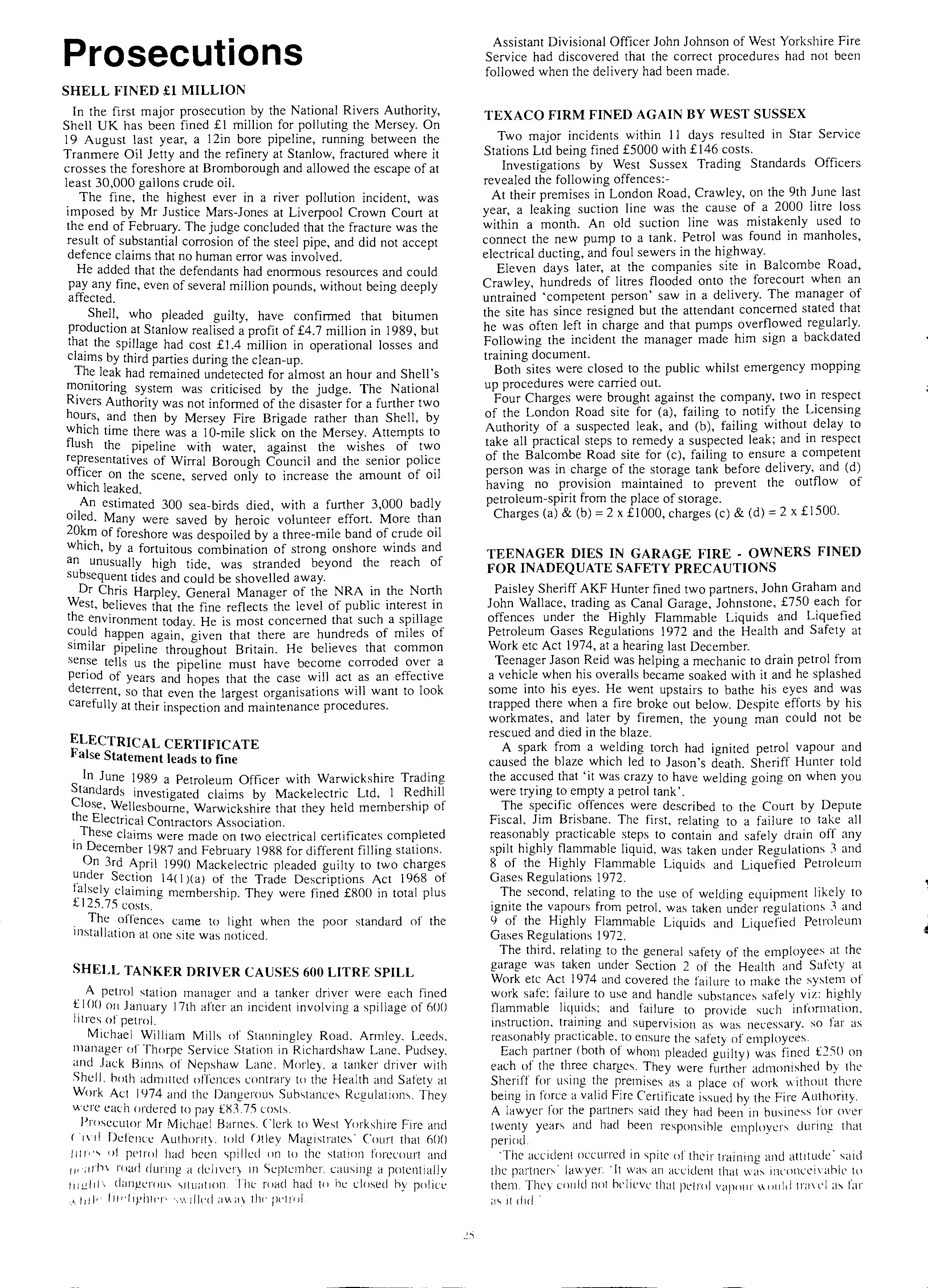

DESCRIPTION

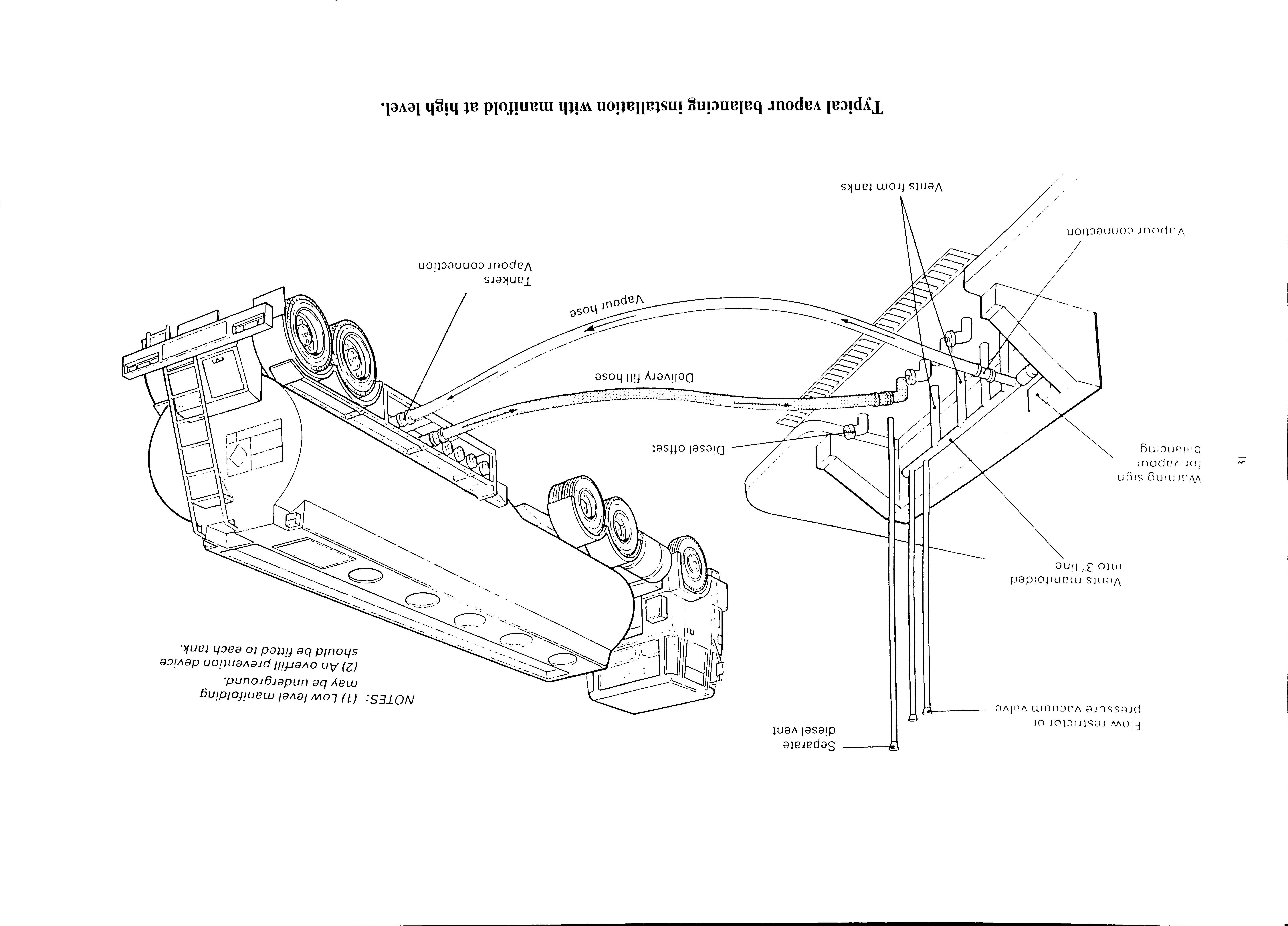

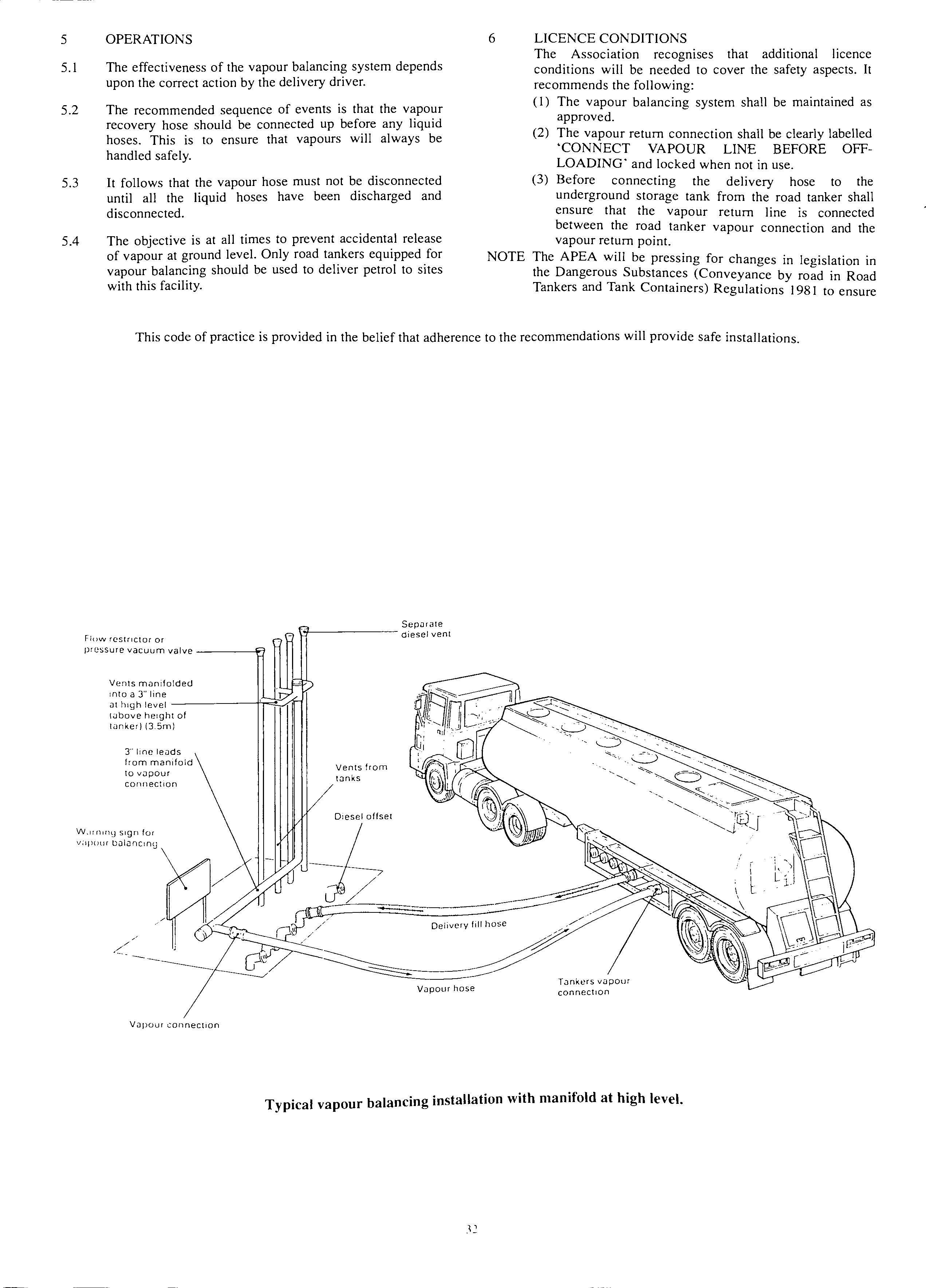

Vent pipes to petrol storage tanks provide a means of venting tanks during normal operation. For most of the time they allow air to be drawn in to replace petrol as it is drawn from the tank. During a road tanker delivery a large volume of vapour is discharged from the vent pipes into the atmosphere. While safety precautions are taken to ensure that ignition sources are sited away from vent pipes, fires and accidents still occur. In addition petroleum officers, fire officers are often called to deal with complaints from members of the public about smells and alleged fire risks from vent pipe discharge.

Developments within the Oil Industry in recent years with 'bottom loading' road tankers has provided the opportunity to control vapour recovery emissions during filling of the road tanker at the terminal (stage IA) and also for the control at the petrol filling station (stage I B).

At the time of publication of this code the major oil companies have these facilities, but it is expected that others will follow. Stage 1B aims to cut discharge level by at least 95% by returning displaced vapour back into the road tanker.

