The wrong underground

p1p1ng material could put your entire business in the hole.

If you're rebuilding your station, you're probably in a rush for the pipe to be in the ground and tested so you can get on with your real business of selling fuel.

But don't forget to take a close look at your choice of piping materials.

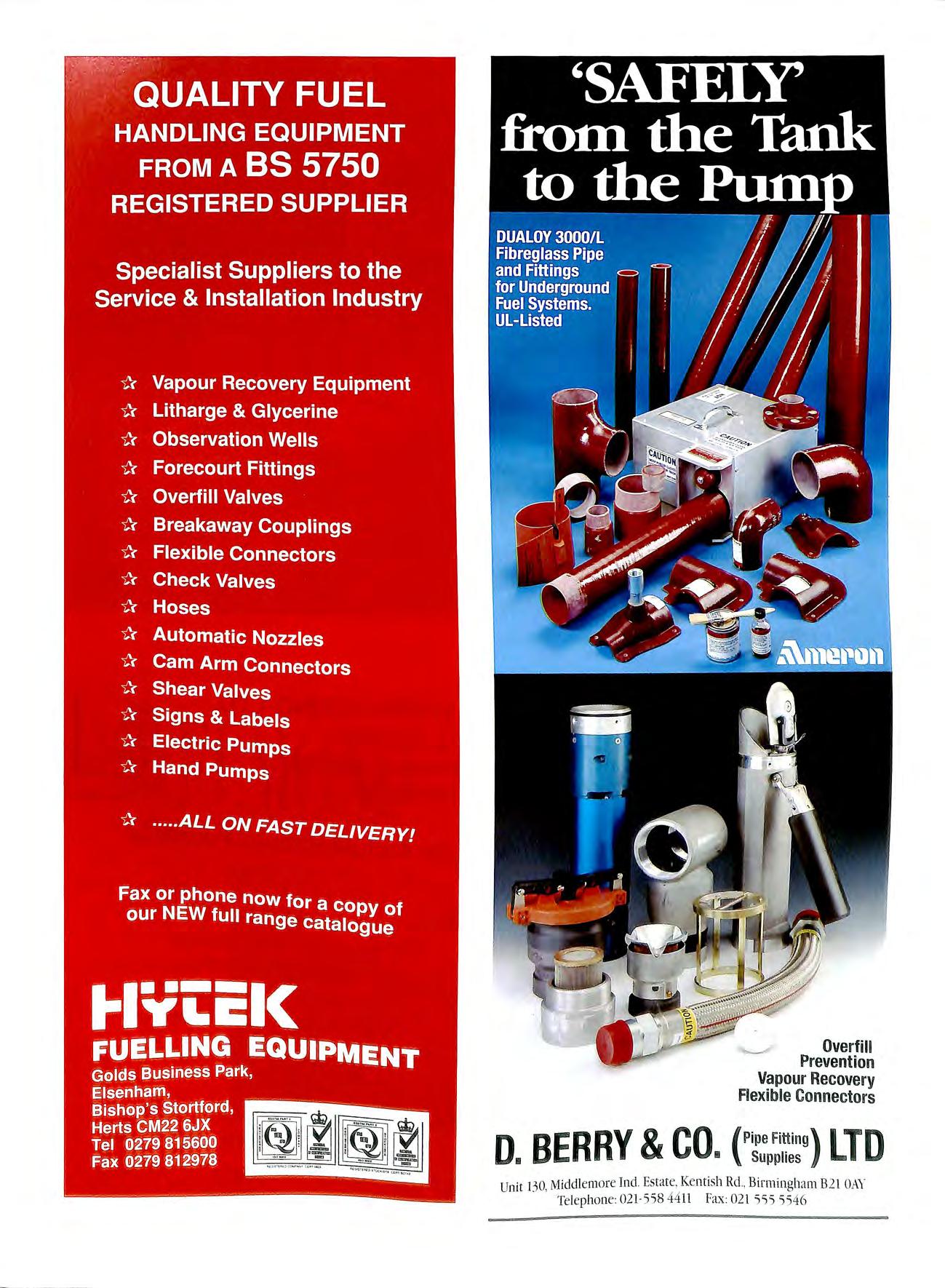

Here are three things to think about when you choose between 'hard' piping like Dualoy®3000/L and the 'soft' system that 's just come on the market.

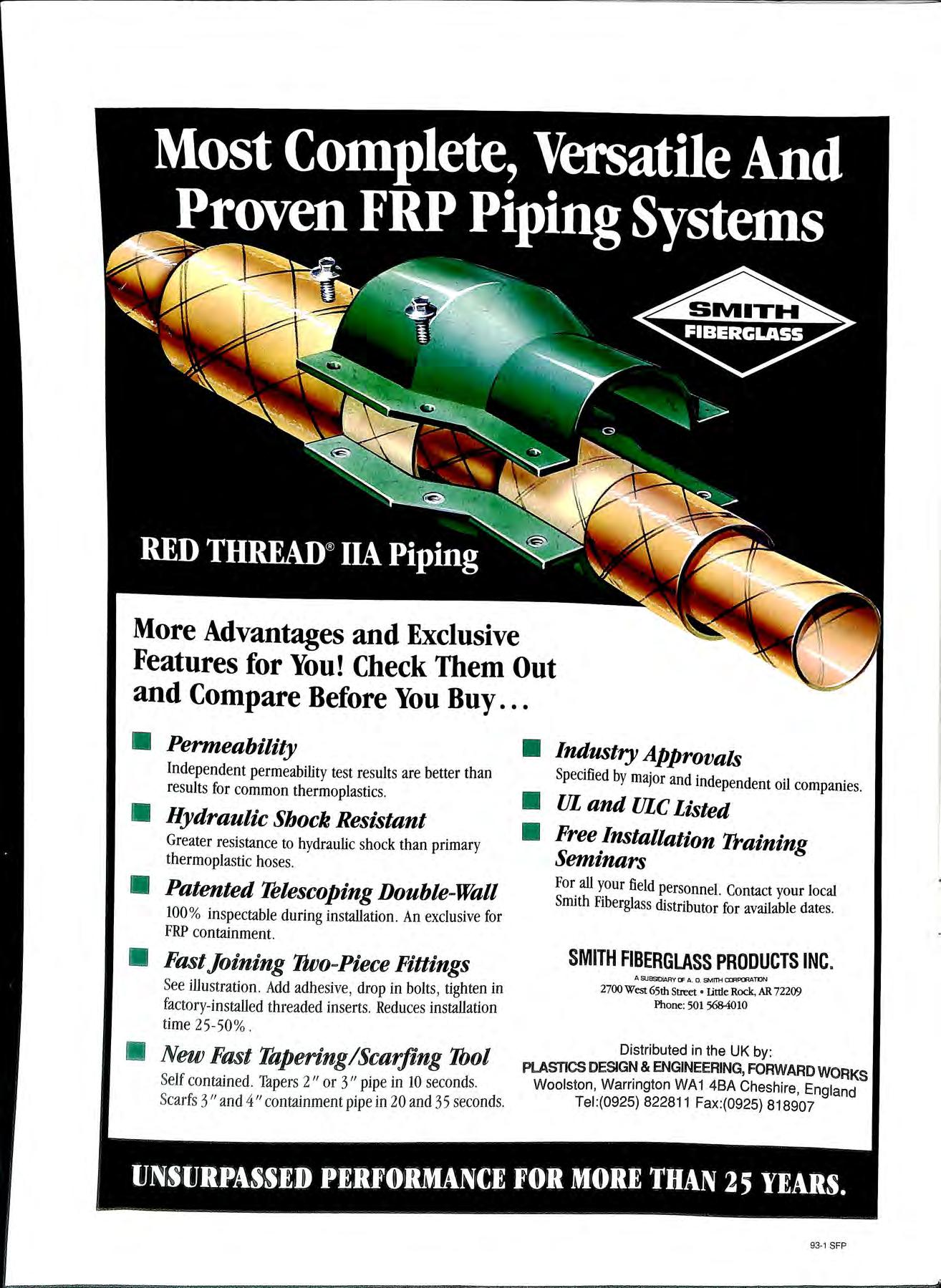

For starters, there's fluid hammer. Topping off can cause pressure spikes of 20 atm or more. Soft systems use thermoplastic hoses in the primary with safety factors of 3:1 or less. That's not a lot of margin for failure. With Dualoy 3000/L rigid-wall fiberglass pipe from Arneron you get a safety factor of over 10:1.

Second, there's UL-listing. Soft system containment doesn't have it. Wouldn't you want the assurance of a Inc .@ third party like UL that the containment can prevent soil contamination in case of a le ak? You have that assurance with Dualoy 3000/L.

Next, there's retestability Hos e syste ms give you soft containment and sump penetrations that rely on soft flexible boots with minimal press ure capabilities. With soft containment it 's a chore to retest the system once in service-if yo u can rete st at all. Dualoy 3000/L provides rigid-wall, adhesive-bonded co ntainment and sump penetrations with an interstiti al space that 's unbroken from pump to dispen ser: yo u ca n retest the e ntire sys te m in a jiffy so you 'II know it 's really wo rking

'/ r·-

We can tell you a lot more about the differences between 'soft' and ' hard ' buried fuel systems. For your own peace of mind, get the whole story by giving us a telephone call at 0233 613 884. Today. Your business is too import ant to take a chance on anything less than th e pro ven best: Dualoy 3000/L from Arneron

has a network dist r ibutors th r oughout Eur_ope. E ach has bee n selected f or i ts high standa rd of expe r tise and k n o w le dg e of the in dus t ry.

Opinions expressed in this Journal are not necessarily the views of the Association

Talking Point

In recent months following the deregulation debate it has become fashionable to criticise the petroleum licensing authorities over bureaucracy and inconsistency. Indeed this journal has published much of that comment.

Industry should not however feel that all the problems lay at this door. They should look carefully at the difficulties they create themselves.

How often does the petroleum officer get called to a site to find that work has started on a development, yet no plans submitted and no approval given. Particularly gmlty m this area are the Hypermarket chains who know for they are to build the site but do not seem capable of bemg able to submit the plans until the excavations for the tanks have been started.

!he. Oil industry are no exception, quite recently one maJor .m a series of shop improvements on some of sites which would not otherwise affect the filling decided on some sites to rip up the forecomt, affectmg the drainage and lines, without telling the PLA, and wonders why the petroleum officer gets upset.

IRISH BRANCH EASTERN BRANCH

The equipment supplier also decides to modify his separator to make it cheaper, without o-ettino- the modification tested to verify compliance. 0 0

The filling station operator who has been operating petrol stations and should be fully aware of the implications of licence conditions and HS(G)41 who fails to comply with basic safety conditions and is surprised when the PLA takes action (see notes and news).

The real problem, is one that all sides of Industry must face, We must communicate better, and have a greater understanding of each others problems. There could even be some merit in changing sides for a few weeks to experiencing the other view point, it is a scheme that operates successfully in other areas of Industry.

