c , P . The •

THIS ISSUE ENVIROFLEX PIPEWORK NEW LEAK DETECTION SYSTEMS TANK REPLACEMENT PROGRAMME VOLUME 29

· Journal of the Association for Petroleum and Explosives Administration

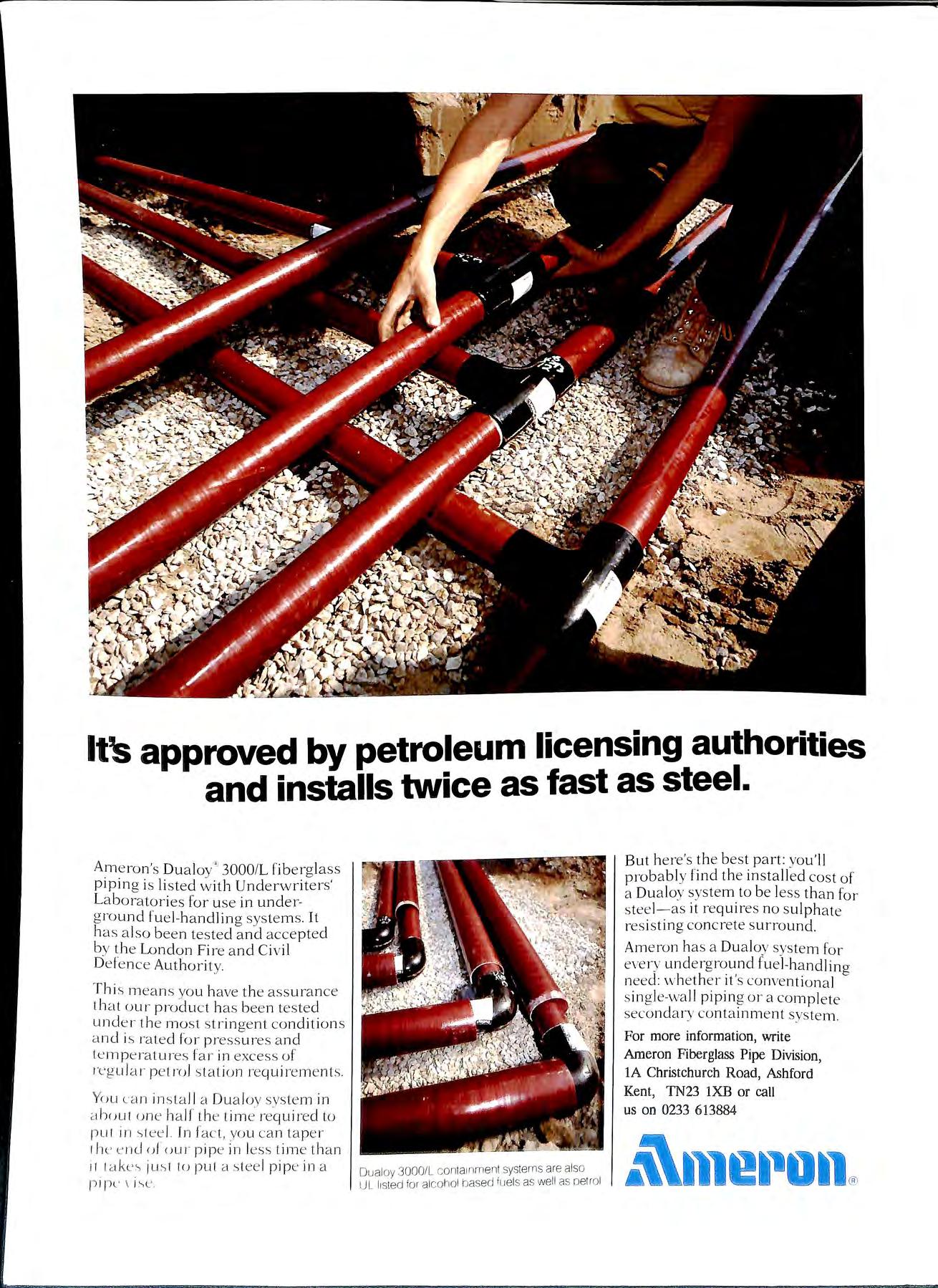

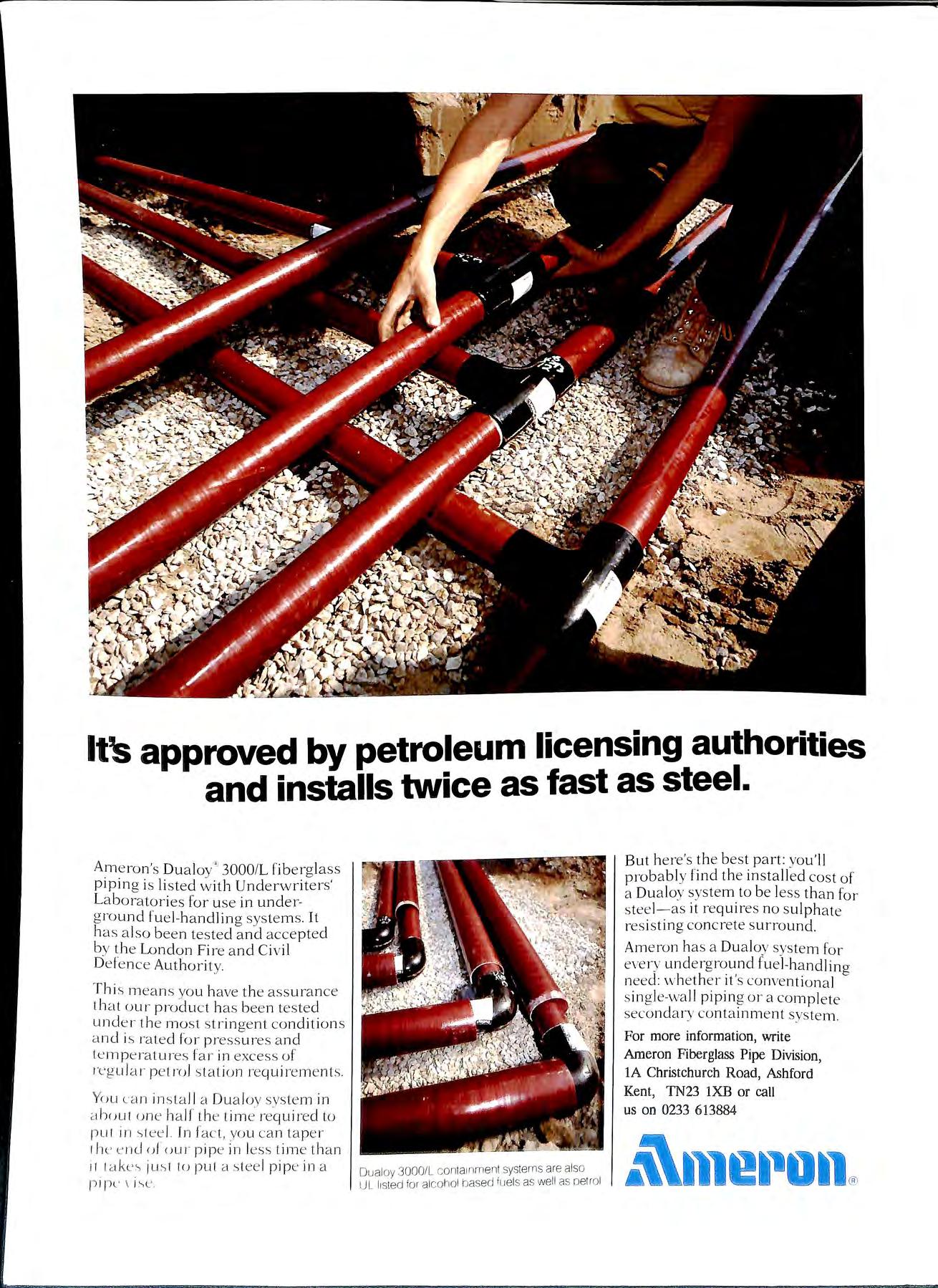

Am e ron's Dualoy" 3000/L fiberg la ss p1pmg is listed with Underwriters' Laboratori es for us e in undergro und fuel handling sys te m s It ha s also been tested and accepted b y the London Fi re and Civil Def e n ce Authorit y

Thi s mean s yo u ha ve the a ss uranc e that our produ c t ha s b ee n tes t e d und e r the mo s t s tring e nt co ndition s a nd is rat e d for press ur es an d te mp era tures far in excess of re g ul ar p e tro l s t a tion re quire m e nt s

Yo u La n in s t a ll a Dualoy s ys te m in a huut one h a lf th e t im e re quire d to put in s tee l. Jn fac t , yo u c an tap e r lh ee nuo f uur p ip e in le s s t im e t han 11 take s ju s t tu put a s te e l pip e in a p ljll' \ ' J.'-,t'

But here 's the best part: you'll probabl y find the installed cost of a Dualoy system to be less than for stee l-:- as it require s no su lph ate re s 1st111g concrete surround .

Ameron ha s a Dualoy system for eve r y und ergro und fuel-handling n ee d: w h ether it' s conventiona l s in g le-wa ll piping or a complete secondary containment system.

For more information, write Ameron Fiberglass Pipe Division, lA Christchurch Road, Ashford Kent, TN23 lXB or call us on 0233 613884

It's approved by petroleum licensing authorities and installs twice as fast as steel.

Oualoy 3000/L containment systems are also UL listed for alcohol based fuels as well as petrol

Maj_or oil companies are investing large sums to control hydrocarbon emissions during fuel transfer. Vapours which up until now, have escaped into the atmosphere.

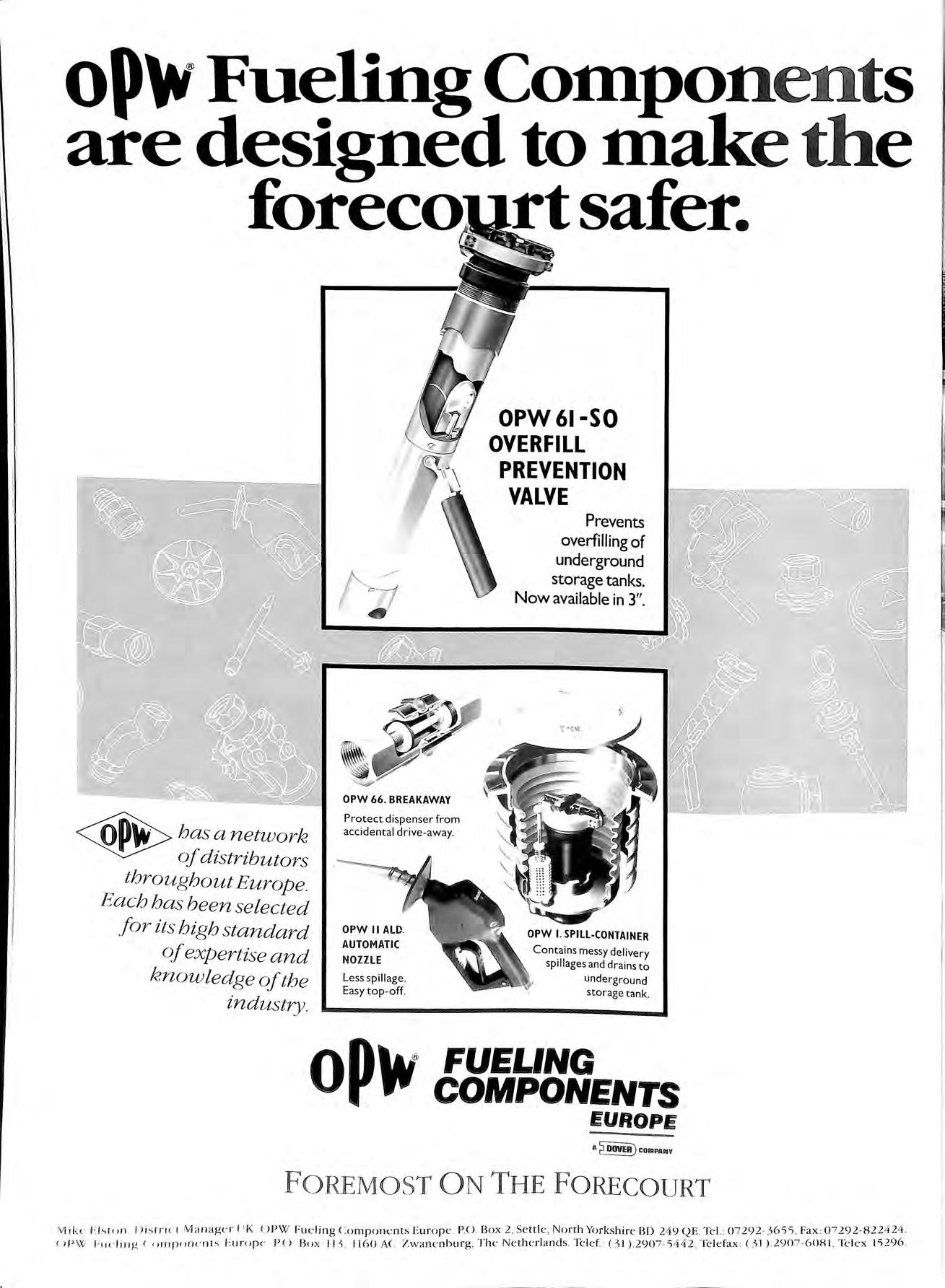

OPW Fueling Components are proud to have played a leading role in this development, by supplying the special valves and know-how, gained from I0 years experience of similar development in the U.S.A

FLOAT VENT VALVE OVERFILL PREVENTION OPW 320-DVB TANK-TRUCK RETURN ADAPTOR OPW 1611-AVL PRESSURE VACUUM VENT VALVE OPW523 FITTING FOR UNDERGROUND TANKS O PW lbll-AV FLOAT VA LVE FOR UNDERGROUND TAN KS '0 FUEi.iNG COMPONENTS O PW 233-SO W ITH O PW 53-VM EU R OPE A 2: oov® C OMPfliNV FOREMOST ON THE FORECOURT Mike Elston, District Manager LIK. OPW Fueling Compow·nt< E'ti roi)e 1>' ) 13 2 c I N I ' " ·' ox ,ctt e. ort l Yorkshire BO >4 OPW FuelingComponents Europe PO Box 11 ,. ll 60 AC Zwanenburg T he N , 1 ,.1 d T l ·f · 9QE1cl. : 07292·3655.fa.x: 07292· 8 22 12'1 · · et l e 1 <1n 5 e t ·· ( 31) 29()7 544 2. Telefax: ( 31). 290'·6081. ' lei ex 15 296

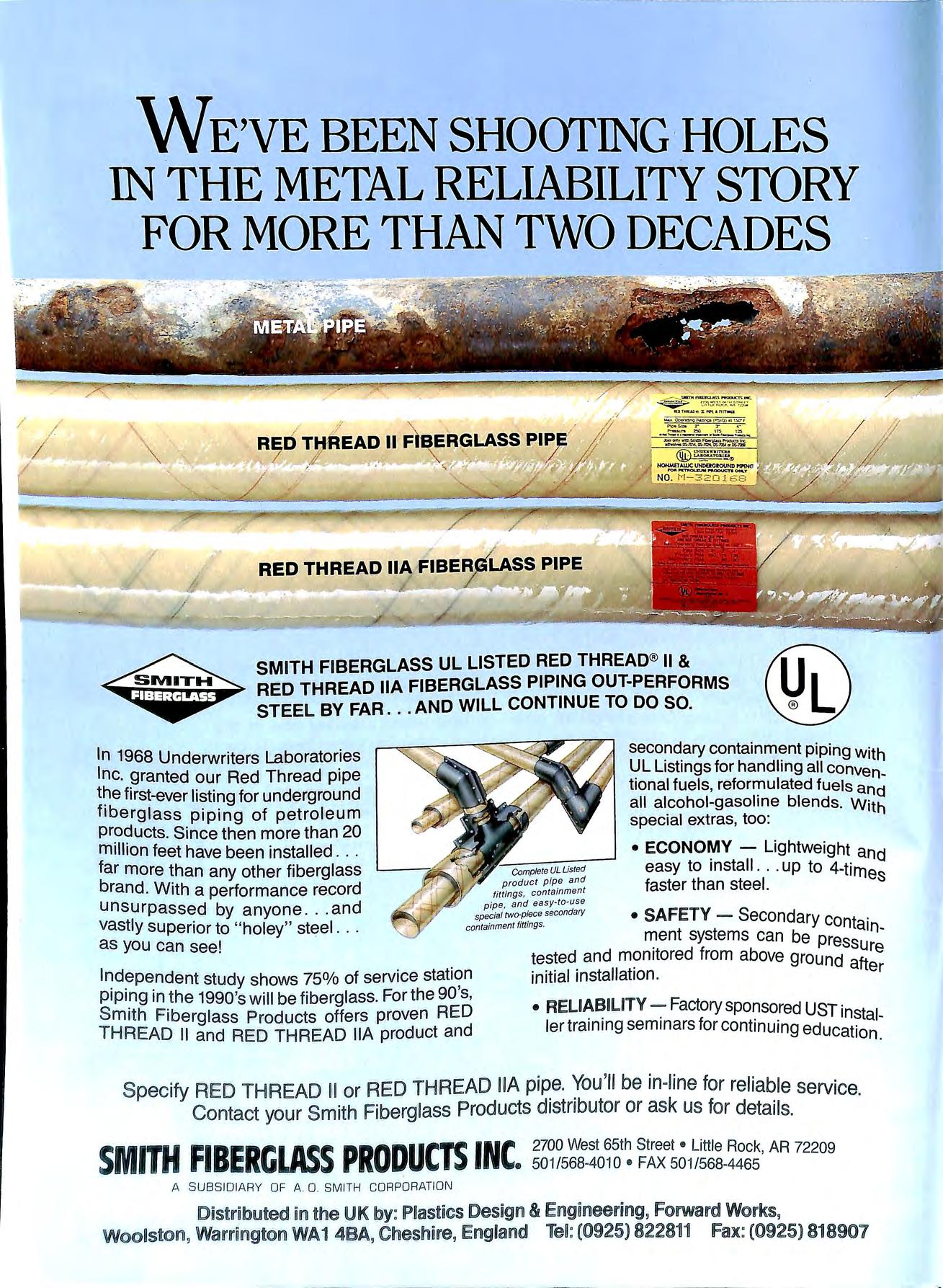

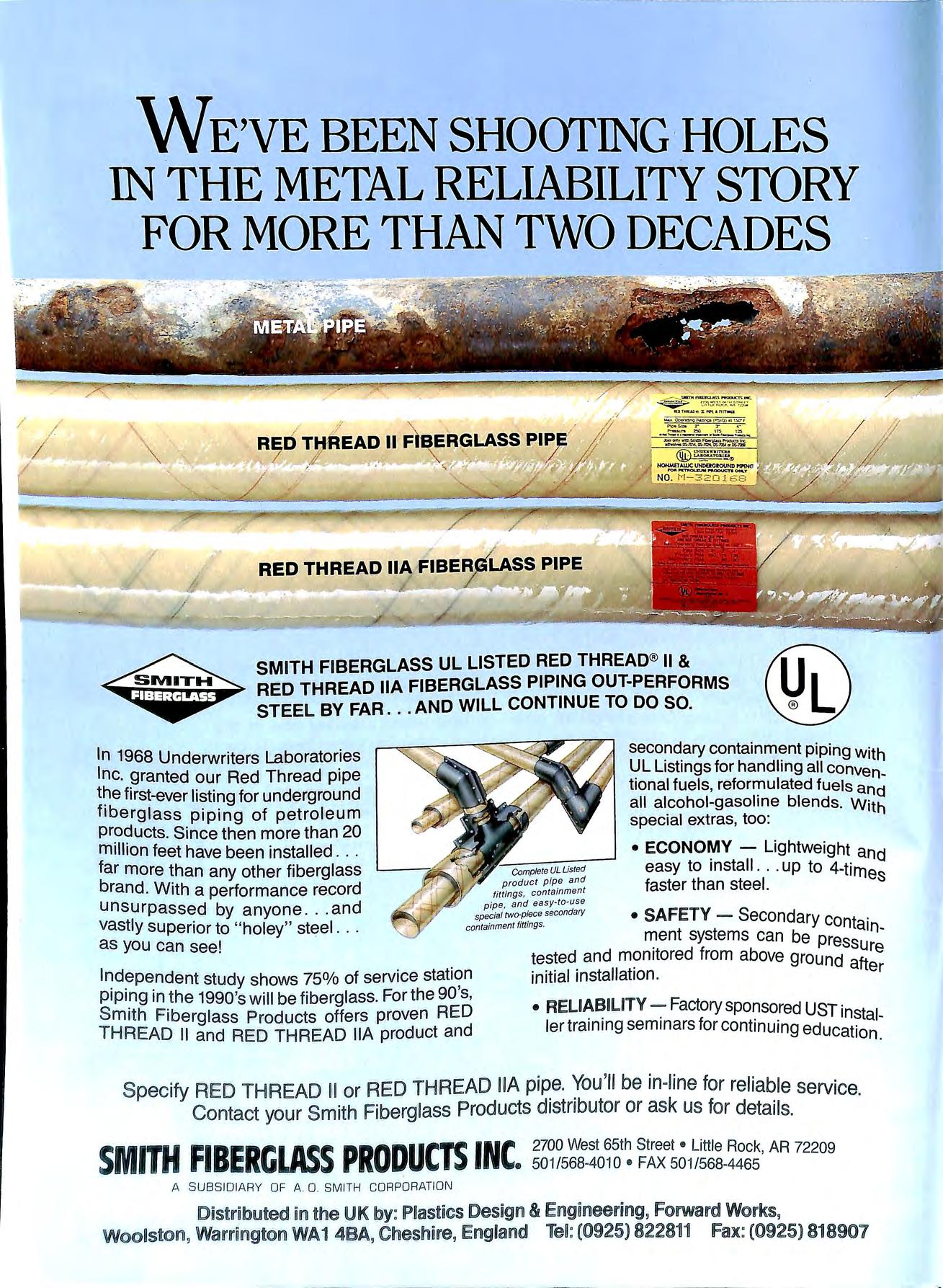

1968

Laboratories Inc. granted

Red Thread pipe first-ever listing for underground f1berglass piping of petroleum products. Since then more than 20 million feet have been installed far more than any other fiberglass brand. With a performance record unsurpassed by anyone and vastly superior to "holey" steel

shows 75% of service piping in the 1990's will be fibe rgl ass. For the 90 s, Smith Fiberglass Products offers proven RED THREAD II and RED THREAD llA product and

Lightweight and easy to install up to 4-tirne faster than steel.

