It's approved by petroleum licensing authorities and installs twice as fast as steel.

Am ero n's Du a lo/ 1 3000/L fib ern: lass p ipin g is li s ted w ith La bora tor ies for u se in und er gro und fu e l ha nd ling sys te m s It h as a lso bee n tes ted and acce pte d by t he Lo nd o n Fire and Civil Defe nce Au t ho rit y.

T hi s m ea n s yo u h ave th e ass u ra nce t hat o u r produ c t h as b ee n tes te d un der t he m os t s t r inge nt co nditi o n s and is ra ted fo r pres s u res a nd te mp e rat u res fa r in excess of reg u lar pe t ro l s tat io n req uire m e n ts.

Yo u can in s ta ll a Du a loy sys te m in a bout o ne h a lf t he t im e re qui re d to put in s tee l. In fac t, yo u ca n ta p er t he e nd o! ou r pip e in less tim e t h an it ta kes JU St Lo p u t a s tee l p ip e in a pip e vise.

But h ere's .th e b es t part: yo u ' ll pro b ab ly find the in s tall e d cos t of a Du a loy sys te m to be le s s th a n for s tee l-:- as it r e quire s no s ulph a te res 1s t1n g co n c ret e su1-round. Ame ro n h as a Du a lov sys te m fo r eve r y und ergro und fu e-1 h a ndli no n ee d : w h e th er it 's con ve nti o n a l b s in g le-wa ll pipin g or a c o mp le te seco nd a r v c ont a inm e nt sys te m

For more information, write Ameron Fiberglass Pipe Division, lA Christchurch Road, Ashford Kent, TN23 Dill or call us on 0233 6 13884

Dualoy 3000/L cont ainmen t systems a re also UL listed fo r alcohol l)ase d fuel s as well as petrol

In 1968 Underwriters Laboratories Inc. granted our Red Thread pipe first-ever listing for underground hberglass piping of petroleum products. Since then more than 20 million feet have been installed far more than any other fiberglass brand With a performance record unsurpassed by anyone and vastly superior to " holey" steel as you can see!

Secondary containment systems can be pressure tested and monitored from above ground after initial installation.

secondary containment piping with UL Listings for handling all conventional fuels, reformulated fuels and all alcohol-gasoline blends. With special extras, too: • ECONOMY - Lightweight and easy to install up to 4-times faster than steel. study shows 750/o of service p1p1ng in the 1990's will be fiberglass. For the 90 s, Smith Fiberglass Products offers proven RED THRE AD II and RE D THR EAD llA product and

The annual seminar in Dunstable has literally just closed as this talking point is being written. The speakers and exhibitors made this a memorable occasion for the APEA Council and the fact that a record number of delegates attended made the hard work the Council members (and wives) put in, well worth while.

The Council would like to thank all those involved in attending, exhibiting and speaking -a total of 440 persons, a record for Dunstable.

THANK YOU

notes and news

NEW REGULATIONS OFF TO A BAD START

The new conveyance regulations for petroleum spmt have been published, and a number of what can only be described as "cock ups" has meant that a series of exemption notes and notes to Chief Officers have had to be issued to try and get over problems unseen by the legislators at the HSE.

The Road Traffic (Conveyance of Dangerous Substances in Road Tankers and Tank Containers) Regulations 1992 were laid before parliament on 13 March but only available from HMSO at £8.15 a few days before the enforcement date of 1st June 92.

Almost immediately the HSE were asked why no instructions had been given to HMSO to print the new delivery certificates, to be told that it would take some months to prepare them and have them ready for both Driver Controlled Delivery and also the Licensee Controlled Delivery. The delay meant that an exemption certificate had to be issued to put the enforcement date off to I October to give time for HMSO to provide enough certificates for delivery. With a month to go before enforcement HMSO had nm out of certificates as the HSE had estimated incorrectly that amounts required and therefore licensees would be breaking the law by using old certificates. The next problem was the cost of the new certificates this was raised by the Petrol Retailers and others who objected to the massive increase in fees for the certificates, this was we were informed to re coup the losses from the thousands of old certificates left at HMSO. A compromise was reached and the price reduced.

The latest and hopefully the last problem was that all petrol tanks, fills points and measuring devices (dip sticks or tank gauges) have all to be relabelled to confcmn with the new requirements to have tanks labelled not only with the tank or compartment number, but also the grade of product and the "safe working capacity" of the tank which must be measured to be 97% of the actual capacity of the tank. This will mean much work for the Oil Industry and one company estimated that this would cost them £ 1.25 million pounds and take 6 months to carry out. The HSE have granted an exemption until the end of the year.

APEA ELECTRICAL COURSES

The first electrical course run by the Association has proved a popular choice for members with an overwhelming number of applicants. The Association has already decided to run another to supplement the needs of members and to ensure that those unable lo attend the first course will have another chance. those interested in the new dates can make first enquiries to Mrs E Taylor the course senetary on 0582 882170.

APEA

INAUGURATES

ITS FIRST OVERSEAS BRANCH

Following an earlier approach by some members in the Republic of Ireland, the Vice Chairman, Editor and immediate past Chairman of the Association travelled to Dublin at their invitation with a view to forming an Iiish Branch. were held during the day with of authorities, oil companies and mstallers and all mterested parties had been invited t d 0 atten a meetmg at The Royal Marine Hotel in the evening.

A total of 27 members attended the meetina repre · '°' sentma the HSE, a consultant and an architect as well as th th '°' . · e ree major mterests. This was a very encouragina start t h c c Ote evemng, part1cularly so as one delegate had travelled from Northern Ireland. After welcoming the deleaates M" h '°' , 1c ael Lugg gave a short presentation on the aims and obiective f h A J so t e ssociat10n and its role within the industry " II · . ro owmg which Jamie Thompson and Brian Taylor spoke · 111 greater detail about the use of The Bulletin by 111 b . em ers to d1ssemmate 111format1on, the oraanisation of a B . h . '°' 1anc and the duties of its officers, the opportunities tra· · mmg and the_ of and, in particular!;, the fac1hty for all sides to discuss contentious issues and resolve differences.

Following these presentations the II ff" cl meetm a y af mne resolve to fom1 a Branch. Th: formal busmess o the election of officers was pre ·d d c. s1 e over by the national Vice Chainnan and the followina elected: '°' were

Chaimian: Vice Chairman: Secretary:

Declan Ryan Gabriel Howley Enda Riney Branch Representative: Brendan Kavanaoh e Treasurer: Mark Elmore

Executive committee: Nat McCoy Bill Flynn Michael O"Kane Denis Whelan Jim Brett

Statoil Dublin Fire Brigade Texaco Pump Services Forecourt & Technical Services Irish Pump & Tank Conoco Texaco Ryan. O'Brien Handy Maxol

The new Branch . was congratulated on its <1nd the meetmg was then In 1'd mauguration . '11l c over to the B Chairman who. supJ)Orted by h S new ranch is · ecretary · :I T. then conducted the business 01... 1 ,lnL ieasurer. · lts 11stmeL'tmo /:'.""

It was deciLkd to hole\ th. _,, ltL meet mos ·iv,.. tl 1 be al Statoil and to induclc' LI.. c:· ' . c,\l. 1e irst lo 1scuss1011 ot: the abilit\ to inflii ,11 1 1 • L ce cgis atmn and regulatiuns

-a l.llle day seminar on safety \\"ith l"lliltributions from HSE. an oil company engineer and a Fire Officer

l"l 11l1111on and sharing nf soluti<ll1S

An important objective of the Branch was seen by the Chairman as being to encourage e very one to start talking toge ther , so mething which apparently has not happ e ned too much in the past.

At the conclusion of th e meeting, which had been mo st efficiently organised and alluringly administered by Reb ecca B oo th to whom we extend our sincere thanks, the three UK executives made their way the bar with the satisfied feelin g of a successfully accomplished mission. Imagine their cons ternation when on arrival they found that they were on their ow n; no one had followed them After a mom e nt of panic , they reali sed that the new Branch members were so bu sy talkin g amongst th emse lves that the y hadn ' t mo ved from the meeting room! Totally out of character, but what a splendid augury for the future!

