20 minute read

Best practices for air

from Auto Service Professional - April 2018

by EndeavorBusinessMedia-VehicleRepairGroup

Best practices for air conditioning service

Tips for servicing today’s increasingly complex A/C systems

Automotive A/C systems, once a stand-alone and relatively simple design, have evolved and continue to evolve, offering greater efficiency and reduction of atmospheric pollutants. However, due to increased regulatory mandates and a seemingly overwhelming system complexity, the need for updated service equipment and enhanced diagnostic and service training is critical.

By Mike Mavrigian

In order to better maintain their vehicle’s air conditioning (A/C) system between service visits, recommend the following to your customers:

1. Whether or not the customer feels the need to run the A/C system in terms of cabin comfort, recommend that they run the system at least once each week for perhaps 10 minutes or so. This helps to maintain a healthy system in terms of compressor function, and provides for longer life of system hoses and seals. 2. Run the defrost mode on occasion for 5 to 10 minutes. This helps remove moisture from the cabin, preventing mildew and reducing the chance for odors. 3. Remind them to use (exercise) the system once in a while during the winter. This helps to keep hoses and seals healthy and removes humidity from the interior. 4. Urge your customers to visit your shop for a complete A/C system check and service (refrigerant and lube change) at least every two years to help avoid system problems. 5. A properly working A/C system should be able to obtain 42 degrees Fahrenheit cabin temperature (or lower).

If cooling is not as effective as it should be, in addition to normal diagnostics, be sure to check the sealing of vent doors/flaps. Checking for proper door/flap sealing is sometimes overlooked.

Servicing modern A/C systems

(Information courtesy of Eric Shultz, engineering manager for Mahle Service Solutions.)

Have you had customers come to your aftermarket repair shop with vehicles that are factory filled with the new R1234yf refrigerant?

If you haven’t yet, it is safe to say that you will see more of these types of vehicles in the very near future.

R1234yf is the new worldwide A/C refrigerant that has entered the U.S. market. It is environmentally friendly with the intent of reducing the impact of global warming.

Here are some things you should be aware equipment performance, purity and safety of as you begin working with R1234yf: guidelines for the recovery and recycling of • It is very expensive in comparison to motor vehicle A/C refrigerant. Refer to the

R134a, so you’ll need to be prepared to SAE J2788 guideline for R134a refrigerant and educate your customers as to why your the SAE J2843 guideline for R1234yf refrigerestimate is considerably higher than it was ant before purchasing a product. before. At this point you might ask: Should my • To prevent cross-contamination with difshop purchase a new machine to handle the ferent refrigerants, vehicles with R1234yf R1234yf refrigerant? Keep in mind that older have different service fittings. A/C machines that worked with R134a will • R1234yf refrigerant is mildly flammable, so not be able to service the new refrigerant. So, safety in handling is very important. you will need a separate machine for servicing • The procedure for servicing vehicles with R1234yf-equipped vehicles.

R1234yf is going to take longer than with There’s no doubt that purchasing one of the

R134a vehicles. new machines is a serious capital investment. • Increased service times are due to extra Our work with service providers in the field safety processes built into the new service has shown that the payoff is quick for getting equipment to ensure a vehicle A/C system a return on your investment and A/C service is leak free prior to a recharge. is still one of the most valuable services • More leak and purity check capabilities are aftermarket shops can provide. built into new A/C machines for R1234yf that comply with SAE standards. Contamination is getting worse The chance of refrigerant contamination