/ ./ I WE'VE BEEN SHOOTING ·HOLES IN THE METAL RELIABILITY STORY FOR MORE THAN TWO DECADES SMITH FIBERGLASS UL LISTED RED THREAD® 11 & RED THREAD llA FIBERGLASS PIPING OUT-PERFORMS STEEL BY FAR AND WILL CONTINUE TO DO SO. Complete UL Usted product p i pe and fittings, containment pipe, and easy-to -u se secondary

•

...

spectattwo-pieceseco ndary • SAFETY -

· con tainment tJttmgs

and

• Factory

Specify RED THREAD 11 or RED THREAD llA pipe. you'll be in-l ine for reliable service. Contact your Smith Fiberglass Products drstnbutor or ask us

details. SMITH FIBERGLASS PRODUCTS 'Ne 2700 West 65th Street • Little Rock, AR 72209 • 501/568 4010 • FAX 501/568 4465 A SUBSIDIARY OF A 0 SMITH CORPORATION Distributed in the UK by: Plastics Design & Engineering, Forward Works, Woolston, Warrington WA1 4BA, Cheshire, England Tel: (0925) 822811 Fax: (0925) 818907

containment piping with Listings for handling all conventional fuels, reformulated fuels and all alcohol-gasoline blends. With special extras, too:

-

s In

Underwriters

our

as you can see!

Secondary

conta1 nment systems can be press study

m?nitored from above ground initial 1nstallat1on. er

sponsored UST installer training seminars for continuing education.

for

TAMES LUKE Safety & Training Consultants to the Petroleum Retail Industry !: llllllllt11111tllI u > §fl ll11111111111i1lll11 11 1 SALUKI HOUSE 4 BURNT COMMON CLOSE RIPLEY, SURREY GU23 6HH Tel: 0483 222946 - Fax: 0483 211328 Jf obn Migfull & <!o. lltb. FIRST HANGINGS BLABY ROAD ENDERBY LEICESTER LE9 SAQ Telephone (0533) 862287 Fora Comprehensive service for liquid fuel & LPG installations Consullancy, design, installation, maintenance & decommissioning Gasafree certificates Site surveys LPG vessel 5 & JO year inspections MEMBER APEA, LPGITA DESIGN FUELLED B EXPERIENC Personal attention in design & development for the petroleum retail industry • Principal with over 25 years experience • Project Management specialists •Progressive & innovativ e outlook •Consultants for statutory & planning requireme nt-; • Comprehensive or tailored service to suit PLANACOURT Planacourt Limited PO Box 27 Bille1icay Essex CMll 2ES 0277 630868

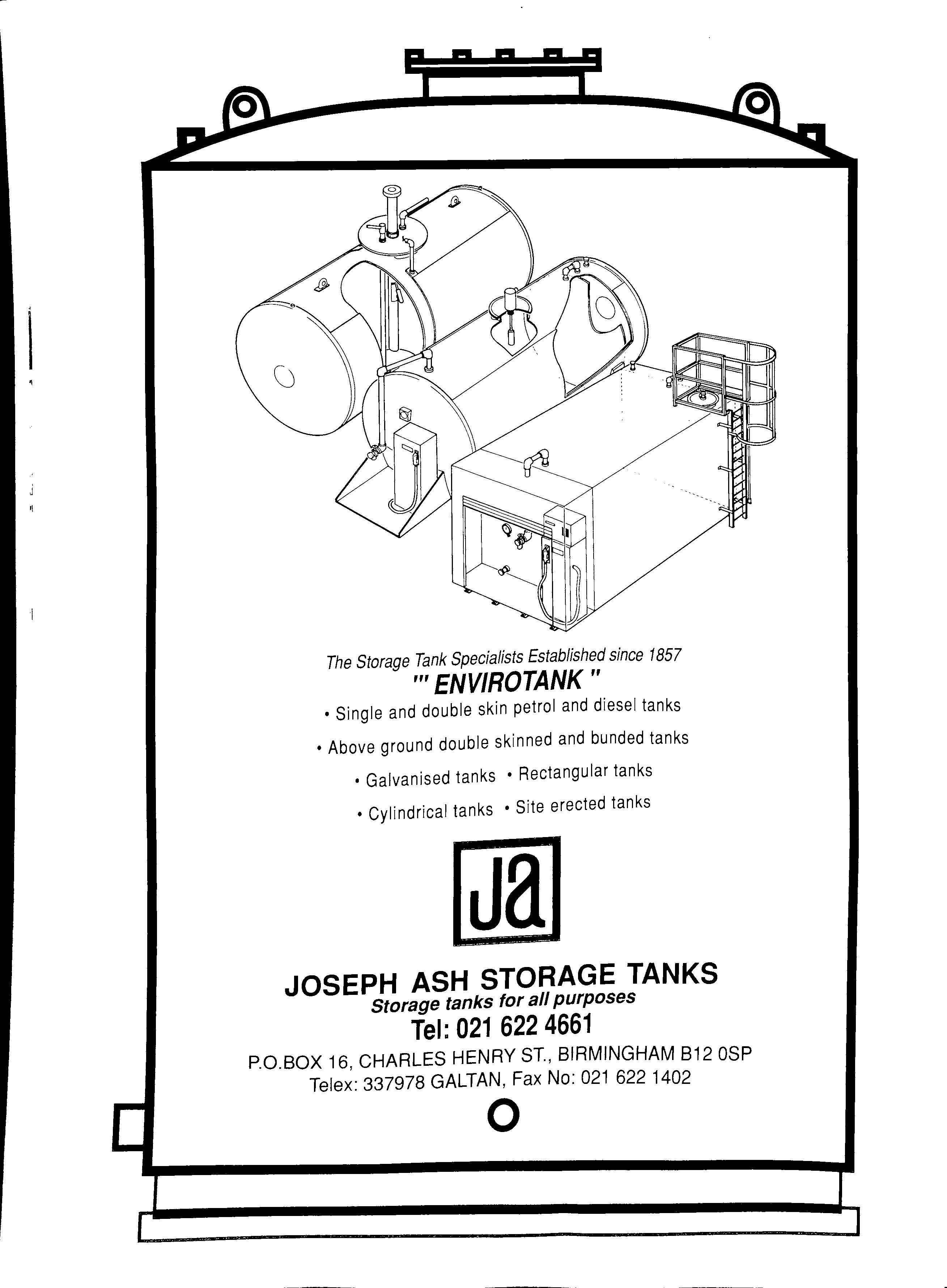

I The Storage Tank Specialists Established since 1857 "' ENVIROTANK " • Single and double skin petrol and diesel tanks • Above ground double skinned and bunded tanks • Galvanised tanks • Rectangular tanks • Cylindrical tanks • Site erected tanks Ja JOSEPH ASH STORAGE TANKS Storage tanks for all purposes Tel: 021 622 4661 PO.BOX 16, CHARLES HENRY ST., BIRMINGHAM 812 OSP Telex: 337978 GALTAN, Fax No: 021 622 1402 0

C · S ·S TANSFIELD MECHANICAL SPECIALISTS IN FORECOURT PETROLEUM INSTALLATIONS SERVICES Unit 10 Boundary Road Industrial Estate Sturmer, Haverhill Suffolk, CB9 7VH Tel: 0440 712505 Fax: 0440 712506 BELHAN CONSTRUCTION CO LTD Building Contractors (Est 1970) Comprehensive Development and Maintenance Services By Petrol Station Specialists 60 Connaught Gardens Shoeburyness Essex SS3 9LR Tel: 0702 295197

NATIONWIDE FORECOURT DRAINAGE AND INTERCEPTOR SERVICE

INDUSTRIAL

BULK WASTE

NATIONWIDE TANK CLEANING SERVICE Petrol, oil and solvent tanks cleaned to associated petroleum industry standards. TEL: (0489) 783462

Factory clearances, decontamination of buildings and removal of laboratory chemicals.

CLEANING

The regular removal of silt and debris from drain-lines, gullies, interceptors and catch-pits, helps to keep your garage safe from fire and forecourt flood. TEL: (0386) 47190 TEL: (0452) 507432

containers

TRADE EFFLUENT AND SPECIAL WASTE TREATMENT AND DISPOSAL 24 HOUR EMERGENCY HOTLINE SCHEME ALSO:- SKIPS INDUSTRIAL CLEANING GULLY CLEANING WATER JETIING CESSPIT EMPTYING CLEANSING SERVICE GROUP LTD Head Office : Grange Road, Botley, Southampton , Hants. 503 2GD TEL: BOTLEY 782232/6 FAX: 0489 789821

SERVICES Wide range of

for dry industrial waste Static compactors installed and serviced.

C p INSTALLATIONS LTD. (Established 1968) Specialists in Petroleum Pipework Installations New and existing Tanks and Lines tested Modifications to existing Installations And all work associated with Forecourt Pipework Ameron approved for Fibre Glass Installations 39 BROOK ROAD, RAYLEIGH WEIR INDUSTRIAL ESTATE RAYLEIGH, ESSEX SS6 7XN Tel: 0268 781184 / 781859 (24 hrs ans) Fax: 0268 776697 PHONE: 071-739 9538 FAX: 071-729 6108 TUBEFLOW LTD SPECIALISTS IN PETROL PUMP, TANK AND PIPEWORK INSTALLATIONS AND ASSOCIATED WORKS APPROVED CONTRACTORS TO THE PETROLEUM INDUSTRY AND LOCAL GOVERNMENT AUTHORITIES 29 TEMPLE STREET9 LONDON E2 6QQ MEMBER A.P.E.A.

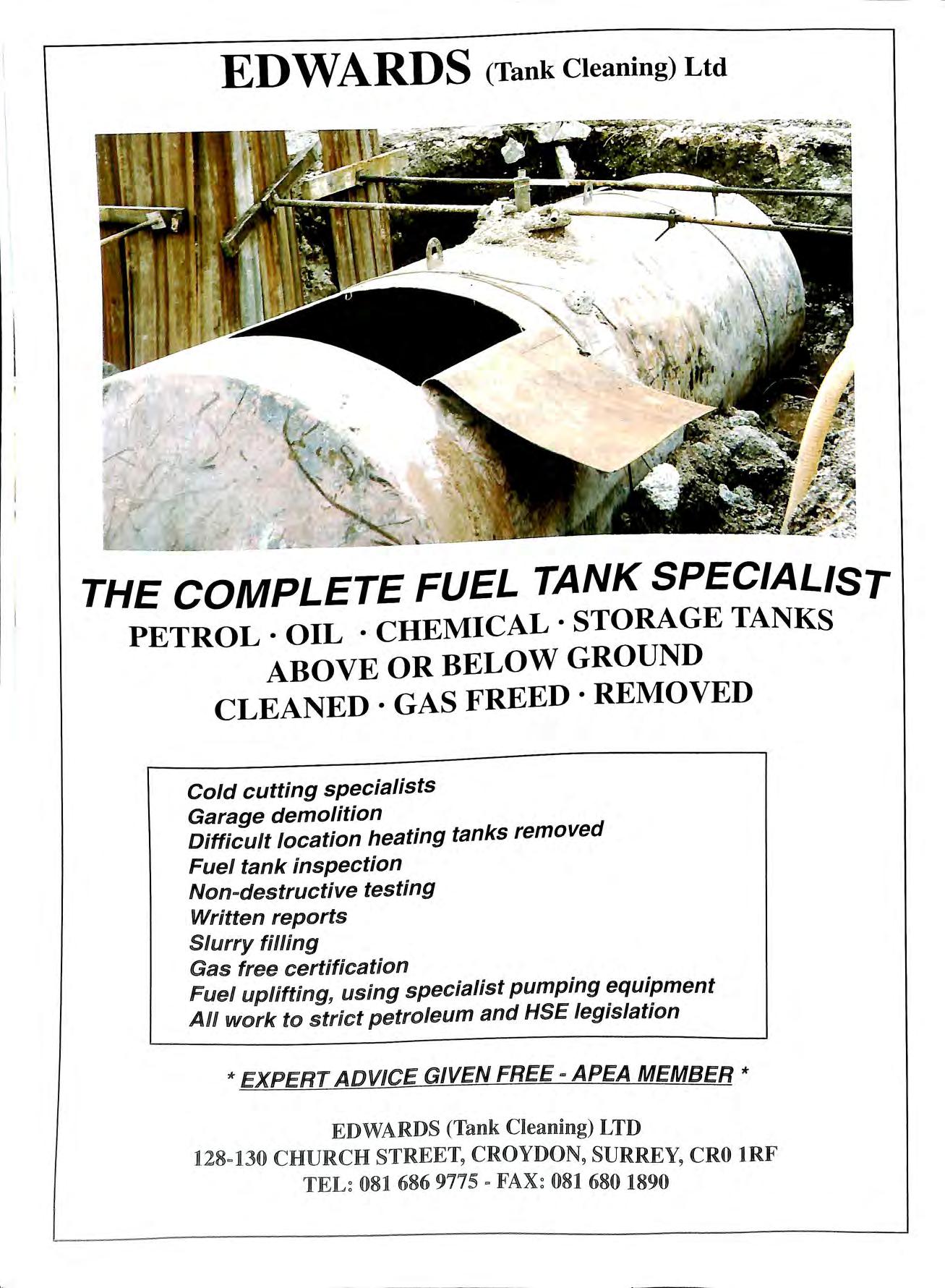

EDWARDS (Tank Cleaning) Ltd THE COMPLETE FUEL TANK SPECIALIST PETROL · OIL · CHEMICAL · STORAGE TANKS ABOVE OR BELOW GROUND CLEANED·GASFREED·REMOVED Cold cutting specialists Garage demolition Difficult location heating tanks removed Fuel tank inspection Non-destructive testing Written reports Slurry filling Gas free certification Fuel uplifting, using specialist pumping equipment All work to strict petroleum and HSE legislation *EXPERT ADVICE GIVEN FREE - APEA MEMBER * EDWARDS (Tank Cleaning) LTD 128=130 CHURCH STREET9 CROYDON 9 SURREY, CRO lRF 081 686 9775 081 680 1890

u ILL POINT ADAPTORS D HEAR VALVES ISPENSING NOZZLES ll REAK AWAY COUPLINGS PETROLEUM SERVICE STATION EQUIPMENT SPECIALIST l!jAPOUR BALANCING VERFILL PREVENTION BSERVATION WELLS U OTAL CONTAINMENT ii 0708 863931 m0708 868226

WELDEM LIMITED CONSTRUCTIONAL ENGINEERS CHESHIRE STREET, MOSSLEY, ASHTON-U-LYNE, LANCASHIRE, OL5 9NG MANUFACTURERS OF QUALI1Y STEEL STORAGE TANKS FOR THE PETROLEUM AND CHEMICAL INDUSTRIES UNDERGROUND SINGLE AND DOUBLE SKINNED ABOVE GROUND · OPEN OR SECURITY SELF BUNDED DIPSTICKS • GAUGES • LEAK DETECTION • OVERFILL PREVENTION FULL RANGE 500 GALLONS TO 40000 GALLONS 1963 g (i} \ \\ I PRICE LISTS AVAILABLE · SPECIALS ON REQUEST GENERAL FABRICATIONS · VESSELS · STEELWORK LARGE PIPEWORK TEL: 0457 833211 FAX: 0457 833185 INDEPENDENT PUMP SERVICES Pumps & Tanks (Shoreham) Ltd Est 1963 ADUR BOATYARD, OLD SHOREHAM ROAD SHOREHAM-BY-SEA, WEST SUSSEX, BN43 STA 0273-454831 FAX: 0273-464863 1991 43p LITRE A COMPANY STAFFED BY ENGINEERS CAPABLE OF MEETING THE DEMANDS OF MODERN FORECOURT SERVICE STATIONS • ALL PUMP TANK & PIPEWORK INSTALL.A TIONS - FIBREGLASS & STEEL • LARGE MODERN FACTORY WITH COMPJ£TE PUMP OVERHAUL TEST & REPAIR FACILJnES •LARGE PUMP STORAGE WAREHOUSE WITH SPARES FOR MOST TYPES OF EXISTING PUMPS ALL WORK TO BS5750 PARTS & m(PENDING CERTIFICATION} COMPLETE PROJECT ENG~NEER~NG SERVICE AVAILABLE

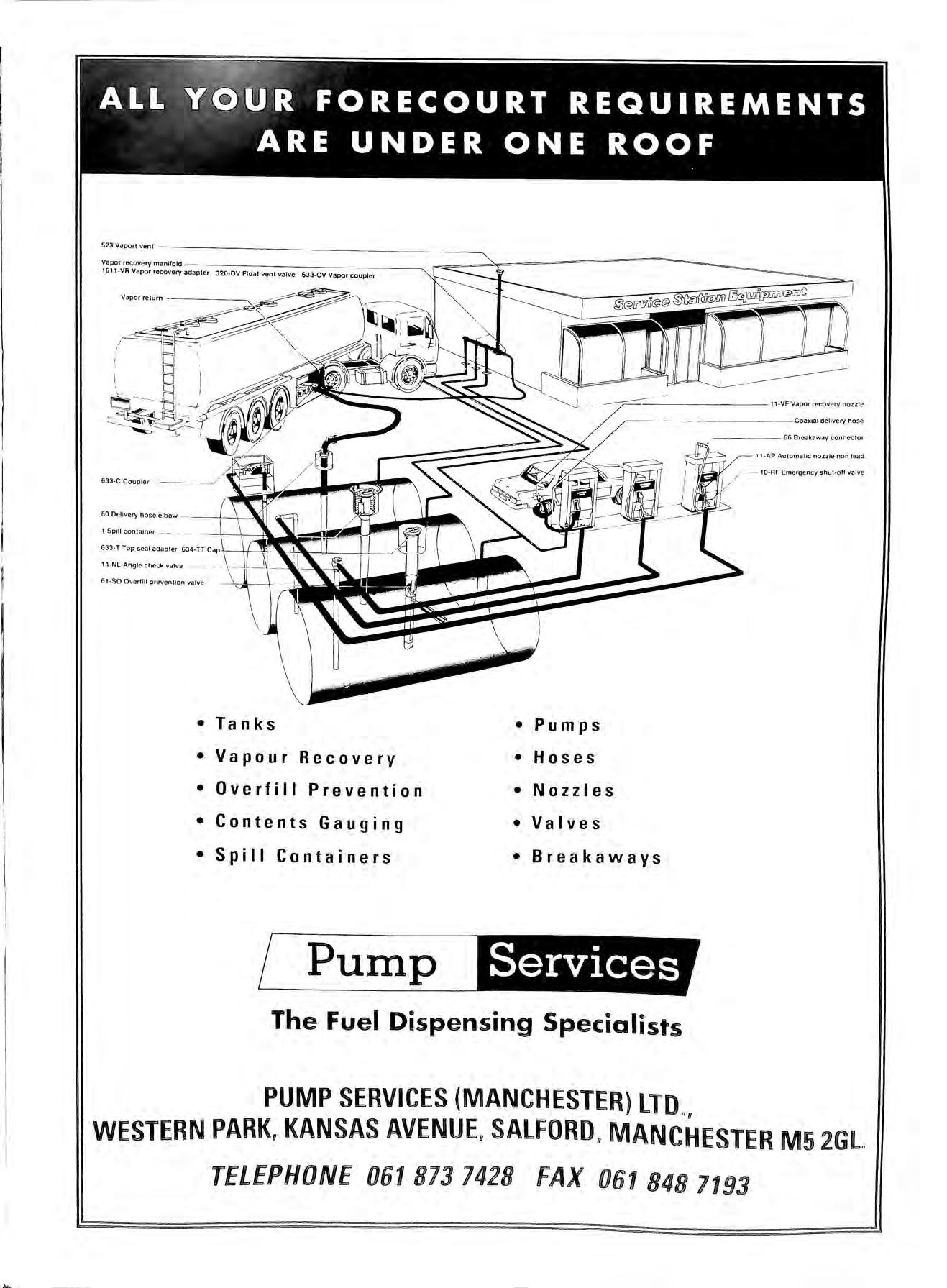

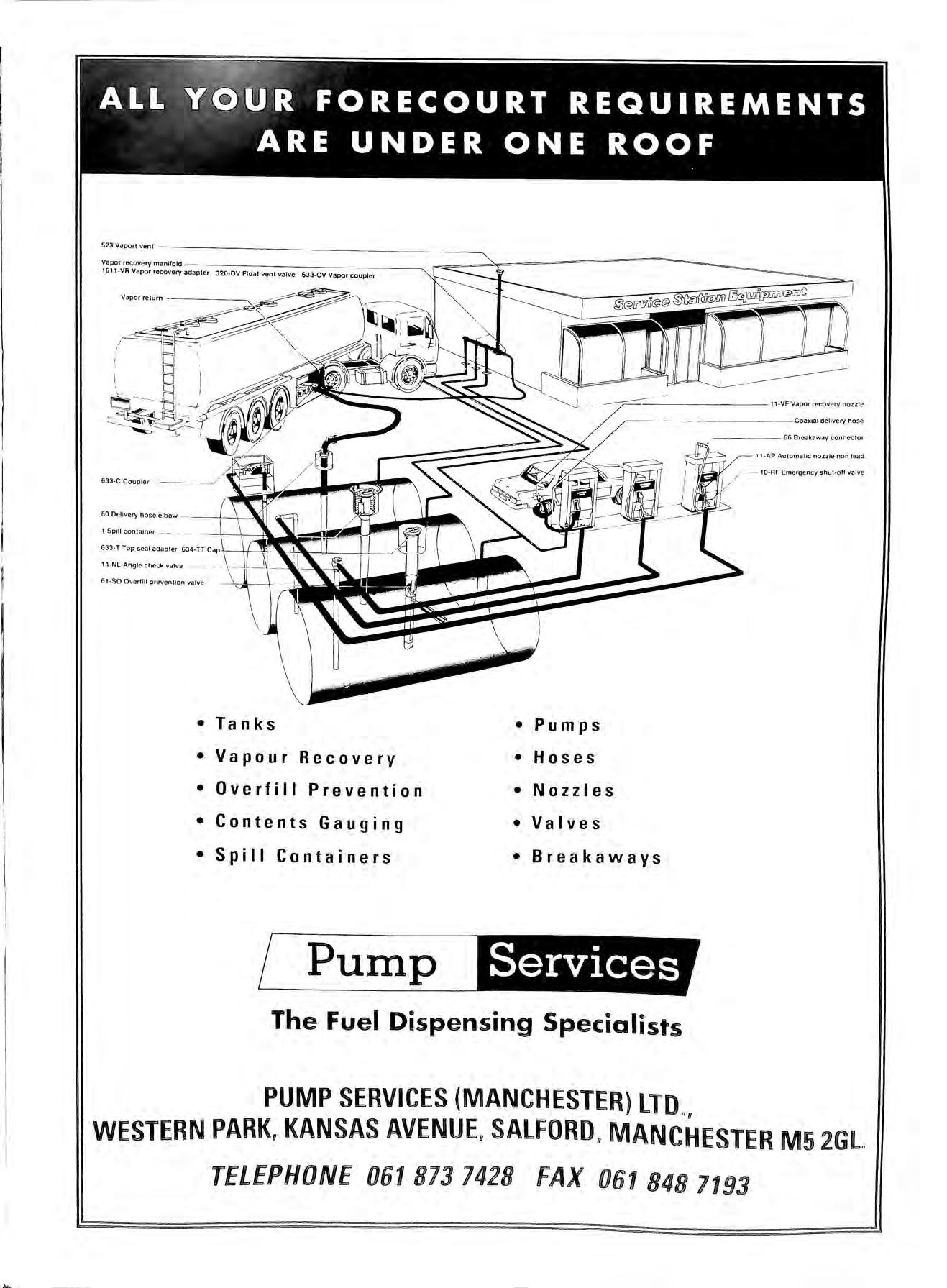

Coaxial delivery l'lose 66 Breakaway connec1or 11 AP Au1oma11c no:t:zle non lead ,- 10-RF Emergency shur-ott valve 633 T Top sea l adapter 634-TT 14 NLAnglecheckvalve "'""""'""""""""''" \\I • Tanks •Vapour Recovery •Overfill Prevention •Contents Gauging •Spill Containers •Pumps •Hoses •Nozzles •Valves •Breakaways / Pump E1511!!J The Fuel Dispensing Specialists PUMP SERVICES (MANCHESTER) LTD,, WESTERN PARK, KANSAS AVENUEu SALFORDg MANCHESTER M5 2GL TELEPHONE 061 873 7428 FAX 061 848 7193

There is an urgent need for the H.S.E. to revise the installation section of HS(G)41, some 12 months after publication, as it is out of date.

