OVERNIGHT

Telephone: 01843 221555 Fax: 01843 295444

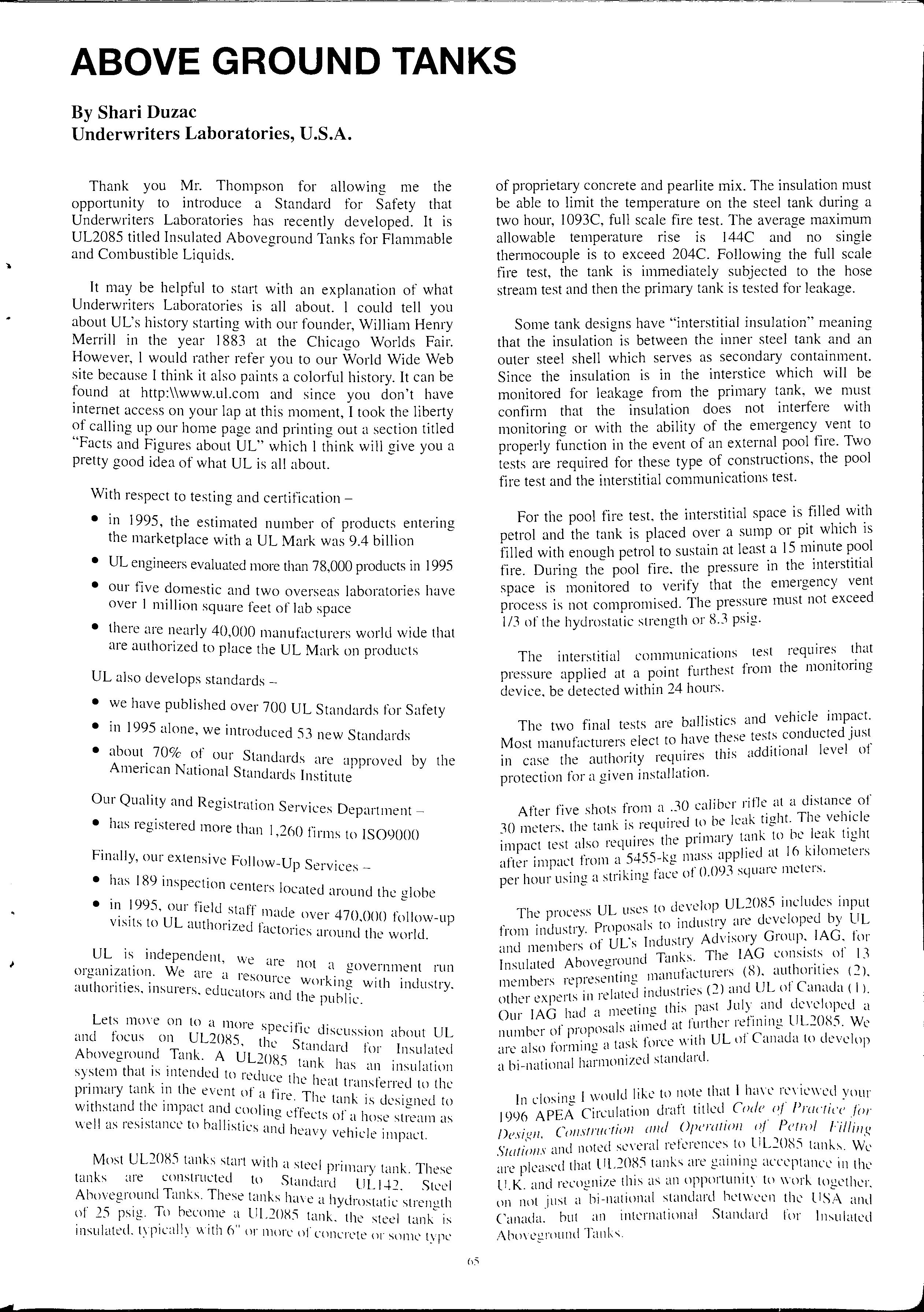

The Conference issue of the Bulletin publishes the papers given at this years Conference and a special thank you for all those speakers who came to give presentations. A particular honour to the APEA was the attendance by the President of the PEI Carl Dean, this was the first official visit of a PEI president the USA, we hope that this will perhaps be the begmnmg of closer liaison between the two organisations.

The council of the APEA oratefully acknowledges the support of the Exhibitors sponsors who made the whole event possible.

THE PETROLEUM EQUIPMENT INSTITUTE: A GLANCE BACK; A LOOK AHEAD

By Carl Dean President, Petroleum Equipment Institute

By Carl Dean President, Petroleum Equipment Institute

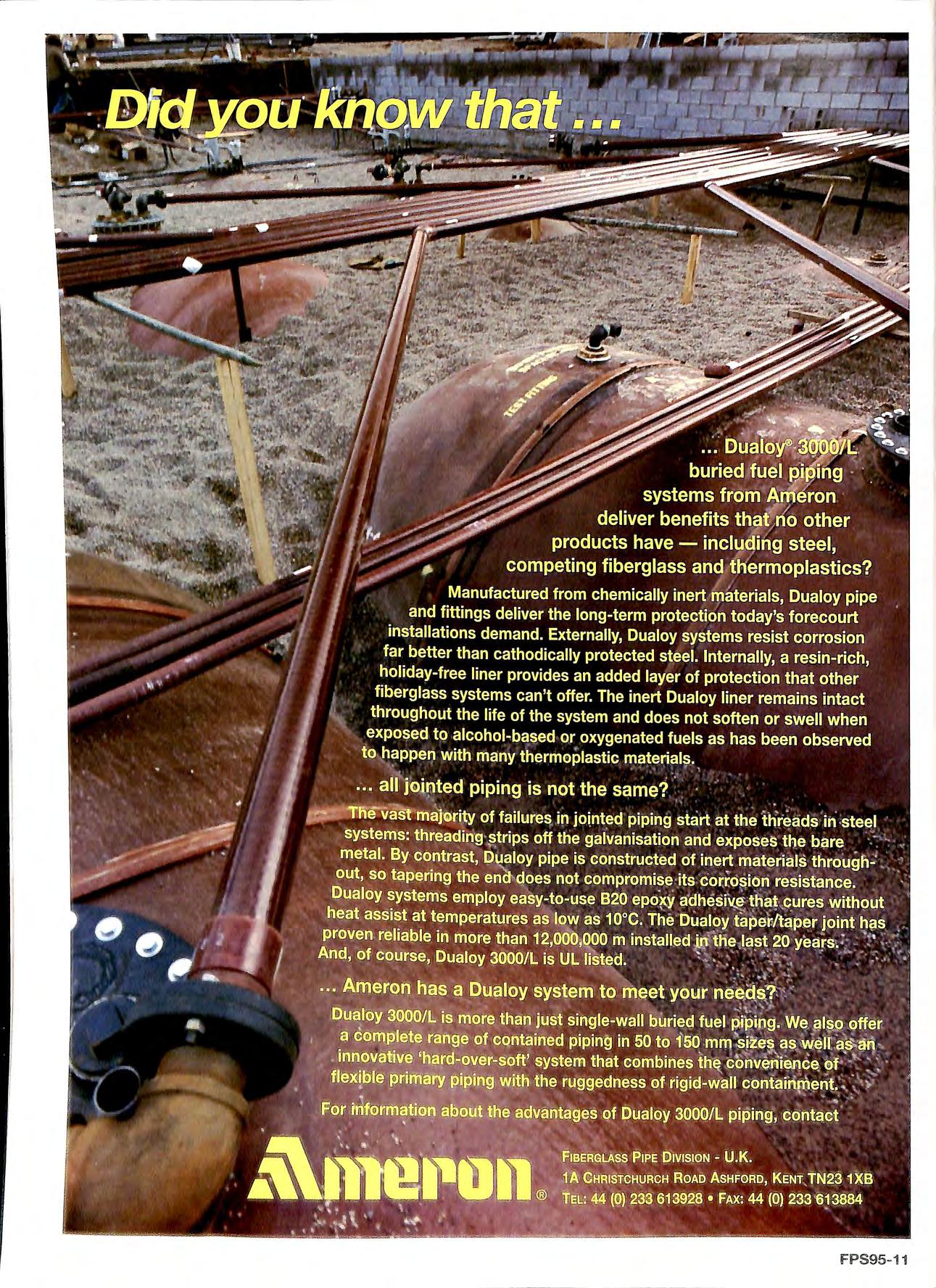

headquartered in the U .K. Lookin g through a recent issue of The Bulle1in , I noticed many PEI manufacturer members that I'm familiar with Ameron , Scully, OPW, Emco Wheaton , Gilbarco , Tokheim , Petro Vend and Veeder-Root , to name a few maintain offices here So even though I'm a long way from Dayton , Ohio, I feel like I'm among industry friends.

PEI member companies are the leading manufacturers , distributor s and install ers of equipment used in service stations. terminals , bulk plants , fuel oil and gasoline deli very, and similar petroleum marketing operations. PEI member firm s are in the mainstrea m of the petroleum marketing equipment industry With very few exceptions , every significant U S firm engaged in the manufacture and di st ribution of petroleum marketing equipment is a member of PEI.

PEI member companies manufacture, sell , install and service equipment used in the handling of pe_troleum products and indu strial liquids. We are very fam1har with the types of e quipment that a re featur ed in your trade show, such as pumps , me ters. tanks , valves, nozzle s, ho se ree ls , lifts , lube equipment. canopies and similar it e ms.

Th e Institute 1s o rgani ze d into three divisi o ns: Di stributor, Manufacturer ;nd Affiliate

Thank you Mr Cha·. 1 . ' · '11 ma n. am1e Thompson asked me to speak to you today about t E wo spec111c topics: th e Petroleum qu1pment Institute and the future 111clu stry I JJromi s t d . ot th e e quipment · · e o o Ju st that.

But le t me preface my rem ·k b _ honored and pleased t b ai s Y say ing that I a m o e with you this mo .. o I' Id by our headquart e rs t· ff · · 1n11i,,, m to ·c1 t t dd. s" 111 Tul sa that I am th e first PEI p1es1 e n o a 1ess a oro A .· c ·1 0 up such as this outside North me11ca. on s1c e nn g that 45 men cl Preceded me 111 thi s p t · dn wom e n ha ve os Slll ce the assoc· t. f d in 195 I I"m humbl ed t 1 , '· · ia ion was oun eel ' o l ave thi s o p ·t · yo u. On a pe rso na l 11 t ' 1 · urnty to speak to 0 e, mu st confes s tl . t· ·1· Marianna. a nd f h· _ · · · la m y w1 e , ave neve 1 v1s1ted E I thorou ghl y e nJ·oye cl o ui· t·.· . . ng and. We ha ve 11 P so 1ar a J I k 1· see ing more of yo ur <Yrea t c _< nc oo ' orward to "' ' co unt1 y dunn o tl _ 1 I· Th a nk yo u tor makin o us f 1 _ "' l e nex t ew c c1ys. "' ee so we lco me

Le t me beg in by te llin o y . · · c- o u so me th1nu about th e o rga 111 zat 1011 tha t I re prese nt he 1 '°' Eq uipm e nt In stitut e PEI s ie toe ay th e Pe trol e um • .·. · 1. th e lllte rn at 1o na l trad e assoc 1dt1 0 11 10 1 co mparn es co nce rn I · 1 . · · ec w 1t1 all aspects ot e quipm e nt used 111 pe troleum nnrk e ti 1 1 · · ' ng a nc 1qu1d handl111 <> ope rat:1on s "'"

Th e In stitut e is co mpri sed of I 'i97 · · 1 c ompani e s 111 t1 e U nit e d S tat es a nd 6 1 othe r count ri es. Whil e must PE I me mb e rs a re loca te d 111 th e U.S a clo ze n PE I me mb e rs are

Th e Di stributor Di vision is t le a rge distribut o r memb e rs . PEI was founded in 195 l by f t Oleum mark etin_g ind e pend e nt , stocking distributors o pe r eq uipm e nt. cl f 367 firm s Th e Manufa c turer Di visio n is compo se 0 _ 1 1 m anuh ct ure petro eum which , as th e nam e imp 1es , ' ' , t cl w hi c h JJnn cipa ll y 111 ,uk et th e11 mark et ing eq u1pm en , an products through di stributors.

I l St with 683

·f·i· D 011 con s ists of ot her firms in th e Th e A1 ·1 1ate 1v1s1 · · · 1 .• 1 1 a bu sin ess in te res t 111 peti o le um indu stry w lI Cl la ve ' · _ b 1 t· but do not quali1y 101 me m e1s 11p 111 mark e tin g equ1pm e n ' · · · TI M· f· t 11.e o r Di st ribut o r D1 v1s10 11. _ 1e 547 e ith e r th e c1 nu dC L ·. 0 1 OLII- at·t·iliate clivi s io n 1n c lud_e ma nuld c tL11 e 1 me mb e rs t ma nage rs insta llat1 o n co ntra cto rs. rep rese ntati ves, ex·por Publi she rs, a nd e n vironm e ntal ser vice compani es consu Itin g firm s.

PEI o ffer s a vas t a rra y of memb e rs hi p se rvic e s to its TI .,ss oc iat io n' s awa rd -w 111n111 g new s le tt e r me mb e1s . i e ' "· ' . . k tl 7 11 /i·{tletrn is publish ed two n r three tim es ,1 now n as l e · · 1 PEI direc to ry 1s p ubli s he d annuall y <llld mont 1. s )o '°' · 1 .- II Lle nil s on th e In sti tut es me mb e r t 1rm s· cont a 1ns u ' · · · 11 _ tlf'l' i· c·' i·s 11·11e s hand le d. prnduct s manula c tur e ll ac c re ss es v • • • se rvice ca pabiliti es a nd phon e a nd ta x Hundr e ds of o il co mpan y e ng in ee rs a nd bu ye rs thrnu g hm1t th e \Vorld re ly o n rh e d ir ec tor y as a re fe re nce so ur ce f"ur th e ir petrol e um equipm e nt nee ds. If you re pr ese nt a n oil co mpan y and w ish tu reL·e 1ve _a cornp l1111 e ntar y cup y, gi ve me yo ur bu s in ess ca rd w hi le 1 rn he re a ncl I II see you a re se nt a direc tor y

PEI does a very good job of promoting safety in our industry. The Institute publishes a monthly SafetyLetter that contains reports about accidents in the petroleum marketing equipment field. A publication entitled Safe Practices, also published monthly, suggests positive ways members can maintain a safe operation. The association also publishes a model employee safety manual and provides safety training videos.

Each year, in conjunction with our annual convention, PEI sponsors the world's pre-eminent exposition of petroleum marketing equipment. Convex, as it is called, features exhibits from more than 200 manufacturers of equipment used in petroleum marketing and liquid handling operations. The exposition has been held annually since 1952. This year Convex will be held October 8 through 10 in Orlando, Florida. It will feature 708 booths. About 5,000 people are expected to attend. If you have never visited Convex, I would encouraoe you to oo to Orlando next 0 0 ?1onth and see all that the petroleum marketing equipment mdustry has to offer.

The association also publishes manuals and recommended practices covering technical, regulatory and management information of special interest to our members

Our recommended practices on the proper mstallatlon of underground tanks, aboveground tanks, and recovery equipment have been widely accepted in the and are being used by installers and regulatory officials m other · countries with mcreasmg frequency.

