THE BULLETIN

Journal of the Association for , Petroleum and Explosives Administration

VOLU ME 25 . 3

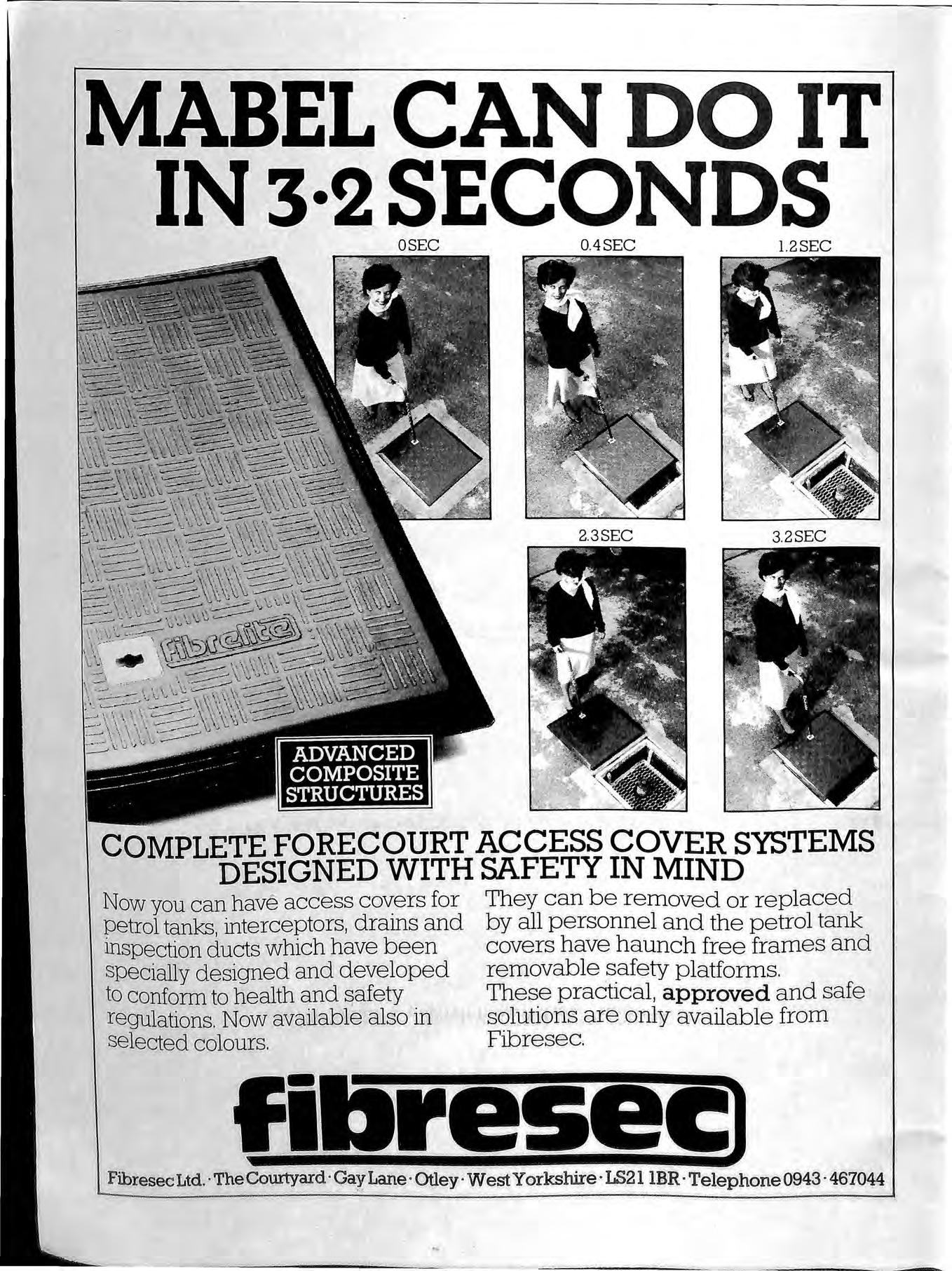

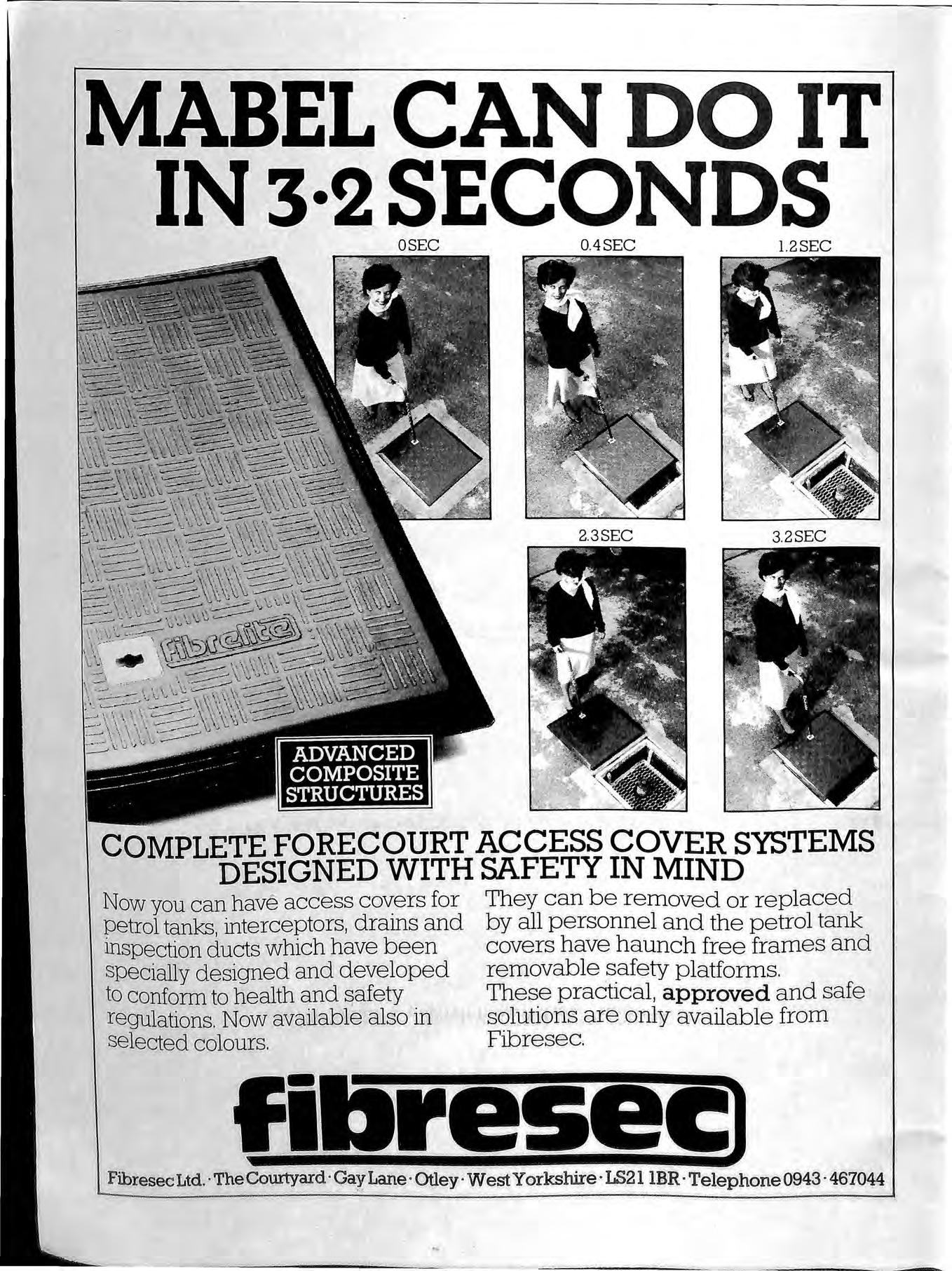

MABEL CAN DO IT IN 3-2 SECONDS OSEC 0.4 SEC 1.2 SEC .,........,,=-"""" 2.3SEC COMPLETE FORECOURT ACCESS COVER SYSTEMS DESIGNED WITH SAFETY IN MIND Now you can have access cov:ers for petrol tanks interceptors, draIns and mspectlOn.'ducts WhICh have been specially designed and developed to conform to health and Elafety regulations. Now available also in selected colours. They can be removed or replaced by all personnel and the petrol tank covers have haunch free frames and removable safety platforms. These practical, approved and safe solutions are only available from Fibresec. Fibresec Ltd .. The CourtYard . Gay Lane ' Otley ' West Yorkshire' LS211BR· Telephone 0943' 467044 L· rW

OIL POLLUTIO CONTROL Rapid Response Units on call 24 hours a day for Land or Water Borne incidents..--........... 24 HOUR EMERGENCY TEL: 01-8051856 DEWCO 'PROTECTING THE ENVIRONMENT ' FOR D E TA ILS OF T HI S AND O T H E R OIL R E LA T E D SER VI CE S : Co ntac t : Sales and Marketing Departme n t DEWCO SERV ij CES li M ITED ' H ER TFORD ROAD , ENF ij E lD WASH, T ELEP HON E: 01 804 109 5

MANGAN BROS. LTD. Building Contractors 402 Seven Sisters Road, London N4 2LU (REGISTERED OFFICE) Telephone: 01 800 4651 Specialists in Petrol Filling Stations D. S. Leggett (Electrical) Limited ELECTRICAL CONTRACTORS NICEIC APPROVED 181 VICTORIA ROAD, NEW BARNET, HERTS. 01 =441 3958 SPECIALISTS IN PETROL STATIONS