Major Oil Companies are fully aware of in __ E:C. legislation which will affect owning and stations. The responsible majority are already mstallmg double skin storage tanks and using pipe materials which will not corrode, this reflects their increasing concern for the environment.

The H.S.E. should also match this commitment with finn guidance to petroleum licensing authorities on new materials and installation techniques.

The front cover shows new flexible pipe being installed in the UK, no doubt the first of many such systems!

Bulletin

the Association for Petroleum and Explosives Administration

29

November

A company Limited by Guarantee registered in England No. Reg. Office: Stoughton House, Harborough Road, Oadby, Leicester LE2 4LP £5.00 (Free to Members) ISSN 0263 4597

this Journal are

the Association Contents Talking Point TALKING POINT NOTES &NEWS ATTINGHAM REVISITED LETTERS TO EDITOR ENVIRO FLEX PIPEWORK 57 58 61 62 63 APEA INTERNATIONAL PETROLEUM SEMINAR 70 ENVIRONMENTAL FRIENDLY LEAK DETECTION 71 TOTAL TANK REPLACEMENT PROGRAMME NEW MEMBERS 75 78 HUMBERSIDE BRANCH J. Horsburgh

BRANCH M.Cox Normond Instruments Ltd.,

The

Published by

VOLUME,

Number4

1991

Opinions expressed in

not necessarily the views of

SOUTHERN

MEMBERSHIP SECRETARY B. J. Thompson

BRANCH R. G. Green Honorary

Mr. D. Bucknall. Humherside Trading Standards. MIDLAND

Mr.

CMS

ADVERTISING SECRETARY J. Luke Honorary Editor: Mr. J. A. J. Thompson.

EASTERN

Secretary:

BRANCH

L. Lloyd

Ltd.

notes and news

VEEDER ROOT

ACQUIRES

NORMOND & CMS

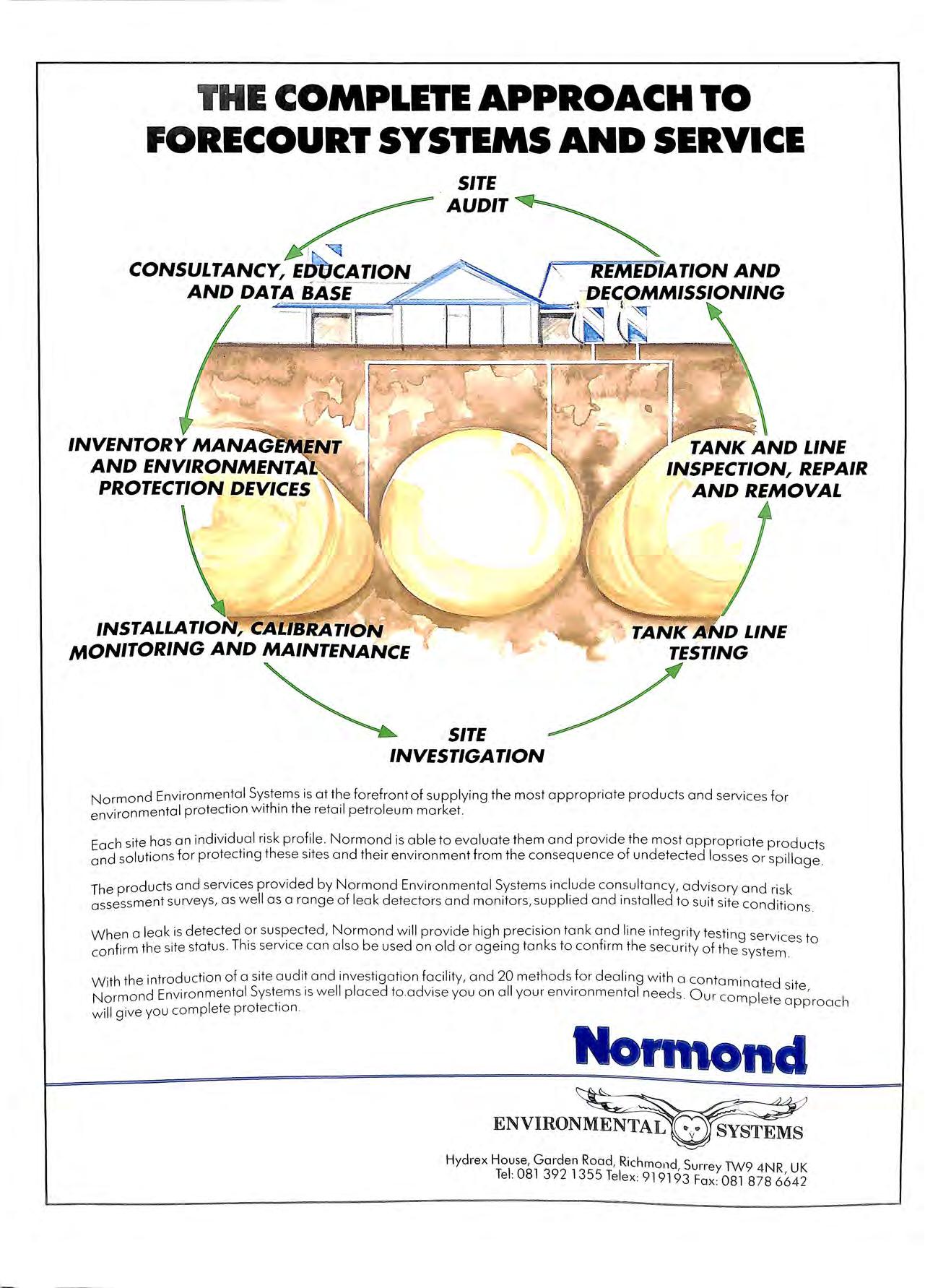

Micralec have announced that Normand Instruments Ltd, C.G.F. Automation, and Contents Measuring System have been sold to Veeder Root Inc, a subsidiary of DANAHER a major US Corporation.

Mr P. Whitehead will become the Executive in charo-e of the Veeder Root/Normond CMS tank o-auo-ino- 0 leak b b l:!' detection and environmental products businesses.

Micralec has retained the precision tank testing and environmental remediation business.

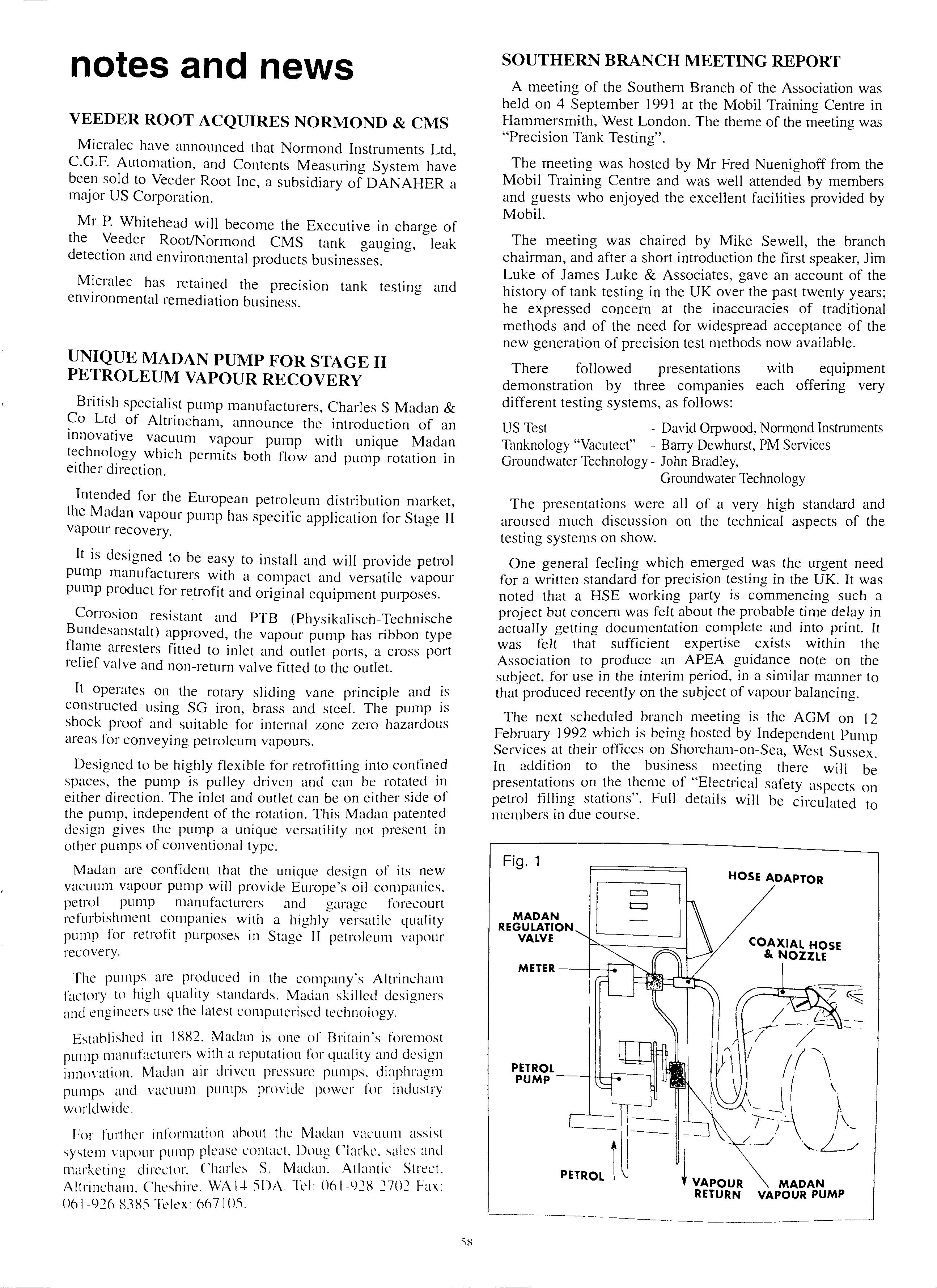

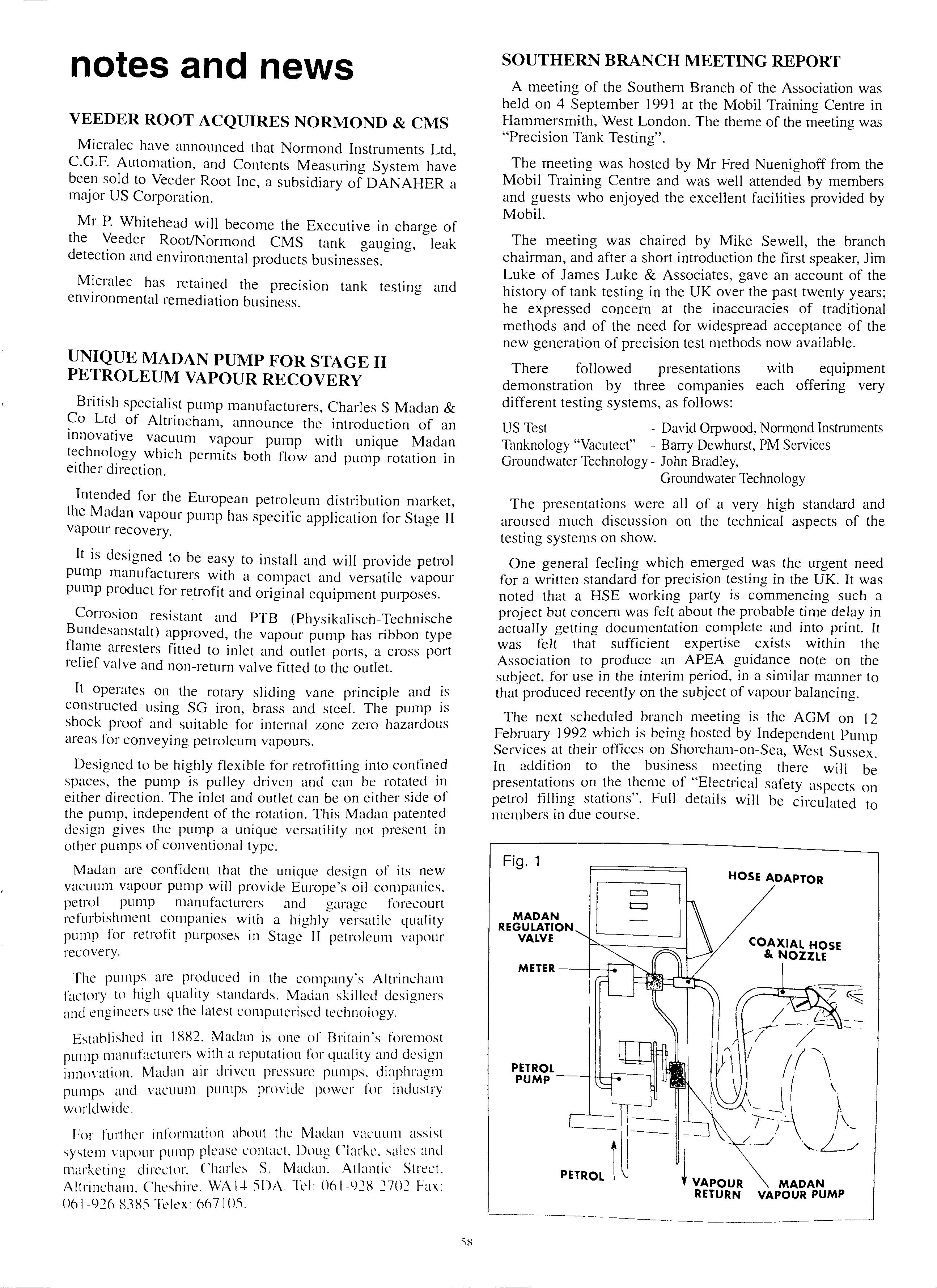

UNIQUE MADAN PUMP FOR STAGE II PETROLEUM VAPOUR RECOVERY

B1itish specialist pump manufacturers, Charles S Madan & Co Ltd of Altrincham, announce the introduction of an innovative vacuum vapour pump with unique Madan which permits both flow and pump rotation in either direction.

Intended for the European petroleum distribution market, the Madan vapour pump has specific application for Stage II vapour recovery.

It is designed lo be easy to install and will provide petrol pump manufacturers with a compact and versatile vapour pump product for retrofit and original equipment purposes.

Corrosion resistant and PTB (Physikalisch-Technische Bundesanstalt) approved, the vapour pump has ribbon type fla?1e arresters fitted to inlet and outlet ports, a cross port rehef valve and non-return valve fitted to the outlet.

It operates on the rotary sliding vane principle and is constructed using SG iron, brass and steel. The pump is shock proof and suitable for internal zone zero hazardous areas for conveying petroleum vapours.

Designed to be highly flexible for retrofitting into confined spaces, the pump is pulley driven and can be rotated in either direction. The inlet and outlet can be on either side of the pump, independent of the rotation. This Madan patented design gives the pump a unique versatility not present in other pumps of conventional type.

Madan are confident that the unique design of its new vacuum vapour pump will provide Europe's oil companies. petrol pump manufacturers and garage forecourt refurbishment companies with a highly versatile quality pump for retrofit purposes in Stage II petroleum vapour recovery.

The pumps are produced in the company"s Altrincham factory to high quality standards. Madan skilled designers and engineers use the latest computerised technology.

Established in 1882. Madan is one of Britain ·s foremost pump manufacturers with a reputation for quality and design innovation. Madan air driven pressure pumps. diaphragm pumps and vacuum pumps provide power for industry worldwide.

For further information about the Madan vacuum assist system vapour pump please contact. Doug Clarke. sales and marketing director. Charles S. Madan. Atlantic Street. Altrincham. Cheshire. WA 1-J. :'iDA. Tel: Oo 1-928 2702 Fax: 061-926 838) Telex: 66710.'i.

SOUTHERN BRANCH MEETING REPORT

A meeting of the Southern Branch of the Association was held on 4 September 1991 at the Mobil Training Centre in Hammersmith, West London. The theme of the meeting was "Precision Tank Testing".

The meeting was hosted by Mr Fred Nuenighoff from the Mobil Training Centre and was well attended by members and guests who enjoyed the excellent facilities provided by Mobil.

The meeting was chaired by Mike Sewell, the branch chairman, and after a short introduction the first speaker, Jim Luke of James Luke & Associates, gave an account of the history of tank testing in the UK over the past twenty years; he expressed concern at the inaccuracies of traditional methods and of the need for widespread acceptance of the new generation of precision test methods now available.

There followed presentations with equipment demonstration by three companies each offering very different testing systems, as follows:

US Test

David Orpwood, Normond Instruments Tanknology "Vacutect" Barry Dewhurst, PM Services Groundwater Technology John Bradley, Groundwater Technology

The presentations were all of a very high standard and aroused much discussion on the technical aspects of the testing systems on show.

One general feeling which emerged was the urgent need for a written standard for precision testing in the UK. It was noted that a HSE working party is commencing such a project but concern was felt about the probable time delay in actually getting documentation complete and into print. It was felt that sufficient expertise exists within the Association to produce an APEA guidance note on the subject, for use in the interim pe1iod, in a similar manner to that produced recently on the subject of vapour balancing.

The next scheduled branch meeting is the AGM on 12 February 1992 which is being hosted by Independent Pump Services at their offices on Shoreham-on-Sea, West Sussex. In addition to the business meeting there will be presentations on the theme of "Electrical safety aspects on petrol filling stations". Full details will be circulated to members in due course. Fig. 1

MADAN REGULATION VALVE

MADAN REGULATION VALVE

HOSE ADAPTOR COAXIAL HOSE & NOZZLE

ASSOCIATION MEMBER BECOMES IFE

PRESIDENT

P A D Sheen has b e come Pres ide nt of the In s tituti o n of Fire En g ineer s a t th e annu a l co nfe rence of the Instituti o n in T o rquay

Th e !n s titution, which h as o ver 11 ,000 members in 31 c o untnes , has branches in 15 co untrie s from Iceland to N e w Z eala nd and rapidly in Europe. Found e d in 19 18, In s tituti o n 1s co nc e rn ed with Fire Extinction Fire Preve nt10n and Fir E · · . e ng m eenn a and althouah th e m aJOnt y of its wo rld w ide me b h 0 0 b m e rs 1p are m the Fire S e rv ic e a s u minority (a nd th e mos t rapidl y aro w ina) se c tor o f e rship are p eopl e wo rkin g in Fi; Re s;arch Fire Fire In s ura nc e a nd in De s ian ' a nd C a nuflac turm g Mr. Sh ee n, wh o has a practi ;e as a o ns u tm a Fore · E . Pres ident '? h ng meer, will only be the s ec o nd fire offic e ; n t e history o f th e In s titution who is not a se ni o r

w ould obtain e d by a tte ndin g an appro ve d t ra inin g co urse and pa s sm g an appro ve d exa mination.

Courses will h av e to b e a ppro v ed b y th e gove rnm e nt. It is thought that sev e ra l e x is ting cours e s m ay b e s uit a bl e with some modific a ti o n E xa min a tion s will a ls o b e gove rnm e ntapproved , with pap e r s b e in g se t by a s in g le b o d y th a t w ill b e independent of a ny provider of training C e rtifi ca tes w ill b e valid for five y ear s. R e n e wal would e nt a il a tte nding a pproved refresh e r c o urses a nd re-examination.

