The annual seminar at Dunstable has been viewed by many within the Association as a forum for safety, where industry and local authority members debate the issues of today and tomorrow. In view of the number of comments the secretary has had, and from the large attendance and full exhibition hall, the seminar has this year been considered a special success. Papers presented on the day will be published in this, and future Bulletins.

"A view from the Oil Industry" on forecourt spillages (Vo! 27 No3) has produced a response from a petroleum officer in this issue no doubt the debate will continue. The Oil Industry figures on overfills support the claim from the Association that overfill prevention devices will stop a large section of those forecourt spillages during delivery- whoever the fault lies with!

British Petroleum Ltd announced at the A.P.E.A. seminar at Dunstable that they intend fitting overfill prevention devices to tank fills on all new developments and tank installations.

This announcement ties in also with their plans to provide vapour balancing on new sites and places the company in front on commitment to public safety at the filling station.

The APEA has constantly campaigned that overfill prevention devices should be fitted to prevent over filling of storage tanks.

Petroleum Officers come in all shapes and sizes. You have to make the best of a bad job, whether they are strict or lenient, tactful or sloppy, knowledgeable or ignorant, experienced or wet behind the ears.

Alf was a nice P.O. He liked his fishing did Alf, and having got into petroleum found that it suited both him and his hobby and soon saw that he might get to stay in the job until he retired. Soon after he got the job, Alf found himself the senior P.O. since both of his colleagues were reorganised into another department and he then had to guide himself. Gradually, over the years he became fairly knowledgeable if a bit lazy. Take the time a year or so before he retired. On his way to a spot of trout fishing up on the northern end of the country, he called in to one of the farmers with a 500 gallon petrol tank and an old hand wind pump stuck on top. The farmer wanted rid of it to save the licence fee and test costs. Alf gave him the usual advice fill it with diesel or gas oil, have it taken out, but that the usual thing was to fill with slurry. He would send a sheet when he got back to the office.

At the beginning of the next fishing season Alf found himself, with his rods travelling up to the same reservoir. He thought of the farmer, remembering that he had forgotten to post the guidance note, called in to check on the tank. "Did you decide on what to do with your tank, I can't whether I sent you one of our guidance notes"

Not to worry lad, I did as you said took the top off and filled it, come over and have a look"

Alf did. As he got to where the tank was he smelt something was wrong, "What did you fill the tank with"?

"Slurry like you said, from the pig shed from over there" If only he had posted the guidance note.

IVOR STILSONRichardson, the Proprietor of the Chapel House Filling Stat10n West D t N · · en on, ewcastle was prosecuted under the Petroleum (Co I'd · . nso 1 at1on) Act, 1978, for storing petrol at the Garage without a licence had expired and two reminders had been sent but the licence had not been renewed.

M.r Richardson pleaded guilty. His Solicitor said an application to renew the Iicence had been put in the post after first reminder had been received. A member of staff had then mistaken the second reminder for the renewed licence and had filed it.

Mr Richardson was fined £200 and ordered to pay £20 costs hy Newcastle Magistrates' Court on 30 May 1989.

Smith Fiberglass Products Inc. has introduced a new double-wall secondary containment fiberglass piping system for the petroleum marketing industry, according to Richard H. Hickman, executive vice president, marketing.

The DW Quickset ™containment system is currently available in 3" and 4" diameter sizes and features a rapid cure adhesive. Developed for fast installation, the adhesive will cure in 20 minutes at 75°F and approximately 90 minutes at 45°F. No heating collars are required.

No nuts and bolts are needed for installing the new containment system which is chemically resistant to all alcohol blends, and more cost effective.

The system is pressure-testable at installation and can be retested as required.

Smith Fiberglass Products has served the petroleum marketing industry since 1968 when it was awarded the first UL Listing for fiberglass pipe for conveying petroleum products underground.

"We share the concerns of our customers in protecting our environment as well as meeting new regulations," Hickman stated; "The DW Quickset system will give our customers an economical answer to those concerns."

Smith Fiberglass Products manufactures fiberglass reinforced piping systems in 1" through 48" diameters for a variety of applications in many industries including chemical and petroleum.

Smith Fiberglass Products are available from Plastic Design & Engineering in Cheshire 092 576 4221.

A woman customer was turned into a human fire ball at a Norwich filling station while filling up her car. She was in intensive care after suffering from 50 per cent bums to her upper body.

There were strong indications she had been smoking as she filled up the car with petrol.

A Norfolk fire prevention spokesman said this was the second incident in a week in Norwich. People became complacent they fill up the car regularly with petrol and forget what a hazardous substance it is.

The suitability of alloy internals for petrol tanks has been brought into question in recent months and the problem of them turning and "dropping off' into the tank has reported in the Bulletin by both petroleum licensing authorities and also installers. The fact that this occurs creates a safety hazard at the fill point as there is no liquid seal and the tank contents vent to that point.

Another problem that has also arisen is the splitting of the internals which once again causes a failure of the liquid seal.

The photographs attached shows an internal which has been removed from a tank last month. It has been damaged and split by the action of the operator of the site who when reading the dip stick, bends the stick over and in fact the end digs into the alloy internal. How many sites exist like this?

It is time that installers and Oil Companies consider requiring that:-

]) Internals are to be installed and removed from the tank top, without removing the lid or flange

2) Dip sticks are not permitted to be left in tanks where offset fills are used.

3) A stronger material is used to prevent the damage illustrated in these photographs.

THE REAL PROBLEM IS THE OIL COMPANY ATTITUDE. A PETROLEUM OFFICERS VIEW

On reading the paper in th e last Bulletin giving an Oil Industry view, l along w ith colleagues in my County felt some response was necessary to further the debate.