U be the first to admit that PEI does more for us in the States than for members elsewhere. For instance, we m a better position to avail ourselves of PEI's liability msurance proonm . d d . . c h o ' s an e ucat10nal sem111ars. And 1or years t e assoc1at1on has se d · · · d s b . . · · rve Its members 111 the Umte tates . Y our interests with lawmakers and regulators ds lllgton, much like. I assume. the Petroleum quipment l?stallers and Maintenance Federation does for Its members Ill the United K' ad lll 0 om.

PEI's Board f o·. . . f 0 Hectors has spent a considerable amount o tune recent! h' k' 0 • • Y t Ill mg about ways to better serve our ofOWmg llltern· f I PEI t 1 a Iona membership. We assume members join ( network with th . . . h newslettei· .. . . 0 111 the mdustry: to rece1 ve t e , salety public·tt d . t' . . b included · h . ' ions an 111 ormat10n services: to e in t e Direct( d h Jry. an to pai11c1pate 111 the trade s ow.

I can le II you th sponsoring . at . we have lllvest1gated the idea ot our re'se·ii· ,1°Lhll own trade show outside North America. but · ' cl ·is sl .. is little enth : 10\'."n that the held is overcrowded. There thought . b usrnsm for another trade show. We have also ' 1 out est-tblish· ... Europe·tn b. ' · mg an oft1ce in Europe to serve our ' n1em ers b t (.J' 1· d that we w Id · · u 1sm1ssed that idea when we rea 1ze Africa. the hav_e to set up offices in South America. 1 die East and the Pacific Rim as well.

I do want to t· k, -;ervice th· 1 11 d e d moment to tell you about a new in my opd. WI be launched sometime this week that will. PF/'s he helpf'ul to all of you here today. That is , e on the I t,. d w11·wi>ein , 1 n e1 net which can he Imm at l Our W'b · · · · · I I d v. ill cont·· · e site. alter 11 1s tully Leve ope <1111 an up-t I 1m ludinµ n, 0 -L ate listmg ot all PEI members. . 1 ew member listin°s ·1s well ·1s ·1ddress clrm"e" /X'l\onne chanocs . . t::-·. " : . .' t::1·x1,1 111 u 111 , h 1::- • • nev., lax numbers and the like tor ()lff" i- e Ill ers It ,- l1 1111 / 11 .., 1n tl. · " 1 Lonta111 an f.-rnatl directory for Clllf" ldf will h· · I 111 ,, ., '" Pl·f , t uint1nually monitored and updated. I I · lllemher.., with Web ..,ites haw been estahli .... hed. 111 • I• fllil\ 111i_.<1 I(/ t ·· , ldt l and the tradl' press in

our industry throughout the world. Users of our Web site now can access governmental agencies and download the most current legislation and regulations. All this without leaving your desk.

Additional features to our Web site are either under development or consideration. We have received a proposal to add an electronic commerce, or EDI, component to our site. Scores of written articles on management topics will soon be added. Technical papers may be solicited and made available through our site. Network conferencing is being considered. And the day will come in the not too distant future when members around the world will be able to receive PEI publications at least a day before they are returned from the p1inter.

PEI exists to serve its members and our customers. It has done a remarkable job for the last 45 years. I have every confidence that it will continue to do so because we are resp?nsive to the needs of our members. So, in closing this portion of my talk, I want to encourage PEI members in the audience to communicate with me or our staff in Tulsa about the services you want PEI to provide. You have my personal assurance that your ideas will be given every consideration.

Now_ let_ me shift gears a bit and talk about the industry. I am begmnmg my fifth decade in this business. I have seen firsthand the retail_ expansion of the '50s and '60s; the oil embargo, the dechne of the traditional full-service station, the ?rowth self-service gasoline and convenience stores in the 70s and. 80s; and the industry-wide downsizing that has taken. place m recent years. We are also about to conclude the eighth year of an ambitious ten-year federal program to or remove 2. I million underground storage tanks m the States. That program has meant a lot of work for our mdustry but that will be winding d . d 'II b b own soon an we e ack to business without government-mandated programs. Let me share what I believe this me· . t . · h · d · dnS 0 LIS m t em ustry.

The numbers are clearly not on our side Thei·e · · are more than 5,00? fewer outlets in the United States this year m 199?. This latest count puts the number of motor sites at a !1ttle over .a decline of 2.7 percent from last years total. The declme 111 station population h· I <IS been a most contmuous smce 1991, a situation attributable t . . 1 I . 0 stnngent env1ronmenta regu at1ons which have wiped 0 t I I I . u thousands of margma. ow-vo urne units. I frankly don't se the total station count improving in the foreseeable future. e

Jn reading Jamie "s editorial in the August issue of The Bulleti11, I noticed that we share some of the same problems with you here in the U.K. Let me read part of the editorial to you:

In the lf.K. the petroleum industry i' 'till reeling from the effech of the price \Var at petrol 'tatinn,. The major pla_yer' are 'till in a pu-;ition lo 'land the Io,-,e, being made, hut for how much longer'!

A result of thi' war is that more and ll1llre sen ice station' are clusing down a-, they lose our to the hig plaver,. and many of those -,1ation' are independent dealer '>ite·, rural communitie,.

The effect has abll been felt by the shortfall in tlw amount ol '-L'f'\ ice statilln' being d1:\ eloped and the e4uipm1.:nt being <illld and till' L'ftl:ct that it i' ha\ ing un the ,upplier' and L'l1ntracll1r' With a nt11llbl'r lll L'Ompany !'aiJUrl.'.'- being r1.:p01"!1.'.d.

There h<I\ e hl:L'n prediction' that !hi.'. number ur 'Cl"\ ice 'tati1111' \\ill ha\·e t« drop to 10.0ll() before a L'hange j, ,1.:e11.

As I see it, we are both faced with the same challenge: a shrinking customer base. Ours is the result of regulations while yours is caused by the self-mflrcted wound called competition.

So where are we headed next? Where do we go from here?' The trends indicate that there will be_ fev:er companies in the retail marketing business. They wrll burld fewer, but larger, gasoline outlets.

This will affect our members in several ways.

First, profits will remain thin as long as the supply of petroleum equipment and service exceeds demand.

Second, our customers, our equipment manufacturers, and our equipment distributors, installation contractors and service companies will consolidate with increasing frequency.

Third, companies will continue to leave our industry. With thinner margins and persistent competition, there will be less room for error. By this I mean we will no longer be able to make big mistakes in bidding jabs, installing tanks, purchasing adequate liability insurance, hiring employees, or opening new markets. The market will make our businesses less forgiving than ever before.

Fourth, dangers may await some medium-sized companies in the equipment industry. Smaller companies seem to be able to capitalize on niche marketing and have some marketing flexibility. Larger companies can use their muscle to capitalize on their resources and significant economies of scale. I expect that medium-sized firms will have trouble fighting the battle on both fronts.

Despite these negative effects, I remain confident that the equipment industry will survive, and in some cases, thnve, as we prepare to usher in the new millennium. Here are two reasons why I believe I can make that statement.

Number One. The market in the United States for liquid fuels used in cars, trucks, buses, tractors and arrpla?es will to increase at a healthy rate. Gasolrne is to rise 2.1 percent this year in U.S._, with mcreases 111 the total vehicle fleet and total mrles dnven greatly contributing to this growth.

Two. marketer customers will want to operate first-class fuelinn outlets Ml)Iley 11 b 1 "" · wr e spen on butldmg and renovat1no stations tli·it ·ii·e tt t' II "" · · ' , a rac 1ve, we lighted. customer fnendly ai1d techii 1 II d d · o og1ca y a vance

The ma1onty of the small old · d · f"t" · · : · ' · an me 1c1ent mom and pop st,1l1ons will he squeezed out of the 1 TI .· , bi 11 1 d · pie Lile. 1e motrn 111,1:. Pu 1c w1 ( eman more ·111d ·1 ' ou1 OI company customers will give 11 to them. For exampl•' li'st, t 1 t 1 h en o w 1a u1s ecn happenmg recently 111 the United States:

• Jobber incentive JJro"ra 111 s 11 1ve he b t. 1 b 1 . . "" · ' en ee e( up y l 1e ma1nr rn I companies TI · · l I · · . . · · 11s 1lll es well tor such items as canopies. card readers c·ii· w· ·h 1 . · . ' <1s es ant . 111 some cases. fuel storage systems.

• Major-h_rand gasoline stations· acceptance of debit cards will become almost unin·rsal in 1997.

• A nevv prnprietary. pre-paid oil card that can be used to buy gasoline or merchandise al outlets across the country currently being ksled.

• And touch-screen technology at the pump used to order food from a quick service restaurant connected to the fueling outlet has been tested in different parts of the U.S. this summer.

I don't pretend to know how the oil companies will market their product in the future. There are many people in this room who are involved in discussions of that sort. But I'm not one of them. It may be robotic fueling, or it may be unattended self-service.

It might be something else. I just read about a new system Mobil began testing in August that gives the driver a transponder which can be carried on a key chain, in the car's rear window, or on a wallet card. The dispensers automatically scan the transponder either when the vehicle pulls within five feet of the pump or the driver holds a small device in front of the pump to activate the system. The syste1n knows which credit card to bill and if the driver wants a receipt. Everything is automatic but the fueling itself.

Time will tell if this or any other idea will catch on. The point is, I'm convinced that both the oil industry and the petroleum equipment industry will continu_e to v:ays to better serve the customer and make a profit while domg so. And that makes me feel positive about the future.

Let me use my remaining time to talk the future of companies that operate like mme by selling, installing and servicing petroleum marketing equipment. I believe company owners will have to constantly evaluate what business they are in. For instance,. we been successful over the years by selling and mstallmg equipment.

We see that market changing, however, and. . . k h . y steps to chancre wrth 1t. I becr111111110 to ta ·e t e necessar · e d ""' k "' ·t· f" yotI know that total operatmg on t ·now 1 many o d' 'b er·acres about 23 percent. expenses tor a PEI rstn utor av '"" · t the sale ot dispensers, The margins we are able to ge on · 1 ·' t 1 d • nopies don t come c osc o tanks. lights. nozzles, 1fts an ea · 1 b 1 I . .· . . I addition lo that, dll"ect sa es ) ie cover mg expenses. n dium-sized oil compames manufacturer to large and me · . . .. d . d mr s·1Ies volume. have s1g111hcantly re uce l ·' ·

, , iur company wilt concentrate

To survive 111 the lulw1:. t 1 sold direct by the k , nenl that Is no on sloe ·mg equipi . 11 p·trts that only a local manufacturer. We plan 10 se 11 ' 1;TY Thal way we can stockino warehouse distnbutor_ WI L,. , "' 1'·1ir profit to ou1 Lomp,my. sell items that 1etUI n a '

j 1 ·ze the construction end of our W , I . 1 plan lo (owns e d sl • f d that barners to entry • • 1 ·e new contracto1 s 111 busmess. w 1e1 ,·11 put more effort 11110 our , · · ·ii Instead. we "' 1 are 111111 1111, • ·. 1 ., ·ently figured out that rl costs my ·e1·vice o11erat1ons. Iec 1· 1· s ' .., ?')U.S. dollars to have 11\'e actones cert1 y company .(L. ·k on their equipment. Not manv 1ech111cnn to wm · one ' . . · dustry ·ire ready or able to connanies entering ou1 111 " .·:, , ·" I . k' d t' i·eslllII"L'es to 11 <1111 se1' 11:1: kch111u<1ns. 1 those 111 o · · Lnmmi · tlie future will be In bu!ld a cnmpanv So our thrust 1n y · ' . I nrts sales and servICe. ou can call me 111 pri man Iy arou Ill f ' · · · , 1 find out if our strategy was ClllTL'L'l. a few yea1 s ,111L

I , 111 tll" n·ist 1') minutes telling \'llU somethin<> I ia\'e sp1: ' ' · -:· ' · cl I , Petroleum Equipment lnst1tulL' and the mdustn a 1oul 111: 1 1 · .• J·1111 ' 1e ·1sked that I lea\e a Ill L' l1mc tor q11es11011s. We SCl\t.:. ·' '· Before I entertain qui.:-stions. howcn:r. let lllt' agam express my thanks to you for in\iling me hne tu and for the atii.:-ntion and hospitality you han· slwwn llll'. 1 hank you.

A COST EFFECTIVE WAY TO UPGRADE FUEL TANKS

By Winfried Zimmerman & Barry GardinerGood morning ladie s and ge ntl e m e n , my name is Winfried Zimmerman; I am the Sales Director of Wulfin g & Hauck , based in Kaufun ge n , Germany. The company was set up in 1964 to manufacture liners for a w ide range of u s es , including ponds , sw imming p ools, and fuel storage tanks

To date , approximately 800,000 lin e rs ha ve been installed in oil and diesel tanks in Germany, over 150,000 of wh ic h have been made by Wulfin g & Hauck at one of o ur manufacturing sites in K a ufun ge n or De ss au. Over 250 staff are currently employed , a nd current production capacity for liners is 350 per week, w hi c h can be increased to I OOO per week to accommodate demand.

In o rd e r to exte nd our product range , a liner ha s now been. de ve loped for u se in petrol s torage tanks , approval fo r u se 111 Germany is ex pected in November 1996 from the three main regulation bodies , TUY, PTB and BAM.

Th e Czech Republic h ave a lready a ppro ved the u se of tank lin ers for al I grade s of product: ove r 250 h ave been 111 sta ll ed s m ce 1990

We are plea sed to an no un ce that UL approva l for o il and d iese l fu e l tank lin ers was g ive n on Monday 2 nd S e ptember 1996 , a nd a ppro v al for petrol tank lin e rs is expected b y ea rl y Octob e r 1996.

It is planned to obta in approva l for use in fuel tanks fo r a ll 0 rades of prodLt t th. h · 996 "' c 1o ug o u t E u rope by th e e nd of 1

Wulfino & H· k "' auc have se lected GCS Gara 0 e Co nsu lt a ncy Service · L d "' · 11 s t of M1cl Glamoraan to becom e an e r a nd ou r so le di stributor in th e UK · I wou ld now . 1 , <11e to intr od u ce Mr. Barri e Ga rd ne r of Gcs' Ltd . w h o w ill te yo u more abo ut 1 ou1 product and answe r a n y que s tion s yo u ma y i ave. ·

Good 111ornina l· I' . .

Wulfino & H· "'. cK ies <1nd ge ntl e men , may I firstly thank ;; uc cessf ull h av in g th e co nfid e nce in GCS to for w cird xluce th e ir produ c t to the UK: we look c dll exce ll e t 1 c ompanies. n Wo r k in g re lat 1o ns h1p betwee n bot l

New nati o nal reo I· . I d hi I ,,, u a t1on s reco mm e nd tu e l s torage tank s 1e ou e s< inn e d f h · 1 °1 sec u n ty a nd e n v 1ron me ntal reaso ns : t J\ c c1 n 1e ac hi ev 1 1 ec w ithout t he ex 1) e nse and d ow ntim e of CX Ld Vd ion wo rk s 1 II .- · c1 n c re plac e me nt fu e l tank cos ts by lll g a rUe l tank lin e r.

