E. V. BEEBY J. BEER J. BIRKS R. L. BLOOR J. W. FRID H. GRIFFITHS D. HALL

E. V. BEEBY J. BEER J. BIRKS R. L. BLOOR J. W. FRID H. GRIFFITHS D. HALL

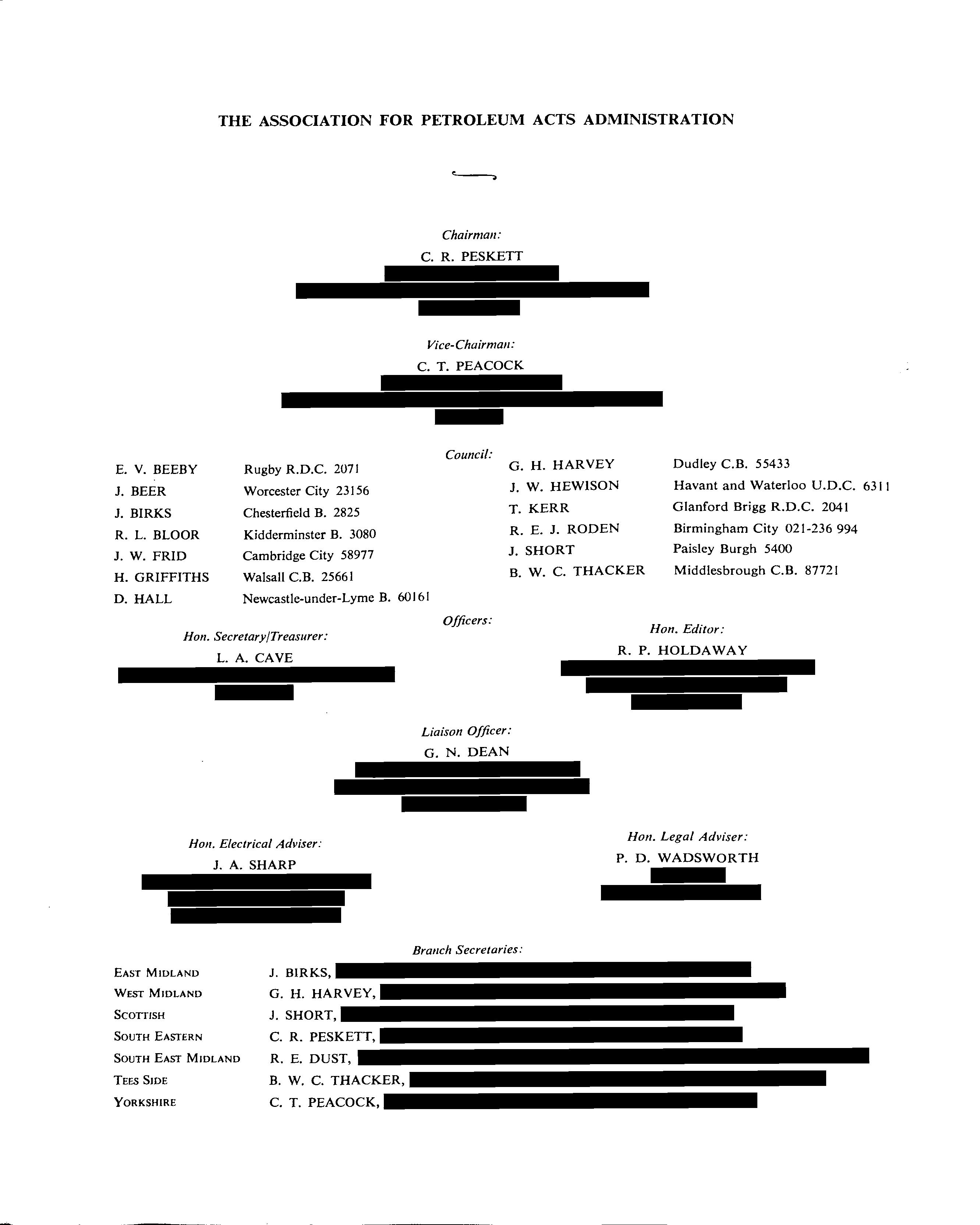

Chairman: C. R. PESKETT Vice-Chairman: C. T. PEACOCK

Rugby R.D.C. 2071

Worcester City 23156

Chesterfield B. 2825

Kidderminster B. 3080 Cambridge City 58977

Walsall C.B. 25661

Newcastle-under-Lyme B. 60161

Hon. Secretary/Treasurer:

Council: Officers:

G. H. HARVEY J. W. HEWISON T. KERR R. E. J. RODEN J. SHORT B. W. C. THACKER

Dudley C.B. 55433

Havant and Waterloo U.D.C. 6311

Glanford Brigg R.D.C. 2041

Birmingham City 021-236 994 Paisley Burgh 5400

Middlesbrough C.B. 87721

Hon. Editor: L. A. CAVE R. P. HOLDAWAY

Liaison Officer: G. N. DEAN

Hon. Electrical Adviser:

Hon. Legal Adviser: J. A. SHARP P. D. WADSWORTH

EAST MIDLAND

WEST MIDLAND

SCOTTISH

SOUTH EASTERN

SOUTH EAST MIDLAND

TEES SIDE

YORKSHIRE

Branch Secretaries: J. BIRKS, G. H. HARVEY, J. SHORT, C. R. PESKETT, R. E. DUST, B. W. C. THACKER, C. T. PEACOCK,

OCTOBER, 1967

Published quarterly by the Association for Petroleum Acts Administration

Opinions expressed in this journal are not necessarily the views of the Association

TALKING POINT NOTES AND NEWS LETTERS CURRENT AND FUTURE TRENDS IN DESIGN OF CRUDE OIL TANKERSNORMAN JENKINS

THE SAFE KEEPING OF PETROLEUM SPIRIT-H. E.T. JACKSON THE ALARMING FACTS ABOUT SMALL FIRE EXTINGUISHERS-IAIN ADAMSON OLD PETROL TANKS TO BE TESTED AFTER MYSTERY •• PLANNING AND THE PETROLEUM 0FFICER-W. C.R. DALE APPEAL TO HOME OFFICE BRANCH MEETINGS : SOUTH EASTERN-GODALMING WEST MIDLAND-WALSALL A.M.C. COMMITTEE REPORTS LEGAL PROCEEDINGS THROUGH THE PIPELINE Chairman: C. R. PESKETT Honorary Secretary/Treasurer: L. A. CAVE

Editor: R. P. HOLDAWAY WEIGHTS AND MEASURES DEPT GUILDHALL, SHREWSBURY

Subscription: 30s. per annum

Any new publication on Petroleum Law and Practice is an event. Two such books both published within the last quarter is a welcome bonus. We refer of course to "The Storage and Handling of Petroleum Liquids : Practice and Law'', by John R. Hughes, Group Chief Safety Engineer of the British Petroleum Company Ltd., and "Petroleum Officers' Handbook", by A. L. Good, Chief Public Health Inspector to Bishop's Stortford U.D.C. Both books fulfil their purpose admirably and are a must for all concerned in petroleum administration in its widest sense.

The increasing use of the correspondence columns of The Bulletin by members is a source of gratification. We thank our contributors sincerely for their interest and remind all members that, unlike the Ritz Hotel, this column is open to all.

In a more serious vein it is disquieting to read in the 1965 Report of H.M. Inspectors of Explosives that of twenty local authorities visited by H.M. Inspectors, two urban districts had not appointed a petroleum officer. Under the circumstances, it is hardly surprising that in one of these areas no efforts were being made by the licensees to comply with the relevant section of the conveyance regulations.

We read that the Kent Fire Brigade was called to licensed premises when a quarterly audit had disclosed a a loss of approximately 1,500 gallons from a 500 gallon capacity storage tank over a period of about two months. The Chief Fire Officer concluded his report on the incident with the observation that one advantage to accrue as a result of this leakage is that the local authority has now approved a recommendation that all storage tanks should be regularly tested in accordance with the Home Office Model Code procedure.

We can only comment that examples of this nature indicate that in some areas there is still a great deal to be done in educating local authorities on their obligations under the Petroleum Acts.

Aberdeen Hertfordshire

Ipswich

Inverness

Inverness

Liverpool Melford

Oxfordshire

Renfrew

Ross & Cromarty

Stirling Tynemouth

c.c. c.c. C.B. Burgh c.c. City R.D.C. c.c. c.c. c.c. c.c. C.B.

East Suffolk Lancashire West Suffolk Northumberland

WM. F. WM. WM. WM. F. H. F. c. WM. WM. F.

Altrincham, M.B.C., Cheshire. Borough Surveyor, Town Hall, Altrincham.

J. W. Barnes, Chartered Engineer, Shell-Mex & B.P., Ltd., Birmingham.

J. Dick, Managing Director, Yorkshire Pump & Tank Co. (Wakefield) Ltd., Wakefield.

J. G. Hurst, Petroleum Consultant, Equipment Handling Engineers, London.

Mr. W. Smith, Chief Fire Officer, Stoke-on-Trent, since 1948, is to retire in October. We wish Mr. Smith a long and happy retirement.

