26 minute read

News

markets not to have experienced a decline in petrol station numbers over the last 5 years are Finland and the southern European markets of Spain, Greece and Portugal.” “In Finland new station openings are generally lowinvestment unmanned sites, whilst in Spain, relatively new market entrants such as Italy’s Agip and the French supermarket chain Carrefour are responsible for many of the new builds,” she says. The UK was amongst the most heavily affected by petrol station site closures between 2004 and 2005, along with Belgium, Denmark and Ireland. Denmark experienced the most significant network shrinkage with a 7.5% decrease in total site numbers, whilst the rate of closures in Ireland, the UK and Belgium was only slightly more modest with a 5-6% decrease in the number of petrol outlets.

Those Remaining Work Harder To Satisfy Demand

Advertisement

With this national network rationalisation occurring against a backdrop of minor increases in demand for fuel, the average volumes of petrol and diesel passing through western European sites over the last 5 years has increased significantly. The remaining fuel retailers have seized the opportunity to increase individual petrol station sales with investment aimed at maximising the efficiency of each site, Davis says. “In 2004, around 2.6 million litres of fuel was pumped through each western European site on average, compared with 2.3 million litres in 2000, representing a 3% year-on-year increase.” The rise in site efficiency in the last 5 years has been most pronounced in Spain and Luxembourg, with average petrol station volume sales increasing by 10.7% and 8.4% year-on-year, respectively. These two markets, alongside the UK, Austria and Germany had the highest average fuel throughputs in western Europe in 2004. Luxembourg, with a vast number of commercial motorists filling their tanks within its borders, has an exceptional average annual site throughput of 11.5 million litres, compared to 3.7 million litres in the UK, Davis says. “On average, each Spanish site retails 4.7 million litres of fuel and in Austria and Germany, 3.5 and 3.2 million litres per annum, respectively.” These examples help to paint a picture of the potential situation faced by the petrol station networks in those markets with relatively lower fuel throughputs. Sites in markets such as Belgium and Switzerland still only have average throughputs of 1.5 to 2 million litres per annum despite being far more geographically concentrated than their doubly efficient Spanish counterparts. On this basis there is scope for further closures without too much of a furore about petrol station accessibility amongst the motorist population.

Motorist Demand Drives Central And Eastern Europe's Growth

Unlike the situation in western Europe, most central and eastern European (CEE) petrol station networks are increasing in size. Bulgaria and Slovakia are among the markets to have experienced the greatest growth over the last five years with the number of sites increasing 13% and 7% yearon-year, respectively. Asignificant increase in the demand for petrol among motorists in the 9 CEE markets assessed by Datamonitor is driving these investments and means that average site efficiency is still on the up, Davis says. “The 2.3 million litres of fuel sold by the average CEE petrol station in 2000 had increased to 2.5 million litres by 2004.”

Foreign Entrants Reap Benefits

In Bulgaria, it is Austria’s OMV and Shell which have the highest market shares on a per site basis, whilst Shell and BPown the sites with the highest annual fuel throughput in both Poland and the Czech Republic. ConocoPhillips’Jet branded sites feature among the top three most efficient operators in Hungary and have the greatest annual throughput in Slovakia and the Czech Republic. Furthermore, OMV’s average fuel throughput is in line with that of Rompetrol in Romania whilst in Estonia, Norway’s Statoil and Russia’s Lukoil are the two leading players in terms of average annual petrol station fuel sales, Davis says. “Ultimately, it is no surprise that the companies with the highest performing sites in terms of fuel sales across CEE generally belong to foreign new entrants. Where it is a difficult task for national players to rationalise sites without compromising market share and national coverage, it is much easier for new players to enter the market, cherry-picking the best petrol station sites or indeed building super-efficient new ones.”

USA, Petroleum Equipment Institute previews online training program at PEIshow

The Petroleum Equipment Institute (PEI) previewed a new online training program at the 2005 Show in Las Vegas, Nevada.

