September

2023

September

2023

Depending on your point of view, sustainability was either born yesterday or is the oldest trick in the book. The subject is either endlessly fascinating or the site of cringeworthy greenwashing efforts.

The reality is that even by conservative measures, the environmental movement is at least 50 years old, if you count the United Nations Conference on the Human Environment, held in June 1972 in Stockholm, as an origin point. (By then some scientists had known about the potential for human activity to change our climate for over 60 years, though the term global warming wouldn’t be used until a 1975 paper in Science.) Which means: By building standards, the climate crisis is now old enough to be eligible for historic preservation.

Today, we know all too well that construction and the built environment has been a major contributor to carbon emissions, so the many ways that architects can work to reduce future outflows of greenhouse gases into the atmosphere— from small-scale changes in specification and assemblies to advocating for policy that makes a big difference—are valuable. Given this summer’s extreme heat and environmental weirdness—we’ve seen wildfires in Canada and on Maui and the combination tropical storm/earthquake in Los Angeles—the urgency for this work only increases every year.

Building regulations and conventions lag behind the science. Early awareness about architecture’s role in creating sustainable buildings proliferated in the 1960s, but it took until 1993 for LEED certification to be established. Thirty years later, it remains a widely known standard. Still, building codes vary from city to

city, and some municipalities need to catch up to the latest versions of the International Building Code, to say nothing of loosening their zoning strictures. There are many factors that contribute to the carbon footprint of a building; architects should advocate to minimize the items they have control over. Sometimes this manifests in the form of refusal, by delivering buildings with fewer bits and bobs that will break or—to invoke Mies—by simply doing less. Some advocate for an even stricter paradigm under the rallying cry “No new buildings.”

AN takes a material-forward approach to sustainability in this Focus section. Jonathan Hilburg examines a range of companies seeking to decarbonize cement production, including Prometheus, which uses cyanobacteria to produce bio-cement. An interview with William Beer, a decarbonization consultant, establishes major pitfalls for architects when they look to specify low-carbon materials. Alison Mears and Jonsara Ruth of The Healthy Materials Lab at the Parsons School of Design share their work through five vignettes. And Ellen Peirson reviews How to Build a Low-Carbon Home, an exhibit currently on view at the Design Museum in London that explores how our homes could respond to the climate emergency. Beyond these stories, a wealth of products illustrated by Contributing Products Editor Rita Catinella Orrell showcase forward-thinking offerings across four categories.

and take your next project from render to reality

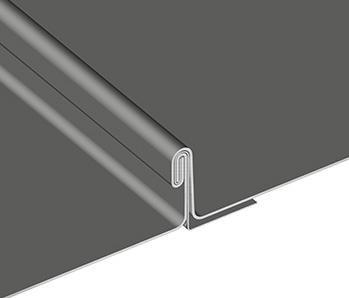

Standing seam metal roofs are the best choice for crystalline PV and thin film solar panels because, unlike other materials, metal offers the longest service life. When installing a crystalline system that typically is warranted for 25 years of power generation, a building owner is going to benefit from a roofing substrate that has a greater life expectancy than that of the solar panels. Standing-seam panels also provide a natural platform for attaching crystalline systems without any roof penetrations. Additionally, highly reflective cool roofs and above sheathing ventilation (ASV) help keep rooftop temperatures cool, resulting in better performance from solar panels.

“As an architect, you don’t want to compromise your design in order to get what you want. You want to have a product that can meet what you need it to do. And we’ve found that Western Window Systems works very well for us.” James M. Evans, Collaborative Designworks

July 2023 was the hottest month ever recorded. Scorching heat, droughts, a disruption of the polar jet stream, and record-high ocean surface temperatures offer just a taste of how climate change is affecting the planet. Yet while the architecture industry is making strides toward shrinking its footprint—firms are doing everything from designing tall timber towers to actively declining commissions for projects like airports— the world is in the midst of a building boom.

That’s a problem if countries want to avoid the worst impacts of climate change, as the 4 billion tons of cement produced every year accounts for 8 percent of total CO2 emissions. That’s over three times as much as the aviation industry produces (2.5 percent) and right behind the U.S. and China, the world leaders in terms of total CO2 produced by entire nations.

Portland cement—the most common type—is

For companies like cement producer Holcim, which joined the Better Climate Challenge in April 2023, that involves a two-step emissionsreduction process. The first is adapting the company’s 13 U.S. cement plants to run entirely on sustainable power by 2030; the second is reducing total greenhouse gas emissions to zero by 2050. Holcim is the first cement manufacturer to partner with the DOE (the other partners are cities, like Philadelphia, and consumerfacing companies, like Kohl’s and 3M).

Holcim has developed a new type of cement that it hopes will lead the sustainability charge. The company reports that producing its ECOPlanet cement creates 30 percent less emissions, even though the result is a material just as strong as Portland cement. It’s able to achieve those reductions by introducing slag and other cement production waste

and coral are built with) in bioreactors using LED lighting that mimics natural daylight. Ambient air from the room is pumped into a tank containing the algae; this supplies the CO2. The algae are then harvested and transferred to a second tank that stimulates calcium carbonate production. This process is complete when all the algae sink to the bottom of the tank, where they’re then collected, dehydrated, and mixed with other natural binding agents. The result is a bio-cement; it’s then ready to be mixed with aggregates to create concrete. When asked whether Prometheus was also seeking to replace the aggregates, Burnett said the company is actively “looking into sustainable replacements for traditional concrete aggregates, including crushed glass, mirror, and shredded rubber” salvaged from construction sites for a true cradle-to-cradle material.

In July 2022, Prometheus Materials closed its Series A funding round, led by European venture capital firm Sofinnova Partners, with $8 million. Funders included industry luminaries like the Microsoft Climate Innovation Fund, SOM, roofing giant GAF, and the Autodesk Foundation. According to Burnett, as Microsoft ramps up construction of data centers around the world, the company wants to use Prometheus’s bio-composite cement to help hit its sustainability targets. The company has also added PAU founder Vishaan Chakrabarti to its board of directors: Burnett said he watched a video on the environmental costs associated with concrete production that featured Chakrabarti and was so inspired that Chakrabarti was subsequently offered the role.