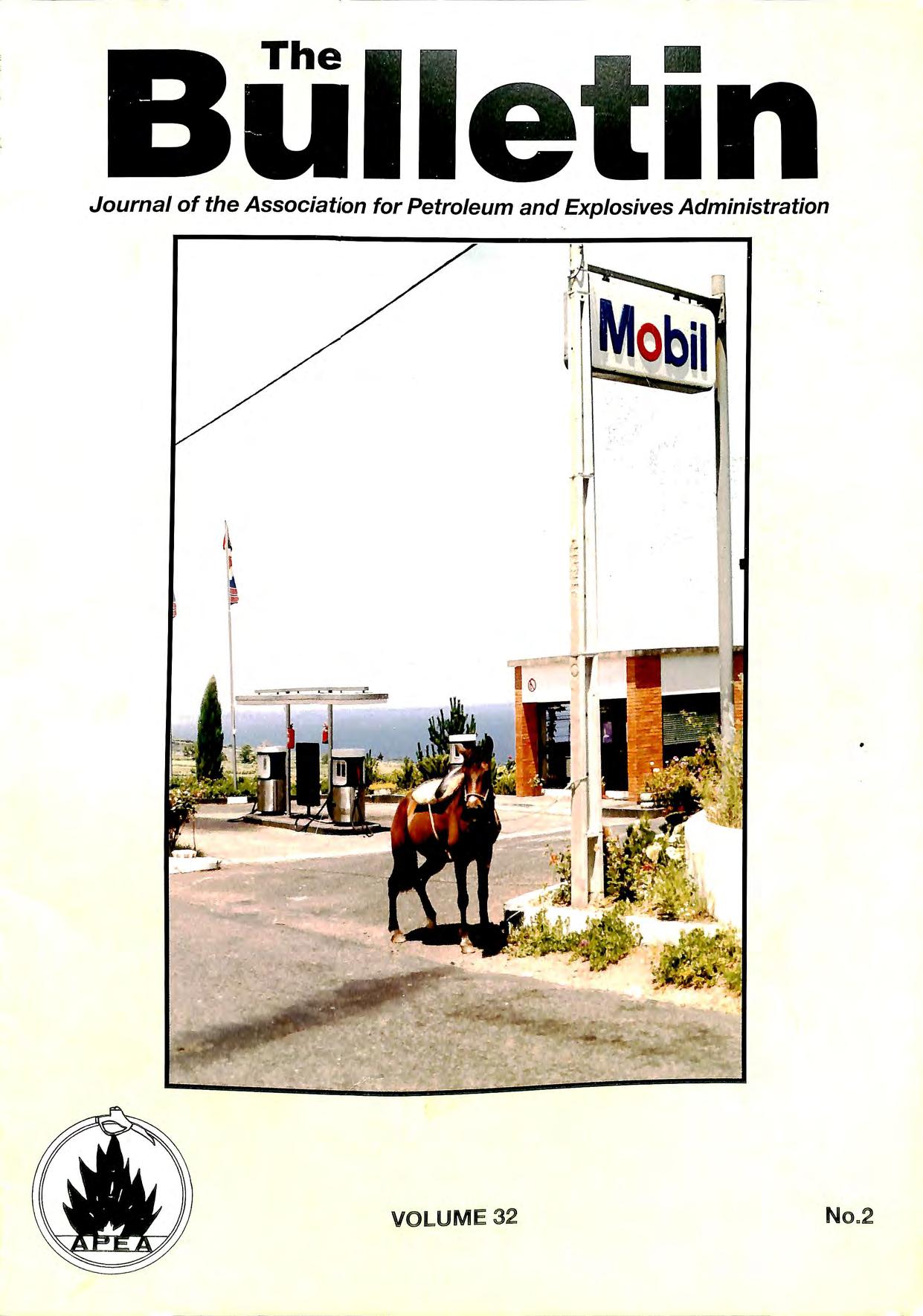

FRONT COVER . . . . . Mobils "Pegasus" spotted havmg a rest at a f1llmg stat10n m the Azores.

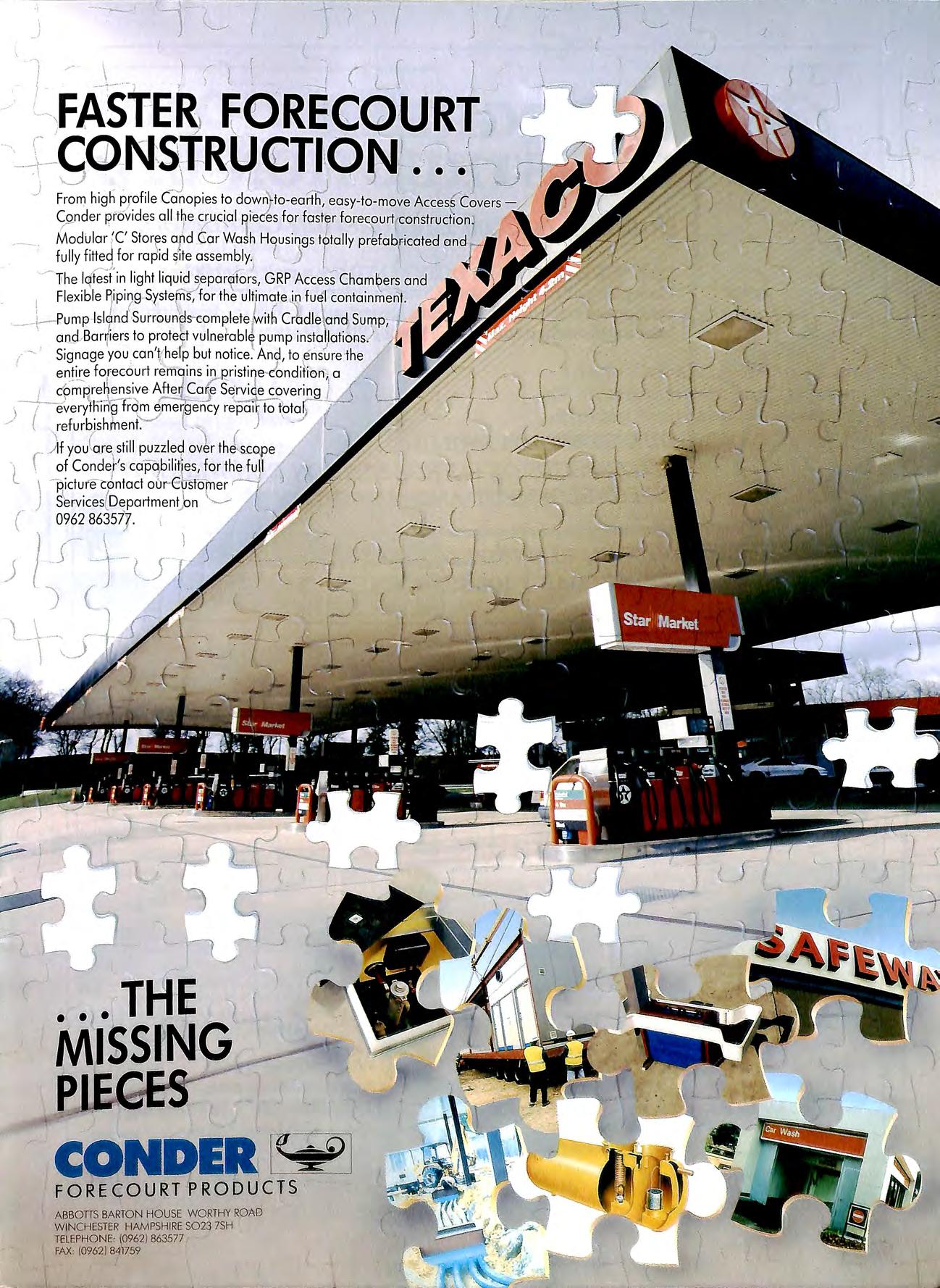

FIRE AND EXPLOSION AT TEXACO SITE

The London Fire Brigade were called to a fire and explosion at a Texaco petrol filling station in SW London which had been closed for redevelopment.

The explosion occurred in the drainage system and had originated in the Conder petrol separators installed at the site.

The contractors had incorrectly manifolded the vent pipes of both the car wash separator and the forecourt separator together. One of the contractors in rectifying this mistake was cutting these vents when the explosion and fire occurred. The force of the explosion lifted the very heavy steel covers into the air and they hit the underside of the canopy, damaging both the canopy and also the forecourt surface when they came back down to earth. The fire in the separator was extinguished by a contractor using a dry powder extinguisher. The separator was not damaged, although the vents were scorched and distorted.

Investigations afterwards revealed that the contractor had previously pumped some water from a waterfilled tank through the separator and it was felt that the build up of vapour from the small amount of petrol that would also have come from the tank was enough to cause an explosive mixture. The contractor concerned, who was not hurt, insisted he was only using a hack saw and a 141b hammer (which was later found at the back of the site). An electrical wheel disc cutter was also found nearby. The GRP separator was examined after the fire and explosion and proved to be sound and in working order.

LEAK DETECTION SYSTEMS ON DOUBLE SKIN TANKS

A number of petroleum licensing authorities have recently been complaining to the Bulletin about the lack of knowledge generally in the Industry by both manufacturers and Oil Company engineers over the suitability of electrical equipment being installed on forecourts. The fact that the equipment has a Baseefa certification seems to be enough for some people, but little or no thought is given to the hazard zones and the suitability of equipment placed in these zones.

A prime example is of one steel tank manufacturer who, on having a leak detection system they supplied recently to one site in Scotland queried by the petroleum officer; turned around and informed them that they all have certification for hazardous areas, and have been accepted elsewhere with no problem.

This is of course not true.

Tank manufacturers have from the outset of building double skin tanks been supplying leak detection systems for those tanks. What is clear is they are not always suitable for the danger zones that the equipment is situated in. Indeed many unsuitable systems have already been installed and are in use. A commonly used system is the Eurogauge LAG 14E system which is certified for Zone I only (EEx ib II C) and is supplied by all the tank manufacturers. This (plastic box with the probe inside) may be suitable for a tank chamber with an offset fill which may be defined as a Zone I area, but where a direct fill is used then the certificate must be for Zone 0 (EEx ia IIC) and this is a different design and considerably more expensive to supply.

To check the system look at the control box which is usually situated in the building, this is where the EEx number is displayed.

HEAVY FINES FOR TEXACO

The Oil company Texaco found themselves in Chichester Magistrates court on 2 March 94 to answer charges of breach of licence conditions involving 5 of their filling stations operating in the area of the West Sussex Trading The inspections followed the discovery of water mgress into a tank during a routine inspection and a seized pump. Texaco trading as Star Service Stations pleaded guilty to eleven breaches of licence conditions committed at five of their filling stations operating in the West Sussex area.

On all five sites there was no licence or copy available The fine was £800 for each site

On three sites there was no notice to employees displayed The fine was £500 for each site

On three sites the company had failed to notify gains/losses in excess of 0.5o/r The fine was £800 for each site.

fn mitigation the company said that administrative changes had caused the licences and notice to employees not ro lw on site. hut the other offences were clue to oversight.

I lie rota! fine!'> were £7900 plus £8() costs.

Some readers will recall though the Bulletin of one tank manufacturer in the UK who found a cheaper source of leak detectors, purchased them and sold them with petrol tanks, only to find out later that they were not even suitable for hazardous zones at all as they had been made for above ground diesel tanks.