Congratulations Ireland and all aood wishes for th e furure. 0

HSE ELECTRICAL COMMITTEE EXAMINES PME COMPLAINTS

The HSE is e xa minin a comp laints about th e e nfo rced removal t· p · 0 0 rotect1ve Multiple Eart hing (PME) from filling station s fo ll owi n a ac tion by petro leum icens mg au thoritie s after a was iss ued to Chi ef Officers last h yea1 o n thi s s ubj ect. The a uid ance suggested t at all P. c i e mi ses be ch a nged w ith in a three year pen od. A numb er of 1 . tl h. co mp amt s a re be in g made by th e Oil Indu st ry on igh cos ts, a nd are que stionina the need for its re mova l. t; 1 eb e ng in ee r has c ited that ha ve bee n no acc id e nts a 1 1 1 ut ed to PME , and th at other indu strie s such as the Gas inc ustry also sy. operate 111 haza rdou s atmosp here s with PME . ste ms but no h . to be . s ue 1estramts were impo sed. There 1s likely and a debate ove r th e me rit s of makina thi s retros pective, < s ugoest io ns 1 b c the 0 • rnve ee n made that persons work in g 111 se a reas wh protected cb 0 a re pote nti a ll y at ri sk mi ght better be them Y ha ving a safe sys tem of wo rk imposed upon

lP'OLY-TEC lP'ERME H PASSES INDEPENDENT AT IO N T ESTS

Po ly-Tec h 11v1 • p ip in o sys t f, cl new ly de ve loped fl ex ible und e rgro un d "' e m rom AP 1ncl e pe ndeilt T , In c., rece ntl y met and exceeded met hanol d tes t111 g. T he rov an etha no l fuel blend perm eation conjun c tion 1P e n Ny lon-12 fu e l barri e r !111 er 111 W1t 1Po ly- T 1 . . h un a l cove r . . ec 1 s re in forceme nt layer a nd direc t p1ov 1de nn · . . . and re tro fit 1 < xim um e m1 ss 1o n secu rit y facing new clpp 1ca t1on s

The Fede ral EPA . rc-. tin u l<i a ncl Ca l1f o rn1 a CA RB are red uc ing t:- ss o r e . · va po rat 1on 01 · h cl b f o 11 a -. 1<111d111g a ut omo h I ·· y rocar o ns r 1 hc>t ll '- Pc rn1 ,. 1 e. c1bout te n fo ld to limits of 2g/24 eu tl()n 1111 t I 11 " co nce rn111 0 und e roround storag e d /IL p 1p111 !2 'Ys ten1s f c "' I I LI 1 · 01 pe tro le um product deli ve ry are no w 1c 111.;I 111<1 11cc. Po ly- T h . c pn ma ry and secondary fl ex 1ble p 1plll µ -..\ ' ' '-' Ill ., a re , , · · »e t1ng the standa rd s f'or perm ea ti o n 11111!<..'( IJt•ll ; 111J ffl s tall c·ltJ <lil sec unt y.

For more inform ation and te st data on Pol y-Tec h , please contact Andy Youngs, President, Advanced Polymer Technology, Inc. , 28605 County Road 6, Elkhart , I N 46514, or call (219) 262-9899.

APT, Inc., provides adva nced flexible und ergro und piping systems, both direc t burial and secondarily co ntain ed, for use with regular and alcohol-based fuels. APT se rv es the global market in th e petroleum delivery indu stri es.

NEW FLEXIBLE UNDERGROUND PIPING SYSTEM DEVELOPED BY APT

Advanced Polymer Technology, Inc. (APT) a nn o un ces the release of Poly-Techrrvi, a new produ c t fo r fuel di stribution and storage sys tems. Poly-Tech (patent pe ndin g) is an undergro und piping sys tem de s ig ned to red uce insta ll at ion cost wh il e providing du rabi lit y and enviro nment al sec urit y superior to any other produ c t o n the mark et.

The Pol y-Tech system is made up of a multi laye r primary co ntain ment pipe with a con form ab le seco nda ry co nt ainm ent j acket. The primary con tainm e nt pipe is produced with three layers to maximize it s durability a nd prov ide in stallation fl ex ibilit y. The inn e r laye r is th e fue l barri e r lin er, mad e of Ny lon -1 2, a tes ted and pro ve n mate ri al in fu el sys tems worldw ide . The inte rm ed iate layer is a rein fo rce ment of nylo n mes h The out e r laye r is a pol yethylene direc t buri al cove r. to red uce bl e nd ed fu e l pe rm ea ti on ancl add stre ngt h. APTs Pol y- Tech p ipin g is des igned with a smoot h I i; :i" nominal inte rn a l p ip e diam e te r, whi ch pro vid es the advantag e of a greate r !lo w ra te ove r I 1h " piping c urrentl y be in g used on th e mark e t.

Fo r more informati on. please co nt ac t Pau l Rey ne r on 06 35 5242 00

WORKERS

It "gives guidance to employers of peripatetic workers, occupiers of premises where they work and to peripatetic workers themselves on how to comply with the Control of Substances Hazardous to Health (COSHH) Regulations "

"These peoples' jobs vary considerably, but all of them have one thing in common; They do not have a fixed workplace and often work away from direct supervision".

This therefore covers everybody, contractors employees, oil company engineers and workers, and Petroleum Officers.

NOTICE TO UK PETROLEUM OFFICERS

There is concern throughout the industry that during Stage IB Vapour Recovery operation, where manifolded vents are employed, there occurs a transfer of vapour pressure to the fill-pipe.

This can be caused by several factors, not the least of which can be badly designed or installed vent pipework.

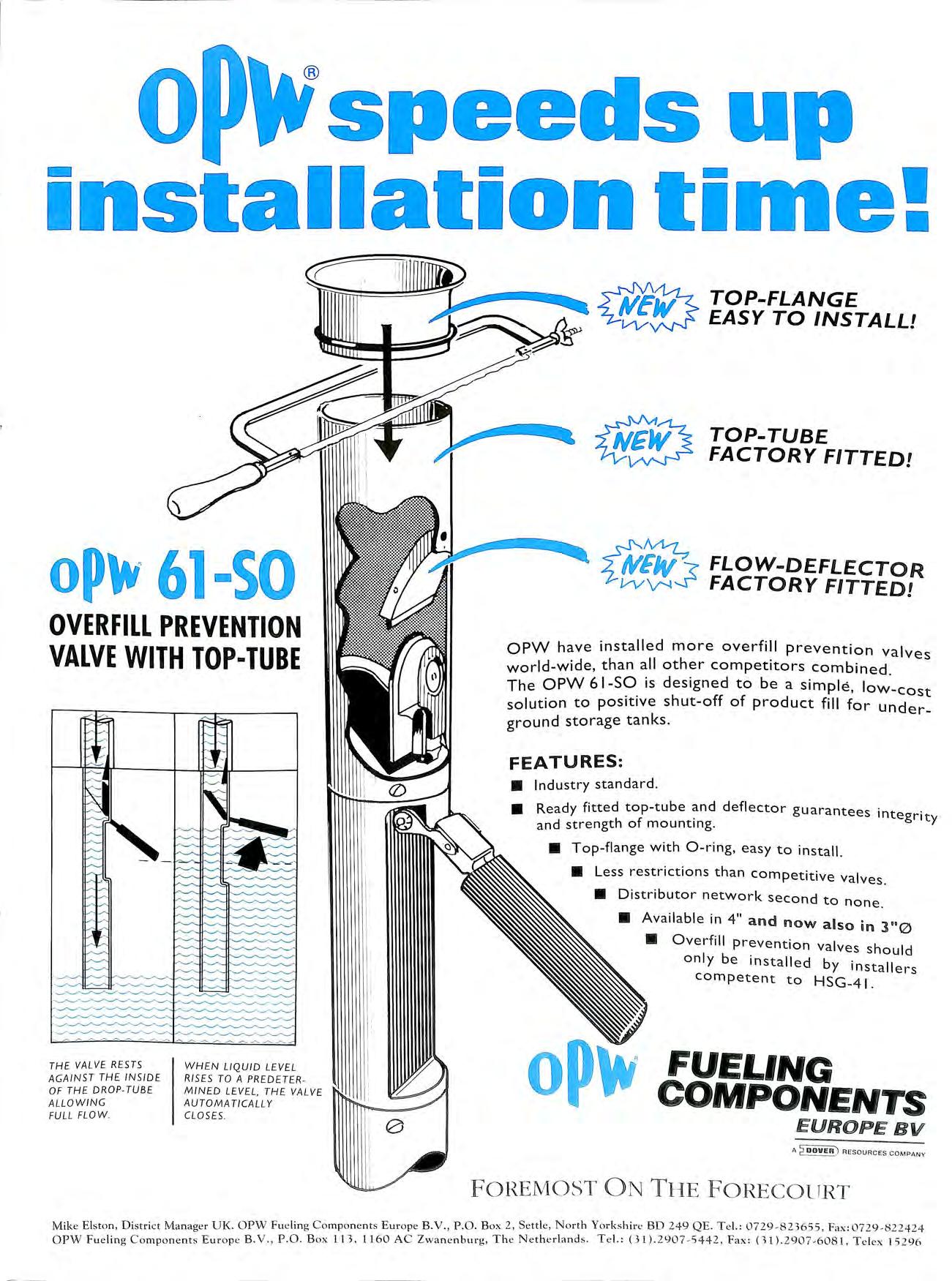

Where an Overfill Prevention valve is installed, the joint between the bottom tube and the valve body may allow a minimal vapour flow, particularly if it is incorrectly fitted, or if the wrong size tube is fitted.

