Scully On·Truck Computer

Scully On·Truck Computer

•

Scully On·Truck Computer

Scully On·Truck Computer

•

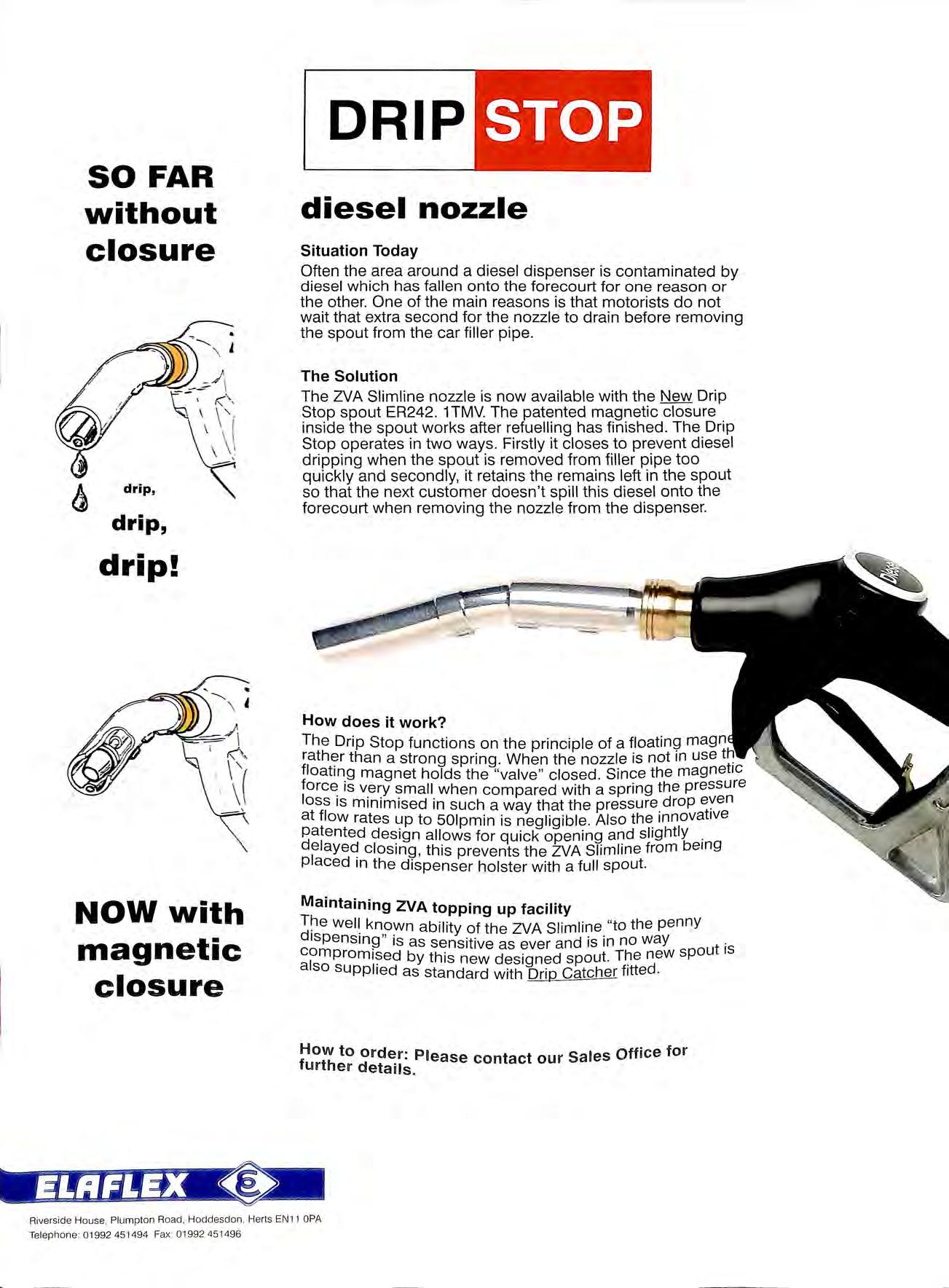

Often the area around a diesel dispenser is contaminated by diesel which has fallen onto the forecourt for one reason or the other. One of the main reasons is that motorists do not wait that extra second for the nozzle to drain before removing the spout from the car filler pipe.

The ZVA Slimline nozzle is now available with the New Drip Stop spout ER242. 1TMV. The patented magnetic closure inside the spout works after refuelling has finished. The Drip Stop operates in two ways. Firstly it closes to prevent diesel dripping when the spout is removed from filler pipe too quickly and secondly, it retains the remains left in the spout so that the next customer doesn 't spill this diesel onto the forecourt when removing the nozzle from the dispenser.

The Drip Stop functions on the principle of a floatin9 magn than a strong spring When the nozzle is not in use floating magnet holds the " valve" closed. Since the magnetic is very small when compared with a spring the pressure loss is minimised in such a way that the pressure drop eyen at flow rates up to 501pmin is negligible. Also innovative patented design allows for quick opening and slightly closing, this prevents the ZVA Slimline from being placed in the dispenser holster with a full spout.

The known ability of the ZVA Slimline "to the penny dispensing" is as sensitive as ever and is in no way t · compromised by this new designed spout. The new spou is also supplied as standard with Drip Catcher fitted.

The product range consists of a range of pipe, fittings and tooling in the size range SOmm, 63mm, 90mm, 11 Omm. The pipe outside diameters are based upon BS 5556 and ISO 161 I I All of the pipe and fittings are black pigmented. Black has been carefully selected as it affords the best and most cost effective solution against environmental UV degradation, that can occur with polymers.The polymer has also been carefully selected to provide the 30 year design life required by the specifications of the industry

of the Association 30 31 32 36 38 39 41 44 45 47 48 SIMON WHITE SOUTHERN BRANCH SUE MEADOWCROFT WALES /IRANCH STEPHCROW BRANCH

The front cover shows the use one couple found for a I 91 I petrol pump!

They had some probleins exporting it from the USA with their luggage, as customs thought it was a gun, however should you venture into the White Swan in Cambridge be prepared for an unusual pint!

\/J\ERTISIN<; SF( 'N/:T-\Rl

TALKING POINT 40YEARS ON NOTES & NEWS PROSECUTIONS VAPOUR RECOVERY DIP STICKS & VAPOUR RECOVERY VAPOUR RECOVERY STAGE 2 SOUTHERN BRANCH LETTERS TO EDITOR POLYETHYLENE PIPEWORK PETROFUSE MIKE SILMON NORTH EAST BRANCH RUTH SUTHERLAND SCOTLAND BRANCH LINDSAY LLOYD MID/ANOS BRANCH STEVE BLANCHARD HlfMBhRSmE BRANCH HARRY REID N< JRTH Wl:'ST II RANCH NATHANIEL MCCOY IRl:'LAN/J llRANCH JAMIE THOMPSON EDITORIAL TEAM fl>ITOR ROB GREEN s:

The report on the passing of Be rt Griffiths and D enis Hall, founder members and past Chairmen of the APEA brings b ack memories of the inaugural meeting of the West Midlands Petroleum Acts Administration Group , he ld at Dudley in April , 1958 The delegates, so me 35 petroleum officers within the area were welcomed by the Mayor of Dudley, Councillor Danks, who was un a nimously e lected Chairman of the Group for the next twelve months Ernest Vaughan , CPHI , Solihull was elected Vice Chairman and Len Cave, CIWM, Dudley, Secretaryrfreasurer. So, off to a flying start.

For the first two or three years membership of the Group was confined to represe nta ti ves from local a uthoriti es within the counties of Shropshire, Staffordshire , Warwickshire and Worceste rshire. Four meetings a year were held within the area, at which papers on a diversity of petroleum matte rs were presented by experts, not only in the local government service but, due to th e persuasive powers of Geoff Dea n, who, if he didn ' t walk o n water certainly trod the corridors of power, illustriou s representative s of the major oil companies, manufacturers of petrol pump s, togeth e r with H.M. In spectors of E x plos iv es. Sadl y in 1960, Councillor Dank s died Hi s was a cons iderabl e influ e nce in ge tting the Group reco g ni sed in loca l a nd central gove rnm en t ci rcl es as a seriou s voice on petrol e um admini stration .

With the publication of The Bull e tin in 1962 membership increased far beyond the boundarie s of the West Midlands Branches were formed res idential co urses held initially at Attingham Park , and later due to demand for place s at the Univers iti es of L a ncas ter, Surrey and York Vi s its we re made o n th e Co ntinent of Europe to refinerie s, manufacture rs of plas tic ta nk s, se lf se rvi ce pe trol station s a nd other, in those d ays inn ova ti ve projects.