The PEI Learning Center is an Internet-based learning program designed to help owners and operators of petroleum storage systems better understand their equipment. Each course features streaming video, interactive quizzes and downloadable support material.

The training is geared toward the owners and operators of petrol stations, convenience stores, truck stops, fueling depots - any facility that stores or dispenses automotive fuel. “Until now there has been no standardized training available for the tank owner and operator,” Robert Renkes, executive vice president of PEI announced. “These courses allow owners, managers and employees to learn the mechanics of proper maintenance and operation of their underground petroleum storage systems.”

Each course is compiled with input from a panel of industry consultants, equipment manufacturers, installers, distributors, service companies, tank owners and environmental regulators. Courses currently available pertain to automatic tank gauges, single-walled pressure systems, secondary containment and spill/overfill protection. “These are just the first offerings in our course catalog that debuts December 1,” said Robert Renkes, adding, “Future courses are already being planned.”

Courses are priced at $79 each and generally can be completed in one hour. Quantity discounts and customized solutions are also available. To learn more, visit www.pei.org/learn or contact the Petroleum Equipment Institute.

News USA, PEI releases new document for inspection and maintenance of motor fuel dispensing equipment

The Petroleum Equipment Institute (PEI) has produced and released a new Recommended Practice aimed at inspection and maintenance of motor fuel dispensing equipment. This new document applies to fueling equipment intended to dispense gasoline, diesel, and related petroleum products into motor vehicles at commercial and retail fueling facilities. Equipment covered includes all above-grade, liquid- and vapor-handling components, from the base of the dispenser cabinet to the nozzle spout.

The purpose of the document is to provide a basic reference that consolidates published and unpublished information from equipment manufacturers, installers, and end users concerning the proper inspection and maintenance of motorvehicle fuel-dispensing equipment.

The intent is to provide recommended practices that will:

•Minimize the possibility of fueldispensing system failure

•Reduce fire hazards

•Promote fueling safety

•Minimize environmental hazards

These practices are the consensus recommendations of the PEI Dispensing Equipment Inspection and Maintenance Committee. The committee includes representatives from petroleum marketing, equipment manufacturing and service and installation contracting companies.

Single-copy price for the 54 page RP500-05 is $75 ($25 for PEI members). Discount rates apply for quantities of eleven or more. You can order online at www.pei.org/shopping or www.pei.org/RP500/index.htm or request an order form by calling + (918) 494-9696.

APEA2006: combining AGM, Exhibition, Conference and Industry Awards 2 November 2006, Warwickshire

Aprestigious conference program, an exhibition featuring some of Europe’s leading retail equipment and service providers and an Awards Dinner combine to produce a dynamic and highly memorable industry gathering –APEA2006.

In line with creating a high profile event, the APEAis introducing a series of Industry Awards to the event. These are aimed at recognizing achievement in and contribution to the industry. The four categories will celebrate the best in Health, Safety & Environmental, Quality, Customer Service and Innovation. Nomination forms can be obtained from admin@apea.org.uk and winners will be presented with the inaugural APEAaward at the event dinner.

Debate and case studies will be at the heart of the conference centering on the themes of innovation and legislation.

The event takes place on November 2nd 2006 at the prestigious Royal Court Hotel, Warwickshire.

The central location is close to all of the major road networks and is just 15 minutes from Birmingham International Airport, making it the perfect UK venue for a truly European Event. In addition, the choice of country hotel makes for an informal working environment which brings the industry together.

“By making this move to an affordable, residential hotel dedicated specifically to the APEAevent and its delegates, we are offering the industry a truly focused industry event”, says Bob Conlin Chairman of the APEAEvents Committee.

The APEA has appointed professional organiser Downstream Events Ltd to manage its annual event. “After nearly 50 years, it is time for the event to be revamped. The introduction of the Industry Awards, combined with the skills of an experienced organising team, will help us make APEA2006 an industry date not be missed”.