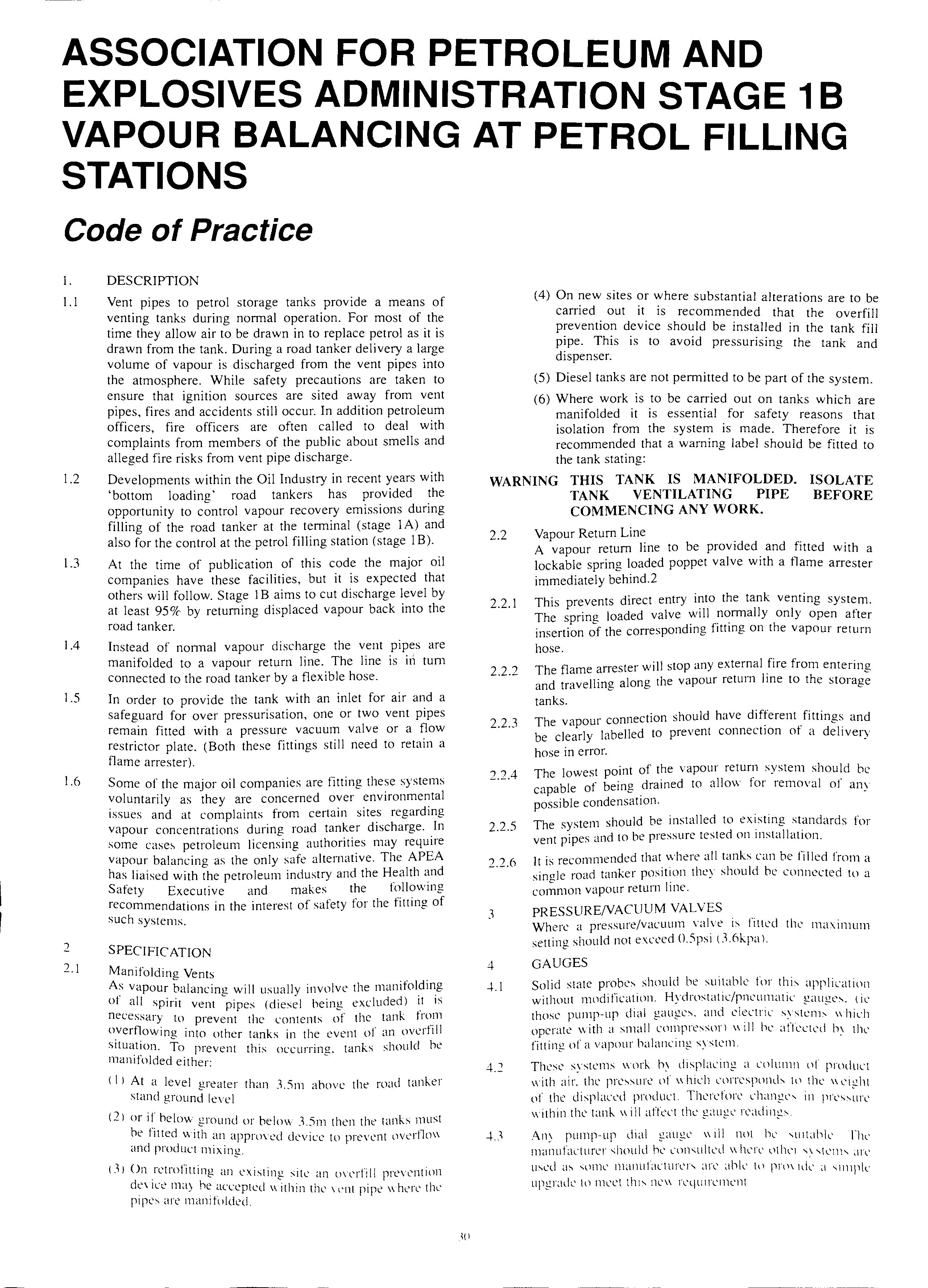

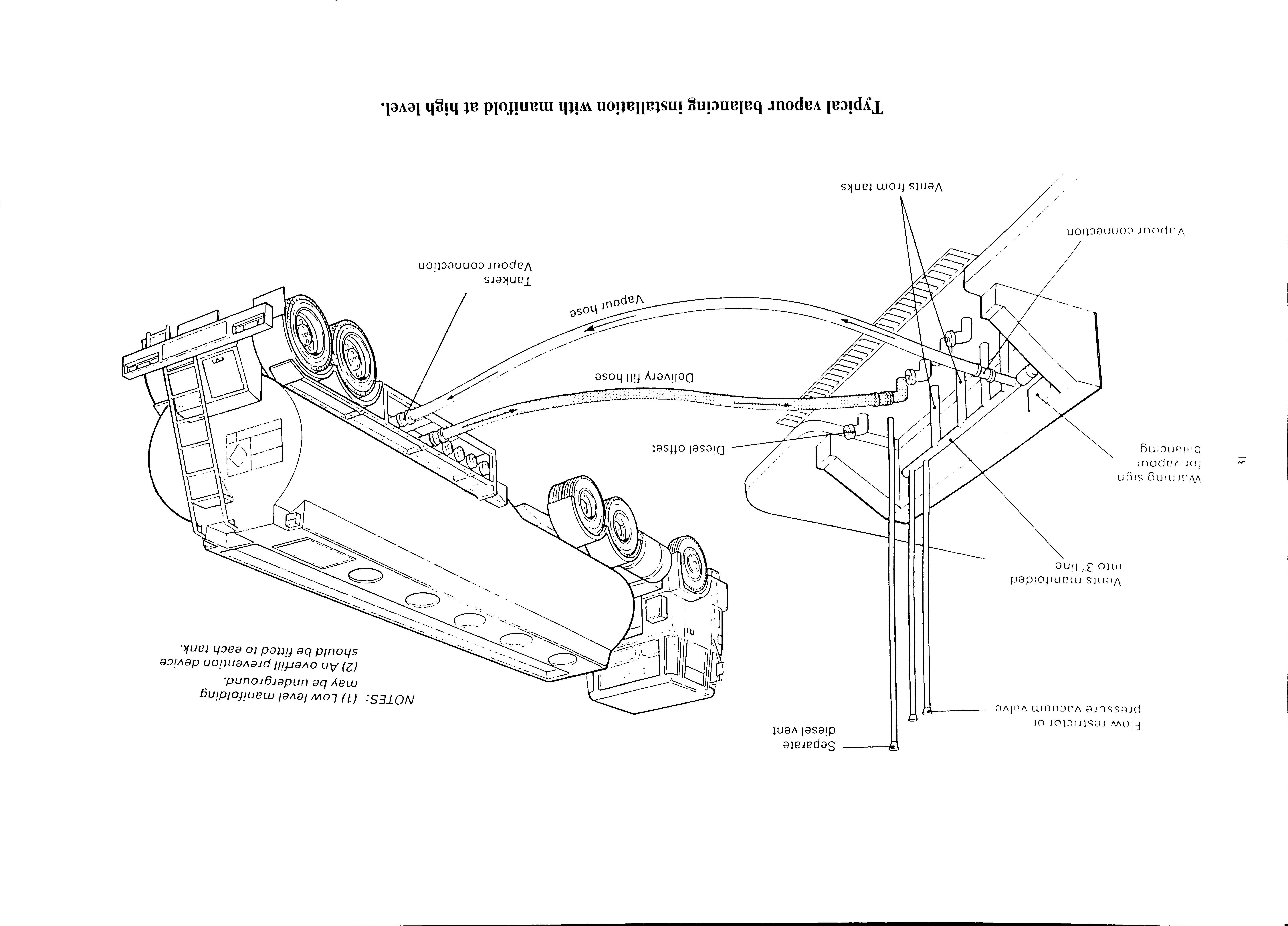

Instead of normal vapour discharge the vent pipes are manifolded to a vapour return line. The line is iri tum connected to the road tanker by a flexible hose.

In order to provide the tank with an inlet for air a safeguard for over pressurisation, one or two vent pipes remain fitted with a pressure vacuum valve or a flow restrictor plate. (Both these fittings still need to retain a flame arrester).

Some of the major oil companies are fitting these systems voluntarily as they are concerned over issues and at complaints from certain sites regardmg vapour concentrations during road tanker discharge. _In some cases petroleum licensing authorities may require vapour balancing as the only safe alternative. The APEA has liaised with the petroleum industry and the and Safety Executive and makes the followmg recommendations in the interest of safety for the fitting of such systems.

SPECIFICATION

Manifolding Vents

As vapour balancing will usually involve the of all spirit vent pipes (diesel heing excluded) 1.t is necessary to prevent the contents of the tank overflowing into other tanks in the event of an overfill situation. To prevent this occurring. tanks should he manifolded either:

( I ) At a level greater than .l5m ahove the road tanker stand grounti level

<2 l or if below ground or below 3.5m then the tanks must be fitted with an approved device to prevent overflo\\ and product mixing.

l On .retrofitting an existing site an overfill prevention de\ ice ma} he accepted within the wnt pipe where the pipes are manifolded.

(4) On new sites or where substantial alterations are to be carried out it is recommended that the overfill prevention device should be installed in the tank fill pipe. This is to avoid pressurising the tank and dispenser.

(5) Diesel tanks are not permitted to be part of the system.

(6) Where work is to be carried out on tanks which are manifolded it is essential for safety reasons that isolation from the system is made. Therefore it is recommended that a warning label should be fitted to the tank stating:

TANK VENTILATING PIPE COMMENCING ANY WORK.

Vapour Return Line

A vapour return line to be provided. and fitted with a lockable spring loaded poppet valve with a flame arrester immediately behind.2