Followin g the principl e that "A ll wo rk and no play make s ", eve ning exc urs ions by ' D ea n 's crocodi le' as it was kno wn we re und e rtak en to the mg htspo ts of Amsterdam , Pari s and H a mburg. Im ag in e the co nste rn ation and squ ea ls of the rapid ly di sa ppea rin g 'g irl s' whe n Geoff introdu ced th e m to H.M. In s pector of Exp los ives, Dr Jim Jeacock , g ivin g him hi s fu ll titl e if no t hi s co rrec t surn a me ' W hil e wa tc hin g th e g irl s in a Ha mburg ni g ht c lub o ne remark made was that s he co uld be no more th a n s ize 14. Now pri o r to e mbarkin u o n thi s trip. Geoff Dea n, Jim .l eacoc k a nd Bill Da le , h: cl been rev is in g th e Hom e Office and Assoc iat io n ' s Code of Prac ti ce T he o nl y stick in g po int bei ng lo w ha t e xte nt the th e n 20ft safe ty di stan ce co uld be redu ce d O n he a rin o ·ro un ee n '. Geoff looked up a nd sa id in b a n e nquirin o to ne ·Fourt ee n ·1 w he re up o n a g reat ly re li eved Ji m Jeaco c k said o K ]' JI se tt le for fo urt ee n· A nd that. dea r read e r is how the 14 n s afel y di sta nce fo und its way into a rev i!>e d cod e. Tru e''

Bec om in g a nation <il bod y Ill J 96.'i. me rnh e rship L' lllh 1-; 1c-c d lllll <lil ly loca l a uthorit y pe 1rn le um offi ce rs. hut

also associate members represe nting industry. The support given to the Association by these members granted full membership in 1982 cannot be overstated and the APEA's success in represe nting both a regulatory serv ice and industry in a singl e forum is both unique and effective. An early associate was John Wigful, father of Tim Wigful th e present Treasurer The value of industry's support which initially was based on the mutual aim of the a ttainment of uniformity in the admini stration and e nforcement of petroleum legislation, was manifes ted in th e immediate years following local governme nt reorgani sation in 1974 , when petroleum enforcement was vested in the county councils , who on taking over thi s function were in the main un apprec iative of the se rvices offered by th e APEA and its members. Associ ate members as they were then , were more forward looking and the very real danger of the demise of the Association due to the lack of fundin g was happily averted

And so tod ay what do we see ? We see g reat advances never dreamed of by tho se pioneers of 40 years ago. A strong profess ion a l body reco g ni sed as an a uth o rative voice o n petroleum ad mini stration throuahout th e U.K. and b beyo nd. A scintill ating and brilliant annual se minar, a n exhibition compri sing of I00 stands , speakers from Europe and the USA. A membership of over 1OOO , nine branches and an annual yearbook containing a wealth of information How gratifyin g for tho se of us who were in at the beginning, to know the Associ ation is in suc h good ha nds.

On a personal note , lets go back, not 40 years, but l 05 years I wonder what my grandfathe r would have made of self se rvice , GRP tanks, cathod ic protecti o n, e lec trostati cs, vapo ur recov e ry and so on. No such probl ems in 1893, th e yea r he was appointed to th e C it y of Winc hes te r as in spector of weights and measures and petroleum.

The number of incidents of P& V valve failures on stage IB vapour balancing has risen considerably during the last 12 months as the industry installs new systems. A number of these failures have been caused by valves, which have not complied with the stated settings.

One manufacturer concerned has recently agreed to replace a large number of valves distributed across the UK. A design fault was identified following a number of overfills. The plastic guide inside the valve was found to react with petrol vapour and valves eventually ceased solid. Wright Engineering apart from making valves in their own name also manufactured valves for Berry and Hytek and is in the process of replacing these valves.

There is some concern in the industry that there are no proper standards for these valves, and this is causing public safety problems.

The UK is expecting legislation covering stage 2-vapour recovery to come into effect in 1999. A document is to be published this summer setting out the proposals for the introduction of legislation requiring vapour recovery at the petrol pump. At this time the proposals are to introduce this to new service stations that are constructed next year, with retrospective application to the larger service stations over the next few years. 1 Sainsbury the Hypermarket operator has by far the largest number of service stations in the UK already operating stage 2 pumps and will have more experience than other operators in this market.

The Government have acted upon consultants report on ·icre 2 a copy of this report is availahle for APEA P' e ' _ members who contact Guy Turner at ENTEC (telephone 0 l 606 49077) at a charge of £20 each.

A petrol station under modification in London's East End was subjected to an explosion scare last month. Fitters working on pipe work alterations ran from the scene as fittings that were being thermo-welcled caught fire. Flames were seen coming out of the pipe work which was connected to a live tank. The fitters returned when the flames subsided and fittings and welding machine were removed to cheek for faults. Al present the manufacturer is investigating the fillings. which caught fire The London Fire Brigade is advising contractor-; lo n1mplelt' thcnno welding before L'onnecting pipe \\ork lo the tanb.

The Environment Agency has chosen the APEA and Bulletin to publish the new drainage guide for petrol separators to the UK industry. In each of the UK distributed Bulletins there is a copy of the guidance Use & Design of Separators in Surface Water Drainage Systems PPG 3. This guidance applies to the Environment Agency in England and Wales and SEPA in Scotland.

The AGM of the Association was held on April 18 the following officers were elected to the Council.

John Boudry Chairman Ian Taylor Vice Chairman Andy Berry Secretary Jamie Thompson Editor Robin Green Advertising Secretary Council Jack Samson Chris Knight Philip Monger

The latest annual Retail Marketing Survey. a supplement to Petroleum Review. provides a detailed breakdown of UK filling stations by company and A new is this , y pi·ovi'des details of the number of forecourts year s surve · I I I P attached broken down by company. t 1at 1ave s 10 s , ·

By working closely with industry tl.1e survey has 'd t·i·· d addi't 1011 aJ 871 small sites which have not 1 en 1 1c an ' featured in previous surveys'. Typically are single pumps attached to small shops m remote locations.

These newly identified sites mean that as of end 1977 there were 14,824 operational sites selling petrol and/or diesel in the UK and Northern Ireland. an apparent rise of 76 over end 1996 levels. In fact 795 sites closed in 1997. a rate of roughly three sites/working day. Although this is a considerable reduction over the 1.496 sites closed in JL)96 it does reflect the competitive pressure in the marketplace.

The supermarkets have continued lo inncasL' llwir presence relative to the oil companies. In Jl)97 thL're wne 9J.J. supermarket sites selling petrol. a gain or 57 (or 6.5'/r) on 1996. The four largest nil L'ompan:i were Esso. \Vith I JO.+ BP (which nm\ tlw Mobil network) with 1.831 sites: Shell. with. l .45L) and Texaco. v. ith l .1-+ 7 The frum \ear L'arl IL'r ll'\cls \\ere a dcl'linc of 106 fur Essl1 and a net ga111 ul 542 l'nr HP. relkL·ting the I1lL'rg111g of tlw Muhil and HP nctwnrb. Shell"-.. nt'lwork rL'dllL'L'd b\ 2-+' uutkh 111 ll)l)7 Whik l'L'\al'\l.;., nL't\\lll"k

that they have taken over a number of small companies. The takeover of Gulf sites by Shell, and to a lesser extent Texaco, are not reflected in the survey as the formal changeover was at year end.

This survey is based on stat1st1cs relating to end-1997 and therefore does not reflect changes that have been announced or taken place since that date.

• Oil leak due to failed buried pipes.

• Environment agency called in.

• Pipes installed for only eight months before failure.

• New 25mm multi-layer twin wall plastic pipe replaces failed black iron.

• 120 metres laid in 30 minutes

A buried oil line which had only been installed for eight months recently failed at the newly built Vodaphone call centre in Chelmsford, Essex. The original line which was installed in denso wrapped black iron pipe was supplying an emergency generator inside the building. When it failed approximately 200 litres of oil leaked into an interceptor on site. Alert Vodaphone staff quickly spotted the leak and notified the Environment Agency, who after checks were satisfied that all the leak had been contained with the interceptor. It was then that the corroded iron pipework was discovered. After examining suitable alternatives, APT POLYTECH 25mm flexible twin wall pipe was specified after approval by the site architect and the Environment Agency. 120 metres of pipe were installed and tested in under half a day and Mr Bernard Cansdale who has over 30 years experience of pipework installation commented "the pipe was extremely quick and easy to lay, with no jointing and only two end fittings to assemble, testing could not be easier". APT Polytech is adaptable. environmentally secure and cost effective.

Inspectors from the Health and Safely Executive (HSE) will be giving priority to reducing the numher of workers Who suffer serious or fatal hurn injuries through mishandling petrol. at their visits to vehicle repair garages over the next 12 months.

Fire and explosions associated with leaks and spillages or petrol during routine repair work on vehicles is a major area or concern and checks will he made to ensure that employers have suitable procedures and equipment to 11re I · vent tie dangerous escape ol petrol.

As part of the mitiative. recent approaches have heen lilade to car manufacturers and importers towards ensuring

that they can provide specific guidance on safe procedures for work on petrol fuel systems. For, although the basic principles are the same for all work of this type, each vehicle model should be individually considered.

Bernard Robinson, Head of HSE's Engineering National Interest Group said: "The misuse and mishandling of petrol contributes to a relatively high incidence rate of fatal and major injuries in the motor vehicle repair trade. The accidents are not always confined to the person doing the job, other employees and even customers have received serious or fatal bum injuries. In almost all cases, there has been very significant property damage as well."

The use of a proprietary 'fuel retriever' with suitable adaptors is the recommended equipment for removal of petrol from the tank. Additional or alternative equipment may be needed for other petrol related work to be carried out.

Around 3,000 accidents of all types in motor vehicle repair are reported to the HSE every year. It is thought as many as 60 per cent of such accidents go unreported, so this means that the actual figure could be as high as 7 ,500. In financial terms, this would give a total bill to the UK motor vehicle repair industry of around £250 million every year or about £5,000 per garage.

"This represents a tremendous financial burden to the industry as well as a great deal of suffering and hardship for all involved," added Mr Robinson. "Inspectors will take appropriate enforcement action where inadequate arrangements are revealed."

