' (1 ' . ' " . '., .I., The • '>.. •

',, VOLUME 37 No"4

Journal of the Association for Petroleum and Explosives Administration

,, .,

FUELING COMPANY A DOVER RESO I I ' • • • I

Everyone needs to know how good a Stage 1B really is Petroleum and Fire Officers, Environmental Officers , Trading Standards Officers and, of course, site owners

Complete knowledge of a site's Stage 1B reduces risk for the site operator, delivery driver, site personnel and the general public, as well as protecting the environment

Poorly designed, inefficient Stage 1B systems may appear to be working safely, but could fail on the next delivery, causing a major incident! There are many sites in this situation!

Th e Petroman Interactive Test offers the following:

•Testing of all components of Stage 1B including the delivery tanker.

• Accredited , fully trained and experienced engineers.

• Full annual certification provided.

• Ful I UK coverage.

•Blue-Print Testing service for new and refurbished sites.

• Testing of sites without Stage 1B for compatibility with vapour recovery

• Already being adopted by major oil companies.

•Testing carried out to ISO 9002 Quality Assurance Standards

Ignorance of Stage 1B and its operation is no longer an acceptable excuse for incidents and high risk situations during a delive1y.

Testing is now compulsory, so it makes sense to use our system Petroman provides the only fully comprehensive test available.

/ /

.. J

0

• Tank cleaning • Gas free certification • Safe excavation and removal of petrol tanks • In-si tu tank decommissioning • Foamed concrete filling • Hydrophobic foam neutralisation • Mobile oil/water separator for low cost interceptor drainage • Supply of rotationally moulded or GRP interceptors • Emergency oil spill response contractors • Land remediation OTS are Licensed Waste Carriers and operate our own Licensed Petrol Tank Disposal Site No: SY-40 We are a Quality Assured Company to BS/EN/ISO 9002 Head Office 01386 853409 F ax 01386 858928 Bri stol 011 79 304545 D erby 01332 385892 N ewport 01633 250003 Po rtsm outh 01 70 5 3810 66 Re ad ing 011 89 50 5556 ri1b O TS L td, I-l ead Office, Springhil l Industri al Es t ate ,S pringhill , Mo ret on-in -Mars h, • Glouces t ers h ir e, G L 56 9TP

r I High integrity pipework systems for forecourt installations Distributed by PURFLEET FORECOURT SERVICES PURFLEET FORECOURT SERVICES LTD 520 London Road, West Thurrock, Grays, Essex RM20 3BE )!etrol·line 11_lus Durapipe - S&LP • No 1 UK manufacturer of polyethylene pipes • Superior electrofusion jointing system • High flow rates • Available in five sizes for suction, pressure and vapour systems • Competitive prices • Nationwide delivery Tel: 01708 863931 Ext. 219 Fax: 01708 864140 e-mail: purfleet forecourt services@harris group.co.uk LEDBURV WELDING & ENGINEERING LTD. NEW MILLS INDUSTRIAL ESTATE LEADON WAY, LEDBURY HEREFORDSHIRE HR8 2SR (TEL : 01531 632222 ) (FA X: 01531 634718) A COMPLETE RANGE OF ABOVE & BELOW GROUND STORAGE VESSELS QUALITY UNDERGROUND TANKS QUAUlY UNDERGROUND TANKS SPEC IA LI ST COATING DOUBLE AND SINGLE SKIN LEAK DETECTION OVERFILL PREVENTION DEVICES MANWAY ACCESS FRAMES _ MULTIPLE COMPARTMENTS ABOVE GROUND 9 FUllY BUNDED 'fO'fAllY !ENClOSED 6 DERV=PACK§ 9 600 GAllON TO 2 0 9 000 GAllON ,

Ken Wilcox Associates, Inc.

Summaries of 300+ Leak Detection Methods from 100+ Vendors

Third-Party Evaluation Procedures from USEPA, KWA, MRI and Others

Full copies of Third-Party Certifications from Leading Vendors

Fully Searchable and Printable

Software: PC Tank Gauge, Inventory Calculator, Tank Calculator,

Netscape Navigator 4.5, Internet Explorer 5, Adobe Acrobat 4.0 and more Leak Detection 99 CD-ROM \ 11 I 1 I \ Order by phone, fax, mail, or internet, £70 or US$100

443 2494, Fax

443 2495 E-mail: info@kwaleak.com, Web:

Valley Ridge Drive

USA Some supp li ers best engineering for a Seconda ry Contained Tee Our engineering. I f " <i \\ \ H I r, 11 I We run the R&D giving yo u: Cos t saving Time saving You 1,cho ice Orne r r -ae ml •oi · · · · · · ···· PETROL PI PE SYSTEM l'li1JIW l :t \ + 1r1 11 11 1

•

•

•

•

•

•

Phone (US) 816

(US) 816

www.kwaleak.com 1125

Grain Valley, Missouri, 64029,

C.P.INSTALLATIONS (SOUTHERN) LTD. (Established 1968) • Specialists in Petroleum Pipework Installations. • New and existing Tanks & Lines tested. • Modifications to existing installations. • And all work associated with Forecourt Pipework. • Approved for UPP, Durapipe and Enviroflex Pipework Installations. • Approved for Ameron and Smiths Fibreglass Installations. Unit 2, 275 Prince Avenue, Westcliff on Sea, Essex 550 OJP. Tel: 01702 392110 (24 hrs ans) Fax: 01702 392126 WASTE MANAGEMENT NATIONWIDE FORECOURT DRAINAGE & INTERCEPTOR SERVICE Cleaning & emptying of interceptors and associated drainage systems found on garage forecourts • Interceptors • Catch Pits • Tank Tops • Gullies • Car/Jet Wash Pits • BucketTraps • Surface Drainage • Below Suriace Channels Drainlines Water transported for tank testing plus treatment & disposal of the contaminated water. if EVE SHAM (01386) 47190 INDUSTRIAL & TANK CLEANING Petrol, oil & solvent tanks cleaned to OCTEL and Pet roleum Industry specifications ir GLOUCESTER (01452) 507432 Head Office: Grange Road , Batley, Southampton , 8030 2GD Tel (0148 9) 782232/6 Fax (01 489) 789821 CLEA NSI NG SERVICE GROUP LTD PETROLEUM PIPEWORK SPECIALISTS 0 VAPOUR RECOVERY 0 TANKAND LINETESTING TANK AND PUMP INSTALLATIONS 0 EMERGENCY CALL OUTS 0 2 Bercta Road New Eltham London SE9 3TZ Tel:Ol818502211 Fax : Ol81 850 5599 Email: tubeflow l@aol.com D DC BUILDERS LTD FOR BILITY SERVICE QUALITY & RELIA COMPLETE WE OFFER AMAINTENANCE SERVICE ON MENT WORKS AND IMPROVE T R o L E U M TO THE PE RETAIL MARKET D DC BUILDERS LTD 7 ST CLAIR CLOSE CLAYHALL I LF ORD ESSEX IGS OPA Te B : 0181055 0 52 16 Fax: 01 81055 0 6095

Forecourt Specialists Electrical Maintenance Design Testing Unit2 Gregorys Bank Trading Estate Worcester WR3 8AP TEL: 01905 28402 FAX: 01905 28410 FOAM SPEC/Al/STS RESIN GENERATED FOAM FREEPHONE : 0800-592-573 FAX: 01639-821-651 For safe handling and dispo sal. WEHAVEoflALL U S FIR S T A ND EXPERIENCE IN THE PETROLEUM INDUSTRY 0 GIVE YOU A QUALITY, PERSONAL SERVICE Professional development TRAINING IN-COMPANY SHORT COURSES • Electrical Requirements for Petrol Filling Stations • Management overview of HSW Statutory Regulations, including : _Management of Health & Safety at Work Regs (MHSWR) _Workplace Health, Safety and Welfare Regs (WHSWR) Provision & Use of Work Equipment Regs (PUWER) _Personal Protective Equipment at Work Regs (PPER) • Essentials of Health & Safety at Work Sites • Introduction to Health & Sa fety Risk Assessment • ELECTRIC/TY AT WORK REGULATIONS (EWR) • construction (Design & Management) Regs (CDM) • BS7671 Requirements for Electrical Installations (16th Edition Wiring Regulations) • Inspection and Testing of In-Service Electrical Installations • EARTHING AND BONDING Reviews a wide range of national Cod es of Practice and Statuto ry Requirements Prese nter: TERRY HEDGELAND BA. F!EIE. MIQ A. Member of APEA and !OP Phone: 01737 553328 ___._SPECIALIST BUILDERS TO THE PETROLEUM INDUSTRY • FORECOURT INSTALLATION INCLUDING STEEL & PLASTIC PIPEWORK • SHOP REFURBISHMENTS • ELECTRICAL INSTALLATION • MAINTENANCE AND REPAIR 01269 831038 FAX(01269}831201 Ace r Court , Cross Hands Business Park , Cross Hands ,Carmarthenshire The Association for Petroleum and Explosives Administration SA1 46R E ISO - [;

[ D1111ra1p.i1pe - SalP · ·-- '

the complete forecourt advertising kit For further information on the full range of Elaflex products contact: Riverside House, Plumpton Road, Hoddesdon, Herts EN11 OPA. Telepho ne 01992 451494. Fax 01992 451496

An J. Bayliss (Stourport) Ltd Petroleum Engineers Petrol, Fuel Oil and Electrical Installations 11/12 HODFAR ROAD, SANDY LANE INDUSTRIAL ESTATE, STOURPORT-ON-SEVERN DY13 9QB TELEPHONE: 01299 824541-2-3 FAX: 01299 827638 SPECIALISING IN ALL ASPECTS OF FORECOURT PETROLEUM INSTALLATIONS, SERVICING AND PRECISION TANK TESTING FULLY ACCREDITED TO BS EN ISO 9002: 1994 Care For The Environment.. . Make Forecourts A Safer Place To Work And Visit.·· Provide Quality Solutions To Forecourt Engineering Pr oblems ... RI SBRllDGER VAPOUR RECOVERY PRESSURE VACUUM VALVES VAPOUR LOSS REDUCTION SYSTEMS UNDER PUMP/CHECK VALVES DESIGN & DEVELOPMENT INSITE TESTING IDS STOP OVJERFHJL PREVENTION DJEVJrC JE RlI SlBRJID G JEJR LTD . Sfydhi.el!11§ Laine, Su rrey Rll-ll li 4- LN Td : ( +44 Oli 883 7 43 ll07 lFaix: ( + 44 01883 7 443 4 2 -

Forecourts

so much

with the Sof itam touch

' ' / NASH Nas h & p . a 1b1 e rs h a b Re ta i l p ve ee n wo rk111 g 111 parh1e rs h1 p w ith th e e tro le um ind d eve lo u s tt Y for alm os t thirty years, p lanmn g and p in g re ta il in II c ha n ge t E s ta ati o ns fr o m a s tr a ig htfo r wa rd pump 0 uro p e' I s a i ges t filli n g s tat io n. Eve ry s te p o f th e wa pr o ject 111 y, fi o m fe a s 1b1lt ty s tudi es and s ur vey m g, a na ge m e nt a nd d e ta il WI 1 co mm 1ss1o mn g, we take care o f ev ery i e t1 e r a rn a o r 1 o u r c li e nts J 0 1 co mpa n y o r a n 1nd 1v1dua l d ea le r, ai e a ss u re d f I a d he re nce 0 t i e N as h co mmitm e n t to qu a li ty and ::i 7SO back d b •nn ova ti o n a d ' e Y u p- to th e -mi11ute te chn o logy, , n ex p e rti s e Fro m a , g ree n fie ld s ite to Pa rt n e rs d e liv a ful ly op e ratio n a l ms ta ll a t1o n, N a s h & e i c re a ti ve t I I ye 11g 1l y pr a c ti ca l s o lut io n s ,. A RCH ITECTS -. SU RVEYO RS • TOWN PLANNE RS + PR OJECT MANAGE RS ry CONSULTANTS \!\'>II& ta tion A pprnach C hi ch es te r +

o

r

work

better

Major projects undertaken including construction and pipework installation NATIONWIDE. o Suppliers of fuel dispensing equipment, tanks and all associated items. o Suppliers and installers of LPG equipment. Cost effective service and maintenance , tailored to individual requirements including vapour recovery maintenance. o High quali ty refurbished equipment. Sofitam Pump Services Ltd Adur Boatyard, Old Shoreham Road, Shoreham by Sea, West Sussex . BN43 STA. ACTION LIN IE: 01273 454831 Fax 01273 464863 Regional Office: 132 Gulson Road, Coventry CV1 2JF Tel: 01203 633312 Email sales@sofitam.com www.sofitam.com

©© 1: r ©J 169 Frenches Road, Redhill,

Telephone : 01737 767524 Member A PE A. Service to the Petroleum Industry Since 1966 Professional Tank Cleaning and Removal from the No.1 Tank Specialists Safe xcavation and removal of underground storage tank installationsa Tank Cleaning and Gas-Freeing by fully equipped Tank Cleaning Crews. Please call Nigel or Kathy on 01737 767524 (fax 762524) for details of these and other services we provide

RH1 2HZ

Ci-fE/i.POS l\/T

BOTCl-fED

ET/i f _ FUD G ED

NO-ONE ELSE WILL MAKE YOU A BETTER OFFER.