OPW has some evidence that some 61-SO valves have been installed using non OPW oversize bottom tube. There is also evidence which suggests that 8ft model valves have been installed in large diameter UST's. This could leave the fill tube above the minimum liquid level.

At the request of several Authorities, OPW have modified the valve kit, to include an 'O' ring seal, where the lower tube is fixed to the valve body. We believe that, although this may minimise the problem. the solution lies in re-assessing system design and installation.

OPW also emphasise that the 61-SO valve must not be installed, using non standard aluminium tube, and that the complete assembly must be the CO!Tect overall length.

The modified version of the OPW61SO is available ONL y in the UK. and should be purchased from authorised OPW UK distributors.

SHELL U.K. OIL USE GUARDIAN PRODUCTS

Streets Ahead arc pleased to announce that Shell U.K. Oil have decided to use the Guardian reflective safety products on their forecourts and delivery tankers.

The Guardian strip and harrier are all manufactured in the family of ··Quazar·· products and carry the quality of manufacture now expected by Streets Ahead and Quazar.

The mounting of the Guardian strip on Shell tankers is an exciting new development on from the use on forecourts of the Guardian barrier.

PROSECUTION

On 20th August 1992 at Worthing Magistrates Court, Adrian Cooper, the Licensee of Littlehampton Road Service Station, Worthing, West Sussex pleaded guilty to three summons brought under the Petroleum (Consolidation) Act 1928.

The offences involved breaches of the Conditions of his Petroleum Licence, discovered during a routine visit in February 1992.

First, although he kept detailed computer records of throughput he failed to keep daily records of the % loss or gain in respect of each tank.

Second, his licence conditions required him to tell his Licencing Authority if % losses exceeded 0.5% over a period of a week. He in Court that from August 1991 the records he was keepmg frequently showed 3 and 4 day losses exceeding that figure. In addition his Computer System put up a "flag" to "Call W & M" but he did not do so. He told the Court that he thought he had the problem under control and that he was not losing fuel. He had been seeking advice and assistance from his Petroleum Company.

When the tanks and lines were tested, three lines failed.

Third. Mr Cooper cou_ld not produce records of his inspections of manholes, mterceptor and pump hou · smgs. required by his hcence to be cam.ed out and recorded weekly.

Mr Cooper was fined a total of £300 ai1d Was also ordered to pay £80 towards prosecution costs.

WEST YORKSHIRE FIRE SERVICE

The former licensee of Springs Garacre Hal·f· R c- • 1 ax o·ict Todmorden. West Yorkslme was fmed a total of £900 '. · £354.90p costs by Todmorden Macristrates f . 1 1 with · · · "' · 01 ai 111° to comply with the Cond1t1ons of his Petroleu 111 L. c- 1cence.

The prosecution was hroucrht h,, W, ·t y . c- J es orksh ·. F Service on 21 August 1992 followinn 1 • · 11 e II e c- c n c1nnounce I · · the filling station by two Petrol l visn to · cum Othcer · I subsequently found six breaches of tl1, L. . s w 10 e 1ccns1nu C d" · when carrymg out the inspection. c- on ll1ons

Mr Sahib Parshad Saini wh, 1 1., 1 · ' e 111qu1shed tl p Licence prior to the hearino pi ,.11 d . ' 1e etroleum c-· e, c e nu1ltv t th offences. c- J 0 e following

Contravened conditil111 llf. 11 p cence ·irt y s l . in that storage tank numb,. ' · · u 1 Section h. c1 _1 was not provi I d ,. I d1pp111g pipe \ apour prnllt' cap. t e \\ 111 a

NOPFNALTY

2 Cl1ntravened rnndition of licence P·1rt V S, ·t' Is thatel'·t·'··I· ·. ' ,,l(!Oll _,Ill cc I Il.t .tpparatus hkl'I) to ignite tlammahle vapour was mstalkd \\ithin the hllusing of petrol pump number 2. naml'l) a rlanwproof enclosure junction bo\ with two retaining bolts fro111 the ac:ess cm·er plate.

FINED t: I 00

3 Contravened condition of lice nce Part V , Section 7, Sub Section b , in that the double pole master sw itch controlling the petrol pump s was not marked ' Petrol Pump Switch Off Here '

FINED £200

4 Contravened condition of lice nce Part II, Section 21, in th at you did fail to mai ntai n in good working condition th e firefighting equipment namely two 4.5 kilogram dry powder extinguishers provided for the protection of th e filling station.

FINED £100

5 Contravened condition of lice nce Part II , Section 21 in that you did fail to provide a supply of dry sa nd for use on the forecourt for minor petrol spillages when dispensing petrol from the pumps .

FINED £300

6 Contravened condition of li cence Part V, Section I 0, Sub Sections a and d , in that yo u did not ensure th at all forecourt surface wa ter drainage be passed throu gh the ap pro ve d petroleum intercepting chambers name ly th e lower entrance drain gu ll ey was blocked by slud ge.

FINED £200

As_sistan t Divisional Offi cer R Man·is Bngade P etroleum Offic er

stop press

Bedfordshire Police have asked th e APEA members if they can help by id entifying a plastic deton ato r box used in the explosives field.

The box contained 20 ICI No 6 copper e lectrical detonators and appro x 6ft of ye llow wire.

Its size is IO x 8 x 2 inches white plastic with a c ream coloured sliding lid which is locked with what may be a firing pin key.

The in si de of the bo x is sectioned off by a blue in se rt for 20 separate deton ator compartments, the outside has two belt loops.

Any colleague who may be able to identify the so urc e please contact PC Bill Robe rts Bedfordshire Poli ce o n Tel 0582 391339 or Fax 0582 482396

EUROPEAN EXPERIENCE WITH DOUBLE SKIN PETROL TANKS

" Whereas Member States are responsible for ensuring that building and civil engineering works on their tenitory a re designed and executed in a way that does not endanger the safety of person s domestic animals and property, while respecting other essential requirements in the interests of general wellbeing.

Whereas Member States have provisions , includino requirements relating not only to building but also health. durability. energy economv. protection of environment, aspects of economy , and other aspects important in the public interest. "

Plants for storing, filling, and tran s porting hazardous liquids must be designed , constructed , installed, maint ained and operated in s uch a way that contam.ination of the water or other lasting detrimental changes in its character a re not to be feared.

With those essential requirements , and for to re s olve th environmental pollution problem since many years, Germany , Holland use double skm steel ta nks.

DESCRIPTION OF THE TANK:

The doubl e sk in steel tank s a re u s u a ll y us e d for th e und e raround storage of ll a mmabl e and non Jlammabl e b pollutin g liquid s

Double sk in tank consisting in: a n internal ta nk. an ex te rn a l parti a l skin around th e t· k· . . ·l d d · e cln c 1ea t111 0 a n e nc ose space es 1gn ed to p e rmit th · "" e c 1 I cu lat1 on of tlu1cl used for the detection of an v le lk · tl d J 111 1e 111te rn a l k or ot the exte rnal cas rn g. ' ta n ·

Yves Marez ( Cerec-France)The european ex perien ce w ith double skin pe trol tank is b e d on th e ex p e rienc e in Franc e a nd G e rman y for over as tw e nt y years.

Th e e n v iro nm e nt a l polluti o n probl e m cause d b y a le ak o f wat e r polluting liquid s mu s t be co nsid e red lik e an ex tre m e ly ex p e nsive haza rd.

T he Co un c il Dire c ti ve o f D ece mb e r 2 1s t 19 88. on th e approx im a ti on 0f laws. reg ul a ti o ns. a nd admini s trati ve pro v is io n s of th e Mem be rs S tat es rdat111 g to con s truction product s (89/ 106/EECJ th e Cu nstructJon Products D1rec t1 ve (CPD). in w hi c h the s tora ge pe trol ta nk s a re in c lud ed indi cates in it s first paragrap h

Th e 0ute r sk in shall co ve r y7 c1 · " ot th e capac it y t l clear. 111 the top part o f th e int e 1 k 0 e c1 ve i na tan , at lea t 1 m a nh o le a nd lt ftm g lu gs. (figure 1) ' s t 1e

Th e lea k indi ca tm s a rc d e, ices 1 ,1 · · , · · w 11 c 1 aut oma t1 c all y 1nd1c c1te lec1 ks 111 th e w all s of l'1 1.. , t 1 .d l I ' n '" " · ,11o ve a nd be low th e 1qu1 eve

Flam e prnuf fitting " are d e , 1ces lo r protect in g ta n ks m part s frn111 p e ne tration b y flam es.