Regardless of what machine you use to has gotten worse, so taking preventive steps service A/C systems, Society of Automotive to preserve the life of your A/C machines is Engineers (SAE)-certified processes ensure imperative. the machine will operate with specific Refrigerant identification tools are the best line of defense against counterfeit or contaminated refrigerants. The options range from external hand-held units to internal/embedded options included in the A/C machine. Refrigerant identifiers vary in price and in the detail of data collected. One of the best ways to safely recover contaminated refrigerant is the use of a recovery only unit (ROU). An example is the Mahle Service Solutions ArcticPRO® ROU250, a recovery-only Yellow Jacket’s ManTooth Wireless pressure/temperature gauge set unit designed to safely includes high and low pressure connections (R-134a and R-1234yf remove the new R1234yf included) with 2 Bluetooth wireless gauges, 2 temperature clamps, an A/C charger and USB cable. The ports on the wireless gauges provide refrigerant even if it is connections for both the pressure gauges and the temperature clamps. contaminated. It will

required for all technicians who will repair or service vehicle air conditioning systems, including the new R1234yf refrigerant. This training will ensure safety for your staff, customers and the environment.

Starting Jan. 1, 2018, the EPA has reinforced that those purchasing refrigerant will need to show an EPA-approved 609 certification card. While we are not sure everyone you buy from will ask to see your card, you should be ready just in case.

Understanding the changes

(The following was supplied courtesy of Peter McArdle, senior master tech and trainer/developer for the Four Seasons Division of Standard Motor Products.)

A/C compressor replacement is one of the highest warranty return repairs. This is

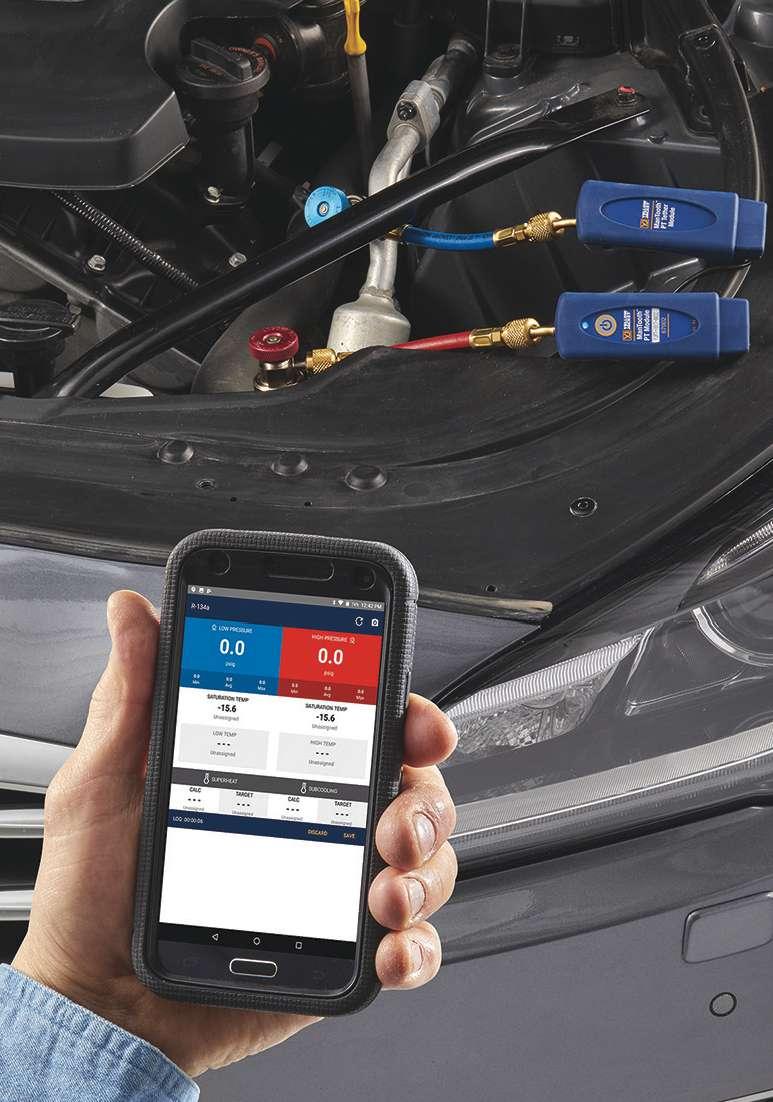

Once the A/C system’s high and low side connections are made, pressure and temperature information is immediately available on a smartphone or tablet using the ManTooth app. This represents a quick and efficient way to determine if the system requires attention. In this example, the gauges reveal zero pressure on high and low sides. primarily due to the root cause of the original failure not being identified and poor repair procedures that result in contaminants from the original compressor failure being left in the system.