No other company is quite like Veeder-Root.

We're the world's leading supplier of tank gauges, wet stock reconciliation and leak detection systems. Our equipment monitors over 300,000 storage tanks throughout the globe. We supply most of the major oil companies, as well as supermarket groups and other major petrol retailers.

And no wonder. We built our reputation on developing leading-edge technology of outstanding quality. Every tank gauge we

produce is proven to be accurate, reliable, and easy to use.

We also listen to what our customers have to say. Our attitude to service, coupled with our wide range of gauges, means we can put together systems that are exactly right for you.

Call us on 0800 3285931 and talk to the experts in wet stock control and leak 't mes detection. You'll soon find that when 1 co to great service, unbeatable products and to offer than real value, no-one has more Veeder-Root.

a VEEDER-ROOT Precisely the right deal for your business., Hydrex House, Garden Road , Richmond , Surrey TW9 4NR Tel : 44 (0) 181 392 1355 Fax : 44 (0) 181 878 6642.

.• ADVANTAGES • Hermetically sea1led for liquids and gases @ Lightwe igbt • Loading Class No maintenance • Lockable • Different colours available •.• Clarksteel, one of Europes largest suppliers of manhole covers to the petroleum, telecommunication, water and construction industries are proud to announce the launch of a new range of Hermelock polyurethane strengthened with glass fibre manhole covers and frames. For full information call our sales hotline on 01733 765333 or email mik'e@clark-steel.com SUITABLE FOR • ,petrol fore,courts e Servi'ce· areas ® :Leisi\Jre parks 8 Retail· deve·lo·pments -- '1 THE Cl ARKSTEH TECHNICAL ADVICETEAM ARE 0 1\1 HAl\ID TO HELP WITH ANY QUERIES ;1£\1/ X I Stat ion Road Yaxley Peterborough PE7 3EG «Jl1733 765333 Fax: 01733 246913 e mail: m ik e@c lark steel.com Web site:http://www. clark steel.com

Talking

The Associations Annual Conference and Exhibition was held at Telford International Exhibition Centre on 26 & 27 October and was well supported. Over 450 were registered for the conference sessions over the two days and 400 attended the annual dinner held in the Conference centre. There were also a record number of exhibitors and an LPG village.

The HSE have also finally given full endorsement to the APEA/IP Code of Practise on Petrol Filling Stations and this is at this moment being printed. Members will be receiving a copy as a benefit of membership.

VOLUME37 Number4 NOVEMBER 1999 The Bulletin Published by the Association for Petroleum and Explosives Administration

A company Limited by Guarantee registered in England No. 2261660 Administrator: Brian Taylor

£10.00 ISSN 0263 4597 Website: www.apea.org.uk Opinions expressed in this Journal are not necessarily the views (Free to Members)

Point

the

Contents TALKING POINT NOTES&NEWS PROSECUTIONS NW BRANCH REPORT EXHIBITION ABOVE GROUND TANKS US EXPERIENCE ABOVE GROUND TANK AT RETAIL SITE WETSTOCK MANAGEMENT AUTOGAS A NEW NOZZLE? APEA BRANCH SECRETARIES 79 80 82 84 85 88 91 93 97 SIMON WHITE SOUTHERN BRANCH MIKE SILMON NORTH EAST BRANCH SUE MEADOWCROFT itJlLES BRANCH ANTON MARTINIVSSEN EASTERN BRANCH STEVE BLANCHARD HUMBERSIDE BRANCH

THOMPSON EDITOR RUTH SUTHERLAND SCOTLAND BRANCH BOB CONLIN NORTH WEST BRANCH EDITORIAL TEAM DENNIS O'DEA MIDLANDS BRANCH NATHANIEL MCCOY !RELAND BRANCH ROB GREEN AD\ ·t.:RTIS!NG SECREr.\Rl

of

Association

JAMIE

LPG LEAK AT SHELL PETROL STATIONS

A Shell site in East London was closed and emergency services called after a large gas cloud was seen coming from the LPG fuelling installation in the tank compound. The site was made safe and investigations followed into the cause.

It would seem that this was the fifth incident at similar installations. The leaks were caused by the failure of a pressure relief valve, which did not close.

Investigations by Shell revealed that the installers had placed a jointing compound in the joint when making it, which in turn caused the valve to jam open. The valves were replaced and a number of installations that may have been similarly effected are being checked.

YEAR 2000 CALENDAR AND YEAR BOOK

The APEA has this year chosen to produce a calendar to mark the millennium, it has some old photographs some of which members would have seen before -;nd new ones. The calendar is included with this issue of the Bulletin. The Year book is now with the printers and will be with members before Christmas.

AGM

Advance notice that the Associations AGM will be held on 17 April 2000 at th s 11 e wa ow Hotel m Northampton.

FAIRBANKS' ALTERNATIVE TO STATUTORY TANK TESTING

LFCDA has accepted Fairbanks Environmental 's Wetstock WizardTM management system as an alternative to tank They have based this decision on eLvi dence of Fairbank's successful track record within the on on area.

There is a require i audit which 11 men.t or sites to undergo a compliance wi 1dent1fy an Practices do Y areas where the current · not meet th achieve this 1 d e acceptable standard. Sites which . s an ard and b . data to Fairb· k su m1t wetstock reconciliation an s for anal .·. ·11 Compliance Ce t'f· ysis w1 be issued with a r 1 JCate a d · tank testing. n will be freed from the burden of

Fairbank 's BS EN ISO 9()() I variance lev l. system monitors wetstock e s and auto · when <:t v- 11.1·a . matically m1t1ates an investigation ' nee starts t established for 1 · 0 exceed the ·acceptable' level eac l tank on th Th b ·1do1Jted on ·uiy " . e site. c system can e ' ' site 1rresp · t'C)Utpmen1 · ective ot the level and type ot

I :11rhanl,' welcomes 1 , , •1 11 , 1,, .di PI '\ s. · to demonslrnte thetr >I further mformat1011 call 01695

OIL ASSOCIATION MERGER IS OFF

Despite very lengthy and intensive discussions, the planned merger of FPS (the Federation of Petroleum Suppliers Ltd) and OFfEC (the Oil Firing Technical Association for the Petroleum Industry) which has been under negotiation since April this year, has been called off. This means that the proposed new joint organisation, which was to be known as CODEC, will not now come into being, and both associations will retain their original names and functions.

"Many people who have put in a great deal of personal time and effort in a sincere attempt to carry the process forward will be disappointed, but both organisations can now wholly focus their attentions on their own specific objectives in order to benefit their membership" said John Eveson, President of the FPS.

"Both organisations have gone to considerable lengths to accommodate each other's requirements," added Andrew Evitt, Chairman of the CODEC shadow board. "But unfortunately we have not been able to reach agreement, and now have to recognise that we cannot continue with endless non-productive negotiations activity without achievement has zero value for members of both organisations."

Both John Eveson and Andrew Evitt expressed their thanks to all of those who had participated in the discussions.

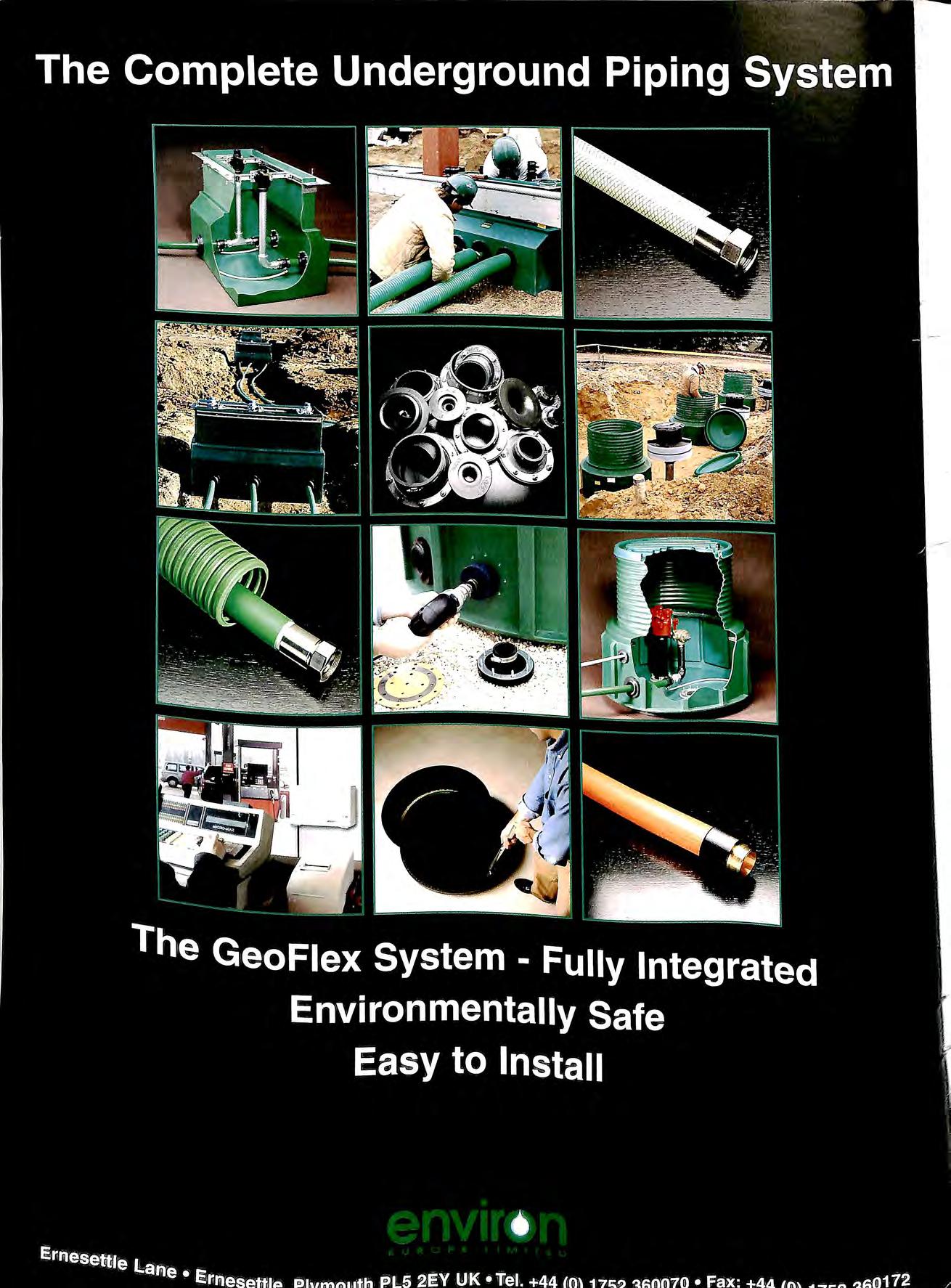

ENVIRON

Environ are pleased to announce that it has received product certification from the Dutch authority, Kiwa, for its "GeoFlex" fuel pipework system. GeoFiex has a special non-metallic pipe construction, which is compatible with all fuels and is directly buried underground in petrol service stations.