Thnc arc'' c u1T e ntl I Y ov e r 48 000 be low orou nd a nd man y 111 •J'L' ii 1o ve t! roun I · c 1 K 1 L l \ in g le s _· k1n s tee l fu e l s tormre tanb 111 1/J, · I K' I we e n I1ve I ·· · . c1nc lilt y ye a rs o ld at var y in g degrees I i llt ' ll J\», P l'L"li VC l't• ·, II '' 1 e anJ the re lore p0l e nt1 d Y , 1111 ; 1hl« 111 1 l't ' /1 n1ng

To determin e th e stat us of a n ex istin g fu e l tank. the fo ll ow in g va ri o us criteria are taken into account.

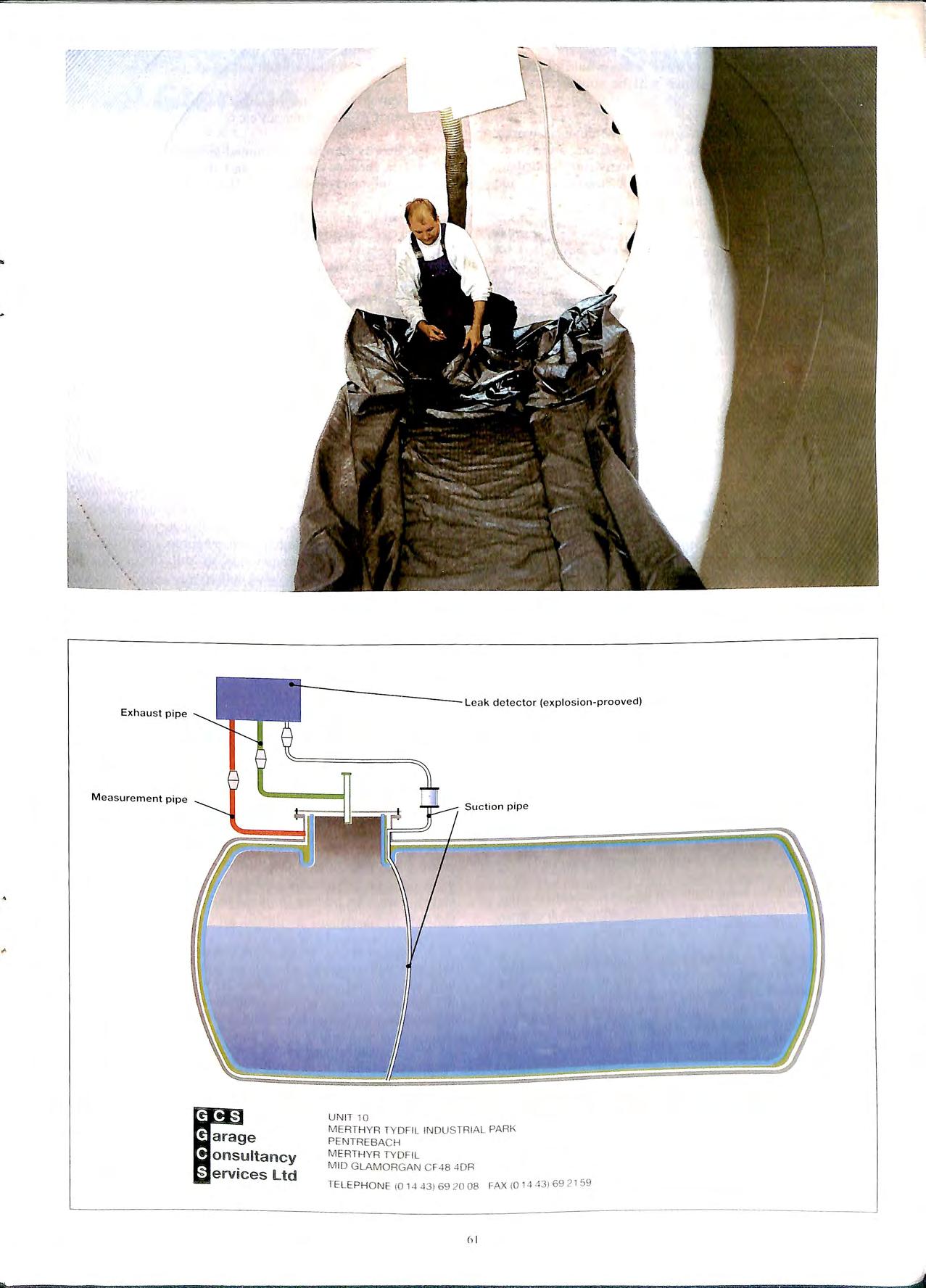

A vo lum etr ic test is carr ie d o ut to es tab li s h initial sou ndn ess: w he n th e fu e l tank is co mpl e te ly e mpti e d. it 1s th e n d e-gassed to a ll ow e ntr y for c le aning and in s pe ction.

Th e fu e l tank lid o r li ds a re then ca re full y re mo ved. a ncl a ve ntilati o n sys te m operat ed in s id e th e fu e l tank fur sa feiy re aso ns : the fu e l lank is th e n sa fe to e nt e r.

A comp re he ns ive in s pec tion re port in corporat in g a ri s k ass ess me nt. w ill th e n be comp il e d. s tating ta n k ag e. backfi ll mat e ri a l (w he re known). cuncl iti o n of th e int e rn a l s urface: a nd res ult s of exte nsi ve ultra sonic thi ck ness tes ting of th e w ho le \ Ur fac e of th e fue l tank

Should repairs to the fuel tank be necessary prior to linincr, a laminated material or steel plates would be used: a full ':'nethod statement for which will be submitted to the local licensing authority.

When approval has been given to commence works, accurate measurements will be taken of various dimensions in the fuel tank, and faxed to Germany for immediate manufacture; all liners will be made to measure and despatched within three working days.

The liners are made from soft PVC foil, each seam is thermally welded, pressure and colour indicator tested for leaks before being packed for despatch.

In preparation for the installation of the fuel tank liner, all sharp edges and welding beads must carefully be removed, and the inside wall of the fuel tank must be cleaned thoroughly with a broom; all material is then removed in a plastic container.

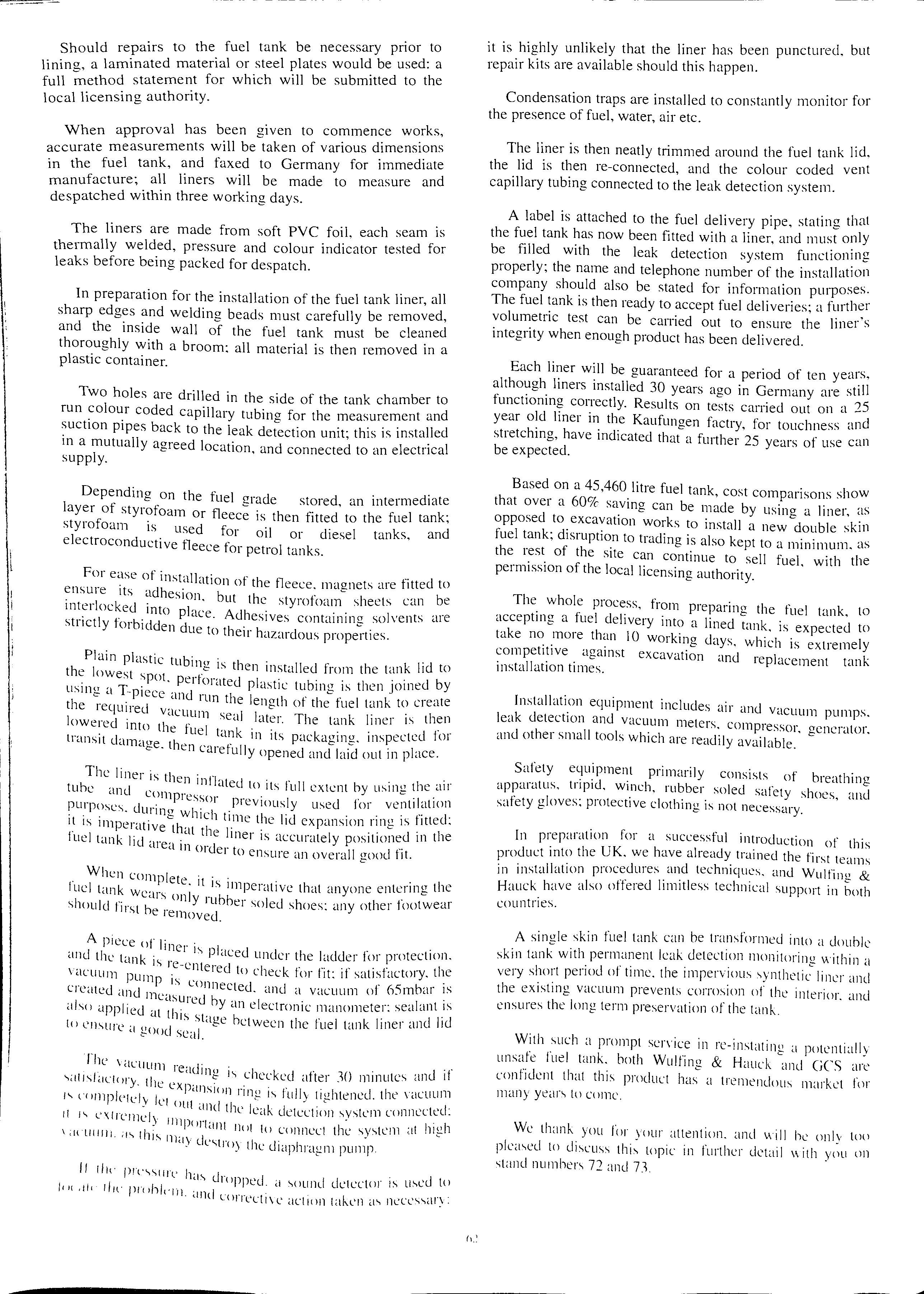

Two holes are drilled in the side of the tank chamber to run colour coded capillary tubincr for the measurement and • b suct10n pipes back to the leak detection unit; this is installed in a mutually agreed location, and connected to an electrical supply.

Depending on the fuel grade stored, an intermediate layer of styrofoam or fleece is then fitted to the fuel tank; styrofoam is used for oil or diesel tanks, and electroconductive fleece for petrol tanks.

For ease of · ·t· II · d . · ms a at1on of the fleece, magnets are fitte to ensure its ·1dhes1 · b h · b · ' · on. ut t e styrotoam sheets can e mterlocked into place Adh · · · I t · · · · es1ves contammg so ven s me strictly forbidden d h . ue to t eir hazardous prope111es.

Plain plastic tubing is then installed from the tank lid to the lowest spot perfci. t d 1 · · · · · d b · • Ja e p ast1c tubmo 1s then JOllle Y usmn a T-piece a d . h '= · th '= n 1un t e length of the fuel tank to create I e required vacuum seal later. The tank liner is then owered mto the f I . . t ., _. d ue tank Ill its packaoincr inspected tor 1<1ns1t amaoe th t· c c• '= • en care ully opened and laid out in place.

The liner is the · 11 t h, · n Ill ated to its full extent by the air u e and con1pr'.. _, esso1 prevmusly used tor vent1 lat1on pu1poscs. dunno wh· h . . . . . d· it is · '= IC tune the lid expansion nno 1s htte imperative th·tt tl 1· '= I fuel tank 1-d , , ' ie Iller 1s accurately pos1t1oned m t 1e ' <11e<11ncli·de·t d ·· 1 o ensure an overall goo flt.

When corn pi et, fuel t·iiik e. ll is imperative that anyone entenng the ' Wears o ] b . . . should r b n Y ru her soled shoes: any other footwem 'I st e removed.

A piece of Jin,. · and the lank _ CJ is placed under the ladder for protection. vacuum 1 ) is 1.e-entered to check for fit: if satisfactory. the uinp 1s co d · 5 b · created ·iiid · nnecte and a vacuum ol 6. m ar is ' ll1e·1su · d h · also applied at _ ie Yan electronic manometer: sealant _is t() ensu 1., lis stage between the fuel tank liner and lid e <l good seal.

The vacuum r . d' t- 1 -. e.i ing is checked after 10 mmutes and ii ..,d 1s dLtory_ the ex ,- ._ I P<111s1un 11n° 1s lull)· tiuhtened the vacuum '" ci imp etely let t ,,. ,,.. • _ · !lU <1nd the leak detection wsll'm connected: 11 '" t xt1emel)· 1111 • · I _ portant ll!lt to connect the system at h1g 1 1.itu11111.;i-.1hisin;, _ I) l t st1 <>y the diaphragm pump.

II rltt· prv-.s11re h· I d "" L 1opped. a sound detector 1s use lo f, 11 .tl• rl1t· 1m 1h1L-1n I <lilt correct 1\ e acl ion taken a-. ncces..,ary:

it is highly unlikely that the liner has been punctured, but repair kits are available should this happen.

Condensation traps are installed to constantly monitor for the presence of fuel, water, air etc.

The liner is then neatly trimmed around the fuel tank lid, the lid is then re-connected, and the colour coded vent capillary tubing connected to the leak detection system.

A label is attached to the fuel delivery pipe, stating that the fuel tank has now been fitted with a liner, and must only be filled with the leak detection system functioning properly; the name and telephone number of the installation company should also be stated for information purposes. The fuel tank is then ready to accept fuel deliveries; a further volumet1ic test can be carried out to ensure the liner's integrity when enough product has been delivered.

Each liner will be guaranteed for a period of ten years, liners installed 30 years ago in Germany are still funct1omng correctly. Results on tests carried out on a 25 year old liner in the Kaufungen foctry, for touchness and stretching, have indicated that a further 25 years of use can be expected.

Based on a 45,460 litre fuel tank, cost comparisons show that over a 60% sa_ving can be made by using a liner, as opposed to excavation works to install a new double skin fuel tank; to trading is also kept to a minimum. as the rest of the site can continue to sell fuel with the permission of the local licensing authority. '

The_ whole process, from preparing the fuel tank, to acceptmg a fuel delivery into a lined tank, is expected to take .more th?n 10 working days, which is extremely agarnst excavation and replacement tank mstallat10n tunes.

Installati.on equipment includes air and vacuum pumps. leak detection and meters. compressor. generator. and other small tools which are readily available.

Safety primarily consists of breathing apparatus. tnp1d. wmch, rubber soled safety shoes, and safety gloves; protective clothing is not necessary.

In preparation for a successful introduction of this product into the UK, we have already trained the first teams in installation procedures and techniques. and Wulfing & Hauck have also offered limitless technical support in both countries.

A single skin fuel tank can be transformed into a double skin tank with permanent leak detection monitori1rn: within a very short period of time. the impervious liner and the existing vacuum prevents corrosion of the interior. and ensures the long term preservation of the tank.

W!th _such a prompt service in re-instating a potentially unsafe luel tank. both Wulfing & Hauck and GCS are confident that this product has a tremendous market for many years lo come.

We thank you for your attention. and will he only too plca-.ed to di-.cuss this topic in further detail with you on stand numbers 72 and 73.

Above Ground Storage Tanks: New Wave in Fuel Storage

By Paul McWhorterWhen the petroleum industry was in its infancy. the storage of crude and refined fuel was relegated to steel tanks. No fire codes or regulations were originally considered in the mid- l 800's when the industrial revolution was recognizing the value of the internal combustion engine. Therefore. the cheapest method of storage was initially utilized, noting that the petroleum pioneers held to only one concept: do not store fuel in flammable and combustible vessels. Factors such as contamination. leaks, monitoring. remedial costs of cleanup and incidental insurance requirements were simply not part of the formula for consideration on the part of petroleum fuel producers.