This prevents direct entry the tank venting system. The spring loaded valve will normally only open after insertion ;f the corresponding fitting on the vapour return hose.

The flame arrester will stop any external .fire from entering d travelling along the vapour return lme to the storage an tanks.

The vapour connection should have dif'.erent and be clearly labelled to prevent connection of a delivery hose in error.

The lowest point of the vapour system be capable of being .drained to allow for removal ot any possible condensation.

The system should be installed to existing standards for vent pipes and to be pressure tested on mstallauon.

It is recommended that where all tanks can be filled from a single road tanker position they should be connected to a common vapour return lme.

PRESSURE/VACUUM VALVES

Where a pressure/vacuum valve is fitted the maximum setting should not exceed 0.5psi (3.6kpa l.

GAUGES

Solid state prohes should he suitable for this application without modification. Hydrostatic/pneumatil· gauges. ( il' those pump-up dial gauges. and electril· system, \\ hich operate with a small compressnrl will be alll'L'ted till' fitting of a vapour balancing system.

These systems work displal·ing a column llf product with air. the pressure llf which corresponds tP the 11 of the dispi<tL'L'd product. Thnl'fort' L'11ange' in prl'ssurl' within the tank\\ ill afkct tht' gaugL' read

WARNING THIS TANK IS MANIFOLDED. ISOLATE BEFORE 2.2 2.2.1 2.2.2 2.2.3 2.2.4 2.2.5 2.2.6 3 4 4.1 4.2 -U

An) pump-up dial gaugL' \\ill not lw 'uilahk Thl' manufactllrer should hl' l'lll1'tiltl'd \I hl'rl' ,it her" 'tL'nh ,\I\' used as Sllnll' manufacturer' arl' ahk tll pnn 1dc a '1111pk upgrade to llll'l't tlw, lll'\1 rl'qu1remcnt

ASSOCIATION

PETROLEUM

1.1

1.3 1.4 1.5 1.6 2 2.1

1.

1.2

Flow restr 1ctor or

V<lCuum valve 'I

Separate diesel vent

W.1rn1n9 for ·Japour b.ildllC!lly

Verns mon1folded into 3" l111e

ll.1µuur connection //

Vents from tanks

Diesel offset

Tankers Vapour connection

NOTES: (1) Low level manifolding may be underground.

(2) An overfill prevention device should be fitted to each tank.

Typical vapour balancing installation with manifold at high level.

OPERATIONS

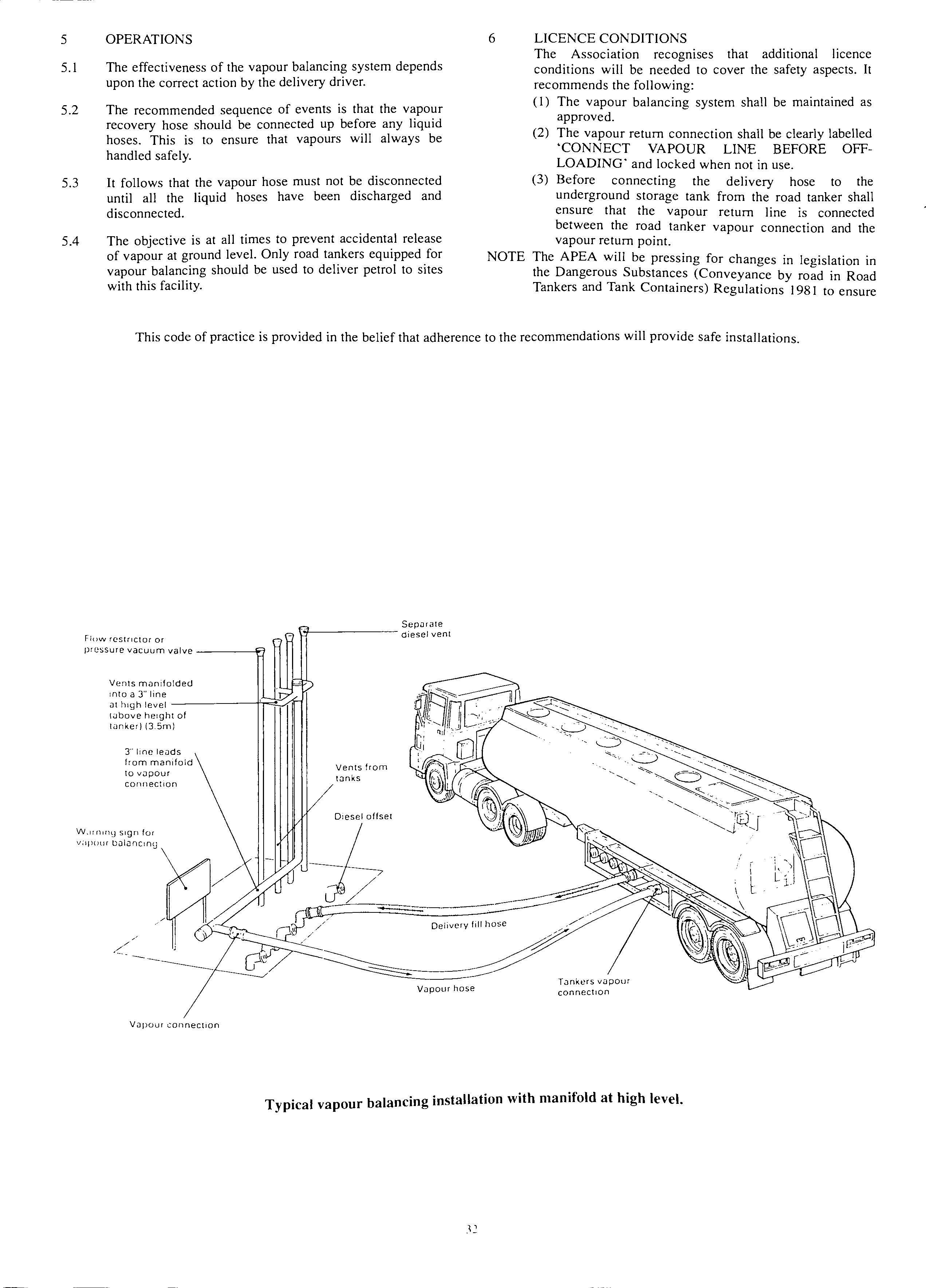

The effectiveness of the vapour balancing system depends upon the correct action by the delivery driver.

