Mass Timber

The Architect’s Newspaper’s special, digi tal-only mass timber issue is now in its fourth edition. As always, this focused publication sur veys the growth of one of today’s most promis ing new industries in the world of architecture and construction. This year, we collect relevant project stories from AN’s ongoing coverage of wooden architecture; showcase the winners of the U.S. Forest Service and Softwood Lumber Board’s 2022 Mass Timber Competition:Build ing to Net-Zero Carbon; present an updated industry map that tracks the schools, organiza tions, and manufacturers who are pushing the envelope of this engineered building system; and feature a bevy of new products relevant to timber design and construction.

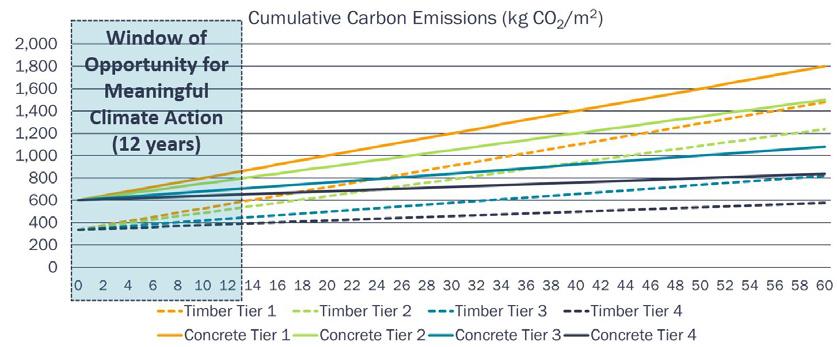

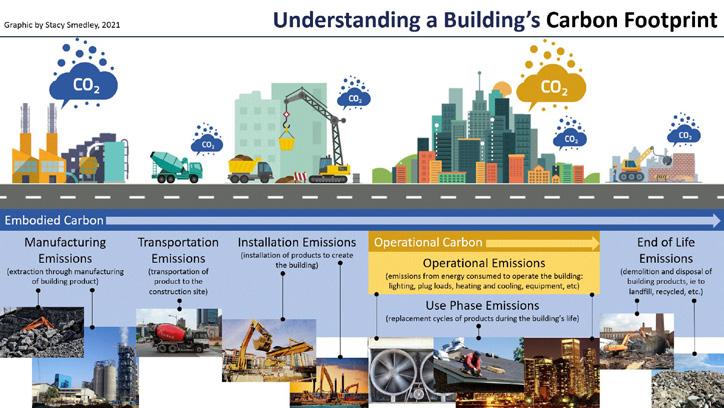

The speed with which mass timber has been adopted as a viable solution for large building types is exciting. In 2021, the Interna tional Building Code approved the material for structures up to 18 stories. And as fire rating concerns continue to be answered positively, the code is also allowing more and more of the wood structure to remain exposed, bringing occupants into direct contact with the beauty and biophilic benefits of wood construction. These advances are especially heartening because the use of mass timber can significantly reduce the embodied car bon of the built environment, though archi tects must be savvy when specifying their

timber products to ensure they come from properly managed forests and along supply chains that don’t cancel out carbon benefits through long transits.

Architects are also having fun with mass timber, which happens when they push the boundaries of structural systems in buildings that are as inspiring as they are ecologically kind. As this issue’s feature, AN Managing Editor JackMurphy conducted an in-depth interview with Pritzker Architecture Prize win ners Yvonne Farrell and Shelley McNamara of Irish firm Grafton Architects. In this piece, they discuss their design for the Anthony Timberlands Center for Design and Materi als Innovation at the University of Arkansas. Through a robust exploration of a material’s expressive possibilities, the architects are now realizing the sectional wizardry for which they are famous in mass timber, a material with which they had not previously worked. The results promise to be truly stunning.

Finally, we recap TimberCon, our annual timber conference, which took place virtually on September 28 with the theme Reducing Embodied Carbon Through Mass Timber . If you missed it, stay tuned for announcements about its 2023 edition. It’s a great way to stay current on the latest in tim ber innovation. Aaron Seward

Cofounder and CEO

Diana Darling

Editor in Chief Aaron Seward

Art Director Ian Searcy

Managing Editor

Jack Murphy

Senior Editor

Matt Hickman

Web Editor

Kristine Klein

Contributing Editor

Samuel Medina Market Editor

Sophie Aliece Hollis

Associate Newsletter Editor

Paige Davidson

Editorial Intern

Trevor Schillaci

Vice President of Brand Partnerships

(Southwest, West, Europe)

Dionne Darling

Manager of Brand Partnerships (East, MidAtlantic, Southeast, Asia)

Tara Newton

Brand Partnerships (Midwest and Canada)

Neill Phelps

Ad Sales and Asset Management Assistant Heather Peters

Program Director

Marty Wood

Program Assistant Chris Walton

Audience Development Manager

Shabnam Zia

Events Marketing Manager Charlotte Barnard

Business Office Manager

Katherine Ross

Design Manager Dennis Rose

Graphic Designer Carissa Tsien

Associate Marketing Manager

Sultan Mashriqi

Media Marketing Assistant Max Gus

Architect’s Newspaper

1552-8081)

by The Archi tect’s

LLC, 25 Park Place, 2nd Floor, New York, NY 10007.

postage paid in New York, NY. Postmaster, send address changes to: 25 Park Place, 2nd Floor, New York, NY 10007.

subscriber service: Call 212-966-0630 or fax 212-966-0633.

$3.95/copy, $45/year; international $160/ year; institutional $160/year.

Entire contents copyright 2022 by The Archi tect’s Newspaper, LLC. All rights reserved.

Please notify us if you are receiving duplicate copies.

The views of our reviewers and columnists do not necessarily reflect those of the staff or advisers of The Architect’s Newspaper.

Skidmore Owings & Merrill (SOM) has com pleted work on the Wellesley College Sci ence Complex, a dramatic redesign of the school’s existing science research and learn ing facilities anchoring the campus’s aptly named Science Hill. Spanning 100,000 square feet, the reimagining project involved both a significant expansion incorporating mass timber and recycled materials as well as the renovation of outdated science build ings on the northern edge of the 500-acre campus of the all-women liberal arts college in suburban Boston. The redesign takes the original science buildings, an array of struc tures designed over the span of several de cades in various architectural styles, and the surrounding landscape to reimagine the en tire site as a cohesive “village.”

A major component of the design was deciding which of the existing buildings could be remodeled and expanded to accom modate the needs of the ambitious refresh while paying mind to historical value and the programming and technological mod ifications required by the renovation. Ulti mately, the L-Wing, a modern 1977 addition to the 1920s-era brick Sage Hall was chosen for its flexibility. Also integrated into the ren ovation and expansion are the several other existing structures and facilities located on Science Hill, including the Whitin Observa tory, the Global Flora Conservatory, the ar boretum, and the botanic gardens.

“Wellesley College is proud of our record educating the highest number of women who go on to receive PhDs in STEM fields among our liberal arts peers,” said Wellesley College President Paula A. Johnson in a state ment. “The new Science Complex will allow us to strengthen our commitment to educat ing the next generation of inclusive STEM leaders by creating a collaborative hub for teaching and research where students, facul ty, and staff can discover and learn together.”

Wellesley College offers a number of de grees within the STEM field; the classrooms, offices, and laboratories housing these facil ities are spread across several buildings. To make way for the reimagined Science Com plex, the architects demolished a portion of Sage Hall, keeping an original brick wall and incorporated it into the new design, re alized as a series of smaller structures. Ship lap and zinc paneling on the facade of the Science Complex and the exposed concrete of the interior inside stand out against the neighboring buildings dotting the college’s lakefront property.

“We reimagined the science center as a village for teaching, learning, and research,” added SOM Design Partner Colin Koop. “The project is a careful mix of removal, renovation, and addition that will give stu dents and faculty a more inviting and en gaging experience.”

At the intersection of the L-Wing and re stored portion of Sage Hall is the Focus, an atrium that spans several floors and opens directly to the outdoors and adjacent hall way with a seamless transition guided by the introduction of new materials including mass timber, which forms the core of the expansion. Staircases, ceiling rafters, win dow framing, and even sculptural furnish ings were constructed using the sustainable building material.

In the L-Wing, a 200-foot-long hallway was transformed into “whiteboard alley.” Off of the main volume, several outdoor decks

were erected, placing study and gathering spaces directly within the landscape. Spatial ly, the layout places the classrooms, offices, and laboratories for similar disciplines near by to one another, with couches, chairs, and tables for gathering integrated throughout.

Henry Fowle Durant, founder of Welles ley, adamantly thought women should be “educated in the midst of beauty,” and there fore the college later commissioned land scape architect Frederick Law Olmsted, Jr. to design the campus to give it that desired beauty. This latest renovation rekindles the original vision of Olmsted, while also intro ducing new gardens or “living laboratories.”

This interactive landscape will be realized

on the site through classroom instruction during the upcoming spring semester.

Before the reimagining project, Welles ley’s science buildings were the least energy efficient on campus. Now, following a retro fit and overhaul involving stormwater cap ture, updated mechanical systems, natural light, recycled materials, and more, the com plex is among the most sustainable on cam pus. As a result of these thoughtful sustain ability measures, the project has achieved LEED Platinum certification—a solid step in the college’s goal to achieve carbon neutrali ty by 2040. Kristine Klein

Above, top: Layered zinc shingles are used on the ex terior of the new portions of the science complex.

Above, left: New construc tion is structured in mass timber columns, beams, and ceilings.

Above, right: The Focus offers seamless transitions to the various existing buildings.

