13 minute read

Technical

from Auto Service Professional - August 2017

by EndeavorBusinessMedia-VehicleRepairGroup

EVAP monitor on European cars

Real world diagnosis of DMTL systems

Chasing down evaporative emission control system (EVAP) fault codes can be difficult and frustrating due to the variety of equipment and strategies on the market. But it’s profitable work if you understand the system. This article focuses on EVAP system diagnosis on European (and some Asian) vehicles equipped with a DMTL (diagnostic module for tank leakage), offering helpful insights for the service of these imported vehicles.

By Jacques Gordon

On a business trip several years ago, I was in a country that has no emissions regulations. The hotel parking lot was filled with late-model rental cars, but cars parked on the street were much older and obviously well past their best years. The strong smell of gasoline on those sun-baked streets made it obvious that a functioning evaporative emission control system (EVAP)

The DMTL (diagnostic module for tank leakage) is a Bosch part that includes the air pump, switching valve, reference orifice and heater. The outlet is connected to the charcoal canister. was not important there. That smell also provided a dramatic example of just how effective our modern EVAP systems are. Our federal emissions regulations require that EVAP systems be tested for leaks as frequently as possible by on-board test equipment. The malfunction indicator light (MIL) will turn on if a leak is detected, and it will also turn on if any faults are detected in the leak testing equipment.

All EVAP systems work basically the same way to capture and store fuel tank vapors, but car makers have devised several different methods for on-board leak testing. Given the variety of on-board test equipment and strategies, chasing down EVAP fault codes can be difficult and frustrating. But it’s important work that can be profitable if you understand the system. Here we’ll discuss the on-board test used on almost all European cars and also on a few Asian models, too.

On-board test

When the powertrain control module (PCM) tests the EVAP system for leaks, it measures one of three parameters; pressure, time or current draw. About half of all cars

sold in the U.S. have a fuel tank pressure sensor, and the leak test runs with the engine running. The PCM closes the vent valve, operates the purge valve to put the fuel tank under vacuum and looks for a specific pressure drop in the fuel tank.

On vehicles without a pressure sensor, the leak test operates a switch. With the engine not running and both valves closed, the tank is either pressurized with a leak detection pump (LDP) or it’s put under vacuum naturally as the fuel cools down. Either way, the pressure change in the tank operates a reed switch, and the PCM calculates the size of any leak by measuring the time required for the switch to change state (open or closed).

The third method of on-board leak testing does not use natural vacuum, engine vacuum or an LDP and it does not have a pressure sensor or reed switch. Instead, a pump pressurizes the fuel tank and the PCM monitors the current draw of the pump motor. As tank pressure increases, current draw will change. There are several advantages to this strategy that become clear when you understand how the system works.

Originally developed by Bosch in the late 1990s, the name of the device translates as “diagnostic module for tank leakage,” or DMTL. It consists of a small vane-type air pump on a 12-volt electric motor and a solenoid-operated switching valve with a reference orifice. Newer models have a heater in the assembly housing to dry out moisture and prevent ice from locking up the pump. The reference orifice is 0.020 of an inch (0.5 mm), which is the definition of a “small leak” in the EVAP leak test regulations.

Sometime after the engine is switched off, the pump turns on and blows air through the reference orifice while the PCM measures the motor’s current draw. Then the switching valve is activated, switching the pump’s output from the reference orifice to the fuel tank. The PCM continues measuring the pump motor’s current draw as it builds pressure in the tank. If current draw does not at least equal the reference measurement, the PCM will interpret this as a small leak in the EVAP system and set the appropriate fault codes. If current draw does not change at all, the PCM will decide there is a large leak.

The beauty of this system is that each time the test runs, the PCM establishes a new small-leak calibration based on existing conditions. The accuracy of the test does not rely on computer algorithms to compensate for ambient conditions or the mechanical condition of a sensor, switch, pump or air filter. It also doesn’t require a specific drive cycle because the test runs when the engine is off, and it can run successfully under almost any ambient conditions because it self-calibrates at the beginning of each test. Ultimately, each test is more accurate and less likely to produce false test results that will turn on the MIL.