Subsequent history accumulated numerous incidents where a local fire would cross the path of a fuel storage facility with disastrous results an already aggressive fire :vould find a fuel reservoir in its path and the damage to the surrounding area. With the mcreased conversion of the internal combustion engine to automobiles, the concept of rural fuel storage began carrying a more significant concern as local fires reminded the populace and fire authorities who were required to respond to fuel-fires of inherent danger and consequences of inadequate fuel storage safety.

Around the end of World War I, global consensus determined the preferable method of fuel storage was to "bury the problem" using underground storage tanks (USTs). The immediate benefit was to move the fuel from the path of an oncoming fire. The inconvenience of the costly excavation to prepare the site for a UST was traditionally offset by the dual use of the real estate: a UST buried allowed for reduced space aboveground. Military considerations on a worldwide basis were heightened by WW!. WWII, the Korean conflict, Vietnam. etc. due to the fact that an AST could become a tactical liability if in the line of small or large firearms.

The fire protection industry recognized the need to supervise the storage of fuel in underground facilities and submitted its concerns for legitimate quality control in the manufacture of USTs through a third-party agency. Underwriters Laboratories. Inc. and Underwriters Laboratories of Canada. The rationale for referring these issues to the third-party was that actual testing would confirm various technological designs as either acceptable or dan"erous. In addition. UL and ULC monitored the actual ;roduction of USTs to insure that the models tested were being manufactured in the UST plants.

Jn 1970. as the result of numl'rous environml'ntal catastrophes such as "Three Mile Island" where the military/industrial rnmplcx casually contaminated areas around plants with little or no thought about the general public. the US EPA was brought into existence by Congress to monitor these oversights. The initial legislation considered hv the US EPA \Vas to ill\ L'stigate the status of fut'I storage- which had sinn.' been confirmed as a

carcinogen. as well as retaining its normal flammable and combustible properties. A of proposals resulted in passage of The Oil Pollution Act in 1973. This law finally defined jurisdiction of the US EPA as well as some general guidelines on both underground and aboveground storage fuel. An incidental footnote was registered with the act to stimulate the cooperation of fire and environmental forces to jointly supervise the fuel storage industry.

In the mid- I 980's in response to an alarming accumulation of data obtained as the result of implementing the Oil Pollution Act as well as a catastrophic fuel spill at the Ashland Oil Refinery at the junction of the Mononcrahela River in Ohio/Pennsylvania in the Umted States, fhe Oil Pollution Act was updated to reflect: a) leak detection, b) needs for corrective action in the event a fuel "discharge", cO fire protection concerns. d) h_eld 0 I d t "ndependentl)' momtor 111spect1on needs. and e t 1e nee o 1 . the intecrrity of fuel tanks by such tlmd-party as UL and ULC. Coincidentally. as the field inspections commenced. the early returns of I in 5 thought to leaking due to the dynamic wherein a buned tank becomes · · 1 harcred on neo-atively charcred on one end and pos1t1ve Y c < e I "' "'. "th the Sl11·1 '111d immediate t 1e other end while m contact w1 · < aggressive corrosion occurs. were discovered in some cases to be 2 of 3 USTs leaking. The US government responded by enacting a series of environmental laws designated CERCLA, RCRA. and CACW Acts. Did these laws.end the problems? NO. The good in environment, remediating contammated sites. monitoring the air and water we ingest daily were lost 111 bureaucratic confusion and red-tape. A program implemented under the dubious acronym "LUST'' for leaking/underground/storage/tanks did not the rate of leaks or contamination. Ultimately, environmental and fire protection authorities consolidated these plans into statewide or provincial action plans. A consistent theme resulted: the regulatory authorities longed for technology which would be readily visible for leak detection but \\'.OL.dd resist the danger of fire. vehicle impact. and ball1st1cs ineursions (vai;dalism). Jnto this demand. came the new vaulted aboveground storage tank technology: in 1986. the first vaulted ConYault AST. was developed and patent protection filed prior to introduction into the marketplace. The response was immediate and significant: the technology which incorporated an inner (primary) steel tank within a poly membrane which was subsequently entombed in a six-inch reinforced concrete vault without seams met all the regulatory requirements. This was submitted to LI ndcrwritcrs Laboratories 1nc. and Underwriters Laboratories of Canada for sc\ crL' tl'sting and earnl'd all of the strictest listings for storage of rlamlllabk and rnmbustible liquids by both agL'nciL'S. The ll\erall listing" represents the fact that llL and l lLC l'llnducll'd scwre preliminary tests on an and that tlw 111lldl'i being purd1ased h\ the custolllt'r is hL'ing built IP the precisl' specifications of the original unit tt·-..ted a snics of fire exposure-... \chicle impal·ts and prn.iL'l'tik (hallistic-..i ill\cstigations. (\1nVault Inc. including the latl'-.;t licensL'Li

manufacturer Breton Ro e Crete (Republic of Ireland/United Kingdom) , installed over 16 ,000 AST s.ites globally in a ll 50 states of the Unite d States, every province of Canada, P a nama, Puerto Rico , Guam, West Afric a, the USSR , the Virgin I s lands , Mexico , Irel a nd a nd Wale s without a single system failure/any petroleum discharge.

Wh y has thi s original d es ign spawned over 103 competitors, earned th e hi g he st avai labl e UL and ULC ratings (as a Protected Tanks) while mee tin g virtually all regulatory requirements? As prev iou sly stated, the s implicity of the design allows for all contin ge nci es in fuel s torage s uch as the ability to easily in s pect the system through a leak detector tube which accesses th e li sted s econdary containment, th e re s istanc e of the concrete vault to b o th ex te rnal co rro s ion a nd catas troph es w hil e the co re of the s ystem rema in s a high-qu a lity steel primary ta nk w hich is ex h a u st ively te s ted durin g the production cycle . Th e fact th at th e eventual co s t is le ss than undergro und sto rage of fu e l w ith hidden co s ts such as hi g h in s urance premjum s, a fr eq uent requirem e nt to conduct third-p a rt y in s pections of th e UST as it is buri ed a nd un avai labl e for vi s ual rev ie w, cath od ic p rotec ti o n from th e seve re co rro s ion of buri a l in th e s oil , and its portability remain factors fav o red b y fue l co n s umers tod ay In addition , th e peace of mind fo r va ult e d ASTs traditionally carrie s a 20- yea r (30-year wa rranti es a re op tion a l if a thi cker s teel primary tank is ordered a t a s li g htl y hi g her cos t). The comc 1de ntal " c lea n bill of h ealth " re prese nte d by 16,000+ m stall a tion s w ith o ut probl e m s remain s a tes tame nt eva lu ated b y pro s pec ti ve c li e nts · whe n we i a hin a th e of w h e tl::r to " bury their probl e m s" Y t he fo lk s w ho brou g ht yo u LUST (l ea kin g und e rgro und s torage tank s) " Current s al es of co mp e tit o rs w ho ca rr y both AS T s a nd U STs in thei r product lin e indi ca te th at in th e rnicl I 980 ' s sa le s o f A STs vs U STs we re s li g htl y less 1 o f 5 purcha ses : cu rre nt s a le s figur es re le a sed in d icate ti is tre nd h as been rev e r e el to th e that 3 o f 4 fu e l tank s so ld a re now AS T s. 0

What type s o f c u sto m e rs are purc ha s in a AS T s 7 In a cld1t1on to re I· · 1 . 0 P ac 1ng ea k 1n g und e roro uncl s torage ta nk s, new c li e t · · 0 11 s c1 i e ge ne ra ll y rep rese n te d by 65 % publi c sec to r purc h a se rs s uc h 1 f I · · · a s 1111 1ta ry, b 10 aove rnrn e nt w ith fl ee t u e m a nee ds db o o 0 · 0 1 s tc1 n y generato rs for e m e r g_ e ncy po we r s uc h a s a 1r1Jort . I · I I s 1os pn a ls e du c ationa l fac il1t1 es as w e ll as oca 0 ove rn111 e t· J · .'=' n a need s s uch a s a irp o rt s. hosp it a ls e duc a tiona l h " l't . . h cC I 1 ies a s w e ll a s loca l aove rnm e ntal needs s ue a s tire d epa rtm e nt s (o ve r 400 a nd po lice p1ot ec t 1o n Th e b· 1. , _. .. I d cl nce ol p ri va te se ctor f ue l needs fulhll e d Jy AS Ts <a 1)p rci · I x imc1t e y 3) c/c of the m arke t) 1s based upon e nt e r pris e s SL I t 1 • · ic 1 c1s go ll co ur ses (ove r 400 s ites g loba ll y ). .e. e comm u n ica ti o n fac il iti es w ho u tili ze t he ASTs fo r s t<1ndb y "e ne 1" t c d io n n l e rn e roe ncy powe r d unn o o ut aae s ( u ve r 70() 1., it .· ':' . <= c · 1 · e 1., ) P11va te ag ri c ultu re a nd bot h J1 g ht / he a vy 1n c us tr y L

Th e pe · · i rnittin g proc e:-- s for AS T s ha s a lw a ys be e n a va ri e d in e th< I I ' )C 0 it 1s traJitiona ll y c lass ii 1e d as c o n ve rse 111 1·I t · ..

1 c 1 <e 111 g bec au s e th e s to rau e of l"lammab le a nd u l111 1u s t1h le li c1u I t "' T I . l l s is x 1se cl upon re qui re m e nt s. wi e l o re. hef'ore a n i ve n is id e ntifi e J a nd pc nc t n1 te d tl , h ., .. "" , . le o sc 1vat1< Jn o l re l! u lato r y a ppro va l mu st ( lLL UJ r1io .i.: w l I. L • I , I l ( J 1<1 ve v iol a te d t hi s pub lic trust i c1v c e arn e d t h ·1t e r " 1· · I I 1 ' c c1 111 g a ckmand do cs not n ua ra nt ee that t l C <JLd a uthorit \ 11 "" w I <1 ha 11don hi s/h e r n:: s p o n..., 1bil1 ty to d l L'< im1n 1>d a te t h , I . 1' 1 , < l s ,1 e ol an unapp rm e d fuel tank . le 11 11 f nc I · · ill s 1ness 111u .., h rrn im e d bec au s e 1t ays 11 11Id1 nnl ""' d i • f' I l <) l 11 s necessa r ) in pu t lrnm t he: rcg ul<1 t01 )

community prior to commencing a marketin g campaign. In the R e public of Irel a nd and United Kingdom , for in s tance , Breton RoeCre te conducts ri s k assess ments in advance o f pre se nting th e product for sale. Thi s allows early evaluation and recommendati o ns by th e authority h av ing jurisdiction so that all parties recognize the need s pri o r to in sta llin g a fuel s ite

In clo sing, it is worth noting that the vaulted AST technology such as ConVault , Inc. provid es has e a rned a n admirable track rec ord but there is nev e r an option to s impl y let the s ta tu s quo remain. This is evidenced by refining the s uccess ful d es ig n to include a re cent evaluation that ConVault ASTs h av e ea rn ed a "ve nting by form-ofcon s truction " listing by Underwriters Laboratorie s, In c. This s imply mean s that the u se of a webbing medium and communication fittin g to the inte rs ti ce a llowe d a n in ves ti ga tion wherein a te st tank was submitted to a p oo l fire w ith unleaded gaso lin e in th e inte rs tic e. The re s ultin g vapo r grow th crea ted a pass ive vent which safe ly a llowe d the fuel to exit. Some competitor critici s m h a d indic ate d that thi s dynamic would create a "arenade" effec t in a Con Vault-style A ST. Th e tes t , c;nducted und e r the s up e rvi s ion of UL , ge nerated a findin g that th e safe o f th e va ulted AST is a predictable eve nt (as witnessed o n seve ral ot her o cc asion s a nd reco rd e d on v id eo tap e), so m e thing eve ry firefighter re quires as he/s he respo nd s to a fuel fire. The co mmitme nt to sa fe a nd eco no mical fuel storage is a n ongoing commitment worthy the 16 ,00.0 prev iou s cli e nt s , re g ul a tory authorities and lt st111g agenc ies w ho re lied o n th e va ult e d AST te chnology.

ABOVE GROUND TANKS

By Shari Duzac Underwriters Laboratories, U.S.A.Thank you Mr. Thompson for allowing me the opportunity to introduce a Standard for Safety that Underwriters Laboratories has recently developed. It is UL2085 titled Insulated Aboveground Tanks for Flammable and Combustible Liquids.

It may be helpful to start with an explanation of what Underwriters Laboratories is all about. I could tell you about UL's history starting with our founder, William Henry Merrill in the year 1883 at the Chicago Worlds Fair. However, I would rather refer you to our World Wide Web site because I think it also paints a colorful history. It can be at http:\\www.ul.com and since you don't have mternet access on your lap at this moment, I took the liberty calling up.our home page and printing out a section titled Facts and Figures about UL" which I think will give you a pretty good idea of what UL is all about.

With respect to testing and certification

• in 1995, the estimated number of products entering the marketplace with a UL Mark was 9.4 billion •UL engmeers evaluated more than 78,000 products in 1995

• our five domestic and two overseas laboratories have over I million square feet of Jab space

• there are nearly 40,000 manufacturers world wide that are authorized to place the UL Mark on products

UL also develops standards

• we have published over 700 UL Standards for Safety

• in I 995 alone, we introduced 53 new Standards

• about_. our Standards are approved by the Ame11can National Standards Institute

Our Quality and Reaisti··it" S 0 · ion erv1ces Department

• has registered more th·m 1 260 t·· ' , 1 mns to IS09000

Finally, our extensive Foil U S ow- P erv1ces

• has 189 inspection . centers located around the olnbe

• in 1995, our field staff made ov 0 visits to UL authorized .. .· et 4 70,000 toll ow-up · tc1cto11es around the world.

UL is independent we ·ir organization. We are '. ' e not a government run d tesnurce work· a I I authorities insurers edt t . me wit 1 tm ustry. , , ICd o1 s and the public.

Lets move on to a more s . f and focus on UL ?()SS · peci tc d1scuss1on about UL · the Stan(hrd f I I I Aboveoround Tank. A UL? ' or nsu ate( e -085 tank h·ts ·1 · · J· t. S)'Stem that 1s mtendec.I t ., 1 , '· 'n 1nsu .i 1011 o le( uce the he·1t t ·f I I , primary tank in the ev, t f" • ' '<1ns e11 el to t le en ° d hi e. The tank is cJ, ··a , J t w1thst·md the 1mp·1ct and 1 · cs1enel o · ' ' ' i.:oo mg dkcts of a I · ·t. well as resistance to ballistics. · loses 1e,1111 ,is · · c1nd heavy vehicle impact.

Most UL2085 tanks start with 1 steel pi·· . k TI ' · 1mai y tan ·. 1ese tanks are constructed to Stanc.lard UL 14.::!. Steel Tanks. These tanks have a hydrostatic '.1t 25 ps1g. To a UL2085 tank. the steel is msulated. typically 'A'1th 6" or more of concrete or sonw type

of prop1ietary concrete and pearlite mix. The insulation must be able to limit the temperature on the steel tank during a two hour, 1093C, full scale fire test. The average maximum allowable temperature rise is 144C and no single thermocouple is to exceed 204C. Following the full scale fire test, the tank is immediately subjected to the hose stream test and then the primary tank is tested for leakage.

