•Full annual certification provided.

Everyone needs to know how aood a Stage t B b really is Petroleum and Fire Officers , Environmental Officers Tradina Standards Officers and, of course , site b

Complete knowledge of a site's Stage 1B reduces nsk for the site operator, delivery driver, site p e rsonnel and the general public , as well as prot ect ing the environm e nt

Poorly designed, inefficient Sta ge 1B systems may appear to be working safely, but could fail on the ne x t d e livery, causing a major incident! There are many sites in this situation!

The Petroman Interactiv e Test offers the following :

•Tes tin g of all components of Stage 1 B includin g th e delivery tanker.

• Accre dited , fully train e d and ex pe ri e nc e d engineers

•Full UK coverage .

• Blue-Print Testing service for new and refurbished sites.

• Testing of sites without Stage 1B for compatibility with vapour recove1y.

•Already being adopt e d b y major oil companies

•Tes ting carried out to ISO 9002 Quality Assurance Standards

Ig norance of Stag e 1B and its operation is n o lo nger an acceptabl e exc u se for incidents and hi g h risk situations durin g a d e live1y.

Testing is now compulsory, so it makes sense to use our system Petroman provides the only fully comprehensive test available .

.until now!

Who Should Attend Industry personnel who wish to obtain, in depth understanding of the areas of risk assessment at Petrol Filling Stations.

Subjects Covered Hazardous areas, Construction safety, Maintenance & repairs, Decommissioning, Environmental.

Certificates of attendance will be issued. Fees Members £160 + VAT. Non-members £210 + VAT

Please Contact Mr Bob Conlin at Fairbanks Environmental Ltd Tel: 01695 51775 Fax: 01695 728 898 E-mail: bobconlin@fairbanks.co.uk Web: www.fairbanks.co.uk

Who would be pleased to arrange a course to suit your requirements Fees to be agreed --------------------------------------------------

To suit your Timetable, Venue, Delegates. Fees to be agreed --------------------------------------------------

Deadl ines for all Courses are 2 months prior to event. Contact the Administrator to register your interest Tel: 01582 882 753 Fax: 01582 882 754 E-mail: admin@apea.org .uk

Updates of the training programme are available on the web site www.apea.org .uk

Combining the strengths of sophisticated materials and technology Petrol-Line Xtra is tough, strong and 'fuel proof'the ideal choice for all service station applications.

Manufactu red 'in line' our system combines the integ r ity of Petrol -Line Xtra with a robust close fitting polyethylene oute r sheathing to satisfy the environmental concerns with the emissionof VOC's and accidental fuel losses Glynw ed Pi pe Systems Ltd,

It's no coincidence that Shell, Esso, and BP all use the same tank gauges. The world's biggest oil companies want the world's best wet stock management systems. And that's what they get with Veeder-Root.

We invest heavily in research and development in order to ;(:J produce technology which is f;: superior to anything else on the market. No other tank gauges are more accurate, reliable, effective or easy-to-use

In fact, our equipment monitors over 300 ,000 storage tanks around the globe. All these

gauges are comprehensively supported by a network of highly-trained distributors, backed up by Veeder-Root technical support staff So it's not surprising that our levels of support are famous world-wide, too.

But our global reach is based very .• firmly on local relationships And '\i · when it comes to cost, our customers find that a VeederRoot system can be very competitive indeed.

It's why oil companies both big and small all put the same thing in their tanks VeederRoot tank gauges.

IFFE 2001 Exhibition will be

bi I 5· be-1ng 1:aken-over unrecogn1sa e. 1nce by William Reed Ltd i"t will expand across "the entire fuel and fuel equipment spectrum service stations, "truck/car fleet operators, marina operators, airfield operators, engineering specifiers, architects. In fact i"t will bring ideas and products from all the sectors "together under one roof-the benefits "to you vvill be enormous.

UK and EU departments responsible for "the fines currently being "targeted a"t "the industry.

Everyone vvi"th a fuel retail outlet, everyone involved in fuel management and fuel equipment in "truck fleets. marinas, airfields and emergency services fleets and every specifier and engineer. This is "the only integrated show of its kind anywhere in Europe. i"t will prove invaluable "to your business.

and d evelopments than y o u "H see all year!

Over 90 manufacturers from around "the vvorld will be a"t "the shovv. They vvill present you vvi"th a unique opportunity "to get hands-on experience of their products and ltllew launches.

The Institute of Petroleum is lhioDdinig ats ondustry coniferenice at: 1l:he slhow. Rt: woB H take pOace across t:hiree days E verythall1lg of importance <ailllldl ILllirgellllc y to the 01J11d1U1stiry w m be dusc lLlls scedl i1nw:::DlL!ldill1lg "Best Pirac fl:kce' tpirese1l1l1!:ai!:uorr11s a!llldl 1r'<eIPireseell1l"ft:<arfl:avces fire !l1r1I

And, don't forget , IFFE is on at the same time as the Convenience Retailing Shovv in the adjoining hall of the NEC Birmingham UK on 13 14 15 March 2001.

As the year 2000 comes towards its end we in Europe have suffered this year the problems associated with petrol shortages. The picketing of depots and terminals in the UK soon brought this country to a standstill and perhaps made everyone aware how reliant we are for fuel in our everyday lives. It also made some question if our journeys were necessary. The shortage caused political problems for the Prime Minister and the Government and safety problems with people storing petrol in unusual and often dangerous circumstances.

It seems likely that these challenges may well affect the industry again in the months to come. This year our conference will be opened by Ray Holloway of the Petrol Retailers Association who has frequently given a view of the industry to this problem.

This year the Association is holding its Exhibition and Conference at the splendid new venue in the Royal Docks in London. This prestigious venue will be opened for a few weeks before our event and already it is proving a success with more Exhibitors already booked than in other years. The APEA has taken two halls and the facilities for exhibitors and visitors alike are excellent.

Access to the site in Docklands is exceptional with public transport running to the door and motorway access and City airport on the doorstep make European visitors access very easy. In each copy of the Bulletin you will receive a conference and exhibition registration form which is free to members who register before the event.

Hotels are available close the halls at reasonable rates for those staying over. The APEA Council has also made available funds to Branch Secretary's to ensure that if the interest is there from Branches then coaches or minibus travel to the event can be arranged. If you are interested in taking up this offer please contact your branch secretary the number is in this edition.·

BP AMOCO to announce new plans on design and engineering changes in European forecourt design, which will enable all in the Industry to learn how it will affect us Regulators will be able to see how these designs will affect approvals for new service stations and they will be able to question the engineers about these changes. Manufacturers will be able to see how they can adapt products to meet these new requirements.

The MTBE issue will also be raised in presentations from both the US and the UK and the problems that leaking lines and tanks raise. There are also radical design changes in modular forecourt design and forecourt drainage treatment, which will be of special interest.

The Conference Dinner is to be held at the ExCel centre on Monday 2th November in the purpose built banqueting rooms on the first floor. 1\1 addition to the dinner where the industry can meet customers and colleagues in an informal atmosphere there will be a high quality guest speaker at the event. Tables can be booked by contacting Brian Taylor on at £470.00 for a table of 10 including VAT or £47.00 for individual seats.

If you are interested in taking an Exhibition space please contact Brian Taylor on £650 per 4m x 2m block.

For more information on the ExCel Exhibition centre try www.excel.london.co. uk

Members who are visiting the Conference/Exhibition, and who wish to arrange their own overnight accommodation, are advised that there are several nearby Hotels to the Conference Centre and which are close to the underground, railway or the Docklands Light Railway system.

There are three stations on the Docklands railway alongside the ExCel Conference Centre, and the central station Custom House will lead you into the main entrance of the complex.

The Association's Exhibition Halls are situated a few years on the left side of the concourse.

These are as follows:-

Central

Hotel Telephone Reservations

Ibis Docklands 020 7517 1100 0208 283 4500 Ibis Greenwich 020 8759 4888 as above Etap Victoria Docks Opening July 2000 as above Fomiule 1 East Barking 0208 507 0789 as above Travel Inn Beckton 020 7511 3853 0870 242 8000 Premier Lodge Southwark 0870 700 1456 08702 01 002 03

Members wishing to make there own arrangements should contact the hotel of their choice for availability and prices.

Residents were forced to flee their homes when it was discovered that a taxi driver was hoarding hundreds of gallons of fuel in his home.

The driver. from the Normanton area of Derby. had stockpiled the petrol in a 55-litre beer barrel. a commercial sized paint tub and a bin.

The alarm was raised when about 140 litres of the fuel seeped through a split in the bin and neighbours reported smelling petrol.

When the fire crews arrived they evacuated 20 homes. The residents then has to wait for six hours in a local school as the area was made safe. A fire service spokesman admitted that the officers were horrified when they discovered the source of the smell.

The driver. who has not been named. was last night being questioned hy police.

The United States based Tokheim Corporation, of which Tokheim UK is a key subsidiary, has announced that it has successfully concluded its Chapter 11 financial restructuring plan.

The jurisdiction, which applied only to the Tokheim Corporation and not to any of its subsidiary companies outside the United States, effectively gave Tokheim court protection from its creditors whilst the company carried out a major debt restructuring programme. Nearly half of the company's debt has been eradicated and an injection of an additional $48 million of working capital provided.

Confirmation comes only 38 days after Tokheim filed its pre-packaged restructuring plan with the United States Courts.

Douglas Pinner, Tokheim's Chairman, President and Chief Executive Officer said the company had received strong support from customers, suppliers, employees and advisors throughout the restructuring period which had been confirmed on an accelerated timetable. "We are now positioned to capitalise on our technological superiority and thus to reinforce our position of leadership in the industry" he commented.

Meanwhile, Tokheim UK's General Manager Steve Del said the prompt return to a normal trading pattern was the best possible news for the company as a whole and would be welcomed by everyone connected with the company's extensive UK operation.

"For our customers, suppliers and members of staff here in the UK the message is clear. It is very much business as usual. We are and always have been at the forefront of the UK petroleum industry and we look forward to consolidating our position in the coming years," said Mr Dell.

BP has announced a new alliance with Suresite Limited, the Health and Safety compliance specialists, which will help their dealers comply with the increasing burden or legislation relating to forecourt operations. As of the first of September. all new dealer contracts will include Suresite forecourt audits.

Jason Bayliss, Dealer Programmes Manager for BP. stated; "We have recognised that there are not short cuts to be taken with Health and Safety in forecou11 operations and we want all BP sites to take the lead in this area. We are therefore supprn1ing our dealers with this additional benefit. We beJ ieve the Suresite service will offer our dealers greater peace of mind and assistance in maintaining high levels of 4uality operation

Suresite was cstablished in 1994 to assist forecourt (Jperators to comply with petroleum licensing conditions. id fl" 1 111.!.' I hem of the pressure associated with increased and

changing forecourt regulations. Used by major oil companies, major retailing groups and over I OOO independent operators, Suresite ensures that site records are correctly maintained and appropriate health and safety procedures are in place.

