'• , · , · The •

THE ORIGINAL PETROL STATION I CONVENIENCE STORE VOLUME 35 No" 4

Journal of the Association for Petroleum and Explosives Administration

introduce the OPW drip-less nozzle A 110V1'R RESOURCES COMPANY STOCKHILL HOUSE, STAIN FORTH , SETTLE , NORTH YORKS , 8024 9PJ TEL : 01729 823655 FAX : Q1729 822424

Betty is happy to

AllT" ,/,,.. CT'IV ID ,..,.., . .., 7 .., . ,. .. .,,, .. . ISO 9001 CERTIFIED : · *Independent testing shows these products exceed EPA requirements for leak detection

@© ® a rage © onsultancy ervices Ltd Nationa Inspection Counci for Electnca Installation Conirac ing • •IC E•C APPROVED CONTRACTOR UNIT 10 MERTHYR TYDFIL INDUSTRIAL PARK PENTREBACH MERTHYR TYDFIL MID GLAMORGAN CF48 4DR TELEPHONE (01443) 692008 FAX(01443)692159 FUEL TANK INSTALLATIONS APPROVED INSTALLERS OF STEEL, UPP, APT, DURAPIPE & ENVIRON PIPEWORK FUEL MONITORING AND METERING EQUIPMENT UL APPROVED FUEL TANK LINER AND LEAK DETECTION SYSTEM INSTALLATIONS 1973 - 24 YEARS OF SERVICE TO THE PETROLEUM INDUSTRY - 1997

ED WARDS (Tank Removal) Ltd THE COMPLETE FUEL TANK SPECIALISTS PETROL · OIL · CHEMICAL · STORAGE TANKS ABOVE OR BELOW GROUND CLEANED·GASFREED·REMOVED SERVICES INCLUDE: • Ga s Free Certifi cation • Ta n k R e mo va l - Disposal • Cold Cutting • Hot Cutting • Bulk Fuel Upli f ting • Slurry Filling • Garage Demolition • Baffle Plate Cutting • Basement Tank Removal • Foam lnerting ALL WORK IN STRICT ACCORDANCE WITH CURRENT HSE AND PETROLEUM REGULATIONS We specialise in the removal by cold cutting of solid filled tanks and disposal of thes e tanks from site EDWARDS (Tank Removal) LTD 128=130 CHURC H STREET9 CROYDON 9 CRO lRF 0816869775 ° 0816801890

High integrity pipework systems for forecourt installations Distributed by )!etrol·line "R_/US S&LP • No 1 UK manufacturer of polyethylene pipes • Superior electrofusion jointing system • High flow rates • Available in four sizes for suction and pressure systems • Competitive prices • Nationwide delivery PURFLEET FORECOURT SERVICES 520 London Road, West Thurrock, Grays, Essex RM20 3BE Tel: 01708 863931 Ext. 219 PURFLEET FORECOURT SERVICES LTD Fax: 01708 864140 e-mail: purfleet forecourt services@harris-group.co.uk LEDBURY WELDING & ENGINEERING LTD. NETHERWOOD ROAD, ROTHERWAS INDUSTRIAL ESTATE, (TEL: 01432 275566) HEREFORD HR2 6JU (FAX: 01432 358493) A COMPLETE RANGE OF ABOVE & BELOW GROUND STORAGE VESSELS QUALITY UNDERGROUND TANKS / QUAlffY UNDERGROUND TANKS SPECIALIST COATING DOUBLE AND SINGLE SKIN LEAK DETECTION OVERFILL PREVENTION DEVICES MANWAY ACCESS FRAMES MULTIPLE COMPARTMENTS ABOVE GROUNDi FULLY BLINDED TOTAllY ENCLOSED "DERV=PACKS 9 600 GALLON TO 20,000 GAllON° 1

FIBRE OPTIC CAMERA I PUMP SYSTEM Cleans Live Petroleum & Chemical Tanks without removing Product, Lids or Customers OIL AND GREASE ELIMINATING PRODUCT Ideal for Tank & Forecourt Cleaning [ ENVIRONMENTALLY FRIENDLY] + Free Video Sub Distributors Wanted- Excellent Discounts. Great Technical Support Leif Dige UK Ltd 9 The Colonnade Woolston Southampton 8019 70T Tel: 01703 444877 Fax: 01703 447791 ' 111 -.-,. lfn.. m .···· SS 11:1SO!IOO'

2 BERCTA ROAD, NEW ELTHAM LONDON SE9 3TZ

TEL: 0181-850 2211 FAX: 0181-850 5599

BACEL HARDFOAM RG30 For surrounding new tanks...SNUGLY ! RG22 old tanks safely.... Without spoiling your future options RG15 Mothball your Underground storage tanks. you may need them again RGB The safest way to remove tanks. No men needed to enter tank Little use of water Geoffrey Wheeler Marketing 0831 132394 offfice 01703 446044 RT.I. Rep. for UK, Eire, Scandinavia & Germany WASTE MANAGEMENT NATIONWIDE FORECOURT DRAINAGE & INTERCEPTOR SERVICE Cleaning & emptying of intercepto d . d · rs an associated ra1nage systems found on garage forecourts • Interceptors • Catch Pits • Tank Tops • Gullies • Car/Jet Wash Pits • BucketTraps • Surface Drainage • Be1ow Surface Channels Drain lines Water transported for tank test· 1 ing pus treatment & disposal of the contaminated water tr EVESHAM (01386) 47190 INDUSTRIAL & TANK CLEANING Petrol, oil & solvent tanks cleaned to OCTEL and Petroleum Industry specifications. tl GLOUCESTER (01452) 507432 Head Office: Grange Road, Botley, Southampton, so30 2GD Tel: (01489) 782232/6 Fax: (01489) 789821 CLEANSING SERVICE GROUP LTD SPECIALISTS IN PETROL PUMP AND PIPEWORK INSTALLATIONS. APPROVED INSTALLERS OF: AMERON AND SMITHS GRP. DURAPIPE AND UPP. ENVIROFLEX AND ENVIRON. PRECISION TANK AND LINE TESTING EMERGENCY REPAIR SERVICE.

D DC BUILDERS LTD FOR SERVICE QUALITY & RELIABILl1Y WE OFFER A COMPLETE SERVICE ON MAINTENANCE AND IMPROVEMENT WORKS TO THE PETROLEUM RETAIL MARKET D D C BUILDERS LTD 7 ST CLAIR CLOSE CLAYHALL ILFORD ESSEX IGS OPA Tel: 0181=550 5216 Fax: 0181=550 6095

BUILDING AND CIVIL ENGINEERING CONTRACTORS TO THE OIL COMPANIES FOR 24 YEARS C.R. RICHARDSON (CONTRACTORS) LTD DESIGN & BUILD Anerley Court, Half Moon Lane Tel: 01732 838608 Hildenborough , Kent TN11 9HU Fax: 01732 838064 FOAM SPECIALISTS RESIN GENERA TED FOAM : 0800 592573 BACEL APPROVED APPLICAT ORS OF THE PROVEN AM · SOUND AND ENVIRONMEN TALLY NEUTRALISATION FOR THE HY DROPHOBIC FUELS T ORAG E OF ALL UN DERG ROUND TANKS RG8 FOR THE . OF T A TE MPORARY NEUTRALISATION PRIOR TO EXCAVATION , RG15 FOR T AL AND DEMOLITION. OFT SHORT TERM "MOTH-BALLING" WHICH MAY REQUIRE TO BE RG22 FOR T ED FOR FUTURE RE-USE. REDu::; SAFE NEUTRALISATIO N OF lRG.30 FOR S NT. AL NEW TANKS AS AN S VLPHA TO PEA SHINGLE OR UJT/ ii SISTANT CONCRETE /Y/Y e r!'UJJ ve over 2 5 Petroleum Ind · years experience in the {)8{}{) 'f92)?? ustry. Call us on Freephone · · · or Mobile.· 0836 740500 Professional development TRAINI NG IN-COMPANY SHORT COURSES • Electrical Requirements for Petrol Filling Stations • Management overview of HSW Act & related Statutory Regulations associated with electrical safety, including : Management of HSW Regulations (MHSWR) Provision & Use of Work Equipment Regs ( PUWER) Personal Protective Equipment at Work Rags (PPER) Construction (Design & Management) Regs (CDMR) • ELECTRICITY AT WORK REGULATIONS (EWR) • General Safety at Work Sites • 887671 Requirements for Electrical Installations (16th Edition Wiring Regulations) • Inspection and Testing of Electrical Installations practical problems reviewed • EARTHING AND BONDING reviews a wide range of national Codes of Practice and Statutory Requirements Also In-company 'workshops' addressing cllenrs electrical and safety problems Presenter: TERRY HEDGELAND BA. FIEIE, MIQA. Member of APEA and !OP Phone: 01737 553328 • SPECIALIST BUILDERS TO THE PETROLEUM INDUSTRY • FORECOURT INSTALLATIONS INCLUDING STEEL & PLASTIC PIPEWORK • SHOP REFURBISHMENTS • ELECTRICAL INSTALLATIONS • MAINTENANCE AND REPAIR 01269 831038 FAX(01269)831201 Acer Court , Cross Hands Business Park Cross Hands, Carmarthenshire 0 SA14 6RE The Association for Petroleum Wei'/ Wa l es TEC and Explosives Administration

A. J. Bayliss (Stourport) Ltd Petroleum Engineers Petrol, Fuel Oil and Electrical Installations 11/12 HODFAR ROAD, SANDY LANE INDUSTRIAL ESTATE, STOURPORT-ON-SEVERN DY13 9QB TELEPHONE: 01299 824541-2-3 FAX: 01299 827638 SPECIALISING IN ALL ASPECTS OF FORECOURT PETROLEUM INSTALLATIONS, SERVICING AND ELECTRONIC TANK TESTING FULLY ACCREDITED TO BS EN ISO 9002: 1994 Care For The Environment... Make Forecourts A Safer Place To Work And Visit.. · Provide Quality Solutions To Forecourt Engineering Problems R SBRllDGIER VAPOUR RECOVERY PRESSURE VACUUM VALVES VAPOUR LOSS REDUCTION SYSTEMS UNDER PUMP/CHECK VALVES DESIGN & DEVELOPMENT INSITE LINE TESTING RIS STOP OVERFILL PREVENTION DEVICE RISBRIDGER LTD . Stychens Lane, SuITey RH 1 4LN Tel : ( +44 01883 7 43107 Fax: ( +44 01883 7 443 4 2