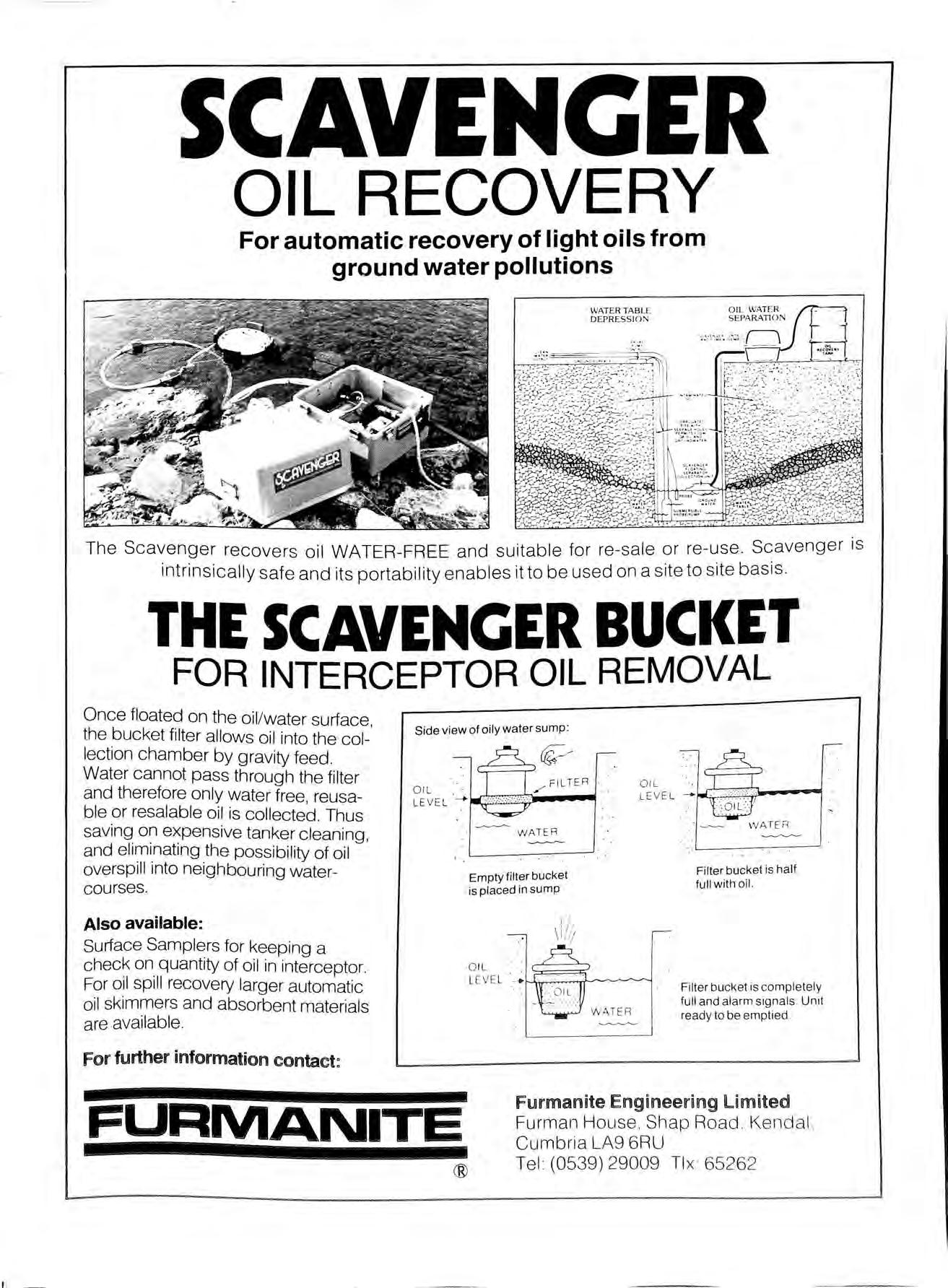

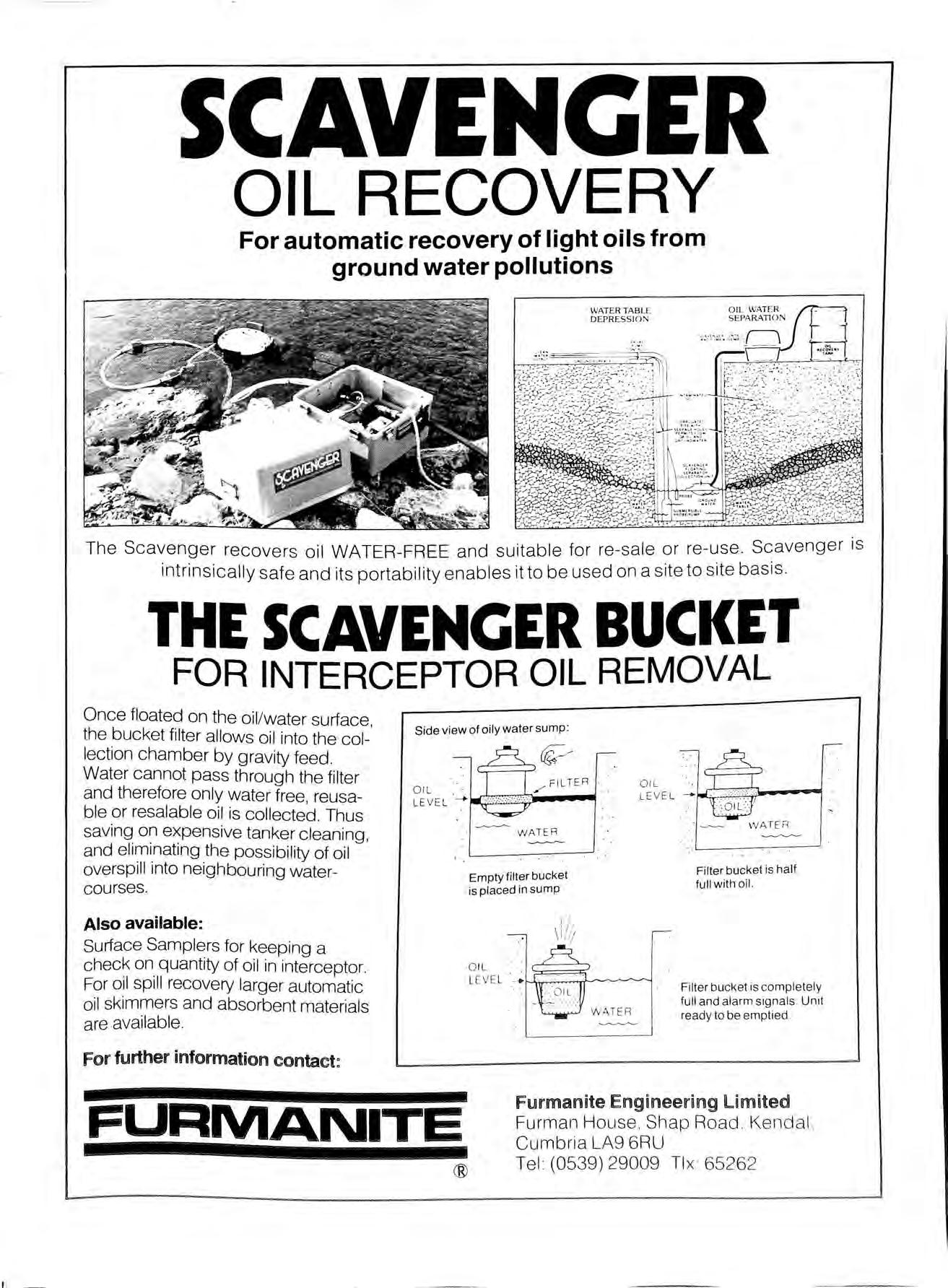

Once floated on the oil / water surface the bucket filter allow s oil into the cOI-' lection chamber by gravity feed. Water cannot pass through the filter and therefore only water free , reusable .or resalable oil is collected. Thus saving tanker cleaning, and e liminating the possibility of oil overspill Into neighbouring watercourses.

Also available: Surface Samplers for keeping a check on quantity of oil in interceptor . For 011 spill recovery larger automatic oil sk immers and absorbent materials are ava ilable . For f urther information contact:

ENCER OIL RECOVERY For automatic recovery of light oils from ground water pollutions WAT E R TABL E DEPR ESS I ON O IL WAT ER SEPA RATI ON The Scavenger recovers oil WATER-FREE and suitable for re-sale or re-use. Scavenger is intrinsically safe and its portability enables it to be used on a site to site basis THE SCAVENGER BUCKET FOR INTERCEPTOR OIL REMOVAL

Side view of oily water sump:

FURMANITE ® OIL LEVE L WATER Empty filter bucket is pl aced in sump O I L WATER W A T ER F ilter bucket is half full with oil. Filter bucket is co mpletel y fu ll and a larm s igna ls U nit ready to be emp ti ed Furmanite Engineer ing limited Furman H OLlse , Shap Road , Kend a l , Cumbria L A9 6RU Tel (0539) 29009 Tl x 65262

W. LAMB LTD. THE PREMIER PUMP AND TANK COMPANY Forecourt and Commercial Above and Below Ground Supply - Test - Exchange - Service - Instal Product Transfer De-Watering Removal Purchase Tank Demolition Removal Safety Filling Large Stocks of New and Secondhand Petrol and Diesel Pumps, Tanks and Accessories DAYBROOK STREET, SHERWOOD, NOTTINGHAM 0602 621511 + 608084 TRINITY WORKS, BOURNE END LANE, HEMEL HEMPSTEAD 0442772296 Telephone 021-236 0347 w. J. FINCH (Installations) Ltd. Steaming out and de-gassing petrol tanks; issuing gas free certificates Complete petrol and fuel oil bulk storage tank installations Petrol and fuel oil tank cleaning service Pressure testing tanks and pipe work Heaton House, Camden St., Birmingham BI 3BZ

Talking Point

The number of accidents and incidents during delivery of petrol to public filling stations is on the increase., Industry itself is reporting concern on the frequency of spill ages and crossovers during delivery in the year of the driver controlled delivery experiment. It is clear that training is an area which must be improved Enforcement by the HSE on drivers of road tankers IS abysmal, due mainly we are told to manpower shortages and this year numerous problems unpunished, including a driver smoking dunng dehvery while leaning against his tanker! It is time this anom?ly ceased and while the road tanker is on the filling station petroleum licensing authorities should be responsible for all aspects of these regulations.

One trade journal advised its readers be as petroleum officers were showing more mterest m cases. They are however only responding to the nsmg number of incidents by taking offenders to court .... as this edition reports.

The Bulletin ISSN 0263 - 4597 VOLUME,25 Number 3 SEPTEMBER 1987 £3.00 (Free to Members)

the

Contents TALKING POINT NOTES & NEWS LPGNEWS NEW MEMBERS UNLEADED PETROL HEAVY FINE AT CROWN COURT PROSECUTIONS NITROGEN FOAM INERTING WIRE V TEXTILE PETROL HOSE

Published by

Association for Petroleum and Explosives Administration Opinions expressed in this Journal are not necessarily the views of the Association

HUMBERSIDE BRANCH R. G. Kitching Humberside County Council,

37 38 39 40 41 43 45 47 49

EASTERN BRANCH F. C. Rason Honorary Secretary: Mr. B. D. Taylor, Cambridgeshire County CounciL

SOUTHERN BRANCH M. Cox Normond Instruments Ltd.,

MIDLAND BRANCH Derek Hopkins Warwickshire County Council.

--------------------------_.-

Honorary Editor: Mr. J. A. J. Thompson.

LEAKING SUCTION LINE JOINTS

The last issue of The Bulletin highlighted concern over leaking suction line joints. The returns from a survey which was sent out with the Bulletin indicate that the leaking joints were confined to a very few new sites. There have also been no further incidents reported to the Association. Tests carried out bv various bodies have indicated that litharge and suitably mixed and applied is petrol resistant. It is hoped that further technical information will be provided in a further edition.

ROAD TANKER FIRE HEBRON W. GERMANY

In July a Road Tanker overturned while negotiating a ?end, ruptering its tank compartments. Petrol flowed mto nearby basements and down drains to the river. An ice cream parlour next to the accident had a number of people inside, and the delay between the crash and ignition was enough to allow people to escape. Five persons died in the explosion and fire which followed, which devestated the immediate area. Kent County Council sent a team of Fire and Petroleum ?fficers to Hebron to report on the incident and a video IS available from Kent Fire Brigade.

COMPUTER SYSTEM KEEPS TABS ON DANGEROUS SUBSTANCES

Computer Services Ltd, a wholly-owned SU.bsldiary of ABP Holdings PLC, has developed a system to help ports comply with the notification and record-keeping requirements of the Substances in Harbour Areas Regulations :v hlch come into force on 1st June. The system is already m use at the port of Southampton.

(VThe Trident Vessel Traffic Serivce Managemant bS™) system records movements of dangerous su stances and h d . . . . d as an a dItlonal module for mOnItorIng an Controll' mg vessel traffic movements. This module can provide d' m Up-to- ate mformatIOn on shlppmg ovements b th . ch ,er occupancy the raising of traffic arges and' ' be d . a vanety of other data. The two modules can Suse .m.dependently or linked together.

ophlstIcated " " .' users to menu and "prompt" facilities assist . . enter dat . kl infor t' a qUlc y and accurately and to retrieve ma IOn from the s ,t Th '" for d ys em. e codification structure angerous sub t . I t · . s ances IS consistent with the n ernatlonal M " d antlme Dangerous Goods (lMDG) co e. usualIy k h nown as the UN number Up to 700 c aracters of d '. d' esCnptlOn can be displayed to verify angerous substance details.