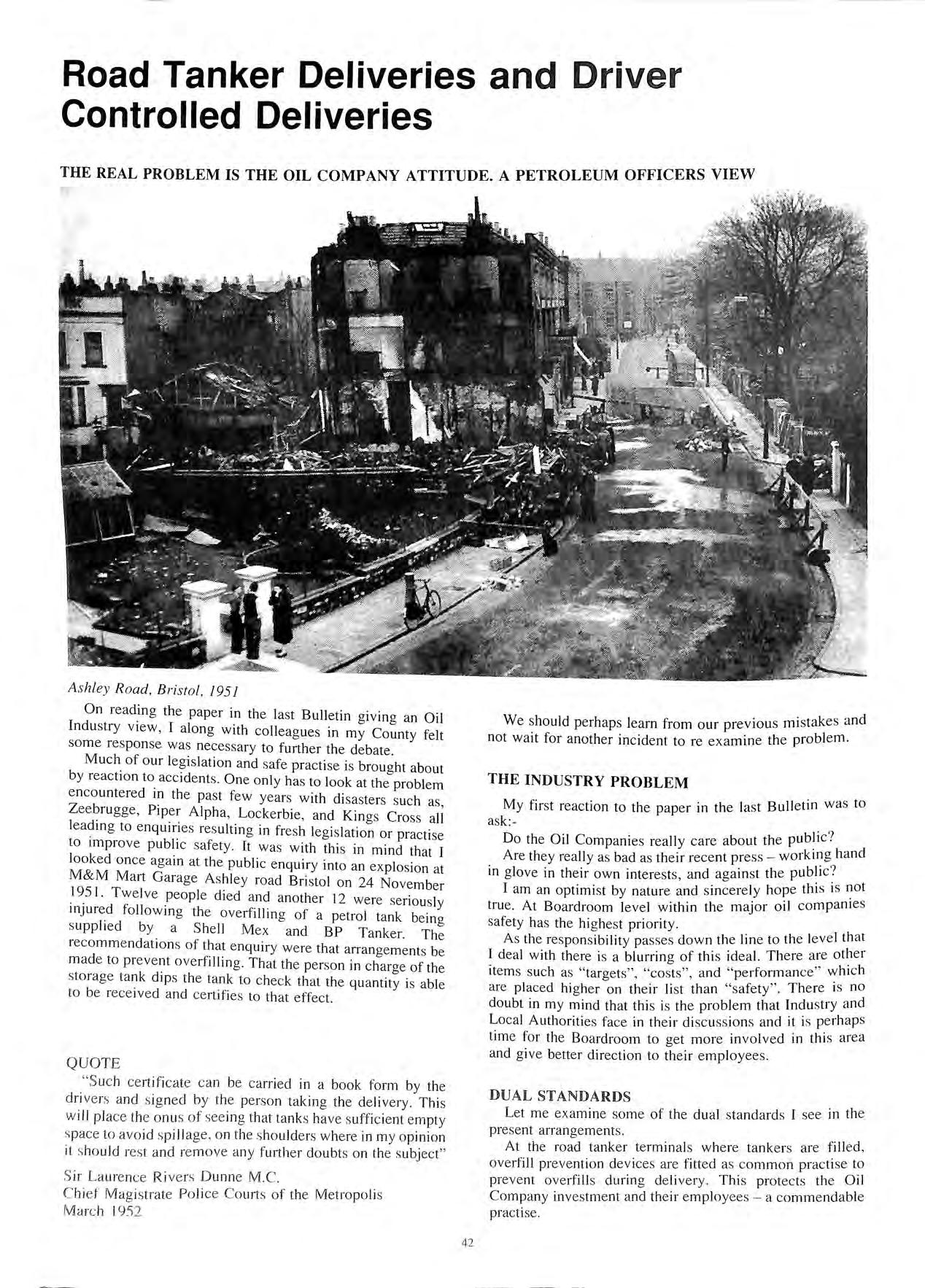

M uch of our legis lation and safe practise is brou ght about by reaction to acc ide nts . One only has to look at the problem e nco untered in the past few yea rs with disasters such as, Zeebrugge, Piper Alpha , Lockerbie, and Kin gs Cro ss all lead in g to enq uiri es re sultin g in fres h legis lation or practise to improve public safety. It was w ith thi s in mind that I looked o nce aga in at the public enquiry into an ex plo sio n at M&M Mart Garage As hl ey road Bristol o n 24 November 195 1 Twelve people died and another 12 were seriou sly inju red fo ll ow in g the overfi llin g of a petro l tank being s uppli ed by a S he ll Mex and BP Tanker. The recommendation s of that enquiry were that arrangeme nts be made to prevent overfillin g. That the person in charge of the storage ta nk dip s the tank to c heck that the q uantit y is ab le to be received and certifi es to that effect.

"S uc h certificate can be carr ied in a book for m by the drivers and s ig ned by the person taking the de li ve ry. Thi s wi ll p lace the on us of see in g that ta nk s hav e suffi c ie nt e mpty space to avo id spillage , o n the shoulders where in my opin ion it s ho uld res t and re move any furth er doubts on the s ubject"

S ir Laure nce Rive r s D unn e M.C. C hi e f Magi strate Pol ice Co urt s of the Metropo li s Ma rc h 1952

We

· k sa nd

s

. h I t Bulletin was to M y first re ac tion to the pape r 1n t e as ask:- bi" 7 Do th e Oil Companies re ally care about the pu _ic · h d . workmg an Are they reall y as bad as their recent press 7 in glo ve in the ir own interests, and again st the . · I h pe thi s 1s not I am an opt1m1 st by nature and since re Y o . true. At Boardroom level within the m aj o r oil comparnes safety has the hi ghest priority· 1tl t

.

As the responsibility p asses dow n the line to the lev e 1 a. I deal w ith the re is a blurrin g of thi s ideal. There are otheI items such as " targets", "cos ts", and "pe rformance" which are placed hi gher on their li st than "safety " . There is no do ubt in my mind th at thi s is the problem that Local Authorities face in their di sc uss io ns and 11 IS pei h P time for the Boardroom to get more inv o lved in thi s area and g iv e better direction to the ir em plo yees.

Let me examine some of the dual standards I see in the pre sent arra ngeme nts

At the road tanker te rmin als wh ere tankers are fi ll ed , overfi ll prevent ion devices are fitted as common practi se to prevent overfill s during deli very. Thi s protects the Oil Co mpany in vestment and the ir employ ees a comm endab le practi se

should perhap s learn from our previou

m1 sta e not wait for another incide nt to re examine the probl em

"'""

At th e pe trol filling st a ti o n th · a d e vic e, w hi c h if fitted not o nly fit s uc h Inv es tm e nt , a nd their e m lo ees -e I . omp a n y pe rso n of a ll Th p y but th e mo s t 1mpo 11a nt e cu s tom e r - a nd f h publi c ! o t e co u rse the ge nera l

I ca n und e rs ta nd th e re lu cta nce f diffi c ulti es in retrofittin g d e vi ces w h o co mp a nie s ha v in g e n ta nk lid s h b re m ove d I ca nn o t und e rs ta nd th e· ave to e 11 a ttitu de now w h d · a re a va il a bl e o n the m arke t w hi'c h en e v1 ces ca n be re trof tt d ·1 a nd th e wo rk c anied out saf e ly. 1 e eas 1 y

It is tim e th e indu stry re- e xa min e d its sta nd . It w o uld be far more produ c tiv e if D C D is on th ese iss ues. Indu stry to w ork with th e safe ty a uth o rit' to s uc c ee d ,. fo r th e m . ies and not aga m s t

Th e re is a g ro w in g tre nd w ithin the Oil r d . to exa m ine th e ir di s tributi o n ne two rk dn us ti y fo r th e m h a n to s ub c t is wo rk o ut. T exac o , Pe trofi na , th e G If 1 o ntrac t ca rri e d o u t thi s exe rci se how Io n a E 1a ve a lready a nd M o bil d o th e sa m e? A Pe tro le"' L. sso BP , S he ll I um 1ce n s 111 a A tl · 1ap p ily ag ree in g to a n Oil Co mp a n y . · . 0 u 1o nt y I un o pe ration f . D C co uld fmd th a t d e liv e ri es run by a n 0 0 1 D t · d c pe 1ato r with po .1 1a me sta ff a nd o t co ur se w it h bot h . · " 0 1 Y b k ,, pa 1t 1e s pas s 111 a tl uc w he n pro bl e m s a ri se. Thi s s it ua ti o n h as c "'. i e DCD wa s fi rst di sc ussed . ha nge d s m ce

It ha s lo ng bee n th e co m p la int of pe tro le 1 h um 1c e ns 111 a a ut o nt1 es th at th e HSE go t it wro n a w l 1 · "' R "' 1e 11 t 1e 198 I eg ul at 1o n s we 1e 1nt1 od uced. Co nfu s io n fo ll ow d d · I e as nve rs 1ave co ns 1sta ntl y esca ped pro se cut io n w he n co t ·· h n 1ave n1n a t e Reg ul a ti o ns T he HSE nee d to m a ke the t. 1 "' r . .. . . pe 1o e um 1ce ns 111 g a u t ho riti es respons ib le tor e n fo rce m e n t of 1 Re l 1 . d 1 1 t 1ese gu at 1o n s. t 1s sa t 1at co n us 1o n s t ill re i a ns e · 1 D C "' ve n W it 1

D , on the fir s t ove rt ill on a DC D s it e it has beco m e c le a r th_a t t he petro le um li cen s mg a ut ho ri ty ha s no powe r to p1o sec ute t he dn ve r. Pe rh aps u nt il th e HSE ae t it ri a l t I Id 1 · "' 0 1 w e s 1ou a I stop ag ree mg to c oop e rat e w it h thi s expe ri m e n t.

It is a fact th at UK Pe t ro le um Industry A ssoc ia ti o n re viv ed th e Driv e r Controll e d D e li ve ry propo sa ls for cos t sav ing reaso ns, a nd I wo uld no t obj ec t to thi s a s lo ng as safe ty is no t co mpromi sed Th e ir mi stake in m y opinion w as not to in vo lve the A P EA o r Pe tro le um Li ce ns in g A uth o riti es in th ese di scu ss ion s, but res tri ct th ese to th e ir " in ho use" di scu ss ion s s uppl e m e n ted by th e HS E , wh o have no p rac ti ca l ex pe rien ce in e n fo rce m e nt. Th e co d e of p rac ti ce th erefore h as no w id e base d s upp ort fro m sa fety a uth o riti es, w hose co ntribution s if co n s ulted m ay we ll hav e le d th e Indu s try d o wn a more cost effec tiv e route

Within thi s publi ca ti o n th e re h ave be e n num ero us re po rt s o f o ve rfill s a nd p rosec uti o ns , so m e re porte d b y m y ow n Co unt y a nd t he re is in m y o pini o n a nee d to imp rove bot h th e li ce nsee d e li ve r y a nd th e p ro pose d D C D I s up po rt th e a rg um e nt put fo rw ard th a t imp roved trainin g be p rov ided a nd th a t a n ove rfill preve nti o n d ev ic e be fitt e d o n s uc h m s t a ll a ti o ns. I have hea rd a rg um e nt s th a t suc h dev ice s a re esse nti a l o nl y in Urba n areas, b ut wo uld impress up o n m y co ll eag ues in L o nd o n th a t a m arke t tow n in m y Co unt y is ju s t a hi g h ri s k as th o se in th e C iti es o f th e UK.