Suresite spokesman, Matt Oldham, states; "In an environment where many petrol retailers are feeling under pressure, Health and Safety documentation can sometimes be forgotten, We are delighted to be working with BP to offer our support to their Dealer Network".

The Association has been advised that it is a requirement of the Data Protection Act, to remove records of members who have allowed their membership to lapse, therefore the details of persons that have not renewed their subscription for the year 2000 will be deleted from the Association's system and will no loncrer receive the benefits of b membership.

Members are advised that the development of the site ?as progressed further and more information is gradually bemg inserted into the pages. However we are anxious to ensure that more news items are submitted and members can log on to the site www.apea.org.uk and click on the News tab on the left side of the front page, then scroll down to the bottom and click on the submit button. This will allow members to enter the information they wish to share with others and also the visitors from all over the world who have visited our web site.

The type of information required for the news pages, are short items such as incidents on a forecourt, details of tank or pipe work failures, overspills, or any thing members think may be of interest to others in our industry in the UK and the rest of the world.

Persons who submit news items can, or not, be named as supplying the information.

Obviously information should not be submitted, if it is subject to legal proceedings, this information should b_e sent_ to the editor for inclusion in the Bulletin on completIOn of any proceedings.

Members are advised that all submissions for the News page will be at the discretion of the Web site manager and the information should not be a vehicle for advertising.

Pai1 of the development of our web site allows members to send e-mail messages direct to the various Committee Chairmen by using the web site feed hack form on the front page of the site. Just click on the feed hack tab. fill in the selected boxes at the top then scroll down to the message section and enter your message click on the tab at the bottom of the page and select the Chairman you wish to receive your message.

Alternatively you can send your e-mail information direct to the Chairmen at the following addresses:-

associationsecretary@apea.org. uk publicationschairman@apea.org.uk technicalchairman@apea.org. uk advertisingsecretary@apea.org. uk eventschairman@apea.org. uk

associationtreasurer@apea.org. uk trainingchairman@apea.org. uk adrnin@apea.org.uk

Mr A BerryMr Jamie Thompson

Mr Jamie Thompson

Mr Robin Green

Mr Chris Knight (Conference/exhibition)

Mr Mike Silmon

Mr Barry Gardner

Mr

Brian TaylorThe owner of a former service station received burns to most of his face when the underground gasoline tank he was trying to empty exploded.

Sam Gibson, 60, of Soldotna, was to stay overnight at Central Peninsula General Hospital in Soldotna so that doctors could be sure he did not develop breathing problems after inhaling hot gases from the explosion. Gibson, his face swollen and red, was listed in stable condition.

"It's just one of these freakish things, I was aware that it can happen," he said. "You take all the precautions. I"m sure it was static electricity. I don't know where it came from."

Gary Hale, fire marshall for Central Emergency Services in Soldotna, aid there was not apparent damage to the building at Gibson's former SS&T Tesoro station near Mile 91.3 on the Sterling Highway east of Soldotna.

"It was like and earthquake," said Sandy Gries, a cashier at Big John's, across the highway from SS&T. "It shook the whole ground and the building."

The incident occurred about 9 a.m. as Gibson was attempting to pump the remaining tow inches of gasoline from an underground 12,000-gallon storage tank to a 55gallon drum. He closed the gas station about two years ago. e was preparing to flush and decommission several tanks there to comply with Alaska Depmtment of Environmental Conservation and fire code requirements, Hale said.

Gibson's electric pump quit moving gasoline after about a minute, Hale said. he shut it off. allowed the gasoline to drain and turned it on again. Nothing happened. He turned it off. moved the pump to the side and peered into the tank. That is when the explosion occurred.

'"It was just a big flash. Bam!" Gibson said. '"She just rumbled and hissed and blew for a while".

Flames shot I0 or 12 feet above the access hole for a couple of minutes.

'"It sounded like a 747 trying to get off the ground:' he said.

Gibson received extensive first-degree burns and some second-degree bums to the face. His wife, Susan, drove him to the hospital before Central Emergency Services arrived.

Several 911 callers reported the explosion. Hale said two Enstar Natural Gas Co. workers on Southern Bluff Street behind Big John's reported hearing two explosions followed by a whooshing noise. CES answered with two tankers, an engine, ambulance, three command vehicles and 12 firefighters and medics.

The first firefighters arrived within about three minutes, Hale said. A small flame burned briefly at the end of the vent pipe from the tank, then went out by itself. Firefighters found carbon deposits on the vent pipe, but no apparent damage to the SS&T building. The transfer pump was bent during the explosion and could not be removed from the tank.

Hale said Gibson was wearing coverall made from 65 percent polyester, 35 percent cotton cloth. Around North Slope oil and gas fields, he said, polyester cloth is known for producing static electricity and sparks.

"We've experienced static arcing from our clothing to equipment", confirmed CES engineer Dick Krapp, who has worked on the slope. "Especially in a gas situation, we hooked wires to ourselves and grounded them before we should go in".

Hale said proper earthing and a through knowledge of the equipment being used are essential for safe transfer operations. Gibson said his pump was earthed.

DEC workers visited the site of the blast.

"We saw a singed hat and looked at a singed pump,'' said DEC environmental specialist Gary Folle. "Around a manhole cover, there was some burnt grass."

He said he believes Gibson gave proper notice that he intends to remove the tanks. Gibson is required to take soil samples when they are removed, Folley said, and that will detect if there is any contamination.

Total ContainmentlD, Inc is pleased to announce the following recent additions to the United States sales force.

Tony Adamson has been appointed Vice President of Sales and Marketing. He is responsible for all sales and marketing activities globally. Formerly of Tokeim Corp., Tony will be working out of the Oaks office.

Joss Yornm has been hired as Eastern Regional Vice President. Joss will oversee all Total Containment sales managers and sales representatives in the eastern U.S.

Brian Ott has been hired as a Sales Representative. Based in Oregon, Brian will cover accounts in the states of Oregon, Montana, Colorado. Wyoming. Utah and Idaho.

Steven (Eddie) Hughlett has been hired a Sales Representative. Based in Texas. Eddie will cover account>. in Texas. Louisiana. Ne\\' Mexico and Oklahoma.

Chevron has reached a deal to acquire Texaco for about $45.4 billion in stock and debt assumption, creating the world's fourth-largest oil company. The boards of both companies have approved the transaction. A formal announcement is expected this morning. Chevron values the stock portion of the transaction at $35.3 billion. It will also assume $7.4 billion in Texaco debt and preferred stock, and $2. 7 billion more of the debt carried by Caltex Corp, the two companies's Asian refining venture. The combined company will be called Chevron Texaco, and joins the ranks of other industry powerhouses formed by similar mergers. About 4,000 jobs, or 7% of the 57,000 combined workforce will be eliminated as a result of the deal. Antitrust concerns are likely to be raised because the combined company would have an interest in 40% of the retail gasoline market and a third of the refining capacity on the West Coast. Chevron's top executive David O'Reilly will be chairman and CEO of the new company, while Texaco CEO, Peter Bijur, will be vice chairman. Under the terms of the deal, Chevron will pay about 0.77 of one of its shares, worth $64.87 based on Friday's closing price, for each share of Texaco, an 18% premium. Chevron also will assume $8 billion of Texaco's debt. The deal could require the companies to sell possibly thousands of gasoline stations in order to resolve regulatory issues. But by combining forces, they could create as much as $1 billion in operational savings and would become more competitive in developing new fields. The deal would close the gap between the combined company and Exxon Mobil, which had 1999 sales of $160.9 billion. Chevron had 199 sales of $31.5 billion, while Texaco had sales of $35 billion last year. The companies held negotiations that collapsed in June 1999 when Texaco turned down an offer of $70 per share as too low. A change in Chevron's leadership and Texaco's inability to boost its share price eased the way for new negotiations. The difference now is that Texaco can see its stock is dead in the water and they need to do something. Although crude oil and natural gas prices are near record highs, Texacos shares have fallen 12% since April 1999. Chevron shares have fallen l 6o/c. So both companies stockholders were unhappy. Investors want Chevron and Texaco to raise earnings by cutting costs the way BP Amoco did after buying Arco and Exxon did after acquirin<> Exxon said it save £4.6 billion per year, in pai1 cutt111g 19,000 jobs, after it merged with Mobil in December 1999. BP estimated it could cut more than $1 billion in expenses after the Arco buyout in April. Texaco and Chevron can save about a $1 billion also. But, Chevron must overcome tough antitrust obstacles if a buyout is to succeed. Consumers were angered when gasoline prices surged above $2 per gallon this summer. and the two leading presidential candidates both have made higher energy prices and campaign issue. Texaco is in a US refining alliance with the Royal Dutch/Shell Group and Saudi Arabia "s slate-owned refining company. The alliance. created by two. complex joint ventures called Equilon and Motiv<i is the largest seller of fuel in the US. operating 21.000 gas stations. That alliance would almost certainly have !" he dissolved m mnclifiecl before a Chevron-Texaco merger Texac() and Chevron have developed ways of dealing with the Saudi-Shell alliance and Chevron's l'()Jlcentrati()Jl of refining on the East Coast. Texaco shares fCJI I 88 to ')'i I 2'i Fri<fay Chevron fell '.-Hl6 to 84.25.

KPS Petrol Pipe System, company headquartered in and specialising in petrol pipe has mto a strategic partnership with two Malaysian companies, with a total investment worth RM5 million.

The venture involves the manufacture of the KPS polyethylene petrol pipes in Malaysia and distribution to strategic clients within the country and in neighbouring countries.

The first agreement was signed between KPS Petrol Pipe System and Forenede Plast (M) Sdn Bhd to Manufacture the KPS petrol pipes in Klang, Selangor.

The second agreement was signed between KPS Petrol Pipe System and Guardian Venture (M) Sdn Bhd, for the marketing and installation of these pipes for both the local and regional markets.

Spe'.11<.ing. at the signing ceremony, Mr Thomas Andersson, managmg director and chief executive officer of KPS Petrol Pipe System, Sweden, said, "Although KPS is an established global brand and has been around for the past 20 years, we in establishing smart partnerships with local players equipped with in-depth knowledge about their own markets.

We are that this partnership with Forenede Pl.ast and Guardian Venture will pave the way for Petrol Pipe to secure many contracts in the local petrol/011 mdustry.

The of pipe to be manufactured by Forenede Plast Malaysia 1s the KPS Extra ran<>e usinu polyethylene as the general base of material. 90 per ofthe raw material_ used sourced locally and only 10 per cent or less will be This strategy will ensure that our products are pnc_ed at competitive rates that would be affordable, and_ yet eqmpped with the same features that have earned our pipes renown throughout the world.

To underline determination to become a long-te1m player the Southeast Asian market, we have set up base here Lumpur by opening our own office through an m1t1al mvestment of RM2 million.

We have mapped out a business strategy to capture at least t? 30 per cent of the petrol pipes market in Malaysia w1th111 a year.

This plan will see us achieving a projected turnover of around RMS million to RM7 million for the first year of our operation.