The system has b d' een eSlgned to operate simply and reliably and 11' . ' IS we sUIted to the round-the-clock nature of port work Furth f '1" er aCI Itles are planned, including an mterface WIth port radar systems.

The Trident VTSM system is available from ABP (omr uter Services Ltd. Hayes Road, Southall, Middlesex UB2 5NE (telephone: 01-573 S(45).

HSE issues LPG advice

The Health & Safety Executive has published guidance on the safe storage of liquefied petroleum gas, applicable to thousands of small to medium-sized installations in the UK.

The document covers storage of LPG at ambient temperatures in fixed vessels larger than 150 litres capacity, used extensively at petro-chemicals sites, industrial and commercial premises and hospitals. It includes guidance on: the hazards of LPG; siting of vessels; security; fire precautions; maintenance and operating procedures.

The document is the last in a series of four HSE guides on LPG. Those already published cover: storing LPG in cylinders; storage and display in shops; and, storage at metered estates.

*Storage of LPH at Fixed installations, HSE Guidance booklet HS(G) 34 (£6.00).

CODE OF PRACTICE FOR DRIVER CONTROLLED DELIVERIES TO PREMISES LICENSED FOR THE STORAGE OF PETROLEUM SPIRIT

This Code of Practice has been published by The Institute of Petroleum on behalf of the United Kingdom Petroleum Industry Association. It has been prepared to serve two purposes:

1. Initially, to provide a safe and practical operating framework under which authorised trials of driver-controlled deliveries (DCDs) can be carried out.

2. Ultimately, to provide agreed guidance to persons concerned with DCD operations.

Although DCD operations are common practice in many other countries in Western Europe and in North America they are not permitted in the UK under present road transport legislation as contained in the Dangerous Substances (Conveyance by Road in Road Tankers and Tank Containers) Regulations 1981 (SI 1981 No. 1059). However, the Health and Safety Executive (HSE) has prepared draft revisions of Schedule 4 to the Regulations which would permit DCDs and has obtained public comments on the draft. In the meantime, HSE has indicated a willingness to issue a number of certificates of exemption at specific sites to allow trials to proceed. These certificates will be issued subject to conditions based on Part III of the draft revised Schedule 4.

Trials of DCD operations have commenced and will last for several months. If necessary, any particular experience gained from the trials will be into the Code of Practice when the trials penod IS complete.

Although it is belived that adoption of recommendation of this Code will help to reduce the nsk of accident, neither The Institute of Petroleum nor the United Kingdom Petroleum Industry Association accept any responsibility of whatever kind, for damage or alleged damage arising or otherwise occurring in or about premises, areas, or vehicles, to which this Code has been applied.

Copies of this Code are available only from The Institute of Petroleum. 61 New Cavendish Street. London WIM 8AR. U.K. at a cost of:

£5.00 (U.K. and Europe)

£7.00 (Overseas)

notes & news

GRPTANK

Following the launch in March 1987 of their range G.R.P. Underground Petroleum Storage Tanks, Ferranti Resin Limited have recently installed for Mr. D.D. Endersby, Proprietor of the Flintcross Garage, Nr. Royston, Cambridgeshire, a 10,000 gallon tank.

On arrival the tank was checked for any damage in transit by applying a 5 p.s.i. aerostatic test and soaping over.

The tank was installed in pea gravel and anchored by 4 "Tanklash" straps to a 150mm thick reinforced concrete slab. The straps were supplied by Webbing Products UK Ltd.

A local pipework contractor fitted the galvanised steel pipework using flexible connectors within the Fibresec access chamber. The tank and pipework were pressure tested to the same requirements as a "steel tank" installation. The pipe work was then totally encased in sulphate resistant concrete 150mm thick, and covered with the required amount of pea gravel.

Finally, a 150mm reinforced concrete traffic slab was cast directly over the tank using a Fibrelite cover and frame over the access chamber.

The installation and tests were witnessed by the Cambridgeshire Trading Standards' Technical Officers. Technical Officers from other authorities and oil company engineers also visited the site during installation.

Civil work was carried out by Seearo Contractors and pipe work by Mr. Tom Cole.

LPG NEWS

NEW GUIDANCE NOTES:

The Health & Safety Executive have recently published the following guidance notes.

HSG 34. The storage of LPG at fixed installations.

CS 11. The storage and use of LPG at metered estates.

CS 4. The keeping of LPG in cylinders and similar containers.

GS40. The loading and unloading of bulk flammable liquids and gases at harbours and waterways.

New Codes of Practice

The LPG ITA recently published or revised the following Codes of Practice.

C.O.P. No. t, Pt 3 Installation and maintenance of fixed bulk LPG storage at consumers premises. Periodic Inspection and testing.

Storage of full and empty LPG cylinders and 7 cartridges.

Outlet valves for butane cylinders quick 15 Pt 2 coupling types.

Guidelines for caravan ventilation and 21 flueing checks.

The above codes and a full list of the Association codes can be obtained from: William Culross & Son Ltd, Coupar Angus, Perthshire.

Dear Editor

THE BULLETIN PETROLEUM EMERGENCIES

About a year ago I was involved in a specific petroleum emergency which was believed to have resulted from. a tanker spillage. Whilst the department at that time equipment and experience officers to cope with the situation I was concerned that we did not have any adequate guidance notes that could assist less .experienced officers. Consequently I prepared some gUidance notes and distributed them to all Enforcement Staff in the office. At this time it was suggested that the notes could provide the basis for a paper in the bulletin.

1 believe it .is such an important issue that as man\, people as pOSSible should be involved in the imput and -I whether would be kind enough to include an entry 111 the l:nagazlOe requesting either departmental or company notes on emergencies to be sent to me to culm1l1ate in a paper.

Yours sincerely.

K.F. Eaglestone TRADING STANDARDS OFFICER

New Director General LPGITA. Ray Holder, former head of BP Oils Gas branch has been appointed to be the first Director-General of the LPGITA. He wiII head the small executive team that runs the Association. The other members of the team are: Reg Shipman Technical Manager. (Ex BP) . Jack Chambers Training Officer/Techl11cal Assistant (Ex Air Products) Peter Bown Association Secretary. (Ex ES50).

The LPGITA (Liquid Petroleum Gas Industry Technical Assistant (UK) was formed in 1970 out of a LPG Technical Committee having seven member Companies. It now has a membership of IOX including manufacturers. distributors. suppliers and installers.

The object of the Assocation arc:

a) To pwmote for the benefit of the public of the United Kingdom the advancement of the scientific and economic development and efficiency of those branches of the commerce and industry of the Unilt'd Kin}!dom concerned with or imohed in the manufacture and safe utilisation of liquefied petroleum gas.

h) To promote st udy and research inlo till' prilll"ipks. metlll1ds and techniques concerned wilh tht' safe development. manufacture. liSt'. application. storage and transporlalilln III I iq udied pt'lrolt'U11l gas and to puhl ish 111t' result.., of all sUl'il "Iud\ and rt'searl'h

HF

New Members

The Association welcomes the following new members R. Trousdale, Peter Muir, Total Oil Great Britain Ltd.

Anthony Douglas Robertson, Trading Standards Department, Dorset County Council, John W. Wenham, Akzo Coatings plc,

Mr. P Godfrey, WTS Engineering, GMP Bowles, Jack Brinkhurst, A. Boyce, P.M. Services Ltd, J.H. Frith, A. Lambert,

The Association welcomes the following new members R. Trousdale, Peter Muir, Total Oil Great Britain Ltd.

Anthony Douglas Robertson, Trading Standards Department, Dorset County Council, John W. Wenham, Akzo Coatings plc,

Mr. P Godfrey, WTS Engineering, GMP Bowles, Jack Brinkhurst, A. Boyce, P.M. Services Ltd, J.H. Frith, A. Lambert,

4(J

C. Monre, G. W. Oshorne.

Ronald W. Robertson, Consumer & Trading Standards Dept.

Colin M. Richards, John H. P. Dunk,

M. Parkin,

Mr. B. Childs, K. Beaumont, Flow Measurement and Automation, A Berry, B. Barber, H.E. Berry, A.C.T. Plumpton, LA Swepson,

ROAD TANKER REGULATIONS

Further certificates of exemption under the Dangerous Substances (Conveyance by Road in Road Tankers and Tank Containers) Regulations 1981 have been issued by the Executive. No. 6 of 1986

During 1985 consultation took place with interested associations regarding the possible revision of Schedule 4 to allow driver-controlled deliveries at petrol filling stations ie deliveries during hours when the filling station is closed and only the tanker driver is present. Subsequently, HSE decided to allow trials to take place at a limited number of filling stations throughout Great Britain in order to gain experience of this type of operation before taking a final decision on revising Schedule 4. The first site in South Shields is now operational under the terms of Certificate of Exemption No 6 of 1986 and further sites are being considered. No. 1 of1987

The regulations do not cater in all respects for the circumstances where a road tanker or vehicle carrying a tank container may have crashed and is being towed or otherwise moved by a recovery vehicle. The tank may be punctured and so not comply with Regulation 6 (construction of vehicles and tank containers).

In addition, the driver of the recovery vehicle may not have recieved instruction in line with the requirements of Regulation 21 (instruction and training for drivers).

The new certificate, therefore, exempts the operator of a road tanker or tank container from the requirements of Regulations 6( 1)(b) and c(i) in circumstances where the tanker of tank container is damaged and is being moved to the nearest safe place for repair or for cleaning or purging, provided that steps have been taken to make it as secure from leak as is reasonable in the circumstances and the vehicle is escorted by a police or fire brigade vehicle.

In addition, the certificate exempts the operator from Regulation 21 in like circumstances if the driver of the recovery vehicle is accompanied by a person who has received training in accordance with Regulation 21 or if the recovery vehicle is escorted by a police or fire brigade vehicle. No. 2 of 1987

Certificates of Exemption Nos 4-7 of 1 were Issued to specific firms or organisations which exempted them from the requirements of the regulations in respect of the conveyance of products in volumetric provers subject to certail1 conditions. Volumetric provers are tanks or prover pipes used for the calibration of metering equipment or the measurement of fuel deliveries and which are structurally attached to, or are an integral part of the frame of a vehicle.

Certificate No 2 of 1987 exempts any operator of a volumetric prover subject to the same conditions. The earlier certificates have been revoked.

Copies of all three certificates of exemption can be obtained from:

Health and Safety Executive HSD-A3

Room 417 I Chepstow Place London W2 4TF

Tel: 01-2293456 Ext 6207

NEW INTERCEPTOR BEATS OIL POLUTION

;fhe 'Half-Acre' By-Pass Interceptor is the latest GRP. product to leave the drawing board of Accord Marine Ltd.

Robust, with a novel design, demonstrating and exceptional ability to separate petroleum products from waste water, the performance efficiency exceeds that obtained with any previous make of interceptor.

The 'Half-Acre' By-Pass Interceptor, through vertical positioning of its cylindrical body, will allow substantial cost savings to be made on installation.

Test results for the 'Half-Acre' By-Pass Interceptor have been monitored and approved by the Thames Water Authority and it is felt that by introducing this Interceptor to the Civil Engineering and allied markets a major contribution to environmental protection will be made.

A Patent is pending for the 'Half-Acre' By-Pass Interceptor and a full Patent is anticipated by the end of the year.