In the past, most condensers featured tube and fin construction. Today, the industry uses flat-tube/multi-pass, multi-path condensers that feature very tiny tubes, making it difficult, if not impossible, to flush out debris that resulted from the original compressor failure. A clogged micro-tube condenser is one of the most common causes of repeat compressor failure.

About 20 years ago, the average refrigerant charge amount was about 44 ounces. Today, the average charge is about 20 ounces. The amount of oil was about 8 to 9 ounces, and today it’s about 3 to 5 ounces. Today we are getting the same job done with half the amount of the refrigerant and oil. A/C efficiency has doubled, with improved heat exchange.

Evaporator technology has also evolved from tube and fin to flat tube multi-pass, multi-path designs making oil circulation through them and flushing them more difficult. While the drier must be replaced as a mandatory step, if a catastrophic compressor failure occurred, every inch of the refrigerant path needs to be either flushed or replaced. Compressors are not warranted unless the accumulator/receiver dryer and orifice tube has been replaced. Hose assemblies with in-line filters or mufflers cannot be flushed and should be replaced. Quite often lines are contaminated with debris.

Because R-134a is a global warming gas, vehicle manufacturers have striven to increase system efficiency to use less of it and also to improve fuel economy and reduce tailpipe emissions.

The problem is that today’s systems are so efficient that they are somewhat “delicate,” requiring increased precision in terms of diagnostics, flushing and charging accuracy.

A 2 ounce charging error has double the impact on a 20 ounce system than it has on a 40 ounce system; the same leak results in low charge, oil drop out and compressor failure twice as fast!

On the Prius pictured here, the bright orange wire harness leads to the electric air compressor. replaced and especially of the evaporator is so important.

With regard to hybrid A/C service, it’s important to note that many hybrid vehicles feature all-electric, high voltage A/C compressors. Windings are in direct contact with oil, requiring the use of special POE (polyolester) oil with high dielectric properties.

The industry is currently at the front end of a transition from R134a to R1234yf.

Fiat Chrysler Automobiles (FCA) has taken the lead in this regard. About half of its 2014 model year vehicles feature R-1234yf and with a few legacy exceptions, virtually the entire 2018 fleet is now R-1234yf. Most other car makers have at least one model using R1234yf, with this number increasing as the transition occurs.

In order to service the new refrigerant systems, shops must purchase all new recovery/recycling/recharging machines that meet SAE J2843, with either a built-in or offboard portable refrigerant identifier. Portable identifiers are appealing due to quick use and flexibility. They will also need leak detectors that will work with the new refrigerant. A conventional style R-1234yf manifold gauge set is highly recommended for fast diagnostic pressure checks.

Most modern compressors feature internal valving that retains more of the oil within the compressor body. This reduces the total amount of oil required and improves system efficiency by reducing the thermal insulating film of oil coating the heat exchange surfaces of the condenser and evaporator.

We are also seeing electronically controlled variable displacement compressors (ECVs) that can vary pumping displacement as the heat load changes. The computer varies the duty cycle command to the ECV solenoid to increase or decrease the piston stroke as necessary.

Many shops don’t realize this computer control issue, often replacing a compressor when in fact the concern is an issue with the command/control system. This is an example of how the need for more sophisticated diagnostics is so critical.

A/C system complexity is increasing at an exponential rate. Rather than the stand-alone A/C system of the past, the A/C system is increasingly called upon to integrate with other systems and components. For example the 2018 Supercharged Dodge Demon can divert the A/C system refrigerant to an intake “Air-charge Chiller” during “Drag Mode” operation to improve performance. It is common for the A/C system on hybrid vehicles to be called upon to cool the high voltage batteries, power inverter, etc. Servicing modern A/C systems now requires specialized equipment and training to understand and utilize network scan data.