INSTALLING NEW TANKS?CV G22 for permanent tank abandonment RGl for tank mothballing or safer tank excavation USEBACEL HARD FOAM RG30 for backfilling tanks • Absorbs hydrocarbons • High rigidity and cohesion • Insulates tanks on 't slurry in a hurry - call now for a free estimate ksafe · 4/5 G · h Square· London· EC4A 3DE ·Tel 0171583 2007 ·Fax 01715832008 NASH Nas h & Partn ers ha b R ve een wo rkm g m parh1ersh1p w ith the e ta II Pe troleum ind u s tt y fo r a lm ost thir ty yea rs, planning a nd d eve lo pm g retail in t II s a at1o n s fro m a s traightfo rwa rd pump ch an ge to Eu ro , 1 p e s a rges t fillin g s tati on. Eve ry s te p of th e w f. ay, 1o m feas 1b1Iity s tudi es and sur vey in g p roject mana ge men t d ' :i a n commi ssionin g, we take care of eve ry L e ta 1I. Wh e th e r a n I 1a10 1 o il co mp a ny or an indi vidu a l d ea ler, o ur c ie nts a re ass u r d d i e of the Na sh co mmitm en t to qua li ty and a 1e rence to BS57SO , backe d by u p to- th e- minute tec hn o logy innova ti on a n d ex perti se. ' Fro m a g reenfie ld · p s ite to a fu ll y ope ra ti o na l in sta ll a ti o n, Nas h & a rL-J1e rs d e live r er t· ea 1ve ye t h ig h ly p rac ti ca l so luti ons. * ARC HI TECTS + S UR VEYOR S + TO W N !)LANNE RS • f) ROJ ECT MANAG ERS • PRO PERTY CONSU LTAN TS

• Zero Permeability •Lightweight •Robust • Non-corrodible • Electrofusion jointed • Designed and manufactured under a BS EN ISO 9001 Quality management system • '1'44 (01 ) 1543 279909 .:i-44 (0) 1543 279450 +44 (©) 1543 27-8095 3399 45 DUPIPE G l!etrol·line Rius Suitable for vacuum and pressure app l ications i n somm, 63mm, 90mmand £11omm sizes

the comp lete foreco urt adverti sin g kit For further information on the full range of Elaflex products contact: Riverside House, Plumpton Road, Hoddesdon, Herts EN11 OPA. Telephone 01992 451494 Fax 01992 451496

DAVID PLUMB & CO LTD 169 Frenches Road, Redhill RH1 2HZ Telephone: 01737 767524 Service t o the P +etroleum ] Member A.P.E.A. The safe alternative to water-filling of petrol tanks for certain applications Using our oil/water separator we can dispose of water from p etrol tanks at a fraction of th e co s t of tanke r hire Work undertaken by fully trained and medically certificated personnel Hot and co ld c utti n g, removal a nd do c um e nte d d is p osal of r e dund a nt oil an d pet rol tanks. Product uplift and transfer. Converting double-compartment tanks to single Solid filling of redundant tanks • Cold cutting open and disposing of solid-filled tanks Excavation• Tank removal. Contaminated soil disposal and reinstatement

We're back selling directly to the UK market, our world leading GRP access chambers and composite access covers. Call 01 756 799 773.

I I ! ; \ i I l I I !

'1

DRIP STOP , I diesel nozzle

Situation Today

Often the area around a diesel dispenser is contaminated by diesel which has fallen onto the forecourt for one reason or the other. One of the main reasons is that motorists do not wait that extra second for the nozzle to drain before removing the spout from the car filler pipe.

The Solution

The ZVA Slimline nozzle is now available with the New Drip Stop spout ER242. 1TMV. The patented magnetic closure inside the spout works after refuelling has finished The Drip Stop operates in two ways. Firstly it closes to prevent diesel dripping when the spout is removed from filler pipe too quickly and secondly, it retains the remains left in the spout so that the next customer doesn't spill this diesel onto the forecourt when removing the nozzle from the dispenser. --

How does it work?

The Drip Stop functions on the principle of a floating magn rather than a strong spring. When the nozzle is not in use floating magnet holds the "valve " closed. Since the magnetic force is very small when compared with a spring the pressure loss is minimised in such a way that the pressure. drop eyen at flow rates up to 501pmin is negligible. Also the. innovative patented design allows for quick opening and slightly delayed closing, this prevents the ZVA Slimline from being placed in the dispenser holster with a full spout.

Maintaining ZVA topping up facility well known ability of the ZVA Slimline "to the penny dispensing " is as sensitive as ever and is in no way compromi:>ed by this new designed spout. new spout is also supplied as standard with Drip Catcher fitted.

Ho w t o ord e r: Ple a s e con ta c t o ur S a les Of fic e f or fur the r de ta i l s.

SO FAR without closure drip, drip! NOW with magnetic closure

Riverside House, Plumpton Road , Hoddesdon, Herts EN 11 OPA Telephone: 01992 451 494 Fax: 01992 451496

Administrator: Mrs Barbara Jacketts Number4 NOVEMBER 1997

£8.00

Opinions expressed in this Journal are not necessarily the views (Free to Members) ISSN 0263 4597

of the Association

Talking Point

The draft regulations concerning petrol safety at filling stations and in the home are out for consultation, whether you are an individual or an organisation the HSE want to hear what you think of these proposals. We urge you all to respond.

So far Dr Steve Rooker and colleagues at the HSE have been visiting all parts of the UK to explain the thinking behind the new proposals. It is certainly evident that "Rookers Road Show", as it is popularly known as, has failed to convince the rank and file petroleum officers that petroleum licensing should be replaced with the new consent regime. There is also evidence that they are supported by many of the small station owners who are also happy with the existing arrangements

In _the main however the larger organisations support the pnncipal of change but many have voiced concerns about .detail the proposals for delivery at petrol stations which will reduce the present level of public safety.

Two papers in this edition give opposing views.

TALKING POINT NOTES &NEWS

ECONOMIC ALTERNATIVE TO TANK REPLACEMENT

NEW PETROL LEGISLATION FROM HSE

PETROLEUM LEGISLATION IS IT BEING SPIRITED AWAY?

ELECTROSTATIC HAZARD FACT OR FICTION

11° I'll I'i i

VOLUME 37 The Bulletin Published by the Association for Petroleum and Explosives Administration

A company Limited by Guarantee registered in England No. 2261660

Contents

APEA BRANCH SECRETARIES 56 57 60 62 64 68 SIMON WHITE SOUTHERN BRANCH MIKE SILMON NORTH EAST BRANCH SUE MEADOWCROFf WALES BRANCH STEPH CROW EASTERN BRANCH RUTH SUTHERLAND SCOTI'ISH BRANCH LINDSAY LLOYD Mf[)LANDS BRANCH STEVE BLANCHARD f-flJMBERSf[)f'. BRANCH HARRY REID NORTH WEST BRANCH NATHANIEL MCCOY !RELANO BRANCH JAMI!·: THOMPSON EDITORIAL TEAM f:'/JfTOR 56 ROB GREEN Af)Vf:RTIS!NG S£CRE7Am'

notes and news

FIRE ON FORECOURT

R. A. Hamilton, Fife Council

Petroleum officers were contacted by the Fire Service to advise them of a fire that had occurred on the forecourt of a filling station owned by a large oil company. The premises are situated in an urban area with nearby housing, and within 200 metres of a main railway line. After investigating the incident the following was determined:

Background

The site operates 24 hours. At approximately 1: lOam a tanker arrived on site to make a delivery and parked at its unloading point. Preparations to take the delivery included closing the site to the public, and strategically siting several extinguishers. The delivery would be to the underground tanks via offset-fills set in a manhole chamber. The chamber was approximately 400mm deep with the man-lid and its bedding rim made of metal, in this case forged steel.

The tanker driver attempted to lift the man-lid but struggled to do so. He was obliged to hurriedly put it down (effectively dropping it a short distance). This caused a spark and a blue flame was seen to propagate along two edges of the man-lid rim. The flame apparently then fed into the man-chamber and a large flame shot upwards from it.

Both the kiosk attendant and the driver used the nearby fire _extinguishers to put out the fire and the emergency services were contacted.

Conclusion

The method of re 1 f h . mova o t e man-hd caused a spark that a flammable/explosive atmosphere which filled and possibly surrounded to some extent, the man-chamber'. The man-chamber is · · . a recogmsed hazard area (Zone 0) but 1t may be that m this . · . ' b . case Its relative shallowness caused it t tho ea grehaterbnsk than a deeper one. The effective depth of e man-c am er was furth d · er re uced by the presence of ram water.

Neither of the persons involv d . d" 1 · e 111 1cated that there was any 1qmd petroleum in the man h b · -c am er and a11 ext l source for the flam bl . ' erna ma e vapou1 has not been identified.

Action

The oil company involved has removed all metal lids and surrounds from the site and re laced . ' · metal ones They 1 p them with non are a so accelerating their risk assessment of sites that still have metal lids a d · n sm rounds.

l bring the above to you tt . 1 a ent1on as there are still a large number of sites around the cotint. h' ·h h 1y w 1c ave forcred steel man-hds and suITounds Operatoi·s ·h Id "' · ' · s ou ensure that part of the nsk assessment of the site 1 · 1 ·I d · k · 1c u es any ns to the mate_nal of man-lids and surrounds. their weight, the depth ot the chamber. and how personnel are trained to remove/replace the man lids.

Your readers may like to know that this Authority has sent a letter of commendation to the two persons involved, as their prompt actions, calmly and methodically carried out, stopped a dangerous situation from becoming potentially much worse.

COMPANY FINED FOR ILLEGALLY DUMPING FIREWORKS

In January 1997 Gloucestershire County Council Trading Standards Department received reports that a large quantity of fireworks had been off loaded by a refuse contractor at the Waste Company's landfill site at Hempstead Gloucestershire.

Investigations by Trading Standard Officers revealed that approximately 44 kilograms of fireworks had been placed in a refuse skip by E. M. Merrett & Company Limited at their warehouse premises at the Madleaze Industrial Estate Gloucester on the 9th or lOth January 1997. On the lOth January these fireworks were unknowingly taken to the Waste Company landfill site at Hempsted Gloucester for disposal with other rubbish, by the waste disposal contractor. Fortunately the Waste Company staff spotted the fireworks and they were safely isolated and returned the same day to E. M. Merrett & Co Limited.

Enquiries of the company revealed that the disposal of the fireworks happened in error whilst the warehouse was being emptied for transfer to another site in the City and that it was due to staff sickness and absence that damaged fireworks became thrown out with other damaged stock.