Testing and certification work has taken three years to complete on the Geoflex system and the Company is delighted to be the first manufacturer of this type of product to meet the latest guidelines and receive this influential approval for The Netherlands.

. GeoFiex is manufactured in the USA by environ Products me. based in Exton, Pennysylvania. Environ established a base and distribution centre in Plymouth. England m 1994. The product will be made available in The Netherlands through a locally appointed distributor. TSE. located near Amsterdam.

notes

and news

XO

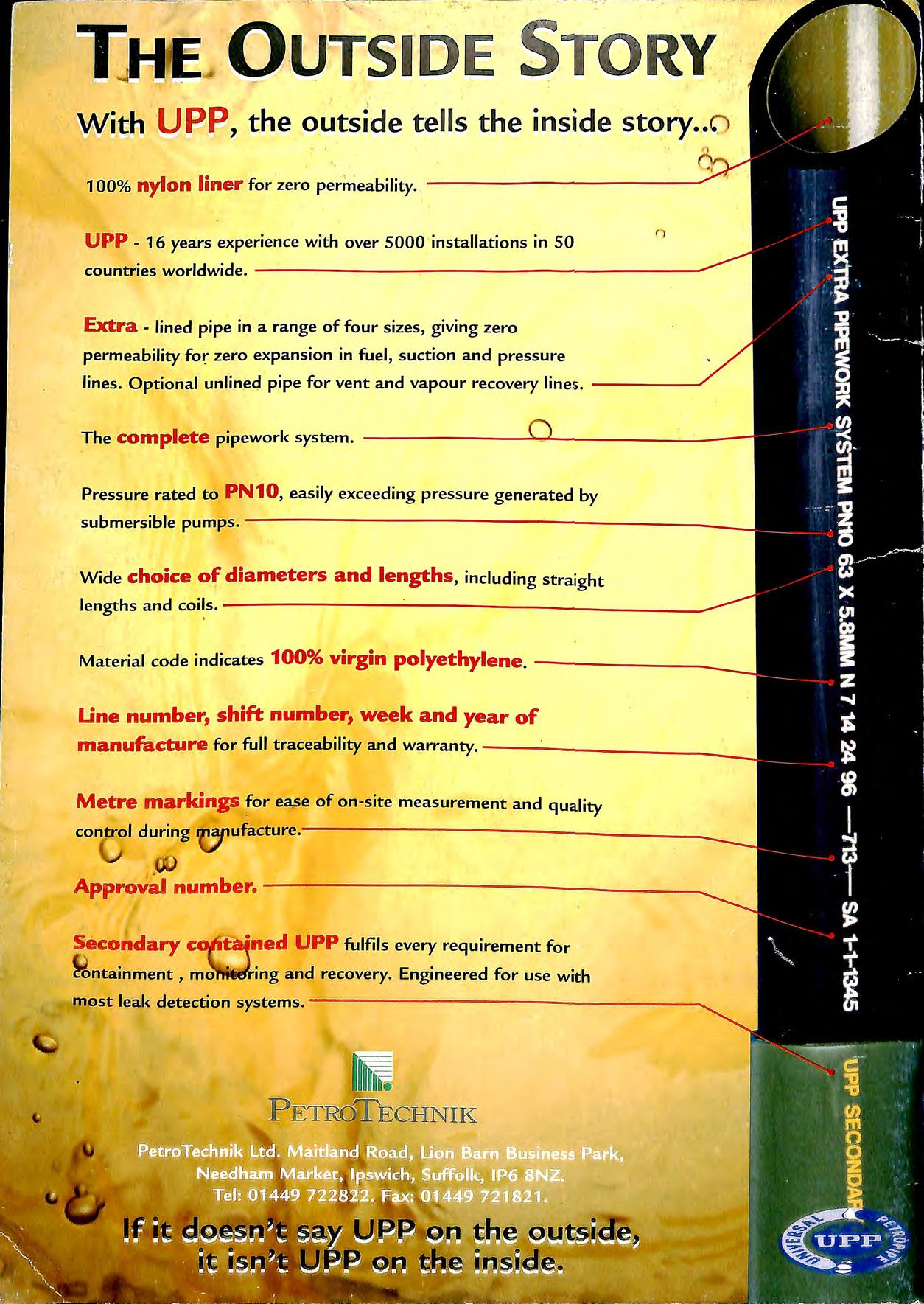

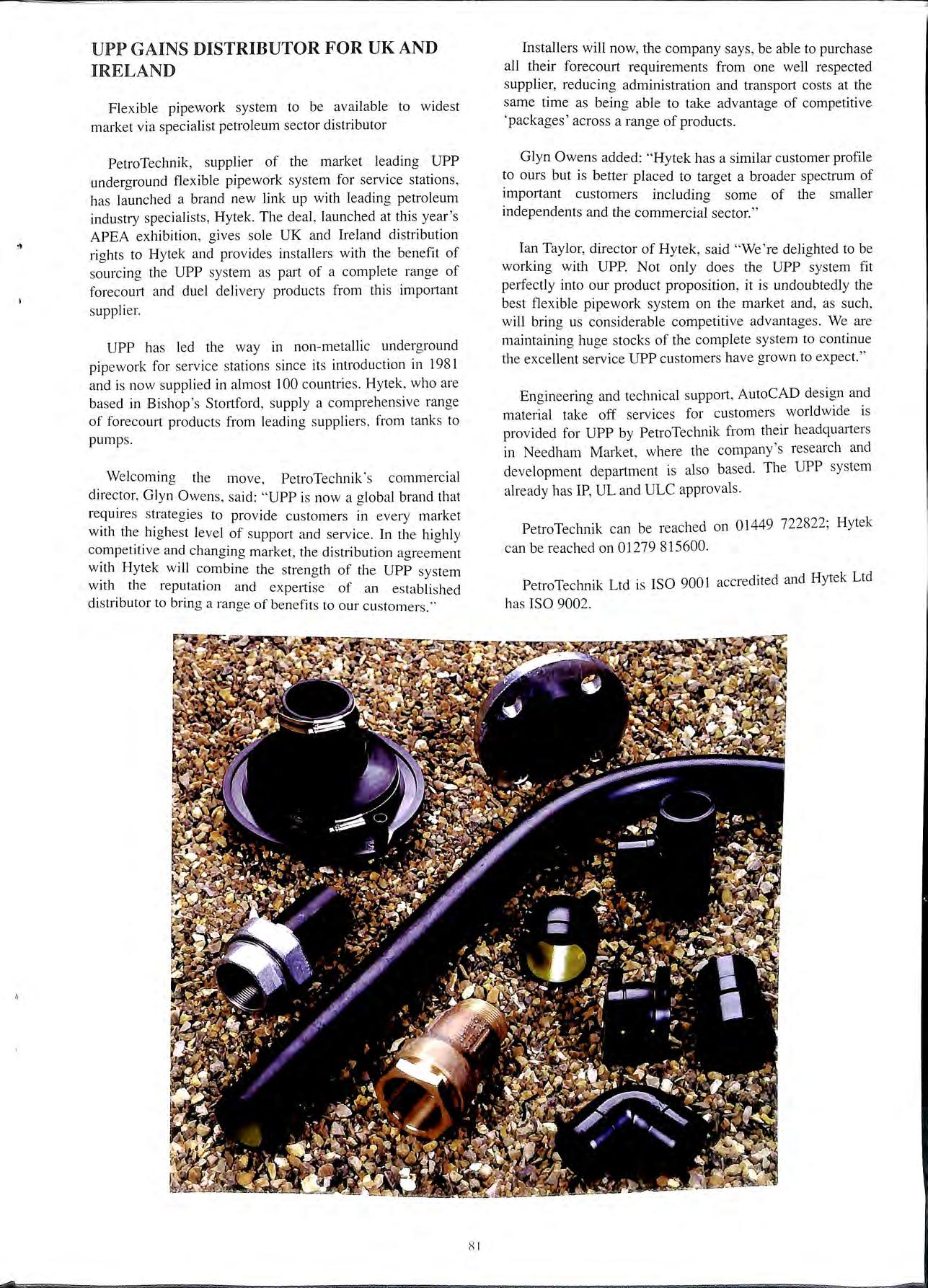

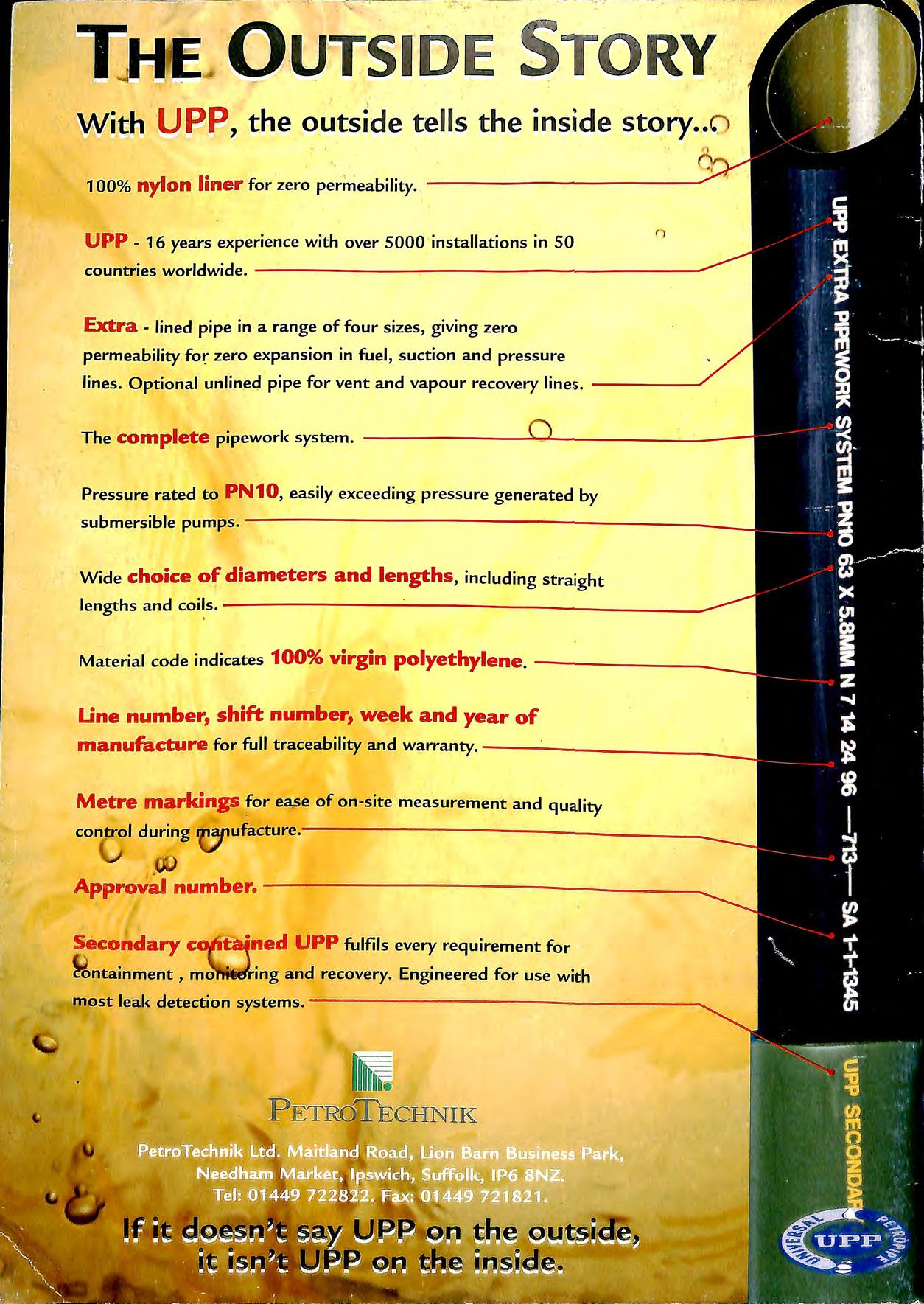

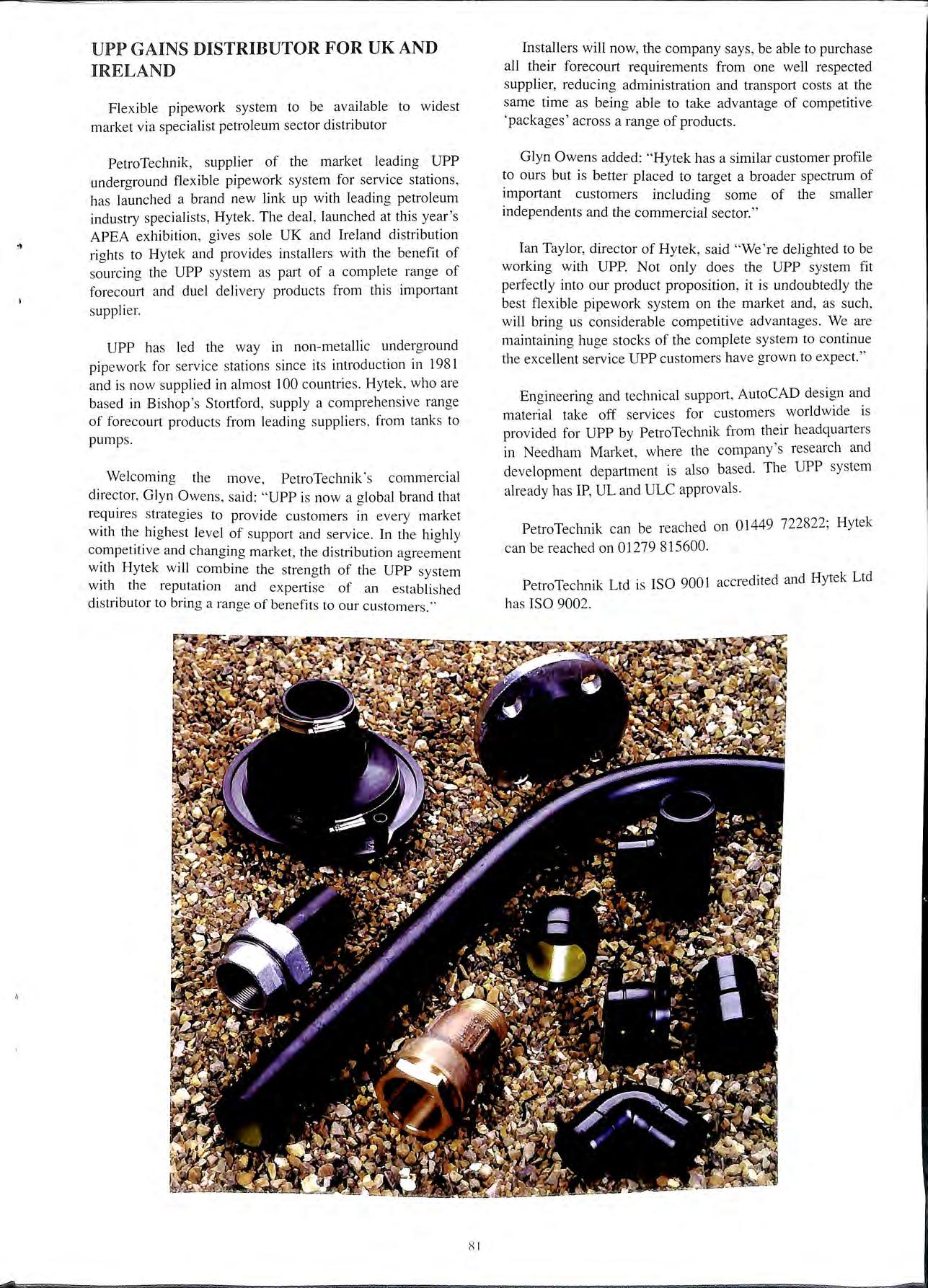

UPP GAINS DISTRIBUTOR FOR UK AND IRELAND

Flexible pipework system to be available to widest market via specialist petroleum sector distributor

PetroTechnik, supplier of the market leading UPP underground flexible pipework system for service stations , has launched a brand new link up with leading petroleum industry specialists, Hytek. The deal , launched at this year's APEA exhibition, gives sole UK and Ireland distribution rights to Hytek and provides installers with the benefit of sourcing the UPP system as part of a complete range of forecourt and duel delivery products from this important supplier.

UPP has led the way in non-metallic underground pipework for service stations since its introduction in 1981 and is now supplied in almost 100 countries. Hytek, who are based in Bishop 's Stortford , supply a comprehensive range of forecourt products from leading suppliers , from tanks to pumps.

Welcoming the move , PetroTechnik 's commercial director, Glyn Owens, said: " UPP is now a global brand that requires strategies to provide customers in every market with the _highest level of support and service. In the highly and changing market , the distribution agreement

Hytek will combine the strength of the UPP system with the reputation and expertise of an establi sl1ed d1 stnbutor to bring a range of benefits to our customers. "

Installers will now, the company says , be able to purchase all their forecourt requirements from one well respected supplier, reducing administration and transport costs at the same time as being able to take advantage of competitive 'packages' across a range of products.

Glyn Owens added: " Hytek has a similar customer profile to ours but is better placed to target a broader spectrum of important customers includina some of the smaller b independents and the commercial sector."

Ian Taylor, director of Hytek , said "We're delighted to be working with UPP Not only does the UPP system fit perfectly into our product proposition, it is undoubtedly the best flexible pipework system on the market and , as such , will bring us considerable competitive advantages. We are maintaining huge stocks of the complete system to continue the excellent service UPP customers have grown to expect. "

Engineering and technical support, AutoCAD design and material take off services for customers worldwide is provided for UPP by PetroTechnik from their headquarters in Needham Market , where the company's research and development department is also based. The UPP system already has IP, UL and ULC approvals.

PetroTechnik can be reached on 01449 722822 ; Hytek can be reached on 01279 815600.

PetroTechnik Ltd is ISO 9001 accredited and Hytek Ltd has ISO 9002.

RI

Prosecutions

MURCO PETROLEUM FINED £23,500 FOR BREACHES OF LICENCE CONDITIONS

Murco Petroleum Ltd were heavily fined recently by Suffolk Magistrates following failings in safety standards found by petroleum inspectors of Suffolk Trading Standards.

The company pleaded guilty to nine charges of failing to comply with conditions of their petroleum licence.

An inspector found that self-service petrol pumps were being activated automatically by customers without the attendant's knowledge, and that daily records necessary to detect potential leaks from the station were inadequate.

In mitigation Murco stated that they took Health & Safety seriously and that the two sites in question there had been lapses in supervision of procedures.

TESCO TAKEN TO COURT & FINED £9000

Tesco Stores Ltd was heavily fined recently following damaged vent pipes being found at one of their filling stations in Aylesbury.

In taking the company to Court in August, Buckinghamshire County Council Trading Standards brought its first prosecution under the Petroleum (Consolidation) Act 1928 since responsibility for enforcement was passed on from the Fire Brigade in April 1998.