A no th e r a rea o f co nfu s io n li es w ith th e eq ui p me n t be in g used b y th e co m pa n ie s a t these DCD s ites . S ta nd a rds va ry be twee n s uppli e rs a nd it is obv io us th a t as th ese pro li ferat e co n fus io n w ill re ig n as ta n ke r dr ive rs have to ge t us e d to t he va ry in g s ta ndard s a re cipe fo r a n acc ide nt.

T he re ha s bee n no a tt e m pt to reac h an ind us try s ta nda rd by e ith e r coo perat io n be tw ee n O il Compa ni es or by th e ga uge m a nu fac ture rs

_T he APEA ha s a d u ty to rep rese nt its m e m be rs v iews in t hi s are na a nd in m y op in io n is do in g a gra nd job. m e mb e rs s ho ul d re m e mb e r t hat w he n it co m es clow n to a pub I ic e nqu iry t hat th e fin ge r wi ll poi n t ve ry firml y (as it ha s do ne in ot he r e nq uiri es rece ntl y) to the pe rso n w ho agreed to lice nce t he arra nge me nt s. T he O il companies in t hese cases w ill be fa llin g a ll ov e r the m se lf to ta ke a rap id step back w ard s !

The Association welcomes the following new members

Alan Vail Clive G. Bainbridge Kent County Council

David Harrison Bizley Cleaning Services

John Frodsham Clovemead Limited

Michael G. Piggot Veeder-Root Ltd

Alistair F. Clarke Veeder-Root Ltd

Alan A. Charlton J Sainsbury pie

Granville Ward (Managing Director) Yorkshire Pump & Tank Co. Ltd.

D. A. Hughes Shell UK Oil Ltd

Robert W. Treehy

The Association welcomes the following new members

Alan Vail Clive G. Bainbridge Kent County Council

David Harrison Bizley Cleaning Services

John Frodsham Clovemead Limited

Michael G. Piggot Veeder-Root Ltd

Alistair F. Clarke Veeder-Root Ltd

Alan A. Charlton J Sainsbury pie

Granville Ward (Managing Director) Yorkshire Pump & Tank Co. Ltd.

D. A. Hughes Shell UK Oil Ltd

Robert W. Treehy

. '

The followi ng is a brief history of vapour recovery and vapour balancing, some definitions, basic design principles and the methods that BP propose for installations

The Oil Industry started to look at Vapour recovery about 15 at Terminals when storage tanks had fixed roofs and .a s1gmf1cant volume of vapour was being Jost.

Smee then t.here has a change in emphasis. Tank s now have floatmg roofs m1111mi s ing vapour loss , shifting the source of vapour losses to the loading and discharging of road tankers and vehicles refuellin g at ret a il sites.

The introduction of bottom loading road tankers gave new impetus to the technique.

.This. starting point, combined with important factors g reater awareness of the environment , but also 111clud111g, t.he greater volumes of fuel being delivered to fewer location s with ?reater frequency and changes in the odour of fuel s, cuhrnnated in the need for research and development.

The ability to handl e the vapour at th e te rminal a nd the road. tanker exists, although Re sea rch a nd Development contmues on the mo st effective means of condensino th e vapour back to a hydroc a rbon liquid . "'

The filling station was the nex t area to be addressed.

So far I have refe rred to Vapour Recovery, before proceed ing further I wish to clarify the difference be tween

RECOVERY and BALANCING and to oive so me definitions of th e various s tage s of tran sfer in th e distribution chain.

STAGE la STAGE lb STAGE 2

The tanker loading stage at the distribution terminal. d.

The retail site -de livery stage, the re 1rect1on of the majority of the vapour from the vent stack back into the road tanker. · tor vehicle The retail site pnvate mo refuellin g stage

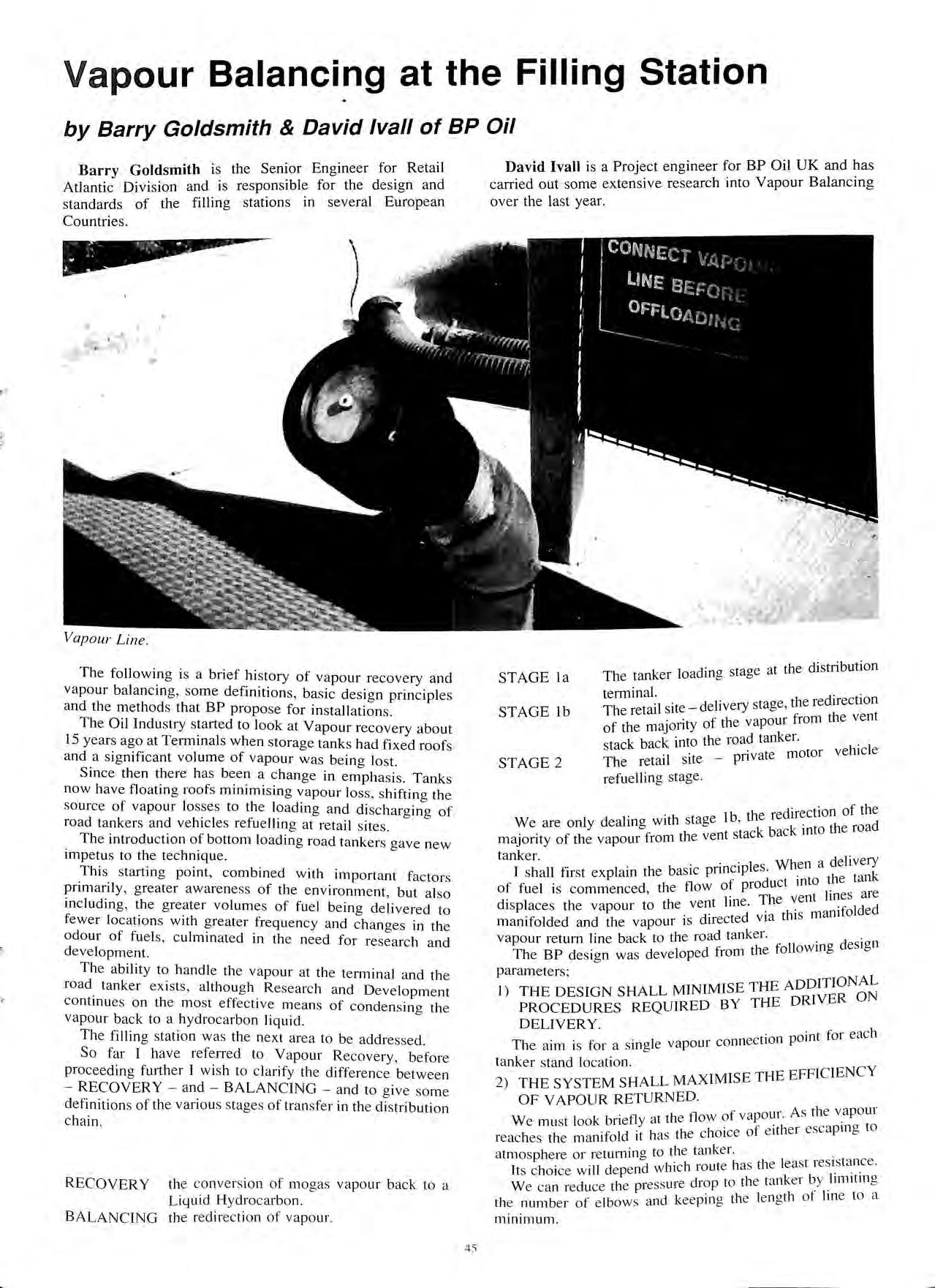

. lb the redirection of the We are only dealmg with stage , . d t ck back mto the 1oa maJonty of th e vapour from the vent s a tanker.

· · 1 s When a delivery

I shall first explam the basic pnnc1p e · nk of fuel is commenced the flow of product into th e ta ' 1· The vent Im es are displace s the vapour to the vent me . . Id d m a nifolded and the vapour is directed via thi s mamto e vapour return line back to the road tanker.

The BP de s ign was developed from the following de sign Parameters · , L

I) THE DESIGN SHALL MINlMISE THE ADDlTIONA PROCEDURES REQUIRED BY THE DRIVER ON DELIVERY

The aim is for a sin g le vapour connection point for eac h tanker stand lo cat ion.

2) THE SYSTEM SHALL MAXIMISE THE EFFIClENCY OF VAPOUR RETURNED.