For further information on APEA2006 please contact Emma Faure or Fiona Horan by email on info@downstreamevents.com or on +44 (0)208 932 4505.

Buncefield Storage Terminal Explosion

The oil industry continues to assess the impact of the incident at Buncefield terminal, Hemel Hempstead, this morning and is working together to minimise the effect upon fuel distribution, drawing upon the industry’s and the DTI’s response plans for such a contingency, which UKPIAis helping to co-ordinate.

All nine oil refineries in the UK are fully operational. There are no problems with any other aspects of the manufacture of petroleum products or their distribution, other than at Buncefield.

In order to assist with managing the immediate impact upon distribution from Buncefield terminal, motorists are urged to maintain their normal pattern of refuelling.

Enquires to: Nick Vandervell Tel. 0207 632 9880 or Chris Hunt, UKPIATel. 020 7240 0289

HSC orders HSE investigation of Buncefield oil depot incident

The Health and Safety Commission (HSC) has formally asked the Health and Safety Executive (HSE) and the Environment Agency to investigate to investigate the incident which happened on December 11th 2005 at the Buncefield oil depot; to appoint an Investigation Board with an independent chair and to make a special report to the HSC as soon as possible.

Announcing the decision, Bill Callaghan, Chair of the HSC, said: “Earlier today I met representatives of the local authorities with responsibility for environment, regulation and business. They made clear their concerns that there should be no delay in sharing with industry and communities close to major hazard sites the lessons learnt from this incident. I fully agree. Given the nature

of the incident, both on- and off-site risks need to be examined. The HSC has made clear the need for the investigation to proceed impartially and without delay and for the conclusions to be made public.

“I know that HSE and the Environment Agency are committed to speedily publishing information on matters being scrutinised by the Investigation Board that require immediate attention by the industry and other stakeholders.”

HSE and the Environment Agency’s terms of reference with regard to this incident are to: ·ensure the thorough investigation of the incident, the factors leading up to it, its impact both on and off site, and to establish its causation including root causes;

·identify and transmit without delay to duty holders and other appropriate recipients any information requiring immediate action to further safety and/or environmental protection in relation to storage and distribution of hydrocarbon fuels;

·examine the HSE’s and the

Environment Agency’s role in regulating the activities on this site under the COMAH Regulations, considering relevant policy guidance and intervention activity;

·work closely with all relevant stakeholders, both to keep them informed of progress with the investigation and to contribute relevant expertise to other inquiries that may be established;

·make recommendations for future action to ensure the effective management and regulation of major accident risk at COMAH sites. This should include consideration of offsite as well as onsite risks and consider prevention of incidents, preparations for response to incidents, and mitigation of their effects;

·produce an initial report for the HSC and the Environment Agency as soon as the main facts have been established. Subject to legal considerations, this report will be made public; ·make the final report public.

The investigation will be overseen by a Board, which will report to both HSC and the Environment Agency. The Board chair will be independent of both bodies. It will also include independent members with relevant expertise, as well as staff from the Environment Agency and HSE. The HSC Chair will approve the membership of the Board.

The Commission will publish the special report, pursuant to section 14(5) of the Health and Safety at Work etc. Act 1974. The Commission has also requested that any information transmitted pursuant to the second indent of the terms of reference above should be made publicly available.

Bill Callaghan concluded: “Our aim as an independent Commission is for the investigation to engage with the public and the local community in as open and transparent a way as possible. We will want the investigation to have the fullest engagement with those running the site, those employed on the site and the wider industry.

Notes

·HSC is an independent body of ten people, appointed by the Secretary of

State for Department for Work and

Pensions, after consultation with organisations representing employers, employees, local authorities and others. HSC’s primary function is to make arrangements to secure the health and safety of workers and the public in the way work activities are conducted; including proposing new law and standards, conducting research and providing information and advice.