O_ur target clients are the major oil compan_ies and the forecou11s and petrol stations as our pipes_ are to caJTy fuel. Our pipes are made tn:m h1gh-dens1ty polyethylene. which has excellent expectancy, far above any other polymer used for underground pipework.

The comes with a 30-year guarantee. PE pipes easy to mstall and more resistant to punctures by sharp objects. than other hose systems, and undergo severe stress tests pnor to commencing service.

By using state-of-the-art technolooy. we offer highly competitive solutions for the future. a design that has been tailored to prevent all leakages."·

In the late l 950's The Midlands Petroleum Acts Administration Group was formed, consistincr of Administrators (Enforcers/Regulators) from and Measures, Fire Brigades and Public Health Departments of Rural, Urban and Borough Councils, with a small associate membership of Installation and Maintenance Companies.

1965 saw the membership rise to 350 Local Authorities and Associates from all over the British Isles. In 1966 The original Midlands Group become The Association for Petroleum Acts Administration, during the l 970's further changes took place the association added explosives to its agenda and changed its name to the preset day The Association for Petroleum and Explosives Administration (APEA).

Although initially established as an association for the administrators/Regulators of Petroleum and then explosives, today's membership encompasses Regulators, Installers, Maintainers, Manufacturers, Consultants, Major Oil Companies, and Major Retailers (i.e. Tesco, Granada etc.)

Perhaps with the onset of the new Millennium and the almost certain changes in the Petroleum Lecrislation and other Environmental Issues. Now is the time chancre the b Association.

general council to realise that the admission of the licensee is the next logical step in the APEA's progression.

With the dawn of the new Millennium this could also be the dawn of a new APEA with increased membership surely comes greater credence, leverage and lobbying powers both at home and in Europe.

There need be no change in the Association's name as it reflects our starting point and history. And at the end of the day it can be said that Licensees are also Administrators of the day to day running and safety of Petrol Filling Station's in their charge/ownership.

On several occasions recently that Bulletin has been lent to Licensees to highlight the problems with certain hoses and connections, prior to any official notification beincr available from HSE/HELA as to the products safety and replacement.

Having not only read the relevant article but also the whole magazine, a vast variety of comments were made all highly complimentary about the Bulletin and its contents.

The major comment being can we become members, if so how and at that cost?

Robbie Robson. Cornwall Fire Brigade

Editors Note: Under existing rules which are placed on our website licensees can be members.

In the past ten years there have been many noticeable changes in the Petroleum Industrial and in the APEA, in particular the attitude of the Regulators and licensees to communicate with each other more, although there are still some exception on both sides. Out of this ability to communicate has come trust, understanding and the capacity to get things done or changed without confrontation in many cases.

But one of the biggest stumbling block still. is ignorance of the Legislation and current guidelines, and the difference between the two.

Opening up membership of the APEA to Licensees. will allow them access to information. knowledge. expertise and an excellent magazine which will benefit all concerned. knowledge, expertise and an excellent magazine which will benefit all concerned. Especially in the future with the envisaged changes to Petroleum Legislation and present day society's tendencies towards Risk assessment and Environmental issues. What better way to learn of the change than from with the APEA. Some may say there are already Associations available to Licensees. that may be so. but the cost of membership. to the small independent or individual is in most cases prohibitive.

As the APEA is no longer exclusively and Administrative Association. you only have to look at the occupations of our membership. committees or

August 21, 2000 The Office of Naval Research (ONR) OF THE U.S. Navy awarded a $2,060,000.00 contract this July to the naval architectural and analysis firm, MH Systems, Inc. of San Diego, California for the test and validation of the American Underpressure System (AUPS) on a tanker of the Ready Reserve Fleet.

The American Underpressure System (AUPS) was conceived in 1989 as a means of virtually eliminating oil spills from tankers involved in accidents. The system modifies existing crude oil tankers so that their vulnerability to cargo loss is significantly reduced.

The AUPS creates a slight vacuum in the inerted ullage space above the oil within the tanks of an oil tanker, and dynamically controls this negative pressure and maintains inertness throughout the voyage. In the event of rupture(s), the pressure forces are balanced at the rupture location to prevent or minimize any outflow of oil.

Mo Husain, President of MH Systems and developer of the AUPS states that the replacement of the world tanker fleet by a completely new fleet having double hulls will require enormous investment and many years of construction effort. While this takes place, environmentally unsafe tankers will continue to operate and accidents will inevitably occur. The Congress therefore mandate and funded a validation test of the AUPS system.

According to Mr. Husain, the capability of AUPS to reduce spillage of oil in tanker accidents is in statistical terms, an approximate 65% average reduction in outflow _ about the same as that of a double hull. with appropriate engineering completed in advance, the AUPS could be retrofitted on an existing tanker in about a week.

corporate@mhsystemscorp.com

A yearlong review into the future requirement for and covers rolled out in March in a range of high systems for forecourt to tank interfaces. They have financial savings without any compromise on quality. The rationalized range helps the customer to select their specific installation by budget, performance or personal preference.

This re-look at producing better solutions to old problems has been led by Fibrelite"s new managing director Ian Thompson. who was appointed last year. in place of Trevor Pardoe. Trevor is concentrating his time and energy in the USA. developing a whole new generation of petroleum forecourt products to answer the particular needs < d the American market.

Five years ago. Fihrelite started along the road of adaplIIJ_!.' lechnology lo the industry. in the belief that

the only possible solution to producing high quality yet cost competitive products was by automating the processes. This would not only enable greater volumes (with their attendant financial benefits), but also improve beyond anyone's expectations the consistency of manufacture and enable real engineering solutions to be achieved. The result of this program rolls out this month

Thompson commented on this approach"Fibrelite is a well respected olobal brand and historically the preferred choice of mos; installers. We are also recognized as the 'shakers' and the ·movers' in the We realized that radical changes were happening 111 the petroleum forecourt industry and that price was going to be a major issue when choosing equipment.

Many people still regard 'Fibrelite' as premium priced products suitable for problem sites only, so we are now trying to change this image with what we believe is a range of systems for 95% of all commercial requirements. The range is competitively priced and performs to or better than all current legislation/requirements and it is significantly more comprehensive and better than any offered by any competitor.

Savings as a result of max1mIZing of our RTM the streamlining of the product range and huge efficiency improvements in manufacturing are being passed on to our customers. The aim is to remain the No I preferred choice for installers of forecourt products to continue to develop ever improving and mnovative solutions, in order to make the forecourt cheaper safer and environmentally better

Fibrelite endeavour to offer the forecourt industry more choice with the introduction of the new Standard Plus Chamber Systems.

There are a huge number of variations available to suit customer's preferred size of cover and chamber. All systems are fully testable to ensure a watertight mstallation. Please refer to the adverts in this issue for more details.

New price lists for all Fibrelite products will be issued from I May 2000.

Please contact our Sales dept for details on 01756 799773. Or e-mail covers@fibrelite.com

Fibrelite's new streamlined range has major price and performance benefits for the enduser

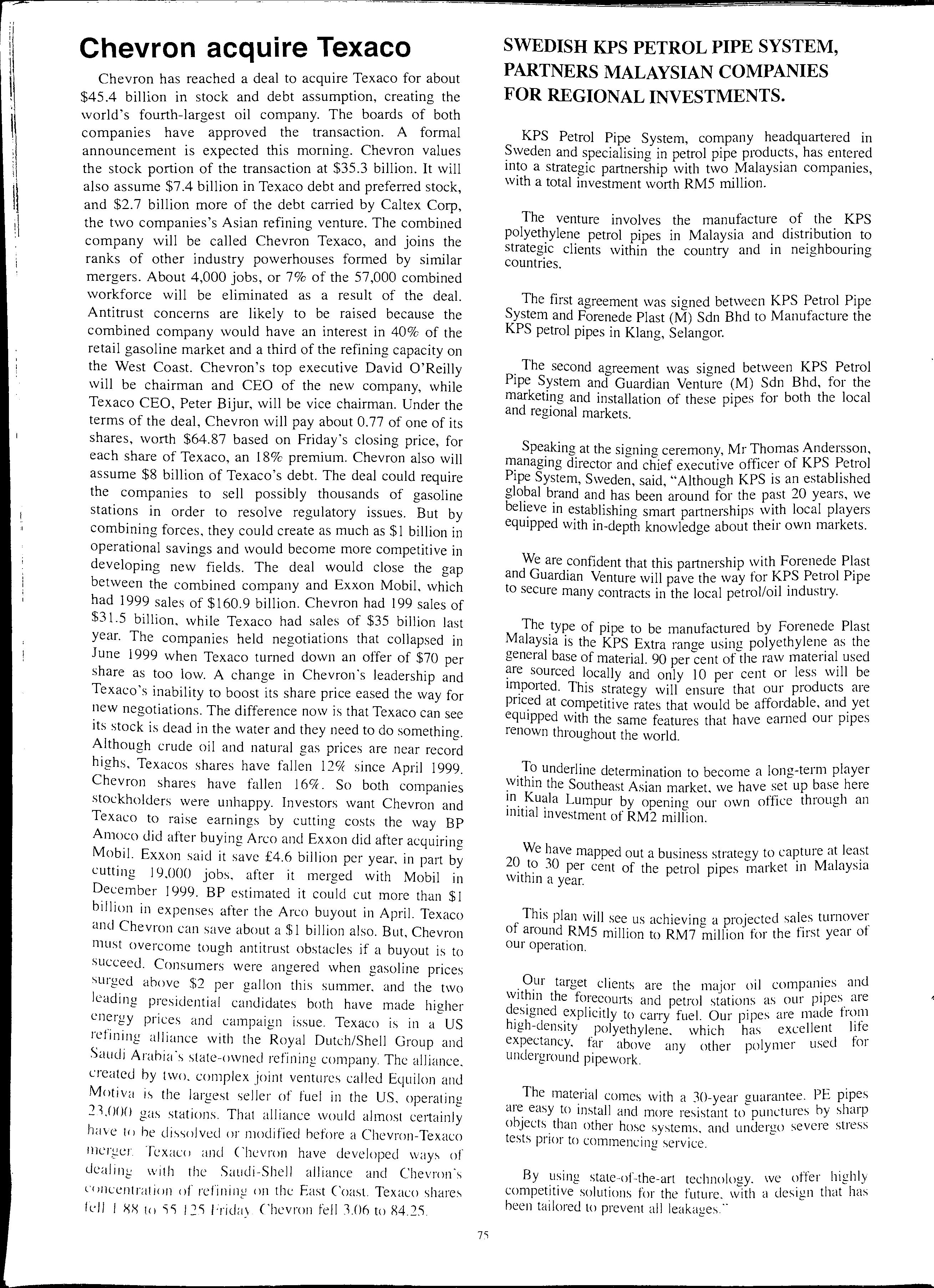

We all recogni z e th e ne e d to protect our en v ironm e nt and reg ul a rl y se e n e w require ment s introduc e d to pre vent or re duce th e lik e lihood of cont a mination of th e soil. Wh e re c o ntamin a ti o n does o c cur, cle a nup c o s ts ca n be ruinou s to th e pe rpetrators The safe s torage o f p e troleum fu e ls ha s be en th e s ubj e ct o f mu c h d e ba te a nd Jea is la tion sinc e th e b ea rl y d a y s o f th e m o to rca r, but ne ve r m o re so th a n in th e la s t d eca d e.