W e must look briefly at the flow of vapour. As th e v.apour . I · f ·ther escap m 0 to reac hes the m arnfold 1t has the c i o1ce o e 1 "' atmo sp here or returning to the tanke r. . " , ,

Its c ho ice will depend w hi c h route ha s th e least 1es 1.sta n.ce.

RE CO VERY the conversion of moga s vapour back to a Liquid Hydrocarbon. BALANCING the red irect ion of va pour.

W e can red uce the press ure drop to the tanke r hmttm g the numb e r of e lbows and keeping the lengt h ot lm e to a minimum.

We can provide a restriction at the vent top to assist in the flow

There are two methods of achieving this a) A pressure vacuum valve or

B) An orifice plate.

A pressure vacuum valve is a two way spring loaded valve at the vent top. It allows air in but prevents vapour escaping until it reaches a pressure set by the valve (0.5psi).

Our trials show that this system gives 100% return of vapour.

An orifice plate places a restriction in the vent , it is non mechanical and can give 95 % return efficiency

3)

A typical site with an 8 pump limiter may be pumping 300 litres of product per minute.

This product will be replaced by the air entering the vent stack.

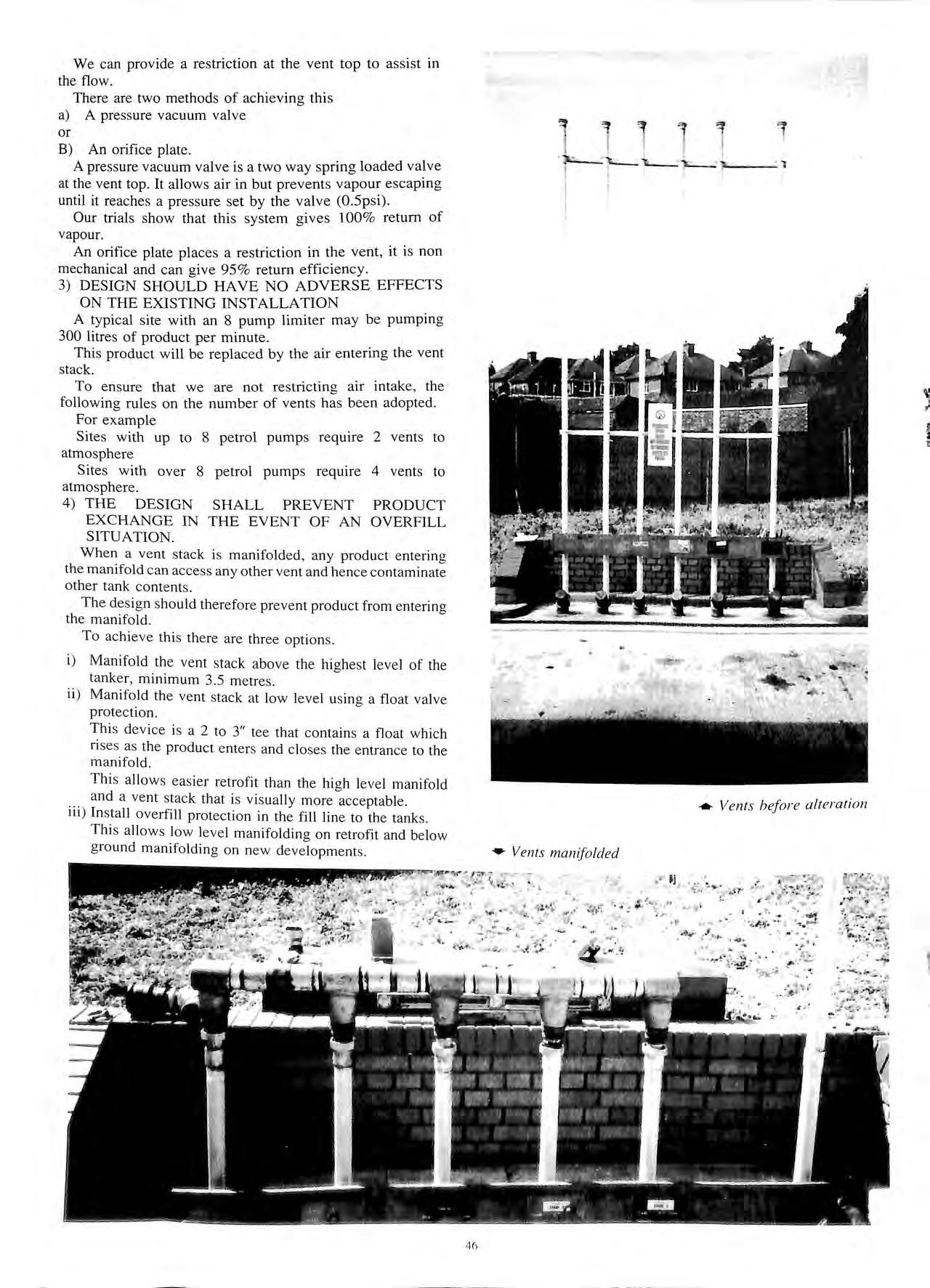

To ensure that we are not restricting air intake, the following rules on the number of vents has been adopted.

For example

Sites with up to 8 petrol pumps require 2 vents to atmosphere

Sites with over 8 petrol pumps require 4 vents to atmosphere.

When a vent stack is manifolded , any product entering the manifold can acce ss any other ve nt and hence contaminate other tank contents.

The de sign should therefore pre ve nt product from entering the manifold

To achieve this there are three options .

i) Manifold the vent stack above the highest level of the tanke r, minimum 3.5 metre s.

ii) Manifold the vent stack at low level using a float valve protection

Thi s device is a 2 to 3" tee that contains a float which ri ses as the product enters and closes the entrance to the manifold.

This allows ea sier retrofit than the high level manifold a nd a vent stack that is visually more acceptable.

iii

) In stall overfill protection in the fill line to the tank s.

Thi s allows low level manifoldin g on retrofit and below ground manifolding on new developments.