Trading Standard Officers were extremely concei:ned at the potential consequences of this apparently accidental action since large quantities of methane is produced at the landfill site which could have ignited in the wrong circumstances.

As a result a summons was heard at Gloucester Magistrates Court on Friday 22nd August 1997 under the E I . A t 1875 allegincr that E.M. Merrett had not xp os1ves c o I. d "tl th coil·ect storacre cond1t10n for fireworks, comp 1e WI 1 e · "' .· . h h t kept secure from unauth011sed access 111 t at t ey were no . f 12 05 kcr of fireworks. The company had com respect o . "' d f II "tl tile Tradincr Standard Departments operate U y WI 1 ' e , · · · d ·11 the court entered a plea of gmlty. The mvest1gat10ns an 1 · k ledaed that this had been an isolated magistrates ac now "' . .d h t th company had co-operated, and pleaded mc1 ent, t a e ·i b h · posed a fine of £3.000 and awarded full gm ty ut t ey 1111 · ' departmental costs of £552.

Paul Galland County Trading Officer says. "The department licences and register the storage of explosives and ensures that tt:ey are .stored correctly and safely. Fireworks are explosive devices and should be considered as such and not taken tor granted. Complacency with fireworks of any description is unacceptable and this instance of fireworks being clumped could have had very serious consequences".

57

DEATHS AT SERVICE STATION

A coroner in the Midlands recently pronounced accidental deaths on two women who were badly burnt at a petrol filling station after refuelling their car. The cause was thought to be a fault in the fuelling system, which allowed vapour to build up in the vehicle. Ignition was caused by one of the women lighting a cigarette ..-

40th BIRTHDAY!

1998 will be the 40th anniversary of the APEA and it is proposed that a special supplement of the Bulletin will be printed. The Editor is especially interested in unusual photographs of service stations both old and new.

H OW TIGHT ARE YOU?