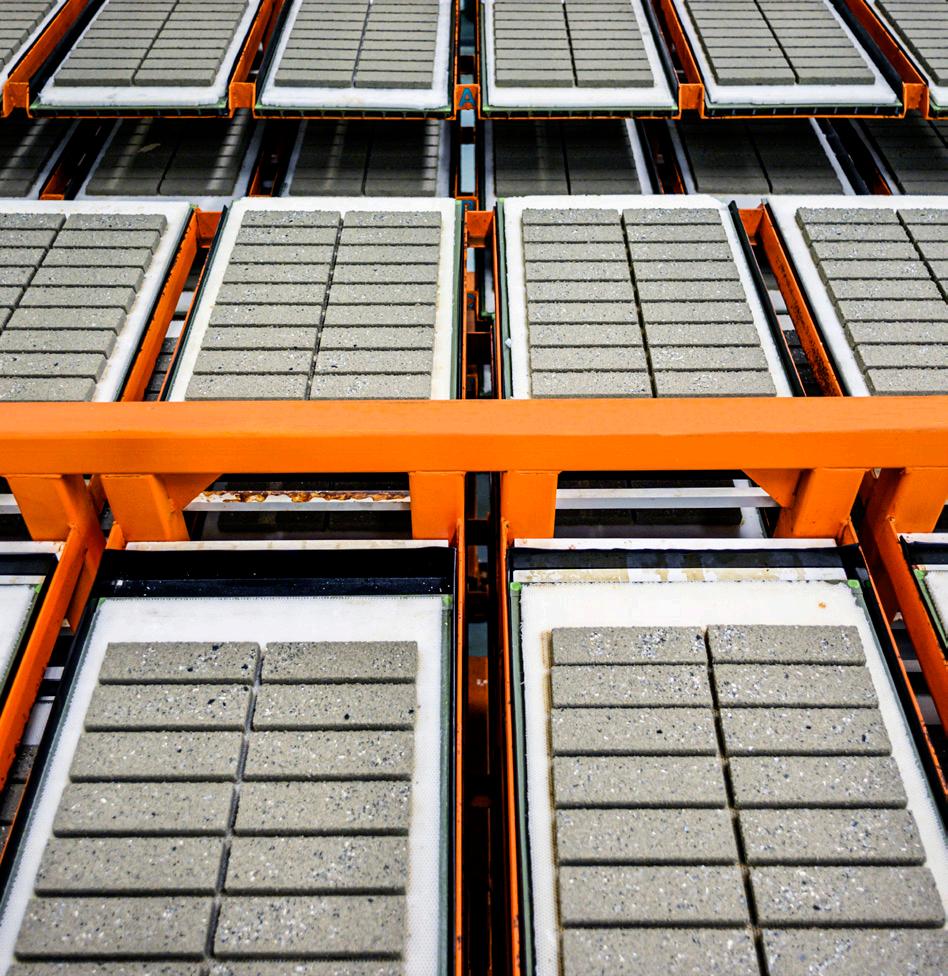

The material, according to Prometheus, outperforms traditional concrete in flex-roll strength by up to four times. It’s 90 percent less thermally conductive, and Prometheus even boasts that its bio-composite concrete is up to 12 times better at absorbing sound, opening up a broad range of applications. Thus far, the bio-composite has received American Society for Testing and Materials C90 (load-bearing concrete masonry units) and C129 (non-load-bearing CMU) certifications. Accordingly, the Series A funding is being used

to develop a line of CMU blocks, permeable pavers, acoustic panels and tiles, and potentially even thermal panels as Prometheus puts out its first “go-to-market” products to establish a foothold in the space.

Prometheus Materials is currently in its Series B funding round, which it expects to close before the end of the year. Then, in the first half of next year, the company plans to use that funding to build out a new precast production facility so it can begin selling products at scale. Rather than attempting to compete with traditional cement and concrete manufacturers, the company wants to license its technology to other companies worldwide and then ship cement mix produced at the factory to licensees as a drop-in product replacement in their own lineups.

The MIT Media Lab is also investigating a similar material, a bacterial bio-cement grown through a similar process around aggregate. This research takes things one step further than Prometheus’s work, prefiguring a world where bacteria has formed a living, embedded web in bricks that can relay pollution measurements or structural health by changing color. While this technology is much more in the realm of theoretical, it’s not hard to imagine a future where even concrete buildings can be built as embodied carbon sinks and relay information without deep technical analysis.

Jonathan Hilburg is an electronics editor at Reviewed who focuses on gaming. Previously, he was The Architect’s Newspaper’s web editor. He lives in Manhattan and is keenly interested in the intersection of art, architecture, and context.