The flu1cl inL \u de d b e t wee n th e s kim s ha ll not. be li ab le e ith e r to corrode th e s tee l nor to so li d i fy a t t he lowt>st vv mt e r ant ic ip a ted te mp era tmes tak in g into acco unt th e dept h a t w hi c h th e tank is buri e d. a nd loulli o n of th e \ )' Ste rn of d e te l'lion .

mon\.io\c.

II double skin.

The usual material is Fe 360 B of the new european standard (EN 1o · f h 025). If the mechanical properties o t e container m t . 1 1· "d h a ena s are influenced by the stored 1qm s or t e environm · . h t em, or 1f matenals have not been s own o possess adeq t h · 1· "d t b ua e c em1cal resistance to the 1qu1 s o e stored . · · . I . . ' must be provided with an internal coatmg or mmg.

The tank must be equ1ped with a connection for anode external cath d. 0 Ic corrosion protection.

DIMENSION

Th S AND THICKNESSES: e usual d. . table 1 1mens1ons used in europe are given in the

At this date th d. Europe H e 1mens1ons are not really harmonised m · owever a · last enqu·. · n important petroleum company, m its II y asks the dimensions as follow:

For capa .t. b I c1 ies etween 30 and 60 in'1· nner w· II · 7 111111 wha (shell and dished ends): 6 mm thickness; eie DIN applies. Outer Wall· sh 11 · · e 4 111111 thickness, ends 5 mm.

Forcapac·t" i... I I ies uetween 80 and I()() in'1· nncr w· II · l' " (shell and dished ends J 6mm thickness; :1m111 where DIN. 1 <tpp 1es. Outer wall· slPll 4 · · e 111 111 thickness. ends 5rnm.

I 11 fact. we are 0 · crnng to an European tank. with an '111h1dL· d1arneter 1soo -· mm. and a thickness 6 mm. Where 1lil' I >IN a pp lie-, the tl · ·I· lie \ness is greater than the others '•HllJlriL·.., 111 I·uro11c hLil ·f h · · w icn I e european standard shall be ipplit·d 1 Ut1)..!t'I d<1tl' is f'or December 1995). the thicknesses ./J;ill dt'pr·11d 11nl\ •if rh1· 1ype of' tank.

FIGURE 1.

The different types of tanks depend on the specific gravity of the liquids ( 1.1 or 1.9), and the explosive resistance of the tank, which is either included in the design of the tank, or given by the adjonction of a flame-arrestor.

TEST PRESSURE OF INNER TANK AND BETWEEN SKINS:

Test pressure of inner tank:

Hydraulic Test pressure of inner tank is required by the French standard (3 bars), German standard (2 bars), and UK standard (0.7 bar).

The Pr EN standard requires 0.75 bar for type A. and 2 bars for the other types. In fact those tests are required to be sure that there is no leak in the welded parts. It is not really a test pressure like in a pressure vessel because the "working pressure" of storage tank is less than 0.5 bar.

Test pressure between skins:

Between the skins, the test pressure is also required by French and German standards.

The pressure for the test if 0.5 bar measured at the bottom of the tank.

The PR EN standard requires 0.6 bar for all types of tanks.

Certain manufacturers have had problems \Nith tanks failing on site during pressure testing of the interstitial space of double skin tank: but in fact the collapse during testing appears if the of construction and the test procedure are not respected.

FRANCE GERMANY

Diameter of inner 1900 * 5 2000 * 6 tank and thickness 2500 * 6 2500 * 7 shell and ends 3000 * 6 2900 * 9

Diameter of outer 1908 * 3 (4) 2008 * 3 (4) tank and thickness 2512 * 5 2512 * 4 (5) shell and ends 3012 * 5 2912 * 4 (5)

An UK manufacturer of tank had published in the "Bulletin" Volume 30 No 2, a test pressure procedure.

Double skin tank shop procedure shall be carried in the following method.

Test pressure for inner tank:

(I) Fill tank with water (using tank manway covers fit to tank and blank off all connections).

(2) Remove one of the blanking connections on cover and insert testing rig which is fitted with pressure gauge.

(3) Apply pressure slowly and steadily to 0.7 bar, measured at top of tank.

(4) Maintain pressure slowly and carry out thorough examination to ensure no leaks

(5) Remove pressure, empty tank and dry out.

For compartment tanks, each compartment must be tested individually under the hydraulic pressure applied on the convex side of the intem1ediate end.

Test pressure between the skins:

Maintaining tank upright position, connect J;lressure hose on one of the mlet connections attached to th k. e s 111. Leave vent connect10n open on skin.

(1) Turn on pump which is connected to contammg mono-propylene glycol solution (-20°C).

UK Pr EN standard A Pr EN (b)

2000 * 6 (6) 1601 to 2000 * 6 (6) 6 (6) 2500 * 6 (8) 2001 to 2500 * 6 (6) 7 (7) 2750 * 6 (8) 2501 to 3000 * 7 (7) 9 (9)

1601to2000 * 3 (3) 3 (3) 2512 * 5 2001 to 2500 * 4 (5) 4 (5)

2501 to 3000 * 4 (5) 4 (5)

These procedures shall be certainly required in the next european standard, and provides a safety margin over the normal operating conditions.

MANHOLE AND INSPECTION COVER:

Each tank compartment must be fitted with means of inspecting the internal condition of the tank.

The inside diameter of the manholes depends on the diameter of the tank, but the usual dimensions are for France 500 mm; Germany 600 mm; and UK 600 mm for the with a diameter above 200 mm. Pr EN standard shall applies 600 mm.

SYSTEMS OF CONFORMITY ATTESTATION:

In each country, the inspector representing the purchaser shall have free access, at all reasonable times. to those parts of the manufacturer's work which are concerned with the manufacture and testing of the tank and he shall be afforded all reasonable facilities to satisfy himself that the tank is being manufactured in accordance with the requirements or standard which are applicable.

In the european market. with the free circulation of the products. it is necessary to have the same references to give the conformity attestation.

storage tank anti-freeze

(2) Continue to pump until anti-freeze mixture flows from the vent.

(3) Cap of vent. (bleed through valve)

(4) Reverse pump inout through vent. B Ieed on fi II connection (to ensure no air trapped between the skins).

(5 J Pump on over liquid to 0.6 bar at bottom. and hold pressure check for any leak.

(6) Release pressure.

For the storage tanks. the next curopean standard. which is attached at the CPD Directive. gives the following system of conformity attestation:

Declaration of conformity of the product by the manufacturer on the basis of:

a) Tasks for the manufal'turcr:

(I) Initial type-testing of the product.

(2 l produl'tion nmtro\.

(3) Pm.sibl). te..,ting of -.;arnpk.., taken at tht· Lll'tlll') 111 aL·uirdancc with a pre cribt'd tc-..t plan

b) Tasks for the approved body:

(4) Certification of factory production control on the basis of: initial inspection of factory and of factory production control.

Table 2 Tank t d. ypes, 1mens10ns and test pressure.

outer skin 3 3 4 4 > 0.75 bar 2 bar 2 bar --1 I

possibly, continuous surveillance, assesment and approval of factory production control. The application of this procedure shall permit to put the EC conformity mark on the product.

Test Pressure between skins 0.6 bar 0.6 bar 0.6 bar

outer internal skin skin 3 3 4 4 r-----____~~-r~~--~~~--t-~-~--1.,lk_g_/l~~~~~-,--~~-i.-~~-r-~~--l

5 6 7 9 r-----___---r~~--1------+-~---t---~--1

s.g. of stored m d" e ia

dished ends 1.9 kg/I 1.9 kg/I compartment ends 800 to 1600 1601to2000 2001to2500 2501 to 3000 800 to 1600 I 60 I to 2000 2001to2500 250 I to 3000 5 6 6 7 5 6 6 7 3 3 5 5 5 6 7 9 5 6 7 9 3 3 5 5 5 6 7 9 10 14 16 18 3 3 5 5

5 6 7 9 -------------L____J__ _L__l__J_ _J__ _j__ _J 75

HS(G)41 TANK TESTING

Clive Stephenson Warwickshire Trading StandardsOn the 3lst July 1992 the HS(G)41 working party issued guidance on the subject of precision tank testing and the frequency of testing of petroleum storage tanks. The guidance specifies criteria for testing and lays down the accuracy required by the various test methods.

In brief a precision test must be able to detect a leak of 380ml/hr and meet the requirements set out in the U.S. EPA "Standard Test Procedures for Evaluating Leak Detection Methods".

There are several aspects covered by the guidance document but I would like to evaluate just one of them; that is the method of testing laid down in Appendix I of the guidance, "Hydrostatic testing of Underground Tanks".