Officers visiting Tesco's Broadfields site in Aylesbury in November 1998 to inspect vapour recovery facilities noticed on their arrival that the vent pipes were not fully vertical. Closer inspection revealed that two of the pipes were broken and others cracked about one metre from ground level. There was also a strong smell of petroleum vapour in the air the vapour was now venting at low level. Despite daily checks by staff the damage had gone unnoticed. It is not nown how the damage was caused but the circumstances suggest that a vehicle may have collided with the pipes, although such an accident was never reported to Tesco.

At the Officers request the site was voluntarily closed down for 36 hours whilst remedial work was carried out.

Tesco were charged with breaching 2 conditions of their petroleum licence, namely failing to take all practicable steps_ to prevent an accident by fire or explosion to maintain the licensed premises in a condition tree from. fire hazards. The Court was also told of the great potential for danger that this situation caused.

The Company pleaded guilty to the two charges and lllllig:ated that in its 26 year history of operating nearly 300 IJ'Jing 'ita11ons. it was the first time such damage had been found ft was also stated that a crash barrier had now been pl<t< ('d <tround the pipes to help prevent a similar situation

In coming to their decision as to sentence, the Magistrates' considered that the situation was potentially dangerous and hoped that the Health and Safety procedures in place would prevent it from happening again.

Tesco Stores Ltd was fined a total of £9000 and ordered to pay costs of £372.79.

LICENSEE PROSECUTED FOR NOT KEEPING TRAINING RECORDS

Staffordshire Trading Standards successfully completed a prosecution on 12th April 1999 at Cannock Magistrates Court against the partners of a business within the County.

The two partners operate 4 sites within the region and together with an employee of the business, were charged with, and pleaded guilty to a total of 4 offences.

The case arose when one of the Counties Petroleum Officers observed a delivery of petroleum spirit taking place into underground tanks without there being in the vicinity of the road tanker, the driver or a competent person. The site did not operate a D.C.D. system and to further compound the seriousness of the situation the certificate of licensee controlled delivery had not been filled out.

The subsequent investigation into the incident by Petroleum Officers of Staffordshire Trading Standards. discovered that the partners failed to keep training records for staff employed on a petroleum forecourt.

The alleged "competent person" on the day of the incident was charged with 2 offences. Firstly that he. acting as competent person did not complete a certificate relating to the delivery of petroleum. Secondly, that he, acting as a competent person failed to stay in close proximity to a road tanker and storage tank for the purpose of preventing any hazardous situation arising.

Interestingly, throughout the investigation was the competent persons insistence that he had been called away seconds before the arrival on site of the Petroleum Officer.

The Magistrates took a dim view of the procedures put in place by the Partners and fines of£ 1500 each were imposed with costs of £352. The competent person was fined £500 with £200 costs for his part in the incident.

PROSECUTION

A petroleum licensee from Hampshire has been prosecuted by the county's Trading Standards Service for failure to comply with an Improvement Notice

, I '

n·1 82

MVF Ltd held a petroleum licence for premises in Petersfield which had formerly been a filling station. The licence expired on 31 st May 1998 and was not renewed.

On l 7th June 1998 at the company's request a Petroleum Officer visited the site to give advice on making the underaround tanks safe. An advisory letter followed on 23rd b June which agreed to a period of grace ending on 21st August 1998 during which the necessary decommissioning work would be carried out. Checks on progress on 3rd August and 17th September revealed no action had been taken so on 23rd October 1998 an Improvement Notice was issued requiring the tanks to be made permanently safe by 26th November 1998.

The company requested a further period of grace which was declined and on 11 th December 1998 all four tanks were still found to contain petrol. The tanks were finally made safe on 25th January 1999.

The company pleaded guilty and was fined £1,300 (discounted from £2,000 for an early plea of guilty) and £300 costs.

GARAGE FINED £3000 WITH £1004 COSTS FOR BREAKING PETROLEUM LICENCE SAFETY CONDITIONS

Henry Gibbs (Oxon) Ltd , Aerodrome Industrial Estate, Haddenham, Bucks, T/a Gibbs Garage, Bouncers Lane, Cheltenham, Gloucestershire faced two charges under the Health & Safety etc. At Work Act 1974.