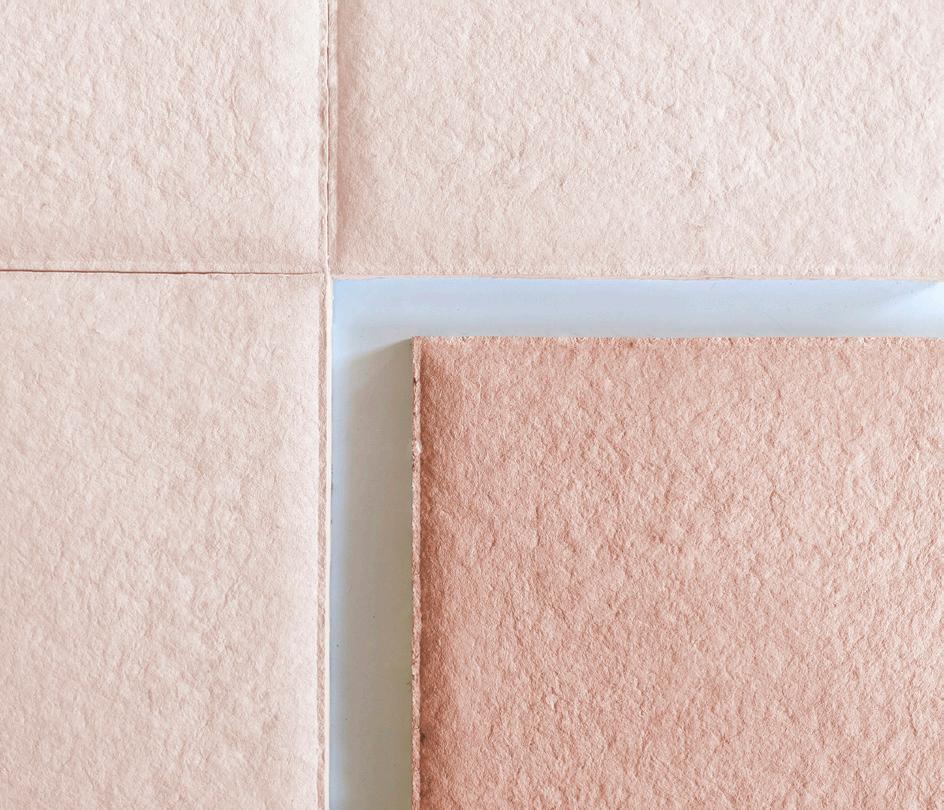

Facing page: Equipment for growing algae in the Prometheus lab.

Below: Finished cement blocks, made with the lab-grown algae.

the binder that, when combined with particulate like sand and gravel, forms concrete. Limestone and silicate clays like feldspar, slag, and shale are sintered together in a kiln to form clinker (small balls of aggregate), which is then ground down further. The majority of emissions from cement production come from this stage, and a reduction of 4 percent in annual emissions yearover-year is required to hit net-zero emissions, according to the International Energy Agency. But in 2022, we didn’t just miss this mark: We increased these CO2 emissions by 1 percent.

With the passage of the Inflation Reduction Act in 2022, $350 million was allocated to the EPA for technical grants, product labeling, and sourcing tools to help manufacturers produce building materials with less embodied carbon and to bring awareness to consumers about these emissions-intensive materials that, ironically, make up most of our built environment. That money will also go toward increasing transparency about the embodied carbon of building materials throughout their life cycle.

The U.S. Department of Energy’s (DOE) Better Climate Challenge is another avenue aimed at helping manufacturers decarbonize. The department offers grants and technical assistance to help partnered companies reduce greenhouse gas emissions by at least 50 percent within 10 years of signing on.

products into its mix. Taking things one step further, Holcim’s ECOPact concrete, which uses ECOPlanet cement and recycled aggregate made from cast-off building material, is already widely available. At the Robert A. M. Stern Architects–designed ELEVEN, a 41-story, 550-foot-tall condo tower in Minneapolis, more than 9,000 cubic yards of EPOPact were used, and Holcim estimates that the switch reduced emissions in the production by 32 percent compared with a typical concrete mix.

There are also companies and research initiatives taking a slightly different approach to decarbonization. Some are looking to grow cement from biological sources and skip the mining, refining, and grinding altogether. The Colorado-based start-up Prometheus Materials began at the University of Colorado Boulder in response to a 2016 building materials grant from the U.S. Department of Defense to use “living materials.” These materials were to be easily grown and able to bind with local, in-situ aggregates, with the goal of protecting high-value assets. Although the brief was more focused on material durability, Prometheus CEO Loren Burnett said the resultant cement replacement also happened to produce zero emissions.

Prometheus is growing cyanobacteria (algae that photosynthesize carbon dioxide into calcium carbonate, the same mechanism shells

“There are also companies and research initiatives taking a slightly different approach to decarbonization. Some are looking to grow cement from biological sources and skip the mining, refining and grinding altogether.”

These new textiles and acoustic surfaces prioritize sustainability. Many products meet or exceed the criteria required to help projects earn LEED, GreenGuard Gold, WELL, and other certifications.

Rita Catinella Orrell

FeltWorks Blades VarAffix Panels Armstrong armstrongceilings.com

RE/8 Bio-Circular Architectural Mesh Kaynemaile kaynemaile.com

Pindrop Rigid Acoustic Solutions Momentum Tiles momentumtextilesandwalls.com

Silicone Symphony Textiles Designtex designtex.com

Nova Textile Keilhauer keilhauer.com

Soltis Loop Sunmate Serge Ferrari Group sergeferrari.com

ARCHISONIC Cotton Acoustic Absorber Impact Acoustic impactacoustic.com

Dash Tile Kirei kireiusa.com

Rita Catinella Orrell

FeltWorks Blades VarAffix Panels Armstrong armstrongceilings.com

RE/8 Bio-Circular Architectural Mesh Kaynemaile kaynemaile.com

Pindrop Rigid Acoustic Solutions Momentum Tiles momentumtextilesandwalls.com

Silicone Symphony Textiles Designtex designtex.com

Nova Textile Keilhauer keilhauer.com

Soltis Loop Sunmate Serge Ferrari Group sergeferrari.com

ARCHISONIC Cotton Acoustic Absorber Impact Acoustic impactacoustic.com

Dash Tile Kirei kireiusa.com

All our products come with a lifetime anti-rust warranty, 15-year adhesion warranty on powder-coated surfaces, 15 year anti-rot warranty on standard wood, and spare parts are always available. This means everything will be looking fresh for years to come.

vestre.com

Bloc Designers Lars Tornøe & Atle Tveit

Bloc Designers Lars Tornøe & Atle Tveit

Our roundup of the latest sustainable insulation and cladding products includes innovative products like power-generating roof shingles, carbon-sequestering building panels, upcycled rice hull siding, and hemp-wool insulation, to name just a few. All prioritize natural and recycled materials in their fabrication. RCO

ALL IMAGES COURTESY THE RESPECTIVE MANUFACTURERS

Carbon-Sequestering Building Panels Croft croft.haus

Hempwool Hempitecture hempitecture.com

The Solstice Shingle System CertainTeed certainteed.com

Natural Cork Insulation ThermaCork thermacork.com

Acre Shiplap Siding Modern Mill modern-mill.com Wildwood Composite Cladding Fiberon Composite Cladding fiberoncladding.com

Comfortbatt ROCKWOOL rockwool.com

TimberFill TimberHP timberhp.com

Carbon-Sequestering Building Panels Croft croft.haus

Hempwool Hempitecture hempitecture.com

The Solstice Shingle System CertainTeed certainteed.com

Natural Cork Insulation ThermaCork thermacork.com

Acre Shiplap Siding Modern Mill modern-mill.com Wildwood Composite Cladding Fiberon Composite Cladding fiberoncladding.com

Comfortbatt ROCKWOOL rockwool.com

TimberFill TimberHP timberhp.com

customers wouldn’t accept the longer lead time, but they told them that the benefit from this change was a reduction of millions of kilograms of carbon dioxide per year. All of their customers accepted the lead times and still paid their invoices, which were due upon dispatch, not receipt. This meant that there was no cash flow change for the company, and they saved money on shipping costs. This is amazing, because we helped them quantify and reduce emissions, and now they have cash to further invest in the business.