In th e ge ne rall y limite d space o f the typi cal se r v ice s ta tion , th e use of underg round s tee l tank s for pe tro le um s to ra ge h as beco m e the no rm By th e ir ve ry na ture th ey c ann o t be se e n or in s pec te d fo r le ak age a nd tot a lly re ly o n m o de rn tec hn o logy to sound th e a lert s h o uld th e wo rs t happe n . In fac t som e mi g ht no t eve n includ e a ny lea k det ec ti o n s ys tem.

Howeve r, th e re is a no th e r way Wh e re s m a ll e r qu a ntiti e s o f fu e l, o r oth e r c he mi ca ls need to be s to red th e use o f a boveg round s to rage tank s (A ST) is beco min g in c reas in g ly po pular B eca u se th ey are abo veg round th ey ca n be v is ua ll y in s pec te d a nd d o no t re ly o n hidd e n tec hn o log y fo r leak d e tec ti o n a nd protec ti o n.

Th e principa l appli c ati o n s fo r Ab ov eg round S to ra ge Ta nk s - AS T 's inclu de co mp a ni e s o pera tin g th e ir ow n fl ee ts s uc h as po li ce . fir e a nd a mbul a nce se r v ice s, bu s co mp a ni e s, ag ri c ultura l e s ta bli s hm e nt s a nd fac iliti e s th a t use bac kup pow er s ys te m s a nd fo r was te o il s torage. Th ey in c reas in g ly be in g used fo r li g ht a irc ra f t re f ue llin g fa c iliti es, o n go lf co urses, m ar in e appli ca ti o ns a nd ca r re nt a l co mp a ni es a nd und e r ce rt ain c o nd iti o ns a re used o n se r v ic e s ta ti o ns fo r no rm a l ca r re fu e llin o "'"

A bo veg ro und S to rage Ta n ks m a y be s in g le or do u b le wa ll s te e l, s tee l c oat ed . s ta inl ess st ee l a nd be prote c te d or

unprot ec te d , d e pe ndin g o n the application Protec te d tank s , w hi c h are enc ase d in a co n c rete s urro und . a re be co min g pre d o minant. Th ey typi call y c o mpri se an inn e r stee l tank for prim ar y co ntainme nt a nd there w ill be a leak proof m e mbrane to c o ntain th e pote nti a l fu e l leak fro m the prim a ry c ont a inment. Thi s a lso a c ts to isolate th e inner s te el ta nk fr o m th e co ncrete s urro un d to g i ve impro ved c o rro sio n p ro tec tion Th e o uts ide may c ompri se a s ix in c h re in fo rce d co nc re te e n c a se me nt for fire re s is tan ce and s tru c tu ra l protec tion w ith o ne o r m o re ty pes of s urface aggrega te o r p a inted fini s h to pro v ide a pl eas in g a nd ae sth e ti c o ut sid e app eara nce These ty pe s of ta nk s c an be s uppli ed 111 ca p a citi es fro m 1.00 0 to 45 ,000 litre s , e ith e r s in g le o r multi -co mp a rtm e nte d.

Ta nk s ca n be rec ta ng ul a r o r cy lindri ca l in s h a pe d e pe nd in g o n th e a ppli c ati o n Th e prim a r y ta nk s are ge ne rall y stee l fo r th e s torage of pe tro le um s pirit o r s ta inl ess s tee l o r s tee l coa ted fo r th e s to ra g e of Av ia ti o n fu e l o r o th e r c he mi ca l liquid s . Th e ta nk s a re fr ee s ta ndin g a nd o nl y need a s impl y co nc re te b ase. re quirin g no ex c ava ti o n. Fo r s pec ia l a p p li ca ti o ns th e y ca n be in sta ll ed und e rgro un d in a va ult ed a rra nge m e nt , pro v idin g space fo r v is ua l in s pec ti o n a nd access.

A ta nk wo uld ty pi ca ll y co mpri se th e ta n k it se lf. a fu e l ve nt. a n e m e rge ncy ve nt in ca se of pre ss ure build up th ro u g h fir e . acc ess to the int e rsti t ia l s pac e a nd fit t in ;s fo r th e a nd d isc ha rge co nn ec ti o ns T hey ty pi c; ll y in c lud e a me ter/ reg is te r or a m o re so phi s ti ca te d fu e l di s pe nse r fo r m o ni to rin g th e d e li ve ry to th e ve hi c le be in o fu e ll e d. A n ac ce ss la dd e r a nd pe rsonn e l p ro tec ti o n ra il in;s are a ls o a va il ab le

U nd e rg ro un d S torage ta n k s (U ST ) a re rn ns ta nt!\ co rro de d by e xpos ure to m oi s ture a nd corros ive in th e so il. T he o w ne rs o f USTs a nd t he H a\ "Jll<' .Juri sd ic ti o n ( A H.I ) re l) o n cat hot iL · prntt'L"t iun a nd L·mrn s io n preve ntiPn Hll\\ 't'\ 'e r. t lw fo1. t t h <ll

USTs corrode and leak The leakage might not be detected for a prolonged period of time and before major spillage occurs affecting ground water and other natural resources. The cost of cleaning and decontaminating the affected soil can be devastating. The leakage and contamination caused by thousands of leaking USTs in the United States has prompted the US Environment Protection Agency (EPA) to impose strict regulations on USTs. The December 1998 EPA deadline resulted in removal or abandonment of hundreds of thousands of USTs in the US.

Using Above Ground Tanks (AST's) relieves the tank owners and the AHJ of all the uncertainties of potential leakages, financial burdens and the threat of soil and water contaminations. ASTs are aboveground and can be visually checked and inspected as often as one wishes. ASTs are equipped with leak detection systems, which alarms the tank owner of a potential leak before a single drop of fuel is leaked on the ground.

AST's are of American design and as s uch are governed by US regulations in terms of both manufacture and installation. Individual country requirement s tend to be based on the US approval s amended to satisfy local codes. The main approval specifications are:

Underwriters Laboratorie s UL 142 Standard for Above Ground Steel Tank s for Flammable and Combustible Liquid s This covers the construction and material s pecification of the primary stee l tank.

UL 2085 , Protecte d Above Ground Tanks for Flammable a nd Combustible Liquids. This standard covers secondary co ntainment tanks and includes two hour fire pro tect io n. vehicle impa c t protec tion and proje c til e res is tan ce. The se are the tank s described he re.

Th e re a re also three main National fire codes that apply to AS T' s. nam e ly NFPA 30 , Flammable and Combu stibl e L iquid s Co d e, NFPA 30 A , Automotive and Marin e Ser v ice S tation C ode and UFC, Article 79 , F lammabl e and C ombust ibl e Liquid s Th ese US co d es provide man y '- p ec ification s re quire ment s for AST' s in c luding ite m s suc h a '- ve ntin g s pilla ge co ntrol. 111 s tallation separation co ntro l, p 1p 111g tes tin g and man y o th e r ge nera l requirem e nt s " "" ci c 1a le d w ith 111 s tallati o n s at se r v ice s tation s and at 111 du , 1r1a/ /c o m111 e rc iaJ s it es.

(

Where quantities up to 45,000 litres of petroleum spirit , diesel , aviation spirit or many other products need to be stored and/or dispensed then the modern, safe and environmentally friendly' solution is to use Protected Aboveground Storage Tanks.

The benefits of a fast and safe installation and minimum disruption of the site, particularly related to excavation requirements makes AST's the first choice for many applications. Simple ancillary equipment installation and operation adds to the attraction of this type of design. Costs will vary from site to site but can often be less than below ground installations, especially when considering the s ub stantially les s down time involved.

Th · cl AST's is e mdu stry leader rn the supply of protecte Convault Inc. Convault was founded in 1985 and has · · ystem mstalled over 25 ,000 tanks world wide , without a s f ·1 d des I an a1 ure. Convault tank s are of a vaulted or protecte 0 whereby the concrete is poured in one continuous process ensuring a monolithic construction with no cold JOII1t S sea m s or gasket s Thi s proce ss combined with the · · b ·t ossible imp e rviou s leak proof membrane provides the es P co rro s ion and leak protection.

l · t its from o nvau t tank s have prot ecte d their con ei , earthquakes , hurri ca ne s, seve re flooding, fire , from vehicle impact and even from aircraft co lli s ion. Depending on th e t k · J · h 1· 1·· J Convault an s ize, w 11c ca n be re c tangular or cy 1n c 11 c a · w ill provide a 20 or 30 year warranty

To find o ut more about Co n va ult tank s co nta ct .I C. Samso n at Tel/Fax +44 (0) 1268 711680 , ema il Ja e kcsa rn so n @com pu se r ve. co rn.

Following almost a year of both internal consultation and discussions with suppliers, the first of the Tesco "new concept" underground aspect of th e modular service station desi g n is currently being in st a lled on their redevelopment a t th e Tesco Store, Poole Road , Brank so me The initial design bri ef was to " re-think " the whole of the de s ian of a se rvic e s ta ti o n to see if significant cost re duction s efficiency could b e produced The result is a the new Mod-Court modular design which to ge th er with the other site desian b improv e ments "on paper" appears to offer a total s it e re duction cost of 26 % When the car wash is take n into ac count the theoretical cost reduction appears to be 43 % !