A new academic building on the campus of Trinity University, a small liberal arts col lege in San Antonio, is one of Texas’s first completed cross-laminated timber struc tures and the first mass timber structure in a higher education setting in the sec ond-most populous Texan city. Dicke Hall will house the University’s English and Re ligion departments and serve as the gate way to Trinity’s Business and Humanities District. The 40,000-square-foot facility, de signed by San Antonio’s own Lake|Flato Ar chitects, houses six classrooms, one large lecture hall, a screening room, and multiple collaborative spaces for students in a care fully designed and sustainable building.

Dicke Hall is the first installment of the Chapman-Halsell-Dicke Complex, which is the largest construction project to take place at the university to date. Over the past decade, Trinity has risen steadily in region al and national college rankings thanks to its sizable endowment and 10-year strate gic growth plan titled Trinity Tomorrow. The lecture hall is named after Jim and Janet Dicke, members of Trinity’s board of trustees and alumni of the university. Jim Dicke is the chief executive officer of Crown Equipment Corporation, one of the largest manufacturers of industrial forklift equip

ment in the world. The building’s grand opening on September 23 was attended by Ron Nirenburg, San Antonio’s mayor and an alumnus of Trinity University.

Comprised of large floor-to-ceiling win dows supported by exposed timber beams, Dicke Hall’s minimal modern design com plements the campus’s original red-brick midcentury architecture designed by O’Neil Ford in the late 1940s. Ford designed build ings for college campuses across Texas, including the University of Texas at San Antonio, University of Dallas, and Texas Woman’s University. Ford’s most iconic project, the Tower of the Americas in down town San Antonio, is based off of Murchison Tower, a 166-foot tower he designed for the Trinity University campus.

The founders of Lake|Flato were men tored by Ford and incorporated his for ward-thinking, sustainable practices into the building design. The firm is no stranger to mass timber structures in the state of Texas. Its SOTO office building was named the first mass timber structure in Texas and its Hotel Magdalena in Austin was the first mass tim ber boutique hotel in North America.

“The gateway to the new Business and Humanities District, Dicke Hall establish es a significant urban edge to campus,

bridging town and gown and creating a welcoming portal to the broader San Anto nio community. The craft of the building’s mass timber structure pays homage to the campus’s mid-century modern design her itage while expressing the university’s for ward-looking commitment to innovation in liberal arts education and environmen tal stewardship,” the University stated in a project description.

Dicke Hall features the latest develop ments in green technology by using mass timber instead of steel or concrete. In doing so, the architects dramatically reduced not only the project’s cost, but also its green house gas emissions. According to the uni versity, the carbon sequestered by the tim ber building amounts to 374 acres of forest. Other green solutions include a rooftop pho tovoltaic array capable of generating 78 per cent of the building’s energy. Similarly, hy drology systems within the structure collects and reuses the condensate water for toilet water and for irrigation. The exterior court yard is landscaped with drought-resistant grass and native flora to improve water effi ciency. Pavers and drought-resistant native plantings improve water efficiency around the campus, decreasing the amount of land scaping that regularly requires watering.

The building has also been designed to be free of volatile organic compounds and 98 percent of its occupied space has access to natural light, which also contributes to the building’s energy efficiency while also connecting its inhabitants with the natural environment. Trevor Schillaci

Lake|Flato Architects designs a mass timber structure for Trinity University in San Antonio Dicke Hall is the first installment of Trinity Uni versity's Chapman-Halsell-Dicke Complex. Subsequent updates are expected in ANHerzog & de Meuron has pulled back the curtain on Sixth & Blanco, a mixed-use infill development encompassing an entire city block in Austin’s historic Clarksville neigh borhood, just west of the Texas capital city’s downtown core.

The low-slung mass-timber project fea tures an “urban carpet” of restaurants and retail at street level topped by offices, a hotel, and apartments on the third and fourth floors, which “steps back from the street and decreases in density as it grows taller, allowing for a network of exterior circulation spaces with gardens, court yards and porches on all levels,” the firm detailed. As recently released renderings show, the wood-clad structure (technically a cluster of breezeway-separated buildings oriented around a central plaza and mul tiple internal courtyards) doesn’t so much insert itself into streetscape but politely slinks behind it, rising behind and above existing homes and storefronts fronting West 6th Street in deference to the historic fabric of Clarksville.

Sixth & Blanco isn’t the first project in Texas—or in Austin, for that matter— taken on by the Pritzker Prize–winning Swiss firm. Three years before their 2001 Pritzker win, Jacques Herzog and Pierre de Meuron were commissioned to design the Blanton Museum of Art at the University of Texas at Austin. The duo pulled out in 1999 after deciding that “it would not be practi cal to bridge differences over the interpre tation of the project in the context of the Campus Master Plan,” the university said at the time. The conflict and Herzog & de Meuron’s subsequent withdrawal from the high-profile project prompted the depar ture of Lawrence Speck, dean of the UT Aus tin School of Architecture, who resigned in protest stating that Herzog and de Meuron were put into “positions that compromised their professional integrity in a manner that no top flight architects should toler ate.” The museum was ultimately designed by Boston-based Kallmann McKinnell & Wood Architects.

Over two decades later, Herzog & de Meuron has returned to Austin for a com mission of a totally different kind: a rede velopment project that the “brings a human scale and a sense of domestic comfort to all — instead of a singular uniform gesture, the project is a complex sum of its many individual parts,” the firm said. As men tioned, the design of Sixth & Blanco makes a gracious, Texas-sized effort to blend into its historic trappings, borrowing choices elements of the surrounding environment and incorporating these disparate bits and parts into a “dense yet permeable program” with ample greenery, lively storefronts (new, existing, and reconstructed), and breezy sheltered outdoor spaces including the aforementioned plaza and courtyards. The development also includes plans for a large subterranean parking garage.

As reported by TOWERS last month after developer Riverside Resources went before the Austin Historic Landmark Commis sion’s Architectural Review Committee to present its plans, some existing buildings at the site will be demolished to make way for the new development, also known as Clarksvillage. One business exiting will be the original 6th Street location of chili pork verde-slinging Southwestern chain Z’Tejas.

Properties not demolished will, as men tioned above, be preserved as-is or be recon structed with new facades.

Joining Herzog & de Meuron on the proj ect are Page Southerland Page in the role of executive architect, Ten Eyck Landscape Ar chitect, structural engineer Fast & Epp, and MEP engineering firm Bay & Associates. Flint co has been tapped as general contractor.

AN will report back when further details of Sixth & Blanco/Clarksvillage emerge and the project moves ahead through the devel opment process. Matt Hickman

Sixth & Blanco is a mixeduse infill project in Austin's Clarksville neighborhood that clusters new mass timber buildings around a central courtyard.

Herzog & de Meuron reveals design for mass-timber mixed-use development in Austin

Herzog & de Meuron reveals design for mass-timber mixed-use development in Austin

Timber structures are seeing new heights— quite literally, as the Council on Tall Build ings and Urban Habitat (CTBUH) has named 25-story Ascent in Milwaukee the world’s tallest timber structure. The mixeduse luxury development also received des ignation as the tallest concrete-timber hy brid building. Its first five stories, housing ground-floor retail and parking, rise on cast-in-place concrete.

Designed by Milwaukee-based firm Korb & Associates Architects, this 284foot tall timber tower stole the title of the world’s tallest timber building away from 280-foot-tall Mjøstårnet in Brumunddal, Norway and has also surpassed Vienna’s 276-foot-tall HoHo building as the tallest concrete-timber hybrid building, according to CTBUH.

Although Ascent topped the previous re cord by only four feet, one small margin al victory for tall timber means one giant leap toward more sustainable cities. This tall timber triumph also marks significant progress in mass timber construction at large and a greater effort to build healthier and greener cities under the growing pres sure of climate change.

“We didn’t set out to break records,” CEO of developer New Land Enterprises Tim Gokhman said at the certification cer emony, “We just wanted to create the best experience within the built environment for our residents. Mass timber is faster, more precise, lighter, more sustainable, more beautiful, and supports our commit ment to biophilic design.”

Ascent was the result of about two years of research, testing, and planning, along with the collaboration of external stakeholders and experts from around the world. The tower also received city support: In 2019, the project received unanimous site rezoning approval from the Milwaukee City Council’s City Plan Commission.

According to CTBUH, the use of mass timber for the Ascent’s structural system also decreased construction time by ap proximately 25 percent, compared to a con ventional concrete building of the same scale. Using the “digital twin” construc tion technology, every beam, column, and panel arrived on site with holes pre-drilled to within 1/16-inch accuracy and ready to be assembled. The mass timber is fastened with steel connectors.

The building broke ground just two years ago in August 2020, topped out in De cember 2021, and opened last month, with tenants beginning to move into the luxury development on July 15th.

The mixed-use timber tower comprises ground floor retail, parking, 259 apartment units, with a pool on the sixth floor. Korb & Associates also made a point to leave about half of the wooden elements exposed inside the building, giving the interior a warm finish.

“Ascent is a very exciting project,” said CTBUH Director of Research and Thought Leadership Daniel Safarik. “It is helping ad vance the conversation about how we build more sustainable and healthy cities, espe cially in the face of mass urbanization and the increasing effects of climate change.”