The recommended sequence of events is that the vapour recovery hose should be connected up before any liquid hoses. This is to ensure that vapours will always be handled safely.

It follows that the vapour hose must not be disconnected until all the liquid hoses have been discharged and disconnected.

The objective is at all times to prevent accidental release of vapour at ground level. Only road tankers equipped for vapour balancing should be used to deliver petrol to sites with this facility.

6 LICENCE CONDITIONS

The Association recognises that additional licence conditions will be needed to cover the safety aspects. It recommends the following:

(I) The vapour balancing system shall be maintained as approved.

(2) The vapour return connection shall be clearly labelled 'CONNECT VAPOUR LINE BEFORE OFFLOADING' and locked when not in use.

(3) Before connecting the delivery hose to the underground storage tank from the road tanker shall ensure that the vapour return line is connected between the road tanker vapour connection and the vapour return point.

NOTE The APEA will be pressing for changes in legislation in the Dangerous Substances (Conveyance by road in Road Tankers and Tank Containers) Regulations 1981 to ensure

This code of practice is provided in the belief that adherence to the recommendations will provide safe installations.

5 5.1 5.2

5.3 5.4

Flow reslr1ctor or pressure

Vents

into

3"

Sep.:irale t-7------- diesel venl Vents from tJnks Diesel offset W.uninq sign for v;ipour

_j/ / -·----= Delivery fill hose VJpourhose connection Vapour connection Typical vapour balancing installation with manifold at high level.

vacuum valve -----\ri

manifolded

a 3" line at high level 1above height of lanker) (3.5rn)