The lack of communication between the designer of the petrol station, be they Oil company engineers, or architects _ and the person purchasing the tanks and more especially the tank manufacturer has led to a slap dash arrangement where everyone is assuming everything is OK. IT IS NOT _ HA VE YOU CHECKED YOUR SYSTEM??

Essex County Council trading standards department prosecuted Swan Garage (Wick ford) Ltd on I0 January 94 at Basildon Magistrates court for operating a petrol filling station after dark with inadequate levels of lighting. The offence originally occurred on 14 Jan 93 and was proved in the defendants ahsence in Septemher 93. but was set aside. and re-heard on 10 January. The company were fined £1000 with £I 05 costs.

ENVIRONMENT THEME FOR 1994 APEA CONFERENCE AND EXHIBITION

"Working together to protect the European environment" is the theme of this year's APEA International Conference and Exhibition.

The event takes place at the Birmingham Metropole Hotel at the National Exhibition centre, Birmingham, on September 26 and 27.

The APEA Conference and Exhibition is one of the major events in the international petroleum industry calendar. Last year, 450 delegates from around the world attended the conference, and more than 80 companies exhibited in what was one of the largest industrial shows of its kind in Europe.

In 1994, the APEA is celebrating the l 4th anniversary of its International Conference and Exhibition and forecasting a record number of delegates and exhibitors. One of the highlights of this year's event will be a pre-conference Anniversary Dinner.

"The annual Conference and Exhibition is always special for the APEA," says the Association"s Chairman, Mike "and this year we can promise a line-up of highquahty speakers and an impressive showcase of the industry's products and services. It will be an event not to be missed and my advice is to book early as both conference seats and exhibition space are limited."

Mr Lugg adds: "Environmental issues are at the top of the agenda for the industry and its regulators, and this year's Conference and Exhibition will focus on latest developments from around the world."

1994 - APEA CONFERENCE AND EXHIBITION CONTACTS

APEA EXHIBITION

Date: Monday and Tuesday, 26 and 27 September, 1994 Venue: Metropole Hotel, The National Exhibition Centre, Birmingham

Contact: Chris Knight (Tel: 0992 451494/Fax: 0992 451496)

APEA PRE-CONFERENCE DINNER

eate: Mon_day, 26 September, 1994 enue. Hotel, The National Exhibition Centre, Bmnmgham

Contact: Mrs. Eileen Taylor (Tel: 0582 882170)

APEA CONFERENCE

Date: Tuesday, 27 September, 1994

Venue: Metropole Hotel N · ' ational Exh1b1t10n Centre. B1m1111gham ·

Contact: Dave Bucknall (Tel: 0472 341344)

HARD HATS-Wear Them!

At a recent meetino with th , · · · b e engmeers from the Institute ot Pet1oleum Panel A committee tll APEA . d e receive complamts that 111 some areas peti·clletiin . . . .. · mspectors were 1etusmg to wear hard hats and other saf'ety . . hei1 d • ge.u w atten mg sites under construction The A · · I · · ssociat10n ms the need to maintain safety standards on buil_d_mg. and engineers put in this pos1t10n future may hke to wnte to the officers employer to complam.

NORTH WEST BRANCH AGM

The branch held its AGM on the 9the February at "The Firs" near Altrincham and it was attended by 40 members.

The topic of the meeting was the testing and monitoring of tanks and pipework external from the tanks. This completed a programmed series of meetings which previously dealt with the material technology of tanks and pipework, followed up by precision tank testing.

Mr Frank Hare of Pumptronics presented the Red Jacket EL03 programmable electronic leak detection system providing line pressure and vapour monitoring as well as hydrocarbon leak detection.

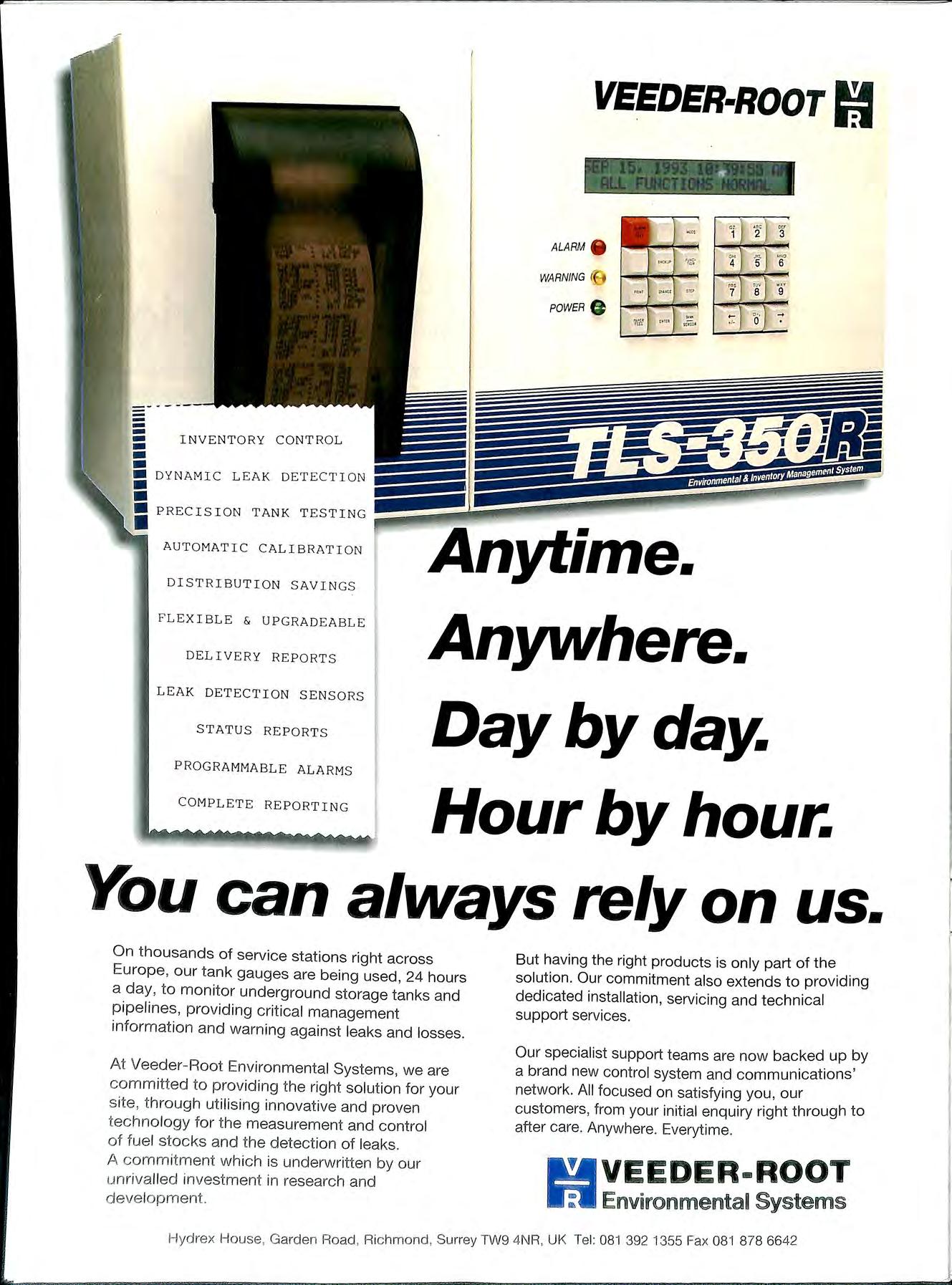

Mr Robert Weeks of Geotechnical Instruments presented the Tracer Tight system for detecting leaks from tanks by detecting special volatile chemical tracers which are added to the contents of a tank.

Both companies utilise the principle of installing test probes at strategic locations to provide accurate detection of leaks over the entire site. Both presentations were enthusiastically received.

Our national Chairman Mr Michael Lugg, presented a "state of the union" address to the members covering the challenoes and developments of the APEA in the past year, and a vision of the future for the association. All the branch members were pleased to see our national chairman and to receive the benefit of his insight into our industry and the contribution of the APEA within it. This visit to our branch completed his attendance to all branches his term of office and he should be congratulated for this.

The business section of the AGM followed. This included reports from the secretary, treasurer and branch t t The election of officers took place, and as a represen a 1ve. d b h · 1 th " llowi·no officers were approve y t e meetmg:- resu t, e 10 b

Chairman Secretary Treasurer

_ Tom Casey (Qualitech Services Ltd)

_ Haffy Reid (Pump Services (Manchester) Ltd)

_ Paul Cooper (Micrelec Ltd)

Branch Representative Haffy Reid

Committee members

HReid Secretary APEA

_ Mike Marcynski (Tankclean Ltd)

_ Martyn Jowett (Cheshire Fire Service)

The AGM of the Association was held on Tuesday 26 April 1994 at Dunstable. The following were elected to office for the next twelve months:-

Chairman Vice Chairman Secretary Treasurer EditorMembership Secretary Advertising Secretary

Gordon

Jack

Dave

Kinear Samson BucknellTom Wigfall

Jamie Thompson Barry Thompson

Rob Green

Council Members elected were Philip Monger, Clive Stephenson, Chris Knight, Mike Sewell.

SUBSCRIPTION REMINDER

The membership secretary has asked the Bulletin to remind all members that if they have not already paid the 1994 subscription of £20 to do so straight away. Unless this payment is made this will be the last Bulletin you receive.

Queries over membership or payment is dealt with by the Membership secretary Mr B Thompson on 0727 863448.

site. The reason is that there is not enough flow on the vacuum side when the pumps are delivering to balance the vacuum drawn, hence the dispensers labour to deliver fuel.

A simple calculation illustrates how much more flow is achieved with a pressure vacuum vent.

Consider the vase of two vents fitted with l Omm diameter oriffice plates against a single vent fitted with a Pressure Vacuum Vent. (For simplicity I will use cross sectional area only).

AREA 2 off Diameter 1Omm Orrifice Plates = 2 (3.142 x 5 x 5) = 157 square mm v

I off Pressure Vacuum Vent with a Vacuum port vent size of 22 mm diameter, =3.142x 11x11 =380squaremm

or 40 mm diameter, = 3.142 x 20 x 20 = 1256 square mm

In addition to this do not forget that the PVV also helps to retain the vapour during a delivery and is not a permanently open vent therefore reducing evaporation losses.

Situation No. 3 "The HSG 41 clearly shows two vents on an above ground manifold"

Yes the diagram does show two vents but in most cases as we can see from the previous calculation one with a PVV will do in place of two vent lines with orifice plates.

THE CASE FOR PRESSURE VACUUM VENTS

By Paul Chawner, Purfleet CommercialsWhilst trouble shooting for our customers, following advice to them regarding Vapour Recovery Systems, I have become aware that Pressure Vacuum Vents are being unfairly blamed for several problems occuITing during delivery of fuel.

Situation No. 1 "'The underground tanks are over pressuring"'

Unless the delivery tanker is pumping i.e. not gravity dropped then you cannot pressurise an underground storage tank any more with a Vapour Recovery System than in a conventional delivery.

The maximum pressure you can exert in both situations is with a full tanker delivering to a full compartment. This is. of course. due to maximum liquid head.