Mr. Owen Burn, Deputy Chief Fire Officer, Leicester, succeeds Mr. Smith at Stoke-on-Trent.

Mr. C. H. Clapham, Engineer and Surveyor, Horbury U .D.C., has been appointed Borough Engineer and Surveyor, Richmond, Yorkshire.

Mr. J. W. Frid, Deputy Chief Inspector of Weights and Measures, Cambridge, has been appointed Inspector in succession to the late Mr. F. W. Cartwright.

Mr. J.M. Hambley, Lanarks C.C., has been appointed Chief Inspector of Weights and Measures, Burgh of Coat bridge.

Scunthorpe M.B., Lines., now WM.

Mr. C. D. Henden, G.L.C.

Petroleum Officers Handbook by A. L. Good, Chief Public Health Inspector, Bishop's Stortford U.D.C. Published by Charles Knight & Co. Ltd., Dowgate Works, Tonbridge, Kent. Price 45s., postage 2/6d.

The Storage and Handling of Petroleum _Liquids : Practice and Law, by J. R. Hughes, Chief Safety Engineer, British Petroleum Co. Ltd. Pubhshed by Charles Griffin & Co. Ltd., 42 Drury Lane, London, W.C.2. Price 84s., postage 4/6d.

Would members please inform the Hon. Secretary of any change of their address or telephone number over the past twelve months.

Would Branch Secretaries let the Hon. Secretary have their claims for capitation fees for the year 1967 not later than the 30th November, 1967.

Japan's shipbuilding the. bigges.t the world, 1s planning further expans10n of its fac1ht1es to meet demands for super-sized vessels.

Industry sources reported in Tokio orders for super-sized vessels from Japanese sh1pbutlders had increased markedly since the Middle East War.

The Japanese Transport Ministry approved an application from the Kure Shipbuilding and Engineering Co. for enlarging the company's existing dockyard to a capacity of 225,000 deadweight tons.

The first production model of the Beckmeter Pathfinder coin-operated pump was launched in August at a garage at Wisborough Green, Sussex.

National Benzole plans to have a network of these pumps, offering a 24-hour service, at selected sites throughout the country.

By inserting two half-crowns in the slot, the motorist 5s. worth of Premium petrol and then serves himself. This get-you-home service is particularly useful for drivers who have a near-empty tank at night. . A cap fits over the head of the pump. The operating mstructions are silk-screened on a translucent Perspex head plate positioned above the cap, which is illuminated at night.

During normal opening hours the pump can be switched to conventional working by the forecourt staff, and a cover fits over the self-service instructions.

Mr. Mark Mothio, Director and General Manager of National Benzole, said, "Already a number of local authorities have given permission in principle to the installation of coin-operated pumps on an unattended basis. This will enable more National garages to offer a round-the-clock service where normally it would be uneconomical to remain open late or through the night".

The first self-service multi-coin operated petrol pumps to be operated in the United Kingdom were inaugurated last month by racing driver Stirling Moss at a garage at Blackheath, Birmingham.

From now on motorists who use the garage will be able to buy up to 14/- worth of grades of B.P. Super, Blend and Regular, usmg half-crowns or They will select the grade required and feed the coms mto the computer on the wall of the The computer checks the coins and through electrical impulses frees the petrol to the selected pump. The drivers then help themselves.

A similar system to this with which B.P. has experimented in Western Germany is proving highly successful. There is little danger of accidents; in West Germany, out of 11-'- million fill-ups, there have been only two, and . 2 neither was serious.

Five new road tank vehicles, each with a capacity of 6,300 gallons of motor spirit, are to l;>e built for B.P. Weighing thirty-two tons each, they will be among biggest on Britain's roads, and. have been m accordance with the Group s pohcy of developmg for the future coupled with At present, the biggest petroleum spmt tankers m the have a 4,000 gallon capacity, but new Petroleum Spmt Regulations now allow a maximum load of 6,600 gallons of motor spirit to be carried by a road tanker.

ln spite of their vast bulk, power-assisted steering on the first two of the five axles make them easy to handle in the heaviest traffic and able to manoeuvre into awkward discharge spaces.

Mr. R. A. T. Kemp expresses doubts about the efficiency of latched nozzles and expresses the opinion that these should be thoroughly tested before being approved. l could not agree more, but would like to know what kind of on the site test can be effective? If the garage proprietor is co-operative and provides a car to be filled to capacity it is possible to test the safety-cut-out but how can you test the safety swivel ? It is obviously unwise to test the shock release mechanism while petrol is flowing (even if the proprietor would let you) and when I recently tested this without any flow the latch failed to release on an average of every other occasion.

I am also concerned about the possible danger of a careless attendant returning the nozzle to the pump after delivery without releasing the latch. Should this pump then be re-started for another delivery a risk of petrol spillage arises. I feel that the answer to this problem lies with the Home Office. Having given approval in principle to latched nozzles they should test these on the market and circulate to Local Authorities the brand names of those satisfactory as approved patterns.

Wakefield City L. GILBERTl read with interest the 'Faster Service on the Petrol Station Forecourt' article that had been reproduced from the F.P.A. Journal in the July edition of the Bulletin.

Although I may be wrong, I feel that a slight misunderstanding has crept in when the writer refers to coinin-the-slot pumps and says that "Two of the first coin operated self service stations in this country are at Southampton and Plymouth". He is probably referring to Turnbull at Plymouth and Mobiloil at Southampton which are, of course, cashier controlled post payment selfservice stations. The conditions of licence issued by the Cities of Southampton and Plymouth refer, of course, to this type of operation and not to coin acceptor pumps, which one presumes would be unattended.

I agree entirely with the attitude towards unattended self-service which you express in "Talking Point". l feel sure that a mutual examination of this problem does much to help all parties arrive at a considered opinion.

B.P. Co., Ltd.

London, E.C.2

M. T. R. BOWEN, Automotive BranchAs one who did not go to Germany and therefore owes no-one a tangible return for anything, may I comment on Mr. Domoney's letter in the last issue of the Bulletin on the subject of unattended self-service ?

Mr. Domoney makes the point that experience is necessary before informed decisions can be made. If no, or very few, such sites are to be permitted in this country until we have had this experience then it seems to me axiomatic that such experience may only be gained by going overseas where several years practical knowledge is available for the asking. I certainly have enough confidence in my colleagues to believe that hospitality will make no material difference to their opinions.

" in order to determine just how much public demand there is for unattended self-service". In my opinion there is and will be very little public demand; if so, the provision of the more expensive equipment necessary will not be justified by the returns. Yet I am left aware of the fact that this has nothing whatever to do with whether or not my Authority, acting under the terms of the Petroleum Acts, approves such sites. Town planningmaybe, Petroleum Acts-never ! If a licensee wants to operate an uneconomic site, that's his business; if he wants to operate a dangerous site, that's my business.

" . . or if the Greater London Council allows even one experimental station in its area, the flood gates will be open If ... the G.L.C. would issue a statement that the question of unattended self-service will be looked at again we should all be given a breathing space". The inference to be drawn from this surely can only be that the G.L.C. should determine, or determine to a large extent, the rate of progress or acceptance of new features. This inference would seem to be supported, however unintentionally, by both the Home Office and the Petroleum industry generally. If any of my colleagues recommends anything to his Authority solely on the grounds that the G.L.C., or for that matter the Newcastle-underLyme Authority accepts it then he runs a very real risk of finding himself having to justify his advice sooner or later. Unfortunately I do not know Mr. Domoney personally, but I do know his colleague, Mr. W. C. R. Dale, very well indeed, and his knowledge and experience demand that his views be heard and taken into account. Yet Mr. Dale would certainly never claim that his opinions were the only valid ones available. The whole purpose of the Association is that the total accumulated knowledge of its members be readily available-"Rome today-the world tomorrow" is a dangerous doctrine unless it can be guaranteed that "Rome" will always be right.

" ... adequate number for experimental purposes". Many things can be shown experimentally in a laboratory; unattended self-service can only be proved in public use. It follows therefore that some Authority or Authorities must be prepared to take the first step, and for myself it seems unreasonable to expect that this must always be some Authority other than mine.

These are my comments on certain remarks made by Mr. Domoney in his letter, but let me hasten to add that I make them only because I feel they should be made to rebut what I feel are unfortunate inferences contained therein.

J agree entirely with what I believe to be the real motive behind _his letter, since he is really trying to say IS that the respons1b1hty 1s ours. Pressure from other is understandable and to be expected, yet because 1t 1s strong pressure with voices in high places it must not be allowed to precipitate ill-considered action.

On the other hand, hqwever, it cannot in fairness be dismissed simply because it has a commercial involvement; a lot of knowledge and experience is available to those interests, and their opinions are not necessarily flavoured by commerce.