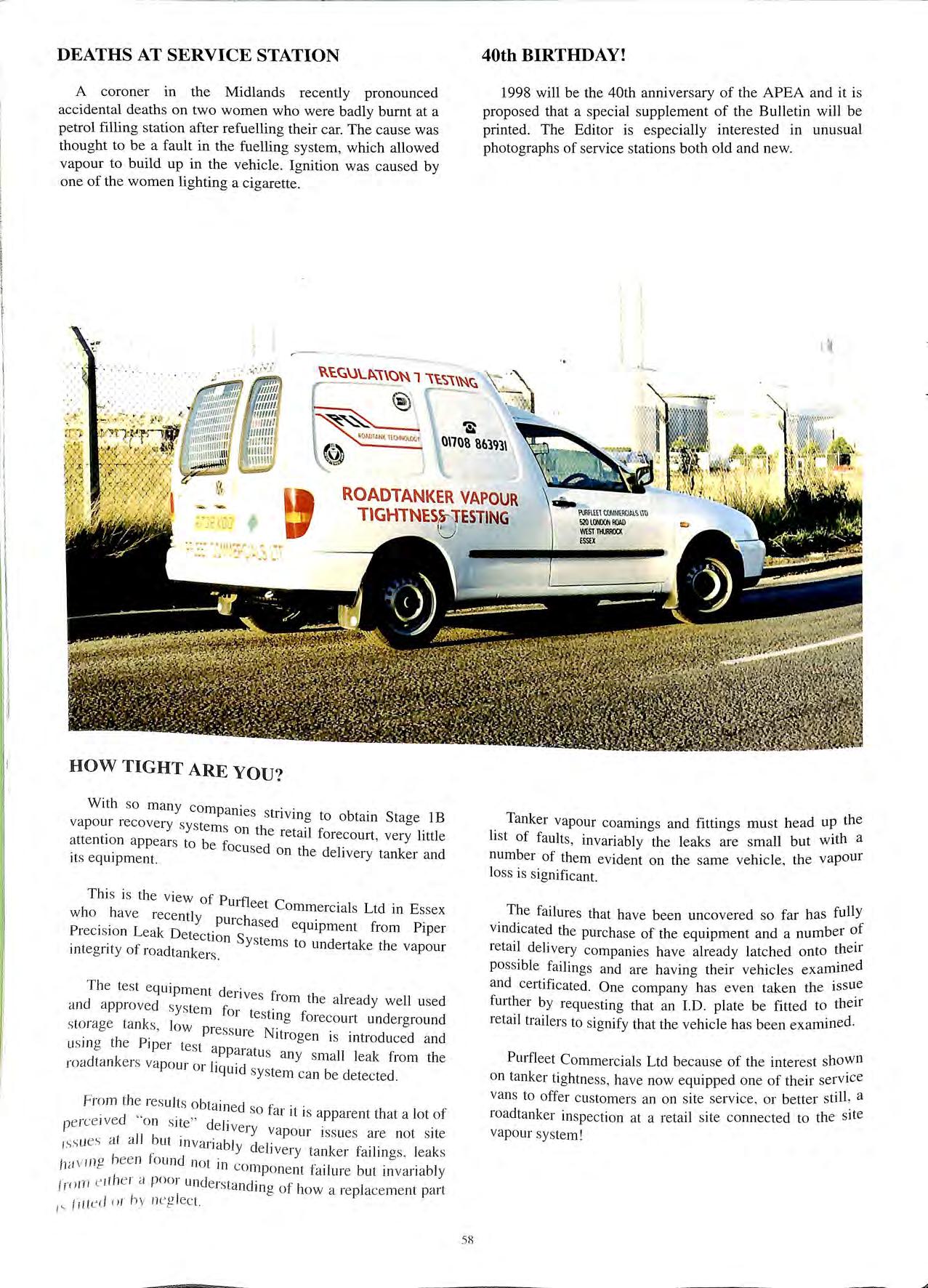

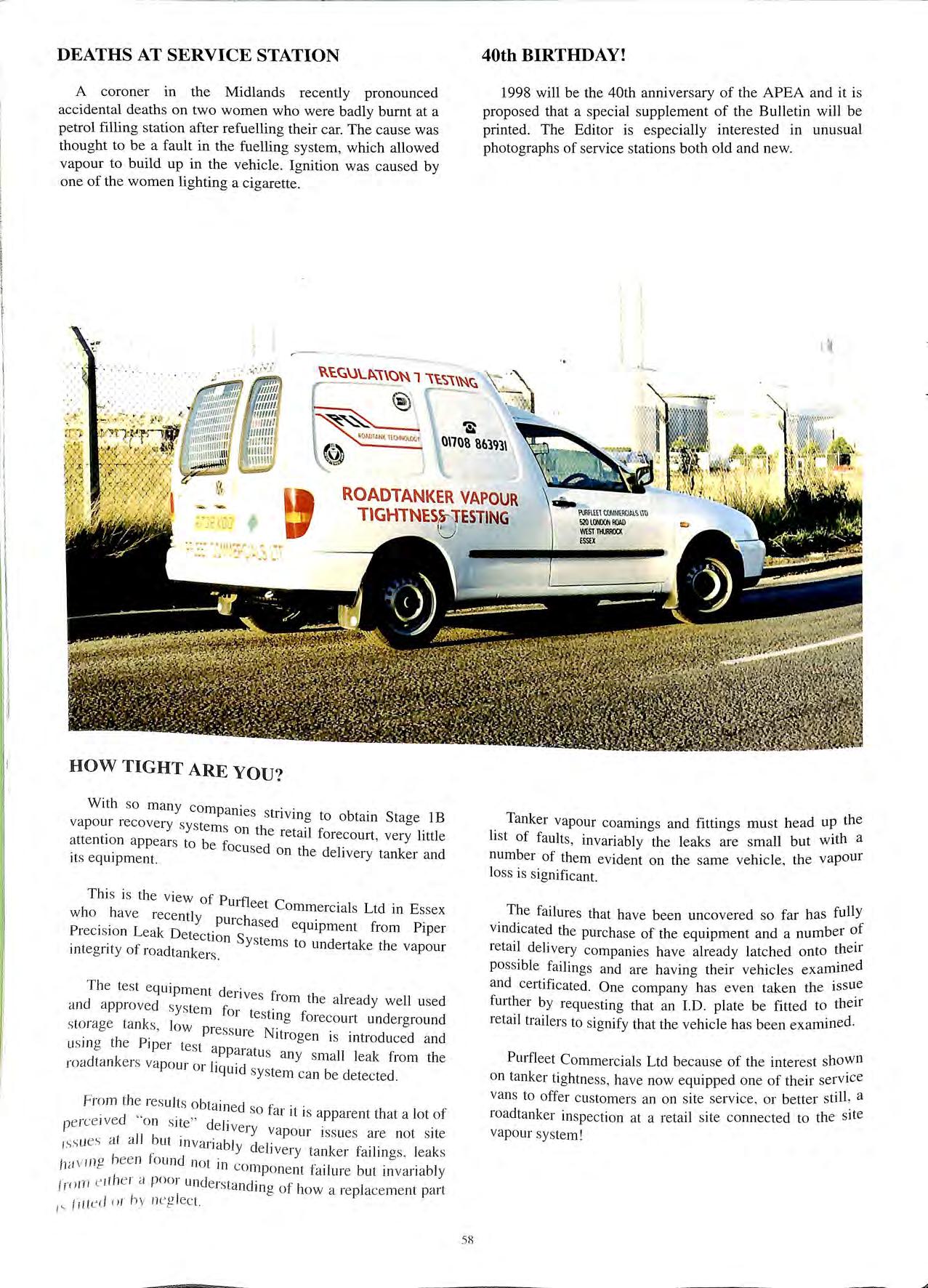

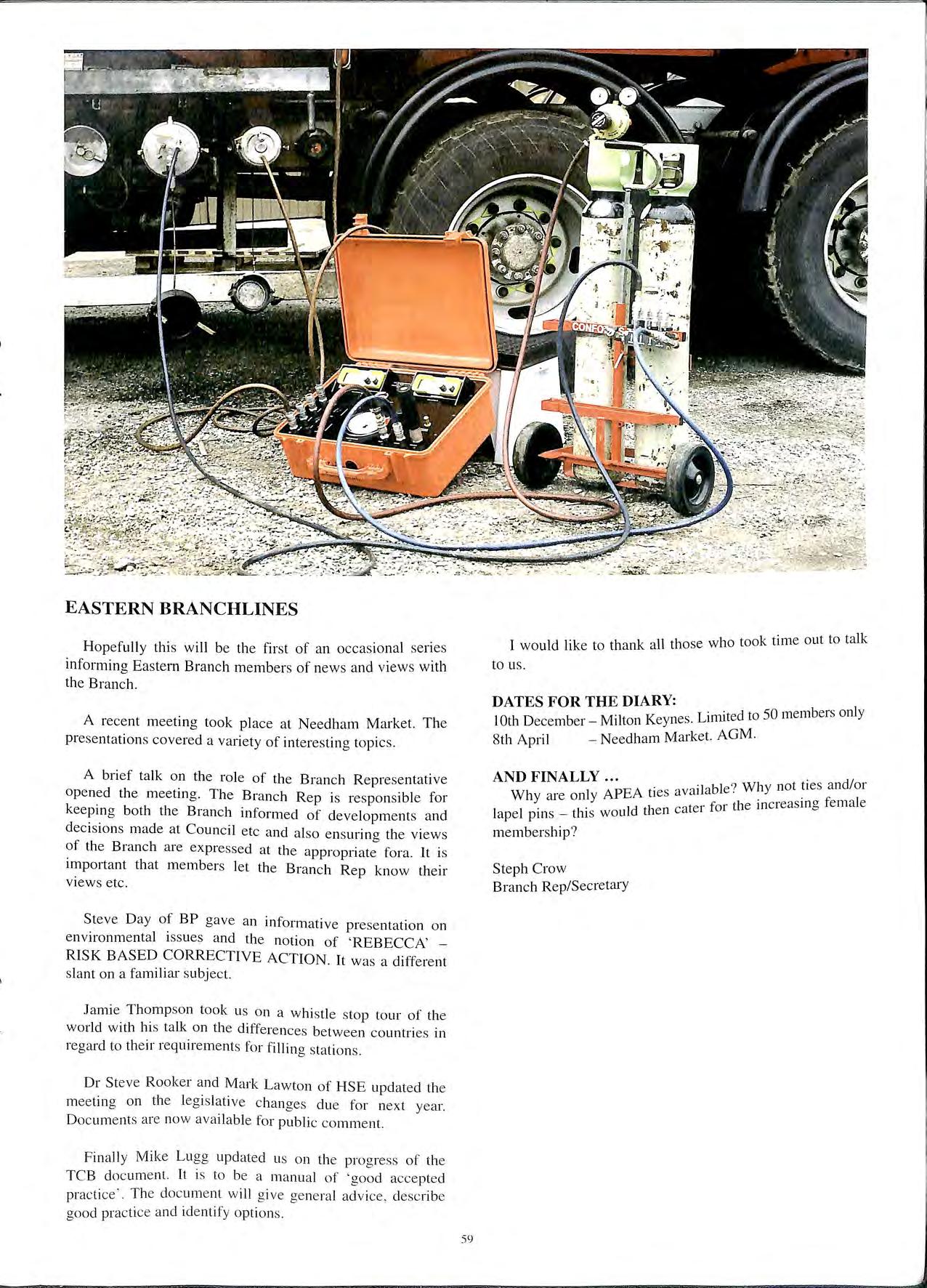

With so many corn · . . parnes stnvma to obtain Stage lB vapour 1ecovery systems b . on the retall forecourt very little attention appears to be foe d . ' its equipment. use on the delivery tanker and

Thi s is the view of Purfl wh o have rec tl eet Commercials Ltd m Es sex en Y purch ased · · Preci sion Leak D t . eqmpment from Piper e ect1on System t d integrit y of ro adt nk · s o un ertake the vapour a ers .

The tes t equipment d .· ei 1Yes from th e air d 11 d and a pprov ed s ·t ea y we use yse m for tes trna f. d sto rage ta nk s, low res b OJ ecom t un erground · th p · P s ui e Nitrogen 1s rntroduced and us111 g e rper tes t ap d k . paratu s any small leak from the roa tan e1s vapour or 1· ·d iqui system can be detected.

Fro m the resu lts ob ta i d . " . ne so fa r 1t 1s apparen t that a lot of ' Je rce 1ved o n s1te" de ]" . . . ive1 y vapo ur issues are no t site a t a ll but rn varia bJ d 1 · · 1 f Y e 1very ta nker failin as leak s 11'1 v1ng Jee n ou nd not in b ' c co mp one nt failure bu t in variably t 111 t' 1t h e 1 · a poor un derst d. 10 · a n 1ng ot how a re pl ace ment part tiued 0 1 h v neg lec t

Tanker vapour coamings and fittings must head up the hst of faults , invariably the leaks are small but with a number of them evident on the same vehicle , the vapour loss is significant.

The failures that have been uncovered so far has fully vindicated the purchase of the equipment and a number of retail delivery companies have already latched onto their possible failings and are having their vehicles examined and certificated. One company has even taken the issue further by requesting that an I.D plate be fitted to their retail trailers to signify that the vehicle has been examined.

Purfleet Commercials Ltd because of the interest shown on tanker tightness , have now equipped one of their service vans to offer customers an on site service , or better still , a roadtanker inspection at a retail site connected to the site vapour sy stem!

I' ,I I I I I :1 l

1'c'1\>I<. •no-:: • , L.. ROADTANKER VAPO UR TIGHTNEStJ ESTING

58

EASTERN BRANCHLINES

Hopefully this will be the first of an occasional series informing Eastern Branch members of news and views with the Branch

A recent meeting took place at Needham Market. The presentations covered a variety of interesting topics.

A brief talk on the role of the Branch Representative opened the meeting. The Branch Rep is responsible for keeping both the Branch informed of developments and decisions made at Council etc and also ensuring the views of the Branch are expressed at the appropriate fora. It is important that members let the Branch Rep know their views etc.

Steve Day of BP gave an informative presentation on environmental issues and the notion of 'REBECCA' RISK BASED CORRECTIVE ACTION. It was a different slant on a familiar subject.

Jamje Thomp son took us on a whi stle stop tour of the world with hi s talk on th e differences between countrie s in regard to their requirement s for filling stations.

Dr Steve Rooker and Mark Lawton of HSE updated th e meeting on th e legi slative change s du e for next year. Docum ents are no w av ailabl e for public comment.

Finally Mike Lugg updated us on the progress of the TCB do cument. It is to be a manual of ' good acce pted practi ce' Th e doc um ent w ill giv e gene ral ad vic e , desc ribe good practi ce and ide ntify option s

I would like to thank all those who too tune ou to us.

k · t to talk

DATES FOR THE DIARY: b . l L ·t d to 50 mem e1s on y IOth December Milton Keynes. mu e 8th April Needham Market. AGM

AND FINALLY···

1 ble? Why not ties and/or Wh . I APEA ties avai a . . y a1e on y t for the increasmg female lapel pins this would then ea e1 membership ?

Steph Crow Branch Rep/Secretary

59

An Economical Alternative to Underground Tank Replacement

In anticipation of new rules being written by the HSE and other jurisdictions, underground tank owners will be faced with the challenge of how best to comply with laws governing the operation of petrol filling stations. Although the primary drivers for choosing a replacement or upgrade alternative will be safety and environmental protection, tank operators will also want to enjoy the greatest return on their tank system investment.

There has long been available a highly economical alternative to tank replacement called "cathodic protection" an electrochemical process which stops corrosion. In fact, the United States Environmental Protection Agency, which has regulated the installation and operation of tanks in America since the early l 980's, gives the same regulatory status to an existing underground steel tank system which is properly upgraded to that which is replaced with a brand new tank, regardless of its age. This means that an owner of an tank system can usually retrofit a cathodic protection system for 10% of the cost of tank replacement.

Experience in Arne · d . nca an elsewhere m the world has proven that existino t 1 k . · o s ee tan s can be economically and effectively upgraded · h . wit cathodic protection. Once properly applied and · k mamtamed, cathodic protection can · undergr?und steel tank systems includino pipeworks JOmts and fittmgs leak f . 0 th ,.. ree, virtually forever at a fraction of e cost ior replacement.

What Is Cathodic Protection?

Steel used to manufis not found · acture underground tanks and piping m nature as . with other ele · a pure matenal. It is combined ments such a . called iron ore ..,., b. . s oxygen formmg a compound · 10 0 tam ste 1 f · is subjected to t · e rom iron ore, the compound ex reme heat d .· h . . break the che 1 lll mg t e refmmg process to mica att, · Therefore the P raclions between the elements. ' 1ocess of tra .· · . . energv to the metal. ns1tion111g iron ore to steel adds

the steel tank : remov111g the e system is buned, nature begms nergy from th · f. · return to its nar e 1e 111ed steel 111 an effort to · 1ve state The energy from a . t·· · PI ocess of nature removing ie ined metal . h corrosion Left h is w at we commonly call unc ecked steel to revert b· ·k ' natute will eventually cause the · ac to Its naf · time the failed Ltr)d .. · ive iron ore (oxide) at which e1g1ound t I . . release of stored p. 1 see t<1nk system will allow a I oc Lict Into the environment.

Cathodic f)l"<>tecti· ,.. on •or ex ·f '>V'ilems uenenfly · ·J is ing underground steel tank tnc udes th . . . . . . . lhc oround IC'tllcd 1 e mstallat1on of electrodes 111

t:- ' <1noc CS) Whi ·h . b d. cu1Tc111 rf)('/ f)OW>-. · c are energ11:ed y a 1rect e1 supply. called , WIJl·n turned on 1 11 a 1ectif1e1 lsee F1gu1e I J. , Silla '11110 f' ' unt o energy passes from the /I'( 11/wr lo fill' illlodes thr ... II I · · ough the soil and onto the tank 1, ''t'lll 11 ;i t"< lhc 1. ;ifhode · 1 rn t i1s elcctncal circuit).

Because energy is flowing to the tank, corrosion stops. Since the tank, or cathode, is protected from corrosion using this process, we call the process cathodic protection.

It is important to note that properly applied and maintained, cathodic protection will keep a tight tank system leak free forever. Therefore, replacement should never be necessary.

Some operators have expressed concern about the ongoing cost of cathodic protection. The cost for electricity for these systems is usually less than the cost of operating a 100-watt light bulb. This means the power cost is less than £60 in most areas of the country. Further, with the implementation of relatively simple remote monitoring devices, ongoing inspection costs become insignificant.

