DO OR DO NOT. THERE IS NO TRY: the STATE of DISTILLING

WINTER 2023

BATTLE ROYAL : THERMAL OIL vs STEAM DISTILLATION THAT DARNED cat! TALES of TERROIR

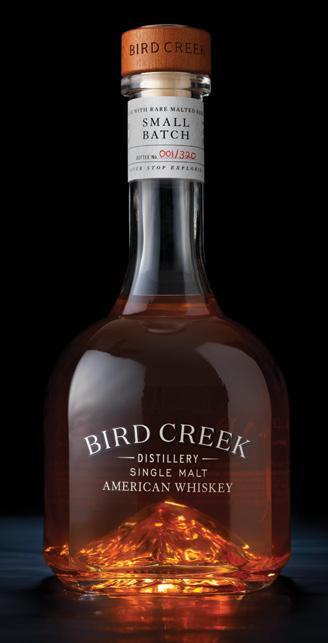

BRAND STRATEGY | STORY DEVELOPMENT | NAMING LOGOS | PACKAGING | CUSTOM BOTTLES | PRINT | DIGITAL DRINK WITH YOUR EYES ® 2787 NAPA VALLEY CORPORATE DR, NAPA, CALIFORNIA 94558 T | 707 265 1891 WWW.CFNAPA.COM CFN216_ArtisanSpiritsAd_2_ FALL_2022.indd

TABLE of CONTENTS

A LETTER FROM THE EDITOR 10

QUARTERLY GUILD & INDUSTRY REPORTS 13

Updates from guilds and associations within states, across the nation, and beyond!

WHY WORKING WITH A BRANDING EXPERT MATTERS 27 Brand Buzz with David Schuemann

THERMAL OIL DISTILLATION VS STEAM DISTILLATION 31 From the Good Guy Distillers

ETHANOLIC ODDITIES 35

Three obscure spirits from around the world

A GENUINE NEVADA PARADISE 39

Frey Ranch delivers award-winning craft whiskey from an unexpected place

THE STATE OF THE CRAFT DISTILLING INDUSTRY 44 Part 1: The distillery’s viewpoint

MCCLINTOCK DISTILLING LOOKS CLOSE TO HOME 48 Beyond the Bottom Line

DIARY OF NOMADIC DISTILLING 53 The journey continues

A TRUE TEXAS PEACH 56

Dietz Distillery brings Old World distilling to the heart of Texas

WHEN IT COMES TO SPIRITS AND COCKTAILS PRODUCTION, SHOULD YOU CAN IT? 60 Part two

INSIGHT AND INNOVATION 66

How kaizen helps teams identify improvement projects

SWAMP SPIRITS 69

Sugarfield Spirits makes craft expressions in Louisiana’s climate

OUTSIDE-THE-BOX EVENTS OFFER DISTILLERS

ADDITIONAL OPPORTUNITIES 72 Learn, network, and witness new perspectives

THE HISTORIC ART OF THE INDEPENDENT BOTTLER 76 Pushing the bounds of history and tradition

GLYCOSIDIC NITRILE AND ETHYL CARBAMATE IN MALTING BARLEY 78 How serendipity leads to GN0 varieties and an outlook for the barley supply chain

GROWING NEW CUSTOMERS IS THE BEST WAY TO GROW TASTING ROOM SALES 83 Building a bigger base

MIDWEST VALUES 85 Worker-owned Switchgrass Spirits strives to bring manufacturing back to St. Louis

THROW AWAY YOUR MBA 90 Going small to grow big

GREEK SPIRITS 93 Tsipouro, mastiha, and ouzo.

WELCOMING THE FIRE DEPARTMENT 96 Fire and Life Safety Corner (AW,

RE-WRITING HISTORY 102 After a decade of damning distilled spirits, WanderFolk aims to transform Oklahoma’s narrative

THE EXPANDING DEFINITION OF TERROIR 106 Tracking the intersection of culture, nature, and production

DISTILLERY ANALYSES: PART ONE 109 Basic analyses: Giving context to analytical requirements

UNAPOLOGETIC 113

The couple behind Wisconsin’s Plank Road Distillery take big pride in the little things

THE HUMBLE FELINE 116 Honoring the renowned distillery protector ADVERTISER INDEX 118

from the COVER Greenbar Distillery in Los Angeles, California. Image by Amanda Joy Christensen. See the story on

page 44

IT’S

MAW YOU’RE JUST JEALOUS)

THE YEASTIE BOYS 98 Let Me Tell You What I Wish I’d Known

Carrie Dow

SENIOR WRITERS

Reade A. Huddleston, MSc.