There are, obviously, inherent dangers involved in unattended self-service which do not apply to attended self-service, which is itself open to objections which do not apply to non-self service; electrically-operated pumps present hazards which do not exist with hand-operated pumps-but how far do we go back-to the horse and cart ? The point I am trying to make is that progress, as distinct from change, is inevitable; to refuse progress simply because it is unfamiliar is unrealistic. Conversely change is not necessarily to be welcomed.

All new ideas should be examined with all the collective knowledge and experience that our Association can marshal, bearing in mind that what is good practice in one locality may not be so, for demonstrable reasons, in another. When I make a recommendation to my Authority I am not in the least influenced by what "they" do elsewhere.

Any one of our decisions may be challenged. It would be a very foolish man indeed who did not know thoroughly, and sincerely believe in, the reasons for his opinions. Newcastle-under-Lyme B.C. D. HALL

I find all subject matter in The Bulletin of great interest but several items in the current issue are particularly so, and I would like to comment on some of them.

In the Report of the South East Midland Branch on page 72, reference is made to the provision of heating and electrical appliances on licensed premises, situated "some distance" from the licensed store. Whilst I agree that petroleum officers are not responsible for such appliances, I submit we have a responsibility to see that they are so sited as "not to endanger the safe-keeping of petroleumspirit" and to this extent I would feel justified in making recommendations as to screening or enclosing the apparatus, after consultation with the Fire Prevention Officer, whose guidance is invaluable in such matters.

On page 74, in the Report of the East Midland Branch, under "Any Other Business", the question of dual or multi-filling of underground tanks from one road tanker and of periodical testing of electrical installations are raised.

Jn the former case, my Council recently considered a similar enquiry from one of the larger oil companies, and it was resolved that six additional conditions shall be attached to all licences to control the position as far as seems possible. I enclose a copy which may interest members.

Whilst the position would be very similar to having two tankers discharging at the same time, one important difference, it was felt, would be that there are always at least two drivers in attendance in this event to act in any emergency, whereas it is not uncommon for a single tanker to carry the driver only.

These conditions have now been in the hands of licensees in the district, and the oil company who made the approach, for some weeks and so far there has been no comment, adverse or otherwise.

It might be argued that they go beyond the scope of Section 2 of the Petroleum (Consolidation) Act, 1928, as they deal with the delivery of petroleum-spirit, but I contend they come within the term "and generally as to the safe-keeping of petroleum-spirit" in the Section, and place the _onus on licensees to see that the reasonable precaut10ns are taken.

As to the testing of electrical installations, it has been the practice in this district for the last six years to require a certificate accompanies all applications for renewal of licences.

There was some criticism from a few licensees in the early days on the necessity to produce an annual certificate, but when it was pointed out that these installations can or possibly suffer hidden damage in a year, the requirement was accepted.

A. covering letter points out that the certificates n:ust signed by a person qualified to carry out the exammation.

Chertsey U.D.C. G. H. BIRCH CHERTSEY URBAN DISTRICT COUNCILAdditional Conditions to be attached to Licences

(

l) The hoses shall be laid side by side in as close imity as possible to reduce the area of potential danger.

(2) Each hose must be coupled to the tanker and the underground tank or tanks before either hose is brought into use.

(3) The tanker must always stand as close to the filling point as possible.

(4) The system of dual or multiple discharge to underground tanks shall only be permitted where the tanker can stand off the highway.

(5) Adequate artificial lighting shall on site when delivery of petroleum-spmt is made dunng the hours of darkness.

(6) The tanker shall be so manned _that each valve can be shut off immediately m case of accident or emergency.

The advent of new petrol dispensing equipment and methods over the past year or two has caused a number of Petroleum Officers to devote a tremendous amount of time in examining and considering. new and devices. They have _the m light of technological progress y_et reahsmg their own important role as guardian of pubhc safety.

Before the Home Office gave its blessi1!g to the of latched nozzles I had to advise my CouncII on an application for one of' these devices to be attached to a new type of petrol dispenser. The petrol company co_ncerned very helpful, except when I requested certam destructive tests. For manufacturers to repeat such tests for all

authorities is obviously a waste of time and money and often impracticable because of various dangers on sites. Thus we come to the existing state of affairs where the smaller authority is referred, as a matter of course, to the larger authorities such as Greater London Council, whose officers have seen demonstrated and fully tested such devices on manufacturers' premises. Alternatively, one has to accept the manufacturer's word as to the capability of his products.

I sought the advice of the Association on latched nozzles, expecting them to have been actively engaged in discussion with industry and the Home Office on this matter. To my surprise, without reason, the Council did not advise acceptance of such nozzles. However, I felt at the time that the existing Council system could well have been the cause for such a decision. "Talking Point" in the January, 1967, issue of the Bulletin supported my feelings in that it was suggested such decisions are often snap decisions at meetings already overloaded with general business. The Editor called for a much closer liaison with industry if the Association is to wield the influence expected by its members and give guidance when needed. I wholeheartedly agree ! Let the manufacturers know we want to keep up with them, rather than them having to slowly 'convert' Petroleum Officers in various parts of the country until new ideas are accepted nationally years later. Cannot an "Equipment Panel" be formed, whose job it would be to examine, test (to destruction if necessary) and witness demonstrations of new devices, fire appliances, ideas, etc. ? The need for this is continually growing. Recently we have had Z.V.A. and O.P.W. nozzles, there are bound to be other makes coming along. Now that we are moving closer to the unmanned self-service filling stations, information on the efficiency and effectiveness of air-purging protection systems and other safety devices would no doubt be welcomed. Here, I feel, a close cooperation with the Home Office Inspectorate would also be necessary.

The G.L.C. Officers have done a considerable amount of work in this field and have gained great respect from us all, but is it right for the Association to sit back and leave this important matter more or less in their hands ? The Association ought to be recognised by manufacturers as the Petroleum Section of the G.L.C. apparently is now.

I feel that it would be welcomed by most members if the Association took the lead and sought greater cooperation with industry and considered each item of equipment or new idea carefully and issued technical information bulletins of their findings, good or bad, at an early date. The manufacturers and petrol companies may welcome such views since the Association now represents and could undoubtedly influence many hundreds of authorities.

I make these comments in full knowledge of the present constitution and resources of the Association and appreciate the possible magnitude of such an additional suggested burden-perhaps we have some technically interested members who would be pleased to serve and make a useful contribution to the Association's activities.

Are there any other ideas that might help members to mould a uniform future policy in petroleum administration matters?

Hastings C.B. G. BERESFORD by NORMAN JENKINS

by NORMAN JENKINS

There is no shortage of oil in the world but it ·is not found in the most convenient places since the vast Middle Eastern and African reserves are situated far from the main area of consumption, i.e. the Western Hemisphere. This means that oil companies have to ship their crude oil in tankers to refining centres in Western Europe, although to extent the same problem applies to the Far East, e.g. Japanese and Australasian markets.

Provision of facilities to cope with the trade of an existing oil port in ten years' time is a constant problem faced by those concerned with tanker economics on the one hand, and port administrators on the other, who within a short span in the past have watched the growth of crude carriers develop from 32,000 tons to those of 300,000 tons deadweight, similar to those now under construction for Gulf Oil scheduled for completion in mid 1968.

An announcement by Lloyds that the first of the halfmillion-ton giants may be on the stocks in the next three to four years may be disquieting for the politicians who are deeply concerned by the damage done by the wreck of the 118,000-ton Torrey Canyon off Cornwall; but a halfmillion-tanker makes economic sense to oil companies and shipowners. It might halve the cost of carrying oil in today's mammoth ships.

The following notes attempt to describe in brief detail some of the answers to a question which might well read 'What are the oil companies thoughts on current and future trends in design of crude-oil tankers ?

Current trends in building the maximum size of crude carriers afloat today have been dictated by economic and navigational constraints to allow for vessels of between 80,000 tons and 300,000 tons. Ships in the 80,000/100,000/ 200,000-ton class comprise a combination of either oil company owned or chartered thus whilst six 300,000-ton carriers are under construction for Gulf Oil to be owned by Ludwig and chartered by Gulf, Shell are about to build twenty 200,000-ton vessels for their own operation.

The rapid increase in tanker sizes in recent years has had a startling effect on transport costs. With all other things equal, it costs 5s. lOd. a ton to bring oil from Libya to Britain in a 100,000-ton ship, compared with 16s. 6d. a ton in 20,000-tonners.

The 152,000-ton Tokyo Maru carries oil from the Persian Gulf to Japan at two dollars a ton, compared with four dollars by the 50,000-ton ships.

And the 200,000-tonners being built in Japan for Trident Tankers, a P. & 0. subsidiary, for charter to Shell and B.P. will shift oil from the Persian Gulf to Europe at around 19s. a ton compared with 37s. 3d. in the 35,000-tonners, considered giant ships only a few years ago.