The visits will be targeted at the employers arrangements to prevent leaks, spills and spraying of petrol when working on any part of the fuel system. Removal of fuel from the tank and replacement of the fuel sender unit or fuel filter are common examples of jobs which can too often result in a serious fire with tragic consequences.

At approximately 0800 hours on the morning of Monday, 5th January 1998 a delivery of fuel was taking place at Tesco's Filling Station, Watling Street, Bletchley.

During the delivery, the Tanker Driver accidently operated the wrong outlet valve which caused a surface spillage of ahout I00 litres of unleaded petrol.

Due to the swift action of staff hy stopping the delivery. evacuating and closing the forecourt and raising the alarm. a potentially dangerous situation was averted.

The Fire & Rescue Service attended. followed hy the Council's Fire Safety and Petroleum Officer and a detailed investigation of the site took place which estahlished that the spilled petrol contained to the site.

The forecourt remained closed and finally re-opened 3 hours later.

P e trol and diesel leaks in all types of unde rground pipelines ca n now be lo cat ed with a speed and pinp o int accura c y n eve r previ ously seen in th e UK.

G eo tec hnical Instrum ents (GI) of Leamington Spa have tea m ed up w ith Trac e r Res ea rch Corporation (TRC) of Tu cso n, Arizona to provide a system whi ch has proved itse lf throu gho ut North America as the fastest, most precise and c os t- effecti ve m e thod of lea k d etec ti o n.

The fo llo win g report and ac c om pan y in g photog raph s d e111 ons t rate th e rapid and re liabl e ident(fica tion of a recen t lea k in a 50111 suction lin e of unleaded p e troleum

Small hole s, 75cm deep and 40mm di a m e te r were th e n drilled into th e fo recourt at 3m interval s so that PVC sampling probe s could be in stalled.

Soil vapour samples were obtained at inte rv a ls from the probes and th en. an a lysed u s 111 g a gas c hromatog raph in Trace r ' s mobile la boratory.

Ju s t a few hours late r, the gas chromatograph provided data a nd print-o uts s how in g the exac t locati o n of the leak. H av in g pinpointe d th e precise problem area , o nl y a ve ry s mall sec ti o n of th e foreco urt ha d to be removed As Tracer ' s European M anage r J eff Sh e rrard ex plain s. a significant cos t sav in g o n excavation is ju st o ne of th e many customer be nefit s.

" With co n ve nti o na l eq uipm e nt. maJor disruption and loss of bu si ness is in ev it ab le ," he says.

" But this far more sc ie nti fi e m et hod of lea k d e te c tion mea ns th a t onl y a n abso lu te minimum of e xcavat ion is required. leavi ng s it e s free to op e rat e w ith littl e or no 1n co n ve n1 e nce.

A ft e r c arefull y remuv in g th e c on c re te to rev e al the pipe a profu s ion of bubble s app e are d from a le ak in g rn uplin t! w he n a s impl e mi x pf" soap y wate r wa s pPure d ll\'C r 1t proving that the Trac e r sy ste m had lo cat e d th e kak \.\ 1th pe rfe ct accurac y les s than Scm from th e· prc d Il "lL' d loc al io n

Recently, a serious incident occurred on a Driver Controlled Delivery (DCD) site operated by BP where a crossover of tanker delivery lines took place.

It appears the driver connected up the wrong lines to the off-set fills resulting in over 2,000 litres of diesel being discharged into a Four Star tank and over 300 litres of Four Star delivered into the diesel tank. More concerning as that the tanker driver left the site in this condition and failed to report the matter to the site operators.

Some 12 hours later reports were being received by the Site Manager that contaminated fuel had been dispensed mto motorists fuel tanks resulting in numerous breakdowns close to the site.

On receipt of the first complaint and a cross check on site uUage, the crossover was discovered by the Manager who immediately closed the site and contacted myself as Petroleum Officer.

On investigation 65 transactions had taken place on Four Star and a further 20 on diesel during the 12 hours that elapsed from delivery to discovery.

The "Form of Certificate" in accordance with Part III of Schedul_e 4 of the " Carriage of Dangerou s Goods by Road" R_egulat10ns 1996 had been completed correctly by BP's Si te Manager but signed off as correct by the DCD Tanker Driver.

Arrangements were then put in hand to deal with by now, several complaints to BP 's Cu stomer Care Section as well

as arrangements for the uplift of all contaminated product with the foercourt and shop remaining closed.

The whole operation took 24 hours to complete before the site could re-open which cost several tens of thousands of pounds in Jost business and compensation.

It is understood that appropriate disciplinary action has been taken against the d1iver.

The Pumptronics Series C Compact offers a range of innovative electronic single and twin grade pumps of unprecedented quality.

Using the latest electronic technology, world beating hydraulics, and fabricated from solid stainless steel, dispensers are suitable for use in the most demandmg conditions found anywhere in the world , from modern service stations to commercial and heavy plant refuelhng facilities, to marinas.

Attention to detail throughout the design and the use of top quality materials has resulted in a range of pr_oducts which exceed the expectations of customers. With all functions accessed through a password controlled infra-red controller, this new equipment from Pumptromcs raises the quality standard of fuelling equipment.

Also available in a vers ion to dispense bulk lube oil as well as all standard fuels Series C equipment is manufactured to BS7 I I 7 and by UK & Measures for re-sale use in both attended and self-service operation

A chairman of Nuneaton magistrates hearing a case against a Coleshill petrol station owner (Monday 30 March) this week referred to the companies attitude to dealing with hazardous substances as "laissez-fair".

Woodall Transport (Birmingham) Limited trading as Woodall Motor Services at High Street, Coleshill pleaded guilty to three charges under Health and Safety Regulations brought by Warwickshire County Council Trading Standards Department following a petrol spillage emergency in June last year.

Following a hearing (Monday 16 March) at which a tanker driver, his mate and a forecourt manageress were fined a total of £2,600 for their part in the spillage described in defence mitigation as being caused by a "too many cooks scenario", the company pleaded guilty to:

• Failing to ensure a member of staff nominated to oversee petrol deliveries received adequate training enabling her to understand her functions under Health and Safety Regulations.

• Failing to keep records of training required by the Regulations and received by nominated staff. at the premises.

• Failing to ensure tanks at the premises were clearly marked with maximum working capacities and grades, permitted to be stored.

Noel Hunter, Warwickshire County Trading Standards Officer commenting on the outcome said "We are pleased to receive this endorsement of our actions by the Court. At a 'me when many often regard Health and Safety regulations being a burden this incident is a timely reminder of the as . d . ·1 need for tight regulat10n an v1g1 ant enforcement in this particular area".

Defence lawyers mitigating for the company said it had been in business for fifteen years and had only once previously been before the courts. many years ago. The manageress had been employed at the site since it started and for five years before under previous ownership. She had enty years of cumulative experience. it had been a wet tW k.. . 1 i , and there had been too many coo s wit 1 a tanker lay d . 1 cl l' . driver and his mate also present unng t 1e e 1ve.ry at which a value to an unconnected hose had been opened 111 error.

The proprietor had not realised the tanks were not properly marked and apart from her long experience the site manageress had nominal 1ra111111g and 11 had not been considered necessary lo keep a renird of it.

For Warwickshire County Council, Ms Sarah Burke reminded the Court that the regulations were framed to prevent petrol spillages and if the person nominated by petrol site owners to oversee petrol deliveries were to comply with the regulations then they needed a knowledge of the regulations, to understand them and to be trained. Experience alone was not sufficient. When interviewed after the spillage the manageress had admitted she now knew more about the Regulations.

In fining the company £3,000, the Chairman of the bench also commented that it was important that the management of a company understood that where dealings in dangerous substances such as petrol occur on a regular basis that its "responsibility for training was quite awesome".

Warwickshire County Council were also awarded £590 costs.

Following a joint initiative with West :orkshire Fire Service (WYFS), the West Yorkshire Tradmg Standards Service (WYTSS) ..prosecuted three h k I hop assl.stants f'or sellmg fireworks to persons s op 'eepers s · · · . .. . , . . . under the age of 18 years dunng last yems firew01ks season.

. h h er f urchase due to be increased from 16 to Wit t e aee o P . . 1 f- ·ks season WYFS (as the enforcmg 18 dunner t 1e irew01 · · · . · ef h E plosives Act 1875) assisted WYTSS by authonty or t e x · · ·f · th certificate of Reg1strat10n not1 ymg attachmg a letter to e . f h · pendincr change to Regulat10ns and the shopkeeper o t e 1m e / · . . f 1 WYTSS to carTy out test pure wses by of the mtent10n o t 1e . . . TI , purnose ot tlus exercise was to under acre pe1 sons. 1e r e II h k pers ]awfully retailmg fireworks were ensure that a s op ee · aware of the new Regulations i.

S b I tl WYTSS carried out a number of test u sequent y 1e · 14 · · l)ld bO)' A child of 14 was purchases usmg a ye,u · . . . . specifically chosen to counter any that. the offender was unaware of the recent mcrease 111 the age ot purchase.

All three defendants pleaded guilty before various West Yorkshire Magistrates Courts when fines of£ I 00 with £200 costs were imposed on each defendant.

Trading Standards Officers requiring more detailed · J1·1se method of mformation regarding the test pure '· enforcement arc welcome to contact David Lodge of the WYTSS on 0 l l .1 2530241.

Texaco Ltd pled guilty at Aberdeen She1iff Comt on 10 February 1998 to offences under Section 1(3) of the Petroleum (Consolidation) Act 1928 and Section 33(3) of the Health and Safety at Work etc, Act 1974 relating to a loss of petrol at Crathie Service Station , 515 Holbum Street, Aberdeen and were fined a total of£ 1250.