I am sure we are all familiar with this method of test so I will not go into detail about procedures but simply make a few observations.

We are told that as a minimum, a suitable gauge would be of lOOmm diameter, with a full scale deflection of 30 p.s.i. and scale intervals of 1 p.s.i. This gauge should be read to the nearest 0.5 p.s.i.

The allowable pressure variation over a one hour test period is minus O p.s.i. and plus 0.5 p.s.i.

Having established these facts, let us look at the necessary volumetric losses in a tank, required to give a resultant 0.5 p.s.i. drop from 7 p.s.i. healing in mind we are only reading the gauge to the nearest 0.5 p.s.i.

If we assume the water level in the tank is 2" from the top (in fact it should be within 2" of the internal manhole neck which would make the water level even lower) then for a 1 OOO aallon tank we would have an air space of _, e , approximately 55 and tor a 10,000 gallon tank of approximately 150 litres.

To carry out the hydrostatic test we pressure this air space to 7 p.s.i. If we now apply the basic of pl:ysics and without going into the mathematical detail. we fmd that in excess of 1.25 litres must be lost from the 2,000 gallon tank in order to reduce the pressure from 7 p.s.i. to 6.5 p.s.i.

In the case of the I0,000 gallon tank then a loss in excess of 3 litres is needed to produce the same pressure drop.

So for the range of tanks normally encountered we require losses between 1.25 and 3 litres in order to detect a 0.5 p.s.i. drop in pressure.

Considering the stated leak detection level of 380m1/hr then this test would need to be on for between 3 and 8 hours in order to satisfy the necessary accuracy.

If indeed we leave tanks on test for this period of time, then we must also consider atmospheric pressure changes and in the case of new tanks that are not encased, temperature changes within the tank.

I would therefore suggest that the minimum requirement for a suitable gauge for this test, would be one with a full scale deflection of between 10 and 15 p.s.i. calibrated in 0.1 p.s.i. increments and capable of being read to 0.05 p.s.i. This would immediately increase the sensitivity of the test by a factor of I 0.

I would also question the allowable pressure variation of plus 0.5 p.s.i. over a one hour period.

There should be no change in pressure in the tank (apart from leaks) other than that caused by a change in atmospheric pressure or a change in temperature within the tank.

If either of these two elements are going to change then there must be a facility for measuring the change and a compensation factor applied.

This is particularly relevant for a new uncovered tank where changes in temperature within the tank in exc t' 0 ess o 10 C commonplace. Such a rise in temperature would result 111 pressure changes of around I IJ s 1 · 111 ·l L SUL 1 circumstances a Ink f I · ' o p.s.1. over one hour would go undetected.

The hydrostatic test may not be ideal but the criteria laid down in the guidance document does seem to conflict with EPA's standard and \\ill do nothing to improve the test's image among tank installation contractms or enforcing authorities.

Conder's aim has always been to develop better products and build ing methods to accelerate the construction proce ss th e soo ner your forecourt is up and running, the sooner your return on in ve stment. 30 yea rs ago we introduced th e prefa bricated Canopy, later the GRP Interceptor and most recently the revolutionary Fibrelite Acces s Covers with their light weight, you don't need a 'feat' of strength to lift them. Now, Conder can offer a complete range of ready-made products designed specifically for the forecourt.

Modular Con ve nien ce Store and Car Wash buildings deli ve red to site read y wired, plumbed and fitted out for rapid assembly; Access Chambers to contain possible fuel spi llage and keep out sub-soil water; Silt Traps to avoid drain blockages and last, but not least, Pump Isl and Barriers all from one source and de li vered to si te

A RANGE OF OPTIONS

By P Whitehead of Veeder-Root Environmental Systems Normond CMSTANK 2 FOUR STAR TANK TESTED = 74 PERCENT 0.378 Lll'RE TEST FAILED

VEEDER-ROOT

The demands placed upon petroleum retailers to accurately mea sure wet stock and to cany out accurate reconciliation between sales and stock has never been greater.

They face pressure from many different direction s : from th e need to run a profitable a nd we ll managed bu siness in a competitive market through to retailing a relatively high vo lum e, low margin produ c t. There are also the added press ures from Local Authority Licen s ing Officers who mu s t e ns ure th a t the s ite is operating s afely. And there is the ultimate threa t of an undetected leak a nd the s ub sequent co s ts w hi c h re s ult from polluting th e env ironment.

O ne of the ke y re quirement s in we t s to ck reconciliation is to achie ve acc ura te, re lia bl e a nd ea s ily collec ted inform ation o n ta nk s to c ks , a t pe ri o d s w hi c h c o in c ide w ith s ale s d ata be in g co ll ected for co mpari so n

S o w ha t a re th e o ption s for co ll ec tin g thi s data ? Perhap s t h e most w id e ly use d me th o d is the dip s ti c k , but it ca n res ult in m a ny una cce ptab le di s c re p a ncies In c rea s in g ly , pe tro l c o l Iee l the ir s a les data thro ug h acc urate a nd pump co n tro l and point of sale dev ices Wit h -·d ry" they a lso ha ve an e a sy wa y of accurate ly i:ll'L'<J Ul1 t in g for th e re lati ve ly lo w va lue c o mp o nents bec au se

they can physically count them. But the most valuable stock component on the site, petrol, is often measured with a dipstick -a rod calibrated normally to the tank dimen s ion s with a Briti sh Standards (B S 2594) tolerance which. may we ll be outside. a tolerance of 0 5% and, more to the point , 1s used by vanably trained operators who judge the stoc leve l from how wet the stick is and then enter the information manually into the re st of the sys tem' Whil st it is acce pted that some dip stick s will be calibrated accurately by luck, and that the dimen sion s supplied accurately conform to · are reality, most measurements will not be accurate. Thei e 1 a lso the added ri sks of human e rror , human nature , po te nti a d d' d' sucks amage to 1pst1ck s, th e pos s ibilit y of confu s111 g 1p a between tanks and the in ev itab le difficult y of coincidino reading s w ith other data_ All thi s makes the u se of a dip sti ck ex treme ly difficult and haph azard in an area w he re c han ce shou ld not have a ro le. Th e latest BS 2594 no w co nta in s th e " I . d are not wa 1nrn g ··- comrne rcia ly pre ca librated d1pro s no rm a ll y co ns idered to be an acc ur ate mean s of rank co nt e nt meas ure me nt. "

Th e a lte rn ative to Lh e dip sti ck is the tank u-a u ae. The UK ha s led th e re st of the wo rld in th e of stock reco nc ili at io n. Gauges ha ve ev o lve d to th e point w he re th e y now pro vid e ex tre me ly accurate in fo rmati o n . a re eas y to use a nd offe r a num ber of sto c k co ntrol fac iliti es.

There are three main criteria when selecting a tank gauge: the probe

the calibration of the probe

the electronics facilities which assist the manipulation and control of the data provided. It is worth noting that the latest generation of tank gauges such as the TLS 350-R, can also control other sensors for leak detection, perform precision tank testing, monitor double-skinned tanks, and accommodate driver controlled delivery.

The Probe

The first consideration is height accuracy all gauge probes (even the dipstick) measure height. Therefore, it is critically important to know that the probe measures height to sub-millimetre accuracy. This is because with any measuring technique there will be some variance of height measurement particularly in the centre of the tank, where the volume corresponding to this height measurement is at its highest level.

The second important criteria is repeatability, in other words the ability of the probe to measure the same height reading every time it passes through any given point. This means that any discrepancy in the height reading will be taken into account by the repeatability of the gauge thus ensuring that the same information is being compared on each occasion.

The third factor is resolution: the ability of the probe to measure changes in height, paiticularly during a quiet period in the tank. In this instance, a high resolution probe can be used as a precision tank test which negates the need for expensive mobile services and provides an easy payback and added security from the tank gauge investment.

Calibration

The second critical factor is calibration. All tank gauges measure height, but fillino station operators need volume, not. height data and, the tank gauge must be caltbrated_ to convert the height readings in to corresponding vol_ume. m litres. There are broadly six methods of caltbratmg a tank gauge:

* Copyino d" · "' ipstick measurements which provide you with a tank gauo th · d "'e at performs as a consistent an correctly used d. · k ipstic • but it will adopt the same enms as were mhe1·ent 1 · th d" · II 1· n e 1pstick. potentia y + o -5%.

* dimensions may be copied and interpreted using special software programmes. but aoain the tank gauge will then he calibrated only to the toierances of the tank.

* Where water has been used in tanks during construction. this can be dispersed through proving vessels and as measured amounts of water are removed from the tank. height readings are taken to provide an accurate look-up table.