Transition period

For g ood s c arri e d in ro a d tanke r s a nd tank co nt a in e rs a nd for ex plosi ves, th e prop osed re g ulation s w o uld co m e into e ffe c t from July 1, 1992. F o r pack a ged goo d s, h oweve r, th e y w ill appl y from Janu a ry I , 1995

Since it w o uld n o t b e p oss ibl e to pro v id e a d e qu a te pl ac es on trainin g c o ur ses by July 1992, it is prop ose d to aw ard provi s ional certifi ca tes to driv e rs w ho c a n s h o w e vid e nc e of completion of a n exi s tin g training course jud ge d to be s uitable. They will b e v a lid for a maximum of fiv e y ea r s, but none will b e valid afte r D e c e mber 31 , 1994.

SUPPLIER AND RETAILER FINED FOR SUPPLYING CONTAMINATED PETROL

Follo w in g a tip- o ff to Yo rk s hire Tradin g St a n da rd s Offi ce r, a routine sampl e w as ta ke n fr o m e ach of three p e trol pump s situated on th e fo reco urt o f G. W. R ea d e r & So n , 140 Milg a te , Selby, Yo rk s hire . E a ch pump w as c onn ec te d to th e s ame single I 0,000 ga ll o n s torage tank . Eac h pump wa s marked "4 STAR " but did not bear the a ppro pri a te s ymbol for Four Sta r p e tro l, as re quire d by BS 4040. Tes t res ult s s howed that th e p e tro le um did n o t c omply w ith th e B riti s h S ta ndard in re la ti o n to Fo ur St a r p e trol and th e s ub sequ e nt in ves ti ga ti o n revea le d th a t th e s upplier 3 0 Pe tr o le um h ad o btained th e co nt a min a ted p e trol from a ga ra ge w hi c h was s us p ected of h av in g co nt a minate d p e trol e um

NEW TRAINING R TANKE R D RIVE RSE QUIREM ENTS FOR RO A D

T he UK is p ro pos in o , . . d ri ve rs o t· ve t11·cl "'a _s m g le set o f tra 111111 g reg ul a ti o ns fo r es ca rr y d ex ist in g sys te m a nd r a m g goo d s to s impli fy the a 1o n m o 1e w ith E u ro pe. T h e U K 's hea lth pro p osed new ; a nd Safety Co mmi ss io n ( H SC) h as ve hi c les 1 fo r th e tra inin g of dri vers of w it h the a ppro ac"'h go_ods to brin g th e UK into lin e e n 111 the 1es t of E urop e A co n s ul ta ti ve d oc u o nl y d raft rea ul a t" me nt pu b li s h e d las t mo nth co nt a in s no t bas e d o n E ' ? n s to m lp leme nt a Co mmunit y Direc ti ve u1 ope-w 1de ADR A tra n s p o rt of da n aer g ree me nt on th e road ex p la inin g t he ·0 1 o us goo d s b ut a lso a co mm e nt a ry im p icat1o ns of tl l B . . , ex is t in g re q uire i · 1e prop osa s. nta 111 s n ents a re cu rre 1tl . . f reg ul a t io n s dea l· 0 1 Y se t o ut 111 a se ri es o · 111 0 With the ca rri aoe of di ffe re n t kinds of ctnge 1o us s ub s ta nces (b lk "' . co nta ine rs· ·k d u goods 1n ta nk e rs a nd ta n k . . pctc age goo ds· ex I · I ., 1· s u bsta n ces). It ' P os 1ves, a nc 1ctc 1oac l! ve · is p i oposed to rep lace th e dri ve r tra inin g ion s_ 01 e ac h nf th ese reg ul a ti o ns w ith a s in a le o f d11 ve 1 lla 1111n o rea u ht , 0 c "' c io n s cove ri ng a ll typ es of cla n oe ro us g "od s. o

Qualifications

The mwn proposa l in t he clrart reg u la ti o ns is th at d ri ve rs w o uld ha ve to ho ld ' ' ce rtifi ca te of d ri ve r tra in ing . w hic h

Thi s cont a min a ted pe tro le um w a s so ld to Mr Rea d e r o n three sep a rate occas io ns a t a kno c kdo w n pri ce, a lo n g w ith a quantit y of un co nta min a te d p e trol at mark e t pri ce. Th e tw o fuels were th e n d e liv e re d to the sa m e F o ur Sta r c ompartm e nt a t Mr Reade r 's ga ra g e. It w as ca tego ri ca lly s tate d b y 30 P e tro le um th a t Mr Reader kn ew th e p e tro l h e w a s bu y in g a t th e m a rke d cl ow n pri c e w as co nt a min a te d , a nd the ev id e nce wo uld s u gges t th a t thi s was th e c ase Howeve r, _ thi s was fl a tl y d e ni e d b y Mr R e ad e r. b o th in th e 111 ves t1 g at1 o n and a t th e Co urt hearin g.

The c o urt cases we re he ard sep a ratel y, w ith Mr Read e r· s case he a rd fir s t. He pl ead e d g uilt y to offe n ces of ap pl y in g a fal se trad e d esc rip tio n to F o ur Star p e trol a nd no t la b e llin g th e pump s 111 acco rd a nce w ith BS 4040. Hi s miti ga ti o n w as th at h e did not k no w th e petrol wa s co nt a min ate d Th e M ag is trate defe rre d se nte n ce o n Mr Read e r un t il th ey ha d d ea lt with the case aga in s t 3 0 Pe trol e um a t a la te r el a te , a nd de ma nd ed th at Mr Rea d e r a nd th e Direc tor o f 3 0 Pe tr o le um Limited a tte nd the Co urt a t th e la te r he arin g to bo th g ive ev id e nce in pe rso n

A t th e co nc lu s io n o f thi s seco nd h ea rin g , th e Mag is t rates sa id th ey co ul d no t dec ide w he th e r M r Reade r k new a bo ut th e co nt a min ati o n, b ut fe lt th at th e pri ce di ffe re nti a l s h o uld have a le rt e d him to a pro bl e m w ith th e fu e l. f\tJr Rea d e r wa s fin e d £450 o n th e Trad e Desc ripti o n s Ac t of-f e nces , a nd £75 o n the Co ntrol n f Po llution Ac t o ffe nces. He was a lso o rde red to pay £ I 50 pro sec uti o n cos t s.

3 0 Pe tro le u m of Normanb y, Sc unth orpe we re fin e d f I OOO o n o ne offe nce th at clu e to the ir ac t a no th e r so ld pe tro l fa lse ly d esc ri bed a nd we re orde red to pay £:\()() p rosec u t io n cos ts.

-

NEW METRICATION REGULATIONS

PROPOSED

Th e He a lth and Safe ty Commjssion (HSC) ha s publi s hed a Con s ultative Document proposin g leg islation to m e tricate all health and safety le g islation not previously met1ic a ted , except th a t relating to offshore safe ty

This Consulta tive Document see ks comments on proposed regulations to convert all re maining imperi a l unit s of meas urement in health a nd safety legi s lation (tho se in offs hore safety will be de a lt with separately) to met1ic units of measurement. Some of the propo sals go beyond s imple conversion where HSC believe s this is nece ss ary to provide practicable statutory require ments.

The proposed regul ation s are in three part s:

Part I covers legislation where the only ch a nge need e d is to convert the imperial unit s of mea s urement to m e tric ones.

Part II deal s with legislation on the mea s urement of humidity, and temp e rature and humidity thres hold s, in humid tex tile factories.

Part III deal s with the fl as hpoint provisions of petroleum le g islation.

Metrication of hea lth a nd sa fet y legi s lation and any a sso ciate d Approv e d Codes of Practic e or guidance is required under the provi s ions of a European Community Direc tive relating to units of measure ment.

A c o s t be ne fit assessment of the proposed Regulations ha s concluded that both costs a nd be nefits will be very sm a ll and in te rm s of the eco nomy as a whole a lm os t neg ligibl e, and th at eco nomic impact will be clo se to neutral.

Th e Direc tiv e requires th e R eg ulati o ns to c om e int o for ce by 31 Dece mber 1994. Howev e r, HSC propo ses th at th ey s ho uld co me into effect much ea rlier, about two month s after th ey have been laid in Parliament, probably in mid 1992.

Co mm e nts o n th e prop osa ls s hould be sent to : Mr R Vau g han, SGPB I , Health and Safety Executive, Room 364, Bay nard s Hou se, I Ch e ps tow Plac e, Westboume Grov e , London W2 4TF, to rea c h him no la te r th a n 20 Dec e mb e r 199 1.

AREA CLASSIFICATION CODE FOR PETROLEUM INSTALLATIONS

Institute of Petroleum Model Code of Safe Practice, Part 15

In 19 65, th e fir s t c hapte r of Part I of th e Mode l Code of Sa fe Prac tic e (E lec tric a l) was devoted to g uid a nce on th e cla ss ifi cat ion o f a reas S inc e then, the techn o lo gy has ex pand e d to s uc h a de g ree as to require a separate Co de w hi c h ca n in a consi s te nt ma nn e r, be a ppli e d to a ll sec to rs o f th e pe trol e um indu st ry both up s tream a nd downstream. and to re late d petro le um use r mdu s tn es.

The qu a ntifi ca tion of hazard di sta nc es from so urces of . lease has always pro ven to be o ne of th e mos t difficult to reso lv e. In to this diffi c ult y, th e Code mclude s a lai ge numb et o1 exam pl es which have new I h i· I b been d raw n from th e wea t . o · ex pe ri e nce ac qu1rec y be t co tiip a ni es of the In s titute. These ex ampl es e nabl e me m · th e pra ct ica l appli ca ti o n of th e reco mm e nd a tion s contained in th e Co de to a numb er o f th e more c ommon types o t fac iliti es. in c ludin g drillin g wo rk ove r a nd we ll a he ad o pe rati o n bul k storage tankag e. road. rad a nd marin e load in g a nd discharge. con tain e r stor age and fill111 g. a nd th e se rvice s tati on fo reco urt. h ir le ss u111l o rm ty pe s o l plant. e.g.

proc ess ing plant and crude oil/gas separation , an altema.tive 'point source ' procedure is recommended , whlch def mes petroleum products in four fluid categories. Tables can be used to assess the hazard radius for different size equipment sources of relea se. A detail ed chapter is devoted to the effect of variation in ventil ation level , and the effect of its failure.

Series: Institute of P e troleum Model Code of Safe Practice £69 .9 5 Published on Behalf of the Institute of Petroleum, London, UK. John Wiley & Sons Ltd. Tel. 0243 779777.

NEW 5 GALLON SPILL CONTAINMENT MANHOLE FROM EBW

EBW is announcina their new 705-5 gallon spill containment manhole. The 5 g allon catchment size is ideal for smaller a pplications and adds the benefi ts of an underaround installation The new model features a polye;hylene s hell , cast iron b ase, and lid , in addition to a new Cover Actuated Pu s h Drain (CAPD). The CAPD re main s clo se d while the lid to the co ntainment manhol e is op e n ; and is pushed open when the lid is closed ag a in . The new drain kee ps operations runrun g smoothly and prev e nts de b1is build-up.

For more information on th e new Fl ex Catch equipment, plea se call, Link Hampson 0635 524200.

WATER FINDING PASTE

Evidenc e ha s co me to li g ht th a t Wat e r F indin g Past e ma y not al ways detect th e pres e nc e of a c idi c wate r be neat h o i I. Ac idi c wa te r .ca n res ult fr om mi c rnbi a l grow th. Thus , sta g nant _wa te r tn th e bottom of a n oil/ fu e l ta nk may beco me acidic 11" mi crobia l grow th occurs. a nd mi ght no t th e n be detected by Wat e r F indin g P as te Fo r this reaso n it is rec ommend e d th a t Water Fi ndin g Pa s te s ho uld not be used t.n tes t av iation fu e l o r any ta nk in w hi c h s ig nifi ca nt mi crob ia l growt h m a y have occ urre d .

60

J I ..

Attingham Revisited

Bob Holdaway. Hon. Member

Set in extensive landscaped gro unds and bounded _o n ho ne fl a nk by the ri ve r Tern a t1ibutary of the Severn, Attrng P ark was built in the years 1783-87 by George the 1st Lord Berwick , a nd is a very beautiful example 0 t e arc hitecture of the period

In 1947 the 8th Lord Berwick s hortly before hi s death beq uethe d the whole estate and to the National Tru st. Lady Berwick continued to liv e in apartments on th e east s ide of the main block th e rest of the house being le ased to the Governors of the Shrop s hire Adult Colleg_e as a reside nti a l c entre for adult ed uc a tion . So it was that 10 I 9 62 • afte r much plannin g the Association held the of seve n co n sec uti ve sc hool s in thi s most d es ira ble locat10n.

· · warm

Students were always fortunate in recei vin g a welcome a nd conducted to ur of the hou se b y Sir Trevalyn. Bt. , M.A. , the eb ulli e nt Warden , who is remembered b y many in Shropshire and elsewhere wit gratit ud e and affection. He so eas ily shared hi s lov e of Attingham with all who met him , and hi s convi c ti o n that " Something strange happ e n s to time here" , although so tru e, s till left students with the feeling that even so,. such protracted time was often a ll too sh o rt to absorb and di sc u ss the many facets of pe trol e um a dmini s tration

Fo ll ow in g th e d ea th of Lady Berwick in 1972 a nd th e clo s ure of the Shrop s hire Ad ult Co lle ge in 1976, the Nat io na l T ru s t took c u stod y of th e e ntire hou se a nd have o ver the years gradu a ll y re s tored th e room s to their rege ncy s plendour.

T hi s yea r I beca m e a National Tru st volunta ry room s te w a rd a nd durin g th e sea so n ca n be found every Tu esday afte rn oo n , ge nera ll y in the Nash picture gallery with it s co ll ection of French an d It a li a n paintings , lit nat ur a ll y from abo ve by a s plendid coved cei lin g, the framework of ca st iron a rch es be in g m ade in Abra h a m Darb y ' s work s at Co a lbrookda le , th e n th e c e ntre of the indu strial revo luti on O cc a s io na ll y I hav e a s p e ll of duty in the dinin g room (th e fo rm e r le ct ur e room) w ith it s pompeian red wa ll s, th e libra ry a nd th e d raw in g room , so fa miliar to s tude nts of yes te rye a r. M e m o ri es of d a y s pa s t fl ood my mind a nd o ne afte rnoon w he n a y oung tee n age r a s ke d if there were a ny g ho sts in th e hou s e, l unthinkin g ly re p li ed " Yes, hundre d s of th e m "

A nd th e re are hundre d s o f t he m . C o ll eag ues w ho organ ise d th e c o u rse s. le c ture rs from the pe trol e um indu s try and loc a l !.! Ove rnrn e nt and s tud e nt s of a ll a ge s a nd di s c ipl in e s w ho e a ge r to le arn a nd be ne fit from thi s tranquil and concluc i ve a tmo s ph e re.

Today althou g h hundred s of people of a ll na ti o na li ties pass through the hou se a nd woodlands every week , their vis it is a tran sient one and in a n hour or so the y a re go ne a nd at 5 o'clock the hou se is put to b ed until 1.3 0 th e next afte rn oo n when the procedure is re pea ted Thi s more than a nyt hin g brina s home to me how fortunate were tho s e of u s w ho we re privileged to live in the hou se for over fort y e ig ht h o urs and to enjoy the unique atmosphere.

To those pres e nt day members of the As soc iat ion who as "yo ungsters" shared this experience, to any re tired member who may re ad thi s article , a nd to all memb e rs I se nd my reaards and bes t wishes for the continued su ccess of th e b APEA.

ABOVE GROUND TANK

Aboveground storage tank s (AST) have been described as be ing the most attractive or safes t pieces of equipment on th e petrol e um market. How eve r, _ so urc es report that a new aest hetically designed , lo w-n sk AST model that has ap peared in the US marke t is ex pec ted to red efine the liquid storage tank market in th e years a h ead.

Manufacture d by Clawson Tank Co ., based in C la rk so n , Mich. , Liqui-Vault ha s bee n praised for it s attract ive a ppearance coupled w ith a ho st of impress ive safe ty features.

The Liqui-Va ult , which is available in capac iti es from 1,000 gal, to 15,000 gal., was designed by an a rti st a nd not an engineer, so it is arc hitecturally pleasin g That lead s to planning advantages in that a Liqui-Vault ow ne r doesn't have to build barri ers aro und th e tank to hid e it because it' s not aest hetic . A variety of color tint s are available to a ll ow Liqui-Vault to bl e nd in w ith its smrnundin gs a nd e liminate the need for fr eq ue nt paintin g.

Official s say putting looks aside, the tank is built lik e a fortress a nd has a low li a bility quotient. That e le m e nt has helped sales the most. Liqui-Vault is in s tall ed in s id e a 6-in. co ncrete enca se me nt a nd fea tures double-w a ll prot ect ion and a two-hour fir e ra tin g It provides durabl e, safe s torage of flammable and co mbu stible liquids and fuel s. Th e sys te m include s electronic lea k mon itoring and w ater de tec tion. While other abo vegro und tanks are s usce ptibl e to damage , thi s tank is vandal-proof.

The tank is a lso impe r vio us to the el e m e nt s. A stee l roo f w ith eave s ex te ndin g beyo nd the tank preve nt s rain a nd s now from en te ring the inters ti ce bet wee n th e stee l and concrete walls.

6 1

Dear Editor,

It has become apparent over recent months , that there has been a negative reaction by some people concerned with the installation, inspection and authorisation of underaround b pipework used at petrol filling stations, to the fact that 'HITACHI ' Gourd Brand Malleable Pipe Fittinas do not carry the 'KITE' mark. b>

In order to dispel any doubts that may exist we would make the following points:-

I. They are manufactured by a BS. 5750 quality assured company.

2

. They have been sent to the British Standards Institute for testing and conformed to BS. 143 on all the tests carried out.

3. In some respects they exceed the requirements of BS . 143, particularly the of the whereas BS 143 calls for :12coatmg mass of G/M 610 min. Hitachi rates at G/M 1265

4. fittings have undergone testing by one of the 011 companies and have been approved for use on thelf mstallations .

5 We have supplied Hitachi fittings for over 20 ye<u-s and have never in all that time had a fittina returned with any fault. 0

If a ny member wishes to have a s ample of either the fitting or the BSI report we shall be pleas e d to oblige.