Economics of Upgrading Versus Replacement

To demonstrate the economic benefits of cathodic protection, we present an example of the savings achieved by one operator who chose a corrosion control upgrade program over replacement. This relatively small petrol station operator in the mid western United States owns five sites, each with three 8,000 gallon tanks. He had initially planned to replace his tanks and lines at a total cost of about £300,000, plus the cost to clean up any contamination he might have discovered. He found that he could apply cathodic protection for a cost of approximately £30,000, or a savings of over £270,000!

No Business Disruption with Cathodic Protection Upgrades

Tank replacements are not only a costly capital investment, but also require disruption of service and .a facility, often for several weeks. However, cathodic protection upgrades can usually be accomplished while business stays open. Installation of cathodic protectton devices can be accomplished in one day without requiring any business shut down. This means no loss of revenues or customer loyalty.

Human beings are truly creatures of habit. This is demonstrated by a story recently told to us by a local convenience store operator. During a remodeling progran.1 each of his facilities was closed for 48 hours. Naturally, his regular customers found alternative places to do business during this period. Unfortunately, they did not immediately return after he reopened. In fact, it took him an average of 60 days to recover to his previous business volume after being closed for only two days! Therefore, by upgrading a site with cathodic protection rather than replacing his tank> he gains the added economic benefit of continuing his business. uninterrupted. while the tank system modifications are accomplished

I' ,I

(i(J

Summary

Owners and operators can upgrade their underground steel tank systems at a fraction of the cost of replacement. By properly installing and maintaining a cathodic protection system, underground steel tanks can be kept leak free. Since the rules for the operation of petrol stations allow for the modification of underground steel tanks with cathodic protection, operators can greatly benefit from this economical alternative to tank replacement while assuring a safe, environmentally protective petrol storage operation.

This article was prepared with the assistance of Mr. Michael Baach, Executive Vice President of Corrpro Companies, Inc., the world's leading provider of corrosion control services. For more information, M1: Baach can be contacted at Corrpro Companies, Inc., 1090 Enterprise Drive, Medina, Ohio 44256, 330-723-5082 (phone) and 330-723-0244 (fax).

mkb9344( wpm lad) I 0

RECTIFIER CONN E CTION TO TANK '/, IMPRESSED CURRENT ANODE ' /' ' ij CURREN1 P A1H IMPRESSED CURRENT CATHODIC PROTECTION SYSTEM CAMERON TECHNICAL SERVICES Forecourt Contractors /7 Specialist L.--011ttzact 'We offerpeace ofm/hdstoufiil ..,;. the clock to keep equipment ss'fe sn operations/, with s dedlcsf!!hd aut of hours phone 1/ne wit engineers on standby• .q 1 0 Up to 7 days I week -ffi.. 0 For all your forecourt and point of sale requirement 0 Environmental, emergency and accident expertise c o1 1t tt t Clf{7 7.S. t1'll1:-' l 1. 11 ,>'}" fOICl l'>hiUi711':-." lt' l! \., IC'lit' >!1..."i.' (l/{'(' L'tl H \Hti ft,d f,l l((lf{ /1ti r /i l}\ tel 01226 742441 fax 01226 747441 tl>1d :- 1'111i t.:1·. 61 CAMERON TECHNICAIL SERVICES ll..IMDTED Industrial Estate Platts Common Barnsley South Yorkshi re S74 9SE

New Petrol Legislation - Some Further Thoughts From HSE

Steve Rooker HSE's Flammables and Gas.Policy Division

I hope that most readers will know by now that on 1 September, the HSC published a Consultative Document (CD) "Proposals for new petrol legislation". This contains a set of draft regulations to replace the Petroleum (Consolidation) Act 1928 (PCA) and related legislation dating back to the 1920s. These new Regulations aim to clarify the law on petrol, update it to reflect the way petrol stations operate nowadays, and remove inconsistencies, for example relating to petrol containers. The formal consultation period ends on 1 December and after taking account of all the comments received, the HSC hopes to have the Regulations in force by mid-1998. I'd like to take the opportunity to explain some of the background to the work that has been done, and why we believe that the change is for the better.

Why the change?

The work follows a recommendation in the HSC's 1994 "Review of Health and Safety Regulation". This 1dentif1ed on flammable substances, including as. m need of modernisation, so HSE agreed to review this law. The original intention was to look at all flammables legislation at the same time. But work on nonpetrol areas is now being looked at separately because of the emergency of a relevant EC Directive. The HSC asked us to press on wi'th th 1 e petro review because 1t was a discreet package of legislation and it went beyond the workplace application of most of other flammables

well as the impetus of the I994 report one of HSC's ongomg obje r . ' Ieg'isl t' I ives Is to progressively update old . a ion. thmk mo ·t I . . that th t' . . s peop e m the mdustry now believe e ime is npe tor " h' e1orm t 1s 70 year old leg1slat10n.

In drawing u th with all those . p e HSE has worked closely has b · kmvolved Ill petrol safety. The work on the CD een ta en fo . d b Adv . C rwar Y a sub-committee of HSC's 1sory om ·t · compr1·,.1·ng m1 tee on Dangerous Substances (ACDS) ., represe t· · _ t· 1 · natives from enforcmg authorities the i e a1 petrol industr , D · y, trade umons and Government epartments. '

Main proposals

It goes without s· . h r I h · <1ying t at the need to ensure the safety o I 1e pu lie on or ·1r d r·11· . . ' oun 1 mg stations has been the main rn 11 uence 1n the cl 1 h eve <>pment of the new Regulations. It euune clear earl · . . . Y on in the process that some kmcl of pl'r1JJ1ss11m1ng· sch . . · eme was needed for the safety authority '" \LJIJ\f\ 1lselt that a I · · pet1 o stall on was to be cles1gned and · It'd lo an acceptahle standard hefore it started

operating. So the new regulations propose that anyone building, or making significant changes, a petrol station needs prior consent to do so from the enforcing authority. The consent focuses on the hardware at the site petrol stations these days are such that safety can, to a large extent, be designed in and so we feel it is right that enforcers have the opportunity to check that new operators/owners are putting appropriate hardware safety features/controls into a site. This approach builds on the excellent work done by Jamie Thompson and other enforcement colleagues, as well as the petroleum industry, to develop good British and European standards. It is a tribute to this work that the safety record at petrol stations is to good. It is many years since there was a death from a fire or explosion accident.

We know that an authority will need certain to decide whether it is happy with the proposals for a site, and so the regulations require this to be provided with the consent application. Petrol stations with a current licence issued under PCA when the new Regulations come into force would automatically receive consent, but would ?e required to submit certain details to the enforcing authonty within a specified time to ensure that broadly similar information about all sites was held by enforcing authorities.

Consent for a site as a whole would be granted in perpetuity but significant changes to the petrol station which could affect people's safety would require further consent. The CD proposes that authorities could charge the actual cost of deciding whether to grant consent. Clearly this would be a one-off charge applicable to each consent application considered, and should, we think, include the costs of any visits to the site the authority may need to help its decision on consent.

The initial integrity of a site is important enough,. w_e believe, to warrant a consent scheme as described. but It is not sufficient alone to ensure continuing and long term safety at a site. So the regulations introduce new duties on operators to take reasonably practicable measures to run their sites safely. There are specific requirements to:

• make and record an assessment of fire and explosion risks;

• store and dispense petrol safely;

• ensure equipment no longer in use is maintained in a safe state or made permanently safe:

I 11 1: H 1; ii '1 'i

62

• ensure petrol is unloaded safely from road tankers -a schedule to the Regulations simplifies and clarifies the current procedures in the Carriage of Dangerous Goods by Road Regulations 1996; • provide means to detect petrol leaks, either by wetstock reconciliation techniques or leak detection equipment; and

• maintain in a safe condition equipment for unloading, storing or dispensing petrol.

What is reasonably practicable to do depends to an extent on the circumstances at individual sites. It involves deciding whether the cost of a measure (in terms of time, trouble, expense etc) is in proportion to the risk being considered.

There is no justification these days for treating workplace storage of petrol any differently from other highly flammable liquids, so there is no special control in the new regulations over things like can stores at factories or other. The Highly Flammable Liquids and Liquefied Petroleum Gases Regulation 1972 would be amended to cover storage of petrol.

The draft Regulations do, however, contain some controls over the storage of petrol at domestic or private premises, with the limits on quantity remaining broadly the same as those in the existing legislation. We hope, however, that the requirements are much simpler and easier to understand than at present. Similarly, controls over petrol containers would also be simplified and clarified.

Enforcing the new Regulations

The combination of a consent scheme and general duties to run a site safely provide, we believe, a sound and sensible framework to regulate safety at petrol stations. The initial consent phase provides enforcers with the security of knowing that a site has adequate hardware arrangements in place before it starts operating. And the ongoing duties on the operators provide two main things. First, they make it absolutely clear that the responsibility for a safe site rests with the operators. And second, they provide the legal means for enforcing authorities to ensure that all relevant aspects site safety are adequately managed. Where are found, the powers that can be exercised by mspectors make enforcement of adequate controls (ie those that are reasonably practicable) a straightforward task. This will bring petroleum enforcement into line with most other health and safety at work legislation. It represents a more flexible and proportional way to deal with shortcomings at petrol stations than the current practice of altering licence conditions at renewal.

Appointed safety inspectors can be given powers under the Health and Safety at Work etc Act 1974 to carry out inspections, give advice and guidance and, when necessary. take enforcement action such as requiring improvements. stopping unsafe practices and prosecuting where appropriate. Rest assured that powers under section 20 of the Health and Safety at Work etc Act 1974 have provided a very successful enforcement framework for most health and safety enforcers for more than :w years now. as can be seen

from the fact that Britain's safety record is amongst the best in the world.

The proposals keep the allocation of enforcement responsibilities where they are now. This has been proposed on the basis that it will maximise existing expertise in local authorities, although we all know that local government reorganisation has and will continue to affect enforcement arrangements.

Guidance

As with all new laws, parts of the text of the regulations are necessarily written in legal language so we will publish a guide to explain the law in simple terms. A first draft of this has also been out for comment during the consultation period. And because the Regulations propose a fundamentally different approach to the way petrol stations are regulated, with a significant new element of general duties, HSE is also preparing some practical guidance on managing fire and explosion risks. This will contain good advice and information on a whole range of practical issues to do with managing safety at a petrol station. There will be guidance on ways certain activities can be carried out which, in the view of HSE and others who have helped us put the booklet together, constitute reasonably practicable measures and thus compliance with general duties. It is aimed at petrol station owners and operators, but will also be of interest to others in the industry, and we would hope and suggest that inspectors will refer to it as illustrating good practice. Although only guidance we hope that it will provide advice on most of the significant issues at petrol stations and will become an accepted reference document. As a final piece in the jigsaw, a leaflet for the public will also be produced to raise awareness of the dangers of petrol and give advice on how to dispense it and store it safely at home.