They pleaded guilty on both counts and were fined £3000 with an extra £1004 being awarded as costs and solicitors fees.

They fa_iled to comply with two conditions of the petroleum licence issued by Gloucestershire County Council Trading Standards Department. That was:-

• Allowing Gibbs Garage at Bouncers Lane, Cheltenham to be open for business whilst not being supervised by a competent person over the age of 18 , and

• Allowing a pe:son under the age of 18 to be left in sole charge of a f11lmg station.

After receiving a complaint from an ex employee The Trading Standards Department carried out an investigation relating to an accident that took place on Sunday l Sth October 1999.

A young 16 year old girl was left on her own in at th · petroleum filling station for long periods durina her which lasted from approximately 7.30 a.m. in the mornina until 10.30 p.m. in the evening of the same day. 0

She was originally employed to cany out general shop duties relatmg to new spaper sales on that morning . Howev e r she was put in the po sition of running the forecourt sales and other activitie s on her own because of staff si c kne ss and shortag es occ urring that da y, along with inade quate compan y control and sup erv is ion Although she had some gras p of working th e fo rec ourt sys te m s. she was ne ithe r

properly trained, or a competent person, or old enough to be in sole charge of a licensed petroleum filling installation. This could have caused a significant danger to customers using the site in the event of a fire or petrol spillage.

County Trading Standards Officer Paul Galland said that the purpose of the petroleum licence was to ensure the safe keeping and use of this dangerous and volatile substance, and to mimimise the risk to staff and customers using petrol filling stations. On this occasion it was clear the company fell unacceptably short of the required standards. Experience has shown that whilst the number of recorded incidents at licensed sites are small, when they occur staff must have the ability to be able to react to situations in an immediate and effective way.

LOYALTY FOR 21 YEARS WORK REWARDED

Faradays Electrical Contractors of Chandlers Ford, Hampshire recently rewarded Mark Elgar for his 21 years of service to the company. Managing Director, David Spratt presented him with some tools and a £500 Dixons Voucher and said "Fairadays are enormously grateful to Mark, from day one he has been conscientious and has worked hard and helped the company to be the success it is today, we shall look forward to many more years of working together".

Mark who started working for Faradays aged 22 in 1979, a year after the company was fo1med, is now their Senior Electiical Engineer, a key figure. His work has contributed significantly to the growth and expansion of Faradays which specialises in Industrial Electrical Services. Examples of the type of work Mark is responsible for today is the M40 and · ll · 'Mark elaar on the M27 Services Forecourt msta at1ons. "' ' left, receiving the £500 Dixons Voucher from David, Spratt Managing Director of Faradays Electrical Contractors ·

8.i

___J

Chairman's Report

Present

Alan Penton, Alex Myles, Andy Berry, Ariff Patel, Barry Gardiner, Bob Conlin, Brian Womast, Clive Drake, Dave Scott, Ian Taylor, Jeff Oldham, Maurice Randall, Maurice Tennick, Mel Chunn, Paul Chawner, Steve Devine, Steve Jones.

Chairman's Welcome

The meeting commenced at 1:15 with the chairman welcoming all in attendance, and remarking on his pleasure at the rekindling of the branch after a dormant period of some 18 months. He extended a particular welcome to the members of the APEA Council who had come to support the reactivation of the North West branch, namely Chairman Ian Taylor, Secretary Andy Berry, Welsh Branch Representative Barry Gardiner and Yearbook collator Paul Chawner.

The branch has been inactive for a long period due to the work commitments of the previous committee and the uncertainty within the industry caused by the on off nature of legislation changes.

The chairman expressed his thanks to the previous committee for the past hard work, in particular Harry Reid and Joe O'Riley, and he sent best wishes to Joe for a speedy recovery from his recent surgery.

The chairman expressed his thanks to Bob Conlin for being the main driving force behind the reactivation of the branch.

Apologies

There were 11 apologies received in advance with a further 3 on the day of the meeting.

Minutes of Last Meeting

As it had been so I · h . ong smce t e last meetmg there was a degree of uncert · t . . am Y as to the relevance, or mdeed existence of these · I h ' mmutes. t was agreed that the minutes s ould be taken d h as rea . Alex Myles reported that he did ave a copy of the m· f mutes rom the previous meeting if anybody was interested in seeing them.

Matters Arising

There were no matters ansmg.

Correspondence

The only recorded to this meeting. correspondence was that which related

Election of Officer

There had b s and Committee Members through the po ·te:n a number of nominations received s •Or the vacant · · h · · were read out , d pos1t1ons. T e nommat10ns · an the eh-· opportunity t k airman gave those present an o ma e alternativ dd" I . . There were n dd" . e or a 1t10na nommat1ons. 0 a !lions o It · for an election Th r a erat1ons so there was no need · e officers are:-

Chairman

Vice-Chairman

Secretary Treasurer ( ·ommittee Member

r 1111J1n111ee Member

Mel Chu1m

Joe O'Riley

Bob

Conlin

Steve Jones David Scott

Cameron 2000 Pump Services Fairbanks Environmental Fairbanks Environmental Lancashire Trading Standards

Steve Devine Ronco! Services

With the branch Chairman having addressed the gathering by way of his welcome, this gave an opportunity for Council Chairman, Ian Taylor, to say a few words on behalf of the APEA as a whole.

Ian spoke of the benefits of being an APEA member, in particular the Yearbook, the Website and the annual conference and exhibition. He gave an overview of the forthcoming conference and exhibition in Telford, stating that some 30,000 invitations had been sent out, with the aim to make this the most successful conference to date. On being elected Chairman Ian recognised that there was a need for the APEA to change, if it was to maintain its reputation as a source of great technical knowledge, an influencer of policy and a forum where the whole of the industry could share good ideas and good practice with similar thinking organisations. He appealed to the branch, as he already has to a number of other branches, to feed-back to him ideas on the way in which the APEA needs to change to ensure that this is the case.

Ian made reference to two trade organisations, the PEIMF and the ASFC which have recently raised their profiles. He has been in contact with the ASFC and applauds their aims of increased safety awareness on the forecourt, but wondered if the APEA has let down its members by not championing the cause. He intends to meet with the PEIMF and again with the ASFC to see if there is a possibility of working together to raise the standards across the industry.

Secretary's Report

Bob Conlin had sent out a questionnaire with the invitations to attend the AGM. This was an attempt to mould the way the branch was to run in the future. The feed-back from the questionnaire, and from those present, indicated:

General acceptance that the NFU building was a suitable venue for meetings. It was agreed that it should be used for all meetings for at least the next 12 months.

As the number of members in attendance showed, there is a keen interest in reforming the branch, with 3 meetings per year.

There was some debate as to the relative merits of morning or afternoon meetings, with the consensus being for afternoon meetings in future.

It was agreed the topics for the future meetings should include:-

Environmental Issues Legislation

Of Site Health & Safety Equipment

New Innovations

There was a general consensus that site visits would be both interesting and informative. with possible venues being:-

Refinery/Supply Terminal Airp011

Fire Training Ground

APEA NORTH WEST

AGM 30th September 1999

BRANCH

84

Treasurer's Report

Steve Jones reported that due to the fact that the branch had been dorniant for a period there was little report , except that the branch was solvent with the capitation payments from previous years being held in the bank. On the basis of the feed-back from the questionnaires it was agreed that a branch levy of £8 per year would come into force from 1st January. Steve will be sending out invoices in the new year. It was also suggested that payment for buffets is made when booking, rather than on-the-day. This would reduce the cost to the branch of over-catering when a member is unavoidably delayed and unable to attend.

Any Other Business

Alex Myles enquired if the unitary authorities had been invited to join the APEA. Bob Conlin reported that a number of the authorities had indeed joined the branch , but unfortunately none had been able to attend the meeting. Those who were unaware of the APEA should be contacted , perhaps via Petroleum Liaison Group meetings.

It was suggested that the Bulletin was sometimes a little light hearted for what should be a leading journal within the industry, and that maybe the editorial style should try and reflect the status of the publication.

It was suggested that the AGM should be the forum for electing the Branch Representative to the national council. Jeff Oldham nominated Mel Chunn to continue in the post, and Mel kindly agreed to continue in post for the next 12 month s.

The role of the Branch Representative was discussed, and it was agreed that the Branch Rep was there to put forward the views of the branch as a whole, and the views of individual members to the national council , and to liaise with other branches.

The rapid growth of LPG availability was a subject of concern , in particular the issue of the scope of the Petroleum Act in relation to LPG. It was agreed that the APEA should be putting pressure on government, both National and European, to ensure that any legislation changes are effective, and that the level of competence at all levels is increased.

It was felt that it was difficult to get details of the training courses available via the APEA. Paul Chawner replied that the delay in the publication of the TCB document had led to a delay in the publishing of the training timetable, but it was hoped that this would be available on the Website, and in the next issue of the Bulletin

The meetino closed at 3 o'clock and was followed by a b technical session on vapour recovery, a topic which some might say has been " Done to death" , but judging from the fact that the session went on for 2 hours , with a great deal of debate and shared experiences the subject may still have plenty to offer.

EXHIBITION 1999

WHO RECOGNISES ELLIOT NESS'?

Chairman prese nt s Awards a t Dinn e r

Chairman prese nt s Awards a t Dinn e r

8111 .,. 1· & ! 11/11' Thnmprnn & /) 01 '1:' B11C k. 11 a / / I n t ens e Di sc u ss ion 86

Alan Chandler & Ken Wi lcox

STAGE 2 EXHIBITS

87 _J

What's changed in the U.S. petrol tank mar ket? What hasn't changed?

By Wayne B. Geyer Executive Vice President Steel Tank Institute

Gasoline is a flammabl e liquid. Gasoline is a hazardous liquid Thanks to the advent of self serve pumps, individuals with little or no knowled ge of gasoline's tremendous hazards dispense billions of gallons into motor vehicles every year.

In the early history of motorized vehicles, gasoline was stored aboveground, in the dispenser, but in very quantitie s. As both hi ghway systems and the automotive industry grew worldwide, so did the need for petroleum storage.

The need for public safety also has grow n.

In the U S. , underground tank systems for decades have been the approac h for storing gasoline at service stations (on forecourts, which are most common in the U.K.) The emphasis on underground storage tanks (US Ts) was sp urred by tragedy.

Several major fires and explosions from aboveground tanks in the U.S. during the 1960s and 1970s killed firefighters and innocent people. A typ ical event entailed the overfilling of an unatte nded tank, which would lead to the sp ill of com bu stible liquid around the vessel. The fluid ignited , which re s ulted in a major pool fire around the tank Gasoline , being very volatile, would quickly vaporize due to the ri se in temperature. Without adequate venting, the tank wo uld over-press urize and the tank heads wo uld rupture o ut ward s

To avoid this circumstance , tanks were co mmonly buried underground. Soil is a great insulator aro und th e tank. It re mo ves the potential of a catastrophi c storage tank failure. PI acmg a tank und ergro und was a perfect spot for the storage of gasoline at fo reco urts or service station s. The publi c cou ld dispense gaso line into their motor vehicl es with virtually no ri sk of catastrophe.

Market demand shifts

By l 9 80 , nearly a ll storage syste m s both priv ate and public re tail _ w d . ere un ergro und. While fire-safety co nc ern s fo r unde rg ro I I , unc tanks had larg e ly been addressed , t 1e publi c s aware ness of e n vironmental impact was on ly beginnin g to take root. Nasty spill s and cost ly clean-up s of US T sys te m s we1·e · d · I h t th · 1e porte 111 new spapers t 1roug o u e wo rld.

overfill containment and spill prev ention were designed by manufacturers and ultimatel y accepted by tank owners.