·The Health and Safety Executive is a body of three people appointed by

HSC with the Secretary of State’s approval. The Executive advises and assists HSC and has specific statutory responsibilities of its own, notably for enforcing health and safety law. The Executive’s staff of around 4,000 (inspectors, policy advisors, technologists, scientific and medical experts etc.) - is collectively known as HSE.

·The Commission has exercised a power under Section 14(2)(a) of the Health and Safety at Work etc. Act 1974, under which it: “may at any time direct the Executive... to investigate and make a special report on any matter.”

·The Buncefield oil depot is subject to the Control of Major Accident

Hazards Regulations 1999 (COMAH) and HSE and the Environment

Agency are the joint Competent

Authority for these regulations. ·HSE’s Major Incident Investigation

Policy and Procedures can be accessed at: http://www.hse.gov.uk/enforce/docum ent_g.pdf

Public Enquiries HSE InfoLine, tel: 0845 345 0055, visit: http://www.hse.gov.uk/contact/index.ht m or write to: HSE InfoLine, Caerphilly Business Park, Caerphilly CF83 3GG.

E & S Environmental Services Links up with leading UK Fuel Management Company

E&S, the Witney based specialists in diagnostic tank testing, has been chosen by leading US company AlgaeX to market their innovative range of fuel systems management units within the UK and Ireland.

Mobile and static tank cleaning systems, on board fuel conditioning units, fuel polishing and filtration systems, and highly advanced fuel catalysts are some of the products available through a new subsidiary company – E&S Fuel Improvement Systems Ltd.

Engine mounted units (LGX Series) convert a higher proportion of each litre burnt into useable energy, improving mpg, reducing exhaust emissions and increasing filter and injector life. At today’s high fuel prices even a 1% saving can be substantial – but at a typical range of 2-8% saving, serious reductions in fuel bills are already being made by fleet operators.

Mobile tank cleaning machines (MTC Series) restores dirty fuel to optimum combustibility while cleaning the tank at the same time. Wall mounted fuel polishing systems (FPS Series) keeps fuels in pristine condition while removing sludge and water from tanks and the STS Series conditions and

filters stored fuel for emergency generators. And with the inclusion of the advanced catalyst, more of the tanks residue is converted into usable fuel, with any fungal build up removed and the fuel stabilised and quality restored.

All diesel, gas oil and petrol users can benefit – bus & coach fleets, heavy and light commercial vehicle operators, generator hire companies, contractor’s plant, quarries, marine vessels, military vehicles – in fact cost savings and environmental and operational advantages are there for any organisation that uses or stores fuel.

E&S have recruited James Davies, late of Kuwait Petroleum and Texaco, to head up the marketing effort as Sales Manager. Gilmore Services of Belfast are appointed distributors for N. Ireland and Irish Pump & Tank of Dublin will cover the Republic of Ireland.

E&S Fuel Improvement Systems Ltd Unit 14 Viscount Court Ind. Est. Brize Norton Oxon OX18 3QQ

Tel: 01993 852419 Visit web: www.algae-x.net for more details Contacts: E&S: James Davies (M) 07812 166209 Gilmore Services: Matthew Gilmore 028 9065 1234 Irish Pump & Tank: Nat McCoy 0035 31 6267544

BPTeams up with Marks & Spencer

In a new concept for BPis to be on trial at eight key BPConnect petrol stations as the major UK food and clothing manufacturer Marks & Spencer have launched a “Simply Food” concept at the BPflagship site in LondonFlyover in Hammersmith. The concept will be targeting customers to use the very popular branded M&S convenience food at the petrol station forecourt. Graham Sims the BPRetail Director says this exciting pilot is moving BPfrom a fuel retailer to a true convenience retailer.

Shell Appoints New Contractors

Shell has appointed JOHNSON CONTROLS to provide facilities management at 13,000 of its retail petrol stations in 24 countries throughout Europe and Asia under a five-year, multi million-dollar contract.

This is reported to be the largest contract ever made in the retail fuels market. The contract includes responsibility for the maintenance of Shells retail fuel systems, forecourt image, retail facilities, infrastructure including mechanical and electrical services as well as providing safety and security systems.