Another example: PurOptima has a furnace to dry solvents on their paint line. (They recommend powder coating instead of anodizing because it makes it easier to refinish components.) We made the (expensive) recommendation to capture the heat that was previously lost and to warm their offices with that heat. They soon signed off on it, and it is now in use.

3, which is essentially your supply chain. Often the biggest footprint isn’t what happens in the company but the materials you purchase. You might invest in solar, but you’re still buying steel from India or Turkey, or you’re buying timber but it’s not FSC-certified that comes from Brazil or Indonesia. We try to home in on scope 3—this is where companies are focusing their attention if they’re ahead of the game.

What should architects be aware of when trying to make environmentally sound sourcing decisions?

There’s one main thing that buyers get wrong. They look at environmental product declarations (EPDs), and 90 percent of those aren’t worth the paper they’re printed on. If an EPD covers multiple categories of products, it’s absolute garbage, and I don’t think these should be allowed.

Greenhouse gas emissions fuel global warming. How can we accurately reduce them?

Measurements are a good place to start, and we currently track them across three distinct scopes: (1) direct emissions; (2) indirect, owned emissions; and (3) all other indirect emissions, upstream and downstream. It’s often not an expertise that companies possess internally, so a consultant can aid in this process.

To learn more, AN ’s executive editor, Jack Murphy, spoke with William Beer, CEO of Tunley Environmental. Trained as an engineer, Beer now leads a team of scientists who work with companies to provide assessments of carbon, biodiversity, toxicology, and resources. They have handled assessments of everything from Botox to the Port of Detroit.

PurOptima, a commercial glass wall partition system specialist for offices in the U.S., is a client of Tunley’s and appears in the following conversation as an illustrative case study. The company, known as Optima in the U.K., where it is headquartered, manufactures its systems using Hydro CIRCAL 75R recycled aluminum, which includes a minimum of 75 percent recycled, postconsumer aluminum scrap. To deal

with the full life cycle of its products, Optima also repurposes build-outs as part of its Reuse and Take Back services, in which products are demounted, disassembled, and readied to be reintroduced into the supply chain for new building. (For now, this service is only available in the U.K.) Internal estimates indicate that there will be significant growth in the use of this service by the end of the decade.

When your company conducts a report and presents it to a client, what action do you see? What changes?

Probably 20 to 30 percent of the time, they don’t care. It’s box ticking, or they’re being forced to go through the motions. Cost is a factor, but for some companies, sustainability is actually becoming part of their business model.

I’ll give you an example. We had a pharmaceutical company as a client. We convinced them to stop overnight shipping their products, which are somewhere between drugs and cosmetics. These items aren’t affected by heat or cold, so they don’t need temperature-controlled transport, and they have an incredibly long life span. The company was worried that

How dependent are these assessments on local conditions, like electricity generation? For example, about 60 percent of the power in the U.S. comes from fossil fuels.

That’s a wonderful question. Let’s pick on South Africa for a moment: If you have an electric car in South Africa and you charge it from the grid, it’s worse than having a diesel engine, because their electricity largely comes from coal. And we see very similar examples to that in India and, to a lesser extent, China.

The challenge in the U.S. is that the grid varies from state to state. What that means from an assessment perspective is we actually have to understand that, and our recommendations need to be based on this reality. If you’re in a state with good renewables, we’re more likely to not recommend things like solar because there are probably initiatives that have the same cost that will get a better return on carbon investment. Compare this to states which are more reliant on coal, where we’d have to account for that when trying to achieve net-zero carbon.

Remember: You don’t want to get too caught up in the energy consumption of your organization, because most of your footprint is in scope

So, my first advice is that if a productspecific EPD isn’t available, don’t buy from the company. This requires no real knowledge to implement. This will tell you two things: One, if they don’t have it, they don’t care about the environment; and two, they’re not investing money into being more sustainable.

I’m also always wary of companies that talk about how many trees they plant and stuff like that, because while it is a lovely team-building exercise, it’s not going to make a difference unless you’ve planted millions of trees.

Architects need to understand what carbon is. Why is CO2 bad? They should know this scientifically and be able to deal with the numbers involved. You architects are a huge part of the problem, but you can be a part of the solution. Part of this means you need to understand, learn, and implement this before you talk publicly about it.

Another big piece of advice for architects is to stop buying low-quality products. If something breaks and needs to be replaced, it means this is going to keep happening over the course of a building’s life cycle. It’s important that architects consider maintenance and design with a maintenance strategy in mind. Where

“Updating the relationship between architects and project management could make a difference in the carbon footprint of a build, like with the mobilization of cranes and other pieces of equipment. When your goal is to reduce the footprint of a build, then a WLC is valuable because it allows you to target the points of greatest carbon return.”

possible, it’s best to specify products that can be disassembled, repurposed, removed, and recycled easily, whatever the case may be. Unfortunately, sometimes you might have to take what’s perceived to be a higher carbon cost up front to have a lower life cycle cost overall.

An example: The bulk of a smartphone’s environmental footprint comes from its manufacture, not its use. The takeaway for anyone reading this should be: Keep them longer, and when possible, buy secondhand ones. But then if you look at something like a washing machine, you want to buy a better product with a lower operational footprint, because most of its consumption occurs through use, not manufacturing. This means knowing the difference between embodied carbon and a life cycle carbon assessment (LCA), which is sometimes referred to as whole-life carbon assessment (WLC). Always understand that there are different stages of emissions across a product’s life span.