Moving forward, Ascent will serve as a model for mass timber construction, a construction method that has seen signif icant growth in recent years. The building

is a key case study in a CTBUH research project, “Future Timber City: An Aware ness and Educational Program for Future, Sustainable, Dense Cities.” On September 28, AN will host TimberCon in partnership with the Mass Timber Institute, the on line event will showcase exemplary timber

projects across North America—including Ascent in a discussion with Korb & Associ ates Principal Jason Korb—and spotlight emerging technologies within the exciting field. Hannah Su

CTBUH declares Ascent, a tower in Milwaukee, the world’s tallest timber building. At 25 stories and 248 feet tall, Ascent in Milwaukee is currently the world's tallest hybrid concrete-timber structure. COURTESY

The United States Forest Service, an agen cy of the U.S. Department of Agriculture (USDA), and the Oregon City, Oregon-based Softwood Lumber Board (SLB) have an nounced the six winning proposals in the $2 million design competition, Mass Timber Competition: Building to Net-Zero Carbon. The winning submissions—all of which “ex emplified capabilities to design and con struct mass timber buildings in the U.S. that are repeatable and scalable”—were revealed at a press conference held in June at the 2022 AIA Conference on Architecture in Chi cago. Hartshorne Plunkard Architects, ZGF Architects, and LEVER Architecture are just a handful of firms that comprised the win ning project teams. Not surprisingly, Pacific Northwest-based projects dominate the list, joined by winning submissions for mass tim ber efforts in Ohio, New York, and Colorado.

Launched last October with the submis sions period opening in February, this is the second national timber design compe

tition launched in partnership between by the USDA and SLB. The nonprofit Wood Works managed all aspects of the com petition, which aimed to “showcase mass timber’s innovative applications in archi tectural design and highlight its significant role in reducing the carbon footprint of the built environment.”

A wide range of building types—com mercial, institutional, educational, indus trial, mixed-use, and affordable multifami ly housing developments—were eligible for submission so long as the timber sourced for the project demonstrates sustainable forest management and contributes to forest and watershed health. Single-fami ly homes were not eligible and evaluation preference was given to typologies in which timber construction is largely underrep resented including healthcare facilities, large warehouse distribution centers, bigbox retailers, and tall buildings ranging from 6 to 18 stories. Hybrid projects incor

Vancouver Ambulatory Care Center

Vancouver, Washington Medical center

ZGF Architects, Timberlab, Swinerton, and PCS Structural Solutions

According to the team's es timates, the choice of timber saved 1.6 million kgCO2e over a structural steel alterna tive, with another 1.6 million kgCO2e saved in the wood's biogenic storage properties.

High rise multifamily w/ affordable housing units

Katz Development, Timberlab, KL&A Engineers and Builders, and Tres Birds

The team promised to provide carbon reduction and storage benefits in the form of "Car bon Impact Reports" through out the design process.

porating other structural building materi als were also eligible provided that timber products—preferably domestically manu factured—such as cross-laminated tim ber (CLT), nail-laminated timber (NLT), glued-laminated timber (glulam), and dow el-laminated timber (DLT) are the dominant components used.

Winning teams will receive up to $500,000 in grant funding, enabling them to design and build their respective proj ects. As noted in a press announcement, the winners must provide quarterly updates to keep stakeholders abreast of their prog ress, and payouts of competitions funds will correspond to each project’s progress as reported. “Lessons learned from the competition projects will be shared with the broader design and construction com munity to help support future projects, including cost analyses, life cycle assess ments, and other research results,” the an nouncement elaborated.

“The SLB is gratified to see the breadth of concepts and building typologies entered in the competition. With nearly 60 submis sions, we saw excellent examples of the in novative designs mass timber makes possi ble,” said SLB Chief Marketing Officer Ryan Flom in a press statement. “These six win ning designs will serve to advance not just our body of knowledge for mass timber con struction, they will inform the growing shift towards building for occupancy well-being, resilience, and a minimal carbon footprint.”

Without further ado, below are the six winning proposals. Detailed are building type along with the full project team fol lowed by a description and information about each respective project’s carbon im pact as provided by the SLB.

Alaskan Copper & Brass Kent, Washington Warehouse

atelierjones, Foushée, Timberlab, and DCI Engineers

An initial carbon impact anal ysis indicates a 33 percent reduction in carbon emis sions compared to a tilt-up concrete warehouse of the same dimensions.

High rise multifamily

Harbor Bay Real Estate Ad visors, Hartshorne Plunkard Architecture, and Forefront Structural Engineers

According to the Woodworks Carbon Calculator, CO2 sav ings in storage and avoided emissions total 6,483 metric tons, and a 39 percent to 56 percent savings over compa rable alternatives.

Martin Hopp Architect, Consigli, and Odeh Engineers

An early stage estimate using the Woodworks Carbon Cal culator indicates a savings of 359 metric tons of CO2 emis sions through the choice of timber, with another 928 met ric tons of CO2 sequestered in the wood structure.

Killingsworth Portland, Oregon

Community-centric office space

Adre, LEVER Architecture, and Holmes US

According to the team, the use of timber results in a car bon benefit of 407 metric tons of CO2, which is equiva lent to removing 86 cars from the road for a year.

An international design team led by Bjarke Ingels Group (BIG) and St. Louis-founded global practice HOK—in the roles of design lead and aviation architect, respectively— have triumphed in a two-stage design com petition seeking proposals for a new Dock A at Zurich Airport. Located several miles north of central Zurich, the airport is the largest international airport in Switzerland and the main hub of flag carrier Swiss Inter national Airlines. Per a press announcement from BIG, the overhaul of the existing Dock A main terminal facility—a local timber-heavy affair that includes new Schengen and non-Schengen gates, retail, lounges, offices, a new air traffic control tower, and an exten sion of the airport’s existing immigration hall—aims to “strengthen the airport’s con tinued status as the gateway of Switzerland.”

Described by Bjarke Ingels, founder and creative director of BIG, in a statement as “a simple yet expressive design—rooted in tra dition and committed to innovation—em bodying the cultural and natural elements of Swiss architecture,” the future new terminal follows a handful of major new additions to the 74-year-old Zurich airport includ ing the satellite Terminal E and the Airside Center, a multi-building passenger cen ter-slash-shopping mall-slash-parking com plex. Both were completed in 2003. Opening opposite the Airside Center in 2020 as the

largest Swiss commercial development proj ect to date was The Circle, a massive $1.3 bil lion mixed-use complex designed by Riken Yamamoto that features a hotel, convention center, and hospital. The winning team has dubbed the Dock A proposal as Raumfach werk, a German word that, in the words of BIG, can be used to describe a “robust yet flexible structural framework.”

“The name says it all: Space and struc ture get fully integrated and result in a high ly functional and flexible design,” remarked jury chair, the Basel-based architect and ed ucator Harry Gugger. “The backbone of the project is formed by a structure that is not just load bearing, but defines and adapts the space, creates a unique atmosphere, and provides a distinctive identity true to its place and era.”

“This project marks not only a new mile stone for Zurich Airport but for the entire aviation,” added Gugger, noting the jury was “delighted and grateful to endorse such a groundbreaking project that will help to revive sustainable wood construction for great infrastructural projects.”

Joining BIG and HOK on the winning team are Buro Happold (structural engi neer), 10:8 (local architect), Pirmin Jung Schweiz AG (structural engineer timber/ building physics), NACO (aviation consul tant), Haerter & Partner AG (mechanical en

gineer), TLP (electrical engineer), and oth ers. The team’s vision won out over 10 other proposals from a blockbuster roster of firms vying for the project, including Foster and Partners, Grimshaw Architects, and SOM. The win marks the second major European project secured out of closely watched com petition by BIG in a matter of weeks, fol lowing last month’s selection of the firm’s proposal for the future Vltava Philharmonic Hall in Prague. HOK has helmed numerous airport and transportation infrastructure projects, including the lauded new Termi nal B at Laguardia Airport in New York, a major expansion of Terminal D at Chicago O’Hare, and the new Salt Lake City Interna tional Airport that debuted in 2020.

“As airports grow and evolve and as inter national guidelines and safety requirements change, airports tend to become more and more complex: Frankensteins of intercon nected elements, patches and extensions,” said Ingels. “For the new main terminal of Zurich Airport, we have attempted to answer this complex challenge with the simplest possible response: A mass timber space frame that is structural design, spatial ex perience, architectural finish, and organiza tional principle in one.”

In addition to an abundance of locally sourced prefabricated wood elements, in cluding the building’s floors, ceilings, and

V-shaped timber columns that provide “a structural function while also serving as a reference both the iconic Swiss alpine land scapes and the centuries-old tradition of timber construction and traditional pitched roofs,” other notable elements of the new Dock A are set to include a solar shin gle-clad roof with integrated shading, sus tainable cooling and heating systems, and a soaring, natural light-flooded central atrium that serves as the connective tissue between all seven floors, from the subterranean im migration to the upper-level lounges, of the complex. The new air traffic control tower will be placed at the center of the new struc ture, “experienced from the inside as a bea con that creates a sense of place, akin to a town square rather than an airport,” accord ing to the team.

Per Zurich Airport, construction on the new Dock A at Zurich Airport is slated to commence in 2030. The existing Dock A, lo cated just to the north of the planned new facility accommodates roughly one third of arriving and departing passengers, and will remain open as usual while work on the new terminal is underway. It will be disman tled once the new facility is opened.

Matt Hickman Locally sourced wood is featured throughout the ter minal, in the floors, ceilings, and the robust and flexible structural frame, whose V-shaped timber columns recall Swiss alpine landscapes, per the designers. Construc tion is slated to begin in 2030.

Last November, LMN Architects celebrated the completion of its Lakeview Office Build ing. Built for the Bill Gates–owned firm Cascade Investment, the project occupies an idyllic setting in Kirkland, Washington, just a stone’s throw from Lake Washington. It responds to its context with a mass tim ber structure enclosed within a custom-de signed glass curtain wall facade with opera ble windows.