• Vents manifo ld ed

• Vents before alteration

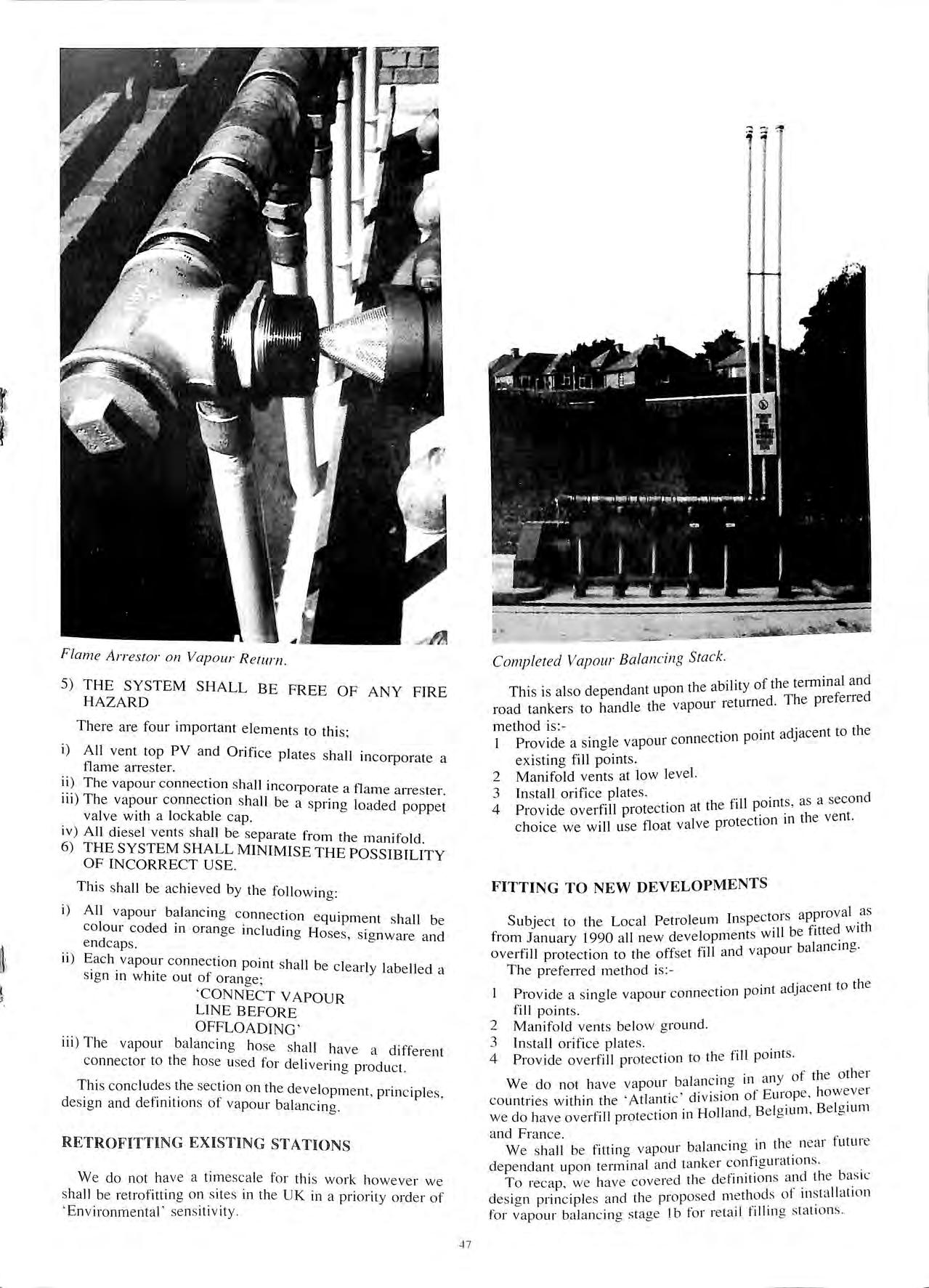

Flame Arrestor on Vapour R e turn.

There are four important elements to this;

i) All vent top PY and Orifice plates shall incorporate a fl ame arrester.

ii) The vapour connection s hall incorporate a flame arrester.

iii) The vapour connection s hall be a s pring loaded poppet valve with a lockable cap

iv) All diesel vents shall be separa te from the manifold.

6) THE SYSTEM SHALL MINIMISE THE POSSIBILITY OF INCORRECT USE

Thi s s hall be achieved by the following:

i) All vapour balancing connection equipment s hall be colour coded in orange includin g Hoses, signware and endcaps.

ii) Each vapour connection point s hall be clearly labelled a s ig n in white out of orange ; ' CONNECT VAPOUR LINE BEFORE OFFLOADING '

iii) The vapour balanc ing ho se s hall have a different co nnector to the ho se used for delivering product.

Thi s concludes the sect ion on the development , principl es, de sig n and definitions of vapour balancing

We do no t ha ve a tim esca le for thi s work how ever we s ha ll be retrofitting on s ites in the UK in a priority order of ' Environm e ntal ' sen s iti v it y.

Completed Vapour Balan c ing Stack.

he ability of the termin al and This is also dependant upon t ed The preferred road tankers to handle the vapour return method is:-

I Provide a single vapou1 conne existing fill points.

2 Manifold vents at low level.

ction point adjacent to the

3 In s tall orifice .plates. . at the fill points, as a seco nd

4 Provide overfill protection rotection in the vent. choice we will use float valve P

I ectors approval as Subject to the Local Petroleum nsp .11 be fitted with from January 1990 all new balancing overfill protection to the offset fill an vap The preferred m et hod is:

1 it adjace nt to tie Provide a s in g le vapour connection pon fill points

2 Manifold vents below gro und.

3 In s tall orifice plates fill oints .

4 Provide overfill protection to th e p _ ·n a ny of th e ot he1 We do not hav e vapour i f howeve r h. I ' Atlantic division o countries wit m .tie Holland , Be lg ium , Be lg ium we do have overfill protection lil and France.

b 1 ia in th e nea r futur e We s hall be htt1na vapo ui a ancn"' · "' 1 d tanker co nfiguration s. de pendant up on tenrnna an ' h I r· ·ri;ns and th e ba s ic T l ave co ve red t e c e mi o re c ap , we l l eel i11ethocl s of in s ta llation .· · l d n e p1opos desi g n p1In c ip es a n 1 fllina stati o n s for vapo ur bal a nc in g stage I b to1 i e tai I ""

The following article outlines the talk given recently at the APEA seminar in Dunstable. It concerns the need for licensing authorities and industry to look to better ways of limiting the fire and explosion risks and environmental damage caused when petrol leaks from one installation.

As you all know there seems not a day goes past when green issues are raised. Incidents such as the Exon Valdez and the pipeline leakage in Merseyside have highlighted the problems and damage caused when petroleum products leak into the environment.

There is much more public awareness and rightly so on environmental concerns. Whilst I am not suggesting that we as licensing authorities and industry will deal with such large incidents, small local leaks cause the immediate community to suffer. Petrol once in the ground is difficult to control and measures to alleviate and contain the problem are costly in both time and money.

At petrol stations we are often dealing with small leakage, maybe_ 1000 2000 litres. All carry a risk of fire and explosion as well as environmental consequences. We are often called to the results of leakage petrol into a basement, a telephone duct, a river, underground railway or even usefully a pub cellar!

can spend, along with the oil company many hours tracmg and ·1llev1·at· th t·· · ' mg e ire nsk when something goes wrong.

The resulting bad pub!" ·t , 1c1 Y can qmckly and easily damage an environmentally consci·e t. . N . n 1ous image. Bodies such as the beatl1onka! R1vfers and the new water companies will oo mg or mancial reco f mpense or damage to water supplies. What I would like to look at is h" I product "I t" f . ways m w IC 1 is os rom a site. Oil companies of course don't have losses only a "negative product" t . s1 uat1on.

There are four mam areas in which d 11 d f pro uct escapes m e ways. rom a site. I shall discuss these and. the poss1 e preventative methods that are ·ivaihbl risks from such leakage. ' ' ' e to limit the

1. Tank and pipework leaks

2. Tank overfills

3. Vent pipe discharge

4. Vehicle tank filling

You will_ read later in detail from the other comprehensive explanations of tl papers, minimise the problems high Ii "ht available to do is show how each one of th e . a ove: What I want to authority an unwanted items giv_es the_ licensing forethought we need not dnd _how with a little more contmue with these losses.

Tank and pipework leaka e is f d I g · probdbly the h1ahest sot11·ce o pro uct oss. '=" • ·

Leakage is the result of corrosion of 111 the construction <it· t· k. , metdls used dn s ctnd pipes.

Trad1t1onally the protection to steelw<ii·k h· . b . as een provided by bitumen. galvan1s111g and concrete stiri·o d I · un . n general we know that this will g1_ve a reasonable service life but who can guarantee the longevity or define the life of sucll. ·t Th . . dsysem.

e mstallat1on is heavily reliant on good workmanship and control during installation.

Leaks from pipes and tanks enter the ground and will

migrate quickly to natural collecting points and sumps. It is often these contaminations that are the first indications of something amiss and involve the licensing authority and emergency services in considerable problems protecting the public from the risks.

There are now technologically better solutions to obviate these losses and these I think should be given serious consideration to replace todays outdated traditional methods of installation. I know there will be cost implications but I understand that 3 1/2-4% of development costs are spent on underground storage and pipework whilst the major expenditure is spent on image. advertising and external finishes so why not spend more on safety There are systems which you will hear more of m detail later that are available now:

I. Double skin tanks and pipes steel or grp.

2. Trench and excavation liners.

3. Non corroding materials grp. poly propylene.

4. Automatic tank reconciliation.

Perhaps I can explain each briefly. . . Secondary containment involves providing a of containment in other words an outer skin which, 1f the inner primary leaks, contains the spillage. The trench and excavation liners provide a controlled environment to contain a leakage. Grp. and poly not corrode. The gas and water industries now use plastics mstead of the . . d 1 d Wh is it that a modem once trad1t1onal steel an ea · Y . . 1 . . d ·. st 1 ·11 archaic usmg stee industry such as the 011 111 ustry IS A t. c tank reconc1hat1on with its corros10n problems. utoma 1 1 h. hout Each has its part is able to morntor stock !eve s t 10ug · to play in stopping product loss.

h th are often Tank manhole spillages are a common sig t, ey as the result of small unavoidable loss but are sometnnes caused by tank overfilling. . · to Spillacre in the manhole migrates and can give nse. 0 · hb Whilst not a major smells and complaints from neig ours. risk they are time consuming and can be haza:dous. ·fi"lls give the sc1me Large spills such as tank wagon ove1 · problems as tank leakage albeit not as a continuing proble_m. · nt practise So how do we stop this problem well our p1ese · is to build a concrete manhole and pass a number of pipes through the walls.

AI( manholes let water in and therefore product _out. I · ht ·111l10Ie Imes me Complete water and petro t1g nh . ·11· >e whv aren t they available which will contam any sp1 ,1g , J specified as standard?