Ironically, while underground storage systems were becoming more reliable than ever, thelf popu ari . · 1 ·ty m the U.S. began to wane, particularly with priv ate fleet users . Several reasons co ntributed to the change in de mand:

• The cost to meet environment al regu lation s for USTs

1 t was

• Tank owners' fears of not bei ng able to see ( unti 1 1 h h dergrouncl too ate) any problems occurrmg wit t e un sys tem

• The development of new tec hnology for aboveg round sys tem s, including num ero us forms of seco ndary containment

• Changing attitudes of fir e code offic ials, who saw th e · cl · · intro uct1on of new aboveground storage eq u1p1 wo uld address their fir e-safety conce rn s

Seeing is believing h

Th e need fo r e nhan ced e nvironm e ntal protection ca used und e rg ro und s to ra ge sys te m s to becom e con s iderab ly more ind · · 1 t· r o i1 s c ex pe ns ive. As e n v1ronme nta reg u et 1 we re e nac ted , inno vati ve sys te m s e mp loying secondary l <' 11 1

;rn rni e nt · re le ase d e tec ti o n co mpute ri zed in ve nt ory

As t e trend took hold many storage sys e1 chose to in sta ll their tank wh ich e nab led the tank ow ner to avoid reliance on elec troni c re lease detection . Id e their tank eq uipm e nt and inventory contro l. They co u se system at any and all time s of th e day. Abov eground tank cl k ere les s own e rs perceived that abov egro un tan s w reg ulated and less ex pen s ive (e ven thou gh that wa s not always the case)

t n owners

88

The end result of all this has been a boon in aboveground tank installations in the U.S. for motor vehicle fuel dispensing. Some tank fabricators report building two to three times more ASTs than USTs of late. Ten years ago, the majority of their production was focused on USTs. In addition, while secondary containment ASTs were very rare a decade ago, such tanks have become a common part of the manufacturers' product lines.

The fleet example

One market sector was quick to seize the new opportunities unfolding during the '90s, the private fleet fueling facilities in the U.S. Leery of underground storage tank systems, fleet operators had three options for environmental compliance: close and remove their underground tanks, upgrade their equipment, or install a tank aboveground.

Fleets in all segments long-haul freight carriers, schoolbus companies, taxis, golf courses, governmental and military vehicles and many others began to uproot their underground systems to pursue aboveground storage solutions. Aboveground storage tank systems have also become very popular at small and intermediate-sized airport facilities.

code modifications paved the way for the fleets, which often could meet requirements for locating fueling tanks far away from adjoining property lines buildings or public thoroughfares. '

However, new AST technologies and standards surfaced that extended for aboveground storage and enabled code-making bodies to decrease setback requirements. In addition, dispensers could be mounted directly atop or adjacent to the tank when additional tank protective measures were provided.

Fire code revisions

As more and more tanks in the U.S. were installed above grade, the fire codes added significant safety requirements to assure the disasters of yesterday were not repeated.

In the western half of the United States, by the mid-I 990s a "protected tank" was the only acceptable type of aboveground tank that could be installed for motor vehicle fuel dispensing. In the eastern half of the States, codes called for installation of "fire resistant tanks".

The protected tank is an insulated tank tested for two hours at 2000°F (1093°C). During that time the interior surface temperature of the primary tank must not increase over 260°F ( l 27°C). The tank must include integral secondary containment. Additional features normally include resistance to impacts from vehicles and bullets.

Fire-safety officials and developers of building codes expressed a common rationale for the protected-tank testing requirement. If a tank was to be installed aboveground, it should emulate an underground tank as much as possible. Therefore. the tank was insulated to slow down the generation of vapors during a pool fire and to give firefighters a greater sc>nse of sc>curity in case the tank had inadequate venting.

The fire resistant tank had to undergo a similar two-hour pool fire test, but the internal temperature was not as limited. Secondary containment also was not mandatory. The fire resistant tank "is a construction that provides the fire resistive protection that prevents release of liquid, failure of the primary tank, failure of the supporting structure, and impairment of venting for a period not less than two hours when tested using a fire exposure that simulates a high intensity pool fire, such as that described in UL 2085," according to the National Fire Protection Association (NFPA).

The NFPA code focused very heavily on prevention of the release of flammable or combustible liquids so that no pool fire would ever occur. This insistence led to the adoption of significant new language for tank accessories. As with protected tanks, all fittings had to be at the top of the tank. Even aboveground storage tanks installed in below grade vaults became a viable option. Codes gave very prescriptive language with vaults, due to confined-space issues.

Overfill warning alarms, overfill-shutoff valves, spill containers, and anti-siphon devices or solenoid valves had to be installed. Sophisticated mechanical and electronic gauges were developed. Important shear valves were required under dispensers. Pressure relief valves were added to aboveground piping to relieve excessive pressure by returning product back to the tank. Regulatory officials even requested a special "system listing" to identify tanks equipped with all such important appurtenances.

Environmental regulations

Also during the 1990s, U.S. environmental regulations took aim at aboveground tanks. Large-capacity refinery tanks, for example, had for many years provided secondary containment through earthen dikes. Because of an incident where large amounts of petroleum migrated more than a kilometer from a storaoe-tank fann to a residential neighborhood near Washin;ton, D.C., federal environmental regulators escalated their concerns to propose additional regulations to make AST diking vi1tually impermeable.

New AST owners also discovered that their facilities, if they were near navigable waterways, would have to comply with environmental policies that called for facility response plans (in case of a release) and other significant amounts of paperwork.

New technologies and standards

Steel Tank Institute maintains a database on several AST technologies that its members are licensed to build. In each of the last two years, STI has seen greater than 40% growth in AST technologies such as F92 l and Fireguard. The F92 l is a double-skinned AST. The Fireguard tank is a lightweight. 3-inch (7.62 cm) thick insulated protected tank. The insulation is sandwiched between two walls of steel, enabling communication of releases within till' interstict' and essential emergetll'\ venting m nlSL' pf a poPI firt'

;\ i

Both F921 and Fireguard followed in the footsteps of an AST built and installed in a steel dike, or a bunded tank, as it's more commonly known in the U.K. The dikes were completely impermeable and could catch overfills and any other releases from nearb y pipe and valves. When tank operators became concerned with contaminated rainwater, rain shields were built into the diked tank design as a unitized system. This prevented rainwater and snow from collecting in the dike. Rain shields came in all sizes and forms, some even completely encapsulating the tank. But a rain shield had a major handicap; it also prevented overfills from flowing into the dike , unles s special design methods were incorporated

Fortunately, the makers of underground overfillprevention valves were able to create a suitable valve for pressurized fill operations with ASTs. This enabled the safe use of rain shields. But soon tank owners figured out that they could obtain the same level of containment from a simple tight-wrapped double-skin construction (F921) or an insulated protected tank (Fireguard).

Third-party testing laboratories have produced a number of new standards to addre ss all of the new construction type s. The Underwriters Laboratories UL 142 Standard for Flammable and Combustible Liquid ASTs nearly tripled its page length during 1993 to cover requirements for bunded tank s , double skin tank s, rectangular tanks, and other new performance standards. Both UL and Southwest Research Institute created standard s for fire resistant tanks and protected tanks. These laboratorie s went in different directions with the mean s to mee t the NFPA fire re sistive tank definition , as some tank s could be insulated and others

could be uninsulated. It is important for authorities having jurisdiction to distinguish between laboratory test protocols More information on standards is included in Table A

The end users

So, who is buying these tanks? Fewer than 5% are going into retail forecourts. In addition to fleets, the growth in AST demand has come from such institutions as schools and hospitals, military bases, golf courses, and other commercial and industrial users.

The other trends worth noting in the U.S tank market is the increase in average capacity and the growth in demand from businesses that wanted to control the fueling of their autos, trucks and other vehicles.

For example, underground storage tanks increased threefold in average capacity from the early 1960s until today at a typical retail station. A 12,000-gallon (45,420litre) tank is now the norm. But during this same period , privatized commercial , industrial, institutional and governmental fleets increased in size and significance Many businesses installed their own storage tank system for dispensingpetroleum into their motorized vehicles using Petroleum Equipment Institute 's RP 200 as guidance.

So, the U.S. petroleum-storage industry has witnessed both revolutionary and evolutionary changes in tanks and the liquids stored.

What hasn't changed ?

Good question.

/

r----ifi, ervaulfMH (BOO) 253-TANK NO SMOKING ' / AN A BOV E GRO UN D TAN K ATTH E EXHIBITI ON l)()

Above Ground Petrol Tanks at a Retail Site

A case study

by Rory Hennessy, Tesco Stores Limited

Of the three it became clear that the prime objections to the original scheme were received from the Environment Agency and any new scheme would have to satisfy their stringent demands. A meeting with their ground and surface water protection officers revealed that the only options open to progress an installation on the site was for the tank storage to be above ground. Double wall pipework , bunding and a below forecourt petrol resistant membrane were also required to ensure no site impact on the local water abstraction system.

Clearly with any undertaking of this nature, as well as the environmental considerations, no risk to Tesco's environmental policy could be countenanced and the spillage and ground leakage risks were uppermost in the design considerations.

Following the meeting I was unsure where I could source above ground tanks large enough for a busy retail outlet. However at the APEA Exhibition in October 1998 I found what I was looking for and a design team was set up to provide a suitable petrol station layout to meet the business case requirements which were:-

1. Four x 45,000 litre tanks.

2. Six dispenser islands.

3. A car wash

4. A kiosk building.

d ·d desian with our 5. The layout should be a stan al "" . d ttirnina crrcle. nonnal dispenser spacmg an ° f· the site and sited away

6. Road tanker direct egress 1om from the forecourt.

Above ground storage tanks for petrol have been used in the U.S.A. on both industrial and retail sites for some years now but there have been no moves in the U.K. on a retail site for such storage as far as I am aware. However, Tesco have been looking at the possibility for one of our sites.

The site is one where a planning application rejection for a petrol station near a. Zone 1 aquifer was given despite underground double skin vaulted tanks be ing offered as the solution for protection of the groundwater from petrol leakage. Following customer fe edback the scheme is be ing re-visited two years after the store was opened.

The re were three main authorities with which to deal with a re-a pplication. namel y

I. The lo ca l authority planning department

2. The En v ironm e nt Age nc y

3. The Pe trol e um Office r

·n the space allocated to The layout proved a challenge l . . 1 I TI . f the orwma sc ieme. ie the petrol station on th e site 01 "' ·kina The space I d . b aiven over to Cal pal o · an had smce een "" bund required for f b round tanks 111 a reqmred by our a ove-g How e ver, after some . d 56 q metres alone. mstance require s iet· as well as the ·. nts were n ' effort all th e above requnem e f· buildin as and the f 12 distance I om o 1equ11ement OI Ill l Officer. Th e tank s " d b the Peno eum bounda11 es 1equu e Y . h f e resis tm g 111te rst1trnl I d bi skin steel wit a II c iosen were ou e · double containm e nt . . . bl 1 offe r aenume mf11l which were a e .o o ertifi ed by SwRI to 1 t n a They we1e c and a four hour Ire ia 1 o· / the 95-03 Multi Ha zard Test and UL- 14_ .

. ·k d oc! to be flexibl e w ith an integ ral Th e ptpe-wo1 , nee c · tl IP spec iti callon co ntmu o us le ngth s doubl e sk m meet.mg i e · . L · I ·1h 10 10111 ts be low arou nd. T he mt ers t1t1al were essen u a w1 1 c:space had to be eas il y monitored.

9 1

Full bunding of the tank s, tran sfe r pumps and pipe-work terminations was included to en sure that no minor spills pe ne trated below ground.

The forecourt slab was selected to provide a continuou s impervious layer of an asphalt/resin mix laid by a hot roll proce ss . This material , used on the continent amongst other applications for leachate m anag eme nt on environmentally se n sitive sites, prevents surface see page into the ground. It requires no expansion joints a so urc e of weakness in any co ncre te slab design A furth er precaution against surface spill seepage was to insta ll a petrol resi stant membran e la id be neath th e entire forecourt slab , including road tanker bay and tank storage bund The me mbrane had to be petrol resistant and one has bee n so urced that is used to form crude oi l reservoirs in the Texas oil fields. The drainage syste m design covers all spillage areas connected via drainage g ulli es to a full retention class l separator.