The triangular site is considered some thing of a gateway into Kirkland, so it was im perative to the design team that the building similarly act as such. “The site is a unique shape, and the design corresponds to that,” noted LMN Architects partner Pamela Trev ithick. “The curve on the west side responds to the shape of the site and maximizes views to Lake Washington.”

The 48,000-square-foot project is the first mass timber office development east of Greater Seattle and includes two levels of of fice space, with two levels of underground parking. The client, influenced by other mass timber projects such as T3 in Minneapolis, was keen to incorporate the material within the design. It also pushed for abundant land scaping on the roof, a feature that required an amendment to the municipality’s zoning code. The mass timber components were fab ricated and installed by the Vancouver area–based firm StructureCraft and consist of a Douglas fir glulam post-and-beam frame and dowel-laminated timber (DLT) floor and roof panels. This kit-of-parts approach, support ed by StructureCraft’s intensive design-assist process, facilitated a rapid structural installa tion: The process took just over a month.

With the structure in place, the team

moved forward with the installation of the building envelope. The curtain wall was man ufactured in a collaboration between EFCO and subcontractor Mission Glass with the assistance of facade consultant Morrison Hershfield. Each of the curtain wall panels measures 5 feet wide and is arranged in 20foot modules. Jeremy Schoenfeld, associ ate with LMN Architects, explained that they “had written a more open-ended spec for the project, which noted that [they] wanted a four-sided, structurally glazed, zero-sight-line curtain wall system with operable vents. The Washington State Energy Code really push es you to create a tight envelope and glazing percentages are limited, and highly reflec tive vision glass at the spandrel helped [them] maintain that total glazing look while miti gating solar gain.”

A NanaWall folding door system opens to the rooftop deck, surrounding garden, and the expansive horizon beyond. (Ben jamin Benschneider) The curtain wall sys tem is not dissimilar to that deployed for a standard concrete building; the panels are fastened to straight steel angles placed atop the DLT floor panels. The operable vents are embedded within the panels and arranged so that each standard 10-foot-wide office module has one.

For the large opening that connects the building’s interior to the rooftop garden, the design team opted for a monumentally scaled NanaWall folding door system, which opens to the elevated patio with views of Lake Wash ington beyond.

Robinhood, the Bay Area–based financial services company, is set to occupy the build ing. Matt Marani

The project's mass timber components include a Doug las fir glulam post-and-beam frame and dowel-laminated timber floor and roof panels. ©Update: Groundbreaking, construction kicked off on this project in July 2022.

Global architecture and design firm NBBJ has shared its design for the Lower School campus of Westmark School, a private school in the San Fernando Valley–bound Los Angeles neighborhood of Encino serving neurodiverse students with language-based learning differences such as dyslexia, dys graphia, and dyscalculia.

Westmark’s Lower School, which serves kids in grades two through five, is current ly housed in an outdated cluster of modular classroom units dating back to the 1950s. The extensive NBBJ-led reimagining will transform the existing Lower School into an inclusive and wholly new net-zero ener gy facility where indoor and outdoor spaces

merge to create a nature-integrated cam pus—a greenery-swathed learning environ ment that both stimulates the senses and provides a soothing, concentration-enhanc ing backdrop for Westmark’s youngest stu dents to study and learn in both individual and collaborative settings.

In 2019–2020, 2.3 million students in the United States were diagnosed with learn ing differences like dyslexia. While teaching methods have evolved and adapted to bet ter meet the needs of neurodiverse children, most physical classroom settings, however, remain specifically geared for neurotypical students to the detriment of those who learn differently.

“Embodying Westmark School’s highly specialized education and individualized in struction model, the Lower School provides

a range of adaptable, choice-driven zones to accommodate different types of learn ing, from independent and focused to more communal and active,” elaborated NBBJ in a design statement. “For example, the de sign prioritizes special acoustical strategies to promote quiet study. Designers selected a variety of sound-absorbing materials for dif ferent spaces, developed reading nooks and other niches for creative learning both in side and outside the classroom, and orient ed views to green space to enhance different educational modes.”

NBBJ is acting as design architect and architect of record for the LEED Gold–tar geting project, which is set to kick off con struction in June. Two crucial aspects of the 15,500-square-foot campus—acoustical de sign and landscape design—are being led by Antonio Acoustics and SWA, respectively. The larger project team also includes Suffolk Construction (contractor), KPFF (civil engi neer), tk1sc (MEP engineering), Fast + Epp (structural engineer), and Atelier Ten (envi ronmental design consultant). NBBJ is also overseeing the new facility’s lighting design and environmental graphics.

“We’re really excited about this project and the incredible impact it will have on students, teachers and staff,” NBBJ design partner Jonathan Ward told AN. “The de sign unites the latest in sustainability and neuroscience research to create an experi ence that is truly supportive of neurodiversi ty. The indoor-outdoor environment literally puts nature at the heart, while highly flexible classrooms support a range of diverse learn ing modes—from group work to individual ized learning and everything in between. We

are so lucky to work with Westmark School, while tailoring the design to support both their teaching model and positive learning outcomes.”

Conceived in partnership with neurosci entist Dr. John Media and the larger West mark community, the design of the campus takes on a pinwheel formation in which the individual classroom spaces—all featuring ample natural daylighting and oversized hangar doors opening up to the surrounding landscape—will flank a central courtyard an chored by a giant California Sycamore tree. What’s more, all circulation paths within the campus are located outdoors to “not only to stimulate the senses and provide delight, but to create regular moments of engage ment with the powerful benefits of outdoor learning beyond the traditional classroom space,” according to the firm.

The building materials used in the proj ect, including mass timber and stone, will provide an additional connection to the nat ural environment as part the design team’s overarching effort to promoting cognitive, emotional, and physical wellness through exposure to nature. In addition to the cen tral courtyard, the design incorporates sever al other outdoor gathering spaces including a sensory garden and sculpture play area.

Joining the dedicated classrooms spaces, the Lower School campus will benefit direct ly from an integrated network of programs currently split between Westmark’s differ ent divisions. These services include occu pational and speech therapy, theater space, and school counselor space.

As mentioned, the project is targeting LEED Gold certification as well as Interna tional Living Future Institute Zero Carbon certification. The emphasis on sustainability will not only help to minimize the facility’s environmental footprint but also educate the school’s “future leaders to be stewards of the world.” Planned sustainable features in cluding solar arrays, insulating rooftop gar dens that double as outdoor learning spaces, a rainwater catchment basin at the cam pus-anchoring sycamore tree, and the afore mentioned use of natural building materi als throughout, which will be left exposed so that architecture-curious students can better understand how a building comes together.

And given its focus on flexible, in door-outdoor learning and a design that lends itself to natural lighting and ventila tion, the Lower School is also “well-suited to pandemic needs.”

As noted by NBBJ, the future Lower School Campus acts as a significant bench mark in Westmark’s broader ambitions to be part of a “vital, networked resource of early intervention” that will have a positive impact on neurodiverse children far beyond the school’s Encino campus. Future strate gic plans include establishing an “institute of research and training” that will dispense insights and knowledge to educators at pub lic and private schools elsewhere in Los An geles and nationwide. Matt Hickman

NBBJ unveils a nature-imbued Los Angeles campus for neurodiverse students The mass timber structures flank a courtyard anchored by an ancient California sicamore tree. Natural materials throught the buildings connect students to nature. COURTESY NBBJ COURTESY NBBJCanada suffers no shortage of flatiron build ings, with historic examples dotting the provinces from Toronto to Vancouver to La combe, Alberta, and beyond. Canada also enjoys its status as a hotbed of mass timber construction with Quebec serving as an epi center of sorts for the movement. However, these two things—flatiron building design and the use of engineered wood products— have never yet been combined.

That could change with the Leaside In novation Centre (LIC), a six-story flatiron of fice building proposed for Toronto that will employ engineered wood elements through out including cross-laminated timber (CLT) floor plates and glulam beams and columns. Per the project website, the LIC is among the first Toronto buildings to take advan tage of a change in Ontario Building Code permitting for heavy timber structures up to six stories tall. Provided that planning ap provals go through this May, construction is slated kick off shortly thereafter at the de velopment site at 154 Wicksteed Avenue in Leaside, an affluent neighborhood north east of downtown Toronto. If this schedule sticks, occupancy could begin in early 2024.

Making the most of an irregular but prominently located lot, the LIC team refers to the Wicksteed Avenue development site as a “gateway” to the “emerging” Leaside business district. “This building is the new class A office building, and healthy struc tures will be in demand going forward,” de veloper Charles Goldsmith told AN in an emailed statement.

Designed by Toronto-based architecture and design firm studioCANOO, the finished building, in addition to enjoying a consid erably lowered carbon footprint thanks to the use of renewable forest products in lieu of concrete and/or steel, will weigh roughly 25 percent less than a comparable conven tional structure, reuding load and minimiz ing the use of concrete in the foundation.

Cladding the structure in a thin-brick veneer panel system further adds to its lightweight nature while also referencing the former his toric-industrial trappings of the surrounding neighborhood and improving the building’s insulation and airtightness. studioCANOO’s design features a 40 percent glass-to-wall ratio that “minimizes the size of mechanical systems required in curtain wall buildings,” per the firm. Additionally, the building’s sustainable electrical grid and air distri bution system will be entirely out of sight, tucked away underfloor.

Joining studioCANOO on the LIC design team are contractor Gillam Group, land scape architects LANDinc, and Moses Struc tural Engineers.