Consultation and beyond

.

There is still time to send us your views winch need to b . d b 1 December We have already begun e receive y · analysing the comments received so far, and to 1 t the ACDS sub-committee 111 revised proposa s o D b 'tl f1'11al draft Regulat10ns going to the ecem er, w1 1 Commission in February I998.

6.1

Petroleum Legislation: Is It Being Spirited Away?

By Nigel Hester BA (Hons.), MBA, C.Chem, MRSC

Petrol is unique, paradoxically unique!

According to the IP annual retail survey about 25 million tonnes of petrol are delivered each year in the UK. That equates to roughly two litres per day for every man, woman and child in this country.

Any car driver may fill a typical 50 litre petrol tank and then drive off, quite legally, with a several more litres in a plastic can in the boot.

In enter any laboratory (be it university, mdustnal or public service) and it is likely that no more than 5 litres of petrol would be found in a metal container with spring-loaded closure. Moreover, qualified scientists and technologists are required to wear overalls, safety goggles (in some labs a full face visor is obligatory) plus gloves and to d1"spe 1 · . nse petro w1thm the confines of a fume cupboard. If not th H 1 h e ea t and Safety Officer may become apoplectic!

This is the paradox Th 1 b . . 1 1 · e genera pu he with very 1tt e knowledge of its p · ' th 1 ropertJes, may effectively take home with ( ehm a arge quantity of petrol. But trained technical staff w o are well aware f th d , take sti·i· . 0 e angers of this material) must · ngent precautJo · h th ns Wit a relatively tiny quantity of e very same liquid. Why?

The following ext f d racted information may be typically oun in any Oil C unleaded petrol: ompany Product Safety Data Sheet for

'Risk Phrases

Rl2 Harmful if swallowed

R38 Irritating to skin

R45 _May cause cancer (category 2 carcinogen)

Exposure limits e Benzine N H xist for the following ingredients: ' - exan .,., 1 e. 1 0 uene, Xylene.

Extremely flam1nab can readily ex <flash point minus 40°C) which plode in pre , f . . fl impingement sence o 1grnt1on or ame on container.

Prolonged and fating of sk. repeated skin contact can lead to de, in and dermatitis.

Accidental ingestio1 "' I he mouth. 1 cc1n lead to chemical hurnrng of

Pl'lrol is classified . . . . . , ·f< L'I< as d,mgcrous to the environment.

I ,,,, ·111p/,,1,,·rl asap t· 1 e 10 eum Inspector hy a Local

Authority. Previously I worked, for nearly 30 years, in technical service laboratories (unconnected with the petroleum industry) and therefore was already familiar with the chemical properties of petrol.

Present most people with a petrol Safety Data Sheet, but without naming the product it describes, and few would wish to go near the liquid without adequate protection, let alone come into contact with it on a daily basis. Health and Safety representatives would find themselves very busy handing out advice and information.

Here we arrive at the central problem to which this article is addressed. Namely that it is proposed to drastically alter existing Petroleum Legislation, including ending Licensing and replacing it with regime of consent.

In my view the proposals represent a weakening of Petroleum Legislation. Further, I contend that licensing must continue.

Give the problem to an unbiased jury and the solution may well be to recommend discontinuation of petrol as a fuel on the evidence detailed in the aforementioned Data Sheets. However, for various reasons, that will not occur and we will continue to use this potentially highly dangerous liquid for many years to come. Therefore, surely it is in everyone's interest to maintain the present tight controls over petrol storage and usage?

Is it not the least the public can expect that ever.y possible precaution is taken (and enforced) for their protection against a potentially lethal material they know little about?

Up until now this public protection has taken the form of the Petroleum Consolidation Act and is part of the triumvirate consisting of legislation, licence and inspections which together have, I maintain, helped to ensure the reasonably safe storage and dispensing of petrol for many decades.

Why the call for change? The nature of the beast has not changed much with time. True, additives are now sophisticated but petrol still consists of highly volatile aliphatic and aromatic hydrocarbons just as it did in 1928 ! <Alcohol-based fuels will still be highly flammable and may not be a viable alternative if too costly.)

There is no doubt that filling stations have changed almost out of recognition especially with regard to the technical improvements in hardware and operational systems. However. in my opinion. the improvements are countered hy the tremendous growth in self-service.

ii ' ''I i

'I .J

astronomical rise in numbers of vehicles and larger tankage which, in many cases, now runs into hundreds of thousands of litres.

The throughput of these big sites is commonly several million litres per year with vehicle queuing during peak periods. Speed of service is definitely the key to increase takings. Taken together these factors indicate to me that the modem filling station is potentially a much higher risk than the small, leisurely, attendant-served version of an earlier era.

I will categorically state that I think it is a tribute to this Country that the Petroleum Act has been in force all these years. (One hears horrendous stories of petrol being dispensed from open drums in third world countries. Their citizens may well envy our legislation.) Granted, some of the wording of the act now appears antiquated but its basic, essential supposition, that petroleum spirit must be fully regulated to ensure safe storage, is just as relevant today as it was 70 years ago.

The Act has stood the test of time primarily because it is an Act of common sense.

The very existence of Licence Conditions allows me, in my capacity as a Petroleum inspector, to discharge my duties effectively. I am on forecourts daily and have yet to meet a licensee who does not agree with the principal of licensing petrol storage. The most common reason given is that they are aware of its dangerous reputation. One site operator graphically explained to me 'I Jive next door to the filling station and don't want the thincr to b blow up!'

Most licensees agree the system is fair as it applied to their competitors, is relatively straightforward to adm1111ster and serves as a reminder of their lecral obligations towards this familiar yet malevolent product. 0

accepts rules in sport. Licence conditions are basically a set. of rules. So why not accept licences in the much more senous business of retailing petrol?

Occasionally members of the public will contact me about some aspect of a . · · p1em1se and generally I am able to assure them that it meets t· · sa ety standards simply because a Licence Con?ition Inspection has been carried out and recorded on file.

I also deal · h · Wit site contractors and here again, the benchmark afforded b h . ' Y t e Licence at least reassures the concerned Petroleum E ,,. h. 1 h n° 111eer that a fillincr station (on w 1c 1 e nny ha e . . ' . . . ve can-y out potentially hazardous w01 k) meets ce1 ta111 basic s·tl'et · ·' Y cntena.

From a Public Relation . . . f s v1ewpo111t alone. even the laraest o company-owned e conglomerates should not be totally opposed to licensing petrol stl)J·ao-e A 1 1 f'I · 'e 11g 1-p1 o 1 e. Natwnal presence. via instantly recocrnised pl)le .·,7 • "" implies a collect1ve responsibility to ensure the s<:i'est possible working environment for staff and customers alike.

Which raises yet another question. Who actually is in favour of discontinuing licences? My experience appears to indicate that it is probably not those people involved ed daily at the blunt end of this industry (i.e. those closest to the product).

' when you have eliminated the impossible, whatever remains, however improbable, must be the truth?' Sherlock Holmes' logic in this case seems to eliminate all but the legislators themselves! This reasoning leads me to the conclusion that the main impetus towards Licence discontinuation must surely be political.

When one considers the enormous number of vehicles on our roads and the fact that the IP tonnage (quoted at the beginning of this article) converts to 33 BILLION LITRES of petrol dispensed per year, then the inescapable conclusion is that the vast majority of people are frequent customers at filling stations.

The Oxford Dictionary defines 'Public' as 'Of, Concerning, the people as a whole.'

Each and every one of us, including senior civil servants and politicians, are members of that 'public'. Chauffeurdriven Chief Executives may well occasionally pull onto a 'public' forecourt.

I have one advantage over most people. When I fuel my private car locally I know those filling stations are up to standard because I have personally inspected them! When I (and my family) travel I am similarly consoled by the knowledge that, at present, any public filling stati_on, wherever it may be located in this country, is also subjected to the clauses of the Petroleum Consolidation Act. I am effectively U th do on me) to ensure relymg on my colleagues ust as ey _ . . L' Condi"t10ns and hence are that hllmg stat10ns meet 1cence operated safely to ce11ain basic, conm10n standards.

f k 'ngly fill up at the sub-standard Would any o us nowi ? ·t· II 'f h'ldren were in the car. Even I one forecourt especia Y 1 c 1 Id b has a vehicle the changes are you wou e next to a petrol pump.

1 'tself of 'Licensing' which is old- Is it the pnnc1pa 1 · h. k t ls my attitude to hcensmg out of fash10ned? I t Ill no · · · · 1 Th ·e ·ire specihc tm ms ol hcensmg date? I hope not. ei ' · · f" le would describe c1s contentious. which very ew peop , , · . . h ·t cre of explosives and the kecpmg of mcludmg t e s orn"" · ·

1• Other licenses. whilst bemg mme dangerous amma s. , , theless e·isy to JUSlify on public p10tect10n crenenl ·ire neve1 · · ' · "' ' ' ' E . les include those for Public (that word arounds. x,unp · "" · E ·t· ·n111ent p·irticularly tor cmemas. theatres aoam !) nte1 ,u · ' " 1 b F of us would risk even the lmmhar 'tnp- and c u s. ew · I l b Y 1 ·t· the boatman was not licensed. rount -tie- a

At the time of writing. fireworks night is not far off. Ao-ain who would question the wisdom of slackening over fireworks? In reality that lcgislatinn is actually heing tightened as each Novcmher passes. (One might briefly mention here the chrc consequences nf attempting to light the bonfire with petrol. l

65

No, I am adamant. To my mind licensing is a necessary and fully justifiable means of controlling certain aspects of human activity that, by their nature, possess inherent risk to life or limb. If a person, or company, enters any business associated with potentially serious risk to the public then controls must be accepted as part of carrying out that business.

Maybe it is the mere presence of legislation any legislation that upsets certain people? Possibly there are some licences which are contentious? Pleasure-angling and the, now defunct, dog licences are certainly debatable issues. Some licences may be forms of revenue gathering for the exchequer although, plainly, that is not the case with that of petrol where the current maximum fee is just £90; the receipts being used to cover administration costs. (Compare that to individual car licences and the ultimate fate of that huge sum!)

Imagine the outcry if it were suggested the Explosives Act be repealed. But is not petroleum vapour, when in admixture with air in concentrations of about 1-8%, explosive? Is not petrol a favourite weapon of the arsonist?