Catalist Limited sign agreement with BPOil UK Limited Retail Dealer Business to provide the daily PriceViewer Service

Catalist Ltd and BPOil UK Ltd announced today that they have signed an agreement to provide Catalist’s PriceViewer service to all BP’s independent fuel retailers in the UK.

Catalist’s unique service for independent dealers will be available to BP’s new dealers and any existing dealers renewing their supply agreement. Dealers mid-term may also take advantage of this service at prices negotiated by BP. The service will enable the dealers to monitor competitors’prices by grade on a daily basis, thus allowing them to manage their own site’s pricing more effectively.

PriceViewer is based on Catalist’s fuel price data, which is obtained for all sites in the UK that accept Fuel Cards. Information on the previous day’s transactions is collected and processed each morning, matched against Catalist's petrol station database and loaded into PriceViewer ready for immediate access.

The system is entirely Internet-based and easy-to-use, enabling the dealers to make informed pricing decisions based on current and accurate data.

“Having reliable price information for your local trade area is a key element of the professional approach to managing any Dealer business and as a consequence of this agreement with BP we are pleased to be providing our daily PriceViewer service“, commented Nigel Lang, Catalist's Managing Director.

“Catalist’s PriceViewer service will save our Dealers the time and expense of checking on their local pump prices every day. Having reliable and accurate local pricing data is crucial in today’s competitive market” said Tim Laffan BP’s Commercial Fuels Manager.

If you would like to find out more about PriceViewer, please contact:

Arthur Renshaw Country Manager, UK and Ireland Catalist Ltd. Tel: +44 (0) 117 923 7113 Fax: +44 (0) 117 923 7166 Email: arthur.renshaw@catalist.com

LCM and Tanknology combine forces to develop petroscope

Following a successful demonstration of Petroscope at Total Hemel Hempstead, Liquid Cargo Management (LCM) and Tanknology have joined forces to market and operate Petroscope within the UK.

Petroscope is a highly capable remotely operated camera that can access the tank through the fuel filler pipe. It enables a detailed visual inspection of an underground storage tank (UST) to be undertaken. The inspection is recorded on DVD and given to the client with a written report and recommendations as to future action that may be considered eg man entry for visual inspection and repair.

Petroscope also enables NDTtesting but only in the area of the striker plate, the most common area of tank failure.

Tanknology will operate Petroscope and LCM will provide all support to the operation; securing the area, degassing of tanks, fuel uplifts, storage on site, pipe work etc.

Anumber of clients have expressed interest in using Petroscope. The usual method of operation will be to agree a 48hr closure of a forecourt site so that all tanks can be inspected. The client then receives a report on the tank condition so that future action may then be planned. The system enables preliminary inspection without the need for man entry.

Darrin Francis, Managing Director of Tanknology (UK) commented: ‘Tanknology enables thorough inspection without man entry and is an ideal first step in reviewing the condition of USTs. Our partnership with LCM enables us to jointly offer the oil companies a first class service of the highest standard’

Bob Burnard, Managing Director of

LCM commented: ‘Petroscope enables companies to quickly survey their ‘at risk’USTinventory and then prioritise those that require further investigation. This minimises tank entry and enhances personnel safety. Our partnership with Tanknology is an important development utilising many of our skills and we look forward to providing the oil companies with the highest possible service.’

Tanknology is the UK subsidiary of Tanknology a US based provider of innovative technology and services to the fuel industry. Petroscope is well proven in the USAand is now being introduced to the UK by Tanknology UK.

Liquid Cargo Management Ltd was formed in 1987 and specialises in the safe delivery of hazardous services to the fuel industry. Accredited to ISO 9000:2000, 14001:2004 and 18001:1999 it delivers the highest possible level of customer service whilst considering the environmental impact of all it does with Safety being our No 1 priority.