Shipowners are coming to the conclusion that the next size increase to give a worthwhile return will have to be from 200,000 tons to 500,000 tons. Hence the studies by Lloyds and their Norwegian rivals, Det Norske Veritas.

The largest vessel which has been built in U.K. shipyards to date is the British Argosy of 113,000 tons deadweight. Japanese, British and Continental shipyards can undertake the construction of vessles in the 200,000/ 300,000-ton category but the Japanese have consistently been ahead of their rivals and could immediately build vessels of 500,000 tons. With regard to the future, however, more than one U.K. shipbuilder, for examples, has made it known that he would physically have the facilities to build ships of this size.

The following applies to a 300,000-ton vessel of the type being built for Gulf oil:

Crude oil discharge into storage at a rate of 15,000 tons per hour.

Each ship is approximately 1, 150 feet long with a beam of 170/180 feet and a draught of 79 feet, conventional turbine steamship with twin screws, and an engine developing 40,000 horse power.

On a round trip between Kuwait and Bantry Bay each tanker is expected to burn more than 10,000 tons of bunker fuel.

A crew of about forty officers and men will be employed in each vessel and as a result of automation and the use of bridge control this represents the same complement as that required at present in a 50,000-ton carrier. The tanker will be able to load in less than twenty-four hours and discharge in about thirty hours and will sail at a speed of some sixteen knots.

The round trip from Kuwait to Bantry Bay and back via the Cape of Good Hope will take two months, and a round trip from Nigeria to the U.K. one month.

Each tanker will carry a maximum cargo of two million barrels of crude oil, enough to run a 60,000-barrel-a-day refinery for more than one month.

The following brief headings describe a number of the more significant design facilities which have been developed either afloat or ashore, to keep pace with the building of larger vessels and which have contributed to marked savings in revenue operating costs.

(1) Bridge control and automation resulting in minimum crew complement with more effective use of personnel on board ship, i.e. reduction of the tedious job of watch keeping for replacement by more efficient programme of preventive maintenance.

(2) Automation of valve control sampling and ullaging by remote control ashore and afloat.

(3) Use of gantry loading arms to obviate hose handling.

(4) Use of computer for cargo handling ashore and afloat.

(5) The introduction of television for communication/ visual purposes.

(6) The use of special deck and hull paint lasting between five to ten years and the epikote lining of cargo tanks to minimise corrosion.

(7) Self-adjusting tension moorings to reduce crew effort.

(8) The increasing of pipeline sizes and capacities at shore terminals, capable of accepting up to 200 pounds per square inch.

(9) In some instances single point moorings have been introduced to reduce the cost of building jetties, dredging berth approaches and to minimise costly tug assistance.

(10) An increase in speed from ten knots post-war to sixteen/eighteen knots today.

Looking to the future, what are Naval Architects' current thouahts on the largest size of tanker which can be built to meetthe continued dictates of operating economics and the limits imposed by navigational and operational constraints ?

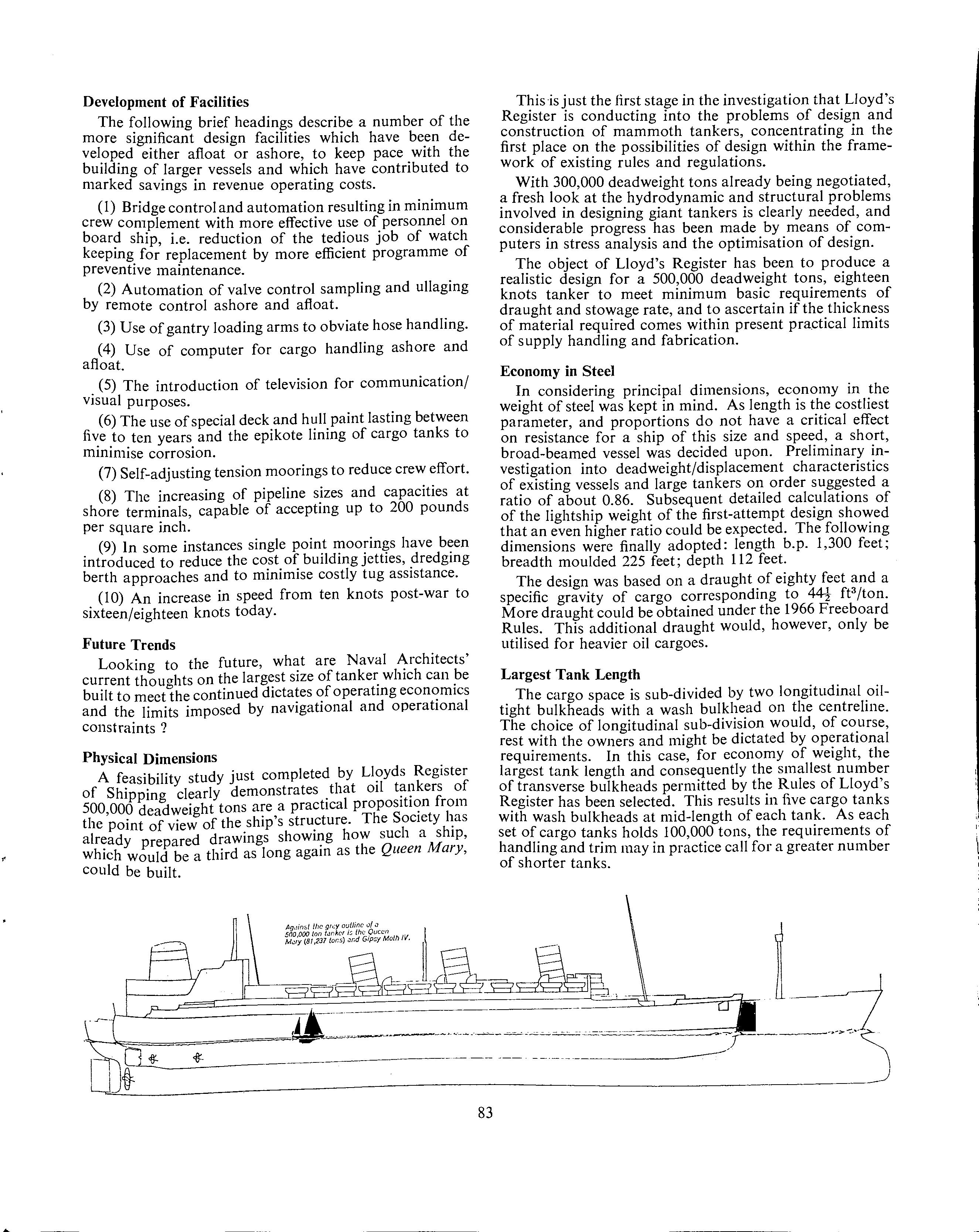

A feasibility study just completed by Ll?yds Register of Shipping clearly demonstrates .that oil of 500,000 deadweight tons are a practical from the point of view of the ship's structure. The Society prepared drawings showiI_lg how such a ship, which would be a third as Jong agam as the Queen Mary, could be built.

This ·is just the first stage in the investigation that Lloyd's Register is conducting into the problems of design and construction of mammoth tankers, concentrating in the first place on the possibilities of design within the framework of existing rules and regulations.

With 300,000 deadweight tons already being negotiated, a fresh look at the hydrodynamic and structural problems involved in designing giant tankers is clearly needed, and considerable progress has been made by means of computers in stress analysis and the optimisation of design.

The object of Lloyd's Register has been to produce a realistic design for a 500,000 deadweight tons, eighteen knots tanker to meet minimum basic requirements of draught and stowage rate, and to ascertain if the thickness of material required comes within present pra.ctical limits of supply handling and fabrication.

In considering principal dimensions, economy in the weight of steel was kept in mind. As length is the costliest parameter, and proportions do not have a critical effect on resistance for a ship of this size and speed, a short, broad-beamed vessel was decided upon. Preliminary investigation into deadweight/displacement characteristics of existing vessels and large tankers on order suggested a ratio of about 0.86. Subsequent detailed calculations of of the lightship weight of the first-attempt design showed that an even higher ratio could be expected. The following dimensions were finally adopted: length b.p. 1,300 feet; breadth moulded 225 feet; depth 112 feet.

The design was based on a draught of eighty feet and a specific gravity of cargo corresponding to 44! ft 3/ton. More draught could be obtained under the 1966 Freeboard Rules. This additional draught would, however, only be utilised for heavier oil cargoes.

The cargo space is sub-divided by two longitudinal oiltight bulkheads with a wash bulkhead on the centreline. The choice of longitudinal sub-division would, of course, rest with the owners and might be dictated by operational requirements. In this case, for economy of weight, the largest tank length and consequently the smallest number of transverse bulkheads permitted by the Rules of Lloyd's Register has been selected. This results in five cargo tanks with wash bulkheads at mid-length of each tank. As each set of cargo tanks holds 100,000 tons, the requirements of handling and trim may in practice call for a greater number of shorter tanks.