D. A. BERRY, D. Be rry & Co. , (Pipe Fitting Suppli es ) Ltd. A PE A. Member

Dear Editor,

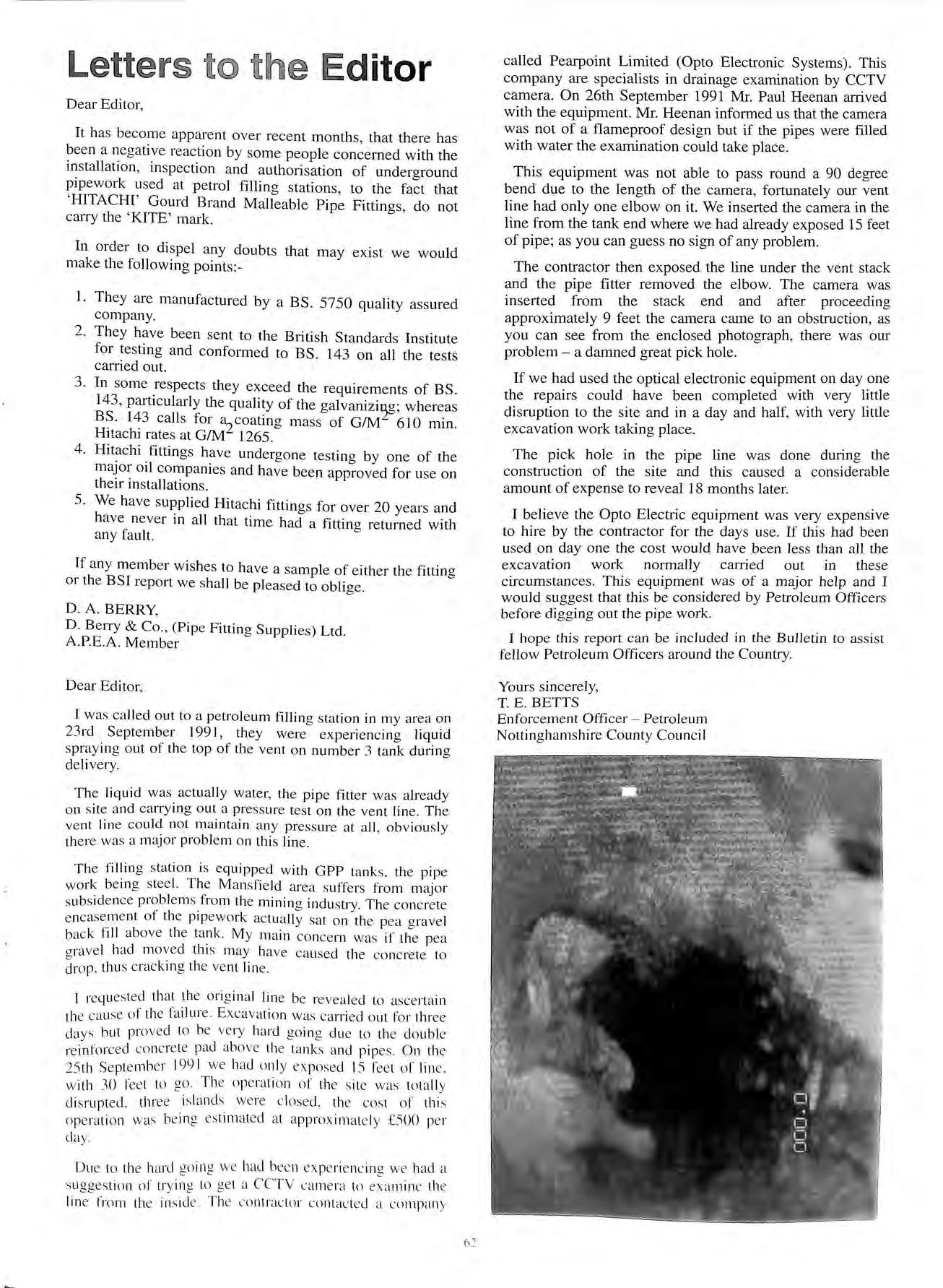

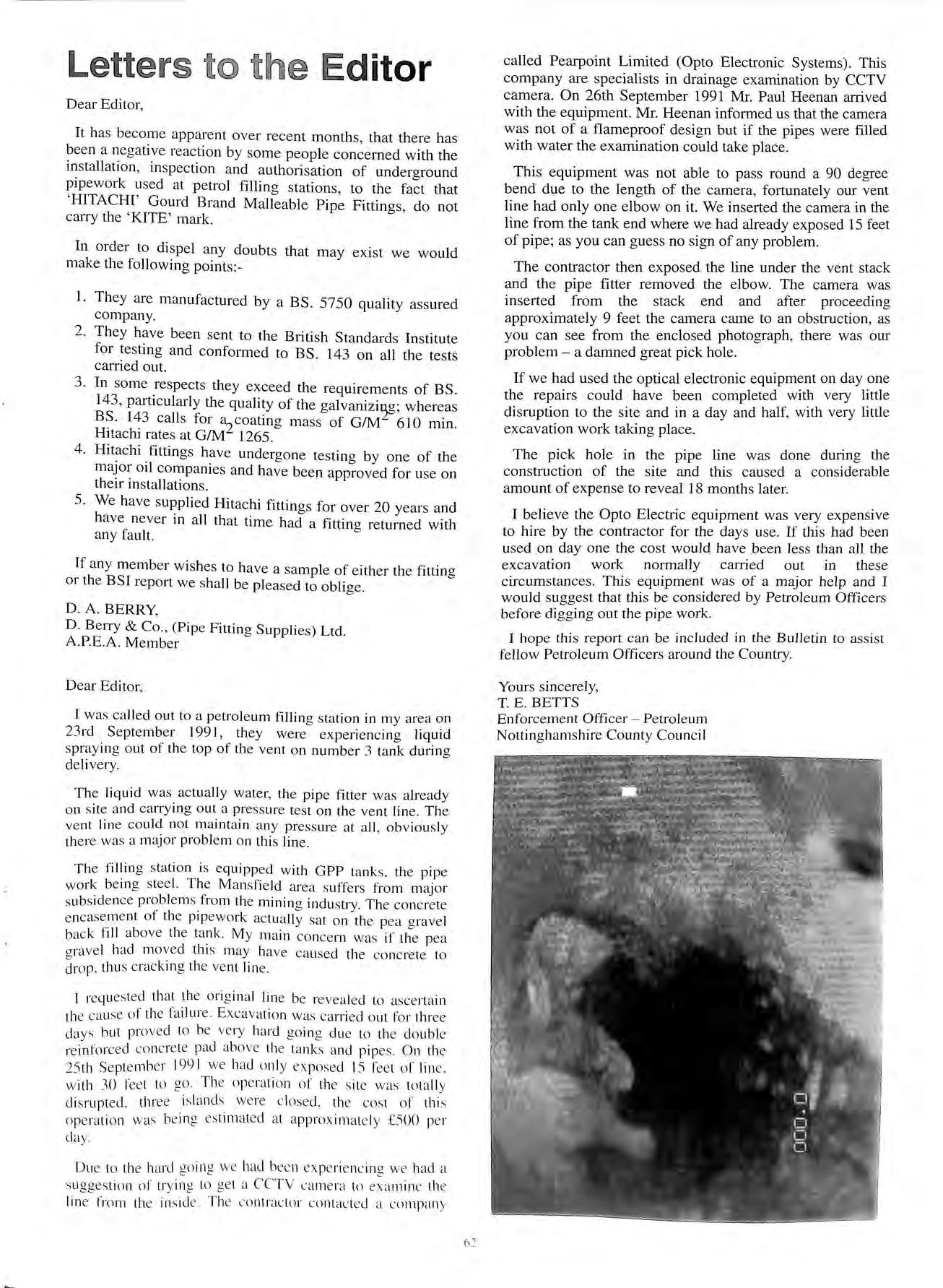

l w as called out to a petrol e um filling station in my a rea on 23rd S e ptember 1991 , they were experiencing liquid sprayin g out of the top of the vent on number 3 tank during d e liv e ry.

Th e liquid wa s actually water, the pipe fitter wa s already on s ite a nd carrying out a pre ss ure te s t on the vent line. Th e ve nt lin e could not maintain any press ure at all , obviou s ly th e re wa s a major probl e m on thi s lin e.

Th e fillin g s tation is equipp ed with GPP tank s, th e pip e wo rk be in g s teel. The Man sfi e ld area s uffers from major s ub s id e nc e problem s from th e mining indu s try. The con c re te e nc ase me nt of the pip e work ac tu a lly sat on th e pea grav e l back fill above the tank. My ma in con ce rn wa s if th e pea g rav e l had mo ve d thi s may ha ve c a used the c oncre te to dr o p. thu s c racking the ve nt lin e.

I requ es te d that the o ri g inal lin e be rev eal e d to a sce rtain th e ca use of th e failure Exc a vati o n was ca rri ed out for three cla ys but pro ved to be ve ry hard go in g du e to th e do ubl e re inforce d co nc re te pad ab ove the ta nk s and pip es On th e 25t h Se pt e mb e r 1991 we had o nl y ex pos ed 15 fee t o f lin e. w ith 30 fee t to go . Th e op e rati o n of th e s ite was totall y clisrupte cl thre e is land s we re c lose d . th e cost of this o pe rati o n was be ing e stimate d at appro x imat e ly ±:500 pe r d ay.

Du e to th e hard go in g we had bee n ex pe ri e nc in g we had a s ugges tion o f tr y in g to ge t a CCTV ca mera to exa min e th e lin e fr o m th e in s id e. Th e contra c to r c ontac ted a c ompan y

called Pearpoint Limited (Opto Electronic Systems) . This company are specialists in drainage examination by CCTV camera. On 26th September 1991 Mr. Paul Heenan arrived with the equipment. Mr. Heenan informed us that the camera was not of a flameproof design but if the pipes were filled with water the examination could take place.

This equipment was not able to pass round a 90 degree bend due to the length of the camera , fortunately our vent line had only one elbow on it. We inserted the camera in the line from the tank end where we had already exposed 15 feet of pipe; as you can guess no sign of any problem.

The contractor then exposed the line under the vent stack and the pipe fitter removed the elbow The camera was inserted from the stack end and after proceeding approximately 9 feet the camera came to an obstruction, as you can see from the enclosed photograph, there was our problem a damned great pick hole.

If we had used the optical electronic equipment on day one the repairs could have been completed with very little disruption to the site and in a day and half, with very little excavation work taking place.

The pick hole in the pipe line was done during the construction of the site and this caused a con siderable amount of expen se to reveal l 8 months later.

I believe the Opto Electric equipment was very expensive to hire by the contractor for the days use. If this had been used on day one the cost would have been less than all the excavation work nonn ally ccuTied out in these circumstances. This equipment was of a major help and I would suggest that this be considered by Petroleum Officers before digging out th e pipe work.

I hope this report can be included in the Bull e tin to a ss is t fellow Petroleum Offic ers around the Country

Yours sincerely, T. E. BETTS

Enforcement Offic e r Pe trol e um Nottinghamshire County Council

Letters Editor

ENVIROFLEX PRESENTATION TO ASSOCIATION FOR PETROLEUM AND EXPLOSIVES ADMINISTRATION

DUNSTABLE, GREAT BRITAIN SEPTEMBER 24, 1991

By Marc Gundon

I would first like to thank the Association for Petroleum and Explosives Admini s tration for the opportunity extended to Total Containment, Inc to pre se nt at the conference at Dun s table and in the Journ a l, its so lution to petroleum underg round piping systems and the contro l of leak s such piping may create

I will fir st try to document the fact that underground piping sys tem s leak, then de sc ribe the specifications Total Containment determined for th e Enviroflex system and what solutions were found to me et the se s pec ification s

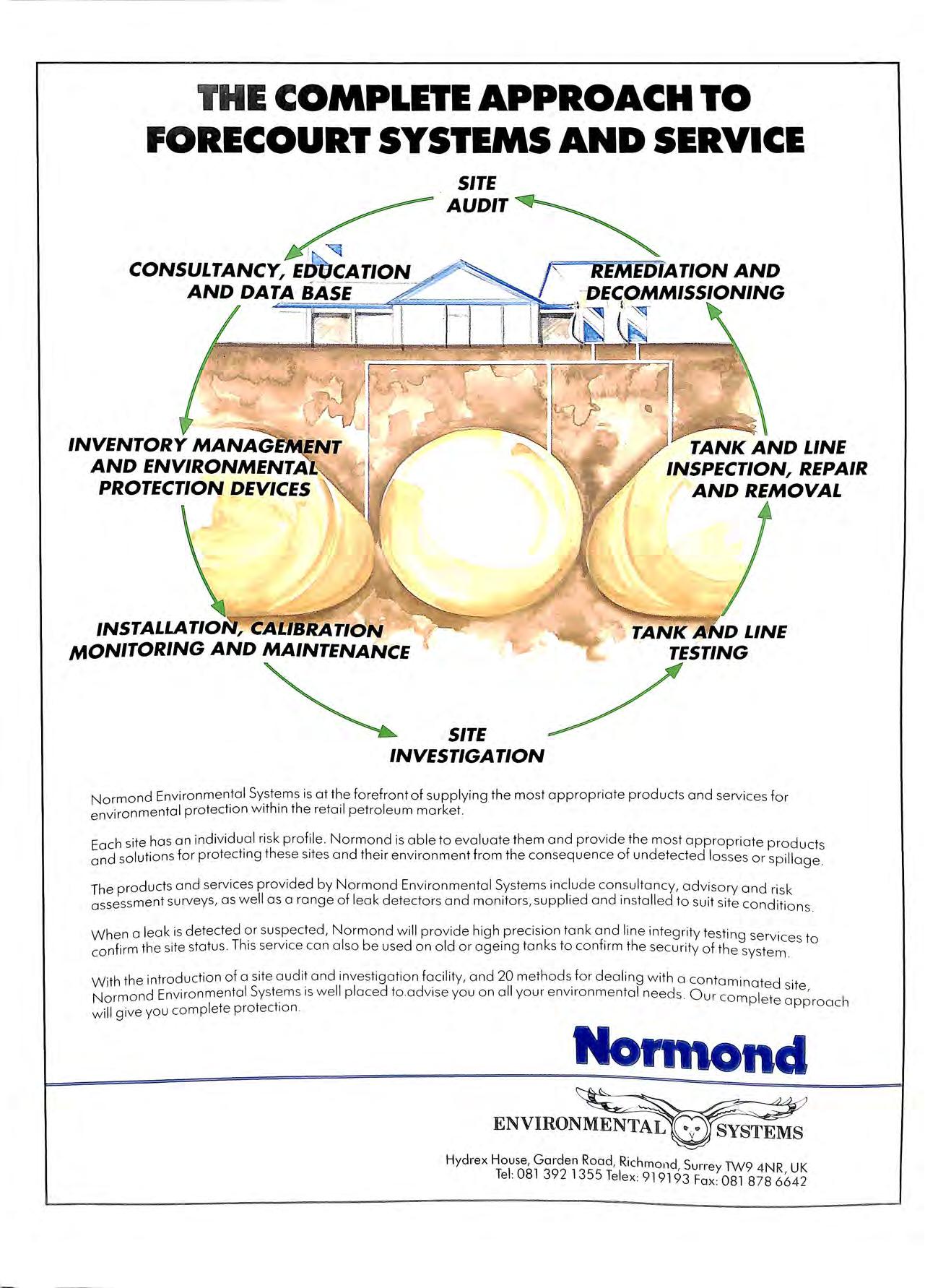

E n v irofl ex is a produ ct of Total Containment , a US co mp a n y s pecialized in the conception, de ve lopment and marke tin g of product s for le ak preve ntion and conta inm e nt. To ta l Containment produc es four familie s of product name ly:

the Total Containm e nt tank, a double wa ll ta nk co mpri se d of an interior s tee l tank and an exterior air tight wall mad e of high d ens ity polyethylene complete ly in s ul at in g the s teel tank and protec tin g it from outside co rro s ion ;

Pipe Jacket a seco nd a r y pipin g sys tem des ig ned to e nc lose primar; rig id pipin g a nd res train any leak from esca pm g it s b o undar y;

tank and di s pen se r s ump s, liquid ti g ht chambers de s ig ne d to co nt a in any leak oriainatina at th e numerou s J·oints found b b a t the ta nk pen e tration s o r at the di s pen se rs;

E n v iroflex , an und e rgro und d o ubl e wa ll fl ex ibl e pipin g sys te m d es ig ned to ca rr y h azard o us s ub s tance s, from o ne point to a nother w hil e co ntainin g any po ss ibl e leaks. E n v 1ro fl ex was d es ig ned pa rti c ul a rl y w ith the forecourt in mind to ca rr y re fin e d petro le um , fr o m a tank to a di s pe nse r a nd c atch a n y drop of pe tro le um that ma y esca pe befo re it reac hes the so i I.

E n v irofl ex is a rece nt sys te m but it is no lo nge r new. It has und e rgon e a n ex ten s ive tr ia l pe ri od w ith ove r 500 sys tem s no w opera tin g. A l th e pres e nt t im e 75 to 100 s ys tems a re h e in g 1n s ta ll e cl eve ry m o nth. T he m aj o r c usto me rs a re FXXON AMOCO a nd SOUT HL AND. The produ c t is used 1 n A merica. E u rope , As ia and So uth America. Willy we need double wall systems. T h <' n ee d for dou bl e wa ll und e rg round ta nk a nd pipin g y 1c 111 s c ame from c oncerns of th e ge ne ral publi c a nd

public institution s about petroleum leak s cau s ing water pollution . In America as in many parts of the world, a large part of the population depends on und erground water resources for its supply of potable water. The general public in America c a me la te to Perrier and other bottled wate rs which are still referred to as designer water in mo st circles. In America , drinking water sti ll comes from the ta p , be it in restaurants or home s and it does not mix h a ppily with refined petroleum. It only takes I part p e r million of gaso line to make water unpotable. 1

Of course legis lation follow s public concern a nd we have see n and will see a myri a d of different law s aimed at pollution control a nd reg ulating th e di s tribution of petroleum product s at the loca l, regiona l and national leve ls. These regulation s have a tendency to add to one another and restrict more and mo re the products and method s one can use to carry petrol e um. Fortunately or unfortunate ly, depending on one's point of view, the regul a tions tend towards double wall sys tems which can contain and monitor leak s .

A s if the impo s ition of re ne wed sys tems w as no t o ne rou s e nou g h , there is a te nde nc y to impose fine s and corrective meas ure s upon th e pollute r which can be very cost ly indeed We have all heard horror s tori es of cost of co rrect iv e mea sure s ranging from hundre d s of thousand s to million s of pound s 2

A third trend , quite perniciou s this one , transfe rs c lean- up liability to th e la st owner of the property, creatin g havoc in property valu es and se riou s ly undermining th e capacity of operators to obtain finan c in g as the mort gage r' s sec urity may beco me more of a liabilit y than an asset. In m o re a nd more c a ses, we see le nd e rs pre ferring to lose th e ir e ntire loa n than to forecl ose o n a prope rt y where be in g ow ne r a lso mea ns bein g li abl e for clean-up costs.

Do they leak ?

A numb e r of studi es have d e te rmined th a t und e rg ro und ta nk and pipin g sys te ms d o lea k. As a matt e r of fac t , some of th ese stud ies show a s ituation so bad that it is hard to be li eve. Th e original ass umpti o n was that tank s were the cu lprit a nd s tudi es were dir ec te d mo st ly to wards tank s. Th ese s tudi es effecti ve ly fo und a n alarmin g s itu at io n with ta nks but thi s was o nl y the tip of th e ice be rg. And w hat a n ice be rg it is' In it s publication s , th e US E PA reports . a nd I quot e: ·'As ma ny as 25 pe rce nt o f al l und e rground storage

tank s are leak in g."' Of course it ha s to be sa id th a t b y tank th e E PA m ea ns both the tank a nd pipin g sys te m Th e EPA also says: "T h e most s ig nific a nt findin gs developed to dat e are: That product d e li ve ry pipin g re leases a nd spills/overfills are the m os t numero us so urces of re leases, and no t th e tank age as o rigin a lly beli eved."-1 It says 111 a noth e r publication: "E PA studies show that m os t leaks res ult from pipin g failure. Pipin g is s maller a nd les s s turd y th a n tank s. It is asse mbl e d in the fi e ld with numerou s connection s a nd u s u a lly installed nea r the s urface. As a res ult pipin g s uffe r s much more than tanks from the effec ts of in s ta llation mi s ta ke s, exces s iv e s ur face loads, th e s tress of und e rg ro und m ove ment and co rro s ion."'> I co uld go o n a nd quot e o r crossrefe re nce m a ny other so urc es . Yes they d o lea k!

Why do they leak?

Based on co ns ultati o n of seve ra l ex pe ri e nce d co ntrac to rs by the EPA , Underground pipin g sys tems leak beca use of co rr os ion a nd leak in g j o int s.C' It is very h a rd to a rg u e with s uc h a s tate m ent.

Other th a n co rro s io n, recogni ze d leak facto rs also point to j o int s as th e c ulprit: so il mo veme nt res ultin g fr o m fr os t o r o th e r rea so ns; th e coeffic ient of expans io n of pipes and joints due to c ha n ge of temp e rat ure and press uri z ation; b ad in sta ll a tion s .

In Britain. the use o f co n c re te tre n c hes enco mp ass in g th e pip e ce rt a inl y dra s ti ca ll y the corrns ion fa c to r by in s ulating th e pip fr om e lec tri c c urre nt s and isolatin g 1t 111 a favorab le env iro nm e nt.

In add iti o n. the use of s uc ti o n sys te m s h e lp by limitin g s ize o f leaks but unfortunat e ly doe s not stop th e m. It does no t sto p th e m beca use se r vice stat ion o pe rato rs ofte n c hea t th e ir s uc tion sys te m s. Th ey c h e at b y us 111 g c hec k va lves al th e ta nk e ncl of t he pip es. c hec k va l ves w hi c h k ee p liquid 111 syste m at a ll tim es thu s ca nce llin g th e safety built in th e syste m .

Specifications of Enviroflex to prevent leaks

Knowin g th ese probl e m s with und e rgro und p1p111 g To ta l Containment se t out to spe cify a new approach which would hopefull y make leaks so mething of th e pa s t. Thi s wo rk was_ d o n e in coo rdin a ti o n w ith EXX ON a nd its gro up o f app li ca ti o n e n g ine e rs in H o us to n

Th e s pecifi cat ion s of the Enviroflex syste m a r e a s fo ll ows: double wa ll syste m becau se o nl y s u c h sys te m s provide fo r co nt a inm e nt of a leak from th e prim a ry pip e a nd for ways to tell the operator if th e prim a ry o r seco n da ry pipes a re leakin g o r could possibly a ll ow a leak to s pill o ut s id e the syste m . n o n corrosive mate ri a ls, because corrosion is th e m a in and mo s t fr e quent so urce of leaks. no j o int s und ergro un d. becaus e j o int s are th e seco nd m os t fr eq u e nt so urce of leaks fl ex ibl e pipes, beca u se fo reco urt pip in g does n o t n ecess arily require th e u se o r 90 ° turns as wo uld b e required in a buildin g; also b eca u se th e primary should be re placeable , 1f nee d b e. by pulling it th ro u cr h th e seco nd a ry wi th o ut teari n g th e forecourtapart. e ease of in sta llati o n , becau se in s tall a ti o n mi s takes are a very imp o rt a nt so urce o f leaks. of le ak.s occurrin g a t th e ta nk pen e trati o n s and at th e dispe n se r J0 1nt s a nd co nn e ·t1 · 11 L 0 p e nrnt easy 111 sta llati o 11 of. lea k detection a nd in spec ti o n. be 111 s tall ed o nl y b y train ed and a uthori ze d co ntra c to rs.