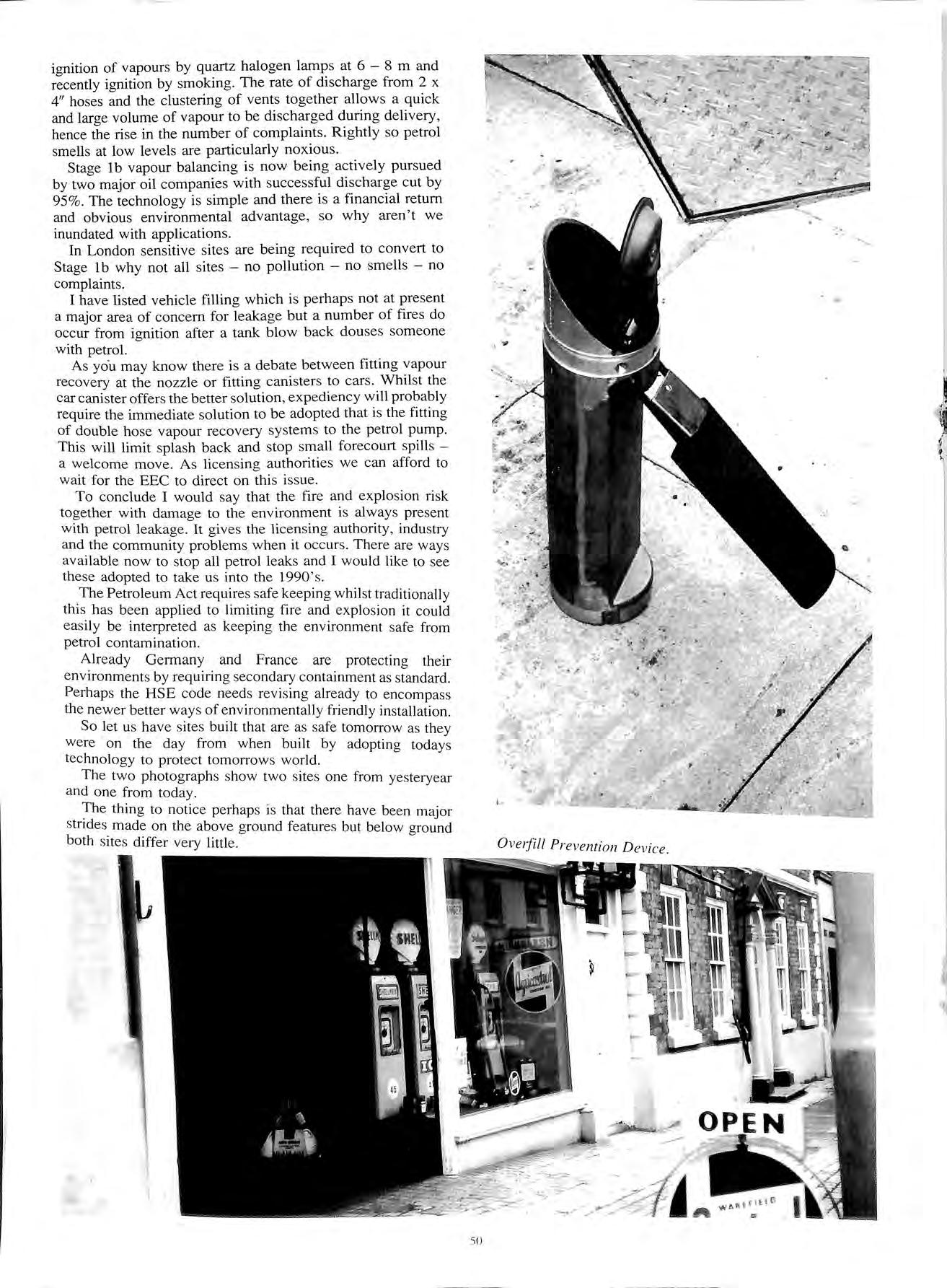

. 1.·ver

Tank overfills can occur for a number ot (ii . . f .1 f auging e11u1pment. All error, hllmg station error. a1 ure o g, .: "t·ve sllttl oft 111 the event can be overcome by httmg a post 1 : , of overfills. An overfill protection device. {see photogi <1ph l .

Vent pipes discharging vapour are an area ot growmg importance for nuisance and fire risk to surroundmg areas. The number of complaints is rising as the public bt'COllll' more environmentally conscious. We in London have had

ignition of vapours by quartz halogen lamps at 6 -8 m and recently ignition by smoking. The rate of discharge from 2 x 4" hoses and the clustering of vents together allows a quick and large volume of vapour to be discharged during delivery, hence the rise in the number of complaints. Rightly so petrol smells at low levels are particularly noxious.

Stage lb vapour balancing is now being actively pursued by two major oil companies with successful discharge cut by 95%. The technology is simple and there is a financial return and obvious environmental advantage , so why aren't we inundated with applications.

In London sensitive sites are being required to convert to Stage 1b why not all sites no pollution no smells no complaints.

I have listed vehicle filling which is perhaps not at present a major area of concern for leakage but a number of fires do occur from ignition after a tank blow back douses someone with petrol.

As you may know there is a debate between fitting vapour recovery at the nozzle or fitting canisters to cars. Whilst the car canister offers the better solution, expediency will probably require the immediate solution to be adopted that is the fitting of double hose vapour recovery systems to the petrol pump. This will limit splash back and stop small forecourt spills a welcome move. As licensing authorities we can afford to wait for the EEC to direct on this issue .

To conclude I would say that the fire and explosion risk together with damage to the environment is always present with petrol leakage. It gives the licensing authority, industry and the community problems when it occurs. There are ways available now to stop all petrol leaks and I would like to see these adopted to take us into the l 990 's .

The Petroleum Act requires safe keeping whilst traditionally this has been applied to limiting fire and explosion it could eas ily be interpreted as keeping the environment safe from petrol contamination.

Already Germany and France are protecting their environments by requiring secondary containment as standard. Perhaps the HSE code needs revising already to encompass the newer better ways of environmentally friendly installation.

So let us have sites built that are as safe tomorrow as they were on the day from when built by adopting todays technology to protect tomorrows world.

The two photographs show two sites one from yesteryear and one from today .

The thing to notice perhaps is that there have been major strides made on the above ground features but below ground both s ites differ very little.

On August 25th the AGM of the Southern Branch of the APEA was held in Swindon.

The m eeting opened with an informal discussion on th e propo sa l to create two branc~e South W estern and South Eastern, in place of the existing Southern Branch. The conclusion of those present was that despite the rece nt questionnaire showi ng 80% .of Southern Branc h m embe r in favour, we needed to establish th e viability of the ex ist in g b ra nch before co ntemplating division.

The formal p art of the AGM was then held , and the following officers were appointed:-

CHAIRMAN MIKE SEWELL, H.S.E. SECRETARY MAC COX, NORMOND INSTRUMENTS TREASURER JIM LUKE, LFCDAThe new committee a nd the m embers prese nt di sc ussed ways to ' rev ive' the branch and fulfil the a im of the ASSOC IATIO N and the Branch.

It was fe lt the fo ll owing act ions were needed:

!) Recruit new m e mb e rs

2) Turn curre nt pa ss ive m e mb e rship in to act ive membership.

To ca rry out this '·miss ion" a Bra nch Deve lopment Co mmittee was formed the m emb e rs of w hi c h are:-

SEWELL cox LUKE DA YID OSBORNE RICHARD GRAHAM RORY HENNESSY BOB THOMSPONtaken up with a f f the day was · . a l pipe

The seco nd hal o FPO of the ir f1b1e o ass b AMERON h n and detailed presentat10n , y . I hardware was s ow e tc An work system. Actua of working pract1c~ I .USA as a1ven . JI at io n 111 t 1e exp lan a t10n w, 0 cl tank 1n sta ' ,, ·c1 o n }Jne a n "D n a 11 R1aht intere stin° v1 eo t·ve view on °1 o "' "' · a aJte1na I gave an inte res tmo

BP Oil (UK) Ltd

PRESENT: Mik e Lugg -_ Burrnah Pe trol e um Mike Ay tes e ncle nt Pump Se rv ices Bill Adams Indep . n FPD Osborne Ame10 David _ Ameron FPD · 1 ·cl Graha m c Ltd Rte 1at Es o Petro le um o Bob Thompson s . S we ll HSE C M1.ke e on _ West Sussex C. · Bnan T hompsH pshire F ire Brigade Fred C lark am . H rnessy LFCDA , . Ro1 y e t L 1 e Forecourt Co ns ult<11K y Bil l L inclop yn e J Luke _ LFCDA im C , No1-111ond Instruments Ltd Mac ox

Dear Editor,

I refer to a letter from Mr. C. Day with regard to drainage channel gratings.