A fine of £500 was imposed for contravening condition B. l.12 of their petroleum licence for failing to provide records showing consistent accurate monitoring of petroleum spirit delivered, stored and dispensed, and a fine of £750 was imposed for contravening condition A3: 12 of their petroleum licence for failing to take all immediate practical steps necessary to remedy any defect or condition likely to cause accident or explo sion , and carry out at their own expense tests and works of demolition, alteration, retrieval, extraction or construction as required by Aberdeen City Council.

The Procurator Fiscal took the case on indictment.

The site operator at the time became aware of a problem with one of the petrol tanks , approximately two weeks after taking over the site, and was concerned that no wet stock records from the previous occupier were available He arranged to have the tank precision tested on 27 August 1996 which it failed. No action was taken to recover the Jost product or di scover how much had been lost until a smell of petrol was discovered in the adjacent premises on 30th September 1996. By April 1997 , 2700 litres of petrol had been recovered from underground boreholes at the premises.

Following the death of the licensee of Morden Garage in Morden, Dorset, the executors of the estate in structed garage forecourt engineers Fuel Flow Services (LG) Ltd of Ringwood in Hampshire to make two tanks safe on the site.

A petroleum officer who was checking to see whether the work had been undertaken requested a copy of the certificate certifying that the tanks had in fact been filled with concrete The owners of the land who had originally leased the site to the licensee supplied a copy certificate confirming that the tanks had been degassed and filled with concrete. The original certificate had been supplied to an agent based in Bournemouth.

A site visit was made where both tanks were found to be empty with pumps removed An explo simeter test indicated a reading that went off the scale with a sample from the residues at the bottom of the tank having similar results.

Mr Lawrence Green land , the Director of Fuel Flow Services (LG) Ltd, stated that the certifi cate was not their normal one and may have been completed by one of his employees to show another how to do it.

On 16 February 1998, in a joint case taken by both Bournemouth and Dorset Trading Standards the company was fined £I ,OOO with £500 costs after the Company gui lt y to the charge Mr Greenland pleaded not gulity to a charge against him personally and no evidence was offered by the prosecution The successful charge was taken under Section 14 of the Trade Descriptions Act 196 8

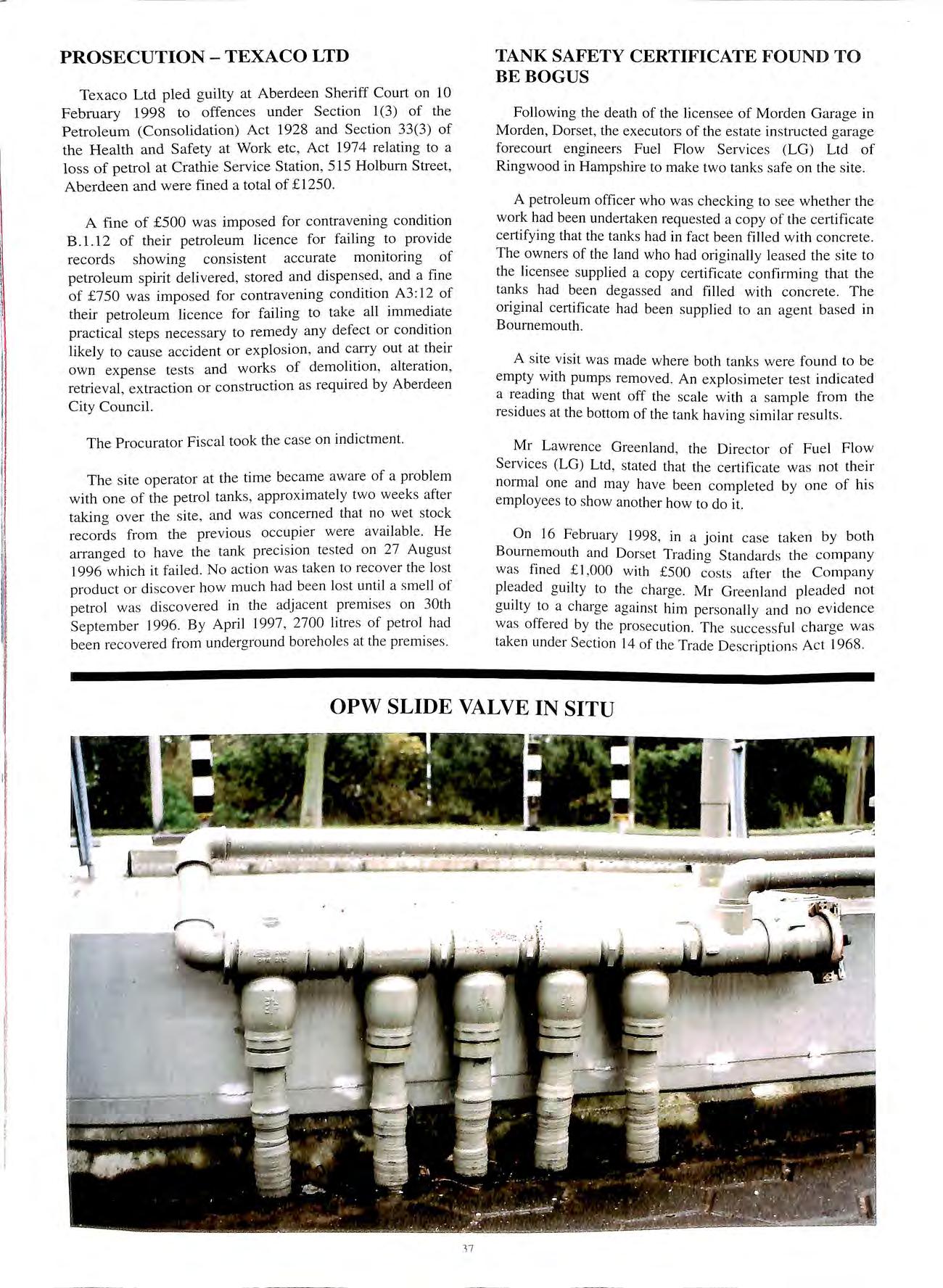

This OPW Vapour valve, has been in use for several years in both the US and other countries where Stage 1-b is in operation. It is designed to assist free flow of vapours being returned from the UST to the road tanker.

Problems experienced during drops at service stations where Stage 1-b systems are installed, fall generally into 2 categories:-

(a) Over-pressure of UST, causing in some instances, overfill spillage from adjacent manifolded UST's.

(b) Over-pressure of UST causing spillage from vents which are manifolded at high level over 3m.

It has also been found that, in some cases, the vapour recovery hose has not been connected to the vent vapour adaptor, effectively blocking the vapour recovery system.

It should also be noted that the road tanker compartments should be air and vapour tight, otherwise atmospheric air will be sucked into the compartment during the drop. This in tum affects the free return of vapours.

Explanation of these incidents varies from malfunction of PY vent (where fitted), to wrongly sized or badly installed, vent pipework.

Fig. I

In the UK it is accepted practise to install PY vents when Stage 1-b is installed. In other EEC countries eg, Netherlands, PY Vents are not considered necessary until Stage 2 YR is installed. The one, common item required for all systems is the adaptor connecting the vent manifold to the road tanker vapour hose_ This is normally a 3" or 4" cam and groove type adaptor with a spring operated non return valve. Eg. OPW 1611-AV.

When connected to the tanker hose, a pin in the hose coupler opens the valve allowing displaced vapour from the UST, to be returned to the tanker.

In theory, ie. if the manifolded vent pipe system is correctly sized and installed, a volume of vapour equal to the volume of liquid dropped, will be returned to the tanker, without any overpressure of the UST. In practise, and for a variety of reasons, restrictions in the vent system do create overpressure, and put simply, vapours cannot be displaced for the given rate of fill.

The OPW 1611 -YR B is an extension of the standard OPW 1611-AV vapour adaptor, incorporating a slide valve. When the tanker hose-coupler is connected to the vapour vent J6 J J adaptor, the slide valve closes the vapour path, to the above ground vent pipe during the tanker drop (Fig I). This ensures the optimum free passage of vapour to the tanker, and no ingress of air from the vent pipe (Fig 2).

It is common knowledge that dipsticks and pre- l 992 hydrostatic gauges are incompatible with vapour recovery installations. The reason being that vapour pressures of up to 35mb (0.5 psi) are deliberately created in the vent system and the tank ullage space by the introduction of a pressure relief valve at the vent head. This valve obstructs the escape of vapour to atmosphere and encourages the displaced vapour back to the road tanker. If the vent system pressure rises above 35mb the valve controls the pressure and discharge any excess to atmosphere. The pressure generated during a tanker delivery decays slowly as product is drawn from the tanks through the dispensers.

In addition to controlling excess pressure the pressure relief valve incorporates a vacuum valve to allow air to be drawn into the tanks as the product level drops. The vacuum valve operates at a pressure of -3mb. The combined valve is generally known as a pressure/vacuum (p/v) valve.

Immediately after a delivery the pressure on top of the product in the storage tank is greater than that in the fill pipe, which is ope; to atmosphere when the fill cap is removed. Therefore, the level of product in the fill pipe is significantly higher than in the tank, which results in severe discrepancies in dipstick readings. Similarly. with the older type hydrostatic gauge. both analogue (pump up type) and semi electronic, discrepancies will also occur with incorrect gauge readings as these gauges use atmospheric pressure as their reference. Later type hydrostatic gauges reference the lank ullage pressure and are designed to operate correctly With vapour recovery and are mainly unaffected by a different pressure.