A CLEANER ENVIRONMENT WITH UNLEADED PETROL

Summary

Pollution from lead-laden clouds in our streets should b b stantially reduced by 1 October 1989. The e su h I Community has, for some time, agreed to t e pnnclp e of elimination of lead from petrol. In 1978 the of Ministers fixed a maximum value for the permitted leadcompound content of petrol between 0.4 and 0.15 es of lead per litre (g pb/l). The measure was, gramm . . . 9 however, superseded by a new directive 111 March, I R'i, designed to promote the widest possible use of unleaded petrol.

The Commission has now amended the 1985 directive other step in the Community efforts to reduce lead as an d"d I pollution. The amendment WOUld. permit 111 ua member countries to introduce a six-month perIod of tice before prohibiting marketing of leaded regular no d" d etro!' The measure would be permissive an IS aIme to help owners of small petrol .stations: countries would not be obliged to abolish the sale of leaded regular petrol until they have a sufficient number of unteaded petrol pumps.

The Council of Environmental M111lsters, meet111g on 19/20 March, 1987. broadly supported the principle of the amendment. but would await a final decision on Opinions from the European Parliament and the Economic and Social Committee.

The Council also approved the limitation of emission!:-> of diesel buses or lorries. but the Spanish and French called for more flexible limits than proposed tl1L' Commission, whereas the Germans. DanL'!:-> and ('reck-. were in favour of more severe standards. Agrcemcnt!:-> on emissions limitations wlluld haw to be \att'!. although Denmark still appear!:-> to ha\c "llmc I"cserYations.

-+1

Encouraging the use of unleaded petrol

The 1985 directive specified that member countries could sell leaded petrol with a range of 0.15 to 0.4 gll. Seven Community members including the United Kingdom now apply the lower figures while France, Italy, Spain and Portugal are still at 0.4 gll, and Greece applies 0.15 gll in the Athens area and 0.4 per cent elsewhere.

At present, member countries have a two-grade system comprising leaded premium and leaded regular. By 1 October, 1989, the 12 member countries must ensure the availability and balanced distribution of unleaded petrol with a motor octane number (MON) of 85.0 and a minimum research octane number (RON) of 95.0 at the pump ('premium'). The 1985 directive allows for the marketing of another leaded grade with lower octane numbers. For a large number of petrol stations it will be physically and financially difficult to stock four types. It will be necessary, therefore, to make a choice. The choice appears to lead to:

a leaded type of petrol that must continue to be available so that cars which require leaded petrol can continue to function. There are also cars which require petrol with higher octane number than unleaded premium. Leaded premium has, therefore, to be retained:

unleaded premium is required by the 1985 directive:

leaded regular. particularly when an unleaded regular comes on the market, is not technically necessary.

At the moment out of 97 millions petrol-engined cars on the road in the Community, 20 million are desgined to run on regular petrol. A high proportion of those modern cars which use low-octane regular petrol can run on eith.er leaded or un leaded petrol -a fact not always apprecIated by their owners and even those vehicles which need lead in the fuel to avoid excessive engine wear will in fact run quite satisfactorily using leaded petrol only once every three or four tanks full. This at least enables drivers to use the less polluting lead-free regular petrol for 75 per cent of the time, switching to leaded premium grade for the other 25 per cent. The result of the switching will not have any effect on the level of noxious emissions in the exhaust gases.

Germany (IOJJOfJ) and The Netherlands (R,OOO) had a substantial network of sites offering 'un leaded' pumps in October 19Ro. Denmark has 9fJO pumps, but there are few in other countries. The UK has 140 pumps, Italy 90 and Frace R9. The Dutch government has already Imposed a heavy additional duty on regular leaded petrol. which has stimulated the spread of un leaded brands. In Britain. following the provisions of the Budget in March. the lower cost of lead-free petrol is CXlwcted to encourage hetter use of pollution-free fuel.

Greater flexibility

Small petrol stations with slow turnover could suffer serious commercial consequences from an immediate ban on the sale of regular leaded petrol. To avoid these the Commission's amendment introduces a permissive measure of six months notice so that neither producer, retailer nor consumer would be faced with sudden changes regarding the marketing of leaded regular petrol. In countries wishing to protect its population from lead poisoning the amendment is intended to encourage faster movement to cleaner emissions.

The Commission considers that there are two advantages in the measure. Where the directive is brought into force before October 1989 small retailers will not need to install extra tanks for unleaded petrol. This means that they can avoid costs of 25,000 to 40,000 ECU (£18,000 to £28,000) for a new tank and pump. Secondly, as the prohibition of leaded regular petrol puts the small and larger stations on a more equal footing there is a further competitive advantage for the smaller retailers. Germany is expected to take advantage of the measure in hastening towards widespread use of lead-free petrol.

Car exhaust emissions

Environment Ministers also at their March meeting gave special attention to exhaust emissions from cars. They recognised that, despite the Luxembourg agreement on 27 June 1985 on reduction in exhaust emissions, there had been little progress. The proposal is based on a two steps approach:

(a) a first move would lower emission limit values to (b)

CO( 45g/test HC + NOx : 15 gltest NOx : 6 gltest

with effect from 1 October 1989 for new models, and 1 October 1991 for all new vehicles.

with effect from 1 October 1995 there whould be a further decrease in limit values to a level adjusted to European conditions, and corresponding to those in force in the USA. The new ranges would be:

CO: 10-35 gltest HC + NOx : 2.6 8.2 g/test NOx : 1.1 4.0 g/test

There was agreement on helping Greece over pollution in Athens, but Denmark considered the first step as too weak. She refused to cooperate with her colleagues. Meanwhile there is a British scheme to produce effective 'lean hums' engines. The technology, it claims, should save the European motor industry hundreds of millions of dollars in reducing exhaust emissions.

42

HEAVILY FINED AT CROWN COURT

The case started on Sunday 16 November 1986 when a Fire Service Officer was asked to attend New Hey Road, Huddersfield, where the Gas Board were excavating a trench in the main road some 50 m from a Filling Station. there was a quantity of what appeared to be petrol in the trench and this was subsequently confirmed following test by the Gas Board.

The Office requested the attendance of a representative of the Filling Station and when a supervisor arrived, advised that there had been a petrol delivery to the garage the previous Friday (14.11.68) at 0730 hours but was not aware of any incident or spillage. The Gas Board were informed not to resume work until further investigation had been carried out. After having been closed by the Police, the road was reopened, the trench cordoned off and conspicuous hazard warning signs provided. The diggings remaining supervised by the Gas Board. Officers started full enquiries at the petrol station on Monday 17 November 1986 and the following is a summary of the findings.

A copy of the petrol delivery certificate for the on 14 November 1986 was not at the premises. ThiS IS an Container Regulations).

The supervisor was mterviewed and it was quite clear from her answers that she did not know what the Conditions of Licence and Regulations were relating to petrol deliveries. This is an OFFENCE (Conditions of Licence).

The station manageress was interviewed and similar to the supervisor she did not known what was required, again an OFFENCE.

Two forecourt attendants were interviewed each of had accepted deIivieries of spirit previously, neither of whom know what was required, one had even used. a n?rmal hand torch to read a tank dipstick because the was not good enough! Multiple OFFENCES (Conditions of Licence).

The attendant who had accepted the delivery of petrol on the morning of Friday 14 November did not remain in constant watch on the underground tanks. Three OFFENCES as three tanks were filled (Tank Container Regulations). He left the driver to fill the tanks while he carried on with other work.

Tank No 1 was overfilled and the driver had to fetch the. attendant. Between them they uncoupled the delivery hose from No 1 tank and petrol escaped at the point. The attendant held up the hose the dnver let the tanker run backwards bv removmg the handbrake. (Note he did not run the enginer!). Until hose could be connected to No 4 tank when more spmt spilt as the connection was made to No 4- tank. An OFFENCE in respect of each tank, plus not know!ng the correct procedure, ie he was not competent. a further OFFENCE (Tank Container Regulations).

Following the interviews the procedure wa,s and samples in respect of each chamber was at the site and the others were retained by the Fire Service for analysis should there by any later contention that the fluid was spirit.

external forecourt area near the petrol tanks was also II1spected and it was found that the lighting for the petrol tank delivery area ,",:as defective. According to the manageress it had been defective for ahout six 1110nths.

Additionally, the drainage safety channelling across the forecourt entrance was completely blocked by dirt and debris. An OFFENCE in respect of each defect (Conditions of Licence).

A total of fifteen summonses were served on the licencee on 17 December 1986. Following discussions between the defence and Fire Servi;e Solicitors agreement was reached to reduce the charges to ten, dropping the charges in respect of tanks not being locked and the repetative charges in respect of not being in constant watch on each tank ie only proceeding with the offence of one tank instead of three. The defence were to plead guilty to the remaining ten.

At Huddersfield Magistrates Court on 6 February 1987 after hearing only the prosecution case and being aware that the defence had entered a guilty plea to all charges, the Magistrates retired to deliberate and on return referred the case to Crown Court. The reason the Maoistrates would not deal with the case is not known butit is felt that as they had not dealt with a case such as this before they were not sure of the amount of penalty to impose. They had been advised by their Clerk there was a maximum find of £2,000 on each charge.

At commital proceedings on 27 February 1987 the case was referred to Crown Court on 27 April 1987. At Crown Court on 27 April 1987 the case was heard by His Honour Judge Myerson QC.. It is a general rule that only sample offences are dealt With at Crown and the number was. therefore. reduced from ten to be dealt with at Magistrates Court to SIX. A gUIlty plea was entered in respect of the six charges.

Indictment details were as follows together With the fines imposed:

The Queen \' Mayfield Garage (Halifax) Ltd. Charges as follows:-

COURT 1 STATEMENT OF OFFENCE

Being the occupier of premises in which petl'l;kum spirit was kept in of conditions attached to a petroleum Sp1l'1t licence contrar\, to Section 1(2) of the Petroleum (Corisolidation) Act 192X.

PARTICllLARS OF OFFENCE

MAYFIELD

GARAGE (HALIFAX)

LIl\tITED on the 14th NOH'mber lLJXb \vere the occupiers of Reil1\\ood Service Station. New He\' Road. Huddl'rsfield. at \\'hich petw!elll;' spirit \\as kept in contran?ntion of Condition ,24( C) l,f part ) of the Conditions of Licence in that the person in charge of a storage tank failed to secure that no petroleum spirit escaped at the filling point of the said tank.

COl'NT,2

STATEMENT OF OFFFNCF

Being the occupier of prcll1ist.'s in \\hidl petroleum spirit \\as kept in clllltraH'lltioll of conditions attached to a pctrllkulll spirit licl'llcl' cllntran III Sl'dion 1(2) ut the Pl't rllieUIl1 (( 'lll{sulidat iun) 'l"l't ILJ2X

An interesting case pursued by West Yorkshire Fire Service writes John Johnson GradlFire E, Assistance Divisional Officer (Petroleum Office).

COUNT 3

PARTICULARS OF OFFENCE

MAYFIELD GARAGE (HALIFAX)

LIMITED on the 14th November 1986 were the occupiers of Reinwood Service Station, New Hey Road. Huddersfield. at which petroleum spirit was kept in contravention of Condition 24(D) of part 5 of the Conditions of Licence in that the person in charge of a storage tank failed to keep a constant watch thereon during the whole time of delivery of petroleum thereto.

STATEMENT OF OFFENCE

Contravening a condition attached to a petroleum spirit licence, contrary to Section 1(3) of the Petroleum (Consolidation) Act 1928.

PARTICULARS OF OFFENCE

MAYFIELD GARAGE (HALIFAX)

LIMITED on the 14th November 1986 the person to whom a petroleum spirit was granted in respect of premises at Remwood Service Station, New Hey Road, Huddersfield, contravened Condition 24B of part 5 of the Conditions of Licence by to secure that a competent person was m charge of a storage tank for the purposes of accepting a delivery of petroleum thereto.