Please find enclosed a copy of a design now adopted by this Authority. Surrey has been using this grating since Febrbuary 1989 with satisfactory results.

Yours faithfully, J.E. Ellis Petroleum Officer Surrey County Council

Dear Editor

PETROLEUM CONSOLIDATION ACT 1928

RE: LETTER TO EDITOR FROM C. DAY (VOLUME 27 NO. 2)

I refer to the requirements of other Licensing Authorities regarding petroleum interceptors as published in the above mentioned "Bulletin".

I fail to see how a petroleum interceptor can be expected to contain the contents of an entire road tanker compartment when under normal working conditions the interceptor will be full of stormwater. The petrol could only occupy the top section of the interceptor chamber to a depth level with the chamber outlet, whereby the petrol would then enter the next chamber and so on until discharging via the final outlet.

Large volumes of contaminant entering the chambers rapidly are also unlikely to separate satisfactorily before discharge into mains foul water course occurs.

No hazardous zones are applied to interceptors and there is no requirement for the interceptor vent to be fitted with a flame trap. I had always believed that an interceptor was only for separating the usual film of contaminant present on petroleum forecourts and I would appreciate any further information offered by Mr Day regarding this matter.

Yours faithfully, M. Redwood Petroleum Officer Gwent Fire Brigade

Dear Editor,

A letter from S. A. Robinson Chief Fire and Petroleum Officer, written in the February '1989 issue of The Bulletin, has recently been brought to my attention.

The _problem highlighted by Mr. Robinson has been something that has concerned this Authority for some time, but with regard only to offset fills.

· It has been the accepted procedure of this Authority to ensure that diprods to tanks are held in the offset 'T' in order that h · a P ys1cal check may be made against the contents the need arise. It was at one time proposed at the d1prod should be checked with the gauge annually to ensure, on the one hand, the accuracy or otherwise of the gauge, and on the other the 'actual' stocks for stocktaking purposes. This proposal, however, was not adopted.

I was aware that diprods held captive in the offset 'T' could c_ause. damage and that, dependant upon the direction of rotat10n, 1.e. clockwise or anti clockwise, the diprod could _the internal fillpipe to 'unscrew' or 'tear' the alumm1um sleeve from the boss. The diprod has also been 'score' on the fittings during rotation and break up.

Smee 1t became accepted that this diprod be held captive I was concerned that after a period of regular rotation, the di prod could possibly bore a hole in the bottom of the tank, especially if it were of metal or had grit embedded in it.

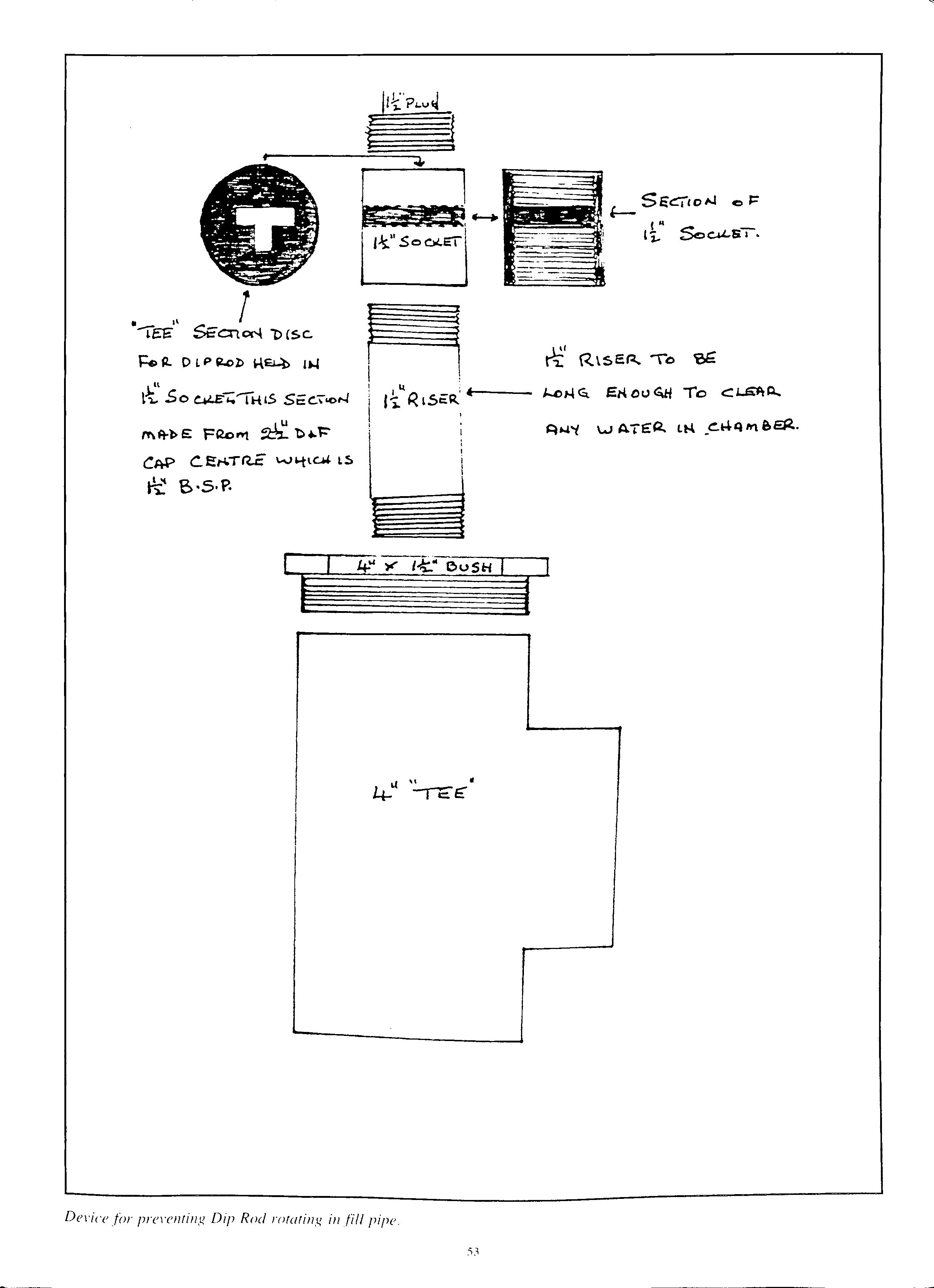

The result of this was that I was sure that this problem was not insurmountable and I enclose a sketch of the device I thought would it. . .

This consists of a 11/2 mch nser placed m a bush in the top of the offset 'T'. This would be_ of a sufficient length to keep the access clear of _any water m the To this riser is fitted a l 1/2 mch T?e T s_ection disc I cut from the main body of a 2 /2 mch dip and fill cap which is machined to I V2 inch BSP thread. The whole is sealed by a 1y2 inch plug. The plug should be "made in" with P.T.F.E. tape in order that the threads can be cleaned easily and the disc removed to dewater the tank.

This method will prevent the rotation of the diprod and allow 'professional' access to the rank for the reasons suggested.

The situation highlighted by Mr. Robinson, however, is different, in that his problem is with a 'direct fill' pipe. I would suggest in this instance that the diprods be made of fibreglass or a similar material and removed during filling.