The diffe re nt part s to b e u se d in th e sys te m had to h ave the lo ll ow 111 g c h arac te ri st ics:

Pe tro le um a nd so il res is t ance p rim a r y to s upport '.'i tim es opera1 in g press ure. 250 ps i 20 yea rs Ill e ex p e ctancy primar y to h ave ze ro rn: n ea r zero permea ti o n t'l ex ibilit y

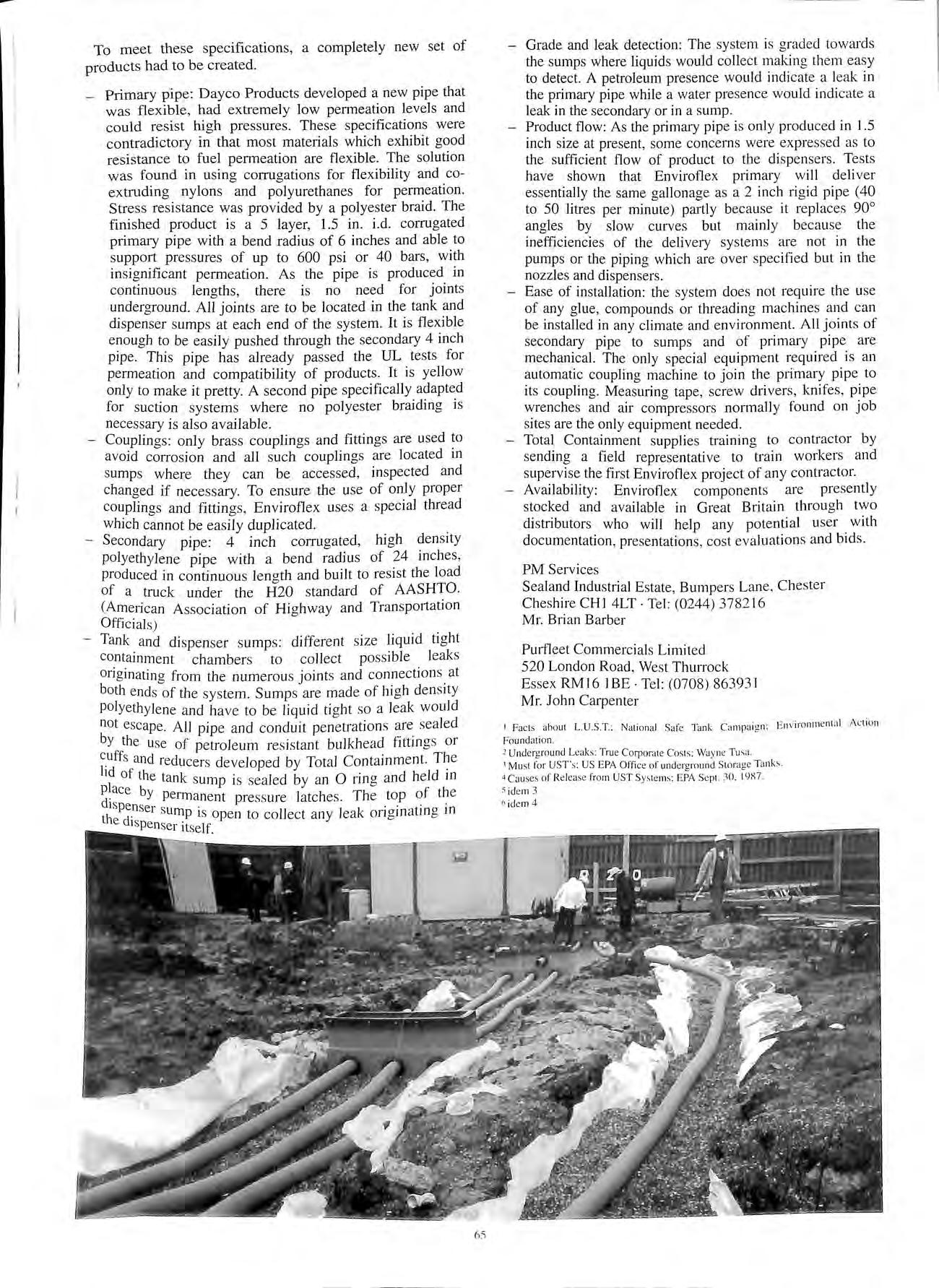

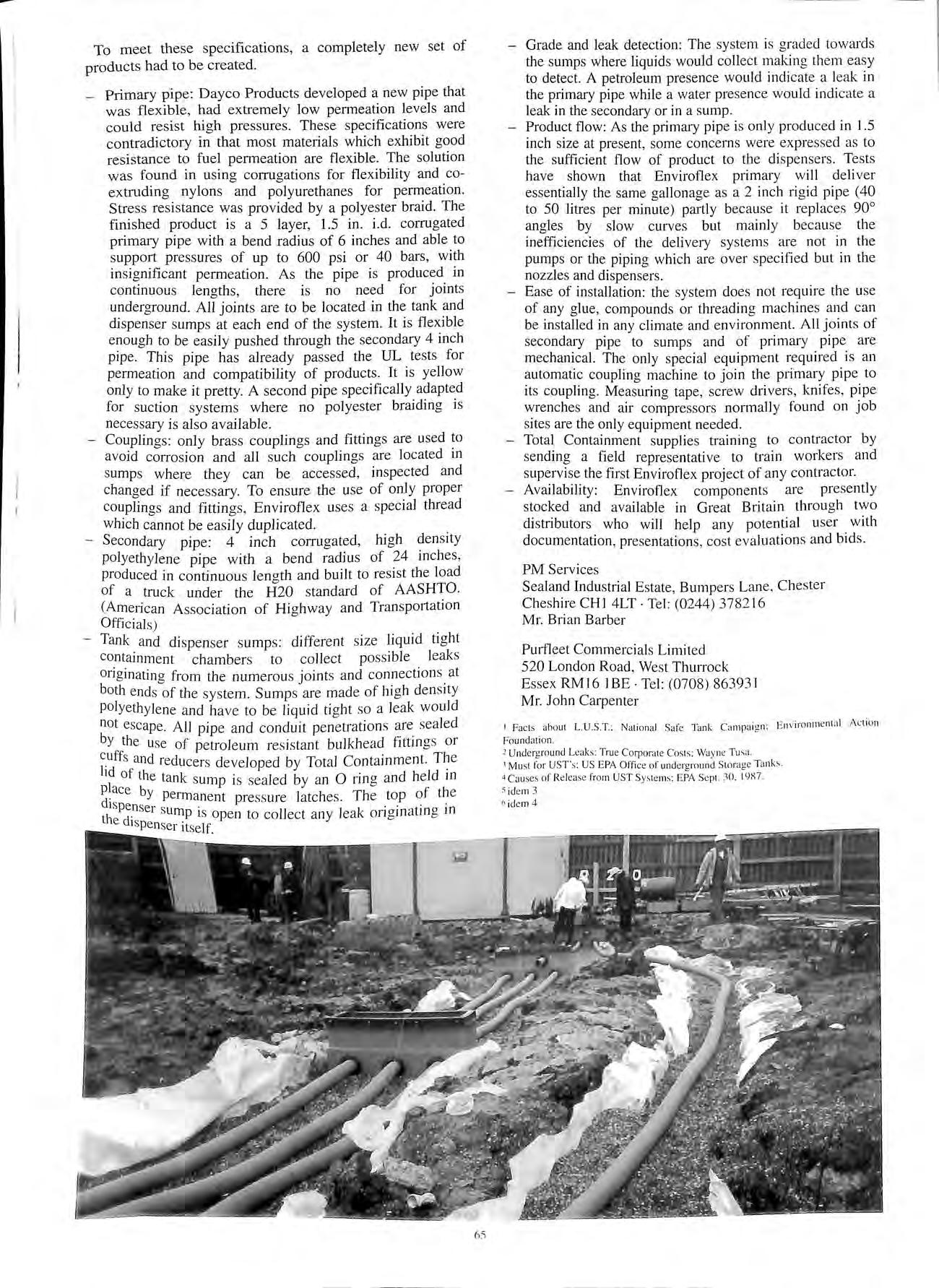

To meet these specifications, a completely new set of products had to be created.

Primary pipe: Dayco Products developed a new pipe that was flexible , had extremely low permeation levels and could resist high pres sures. These specifications were contradictory in that most materials which exhibit good resistance to fuel permeation are flexible. The solution was found in using corrugations for flexibility and coextruding nylons and polyurethanes for permeation. Stress resistance was provided by a polyester braid. The finished product is a 5 layer, 1.5 in. i.d. corrugated primary pipe with a bend radius of 6 inches and able to s upport pressures of up to 600 psi or 40 bars, with in sig nificant permeation . As the pipe is produced in continuous lengths, there is no need for joints underground. All joints are to be located in the tank and dispenser sumps at each end of the system. It is flexible enough to be easily pushed through the secondary 4 inch pipe. This pipe has already passed the UL tests for permeation and compatibility of products. It is yellow only to make it pretty. A second pipe specifically adapted for suction systems where no polyester braiding is necessary is also available

Couplings: only bras s co upling s and fittings are used to avoid corrosion and all s uch couplings are located 111 sump s where they can be accessed, inspected and changed if neces sary. To ensure the use of only proper couplings and fittin gs, Enviroflex uses a special thre ad which cannot be easily duplicated. .

Secondary pipe: 4 inch corrugated, high density polyethylene pipe with a bend radius of 24 inches, produced in continuous Ien oth a nd built to resist the load of a truck under the H20 standard of AASHTO.

(A merican Association of Highway and Transpo11ation Official s)

Tank and di spenser s ump s: different s ize liquid tight co ntainment chambers to collect possible leaks orig inating from the numerou s joints and connection s at both end s of the system. Sumps are made of high den s ity polyethylene and have to be liquid tight so a leak would not escape. All pipe and conduit penetrations are sea led by the use of petroleum res ista nt bulkhead fitting s or c.uffs a nd reducers developed by Total Containment. The lid of the tank s ump is sea led by an 0 ring and he ld in by permanent press ure la tche s. The _top of the th P ser sump 1s open to collect any leak ongmatm g in e di spe nser itself.

Grade and leak detection : The system is graded towards the sumps where liquids would collect makin g them easy to detect. A petroleum presence would indicate a leak in the primary pipe while a water presence would indi cate a leak in the seco ndary or in a sump

Product flow : As the primary pipe is only produced in 1.5 inch size at present, some concerns were expre ss ed as to the sufficient flow of product to the dispen se rs. Test s have shown that Enviroflex primary will deliver essentially the same gallonage as a 2 inch rigid pipe (40 to 50 litres per minute) partly because it replaces 90° angles by slow curves but mainly b ecause the inefficiencies of the delivery systems are not in the pumps or the piping which are over specified but in the nozzles and dispensers

Ease of installation : the sys tem does not require the use of any glue, compounds or threading machine s and can be installed in any climate and environment. All joints of secondary pipe to sumps and of primary pipe are mechanical. The only special equipment required is an automatic coupling machine to join the primary pipe to its coupling. Measuring tape, screw drivers, knifes, pipe wrenches and air compressors normally found on job sites are the only equipment needed.

Total Containment supplie s training to contractor by sending a field repre se ntative to train workers and supervise the fir st Enviroflex project of any contractor.

Availability: Enviroflex components are presently stocked and available in Great Britain through two distributors who will help any potential user with documentation, pre se ntations , cost evaluation s and bids.

PM Service s

Sealand Industrial Estate, Bumpers Lane, Chester Cheshire CHI 4LT ·Tel: (0244) 378216

Mr. Brian Barber

Purfleet Commercial s Limited 520 London Road , We s t Thurrock Essex RM 16 I BE · Tei : (0708) 863931

Mr. John Carpenter

65

1 Fact s about L. U.S.T. ; Na ti ona l Safe Tank C ampaign; Environm e ntal Fou nd at ion. 2 Underg round Leak s: Tru e Co rp orat e Cos ts : Way ne Tu sa ' Mu s t for UST' s : US EPA Offi ce of und e rground Storage Ta nk s •Cau ses of Release from US T Sy s tems: EPA Sept. 10 J 987. .s ide m 3 6 id e m 4

MANGAN BROS. LTD. Building Contractors 402 Seven Sisters Road, London N4 2LU (REGISTERED OFFICE) Telephone: 071 800 4651 Specialists in Petrol Filling Stations D. & S. Leggett (Electrical) Limited ELECTRICAL CONTRACTORS NICE/C APPROVED 181 VICTORIA ROAD, NEW BARNET, HERTS. 081 441 3958 Fax: 081 449 3470 SPECIALISTS IN PETROL STATIONS

Conder's aim has always been to develop better products and bui lding methods to accelerate the construction process the sooner your fo recourt is up and ru nning, the sooner your return on investment. 30 years ago we introduced the prefabricated Canopy, later th e GRP Interceptor and most recently the revolutionary Fibrelite Access Covers with their light weight. you don't need a 'feat' of strength to lift them. Now, Conder can offer a complete range of ready-made products designed specifically for the forecourt.

Modular Convenience Store and Car Wash buildings delivered to site ready w ired, plumbed and fitted out for rapid assembly; Access Chambers to contain possible fuel spillage and keep out sub-soil water; Silt Traps to avoid drain blockages and last. but not least, Pump Island Barriers all from one source and delivered to site.

CONVENIENCE STORES CONDER PUMP ISLAND BARRIERS CONDER INTERCEPTORS CONDER LIGHTWEIGHT ACCESS COVERS CONDER SILT TRAPS ' ACCESS CHAMBERS CONDER PRODUCTS ON THE FORECOURT CON DER PRO DUCTS ABBOTIS BARTON HOUSE WORTHY ROAD W INCHESTER S023 7SH TELEPHONE 109621863577 D. BERRY &CO. Overfill Prevention Vapour Recovery Flexible Connectors ( Pipe LTD Supplies Unit P10 Middlernore Ind Es tat e. Kentish Rei Birmingham 821 OAY Tele phon e 021 ·5'i8 44 11 Fa..-x: 021 55 5 5'i 46

-W. LAMB LTD. THE PREMIER PUMP AND TANK COMPANY Forecourt and Commercial Above and Below Ground Supply Test Exchange - Service - lnstal Product Transfer De-Watering Removal Purchase Tank Demolition Removal Safety Filling Large Stocks of New and Secondhand Petrol and Diesel Pumps, Tanks and Accessories DAYBROOK STREET, SHERWOOD, NOTTINGHAM 0602 621511 + 608084 TRINITY WORKS, BOURNE END LANE, HEMEL HEMPSTEAD WJ FINCH LTD (INSTALLATIONS and CONTRACTORS) Regd. Office: STONE CROSS GARAGE PENKRIDGE, STAFFORD STI 9 SAS 0442 872296 Tel: 0785 715777 Fax: 0785 714123 OFFERING A TOTAL SERVICE COVERING ALL ASPECTS OF FORECOURT REQUIREMENTS, RANGING FROM CONSTRUCTION & INSTALLATION OF COMPLETE NEW BUILD OR REDEVELOPMENT, WITH FULL DESIGN & BUILD OPTION, TO GENERAL PIPEWORK & PUMP=TANK INSTALLATION & TESTING, IN ADDITION TO OUR GENERAL SITE MAINTENANCE WORKS. ESTABLISHED 1964

"IN PE T LEUM SEMINAR " 24 September 1991

Opening

Remarks by D C S Willis Chief Executive MICRELEC GROUP PLC

Two weeks ago when I heard th at Jamie Thompson had b ee n trying to get hold of m e, my immediate reaction w as one of trepidation as I thou g ht he was about to herald news of fresh di s asters on a filling s ta tion in the London area. When he sa id that the purpo se of hi s call was to invite m e to open thi s Conference , I was na tur a ll y extremely flatt e red and very plea sed to have been asked. I was even m_o re flattered when he told me th at in fact I was second choice, and that your Committee' s fir st choice w a s Mini s te r, John Major, who wa s unable to confirm his acce ptance due to affairs in Eastern Europe and undoubtedly, at that time, in Smith Square.

Since we were all here a year ago, much has happened on th e environmental side of our business. The Environme nta l Prot ec tion Act has become law ; HSG 41 ha s been publi s hed a nd new Regulation will re quire Stage I va pour recove ry sys te m s to be in stalled at all s ite s by 1997. In Ge!m a n y_ a n_d other EU countries, seco nd ary Stage II vapou1 1ecove1 y 1s l. k ly to become mandatory within th e nex t 12 m onths, a nd i e . I I b in the UK the National Rivers Auth o rity ms cert a m y ee n t· 11 a 1 ·ts new power s in term s of forecourt wast e asse1 1 o interceptors.

Close to our busine ss, a numb e r of other s tep s I ve been ta ke n to improv e th e sa fe ty of f11l111g s tation s a nd ia h atte mpts h ave bee n. m a d e to reg ul a ri se t e aspe c ts co nce rnin g the protect ion of th e e n v ironm e nt s urroundm g a e tr o l fillin g s tation. Under the a us pi ces of the H ea lth and p k" I b Safety Exec utive , two wo r ' m g parti es rnve ee n esta bli s hed, the M ec h a rn ca l Wo r k 111g P a rt y a nd th e E lec tri ca l Working Pa rty , o n w hi c h a numb e r of nota bl e Jeople are re pres e nte d. J a mi e Thompson sits on both John Dunk._ C hairm an of IP P a ne l A a nd Lu a g: of BP Oil a re also 111 vo lved . So a re Bruce Pe tt e r of the PRA a nd Fred Wil so n of th e PPMA. as we ll a s re pre se n ta ti ve s of th e H SE.

My und e rstandin g is th a t o ne of th e objec ti ves of th ese two C imitt e es is to look a t th e e n v iro nm e nt a l. a s oppo se d to on · · 1 I" th e safe ty. aspect s 01 · th e Hea lth a nd Safety g u1 c e mes pe rt a inin g to petrol fillin g s tati o ns a nd I am s ure a ll ot. u s w e lco m e thi s initi a ti ve. O ne s uh1 e c t c urr e ntl y be in g di sc us sed is prec ision tank te st in g In ad dition LA COTS ha ve be e n look in g a t th e pe troleum li ce nc e 111 ord e r to in corpo ra te ce rt a in iss ue s of e n v ironm en ta l prot ec tion a s we ll a s o f c ourse of s afe ty. int o a sta nda rdi sed se t of g uidin g not es for pe trol e um offic e rs . Ag a in . a we lcom e d initiati ve to e ns ure we are a ll working o il a leve l pla y in g fi e ld

However, d_espite the se initiatives , there is still a g r ea t de a l to be done m te1m s of coordinating the infomiation and ex perience that is b e ing ga th e red both here and on mainl a nd Europe so that the indu stry can agree a se t of sta ndard s aga inst which to wor_k in terms of the various as p ec ts of e nvlf_onmental protection. I believe it is ab so lutely vital that our mdustry become s bett e r coordinated so th a t it can protect itself against inappropriate , unec o nomic a nd unworkable regulation s. Unless the industry become s b e tter coordinated, we are at risk of having hoisted on u s unwanted products fro m th e more environmentally cons c iou s United States o_r, 111appropri a te leg i s lation from th e European co mmurnty.

I believe it is in our se lf interes t th a t tho se of u s h w 0 re pre se nt otl co mp a ni es , lic e ns ing authoriti e s a nd th e pro v 1s 1on of sys te m s a nd se rvi ces , g et toaeth e r to pro v· d t · h o 1 e a urn_ orm v01ce t at h as a n influ e nce in Westminster. as well as 111 B'.·usse ls, to e n s ure that _l eg is la_tion that is c urre ntl y bemg d1afted 1s workable , a nd 111 our mtere s t as well as th e 111teres t of th e ge neral public I do not believe either th e IP o r UKPIA are do111 g e no ug h o r are showina the 1 ·n1·t1·at· h o 1ve s t at I beheve are necessa ry m thi s res pect.

C h a irman. I th e refo re we lc o m e conferences SLI Cll a 11 . I I bi I f s 1e se w 11 c 1 e na e t 1ose o · us who ha ve expe -· · , _ 11e n ce. e ith e r as use 1s 0 1 c1s s upplt e 1s , to exc h a ng e th e ir know I d I b e g e and v iews o n s ue 1 m a tt e rs , ut 1 do pl e a d that we do · · · · I n o t Ju s t li s te n but we act 111 ore e r to e ns ure proactive and 0 I 1 · · · · · . • . I · f i ce i Y 111it1 a ti ve s tor tie p1otect1on o o ur e n v ironm e nt a s well 'ls tl _ · o f o ur profit m a rg in s. ' · 1e p1 o te c tion

As you w ill se e in th e adjoining ex ]. co mp a 111 es . m c ludin g m y ow n ,11.e 1ibit1 o n d lot o l , · · ' puttmo o-re 1t e i11 I · ·· · m a tte rs o 1 e n v ironm e nt 1 d _ t "'" "" ' P 1c1s1s o n 'n sa e ty. Li kew· t th e APEA a re m ak in o a re· 1 l't' ise rn e m )e 1s o ! "'" "'" d e o1 ts to e n s tl I public 1s m ade more iw · ., . · u1 e 1,11 t 1e g e ne 1al ' , 11 e ctnd bett e r , , I t' I ha z ards 111h e re nt in OL t · P1ntectec rnm ti e 11 1Us1n c s s It I I th e se t wo parti e" a e t l h · · . is s u1 e Y og1ca l th a t ' o ae t e r I I · order t d J "" · w i t 1 t 1e o il compa ni es in o o w 1dl we co ll eui ve l b 1· w ha t sa les m e n fr A . Y e ie ve ., is n g ht rath e r than 0 111 m e n ca or J o· ·]· : E believe to be " o l 11 B .· e"'" 1s ato1s l1urn u1 op e "'" t c 01 1 llon s

C hairman I th a nk th e APcA 1 · 1 c t o r orn.a n1 s 11H! th is co nf e re nc e dl1l w is 1 yo u eve r ' _ . ' . , ; s ucc e s s 111 this year 's int c rn a 110n a l se minar o n th e e n v 1r "' 1 · · · I .. . . un m c nta ni nc e pt s pe rt a 111111 Q. lo pe t1 0 lillm g station s