For further information please contact: Darrin Francis, Tanknology (UK) Ltd: Tel 0870 243 3022

Mark Orr, Liquid Cargo Management Ltd: Tel 01884 841387. www.lcmltd.co.uk

Accurate Refuelling for South Yorkshire Fire & Rescue Services

The importance of accuracy in fuel dispensing cannot be over emphasised at petrol filling stations where fuel is dispensed to the public. The metrology laws are quite stringent and meters are checked for accuracy by both the suppliers and by Trading Standards officials.

The same standard is not a legal requirement for installations where fuel is not sold to the public and indeed much of the equipment on the market would not meet the requirements of a public filling station.

These installations however do need to provide good fuel management, the keeping of accurate stock control figures for health and safety, fiscal and environmental reasons is still the responsibility of those who do not dispense to the general public.

When South Yorkshire Fire and Rescue were recently looking to upgrade their fuel dispensing equipment, they asked their Rotherham based maintenance contractor Pump and Tank Services to advise on fuel pumps that allowed greater accuracy and control when refuelling the fire engines and rescue vehicles.

The company recommended the installation of the Alpha dispenser manufacturer by Hytek. They considered the Alpha to be robust and reliable and provide everything required for safe and efficient fuelling. Available at pumping rates of 70 or 90 litres per minute, the Alpha has a backlit LCD display contained within a stainless steel cabinet to prevent corrosion. Furthermore, fuel measurement is guaranteed to be accurate to +/- 0.5%.

Ian Beaumont, T/Estates Manager, at South Yorkshire Fire and Rescue, said, “The fuel pumps we had been using previously were only accurate to within

4% when refuelling. I was keen to improve this margin as part of the upgrade to help us control our fuel usage more effectively and to ensure we comply with all environmental and safety legislation”

The Hytek Alpha fuel pump is also available with an integral fuel management system, the Alpha FC10. With the Alpha FC10, data access, set up and data tag programming can easily be achieved using the PC based Fuel Manager software, which links to the pump via a GSM modem. For security, drivers can only dispense fuel from the pump using a valid data tag. Hytek data tags are small 100% sealed plastic units, which are durable and hardwearing – and they are guaranteed for life! Data tags can be programmed with all sorts of information including vehicle registration and driver PIN code as well as fuel type allowed.

Petrotechnik forms new company in Japan

Ipswich, UK, PetroTechnik International has formed P& D Japan to manage the sales and distribution of its UPPflexible polyethylene pipework system in Japan. The head office is in Kitakyushu.

One of the new company’s key goals is to help reduce costs for companies managing petrol stations in Japan by providing them with one of the world’s safest and most durable flexible pipework systems. The spotlight has been on fuel leakage problems in Japan for some time encouraging the rapid move towards polyethylene from the more traditional steel pipe.

UPPwas the first polyethylene pipe work system to be approved by Japanese regulator KHK in March 2001

and was first installed in Tokyo in the same year. Since then there have been 350 installations involving 88,000 metres of pipe in Japan in the last four years. Users include ExxonMobil, Showa Shell, Eneos, Cosmo and Jomo. PetroTechnik is the leading worldwide innovator, provider and distributor of UPPpolyethylene containment, piping and tightness testing systems for the storage and transfer of flammable liquids underground. PetroTechnik also designs, manufactures and distributes Cookson & Zinn above and below ground storage tanks and pressure vessels.

PetroTechnik was the first company to use polyethylene pipe for the petroleum market and the first to launch an automated electrofusion process for the seamless jointing of its pipe. Now UPPis widely used in a number of markets including aviation, marine and mining and 6,000,000 metres of UPP pipe have been installed in 128 countries. PetroTechnik has offices in the UK, USA, Brazil, France, Sweden, Australia, now Japan and soon to open, China. Contact: Stephen de Wild Vice President - P&D Japan Tel: +44(0)1473 243300