Greg Latimer, principal of studioCANOO, elaborated on the origins of the project and the larger mass timber movement to AN:

“When we began this project back in 2017 we proposed a mass timber structural sys tem to the client. They were immediately intrigued by the possibility of recreating a contemporary version of the highly desirable 19th century warehouses that dot the down town core. The first mass timber mid-rise building in Toronto was just getting under way at the time but since then many projects with mass timber structure have been in de velopment approvals and are now starting to break ground. I think this indicates that mass timber has reached a tipping point and

will become more commonplace both in our local market and throughout North America in the coming decade. These buildings, with their many benefits, are being well received by owners and tenants and it gives architects another major tool to improve the overall sustainability of their projects.”

In addition to its inherently sustainable nature as a building constructed from en gineered wood products, the LIC’s interi or spaces will feature 11-foot-tall ceilings and plenty of exposed wood, which togeth er with an abundance of natural light and easy access to outdoor green space, intends to foster a healthier and more productive work environment—obviously important for a commercial office building. Tenants on the sixth floor will have access to a spacious, south-facing terrace while ground-floor ten ants will enjoy their own exterior amenity space on the north side of the building. The project also entails the creation of a planted parklet at the corner of Clarke and Wick steed, which will be adjacent to a planned ground-floor cafe.

Complementing the project’s sustain able bona fides, LIC will be a convenient five-minute walk from Leaside station, a forthcoming stop on the new Eglinton Crosstown light rail transit line due to open later this year. There will also be two levels of parking tucked beneath the building, with 20 percent of the subterranean space devot ed to parking for electric vehicles. There’s also plans for a secure indoor parking area for bike commuters with space for up to 30 bikes.

“Our triangular site offered an opportuni ty to reinterpret the classic flat iron building with a contemporary approach employing a mass timber structure,” added Latimer. “Ex posed wood structure, open, light-filled floor plates and a dynamic building form contrib ute to a striking building on this gateway site to the Leaside Business Park.”

Toronto’s Leaside Innovation Centre will be the first mass timber flatiron building in Canada AN will revisit the LIC when it begins to take form in Toronto. Matt Hickman The structure is primarily composed of glulam beams and columns, and floor plates made from cross lami nated timber. It is one of Toronto's first buildings to take advantage of code adjustments that allow mass timber structures up to six stories. COURTESY

more

18 stories in

timber

Milwaukee’s Ascent, designed by Korb &

example. To do so, architects and builders will continue to rely on local networks of timber knowledge and sourcing. This year, AN shares its annual map of the schools, organizations, and manufacturers that are leading the way in mass timber research and development. These groups, both in Canada and in the United States, innovate quickly, so AN tracks developments through the WoodWorks Innovation Network, produced by WoodWorks, an educational arm of the Wood Products Council, and the U.S. Forest Service’s Wood Innovations program. We have also split this year’s map into two parts to better break down the mass timber industry’s growth across the continent.

University of Northern British Columbia

Prince George, British Columbia

The University of Northern British Columbia’s Master of Engineering (MEng) in Integrated Wood Design is a unique, intensive yearlong program that focuses on modern wood struc tures. The MEng program is housed in the Wood Innovation and Design Center in downtown Prince George and features the Wood Innova tion Research Lab, in which researchers test next-generation materials. The lab’s design meets Passive House standards.

University of British Columbia Vancouver, British Columbia

The University of British Columbia is home to the 18-story Brock Commons Tallwood House. This student housing project was supported by the Canadian government’s Tall Wood Building Demonstration Initiative. The facility not only houses students but serves as a living lab where researchers study the long-term performance of mass timber structures.

At Washington State University’s Composite Materials & Engineering Center (CMEC), the Wood Materials & Engineering Laboratory allows students get hands-on experience with the design, testing, fabrication, and construc tion of CLT panels. CMEC has partnered with resin suppliers and construction companies to design, certify, and test mass timber sys tems for new and existing markets.

Oregon State University Corvallis, Oregon

Oregon State University’s (OSU) College of For estry is home to the TallWood Design Institute (TDI), a collaboration between OSU’s College of Engineering and the University of Oregon’s College of Design. At TDI researchers and practitioners drive research and education on advanced timber products manufacturing, design, and construction. TDI is working on projects focused on durability, serviceability, adhesives, seismic and structural performance, the fire per formance of mass timber, and more. The Oregon Forest Science Complex, which incorporates extensive use of CLT, comprises OSU’s George W. Peavy Forest Science Center and A.A. “Red” Emmerson Advanced Wood Products Laboratory.

University of Alberta Edmonton, Alberta

The Advanced Research in Timber Systems (ARTS) research group is part of the depart ment of civil and environmental engineering at the University of Alberta and is led by Professor

Ying Hei Chui, who holds the NSERC Industrial Research Chair (IRC) in Engineered Wood and Building Systems. The ARTS group focuses its research on the next generation of mass timber construction with new connection techniques.

This field includes the structural and service ability performance of mass timber elements, especially the performance of lateral load resist ing systems. Furthermore, design methods of connections containing inclined self-tapping screws, and the acoustic and vibration perfor mance of mass timber panel-concrete compos ite floor systems are investigated.

Colorado School of Mines Golden, Colorado

Working in collaboration with industry part ners and other schools on this list, research ers at Colorado School of Mines are using a $1.7 million National Science Foundation grant to develop mass timber structures designed for seismic performance in earthquake-prone regions. With the goal of proving that sustain able timber buildings are just as safe as those built with more conventional materials and with higher resilience standards, the group has suc cessfully tested a two-story building on the Uni versity of California, San Diego’s “shake table” and and is now testing a full-scale, 10-story structure as part of the NHERI Tall Wood Project.

Texas A&M University College Station, Texas

The School of Architecture has conducted stu dios and building experiments about mass timber, including last year’s realization of a “construct” object fabricated by students like by Assistant Professor James Michael Tate. The school operates in concert with the state’s for estry service.

Rice University Houston, Texas

In addition to mass timber research previously completed by School of Architecture professors

Albert Pope and Jesús Vassallo, the school is now the site of a new mass timber dormitory designed by Barkow Leibinger with Kirksey Architecture.

Forestry Innovation Investment Vancouver, British Columbia

Publicly owned and funded by the provincial government, Forestry Innovation Investment is British Columbia’s wood products marketing agency. The agency works to sustain the Cana dian timber industry by developing new market segments and export markets, advancing wood use and construction technologies, and market ing outreach to position forest products.

APA—The Engineered Wood Association Tacoma, Washington

The Engineered Wood Association is a nonprofit trade association that works with its members to create structural wood products of exceptional strength, versatility, and reliability. Combining the research efforts of scientists and engineers at APA’s 42,000-square-foot research center with the knowledge gained from decades of field work, and cooperation with our member manufacturers, APA promotes new solutions and improved processes that benefit the entire industry.

Softwood Lumber Board (SLB) West Linn, Oregon

The SLB is an industry-funded initiative estab lished to promote the benefits and uses of soft wood lumber products in outdoor, residential, and nonresidential construction. Programs and initiatives supported by the SLB focus on increasing the demand for finish and struc tural softwood lumber products in the United States as well as mass timber and hybrid build ing systems.

Think Wood West Linn, Oregon

Think Wood provides commercial, multifam ily, and single-family home design and build resources to architects, developers, and con tractors. In addition to its online educational resources, including e-books and continuing education units related to tall wood and mass timber, the organization identifies and profiles projects and professionals using North Ameri can softwood products in innovative ways.

Forest Business Network Missoula, Montana

The Forest Business Network (FBN) helps busi nesses that manufacture, design, and sell prod ucts made from hardwood or softwood. FBN offers timber consulting services based on its expertise in “underutilized timber and woody biomass,” which include business assistance, grants, and custom reports.

Structurlam Mass Timber Corporation Penticton, British Columbia; Con (CLT, glulam, GLT)

Structurlam, North America’s leading provider of mass timber solutions and our manufacturing partner, has expanded their operations beyond British Columbia, Canada, to the U.S. south with their first manufacturing facility in Conway, Arkansas. Structurlam’s Conway mass timber facility will source wood from the sustainably managed forests in the Natural State.

StructureCraft Abbotsford, British Columbia

(CLT, DLT, NLT, glulam beams, LVL, LSL, PSL)

StructureCraft is an engineer-led construction firm that creates a multitude of mass timber products, including its signature DowelLam, the first all-wood panel manufactured with out glue or nails in North America. Its team includes engineers of record, computational designers, fabricators, and builders. Bring ing craft traditions to high-tech construction, StructureCraft partners with architects, own ers, and general contractors across North America and elsewhere to engineer-build tim ber and hybrid structures.

CutMyTimber

Portland, Oregon (Timber product processing)

According to the U.S. Forest Service, CutMyTim ber is among the top timber product processors in the United States—a growing subsector in the field of manufacturing. With offices in Portland and North Vancouver, Canada, the company uses CNC machines to create customized prod ucts and building systems for projects around the world.