Situation No. 2 "The pumps have stopped working properly -;j nee Vapour Recovery has been fitted"'

/lw, almost certainly due to oriffice plates being used ;1 dicap alternat ivc to pressure vacuum vents on a husy

If you decide that you require two with pressure vacuum vents fitted, as a "Belt and Braces" solution, in the event of one of these failing or on a busy site then the diagram is of course coITect.

Situation No. 4 "The vent has stuck"

I have yet to come across a vent which has failed to operate in normal working conditions, I have however seen several which have stuck after the vents have been painted.

My advice DO NOT PAINT THE VENT.

Situation No. 5 "The tanker delivery is slower since Vapour Recovery was fitted"

This problem sometimes occurs with one delivery and is "exaggerated" to include every delivery.

It is in most cases not the service station equipment which is failing but the tanker valves which are not operational or the vapour hose probe is broken or even worse the vapour hose is not connected at all!

If you have a good efficient system the fitting of vapour recovery will not noticably delay the tanker delivery.

Purfleet Commercials are pleased to offer their customers advice on Vapour Recovery Systems both for new service stations and for retrofit and we hope in the next issue of the bulletin to have an item justifying the use of underground manifolding not only on a Vapour Recovery efficiency basis hut also on a cost basis. Contact No. 0850 803196.

Letters to Editor

Dear Editor

'SWITCH OFF ENGINE'

It has always been forbidden to allow the engines of motor vehicles to run while stationary on filling station forecourts. After a seemingly remarkable experiment on 'Top Gear' a few years ago when hot petrol was dripped onto a hot engine manifold with little apparent affect, I have often wondered exactly what danger is envisioned and whether the danger is real.

Perhaps readers of the Bulletin would render an infonned opinion.

Yours faithfully John Fenton

Dear Editor,

In the February edition of Bulletin, John Dallimore commented on "the possible harmful effects of inttinsicallysafe instrumentation of using impressed cmTent cathodic protection for tanks and pipework." I assume that "harmful" in this respect means unsafe.

It was intended to include cruidance on this topic in the • b revised edition of HS(G)41, however due to comments made by the DTI's De-Regulation Panel when appraising the document and the revised framework of auidance now being developed as a consequence, some d:lay has inevitably OCCUJTed.

The existing edition of HS(G)4 I makes several to BS5345, indeed it states that any person out an inspection must be fully conversant with this standard. Paragraph 233 dealing with mtrmsically-safe cabling refers the reader to BS 5345 Parts I and 4 specifically.

Part 4 of the standai·d ·d "d h. I · p1 ov1 es grn ance on the eart mg anc bondina require t. + • o men s 1or 111tnns1cally-sate systems which may be isol·1ted . h . ' 01 ave smale or multiple earth connect10ns 111 order t . 0 • • • • . . o p1 ese1 ve the safety mtegnty ot the system. This would in I d . . . . . . c u e any effects a cathodic protect10n mstallat1on might have.

A specifier/installer m11 d · 1 ' 1e Wll 1 the mtnns1cally-sate equipment cert1f1cat10n d · ocumentat1on and a working knowledge of the mstallation standard ouaht to be able to ensure that the necessary requiren1e 11t. I 0 t I ·1 s 1ave Jeen met w 11 e an mspector should be able t · · · · , . o 1ecog111se a potential hazard 11. 101 example the cathodic protectl.l)ll 1 l . 11 j ms 1een msta el some tune atter the mtnnsically-safe equipment.

revised guidance should have clarified the above however if the information available in the standard 1s madequate and could lead to an unsafe situation arising i_1s a this needs to be taken up with the appropriate BSI committee who can if necessary authorise amendment-; or additions.

If any readers are aware of specific difficulties in this area would they please let me know.

It may be worth noting that the draft european code of practice (prEN50154 ), which when implemented will supercede BS 5345, does not permit the use of cathodic protection systems for metallic parts located in a Zone 0 area unless they are designed specifically for that application.''

Yourssincerely,

D. Pumford H.S.E. Principal Electrical Inspector DearEditor,

How appropriate was the recent letter to the Bulletin by Daniel Singleton concerning hydraulic line shock. The whole question of adequate long term performance testing of piping products is apparent from this letter and is yet more reason for the urgency of a proper performance standard to be ratified in Europe.

The best wan-anty for a site operator is to specify cl ts that meet an adequate pe1formance standard. pro UC • d J'k E d d time wan-anties on dynamic pro ucts 1 e p1p111g xten e 1. . h t· t aive but difficult to po ice smce t e manu acturer me easy o o d · h · h "de a system which is operate wit associated as to prov1 . t t "de of his control, as the wnter clearly eqmpmen ou s1 · "b d H er any reputable manu1acturer will always descn e . owev · · d h notir aenuine product defects w1thm the recocrmse an o c reas;nable lifetime duration of a site.

D I 1000/L fiberglass pipes and fittings Ameron, ua oy . . . d · d to perfonn 111 excess of the shock have been es1gne . h . . d ··b d For example 2 me pipe 1s rate to 300 loadmcrs desc1 I e . 1· ..,,.,0() . T 1 · te internal pressure o _,_ ps1. he Psi with an u tuna . . b . 1· I (T t ·m hydrostatic design as1c (eye 1c) ol 8 system has a 0110 ei · STM D 299,.,(Al TI· · , _. · ordance with A · 11s x Io· psi 111 ,1cc · healthy safety factor m terms ot any 111d1cates a very d · · T · ' : . I k that is encountere 111 service. yp1cally hydrauhc s 1?c ·iccordance with ASTM D.2992( Al cyclic testmg m ' · 1 I · 111 internal pressure to pipe samp cs at a involves app ymg ' · · I d"ff' · · · · · · I' ?'i ycles/mmutc at se\-e1a 1 e1ent p1essmes 'ycle rate o c . I d . t: d t inpentures. Long term 1y rostatJC strength 1d at elevate e ' di. ' i e or fitting is detenmnecl by an extra polat1on to 01 fcif, cycles (I IA years) on a log-log plot of ISO ' 1 , for hoops stress versus cycles to Iallure 1n re<Tress10n Ille "' ·j• ., with test method ASTM D.-143. accOil c1nt:e

, ASTM 0.2992\A) method is both time rnnsuming. The II ., I. 1 i 11sive to carry out but tu y .iust1 IL'l 111 t 1<1t we can anl cxpe · . . be confident the product_ truly meeh with the demands put upon it in service.

We should not forget that suction systL'llls. which represent the ot: in the llnited Kingdlllll. alsli <TiYe sionificant hydraulic line '>hock \\'lll'n ··to1111inl! olT' I::' I::' • occurs at the dispenser noule. so -.;uction system design needs as careful eYaluation as that for a pressure system.

Ameron has a Cesar II computer programme available to analyze not only hydraulic line shock within a given system but also to take account of the varying ground conditions a system may be required to operate in. We normally use it for our larger diameter high pressure oil flow lines, or fire water systems within the refinery, but it could equally be applied to forecourt piping systems.

Thank you Daniel Singleton for a very interesting article.

Yours sincerely, RICHARD GRAHAM AMERON

Dear Editor

We refer with interest to the article written by Roger Marris headed "HSE Meeting" in volume 32 of the bulletin, and as a specialist stockholder of three different pipeline products we would endorse his comment with regard to standardisation within the industry.

However, we believe there already exists a perfectly satisfactory parameter for pipeline and associated products in the standard UL97 l.

This standard is prevalent in the U.S.A. and is recognised universally, ensuring that products submitted undergo a thorough and rigorous test, mandatory we believe when considering the increased level of additives in fuels.

The adoption of UL97 I as our benchmark would seem to make common sense as the bulk of non-metallic systems in use in the U.K. have been submitted or have attained this standard.

Yours faithfully, R. S. Taylor, on behalf of N.I.P.S. Limited

PETROL LICENCE UNIFORMITYFOREVER A PIPE-DREAM?

By James L Luke, James Luke & AssociatesSixty-five years have passed since the introduction of the Petroleum <Consolidation) Act 1928 and the petrol licensing ..,y..,tem hy this Act still remains with us to this day. The APEA has itself heen in existence for 35 years and not withstanding all of the excellent work done by the \..,..,ul'iation over the years one ohjective is in my opinion ,1111 lar,!.!cly unfulfilled.

The APEA objective to which I refer is "to attain, so far as is practicable, uniformity in the administration of this legislation".

Petrol licences are issued by local licensing authorities, of which there are more than sixty within the United Kingdom mainland and each of these authorities is empowered to grant licences and "may attach to any petroleum spirit licence such conditions as they think expedient" to quote from the 1928 Act. Unfortunately this means that there can be, and indeed are, numerous different interpretations of how things should be done. My own sphere of operation over recent years has involved dealing with more than a third of the licensing authorities and I can quote numerous examples of inconsistencies.

This has been a source of frustration and hindrance to both myself and my clients and is an especially perplexing problem where an operator has several sites located within different counties. Similar cries of frustration were made by some of the speakers at the recent APEA Seminar.

A particular problem affecting the day-to-day operations of a petrol station is the keeping of daily wet-stock reconciliation records and the various forms these should take. There are also radical differences of approach relating to permitted pipework materials and installation methods the use of certain types of equipment (particularly second hand pumps), methods of tank and pipework testing, not to mention the differing degrees of inspection consistency by, and expertise of, the licensing officers in their various identities.

My purpose is not to argue whose approach is right and whose is wrong, it is more a plea for an ideal of a uniform approach across the country without the artificial baiTiers created by county boundaries. Such an ideal is, I believe, no more than a pipe-dream whilst the existing county-based licensing system remains in force.

The governmental thrust at the moment is towards deregulation generally and the petrol licensing system is a pait of the de-regulation review which is now in progress.

Few responsible operators would want to see the complete abolition of statutory control over the safe keeping of the hazardous substance with which we are involved and it is my hope therefore that a national uniformly applied scheme will be developed with requirements formulated to reflect technological advances as they occur and the setting ?f standards through a formalised partnership between mdustry and the regulatory authority.

The present lack of uniformity associated with the current system will remain a bone of contention within the petrol retail industry and is, I believe, fast becoming contradictory and incompatible with the aim of harmonisation being sought within the arena of the European Union.

HOW PRECISE IS TANK TESTING?

Harry ReidWith growing concern· about environmental pollution caused by leaking tanks and pipework, the petroleum industry has taken on board a commitment to improve the quality and reliability of testing underground storage tanks and pipework. This commitment has been equally appreciated and shared by oil companies, licensing authorities, retailers and contractors.

The long standing practice of nitrogen pressure testing has all but disappeared. Hydrostatic testing with water has been severely reduced, due mainly to the cost as a result of the logistical problems associated with emptying tanks of residual product, filling with water and removal and disposal of the contaminated water. The principle of putting water into a steel tank has always been questionable. There are still however some situations where hydrostatic testing is still the most economically attractive solution.

A new generation of test methods, mainly sourced from the USA has been welcomed into the UK Petroleum Industry. Most of these have been broucrht to the market place in the belief that they would be on certain well defined criteria_

I . the test method and procedures are safe and accurate

2· the equipment has BASEEFA or equivalent certification

3. the system has third party approval that the method meets the EPA requ · ,. uements 1or the testing of tanks

4. tests are carried out b Y competent and trained persons.