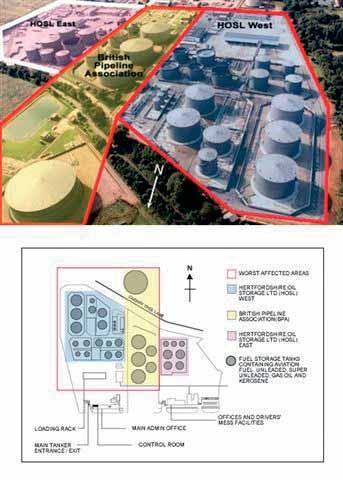

Articles The Buncefield Terminal

By Jamie Thompson

Thanks to Hertfordshire Police Chiltern Support Unit for the photoographs, most were taken from their Helicopter on Dec 12.

The Explosion and subsequent fire at the Buncefield Oil Storage Terminal, Hemel Hempstead, Hertfordshire, soon became national and international news as the dramatic early morning events of Sunday 11th December unfolded on television. Over the following days we continued to witness via our televisions and newspapers detailed film and pictures of ferocious fire and dense smoke plumes such as never seen before We would like to extend our sincere thanks to the Hertfordshire Police Chiltern Support Unit for the dramatic photographs which accompany this article, many of which were taken from their reconnaissance helicopter on December 12th 2005.

The Buncefield Terminal, which is fed by underground pipelines, is a fuel oil storage and distribution depot. It is reasonably modern and is fully compliant with

national guidelines regarding bunds, separation distances etc. There is no reason to consider the facility to be anything but safe and indeed the safety record of not only this terminal but other similar installations within the UK is good.

Viewing the devastation caused by the fire and explosion it is difficult to believe that there was no loss of life. As the explosion happened early on a Sunday morning when there were very few people either on site or in its vicinity it must be assumed that this was the main reason that there weren’t multiple deaths and casualties. It is a spine chilling thought to consider the outcome had this catastrophe occurred during

normal working hours!

The ferocity of the explosion and the engulfment of fire of so many storage tanks caused the emergency services many operational problems. Whilst the emergency services dealt with the incident with true professionalism and bravery it is probable that the industry will learn much from these events.

Following the explosion severe traffic congestion was reported in the area with the adjacent M1 & M10 motorways being closed in all directions. Traffic movement was re-established as soon as it was safe to do so, but much congestion remained thanks to the many sight seers who wanted to witness the devastation first hand and record the incident for all time on their digital cameras!

The Health & Safety Commission (HSC) has instructed the Health & Safety Executive (HSE) to set up an enquiry with an independent chairman to examine the cause and effect of the incident. In view of the substantial damage caused to neighbouring

property it is equally important that the recommended separation distances between installations such as Buncefield and adjacent buildings is reviewed. We await the publication of the report with interest!

What Controls Were In Place?

The Buncefield terminal comes under two principal sets of safety legislation. The first is the Control of Major Accident Hazards Regulations 1999 (COMAH) Statutory Instrument 1999: 743.

These Regulations, which are enforced by the Health & Safety Executive (HSE) require the “Operator” to take all reasonable steps to prevent a major accident and to limit the consequences to the environment should an incident occur. The regulations call for the Operator to prepare a policy document that details the measures taken to prevent a major accident occurring. This document is reviewed and continually revised as and when changes are made. The HSE are also notified of all relevant details appertaining to the site together with details of any significant increase in the quantity of dangerous substances stored on site. The regulations also call for the Operator to prepare an emergency plan detailing both the on and offsite procedures which must be adopted in the event of a major incident occurring.

There is also a requirement for relevant information regarding the establishment to be made available to those members of the public who would be likely to be affected in the event of an emergency. This public information is subject to three years reviews.

The HSE are also required to put in place procedures to carry out an inspection of the site at least once per year.

In the aftermath of any major accident the HSE must analyse all technical, organisational and managerial aspects and is then required to report their findings to the European Commission.

The second item of legislation which applies to installations such as Buncefield is the Pipeline Safety Regulations 1996 Statutory Instrument 1996:825 which provides for the design,