Some tank designs have "interstitial insulation" meaning that the insulation is between the inner steel tank and an outer steel shell which serves as secondary containment. Since the insulation is in the interstice which will be monitored for leakage from the primary tank, we must confirm that the insulation does not interfere with monitorino or with the ability of the emergency vent to properly in the event of an external fire. Two tests are required for these type of constructions, the pool fire test and the interstitial communications test.

For the pool fire test, the interstitial space is _filled_ petrol and the tank is placed over a sump or pit_ which is filled with enough petrol to sustain at least a 15 fire. During the pool fire. the pressure in the mterst1t1al space is monitored to verify that the emergency vent process is not compromised. The pressure must not exceed I 13 of the hydrostatic strength or 8.3 psig.

The interstitial communications test requires that pressure applied at a point furthest from the monitoring device, be detected within 24 hours.

The two final tests are ballistics and vehicle 1 these tests conducted 1ust Most manufacturers elect to MVe · · : · · this ·idd1twnal level ot in case the authority requ!fes · ' protection for a given installation.

t·· 1 . t·· a 10 caliber rifle at a distance of A Her 1ve s 1ots 10111 ' .• 10 meters the tank is required to be leak tight. The veh.1cle im act also requires the primary t'.rnk to be _1.eak P . 54 'i.5-k" m·iss applied at 16 kilomete1 s after impact horn a. • ,,. '· · '· . f o 091 square mete1 s. per hour usmg a stnkmg l<1ce 0 · · ·

. UL . s to develop UL2085 includes input The process use. I d b U from industry. Proposals to industry_ are deve ope y 'L l l' UL'. Jndustr)' Advisory Group. JAG lor and 111em 1e1 s o s · d Ab md '[·rnks The JAG consists o1 13 Insulate ovegi m ' : · , I .· · -, l ·esentin" manutacturers (8), aut 1m 1t1es (_), me,'m 1ers ·+1ted industries (2) and UL of Canada ( l l. nt ler experts Ill It:' ·. • , J 1 .I "l ·d !AG l . d . meeting this pc1st u y dill l t: \ e ope d Olli b 1 hi. at further re.fining UL.2085. We num cro p1opl.,.' ·c· ·d· l', l t · 1 t·isk torce with UL ol dlld d to l eve lop are a so rn mmg ' '· a bi-national harmonized standard.

I 1 ,· a I would like to note that I have 1-c\ icwed ynur n l OSlll1996 APEA Circulation draft titled. Code. of Prucrit·e j(>r Design. Consrrucrion and of Pl'.T!"!>/ Filling Stations and noted several t'.1 UL208.'.'I tanb. We arc pleased that tanks are gam1_1112- in the ll.K. and recognize thts as an opportunity tll work together. 011 not just a hi-national standard hetWL'en the llSA and Canada." but an international Standard for Insulated

Ed Sadler and Bob Conlin Fairbanks Environmental Ltd.

Ed Sadler and Bob Conlin Fairbanks Environmental Ltd.

Introduction

The presentation was deli vere d in a que sti o n and answer fo rm at w ith Bob Conlin asking the qu es tions . Currently the indu stry has too few peopl e that know a nything about, never mind understand fu el management. It is not feas ible to exp ect every one of the 16000 retailers running fillin g station s in the country to be an expert in fuel management

Fuel m a nage ment is e xtremel y comple x and training w ould take too fong a nd be far to ex pe nsive. So alternative metho d s of management have to be found a nd accepted by everyo ne in the indu str y. In o rder to effect thi s c hange of m ind set within the indu stry I re a ll y wa nt to present the subject as it is 'w arts an all '

So le ts st art by identifying th e population , an audito rs term , in thi s co ntext, for those invol ved in the process.

Population

We t stock is di ffe re nt thin gs to d ifferent people. To a reg ul at.o r it is co mpli a nce a nd protec ti o n aga in st fire and ex plosion. To an e n viro nm e nta l officer it is protection pollution and contamination. To an o il company it is their good na me, th e cost of an in ves ti <>ati o n and re m ecli atio n and the p ro tect io n of the asset v:l ue. To a re ta il er w he th e r o ne site ow ne rs o r gro up o perators it is all th e thm gs menti o ne d plu s max imi sin g profit.

What the indu stry rea ll y needs to avo id is thi s :-

How can anyone possibly lo se 32,000 litres of fu e l a nd not know about it.

The tragedy of thi s case w a s that one of th e swans died a mo st horrible death. it' s mouth , palate, esophagus, lun gs and intestines burned away and others had to be tub e fed directl y into there stomachs in order for them to survive.

So what does the industry need.?

Good manage ment!

What do you mean by good management?

To explain this, we re ally have to go back to first principles break the lo ss down into its consti tu ent parts and talk about each one because as I wi ll demon stra te ,

"what you see ain't nece ssarily wh at you got"

So in the industry we talk variously about actual losses, also known as real losses, apparent losses and then leaks. Can you explain the difference between them and use an example to illustrate what you mean.

Categories of Loss

There are two main categories: Apparent losse s -the thin gs that m ake you be li eve th at you have a loss when you have not, and, Real losses the thin gs that cost mo ney a nd do the damage.

Apparent Losses

Administration Errors

I w ill de al with app arent losses fir st. Th ese a re reel he rrin gs and the tim e was te rs that we face wh e n inv es ti ga tin g losses Apparent losses are two thin <>s ad mini strati o n e rrors (rubbi sh in rubbi sh o ut) and 0 tank stock meas ure 111ent acc uracy

Before go in g into th e nuts and bo lt s 1 s ho uld ex pl a in th at a cumulati ve percentage is th e best medium fo r id e ntifyin g what is happe nin g within th e ta nk a nd w he n I say tank 1 in c lu de th e lin es an d th e pumps.

Why cumu lativ e p ercen tag e and not a daily, weekly or lllOllthly?

Beca use th e cumul ati ve pe rcentage is a refl ecti o n of th e lo ss o r gain 's re lati o nship to the sa les throu g hput , th e numbers build a pattern th at is re lati ve ly stabl e a nd so th e effect of the seasons and oth er sm all in co ns iste nc ies are iron ed o ut. ([ wo uld e mp has ise that I use the wo rd s 111 a ll de liberate ly).

A pattern , if c lea n e no ugh. w ill id e ntify ve ry q ui ck ly prob le ms as th ey occ ur if the pe rso n read in g th e dat a knows what it is te llin g him

So daily loss I gain and even monthly loss I gain is really of limit ed valu e ?

Ye s th a t is w h a t I a m say in g Th e re a re a number o f c o mm o n a dmini s tr a ti o n e rror s a ll of w hi c h , if le ft un co rre cted , w ill m ove th e we t stock lo ss o r ga in a round fr o m on e ta nk to a noth e r a n d b a c k a ga in

What about computerised back office sy stems?

Wh a te ve r th e s y stem there is a lways a ne e d to m a nu a lly e nt e r periph era l inform a tion s uch as pum p te s ts , d e li ver ies a nd int e r-t a nk tran s fer s and sto c ks (if di p s tick s a re u se d ) If the s y s te m c a nn o t re c og ni se a nd fl ag w hen an input e rro r h as b ee n m a d e th e rn fo rmati o n be co m es u se le ss.

A cc urac y is al wa y s th e ove r ri d in g require m e nt. Th e s ite o perato r mu s t b e abl e to id e n ti fy w h e n sa le s h ave b e en unders tate d a nd ov ers ta te d and wh e n d e li ve ri es h ave b een u11dersta ted a nd ov e r st a te d , a nd w h e n p u mp tests a nd deh ve n es h a v e b ee n a s s ig ned to th e w ron g t a n k. H e mu st a lso b e a ble to c a lcul a te a fu e l t ra n sfe r co rrec tly w h en re b a la ncm g sto rag e and m ov in g product from on e t a nk to a noth e r with o ut 1t ooin o throu o h tl F II I mu s t kn ow h ow "' "' "' 1e _pump s. rn a y 1e . . to a cc o unt a nd 1ec on c ile for s to c k s w h e n p ro du ct 1s uplift e d fo llowin o a c o nt · t' Add h ' "'• a mm a io n. . to t IS v ig il a nc e th e a bilit y to qu a ntify, v eri f y a nd rec tify th e m is ta k es a11d y I 1 · · · • < a u rn ve t 1e b aste s kill s re qu1re d fo r goo d w e t stoc k m a n age ment. Example

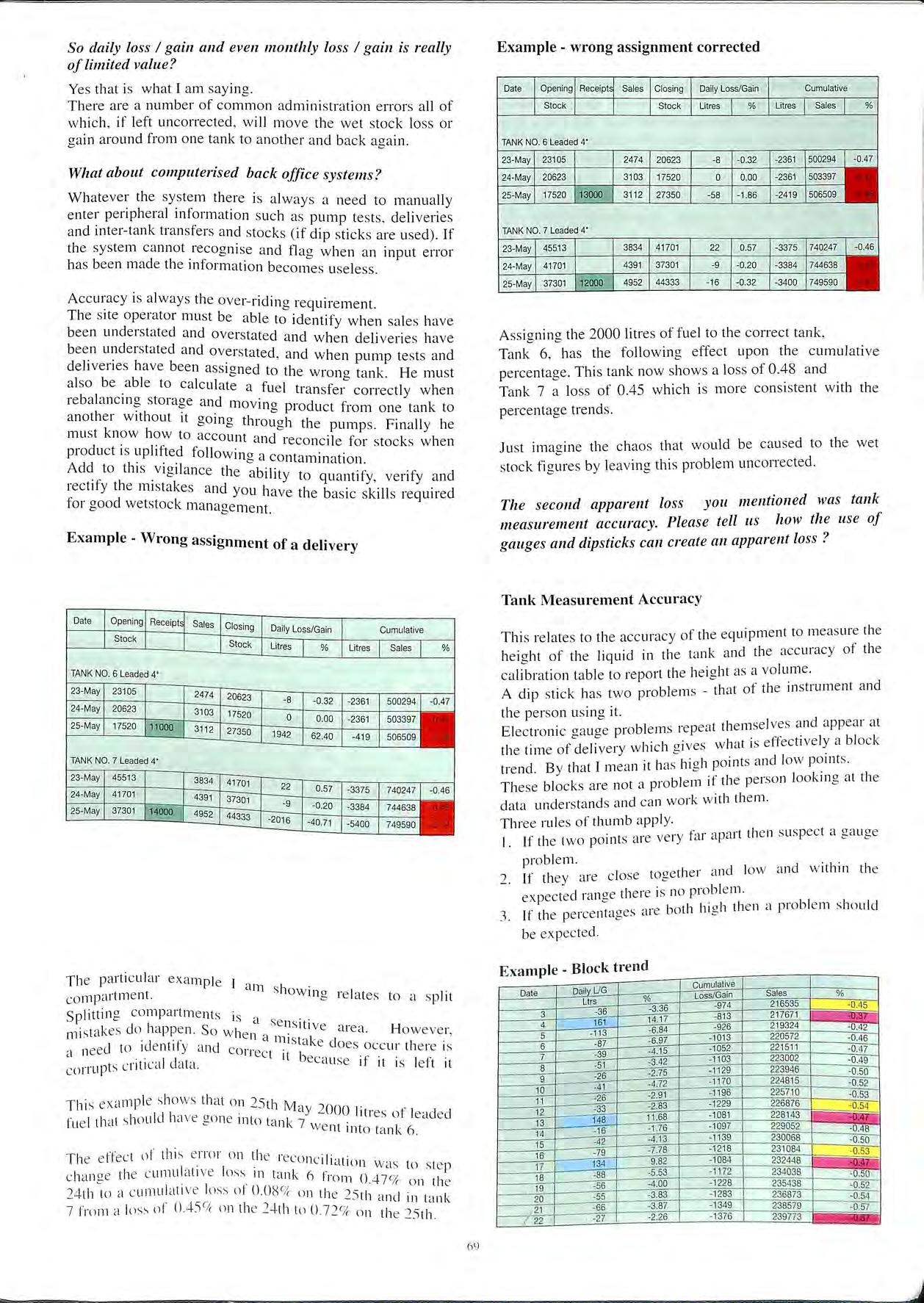

TANK NO. 6 Leaded 4•

23-May 23105 2474 20623 8 0.32 -2361 500294

24-May 20623 3103 17520 0.00 -2361 503397 25 May 17520 13000 3112 27350 58 1.86 ·2419 506509

TANK NO. 7 Leaded 4"

23-May 45513 3834 41701 22 0.57 -3375 740247 24-May 41701 4391 37301 -9 0.20 -3384 744638 25-May 37301 12000 4952 44333 16 0.32 -3400 749590

A ss ig nin g the 2000 litres o f fu e l to th e c orrect ta n k , Ta nk 6 , h a s the fo ll ow in g effe c t upon th e c u m ul a ti ve p erc ent ag e. Thi s tank no w s ho ws a lo ss o f 0 .48 a nd Ta nk 7 a Jo s s o f 0 .45 w hich is more c o n s istent w ith the p e rc e nt ag e trend s

Ju st im ao in e th e c h aos th a t wo uld b e ca u se d to th e wet b stoc k fi g ures b y leav in g thi s p ro bl e m un co rrec ted

The second apparent loss you me n tioned was tank measurement accuracy. Please tell us h ow the use of gauges and d ipsticks can create an apparent los s ?