Every on-board diagnostic test is either passive or active, and either intrusive or non-intrusive. This is an active test because the PCM operates a device in the system and then looks for a specific input signal. It is nonintrusive because it runs when the car is not running. It’s also a Type B or two-trip test, meaning the system must fail the test two times in a row before the PCM will turn on the MIL. Just like in other EVAP systems, the PCM also will turn on the MIL if it detects a short or open circuit in the components used to run the test.

OBD test conditions

Some of the conditions for the leak test to run are the same on every model.

• More than 20 minutes of driving (reaching full coolant temperature). • Minimum 4.5 hours after engine shutdown/ignition switch off. • Ambient temperature between 34 degrees

Fahrenheit (1.5 degrees Celsius) and 105 degrees F (35 degrees C). • Fuel level between 15% and 85%. • No existing EVAP fault codes.

Most manufacturers add to this list some or all of the following conditions:

• Battery voltage greater than 11.4 volts. • Air bag not deployed. • Altitude less than 8,200 feet (2,500 meters).

BUILT TO SERVE, AGAIN.

ACDelco’s Professional Remanufactured Alternators use high-quality bearings with high-temp lubricant and doublelipped rubber seals. Rotors and stators are electronically tested and then sealed with secondary insulating coating. Damaged and obsolete parts are always replaced, including brushes and bearings. All components are 100 percent electronically tested for individual performance and long service to ACDelco specifications.

This alternator’s second life is a great first choice.

©2017 General Motors. All rights reserved. The marks appearing in this ad are the trademarks or service marks of GM, its subsidiaries, affiliates or licensors. Learn more about remanufactured alternators at acdelco.com/alternators

On some cars, if the DMTL pump current never stabilizes during the on-board testing, the test will be aborted but counted, and a code will be set after a pre-set number of aborted tests. Codes also will be set if there is an open or shorted circuit on the pump, heater or solenoid valve.

Part description

The DMTL is a Bosch part. On most applications, the Bosch 10-digit part number is 0 261 222 018. On a very few vehicles, the

This 10-digit Bosch part number (0 261 222 018) is found on almost every DMTL assembly. The last two digits will be different for some applications, indicating different mounting holes.

Terminal 2: switching valve ground Terminal 1: motor ground

Photo courtesy of Motologic Terminal 4: 12 volts

Terminal 3: heater ground

All DMTL connectors are configured the same way. This is the connector view, so terminal 4 is at the bottom right when looking at the DMTL. last two digits will be different to account for different mounting holes, but otherwise it’s the same part.

The DMTL is a complete assembly that includes the air pump, switching valve, reference orifice and heater, all in one housing. A separate air filter outside the housing is often mounted in a remote location and connected by a hose. The outlet of the DMTL is always connected directly to the charcoal canister. The switching valve is spring-loaded to the closed position, aligning the reference orifice with the pump outlet. The valve is only opened during the on-board leak test as the pump tries to pressurize the EVAP system.

The connector has four wires. One supplies battery voltage during the test, and the others are ground circuits operated by drivers inside the PCM for the heater, pump and switching valve solenoid.

As noted earlier, the DMTL is found mostly on European models like BMW, Porsche, VW, Volvo, Mini, Land Rover and a few others. However, it has also been used on Kia, Hyundai and some other Asian models.

Diagnostic testing

We had no trouble getting the genuine Bosch part from our first-call parts house at a very reasonable wholesale price. For this reason, when the MIL is on and the trouble codes indicate a DMTL malfunction, many techs will just replace the part and assume the job is finished. But DMTL codes also can be caused by damaged wiring or failed drivers in the PCM. The fastest way to check these is with a bidirectional scan tool that can activate the DMTL circuits.