Analysis of longitudinal bending moment and shearing forces in the loaded condition by the Society's standard computer programme showed that it was necessary to provide clean ballast tanks at around midships. The analysis also revealed high shearing forces at the forward end of the engine room, which might necessitate re-siting the oil fuel bunkers at the after end of the engine room. Twin-screw propulsion was envisaged and, although the type of machinery plant was not investigated, a weight of 2,000 tons was allowed for in the estimate.

In general, thickness of plating and size of sections are no greater than are already being handled and fabricated by many ship-builders. While no claim is made that the design which has emerged for a 500,000-ton tanker necessarily represents the structural and hydrodynamic optima or the only acceptable internal structural arrangement, the technical feasibility of the project within the Society's present Rules is clearly established. It is equally clear that many of the problems in design and construction of mammoth tankers require further and fuller investigation.

Although it has been possible within a relatively short period to increase deadweight capacity from 32,000 tons to 300,000 tons, there approaches a time in naval architecture when navigational constraints impose severe draught restrictions on the maxim um size of tanker which can be accommodated in the U.K. or European/Scandinavian coastal waters to which, of course, there will be a limited number of exceptions for some years ahead.

When considering North West European ports a limiting factor for draught is the depth of the Dover Straits and English Channel which impose a maximum draught limitation of about seventy-five feet, the alternative being considerable deviation by proceeding north of the British Isles. At the moment there are no ports which have facilities capable of accepting 300,000-ton vessels and in many cases relatively shallow approaches would require a vast amount of dredging to provide the necessary depth of water. Several ports are planning to accommodate 200,000-ton vessels with a draught of about 62 feet and, in the British Isles, suitable depths of water already exist at Bantry Bay and Finnart for the accommodation of vessels between 300,000 and 500,000 tons.

In the case of large crude carriers used to deliver supplies from the Persian Gulf to U.K. waters, a navigational restriction on size is imposed by the Suez Canal which hitherto has been able to accept fully laden vessels drawing thirty-eight feet although it is expected that this is likely to be increased to forty feet in the near future with further improvements at a later date. This limitation means that a fully laden vessel of 200,000 tons capacity has to be programmed via the Cape when loaded and can only use the Canal on her return journey when in ballast.

Factors which determine the maximum size of any new crude carriers not only have to relate comparisons of freight savings with increased capital expenditure in ship building costs, but, in addition, increases in capital expenditure and revenue operating costs to provide extra loading and discharging facilities ashore, together with extra tankage, larger jetties, additional tugs, etc. The need for

flexibility in case of breakdown imposes considerable problems in replacing large carrying capaci.ty at notice, whilst the problem of suitable dry dockmg fac1hties is particularly acute in the U .K. where vessels of 100,000 tons and above can only be accommodated at either Greenock or Birkenhead at present.

In a highly competitive market the decision whether to own or charter becomes critical when related to the amount of capital available for investment in any one year, since a far higher rate of return can be expected for st.at1c projects directly associatied with marketing product10n. For example, in the case of building either a new refinery, or sinking a new gas well in the North Sea, an E.P.R. of say thirty per cent can be reached, as opposed to current acceptable E.P.R. of some ten-twelve per cent 111 the case of ocean tankers. In terms of world-wide oil carrying capacity some forty per cent of tanker fleets are Group owned, the remainder being in the form of short or long term charter.

From brief discussions held with those concerned with Tanker Company economics and who calculate the relative advantages of building or chartering policy (who have warned of the impossibility of being able to forecast with any degree of certainty) it would appear that oil companies and charter owners over the next seven years are likely to continue concentrating on vessels varying in size from 80,000 to 200,000 tons deadweight capacity. A limite? number of 300,000-ton ships will be built, with the possibility of some 500,000-ton ships for special routes, and consideration is already being given to accommodate vessels of this latter size at:

(a) Bantry Bay (b) Finnart (c) Rotterdam

(d) North or North West French Coast

Hovering in the background are Esso's thoughts on 800,000-ton ships and the million-ton tanker projected by the Swan Hunter shipbuilding group. If, however, the economists were asked to give any more definite form of forecasting, they would be inclined to say 'Bearing in mind the over-riding factors of navigational constraints, and the high cost of providing handling facilities to ensure adequate flexibility, the conception of a 500,000-ton tanker is more of a minimum size for the next step, not a maximum for the present development'.

Recent events in the Middle East, involving the closure of the Suez Canal, with its immediate interruption of shipping, resulted in a demand for chartering on a large scale and the diversion of vessels round the Cape, incurring higher freight charges. This turn of events, and the incidence of disruption to shipping using the Canal over the past four years due to political affairs, may well hasten a decision on the part of tanker owners as a whole to accelerate their future shipbuilding programme and thus call for a greater proportion of giant tankers in excess of 200,000 tons than otherwise might have been the case, as a measure of economy and to allow for additional operating flexibility in times of emergency.

With acknowledgements to the Magazine of the Shell Mex and B.P. Group.

I have been asked to talk to you on the subject of Petroleum Regulations and the requirements that may be made thereunder. The time available is rather limited for the size of the subject and I propose therefore to give you an outline of the legal aspect and a rather general indication of the basic principles for safe keeping of petroelum spirit. This again will have to be restricted to the particular conditions, which are your main concern.

To start with let us consider the actual legal enactments. The main Act the Petroleum (Consolidation) Act, 1928. In this Act it is laid down that a licence must be obtained for the keeping of petroleum spirit and that these will be granted by the District or Borough Council except in the London area. In this area the authority was either the L.C.C. or the City Council. Since April, 1965, the Greater London Council is the responsible authority for the whole of the G.L.C. area, including the City. The Act says that the authority responsible for gra!1!ing may make such requirements and cond1tI.0!1s as rt th1_nks fit for the safe keeping of the petroleum spmt. You will see no specific safety reqmrements are made by the Act, 1t being left entirely to the local a_uthority to on the necessary safeguards in This may well mean that requirements will var_y_ m different parts. of the country according to local cond1t10ns. There is !1 nght of appeal from the requirements of a local authority to the Secretary of State.

Provision is made in the Act for the Secretary of State to extend by Order in Council, any or all of its provisions to other Certain provisions of the Act (such as those relating to notification of accidents) have been extended to a number of other substances but the major use of this provision has _been !he application. of all of the major requirements (mcludmg need for hcence) to Mixtures of Petroleum and to Calcium Carbide. The relevant orders are the Petroleum (Mixtures) Order, 1929, and the Petroleum (Carbide of Calcium) Order, 1929. Liquid methane has also recently been covered in the same !11anner. A further important order made under the Act the Petroleum Spirit (Conveyance by Road) Regulatrous, 1957, which governs the conveyance of petroleum

and petroleum by road vehicle and includes detailed rules. for of such vehicles and also rules concermng the loadmg and unloading thereof.

Now let us consider the actual types of materials within the scope of the Act and the Petroleum (Mixtures) Order.

The Act defines petroleum spirit as petroleum which when tested in the specified manner by the Abel (closed cup) apparatus gives off inflammable vapour at a temperature of less than 73°F. It defines petroleum as crude petroleum, oil made from petroleum, or from coal shale peat or other bituminous substances, and other ofpetroleum. This last phrase can lend itself to a very wide interpretation. Products of the oil industry are used for making a wide range of chemicals which can also be made by other methods. For example, ethyl alcohol can be made from petroleum but can also be made by fermentation and other processes. It is thus possible that exactly the same chemical can be subject to, or free from, the provisions of the Act dependent on how it has been manufactured. This of course is nonsense and to avoid it the authority for which I work takes the view that a product of petroleum is a product obtained without the use of any additional chemical constituents, i.e. a hydrocarbon with a molecule of carbon and hydrogen atoms only. This view does unfortunately leave many dangerous liquids free from control but at any rate is more logical and fair than the previous alternative.

There is also a similar difficulty in the interpretation of the Petroleum (Mixtures) Order which defines in effect the materials to be licensed as mixtures of petroleum with a flash point below 73°F.

Note.-It does not specify a mixture of petroleum spirit This means that a high flash petroleum product such as paraffin, when mixed with a low flash product as alcohol, gives rise to a licensable mixture. This is the clear wordin_g_ of Order and it is S? interpreted by many

It is, however, rather illogical and the L.C.C. mterpretated the Order by taking the view that the low flash point must be due to the petroleum content. The G.L.C. kept an open mind but has now decided to apply the strict legal interpretation.

Another point on which authorities differ in their interpretation is on the meaning of "keeping". Some consider that the word "keeping" means storage only. The L.C.C. and now the G.L.C. have always held that the term meant both storage and use up to the point of dissipation and therefore have covered in licences both conditions for

A paper recently presented to the London and Home Counties Branch of the Paintmakers Association of Great Britainstorage and for use in factory processes and workrooms. Usage in a factory is of course also subject to the jurisdiction of the Factory Inspector but requirements do not usually conflict. One or the other may make additional requirements and it is therefore essential to obtain approval of both.