AP

711

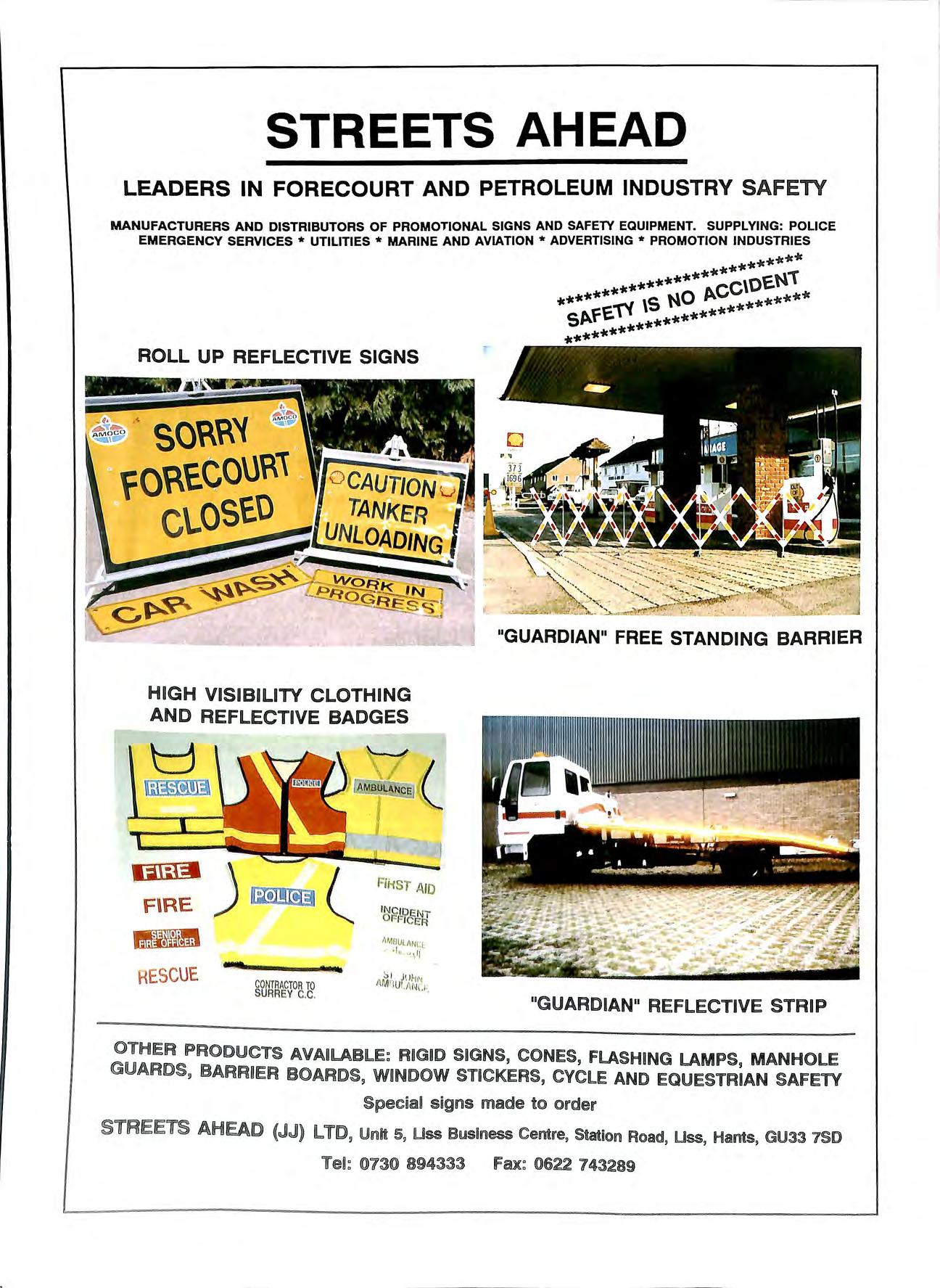

STREETS AHEAD LEADERS IN FORECOURT AND PETROLEUM INDUSTRY SAFETY MANUFACTURERS AND DISTRIBUTORS OF PROMOTIONAL SIGNS AND SAFETY EQUIPMENT. SUPPLYING: POLICE EMERGENCY SERVICES* UTILITIES* MARINE AND AVIATION* ADVERTISING* PROMOTION INDUSTRIES ROLL UP REFLECTIVE SIGNS HIGH VISIBILITY CLOTH ING AND REFLECTIVE BADGES F\RE RESCUE TO RAEY C C .. .. FlkST AI D INCIJ)EN Ol"pfCER AMBULAN CL •l1i \ fi ****** * * "de* ********* C\OEN"T ******* \S NO fl.C * **** *** sfl.fE"f'( ********** ********* "GUARDIAN" FREE STANDING BARRIER "GUARDIAN" REFLECTIVE STRIP OTHER PROIDUCTS AVA RlAB l E : RIGID SIGNS, CONES, FLASHING LAMPS, MANHOLE G!!JJARDS, BARRRER BOARDS, WRNDOW STICKERS, CYCLE AND EQUESTRIAN SAFETY s igns made te» order §TIRIEIETS AHEAD «JJ) l Tto, Uinit 5, IUss BnJSlness Centre, Station Road, Liss , Hams, GU33 7SID @13@ 894333 Fax: «>622 143289

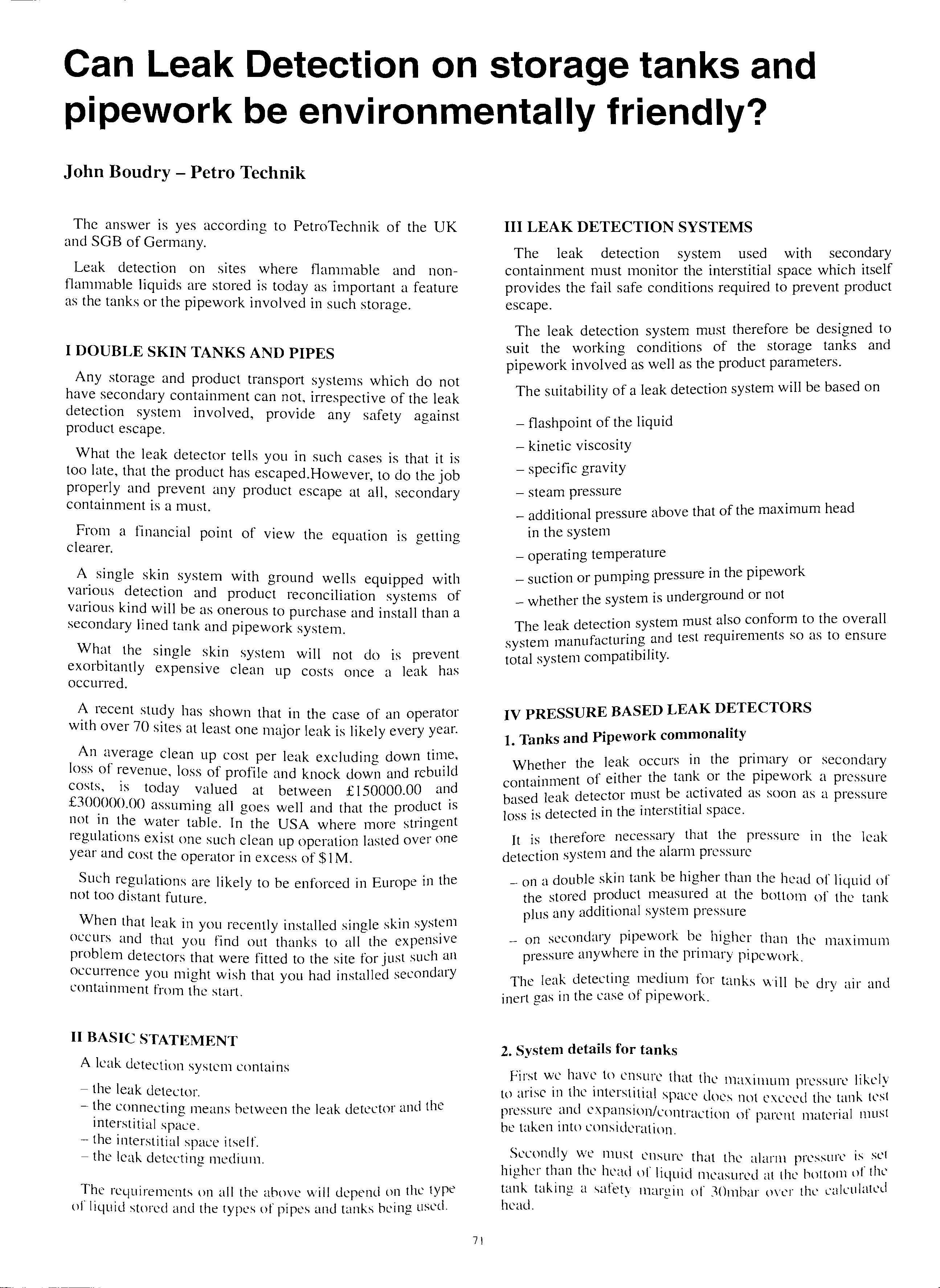

Can Leak Detection on storage tanks and pipework be environmentally friendly?

John Boudry Petro Technik

The answer is yes according to PetroTechnik of the UK and SGB of Germany.

Leak detection on sites where flammable and nonflammable liquids are stored is today as important a feature as the tanks or the pipework involved in such storage.

I DOUBLE SKIN TANKS AND PIPES

Any storage and product transport systems which do not have secondary containment can not, irrespective of the leak detection system involved, provide any safety against product escape.

What the leak detector tells you in such cases is that it is too late, that the product has escaped.However, to do the job properly and prevent any product escape at all. secondary containment is a must.

From a financial point of view the equation is getting clearer.

A_ single ski1: system with ground wells equipped with vanous detection and product reconciliation systems of various kind will be as onerous to purchase and install than a secondary lined tank and pipework system.

the single skin system will not do is prevent exorbitantly expensive clean up costs once a leak has occurred.

A recent study has shown that in the case of an operator with over 70 sites at least one major leak is likely every year.

An average clean up cost per leak excludincr down time, I b oss ol revenue, loss of profile and knock down and rebuild costs, is today valued at between £ 150000.00 and £300000.00 assuming all goes well and that the product is not in the water table. In the USA where more stringent regulations exist one such clean up operation lasted over one year and cost the operator in excess of $1 M.

Such regulations are likely to be enforced in Europe in the not too distant future.

When that leak in you recently installed single skin system occurs and that you find out thanks to all the expensive problem detectors that were fitted to the site for just such an occurrence you might wish that you had installed secondary containment from the start.

II BASIC STATEMENT

A leak detection system contains the leak detector.

the connecting means between the leak detector and the interstitial space. the interstitial space itself. the leak detecting medium.

The requirements on all the above will depend on the type ol" liquid stored and the types of pipes and tanks being used.

III LEAK DETECTION SYSTEMS

The leak detection system used with secondary containment must monitor the interstitial space which itself provides the fail safe conditions required to prevent product escape.

The leak detection system must therefore be designed to suit the working conditions of the storage tanks and pipework involved as well as the product parameters.

The suitability of a leak detection system will be based on flashpoint of the liquid kinetic viscosity specific gravity steam pressure

_ additional pressure above that of the maximum head in the system

_ operating temperature suction or pumping pressure in the pipework whether the system is underground or not

The leak detection system must als_o conform to the overall facturin a '111d test requirements so as to ensure system manu "' • total system compatibility.

IV PRESSURE BASED LEAK DETECTORS

I. Tanks and Pipework commonality

Whether the leak occurs in the or secondary containment of either the tank _or the pipework a pressure based leak detector must be_ '.tctivated as soon as a pressure loss is detected in the interstitial space.

It is therefore necessary that the pressure in the leak detection system and the alarm pressure

_on a double skin tank be higher than the head of liquid of the stored product measured at the bottom of the tank plus any additional system pressure

_ on secondary pipework be higher than the maximum pressure anywhere in the primary pipework.

The leak detecting medium for tanks will lw dry air and inert gas in the case of pipework.

2. System details for tanks

First we have lo ensure that the maximum pressure likely to arise in the 1nters1i1ial space docs not eXCl'ed the tank test pressure and expansion/contraction or parent material must be taken mlo consideration.

Secondly we must l'nsure that the alarm pressure is set higher than the head or liquid measured at the boltlllll pf the tank taking a safety margin of 30rnbar ll\'l'r tl1l' call'ulatl'd head. '