Tank M easurement Accur a cy

T h is rel a te s to th e acc ura cy of th e e quipm e n t to m e as ure the h e ig ht of th e liquid in th e ta nk and th e acc ur ac y of th e ca librat io n tab le to report th e h e ig h t a s a vo lum e A dip sti ck h a s two p ro bl e m s t h at o f the in st rum e nt a nd the p e rso n u s in g it. El e ct roni c ga ug e prob le m s re pea t a nd app e ar a t th e tim e of de li very w hi c h g ive s wha t is eff e c tive ly a bl ock tre nd. By th a t I m e a n it h a s hi g h po ints a nd lo vv po rnt s Th e se b locks a re n o t a p ro bl em if th e pe rson look rn g a t the da ta un de rs ta nd s a nd ca n wo r k w ith them

T hree rul es of thum b app ly

I. If th e two p o in ts a re ve ry fa r apa rt t he n s usp e c t a g a u g e p rob le m. d 1 1 1 1 e to ae th e r a nd lo w a n w it 1rn t 1e 2. It t1 e y aie c a s "' e x e c te d ra ng e t he re is no prob le m. p t are bo th hi o h t he n a prob le m s h o ul d 3 11 the p e rce n ages ' "' be ex pe c te d .

o ne m to ta n! · 7 w . a e c ' e nt int o ta n k 6

T he e ffe ct of thi s e rro r o n th e re co nc ili" ir · . . • io n wa s to s te p c h an g e rh e c umu la ti ve lo ss_ 1n ta nk 6 fr o 111 0 .4 7 % 0 11 t he 74t h to a c u mu la t1 ve lo ss o l ll. 0 8 % o n t h e / 'it ll ., 11 , · t' 1 , _ . _ " er 111 d n , 7 frnm a los s o l 0 .4 :-i c/c o n t he 24 th to 0 72 % 0 11 t he 2 5 t h

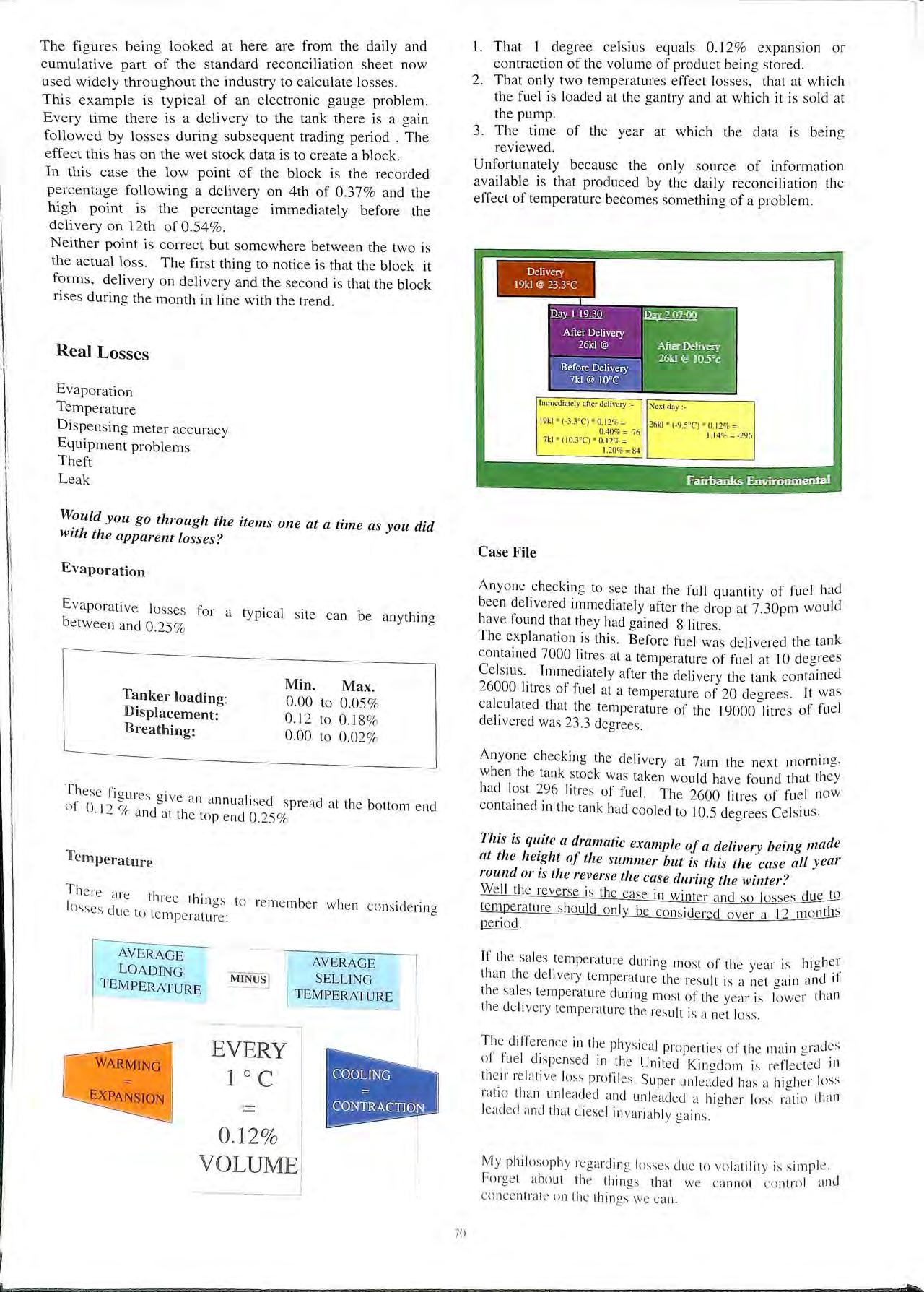

The ficrure s being looked at here are from the daily and cumul:tive part of the standard reconciliation sheet now u sed widely throughout the indu stry to calculate losses Thi s example is typical of an electronic ga uge

Every time there is a deliv e r y to the tank there 1s a gam followed by losses during subsequent trading period . The effect this has on the wet stock data is to create a block. In thi s case the low point of the block is the recorded percentage following a delivery on 4th of 0.37% and the high point is the percentage immediately before the delivery on l 2th of 0.54 % .

Neither point is correct but so mewhere between the two is the actual loss. The first thing to notice is that the block it form s, de li very on delivery and the seco nd is that the block ri ses durin g the month in line with the trend.

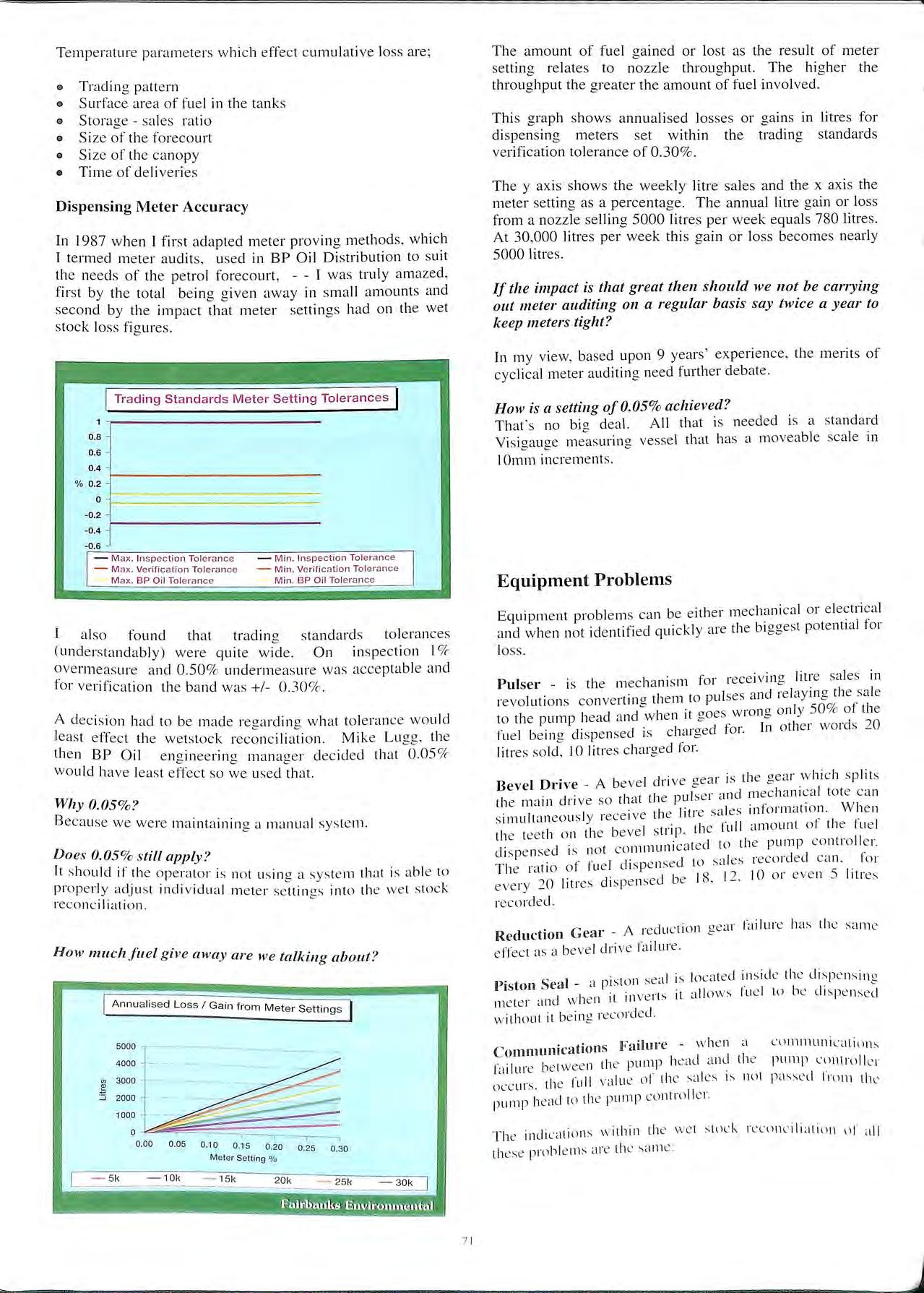

That l decrree celsius equals 0.12 % expansion o r co ntraction the volume of product being s tored.

2. That on ly two temp era ture s effec t losses , that a t which the fuel is loaded at the gantry and at which it is sold a t the pump.

3 The time of the year at which the data is b e in g reviewed.

Unfortunately because the only source of inform a ti o n availab le is that produced by the daily reconciliation th e effect of temperature becomes so mething of a problem

Min. Max. Tanker loading: 0 .00 to 0.05 % Displacement: 0.12 to 0.18 % Breathing: 0.00 to 0.02 %

Case File

Anyone c hecking to see that th e full quantity of fuel had been delivered immediately after th e drop at 7.30pm would have found that they had ga ined 8 litres. The explanation is thi s Before fuel was delivered th e tank co nta ined 7000 litres at a te mperature of fuel at 10 degree s Cels iu s. Immediately after th e de li ve ry the tank contained 26000 litres of fu el at a temperature of 20 deg re es. It :vas ca lculated th at th e temperature of the 19000 litre s of fuel delivered was 23.3 degrees

Anyone checking th e de liv e ry at 7am the next mo rnin g, w he n the tank stock was taken wo uld have found th at th ey had lost 296 litres of fuel. Th e 2600 litre s of fuel now con tain ed in the tank had coo led to 10 .5 deg ree s Celsiu s.

This is quite a dramatic example of a delivery being made at the height of the summer but is this the case all year round or is the reverse the case during the winter? We ll the rever se is th e ca se in wi nt e r and so los ses clue lQ te mperature should o nly be co ns id e red over a 12 mo ntilli period.

ff the sal es te mp e rature durin g mo st o f th e yea r is hi g he r than th e de li ve ry te mp era ture the res ult is a ne t ga in and i1 th e sa les te mp e rature durin g mos t of th e ye a r is lowe r th a n th e deli ve ry te mp e rature th e res ult is a ne t lo ss .

Th e diffe re nce in th e ph ys ica l prope rti es of th e main g rad es of fu e l d is pe nsed in th e Unit ed Kingdom is re fl ec ted 111 th e ir re lat ive loss profil es S up e r has a hi g he r lo ss rat io tha n unl eaded and unl eacl ecl a hi ghe r Joss rati o than lea ded a ncl that di ese l in variabl y ga in s .

My ph il oso ph y rega rdin g losses clu e to vo la tilit y is s impl e. Fo rge t abou t th e thin gs th a t we canno t co ntrol a nd con ce ntrate on th e thin gs we ca n

Temp era ture parameters which effect cumulative loss are;

e Tradin g pattern

e Surface area of fuel in the tanks

o Storage sa les ratio

e Size of the forecourt

• Siz e of the canopy

• Time of deliveries

Dispensing Meter Accuracy

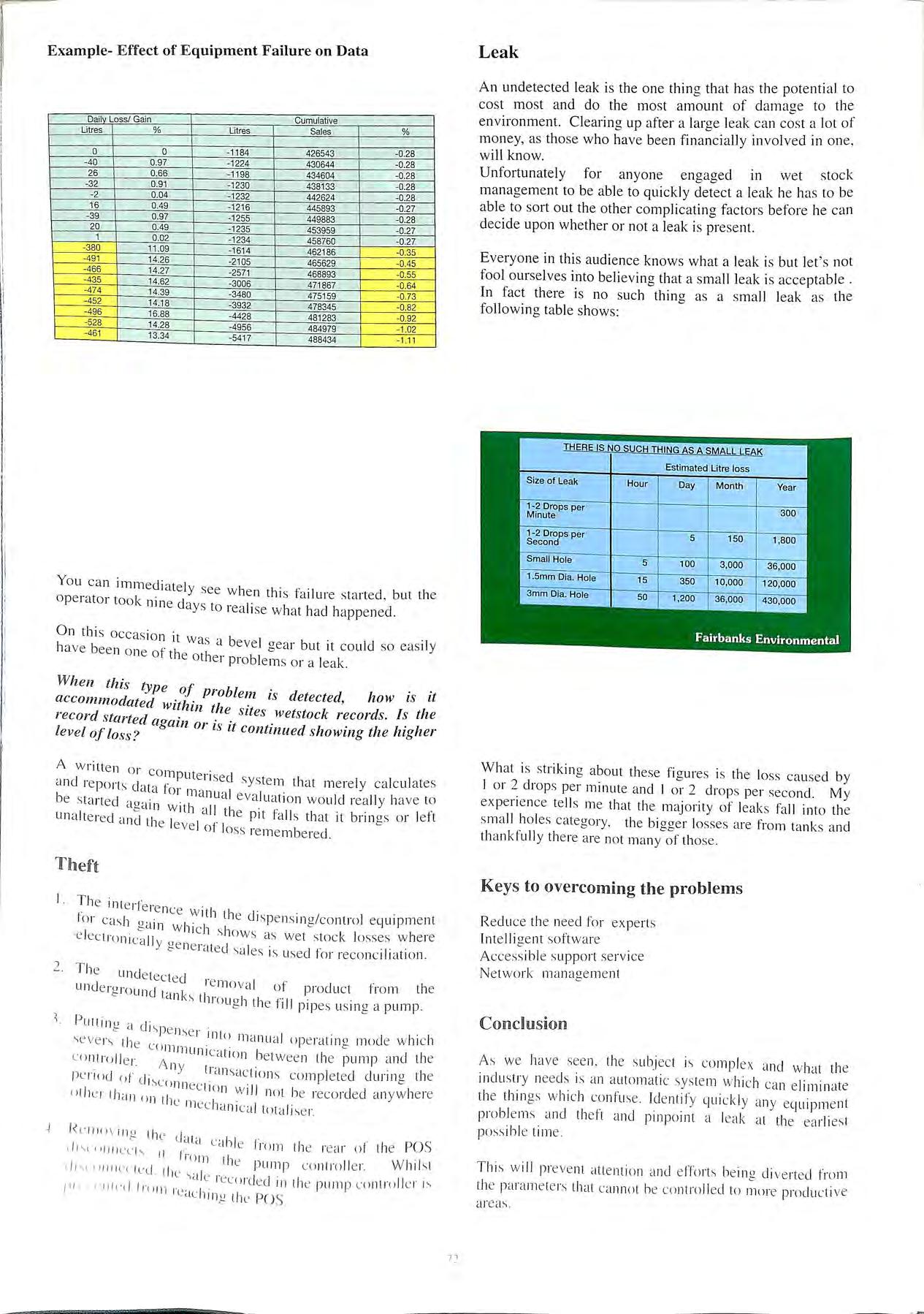

In 1987 when 1 first adapted meter proving methods , which l termed meter audits , used in BP Oil Distribution to suit the needs of th e petrol forecourt , I was truly amazed, first by the total being given away in small amounts and second by the impact that meter settings had on the wet stock loss figures.

The amount of fuel gained or lost as the result of meter setting relates to nozzle throughput. The higher the throughput the greater the amount of fuel involved.

This graph shows annualised losses or gains in litre s for dispensing meters set within the s tandards verification tolerance of 0.30 %

The y axis shows the weekly litre sales and the x axis the meter setting as a percentage. The annual litre gain or loss from a nozzle selling 5000 litres per week equals 780 litres. At 30 ,000 litres per week this gain or loss becomes nearly 5000 litres.