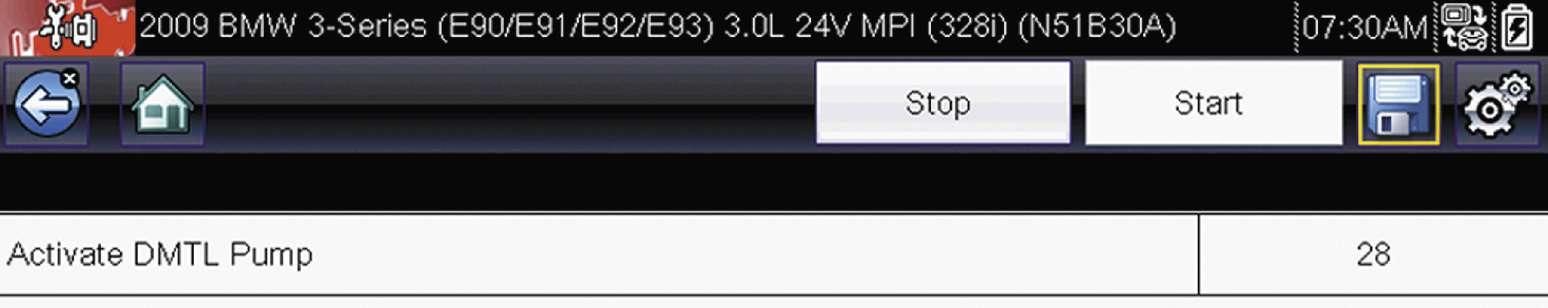

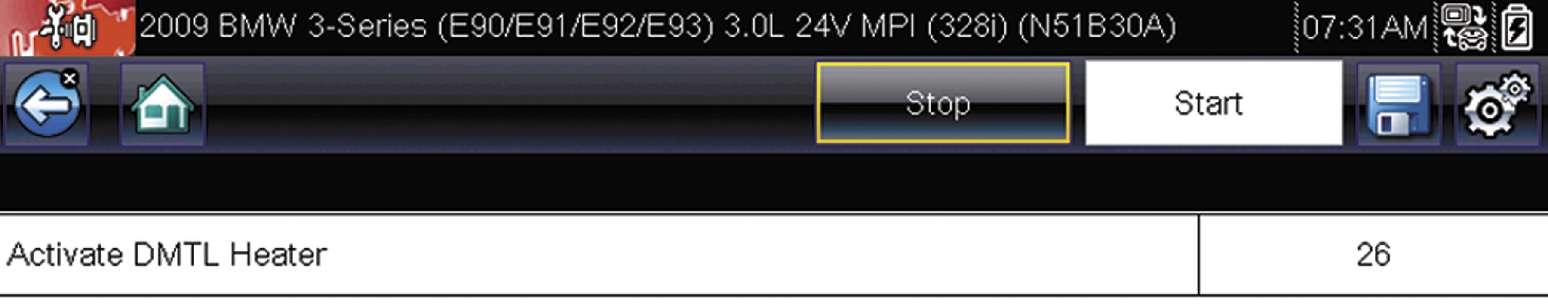

Historically our Snap-on Solus Ultra has not been particularly helpful for diagnosing European vehicles, but after the latest software update we noticed a dramatic improvement, especially on BMW and Mini. We used this tool on a 2009 BMW 328i (E93), and by identifying the vehicle manually instead of letting the tool identify it automatically, we were able to access all of the car’s control units.

Testing a DMTL with a scan tool is the same as testing any other type of EVAP system: clear the codes, force the test to run

and look for “Test Complete” in the readiness monitors. However, before clearing the codes we checked the readiness monitors (scan tool Mode 7) to make sure they had all run successfully. If any other monitors had not run to completion or if any other engine fault codes were set, we would have addressed that issue first. On many vehicles the EVAP monitor won’t run (automatically) if there are other emissions-related malfunctions.