Additional update information

(The following was provided by Tim Wagaman, product manager for A/C and fluid exchange for Robinair.)

Starting in 2012 with 2013 model year vehicles, OEMs began introducing vehicles that used new refrigerant within the vehicle’s A/C system called R-1234yf. This new refrigerant is different from R134a and new service equipment requirements were created to ensure the refrigerant is handled properly and service is performed correctly. New A/C recovery/recycling/recharging (RRR) machines were introduced to work on these new vehicles that use this new refrigerant. Examples include the new R-1234yf A/C machines which include new couplers that allow the connection to the vehicle’s A/C system.

These couplers are different than those found on R134a vehicles. One of the requirements for R1234yf service equipment is refrigerant identification anytime refrigerant

An example of a refrigerant recovery system for R134yf (Mahle ActicPro ACX1280). Features include a fully automatic program to recover, vacuum, leak test and charge without command; a vacuum leak test; automatic air purge; integrated refrigerant identifier to avoid costly cross-contamination, with a clearly visible sample filter for inspection; automatic oil drain integrated hose flushing that eliminates the need for additional or loose adapters; an on-board thermal printer; tool tray; and fan flow ventilation switches to maintain cabinet venting.

is brought into the A/C machine. As a specific example, the new Robinair A/C1234-4 machine comes with a built-in internal refrigerant identifier that samples refrigerant prior to recovery to ensure the refrigerant is not contaminated before it is brought into the A/C machine. Refrigerant must be at least 98% pure prior to recovery and recharging. Servicing R-1234yf systems also requires technicians to manually inject oil into the system. Before injecting oil into the system, technicians should review OEM requirements and use the manufacturer-recommended oil.

Hybrid R-134a

Electric hybrid vehicles typically incorporate an electric compressor. These types of vehicle A/C systems use a different type of lubricant oil, POE, than what is found in a traditional belt driven compressor A/C system. With the different oil types, industry requirements were created for A/C RRR equipment to ensure the equipment could service both types of systems safely and effectively.

With RRR equipment designed to service both hybrid and standard belt-driven types of A/C systems, some expected features like onboard oil injection are no longer available. This is done to eliminate the chance of crosscontaminating vehicle A/C systems with the wrong type of oil as a tech switches between servicing a standard vehicle and an electric hybrid vehicle.

POE oil is required because it is nonconductive. Using the wrong oil can cause the systems to seize up or fail, with some manufacturers not allowing the system to operate if it senses any amount of electrical conductivity within the compressor.

Leak detection

Electronic leak detectors typically have a sensor that reacts to refrigerant and triggers an alarm so the user knows they are close or have found the source of the leak that needs to be repaired.

As an example, the Robinair LD7 leak detector includes both an audible alarm and an LCD display that alerts and shows the user the amount of refrigerant being detected, which helps pinpoint the exact location of the leak. The flexible wand/probe allows the user to search for leaks in hard-to-reach places where other leak detection methods don’t perform well. With widespread adoption of R-1234yf, shops may need to upgrade their leak detectors to one that will “sniff” the new refrigerant.

Newer leak detectors will help locate leaking R-1234yf and most other refrigerants. The new unit displays a proximity meter, helping techs sweep lines and systems to pinpoint the exact location, with the detector displaying approximate proximity to the leak. An LED search light and UV light aid in spotting damaged components or spotting fluorescent UV dye leaking from a system.

PAG vs. POE

When servicing vehicles with A/C RRR equipment, sometimes oil is removed during

refrigerant recovery. When this happens new oil needs to be put back into the system to replace what was removed. In A/C RRR equipment designed to service R-1234yf vehicles and equipment, to service electric hybrid A/C systems they don’t have an on-board oil injection function. In this scenario techs will need a manual oil injector to inject the necessary amount of oil into the vehicle’s A/C system.