line leads from manifold to vapour connection

bu!unc1nu

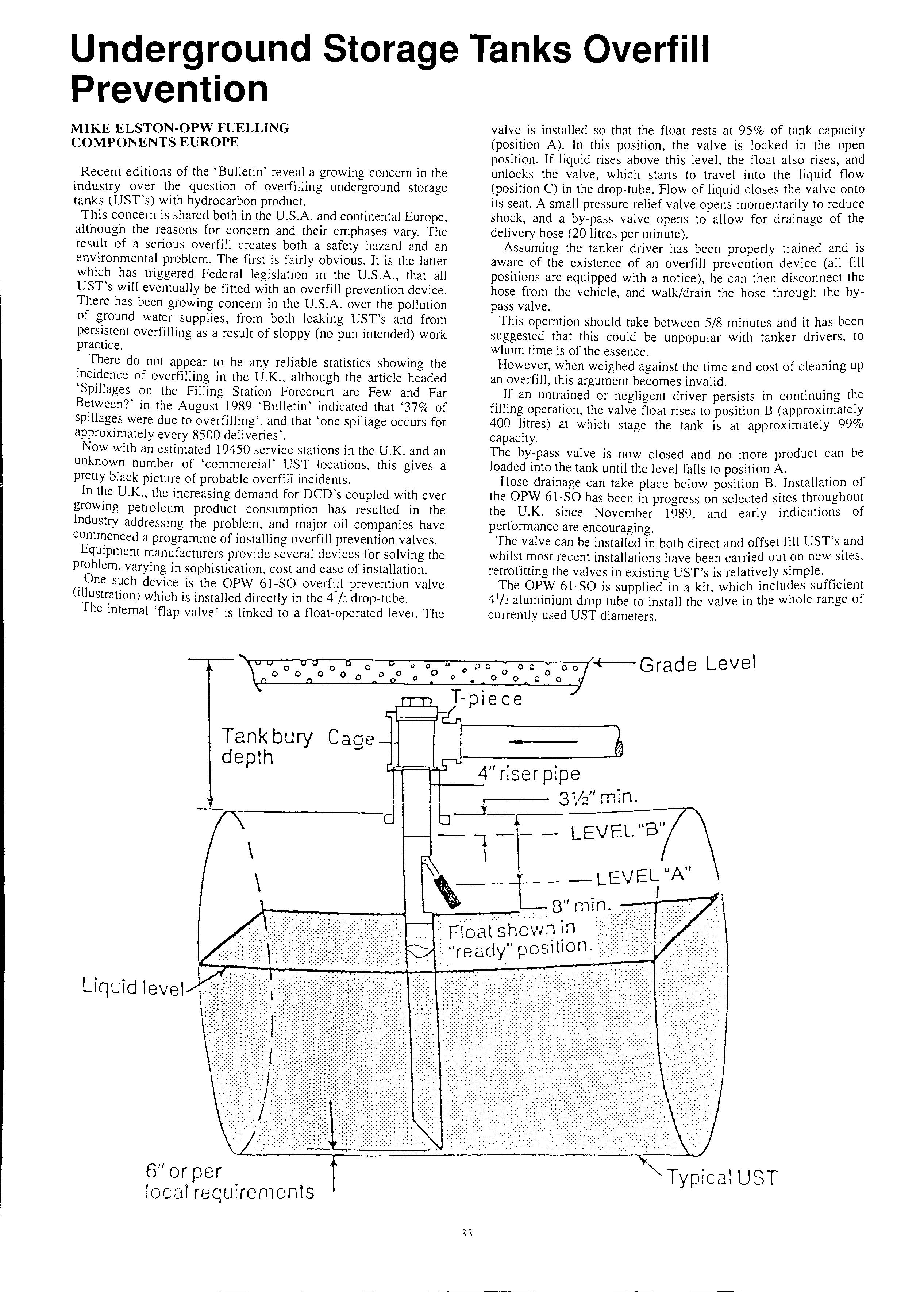

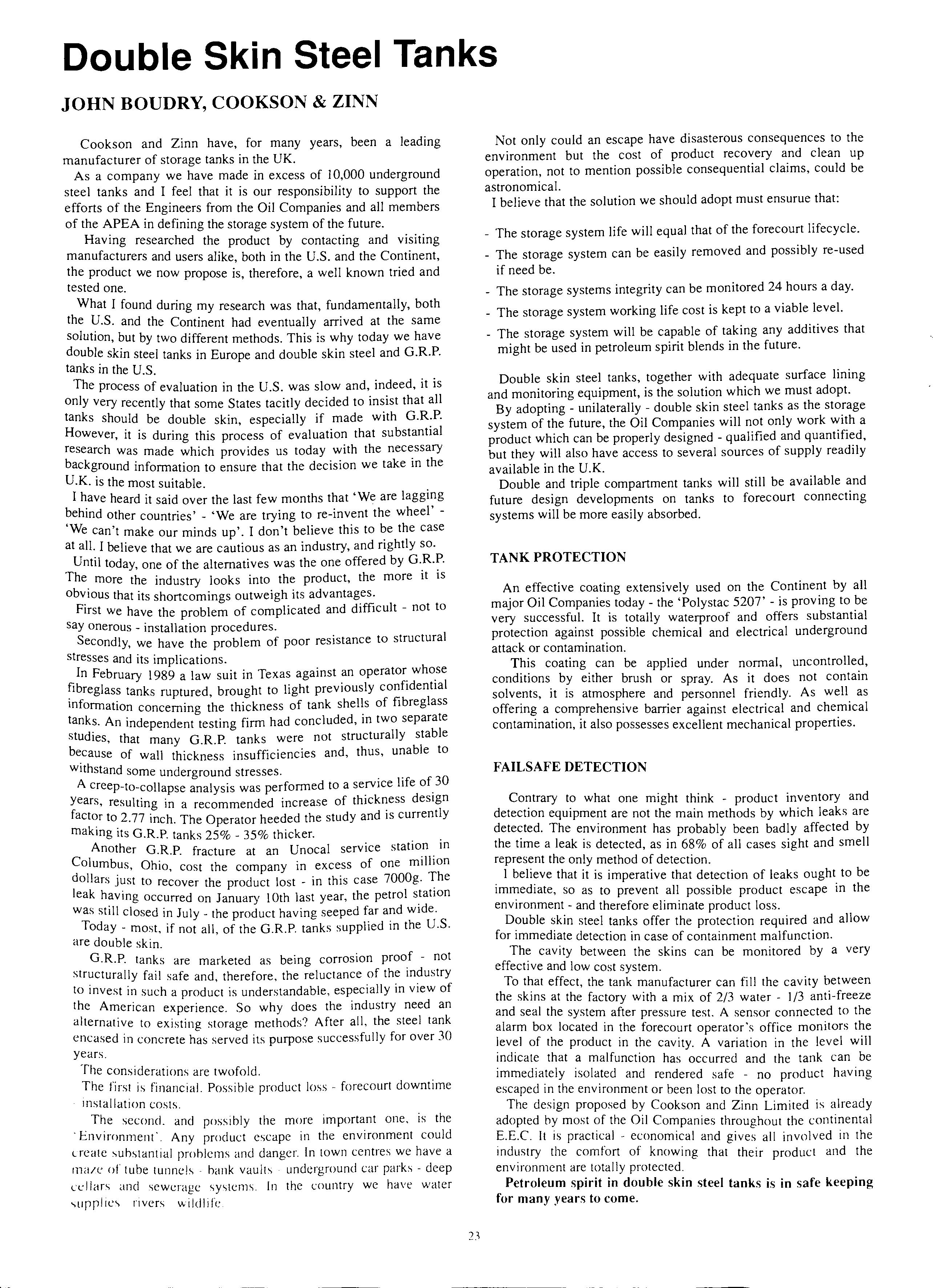

Underground Storage Tanks Overfill Prevention

MIKE ELSTON-OPW FUELLING COMPONENTS EUROPE

Recent editions of the 'Bulletin' reveal a growing concern in the industry over the question of overfilling underground storage tanks (UST's) with hydrocarbon product.

This concern is shared both in the U.S.A. and continental Europe, although the reasons for concern and their emphases vary. The result of a serious overfill creates both a safety hazard and an environmental problem. The first is fairly obvious. It is the latter which has triggered Federal legislation in the U.S.A., that all UST's will eventually be fitted with an overfill prevention device. There has been growing concern in the U.S.A. over the pollution of ground water supplies, from both leaking UST's and from persistent overfilling as a result of sloppy (no pun intended) work practice.

There do not appear to be any reliable statistics showing the incidence of overfilling in the U.K., although the article headed 'Spillages on the Filling Station Forecourt are Few and Far Between?' in the August 1989 'Bulletin' indicated that '37% of spillages were due to overfilling', and that 'one spillage occurs for approximately every 8500 deliveries'.

Now with an estimated 19450 service stations in the U.K. and an unknown number of 'commercial' UST locations, this gives a pretty black picture of probable overfill incidents.

In the U.K., the increasing demand for DCD's coupled with ever growing petroleum product consumption has resulted in the Industry addressing the problem, and major oil companies have commenced a programme of installing overfill prevention valves.

Equipment manufacturers provide several devices for solving the problem, varying in sophistication, cost and ease of installation.

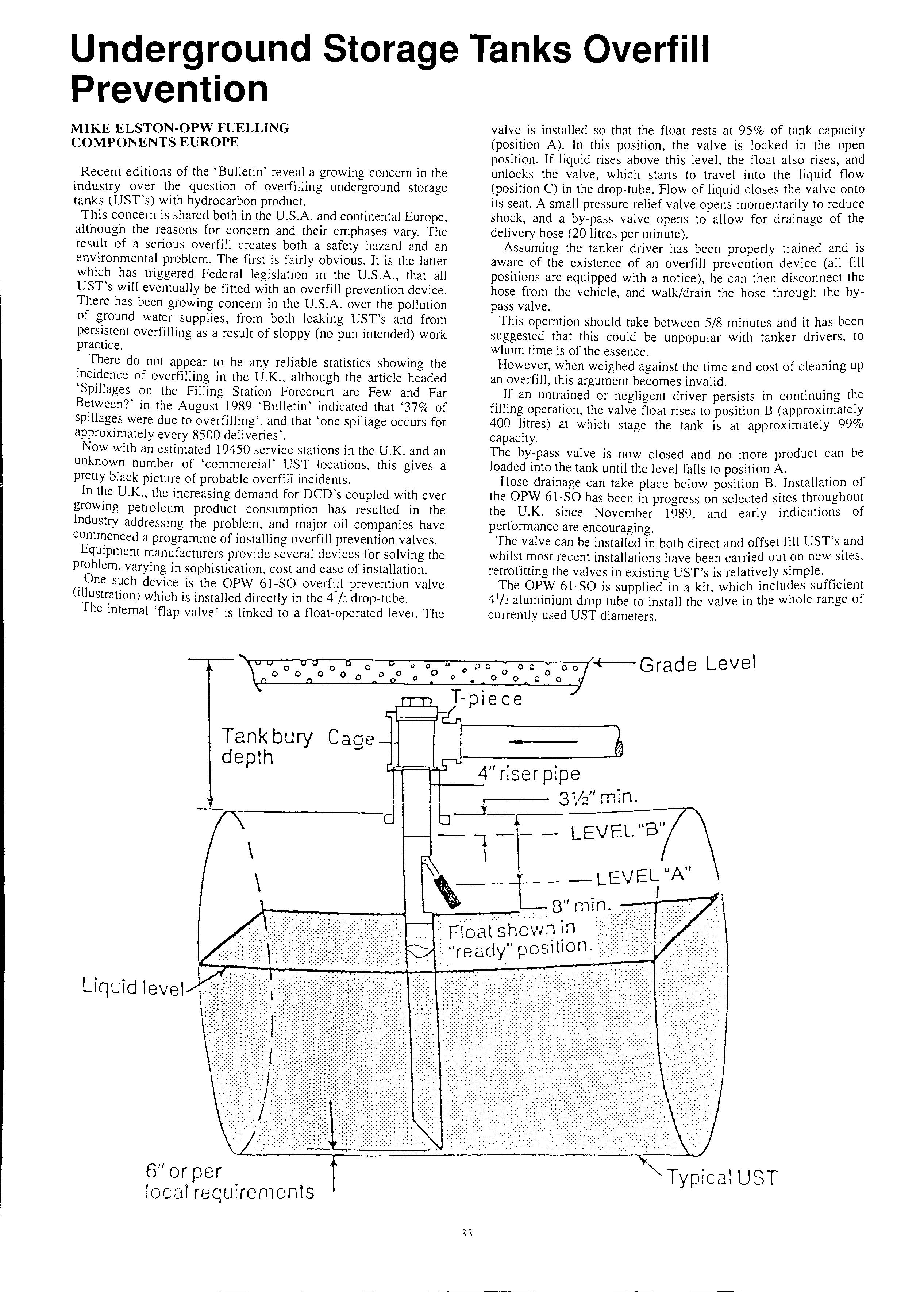

One such device is the OPW 61-SO overfill prevention valve (illustration) which is installed directly in the 4 1/2 drop-tube.