* When tanks are filled with product for the first time, incremental fills using flow meters may be incorporated. This, historically, has proven to provide probably the most accurate calibration data achievable. However, it is an extremely skilled process and it transfers a lot of product into ownership, i.e. the tanks must be filled to correctly calibrate. Logistically, therefore, it is a complex and relatively expensive process and one in which users of gauges have not always been prepared to invest.

* The latest generation of tank gauges such as the TLS 200-R and the TLS 350-R incorporate sophisticated self-calibration facilities. The gauge is interfaced to the pump controller and calibrates itself by comparing height readings from the tank gauge with the volume of fuel dispensed through the pumps. As it is not always practical to run a tank from full to empty in a continuous pass in a live trading situation, the latest gauges are capable of recognising when they are in calibrated and un-calibrated sectors. If an operator "moves" into a sector of the tank that he has not previously accessed, the gauge recognises that this is new, un-calibrated "territory" and will automatically switch back into calibration mode. Obviously, the accuracy of pump meters is significant in this calibration as they are the other measuring device being used. The offset from the meters can be built in to the tank gauge or they can be set accurately at the time that the calibration process is starting. This automatic self-calibration method now provides an easy cost effective route to good calibration.

* If a tank gauge has been calibrated using any of the first four methods, then a process of back calibration by collecting data and running it through our special computer can be used to improve calibration. This rehes on good data being obtained by the site operator over many weeks.

The important message calibration is that you cannot expect the tank gauge to reconciliation information unless it has been correctly calibrated.

Electronics

The third impmtant dimension is h t e electronics incorporated in the tank gauge which record . . · p1 ese111 and calculate data and 1t 1s m this area th·n the t. 1 . . , . . • 1ue va ues ot collectmg automatic stock mtormati 011 ai·e n b . . ' ow emg reahsed.

For too long forecourts have 11·1d 111 c1 1 ·,,1·dt 11 I · . . ' u e ectron1c modules mteliaced together in an ·itte111 pt t) ·c1 ' l p1ov1 e more comprehensive systems. This is particularly true in the areas of stock control leak detection. but it is now possible for a tank gauge to pertorm the follmving functions:

* Inventory control * Automatic wet stock reconciliation

* Automatic compliance to HSG...J. l stock reporting without further number crunching

* Dynamic leak detection by monitorin g variances in the stock control process and analysis of trends

* Alarms covering high levels , low levels, re-order quantiti es, reconcili a tion problems and so on

* Water detection and appropriate warnings of problems

* Pr ecis ion tank te s ting without the need for servic e truck s

* Th e monitoring of double-skinned tanks for l eak detection without the need for separate control sys te ms

* The monitorin g of other external leak detection device s which may be specified in sensitive sites or w here secondary containment is e mploye d for piping . These include vapour se nsors oro undwater sen sors, ' b sump sensors , line leak monitors, all us ing the central control box of the tank oauoe a nd not requirin g b b separate electronics

* The ab ility to run drive r controlled deli very unit s

* The a bility to be re motely inte rrogated a nd to col lec t data at ce ntral po ints for further a nalysis and actio n , such as a utomatic orderino central control of stock in 0' groups etc.

* The ability to interpret a nd communica te other a la rm s on the sites s uch as refrig eration alarms, burg lar alarms etc

''' The abi lity to pro vide historical data for analysi s of proble m s such as pre vio us alarm s, hi s tory recordin g of events o n the site

''' fac ility for low cost up grades to add tanks or fac1ht1e s without repl ac in g equipment

Tank Gauge Probe Technology

Ju st as th e e lec troni cs h ave evo lved to provide more fac iliti es so has probe tec hn olooy mov ed forward Th e ta nk ga ug es of the 1950s were a;aloau e aa u oe s which used h dr , ' o o o d b Y ostatic pnnc1ple s to meas ure the press ure ge ne rate Y the hei ght of liquid ba la nc ed aaa in s t a co lumn of air mtrodu ce.d normall y b y a s mall h:nd-pump These dev ices we re typ ica ll y used w he re s ites were beina built on offse t fill prin c ipl e s . us uall y th ey were calibrated 0 to dipstick s a nd therefore pro vided a mo re co nvenient met hod of re cordin g the dip s ti c k in fo rm at io n a nd Ieoa ! comp li a nce to lice nsin g c o nditi o ns 0

As e lect ro ni c s beca me more widely used in kio s ks, it was log ica l fo r tank ga uge s to beco me e lec tronic a nd th e fir st g a uge s see n in the ma rk et in the late 1970s were e lec troni c va riati o ns o f the hyd i·ostat· " · 1 llo wi ' no th e IC p1111 c1p e , a b 1ntormat1o n to be read throuoh tran sdu ce rs a nd b c o mmuni ca ted to o th e r k io s k equipm e nt s uc h as po in t of s a le ler1111na ls a nd p um p contro ll e rs

Th e o th e r popu Jar probe meas ure me nt tech niqu e is to use c a pa c itan c e tec hnol o gy, whi c h co mp ares the d iffer ence in 1/l e re /ali ve pe rmitti vity of th e air vapo ur a nd the fue l 1111 e r l ac e lo o ht ain its he ig ht readi ng. Ca pac itanc e 1cc hn o log y I ' lh e mo s t w ide ly used a nd deve loped tec hniqu e a nd p rov id e ' t roub le free acc urate gau ge reading s. Jn th e l ' n !l e d J< 111 g dom thi ., tec hn o logy is see n in the C MS 3000.S " n d 1h e a nd 350 R produ c ts

Choice of Probes

The TLS-350R can monitor either capacitance or m ag neto-s tricti ve tank gauge probes. Different type s of probes can be used on the same system allowing you to c hoose the technology best suited to the product being me as ured, or the most suitable diameter probe for the tank tapping s av ail able.

DCD Compatible

The TLS-350R is compatible with the indu stry standard DCD, allowing for flexible deli very schedules , efficiently and safely.

The Environme ntal Protecti on Agency in the USA has created standard s for leak detection equipment which have bee n established through 3rd Party test house certification. These certifications state that a me as uring de vice which is c.apab le of detecting a leak of 0 1 US gallons per hour (0 .378 litres per hour) 1.s. a.cceptable as a precision tank test. It is now possible, ut1h z111g the Veeder-Root CAP! ea ' t c pac1 ance probe or the MAG 1 magneto-strictive measu1,1 · d · ng ev1ce linked to the TLS 350-R console, to autom aticall f . . y per orm Prec1s10n tank te sts thu s pro vidin g co nstant s ui· 11 f ve1 a nce o tank mtegnty. For exampl e, the TLS 350 R d rea s in format ion from th e pump controller and k h h 1 . . ' nows w en th ere 1s a t eoret1ca quiet pen od, 1. e. when th 1 e nozz e 1s ho lstered. If th at qmet penod 1s suffici ent to '"" pe11orm a preci s ion tank test at the end of eac h month a rep t ' or will be printed sho win g the ta nks tested and the statu s If · Yo u wish to do a tank test at a ny time usmg thi s equipment . , a s imple key switch enabl es you to run a precision tank test . a t W1lJ Thi s provides operators with mu ch more th a n a n a 1 · nnua or irreg ul ar MOT tes t on the tank as it offei s co nstant s urve ill a nce and a n early alert of a ny difficulti es.

Al so, th e comp le te system includino 11 · · b · ' b nes, 1s e mg c hec ked through the auto mati c reco nc iliation d d · . a n y na nuc leak detection process which 1s lookin o for " o va11 a t1 o ns o n a co nstant bas is. By ut1h z111 g th ese tec hniqu es · , s ite opera tors are ab le to obtam exce ll e nt mfo rm ation a nd 1 · h. co nt ra 111 t 1s area of their bu s mess

The env ironm e ntal iss ue s and press ures h. 1 f · a w 1c i a re · ac 111,,, th e ow ne rs a nd ope rators of re ta il fi11 111 · . g s tations <LI 111 creas111 g and the co nsequ ences of fai liii o t k ·aper b o ta e pi preca uti o ns to protec t both th e co mm e rcial 0 · of the . ' pera u o n fillm g station , a.nd th e e nviro nm e nt are pote nti a ll y deva s tat mg. Eftect1ve mstrum e ntatio n is now affordab le a nd is a rg ua bl y esse nti a l in helping se rvice sta ti o ns mee t th e ch all e nges of mode rn petrol reta ilin g a nd the g row in g leg is lat ive co mp li a nce require me nts.

Upgrades of ea rli er sys tem s a re ava il ab le a nd th e in ves tm e nt needed for co nt ro l and e nvironm e ntal protectio n is now 111ocles1 compa red to th e ri s ks of ig noring th e se iss ues.