Th e ba s is of the whole des ig n is an evo lutionary m o dular d esig n, which incorporates all th e best feature s of a mo dul ar se rvice station construction with conventional build design c riteria

For exa mpl e, w hil s t the whole sys tem ca n b e prefab ricate d offsite, includin g the in s tall a tion of the ta nk s , th e d es ig n is versatile enough to a llow actual installation in th e excava tion within a very s hort period of time. Thi s in fact was the method u se d for the Poole Road s ite

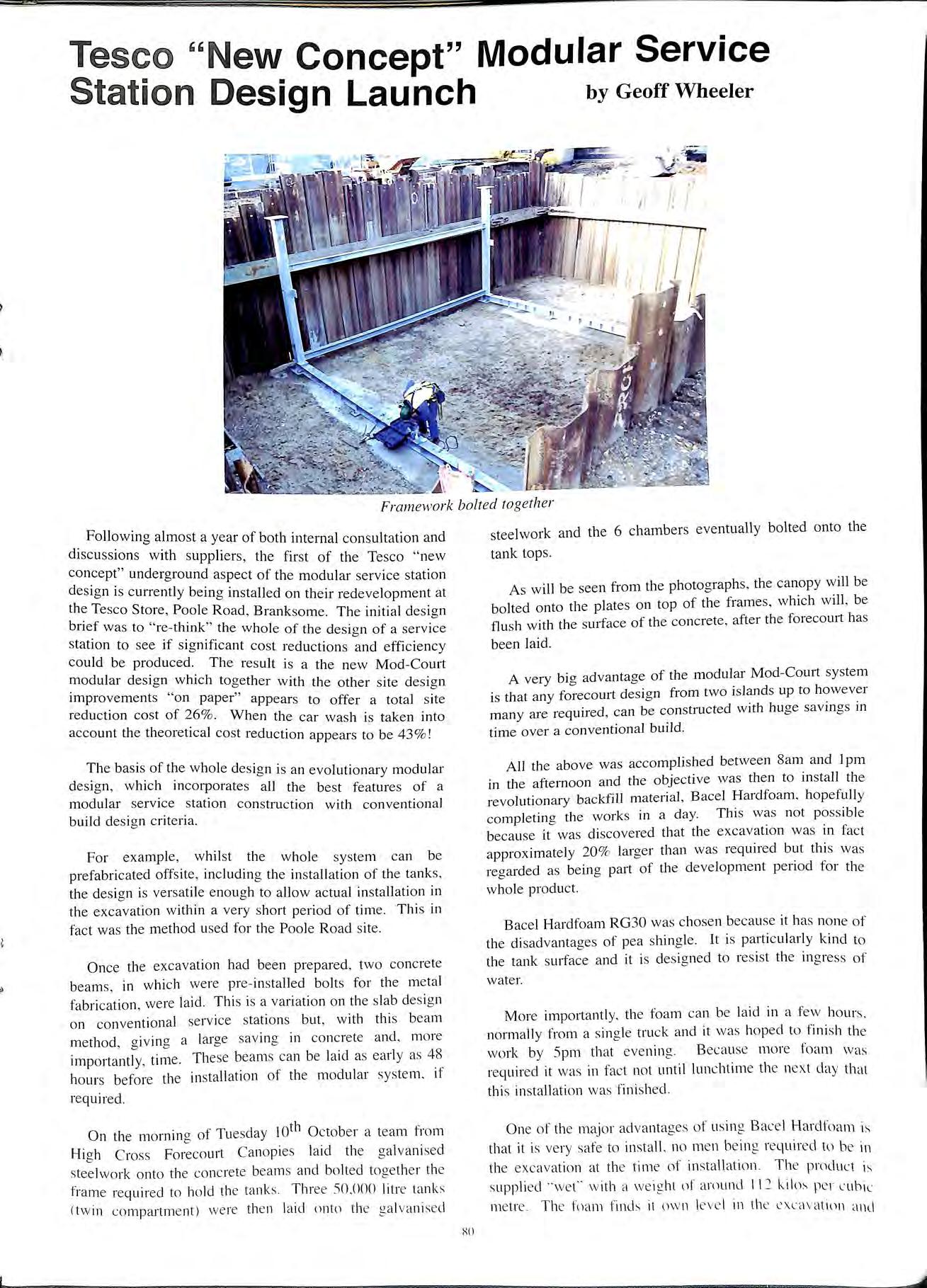

Once th e excavation had been prepare d , two concrete beam s, in which were pre in stall e d bolts for the me t a l fabrication, were laid. Thi s is a varia ti o n on the s lab design o n co n ve ntional se r v ice s tat ions but, with thi s beam m et ho d , g iv in g a large s av in g in conc re te a nd , more imp ortantly , tim e. Th ese beam s c a n be la id a s ea rl y as 48 ho urs before the in stall a ti o n of the m odular sys te m. if required.

On th e m o rnin g of Tu e sday 10th October a tea m from High C ro ss Forecourt Ca no pie s la id th e ga lva ni sed s teelwork onto th e concrete beam s a nd bolted toget he r th e frame required to ho ld t he tank s Thre e 50. 000 litre tank s (t w in compartm e nt) we re th e n la id onto th e ga l va ni se d

steelwork and the 6 chambers eventually bolted onto the tank tops.

As will be seen from the photograph s, th e canopy will be bolted onto the pl a tes on top of the frames , which will, be flu s h with the s urfac e of the concrete , after th e forecourt ha s been laid.

A very bi g advantage of the modul a r Mod-Co urt syste m is that any forecourt design from two i s land s up to how eve r many are required , can be co nstructed with huge sav in gs in time over a conventional build.

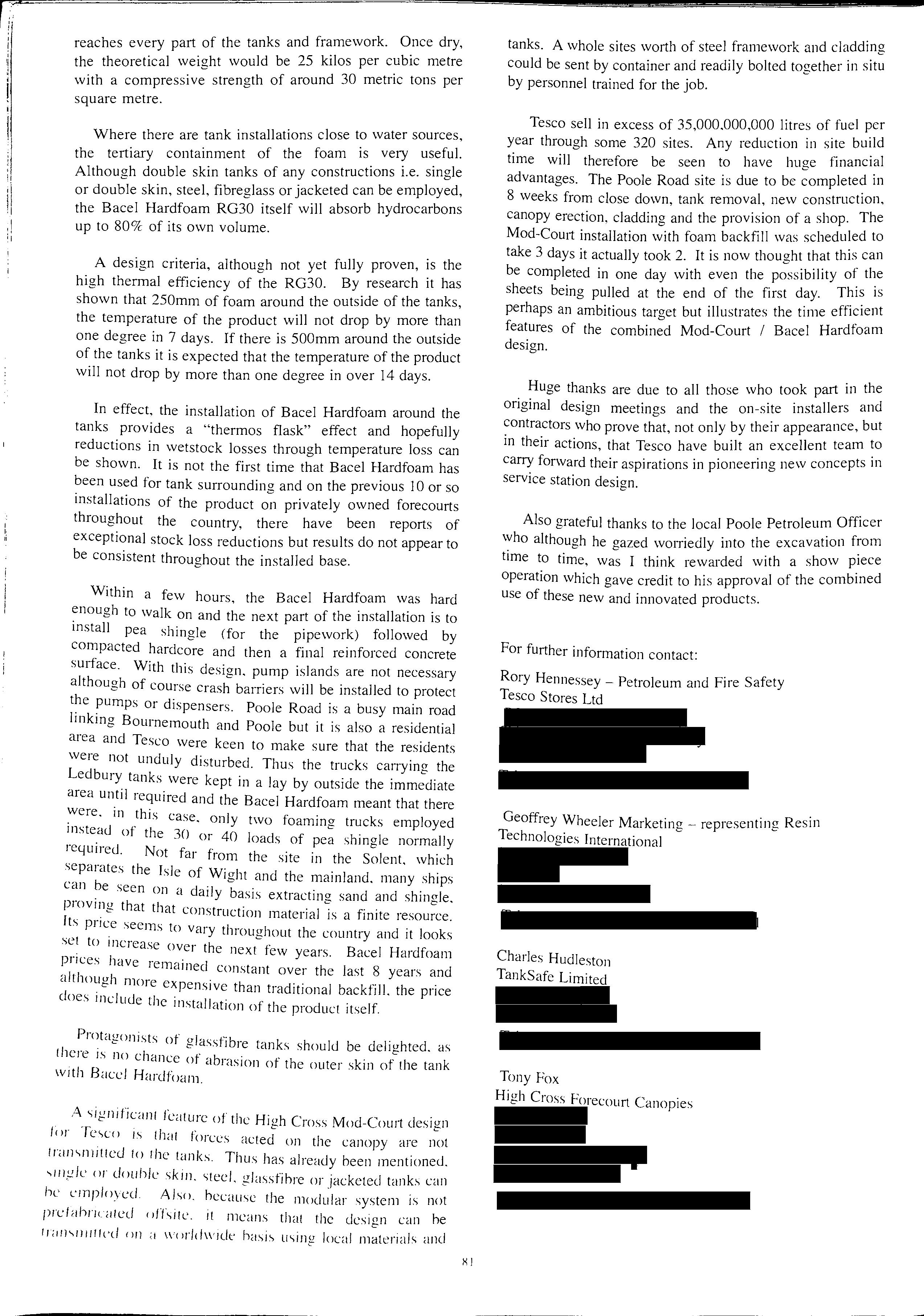

All the above was accomplished betwee n Sam a nd I pm in the afternoon and th e o bj ec tive was then to in stal l th e revo lutionary backfill material, Bacel Hardfo a m , hope full y co mpl e tin g th e works in a da y Thi s was not possible because it was di scove red that the excavation was in fac t approximately 20 % large r than was re quire d but thi s was regarded as bein g part of the development period for th e whole produ ct.

Ba ce l Hardfoam RG 30 was c ho se n beca u se it h as no ne of th e di sadvantages of pea s hin g le. It is parti c ularl y kind to the tank s u1fa ce a nd it is designed to res ist th e in g res s of wate r.

More impo r ta ntl y, the foam ca n be la id in a f e w ho ur s. normally fr o m a si n g le tru ck a nd it wa s hoped to fini s h the wo rk by Spm th at ev e nin g B e ca u se more foa m was req uire d it was in fact no t un t il lun c htim e th e next clay that this in st a llation was finished

One of the major adva nt ages of u s in g Ba ce l H a rclfoa rn is that it is ve r y s afe to in stall. no m en b e in g re quire d to b e in th e e xcavat ion at th e tim e of in stallation Th e produ c t is s uppli ed ··we t.. w ith a w e ig ht of arou nd I I 2 per rnbic m e tre. T he foam find s ii o w n le ve l 111 th e L'XCCl\' at io n and

reaches every part of the tanks and framework. Once dry, the theoretical weight would be 25 kilos per cubic metre with a compressive strength of around 30 metric tons per square metre.

Where there are tank installations close to water sources, the tertiary containment of the foam is very useful. Although double skin tanks of any constructions i.e. single or double skin, steel, fibreglass or jacketed can be employed, the Bacel Hardfoam RG30 itself will absorb hydrocarbons up to 80% of its own volume.

A design criteria, although not yet fully proven, is the high thermal efficiency of the RG30. By research it has shown that 250mm of foam around the outside of the tanks, the temperature of the product will not drop by more than one degree in 7 days. If there is 500mm around the outside of the tanks it is expected that the temperature of the product will not drop by more than one degree in over 14 days.

In effect, the installation of Bacel Hardfoam around the tanks provides a "thermos flask" effect and hopefully reductions in wetstock losses through temperature loss can be shown. It is not the first time that Bacel Hardfoam has been used for tank surrounding and on the previous 10 or so installations of the product on privately owned forecourts throughout the country, there have been reports of exceptional stock loss reductions but results do not appear to be consistent throughout the installed base.

Within a few hours, the Bacel Hardfoam was hard enough to walk on and the next part of the installation is to install pea shingle (for the pipework) followed by compacted hardcore and then a final reinforced concrete surface. With this design, pump islands are not necessary although of course crash barriers will be installed to protect the pumps or dispensers. Poole Road is a busy main road linking Bournemouth and Poole but it is also a residential area and Tesco were keen to make sure that the residents were not unduly disturbed. Thus the trucks carrying the Ledbury tanks were kept in a lay by outside the immediate area until required and the Bacel Hardfoam meant that there in this case, only two foaming trucks employed mste_ad of the 30 or 40 loads of pea shingle normally required. Not far from the site in the Solent, which separates the fsle of Wight and the mainland. many ships can seen on a daily basis extracting sand and shingle. provmg that that construction material is a finite resource. Its price · . · · seems to vary throughout the country and 1t looks set to rncrease over the next few years. Bacel Hardfoam prices have remained constant over the last 8 years and although more expensive than traditional backfill. the price does mclude the installation of the product itself.