If the impact is that great then should we not be carrying out meter auditing on a regular basis say twice a year to keep meters tight?

In my view, based upon 9 years' experience, the merits of cyclical meter auditing need further debate.

How is a setting of 0.05% achieved? That' s no big deal. All that is needed is a standard Visigauge measuring vesse l that ha s a mov ea ble sca le in 1Omm increment s

also found that tradin g standards tolerances (understandably) were quite wide. On inspection 1% overmeasure a nd 0.50 % undermeasure was acceptable and for verification the band was +/- 0.30 %

A decision had to be made reoa rdin a what toleranc e wo uld b b le as t effect th e wetstock reconcili at ion Mike Lugg. th e then BP Oil e ng ine e rin g manag e r decided that would hav e least e ffect so we u se d that.

Why 0.05 %?

Because we were maintaining a manu a l sys tem

Does 0.05 % still apply? It s hould if the opera to r is not u s ing a system that is abl e to properly adju s t indi v idual m ete r se ttin gs into th e wet s to ck reco n c iliati o n.

Equipment Problems

Equipment probl ems ca n be e ither mechanical or and when n ot id e ntifi ed quickl y a re th e biggest potential for lo ss .

Pulser is the m ec hani sm for rece1v111g litre sa le s in revolution s converting th e m to pulses and re la y in go;the sa le to th e pump head a nd when it goes wrong o nl y 50 "fo of th e fuel be in g di spe nsed is charged for. In ot her wo rd s 20 litres so ld , I 0 litres charged for.

Bevel Drive _ A bevel drive gea r is the gea r .which sp lit s th e main drive so th at the puls e r a nd mec h a ni ca l tot e ca n s imultan eo u s ly rece ive th e litre sa les When th e te e th o n th e b e ve l st rip. the f ull amount ot the fu e l cl eel 1s· 110 t communicated to th e p ump co ntroll e r. 1spe n s . . . . 1, d .. · .

The ratio of fuel dispens e d to sa le s 1ec01c e cc1 n 101 eve ry 20 litre s di sp e ns e d be 18, 12. I0 o r e ve n 5 litres reco rd ed.

Reduction Gear _ A red uct ion g e ar failure has the sa m e effe c t a s a be vel drive failure

Piston Seal _ a pi s to n s e al is lo c at e d in s id e th e disp e nsing · · 1 ·t a ll o w s fuel to b e meter and w he n 1t in ve rts w ith o ut it being record ed.

Communications Failure w he n a ra ilure be tw ee n th e pump head and th e occurs th e full va lu e or th e s ales is n ut pump head to th e pump contro ll er.

CO lll 111 LI n ica t illib p ump 1.:untrnllcr pa sse d ln1111 t h e

T he indi u i1ions w ith in th e we t SfllCk of a ll th ese prob le ms a re th e s am e:

Dailv Loss/ Gain

Cumulative Litres % Litres Sales %

0 0 -11 84 426543 0 28 40 0.97 -1224 430644 -0.28 26 0 66 -1198 434604 -0.28 -32 0.91 1230 438133 0.28 -2 0.04 -1232 442624 -0.28 16 0.49 -121 6 445893 -0.27 39 0.97 -1255 449883 -0.28 20 0.49 -1 235 453959 -0.27 1 0.02 -1234 458760 -0.27 -380 11.09 -1614 462186 -0.35 491 14.26 -2105 465629 -0.45 -466 14.27 257 1 468893 -0.55 435 14.62 3006 471867 0.64 474 14.39 3480 475159 -0.73 -452 14.18 -3932 478345 0.82 -496 16.88 -4428 481283 0.92 528 14.28 -4956 484979 -1.02 -461 13.34 5417 488434 1.11

Leak

An undetected leak is the one thin g that has the potentia l to co st mo st and do the mo st amo u nt of damage to the environment. Clearin g up after a large leak can cost a lot of money, as tho se who have bee n financially invo lved in one. wi ll know.

Unfort unate ly for anyon e engaged in wet stock ma nag em ent to be abl e to quick ly de tect a leak he has to be abl e to sort out the ot her complic ati ng factor s before he can dec ide upon whether or not a leak is pre se nt.

Everyo ne in this audience knows w hat a leak is but let's no t foo l ourselves into believing that a sma ll leak is acceptab le In fact there is no such thing as a sma ll leak as the follow ing tab le shows:

You ca n imm ed ia te ly see w he n thi s fai lure sta rt ed , but th e o pe rator to k · d ' o nin e ays to rea lise w hat had hap pen ed.

O n thi s occas io n ·t . b . ' 1 was a eve ! oea r but 1t co uld so eas il y ha ve been o ne o f th 1 ° e ot 1e r probl e ms o r a leak

When th i s type ,/.' b 0J pro Lem is det ected how is 1t within th e sites wetstock :ecords. ls the 1 ecord started ag · . Lev el of loss? · alll 01 is tl c ontinu ed showing the lug her

A w ritt e n o r co .· a nd re iJo t · 1 • 1:11P Ut e i isecl syste m th at me re ly ca lc ul ates I s c atc1 lo r m m I I be st i ·t cl ' ua ev a uat1 o n wo u ld re a lly ha ve to cl e ctoa 1n With II h . una lte red <tn d tl a . t e pit la ll s that 1t bnn gs o r ld t i e le ve l of loss re me mb e red.

'flheft

I. T he int e rfe re nc · 1 fo r c· h e Wit 1 th e d1 spe ns1n"/co nt ro l equipm e nt I ds . ga in w hi c h show s 1s wet·cstoc l< loss e ' w he re e e ctmn 11 ' ' i cc1 Y gen e rated sa les is used for rec o nc il iatio n.

2 T he und e tec ted und e ru r 1 1e mo va l o f prod uc t lro m th e c o un c ta n ks tl1 · I ·· · · · 1o ug l th e h i ! pipes us ing a pump. p . utt 111 g a \e ve rs tl se i llllo manual op e ratJno mod e w hi c h l e c o mm c u lntro ll • uni c at ion be twee n th e pump a nd the e 1. A ny tr· . . I li e ri()cl 1 1 <1n sact 1on s comp le ted du n ng t l e 0 c 1:-,co nn e t · <lt li , i· I c ion w ill not he reco rd ed an yw he re t l a n o n the I lll ec 1a n1 ca l tnta li :-, e r.

-J. lfr mc J1 111 g tlw cl· . , I dtd c c1hl e I rum the re ar o l 1he POS < l \ l\J llll L' L·h II j" · I 10 m the pum1J rn ntrnll e r. W hil st 1 1" ' 1111h ' c 1L d lhe 1, ., . I I \d c Icc o rcl e cl 111 the pump co 11troll e 1 · 1:-, /' I < 1·11 / l'( 1"<1 111 1". 1L· l1 · I p q 1n g t 1c O S

Wh at is strikin g about th ese fi g ures is th e loss ca used by I o r 2 drop s per minute and I o r 2 drop s pe r seco nd. My ex pe ri e nce te lls me that th e maj o rity o f leak s fa ll into th e s ma ll ho les catego ry. the bigger losse s are from tanks a nd th a nkfull y th e re are not ma ny of those .

Keys to overcoming the problems

Red uce the need fur ex pe rt s Int e lli ge nt softw a re Access ibl e support se rvice Netwo rk ma nage me nt

Condusion

As we have see n, the s ubj ec t is co mp lex a nd w hat the indu stry needs is an a ut omat ic sys tem whi c h ca n e limin ate th e thin gs whi ch confuse. Ide ntify q ui ck ly any equipm e nt prob le ms and th eft and pinpoint a leak at th e ea rli es t po ss ibl e tim e

Thi s w ill preve nt att e ntio n and e ffort s be in g div e rt ed from th e param e te rs that cannot be co ntroll ecl to illllre produ c ti ve a reas.

ET OL STATIO NS -

A VIEW FROM GERMANY

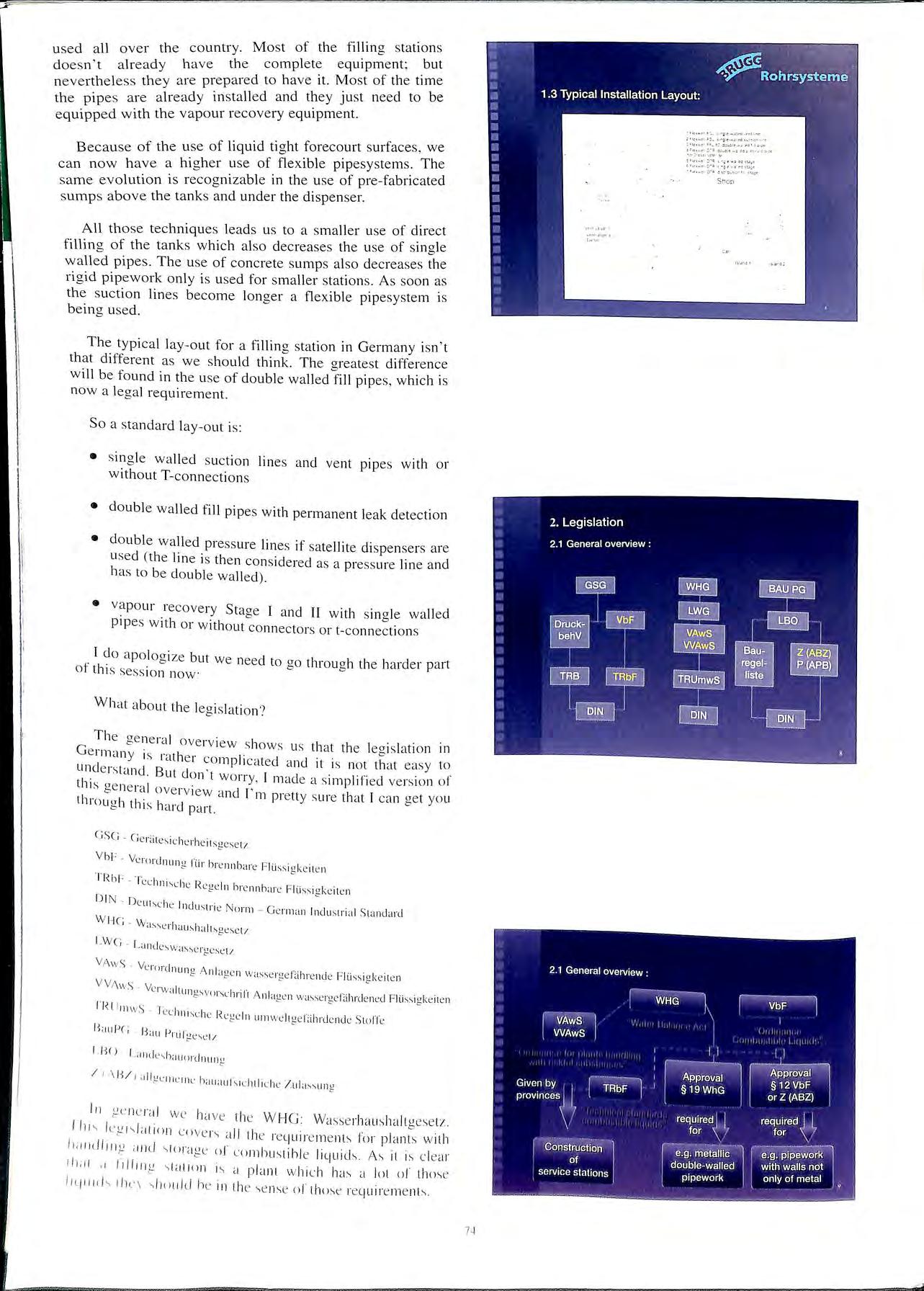

By Rudi VanderpelenWhat about the market?

Germany has 16 provinces (Bundeslaender) and 82.5 Million of people:

Hioh concentration of people around big citie s, s uch as Berli;; Frankfurt; Hamburg etc

The total number of filling stations is (March 1996) about 18.500 which is an average of about 4,460 p eople for each station. Comparing this to , for inst ance Belgium with 4 ,000 station s for l 0 mill ion people , which mean s 400 people for ] station , this number doesn ' t seem too much ; but it is decreasing anyway.

Good afternoon ladi es a nd ge ntl e me n'

I have th e ex pe ri e nce that be in g o n a se minar all th e cla y can be re a l ex ha us ting. But I a m al so co nv inc e d that a ll o r yo u are profess io nal s and int e res ted in w hat 's happ e nin g w ith fillin g s tation s in o th e r co untri es So le t us ju st have " a view from G e rm a ny.

In o rd e r to avo id that we a ll are go in g to fa ll as lee p l mad e three pa rt s in thi s sess ion:

® T he fir s t pa rt to ex plain us a littl e m o re a bout th e mark e t in G e rm a ny

® Th e sec ond part w hi c h w ill ex p la in th e diffi c ul t s ituation o f leg isla tion 111 thi s co untr y.

® a nd la st hut no t le as t th e attract ive pmt of th e sess io n w hi c h \Nill le t you dr snwe r an int e res tin g fl ex ibl e hi g h q wilrt y pip ew ork the fl ex ibl e pi pc,\ stcrn

Th e greates t co nce ntrati o n ca n be found in th e Wes te rn part o f Ger111an y : E ve n after th e gre at numb e r of new built s tati o ns th e East e rn part s ti 11 ha.s a lowe r numb e r of s tati o ns than th e Wes te rn part: Th e big grow th o f th e nu111b e r o f s tation s in th e Eas te rn pa rt is ove r fo r th e mo me nt. Th e 111 a i11 occ up a ti o n now is to mak e th e o ld e r s tati o ns co nform to th e newes t leg is lati o n.

Th e g e ne ral tre nd s in th e fillin g sta ti o n is: I wo uld say th e sam e as in m a ny ot he r co untri es: Fir s t of all th e fo reco urt beco mes g reat e r i11 s m face. Th e 1111pnrtan ce of th e s hop ca nnot be de ni ed a ny m ore . Mo re a nd m o re th e s hop ta kes a g re at e r part o r th e rurn uv e r in a fillin g s tati o n : Beca use of th e s ma ll e r numb e r ol fillin g s tati(ln\: rlw numb e r o f d ispe nse rs pe r fillin g st<lt ion in neas e \: A lrnu s t all 01· th e s ta tiu ns ha \ e multiprndu c t di s pen se rs w ith ) product s: th e un lead ed g asu lin e w irh ll2: l)) and l1l' lan t' di ese l a nd le aded gasl1 1in c.

It cle ar : tfo1t 111 md e r to a\ oid pti llutinn h; th l' lea d the co ns u mpt ion ul' lemled g a\nli11L' i, de nt' a,111g s uL· h "' th e numb e r ul ' ii lin g CJ\ I a li t'<l d) rn c n t1t11 1L' d hdtir t'

The tcc hniL'<i l sta mL11 d\ c hangt'd a hit thL' la s t fci\ I L'< Jrs : t1f <iii there I \ tlw StagL' II

used all over the country. Most of the filling stations doesn't already have the complete equipment; but nevertheles s they are prepared to have it. Most of the time the pipe s are already installed and they just need to be equipped with the vapour recovery equipment.

Because of the use of liquid tight forecourt surfaces, we can now have a higher use of flexible pipesystems. The same evolution is recognizable in the use of pre-fabricated sumps above the tanks and under the dispenser.