Updating the relationship between architects and project management could make a difference in the carbon footprint of a build, like with the mobilization of cranes and other pieces of equipment. When your goal is to reduce the footprint of a build, then a WLC is valuable because it allows you to target the points of greatest carbon return. Maybe you need to switch to electric vehicles or run them on an alternative biofuel. It’s best to start this early, like before the preparation of construction documents, so there can be meaningful improvement and a chance to correct bad decisions.

What about building materials?

A lot of architects will immediately jump to the conclusion that everything’s got to be made of timber. In many cases, it’s a great material. Wood is good for things that will stay in place for a long time, but if something is being replaced every decade, that changes the

equation, as wood is hard to recycle and often winds up being incinerated. Other materials, like polyethylene terephthalate (PET), can be recycled essentially endlessly. A plastic bottle can become another bottle over and over again, but once it becomes a garment, for example, it is hard and expensive to recycle it, so clothing is often burned.

How do you account for the carbon impacts of shipping building products around the world?

We should always be talking about LCAs, not just embodied carbon. The latter is often referred to as “cradle to gate”—essentially from the ground until when the item is about to leave the manufacturing facility. For an LCA, you go through transport, implementation, maintenance, decommissioning, and disposal. You must account for logistics.

One of my annoyances is when companies hide behind where the “gate” is. For example, let’s pick on raspberries: You could argue the gate is at the farm, or you could argue the gate is at the ferry crossing or the supermarket checkout. I believe there’s some hiding behind where the gate is, so if I see an important food and it has a low carbon footprint, I always ask where the gate is.

We can also pick on timber. It’s a pain to transport because it’s huge: It has a low density compared to its structural strength, so it takes up a lot of space during transit but isn’t very strong. Steel, on the other hand, has the opposite problem. You can’t fill a container solely with steel because you can’t move it as it would exceed the maximum weight. Another reason why aluminum is nice is because it has great packing density per unit strength.

Tell me about your experience working with PurOptima.

PurOptima has designed their business model around sustainability rather than trying to shoehorn it in. Beyond their own operations, we’ve helped them develop their suppliers’ knowledge about sustainability. For example, they’ve invested a lot of resources to be able to utilize Hydro CIRCAL 75R recycled aluminum to manufacture their systems. This

product has a carbon footprint below 2.3 kilograms of CO2 per kilogram of aluminum produced. This is the lowest carbon footprint of any commercially available aluminum.

Let’s put that in perspective. Oatly’s Original Oatmilk Ambient has a carbon footprint of 1 kilogram of CO2 per kilogram of oat milk. So this Hydro aluminum is only about 2.3 times more carbon intensive than oat milk, which we consume readily without consequence. PurOptima previously used Hydro Restore, which uses 6.12 kilograms of CO2 per kilogram of aluminum. Even sustainable aluminum in the U.K. is required to be about 11 kilograms CO2, and some “unsustainable” offerings land at 26 kilograms of CO2 and maybe even higher.

This change wasn’t easy; it took two years of ongoing conversations, and now PurOptima is the only supplier realizing it in the U.K. and the U.S.

Other industries that utilize aluminum are taking similar steps. Mercedes Benz recently announced it is working with Hydro to use recycled aluminum in their vehicles, but even that change will use a minimum 25 percent recycled content and is planned to be in place by 2030.

There’s greenwashing out there about what recycled aluminum means. When melting down a billet of aluminum, the metal swarf and off-cooks are added back into the production line. These are inefficiencies in manufacturing that shouldn’t be called “recycled,” as it’s an unavoidable part of the process. This Hydro CIRCAL 75R product is a minimum 75 percent postconsumer waste—think aluminum cans and engine blocks. And this minimum is based on the worst batch, as opposed to the average, which will be even higher.

The aluminum part makes sense. What about glass production?

We’re supporting PurOptima’s glass manufacturers as well, and they’re pushing hard on that. One of the challenges is that the equipment to manufacture glass is super expensive. But we are doing a lot of work on heat recovery from the production process. Glass is difficult to recycle once it has been toughened, so what PurOptima is doing now to reduce its carbon footprint is it takes back the glass from prior system installations and then designs new systems around this repurposed, existing glass. But it’s tougher than aluminum, and currently there isn’t an easy alternative.

The repurpose offering is also important. The company keeps track of its installs and is able to reconfigure them into new spaces or clients. Glass walls can be demounted and reinstalled or returned to the factory to be refinished. It’s not an easy process, as things need to be taken down carefully, labeled, and inspected. And then it needs to be transported, stored, and transported again. It’s not easy, but it works for clients who are committed to a lower carbon footprint.

Another thing the company is doing is that they are about to begin quoting the carbon footprint of each build-out in addition to the financial cost. This means the company has invested in the systems to be able to calculate this instantly versus somebody sitting there with a calculator at the end of the process. All the systems must talk to one another. We know that this carbon number is being asked for in bids by architects, contractors, and anyone who is serious about lowering the carbon content of their work.

What else should we be aware of?

If you want to know how an organization is treating sustainability, you have to ask yourself two simple questions: Is it in the board meetings? Is it led from the top? If the answers are no, then it isn’t genuine.

“Architects need to understand what carbon is. Why is CO2 bad? They should know this scientifically and be able to deal with the numbers involved. You architects are a huge part of the problem, but you can be a part of the solution. Part of this means you need to understand, learn, and implement this before you talk publicly about it.”

At Sherwin-Williams Coil Coatings, color is more than just a coating. Through product innovation, a dedication to our customers’ sustainability goals and to our larger corporate commitments, we can maintain a more vibrant world for generations to come. Together, let’s explore the endless possibilities for how color can change the future.