Protagonists of glassfibre tanks should be delighted. as there is no chance of abrasion of the outer skin of the tank with Bacel Hardfoam.

A -;ignificant feature of the High Cross Mod-Court design tc >r Te-.co is thcit forces acted on the canopy are not tran-;mitted to lhe tcinks. Thus has already been mentioned. ..,,11,!!lc or double skin. -;teel. glassfihre or jacketed tanks can he employed Also. hecause the modular system is not prefohnu11ed olfsite. it means that the design can be !r;lfl..,lllllled ()IJ ;1 worldwide using local materials and

tanks. A whole sites worth of steel framework and cladding could be sent by container and readily bolted together in situ by personnel trained for the job.

Tesco sell in excess of 35,000,000,000 litres of fuel per year through some 320 sites. Any reduction in site build time will therefore be seen to have huge financial advantages. The Poole Road site is due to be completed in 8 weeks from close down, tank removal, new construction, canopy erection, cladding and the provision of a shop. The Mod-Court installation with foam backfill was scheduled to take 3 days it actually took 2. It is now thought that this can be completed in one day with even the possibility of the sheets being pulled at the end of the first day. This is perhaps an ambitious target but illustrates the time efficient features of the combined Mod-Court I Bacel Hardfoam design.

Huge thanks are due to all those who took part in the original design meetings and the on-site installers and contractors who prove that, not only by their appearance, but in their actions, that Tesco have built an excellent team to carry forward their aspirations in pioneering new concepts in service station design.

Also grateful thanks to the local Poole Petroleum Officer who although he crazed worriedly into the excavation from b • time to time, was I think rewarded with a show piece operation which gave credit to his approval of the combined use of these new and innovated products.

For further information contact: Rory Hennessey Petroleum and Fire Safety Tesco Stores Ltd

Jamie Thompson

Jamie Thompson

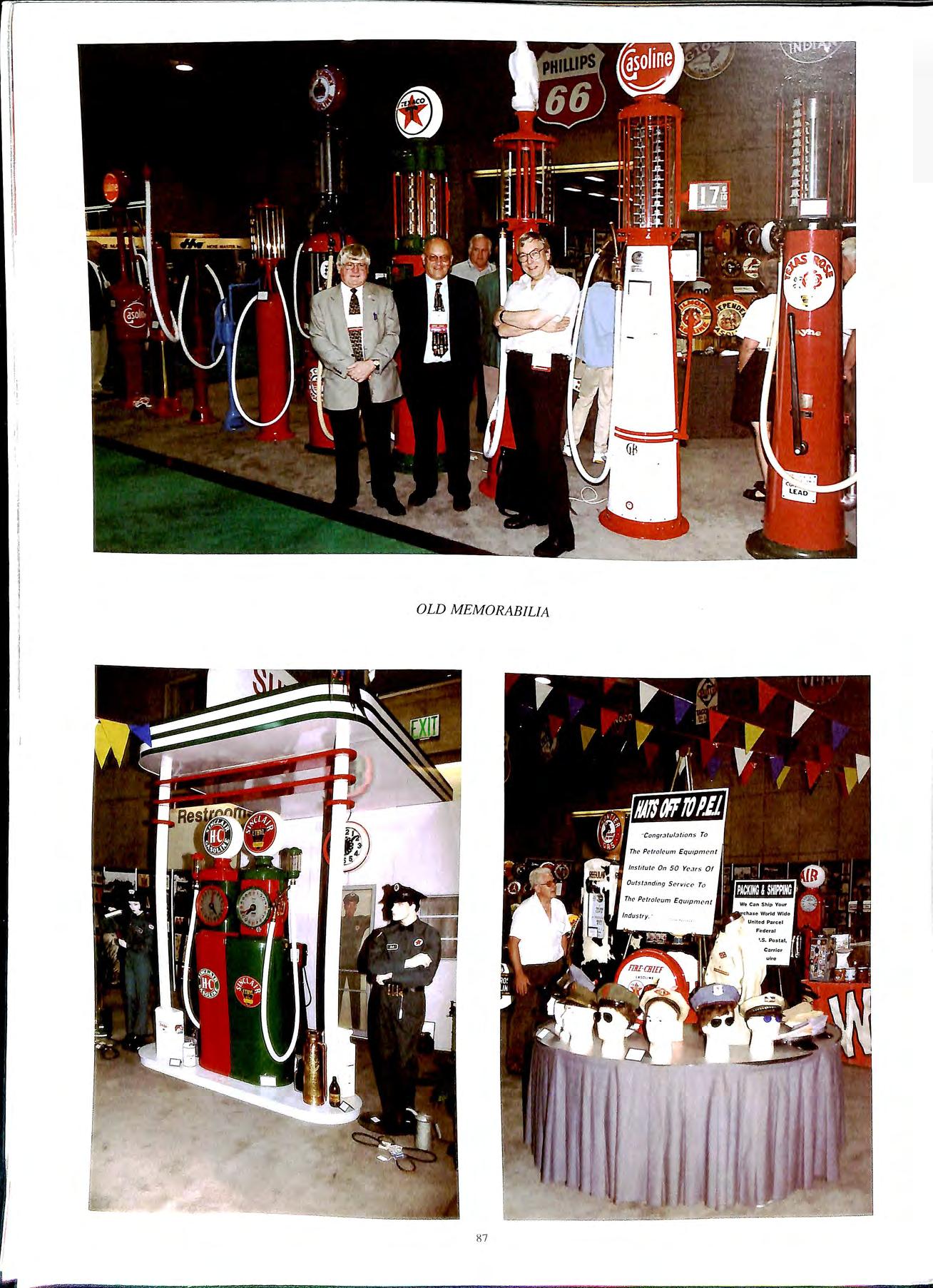

This year in San Diego the Petroleum Equipment Institute (PEI) celebrated 50 years of existence and the 50th year of holding of their annual exhibition in the USA. This petroleum engineering exhibition is the largest held anywhere in the world and around 5000 visitors attended the three days with well over 70 exhibitors showing their wares.

Europe was well repre se nted at the event with a number of APEA members attending. The PEI will this year be introducin g itself to APEA members this year at our Conference and Exhibitio n.

by Alan Ta ylor

It is obvious that we a re keen on our oroundwater in Holland. A third of the country is below se: level and half of it has a very high watertable. Any pollution of gro undw a ter may effect the production of drinking water Th e a uthorities have set out st rict re g ulations for all tank and pip e sys tems containin g h aza rd o u s products. Som e produ c ts, like fuel, contain components that have exce ll e nt quality improving _properti es but are a se riou s thre at to th e environment especially gro und wa te r MTBE is one of th e m. Once MTB E ha s entered g roundwater, it is hard and cost ly to ge t it o ut .

Eve n with a fl ex ibl e pla sti c pip e that meets the E urop ea n p l re quirem e nt it still ma y perm ea te 0.1 g/m2 /da y ( T C 221 ). Pip e s ystems with a goo d barrier la ye r pe rform be tt e r a nd m ay limit pe rmeati o n to approx 0.08 g/ m 2/ da y. On a n ave rage s tati o n w ith l 2 s uc ti o n lin es 11/:. " w ith a n average le n gt h o f 24 m th e total inte rn a l pip e s urface is 288 • 8.38 = 34.37 111 2. Thi s mea n s a to ta l pe rmeation of 2.75 g/d a y. o r ove r I kg/ yea r per st at io n

The Environmental Mini s try, VROM , finds a b ove m e ntioned va lue s un acce pt a bl e and ha s defin e d th a t plastic pip e sys tem s are a ll owe d to h ave a total p e rmeat io n of 30 m g/d ay p e r pipe fr o m tank to dispen se r. As s ump s a re n ot normally used in H o ll a nd, this fi g ure includ es th e fittin gs on the tank. It ha s bee n ca lcul a ted that th ese threade d connections with he mp and lineoil m ay permeate I o m g/ day. (TNO re p o rt Div499. J018 ) With a common 3 co nnection s thi s leaves 0 mg/day for th e pip e. irres p ec tiv e of th e len g th.

R egardin g defining th e p e rmea tion rate we tak e a s omewhat diffe re nt ap pro ac h in H o ll a nd . U nlike m ost co untri es in which th e absorption of fu e l is m eas ured. KlWA in H o ll a nd m eas ures th e diffu s ion speed of spec ifi c fu e l co mpon e nt s and fu e l it se lf.

Based o n th e res ult s th e perme a ti o n is ca lcul ated. MTB E is o ne of th e co mp o ne nts. It s ho ws th at MTB E is o ne uf th e more ac ti ve ly p e rmea tin g co mp o ne nt s .

Lik e Ho ll a nd a lso German y h as d efin e d th a t pla s tic pip e sy s te m s s ho uld ac hi eve a ze ro pe rm eat io n .

The PCU keeps MTBE in by a true zero-permeation

Even with a double wall pipe system amounts like the calculated 1 kg of fuel will get into the ground. The intersticial space will be filled with vapours. They will saturate and condense. The condensated product containing for example toluene, benzene and MTBE will have no problem to permeate the secondary pipe.

Of course this will not happen in a day. For instance it may take toluene 3 weeks to travel through a good quality pipe. But it is just a matter of time and especially the hazardous components eventually will all come through and enter the ground and the groundwater.

However, the interstitial space of a flexible pipe system offers an unexpected possibility to achieve zeropermeation.

Because so much data was available from the permeation calculations, it was possible to define the best way to approach the permeation problem. It turned out to be that if you use a double wall pipe you can effectively remove all permeation products by ventilating the interstitial space.

Calculations performed by TNO show that at an increasing airflow the permeation from the primary pipe to the secondary pipe and thereby into the environment is reduced very effectively. This relationship is shown in the graph. This graph looks at toluene as it travels fastest through most plastics.

The air flow for a typical system per line may be 20 per hour. TNO states that at this flow the permeation of through the secondary pipe can not be detected as It. will be far under the detection limit and is therefore considered zero. ( report Div400.2850 )

4'C Wi_th the knowledge that ventilation would be the most euective way t d o remove permeation products the PCU was eveloped .· ' usmg a vacuum pump.

Permeation I · eff contra usmg pressure is possible but is less ective. It cons·d requires undesired high pressures and is expe1n less safe. It is not maintenance-free and is more s1ve.

The heart of the p . . . handle fuel CU 15 a special vacuum pump able to vapors and Ii .d . . Proof electric qui and is dnven by an explosion s · motor. The rest f" h · pec1al tubing s ·t 0 t e system consists of a th l' · ys em conn t d · e Ines. ec e to the mtersticial space of

, capacity and lay-out is d .· station to guarantee es1?ned to suit an individual · zero- permeat10 1 H Is runnmg intermittently , d . . n. n olland the pump I , an is controlled b . t may 1 un for mst·ince , ,, . Y a tnner. h c a iew mmute. our. The lJUmp i·s bL1'1lt 1· s every quaiter of an · Ill a c 1spenser · h · · cahinct. · or 111 t e f11lmg point

Over I() systems are in operation in Holland by now.