BL AZING PETROL TANKER, NEWCASTLE

ROAD, SUNDERLAND, TYNE AND WEAR, WEDNESDAY 26 AUGUST 1992

W. Dunlop Chief Fire Officer

W. Dunlop Chief Fire Officer

f '

Tyne and Wear Metropolitan Fire Brigade responded to the first of an estimated eighty duplicate calls to a petrol tanker on fire , possibly persons reported , on th e Ne wcastl e Road , Sunderland. The scene of the fire wa s approxim a te ly one mil e from the City centre and on th e main thorou g hfare to the north of the City. The first c a ll wa s rec e ived at 1101 hours, the fir st two appli a nce s arriving at l 105 hours. By 1108 hours the Brigade ha d four Water T e nders and a Re scue Tender in attendan ce The se fir st crews we re confronted with an articulated petrol ta nk e r o verturn e d in a s id e s tree t off th e New c astl e Road and an o ve rturn e d Fo rd Tran s it va n w as lyin g in th e northbound carri ageway o f th e N ewcas tl e R o ad.

Th e Offi ce r-in-Ch a rge o f th e fir st a tt e nd a nce o bse r ved that th e fr o nt e ncl of th e ta nk e r a nd th e trail e r unit we re e ng ulfe d in fl a m e s Th e g utt e r of th e s id e s tree t w hi c h 1vas s lo pin g ge ntl y a way f ro m th e ta n ke r wa s bl az in g fi e rc ely for a di s ta nce of app ro xim a te ly o ne hundre d ya rd s. e ig ht ve hi c le s par ked a t th e ke rb s ide w e re a lso e ng ulfed in fl a mes. A so uth -wes te rl y w in d w as bl ow in g th e m ass ive fl a me a nd

s moke plume away from th e res idential area on th e opp os it e sid e of th e road fr o m w he re th e ta nker la y Thi s s mok e plume w as obser ve d by officers at th e Bri gade ' s Pil o rim Stree t Headquart ers some tw elve mil es a way Shortl y 7iner arri vin g at th e mc1dent th e crew memb e rs h eard two muffl e d ex plo sio ns qui ck ly foll owe d by a third lo ud ex plos ion w hi c h res ulted in th e ta nk e r bla z rn g from e ncl to e i1cl 111c1 b · ' urnrn o pe trol en g ulfin g a noth e r te n to fift ee n ca rs w hi c h we r: Park ed in th e s id e stree t a nd th e publi c sw immin o b tl c a 1s ca 1 park adj ace nt to th e in c id e nt.

Co nfirm ati o n th a t th e evac ua ti o n h a d b e g un fr o m th e surroundin g area. m c luclin g t he sw immin g ba th s, wa s o btain e d fr o m th e office rs of th e N o rthumbri a Po li c e w ho we re in att e nd a nce. Coo lin g j e ts a nd SX foa m mak in o b ranc hes we re rapi d ly in pl ace to limit t he fi re sp re ad th e ta nk e r w hi c h had c o nt a in ed :1 4 .000 lit res o f p re mium a nd unl e ade d pe tro l in it s s ix co m partm e nt s O ffi ce rs fro m Di vis io na l Hea dq uar te rs imm e d ia te ly res po nded. Se ni or D ivis io na l Offi ce r H ug he s ta ki ng c har ge of th e in c ide nt at

Assistance messages making pumps six, eight, twelve and fourteen were sent, the last at 1131 hours. By 1137 hours a foam attack was mounted with two number ten F.M.B .' s using the 3,600 litres of foam compound carried on the Brigade's Foam Tender. A further 9,000 litres were held in a storage hopper at the nearby Fulwell Fire Station and relayed to the incident by Water Tenders.

Dams were constructed with sand across the roadway by fire _ crews to reduce the flow of petroleum into the City ' s dram s Despite this action , the Brigade still had to respond to numerous Special Service calls to deal with petrol in drain s, further depleting the Brigade ' s resources. The last c all of this nature was dealt with on Friday 28 Au oust 1992 u . . b approximately 2130 hours . Standby appliances were called in from Durham Fire and Rescue Briaade and the N o orthumberland Fire and Rescue Service

Of the 34 ,000 litres of petroleum carried by the tanker, 7 ,000 litres was drawn off into a standby tanker, while a

further 5,000 litres was recovered from within th e dam s constructed by fire crew s Of the cars parked in the side street and the adjacent car park inside the grounds of the swimming baths , forty-five were damaged , twenty-five being write-offs. Miraculously, there were no casualties other than the three occupants of the Transit van and the driver of the petrol tanker. All casualties were treated at the scene of the accident by the Northumbria Ambulance Service before being conveyed to hospital. None of the injuries are thought to have been serious.

During the incident, close co-operation was ma intained with the Police , Ambulance (who dealt with a su spected heart attack during the evacuation) drainage and ri ver authorities as well as the Health and Safety Executive.

Enquiries are continuing into the cause of the rupture of the tank.

THE APEA AND BRITISH STANDARDS

Standardisation of Petrol Tanker Design

By Mike Sewell, Chairman of the Southern Branch, APEA and recently retired from the Health and Safety Executive.As many of you will know, I was responsible in the HSE for the legislation concerning the cmTiage by road of dangerous substances which included the design and construction of petrol tankers. Since retiring from the HSE I have been nominated by APEA to sit on a British Standards Committee concerned with the design and construction of petrol tankers. This note is to inform members of the APEA what is happening on this front and also to raise the awareness of members to the British Standards work being carried out in the field encompassing petrol filling stations.

For many years the design and construction of petrol tankers has been controlled by regulations, the most recent of which are the Road Traffic (Carriage of Dangerous Substances in Road Tankers of Tank containers) Regulations 1992 which have replaced the Dangerous Substances (Conveyance by Road in Road Tankers and Tank Containers) Regulations 1981. One of the requirements of the new regulations has been the need to have the design approved by the HSE, but this is now done away with in the 1992 Regulations in favour of an Approved Code ofo Practice (ACOP) covering the design and construction of petrol tankers.

Durin<> 1990 th I · · "' . e nstitute of Petroleum, representmg the 011 companies ·111 d th s · d • • • • < e ociety of Motor Manufacturers an T1 ade1 s, represent" a h . · m"' t e tanker manufacturers, decided that 1t would be benefi 1 (CEN) S icia to Bnt1sh mdustry 1t a European tandai d could b f of the ACOP e prepared based upon the then dra t 1et erred to above I k ·1 1 · EC countries e'. ., 11 · t W.ts nown t iat ot lei · , spec1a y Gen , CEN Standard should nany. were of the same view a in first the UK be prepared. It was felt that by gettmg stood a good 1 h Standard to its w f . . c iance of intluencmg t e · ay o thmkmg.

The British Standards Instit t. · LI ion (BSJ) ·101·eed to set up a Committee to further this <"' · . . . work and the draft ACOP (with certam add1t1ons and amendme t .) CEN Secretariat. The BSJ C n_ s was submitted to the ll omrnittee. AUE/U/-/2. was set up early 111 I ) ) I and I was appoint d . EA e to It, as an AP representative. 111 late 1991. Not 't I 1 h , · u· ' 0 as happened smce then with 1e"',u d to the p1 eparat1on of 1 CFN S . . , ' :. , tandard. but a hrst meeting ut a CEN Committee w· 1 11 p · · • c1s le l 111 ans 111 March 1992. The outcome of this 111eet 111 1 · d · g ias necessitate the rearrangement ot the BSI co111111itte" st. t 1 j . 1uc ure re atel to this \\•ork.

It was ine\itabk that the per.suns attending the CEN Committee meeting would link the wurk of the to the European Agreement concL'rning the international carriage of dangerous goods by mad ( ADR l. As a result the

terms of reference of the CEN Committee were agreed as the standardisation of design, construction, inspection and testing of metallic tanks (of road tankers, tank containers and rail tankwagons) intended for the transport of dangerous goods of a capacity greater than 450 litres.

Thus the CEN work will cover all types of road tanker used for the cmTiage of dangerous substances and not just petrol tankers. As a result BSI is setting up a Committee AUE/18 to deal with the overall issues linked to the CEN Committee. Committee AUE/13/-/2 will become a subcommittee of AUE/18 and it is likely that other subcommittees will be set up to deal with other types of road tanker etc. I will be representing APEA on the main BSI Committee AUE/18 as well as on the sub-committee dealing specifically with petrol tankers.

The next meeting of the CEN Committee will be in October 1992 when a programme of work will be discussed. Inevitably a number of sub-committees will be set up to deal with the various aspects of this work. It is almost certain that the UK will hold the secretariat of the CEN sub-committee which deals with petrol tankers.