COUNT 4 STATEMENT OF OFFENCE

Contravening a condition attached to a petroleum spirit licence, contrary to Section 1(3) of the Petroleum (Consolidation) Act 1928.

PARTICULARS OF OFFENCE

MAYFIELD GARAGE (HALIFAX) on the 14th November 1986 the person to whom a petroleum spirit was granted in respect of premises at Service Station, New Hey Road, HuddersfIeld, contravened Condition 22 of part 5 of the Conditions of Licence by failing to ensure that the said premises were properly supervised.

COUNT 5 STATEMENT OF OFFENCE

Contravening a condition attached to a spirit licence, contrary to Section ) of the Petroleum (Consolidation) Act 1928.

PARTICULARS OF OFFENCE

MAYFJELD GARAGE (HALIFAX) on the 14th November 1986 /m g the person to whom a petroleum spirit was in respect of premises at SerVIce Station, New Hey Road, HuddersfIeld. contravened Condition 16 of part 5 of the Conditions of Licence by failing to keep openings to the drainage system at the said premises free from dirt and destruction.

COUNT 0 ST ATETMENT OF OFFENCE

Contravening a condition attached to a petroleum spirit licence. contrary to Section 1(3) of the Petroleum (Consolidation) Act Ink.

PARTICULARS OF OFFENCE

MAYFIELD GARAGE (HALIFAX)

LIMITED on the 14th November 1986 being the person to whom a petroleum spirit licence was granted in respect of premises at Reinwood Service Station, New Hey Road, Huddersfield, contravened Condition 2 of part 5 of the Conditions of Licence by failing to provide at the said premises adequate lighting for deliveries made in the hours of darkness.

FINES

£

COUNT 1 500.00

COUNT 2 500.00 COUNT 3 1,000.00 COUNT 4 2,500.00 COUNTS 2,500.00 COUNT 6 1,000.00

Costs awarded to Fire Service 389.86

Prosecution Costs 200.00 TOTAL 8,589.86

His Honour Judge Myerson QC enquired in depth regarding the firm's finances and procedures for ensuring that staff were prepared in these matters firm having four retail outlets selling some 2 mIllIon gallons of petrol a year, and how much of. the profits were set aside for training purposes. He dId not take kindly to the company's negative answers. He stated "This case shows an almost complete lack of adequate supervision, either of the premises or staff and see.ms that only good fortune prevented a far worse SituatIOn arising"

Subsequent to the Crown Court Hearing the drainage system was tested with dye and water mix when it was found that, although the original approved pl.ans of the installation held in the Fire Service file indicated the drainage safety channelling being directed through the three stage site interceptor. this was not the case. In acutal fact the safety channelling drainage pipework w?s directed straight into the main sewer under the mam roadway!

The Fire Service wrote to the Licensee in December 1986, following the initial investigations, particuarIy mentioning the drainage system, that it should be fully checked to ensure that all drainage passed through the interceptor. The Licensee had passed the letter to the petrol company who had taken no further action on the matter.

On a revisit to the site following the Crown Court action the Fire Service had to indicate to the Licensee that if the remedial work was not completed within 7 days further proceedings would be Approximately £l2,000 was then involved in a new petrol interceptor because the one ongm?lly installed was set too high to enable the safety channelling to be directed through it. the site levels sloping quite steeply from end to end.

It is quite astonishing that this course of action had to be taken by the Fire Service after the final Court hearing and even up to this time, having written to the Licensee, they or the petrol company did not reply in writing or contact the Fire Service for an Officer to visit the site and explain what was necessary. The remedial work was done. however. within 7 days!

44

Prosecutions

£1800 fines expensive wallpaper.

On 17 August at Waltham Forest Magistrates Court the London Fire Brigade prosecuted a road tanker driver, and a person in charge of a storage tank for failing to keep a constant watch during delivery of petrol to the petrol filling station in Hoe Street, E17.

A petroleum officer was driving past the site and noticed that there was no one at the delivery point, or by the road tanker. He stopped and found that the person in charge of the storage tank, Mr J Dean was in the sales building on the telephone. The driver of the Gulf Oil tanker Mr. J. Chittenden was not on the site but across the road purchasing wallpaper. Both defendants pleaded guilty, and in mitigation pleaded that the delivery had almost finished and that no spillage or incident had occurred during the delivery. The magistrates after retiring stated that they took a very serious view of such infringements which could affect public safety and both men were fined £800 with £100 costs.

Prosecution Research of Conditions of Licence to keep Petroleum Spirit

On Friday 24 July 1987 at Pontefract Magistrates Court, the West Yorkshire Fire Authority successfully prosecuted: .

Racca Green Garages Ltd

for breaches under the conditions of Licence. The and their fines were briefly:

1. SpIllage of petrol when filling an under ground petrol tank.

2. Not remaining in constant attendance at filling point, therefore allowing spillage of petroleum spirit to occur.

3. Failed to ensure the tanker hose was properly and securely connected to the filling point of a petrol tank.

4. Failed to keep the filling pipe of a petrol tank securely locked.

5. Failed to keep the filling pipe of a petrol tank securely closed.

6. Lack of competence on the part of the garage staff and lack of training of the staff by the company, leading to a lack of knowledge of the responsibilities under the conditions of licence.

fine £ 50.00 fine 50.00 fine 50.00 fine 50.00 fine 50.00 fine 50.00

The company were also ordered to pay costs amounting to £2lO.60 to the Fire Service.

The Fire Authority views breaches of conditions as a potentially lethal disregard for vital safety measures. for handling an extremely hazardous product. By publicising cases such as this. other "less responsible" companies will examine their own housekeeping!

Dipping can damage your wealth!

On 5th May 1987, Steeldene Ltd were found guilty of contravening two conditions of the licence to store petroleum spirit at Eykins Garage, Kenilworth, Warwickshire. On 30th October 1986 the Fire Brigade and Petroleum Officer were called to the site. A spillage of about 1500 litres had occurred. Petrol was being delivered from a tanker via an offset fill into two For some reason the quantities to be delivered were reversed and one tank was overfilled. Contrary to approved arrangements, instead of using the contents gauge provided a plug on top of the tank had been removed and a dipstick was being used. The tank manhole was situated on the other side of the tanker. The plug had not been properly replaced after dipping and spirit from the tanker escaped via the offset fill from the tank top. The spillage was not immediately noticed and consequently the quantity lost was large.

The site is fitted with proper drainage channels and an interceptor. The loss was confined initially to the site, unfortunately the brick built interceptor was leaking and petrol escaped into the surrounding ground and main drainage system. This caused complaints from local residents over several days.

Failing to keep a safety device," the petroleum interceptor, in g?od order to the satISfactl?n of the Licensing AuthOrIty

Fmed: £400

Failing to keep and all arrangements approved at the time of grantmg the licence"

Fined: £600

£1000 fine for petrol leak in Chichester

On March 3rd petroleum officers of the West Sussex T ding Standards Dept were called to a petrol smell on a estate. Investigations 80% explosive d "ngs in ducts under one factory whIch was closed for rea I .' d b S h a time. The adjacent premIses occuple . y out. ern Cooperative Dairies had a petrol tank whIch contamed only 37 gallons instead of the 290 of book stock" The last di being taken a month before. " " \v Sussex Trading standards prosecuted the DaIry for not ci1ecking the contents of the tank daily as required by the licence condition.

The company were fined £1000 WIth. £50 ct.>sts. In addition they spent some £600 on emptymg testmg and solid filling the failed tank.

Explosives " _

Massive fines were Imposed on a garden centle warnings were ignored about display and sale of fIre works. Bedfordshire Tradmg Standards Dert. prosecuted. Willington c:entre Ltd" for contraventIOn of the ExplOSIOn Act IR75. , '

Bedford Magistrates fined the £ 1,300 tor the contraventions, trading standards offIcers had made several visits and the company had ignored advice_

£1000 fine for Mobil Oil Company

Mobil Oil Company were redeveloping two filling stations at Southport, Merseyside. New tanks had heen installed and the old buildings. pumps. canopies. ele. had been demolished and replaced with new ones.

During a progress inspection before the was finalised. it was discovered that petroleum SpIrIt had been delivered. 2b,6()(l litres at one site and a similar quantity at the other.

At North Sefton Magistrates Court on the 4th March 19R7. the pkaded guilty to storing petwl without a licence and \-vas fined £50() ",ith £75 l'OSts till each charge

For comprehensive safety and vessel servicing which includes all aspects of work. • Nitrogen Inert Foam Inerting • Gas freeing using various Nitrogen purging techniques • Leak testing by all modern techniques • Hot work modifications, and repairs, to Lloyds/A.S.M.E. • Bottoming, Cleaning, Removal, Slurry Filling • Mothballing • Sprayed Resin, or Glass Reinforced, Spirit, Solvent, and Chemical Resistant Linin gs , engineered to Lloyds inspectorate of shipping approval. • Abrasion to S.A.3, Protective Coatings, and Cathodic Protection. Please Phone (we charge no extra for our knowledge, insurance or experience) STORAGE TECHNOLOGY FRIARY M EWS 28 COMMERCIAL ROAD GUILDFORD GU1 4SU TE LEX 8595 3 5 INTCOM G FAX 0483 571162 • LONDON / SOUTH EAST AREAS 01-546 2754 • SO UTHERN / CENTRAL AREAS & TECHNiCAL ENQUIRiES GU il DFORD (0483) 222307 • SO UTH WE ST AR E A (0822) 2753 • 7 DA Y 2 4 H OUR EMERGENCY CAll OUT (ALL AREAS) G UILDFORD (0 48 3 ) 222307

Making Safe with Nitrogen Inert Foam Inerting·

NIFI (nif'-e)

