5 minute read

Translating human biomedical technology for fish health and nutrition

Marie-Christine Imbert and Timothy A. Bouley, BioFeyn

Better feed for better fish

BioFeyn is a new company applying technology developed for human biomedicine to improve fish health and nutrition. Using specialized methods for protecting marine ingredients, this technology amplifies their effect. A system of biocompatible and biodegradable encapsulations is at the core of this science and requires only trace amounts of marine ingredients to be effective. The new method enhances digestion, absorption, bioavailability and delivery to target tissues helping fish grow and remain healthy.

This method also has scope to minimize environmental pressures, both in terms of sourcing important ingredients, while reducing pollution associated with nutrient leakage from animal feed and animal mortality-related waste.

It is our ultimate intention that this system enables more and healthier fish for farmers, more demand for sustainable ingredients, and more nutrition for a growing fish-consuming population.

The encapsulation concept

Encapsulation has had a long history in human health and medicine and has been extensively deployed as tool to protect and enable bioactive compounds. Using this technique, nutrients, enzymes, antioxidants, medicines, vaccines and others can be both protected against physical, chemical, and biological stresses and optimized for uptake in the gut and target tissues. The basic premise of protecting and boosting the properties of a “payload” by covering it in another substance works across scale, ranging from nanometers to micrometers and in some instances even at the macroscopic scale.