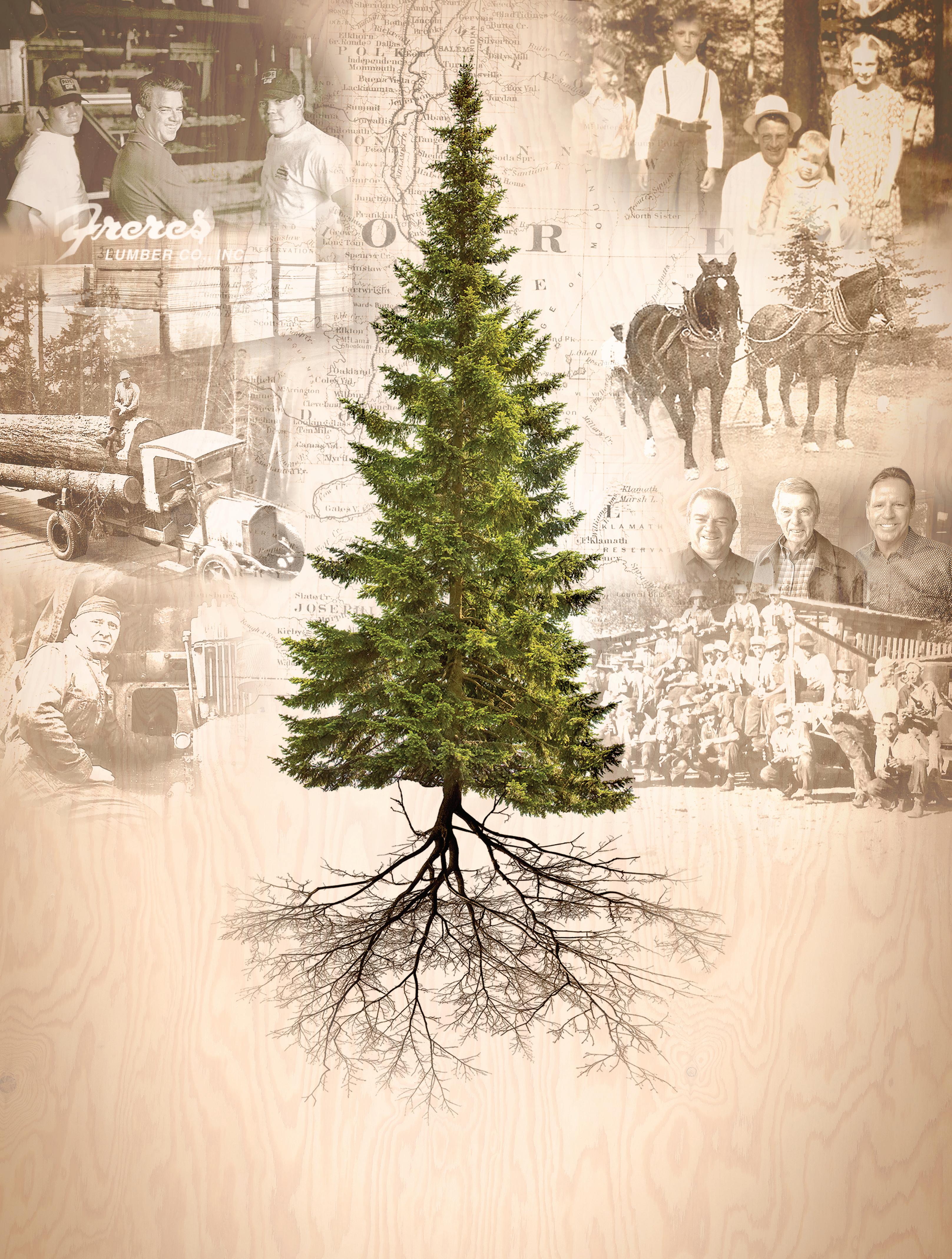

Freres Engineered Wood

Lyons, Oregon

(Mass plywood panels)

Freres Engineered Wood’s mass plywood pan els (MPPs) are a composite, veneer-based engi neered wood product that can be produced using 20 percent less wood than CLT panels. With its MPPs and mass plywood lams, Freres Engineered Wood is certified to produce every structural element for a multistory mass timber structure. Specializing in using small-diameter wood for engineered wood products, Freres now has an Environmental Product Declaration and a life cycle assessment that substantiates its closedloop, environmentally sustainable manufacturing processes. Founded in 1922, the company is cel ebrating its 100-year anniversary this year.

Rosboro

Springfield, Oregon (Glulam, LVL, parallel strand lumber)

Rosboro is the largest producer of glulam beams in North America. Other than its diverse range of Douglas fir glue-laminated timber products, it also produces sawn lumber and studs made from western regional tree species. All manufacturing takes place in two locations in Oregon: Springfield and Veneta. ROSBORO is supplies X-Beam, the industry’s only full-fram ing-width stock architectural glulam.

Riddle, Oregon (CLT panels, glulam beams)

DR Johnson was the first company in the United States to obtain American National Standards Institute (ANSI) certification to manufacture CLT panels. An affiliate company, Riddle Laminators, has been making glulam beams from Douglas fir and Alaskan yellow cedar for over 50 years.

Colville, Washington (CLT, glulam beams)

Vaagen Timbers uses high-tech milling machines to produce products at its Colville, Washington, facility, as well as at two other sites in Usk, Washington, and Midway, British Colum bia. It uses lumber-scanning technology and a portable HewSaw machine to handle underuti lized small logs.

Western Archrib Edmonton, Alberta; Boissevain, Manitoba (Glulam)

From two facilities in Boissevain, Manitoba, and Edmonton, Alberta, Western Archrib designs and manufactures glue-laminated structural products, including beams, columns, studs, and decking. It also provides custom fabrication with 3D-modeling software for CNC framing, steel connections, and finishes.

SmartLam North America Columbia Falls, Montana; Dothan, Alabama (CLT panels)

and

produces CLT panels for floors, walls,

shafts, and

its

Euclid Timber Frames Charleston, Utah (ICLT panels)

Euclid manufactures interlocking cross-lami nated timber (ICLT) for walls and roofs. Unlike CLT, ICLT panels are produced without the use of fasteners or adhesives, relying instead on tongue-and-groove and dovetail joints. Euclid Timber Frames has developed a unique sus tainable building system which uses no chemi cals or adhesives. It has been shown to improve the health and well-being of the building’s occu pants while improving the environment. Euclid Timber Frames, in cooperation with the Univer sity of Utah, Brigham Young University, and the University of Idaho, has developed a completely sustainable wall, floor, and roof system. This is the only system using local standing dead mate rial and assembled without using any adhesives or chemicals.

Kalesnikoff Lumber

South Slocan, British Columbia (CLT panels, glulam beams) Kalesnikoff Lumber plans to open a $35-mil lion-CAN plant in South Slocan, British Columbia. The 110,000-square-foot factory is the 81-yearold company’s first foray into mass timber.

University of Arkansas Fayetteville, Arkansas

The University of Arkansas is an emerging cen ter of design and research in mass timber and wood products. This program is unique in its timber- and wood-specific design-focused processes and hands-on learning environ ments. The M.Des. concentration in Integrated Wood Design soon will be supported by the Anthony Timberlands Center for Design and Materials Innovation, designed by Grafton Architects, a planned center geared to expand ing the use of wood in architectural design, construction, and product design.

Lakehead University

Thunder Bay, Ontario

A department within Lakehead University’s Faculty of Natural Resources Management, the school’s forestry program focuses on the tech nology behind contemporary forest manage ment. Upon graduation, students are eligible to receive their Registered Professional Forester designation and become a member of the Cana dian Institute of Forestry. This feature is unique to Lakehead University and provides alumni with an impressive professional advantage.

Mississippi State University

Starkville, Mississippi

Mississippi State is one of only five institutions across the nation to receive the 2022 Tim ber Education Prize, sponsored by the Soft wood Lumber Board and the Association of Collegiate Schools of Architecture. Associate Professor Jacob Gines and Professor Hans Herrmann of MSU’s School of Architecture are receiving a cash prize and support to lead their proposed innovative course, Forest Strong: Timber Solutions for Disaster Resilient Coastal Development.

Auburn, Alabama

The Auburn University College of Forestry, Wildlife and Environment, in partnership with several other academic colleges and admin istrative offices, recently hosted the first CLT conference in the southern United States at The Hotel at Auburn University and Dixon Con ference Center. The three-day event, titled “The Sustainable Future of CLT in the South: Grow. Design. Build.,” was held April 27–29, with over 160 attendees. Recently, Tom Chung, principal at Leers Weinzapfel Associates, joined the school as a professor of practice.

Laurentian University’s McEwen School of Architecture (MSoA), which opened in 2013, emphasizes timber architecture design and hands-on knowledge of wood craftsmanship in its curriculum. In 2017, the school completed a new building with a wing constructed of CLT that houses an atrium with a wood-burning fire place, a classroom, and a lecture hall on the ground floor, the school's library on the second floor, and a green roof and terrace. The build ing, designed by Toronto firm LGA, won a 2017 Ontario Wood WORKS! Wood Design Award and a 2018 OAA Design Excellence Award, and MSoA hosted the first International Wood Edu cators Conference in September 2019, with key note speaker Brian MacKay-Lyons.

George Brown College is poised to transform Toronto’s skyline with the construction of a tallwood, mass-timber, net-zero carbon emissions building called Limberlost Place. The 10-story structure, an addition to Waterfront Campus, will be the first institutional building of its kind in Ontario.

The University of Toronto has plans to build a Tall Wood Academic Tower that will reach a height of 14 stories. Designed by Patkau Architects and MJMA, the timber-and-concrete hybrid tower will serve as a mass timber demonstration proj ect in Canada’s largest city. The country’s fed eral and Ontario governments provided initial funding for this initiative on the main campus in downtown Toronto.

Clemson University Clemson, South Carolina

Through the Wood Utilization + Design Institute, Clemson University’s engineers and architects are innovating with mass timber. In late 2018, the university’s school of architecture patented the result of multiyear research into Sim[PLY], a wood construction system that the school has already used to build multiple structures.

Blacksburg, Virginia

Researchers at Virginia Tech have been exper imenting with mass timber for more than a decade. In 2018, faculty and students at the School of Architecture + Design designed a CLT train-watching tower as part of a tourism devel opment plan in Radford, Virginia. Their project was completed in September 2019 and recog nized by the AIA Blue Ridge design awards.

The University of Ottawa’s Department of Civil Engineering is home to a research program dealing with the response of mass timber sys tems to the effects of extreme loading such as wind storms, earthquakes, and blasts. For the past fifteen years, introductory and advanced timber design courses have been offered at the undergraduate and graduate levels.