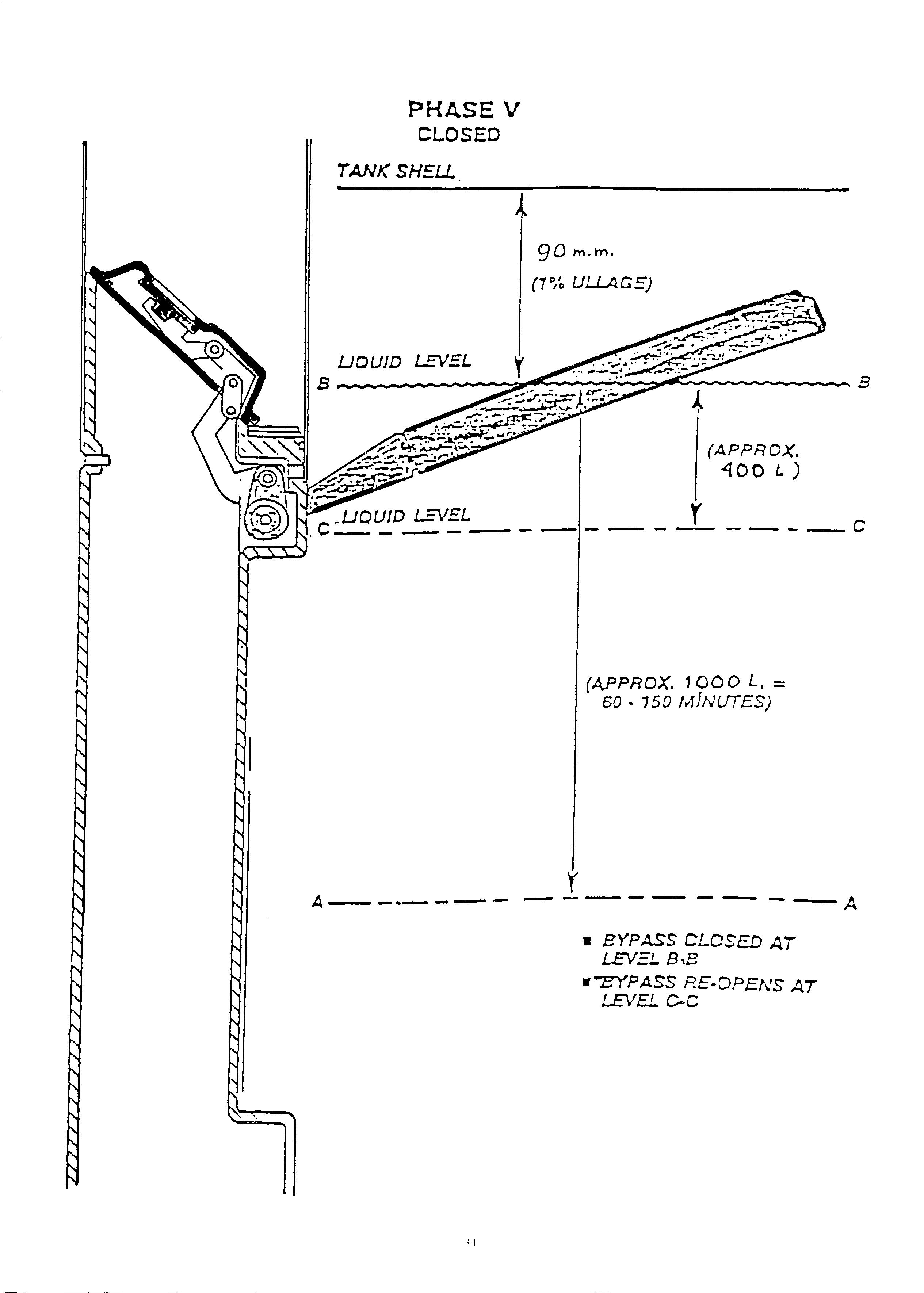

The internal 'flap valve' is linked to a float-operated lever. The

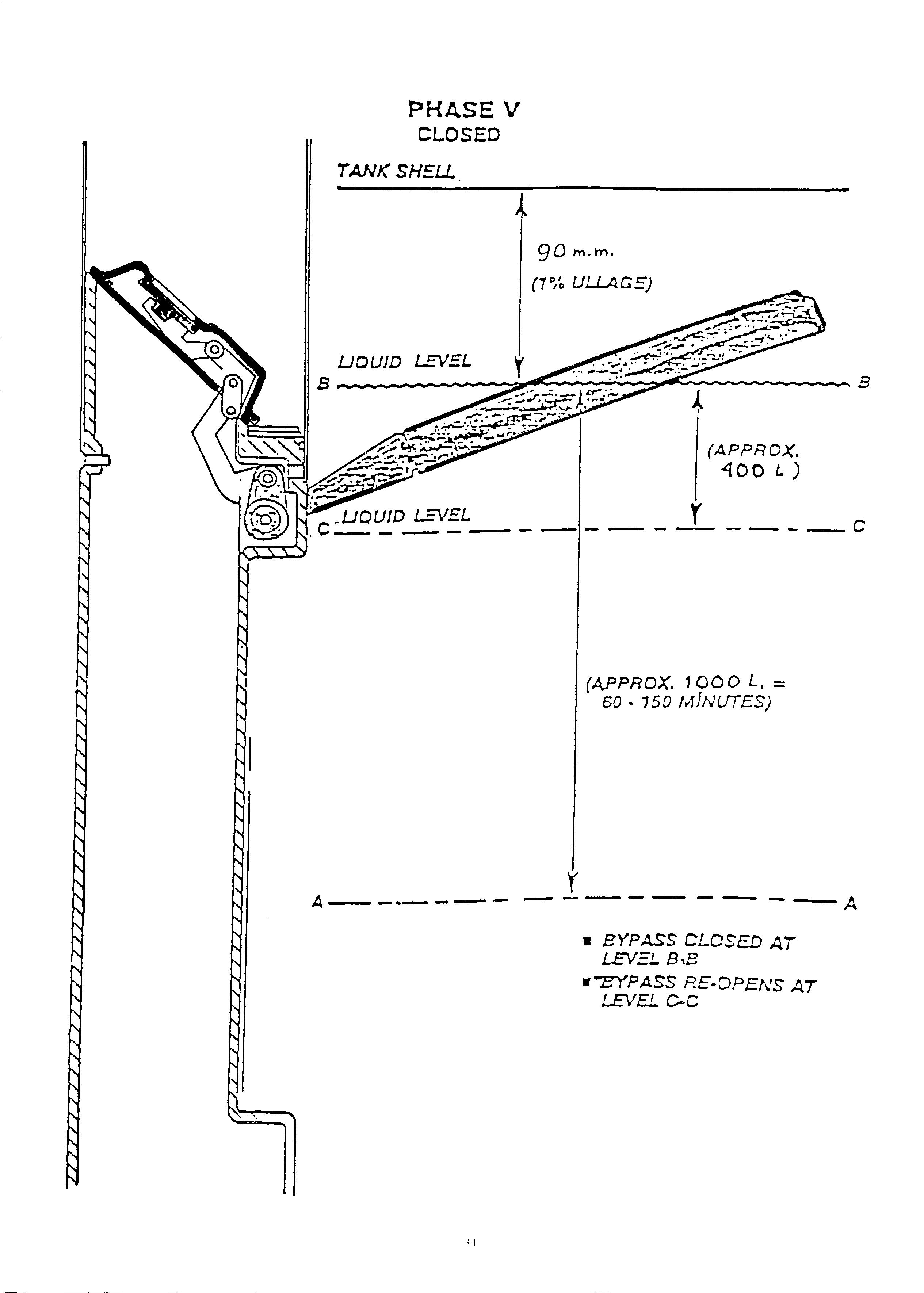

valve is installed so that the float rests at 95% of tank capacity (position A). In this position, the valve is locked in the open position. If liquid rises above this level, the float also rises, and unlocks the valve, which starts to travel into the liquid flow (position C) in the drop-tube. Flow of liquid closes the valve onto its seat. A small pressure relief valve opens momentarily to reduce shock. and a by-pass valve opens to allow for drainage of the delivery hose (20 litres per minute).

Assuming the tanker driver has been properly trained and is aware of the existence of an overfill prevention device (all fill positions are equipped with a notice), he can then disconnect the hose from the vehicle, and walk/drain the hose through the bypass valve.

This operation should take between 5/8 minutes and it has been suggested that this could be unpopular with tanker drivers, to whom time is of the essence.

However, when weighed against the time and cost of cleaning up an overfill, this argument becomes invalid.

If an untrained or negligent driver persists in continuing the filling operation, the valve float rises to position B (approximately 400 litres) at which stage the tank is at approximately 99% capacity.

The by-pass valve is now closed and no more product can be loaded into the tank until the level falls to position A.

Hose drainage can take place below position B. Installation of the OPW 61-SO has been in progress on selected sites throughout the U.K. since November 1989, and early indications of performance are encouraging.

The valve can be installed in both direct and offset fill UST's and whilst most recent installations have been carried out on new sites. retrofitting the valves in existing UST's is relatively simple.

The OPW 61-SO is supplied in a kit, which includes sufficient 4 1/2 aluminium drop tube to install the valve in the whole range of currently used UST diameters.

·\ u_o_o_o_ua_u o_u_o_o_,• a_o_o_o_o_a_a-1/...(;-- Grade Leve I T-pi e ce 7 Liquid level Tank bury Cage depth 6'' or per local requirements 4" riser pipe l-+---min. LEVEL"B" _ -LEVEL"A" .8"min. Float shOVJ0 "ready"

PHASE V CLOSED TANK SHEU.. LJOUID L-CVEL gom.m. (1% ULLAGE) B--------------~~...---;...-.~,,,,-....------------(APPAOX. 400 t.) :• .LJOUID L=-VEL r C---------------C A--·--_..___. (APPROX. 1 OOO L, = 60 • 150 MjNUTES) y ------- -- --A • BYPASS CLOSED AT LEVEL B·B •-eYPASS RE·DPENS AT LEVE!... C-C

HOW WELL DOES THE PET ROLEUM INDUSTRY HOLD ITS LIQUID? NORMOND INSTRUMENTS FOR ALL:• Gauging requirements -Analogue - Electronic - Hydrostatic - Capacitance • Service and Installation throughout UK and NI • Tank Calibration Service with 5 options available. If you require more information about Normand products and services please send off the coupon below or phone Lynda Lightowlers direct on 081-392 1355. Nonnond tank management systems Normand Instruments Limited, Hydrex House, Garden Road, Richmond, SURREY TW9 4NR ------------------Please send me "THE NORMOND GUIDE TO TANK GAUGING" Brochure Name _ Company Name _________ Company Address ____ Position __________ Tel No _____

CAPITAL DEMOLITION <NHEJ LTD Specialist removal of feel tanks General demolition Concrete breaking BYFLEET (09323) 46222 41525 46005 C & S STANSFIELD LIMITED AMERON APPROVED INSTALLER FOR _FIBERGLASS PETROLEUM INSTALLATIONS Unit 10 Boundary Road Industrial Estate Sturmer, Haverhill Suffolk, CB9 7YH Tel: 0440 712505 Fax: 0440 712506

OLD STATION: NEW CANOPY SELF SERVICE : LEAD FREE PETROL PETROLEUM COMPANY BACKING WELL INSURED - WE THINK!! LONG TERM INVESTMENT

COAT OF PAINT: NEW SIGN NEW CORPORATE IMAGE

SHOP WITH MARS BARS ON THE RIGHT SHELF FORECOURT MAINTENANCE CONTRACT SOUND BUSINESS WITH ASSURED FUTURE

BUT '·WHAT REALLY SUPPORTS ALL THIS I SERVICE STATION

Corroshield have been lining petrol storage tanks for over a decade endorsing our quality of specification and experience in this specialist field

SO WHAT HAPPENS WHEN YOUR TANKS FAIL?