BILL DOIDGE

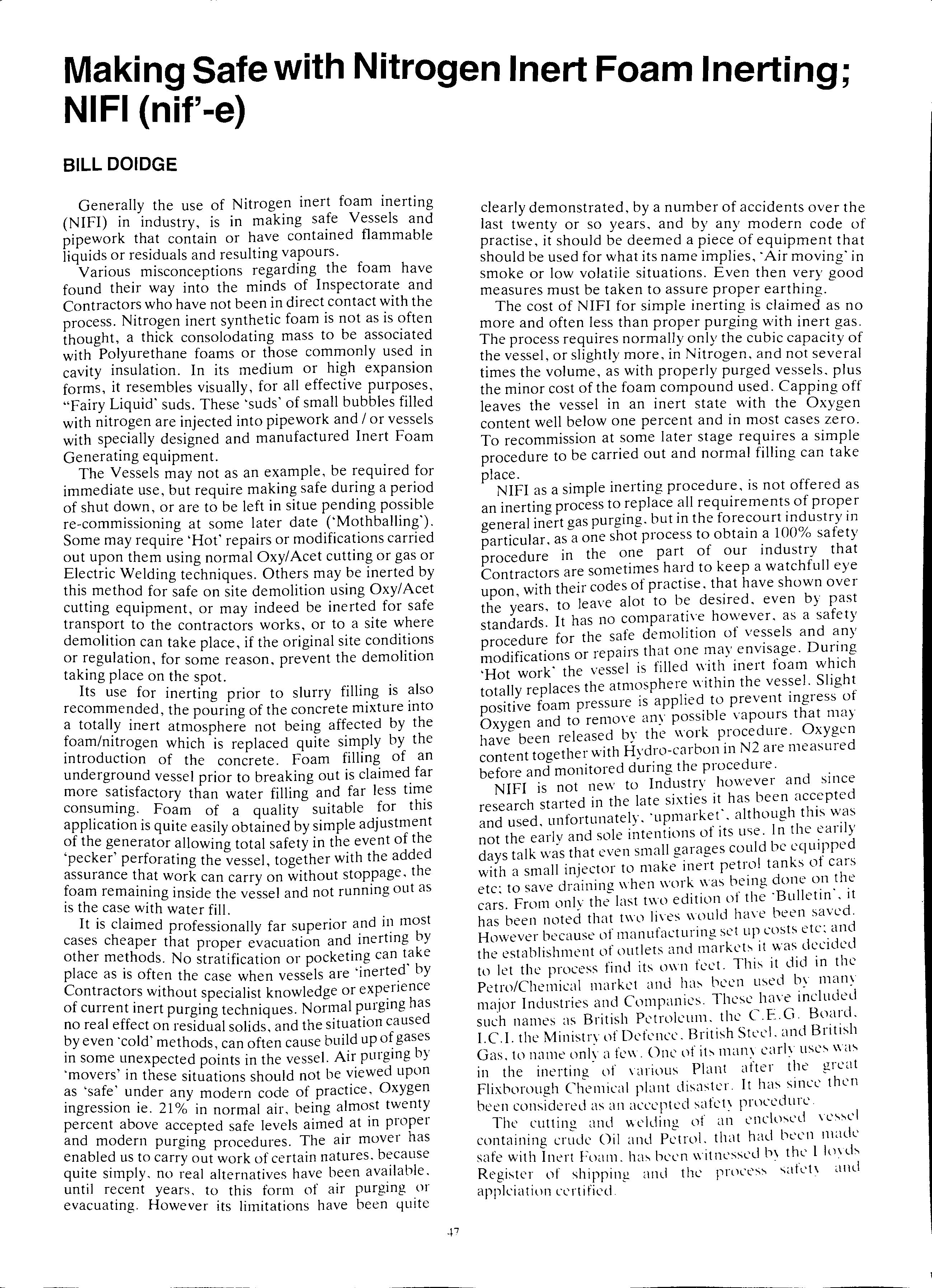

Generally the use of Nitrogen inert foam inerting (NIFI) in industry, is in making safe Vessels and pipework that contain or have contained flammable liquids or residuals and resulting vapours.

Various misconceptions regarding the foam have found their way into the minds of Inspectorate and Contractors who have not been in direct contact with the process. Nitrogen inert synthetic foam is not as is often thought, a thick consolodating mass to be associated with Polyurethane foams or those commonly used in cavity insulation. In its medium or high expansion forms, it resembles visually, for all effective purposes, "Fairy Liquid' suds. These 'suds' of small bubbles filled with nitrogen are injected into pipework and I or vessels with specially designed and manufactured Inert Foam Generating equipment.

The Vessels may not as an example, be required for immediate use, but require making safe during a period of shut down, or are to be left in situe pending possible re-commissioning at some later date ('Mothballing'). Some may require 'Hot' repairs or modifications carried out upon them using normal Oxy/Acet cutting or gas or EI.ectric Welding techniques. Others may be inerted by thiS method for safe on site demolition using Oxy/Acet cutting equipment, or may indeed be inerted for safe transport to the contractors works, or to a site where demolition can take place, if the original site conditions or regulation, for some reason prevent the demolition taking place on the spot. '

Its use for inerting prior to slurry filling is also the pouring of the concrete mixture into a mert atmosphere not being affected by the which is replaced quite simply by the mtroduchon of the concrete. Foam filling of an underground vessel prior to breaking out is claimed far more than water filling and far less Foam of a quality suitable for thiS apphcatlOn IS quite easily obtained by simple adjustment of the generator allowing total safety in the event of the 'pecker' perforating the vessel, together with the added assurance that work can carry on without stoppage, the foam remaining inside the vessel and not running out as is the case with water fill.

It is claimed professionally far superior and in most cases cheaper that proper evacuation and inerting by other methods. No stratification or pocketing can take place as is often the case when vessels are 'inerted' by Contractors without specialist knowledge or experience of current inert purging techniques. Normal purging has no real effect on residual solids, and the situation caused by even 'cold' methods, can often cause build up of gases in some unexpected points in the vessel. Air purging by 'movers' in these situations should not be viewed upon ?S any modern code of practice, Oxygen mgresslOn le. 21% in normal air, being almost twenty percent above accepted safe levels aimed at in proper and modern purging procedures. The air mover has enabled us to carry out work of certain natures, because quite simply, no real alternatives have been available, until rt;cent years, to this form of air purging or evacuatmg. However its limitations have been quite

,

clearly demonstrated, by a number of accidents over the last twenty or so years, and by any modern code of practise, it should be deemed a piece of equipment that should be used for what its name implies, 'Air moving' in smoke or low volatile situations. Even then very measures must be taken to assure proper earthing.

The cost of NIFI for simple inerting is claimed as no more and often less than proper purging with inert gas. The process requires normally only the cubic capacity of the vessel, or slightly more, in Nitrogen, and not several times the volume, as with properly purged vessels, plus the minor cost of the foam compound used. Capping off leaves the vessel in an inert state with the Oxygen content well below one percent and in most cases zero. To recommission at some later stage requires a simple procedure to be carried out and normal filling can take place.NIFI

as a simple inerting procedure, is not offered as an inerting process to replace all requirements of proper general inert gas purging. but in the forecourt industry in particular, as a one shot process to obtain .a 100% safety procedure in the one part of our mdustry that Contractors are sometimes hard to keep a watch full eye upon with their codes of practise. that have shown over the y'ears, to leave alot to be desired, even by past standards. It has no comparative however, as a safety procedure for the demolition of and modifications or repairs that one may envisage. DUllng 'Hot work' the vessel is filled with inert foam which totally replaces the within the Slight positive foam pressure is applied to prevent mgress of Oxygen and to remove any possible vapours that may have been released by the work procedure. Oxygen content together with Hydro-carbon in N2 are measured before and monitored during the procedure.

NIFI is not new to Industry however and smce research started in the late sixties it has been acc.epted and used, unfortunately, 'upmarket', although thIS w.as not the early and sole intentions of its u'Se. In the days talk was that even small garages could be eqUIpped with a small injector to make inert petrol tanks at cars etc' to save draining when work was being done on the From only th; last two edition of the 'Bulletin', it has been noted that two lives would have been saved. However because of manufacturing set up costs ete: and the establishment of outlets and markeb it was decided to let the process find its own feet. This it did in the Petm/Chemical market and been used by many major Industries and Companies. These have included such names as British Petroleum. the e.E.G. Board. 1.e.1. the Ministry of Defence. British Steel. and British Gas, to name a few. Onc of its many earl\" was in the inerting of \"arious Plant at-ter the great Flixborough Chemical plant disaster. It has since then been considered as an accepted procedure.

The cuttinG and we\dinll of an enclosed I:- I:containing crude Oil and Petrol. that had been madc safe with Inert Foam. ha" been witnessed b\ the I lunb Register of shipping. and the proL't's,,' -;afcl\ and applciatiull certified.

.p

19 PLASHET GROVE ,

LONDON. E6 1AD

Telephone: 01-472 6627/8

&

Adencon Draughting Services Ltd.

Specialists in the preparation of drawings for petrol filling service station redevelopments, alterations and tank or equipment installations and obtaining all necessary statutory authority approvals (i.e. planning permission, building regulation approval, petroleum officer approval etc.) MEMBER A.P.E.A. PHONE 01-739 9538 TUBEFLOW LTO and SOUTHERN PUMP SERVICES "WE COVER LONDON" CONTRACTORS TO THE PETROLEUM INDUSTRY AND LOCAL GOVERNMENT AUTHORITIES SUPPLV, INSTALLATION AND MAINTENANCE OF FUEL PUMPS, TANKS AND ANCILLARY EQUIPMENT PIPEWORK INSTALLATIONS. ETC. 27-29 TEMPLE STREET, LONDON E2 6aa

Wire-Braided v. Textile Braided Hose for Petrol Dispensers

C.G. Knight, Permex Ltd.

The use of wire-braided hose for petrol dispensers has been well established for many years. The main reason for this was originally the low first cost as the manufacture of this type is highly automated. Further, because this type of hose is also used in high-pressure hydraulics, it had been (albeit wrongly) assumed that such hoses would be either more durable or safer in service. However during the last 5-8 years there has been a major change of direction, and the UK is now the only country in the world where wire-braided hoses still account for a major part of the market. Now the Health & Safety Executive have made regulations which will make the use of such hoses mandatory under certain conditions, and one could expect that other regulatory bodies (e .g. local authorities) may wish to apply this move to a wider field. It is therefore important that the facts of the case are reviewed and set out clearly and impartially and this report has been compiled to provide these.

General Requirements for hoses of all types

A LINING compatible with the product to be handled must be unaffected by long-term contact and must have anti-static properties.

A CARCASS comprising reinforcements of textile or wire braiding to provide tensile strength, and to resist compression and expansion. At the same time it must permit easy flexing. Depending on the type of hose. the carcass may also incorporate means of dispersing static, by the use of anti-static materials or low resistance conductors.

The COVER must protect the hose against abrasion, weathering and other external forces.

The END FITTINGS must provide a secure and tight at both ends with a large safety margin operatmg pressures and other forces and must permit the dispersion of static.

The relative importance of different factors and depend on the particular application, and reqUirements relating to durability, reliability, safety and cost. A proper analysis of these factors is. an essential part of selection and specifying the matenals and methods of construction to be employed.

Wire-braided Hoses

The most significant characteristics are the ability to resist compression and expansion under pressure. T.hls has made these hoses first choice for high operatmg pressures, e.g. for high-pressure hydraulics working at say 100-500 bar. Until about 1970 this type was also the preferred choice for LPG applications.

Disadvantages are that wire braiding cannot be securely and permanentely bonded to rul:ber compounds. The use of additives and coatings pen11lts a temporary bond but stressing of the structure through bending, elongation etc. causes relative movement between lining. cover and carcass. leading to early breakdown of the bond. In the case of high pressure hydraulics. to overcome this problem. manufacturers specifically recommend that hoses mllst he installed free

of stress and special endfittings incorporating angles and bends are of stress and special endfittings incorporating angles and bends are supplied to minimize stressing. Further installation guides always stress the importanc':'e for long life, of minimizing movement and flexing bv supporting and fastening the hosing to restriC't movement.

In the case of petrol dispeners, hoses are particularly exposed to bending, kinking and being stretched. Additional factors are deformation of the hose by vehicles driving over. As the wire braiding does not recover from such deformation, damage to the bonding is inevitable.

An additional factor is diffusion of vapour through the lining. This contributes to delamination and damage to the cover which will then allow penetration of moisture which in turn leads to corrosion of the wire and ultimate structural breakdown.

Textile Braided Hoses

The last 10 years have seen significant developments of new materials and technology. New synthetic fibres e. g. nylon, polyester, and polypropylene (to mention ol';ly a few) combine high. chemical strength, and excellent with new, highly automated braldmg techl11ques. textile reinforced hoses show a significant improvement over both the conventional wrapped ply textile and wire braided hoses. These improvements are particularly in superior and bonds between components, and mamtenance of the structuralmtegnty under the adverse service conditions which may be experienced in the petl.·ol dispensing field. At the same time the new generatIOn ot hoses have much better handling properties and much service .life and -:e have knowledge of such hoses which were mstalled 111 the mid-70's and are still in service today.

These advances have not gone unnoticed. and the excellent experience in the field since the early 70's has resulted in a major shift from wire-braided hoses to textile-braided hoses throughout the world. except in the UK.