Does your vision include a sustainable advantage? Watch the video to learn how we can help:

coil.sherwin.com/sustainability

Ronald McDonald House Charities | Cincinnati, OH

The latest lighting fixtures shine in more ways than one. Some are 3D-printed from food waste, while others integrate recycled materials in innovative ways or be recycled at the end of life. This roundup offers some of the most responsible new products on the market. RCO

Wood is a leader in sustainable material trends. Among these new products is a technology that uses sliced instead of sawn wood, allowing for ten times more flooring to be produced from the same amount of lumber. Other innovations include a process that ages new lumber naturally and quickly without the need for paints and stains, a chemical-free modified wood made only using heat and steam. All are created with the goal of further optimizing this beautiful natural material. RCO

Kebony Clear Cladding Kebony kebony.com

Coeur D’Alene Wood with Xcelerated Process Coeur D’Alene cdawood.com

Colored Slatpanel Wall Panels The Wood Veneer Hub thewoodveneerhub.com

Lunawood ThermoWood Delta Millworks deltamillworks.com

Wood Composite Air Diffuser InviAir inviair.com

The Montane Collection of Kitchens, Closets, and Furnishings Cabbonet cabbonet.com

Kebony Clear Cladding Kebony kebony.com

Coeur D’Alene Wood with Xcelerated Process Coeur D’Alene cdawood.com

Colored Slatpanel Wall Panels The Wood Veneer Hub thewoodveneerhub.com

Lunawood ThermoWood Delta Millworks deltamillworks.com

Wood Composite Air Diffuser InviAir inviair.com

The Montane Collection of Kitchens, Closets, and Furnishings Cabbonet cabbonet.com

Each chapter of Material Health: Design Frontiers interrogates a material of everyday production.

If we imagine a built world created to support both people’s health and all of nature’s ecologies, environments, and living things, then we need to chart a path different from the one Western culture has forged.

Indigenous voices call attention to the importance of learning lessons from ancient cultures that have lived harmoniously with nature for thousands of years. Indigenous ecological knowledge challenges us to nurture , rather than extract , the planet’s abundant resources. Their regenerative practices support healthy places, and therefore healthy communities, for future generations. Within these Indigenous philosophies there is a fundamental understanding that our shared livelihood is all of humanity’s responsibility. Clean water, clean energy, fertile soils, and healthy, affordable homes for everyone are possible only through reconsidering and regenerating our human activities. What if this were the goal of all of today’s decision-makers?

We—Alison Mears and Jonsara Ruth— cofounded Healthy Materials Lab (HML) at Parsons School of Design in New York City to address these intersectional issues related to designing the built world. As women educators, architects, and designers, we pursue our goal to raise the design and construction bar in housing to provide truly sustainable, healthier, and beautiful housing for everyone.

The problems of climate change and human disease are inextricably linked, and based in large part on carbon emissions. Our work has focused on the field of material health, an ecosystem-first approach. Our work at the lab seeks to understanding the toxic life cycles of common building products—from the mining of raw ingredients to their refining, production, and installation processes. We then move forward optimistically, entering into the discourse and research surrounding emerging circular systems of material reuse. In our recent publication Material Health , we consider these and posit critical points of disruption.

HML works to create a truly sustainable architecture, engineering, and construction industry. We demand ingredient transparency and advocate to reduce embodied carbon levels in the building product supply chain. Our work goes beyond individual materials

or bespoke projects, aiming to influence the industry at scale.

To make change possible, we provide resources to architects and designers so that they can put human and environmental health at the center of all design decisions. Our recent book Material Health Design Frontiers is the outcome of a conference we hosted in 2019, which focused on six themes: air, carbon, equity, ecosystem health, circularity, and ultimately design innovation. Thanks to our 19 expert contributors, including a toxicologist, a pediatrician, environmental justice advocates, materials innovators, artists, architects, and designers, the essays describe many positive ways to change the way we live and build.

Forefronting design examples with a description of the issues that need to be addressed, these case studies show that it is indeed possible to shift the way we conceive

of the design process and the way that has become the conventional construction process.

Our work at HML remains firmly rooted in practice. No content remains purely theoretical. A healthy relationship between the natural world and humanity is fundamental to sustaining and supporting human life. It is time to reject the historic and extractive dualities in Western culture between nature, culture, mind, and body, because they isolate us from the essence of what makes us human and disconnect us from all other species. A new innovative path for decision-making is possible. We need positive, radical collaboration at scale, and the built world will evolve into one that is regenerative, just, healthy, and prosperous for many generations to come.

This change is imperative, and the time is NOW.

“In the Time of the Seventh Fire, which is the time that we are in now, we are told that we would have a choice between two paths: One path they said would be well-worn, but it would be scorched, and the other path would not be well-worn, and it would be green. It would be our choice upon which path to embark.”

—Winona Laduke, Water Protector from the White Earth Reservation in northern Minnesota

The opening chapter of Material Health focuses on the air we breathe—a shared resource that knows no borders. Air quality is a key indicator of both human and environmental health, yet these collected studies here show how the two are inextricable. Laura Vandenberg, a biologist and professor at UMass Amherst, focuses on the distinction between toxic and natural chemicals in our environment; Aaron Dorf, director of Snøhetta U.S. discusses the ramifications of the phrase “healthy materials” for practicing architects today; and Ginger Krieg Dosier, architect and founder of Biomason U.S., discusses how material exploration is, and can, disrupt the construction industry.

The case studies and products explored in the Carbon chapter of Material Health are visually arresting: they playfully present cutting-edge research in forms that are beautiful and often even engaged with pop culture. Items like a new sneaker designed by Adidas appear; the Futurecraft Loop Shoe is made with recyclable Thermoplastic Polyurethane. Also, a designed experiment titled Air-Ink is presented like a tempting Instagram ad: Different plastic containers resembling paint pens, jars of ink and brush marks contain a silky black liquid. What we read as “paint” through this graphic is actually particulate carbon matter ink, dyed with the particular emissions of 19.6 hours of diesel car pollution.

Environmental justice has emerged as a powerful movement in architecture and design circles, asserting that without equal access to clean, healthy environments (and buildings) we cannot claim to reach equity and inclusion goals as a practice or as a society. Collected essays in this Equity chapter highlight the work of Dr. Maida Galvez, whose work as an environmental pediatrician challenges traditional labels and offers “prescriptions” for healthier buildings. But equity in quotidian workplace culture is also explored. Samantha Josaphat-Medina reflects on job (in)security in the AEC profession, particularly for marginalized groups, unpacking the feeling of being “stressed behind the desk,” and she’s not alone.