The majority of forecourts in the UK use dipsticks to measure their tank contents and a significant percentage have incompatible hydrostatic gauges. Many Regulatory Authorities are asking for the hydrostatic gauges to be replaced with a compatible type. It is unreasonable to expect these sites to suffer the cost burden of upgrading to a compatible tank gauge in addition to the not insignificant cost of a Stage I b installation.

There is a solution which, whilst slightly compromising the ideal objective of a fully sealed system. allows the continued use of dipsticks and previously incompatible gauges. This is to install a pressure bleed valve at the head 0 _f a second vent riser. alongside the pressure/vacuum valve. 1his valve. whilst maintaining the system pressure at a maxin1um 3'imb during the tanker delivery. incorporates a small bleed 11pening to atmosphere of 3mm diameter. This permits the controlled escape of very small quantities of vapiiur to atmosphere and allows the tank ullage and vent sysll'.111 pressure to quickly 1·ecover to atmospheric pressure

within a few minutes of completion of the delivery, fully restoring dipstick and gauge accuracy. Taking the worst case the escape of vapour to atmosphere through the bleed valve equates to no more than one percent of the total quantity of displaced vapour. On most installations it will be significantly less.

For the technically minded the "worst case" gas release calculation is as follows

Theoretical gas escape velocity at 0.5psi above atmosphere = 200ft/sec

Factor of discharge for a thin place orifice with sharp edges at 35mb above atmosphere = 0.65 Therefore v = 200 x 0.65 = 130 ft/sec. Volume = v(ft/sec) x A (are sq ft) A (for 3mm orifice)= 0.0000756 sq ft = 130 x 0.0000756 = 0.0098 cu ft/sec = 16. 7 litres per minute Vapour loss during a 15 minute delivery = J 6.7 x 15

Vapour loss during 15 minute recovery to atmospheric pressure = 250.5/2

Total vapour loss through 3mm orifice

= 125.25 litres = 250.5 + 125.25 = 375.75 litres

These are "worst case" figures and they will vary. depending upon the vent system pressure during a delivery and the volume of ullage after the delivery. A large ullage pressure will ohviously take longer to decay than a small one. From tests conducted on a petrol filling station in Worthing the release as around 0.3% of the total vapour displaced. due to a relatively low vent system pressure. of J 4mh and a short recovery period of five minutes. Bearing_ in mind that the target reference value for the release of vapour under the environment legislation is 0.0 I <y, hy weight (which approximately equates to 1or,1r by the dischan.i:e through the bleed valve is between J'/r I0 lr of the pern;issihle reference value.

The bleed valve consists of a 50mm diameter plate with a 3111111 diameter drilled orifice. Housed in the centre or tlK' plate is a spring loaded pres<.,urc release poppet \ahe V\ hid1 provides a secondary llleans of controlling the system prL'.Ssure in the event ol the failure ol the primary pressure/vacuum valve. The valve upcnin.'! pressure should

be set to be 10% higher than the primary valve. Without this secondary pressure release valve a failure of the primary pressure release valve in its closed position will cause severe over pressurisation of the system, resulting in a potential catastrophic blowback through the fill/offset fill pipe with the possible spillage of large quantities of petroleum spirit onto the forecourt.

Unless a device of this nature is incorporated in the system the only way to ensure accurate inventory measurement is to replace dipsticks and early hydrostatic gauges with electronic or compatible hydrostatic gauges. In the Secretary of State's Guidance Unloading of petrol into Storage at Service Stations, paragraph (a) on the cover page stages "ensuring that, in carrying on a prescribed process, the best available techniques not entailing excessive cost will be used". Surely, the inference is that the cost of the Stage 1b vapour recovery installation should be reasonable. Installing new tank contents measming devices will entail excessive costs and is unreasonable.

By installing a pressure bleed valve the reduction in system efficiency is small and the cost benefits are hioh. And it still allows the site to be significantly lower than target reference value.

With the financial problems that many small, independent operators are experiencing it is unreasonable to expect them to invest in new, expensive tank gauges. The cost of vapour recovery on its own is significant and the additional burden of installing new gauges will prove too much for some of them. pressure bleed valve should be accepted by the local Environmental Health Officers as an acceptable trade off between cost and efficiency, at least in the short tenn, otherwise the outlook for many independently owned sites is bleak. UL LAGE

While agreeing to publish the attached, the calculations in this document are all theoretical and each individual site is known to differ according to a variety of arrangements to each site.

A new installation with larger diameter pipework will operate far more efficiently than a site that is retrofitted, mainly due to small diameter pipe work and a tortuous pipe route for the vapour to return to the tanker.

The system described here does not follow the guidance issued by the Industry and in certain circumstances could prove dangerous. The manufacturers of these gauges also do not recommend

this method.

Thl' thl' I effert of .'Sm ullagl' pn•ssun· on l'WI in tlu· fillpipl'.

From 1st January 1998 40% of all new vehicles sold in the United States are required to be equipped with a large carbon canister. With effect from 1st January 1999 it will be 80% and from 1st 2000, 100% of all vehicles sold. This regulation also applies to all European vehicles exported to the USA. All major European car producers have therefore developed large carbon canisters guaranteed for 10 years or 100,000 miles.

According to US regulations the large carbon canister, commonly known as Onboard Refuelling Vapour Recovery System (ORVR), has to have an efficiency of at least 95%. During refuelling not only the HC vapours, normally sucked in with Stage II systems, but also the vapours released during the running and parking of cars (the so called running losses), are collected by the carbon canister. This function used to be done with a small carbon canister.

The alternatives are therefore: A small carbon canister and Stage II or a large carbon canister. The release of HC vapours during vehicle refuelling make up approximately 2% of the HC vapours released during the running and parking of cars make up approximately 11 % of the entire HC emission including households and industry.

Obviously Europe has to face up to the question whether the new large canister is the solution for the future.

In 1976, shortly after the introduction of Stage II vapour recovery, discussions took place as to whether the large carbon canisters or Stage II and the smaller carbon canister was the proper solution. This became a controversy, which lasted for several years. The US environmental agency <EPA) preferred solution has always been the large carbon canister. They take the view that it is a technically better and a less costly option. A US Federal Law was required to enable the introduction of large carbon canisters. Stage II enjoyed more flexibility from the outset. as it was possible to introduce this technology at local level throughout the counties. The stage of California was the first to specify Stage II for its cities.

This Jed to some confusion. The Auto-lobby in Detroit was completely against the use of large canisters. At first it seemed that their case was lost but m 1989 shortly before the Carter administration's term of office ended. the EPA issued a statement that Onboard Systems should be introduced. but it did not materialise. The car industry instructed the Department of Traffic (DOT) to draw up a repo11. which concluded that the large carbon camsters pose "a possihle safety risk'". Contrary reports were drawn up and the case ended up in the courts. In the end Pres1<.lent Reagan. who had just started his term of office. exercised his authority One of his best Mr Dingle the

Chairman of the American motor association.

The 1990 Clean air act was passed shortly after Reagan assumed office. Following this Stage II had to be introduced in polluted areas. The requirements for Onboard systems could be laid down later once the safety concerns had been clarified. According to this law Staae II systems can be cut back as soon as there are sufficient :ehicles on the road with large carbon canisters. In the meantime the safety concerns have more or less been dispelled. The large carbon canister is now a requirement in the USA and it is only a question of time until Stage II systems will die out in the USA.

The decision to favour large carbon canisters in the USA has been mainly influenced because Stage II is only required in areas with poor air quality (non-attainment areas). The most important population centres in the USA are polluted areas, but as the attached US map shows huge areas have never been touched by Stage II. This was the actual reason for the EPA to decide in favour of the Onboard solution.

From the beginning large carbon canisters never really had much chance in Europe. For the large carbon canister an EU directive would be necessary. If one looks back at the introduction of the catalytic converter (catalyst) and consider how many bodies such a project would have to. go through from the planning groups to the national converston become law, a period of 1O years is probably on the low side. Nobody wants to wait that long.

Stage II local laws and requirements are sufficient numbers of politicians from local authont1es, county's and the regions want to present themselves as environmentally friendly. The first local authorities to introduce Stage II were Swedish cities of Gothenburg and Stockholm. District authorities in Switzerland and several German towns and states followed suit. After that the politicians in Sweden, Switzerland, Germany and Austria reluctantly faced up to their responsibilities to make their own national laws. During this political decision large carbon canisters were never really considered. The subject of carbon canisters was pushed to the level of hearings and talks.

The first vapour recovery law was made in Sweden in November 1990. Switzerland and Austria followed shortly afterwards. Finally Brussels got involved in the issue and presented a draft directive in 1992. which laid down the introduction for Stage II in polluted areas. The draft directive also included a second phase where a tight seal connection between the nozzle and filler neck would improve the vapour recovery efficiency to 9Y;f. The large carbon canister is not mentioned in the draft. It was never seriously discussed amongst the group of experts from the EU commission.

The EU-Directive was at no time promoted by the Commission nor especially by its comm1ss1oners responsible for environmental affairs. Their main interest was to find a unified European solution and so avoid the growth of various national Jaws. Time and again decisions regarding a draft were announced. In the end the Irish commissioner for environmental affairs Mr Murphy dropped the whole draft remarking that there were more important environmental issues to deal with such as that of fuel formulations.