PAG or POE oil injectors perform the same function, but are clearly labeled so technicians know which injector to use with what oil. Having one injector dedicated to one oil type and not mixing oils is a good practice to employ. Using the incorrect oil can damage A/C systems, leading to a seized compressor or requiring an entire system to be replaced. Techs should always check the vehicle underhood label to know what type of system they’re working on, what oil and refrigerant must be used, and should seek training to work on R-1234yf and high-voltage systems to learn more about the new refrigerants and service procedures.

The average lifespan of an A/C RRR machine is 7 years, but it varies based on geography, which impacts how frequently a machine is being used over the course of a year. Over the years, A/C systems have become smaller and more efficient, in addition to systems using high-voltage electronically driven compressors used in hybrid and electric vehicles.

System efficiency of A/C RRR equipment has also improved significantly. In 2007, the industry created and implemented new standards for RRR equipment that include the first recovery efficiency and charge accuracy requirements. Machines manufactured prior to 2007 had no specific performance requirements meaning performance could vary from machine brand to machine brand.

Preventive maintenance

1. Clean the condenser to remove buildup of road debris between the cooling fins. Clogged fins can raise system head pressures which can not only affect cooling but can also cause

USA MANUFACTURER OF INNOVATIVE TOOLS & EQUIPMENT

(845) 679-4500 www.ipatools.com

#5700 Alpha MUTT®

• Automatically generate digital reports • Highly accurate diagnostics and pass/fail circuit testing results • ABS diagnostics available on #5700A

Advanced Diagnostic Trailer Tester

Spanish and French Translations Included in App

Bluetooth ®

Includes: Rain Cover, Chassis Ground Cable, 3-Button Remote, 12-Button Remote, 7-Way Cable, 12' Glad Hands and 10" Tablet

compressor clutch slipping. In some cases you may be forced to remove the grille in order to gain cleaning access. A gap between the radiator and condenser can easily trap road debris. 2. Inspect for system service caps, which should be tethered. Make sure that the correct caps are in place. Improperly fitting caps will not seal properly. 3. Verify that the shroud is not missing, as well as inspect for missing airflow seals. This is especially important if the vehicle has been involved in a collision. There’s always a chance that a body shop may have overlooked this. 4. If a clutch fan is featured (as opposed to electric fans), check clutch condition. With the engine cold and off, the fan should spin by hand no more than 5 times. If the fan spin is stubborn, and/or stops within a single turn, the clutch is partially locked up, which will affect engine warm-up. If the fan spins very easily for about 5 turns with very little resistance, the clutch may be worn or leaking. 5. Inspect electric cooling fan operation (even if a clutch fan is present, the vehicle might also be equipped with an electric fan). Test the blend-air or temperature door operation. Make sure the heater coolant valve and outside air flap door are closed in Max A/C. 6. Check engine idle speed stability. If the engine hot idle remains rough (contaminated throttle body, deposits from crankcase ventilation, etc.) the powertrain computer often shuts down the A/C if engine idle is rough. 7. With the engine idling, turn on the A/C and see if the clutch engages smartly. If it doesn’t, check the voltage to the clutch. If it’s marginal (for example, at or under 11 volts), the clutch may slip in extremely hot weather. Look for a loose or corroded connection at connectors. 8. Do an A/C performance test. The correct procedures vary, so check the service manual. With pressure gauges connected, the system should be in “recirc” regardless of vehicle make/model. (Preventive maintenance tips courtesy the Mobile Air Conditioning Society [MACS].)