In the UK there have been 2 major influences to produce a con.trary trend. major have been mall1ly concerned With hrst cost. A hlghgrade textile-braided hose.may cost 10-15% more than a wire-braided hose though It wdl have a 20()-300% longer service life. Further the Health & Safety Executive have based their regulations on the assumption that wirebraided hoses offer an increased safety by being more resistant to wear and accidential damage. These assumptions might have been correct 2() years ago. but can now be proved to be incorrect.

As an example. the HSE wanh to minimize tilL' chance of a leak or structural damagL' to a hose at a high level which \\ould result in the electrnnic cirL'uitn of tilL' pump being inside a hazardous area.

A wire-braided hose was specified presumahlY on the assumption that a wire hraid prO\ides g.reater strlll·tllral strength. or greater prokction against Cln'iLicl1l<li damage

+t)

Comparison tests between 2 types of modern textilebraided hoses and 1 type of wire-braided hose (all NB 16mm) showe d that app li cation of a pulling force resulted in pulling off the fitting without tearin g the hose. The pulling forces for the texitile-braided hoses were 2872 a nd 2678 Newtons, and for the wire-braided hose 2131 Newtons.

Leakage of a top-hung hose could perhaps result from kinking due to a hose being pulled. Flexural endurance tests on both types of hose showed that taking the textile-braided hose as Index 100, the wire-braided hose had splits in the cover fo ll owing delamination and deformation after 20% of flexing

End Fittings

The HSE specifies the use of swaged fittings instead of the so-called " re-usable" type. This term is a mis-nomer as Such fittings are never in fact re-used as it is too much trouble to take them off and refurbish. It is understood that the main concern is to prevent fittings to be assembled to the hose in an inexpert manner , or to preve nt hoses being assembled in the field using endfittings not compatible with the hose.

In Our view , it is essential that the endfittings and hose mu st be compatib le, This can only be ensured if hoses and e nfittings are supplied fully assembled and tested . This can be ensured by marking the fittings to the effect that they are " Factory Fitted" or "Machine Assembled ". This can be done at the time of assembly. It is also possible to modify a compression fitting so that it cannot be assembled without a particular machine , or as a lt e rnati ve, that it is difficult to disassemble without damaging the fitting.

Swaged fittings hav e a number of disadvantages , particularly in the ca se of the bore (l6mm) type , that the outside of the fitting is usually of ferrous materi a l, which is a spa rking m a te ri a l a nd will corrode.

Electric Continuity

The HSE specify th at the m eta llic braiding mu st be connecte d to the end fitting Thi s may be for structural reas on s, or for the sake of e lectr ic continuity.

Mod e rn te xtile-braid e d hoses ma y have m e tallic thre ads woven into th e text il e braiding Typicall y , a 16m m bore ho se ma y conta in p e rhaps 20 such threads Thi s e ns ures that th e h ose ca n b e e lon ga ted without th e co ndu cto rs breaking. Further th e braiding is embedded IJ1 a nti- static rubb e r compo und which will m a intain continuit y eve n if th e m e tallic thr e ads break. Wh e n co mpress ed by th e e ndfitting , continuity is a uto m a ticall y es tabli s he d

Thi s sys te m of m a intainin g co ntinuity has th e a d va nt age that is lasts th e life o f th e ho se. In G e rm a ny, whe re a nnu a l tes tin g of e lec tri c co ntinuit y is m a nd atory , hoses co n stru c te d in thi s way a re exe mpt from thi s re quir e m e nt if mark e d according ly with th e Ohm sig n

Th is re po rt ha s stat e d fac ts whi ch can and have bee n s u bs tanti ate d a nd w hi c h a re rec og ni se d throughout th e Wo rld It is th e r e for e fe lt that th ese qu es tion s s ho uld be ra ise d with a ll co nce rn e d , e.g. t he re lev ant JP and BSI co mmitt e e s th e PPMA and the H SE. It is fe lt th a t t hi s is ju stifie d b y th e he ne fi h ob ta in e d in the wa y o f g rea te r "afe t y g. re ate r re li ab ili ty a nd (I sig ni fica ntl y lo nge r "u v icc lile ll i mociern tex ti le- b r a id e d ho ses.

:'iO DESIGN FUELLED B EXPERIENC Personal attention in design & development for the petroleum retail industry • Principal with over 25 years experience • Project Management specia li sts • Progressive & innovative outlook • Consultants for statuto\\: & planning req uirements • Comprehensive or tailored service to suit PLANACOURT Planacourt Limited PO. Box 27 Bill eli cay Essex CM ll 2ES 027744016

compactable wastes. Also statIc compactors installed and serviced. Skip services FIFTY YEARS OF SERVICE PROCiRESS AND EXPERIENCE A modern fleet of tankers for dealing with general and special industrial effluents. Established services for domestic and farm cesspits and gully cleaning. for the professional builder and DI Y enthusiast A wide pW Jetting services for , garages and industrial commercial :;-/ premises A 'Hotline ' emergenc y serv ice for t he 'ou t o f hours ' une x pe c ted crises. IS WHAT YOU GET WITH CLEANSING SERVICE GROUP specialist Tank Cleaning Service HEAD OFFIC E GRA N G E ROAD BOTlEY SOU T HAMPTON 8032GD BOTl E Y 2232 R i NG WOOD 2008 B RISTOL 552286 NE WBURY 45357 OXFO RD 61150 EVE SHA M 2620 STONEHOUSE 6116 SEVENOAKS 453175 MAR 26 A

BMMER TAB-LINK FOR LONGER LIFE EASIER SERVI

During the past 2 years a different type of drive belt has appeared on forecourt petrol dispensers.

The name is Tab-Link, and its unique polyester/polyurethane construction enables this belt to last a minimum of six times longer than conventional V-belts.

It's easier to service, as one reel enables the service engineer to make up any length of belt to suit all pump assemblies, thereby greatly reducing the stock carried

When it comes to the manufacture of pump equipment a simpler design is possible using Tab-Link, as the tensioning and sliding adjustment systems used with conventional drive belts aren't needed . Tab-Link is in successful use in petrol I dispensers throughout Britain, including those serviCed by Pump Maintenance Limited, and built . by Avery-Hardoll Ltd., Tokheim Ltd. and Ferranti Ltd. '

-.--..,.-=

I BRANlNlER So isn't it time you fotted Tab-link _ you'll fund yourself in very good company BRAMMER TRANSMISSIONS LTD. Hudson Road, Lee ds LS9 7DF Te l (0532) 493486 Telex 556144 The driving forGe in petrol pump V=Belts!

c P INSTALLATIONS LTD. (Established 1968) Specialists in Petroleum Pipework Installations New and existing Tanks and Lines tested Modifications to existing Installations And all work associated with Forecourt Pipework 39 BROOK ROAD, RAYLEIGH WEIR INDUSTRIAL ESTATE RAYLEIGH, ESSEX SS67XN Tel: RAYLEIGH (0268) 781184 / 781859 (24 hrs ans.) }obn & ([0. l£tb. FIRST HANGINGS· BLABY ROAD ENDERBY . LEICESTER . LE9 sAQ Telephone: Leicester 862287 (STD 0533) For a Comprehensive service for Liquid Fuel & LPG insW//ntion s Consultancy, design , installation , lnaint enance & d eco lJlll1issiolling Gas-free certificates Site survevs -' LPG vesse l 5 & 10 year insp ec tions

RONCOL SERVICE S LTD * Z.V A AUTOMATIC NOZZLE F1TTED AS STANDARD * NO HANDLES JUST LIFT NOZZLE _ * LARGE INDIVIDUAL DELIVERY REGISTER * AUTOMATIC RESET ON NOZZLE REMOVAL * 10 ft. TOP QUALITY "ELAFLEX' GLOSSLINE HOSE * NON PAINT, PLASTIc COATED, RUS1'PROOFED A low cost Commercial Fuel Pump + Fuel Management system for th e serious fleet operator