I have been asked to comment on proposed legislation in this field. Obviously l cannot forecast what this will be but I can tell you that a Government Advisory Committee has been formed and is examining the position regarding transport, storage, etc., of flammable liquids and other dangerous substances. In due course this Committee will report and some form of legislation may follow to give effect to its recommendations. What I personally would like to see is an extension of the provision of the Act to all flammable liquids flashing below 73°F. This would remove the anomolies I have previously mentioned and bring under control all the low flash liquids which at present escape from control under the Act. There are already Regulations in draft to govern conveyance of such liquids.

That is a very quick look at the legal position and not a full examination by any means. ln view of your sphere of interest I would just draw your attention to two important provisions of the Act which refer to reporting accidents involving petroleum spirit and petroleum mixture and the correct labelling of such materials. Various other provisions cover right of inspection, etc.

I would like to pass on to the practical considerations of the safe keeping of petroleum spirit and petroleum mixture. These are the considerations borne in mind by a licensing authority when formulating requiremel!ts and conditions for granting a licence. Similar _do mainly also apply to other highly flammable hqmds which are not subject to the Petroleum Act.

There are three main aims first to prevent a fire or explosion, secondly, should occur, to limit its effects and thirdly to prevent outflow of liquid either before or after ignition.

Let us consider the first and most important aim then. To prevent ignition. There are three main areas <?f Exclusion of sources of ignition, ventilation and hm1tat10n of exposure of the liquid. These are interdependent.

Firstly the exclusion of sources of ignition. Sources of ignition include the obvious, i.e. naked flames, smoking, radiant heaters and all such like and the Jess obvious such as sparking electrical apparatus, static electrical effects, frictional sparks and spontaneous combustion. Some of these such as naked flames will have to be dealt with by complete exclusion from the danger area. Electrical apparatus can be obtained in certified flameproof designs (for petroleum work it should be for Group 11 gases) and in some cases in certified intrinsically safe pattern, and also pressurised or purged equipment. The likelihood of the formation of dangerous charges ofstatic electricity depends largely on the types of processes carried on. In an ordinary spray room, for example, static risk would not be large, but in mixing rooms, printing and coating machines, and in the transfer of quantities of liquid from or to containers, a considerable static hazard may exist. The methods to be adopted to combat danger from static will largely

depend on the process involved, but earthing of tanks, pipes, process vessels, portable containers, funnels, etc., is normally desirable in all cases.

In considering the size of danger area from which we must exclude sources of ignition we have regard to the ventilation available and the amount of exposure. If there is small exposure of the liquid and good ventilation, the flammable vapours will be dissipated quickly and the danger area reduced accordingly. Wherever possible it is best to extract the fumes as close as possible to the source by means of hoods over individual machines. Exposure should be kept to the minimum possible for the process. Spare containers, transit vessels, etc., not actually in use should. always be closed. The actual degree of ventilation required will depend on the amount of unavoidable exposure. In high exposure areas such as spray rooms, mixing rooms, etc., mechanical ventilation will always be necessary.

I would like again to emphasise the interdependent nature of these three items. If the nature of the process involves large exposure then ventilation must be stepped up and sources of ignition excluded for a greater distance from the exposure. Since even flameproof equipment if not properly maintained can offer a risk and in view of the possibility of other sources of ignition which are Jess easy to foresee and guard against (such as a dropped tool or a friction spark from some moving plant under fault conditions), I think wherever possible it is best to concentrate first on limitation of exposure and removal of vapours at source. There is then less risk of the unforeseen or unexpected source of ignition causing a fire. If it is not possible to do this and it is thus known that considerable vapour concentrations are likely, then one must have regard to the more unlikely, yet possible, sources of ignition such as steel nails in workers' shoes, metal trolleys, static producing garments such as nylon overalls, etc.

However hard one tries to make ignition unlikely it can never be made impossible. There are always the chances of human error, foolhardiness, and mechanical failures giving rise to an ignition. So the next step is, having done everything possible to prevent ignition, to limit the effects should one occur.

The first pretty obvious step is to have as little flammable material present as the process allows. Store and stocks of liquids should be kept in suitable stores, tanks, etc., located outside the working area. I will deal with construction, siting, etc., of stores as a separate item later. Where it is necessary for the liquids to be piped from the storage tanks to the process area special care should be taken to ensure that this supply can be quickly cut off in case of fire or other emergency. It is usually desirable to arrange for this to be done automatically in case of fire by fusible link operated valves or switches and with manual control for other emergencies.

Minimum exposure of liquids will already have been dealt with but it may also be possible to reduce exposure even further in the event of fire. For example, a process vessel may have to be open topped during use but can be fitted with a fusible link operated lid. Closure of lid in the event of fire could thus reduce exposure and the liquids in the vessel might well not become involved.

large quantities of flammable liquids have to be used m process vessels it may well be desirable to provide means of removing the liquids in event of fire. This can be done b¥ operated dump valves which will allow _hqu1ds to dram to a dump tank situated in some safe pos1t10n remote from the working area.

Tc;> keep amount of flammable materials to a m1!11mum, prevent feed of additional liquids to a fire provide means of removal of liquids from the fire. '

Next is the provision of fir_e extinguishing equipment. This of course must be designed for the risk and also graded according to _the risk. Small usages will be a_dequately covered by hand appliances. Larger nsks may call for the prov1s10n of fixed automatic sprinklers, emulsifiers or C0 2 systems which may cover the whole of the risk area or specific parts of a plant where is a particular risk of ignition. In most cases mechan_ventilation will be and if C0 2 is to be used 1t will be necessary to provide an interlock to switch off the as _the C02 is_ injected. The next step, assummg that prev10usly ment10ned precautions have not been fully effective, is to stop the spread of fire to other areas of the premises. cases it is possible to enclose the whole of the high nsk area with fire resisting partitions and fire resisting self closing doors. The standard of fire resistance must upon the degree of risk offered by the process and size and type of the rest of the building to which a fire might spread. For example a small spraying room in a single storey factory building would be adequately protected by walls, etc., of half hour fire resistance standard but a larger risk such as mixing or room in a upper floors, perhaps with office accommo?at10n, '!11ght require a two or four hour standard. A pomt here 1s that wherever possible the high risk area should be located in a single storey building or on a top floor, thus minimising the risk of upward spread. Where the risk area comprises the whole of a detached building no fire resistance may be necessary unless there are other buildings sufficiently close to be jeopardised by exposure risk, but subdivision, by fire walls and d<;><;>rs, may be d_esirable. In all cases where large quantities of hqu1ds are mvolved doorways, etc., will not offer resistance to fire spread unless retaining sills or ramps are provided to prevent the outflow of burning liquids.

In many cases self closing will be inconvenient if they are required to be used often m the course of the work This should be anticipated and fusible links provided fo; holding the doors open. If this is not done they will almost surely be found to be wedged open by other means and thus serve no useful purpose at all. Similarly fusible link shutters and doors may well be needed in other openings to the risk area such as are needed for conveyor belts and so on. Ventilation ducts from the risk area may offer a hazard if they pass through other parts of the building or their outlets are near openings into other parts of the

This may be dealt with by provision of fusible hnk dampers provided that the ducts are not likely to contain residues from a process which might prevent the operation of the damper, e.g. spray deposits. If dampers cannot be used then the ducts may require protection to give the requisite fire resistance and the outlets positioned at safe locations. (Regard to be had to protection of other nearby premises).

have left the problem of means of escape to a late P?tnt but not of any lack of importance. When highly hqu1ds are concerned any fire which does occur is likely to be of a very sudden nature and the standard of means of escape should be higher than from other occupancies. The :ictual number of escape routes from the danger space will of course depend on the size thereof and its In view of the probable sudden nature o_f a fire m the space the danger of persons being m recesses or dead ends is much higher than m occupancies where a burning fire might be expected. Where flammable hqmds are actually manipulated by the danger of personal burns, probably to hands, 1s high and all escape doors should be free of any locks, _handles, bolts, etc., which would require manual operat10n. _Only bullet catches, panic bolts or similar which can be opened merely by bodily pressure agamst the escape doors should be accepted. Needless to say all doors from the risk area should open in the way of escape.

storage. Bulk storage of solvents, etc., should be m places or store buildings with no communication to ot_her portions of the premises. The actual type of store will depend on the quantities to be stored and also on the distances which possible to _obtain from the storage space to other bmldmgs. There 1s, however, one requirement which should be common to any type of storage and this is that there should be means to prevent outflow of liquids from the storage space. This may consist of bund walls or retaining pits, etc., and where the storage is sufficiently distant from other buildings this may be the only major requirement. Where large distances cannot be obtained tanks should be buried and can or drum storage should be in brick and concrete store buildings, with of course retaining wells. For brick stores high and low level ventilation openings should be provided and these fitted with fine copper or brass gauze. Doors of stores to be fire-resisting and close fitting. Small quantities-up to 50 gallons-may be kept in a metal bin. So far I have not indicated any specific safety distances from stores but as far as brick stores and buried tanks go, it is considered that any windows or doors to other buildings (in same occupation) within 20 feet should be protected. Unenclosed above ground tanks or barrel storage would not normally be acceptable unless at least 40 feet from a building but this is a minimum and greater distances would be required for tanks or large storage of this type. These distances refer to buildings of the factory keeping the materials, and longer distances may be required from premises in other occupation especially if in use for dwellings. Buried tanks and brick stores should be not less than 20 feet from any public way or other property over which storer has no control. The unprotected storage will need larger distances. This is only a quick outline of the more usual methods of storage-special cases may need special requirements. The basic rules-exclude sources of ignition, limit exposure, ventilate, limit effects if fire occurs, apply to storage places just as to places the liquids are used. Since the quantity cannot be lumted greater emphasis must be placed on protection to prevent spread of a fice to other parts of the premises or those adjacent.