“Take-make-waste” is how Kate Daly, who directs the Center for the Circular Economy at Closed Loop Partners, described our current economy and patterns of consumption. And while there are many calls for regenerative, non-extractive systems, these are difficult to realize, or even envision, within the current capitalist system we find ourselves in. Circular economy as a phrase in the AEC industry relates often to material flows and recyclability at the end of a building’s life, emphasizing that the end of a building need not be the end of a material. But even small steps like this are parts of a larger financial, economic shift that Material Health scrutinizes in this chapter.

“The use of so much plastic was by design. How could we have been so misguided?” asked Franca Trubiano, practicing architect and professor at UPenn. When we think of ecosystems as the concluding chapter of Material Health, it challenges us to think deeper and zoom out. What is a measurement or a certification if the building (be it net-zero or LEED platinum) sits on a foundation of polymers and fossil fuels? Holistic perspectives as well as holistics applications of data and method are necessary if we want to make meaningful change in our built projects, as practitioners like Henning Larsen are advocating for in this section. We can’t just unlearn, we must work toward new systems of practice and understanding.

Collecting the stories, research and expertise of leaders in the material health field shared at a 2019 symposium, Material Health: Design Frontiers, published in 2022, is an invaluable handbook for architects and designers looking to cultivate a more responsible practice. Centering on indigenous knowledge and strategies for living with and among the natural world, this is a fresh and grounding take on design innovation that goes deeper: an ongoing mission of the Parson’s Healthy Materials Lab’s co-directors Jonsara Ruth and Alison Mears.

Through March 2024

To grind down limestone and heat it with clay, to mine iron ore and power blast furnaces, and to fire kilns—the everyday processes of manufacturing building materials like concrete, steel, and brick—emits huge amounts of carbon dioxide. Yet contemporary construction industries rely heavily on these basic processes. When we talk about embodied carbon in architecture, we mean emissions associated with the extraction, manufacture, transport, assembly, maintenance, replacement, and disposal of all materials that make up a building. These alone account for over 9 percent of global carbon emissions.

The urgency of this may at first feel overwhelming or only surmountable through innovating wholly new ways of building. However, many of the tools we need have existed for millennia: Returning to time-honored processes that center natural materials—such as timber construction, thatching, and stonemasonry—is the key to a low-carbon future.

These concepts are on full display at the Design Museum in London. Curated by Esme Hawes and George Kafka, How to Build a Low-Carbon Home is full of architects and their drawings, tools, scale models, and building materials—but this exhibition is not just for architects. It is an accessible and instructive guide for anyone, showing a new path forward for home-building during the climate emergency. The exhibition is anchored by three London architecture practices that are spearheading the use of natural materials: Material Cultures represents straw; Waugh Thistleton, wood; and Groupwork is stone. The exhibition forms part of a broader research project on low-carbon housing led by Dr. Ruth Lang and the Design Museum’s Future Observatory.

The first material investigation approaches mass timber by starting with the importance of sustainable timber production and forest management. Trees sequester carbon as they grow, but when they die, it is released back into the atmosphere. Building with timber stores this carbon, while planting new trees sequesters more: This is the carbon cycle, and it can facilitate carbon-negative construction. The evolution of engineered timber—layers of raw wood veneers, fibers, or particles bound together—promises to deliver on much of what steel and concrete can. This Waugh Thistleton proves in its work. Fragments of engineered timber plainly show the differences between cross-, dowel-, and glue-laminated timber (CLT, DLT, and glulam), while images of Waugh Thistleton’s mixed-use Dalston Works in London show these methods implemented in the construction of the world’s largest CLT building (10 stories tall). The intimate details of the material are contrasted with its change-making possibilities to show the potential of timber construction for both the self-builder and the large-scale developer.

The next material on view is straw, still suffering from a ruined reputation thanks to three little pigs and a big bad wolf. This display, drawing on the rigorous work of Material Cultures, debunks these myths. Straw here is a broad term that refers to the stalks of cereal plants, but its resurgence as a building material is due to developments that involve combining it with earth, clay, bio-resins, or lime to

make walls, bricks and insulation. Straw is fast -growing and already a natural by-product of grain production. New architectural processes therefore harness this intrinsically untapped potential. The building components made with it are usually air-dried, making it a low-carbon process by avoiding heat-intensive fossil fuel combustion. The beautiful potential of the material is made more visually clear in this exhibition thanks to photography by Oscar Proktor: A new series showcases the walls of Flat House by Material Culture, constructed from timber cassettes filled with a mulch of hemp, lime, and water.