All those techniques leads us to a s maller use of direct filling of the tanks which also decreases the use of single walled pipes. The use of concrete sumps also decreases the rigid pipework only is used for smaller stations. As soon as the s uction lines become longer a flexible pipesystem is being u sed.

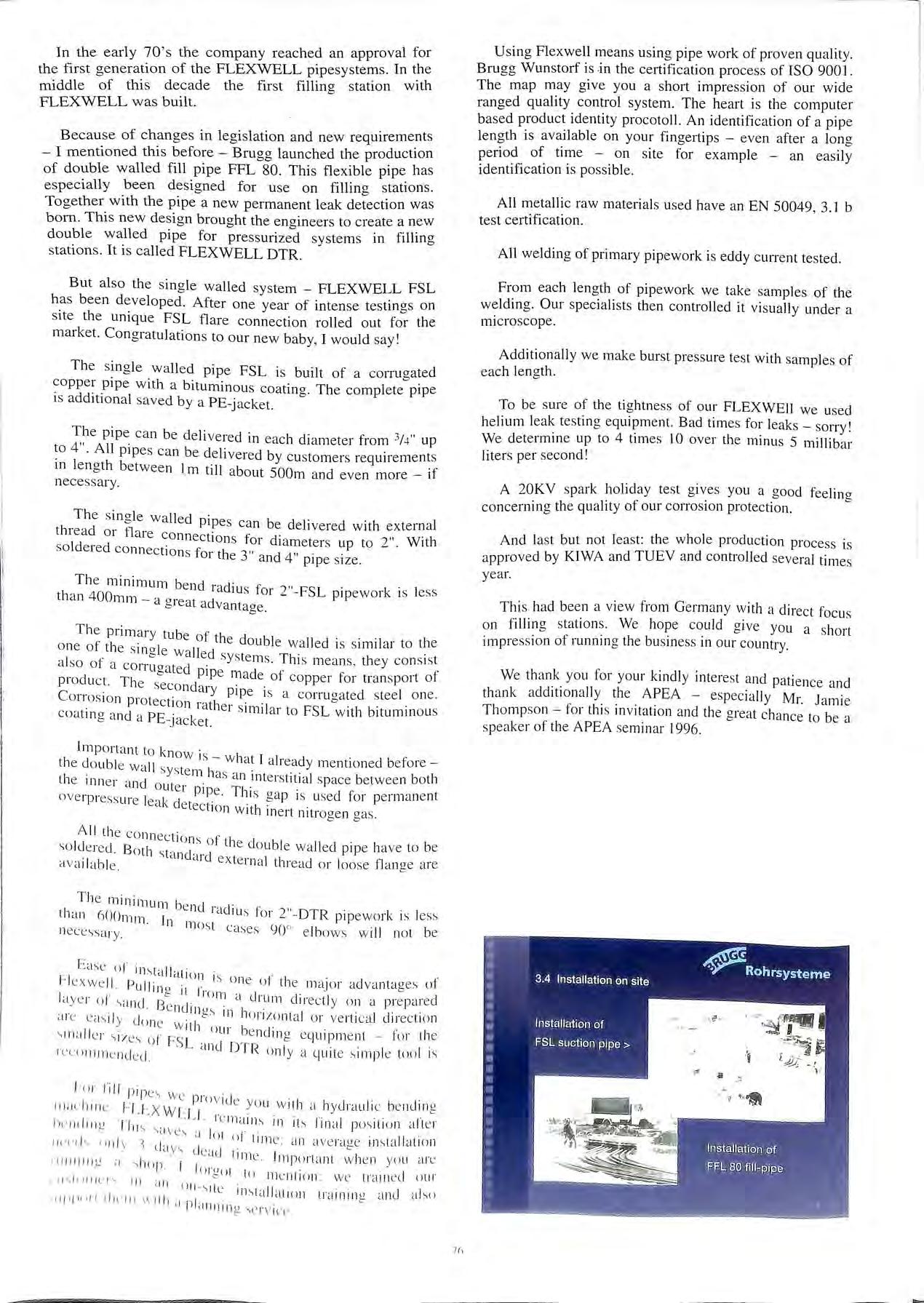

The typical lay-out for a filling station in Germany isn ' t that different as we should think The greatest difference will be found in the use of double walled fill pipes, which is now a legal requirement.

So a standard lay-out is:

• s ingle walled s uct ion line s and vent pipes with or without T-connections

• double walled fill pipes with permanent leak detection

• double walled pressure line s if satellite dispensers are u sed ( the line is then considered as a pre ss ure line and ha s to be double walled).

• vapour re cove ry Staa-e I and II with s ino-le wa ll e d b b pipe s with or without connectors or t-connection s Id 1 · 0 apo_ ogize but we need to go through the ha rder part of thi s sess ion now:

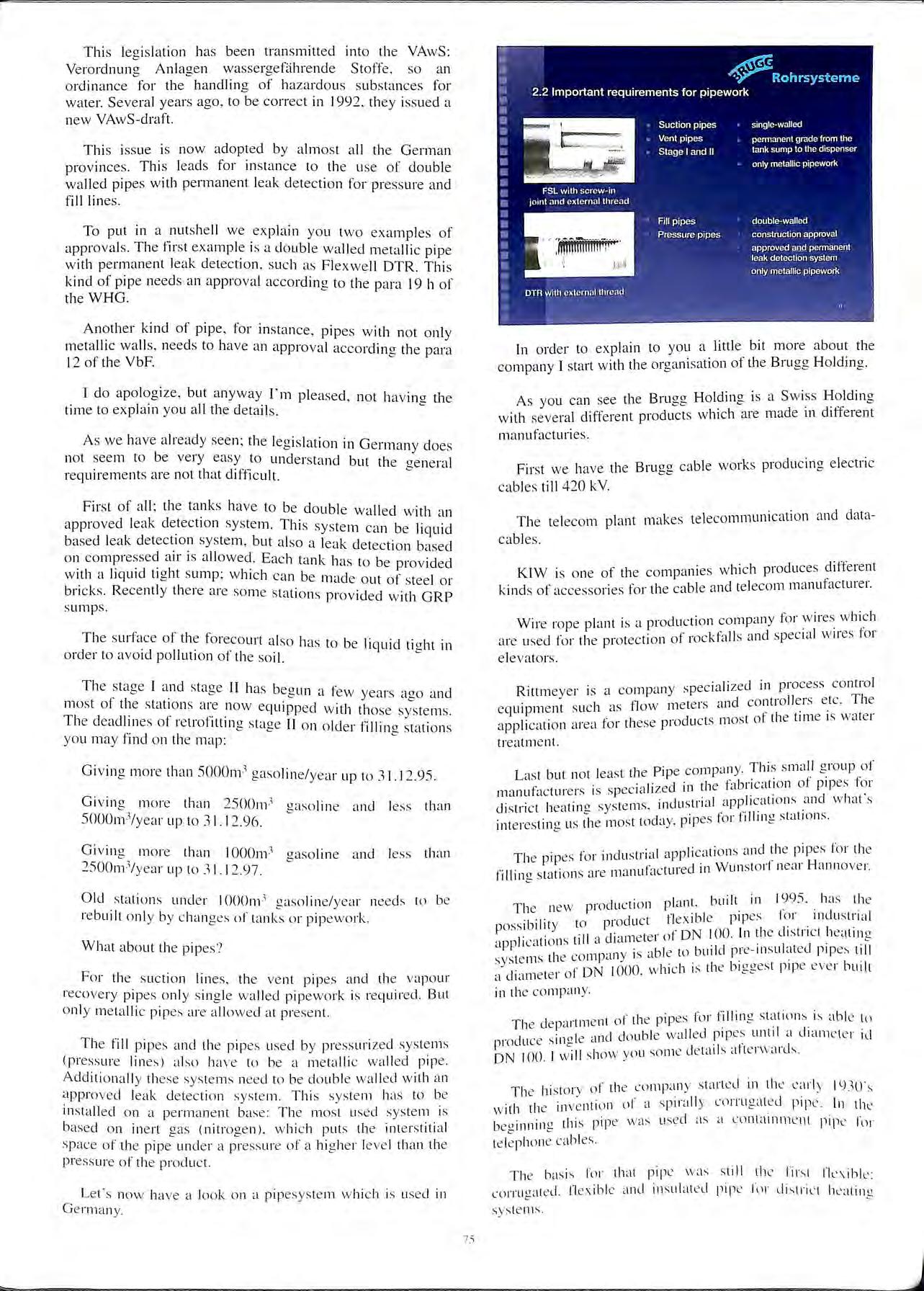

What about the legi s lati on? G The ge ne ral ove r v iew sho ws us that the le g is lation in e rman y is rathe· 1· cl . . · 1 comp 1cate and it is not that easy to But cl 't · · on wo11y , I mad e a s 1mpl1f1 ed ve rs ion of this <>e

This legislation has been transmitted into the VAwS: Verordnung Anlagen wassergefahrende Stoffe, so an ordinance for the handling of haza rdou s substances for water. Several years ago , to be correct in 1992 , they is sued a new VAwS-draft.

This iss ue is now adopted by almost all the German provinces. This le ads for instance to the use of double walled pipes with permanent leak detection for pressure and fill lines

To put in a nutshell we explain you two examples of approvals. The first example is a double walled metallic pipe with permanent leak detection, such as Flexw e ll DTR. This kind of pip e needs an approval according to the para 19 h of the WHG.

kind of pipe , for instance, pipe s with not only metallic walls, needs to have an approval according the para 12 of the VbF.

I do apologize, but anyway I'm pleased, not havina the time to explain you all the detail s <=

As we have a lread y see n ; the legi s lation in Germany does not seem to be very easy to und e rstand but the aeneral requirements are not that difficult. <=

First of all; th e ta nks have to be double walled with an a pprov ed leak de_tection system. Thi s system can be liquid based leak detect_ion system, but also a leak detection ba sed on air 1s allowed. Each tank has to be provided wi_th a liquid tight sump; which can be made out of steel or bricks. Recently there are some station s provided with GRP sump s

Th e surfac e of th e forecourt a lso lia s to b l" ·d · 1 · L e 1qu1 t1g1t in order to avoid pollution of the so il.

Th e stage I and sta ge II ha s begun a few years ago a nd mo st of the a re no w equipped w ith tho se sys te m s. Th e deadl,111e s o1 retrofittin g st age II o n older filling sta tion s you may 1111cl on th e map:

Gi vin g more than 5000m-' gasoline/year up to 31.12.95.

Giving mo re than 25 00m 1 gaso lin e and less than 5000111 ' /y ea r up to 3 1.12.96

Giving more than IOOOm ' gasolin e a nd less than 2500111 1/year up to 31.12.97.

Old stat ion s und e r IOOOm 1 gaso lin e/ye ar ne e ds to be re built o nl y by c han ges of tank s o r pip ew ork.

What about the pipe s?

For the suct ion lin es, th e ve nt pipe s a nd th e vapo ur recove ry pipes o nl y s in g le wa ll ed pipework is req uired. But on ly me ta lli c pip es are a ll owed at pre se nt.

The fill pipes a nd th e pipes use d by press uri zed systems (p ress ure lin es) a lso ha ve to be a metalli c wa ll ed pip e Additionall y these sys te ms need to be d o ubl e wa ll ed with a n approved lea k detec tion sys te m. Thi s sys te m has to be in stall e d o n a pe rm a ne nt base : Th e mos t use d system is bas ed o n in e rt gas (nitro ge n ). w hi c h put s th e int e rstiti a l space of th e pipe und e r a press ure of a hi g he r leve l th a n th e press ure of th e produ c t.

Le t ' s now have a loo k o n a pipesys te m w hi c h is used 1n Ge rm a ny.

As you can see the Brugg Holding is a Swi ss Holding with several different product s which are made in diffe re nt manufacturie s

First we have the Brugg c able works producin g electric cables till 420 kV.

The telecom plant make s telecommunication and datacables

KIW is o ne of th e companies which produc es different kind s of accesso rie s for the cable and telec o m ma nufacture r.

Wire rope plant is a production company for w ires which are us ed for th e protection of rockfall s and special w ires for elevators.

Rittm eye r is a co mpany spec iali zed in proces s control · f"I t · a11d controllers etc. Th e equipment such as ow me et s • . . . app licati on area for th es e products mo st of the tim e is wate1 treatm e nt.

L , t b t 10t le as t th e Pipe co mp any Thi s s ma ll gro up of dS LI l c L f f manu fact ure rs is spec ia li zed in the fabrication o · pipes district heat ing sys te ms industrial appl1cat1ons and what s int e resting us th e mos t today, pip es fo r f1ll111g sta ti ons.

Th e pipes fo r app li c ati ons for 1 th e 1 11· t t. s ai·e manuta ctured in \Vun sto1I nea1 Hdnn o \ e 1. 11 mg s a 10 11 • ' '

Th e new production plant , built in 1995 ha s th e ·b·1· t· product fl ex ibl e pip es lo r indu strial poss1 1 1ty o 1· , I · I. · · t·11 a diam e te r o f ON 100. In th e c 1st11 ct 1ea t1mi_ app 1ca t1 ons 1 ' " · 1 cl · · s ste rn s th e compa ny 1s ab le to .b uild p1 e- 1n su ate pipes till Y1 t 1 ON 1000 whi c h 1s th e b1 g:ges t pip e eve r built a c iarn e e t o · in th e co mpan y

Th e de partm e nt of th e pipes for fillin g stat io ns. is abl e t\l I .· .111cJ do ubl e wall e d pipes until a dtam e te r id proc uce s 11 :::: e ' , ON JOO. 1 will show yo u so me clet<1 ll s

Th e hi sto ry o f th e co mpan y start ed in th e e arl y IY:iO's with th e in ve ntion of a sp irall y c orni ga tecl p ip e. In th e beo innin g thi s pipe was use d as a co ntainm e nt pip e for c abl es

Th e bas is for that pipe was still th e fir s t lk x ihl e: co rru gat ed . fl ex ib le and in sulat e d pipe fl) I di s tri c t ht'.at in g sys te ms.

In order to explain to you a little bit more about the company I start with the organisation of the Brugg Holding.In the early 70 's the company reached an approval for the first generation of the FLEXWELL pipesystems. In the middle of this decade the first filling station with FLEXWELL was built.

Because of changes in legislation and new requirements I mentioned this before Brugg launched the production of double walled fill pipe FFL 80. This flexible pipe has especially been designed for use on filling stations. Together with the pipe a new permanent leak detection was born. This new design brought the engineers to create a new double walled pipe for pressurized systems in filling stations. It is called FLEXWELL DTR

But also the single walled system FLEXWELL FSL h_as been After one year of intense testings on s1te the unique FSL flare connection rolled out for the market. Congratulations to our new baby, I would say!

Th e s ingle _walled pipe FSL is built of a corrugated copper _pipe w nh a bituminou s coating. The complete pipe 1s add1t10nal saved by a PE-j acket.

The pipe can be delivered in eac h diameter from 3/ 4" up to 4" All , · · · 0 pipes can be d.e hvere d by customers requirements in le n '°'th b etwee n 1m till about 500m and even more if necessary.

h Thde s in gflle wa lled pipes ca n be deliv ered with external t rea o r are con t. nee ions for diameters up to 2". With so ldered connec ti ons for the 3 d 4 ,, . an pipe size.

The minimum be nd rad iu s for 2"-FSL i ewo rk is le ss than 400m m -a o reat ad P P o ' va ntage