As a result of that it was left to the EU-members to make their own national Jaws. Today, in addition to the countries previously mentioned Stage II is now law in Denmark, The Netherlands, Luxembourg, Italy, France, Poland, Czech Republic and Slovakia. In other countries, such as the UK, Stage II has been introduced voluntarily by some large supermarket chains. The main difference from the USA is that the legal requirements are nation-wide although some countries are excluding petrol stations with low Is it possible that the introduction of large carbon canisters in the USA can turn back the wheels in Europe?

Several technical questions have been discussed in detail. For some time there was a degree of uncertainty as to whether these problems could be sorted out. Just now, immediately before the mandatory introduction in the USA one can see it more clearly, in particular.

Is vapour recovery with large carbon canisters compatible with Stage II active YR system?

What are the safety risks in the event of fresh air being drawn into the UST during vehicle refuelling with YR systems?

What are the general refuelling problems encountered when conventional nozzles are used?

It is necessary that a slight excess pressure is being created around the canister area in order to force the I-IC vapours into the carbon filter. The vehicle filler neck has to be sealed so that the vapour does not escape from the filler neck area. In this respect one has to differentiate between mechanical sealing and liquid sealing.

The mechanical sealing uses a lip seal or an elastic seal. The internal diameter depends on the elastomer used and is normally just under 21 mm. As only unleaded petrol is permitted in the dimensions for __ spouts other than unleaded spouts me not necessary. A tmal decision as to whether the vehicles arc_ only sold without a restrictor has t Ye t been made. Vehicles supplied in countries such as no Mexico still have lo have a restril'tor. With German vehicle models one has to bear in mind that they are often pid.ed up in CiL'rlllall) by A11ll'rican n1stomers. Without a restril'tm some refuelling prnbkrns occur.

The ( lerman car rnanuLtcturers ML'rcL'des and Audi l!SL' a mechanical seal Liquid seals art' ollned as an option BMW as \\ell a.s all AlllL'rican car manulaL·turns rL'iV on tht'

liquid seal. With this system the ID of the filler neck has been reduced to approximately 20mm, situated 20-25mm below the fill neck inlet. Some manufacturers use filler necks with an ID of approximately 23mm along the entire length.

With both the reduced and the nan-ow fill pipe version the fuel flow causes a Venturi effect through which the HC vapours are transfen-ed into the carbon canister. The Venturi effect does not occur with low flow under I 5 l/min. At high flow rates above 40 l/min blow backs ("spit backs") and premature shut off of the nozzle may occur depending on the configuration of the fill pipe.

Malfunctions are possible during the refuelling process with vehicles fitted with large carbon canisters. The suction effect of the active vapour recovery system is working against pressurising the hydrocarbon vapours and in doing so partly or completely shuts off the efficiency of the large carbon canisters.

One has to distinguish between different nozzle makes. With nozzles such as the European ZVA 200GR where suction occurs at the upper part of the spout, such problems cannot occur as the suction takes place above the mechanical seal position. Air is sucked in.

With American type nozzles, where the suction occurs at the top of the spout area the suction area is under the mechanical seal. HC vapours are sucked in by the Stage II system. It does not have a negative influence efficiency results as the vapour recovery system rs m addition to the carbon canister.

If the ZVA 200GR is used with mechanical sealing filler pipe one has to consider front part of the. spout is 2lmm OD. The middle sect10n 1s only 19.3mm. This means that the mechanical seal with a diameter of 21 mm does not seal on the ZVA 200GR spout. As the ZVA 200GR nozzle is available in the USA this fact is not very important.

We must emphasise that if Europe were to introduce large ·b '"tni'stei·s with mechanical seals at a later date the ca1 on c, ·t· 1 'li' se·ili'nu would have to he raised again. In Europe ques 1rn ' "' there is a clear preference for the ZYA 2000 R vapour recovery nozzle. Alterations to the spout dimension can he ruled out. as this would invalidate the efficiency apprnYals for the vapour recovery nozzle.

The prospects for introducing large L·arhon canisters to Europe looks poor. With active YR systems. suctinn occurring at the upper end of the spout causes pure air lo he sucked hack into the UST during filling nf vehidcs with large carbon canister-..

A closer L'Xarnination as ttl whether a .sal"ct) risk L'otlld lll'l'lir around the area of thL' no11le. the \ aptlur linL's and till' l 1ST"s has not YL'l heL'n L'Slahlished. L'\11L'I'ls takL' till' \in' that till' '->akt\ risk'> arL' n\ll IllLTL'asL'd dttL' t\l till' raptd '->aturatitln \ll the air in thL'SL' areas. This L"';t1mal1\ln h\ tlw SalL'l) autlwrilIL's is mit indisputahk. '[\\ ll l 'S petrol dispL'nSL't manulaL"turL'r" arc \)I thL' llj1Illl\lll \\ ith till' liquid at till' tllp part lll the filk1 IlL'L·k L'\pl1l'->l\L'

vapours can be formed. In the event of these igniting, the flame could be drawn into the UST through the vapour recovery lines. Both the US dispenser manufacturers have pointed out these concerns in an open letter to the American safety authorities.

During the introduction of Stage II vapour recovery in Europe long discussions took place as to whether the recovery lines should be fitted with flame arresters in Zone0 for the transfer of explosive mixtures. In Europe it was decided mainly in favour of these protections because an alternating operation can occur. After refuelling cars with recovery of HC vapours, containers and motorbikes can be refuelled where almost pure air is sucked back. It is possible that explosive vapour mixtures can form this way.

Such a process can also take place if one allows vehicles large carbon canisters to be refuelled on petrol stations equipped with Stage II active YR systems.

. As flame arresters are in use and the vapour recovery Imes are laid out as Zone 0, there should be no hazards.

It should be emphasised that the combination of vehicles '."'ith Iai:ge carbon canisters and active YR systems in Europe is not JUSt a pure academic matter. As already mentioned the American motorist often collect their vehicles directly from the European factory combinincr it with a holiday which could bring them to different countnes 111 Europe where they still sell leaded fuel.

The question of compatibility of large carbon canisters With active YR is often raised in American technical Journals and in discussions. This question has to be put more precisely. As described earlier, there are no drastic objections to the use of active Stage II YR systems for vehicles with large carbon canisters in respect of efficiency and safety. but it is likely that the nozzles will not operate properly on vehicles with large carbon canisters. The Californian Environment Protection Agency issued an ex_tens1ve study about this in 1997. Jn January and February this year a total of 20 American YR nozzles were tested on 17 test vehicles (including Mercedes, BMW, Audi and YWJ on 8 different petrol stations. In nearly 300 combinations, more than 1200 refuelling procedures were carried out and assessed.

The American tests showed that there were refuelling prohkms in Y:Yr of all cases due mainly to premature shutting-off of the noule. This can happen if the sensing port of the automatic shut-off is in an area under pressure or if there is a vacuum. Due to the narrower filler neck with liquid seal. splashing may occur which will lead to the noz;Je shutting oil prematurely. I 'Yr of the cases were due to overfilling. especially when "topping up". It is conspicuous that the American study only included a few test dealinu with lopping up of the tank. These cases are not mentioned Ill the final statistics.

Wit/1 lhc /YA 1101.1les no premature shut off was l<>1111cl wl!c11 lt'sll'.cl hy ( lerman car 111a11ul"aclLll"L'.rs Here ii !urns (liil lo he an advantage that the /VA 200<iR 11oz1.le Wiiii Jh /(J '111111 ()f) -;poul dues 1101 '>l'al tightly in the 2lmm

diameter mechanical seal used with the large carbon canister. The ZVA 200GR nozzle therefore is basically operating under normal pressure conditions.

The American authority that carried out the test in California said that no fundamental problems had arisen. Nozzles with frequent premature shut off had their approval withdrawn.

The large carbon canister manufacturer designed the unit in such a way that they can be used for the entire life expectancy of the vehicle without any need for repair or maintenance. Approvals are given once they can show an efficiency rate of 95%.

Critics have claimed that the carbon filter presently used can not maintain this degree of effectiveness throughout the entire life expectancy of the vehicle. They also _have whether the filter can cope with the other add1t1ves Ill the fuel other than the HC. This report can not say whether or not these doubts are founded as appropriate tests are lacking.

The prospect for the inevitable introduction of large carbon canisters into Europe is poor for several reasons. One cannot help thinking that the American environmental authority forced through the requirements for the large carbon canisters despite existing technical objections. Obviously there is a view that unanswered questions will be solved in the field at a later stage. The California Fire Marshall's Office is examining the fire risks. which could result from low concentration of HC vapours. The results can be expected by the end of the year. A private independent test institute has also been asked to whether a possible over pressurisation of the UST will release emissions, which will reduce the overall efficiency. These results can be expected in 1999.

For Europe one has to consider if one should only permit refuelling of vehicles with large carbon canisters in those countries where vapour recovery is laid down as Zone 0 because of safety reasons. The large carbon canisters should only he used in Europe if a restrictor for leaded petrol is fitted. Tests carried out in the USA showed that the sensitivity of nozzle shut-off increases significantly and causes the nozzle to shut off too early and too often. These disruptions are extremely annoying for the motorists and should not be underestimated.