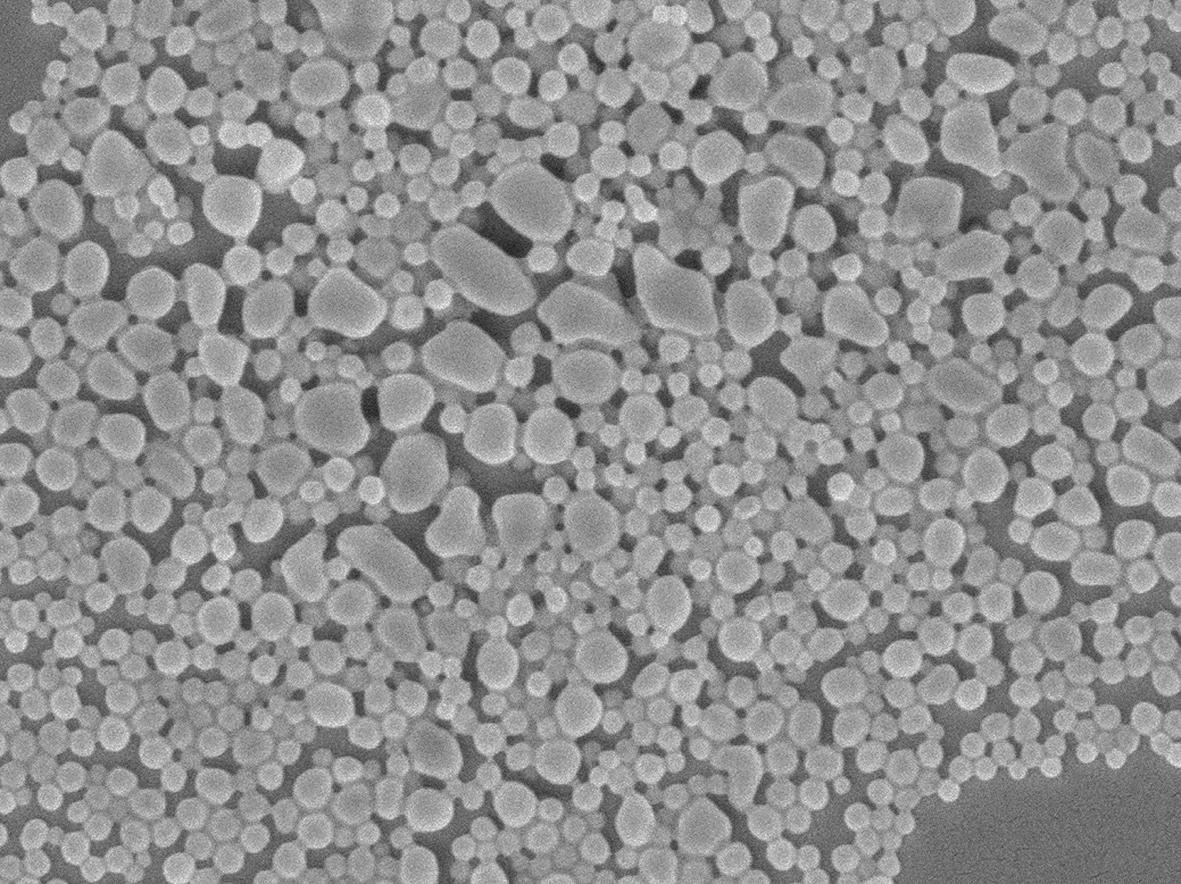

Figure 1. Negatively charged synthetic polymer shell capsules loaded with curcumin.

Table 1. Capsule statistics (from three production batches).

Payload Size (nm) Pdl

Curcumin 196.6 ± 6.14 0.08 ± 0.04

SEM image.

One recent, prominent example of an encapsulation application at the nanoscale is the COVID-19 vaccine. Both the Pfizer and Moderna formulations each contain mRNA encapsulated in a lipid nanoparticle. These landmark vaccines place a spotlight on this critical area of development for future technologies.

BioFeyn products, insights, and challenges

There are many applications of encapsulation technology that can improve aquaculture. BioFeyn solutions, however, focus on protecting the most fragile and limited ingredients. Initially, we have been doing so using nano-scale protections, creating submicron shells and matrices loaded with a compound.

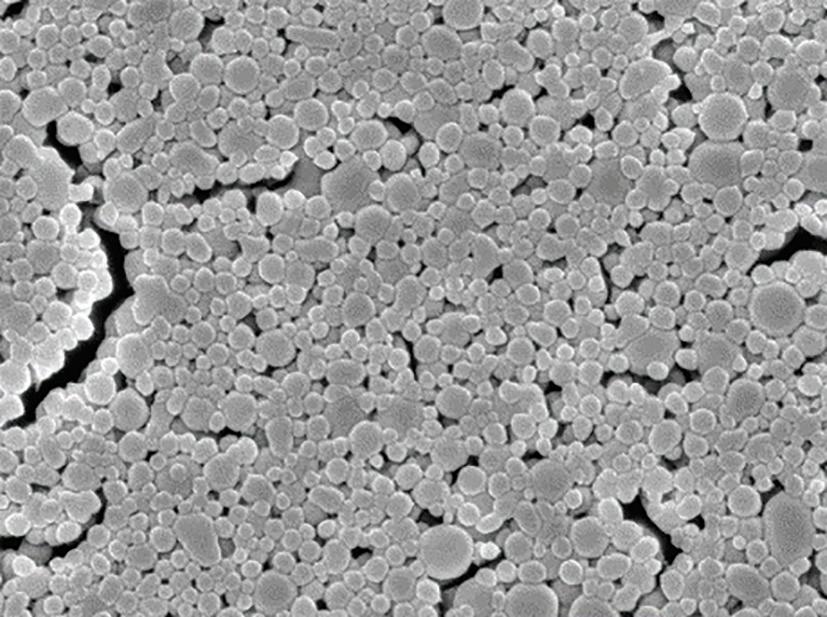

Figure 2. Empty positively charged natural polymer shell capsules.

Table 1. Capsule statistics (from three production batches).

Payload Size (nm) Pdl

Empty 301.5 ± 4.12 0.15 ± 0.01

SEM image.