An argument cannot be based along the lines that just because other industries are being deregulated so should petroleum. If discontinuation of petroleum licensing is part of an across-the-board approach to deregulation then surely we run the danger of casting the proverbial 'baby out with the bath water'· Safety issues must not be allowed to become a subject of political points scoring.

I am not in this arti"cl · · h . . . ' e, gomg mto t e mmef1eld of nsk- gradm<>. My argument h b s ere are not diluted m any way by, companng the nsk of falling off a fairground ride with filling a car with pet I N . . . ro · or am I prepared to be involved with statistics One pe k"II d . . . . · rson 1 e or Illjured by falling off a fairground nde or · th h m e process of refuelling or through w atever cause, is one too many. '

THE CRUCIAL c RITERION IS THAT WE HAVE TO LEARN FROM EXPERIE fact that p 1 NCE. We must never forget the F ·th eop e suffered through accidents in the past. u1 er, some of th . . Preventable g· h mc1dents may well have been iven t e mcrea d k I . . . affords. se now edge which hmds1ght

Fortunately humans are , bi causes of ac ,·d · a e to analyse and record hkely c1 ents. Usually a d , II serious cases . ' n espec1a y m the more , recommendations " result in Statut< L . . · aie put 1orward which may >ry eg1slat1on bei d · d . to prevent 1 rep t f ng passe m or e1 to try ' ea o a tragedy.

Effectively. the conse , llemocncy) d · nsus <which 1s as it should be in a ' eems that s ) + , ·<me 1orm of public protection 1s ni:cessai y 111 order that th . k , , e ns to future participants from thal sowce 1s mmuni. d S . se · omet1mes where mandatory c< 1111rol 1s deemed nece . ., . h' ' ssa1 Y t 1s has led to the system we know as licens1ng·.

Past cxpt:Tience is e · · ncompctssed 111 present leg1slat1on.

I propose lo mention a few matters

which I do not think have been fully addressed by the proposed changes but which are adequately catered for under existing legislation:

(1) Electrical test certification. At present a valid electrical test, carried out annually by a competent electrician, is necessary before a licence may be issued. With no requirement to licence what provision has been made for electrical testing. After all, sub-standard electrics are a significant and obvious potential source of ignition.

(2) Closure of sites. Temporary or permanent closed sites are at present monitored. How are we to ensure that tanks are continued to be made safe in an acceptable manner and that a register of decommissioned tanks is maintained to meet future enquiries? Old tanks are decidedly a serious hazard unless officially confirmed as totally safe.

(3) Inspections. Without a legal requirement, or unless adequate funding is maintained, authorities may no longer be in a position to insist on pro-active, periodic inspections of filling stations. In that event how long may some defects go undetected before leading to a major problem? What of the quality of work carried out (either by contractors or proprietors) on forecourts? Who will ensure in an unbiased manner, that adequate standards are maintained?

(4) Risk Assessment. Initial risk assessment may be carried out in conjunction with Local Authorities but without occasional, official checks how can one be sure the assessment is kept up to date? Changes occur over time which influence associated risk (e.g. new tanks, enlarged shop area, change of use of adjoining premises etc., etc.).

(5) Licence details and conditions. One of the first questions asked by a prospective purchaser is 'Does the filling station have a valid, current licence?'

The licence itself is a factual, administrative document which contains much information including:

Ownership details. (These aid keeping track of changes via the 'Licence Transfer' systems. Also, a few sites still retain 'No Transfer' clauses.)

Licence quantity. (A record must be kept of total petrol stored at a given facility.)

Number, capacity and fuel grades of each tank. (With this statement one can tell at a glance if petrol has been dropped into old, disused or even unsafe tanks, which may possibly have had filling points too close to occupied buildings or some other defect. In addition, it will be obvious if diesel, or paraffin, or heating oil is being stored in a tank previously designated for petrol.l

Definitions and general conditions. (The licence is a authoritative reference book, especially commendable for staff who may be unsure of petoleum regulations.)

Special conditions. (These appertain to a specific site and usually have been added for a very good reason.)

ji ,, ,1 1' i'

I 1,i H,; ii'' 1 I I 'L1 :1 i· ; 'i I '

i jl ,1

I

\J 11 v. '"

....

A licence conveniently encompasses all the above useful knowledge. Without a licence what will become, in particular, of those important Special Conditions and how will they then be impressed?

Withdrawal of licensing consent is, at present, the ultimate sanction should standards deteriorate to an unacceptable level. Conversely, satisfying all licence conditions may be taken as an indication that a site is well run.

It may be concluded, thus far, that it is because I am a Petroleum Inspector that I think licensing should continue! Undeniably, human nature contrives to make impartiality very difficult when one is closely involved.

Yes, I am very concerned about the outcome of this issue but then should not everyone else involved with petrol?

The question over proposed changes is unlikely to entail a public referendum. The main protagonists are petroleum professionals and the legislators. As far as I am aware, there has been no National poll of licensees, or even a survey of forecourt customers, to gauge their response.

If this issue is to be debated and settled out of the public eye then those who are closely involved must carry full responsibility for their actions. Although they are unaware of the fact, very many people are therefore relying on us to get it right Lives may depend on it!

I am aware that many months of consultation have already been conducted into the future of petroleum legislation and it may seem heretical to question the wisdom of my peers at this late stage in negotiations.

However, after considerable thought, and extensive discussions with filling station operators, I have been forced to the conclusion that removal of statutory requirement to licence will ultimately prove to be a retrograde step.

The proposed 'consent' approach does not completely cover the duties as presently cmTied out by Local Authorities. My main concern is that loopholes in the proposed alternative regime will be exposed in the form of an increase in serious incidents. The old adage 'better to be safer than sorry' is never truer than in this context. Loopholes have been known to be exploited!

The current legislation aims to be preventive whereas, I submit, suggested replacements are likely to punitive only after a calamitous event.

It is an unfortunate fact there are people who need protecting against themselves. An inconsiderate minority can cause a disproportionate amount of dan o-er to an b unsuspectmg 1m1Jonty. Human nature is such that complacency often accompanies familiarity and is it not possible for safety measures to be overlooked by complacency (or, indeed, by ignorance of hazard or a blinkered approach to profit)?

Any proposed changes to the Regulations which are not coherent will lead to confusion. Risk assessment, for example, lends itself to varied interpretation, Co-operation between proprietors and inspecting officers is more conducive where legislation is clearly defined.

PETROL IS UNIQUE. It is the only highly flammable substance with which the public deal with in large quantity. Therefore, I am totally convinced that repealing or drastically amending existing Regulations is detrimental to the safety of the vast number of fellow citizens who regularly have to fill their vehicles with which is, primarily, as the data sheets categorically confirm, a potentially very dangerous liquid.

I am in complete accord with Nigel Griffiths, then Opposition Consumer Affairs Spokesman, when he was quoted, in this very journal, as stating: 'The reason why there have been so few explosions or incidents involving petrol is testimony to the effectiveness of the present licensing system. Now Ministers want to throw all this away and put the public at risk.' ('The Bulletin', Vol. 35, No. 1, P.l, February 1997.)

There is still time for a reconsideration. It is not inevitable. Only Parliament can repeal the Petroleum Act and that must not occur by default. We need the letter, not just the spirit, of the law. The present Regulations are substantive and contain indispensable, fundamental principles. By comparison, the alternative is a blunt instrument with ethereal qualities.

My conclusion is now apparent

'KEEP THE LICENCE: ACT WITH COMMON SENSE'

If we do then it will be a triumph over appeasement. If we do not then we may well be fuelling tomon-ows' catastrophes!

NOTE: The views expressed in this mticle. are entirely h d do not in any way, imply or are those of the aut or an • . . t the policy of Cornwall County Fire mtended to rep1 esen , Btigade.

67

Electrostatic Hazard - Fact or Fiction

Graham Hearn Technical Director of Wolfson Electrostatics

In the winter of 1992 a small explosion and fire occurred on an automated process line in a fibreglass mouldings factory just outside Quebec City, Canada. Due to the widespread use of solvents during manufacturing process, the fire quickly spread resulting in the destruction of the entire factory and around $2 million worth of damage (I).

The initial investigation into the cause of the fire yielded few clues. The burning solvent had a flashpoint of 31°C well above the ambient temperature recorded in the factory on the day. The moulding process was purely pneumatic and there was no electrical power source nearby. The process was robot controlled and there were no operators present during the ignition.

Around the same time in Europe similar, initially inexplicable, events were occurring[2]. Between 1992 and 1995, officials in Germany were notified of 36 fires during the re-fuelling of cars at filling stations. Similar incidents happened also in France, the United Kingdom and Ireland.

detailed examination of the events surrounding these mcidents uncovered an interestino- similarity both the factory fire and the · · f h 0 . ma.ionty o t e car refuellmg fires happened dunng cold dry winter months.

In view of the absence of b . . .. any o v1ous 1gmt10n sources there 1s always a tern t t" P a ion to attnbute such incidents to paranormal activity In 1 "d t"f" d . · actua fact specialist mvest1gat1on 1 en I 1e static ele t · · c nc1ty as the ignition source in all cases.

In the investigation f f" f f I d s 0 ires and explosions the source o ue an oxygen are ft , may be in the 0 en readily identified. The fuel orm of a flamm· bi . dust The 1·nve t. . a e gas, vapour or dispersed . s igation m h the fuel was r 1 d ay t en tum to determining how . e ease or how contact with the f 1 0 oxygen or air came mto of these accident u_e · other hand, in only about 50% be determined can the source of ignition any degree of certainty[3J.

Generally, in any indu short list of possible i n· situation there is a relatively are: g Jtion sources to choose from. They

• Thermal s .'ources such as fl· heating, etc. · ame, hot surfaces, self

• Mechanical sources s h . , . . _ · uc as fnct1on and impact.

• Chemical so · urces such as exothermic a11d thermite reacllons.

• f }c'< lncal -;ources su ·h · · 1 1 · · c as static electricity and sparks / rnlll '. n Inc a apparatus.

<if ;JI/ 'lln<' 11 is elect · · · rostatJCs which 1s the most

insidious. Static electricity is the unwanted by-product of many modem industrial processes and can accumulate unseen until discharges in the form of highly energetic sparks are produced. It is also an unfortunate fact that when an electrostatic hazard does become apparent it is often too late to prevent the consequences.