With regard lo efficiency one must emphasise that Stage II and the smaller carbon canisters are meeting the functions of the large carbon canisters. Other than in the USA. the European countries demanding YR introduced it nationally. An expert from the German Ministry of the Environment made the tel Ii ng comment: ""With smal I carbon canisters and Stage II we already have the hell for the trousers. why do we still need a pair of braces·>"

Furlherlllorc we have to avoid adding unnecessary expenditure during a time where there is not much 1rnmey about. The situation in the l JSA i-. completely unsatislaL"lory. Stagl' II sy-.tem-. have yet l" he 111s1alkd 111 "'illL' pollulL'd

areas and after a couple of years will be obsolete. There are reports that the "non-attainment-areas" tripled in July 1997 from 40 to 120 and will probably rise to 200 in I 998 according to the latest decree from the EPA. The oil company syndicates are up in arms against equipping the local filling stations with Stage II and have submitted proposals against it to Congress and the Senate (Supreme Court) of the United States.

After all, the introduction of the large carbon canisters must also be assessed from a political point of view. Here we have very important arguments against introduction. In Europe an EU-directive would be required in order to

introduce large carbon canisters. Several European countries have started to adopt Stage II or are going to do so. These countries will not change their view. Their law making procedure is long and awkward. In view of the known facts strong opposition can be expected from the European car industry. From a realistic point of view a period of between 7-10 years from initial discussions to converting a directive into national laws seem quite realistic. Up till now no European commissions or teams of specialists have shown any signs of tackling the subject of large carbon canisters.

It looks like its going to stay that way.

By Simon White

By Simon White

Annual

Moonrakers, Swindon -5

This meeting was attended by 42 members. The morning session was spent dealing with Branch business and the election of Branch officers. Keith Holmes, Jim Luke, Rory Hennessy and Simon White were elected as Chairman, ViceTreasurer/Branch Representative and Secretary respectively. Other Branch committee members elected were Mile Annie Risbridger and Jack Brinkhurst. Further comn11ttee members are Ph"I M · · 1 onger, the immediate past Chairman and Andy Berry the Nati·o 1 S • na ecretary.

implications of the base on an area designated as Site of Special Scientific Interest. This was followed by a tour of the Depot and training facilities and lunch in the Officers Mess.

In addition to the main meetings the Branch Committee has met four times under the Chairmanship of Keith Holmes to carry out the management of the Branch and once to frame a Branch response to the TCB draft Guidance.

operational lively open

Mike Lugg then gave a p · .d . resentatJon on the review of the TCB gm ance being undertaken tc) fit "tl tl h b · k w1 1 1e new approac emg ta en by the HSE Af f h Hs · te1 lunch Dr Steve Rooker o t e E discussed the 1 1 . . ·d P 11 osophy behmd and the Proaress tow,u s the mtrodti t. e c ion of the nuidance. This was followed b . e Y d very discuss10n.

M eeting on innovations within the i"nd t . . us ry The Churchdhan, Cosham 11 June 1997

At another well attended meeting so b · · mcm crs heard 1Jresentat 1ons f1 om p1 ov1de1 s of new equipment , d , , .in services. In the mornmg heard from Mike Ridgway of Sensor & Systems. Mitchell of S.l.R. International Inc Anrne of w. Risbridger. In tile ·itkrnoon session presentations were oivc 11 l B . ' "' 1 Y nan [)oouett of D. Berry & Co. Bill Warren of The L'l)J", ec- 1- e l'OU rt Channel and Martm Kite ot Eurotest.

Visit to The Army Base and Distribution Agency Petroleum Centre West Moores. Wimborne 22 October

At thl' in\ilalion ol the Co11111ia11da11t. Lt-C11I P. .I. Taylorson RLC '. thirty memhL·rs were given a prL'SL'11latio 11 un the history and work of the l"L'lltre and thl' environnwntal

t g will be held on 14

The Branch's usual Autumn mee 1 d t et aside for November January 1998 as the ongma a e s · 1 h NEC Senunar and Exh1b1t1on. was found to clash wit. 1 t e FCDA Welfare Fund Over fifty members will attend the L . . II 1 hear six presentat10ns on the Sports Ground m Ewe o II 1-ecovery systems. subject of Stage vapom ·

1 , 1 , 1d 1t Moonrakcrs. Swindon on The AGM will agarn K le ' · M· ·I Following Branch bus111css, Wednesday 1 · b the HSE and representatives Pl·ese11t·1t1·l)llS will be m.ide Y I · · ' · ., .· " Authorities on t K' t J:> 't. leum Lllcnsme 1om e I o 1, Stonne Re.,ulat1ons. . . f the new Pet10 t:Ulll, '"' "' 1mplementauon ° . . 1 b, held at which members An Open Forum sesswn will t 1en e can question the speakers.

1• med for June and a site visit· for A further meetmg is P .ii , , · , ·1 , 1 f . ·ill these future mcd11u s w1 I be the Autumn. The detai s 01 '. A · t"t"r. or for . B ·h members. ny o c s . "'cc1rculated to i.inL . 11 t , untdullv rccciVL'd by ·I/ · \'em1es WOll l )L c- ' • • presentations am 01 · · , · , , .· I' "'1tion hv the CommittLc. the Secretary tor consll cl' ·

B.. 1 would like to thank all those who han· hnally the 1,1m 1 • · 1 this vcars 111ec1111gs. II 1s till' q11al1t\ \II u1ven prcse11tat1011s ,1 · ,.. 1 tli·tt continllL'S Ill dra\\ s11d1 -..tr\ll\'' lht'se prescnta 1\lns ' tsuppor1 for these events.

During the relaunch of the British Steel product 'Securipipe', I was greatly assisted and encouraged by many in the retail forecourt industry.

Alas due to commercial considerations British Steel have withdrawn the product from their range. '

spent over a year on the project and obtained imtial orders, this was considerably disappointing to me.

Through your editorial could I personally thank all those who took time to consider the clear merits of the product, but commercial considerations must come first and the matter is now closed.

faithfully Frank Hare Operations ConsultantI have just read the slightly pompous and fatuous article from a Mr Nigel Hester in the volume 35 number 4 publication who appears to have arrived on the scene after 30 years as a laboratory technician and is now in the exalted position of a petroleum officer who is if I read between the a little concerned about his future employment. Typically he has completely missed the point and perhaps I could b.e allowed make some comments having spent 36 years 111 the busmess both as a design and senior engineer for the major oil company and 7 years tradmg under my own partnership with a large number of oil companies, supermarket and private dealers as clients.

The basic problem which still exists in the industry is the clear application of a set of design, trammg and operating standards for petrol stations which should have sufficient flexibility to allow development within the industry and be regularly updated hut which clearly place the responsibility for all of these on the developer and the operators whether they be oil companies. supermarkets, private dealers or groups.

As an example we already work to a set of building regulations for the sales building construction which is clear, concise and rarely subject to the idiosyncrasies of the bui Iding inspectors. They are usually trained and experienced in building construction in any case unlike a large number of the P<Ys who have no real petrol station building experit:nce Perhaps you may conclude that this is irrelevant hut in my opinion too many decisions in this business are made without any real understanding of the construction problems. All too often suppliers and nianuracturt:r\ approach till' local petroleum authorities with

the latest gizmo and the next thing we find is that this is now the standard within their area. Nobody seems to have any experience of the practicalities and all too often regular staff changes in Fire and Trading Standards Depaitments leave you dealing with inexperienced and under trained staff.

Havincr to deal with petroleum officers under the d" e f F1"re Brigades Trading Standards JUns 1ct10n o . . · , _. . _ D t Unl.tary Authont1es County Auth011t1es. not epartmen s, . , . h LFCDA some of whom seem to have either to mention t e , · no views or contrasting views on just about every aspect of . . d h · t·on does make for a petroleum 111stallat10ns an t e1r opera 1 · confused and often frustrating time for those us who are trying to develop a petrol station on time, within and commercially viable for our clients. All of this happens 1 , d subiect to local because the regu at10ns are vague an · J • interpretation by the various petroleum officers and the1r authorities. All too often in the past we encountered th even more ridiculous comment that if they do that in Manchester or the LFCDA then we certainly do not do that here.

Clients cannot understand why having submitted a full and detailed set of drawings for approval all we. receive in reply (assuming their admin dept is funct10nmg properly) is a vague letter which usually contains the caveat that everything is of course subject to site visits by the PO and the HSG 41 document. This effectively gives the PO carte blanche and all too often we agree to can-y out work which is unjustified and unnecessary but to ensure the project stays on contract time and under pressure from th.e marketers we acquiesce and frankly for years I suspect ml company engineers and developers have always e.nsured sufficient contingency is built into the construction to allow them the luxury of meeting these extra costs it arise. Anything for a quiet life and keep the marketmg department off your back.

I can think of many examples I have had to deal with over the years. Pressure testing of tanks after installation springs to mind. Why when the tank manufacturers test back in their factory under safe and controlled conditions and issue the certificates do we then have to a1Tange for further tests after installation on site and before backfill'? The ground is open and the tanks are unfilled and have no surround although strapped down but still at the mercy of any water table problem although this can be alleviated by filling the tanks with water but this could be a further complication on new petrol station sites where access to a water supply is difficult. I cannot believe that a ride on a lorry trailer and a lift into the tank pit excavation is going to render the tank unable to hold pressure and it is a highly dangerous working practice carrying out this test with boards laid over the tank curvature to provide access to the tank man ways for the pipe work technicians. One slip and they can easily fall into the narrow gap between the tanks. Some authorities still insist that it is done hut other don ·1. Why the variations·) Oh for some consistency and understanding of the practical prohlems

These regulations do not have to be highly technical or complicated but to recognise the fundamental dangers of petrol and it's vapours and to clearly state what these mandatory obligations are. Alongside this a Code of Practice should be published which should provide guidance based on current knowledge and up to date procedures but this should not be mandatory nor should it concentrate solely on one type of procedure. It should be updated to reflect the ever changing scenaiio.