Amherst, Massachusetts

Within the Building and Construction Technol ogy program at the University of Massachu setts Amherst, researchers received National Science Foundation and state funding to model and test advanced angle-ply CLT panels made with underutilized tree species Eastern hemlock and Eastern white pine.

Yale University

New Haven, Connecticut

The Yale School of Architecture offers a joint degree with the university’s School of Forestry & Environmental Studies that focuses on sustain able architecture alongside ecology and policy. The two schools have also partnered with local architecture firm Gray Organschi to support the Timber City research initiative, which is funded by the U.S. Department of Agriculture. Addi tionally, a number of interdisciplinary consortia within Yale have established platforms for mass timber research, including the Yale Building LAB and the Yale Carbon Containment Lab.

Orono, Maine

The Maine Mass Timber Commercialization Center based at the University of Maine is work ing with regional stakeholders to promote con struction of mass timber buildings, promote CLT manufacturing through development of a business attraction package, support high per formance grades from SPFs lumber, and con duct analysis of carbon impacts of mass timber construction.

The university is now home to the Kendeda Build ing for Innovative Sustainable Design, designed by The Miller Hull Partnership in collaboration with Lord Aeck Sargent, a Katerra company.

East Lansing, Michigan

MSU has realized the state’s first mass tim ber building and operates MassTimber@MSU, a multidisciplinary partnership between the Department of Forestry; the School of Plan ning, Design and Construction; and the Center for Community and Economic Development. In addition, are developing mass timber adhesives made from lignin, tools to predict construction costs and timelines for mass timber buildings, and mass timber made from salvaged lumber content in mass timber.

The MTI, located within the Daniels Faculty of Architecture, Landscape, and Design at the Uni versity of Toronto, is a partnership of academic institutions, government, and industry. The MTI’s mandate is to position Canada as a global leader in mass timber research and education and in the export of sustainable mass timber products. Its research and teaching interests include sustainability and society; building sci ence and constructability; indigenous participa tion and reconciliation; manufacturing, design, and supply chains; trade and export diversifica tion; and analytics and data synthesis.

The Canadian Forest Service is an arm of the Canadian federal-government department Natural Resources Canada. Operating from a central office in Ottawa and six other research facilities throughout the country, the service fosters environmental leadership, sustainable forest management planning and policies, and ongoing scientific research.

Much like its American counterpart, the Cana dian Wood Council represents wood product manufacturers, develops design and technical standards, and works to ensure its resources are available to professional and academic commu nities. Founded in 1959, the mission of the Coun cil is to expand market access and increase demand for Canadian wood products through excellence in codes, standards, regulations, and education.

Forest Products Association of Canada Ottawa

The Forest Products Association of Canada represents the country’s paper, pulp, and wood industries nationally and internationally. It spe cializes in environmental leadership, forestry management practices, product innovation, workforce advocacy, and other economic and trade efforts. FPAC provides a voice for Cana da’s wood, pulp, and paper producers nation ally and internationally in government, trade, and environmental affairs.

Wood WORKS!

Ottawa

Wood WORKS! was created by the Canadian Wood Council to increase the use of wood con struction for mid-rise and tall buildings in Can ada. Wood WORKS! is a resource for education, training, and technical support for building tall with timber.

Pointe-Claire, Quebec

FPInnovations, active in Quebec City, Montreal, and Vancouver, Canada, is a nonprofit timber construction research institute covering top ics like forestry management and construction products. Currently, FPInnovations has a team devoted to advanced timber building systems, finding efficient acoustic and structural solu tions for projects of every scale.

American Wood Council (AWC)

Leesburg, Virginia

The AWC is the leading voice for America’s structural wood products industry. In addition to advocating for public policies that benefit the wood industry, the AWC promotes oppor tunities for wood products and mass timber in codes and regulations. It also provides Amer ican National Standards Institute–accredited design specifications along with education and training on proper wood design and construc tion. The AWC is partially funded by the Soft wood Lumber Board.

American Forest & Paper Association (AF&PA)

Washington, D.C.

AF&PA advances public policies and funds research to support the production of wood products in the U.S., particularly pulp, paper, and packaging. It also supports wood manufactur ing across the globe and promotes sustainable growth of the U.S. forestry industry. It has col lected data on the resilience of mass timber to promote acceptance of wood building systems.

Washington, D.C.

As part of its mission to manage and protect national forests and grasslands, the USFS works with public and private agencies to build mar kets for sustainable wood products. One such product is CLT produced from dead and dying trees, the harvesting of which could help control the spread of forest fires. The Wood Innovations Program provides funding for projects utilizing CLT and other wood materials.

WoodWorks: Wood Products Council Washington, D.C. WoodWorks provides architecture, engineering, and construction professionals with free tech nical support related to the design and con struction of commercial and multifamily wood buildings, including mass timber structures. WoodWorks also helps educate profession als about wood construction through events, publishes technical resources, and connects developers and project teams through the WoodWorks Innovation Network. WoodWorks is partially funded by the Softwood Lumber Board and the U.S. Forest Service.

Lion Lumber

Phoenix, Illinois; Lufkin, Texas (CLT panels and CLT mats)

Formerly known as Sterling Lumber Company, Lion Lumber is a 70-year-old family company that manufactures cut-to-length lagging lum ber, industrial lumber for transportation proj ect shielding, and pallets and skids for shipping and unloading. Specializing in CLT, Lion Lumber also offers design and build services for custom work. Last year, it opened a massive new facility in Lufkin, Texas, where it continues to make its signature TerraLam mat.

Texas CLT

Magnolia, Arkansas (CLT mats)

Texas CLT is an investor group that reopened the defunct Arkansas Laminating mill in Magnolia, Arkansas, where it produces CLT mats made from Southern pine and Douglas fir. Texas CLT also provides CLT throughout the United States.

Timber Systems Lapeer, Michigan (Glulam, sawn timber)

Timber Systems installs, fabricates, and designs mass timber structural components. With a wide array of timber products, its product catalog includes glulam and solid sawn timber, deck ing, bridges, and shelters. Whether you simply need some suggestions on an upcoming proj ect, or you need three-dimensional CAD design, detailed engineering analysis, timber procure ment, and installation, our Timber Systems’ ser vices team is here to meet your needs.

Element5

St. Thomas, Ontario; Ripon, Quebec (CLT, glulam, NLT, CLIPs, Boxx panels)

Element5 is Canada’s newest and Ontario’s only CLT and glulam manufacturer. The company produces the widest-format panels of any CLT plant in North Amer ica. It also manufactures several value-added, CLTbased components including hollow-core floor and roof panels and Cross-Laminated Insulated Panels (CLIPs), which offer a prefabricated, high-performance building envelope that can be quickly assembled for rapid building enclosure. The company is a dedi cated team of designers, craftspeople and assembly experts. We serve a community of forward-thinking architects, owners, developers, and general con tractors to help effect change by providing timber construction cost consulting, design consulting, engi neering, fabrication and assembly services. We strive

Sauter Timber

Rockwood, Tennessee

Established in 2002, Sauter Timber is the first wood component joinery service to set up shop in North America. The organiza tion expanded its offerings in 2010 to include CNC services for mass timber products like CLT and glulam, as well as other timber frame components, SIP panels, and hybrid home and log home components. In 2014, the company expanded its production facility by adding on a 17,000 square foot building made of a glulam frame and CLT panels. Since that time, it has been providing CNC services with its new Hun degger Robot Drive for mass timber products including CLT and glulam.

Montreal (I-joists, CLT panels, glulam beams)

Nordic Structures sustainably manufactures industrial-grade CLT panels, I-joists, and glu lam beams. The company has expertise in engineered wood products and mass timber construction with vertical integration from forest to structure. Its resource comes from responsi bly managed lands within the regional boreal for est. Vertical integration, from forest to structure, bolstered by Nordic’s experienced design and development team, ensures consistent quality and unparalleled level of service.

Saint-Augustin-de-Desmaures, Quebec (glulam, hybrid timber beams, fabrication)

Structure Fusion is a Canadian company that specializes in wood construction. Acting as a structural engineer, the company partners with Simonin to design and manufacture adapted wood products, including its patented Sapisol and Resix systems.

Bensonwood Walpole, New Hampshire (CLT, NLT, glulam, fabrication)

Bensonwood collaborates with architects and engineers to build small and large projects in mass timber and CLT from suppliers like Nor dic Structures. A special division uses off-site manufacturing to build timber frames with CNC milling machines that are assembled by hand. The company also offers OpenHome, a design system from sustainable architecture pioneers Lake|Flato Architects, KieranTimberlake, and Bensonwood. Tektoniks makes Bensonwood’s unique manufacturing system available to the world, preserving the traditional look and feel of hand-crafted architecture while harnessing the precision and consistency of cutting-edge machine technology.

Lincoln, Maine

(CLT panels, glulam beams)

LignaCLT Maine is LignaTerra’s Northeastern offshoot, which aims to become the state’s first CLT and glulam manufacturer.

SmartLam North America

TBD, Maine

In 2018, SmartLam announced plans to open a factory in Maine in hopes of becoming the sec ond producer of CLT in the state, after Ligna Terra. The project has been delayed because of funding issues.