We cleared the codes and monitors and used scan tool Mode 8 (bidirectional communication) to run the EVAP monitor manually. On most cars the test just runs by itself and the scan tool presents a “Test Complete” or “Test Not Complete” test result. However, on this car we had to command the DMTL pump, vent valve and heater to run individually. This makes it possible to diagnose each circuit with a test light.

The wiring schematic for this car shows that power is supplied to the DMTL at pin number 4, and the ground for each circuit within the DMTL is controlled by the PCM. All DMTLs are wired this way. By back-probing each of the other circuits with a test light connected to ground, the light should turn ON when power is on and the circuit is not active, and turn OFF when the circuit is activated. If the light remains lit when a circuit is activated, either the wiring is faulty

This wiring diagram from a 2005 Hyundai Accent is typical of all DMTL circuits.

On this BMW, each circuit of the DMTL is activated separately when commanding the EVAP monitor to run. This makes it easy to test the wiring as well as the unit itself.

Are you ready for R2R?

Right to Repair (R2R) is here!

R2R grants independent repair facilities equal access to the same diagnostics and programming software that the dealerships use. This software is readily available from the manufacturers’ websites today, so that vehicle owners can utilize the repair facility of their choice. Once again, Drew Technologies is here to provide you with the most tested and validated R2R products on the market so your shop can provide world-class vehicle repair and diagnostics services to your customers! The

CarDAQ-Plus 2 ® continues to be the best J2534 device you’ll need to

get the job done. CarDAQ-Plus 2 ® comes with the

J2534 Toolbox helper application and free, best-in-class technical support for the life of the tool, enabling you to complete vehicle repairs* while saving time.

CarDAQ-Plus 2 ® now supports API 05.00! • Chrysler, Nissan, and Subaru validated for R2R Diagnostics. • Already supports R2R Diagnostics for BMW, Ford, GM, Honda,

JLR, Toyota, VW/Audi and Volvo. • Emission-related module calibration updates for all vehicle makes. • Body control module calibration updates and dealer-level diagnostics for many vehicle makes. • Vehicle Security Professionals/Locksmiths using the NASTF

Secure Data Release.

Learn how the

CarDAQ-Plus 2 ® can grow your business. Call or visit our website today!

or the PCM is not completing the path to ground. Technicians are (rightfully) reluctant to connect a test light to a circuit that leads directly to the PCM for fear of pulling too much current through the driver transistor. However, simply testing for continuity with a high-impedance DVOM can produce a

These photographs show the spring for the switching valve. Note the spring is compressed when the solenoid is activated. false positive. A wire that’s worn through to a single strand will still complete a circuit, but that doesn’t mean the circuit will carry enough current to operate the load. Also, a driver that’s intended to operate a motor, heater or solenoid valve can certainly handle the current drawn by a test light bulb.

A few last details

DMTL assemblies are no less reliable than any other EVAP system components, but when they do fail the failure tends to be intermittent. When using a scan tool to command the test to run, it’s best to run the test several times to make sure it works each time. Here’s where a DVOM or even an oscilloscope can be handy for capturing a glitch that you might not notice with a test light.

There’s probably no reason to measure resistance or current draw of the DMTL, but we did anyway. Using a new part, we got the following measurements: • Pump motor: 14 ohms. • Switching valve: 30 ohms. • Heater: 38 ohms.

We also found that current draw of the pump increases when the switching valve is open because the pump is working harder as it moves more air.

In the real world, most DMTL codes are caused by corroded or damaged wiring. This can be hard to find, so start by looking up service bulletins. Sometimes the unit itself suffers physical damage (it’s often mounted inside a wheel well), and we’ve heard of at least one that was flooded by overfilling the fuel tank. Finally, when replacing a DMTL, don’t forget to replace the air filter, too.

Jacques Gordon has worked in the automotive industry for 40 years as a service technician, lab technician, trainer and technical writer. He began his writing career writing service manuals at Chilton Book Co. He currently holds ASE Master Technician and L1 certifications and has participated in ASE test writing workshops.