As a result, substanti I 1 d b . a mancial mvestments have been b ma e of this service. Such test methods have een categorized as prec · I · · ismn tank testincr and include vo umetnc and non-volumet .· 0 1 11c methods. It 1s not necessary to ana yse each system individual! b appropriate accred't f , Y: ecause each has the I a ion to confirm Its s·1fet . d reliability. Or does 't? All h .. ' y, accmacy an . I . t e test systems whi I h· 1-11 d the criteria and standards · c 1 ave I e · which are supposedly acrreed should therefore be accepted by all th I" ' 0 • . . . . . . . . e Icensmg authont1es. Sadly this mdustiy 1s mcapable of 111 .,. . . . ' Y un1Iorm approach or consistency 111 implementation Ea I . · · c 1 p1ov1der has to approach 69 md1v1dual hcensincr authc)i·i·ti'e. f' d' .d 1 o s or 111 1v1 ua approval to use a system which meets 11 h 11 · a t e genera y ag1eed pc11<1mete1s. This 1s nothmcr less d'·cr·. t' I ff" . b h b • • LI me 1c1ency y a ureaucratic and archai" ': I' . . . . c regime o acl1111111strat10n that allows added costs to the contractors oil companies, retailers and ultimately the cL1stcJinei· I ' . · or ent use1. It typifies the larger general malaise within the Petroleum Industry. namely the fragmented approach to the

interpretation and implementation of legislation, codes of practice and new technology. There has never been any consistent or unified National implementation of HS(G)41 which purports to be the Industries Bible.

Companies engaged in tank testing, have been led to believe that all persons wishing to become engaged in this industry would be playing on the same level playing field with the same set of goal posts firmly fixed in position. It is hardly surprising then that a number are disconcerted by the introduction of certain test methods which do not meet the same requirements as the rest, but yet are accepted by some licencing authorities. Practices such as exerting pressure on the ullage space of a tank containing petroleum spirit when the integrity of the wetted portion has not been established, is both negligent and unsafe. If the portion of tank containing spirit has a leak, then product is forced out into the surrounding ground. How can this be accepted as a professional or responsible action? To relate pressure chancre to leak rate requires extremely accurate data on the space (including any which is tested at the same time), temperature water. table and barometric pressure. With a buned tank and pipework, the II e Volulne cannot be calculated to a sufficient u age spac . decrree of accuracy to make the computat10n of rate e "bi d'ble Combined tests on tanks and pipework feas1 e or c1e 1 · . b · d out at pressures of 1.5 to 2 ps1. Such tests are emg came th previously accepted piact1ce of I 0 psi fm fail to meet e . 1. 1 'd down by licencmg authont1es for such suct10n mes m d to Wl11.ch others have to adhe1e. tests an

b · 111bent on all licencing authorities to apply It must e mcu of reference to all manufacturers and the same te1 ms'ding the same service. How else can one be contracto1 s p1 ov1 f 11 .ty service which 1s reliable, consistent and assured o a qua · of a high standard?

d el1 ising and marketing by certain companies

Current a v tl eir systems meetmg HS( G )41 and EPA attest to 1 · · . t. Do they? Surely the question 1s how precise requiremen s. and safe are such tank tests!

A ple·ise in writing to the Editor of The Bulletin) ( nswe1s '·

Editors Note

The only precision tank testing systems that are known 1t1 have Basecfa certification for electrical safety. and also to have fully authenticated third party tl.'sting to prt1\'t' compliance with EPA requirements are:- Tanknolngy. US Test (or Eurotest ), Camerons & Tracer.

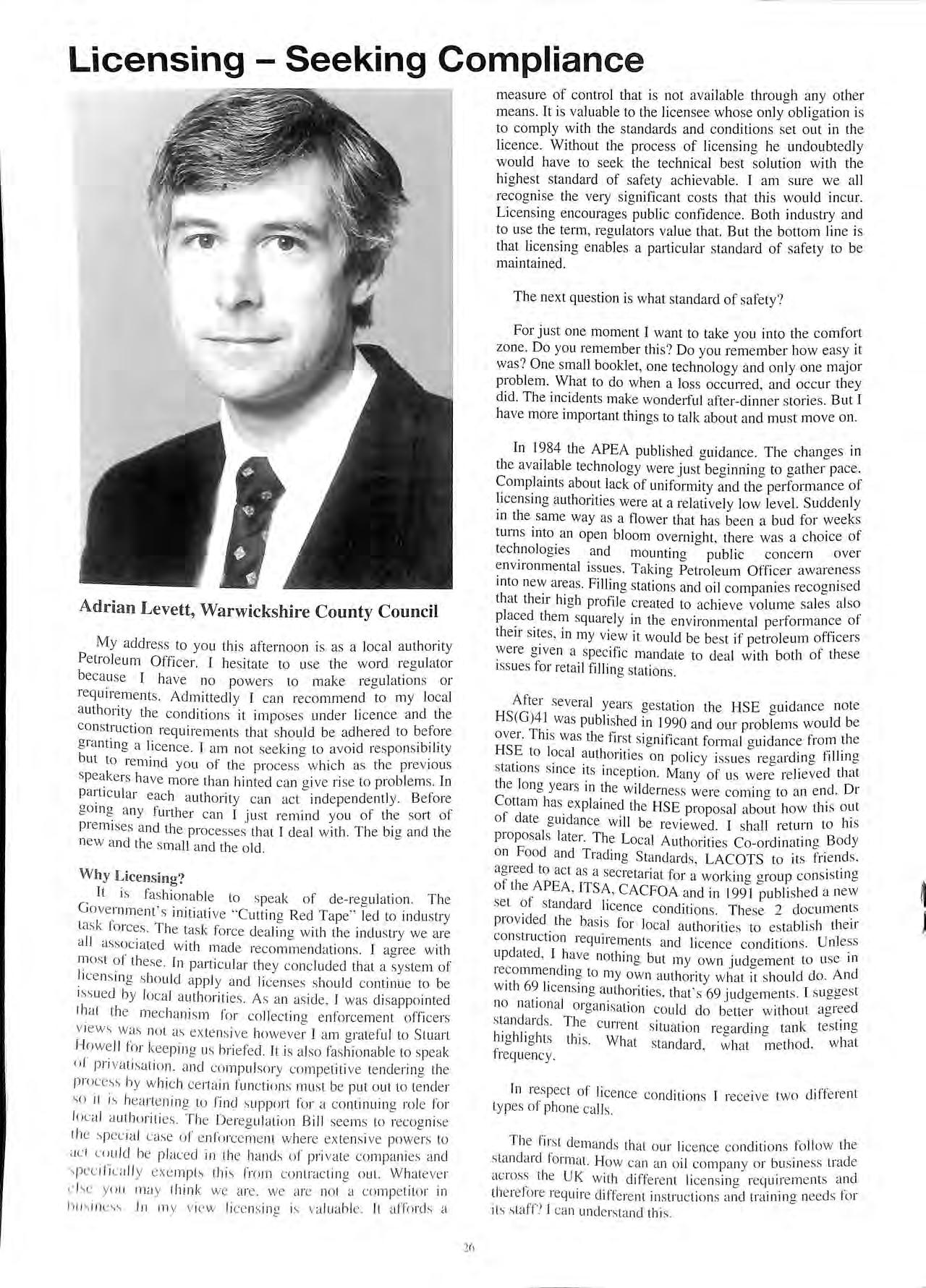

Licensing - Seeking Compliance

measure of control that is not avai lable through any other mea ns. It is valuable to the licen see whose onl y obligation is to comply with the standard s and conditions se t out in th e licence. Without th e process of lic ensing he undoubtedly would have to see k the technical best solution with the hiahest standard of safety ac hievable. I am sure we all b recognise the very significant costs that this would mcur. Licensing encourages public confidence. Both an.d to use the term , re gulators value that. But the bottom lm e is that licensin g enables a particul ar standard of safe ty to be maintained .

The next question is what sta nd ard of safety?

For just one mom ent I want to take you into the comfort zone. Do you remember this? Do you remember how easy it was? One small booklet, one technology and only one major problem. What to do when a loss occurred , and occur they did. The incidents make wo nd erful after-dinner stori es. But I have more important thing s to talk about and mu st move o n.

My add ress to yo u thi s afte rn oo n is as a loca l a uth orit y Petrol e um Officer. I hes itate to use the wo rd reg ul ator beca use I have no po we rs to make regul ati o ns or requirem e nts Admittedl y I ca n reco mmend to my loca l auth ority the co nditi o ns it imp oses und er li ce nc e and th e co nstru ction requirements th at should be adhered to before gra ntin g a li ce nc e. I am not seek in g to avo id res pons1b11Ity but to remind yo u of th e proces s whi c h as th e prev ious spea ke rs have more th an hin ted ca n g ive ri se to prob lems In part ic ul ar eac h auth o rit y ca n ac t inde pendentl y Befo re go in g any fur ther ca n I ju st remind yo u of th e so rt of premises a nd the processes that I dea l w ith . The bi g and the new and th e small and the o ld.

Why Licensing?

It is fa shi o na bl e to speak o f de-reg ul at ion. The Go ve rnm e nt ' s initi at ive " Cuttin g Reel Tape" led to indu stry tas k fo rce s T he task fo rce dea lin g with the indu stry we are a ll assoc iated with made reco mm e nd at ions . I agree with mo st of the se . In parti c ul ar they conc lud ed th at a sys tem of li ce ns ing should a ppl y a nd li ce nses sho uld co ntinu e to be iss ued by loca l a uth oriti es . As a n as ide , I was d isapp ointed that the mec han ism fo r co ll ect in g e nforce me nt office rs views was not as exte nsive how e ve r I am grateful to St ua rt Howe ll fo r kee ping us briefed. It is also fas hionabl e to speak or pri va ti sa ti on. and co mpul sory compet itive te ndering th e process by whi c h ce rta in function s mu st be put out to te nd er so it is he<1rle ni11 g to find s upp ort fo r a co ntinuin g ro le fo r loca l a utho riti es. T he De reg ul ati on Bill see ms to recog ni se th e .., pec ial case of e nforc e me nt where ex ten s ive powers to ac t co uld he plac ed in the ha nds o f pri vale co mpan ies and pec ifi ca ll y exe mpt s th is from contracti ng o ut. Whateve r c J..,c yo u may think we are, we a re not a competitor in h u.., in e"" · In my view li ce ns in g is va lu abl e. It afford s a

In 1984 the APEA pub li shed guidance. The c han ges in th e available technolo gy were ju st beginnin g to ga th e r pace . Complaints about lack of uniformity and the perform ance of lice nsing authorities were at a relatively lo w level. Suclclenly in the same way as a flow er that ha s been a bud fo r weeks turns into an open bloom overniaht there wa s a choice of b , tec hnologies and mountin g public concern over e nvironmental iss ues. Tak in g Petro leum Offi ce r awareness into new area s. Filling statio ns and oil companie s recog ni sed th at th eir hi gh profil e crea ted to achieve vo lum e sa les also pl aced them squarel y in the enviro nmental performanc e of their site s, in my view it would be best if petroleum officers we re give n a spec ifi c mandate to deal with both of th ese iss ues for retail fillin g station s.