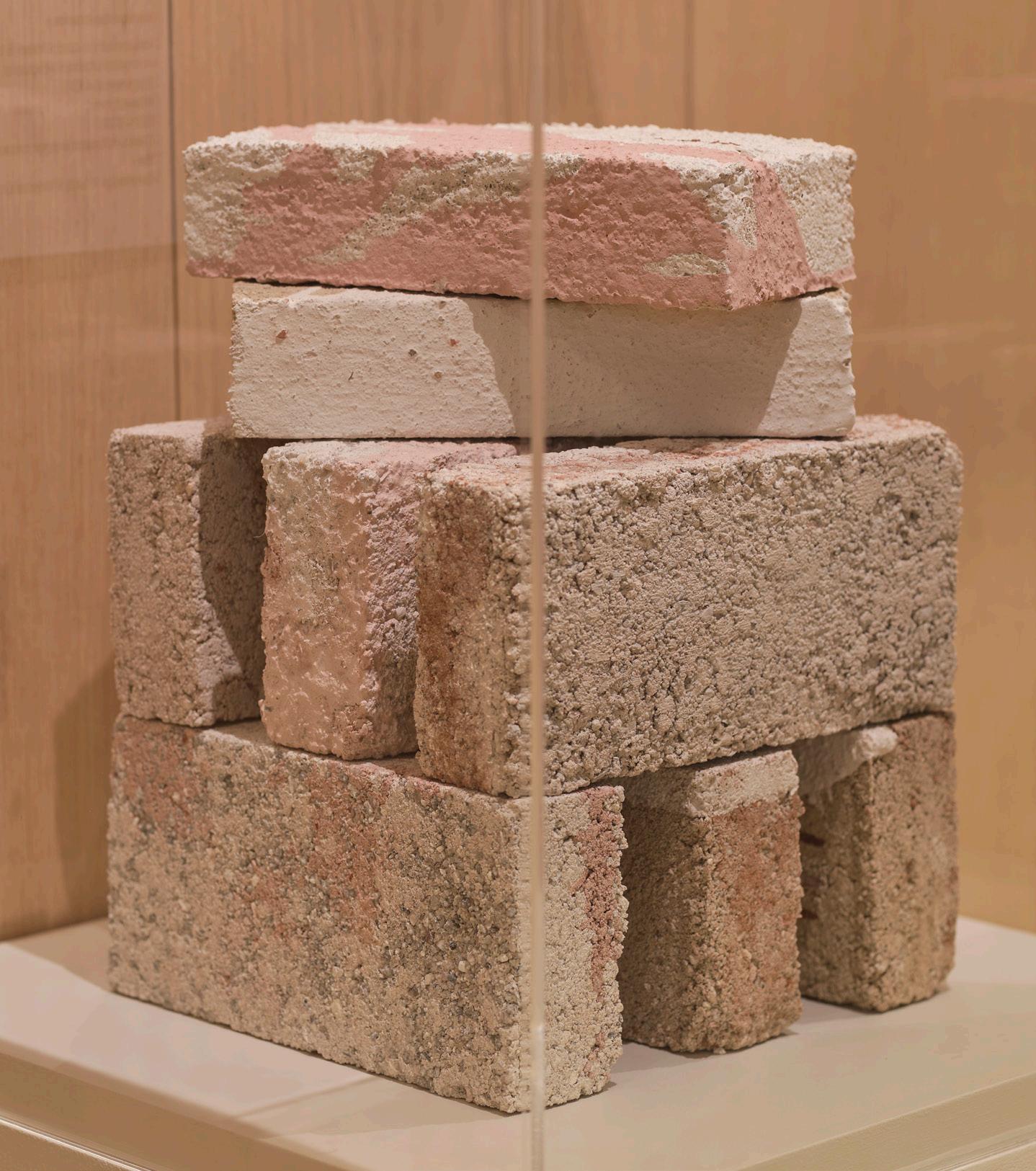

Finally, the stone-focused display shifts gears in terms of technique: Handheld processes replace the loud, invasive ones we usually envision when considering stone. A wire embedded with diamond beads is displayed next to a film by Joseph Bushell that visually describes how something so small and simple can cut through solid rock. A geological map of the U.K. illustrates the makeup of its bedrock and how this has influenced the vernacular. Surrounded by stone samples, the map then illustrates each stone’s material quality and even color, shifting from the burgundy of St. Bees stone to the ashen gray of Clipsham stone. A compelling argument is also made here for the extraction of stone. Unlike concrete and steel, the raw material is construction-ready upon extraction, requiring no intensive

post-processing. The display concludes with the end of the material’s life cycle: the end of the quarry. Quarries can be remediated back to more healthy, natural states, as with the Centre for Alternative Technology in rural Wales, if not completely redeveloped, like Craigleith Quarry in Edinburgh.

So, how can all of this combine into the home proposed in the exhibition’s title? A propositional model by Webb Yates Engineers shows what such a structure could look like. Made with just the materials on display (wood, straw, and stone), it proves the structural possibilities but also displays their charming qualities. Travertine marble is the primary structure, while Douglas fir is used for timber beams. Straw, represented in the model by grass, provides insulation and roofing.

The display shows exceptional work by architects, but it ends with the insistence that projects and practices like these should not be the exception. The wall text asserts the need “to increase the local supply of these materials and train a new generation of skilled construction workers to build with them.” So, How to Build a Low-Carbon Home reminds that we must consider people, labor, and collaboration in addition to materials when building our low-carbon future.

Facing page: Example by Groupwork of straw acting as roofing material.

Left: Installation view on the Design Museum's mezzanine.

Below, left: Model of a stone framing system.

Below, right: New ideas for old masonry technology.

Armstrong armstrongceilings.com

Designtex designtex.com

Impact Acoustic impactacoustic.com

Kaynemaile Kaynemaile.com

Keilhauer keilhauer.com

Kirei kireiusa.com

Momentum Tiles momentumtextilesandwalls. com

Serge Ferrari Group sergeferrari.com

Turf Design turf.design/products

CertainTeed certainteed.com

Croft croft.haus

Fiberon Cladding fiberoncladding.com

Hempitecture hempitecture.com

Modern Mill modern-mill.com

ROCKWOOL rockwool.com

Thermacork thermacork.com

TimberHP timberhp.com

Abstracta

abstracta.se

Empava empava.com

Flos flos.com

Legrand DS+O legrand.us

Light Art lightart.com

Model No. model-no.com

Signify signify.com/en-us

Ty Smyl Lights tysyml.com

Interior & Exterior Wood Bjelin bjelin.com

Cabbonet cabbonet.com

Coeur D’Alene cdawood.com

Delta Millworks deltamillworks.com

InviAir inviair.com

Kebony kebony.com

The Wood Veneer Hub thewoodveneerhub.com

Branch Technology branchtechnology.com

Big Time Software bigtime.net

Buildertrend buildertrend.com

BQE bqe.com

Canvas canvas.io

Codesign getcodesign.co

Configura configura.com

Cove.tool cove.tools

CTRL Building ctrlbuilding.com

Cupix cupix.com

Datacolor datacolor.com

Deltek deltek.com

Dextall dextall.com

Enscape enscape3d.com

FivD fivd.io

Geopogo geopogoar.com

Graphisoft graphisoft.com

ImaginIt Technologies imaginit.com

Langan langan.com

Layer App layer.team

Mercato Place mercatoplace.com

Microsol Resources microsolresources.com

Moetsi moetsi.com

Monograph monograph.com

NavVis navvis.com

Nearmap nearmap.com

NVIDIA nvidia.com

OpenAsset openasset.com

Proving Ground apps.provingground.io

SketchPro sketchpro.ai

Sketchup sketchup.com

Snaptrude snaptrude.com

STRUXI struxi.com

SunStyle sunstyle.com

T2D2 t2d2.ai

Vectorworks vectorworks.net

1to1 plans 1to1plans.com

COURTESY MOMENTUM TEXTILES