Gabe Toth, MSc. Devon Trevathan

Jason Barrett

CONTRIBUTORS

Harmonie M. Bettenhausen, Ph.D. Kris Bohm

Scott P. Fisk

Doug Hall

Patrick M. Hayes, Ph.D. Paul Hughes, Ph.D. Adam Lawrence David Letteney Rich Manning

PHOTOGRAPHERS

Campbell P. Morrissy

Michael T. Reardon, P.E. David Schuemann Caley Shoemaker

Gary Spedding, Ph.D. William Thomas, Ph.D. Lisa Truesdale Mark A. Vierthaler Margarett Waterbury Wes Wooddell

ARTISAN SPIRIT

Save the date for our 20th anniversary Craft Spirits Conference & Vendor Expo! August 23-24 2023 more infomation at distilling.com

41 /// WINTER 2023

EDITOR

ISSUE

PUBLISHER &

Brian Christensen CREATIVE DIRECTOR Amanda Joy Christensen

SALES & MARKETING Ashley Monroe ARTISAN SPIRIT is a quarterly publication by Artisan Spirit Media. www.artisanspiritmag.com facebook.com/ArtisanSpiritMagazine ArtisanSpiritM ArtisanSpiritM General Inquiries (509) 944-5919 Advertising (509) 991-8112 PO Box 31494, Spokane, WA 99223 All contents ©2022. No portion of this magazine may be reproduced without the written consent of the publisher. Neither Artisan Spirit Media nor ARTISAN SPIRIT magazine assume responsibility for errors in content, photos, or advertisements. While ARTISAN SPIRIT makes every effort to ensure accuracy in our content, the information is deemed reliable but not guaranteed. We urge our readers to consult with professional service providers to meet their unique needs.

ARTISAN SPIRIT, we take the opportunity to enjoy many different craft spirits and adult beverages. However, it’s also our responsibility, and yours, to always drink responsibly. Know your limit, and never drink and drive.

Whitney Barclay Amanda Joy Christensen Carrie Dow David Letteney Devon Trevathan

At

’s number one goal is to share and celebrate the art and

But please

to follow

the laws,

and

Be safe, be legal, and we can all be

the industry we love.

science of artisan craft distilling.

remember

all

regulations,

safety procedures.

proud of

Where S cience Meets Ar t

Yeast, Nutrients, and Process Aids

At La l l e m a n d D ist i l l i n g, o u r si n g l e s o u rce p h i l o s o p hy p rovide s t h e hig h es t q u a l i t y i n g redi e nt s, t a i l o re d te c h n i c a l s e r v i ce a n d e d u c at i o n , a n d i n d u s t r y l e a di n g experi e n ce to s u p p o r t yo u r n ee d s. Yo u r spirit s a re o u r p a ss i o n , yo u r needs a re o u r m o t i vati o n . Contac t us to learn more today. w w w.lallemanddistilling.com

Cage and

THANK YOU TO ALL OUR SPONSORS.

Our mission at Artisan Spirit Magazine is to share and celebrate the art and science of artisan craft distilling. We are humbled by the support of our sponsors. With their help, we can further our common goals of supporting creativity, innovation, and integrity within the industry we all love so much.

The American Spirits Exchange is a national importer and distributor serving the alcoholic beverage industry (spirits, wine, and beer). We provide domestic and international companies with access and support to the U.S. market. Regardless of your size — from micro, craft distiller to publicly traded multinational — our focus fuels your growth. Our flagship Foundations™ program provides companies with access to the U.S. market. We handle your business-to-business functions from start to finish: permitting, brand approvals, purchase order processing, invoicing, and compliance.

Boelter is a strategic partner to the most successful distilleries, breweries, beverage distributors, wineries, and cidermakers in the country. With over 90 years of beverage industry experience, we provide guidance and essential promotional products to ensure that through every service and season, our partners are performing at their peak. Our key product categories include glassware, tap handles, coasters, cups, and barware, but we pride ourselves on our willingness to work hard to serve our customers — whatever their need may be. We are passionate and enthusiastic because we believe we have a purpose that transcends the day-to-day work that we all do.

BSG is focused on supplying craft distillers with the best ingredients from around the world. The craft distilling market trusts BSG to deliver the finest ingredients at competitive prices, without sacrificing customer service. With distilling malts and grains from Rahr Malting Co., Weyermann®, Simpsons, Crisp and Malting Company of Ireland, as well as a full range of yeasts, yeast nutrients, enzymes, botanicals, and finishing products, we have a wide range of distilling ingredients to help you create high quality, artisanal spirits.

Distilling Systems build premium distillation systems and equipment

for premier distilleries.

Every element of Cage and Sons equipment is designed and crafted to provide you with the very best distilling experience at an affordable rate because we know that bottom line matters, but so does function. At Cage and Sons, adequate is never an option, and we continue to develop and design new high functioning, cutting-edge distillation systems that enhance the distillation industry. Cage and Sons works every day to bring you the very best distillation systems for the very best value.