So what do you do when your tanks fail_ Telephone (0949 2.1032). They could be rehabilitated and returned to service within 14 days without d1srupt1on

Corroshield System 80 tank rehabilitation is not a repair or temporary solution: (it is new tanks for old) backed by our guarantees extended for as long as you require

In any forecourt operation tank protection should be as t.ank and subsequent replacement could wipe out years of profits and impose 1mmed1ate financial burden.

DON'T WAIT UNTIL IT HAPPENS: Ring now for details on how we can provide protection for your underground storage facility at very little cost.

Unot 1, Hackers East Bridgford, Nottingham NG13 8PG (0949) 21032

TANK PROTECTION FROM l't1111111S111E1,11

0

COMMERCE HOUSE, THE MALTINGS, STATION ROAD, SAWBRIDGEWORTH, HERTS. CM21 9JX Telephone: 0279 723448

Aden con Draughting Services Ltd.

Specialists in the preparation of drawings for petrol filling service station redevelopments, alterations and tank or equipment installations and obtaining all necessary statutory authority approvals (i.e. planning permission, building regulation approval, petroleum officer approval etc.)

Specialists in Forecourt Landscaping, offering National Landscaping Services to all the Oil Companies (Established 10 Years) 32 ONSLOW DRIVE, LEA PARK, TRAME, OXON OX9 3YY TELEPHONE: THAME (084 421) 7134

MEMBER A.P.E.A.

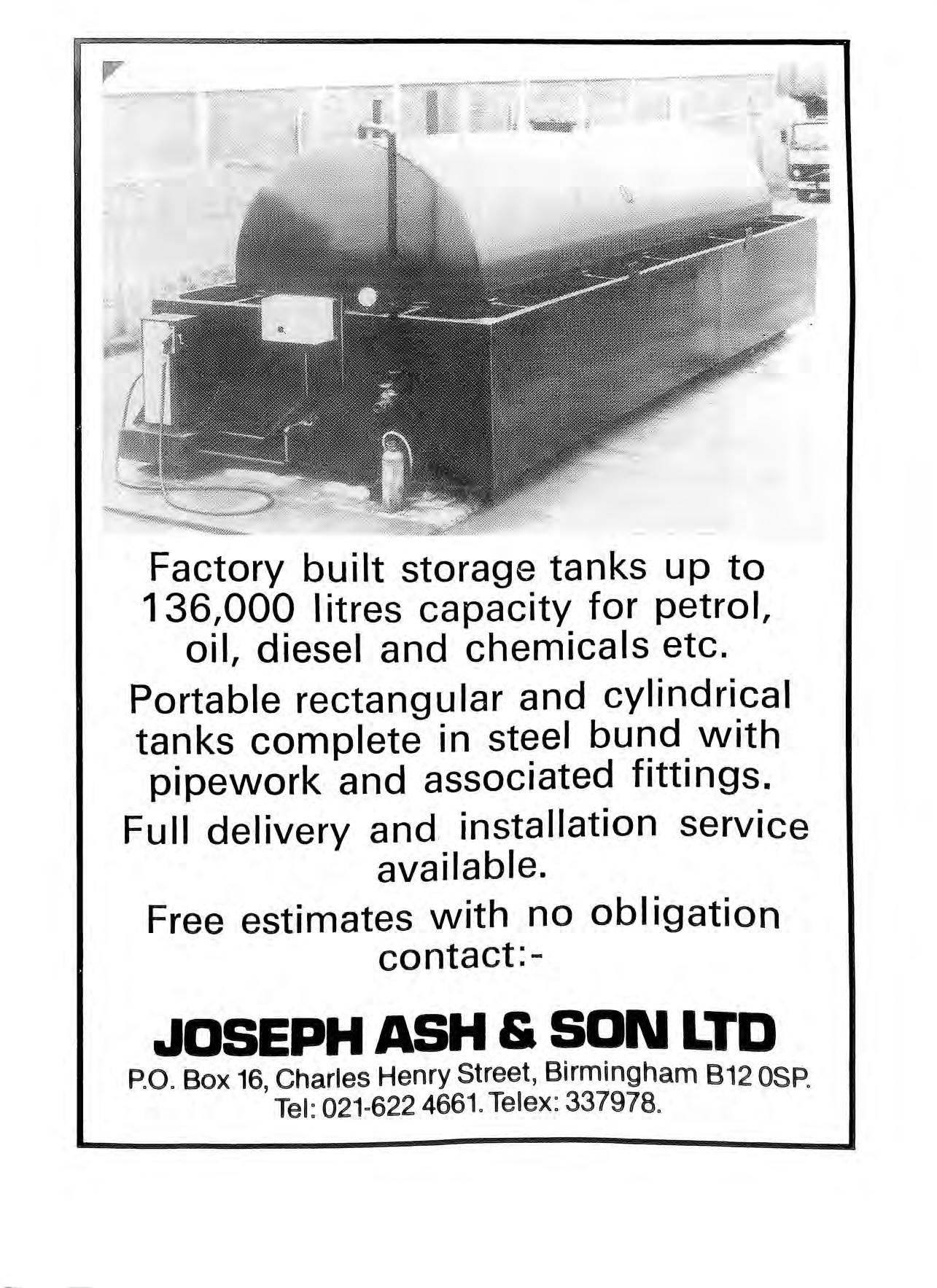

Factory built storage tanks up to 136,000 I itres capacity for petrol, oil, diesel and chemicals etc. Portable rectangular and cylindrical tanks complete in steel bund with pipework and associated fittings. Full delivery and installation service available. Free estimates with no obligation contact:JOSEPH ASH & SON LTD P.O. Box 16, Charles Henry Street, Birmingham 812 OSP. Tel: 4661. Telex: 337978.

LOXDENE LTD FORECOURT SERVICES Established 1984 CERTIFIED AND EXPERIENCED AMERON GRP INSTALLERS PURPOSE DESIGNED ALL WEATHER INFLATABLE TRENCH COVERS FOR WORKING WITH GRP PIPE CONVENTIONAL STEEL PIPE INSTALLATIONS NATIONWIDE SERVICE APEA MEMBER 45 Vivian Avenue Hendon London, NW4 3XA Tel: 081-202 8035 Fax: 081-202 1642 D D C BUILDERS LTD FOR SERVICE QUALITY & RELIABILITY WE OFFER A COMPLETE SERVICE ON MAINTENANCE AND IMPROVEMENT WORKS TO THE PETROLEUM RETAIL MARKET D DC BUILDERS LTD 7 ST CLAIR CLOSE CLAYHALL, ILFORD ESSEX IG5 OPA 081 =550 5216 081 =550 6095