Using a smart sensor which monitors the exhaust of the pump the PCU® will also act as an effective intelligent leak detection system. It can discriminate the acceptable permeation vapors from a small leak and from an alarm situation.

If it is not accepted to vent the permeation vapours into the air the unit will be equipped with an active carbon filter. The costs of the PCU® vary depending on the size of the underground installation but are relatively low and quite acceptable.

Besides Europe the patent for the PCU® is pending for the US and Canada.

To even further reduce permeation we developed a coupling that is directly swaged to the plastic pipe and has a conical end with a swivel nut. It combines the safe swaged connection to the pipe and the conventional conical coupling. This offers a permeation free metal to metal sealing. It is easier to install than clamp fittings and better than couplings with a rubber seal.

For the conical pipe coupling patent is applied for.

So instead of throwing about 1S litres of fuel into the ground during the life time of a service station it can easily be avoided and a truly zero-permeation is achieved by using a PCU®.

Discussions are focussing on MTBE at he moment. With the PCU® you not only prevent this chemical from entering the soil but illlY fuel component.

With a small extra cost you can build a quick and easy to install pipe system with all the benefits of a flexible plastic pipe system, yet have it as tight as a steel pipe.

TSE Fuelling Supplies was founded by Peter Bus and is a trading company that represents a number of international operating companies with quality products for service stations.

TSE is active on the Benelux and German market.

TSE sells Geoflex of Environ, Fibrelite sumps and covers, Roncol's Fuel Scout, electronic gauges. Red Jacket of Marley Pump and leak detection equipment of ASFThomas.

For further information: tel 0031 525 6976 fax 0031 525 9641 e-mail: info@tankstation-equipment.nl

In recent years oil companies and regulatory authorities throughout the world have shown a keen interest in the constant evolution and redevelopment of retail forecourts. Economic, ecological and consumer based interests all have been great driving forces in filling station design, and all parties involved have come to realise the benefits of constantly applying the raising technical requirements and possibilities as they become available. Below ground, the safety of tanks , pipe work systems and electrical equipment have improved greatly since the early days of petrol stations with leak detection systems monitoring each litre of fuel in the tanks. Above ground, the design of the station structure has challenged many architects and engineers as amazingly minimal and delicate structures have appeared on the market. Finally, graphic design e rs often add the finishing touch. Yet , in the midst of this considerable innovation and investment one can only be s urprised by the solutions accepted amongst many profe ss ionals regarding the design and installation of the off-set fills -a critical part of any forecourt d eve lopment.

Very few firms have proposed specific so lution s to thi s area. One company that has taken on the ta s k of rede s igning the off-set area is Ehl er t GmbH of Germany. Founded in 1936 as a family engineering firm, it soo n developed a nationwide reputation for the fabrication of s pecialist plant and apparatus for the petro-ch e mical and steel industrie s Less productiv e time s were ahead however, as the post-war period brou g ht compulsory nationalisation by the East German socialist government and a down-turn in the companies prospects. Following the fall of the Berlin Wall in November 1989 , a nd subsequent Reunifi ca tion in 1990 , th e original owners saw the return of the firm into family ownership and s lowly the busin ess was reb uilt. Production started initially with three people s harin g de s ign , production and organisation ta sks With the acquisition of n ew computer-controlled machin ery, the co mpany was able to restore it s former reputation and began to expand rapidly. Today there are thirty-fi ve desi g n a nd production p e rso nnel and th e m a in produ c tion centres around th e de s ig n and manufacture of s teel products s u c h as pressure and s team vesse ls . h eat exchangers and large-sca le transition couplings for the chemical indu stry, pow e r s tation s, water works and th e minin g indu s try.

One of th e man y problems faced by it s designers at that tim e was th e c hall e nge to de s ig n a single, pre fabricated containment to hou se the off- se t fillin g p o int s for many p e t ro l forecourt s. as new reg ul at ion s d e mand ed a ce ntral containment and hi g he r sta ndard s of leak protection than prev iou s solutions. Th e de s ig n needed to cate r for req u es ts from the authoritie s rega rdm g sa t ety a nd e n v ironm e ntal concerns. and ye t st ill offe r additional s tru ct ur a l , tec hni ca l and eco nomi c benefit s to the oi l co mp a ni es. Still further. th e product nee ded to si mplify th e in s tallation proce ss savi n g the contracto r precious time on s ite It was a c h a ll e rn.?:e that the c ompan y"s prev io u s ex perienc e in s tee l chemic; l production plant mad e them we ll qualified to m ee t.

The ori gi nal brief included many demands and ideas

The unit had to be entirely prefabricated: yet it was clear that each unit would often remain unique to indi vid ual filling stations. De s ign and production would have to provide high levels of flexibility to suit each site's spec ific requirements at affordable price s. Onc e installed, the unit had to be safe and extremely easy to handl e even for oneman delivery operations. It had to support a faster delivery pro cess ensuring no crossovers , no overfilling and no spillage contaminating the gro und. Finally, it s h o uld provide a single tamperproof and lockable co ntainment for the off-sets, vapour r e turns and s h o uld also be compatible with an in c reas in g range of e lectroni c m o nito rin g eq uipment from other manufacturers. Several specifications and mod e ls would be req uired to ensure engineers and designers could find the right so luti o n for their particular site and s ituation

If the tw o th o u sa nd unit s already in sta ll ed throughout mainland Europe are anything to go by. th e e ngin ee r s at Ehl ert GmbH Germany certainly see m to hav e combined th e many require m e nt s s taked o ut in th e bri e f a nd h ave manufa c tured a product wh ich see m s to b e of va lu e to almost any s it e This h as been pos s ibl e by de v eloping a numb er of sta nd a rd d es ig n s wh ich ma y th e n b e c u sto mi sed for each indi v idu a l application. Co mpu te r a id e d design a nd m a nufa ct urin g tec hniqu es are th e m ea n s by w hich this is achie ve d. allowing th e firm to re m a in fl exib le in d e si g n y et s till s uppl y in g an y unit w it hin 10 da y" on any LIK s it e A n int egra l part of any proj ec t is a n ·in hou se" d es ign scr\ i-.·c that is ab le to work wit h any L'llstorner to dc ve lup to th e man y new a nd co mpl ex s itu ation:-. that -.'\ 'oh 111 " fur ecn urt d es ig n routin e !) demands

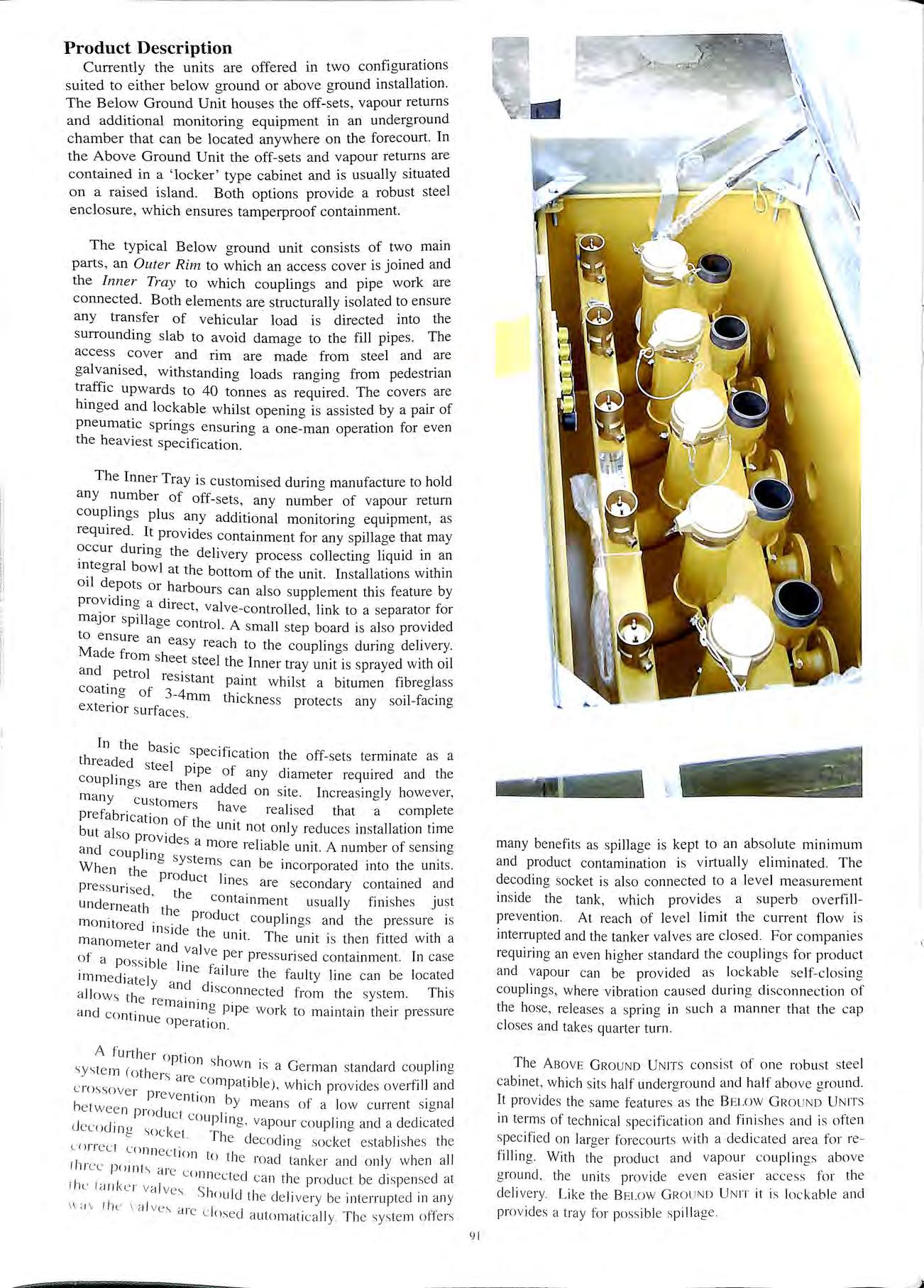

Currently the units are offered in two configurations suited to either below ground or above ground installation. The Below Ground Unit houses the off-sets, vapour returns and additional monitoring equipment in an underground chamber that can be located anywhere on the forecourt. In the Above Ground Unit the off-sets and vapour returns are contained in a 'locker' type cabinet and is usually situated on a raised island. Both options provide a robust steel enclosure , which ensures tamperproof containment.