With any above-ground installation there are additional items to be found w hi ch are not necess ary with a be low gro und in stallation , th ese include:-

I Product tran sfer pumps from the road tank er to th e tanks as pumped deliveries are not currently allowed under current regul ati o ns.

2. Anti-syphon/excess flow valves to prevent sy phon age m the eve nt of acc ide nt a l suc tion line severa nc e. 3 S hear va lve s in stall ed beneath di spen se rs. 4. Press ure rated over fi ll prevention dev ices a nd hi gh level a larm s 5. Tank and sucti on line monitoring. 6. A larm system s monitored locally, remote ly and inte rlocked into th e di spe ns in g sys tem. 7. A n ag reed emergency contin ge ncy pl an to pro v ide a rap id re s pon se in the event of o n- s ite problems.

8. Add iti o na l staff tra inin g targeted specifically to the sys te m s a nd th e se ns iti v ity of th e site

T he sche m e wa s worked up in some detail and afte r ca reful de libe ratio h b n as ee n acce pted by the Environm en t Agency as o ne th ey co uld reco mmend to the Plannino Autho ri ty T he PJ c · A I b . . . . · anrnng ut io n ty had iss ues concern in g v isib ili ty of the 1n stc II· r· TI· · a c1 ion. lI S was ove rcome by lowering th e t k · · · a n s Ill the bund and pro vidi ng screening

Th e Pe t I Off· rn e um 1Cer was ab le to broadly app rove the sc he m e as the re quire me nt s of th e new IP/APEA g uidan ce foi a bo ve- g round tank s had bee n met. So what is th e c omm e rc ia l impac t of th e us e of above gro und tank s and the a ddiliona l e n v ironm e nla l con s id e rat io ns.

T he rt' a re ex tra c os ts incu rre d w ith the tank s th e mem h n mc lhe tra ns fe r o p.cl ·s monitor ing and a larm

There is a savi ng on the civil works assoc iated with excavation and spoil re mov al but this is off-set to some degree by th e provision of bunding. There is an arg um e nt that says bunding is not stric tl y necessary but in this case with ground contamination so critical it is co nsidered an additional precaution

As to the future of above ground tanks in the retail environment it is certainly an option where e nvironmental conditions preclude an undergro und insta llation. The space requirements and costs probabl y make it only viable in certain circumstances where land is available a nd th e return of capital inves tm ent ju stifi es the additional cost. Clearly with a superstore it is anticipated that store sa les will increase as a result of th e ava ilability of petrol which, toge ther with th e petrol sales, certainly mak e it an option that cannot be ruled out.

'\" l l.Tll '>

WETSTOCK MANAGEMENT THE BETTER WAY FORWARD

BY BOB CONLIN FAIRBANKS ENVIRONMENTAL LTD

Tel. +44 (0) 1695 51775; Email: info@fairbanks.co.uk

At the APEA conference three years ago, Fairbanks presented a paper on Wetstock Management aimed at raisino awareness of the importance of good wetstock contr;l. I have to say that not much has changed in the intervening period. Since then there have been some sionificant leak incidents in the UK their identity being well b reported within our industry and in the national press. The common thread is that leakage to ground has continued undetected for a considerable period of time and is largely due to inadequate control systems in place.

Thankfully there has been no fatalities as a direct result of leakage. This however continues to breed complacency amongst petrol service station operators. Sooner or later that luck will run out.

If we are truthful, standards of wetstock control and leak detection in the UK are unacceptably low and I am sure we all accept the need for improvement in these standards, but the debate is how to best achieve this. This paper sets out the Fairbanks proposal which we believe is the 'Better Way Forward'

To put the importance of wetstock Management into perspective, let us consider an overview risk assessment.

The Hazard

• the delivery, storage and dispensing of hazardous products in a public place

• supervised at times by inadequately trained staff

• •

with systems and procedures which can make it difficult if not impossible to know if there is a leak with the majority population of single skin carbon steel tanks and lines placed generally in corrosive ground conditions

The Risk

• that an undetected leak could cause a fire or explosion with the potential to kill people

• that it could cause groundwater pollution

Control Measures

In order to comply with a policy of 'absolutely no oil release to ground· a site operator would need to upgrade the site to:

• full secondary containment of tanks and fill lines

• a minimum of under pump valves to protect lines ensuring that they fall adequately back Lo the tanks. ( a conditi;n often difficult to achieve it seems even on new developments )

• leak detection systems kept in full working order

• a liquid tight pavement and (liquid tight) drainage system with full retention interceptor

• liquid tight sumps and chambers

This strategy is unrealistic and cost prohibitive as a short term objective in the current economic climate. For a typical retail network of 100 sites the cost is likely to be between £20m £25m.

A 10 15 year plan may be to upgrade sites on a risk based prioritisation programme, dealing with high risk sites first. But how do you identify those sites which actually present the highest risk? Do you use tank age as the primary factor or undertake a subsoil survey to determine propensity to corrode or use environmental sensitivity ( source pathway receptor). This is not an easy decision to make; I can recall a leak incident on a tank less than 7 years old costing the oil company in excess of £500,000.

A more realistic strategy involves the implementati?n a 'suitable wetstock management system·. The is that leaks causing 'oil release to ground' will contmue to '": . f The obiective of a occur and at an mcreasmg requency. J · d t et these leaks very Sllltable management system 1s to e e · · · ,,. · ·d nts This approach early so erad1catmg maJor le<u\. mc1 e · . . 1 1 f protect10n whilst a affords the site operator the nght eve o d I mentation programme sensible and adequate upgra e imp e can be planned and budgeted for.

. k s oood business sense

It is also quite obvious that it ma e o to have sound controls in place and wetstock management is no exception.

I . . ·t ··iteoy is the reasonably In risk assessment tenns t 11 s s 1' 0 • , f' the maionty of sites ,md practicable solut10n fo1 by .. ,u_. es of: BATNEEC ( Best certainly conforms to the pnnopl · . . T 0 Excessive Cost). Available Technology Not Entai ll1e

What constitutes a ·suitable· system?

· bi)' be describing the Jn ·mswerino this I will inevita . ' e , w· , ·dii Ser\'ice which has been Fa!fbanks WctstoL k iz.ii 1 able penod ol time and is developed over a consiL er . 1 w ,r 470 nUlJOr oil company providing protecuon 01 ( 1: service stations.

bi t t·t"r .111 •11111roiiriatc k've I of protect ion

It must he a c o o 1: ' '' • t. I l 'v 'I of site eL1ui11mt'nl. \.\ hllst thert' art' trrespect1vc o t 1e t: t · · , 1l, 1,t·1 ·rs of not havttH.'. to rely on use clear operat1011<1 ic r t: · , I l. k. tl1' t"·tl'I ,·" tint a st •>111 ticant numbll ot ..,tit's o ( 1ps11c s. t · · "' ·11 · r ) 'l() s"() t or 1n-111\ vears ll 1 t"Ptnt' and t hn art' wt contmue l ' . . probably those site;. IllPSt at risk

l)

We believe that it should be a 3rd party accredited quality system. Our system and procedures are accredited to BS EN ISO 9001. A site ' s records should be externally audited by those with relevant experience, just in the same way that a company ' s business accounts are.

It should operate to a set of minimum standards. These would commit both the site operator and those managing the system to clearly defined responsibilities such as daily checks , notification thresholds and incident reporting.

It should provide proactive monitoring because if we are serious about controlling leaks to ground then we must be able to notice a leak as soon as it is 'detectable ' when it is only 2 to 3 litres per day.

Finally it responsibility provide the compliance.

does not reduce or remove the legal of the petroleum license holder but should appropriate assistance to ensure legal

I will now describe the 10 elements which make up the Fairbanks Wetstock Wizard Service.

render a monitoring system ineffective. In one e xtreme it will cause false alarms resulting in unnecessary investigations; in the other extreme losses including leaks will be overlooked. Because of this we invest substantial resources in cleaning up erroneous data This involves a high level of contact with our sites by phone , fax or email to clarify anomalies before we make amendments to the data received Through this process we identify instances of split tanker pots overfills and spillages. Direct contact with sites also gives us an opportunity to give feedback , advice and coaching on areas for improvement

Statistical Analysis

This is the process which is at the heart of our proactive monitoring. I would however like to emphasis that for us to achieve our objectives which are the early detection of leaks and reduction in operating costs the statistical analysis must be supported by the other 9 steps. Our analytical techniques have been developed in house and as you will see we have successfully detected leaks in tanks, lines and offset fills in a dynamic environment at leak rates as low as 2 -3 litres per day which is about 3 times more sensitive than the 0.378 litres per hour EPA standard for a static tank test.

Our service monitors the entire petroleum installation; the tanks, lines and offset fills. It will highlight poorly calibrated tank gauges as well as short dipsticks. Through this process we establish tank specific variance profiles be they 0.15% in Manchester or 0.65 % in Glasgow. Much wasted energy ( resource and cost ) goes into investigating leaks that don't exist; where retailers use network wide thresholds . These can be inappropriate and quite dangerous if relied upon to trigger investigations.

Compliance Audit

When. we take on a new site we carry out a compliance audn which consists of a de sktop analysis of hi storic data to establish variance profiles and to determine whether there is an ex is ting leak The on- s ite audit consists of a full of the pe troleum in stallation and equipment , an ssess ment of on s ite procedures and staff competence and a . pump meter audit so th at pump under or over di spens ing IS ta ke n mto account in th e reconciliation proces s . If th e site faJi s be low th · · e m1111mum standard we issue a schedule of non compliances and s ubject to these being remedied we will iss ue a compliance certificate.

All of our s ite ba sed and offic e based procedure s are co ve re d by ISO 900 I qu alit y management sys tem All of o ur ac ti o ns a re trace abl e and auditable.

D a ta Input

T he fo rmat of reco nc ili ati on data and th e me thod in w hi c h it is tr a nsmitte d to us de pe nd s on th e leve l of site equipm e nt . It ca n ran ge fr o m ove rnight electroni c dat a tr a nsfe r to wee kl y rece ipt of pap e r ba sed rec ord s. A vital fe a ture of o ur dat a process in g is its trackin g sys te m whi ch no n rece ipt a nd pro mpt s us to ' c hase ' ove rdu e data.

Data Va lid a twn

T ht· c on1 111ua l e nt ry hy s ites of in acc urate data wi ll

Our service benefits from a large data sample of service stations covering most UK supply terminals.

Exception Reporting

Daily exception reports flag up those tanks exhibiting unacceptable variances. These are then investigated in detail. Variance s can of course be gains as well as los ses. An unacceptable gain could indicate water ingre ss and must be investigated

The sy stem will also run off equipment performance reports for such events as downtime sorting by equipment make and type.

Loss Investigation

Thi s is where factor s creating ' apparent ' variance are accounted for and elimin ated.

Sometimes we will notic e significant changes whi c h a.re common to a group of sites in one area only to di scov e r that it coincides with tenninal gantry meters be ing recalibrated or the supply bein g mad e from a different terminal.

All inv es ti gation s are co ntrolled by o ur man age me nt rev iew process whi c h e nsures that in ves tig a ti ons are formall y esca lated and eve ntuall y signed off.

The urge ncy and pace of an in ves ti gati on de pe nd s on th e de tected lea k ra te and th e e nvironme ntal se ns iti vit y of th e

"' ... " " · w· :it I I • ·1 1 t· 1: •

94

site. Depending on the circumstances we may move to arrange e mergency tank and line testing or even a fuel uplift.

More usually the investigation will progress at a measured pace due to the fact that where a leak is the cause it is still in its infancy and has been detected well before it would be with other reconciliation methods.