I ':"ould again emphasise that l have only been tryin(T to give you a broad outline of basic rules. Detailed

requirements for a particular case can only be formulated when all the aspects of that particular case have been considered.

This concludes the general part of my talk but I would like to mention one specific problem that has arisen in connection with your industry. This is the use of Polythene containers for storage of some petroleum mixtures (mainly those containing acid such as etching primers). The Council's Scientific Adviser has tested such containers and considers that they have grave disadvantages for such storage. The material is weakened by aromatic and other common solvents and may well break down after a few

months. It is also permeable to the vapours of many solvents. Being thermo plastic the containers can also distort easily in quite moderate heat. Further investigations are being made to determine whether the Council should in fact, forbid the use of any such containers.

Following the talk there was a lively question and discussion session and in particular it was decided by the Branch to refer the problem of polythene containers to their Technical Committee for investigation of alternatives.

Some 20,000 small fire extinguishers were sold last week. Another 20,000 or so extinguishers will be sold this week, next week and every week of the year. Nobody knows exactly how many are sold, but sales go bounding up on Father's Day, at Easter and other occasions when sons and daughters search for something useful and not too to give to Dad, and sometimes to Mum, too, if the neighbour round the corner has had a nasty shock when the fat in her frying pan caught fire.

Nobody knows how useful they are and, indeed, whether them are not MORE dangerous than having n? extmgu1sher at all. These small extinguishers, contammg less than 2 lb. dry weight of a variety of extinguishant powders, do not need to reach any standard, pass any test or prove their effectiveness in any way. You or I could start filling aerosol containers with chemicals in a garden shed and hawk them round the door as a fire extinguisher tomorrow.

are many small firms manufacturing such dubious extmgu1shers in Britain today. 'They are made for salesto sell and the public to buy, not for putting fires out', said fire engineer. 'They give the public a false sense of security about fires in their home'. With ninety per cent of all deaths from fire occurring in the home, false security can be dangerous.

Even more alarming is the fact that little is being done to prevent this confidence trick on the public. The British Standards Institution's fire committee contains a majority of members nominated by fire appliance manufacturers and their attitude is hampering technological advance. It is unrealistic, for example, to lay down specifications that fire extinguishers should basically be made of brass, and so prevent the establishment of a standard which would include the small domestic aerosol type of fire extinguisher. A Ministry of Technology spokesman said: 'The Ministry's view is that these standards are better defined on the basis

of performance criteria. This view is being pressed on the B.S.l. Existing standards contain far too many constructional and design requirements'.

One ex-member of the B.S.I. committee said every progressive idea put up by the committee's working party was thrown out when the full committee met. 'What you end up with is the Lowest Common Standard instead of the Highest Possible Standard', he said. 'Nobody wants to be nasty to a fellow manufacturer and so the fire committee is like a manufacturers' Happy Circle. As a result the standard specifies what kind of rivets are to be used, but nothing of real value. Indeed, it's only five years ago that a performance test was introduced-and that's what counts with a fire extinguisher. When it was proposed that carbon tetrachloride should be banned as an extinguishant, because of the noxious fumes it gives off, one manufacturer stood up and said it was not the duty of the B.S.I. to try to put him out of business. So we still have C.T.C.-though it's banned in most other countries-and that manufacturer is still in business'.

Theoretically, said a Ministry of Technology spokesman, if it is thought manufacturing interests are exercising too much control in a B.S.I. committee, it would be possible for other expert organizations to be brought in. But though most fire engineers consider the B.S.I. fire committee laughable or outrageous, according to how you view its responsibility, nothing has yet been done to try to shift the balance of power.

It is common knowledge in the fire-fighting industry that the Joint Fire Research Organisation is not interested in evaluating small fire extinguishers. Some fire engineers maintain they are not even interested in testing larger fire extinguishers.* 'It's dull work so there's always 300 to 600 fire extinguishers waiting to be tested. You get a report in about a year', said a fire engineer. An official of a fire appliance manufacturing firm said sparsely: 'If this

is to be quoted then our statement is, "We know of no obvious reluctance by the J.F.R.O. to test fire extinguishers. We sent ours in and some time later it was returned saying it had passed the tests".'

Since 1964, when the Consumer Council first asked the B.S.l. to consider producing a standard for extinguishers containing less than 2 lb. of powder and the J.F.R.O. was asked to devise performance tests so that a standard might be produced, the J.F.R.O. has been unable to find time to devise any tests. Always there has been talk about their hopes for the future and a vaguely-expressed opinion that things would be different in twelve months' time. On other occasions, however, there has been talk about the 'impossibility' of devising tests that will measure accurately the efficienty of these and other fire extinguishers. The Underwriters Laboratories of America, however, and, more recently, the official French fire research organisation have devised tests to grade fire extinguishers.

Certainly many of the small fire extinguishers sold in Britain are remarkably inefficient. Many are little better than toys. Some are empty after 1-! seconds, which might be just long enough to discover you are not near enough to hit the flames even if you were aiming correctly. One manufacturer said fire extinguishers had a price barrier. People were unwilling to pay more than 22s. 6d. for a fire extinguisher for a car and 30s. for one for the home or caravan. 'Nobody ever buys a fire extinguisher', he added. 'They have to be sold. To stay in business I have to sell to people who sell door-to-door because it's in her home that the housewife realises the fire risks around her'.

At the quality end of the a. manufacturer said the majority of cheap fire extmgmshers were badly designed of uneven quality and questionably efficient. He did sell fire extinguishers with less than 3 lb. of powder because he did not think they were of any value in fighting a fire. 'Talking about price barriers is begging the question' said a fellow director. 'How dare people say that's all they produce because all people. will. pay. lfit doesn't extinguish fires then its not a fire extmgmsher. It's not just a saleable product, it's a product. At 30s. what life expectancy have they? Will they last five or ten years ? Will they operate when you want them ? The Home Office says every portable fire extinguisher in a public building must be dis.charged once a year. We believe that's necessary with our new sealed contamer, we say it will last indefi?itely; but it's a with many other extingmshers He and his chairman feel it unjust that the present low standard, and lack of standard, allow useless fire extinguishers to be sold, swallowing up the market for efficient fire extinguishers.

So the public is still being fooled o_f the. preponderance of trade interests, the weanness or dilatormess of the British Standards Institution's fire committee and the Joint Fire Research Organisation and their failure to put forward tests that will either produce efficient small fire extinguishers or result in their being banned by Parliament.

*British Standard 3465 of 1962 sets out the standard for a portable extinguisher containing not less than. 2 dry weight l?owdcr. There are different standards for ext111gu1shers not contammg dry powder.

Reproduced by permission of Focus, Official Journal of the Consumer Council.

Kent Fire Brigade was called to East Kent Motors, Deal, premises, when a quarterly audit had disclosed a loss of approximately 1,500 gallons of petrol from a 500 gallon capacity storage tank over a period of about two months. Chief Fire Officer W. Babington reports:

"This storage tank had been closed off by operation of a valve in the supply line three days previously and a dip made then showed 450 gallons in stock. The tank was again dipped on the day the fire brigade was called and the quantity in the tank was found to be reduced to 105 gallons.

Tests made at this time with an explosimeter in drains and in surrounding basements were found negative. A further dip was taken after five hours had elapsed when the quantity in stock was again reduced to 95 gallons.

The matter was discussed with the local authority engineer and surveyor, and it was decided to make extensive tests with the explosimeter in sewers and basements on the following morning and to take steps to remove the remaining petrol from the defective tank and to make it safe by filling with a sand/cement slurry.

Tests were carried out by Kent Fire Brigade personnel at a sewage pumping station and in street sewers, and basements. The G.P.O. Engineers' Department were also informed and extensive explosimeter tests were made in underground telephone cable ducts but no explosive _mixtures were ?etected. The defective storage tank on site was filled with a sand/cement slurry seven days later".

Available evidence that approximately 1,800 ga!lons of petr?leum spmt had leaked away into the subsoil over a i:enod of two to three months and no reports of any tangible or even .a smell of petroleum spirit have yet been received or attnbuted to this incident.