The typical Below ground unit consists of two main part s, an Outer Rim to which an access cover is joined and the Inner Tra y to which couplings and pipe work are connected Both elements are s tructurally isolated to ensure any transfer of vehicular load is directed into the surrounding slab to avoid damage to the fill pipes. The access cover and rim are made from steel and are galvanised , withstandincr loads rancrincr from pedestrian ff 0 0 b tr.a 1c upwards to 40 tonnes as required The covers are hmged lockable whilst opening is assisted by a pair of pneumatic springs en s uring a one-man operation for even the hea v ie s t specification

The Inner Tray is cu s tomi sed durincr manufacture to hold any number of off-set s , a ny of vapour return couphngs plus any additional monitorincr equipment, as required It p ·d 0 · rov1 es contamment for any spillage that may occur durincr the d 1 o e 1very process collectmcr liquid m an mte cr ral bowl t h b o . 1 do a t e ottom of the unit. Installations withm 01 epots or h b ar ours can al so s upplement thi s feature by prov1dm cr a di 0 rect , valve-controlled , link to a separator for major s pilla cre t 1 o con ro A s m a ll s tep board is al so pro v ide d to e n s ure an e M d f asy reach to the couplincr s durincr delivery ae r h o o · d om s eet s teel the Inn e r tray unit is sprayed with oil a n p e trol resist t . . c oatin cr f an pamt w hil s t a bitumen fibre gla ss e xt e rio 0 0 ·f 3 4 mm thickne ss protects any soil-facin g r s u1 ace s .

In th e ba s ic .f. th spec1 1cation the off- sets terminate as a re acted s teel co uplin crs pipe of any diameter required and th e o a 1e then add d . man y e on site. Increa s in g ly howe ver, c u stomers h prefabric a t · a ve rea li se d that a compl e te ion of the L .t but a lso p . .d mi not o nl y re du ce s in stallation time io v1 e s a m 1. a nd c oup]. ore re 1a bl e unit. A number of sen s ing m g s y s tem s b · . . Wh e n the ca n e inc o rporated mto the urnt s . p1 oduct Jin press uri se d h es a 1e se condary con tamed and ' t e co t · und e rn e ath the r n a inm e nt us ually fini s he s ju st m o nitore d · ·d P odu c t co uplin gs and the pre ss ure is in s 1 e th e . T m a no mete r a d unit. he unit is then fitt e d with a o f a p oss ibl; p e r press uri se d containment. In c ase imm e di a te ly ailu re th e fault y line c an be loc ated and di sc · a l lows th e . . o nn ec te d fr o m the sys te m . Thi s 1e ma1111n cr · a nd co ntinu e 0 pipe wo rk to ma111ta111 their press ure o pe ra ti o n

A furth e r o ption (o th e . . . s h ow n 1s a G e rman standard co upl111 g i s a 1e co n ·bi c n> ssove r p. ip a tJ e), w hi c h provide s o ve rfill and i eve nt1 o n b h e tw e e n l) l.C) 1 Y mea n s of a low c urre nt s ig na l C UCt COU j" Jecod in g k Pin g va p o ur co uplin g and a d e di cate d S<>c e t T h c o r re ct c ci · e decocl 111 g soc ke t es t a bli s hes the nn ec t1 o n t 1 r hrcc 1)o j Ill 0 t i e road ta nk e r a nd o nl y w he n a ll " a 1e c o nn cl 1hL' 1 11 1k " i· 1 ec te c a n th e pro du c t be di s pe nse d at ' e vc1 ves SI I · · i o u d t he de li ve ry be inte rrupte d 111 a ny 1' " \ r h L' 1 a I ves ar 1 e c osecl a uto m at ica ll y. Th e sy s te m offe rs

many benefit s as spillag e is kept to an ab s olut e minimum and product cont a mination is virtually elimin a ted. The decoding socket is also connected to a level measure ment in s ide the tank , which provides a superb overfillprevention. At re ac h of level limit the current flow is interrupted and the tanker valve s are closed. For companie s requiring an ev en higher standard the couplin gs for product and vapour can be provided as lockable self-c los in g coupling s, where vibration cau sed durin g di sconne c tion of the hose , re le ases a s prin g in s uch a manner th a t th e c ap c lo ses and tak es qu a rter turn.

The AB OVE GR OUND U NIT S c on s is t of o ne robu st ste el cabinet , which s it s half und e rground and half abov e ground. It provides th e s am e fea tures a s the B ELOW GR OUND U NIT S in term s of tec hni cal s pec ifi c ati o n and fini s hes a nd is oft e n s pec ifi ed o n large r fo reco urt s w ith a dedi c at e d a rea for re fillin g. With th e produ c t a nd vapour c ouplin gs abo ve g round , th e unit s pro v id e eve n e as ie r access for th e de li ve ry. L ik e th e B ELOW GRO UND U NIT it is loc k a bl e a nd pro vid es a tra y fo r poss ibl e s pill age

The Filling Units can be provided to many different standards and specifications , and are routinely manufactured as custom units for individual projects. For example, product and vapour lines of various diameters can be used with any number of products being accommodated. Secondary containment is possible and either steel or plastic pipe systems can be connected. Although they can be supplied as a basis skeleton unit (no couplings, no monitoring equipment) many customers have realised that the units are one of the few products that allow the reliable and efficient installation of emerging, and perhaps soon to be compulsory, safety monitoring equipment.

Recognising the Filling Units as a vital connector between road tanker and underground storage tanks it seemed important to rethink this particular area of the forecourt. No new development can be complete without improving the standards at the filling point. Many other European countries have adapted the Ehlert-system, which not only raises technical standards but also provides great installation benefits and offers many advantages to the delivery process.

Since the four years of the initial idea there have been more than two thousand units supplied across Germany, Austria, Poland and France, and the product has developed into well-established system. The company has now dedicated one entire workshop within its factory to the fabrication of the units , which allows manufacture and assembly in just four days in some cases.

The well engineered character, outstanding quality, very short delivery times and flexibility in design, all insured that Oil companies, Installers, Designers and Authorities have appreciated the benefits the EHLERT REMOTE FILLING UNIT offers to the forecourt installation.

Central and collective containment of all off-sets and vapour return couplings for any location on the forecourt.

Robust, tamperproof and lockable containment for couplings and monitoring equipment.

Ease of handling aiding a more convenient, faster and saver one-man petrol delivery Containment of any spillage offering a large environmental improvements.

Fast and uncomplicated installation due to entire prefabrication of the unit in a fraction of the time.

Flexible design service and variety of specifications due to use of CAM.

Fast delivery of the units to site.

Kris Ehlert

31 Dinmont House Pritchard ' s Road London E2 9BW Tel 020 77390438

Mob. +49 171 9559 166 E-mail krisehlert @hotmail.com

1. This circular provides information about recommendations in a report prepared by the Health and Safety Executive (HSE), in consultation with the Environment Agency (EA) ad Gwynedd Council, into a significant leak of petrol from a petrol station in Bontddu, North Wales. Licensing authorities are particularly asked to note the recommendations in the report (paragraphs 9 to 17 and annex).

2. Between 15 August and 16 September 196, approximately 61,000 litres of petrol leaked from an underground storage tank at Bontddu Service Station, near Dolgellau, contaminating ground around the site and entering a nearby river. In April 1997, while contractors were carrying our exploratory drilling to assess the extend and severity of contamination, vapour released from the petrol underground ignited and caused a fireball in a cottage nearby damaging it and slightly injuring one of the residents.

3. The original leak and subsequent fireball caused local residents considerable concern and disruption. A nearby school was evacuated and remained closed for almost six months, and several householders vacated their homes for a considerable period of time, because of the presence of liquid petrol and vapour in the ground around their properties.

4. 5.

Bontddu Service Station has a petrol licence issued by Gwynedd Council. Conditions attached to the licence in force at the time of the leak required the licensee (the site owner/operator) to caiTy out regular inventory checks and record the contents of each tank, and maintain a record clearly showing gains and losses. After investigation, Gwynedd Council concluded that these conditions had been breached, and the licensee was offered, and accepted, formal cautions.

HSE was responsible for enforcing non-petrol health and safety matters at the site (a vehicle repair workshop at_ the_ garage was deemed to be the main activity) and mvestigation prosecuted the contractors in respect ol the circumstances leading to the fireball. The company pleased guilty to offences under the Health and Safety at Work etc Act 1974 (for failing to ensure the health and safety of persons not in their employ during drilling operations) and the Management of Health and Safety at Work Regulations 1992 (for failing to carry out an adc4uate and sufficient risk ! and fined a total of£ 15.000.

fhe :-.itc owner/operator pleased guilty to a prosecution hroupht h)- the Environment Agency under the Water /fr..,, HI rn:'" Ach 1991. and wa'i fined £4000.

7 · In November 1997 the local MP secured a debate in the House of Commons about recent leaks from petrol stations in his constituency. He focussed on the Bontddu incident criticising the length of time the investigations and clean-up operations were taking, and calling for a full public enquiry. The Parliamentary Under-Secretary of State for Wales agreed to provide a full report into the Bontddu case, and asked HSE to prepare this for him.

8 The HSE report responds to the points the MP raised in the debate, explains the arrangements for enforcing petrol, general health and safety, and environmental legislation at petrol stations and at Bontddu in particular, and also includes recommendations to help avoid similar incidents in future. These are reproduced in an extract from the report annexed to this PETEL.

9. Site owners/operators should have suitable arrangements in place to detect leaks. What is suitable and reasonably will vary from site to site taking account of such things as the location of the site, the amount of petrol that could leak and the likelihood of this happening, and the risk if could present to the safety of people both on and off site.

10. Wet stock monitoring and reconciliation when carried out properly is an effective means of detecting leaks from underground equipment. A system which provides accurate and regular information about stock levels can highlight unusual variations or trends which could indicate a leak.

11. At sites where a leak would present a greater risk to people's safety, then a system of higher reliability and accuracy may be appropriate. This cold be a mote sophisticated type of wet stock reconciliation, such as a statistical inventory reconciliation, or proprietary leak detection equipment which, for example, permanently monitors the interstice of double skin tanks and pipework.

12. Where an apparent Joss of petrol cannot be explained. for example by the effect of temperature variations or dispenser metering errors, and a leak is suspected. it should be investigated as quickly as possible. It ma be necessary at this stage for a tank or pipework test to be carried out. A test can indicate whether or not equipment is leaking at the time of the test but dotes not give an on-going assurance about ih integrity. It is therefore impo11ant that wet stock control. appropriate to the on and off site risks. is always carried out.

13. This circular is in addition to PETEL 2/96 \Vhich provides guidance on the frequency uf tank and pipeline testing. When an appropriate wet stol'I<. control

system is in place and it is properly operated and monitored there may be no need to carry out routine tank or line leak testing in accordance with PETEL 2196. Enforcing authorities should not routinely seek periodic tank and line testing when the wet stock control system adequately controls the one and off site risks. Further advice on wet stock control and tank and line testing is in preparation, and this will be issued shortly as a PETEL circular entitled "Leak Detection in Tanks and Lines".

14. Examples of wet stock control or leak detection systems where routine tank and line leak testing is not considered necessary include:

v Statistical Inventory Reconciliation

v Dynamic leak detection based on certified contents measuring and analysing systems

v Double skin tanks and pipework with interstitial monitoring.