After several yea rs gesta ti on the HSE g uid a nc e note HS(G)4 l was publi shed in I 990 and our problem s would be over. Thj s wa s the fir st signific ant formal guidan ce from th e HSE to lo cal auth oriti es on policy iss ues re ga rdin g filling station s sin ce its inception Man y of us we re relieved that th e long yea rs in the wildern ess we re coming to an e ncl Dr Cotta m has ex plained the HSE proposal about ho w thi s out of date guid ance will be rev iewed. I sha ll return to ll!S proposals later. The Loca l Authorities Co-ord in atin g Bod y on Food and Trad in g Stand ard s, LACOTS to its fri e nd s, ag reed to act as a sec retari at fo r a wo rkin a a roup co nsistin g bb of the APEA , ITS A, CACFOA and in 199 1 publi shed a new se t of stand ard li ce nce co nditi ons Th ese 2 docum e nt s provided th e basis for loca l authoriti es to esta bli sh th eir co nstruction requireme nt s and li ce nc e condition s. Un less upd ated, I have not hin g but my own judge me nt to use in reco mm endin g to my ow n a uthor ity what it should do. And with 69 licensin g auth oriti es , th at' s 69 jud ge me nt s. I sugge st no nat ional orga ni sa ti on co uld do bette r with out ag reed stand ard s. Th e current situation regardin g tank testin g hi ghli ghts thi s What standard , what meth od, what frequen cy

fn res pect of li ce nce con diti ons I rece ive tw o d iffe rent type s of ph one call s.

T he first demand s that our li ce nce co nditi ons fo ll ow th e sta nd ard fo rm at How can an oil co mp a ny or busin ess trad e acro ss th e UK with differ e nt li ce nsin g require men ts and the refore requ ire diffe re nt instru cti o ns a nd tra inin g needs fo r its staff? 1 can und e rstand thi s

Adrian Levett, Warwickshire County CouncilThe second type of phone call is one asking for a change in the licence conditions we have so carefully adopted because of local need the site has some special feature. Its operation would be facilitated by a variation in licence condition. My reluctance to give ground on the basis that standardisation is important is met with accusations of over zealousness, bureaucracy gone mad.

HS(G)41 was intended to apply to new installations or those where an alteration has extended its life or chano-ed its character. We have sites under licence built to the of the art construction requirements, circa 1957, and sites such as the new motor way service area at Lighthorne on the M40 built to construction standards not thought of when HS(G)41 was published. The sites do not offer an equivalent standard of safety. I have to ask, "is the worse one safe enouo-h?" and for a new site what is the minimum acceptable of safety which I know is higher than that which would be applied i? 1957. I understand why business by and large needs to improve construction of sites only on a cyclic basis except in special conditions of identified significant risk. Hov.:ever, I. hope I have to try and explain that to a public enqmry following a serious accident.

Setting process for providing adequate guidance to local authont1es and industry of acceptable construction requirements spoken of this morning by Andrew Cottam, do I, a representative of the licensing authority know which products and methods are suitable. There is a severe lack of standards. I would prefer that there was a mechanism for a to have his product approved for use m a petrol hlhng station and then I would know where I stood as would every other licensing officer. Indeed that manufacturer of a product would know where he stood. I am aware of the burden of cost this would impose but at the v_ery a pe1formance specification should be established for all key products used in th . t ·1 d' t ··b t' h · B th · 1 e 1e m 1s 11 u 10n c am.. Y is mean pipes. interceptors. dispensers, Pumps, etc. Such a sittiat 10 · ,, · n exists 1or dispensers via BS7 I I7 I know this 1s not w"th authority and each u. h I .out but at least each P ic asei of a dispenser knows it's performance has been assessed b h. d • Y a t ir party.

I have not answered the que ·r " and I know my suoo-estion 11 s ion approved by whom?" ; 1:om;p d WI not be popular. Approved by rawn from local tl ··t· · d industry or by an mdepe d .., au 1011 ies an n ent .1rd paity to . . d d d The latter is my choice. agiee stan ar s.

It is interesting to consider tll 1 R I e 10 e the Construct1011 Products egu at1011s 1991 imple111 t" ·h C · . . ' en mg t e onstruct10n Products Directive, may have These · h · envisage t at one day all p1oducts used 111 construction whei·e " 1 . . some 1orm o · statutory control is exercised (eg licensino-) will be self Cel·t1·t·1·ed by the manufactt11·e1• t "" ,. · ' o meet per1ormance with iegaid (amongst others) safety in use in case of fire. hygiene and the environment. It must he said that the of the regulations is in its infancy. hut a standard for interceptors and for tanks is in draft form. Interestingly enforcement has been given to trading standards officers.

I heard the criticisms levelled earlier hut I can say 1t 1s extremely difficult for any licensing authority to set construction re4uircments that secure adequate standards of safety. recognise the need for technical innovation and are even handedly applied to ensure fair competition. The recommendation made hy the Tourism and Retail Task Group one of the deregulation industry task forces. for a

risk based approach has been referred to by Dr Cottam. I look forward to seeing this develop, primarily because it links need and outcome. However it will reduce standardisation and uniformity.

I would like to tum to how I seek compliance.

I must firstly say that as in other areas of business there are those that are good and there are those that are bad. !hose that are bad are bad because they are disorganised or incompetent. Or bad because they have some other more sinister reason for being so. I advise, I give guidance, I encourage, I persuade, very occasionally I issue a formal notice and equally occasionally I am forced to prosecute. Each year from the largest category of filling stations I receive a licence fee of £81 (just increased) and for that sum filling stations has access to someone with whom they discuss problems. When the greenfield site is developed or a knock down or rebuild takes place we sometimes spent many hours, most often with the sub-contractors, architects, installers, etc. All for the same sum paid on an annual or three year basis. Construction details are agreed, and if built as planned a licence issued. I don't wait until the site is finished and then tell you it's not good enough try something else. Things do go wrong and I like to think I am as helpful as possible in steering that fine line between representing the public interest and the business interest. When the sub-contractor for a large oil company rings up and says, "we are starting work on the new filling station on Monday", but we have never ever been sent any plans nor heard of it we do our best to process them as quickly as possible. Yes it does happen. When the tanker driver moves his vehicle whilst delivering petroleum spirit into two undero-round tanks I prosecute because it seems such an outra;eous thing to do endangering public safety (the fine was £ 160). When a nozzle drops off in a customer's hand and he is left holding the hose still delivering at several litres a minute I am just plain grateful there is no source of ignition on the forecomt. The court's incidentally, continue to take "licensing" offences seriously, fines are commonly over £I .OOO. A brief flick through a few back numbers of the Bulletin show the range of offences. I mention this matter not to cause embarrassment but to remind all of the industry you need effective regulation there will always be those who take less care, or deliberately take short cuts. It is these people who jeopardise the industries enviable reputation for high safety standards. Sometimes I can't reach agreement with the licensee and she or he appeals. A relatively rare event but an important one because it enables access to an independent tribunal. I would welcome any change which makes this process more open, quicker and the mechanism for enabling results to be published for all enforcement, for all local authorities to see.

Closing the feedback loop will make it easier for both parties to learn from the inevitable disputes. The one thing I am sure because we are talking about real life things will from time to time go wrong. It is the way in which they arc dealt with that makes the difference.

The local authority petroleum officer has a difficuil job. Sometimes I get the feeling industry feel they would dn better without us. I suggest you would not withnut the checks and balances of. to use the word. a regulator vou would have to satisfy a much more fickk public and all on your own. '

In my opinion what we do need to provide a better service i_s clearer guidance. realistic resourcing. an approvab system lnr products and a prompt open appeal:-. svstem.

COSTS OF MAKING SAFE ABANDONED PETROL TANK BORNE BY LICENSING AUTHORITY

Roger Marris West Yorkshire Fire and Civil Defence AuthorityGetting the occupiers/owners of disused petrol tanks to fulfil their statutory obligations under S73 of the Public Health Act 1961 is a problem that most Petroleum Officers will on occasions have to deal with. When the owners of a tank and their solicitors adamantly dispute ownership, there ensues a protracted and time-consuming investigation to establish ownership.

Such was the case with a disused tank situated in Bingley, a small industrial town on the outskirts of Bradford. Although ownership of the tank was eventually resolved, it is the council tax payers of West Yorkshire who will almost certainly have to stand the costs of making the tank permanently safe.

This unfortunate situation followed a considerable amount of research by the Petroleum Officers and the Authority's legal department to finally establish the ownership of the small piece of land in which the 6,818 litre abandoned tank is situated.

the legal owners was a difficult task complicated by the sub-division and consequential sale of the premises to which the tank originally belonged.

The tank fell into disuse way back in 1980 around the time that the premises, as a whole, were sold by the licensee to a property company.

In 1.98 I following correspondence from the Licensing Authority, the property company carried out the necessary to make the tank temporarily safe, ie disconnecting the suction line at the a c v, filling the tank chamber with sand and sealing with a cement screed. This procedure was adopted at the time if the owner of a disused tank claimed it to be an asset and wanted to keep his options open for future use.

Subsequent to making the tank temporarily safe and Without the knowledge of the Licensing Authority the property company put the premises in the hands of their estate agent and solicitor to be sold off as individual units. change of ownership came to the notice of the Licens111g Authority in J 990 when a policy decision was taken to bring to a conclusion the future in a small number of temporarily safe tanks.

The tank was situated in the access road of what is now a small trading estate and the initial contact with the occupiers of the units adjacent to the tank and the associated pump resulted in an expected unec.iuivocal denial of ownership.

Enquiries continued and the occupiers who could t·onceivably be the owner because of the position of their 11'' ipcrty in relation to the tank co-operated by checking their with negative results.

With the deeds of all the adjacent properties excluding the position of the tank, it was apparent that the small area of land in which the tank was situated remained the estate of the property company. This logical deduction was put to the directors of the company who through their solicitor, who carried out the conveyancing, strongly refuted ownership of any land in Bingley let alone a petrol tank.

A land registry search appeared to be the only answer to positively identify the legal owner, unfortunately the rules appertaining to HM Land Registry at that time ( 1989) precluded disclosure to the Authority.

However, all was not lost, HM Land Registry let it be known that the !aw was to be changed and they would then be allowed to divulge the information required. Needless to say a further application for a land registry search was made after the rules had been changes and as anticipated the small area of land in question had not been sold and remained in the (unwanted) ownership of the property company.

Confronted with this information including a land title number, the directors of the company still ms1sted all of the property had been disposed .of and the matter any further referring Officers to thelf sohc1tor.

Assu.red that ownership was firmly established (with the tank bemg located in the access road the occupancy criteria (S.7.3(1) of the 1961 Act) did not ;pply) an Improvement Notice was served on the company to make the tank, permanently safe. This prompted the response from the compan ' l' · · d Y 8 so icitor who requested an extension of ume an stated that his clients were now out of jurisdiction.

The fact that a formal request for an extension of time was made gave th · . . f the land . e impression that ownership o no longer. m dispute and the application was granted extending the original 28 days by a further six weeks.

hopes that the Improvement Notice would be with were soon dashed when the extended time passed without the contravention being rectified and without any fu11her communication from the property company or their solicitor!

To coin a phrase "the ball was now back in the Authority's court" and a decision had to be made as to which course of action should be taken.

