3 minute read

Fabrication: London Timber Pavilion

A Study in Timber

London Timber Pavilion

Designer: Schiller Projects

Local architect: Novak Hiles Architects Fabricator: Weber Industries Precast concrete table fabrication: Cambridge

Architectural Precast Landscaping: Fake Landscapes

One morning in July 2020, architectural designer Aaron Schiller was in his New York offices directing a project installation in London. “It was my first-ever FaceTime install,” he said, wincing at mention of the iPhone app. “It was the middle of the pandemic, but I’d really like to avoid anything like it in the future.”

He didn’t have to fret for long. The entire process, whereby a crane lifted Schiller’s prefabricated curio off a residential street and up and over a three-story townhouse, gently nestling it on a rooftop terrace, was completed in 20 minutes.

Just enough time for a number of onlookers to gather. Schiller could see them only at the corners of his phone screen. “I heard one guy just shout out the word ‘pineapple’ and someone else go, ‘Hedgehog,’” Schiller recalled. The spontaneous epithets—evidence of what he calls “an English tradition of nicknaming buildings”—were good-natured plays on the structure’s bulbous, spiky shell.

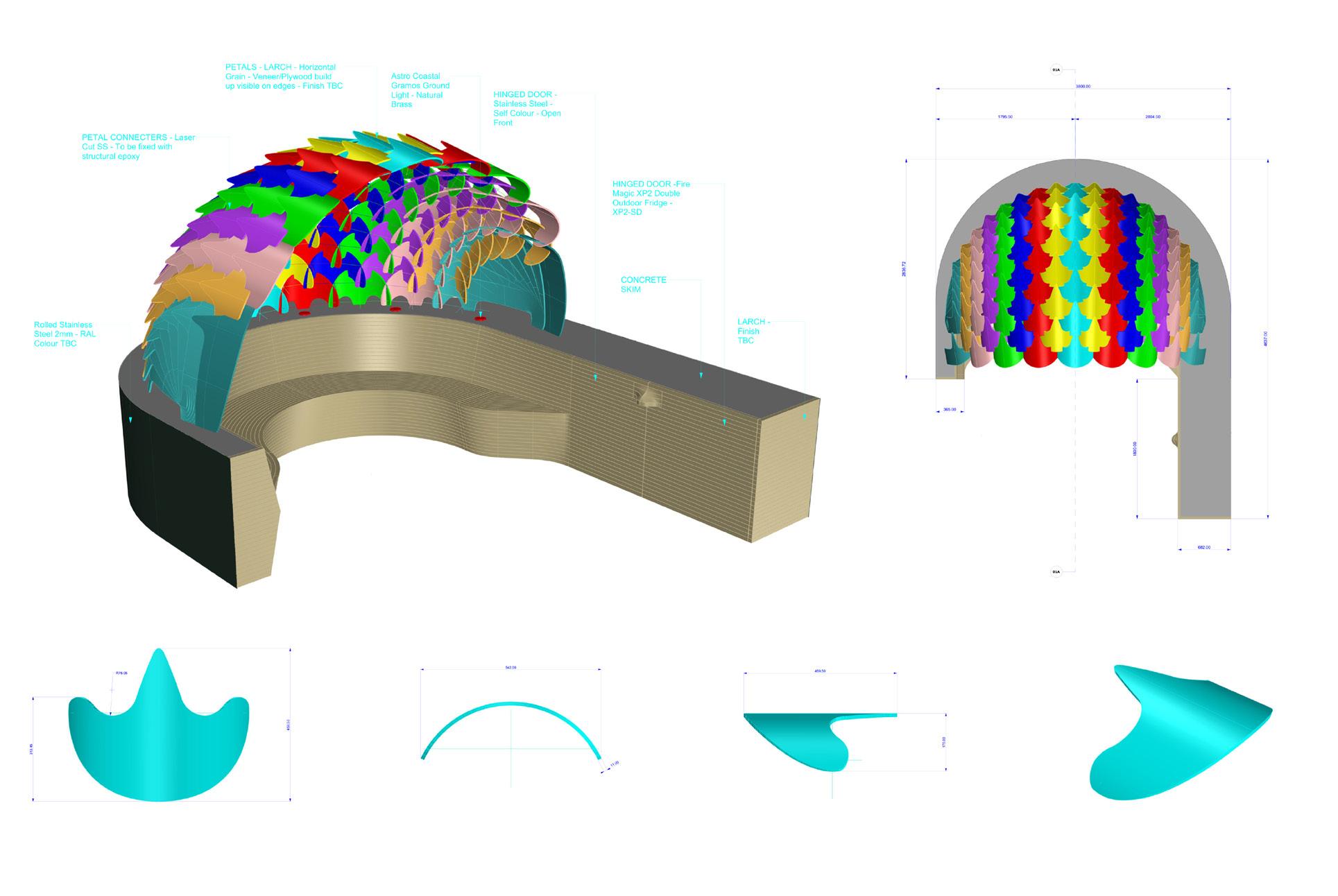

That shell, actually a porous spherical canopy, comprises dozens of interlocking modules made from standard timber sheets. The thin veneers were laminated with epoxy for strength before being milled into individual shapes identical in form but bearing unique cuts called notches. The curvature of each piece echoes the petal-like contour of the greater canopy itself, reinforcing“the self-supporting logic of the structure that makes it possible for the pavilion to be easily replicated at different scales,” Schiller said.

His design practice, Schiller Projects, began by mapping the modules to a sphere while taking into account the head heights of users. The team sent its 3D model to London-based fabricator Weber Industries, which laid it out to the scale of its CNC mill. The laminated, notched “petals” were then steam-pressed over a curved mold. Next, the fabricators fitted the petals together in meridional rows; steel fasteners contribute additional reinforcement in the event of uplift. Once assembled, the quasi dome, accompanied by modular segments of a planter and a curvilinear bench also designed by Schiller Projects, was hauled to the townhouse and craned into place.

Timber, because of its light weight, lent itself well to both the brief and installation, but it also exudes a warmth that is particularly welcoming in a city infamous for its rainfall. The canopy, which, thanks to its shape, readily sheds rain, touches down on the bench at few points. Uplights embedded in the bench cast a moody play of shadows befitting a “garden escape in dense London,” Schiller said.

While he disavows some of the labels the project has inspired (“We aren’t a parametric design office,” he said), Schiller has come to embrace others. “I never really sat down and gave it a name. But ‘hedgehog’ is pretty good, don’t you think?” Samuel Medina

Top: Schiller Projects developed a fabrication model for the London-based fabricator Weber Industries. The color spectrum indicates how the designers rationalized the pavilion’s form.

Middle: The spherical canopy of Schiller Projects’ London Timber Pavilion was prefabricated off-site. house. A crane lifted the canopy up and over the house and deposited it on the rooftop terrace. The same process followed for the accompanying furniture pieces—a bench, storage cupboards, a planter—also designed by Schiller Projects.

Far right: Uplights embedded in the bench create a moody play of light and shadow on the underside of the canopy.

SCHILLER PROJECTS

FRENCH+TYE