Quick system check increases A/C work

With the average age of vehicles on the road today at around 11.5 years, there is an enormous opportunity for A/C charging and related services. When a vehicle enters the shop for work not specifically targeted for A/C work, the system is not likely to be inspected unless the customer has complained about HVAC issues. As a result, the technician may not be prompted to check the system, not seeing the need to roll the diagnostic/ recovery/charging equipment to the vehicle. However, a quick check for leaks and system pressures can be handled using a simple test kit in conjunction with a smart phone

Several manufacturers offer machines for hybrid and non-hybrid applications. An example shown here is Robinair’s 34788NI-H, designed for R134a refrigerant recovery, recycling and recharging. Features include automated refrigerant refill and oil drain, and program to recover, vacuum, leak test and charge. Visual and audible alerts notify the user when service is complete or if a problem has occurred. The machine has the ability to add a printer, USB data sharing, refrigerant identifier and a wireless module for Bluetooth communication.

(or tablet). An example is Yellow Jacket’s ManTooth wireless pressure/temperature gauge kit, which allows a quick connection to high and low pressure sides without the need to use a manifold or machine. Gauges are included for both R-134a and R-1234yf systems. Wireless signals are transmitted to a technician’s smartphone via Bluetooth, providing a fast check of current pressures and temperatures. The check takes only about 3 minutes of additional time as part of standard checks such as tire pressure, fluid levels, etc.

If a leakage/pressure/temperature issue is evident, the customer can then be informed, recommending a system repair or simple recharge. It’s a quick and easy way to up-sell

and increase your A/C work while doing the customer a favor, alerting them to the need for service. Considering the average profit for a recharge is about $70, quick-check technology like this can easily bolster you’re A/C work.

Identifier hose oil contamination

Oil from refrigerant systems is considered a serious contaminant of refrigerant identifiers. This contamination will damage the internal sensitive electronic components in the identifier and must be avoided. There are several known truck A/C systems with a unique low side service point design which have a greater potential to introduce excessive oil into the identifier sample hose. Any vehicle with an under-cab low side refrigerant service port such as those found on 2002 and newer 5000 and 9000 series trucks have this heightened risk.

If refrigerant identification is conducted on these vehicles, the sample hose must be inspected for oil contamination. A reported air concentration higher than 10% could also be an indication of oil contamination. If oil contamination is present, do not continue to test A/C systems. The sample identification hose must be replaced.

Frequently asked questions

Mahle Service Solutions shared a few commonly asked questions regarding recovery/ recharging machine operation.

Q: Why does my machine shut off or work really slow when I try to fill the internal cylinder from an auxiliary cylinder of clean refrigerant?

A. The auxiliary cylinder will cool due to the vaporization of refrigerant. This causes the pressure to decrease. Place the auxiliary cylinder in a bucket of hot water or use a heat belt (available from RTI) to increase the speed of recycling.

Q: Why won’t the compressor come on but the low side gauge has pressure showing?

A. Check the purge gauge (contamination monitor) and make sure the pressure is correct for the ambient temperature. If not, refer to the operation manual for instructions on how to purge the unit or call tech support.

Tracerline’s TP-8692 UV multi-colored fluid dye kit TP-8692 includes three color-coded dyes for petroleum and synthetic based fluids.

Q: Why won’t the machine do a fill during the fill cylinder process?

A: There are two reasons why this might be happening. The first reason is that the yellow hose may not be connected properly. Make sure that the anti-blowback valve is connected to the fill cylinder port and not to the external tank of refrigerant.

The second reason that would cause the fill cylinder process not to work is that the internal tank pressure is greater than the external tank pressure. To overcome this situation, try placing a heat belt on the external tank, or put the external tank into a bucket of warm water. The heat will create a higher pressure, which will help the refrigerant go into the internal tank. If there is no access to a heat belt or warm water, then recycle the refrigerant into the machine.

Q: Why won’t my A/C recycling machine pull into a deep vacuum?

A: The A/C recycling machine must first shut off in a vacuum and hold the vacuum for at least two minutes during the recovery mode. The vacuum process will not run until this happens due to a low pressure switch in the unit not being activated.

Turn the A/C recycling machine to the recycle mode and allow it to pull down and shut off automatically if the low side gauge indicates a positive pressure or is at zero. Make sure the vacuum is stable for two minutes and then start the deep vacuum.