After discussing the matter with the legal department it was that legal proceedings under S.33 of the Health and Safety at Work etc Act I974 <HSWA) should be initiated to reinforce the Improvement Notice (maximum penalty on summary conviction, £20JJOO fine) using the following draft charge:-

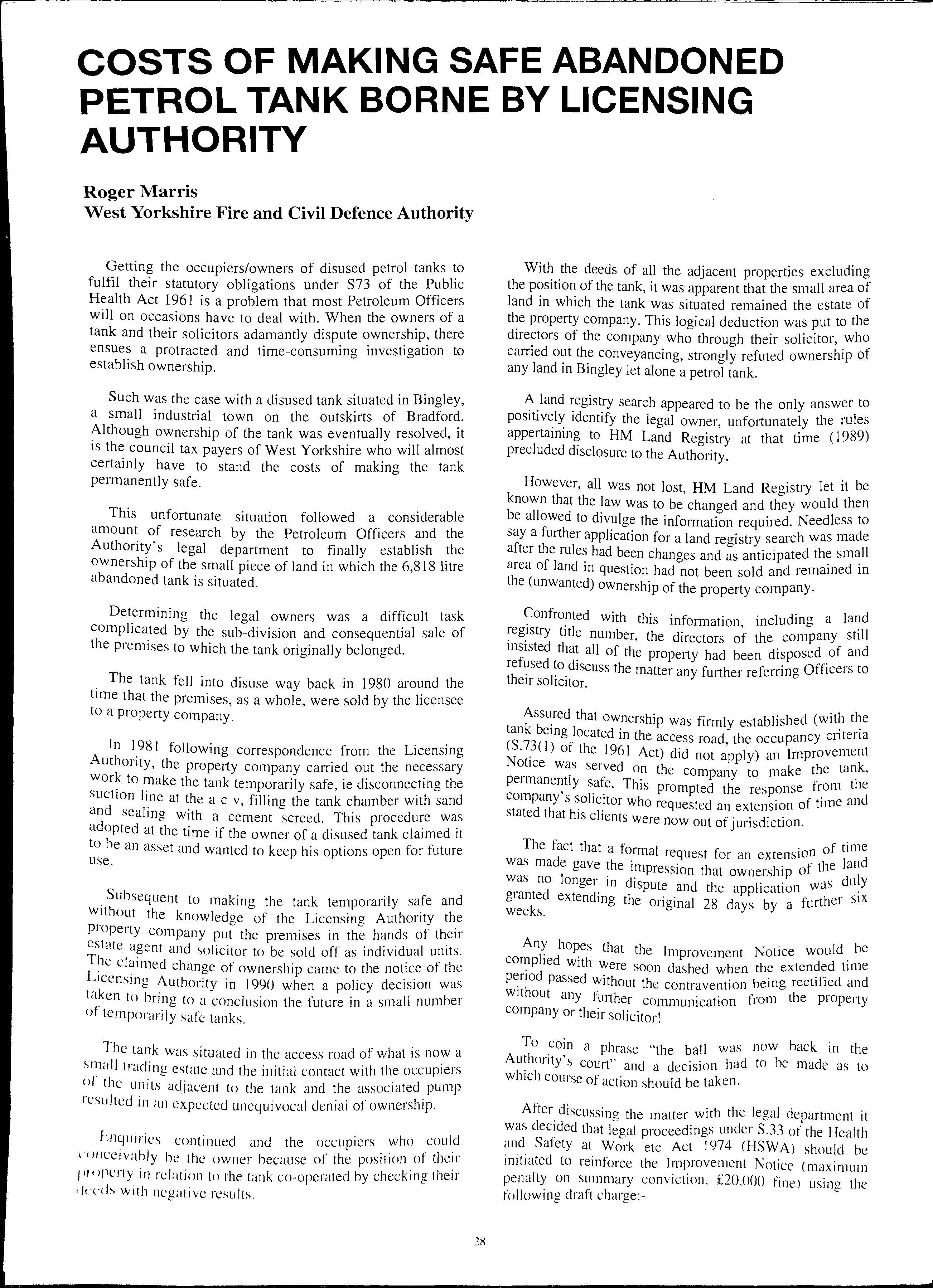

CHARGE: That on the 24the day of August 1993 you did contravene a requirement imposed by an Improvement Notice served on you under Section 21 of the Health and Safety at Work etc Act 1974 in that you failed to comply with the requirement imposed by the Notice to remedy contraventions of statutmy provisions specified in the Notice thereby committing an offence contrmy to Section 33(l)(g) of the Health and Safety at Work etc Act 1974.

It was assumed that a continued disputation over the ownership of the land was the only reason for failure to comply with the Notice.

In order to present a sound case to the Court, the legal department advised that, in addition to a certified extract of the Land Registry records, information regm·ding responsibility of the tank should be obtained by interviewing the property company secretary or director under S.20 (HSW A) powers. Further information concerning the disposal of the land was also required from the conveyancing solicitor and to effect this I had to use my powers under S.20 (HSWA) and required in writing the solicitor to answer certain questions and provide for examination ce1tain documents. The "Statutory Request for Information" served on the solicitor is reproduced below. The solicitor was required to provide the information within 14 days and advised that it was an offence contrary to S.33 (HSWA) to fail to comply.

In the meantime the legal department carried out a company search and as a result of the information received it was decided not to pursue legal proceedings. The reasons supporting this decision, which may at first appear to be a climb-down, were purely realistic under the prevailing circumstances; ie. the company had ceased trading, was the subject of a winding-up order and had no known assets. In addition the two (and only) directors were resident in the Isle of Man (this clarified the previous comment made by the solicitor) and outside mainland jurisdiction. This meant that there would be little point in prosecuting the company since they would be unlikely to pay any fine and by natural implication civil proceedings in the County Court to recover costs for the execution of the work.

On reaching this impasse it was decided that in the interests of public safety, the Authority should execute the works and attempt to recover the costs from the absent owners. In all probability the debt will have to be written off.

When considering the most suitable way of executing the work, cognisance was given to the possibility that at some time in the future the tank may need to be moved. With this point in mind the tank was rendered permanently safe by infilling with the proprietmy RG22 foam.

Fortunately this is not a typical case either in the length of time it has taken to resolve or by the obstructions that were encountered establishing the rightful owner of the tank.

The purpose of submitting this mticle for pu?lication is for the general information, and perhaps assistance, of Petroleum Officers who may not as yet have had to deal with a similar situation.

STATUTORY REQUEST FOR INFORMATION

To: name & ad<ln.-:-.:-.

Pcrsmmt to the powers \'C!'.ted in me by Section 'l() H •. 1 1 Roger Marri..,, As<>i:-.Lant Officer, \Vm:k clc A\..·t 1974 I. appointed under Section 19 of the Hcahh •md S· l' Fire Scrvu:c. hcmg _a:-. Inspector an:-.wcr the following questions and to provide f,a c:ly at Wor_k Act 1974 require you to pos!'>es:-.ion and/or control relating to the ex.ammation a.ny drn.·umcnls in your a:- to your answ1.:rs: llllC:'illon and to :-.1gn lhe dcdaration of truth

For whom did ynu act'! To whom was thi: land cnn\·cycd!lfo.,pn:-.cd to'! ...J On what dak was the cunvcy:.mcL'/di!<.po al com.:ludcd'! D< 1you your po!<...,essit1n.:.mll/nr control anv dol.'Umcnt:-. Cincludin' but not hv w:.1y llf any "ale dc!<.l.Tlpti{l!l, l.'ondititms <1f L"lllltrnct.-dccds or llthcr. dncumenhl rclatmg to that If , ··.Pd · copies to your reply. · · • · Ml. you i:lfl.' require tn att;:tl"h

If !he lh<l ahnvc lhcn dl1 you know whn i!<. now in pns!<.C!<.Silln or · , ..,,,_ plca c itlcmify the Pl.'rson. company or other nrga111:-.a11on Ill of "lt1ch dtll.'Umcnh.

IJECLARATION OF TR L'TH

1ccrlifv th:.tt the which I lrnvc gi\\,'ll tn thc quc 1io1b cnnlaincd in this .;tntutory for Infnrm:.UHlll arc true In the hc!<.t of my knmvkdgc and hclil't·.

J)ati:d:

Although the solicitor had on numerous occasions asserted that the land was disposed of. the completion of the ''Statutory Request proved otherwise.

In the light of this experience I would offer the fo_Ilowing advice to Petroleum Officers where the ownership of a disused tank is contested or not known.

•

Act quickly

• CaITy out a land registry search (approximate cost£ 12)

• If a company is implicated, carry out a company search (approximate cost £15 for a short search).

• If you are of the opinion that a person may be able to give information relevant to the enquiry do not hold back from exercising your powers under S.20(2)0) HSWA even if that person is a lawyer.

• One or more of the above actions should identify a person, company or body etc on whom an Improvement Notice, S2l(HSWA) or a Notice under S73(3) of the 1961 Public Health Act, can be served.

FIRE AND CIVIL DEFENCE Al;THORITY SlcCTION 20 HEALTH AND SAFETY AT WORK ETC ACT 197-1North Yorkshire Fire and Rescue Service

Seizure of Goods Under Section 25 H.S.W. Act 1974

By C. Jones, Chief OfficerOn the 16 August 1993 as a result of an inspection, the Brigade discovered that a large quantity of petroleum spirit mixture was stored in a disused shop premises at 2 Fawcett Street, York, previously occupied by Tenco Industries Limited.

No 2, Fawcett Street, York is a two storey brick built commercial premises having within a mezzanine first floor area, a purpose built petroleum mixture store, and adjacent to this a paint mixing room. The roof structure comprises of asbestos sheeting on steel trussing. The premises is surrounded by domestic flats and commercial buildings and consequently has a high local population.

A detailed examination confirmed that there was a substantial amount of palleted petroleum mixtures, some 8000 litres in total, stored on the ground floor of the premises. In addition two Underground Storage Tanks were discovered, still in situ, inside the building, beneath the ground floor. The Underground Storage tanks had contained Petrol and had not been made safe. An inventory of the petroleum products, detailing the types and quantities found in the shop, was taken. This quantity of material and the manner in which it was stored, posed an imminent danger of serious personal injury, to those living in the immediate vicinity. The investigating officer felt that there was an additional risk of ignition from intruders due to the buildings disused and vulnerable appearance.

visits were made to the premises by the local Fire Salety Inspector to ensure that the situation did not deteriorate further, and early contact was made with the Secretary's Depaitment who provided valuable guidance throughout the investigation.

There was no Petroleum Licence in force for the premises therefore the storage was clearly in contravention of Section I of the Petroleum Consolidation Act 1928. and Section 73 of _Public Health Act 1961. both being relevant statutory of The Health and Safety at Work Act 1974. Evidence including a photographic record was properly gathered with a view to producing a case file for Prosecution.

Attempts were made to establish the identify of the responsible for the petroleum mixtures. However. c1n.:umstances were complicated by the fact that the premises had been. and possibly were still occupied by. Tenco Industries Ltd. as tenants who had gone into administrative receivership. The Premises were in fact owned hy the trustees of the Ellison Valdis Pension Fund.