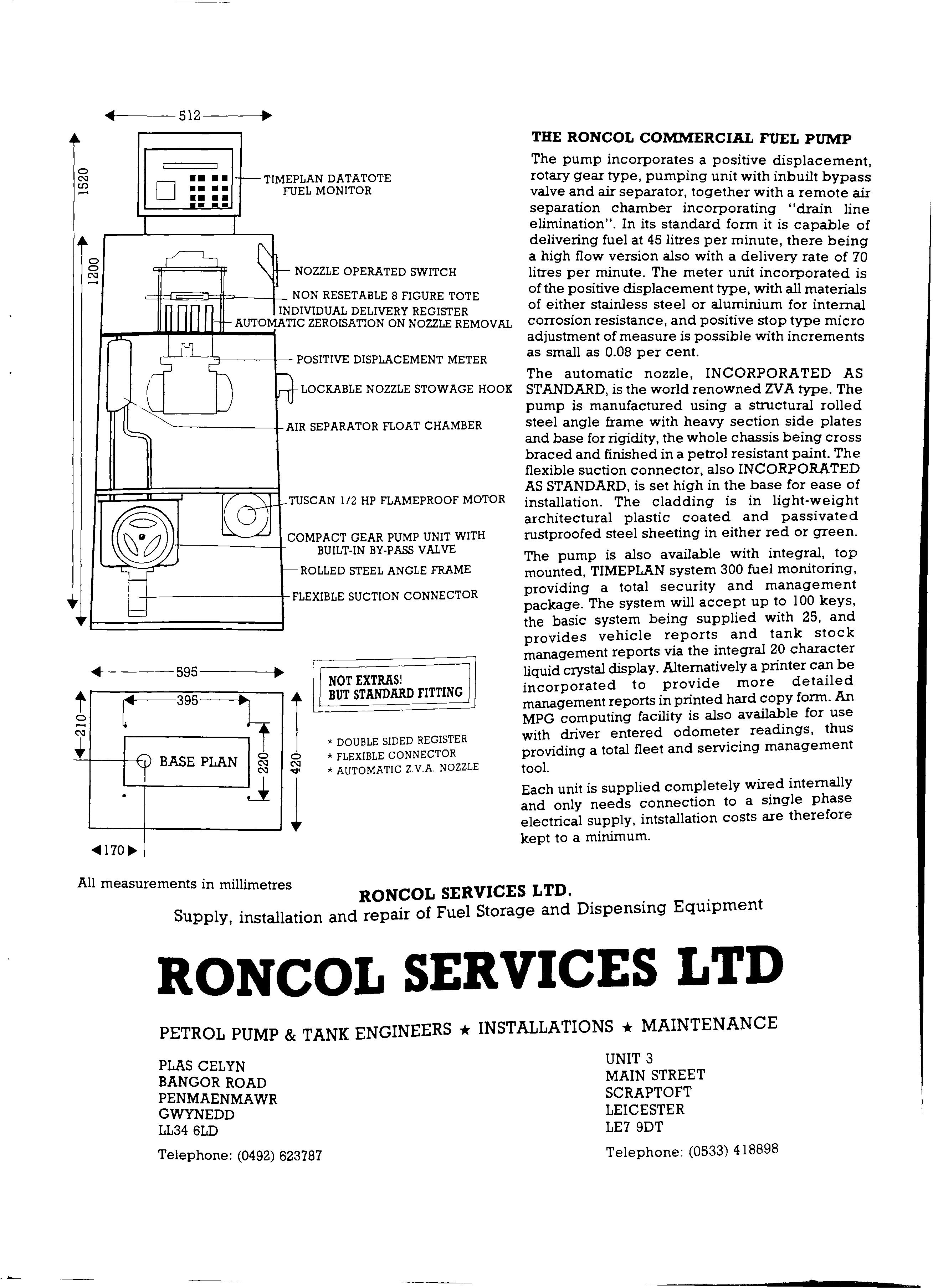

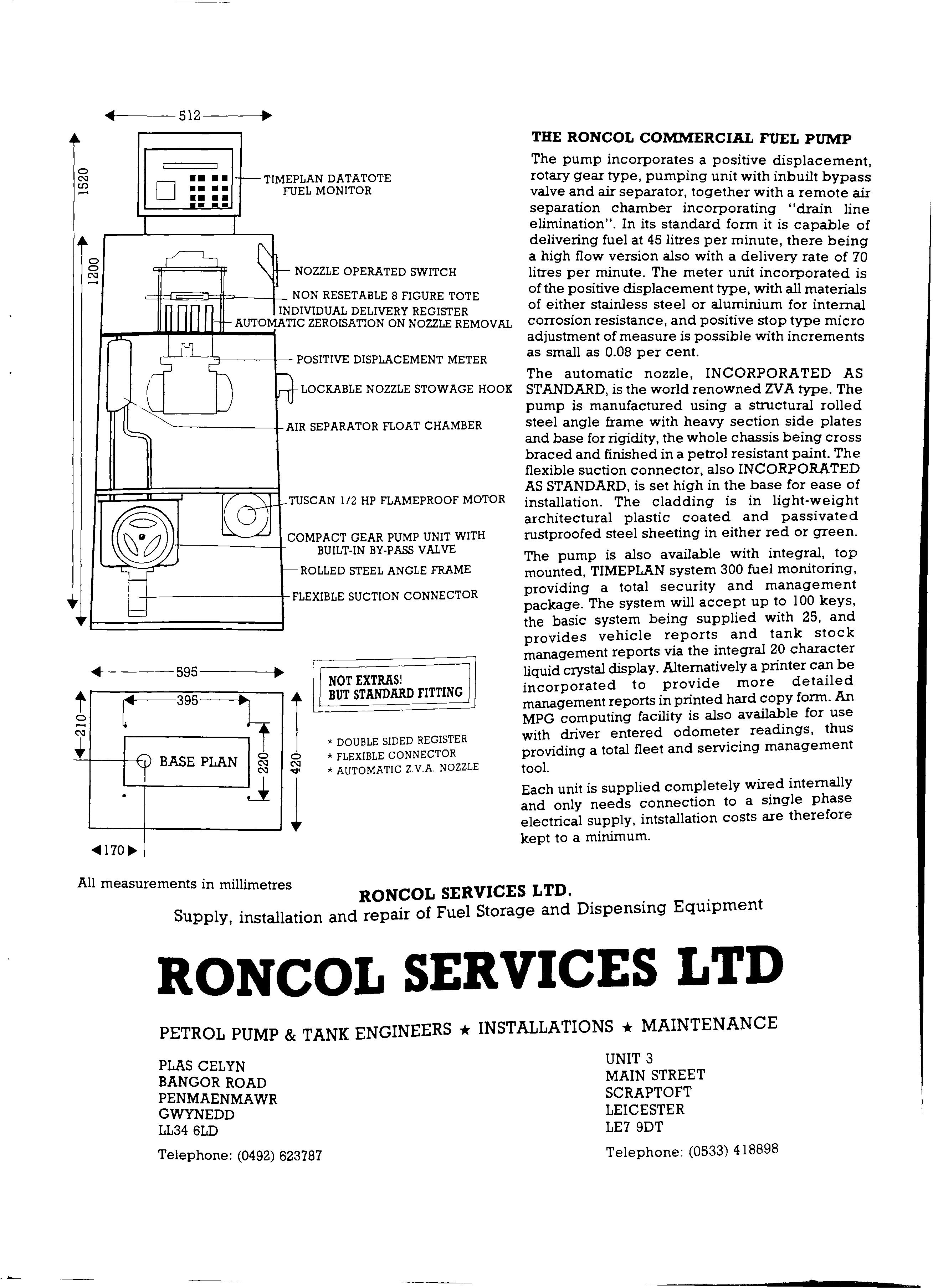

THE RONCOL COMMERCIAL FUEL PUMP

The pump incorporates a positive displacement, rotary gear type, pumping unit with inbuilt bypass valve and air separator, together with a remote air separation chamber incorporating "drain line elimination". In its standard form it is capable of delivering fuel at 45 litres per minute, there being a high flow version also with a delivery rate of 70 litres per minute. The meter unit incorporated is of the positive displacement type, with all materials of either stainless steel or aluminium for internal corrosion resistance, and positive stop type micro adjustment of measure is possible with increments as small as 0.08 per cent.

The automatic nozzle, INCORPORATED AS STANDARD, is the world renowned ZVA type. The pump is manufactured using a structural rolled steel angle frame with heavy section side plates and base for rigidity, the whole chassis being cross braced and finished in a petrol resistant paint. The flexible suction connector, also INCORPORATED AS STANDARD, is set high in the base for ease of installation. The cladding is in light-weight architectural plastic coated and passivated rustproofed steel sheeting in either red or green.

The pump is also available with integral, top mounted, TIMEPLAN system 300 fuel monitoring, providing a total security and management package. The system will accept up to 100 keys, the basic system being supplied with 25, and provides vehicle reports and tank stock management reports via the integral 20 character liquid Crystal display. Alternatively a printer can be incorporated to provide more detailed management reports in printed hard copy form. An MPG computing facility is also available for use with driver entered odometer readings, thus providing a total fleet and servicing management tool.

Each unit is supplied completely wired internally and only needs connection to a single phase electrical supply, intstallation costs are therefore kept to a minimum.

t 0 .-. C'J .. o o C'J r---- 512 o •••• •••• •••• . .. TIMEPLAN DATATOTE FUEL MONITOR NOZZLE OPERATED SWITCH NON RESETABLE 8 FIGURE TOTE INDIVIDUAL DELIVERY REGISTER TIC ZEROISATION ON NOZZLE REMOVAL POSITIVE DISPLACEMENT METER LOCKABLE NOZZLE STOWAGE HOOK '----------t-AIR SEPARATOR FLOAT CHAMBER TUSCAN 112 HP FLAMEPROOF MOTOR 1+_____ iCOMPACT GEAR PUMP UNIT WITH BUILT-IN BY-PASS VALVE ROLLED STEEL ANGLE FRAME -f---------I--FLEXIBLE SUCTION CONNECTOR rNOT EXTRAS! I BASE PLAN 0 >:: C'J C'J i I BUT STANDARD FITTING I * DOUBLE SIDED REGISTER o * FLEXIBLE CONNECTOR * AUTOMATIC Z.V,A NOZZLE . !l 1

All measurements in millimetres RONCOL SERVICES LTD. Supply, installation and repair of Fuel Storage and Dispensing Equipment RONCOL SERVICES LTD PETROL PUMP & TANK ENGINEERS * INSTALLATIONS * MAINTENANCE PLAS CELYN BANGOR ROAD PENMAENMAWR GWYNEDD LL346LD Telephone: (0492) 623787 UNIT 3 MAIN STREET SCRAPTOFT LEICESTER LE79DT Telephone: (0533) 418898 •

* A STEEL CATCH PIT IS MORE FLEXIBLE THAN A BRICK BUND * ALL PIPEWORK FROM TANK TO PUMP IS COMPLETEL Y ENCLOSED * PUMP IS WIRED TO JUNCTION BOX READY TO CONNECT TO MAINS ElECTRICITY * NORMALLY NO PLANNING PERMISSION REQUI REO * AS SUPPLIED TO THE GREATER LONDON COUNCI L AND OTHER LOCAL AUTHORITIES * NO BU! LOING WORK REQUI REO * TANKS CONSTRUCTED IN 6mm (%") T HICK MILD STEEL PLATE AND STAYED INTERNALLY * STORAGE TANK AND BUND WALL REST ON 3" )( Z" )( %" ST EEL CHANNEL * PA I NTED REO OX I DE Illustrated 1800 gal. unit complete with Gasboy model 390 Fuel Control K20 unit. Automatic Nozzle and 12' x '%" hose Throughput 8 10 G P. M. calibrated in imp. gal litre measure to customers requirement s The pump illustrat e d is a K5 k ey controlled unit A full RANGE of fuel control units with or without tank installations Ill us trated belo w 180.0. gal. unit complete with Ga sboy mo d el 1820. Automatic N o zzle an d 12 ' x %" h os e. Throughput 8 - la G P. M. ca lib rate d in imp gal or litre measure to c ustomers re q uirements. TANK HOU SED WITHIN A TANK , OUTER TANK HOLDS 10 % MORE THAN THE DERV STORAGE TANK TO COMPL Y WITH REGULA TlONS. OPTIONAL EXTRAS HIGH SPEED PUMPS 18 20 G P. M. AND OTHER FUEL CONTROL UNITS Complete range of Tanks, rectangular or cylindrical, available from 600 to 12000 galls. capacity. A ll installations can be supplied less catch pit to meet individual customers requirements . S p ec i a li st In e quip ment a ll ied to the Pet rol e um & Ch e m ica l Indu st r y Ta nk a nd Pump Insta ll a ti o ns RiVERS iDE WORKS , CAMBR IDG E ROA D, HARUJW, ESSEX CM2 0 2ET TE l: HAR lO W (0279) 3872 7

LAFON SAFETY FILLING LlMITERS

For above or underground tank storage of petrol and diesel, gravity or pump fed.

With forecourt safety in mind, the Lafon Filling Limiters ensure no overfills, no pollution or environmental damage.

With deliveries out of hours no errors in filling can take place.

Full protection against product overfills, damage and pollution costs.

The LAFON Filling Limiters require no maintenance, are used internationally, and do not rely on extraneous products such as electricity.

Safety

its Best) I . F.l.

(Forecourt

at

Ltd. 160 Abbey Street , Derby DE3 3SS T el : 0332 36 96 14 Te lex : 3 77 106 (I F L)

EASTERN COUNTIES TANK CLEANERS LTD. St. Margarets Wharf STANSTED AB BOTTS, Ware, Herts. 5, Brinell Way, Harfreys Industrial Est. GREAT YARMOUTH, Norfolk. TANK CLEANING, GENERAL CLEANING and 24 HOUR EMERGENCY OIL SPILLAGE ANTI-POLLUTION SERVICE TANKS Oil . Spirit· Chemical . Pharmaceutical . Water · Petrol Aviation Fuel· Tank Painting · Tank Removal Descaling of Pressure or Condensate Tanks Pressure testing of Tanks and Pipes Interceptor Pit clearance · Oil spillages Also rehabilitation of below ground Service Station Tanks. Waste Oil Collection and Recycling. Telephone: Ware (0920) 870343 Telex: 817535 Gt. Yarmouth (0493) 602848 Telex: 975422 EASTE RN COUNTIES mNKCL£ANERS Published by the Association for Petroleum and Explosives Administration and Printed hy Miro Press, Bury St. Edmunds.

The Association welcomes the following new members R. Trousdale, Peter Muir, Total Oil Great Britain Ltd.

Anthony Douglas Robertson, Trading Standards Department, Dorset County Council, John W. Wenham, Akzo Coatings plc,

Mr. P Godfrey, WTS Engineering, GMP Bowles, Jack Brinkhurst, A. Boyce, P.M. Services Ltd, J.H. Frith, A. Lambert,

The Association welcomes the following new members R. Trousdale, Peter Muir, Total Oil Great Britain Ltd.

Anthony Douglas Robertson, Trading Standards Department, Dorset County Council, John W. Wenham, Akzo Coatings plc,

Mr. P Godfrey, WTS Engineering, GMP Bowles, Jack Brinkhurst, A. Boyce, P.M. Services Ltd, J.H. Frith, A. Lambert,