Yours faithfully, J. E. Ellis Petroleum Officer Surrey County Council

Rory Henn essy, LFCDA

David I va!/ and Ball"y Go/dsmirh, BP Oi l

Rory Henn essy, LFCDA

David I va!/ and Ball"y Go/dsmirh, BP Oi l

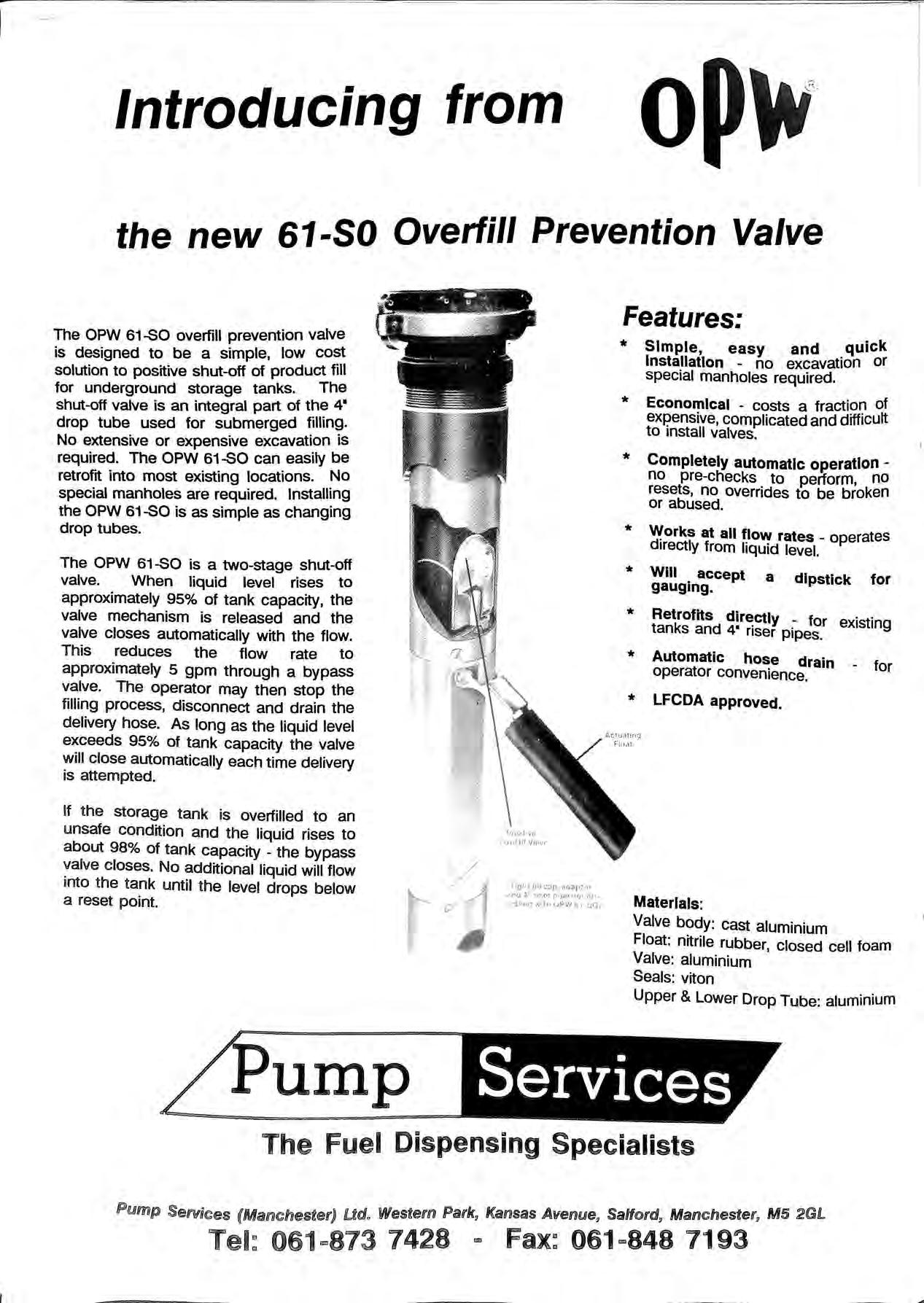

The OPW 61-SO overfill prevention valve is designed to be a simple, tow cost solution to positive shut-off of product fill for underground storage tanks. The shut-off valve is an integral part of the 4" drop tube used for submerged filling. No extensive or expensive excavation is required. The OPW 61-SO can easily be retrofit into most existing locations. No special manholes are required. Installing the OPW 61-SO is as simple as changing drop tubes.

The OPW 61-SO is a two-stage shut-off valve. When liquid level rises to approximately 95% of tank capacity, the valve mechanism is released and the valve closes automatically with the flow. This reduces the flow rate to approximately 5 gpm through a bypass valve. The operator may then stop the filling process , disconnect and drain the delivery hose. As long as the liquid level exceeds 95% of tank capacity t he valve close automatically each time delivery 1s attempted.

If the storage t ank is overfilled to an unsafe condition and t he liquid rises to about 98% of t ank capacity t he bypass closes No additional liquid will flow mto th e t ank until the level drops below a reset point.

Simple, easy and quick Installation no excavation or special manholes required. * Economical - costs a fraction of expensive, complicated and difficult to install valves.

Completely automatic operation no pre checks to perform no resets, no overrides to be broken or abused. * 'JVorks at all flow rates operates directly from liquid level. * Will accept a dipstick for gauging.

Retrofits _ for existing tanks and 4 nser pipes.

Automatic hose drain operator convenience. for

LFCDA approved.

INERT FOAM. THE QUICK INEXPENSIVE 100% SAFE WAY OF INERTING WITH NO PROBLEMS ASSOCIATED WITH WATER SUPPLY AND TANKERING AWAY ETC. OR OTHER COSTLY TIME CONSUMING AND SOMETIMES NON-EFFECTIVE METHODS.

SUB-LICENCES are at the moment being considered to enable Companies to operate this patented process with simple automatic equipment from their own small vans. EXAMPLE: It takes only a few minutes and one cylinder of Nitrogen to totally FOAM inert a 1500 gallon compartment, and so on. The sub-licences, officially registered at the UK Patent Office, will include full training being given in these procedures and other associated ANALYTICAL and NITROGEN services that may be required on the Forecourt, during the Contractors routine day to day work. Training may be undertaken on the Contractors own sites to save staff 'down time' and is simple and non-time consuming. Demonstrations can be arranged on our own glass panelled petroleum vessel.

N_ITROG!£N .INERT FOAM is suitable for 'MOTHBALLING' during periods of shutdown or inert1ng for EXTENDED CLOSURES. After Foam filUng the vessel is sealed off and remains 1 Yo inert with Oxygen content at ZERO, no problems of re-distribution of improperly purged gases, or corrosion etc. as with water fill methods exist.

INE_RT FOAM may be used in most situations for MANHOLE MODIFICATION with product in situ, or if preferred the product may be lifted and quick and simple FOAM inerting may be earned out, before the work is undertaken.

INERT FOAM provides quick and inexpensive inerting prior to manhole removal and slurry f1ll1ng.

NITROGEN INERT FOAM is highly suitable for inerting prior to excavation, and the excavated be loaded .and safely .transported foam filled for disposal if the demolition is not undertaken, Fo_am filled, safety on Foam filled vessels are unaffected by 'Pecker' Perforation or porosity as are water filled vesse and any spirit leakage can be simply blanketed with this process.

NITR<JGEN INER7: FOAM gives 100% safety durin Demolition and as a VAPOUR PLUG •. alterations to be earned out on pipework that has held groduct in domplete safety, in close proximity to hazardous areas. '

We also undertake all other Nitrogen and Hi-tech service associated with the Petroleum and Chemical Industries.

GAS FREEING using inert foam or other nitrog . h · en purging tee mques.

LEAK TESTING by Helium trace and other modern t h · ec mques.

HOT WORK modifications and repairs to Lloyds and ASME.

BOTTOMING and CLEANING, REMOVAL or SLURRY FILLING.

'MOTHBALLING'.

1:1ESIN or glass reinforced, spirit or solvent resistant linings engineered to Lloyds Inspectorate Of Shipping approval. , totally inert or Water Filled conditions, and GRIT ABRASION to S.A.3 using N ®equipment, under totally inert Constant Purge situations.

We/beck House High Street Guildford Surrey GU1 3JF

Tel: Guildford (0483) 38227

OLD STATION : NEW CANOPY SELF SERVICE: LEAD FREE PETROL PETROLEUM COMPANY BACKING WELL INSURED - WE THINK!! LONG TERM INVESTMENT

COAT OF PAINT: NEW SIGN NEW CORPORATE IMAGE

SHOP WITH MARS BARS ON THE RIGHT SHELF FORECOURT MAINTENANCE CONTRACT SOUND BUSINESS WITH ASSURED FUTURE

Corroshield have been lining petrol storage tanks for over a decade endorsing our quality of specification and experience in this specialist field

So what do you do when your t k f . They could be rehab·i· an s ail -Telephone CORROSHIELD (0949 21032). 1 itated and returned to service within 14 days without disruption

Corroshield 80 tank rehabil1tat1on is not a repair or temporary solution: (it is new tanks for old) backed by our guarantees extended for .as long as you require

In any forecourt tank protection should be paramount, as tank failure and subsequent replacement could wipe out years of profits and impose immediate financial burden.

DON'T WAff ff HAPPENS: Ring now for details on how we can provide protection for your underground storage facility at very little cost.

Unit 1, Hackers East Bridgford, Nottingham NG13 8PG (0949) 21032

COMMERCE HOUSE, THE MALTINGS, STATION ROAD, SAWBRIDGEWORTH, HERTS. CM21 9JX Telephone: 0279 723448