Looking to the future and the eventual outcome of this work. a CEN Standard will be produced covering the desi<>n and construction of the tanks and their fittings of tankers. This is unlikely to cover the vehicular aspects which are cuJTently covered in the ACOP. The BSI will then be required to produce a British Standard which effectively reproduces the CEN Standard. By the time these Standards are published it is likely that they will differ from the ACOP in a number of respects, one of which is likely to be the thickness of the tank. The Health and Safety Cornn · · . ,.. 11SSl011 will find it very difhcult to resist having to amend the ACOP to fall in line with the C'EN Standard.

Turni'.1g now to other Standards work. the APEA has been active 111 produc111g B: 71 17 on petrol pumps. a draft BS on GRP and a clralt BS on steel underground tanks. The Council ot the APEA is of the vie" tll'tt tile A ·s · t. " ' · s. ocia ion should be involved in standards work which impinges on. or is directly related to petrol fill in!! stations

The Council would wekonw hearing from members wlw may be involved in BS work not rl'l.crred to abon' m who may be aware of standards wnrk in \\'hid1 the APEA should be i11n1lved. Ideas for 11L'\\ standards work in this field would also be wekome. Any commL'nts \ll1 the abon' slmuld be sent to till' Secretary. Da\L' Rucknall. whose add1\'Ss is .shown on the title page ol Tlw Bulkti11.

SERVICE STATION TANKS & PIPEWORK CORROSION

Some Practical Aspects of Corrosion Prevention

H. M. Hatley, F. I. Corr. Pipeline Maintenance LimitedFollowing the previous article on this subject in The Bulletin, it would seem apposite having spelt out the of a leak of product to enumerate the Vanous options which are available to safeguard against such an occurrence.

Of all the corrosion problems that can be combatted, the type that seems to offer the least chance of success is where the surface requiring protection is permanently buried or submerged in a 'corrosive' medium.

When the medium itself is variable and seemingly mfin t · · a e m size, and the periods involved are upwards of ten years. then the problem of protection would appear to enter the realms of impossibility.

However the first baITier to stop coITosion of buried pipes and tanks is a good quality coatina to prevent contact between the backfill and the

The second is to install a selected non-coITosive backfill washed sand-cement. These precautions however have een proved to be inadequate in preventing corrosion totally.

It further . b · h l'" must e accepted that at some stage dunng t e lie of a serv· . . . h · ice station, ground water will come mto contact Wit the bu _. d . . 11e steel p1pework/tankaae with consequential corrosion_. t "' a an unknown and indeterminable rate.

It must be ·1cce t d h · l' · ·11 in- · ' P e t at a pipe me coating w1 not <Lmtam an inf · t · · · ma e resistance to ground. With t11ne, ground moisture ·11 II wi penetrate any pipe or tank coating, thus d owmg accele · t d · · · · ra e corrosion at the coating 1mperfect1on.

From the ah< , · · · · · JVe 1t is patently obvious that add1t1onal corrosion pre , · vention measures must be taken to avoid the chaJ"<>e of ll r]. "' eg 1gence 111 the operation of plant. The only such me·1sur · · h · '· e is cat od1c protection.

In !he L"tse 1· -, · · '· o se1 vice stations where tanks and pipework v.eic ongrnally huried in a selected non corrosive backfill. it 1" llll'\ liable tha1 thi1., specially selected backfill will become pollu!eJ ih IIHle progres\es hy the ingres<., of natural ground "'<llt'I An\ al tempi to keep the ground water and 1.,elected /-.;1ckf11l aparl '" foreJoomeJ to failure. It must he accepted l1;il l;mj, ;md pqwwork will. g1\e11 time he surrounded by a H''"·l·•· 11wcl1;i

The previous article in 'The Bulletin' refers to the legal requirement for operators of plant to take precautionary action to prevent corrosion of buried plant. This article sets out the only precautionary action that can be taken and further that can be demonstratively be seen to be taken, thereby fulfilling one of the precepts of this life always have your umbrella up. This precautionary measure is the application of cathodic protection, which is the only anti corrosion method which can be seen to be taken. Monitoring and reconciliation of product inputs and outputs, checks on the interceptor, static head tests will tell you only when the unmentionable a leak has happened. These are not preventative measures only monitoring.

Cathodic protection on the other hand whilst not guaranteed to prevent a leak will be seen by all authorities to be a step to prevent corrosion, as compared to a monitoring system which will only tell you. you have a problem after the event.

Cathodic protection is based on a very simple concept. It is accepted that corrosion of buried steelwork is associated with specific electrolytic cells and that one pole of the cell corrodes as in a battery. The other pole is protected during the process; cathodic protection uses this fact in introducina a 'false pole' into the system to 'attract' corrosion. "'

Cathodic protection has been in constant use since 1824 and is not 'black magic'. Basically. a cathodic protection system requires an anode (i.e. the false pole mentioned) and some means of producing electric power to ensure that sufficient direct cun-ent flows in the right direction to prevent corrosion occurring to the opposite pole i.e. tanks and pipework.

Modern cathodic protection system<., are designed for a 20-50 year life, the 'false pole' electrode heing correctly sized to be virtually indestructable.

Cathodic protection design for tanks and pipework include:

a) amount of buried pipework and tanb h) type of backfill

c) age of plant

d) required life of plant

e) quality of applied coating to tanks and pipework

f) existing monitoring systems

g) pipework and tank installation specifications

h) adjacent buried or DC operating plant i.e. DC traction systems (railways).

Any monitoring system installed to prevent c01Tosion is only as good as the regular checks recommended by the applicator (and possibly required by the local Petroleum Officer).

A corrosion prevention system correctly installed and commissioned is worthless and would be seen to be so by the local Petroleum Officer unless it is maintained in constant operation. To ensure this, routine monitoring is a necessity which should be incorporated within the normal maintenance procedures carried out by a service station

operator. An additional overview by a corrosion specialist is advisable from time to time to make sure that the guidelines assetbyBS7361Part1. 1991 are being met.

Adjustment to the cathodic protection system may be required during the routine survey and such action would be mentioned in the survey report.

Clearly the application of cathodic protection is only applicable to service stations with buried steel tanks and/or pipework. A cathodic protection system can be retro fitted and will provide a cost effective alternative to total tank/pipework replacement for the 'aged' non failed senrice station.

The cathodic protection package should be considered a must for recently constructed double skinned steel tanks and pipework and single skin tankage not having reached its 'sell by date'.

Letters to Editor

Dear Editor

The Southern Branch is concerned that the membership is not getting a proper opportunity to elect Council members including the Officers of the APEA. lt has not been necessary for a vote to take place for a number of years, but at the 1992 AGM there were 7 nominations for the 4 places as ordinary members of Council and a vote became necessary.

The Articles of Association of the APEA require that where a vote becomes necessary only those persons present at the AGM are eligible to vote. I am not sure hovv many persons were present at the 1992 AGM, but I doubt whether it was much more than I 00 out of a total membership of about 800. In the view of the Southern Branch this is not very representative of the membership.

Some people may. and do. argue that every member has the right to attend the AGM. and it is their bad luck if they do not attend and hence he able to vote. Hm\e\·er, there are many reasons why members are not able to attend the AGM. most of which are outside the control of the indi\idual member.

The Southern Branch thus feels that every member should have the npportunity to vote !'or the ekction nf officers and ordinary members of Council when such elections become necessary. The proper vvay of doing this is to have a postal \Otc as is dnne for ni<lll) other Ass11L·iatinns.

This would entail a change to the Articles of Association and would have to be voted on at the 1993 AGM and could not come into effect until the 1994 AGM.

Although it would cost money to change the Articles of Association, a postal vote should not be a burden on the APEA's finances. ,Members are already notified of the list of nominations and attached to this list. or enclosed with it. could be a voting form for members to return.

The subject has been raised with the Council of the APEA who are not convinced that there is a case for rnakino any change. They would be interested in the views of members or Branches before taking a decision. If any member wishes to make their views known, would please contact me at the address below. ·

It would also be useful if Branches could suund out the views nf their members at their next open meeting and ask their Council representative to report baL·k to Coui;cil on the result.

MG SEvVFLL

Southern Branch Chairman

MG Sc\\l'll

HE ONLY WAY YOU'LL GET PETROL OUT OF A WEFCO STORAGE TANK.

..

A WEFCO underground storage tank delivers petrol to the nozzle, where it's needed, not into the ground.

That's because at WEFCO we're leading the field in environmentally friendly fuel storage with our double skinned tanks, giving maximum protection against leakage.

Around a conventional single skinned tank we have added an outer skin. Then we have applied a solvent free polyurethane coating to all ' external surfaces , adding cathodic \ protection where required, for increased 1 efficiency.

Jn short, we create a secure leak free 1 environment; and once the tank is I installed below ground we monitor its I performance continually with an 1 electronic leak detection system.

WEFCO is the only 885750 accredited company to offer this level of protection.

Underground storage is just one aspect of the WEFCO range of services and products, all designed

for efficiency, performance and environmental protection