Due to the nature of the materials and the high toxicity of which would he given off should the building become 111volved in f'ire. and the vulnerability of the pn:mises to 'andalism. a decision was taken to remove the petroleum 11 ialcnals using thl' power of seizure under Section 25 of The Ht'alth and Safrtv at Work Act 1974.

As a result a local firm, Leading Solvent Supplies, who were licenced to store petroleum products, and who had the capability to handle the large quantities of materials involved, were contacted. This company subsequently visited the premises in order to assess the possibility of removing the petroleum mixture to a safe place.

A letter of intention to remove the petroleum mixtures from 2 Fawcett Street, was sent to the owners of the premises and to the receivers responsible for the affairs. Both parties declared that they would not oppose t_h1s action. As a result, on Wednesday 1 September, Leadmg Solvent Supplies, were instructed to remove all items from the premises which were identified as a petroleum mixture. This was done under the supervision of the Fire and Service, the enforcing authority for Petroleum regulat10ns 111 North Yorkshire.

The petroleum mixtures were transferred to safe storage and have now been destroyed or re-cycled to render th_em harmless. The cost of this work to Leading Solvent Supphes, originally estimated at some £4000, has been covered by income generated by the re-cycling process. The two underground Storage Tanks have been made safe by the owners of the premises and therefore the improvement notice previously issued on them has been withdrawn.

In view of the company beino in receivership, the County s_olicitor established that the appropriate action? in the circumstances would be to prosecute the directors of Tenco Industries Ltd. However it is doubtful that this course of action would have been worthwhile as it was recognised Tenco's defence would be that they were unable to their responsibilities as the receivers had control of their affairs including the management of the buildings 2• Fawcett Street. It was not considered feasible to instigate d · that as procee mgs agamst the receivers as they would argue · they were immune from prosecution in respect of the act1v1t1es of the principal company.

In addition Tenco Industries Ltd, were claiming that th:Y were not in a position to control the premises hecause they had returned the keys to the landlord and no longer regarded themselves as tenants. In the circumstances it was not considered an appropriate case for prosecution.

In conclusion it is considered that a satisfactory result has been achieved in that a danger to the citizens York was and that the costs to the County Council have heen mmimal. The Fire and Rescue service has been seen to its_ powers and authority in administering the for which it is responsible. As the Petro.leum L1censmg Authority it has also gained valuable in collating the evidence necessary for the production ot. a case file. which it is considered would enable a successful prosecution to be taken.

Tanker Driver, Competent Person and Licensee Find Themselves in Court

Following Spillage

By Roger Marris, West Yorkshire Fire & Civil Defence AuthorityThe failure of the tanker driver to close the faucet of one of his tank compartments before leaving the Immingham terminal (Lincolnshire*) resulted in 900 litres of petrol being spilled onto the forecourt at Whetley Hill Garage in Bradford during a delivery on 1 October 1993.

Under normal circumstances the tanker driver's inadvertency to close the faucet would not have caused the spillage. However, on this occasion his initial mistake was compounded when, towards the end of the delivery, he connected his delivery hose to a compartment he had already emptied. Consequently when he opened the foot valve, from a position on top of the tanker, petrol escaped from the open faucet onto the forecourt.

The escaping petrol would have been immediately noticed by the competent person had he been in close proximity to the road tanker and storage tanks and not elsewhere (probably in the shop!) in which case he would have a!erted. t.he driver who was unaware of the spillage from his pos1t1on on top of the tanker. It was only when he descended the ladder that he noticed the escaping product. The absence of the competent person clearly contributed to the quantity spilled.

After some deliberation between the driver and the perso'. 1 (and after telephonina the drivers the. Fire Service were eventuall; summoned to deal with the spillage.

When. a foam blanket had beeJl l·i·d 1 f" d '1 oveJ t 1e a iecte area by the fire appliance crew the Oft·· Ch f h Jeer 111 arge o t e 111c1dent Jequested the attendance oi' tl p 1 01.t ' 1e etro eum · Jeer to mvest1gate the accident.

Of particular concern was the COJlo ·t· 1 , h t· · oes mn o t e orecourt created by motor cars parked by the li·ceJl. c tl " see 1 or 1e purpose of s<1le. Althouch the licensed pJ·eJ11 ·. ·. t. ft·· · 1ses 1s o su 1cJent dimension for the tanker to manoeuvre so 1 t b, · d. 's o e II1 a forward tacmg of exit during unloading, the large number of cars cluttering the tank farm meant that the fire crews had to reverse the vehicle off the site.

As a result of the spillage and the circumstances surrounding it. the Licensing Authority decided that a prosecution was not the most appropriate course of action.

The Bradford Magistrates at the hearing on I 2 April 1994 shared the Licensing Authority's concern at the offences by the level of the fines they imposed. The three defendants pleaded guilty to all the offences as charged.

Tanker Driver (Douglas Atkinson employed by UK Petroleum Products Ltd)

I) For failing. so far as is practicable. to ensure that all openings in the carrying tank of the road tanker were

securely closed; contrary to Regulation 16(1 )(a) of The Road Traffic (Carriage of Dangerous Substances in Road Tankers and Tank Containers Regulations 1992 (RTR). Fined £300 *

2) For failing to properly and securely connect the delivery hose to the appropriate outlet on the road tanker before commencing the delivery of petrol into the storage tank; contrary to Schedule 4 (art 2 ( l l)(b)(l)(aa)) of the RTR. Fined £300

3) For commencing a delivery of petrol into a storage tank without the competent person keeping watch as required by Schedule 4 (Part 2(12)) of the RTR. Fined £300.

In addition to the £900 fines, costs of £150 were awarded.

Competent Person (Mohammed Nawaz Khan employed by Whetley Hill Garage)

I) For failina to be in close proximity to the road tanker and tanks during the whole of the delivery; contrary to Schedule 4 (Part 2 (12)) of the RTR. Fined £300.

In addition to the £300 fine. costs of £50 were awarded.

Licensee (Mohammed Yaqoob)

I) For failing to ensure that the competent person received adequate training as required by Schedule 4 (Part 2 (8) (a)) of the RTR. Fined £100.

2) For failing to keep a record of the training received by the competent person as required by Schedule 4 (Part 2 (8)(2)(b)) of the RTR. Fined £100.

3) For parking motor vehicles on the filling than to be refuelled without the approval ot the Ch1e1 Fire Officer; contrary to the Conditions of Petroleum Licence. Fined £500.

4) For failing to ensure. by coning off as necessary. that the road tanker had a clear escape route in the case ur emergency; contrary to the Conditions of Petroleum Licence. Fined £500.

In addition to the £ 1.200 fines. costs nf £220 were awarded.

* It is interesting to note that this offence was c\lmmissi\lncd outside the administrative area of the WYFCDA. Sel'tilln Yi of the HSA W makes provision for "treating the llffc11L·c as having heen committed at the place where that plant or substance is for the time being".

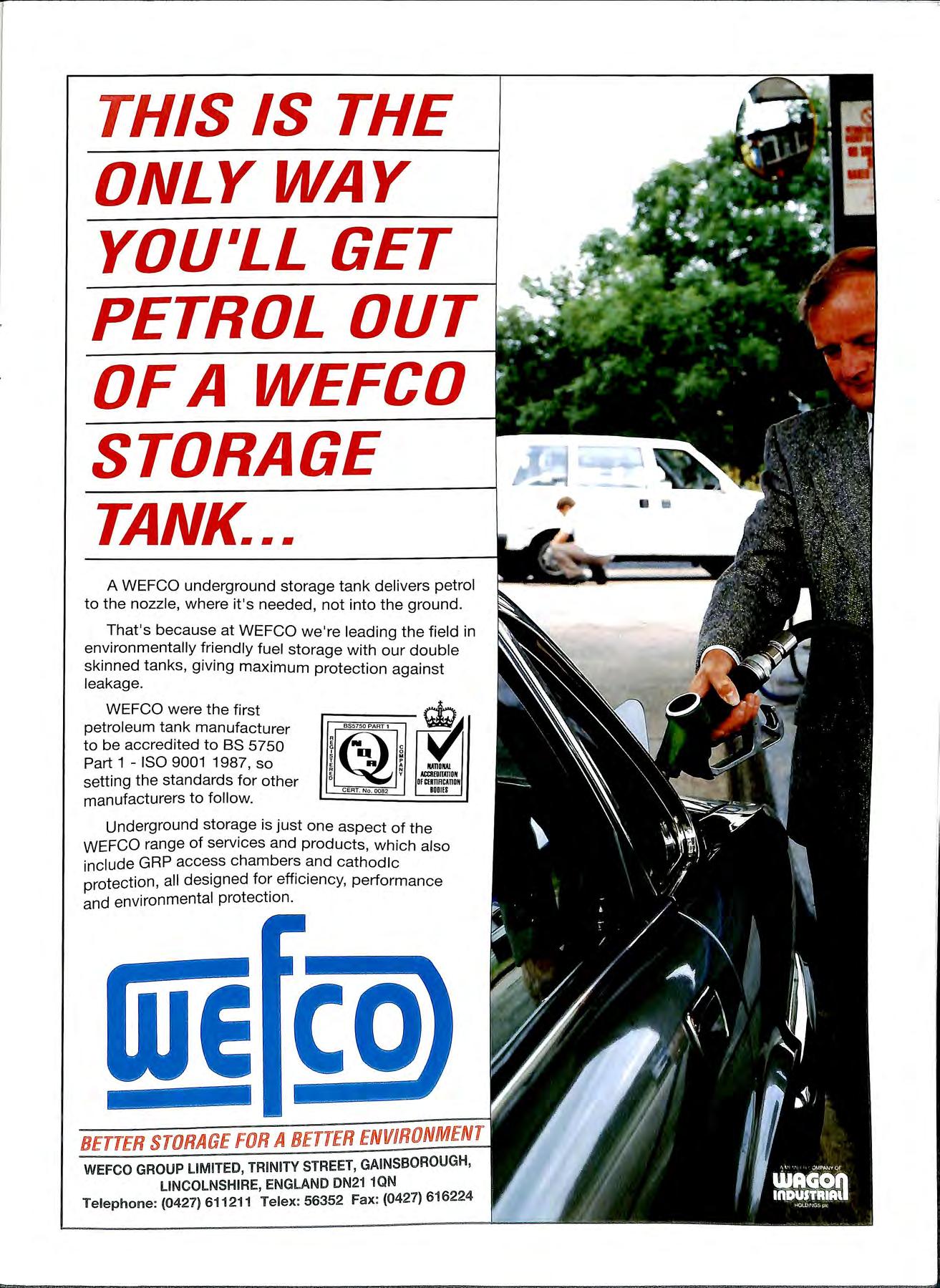

THIS IS THE ONLY WAY PETROL OUT OFA WEFCO TANK.

..

A WEFCO underground storage tank delivers petrol to the nozzle, where it's needed, not into the ground.

That's because at WEFCO we're leading the field in environmentally friendly fuel storage with our double skinned tanks, giving maximum protection against leakage.

WEFCO were the first petroleum tank manufacturer to be accredited to BS 5750 Part1 -18090011987,so setting the standards for other manufacturers to follow

Underground storage is just one aspect of the WEFCO range of services and products, which also include GRP access chambers and cathodic protection, all designed efficiency, performance and environmental protection.