In the case of the factory fire, the fibre-glass and resin spray application system used in manufacturing the mouldings was found to generate high levels of electrostatic charge as the fibres were cut. During spraying this charge accumulated and migrated to an unearthed metal can which had been cleaned in solvent (toluene). The metal acquired a potential and sparked across to the nearest section of earthed plant. The solvent ignited immediately, heating the styrene based resin to above its flashpoint which in turn ignited.

In the case of the vehicle fires, a variety of electrostatic charging mechanisms were identified including fuel flow and human body charge. In all cases, however, the generated static electricity was transferred to an unearthed conductive object which in turn produced a spark to ground.

How hazardous are electrostatic discharges?

Electrostatic charge can be generated in numerous ways. The flow of fuel through pipework is an example particularly relevant to the petroleum industry. Once generated, electrostatic charge can easily be retained for several hours or even days on synthetic materials or unearthed metal work.

For static electricity to pose an igmtlon hazard, an electrostatic discharge must occur. Common types of discharge encountered in industry are the spark, brush and propagating brush all of which are capable of igniting sensitive flammable vapours and dust clouds.

Electrostatic sparks can occur from ungrounded metalwork such as a section of plant which has become charged. Since human skin is relatively conductive, personnel such as plant operators can also give rise to energetic spark discharges if they become isolated from electrical ground by synthetic footwear or flooring. Spark discharges can be high in energy and easily ignite airborne dust and solvent vapours.

Brush discharges occur from highly charged insulating surfaces such as plastics and are limited in energy to a few millijoules. Being of lower energy, this type of discharge is considered less hazardous than the spark. Brush discharges can ignite flammable solvents, fuels and sensitive dust clouds.

f i I· l\

I:

!

68

A propagating brush is a lightning type discharge which can occur under extreme conditions from plastic or glass lines vessels and pipework. This type of discharge can be extremely hazardous in terms of igniting power and physiological shock.

In Europe, it is believed that 8-11 % of all serious industrial fires and explosions are attributable to static electricity. Statistics also indicate that the vast majority of these are spark discharges from ungrounded metal rather than brush discharges from plastic.

Electrostatic Charging ill Fuel Systems

Fuel Ignition Characteristics

It is possible to pass small electrostatic discharges through an explosive or flammable gas without producing ignition. When the spark energy is increased, a threshold energy level is eventually obtained at which the spark becomes incendiary in the sense that a combustion wave propagates from the spark through the volume of gas. This minimum ignition energy (MIE) is a function of variables such as the parameters of the flammable gas, the nature of the electrostatic discharge and the configuration of the spark gap.

The minimum ignition energy of hydrocarbon vapours including petroleum spirit varies significantly over their flammable range. Many of these gases behave similarly in this respect and are generally flammable over the range 1-13% by volume in air. Figure I illustrates this variation, this time as a function of fraction of stoichiometric percentage for various hydrocarbon gasesl4].

It can be clearly seen from this figure that all of these substances have a minimum ignition energy of around 0.2 milliJoules and that the ignition energy increases rapidly as the lower flammable limit and upper flammable limit are approached. It should be noted also that the minimum ignition energy of each gas does not correspond with stoichiometry.

Hydrocarbons are often involved in fires and explosions their low ignition energies. It is possible to generate sufficient ene_rgy for ignition by vigorously rubbing a large sh_ee_t of plastic from which electrostatic discharges of a few milhJoules can be produced. A burning match on the other hand can generate up to I00 Joules of thermal energy per second and is therefore significantly more hazardous as an ignition source.

As the spark energy is increased beyond the MIE value, the probability of ignition also increases. It is important that ignition tests on flammable materials carried out in specialist laboratories take account of this 'statistical' effect.

Electrostatic clwrging i11 fi1el systems

Studies at the University of Southampton[5 I and elsewhercl61 have shown that electrostatic charge is

generated in fuel being pumped along pipes constructed either from metal or insulating plastic.

The charging process arises from the presence in parts per million (or billion) of ions in the fuel. Positive or negative ions selectively attach themselves to any interfacial surface in the fuel, such as the inner wall of the pipe, due to a combination of the following:

• Electrostatic image forces if the pipe wall is electrically conducting (one polarity being held more strongly because the ion is physically smaller).

• Selective chemical adsorption effects.

• Ionic injection from the pipe wall.

As a consequence, the inside surface of the pipe (and any other interfacial surface) acquires a uni-polar charge and ions of the opposite polarity in the fuel are attracted to it. A charged layer then extends from the wall into the fuel. o.f a thickness that increases with decreasing fuel conductivity, although the net charge in the pipe is zero when the fuel is at rest.

When the fuel flows, the ions in the charged layer tend to be carried aloncr with the fuel, while the opposite charge on the wall dissip:tes to earth at a rate depending primarily on the wall material's resistivity. An electrical current called the 'streamincr cmTent' is therefore associated with the flow of fuel. Its 0 magnitude depends upon the · · s in their d1ffus1on between the positive and negative 10n , rates to the pipe wall, and their adsorption rates onto · d end on the fuel s wall. These properties m turn ep h . · f s together with the conductivity and flow c mactens 1c , wall's dimensions, conductivity, chemistry and surface roughness.

1 . the streamincr current reaches a In a long meta pipe, f h cr cr:neration equals the steady value when the rate 0 c ar.,e 0 • ' th Typical values are rate at which charge d1ss1pates to ear · h , A filt rs valves or ot er I()-7 to 10-10 Amperes. ny 1 e ·' . _ ll increase the streammg cunent, constnct1ons will geneia Y · · I -f 1 . f . l clrnrcre separat10n, lug 1e1 ue d to crreater mter acia e ue o ' I s· 1iJarly the presence velocities and increased turbu ence. m .' ., f. 1 , increase the cun ent to seve1 .tl of free water m the ue can .· _. cr f. cl t the charcre separation a11s1110 10111 microAmps. agam ue 0 ' 0 • • · • F . · 1 of the emuls1f1ed mrxtmes. 01 the laroe mterfacia are.i 0 • ·t . ere tank the concentrat1011 of fuel entermg a s 01 a., ' · . 1 . . t oduced is oiven by the radio of the electrostatic c rn1ge 111 r 0 streaming current to the volume flow rate.

t t belnviour of fuels in metal pipework is The electros a re ' II derstood and covered 111 some detail 111 re·1sonably we un · '· · · 1 St i·ii·d <;958171. In contrast, the charge levels the Bnt1s 1 am' · · . . · ·tri·r·e11ts developed 111 piastre and other and strcammg L · · · , denend markedly on the rnner wall rnsulatmu pipes t , chemistr;, and usually cannot _he predicted tor.· new pipe · I Hl)wevc1· 1"11 such pines. tht' strean11ng current matena s. · · t . . · d b d"res··I 11etrol and other rnsulatmg tuels 'of carne y · · · \ conductivity less than 200 pS/m) may with flow time. because charge cannot easily d1ss1pate to earth. and instead accumulates on the inner pipe wall. This charge then opposes further charge separation at thl' wal I.

No electrostatic fire & explosion haz rd.

No No No

Are flammable atmospheres present? es

Is static electricity generated? es

Can electrostatic charge accumulate? es

Can electrostatic discharges occur? es

No Is the discharge energy sufficient to cause ignition? es

Electrostatic fire & explosion hazard present.

Flammable vapours , gases , aerosols & fine dusts. Explosives & pyrotechnics.

Friction, contact , separation High voltage supplies , etc.

Insulating materials , isolated conductors, the human body Spark, brush & propagating brush discharges

Figure 1: ELECTROSTATIC HAZARD ANALYSIS FLOW CHART

Electrostatic Discharge Rupturing Fuel Pipe & Igniting Vapour

nr

Compare discharge energy with minimum ignition energy of flammable atmospheres

70

It follows, therefore, that plastic pipework will generate less electrostatic charge on the fuel than its metal counterpart due to the reduction in streaming current. This may come as a surprise to many who often associate static electricity problems with insulating materials such as plastic.

But what happens to the charge built up on the inner wall? One concern with plastic fuel lines is the possibility of electrical breakdown of the pipewall due to the accumulation of charge on the inner wall surface. The electrostatic charge layer results in an electric field through the wall of the pipe with the possibility of spark-through. Tests on modem proprietary plastic fuel systems have shown, however, that these electric field strengths are very small compared with the breakdown strength of the material used.

Wolfson Electrostatics have just performed a study of the potential electrostatic hazards associated with underground plastic fuel lines and found that there was no danger of electrical breakdown in the two proprietary pipework systems tested. Concerns were highlighted, however, about the presence of unearthed metalwork. In particular, in one of the systems, a metallic barrier layer was incorporated which was found to attain electrostatic potentials of up to a few thousand volts during fuel flow. Large sections of metalwork such as this can give rise to spark discharges which in tum can ignite fuel vapour if present within the flammable range.

Electrofusion couplers, which are used to join sections of plastic pipework together, also contain an unearthed metal component in the form of a heating element. The study at Wolfson Electrostatics found that these couplings do not currently constitute an ignition hazard since the level of electrostatic energy they can store is limited by their low electrical capacitance.

Fuel tanks

Fuel storage tanks come in a variety of forms and can present an electrostatic hazard because unipolar charge enters a tank which may contain a flammable air-vapour mixture.

The amount of charge entering the tank will depend on the streaming current and volume flow rate and, as already mentioned, is likely to be greater for metal pipework feeding the tank than for a plastic pipework system. The charging levels will also be increased by splashing, turbulance, foaming and increased emulsification (eg by the presence of water).

An ignition hazard may arise if the electrostatic charge on the liquid in the tank does not immediately relax to eruth and this can occur with low conductivity fuels and nonconductive tank materials. In this case, electrostatic discharges are possible from the surface of the liquid if the following conditions apply:

• The surface potential is negative and exceeds 20 kilovolts.

• An earthed projection is present near the liquid surface.

• The vapour concentration is within the flammable range.

• The electrostatic discharge exceeds the minimum ignition energy of the fuel vapour.

Naturally, the risk of ignition is greatly increased if ungrounded metal items are present and these may include items floating on the fuel surface. Depth gauging tapes have been known to cause explosions.

The use of plastic fuel tanks for cars is now widespread and a considerable amount of work has been undertaken at the University of Southampton to quantify the electrostatic hazards involved. Electrostatic brush discharges from the plastic surface have been observed under 'first-fill' conditions which take place before the car leaves the manufacturers' production line. These discharges have been found to be non-incendiary due to their polarity and energy content. Fires have occurred, however, due to isolated metalwork on the tank assembly such as heatshields and other metal components becoming charged and giving rise to energetic sparks.