71

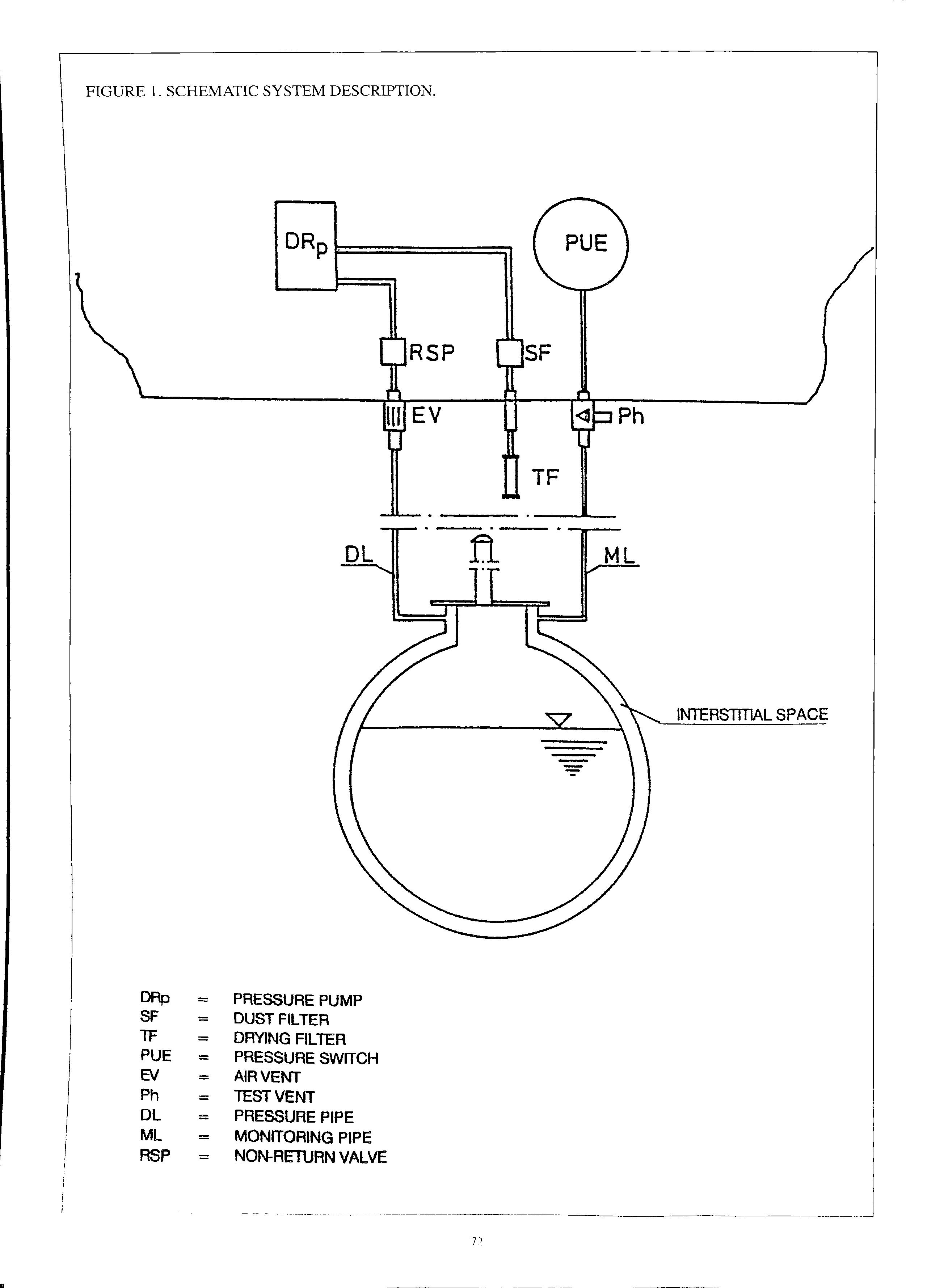

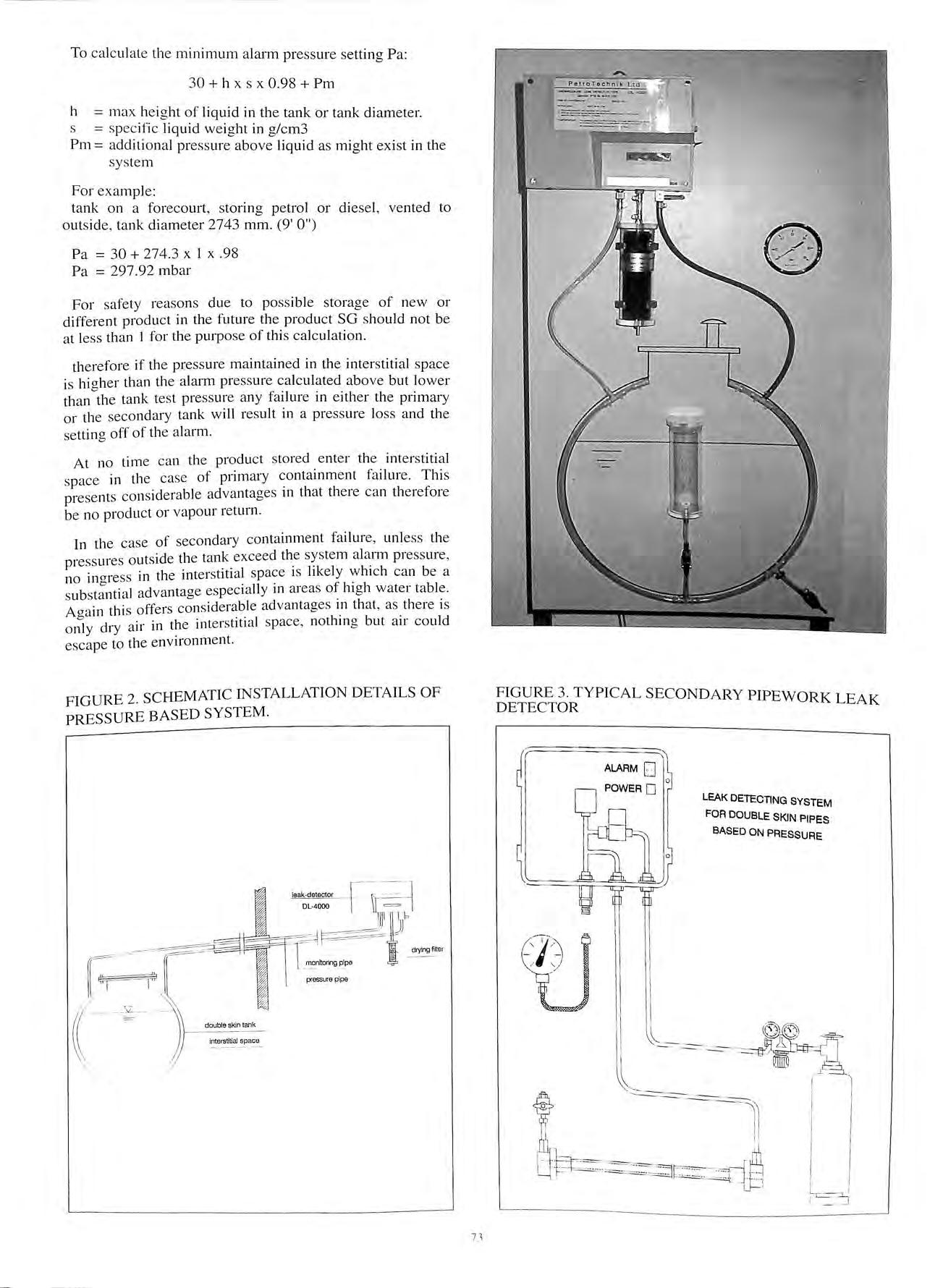

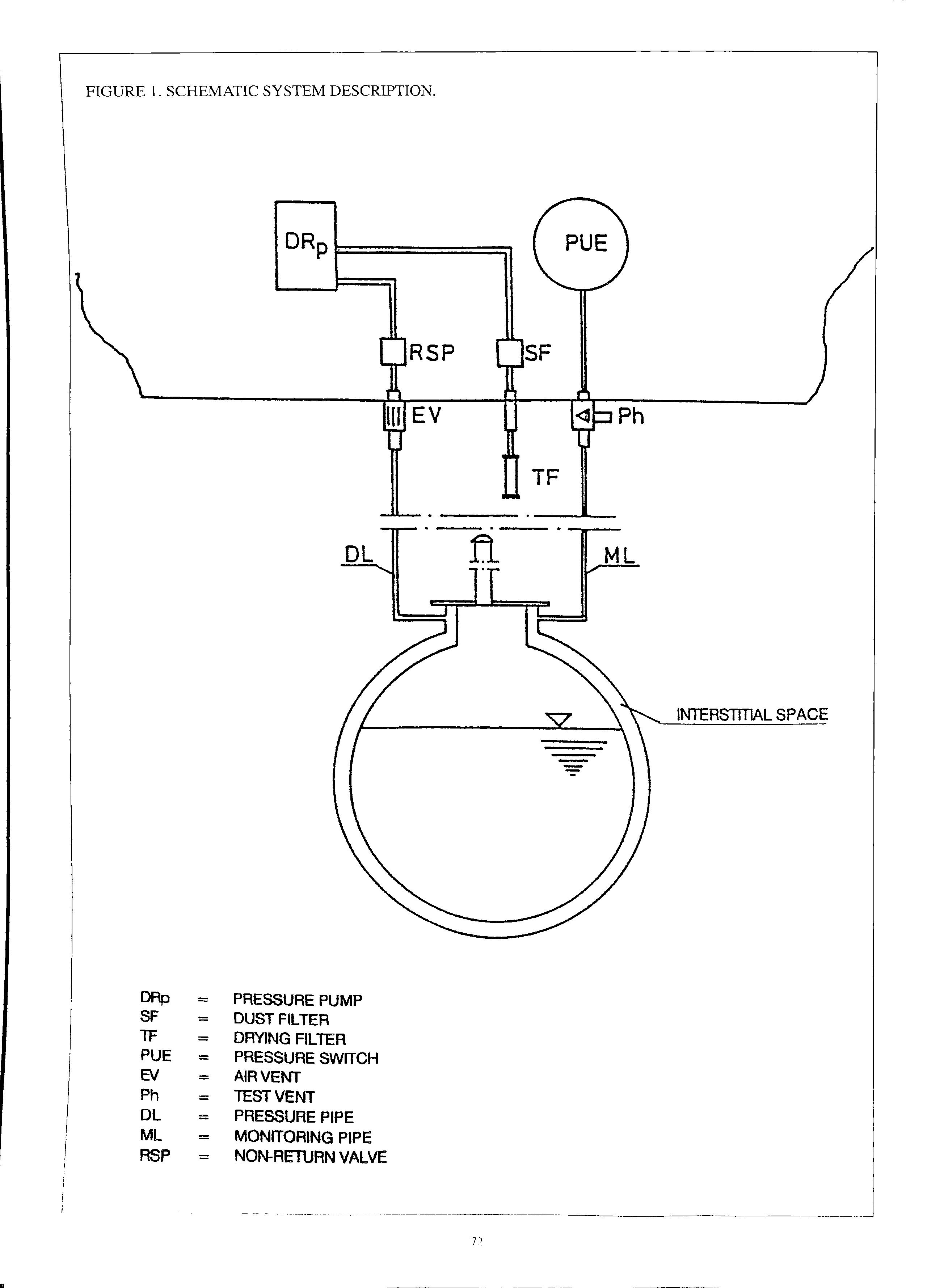

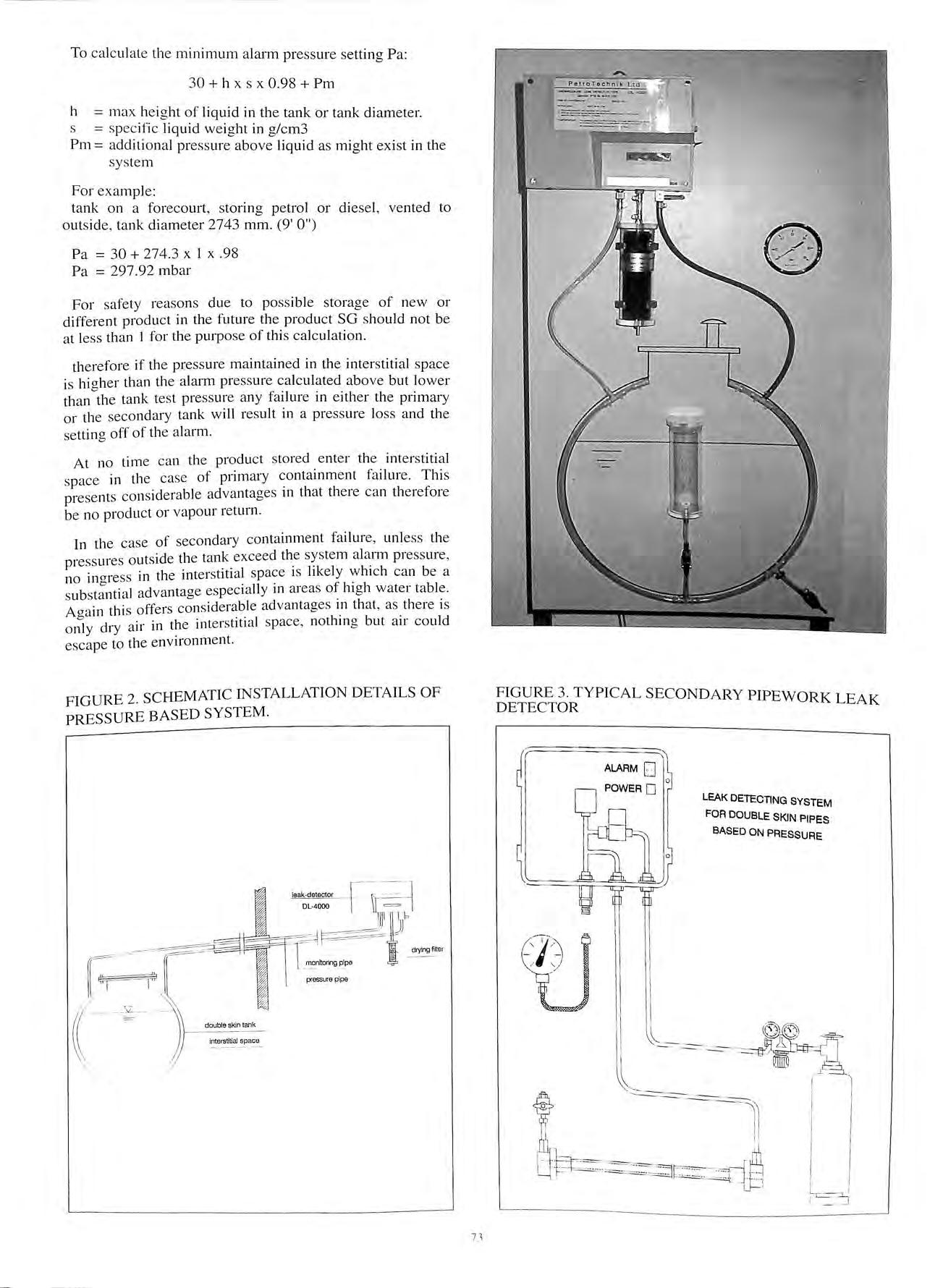

FIGURE l. SCHEMATIC SYSTEM DESCRIPTION. DRp =====1 RSP SF Ph TF ·-·-fi ML INTERSTITIAL SPACE DRp PRESSURE PUMP SF = DUST FILTER TF = DRYING FILTEA PUE = PRESSURE SWITCH EV = AIR VENT Ph = TEST VENT DL = PRESSURE PIPE ML = MONITORING PIPE ASP = NON-RETURN VALVE ·----

To calculate the minimum alarm pressure se tting Pa: 30 + h x s x 0.98 +Pm

h = max he ig ht of liquid in the tank or tank diameter. s = spec ific liquid weight in g/cm3 Pm= additional pressure above liquid as might exist in the sys tem

For exa mple: tank on a forecourt, storing petrol or diesel , vented to outside, tank diameter 2743 mm. (9' 0")

Pa = 30 + 274.3 x I x .98 Pa = 297.92 mbar

For safe ty reason s due to pos si ble storage of new or different product in the future the product SG should not be a t less than I for the purpose of thi s calculation.

therefore if the pre ss ure maintained in the interstitial space is hi g her than the alarm press ure calculated above but lower than the tank test pre ss ure any failure in either the primary or the secondary tank will result in a pressure loss and the setting off of the alarm.

At no time can the product stored enter the interstitial s pace in th e case of primary containment failure. This presents considerable advantages 111 that there can therefore be no product or vapour return.

In the case of secondary containment failure, unle ss the pressures outside t_he th_e system alarm pressure, no in a re ss in the 111te rs t1t1al space 1s hkely which can be a s ubst:ntial advantage especially in areas of high water table. Again this offers advantages in that , as. there is o nly dry air in the 111terst1tial space, nothmg but air could escape to the environment.

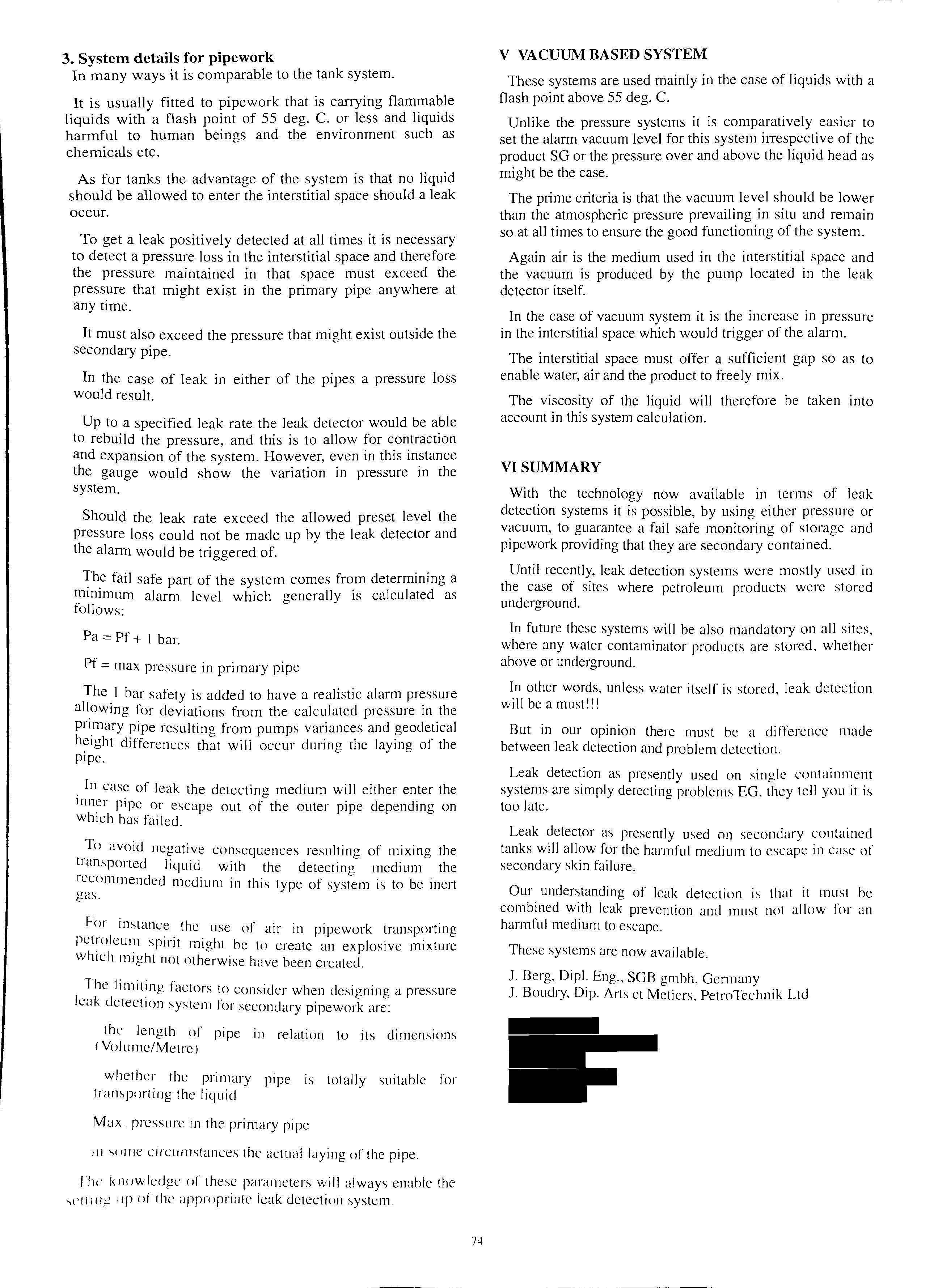

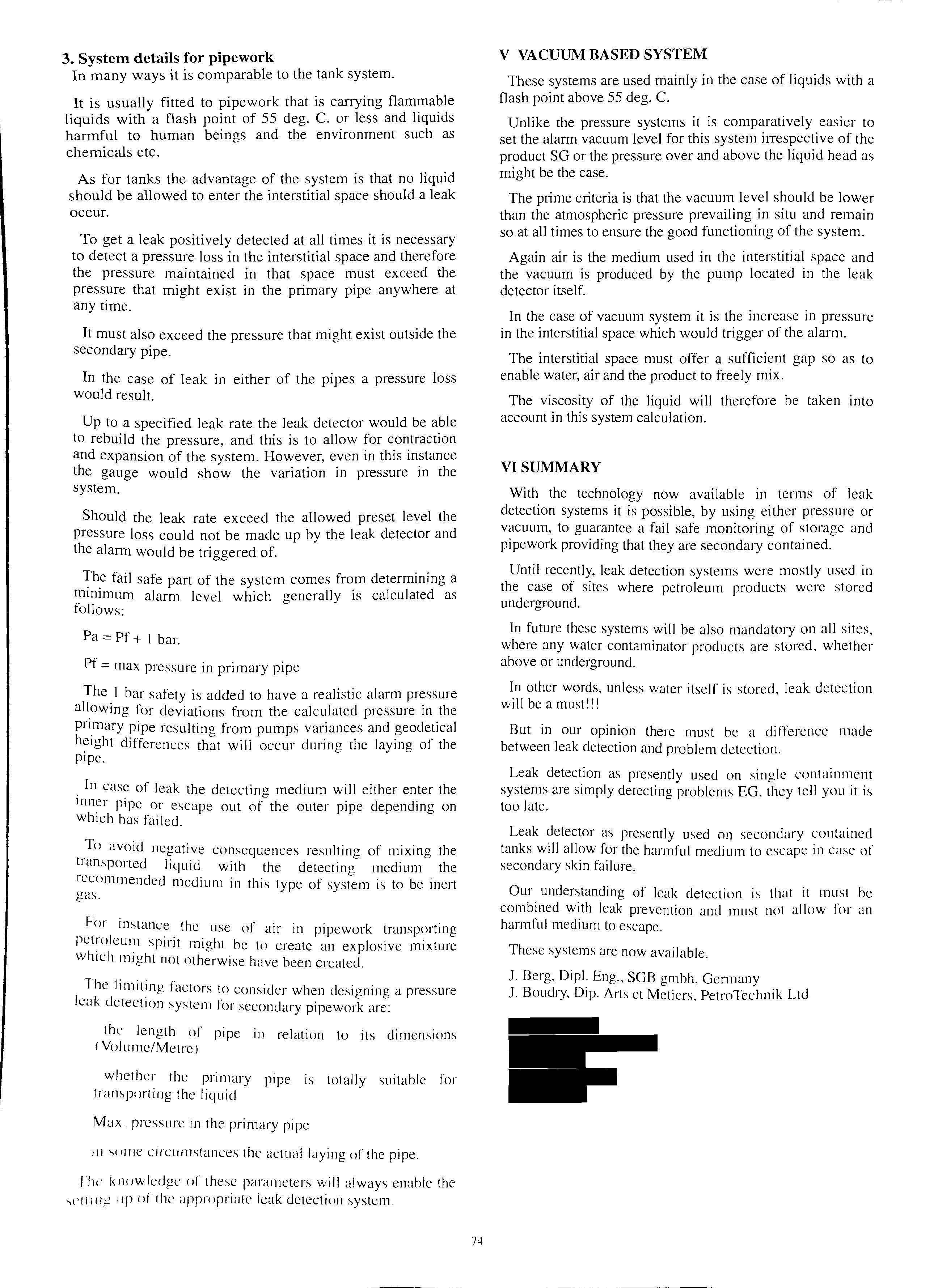

FIGURE 2. SCHEMATIC INSTALLATION DETAILS OF PRESSURE BASED SYSTEM.

FIGURE 3. TYPICAL SECONDARY PIPEWORK LEAK DETECTOR

klak-detector -1 OL-4000 1

i = . """'9 filte< interstitial space ' //

=

LEAK DETECTING SYSTEM FOR DOUBLE

SKIN PIPES BASED ON PRESSURE

3. System details for pipework

In many ways it is comparable to the tank system.

It is usually fitted to pipework that is carrying flammable liquids with a flash point of 55 deg. C. or less and liquids harmful to human beings and the environment such as chemicals etc.

As for tanks the advantage of the system is that no liquid should be allowed to enter the interstitial space should a leak occur.

To get a leak positively detected at all times it is necessary to detect a pressure loss in the interstitial space and therefore the pressure maintained in that space must exceed the pressure that might exist in the primary pipe anywhere at any time.

It must also exceed the pressure that might exist outside the secondary pipe.

In the case of leak in either of the pipes a pressure loss would result.

Up to a specified leak rate the leak detector would be able to rebuild the pressure, and this is to allow for contraction and expansion of the system. However, even in this instance the gauge would show the variation in pressure in the system.

Should the leak rate exceed the allowed preset level the pressure loss could not be made up by the leak detector and the alarm would be triggered of.

The fail safe part of the system comes from determining a minimum alarm level which generally is calculated as follows:

Pa == Pf + 1 bar.

Pf

== max

pressure in primary pipe

The 1 bar safety is added to have a realistic alarm pressure allowing for deviations from the calculated pressure in the primary pipe resulting from pumps variances and geodetical differences that will occur during the laying of the pipe.

In case of leak the detectina medium will either enter the b mner pipe or escape out of the outer pipe depending on which has failed.

Tu avoid negative consequences resulting of mixing the transported liquid with the detectinu medium the recommended medium in this type of is to be inert gas.

For instance the use of' air in pipework transporting petroleum spirit might be to create an explosive mixture which might not otherwise have been created.

The limiting factors to consider when designing a pressure leak detection system for secondary pipework arc:

the length of pipe in relation to its dimensions (Vo! u me/Metre J

whether the primary pipe is totally suitable for transporting the liquid

Max pressure in the primary pipe

111 "')Ille circumstances the actual laying of the pipe. lilt· kn()wledgc of these parameters will always enable the '->L'!l 111µ up c ii the apprnrriatc leak detection systL:m.

V VACUUM BASED SYSTEM

These systems are used mainly in the case of liquids with a flash point above 55 deg. C.

Unlike the pressure systems it is comparatively easier to set the alarm vacuum level for this system iITespective of the product SG or the pressure over and above the liquid head as might be the case.

The prime criteria is that the vacuum level should be lower than the atmospheric pressure prevailing in situ and remain so at all times to ensure the good functioning of the system.

Again air is the medium used in the interstitial space and the vacuum is produced by the pump located in the leak detector itself.

In the case of vacuum system it is the increase in pressure in the interstitial space which would trigger of the alarm.

The interstitial space must offer a sufficient gap so as to enable water, air and the product to freely mix.

The viscosity of the liquid will therefore be taken into account in this system calculation.

VI SUMMARY

With the technology now available in terms of leak detection systems it is possible, by using either pressure or vacuum, to guarantee a fail safe monitoring of storage and pipework providing that they are secondary contained.

Until recently, leak detection systems were mostly used in the case of sites where petroleum products were stored underground.

In future these systems will be also mandatory on all sites, where any water contaminator products are stored, whether above or underground.

In other words, unless water itself is stored, leak detection will be a must!!!

But in our opinion there must be a difference made between leak detection and problem detection.

Leak detection as presently used on single containment systems are simply detecting problems EG. they tell you it is too late.

Leak detector as presently used on secondary contained tanks will allow for the harmful medium to escape in case of secondary skin failure.

Our understanding of leak detection is that it must be combined with leak prevention and must not allow for an harmful medium to escape.

These systems are now available.

J. Berg, Dipl. Eng., SGB gmhh, Germany

J. Boudry, Dip. Arts et Metiers, PetroTechnik Ltd

74

TAN K REPLACE MENT

IT'S DIFFICULT BUT NOT IMPOSSIBLE

By James H. Pim, P.E. , Chief, Office of Environmental Engineering & Pollution Control Suffolk County Department of Health Services

APEA CONFERENCE PAPER

September 24, 1991

Far up in no rthern Mi c hi ga n where Lak e Superior e mpti es into th e St. M a ry 's Riv e r th e re is a littl e v illage with the French-Indi a n name of B a ie de Wa sa i. It is on an island next to the Canadian bord e r a nd now con s ists of nothin g more than a sma ll mi ss ion church a nd a general s tore Thi s year the owner of th e s tore took o ut hi s two s tee l gaso lin e ta nk s an d re plac ed them with one double-walled cathodically protected ta nk to m eet the requireme nt s of th e sta te. It cost him so me money, but h e was able to afford it. However, hi s o nly competition , the owner of the other s to re down th e road , decided the ex p e nse of upgradin g was too hi g h a nd discontinued se lling gas.

Thi s s impl e exa mpl e is o n e of th e m os t re mote pa rt s of the country d esc rib es what is beginning to h a ppen all over th e United States. Th e old pl a in s teel tank s, so Jong th e prefe rre d vesse ls for h o ldin g fu e ls a nd other mate ri a ls, are finall y being re pl aced with modern tank s of other m a te ri a ls de s ig ned to be non-conod ibl e and leak re sis tant. The mi stake is being co rre c ted a nd America is on the way to controlling th e a ppallin g damage that ha s b ee n clon e ove r the years to it s gro undwater reso urc es by lea ks and s pill s from d e te ri ora te d tank s a nd piping. Th e pro cess though, is forcing so me marg inal businesses to s top se llin g gas.

Federal law, passed in 1984, re quires ta nk tes tin g a nd upgradin g o f ex is tin g facilities and requires non -co rrod ible construction w ith leak detection for new facilitie s. M any s ta tes and loca liti es ha ve pas se d more str in ge nt require men ts.

Suffolk Co unty, N ew Yo rk was th e fir s t a re a in th e co untr y to pa ss a comp re h e n s i ve h aza rdou s mate ri a ls control law th at req uired ta nk re plac eme nt. Now. tw e lv e years lat e r, th e program is n ea rly co mp le te and th e expe ri e nce gai ned is probably very s imilar to what the res t of the co untr y ca n ex pect in th e nex t few yea rs.

Suffolk is a n a rea of abo ut 2400 sq. km. co ns is tin g of th e easte rn two thirds of L ong Is la nd. New Yo rk and New York C ity a nd N assa u County on th e weste rn e ncl . Be lo w th e rich laye r o f topso il , the island is a lm os t e ntirely sa nd and grave l. The pop ul a ti o n of three milli o n in the two co unti es is to ta ll y depend e nt o n the gro und wate r of th e is la nd co n tained in the sa nd aq ui fers. New York C it y is separa te fro m thi s s uppl y a nd co m es from inland s ur face reservo irs.

Being ve ry concerned a b o ut g roundwat e r co nt am in a ti o n. the S uffo lk Board 01 · Hea lth pas se d a law in J979 pro v idin g a I0 yea r transiti o n peri o d for th e re place m e nt o f a ll tanks that re main ed in p lace durin g th e te n yea r pe riod a nd tes tin g continu es on th e he atin g oil tanks that h ave not be e n re plac e d.

law covers above ground ,

w

and outdoor tank s, piping , tran sfer

a nd port a bl e container storage, as well as dry bulk s tora ge. It was desi gned to be as comprehensive as po ss ibl e and covers , as hazardou s m ate rial s, virtually a n y thin g that could co nt am inate the g ro undw a ter. An effo rt was made to treat a ll m ate rial s the sa m e and no t make unn ecessar y spec ia l cate go ri es. Petroleum , of co urse, was includ ed.

The basic phil oso phy of th e Jaw was to pro v id e secondary containment for eve ry thin g , n ot just for und ergro und t a nk s . Thi s was a ri sky decision in the beginning s inc e there were n o double-walled sys tems b e in g marketed at th at time exce pt what co uld be imp o rt ed from Ge rm a ny , but it proved to b e a wise choice. Sin g le -w a ll e d tanks did h ave to be a llo wed initi a ll y for pe trol e um for a few years until la rge, doubl e walled tank s be_came a va ilabl e, but th a t was eve ntu a ll y c ha nged to req uire a ll doubl e -w a lled systems. The s in g le wa ll ecl non- co r rodib le tanks in s talled during the ear ly year s of th e law no w h ave until the yea r 20 I 0 b efo re th ey mu s t b e rep laced with double-walled tanks.

So far in th e program, 6,247 no n -co rrodibl e tanks ha ve b ee n in s talled and 8 , 337 o ld pl a in stee l ta n ks re m oved. Of th e n ew o nes 2,83 0 a re double-walled .