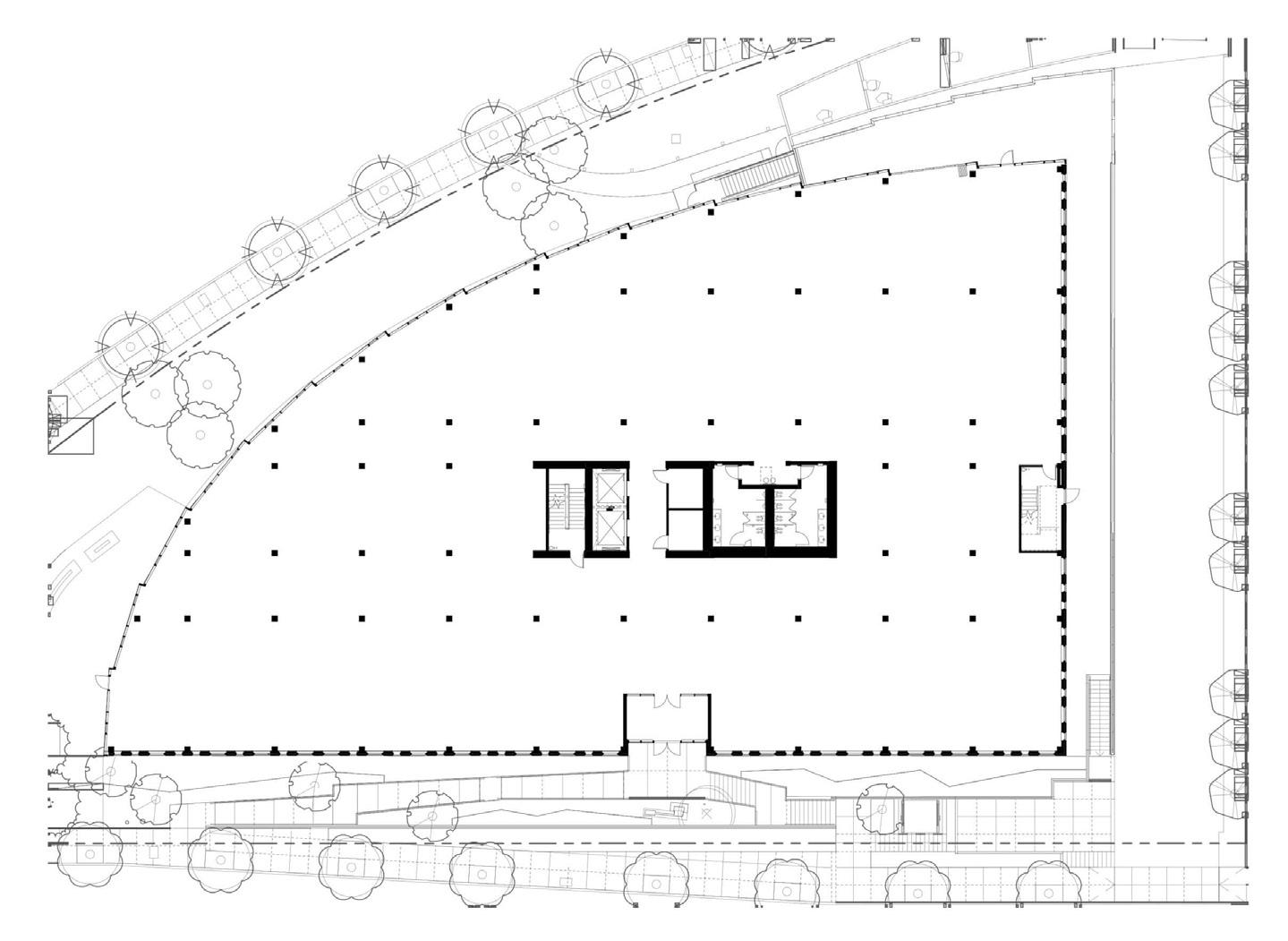

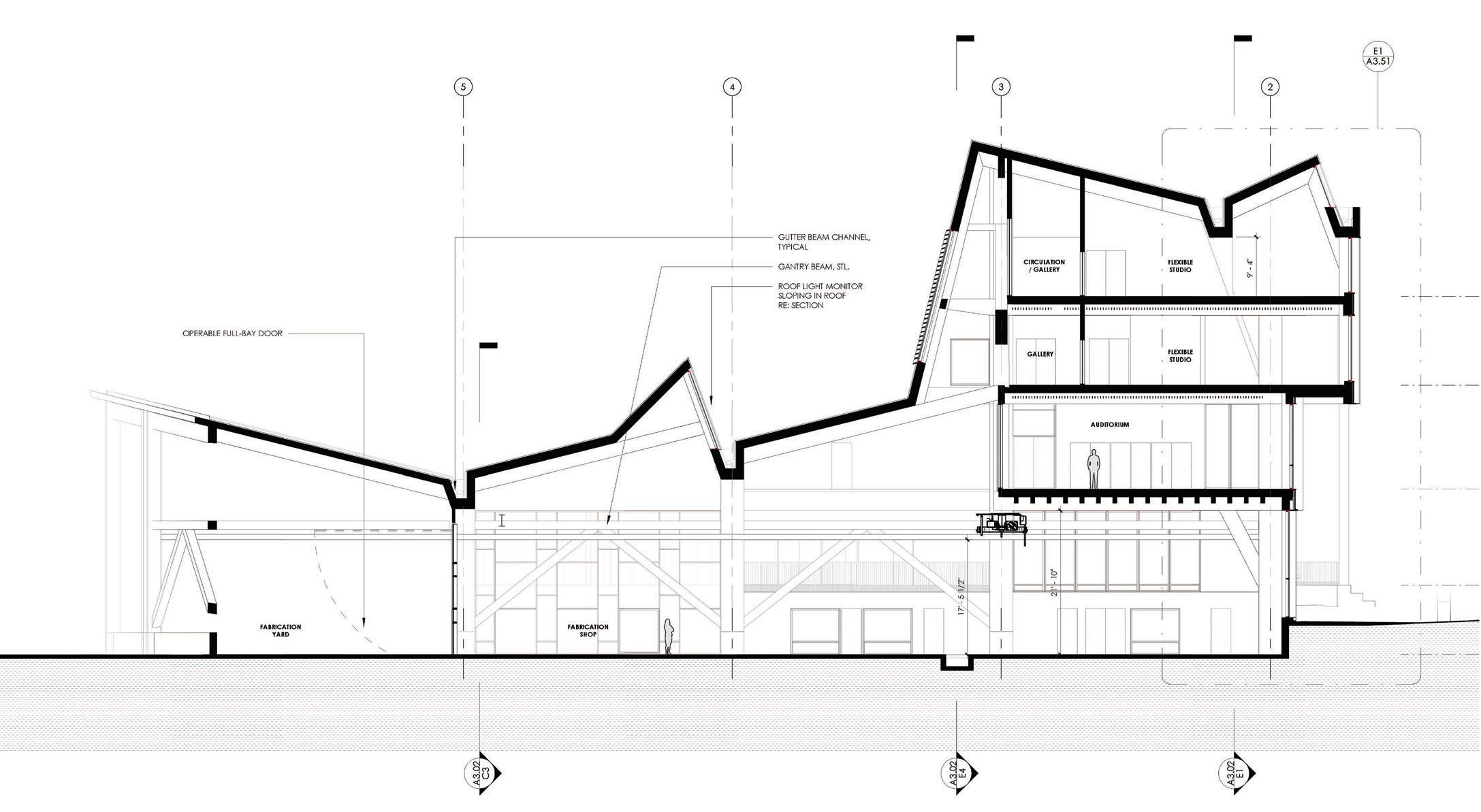

The Anthony Timberlands Center for Design and Mateiral Innovation at the University of Arkansas is a research facility where new products for the state's timber industry will be developed.

The Anthony Timberlands Center for Design and Mateiral Innovation at the University of Arkansas is a research facility where new products for the state's timber industry will be developed.

Grafton Architects has designed its first building in North America to be a masterclass in timber.

To procure an architect for its new Anthony Timberlands Center for Design and Materials Innovation, the Fay Jones School of Architecture and Design at the University of Arkansas, led by Dean Peter MacKeith, conducted an impressive competition pro cess. (Its six shortlisted schemes are acces sible in the competition report hosted on the school’s website.) In March 2020, as the world entered lockdown, a winner was announced: Grafton Architects, in partner ship with modus studio. It was appropri ate timing, as just weeks prior, Grafton’s cofounders Yvonne Farrell and Shelley McNamara were awarded the Pritzker Architecture Prize.

Arkansas is 57 percent forest, and its forest industry has an annual economic impact of over $5 billion, or about 4 per cent of its GDP. The state’s trees create more biomass every year than can be used, which means the underharvested forests are becoming overgrown. As such, the tim ber and wood products industry is in search of new products for which its lumber can be used. In part, this task falls to educa tional entities to research and develop inventive ways to utilize wood. The pro posed Anthony Timberlands Center stands to do just that.

“We seek a building that is redolent of the qualities of the forest, one that imag ines anew timber and wood as materials. We seek a building that is hewn, carved, jointed, woven, and assembled, layered, laminated,” Dean Peter MacKeith wrote at the outset of this design process. The proposal from Grafton Architects appears to get close to this ambition. It masses a taller tower against the street, stages a lower shed at the rear, and unfurls a cas cading sawtooth roof to connect the two elements, resulting in a dynamic section. Its appearance is skeletal and structural, but generous and warm, thanks in part to the biophilic qualities of wood. Inside, large wooden members define the open floor plate of the fabrication lab while structuring an auditorium and classrooms above. It’s a bit like a woody cover version of the interior of Giovanni Michelucci’s roadside San Giovanni Battista near Florence or a scaled-up take on Theo Jansen’s kinetic strandbeests. Either way, it manages to balance a sense of strength with an invitation to public life, a move that Grafton Architects has landed in other major educational commissions like their projects at Bocconi University in Milan or UTEC in Lima.