The reasons for operating at this level and with these techniques are manifold. For example, nano-scale encapsulations can: • Extend shelf life • Improve bioavailability (by increasing solubility), protecting from in vivo degradation, enhancing absorption and facilitating intracellular uptake • Control and sustain release • In some instances, target specific tissues/cells Combining these functionalities can lead to orders of magnitude higher potency. This is as pertinent in aquaculture as it is in human medicine. Adapting nano-encapsulation for aquaculture feed faces two primary challenges: (i) encapsulation of

t0: fluorescently-tagged capsule loaded feed pellets versus control.

t60: fluorescently-tagged capsule loaded feed pellets versus control.

Figure 3. IVIS Imaging of feed pellets loaded with positively charged natural polymer shell capsules with a fluorescent tag.

relevant ingredients and (ii) integration of these enhanced ingredients into feed itself.

Ingredient encapsulation

In collaboration with the “Laboratory of Nanotechnology for Precision Medicine” at the Italian Institute of Technology, we have formulated a range of proprietary nanocapsules containing astaxanthin, curcumin, vitamins and other aquafeed relevant ingredients. Intermediary nanocapsules containing fluorescent payloads for imaging were also produced to demonstrate key attributes of our technology. All encapsulation materials have been GRAS (Generally Recognized As Safe) and/or compliant with EU and US feed additive regulation – critical for future market approval of our formulations. Different capsules were successfully optimized from bioderived and synthetic polymers for each payload. We have achieved consistent quality standards with all formulations, as represented by several wellestablished material science parameters: • Target size below 500 nm • Narrow size distribution with a polydispersity index (PdI) of < 0.3 • High encapsulation efficiencies of the compound, even up to 90% in some cases These parameters are very relevant to application in aquafeed. The small target size allows for the nanospecific properties of formulations (in particular bioavailability benefits) to manifest and means that even compounds added to feed at very low concentrations can be uniformly distributed within the feed. The narrow size range has regulatory and stability implications. The encapsulation efficiency is important for cost minimization.

Figures 1 and 2 show examples of our nanocapsules under a scanning electron microscope (SEM), with the relevant performance parameters for these formulations summarized in Table 1 and 2 respectively, all indicating uniformity in size and shape.

Integration and retention in feed pellets

A range of nanocapsules has been successfully integrated and retained in salmonid feed, visualized by fluorescent-tagging of capsules.

Biomedical imaging systems (IVIS), typically used for 3D visualizations in preclinical testing, were used to

Figure 4. Negligible leakage of fluorescently-tagged nanocapsules from feed.

quantify the integration and retention. Nanocapsulecontaining and control feed pellets were incubated for up to 24 hours in seawater to observe the leakage of capsules. All retention results, even after over 1 hour, were statistically significant. These results clearly demonstrate the suitability of BioFeyn technology for the marine environment and the implications of nutrient retention and therefore animal uptake are self-evident.

Figure 3 shows the strong fluorescent signal from the tagged capsules in the feed pellet versus the autofluorescence of the pellet in the control vials at Time 0 (t0, immediately after immersion in seawater) and Time 60 minutes (t60, after 1 hour of incubation in seawater). The results are quantified in Figure 4. These 3D results indicate the even distribution of nano-capsules within the pellet and suggest they do not leak from the pellet within a meaningful time window for aquaculture applications.

Further results

Beyond the integration into feed, other analyses of the nanocapsules were undertaken - tests of and sustained release profile were all successfully conducted. These results, along with relevant examples of applications in medical and agricultural fields and collaborations with ingredient producers, allow us to anticipate strong results in upcoming in vivo trials. BioFeyn is aiming for commercial-sized feed batches by the end of the year.

Acknowledgments

Paolo Decuzzi, PhD (Italian Institute of Technology) reviewed and contributed to this article.

More information: Marie-Christine Imbert

CSO BioFeyn Inc., US/France E: m.c.imbert@biofeyn.com

cytotoxicity, therapeutic potency in vitro, solubility References available on request.

Timothy A. Bouley

CEO BioFeyn Inc., US/France E: t.bouley@biofeyn.com