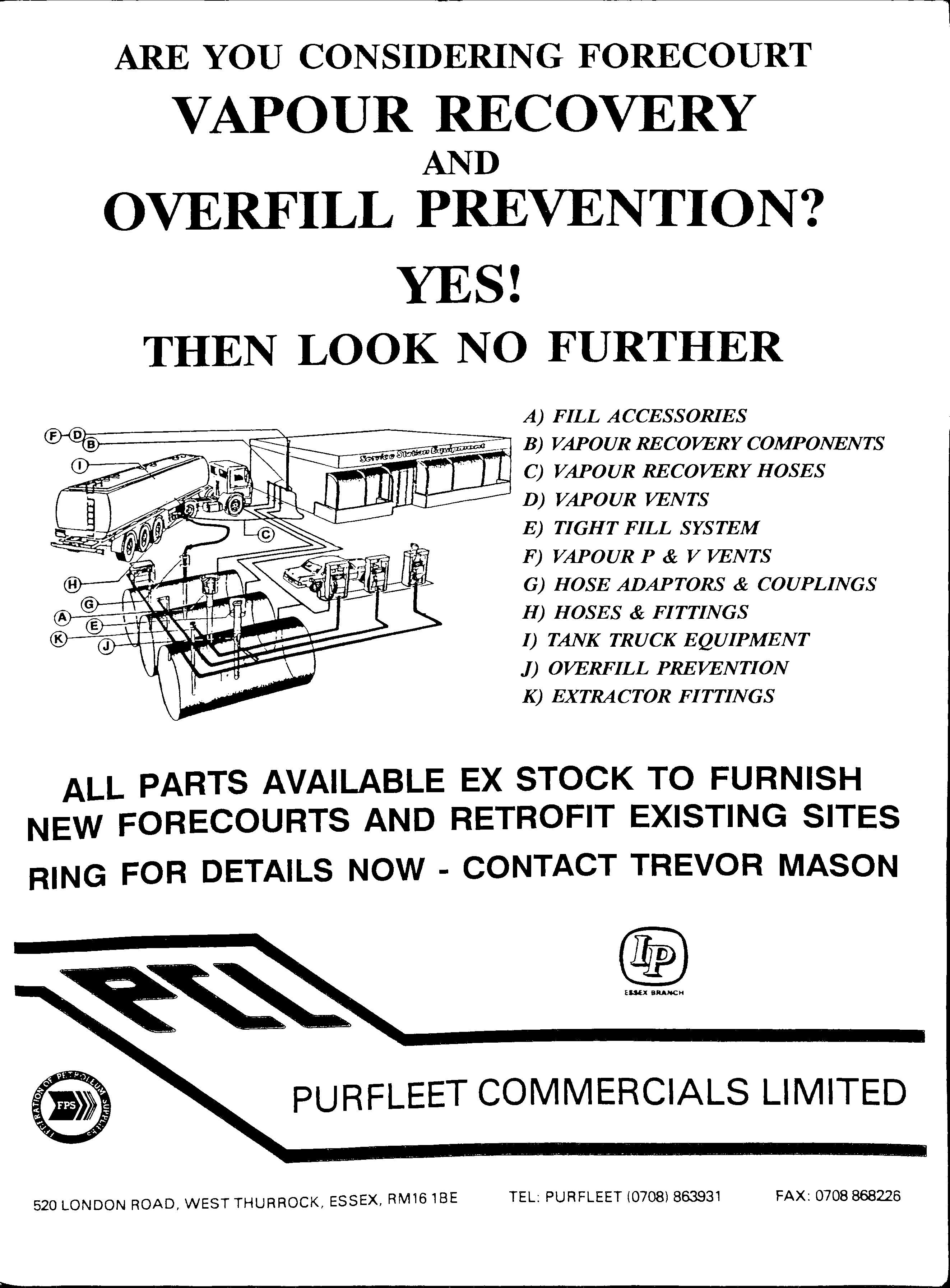

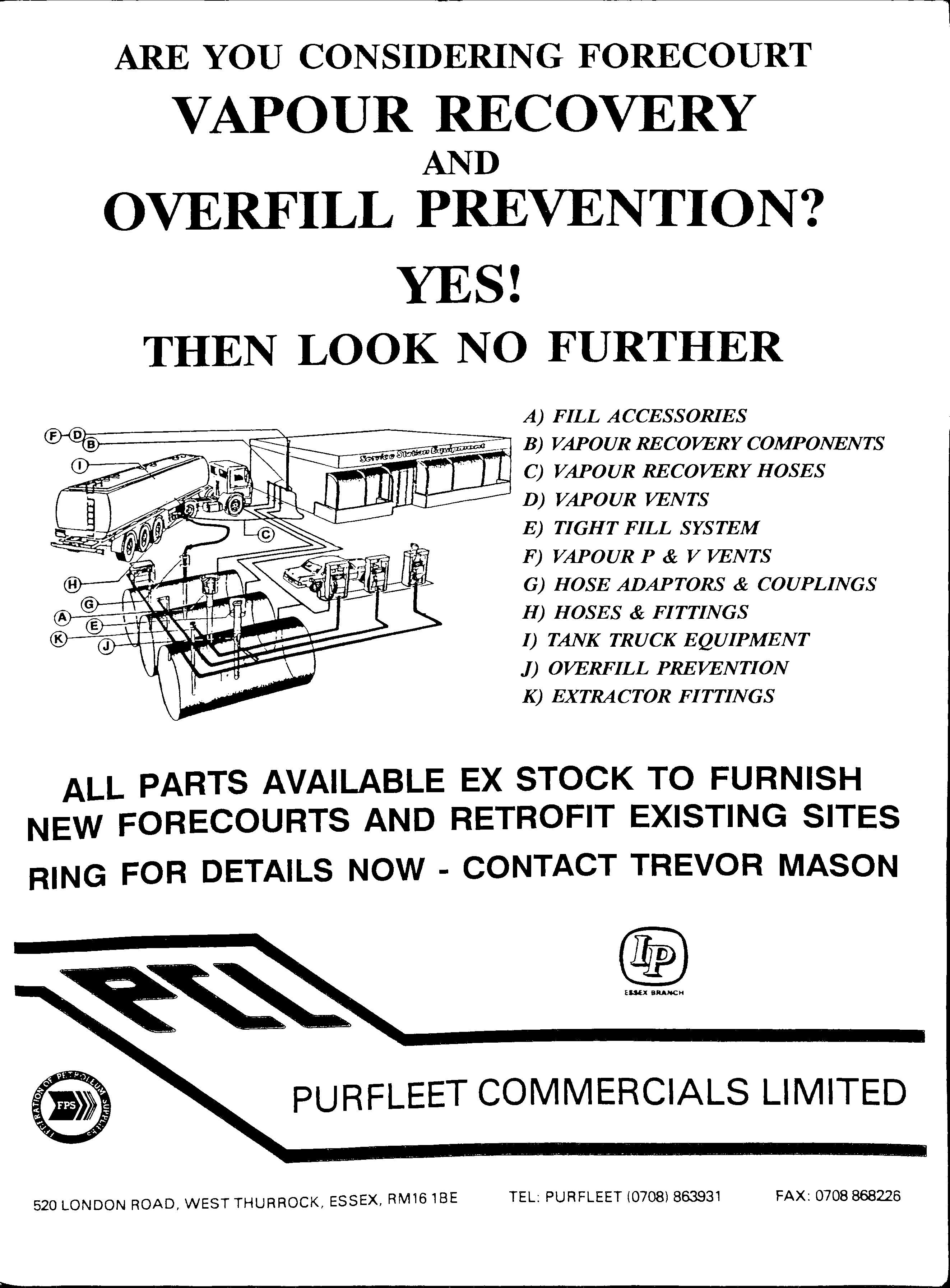

ARE YOU CONSIDERING FORECOURT VAPOUR RECOVERY AND OVERFILL PREVENTION? YES! THEN LOOK NO FURTHER A) FILL ACCESSORIES B) VAPOUR RECOVERY COMPONENTS C) VAPOUR RECOVERY HOSES D) VAPOUR VENTS E) TIGHT FILL SYSTEM F) VAPOUR P & V VENTS G) HOSE ADAPTORS & COUPLINGS H) HOSES & FITTINGS I) TANK TRUCK EQUIPMENT J) OVERFILL PREVENTION K) EXTRACTOR FITTINGS ALL PARTS AVAILABLE EX STOCK TO FURNISH NEW FORECOURTS AND RETROFIT EXISTING SITES RING FOR DETAILS NOW - CONTACT TREVOR MASON ES.SVC. 8RAHCH PURFLEET COMMERCIALS LIMITED 520 LONDON ROAD, WEST THURROCK, ESSEX, RM16 1BE TEL: PURFLEET (0708) 863931 FAX: 0708868226

I c.;j THE WASTE DISPOSAL SPECIALISTS NATIONWIDE TANK CLEANING SERVICE Petrol, oil and solvent tanks cleaned to associated petroleum industry standards. (0489) 783462 FORECOURT DRAINAGE AND INTERCEPTOR SERVICE Drainlines gullies interceptors catch pits All properly maintained to keep your garage clean and safe from fire and forecourt flood. (0386) 47190 TRADE EFFLUENT DISPOSAL Toxic, acid, oily and other noxious wastes.

SERVICES Wide range of containers for dry industrial waste. Static compactors installed and serviced. When the job calls for experts - call in the experts. ALSO: SKIPS GULLY CLEANING WATER JETTING CESSPIT EMPTYING EMERGENCY HOTLINE

BULK WASTE

WHE N YOU REQUIRE QUALITY Petroleum I Speciality hoses Roadtankers I Pipe fittings Hose fittings Fuel Dispensing Nozzles ELAFLEX LTD. Lodge House , Lodge Road, Hendon, London NW4 400 Telephone 01-203 4243 (3 lines) · Fax : 01-203 4853 Telex 25297

Waste Oil Collection and Reclamation. Tank Cleaning, General Cleaning and Emergency Oil Spillage Anti P ollution Services . Other Services offered: Cleaning of All Tanks, i.e. Spirit, Oil, Chemical, Water. Shot Blasting and Painting of Tanks, Tank Removal. Descaling of Pressure or Condensate Tanks. Pressure Testing of Tanks and Pipes Interceptor Pit Clearance. Removal of Vessel Bilge Sludge and Fuel Oil Slops. HEAD OFFICE: The Lodge, Essex Road, Hoddesdon, Herts. ENl 1 OAT Telephone 0992 451090 Facsimile 0992 451091 DEPOTS : Erith Maypole Crescent, Darent Industrial Park, Slade Green, Erith, Kent Telephone 0322 347402 Felixstowe Sub -S tation RoJld, The Dock, Felixstowe, Suffolk IPt l 8sE Telephone 0394 272236 Telex 0206 987185 COMTLX-G Wokingham Langley Common Road, Berkham, Nr. Wokingham , Berks RGl 1 4TS Telephone 0734 760253 Great Yarmouth 5 Brinell Way, Harfreys Industrial Estate, Great Yarmouth, Norfolk NR3 t O'LU Telephone 0493 602848 Facsimile 0493 655459