One accrue as a result of this leakage, says Mr. Babmgton, is that _the local authority has now approved a recommendatJ?n that all old storage tanks should be regularly tested m accordance with the Home Office Model Code procedure.

With acknowledgments to "FIRE".

If the effect of fire is to be minimized adequate fire prevention safeguards must be incorporated in schemes at the construction stage. This means that a petroleum officer's consideration of a proposal at the planning or drawing board stage is of prime importance. The purpose of this talk is to outline some points to be watched.

Objectives must first be established and these are: (a) to prevent outbreak of fire; and (b) to limit the effects of fire.

As we are dealing with flammable a further objective must be set side by side with these aims and that is the prevention of outflow. It could be argued that I?revention of outflow is a factor in each of the other two aims but as it is of such importance it is to treat it as an objective on its own. It is no good makmg an area safe for petrol, if you permit it thereafter to flow out to be ignited and spread fire whenever things go wrong.

Flammable liquids do not burn, it is the give off which burns. This vapour will bu_rn only if it IS mixed with air in the right t?o nor too rich a mixture is required. The hm1ts 'Y1thm a vapour/air mixture will burn are known as its explos1".e (or flammable) range. The volume of vapour present. IS expressed as a percentage of the whole. The range for petrol lies within the limits of l % with air at the lower (weak) end and 8 % vapour. with air a! the upper (rich) end. For acetylene the range 1s much wider, i.e. from about 2.5 % to 80 %.

An explosive vapour/air mixture is not .. It needs a heat source to warm it above its auto-1gmt10n temperature-for petrol, about 300°C.

Examination of this physical data indicates the things to be done to prevent outbreak of fire and these fall conveniently under three heads as follows:

(a) Limit exposure

(b) Ventilate

(c) Exclude ignition sources

Obviously there will be a certain amount of interplay under these heads; for example, where exposures ca_nnot be limited as much as one would like then a much higher standard of ventilation and exclusion of ignition sources may be sought as an alternative.

The steps to limit exposure are self-evident and would include such things as securely closing all storage vessels and delivering whenever possible only under seal.

From a fire prevention point of view, it is necessary to ventilate areas where petrol is kept and handled only sufficiently to keep the vapour/air concentration below 1 %. This ignores the fact, however, that petrol vapour is toxic. An 0.5 % concentration would kill a man in a very short time. In general, you cannot have too much ventilation and the simplest way of arranging this is to arrange storages in the open air.

Excluding ignition sources is a much more complex subject. Firstly we must determine the danger area within which we are work here we enter very much the realms of practical politics. Modern thinking suggests that danger areas subsist only within 8 feet of can stores in the open a!r or 14 feet from the centres of petrol pumps or tank openmgs on open air filling stations. The distance may, however, need to be increased to 50 feet for large distributing depots where there is considerable handling and exposure of petrol.

are s<?me obvious ignition sources like fire, flame and hghted cigarettes as well as some exotic ones like substances which burst into flame when exposed to air. The Office recommends prohibition of all these w1thm the danger areas; in general all these s_ources are easily recognisable. The picture is not so clear m respect of electrical equipment and here some discretion if called for.

electrical is specifically designed for heatmg purposes. Obv10usly the actual heating element must be suitably enclosed and a limit set on the maximum teml?erature the housing may achieve. No-one, I t.h.mk, would disagree with the limit of 200°C. set by British Standard No. 4137. One exception would be unshielded heaters in a cellulose spray room, where because of the tendency of spray deposits to "fume off" at .a lower a figure of so 0 c. is more appropriate. The or frame enclosing heaters should comply 'Ylth the appropriate requirements for other electrical eqmpment with which it is now convenient to deal.

In deciding the type of enclosure for electrical equipment, or in some cases the type of equipment, suitable for danger areas we must classify these areas. British Standard Code of Practice No. 1003, Part 1, sets out to define the different danger areas.

Synopsis of a paper presented by W. C. R. DALE, Greater London Council to Students at the Mid-week School, held at Attingham ParkThe Division 0 area is defined as an area or enclosed space within which any flammable or explosive substance, whether gas, vapour or volatile liquid, is continuously present in concentration within the lower and upper limits of flammability. Inside a tank containing petrol may be regarded as a Division 0 area. In general, only equipment which is certified intrinsically safe or is pressurized with suitable safeguards should be permitted in a Division 0 area.

The Division I area is defined as an area within which any flammable or explosive substance, whether gas, vapour or volatile liquid, is processed, handled or stored, and where during normal operations an explosive. or ignitable concentration is likely to occur in sufficient quantity to produce a hazard. Division I areas would include:

(a) Inside a petrol pump housing

(b) Inside a petrol store

(c) Any pit or hole in the floor of a garage or in the forecourt of a petrol filling station.

The inclusion of (c) above is necessary because petrol vapour is about three times as heavy as air and tends to concentrate at low level. A pit extending through and beyond a Division I area . should be reg:ir?ed as a Division I area throughout its length even if it extends into what would normally be regarded as a safe area.

In a Division I area one may accept certified Flameproof equipment (Group II as an. alternative to Intrinsically Safe or equ1p1pent m a Division O area. It 1s convement to discuss bnefly these types of equipment at this point.

Flameproof equipment has all its electrica_I components housed in flameproofenclosures accordance with British Standard No. 229 and is certified by the Ministry of Power to effect: Flameproof equii;>ment is in no sense vapour tight. b1;1t so that it can withstand an explosion w1thm its housing and yet not transfer to the external atmosphere sufficient heat to ignite an explosive

The Americans have a similar standard in Underwnters Laboratory approval Class I Group D (hazardous equipment which it is customary to accept as an alternative. The same does not apply to German "Explosion Proof" equipment. However, if l.E.C. recommendations are generally adopted and a Jong overdue revision of B.S.229 is completed a common standard for Europe may eventually emerge.

The concept of Intrinsic Safety is set out in British Stand No. 1259 and equipment of this type for industrial application is normally certified by Factor_ies ment of the Ministry of Labour. Bnefly the idea is that it is possible in certain parts of a circuit to limit the current and voltage so that should a fault occur and a spark result, the energy of that spark will be so low as to be incapable of igniting petroleum spirit vapour. As it may

be possible to deal only with parts of a circuit in this way, the certificate issued states what parts may be in a danger area, and what parts must be in a safe area. ,

If one pressurizes an enclosure pressurizing air will flow out and prevent the ingress of vapour. Obviously the pressurizing air must be drawn from a safe location and fail to safe devices fitted to de-energize the equipment in the event of air failure. An extension of this concept is to be found in the ventilated housing method. Both methods are fully discussed in Part 2 of British Standard Code of Practice No. 1003.

The final danger area to define is the Division 2 area and this is an area within which any flammable or explosive substance, whether gas, vapour or volatile liquid, although processed or stored, is so well under conditions of control that the production (or release) of an explosive or ignitable concentration in sufficient quantity to constitute a hazard is only likely under abnormal conditions. The Division 2 area lies between a Division I area and a safe area. Whereas the inside of a store is a Division 1 area the immediate surrounding area outside the store would generally be no more than a Division 2 area.

British Standard No. 4137 provides a guide to the selection of electrical equipment for use in Division 2 areas and it is interesting to note that the Factories Department of the Ministry of Labour is currently approving suitable types of equipment. Any equipment accepted for use in Division 0 or Division 1 areas is of course suitable for use in a Division 2 area.

With the use of equipment mentioned above it is possible to install virtually any electrical apparatus in a danger area. This should be avoided, however, whenever practicable and the golden rule should be never to install electrical apparatus in a danger area if it can reasonably be installed in a safe area.

In limiting the effects of fire, the prevention of harm to persons is of paramount importance. The best way of achieving this is to ensure that easy and safe means of escape are always available from storage areas and buildings which may be threatened.

To limit spread of fire, fire breaks must be established. Distance itself provides an effective fire break if there are no combustibles in the intervening space. Where adequate safety distances cannot be achieved the use of fire-resisting walls or partitions offer an alternative. Any openings in these walls must be dealt with: windows can be glazed with fire-resisting glass in fire-resisting framing fixed shut or, if openings are necessary for ventilation, these openings can be protected by hopper type fire-resisting baffles: small personnel doors can be rendered fire-resisting and self-closing: and large doorway openings can be fitted with fire-resisting shutters held open only by fusible links.

To keep the fire small it is essential to exclude any avoidable clutter of combustibles from a storage area. This means that kiosks and canopies, which may not need to be of fire-resisting construction, should generally be constructed of incombustible material or at least of material having a low surface spread of flame (i.e. Class 2 in British Standard No. 476, Part 1). The same should apply to exposed linings of walls and partitions even if the walls or partitions are themselves fire-resisting.

Under the headings of limiting spread of fire must also come the provision of fire-fighting equipment and means for summoning Fire Brigade assistance.