If we have not been to the site for a reasonable period we may make a revisit. We will check for meter drift or equipment changes since our last visit which may account for problem.

Liaise with Intere sted Parties

When a new customer signs up to our service they agree to our procedure of the earliest possible notification to the licensing authority and environment agency when a leak is suspected. We must ensure that we caITy out our duty of care in notifying and taking the appropriate action so as not to knowingly allow a release of oil to ground. Early involvement of the regul a tory authorities improves overall co-operation and results in an efficient investigation.

During the investigation we make sure that the site operator and where applicable the oil company field and head office management are kept fully infonned and are involved in the process.

Identify Source

Through selective isolation of ta nk s and pump s and assessment of the various s igns and symptoms we will pinpoint the source of the loss. Thi s minimi ses on-site costs which could be limited to a single line test It also minimises the on site disruption which would be caused by say total site testing.

When a leak is confirmed we will quantify th e lo ss a nd pinpoint the st art date

The outcome of so m e inve stig at ion s have been that no leak was found but th e los s rate recovered following th e in depth inv es tigation. Thi s is st ill a sati sfactory for us and our clients.

Leak Incident Management

Wh e n pe troleum or petrol vapour is reported off s ite we are able to .confirm to the re g ul a tory a uthorit y that the s ite be ing momto re d by ourselves is not the so urce of the leak without the ne e d for tank and line tes tin a b"

Wh e n a leak how eve r is co nfirm e d as part of our inves ti gat ion we co ntinu e to support a nd advise the s ite operator by co -ordinatin g further inv es ti ga ti o n a nd re m e di a tion wo rk s , by a rran g in g fu e l uplift s an d by advi s ing on tank a nd pipework repair s o r re pl ace m e nt. We w ill re m a in in co nt act wit the s ite and regulatory a uth o rities until th e site is re nd ered safe.

Management Reporting

W l;ether a s ite has und ergo ne a n in vest igat io n o r not we st ill produc e manag e me nt re port s. Thes e ca n be ne twork s um mar ies by grade reg ional o r <trea reports or s ite by s ite re port s and at the frequ e ncy dema nded by th e c li e nt.

Reports produced can show cash variance as well as litres variance, which for some operators is more meaningful and relevant.

With so much detailed information available it is possible to respond to demands for ad hoe reports such as tank stock holding performance, tank grade change optimisation and tanker delivery optimisation.

Having looked at the I 0 steps of our management service I would like to show you some remarkable results enjoyed by our client sites.

Leak Incidents

Leak Leak Ave rate rale daily

Leak Tank litres litres tank localed Gauge I per per sales

Site in Dipstick day hour litres Cost Notes

A Line Digital 3 0.125 1600 £5.000 phase 1 soil investigation only

B Line Digilal 3 0 125 300 £5.000 phase 1 soil investigalion only

c Line Digital 3 0.125 3300 nil

D Line Digilal 5 0.208 560 nil

E Line Digital 3 0 125 360 £5 000 phase 1 soil investigalion only

F Line Digilal 4 0.167 700 £2 000 checking existing v;ells

G Line Digital 1 0 042 2200 nil

H Tank Digital 3 0.125 5200 nil

I Tank Dipstick 2 0.083 1700 nil no fUel loss water ingress

J Tank Dipstick 7 0.292 2200 £5,000 phase 1 soil investigation only

Thi s is a sample of the le a ks we have detected. You will note aaain the detected leak rates and the number of b occasions when no soil investigation or remediat1on was necessary. A significant success was site J where a tank leak was dete cted on a site with short dipsticks and where tank d '° · . week Aaain the 1ps were taken only a 1ew times pe1 · o amount of fu e l lost wa s such that no cleanup was nec essary Wetstock Loss Reduction 1997 vs 1998

Whil st a 0.03 % l ecluct1·on in los s ma y not seem II of you it act ua ll y repres e nt s an s 1g 111ti ca nt to a f b t· in th e e le me nt ot loss w hich 1s imp rovemen t o a o u c . · I · 1 1 conri·ol ( ,e exc lu cl m g that cl ue tu w1t1 1n t1 e s 1es · ev aporat ion and ne t te mp e ra ture change ).

l)')

+------<

+------< s0

+----;

+------<

0.25% 0.22% 0.19% 0 20%

30 15%

10%

0.05%

1997 cl . rovement in we tstock loss Thi s c ha rt shows a rnarke imp . t. cl more s ites o nto con 1act. durin g 1998 as we took rnoi e an 1 stoi·ic cl·ita prior . . f · ou r cl ient s 11 c c The 1997 fi g ure is take n 101n. . . I 999 so far look 1 11 Our ti a u1 es to1 to o u1 mvo ve 111 e 1 · "' t. I imlJroveme nt s promising and we expect to show u1t1e1 Watch thi s space.

3 of the 4 incidents in 1998 occurred prior to our service being in place. You will note that the number of detected leaks has increased during 1999 but more signifi cant ly the average cost of leak incident has reduced from £245,000 to £10,000 These costs are purely external and incident related and so do not includ e internal company management costs or the cost of eq uipm e nt replacement or site rein statement

Benefits of a Su itabl e Manage m ent System

A sys tem that meets the standards estab li shed by the Wetstock Wi zard will ac hieve the following:

• It will ensu re that the site operato r achieves legal compliance

• It may be accepted as a n a lternative to routine tank te stin g as o urs has been so far by the LFCDA and Kent

• It wi ll minimise the effec t of the next leak

• It w ill minimise demand o n a company's env ironmenta l cleanup fund

• It wi ll introduce muc h tighter busine ss con trol

• It ca n s ignificantly re duce both revenue and capita l expe nditure

• Tt w iII e ns ure that the ri sk to HS&E is co ntroll ed

• It w ill enhance th e com pany 's brand image.

The Better Way Fo rward

In co nc lus io n I offer to yo u th e way we are do in g bu s mess as the better way forwa rd. We bel ieve that it is a re al is ti c so lu tion to a ve ry se riou s probl e m. We clear ly see that pro ·'c t· · 1 ' b -.:, ion is pre ·e ra le to prosec ution and we look to wa rd s s ite o pe rator s and reg ulator y a uth ori ties to em brace th is approach in o rd e r to make the mu c h needed 1111 pro ve m e nt s.

External Cost of Incidents £1 ,000.000 £984 000

£200 ,000 £0+---19 98 1999

£800.000 £600.000 £40 0,000

l)() We are the Specialists for · • Wetstock Monitoring • Loss Investigation • Compliance Certification • Meter Auditing & Re-setting • Wetstock Reconciliation Software • Telephone Advice • Training For Site Staff and Petroleum Enforcement Officers Fa irbanks Environmental Ltd The Technology Management Centre Moss Lane View Skelmersdale Lancashire WN8 9TN Tel : 01695 51775 Fax : 01695 728898 email lnfo@fairbanks .co.uk www .fairbanks .co . uk Ccr11fic alc N" 1853198

Where to from here?

JACK GALL THOMSON

In a country like the U.K. where endless Chancellors have extracted more and more revenue from the poor old motorist in iniquitous petrol taxes, the reduction of tax on autogas in our last budget seemed too good to be true.

Indeed, it was quietly popped out wearing carpet slippers. Very few of our citizens seemed to be aware of this "hand out". But I was , and immediately set about converting my 4.0 litre Range Rover to dual fuel, which was done by a local firm here in the East Midlands.

I wanted a hundred litre tank alongside the existing hundred litre petrol capacity of the car. This seemed to be a desirable arrangement in the light of the present scarcity of autogas refuelling points in the UK.

The plusses of this magnificent Range Rover driving machine are tempered by the minuses of it's thirst for petrol, and I make no excuses that this was my main reason for the conversion. The resulting half price fuel is very rewarding well, it is to a point but could be so much better and then we come down to earth please read on

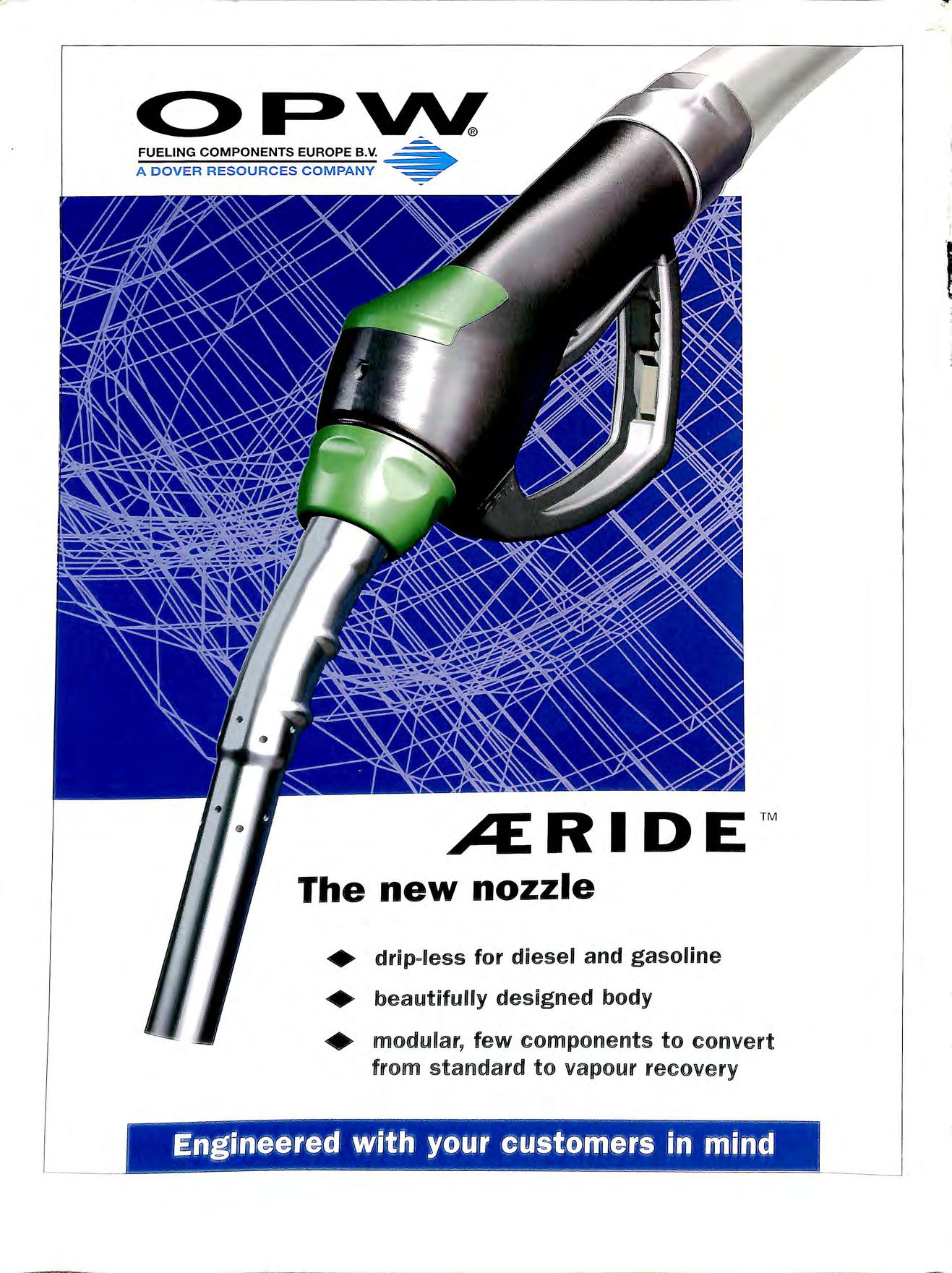

Some time about 1970, give or take a year, it was suggested by the then Shell-Mex and B.P. Ltd. that I should look at the creation of a forecourt LPG nozzle. That, I was assured, was the way ahead, but, as we know, it was premature. However, I did have a look at what was around at that time, and, thirty years on, not much has changed.