I appreciate that an enormous a mount of work is beino e done to produce such a document but in my opinion for it to be successful it must be updated regularly. As a comparison boat owners usually have to purchase each year an upd ated almanac which reflects the changes in annual tides, buoy s, harbour facilities etc and this is usually sponsored. Much of the information stays the same each year and only that which is likely to change is iss ued as an updated amendment in loose leaf format. Surely it would not be so difficult for th e regulators to issue re g ul ar update s which would be financially self funding with an annual fee payment paid b y those in the mdustry who need to ensure they are up to date with all the new development and regulatory requirements.

In conclusion and in re spo nse to Mr Hestor ' s comments that petro.l stations designed and bui.ld today are potentially a much hi gher nsk than the small lei surely attendant-served version of an earlier era both naive and clearly demonstrates that 30 years 111 hi s laboratory ha s not

provided him with any experience of how the old petrol station sites used to work. He should have been a petrol station engineer 35 years ago or even a petroleum officer to see how the standards have improved out of all recognition.

Of course the new petrol stations are much safer ; they are built to much higher standards and specifications; operated by better trained staff; achieve higher environmental standards; handle much higher fuel throughputs as well as a whole variety of peripheral activities including car washes , convenience shops etc. All necessitated by the erosion of profit margins on fuel , customer expectations and new environmental legisl ation and a host of other market driven forces.

To state that the earlier era of petrol stations were a lower risk shows a head in the sand attitude and a complete i onorance of the old operating standards. Perhaps the old alsation dog roaming around the forecourt and the oily overalls huno on the shop shelving is where we should be headino. God forbid!!! Get into the millennium Mr Hestor and o:r off our backs. Get the legislation changed 0 d 1 h · dust:ry oet on with updated with clear gmdance an et t e m e the job that it has been doin g very successfully for ovei 50 years.

Yours sincerely W. G. Warren

· · ngineered vapour Vapa-Sava is a precision e ·th the h. h meets w1 retention system w ic d 's oil industry. exacting demands of to ay valve engineering Tested by Leeds to conform to department, tly tested by the 857244 and. for flow rate National Engineering a. and performance criteria. effectively retains a The Vapa-Sava system f heavily saturated substantial amount 0 tanks where they vapours in the both the should be, therel Y d the environment. operators bank ba ance an

IFor morre information , 896800 or write to us at call 01902 d Morlock House , Vapa-Sava , Wombourne Nr Bridgnorth RoWVS OAL; or just put your Wolverhampton . 0 0 I 902 896104 and /I letterhead on a fax t tafAPA we will do the i·est.

Plastics have during several decades replaced steel in piping systems and been approved in heavy gas and water applications where life time tests indicate at least 50 years of service life. Plastic pipes found a new application area in petrol stations in the early 1980s and is now installed at near 10,000 filling stations in more than 50 countries. Pipeworks of plastics is the preferred system for most oil companies, but are still not fully accepted by the authorities in all countries. Though plastic pipework is the preferred system by most oil companies, the authorities in all countries do not yet fully accept this solution. A debate is currently raging on the necessity whether the pipe needs to be conductive or not, and what are acceptable permeation levels.

International studies on standards for plastic pipes, tubes and fittings have been carried out during 50 years. As soon as available, plastics like PVC and polyethylene were recognised as cost effective alternatives to steel first in plumbing and later in the water and domestic gas industry.

Rigid PVC for ground and indoor sewage piping turned out to be a revolution in the plumbers business, and a threat to the traditional workmanship. Unions in the US even combated the introduction of plastic pipes. However, advantages like resistance to corrosion, lightness and above all fast installation opened an extensive market for plastics piping.

High-density polyethylene (HDPE) was introduced in 1957. HDPE provided higher stiffness and toughness, better chemical and creep resistance and lower gas permeation than the earlier known low density polyethylene (LDPE) and found wide use in blow moulded containers and extruded pipes. When the HDPE pipes capability of withstanding high pressures was shown and accepted the plastics piping market grew even further. By environmental reasons PVC is now successively substituted by polyethylene in several applications and a considerable growth is expected for polyethylene pipes in the future.

General basic and application standardisation for PEpipes has been performed alongside with complimentary commercial and military specifications as well as hallmark codes developed by gas. water and sanitary authorities. Standards and codes arc based on the well known structural heha_viour of polyethylene and comprise pipe series with nommal diameters between about I 0111111 to fully I 000111111. Standardised pc I ·th 1 · d t·· · • > ye Y ene pipes an 1ttmgs encompass gas and water supply, hot water resistant drains, buried drain and sewers et 'l'l · c. 1e systems are generally cxpected to have a service lif 1· 1 c e o .it east ,() years at nom mal pressure when transpon ing • wate1 at 100111 temperature. fh1s has heen proven hy ·t d" 1 . s u 1cs on ong term hydrostatic strength <LTHSJ. Pl>p1pes ar .. 11 · . . . ,.. . e .u.su<1 y UV-stab1ltscd with a few percent ·'11 hon black. Diameters up to 160111111 arc delivered in

m ring bundles or on cable drums. Above these diameters in fixed lengths of 6m to l 2m.

Kungsors Plast AB, Sweden has been manufacturing plastic products since early 1950s. Pipe extrusion became a main business in I 978, when the company started to manufacture polyamide fuel lines for the automotive industry. A new area in the fuel line business turned up in the early 1980s with the growing environmental problems with leaks from corroded steel pipes at petrol filling stations. In comparison with cathodical protected steel plastics should not be corroded in buried fuel piping installations. Thus, the company carried out an extensive investigation with different polymer materials and co-extrusions and favoured MDP-E, medium density polyethylene, for further developments.

Polyethylenes are chemically inert materials and a polyethylene liner system should at normal conditions remain chemically intact throughout its life. However, from the physical point of view they soften and swell when exposed to petrol especially in the presence of ethyl- and methyl alcohol and the permeation of volatilise is rather high. The car industry met the same problems a decade earlier in their development of blow moulded polyethylene tanks.

Mass-produced polyethylene fuel tanks were introduced in VW Passat in November 1973. Short serials of blow moulded HPDE-tanks had then been tested by Porsche since I967 and were approved by authorities 1969. SAAB introduced blown PE-tanks in I 974 and Volvo in the 760 model 1986. The plastic tanks turned out to be superior to the conventional steel tanks except for the emission of petrol vapour. Today, 70% of the private cars manufactured in Europe have plastics fuel tanks. The introduction of plastic tanks has been much slower in the US. much depending on stringent emission standards. The current requirement is a maximum escape of 2g of hydrocarbons per 24 hr measured on the emission from the whole car.

Different barrier layers have been developed to the emission. The insides of the tanks are treated with fluorine (tluorination) which will lower the permeation with a factor of I()() at 40°c. Tanks have also been treated with If 1 1 II 1 b titi··ili·s·ition with ammonia su urtrn>XI( e o owet y ne < • <

1 ·e ·ilso introduced by co- (sullonat1onJ. Barner ayers ai < · hi Id. 1 <>I' multi-layer tanks. Co-extruded extrusion ow mou mg _ b ·II b, n aLlopted in the US. fhe tank wall tanks have a ove <1 ce b ·1 · five hyers with a central may for example he u1 L up 111 < · . 1 . EYC)H ( ·thylcne-vinyl alcohol copolymer) barner o c d · h d h lth si"des of an adhesive layer bonded to san w1c e on < . . · I t I J·iyei·s of HDPE. A further 1s mncr anc ex e1 nd < DuPonts Sclar system hased on polyL·thylene with a nylon additive. When the hlend j,. extruded the nylon Vviil form a

laminar structure in the polyethylene matlix a nd act as an effec ti ve banier. Flumination and Selar have been adopted in Europe and both technologies are under further developments to meet the US emission standards . A new fluorine-based batTier treatment of tanks shows hydrocarbon permeation rate as low as 0.1 g per 24 h. Selar is less effective to alcohol emission but new grades are in development to meet requirements.

Kungsi::irs Plast has tested and evalu ated fluorination and different co-extrusions with banier layers when developing their low emission Petrol Pipe System KPS. Co-extruded pipes of polyethylene with a lining of a Selar system turned out to be the best choice. Not only because of lo w emission but also the ease with which it can be handled when joining parts together. Long term permeability tests for more than 1400 days have been pe1formed. These tests are canied out at 23 °C ambien t temperature by the Swedish National Testing and Research Institute. Alcohol free fuels show a permeability lower than 0.2 g/m 2 per day, which is fai· below the acceptab le limit (coming standards will probably show that the permeability is stati stically significant only at measurements higher than 0.5 g/m 3 and that lo wer values may be regarded as immeasurably low quantities). ASTM Fue l C with 10% methyl alcohol shows permeability somewhat higher. However, new Selai· systems under development are expected to lower the alcohol emission. Ageing of the polyethylene used shows very good results and has been pei·formed by Borealis.

Unfilled plastics are electrical insulators and tend to accumulate static elect1icity until the energy level is high enough to release a spark that may ignite a gas mixture This is why some countries hesitate to replace steel with plastics

NIPS Limited have been Pipeline System Stocki sts and Supp li ers to the Fore_court Industry for the past 1s _years. Ov e r this penod of time , we_ have witnes sed a mynad of h a e s in terms of materi a ls s uitability and sy s te m s c an o · ·ove ments from the trad1t1onal steel pipelme , to a wide 1n1p1 and diversified non metalhc ra nge of products.