Sons

6 WWW. ARTISANSPIRITMAG .COM

Unlike other agencies that work within a blinding myriad of industries; our focus is 100% within the spirits, wine, beer, and other alcohol sectors. This specialization has allowed us to become experts in the alcohol beverage category. We have an exceptional understanding of design that sells, complemented by professional project management and flawless production oversight. The result has been strategic solutions that consistently produce both critical acclaim and strong measurable return on investment for our clients.

The Distilled Spirits Council of the United States (DISCUS) is the leading voice and advocate for distilled spirits in the United States. Representing producers and marketers of distilled spirits, DISCUS advocates on legislative, regulatory, and public affairs issues impacting the distilled spirits sector at the local, state, federal, and international levels; promotes the distilled spirits sector, raising awareness and opening markets in the United States and around the globe; and encourages responsible and moderate consumption of distilled spirits as part of a healthy adult lifestyle based on evidence-based research and policy. DISCUS also powers Spirits United, a grassroots platform for the distilled spirits industry. Spirits United is comprised of a community of advocates united with a common goal: to ensure adult consumers can enjoy distilled spirits where they want, how they want, and when they want. Learn more at distilledspirits.org and spiritsunited.org.

Trusted Oak Expertise Since 1912.

We’ve been in this industry for over 100 years, during which time we’ve learned a thing or two about what makes a great barrel to age great spirits. Our R&D team and account managers have hundreds of barrels currently in experimentation. Partnering with distillers, we think outside the box to develop new products that push your vision forward.

Our Mission: To craft world-class oak barrels and other cooperage products so our employees, customers, and communities flourish.

Lallemand Biofuels & Distilled Spirits is the industry leader in supplying fermentation products and valueadded services to the distilled spirits industry. We specialize in the research, development, production, and marketing of yeast and yeast nutrients as well as a solid belief in education of the distilled spirits industry. A vital part of the alcohol production process, fermentation products from Lallemand Biofuels & Distilled Spirits have been designed and selected to create value by tailoring objective solutions to distillery needs.

Standing out in a crowded marketplace is an ongoing challenge for wine and spirits producers today. MCC’s experienced team of label engineers take a consultative approach, helping guide your project from inception to finished label. Whether it's an existing design, or a highly embellished new project, we are poised to give your brand the look it deserves. Housing many different printing technologies under one roof allows us to match our passion and expertise to your project, each and every time, without compromise. This ensures that your final packaging always achieves the desired look. With MCC and Fort Dearborn recently joining forces, we are poised to provide all spirits customers with amazing service and quality products.

WWW. ARTISANSPIRITMAG .COM 7

Moonshine University is located in Louisville, Kentucky on the Beverage Campus with its sister company, Flavorman. Moonshine University offers a variety of classes for enthusiasts, entrepreneurs, industry professionals, and those seeking careers in the distilling industry. Our distillery was designed as part of our classroom, and all classes incorporate hands-on learning and sensory evaluation in order to provide a complete and comprehensive education. In addition to its knowledgeable instructors, Moonshine University hosts a range of renowned industry experts for specialized instruction and training.

Founded in France in 1897 and based in the USA for more than 30 years, Saverglass provides for the premium & super premium spirits and wines. Over the years, the Saverglass Group has distinguished itself by its undeniable quality of glass coupled with innovative decoration techniques. Today, one of Saverglass’ main asset lies on its product offer: 110 original designs and 425 references which represent the largest selection on the market! Thirsty for genuineness, Saverglass has created exclusive bottles dedicated to Artisanal distilleries: The Craft Spirits collection is designed to convey the image of authentic, locally sourced and rare high-quality products. Recently, the Group has strengthened its presence and service offering in the U.S. by opening an ultra-modern bottle manufacturing and decorating plant in North America.

Southern Distilling Company is one of the largest artisan distilleries in the nation. We offer product development, contract distilling (standard and custom mash bill whiskeys, rum, and agave spirits), barrel warehouse aging, batching, blending, bottling, and co-packaging of award-winning products.

We also keep an extensive inventory of aged bourbon and rye whiskey available year-round.

Our spirits are distilled in top-of-the-line Vendome Copper & Brass Works continuous column stills. Our product development services include working with you to perfect an existing recipe and consultations to help you create your own recipe. We can barrel and warehouse age your product to meet both short and long-term goals. At Southern Distilling Company, you get standout spirits that make brands unforgettable.

For over 60 years Tapi USA has produced cork stoppers and a wide variety of bottle closures. Family-owned and operated since its inception, our company continues to develop new products and enter new markets. Tapi USA is proud to support the growth of the artisan distillery industry and is honored to be the Bottle Closure Sponsor for Artisan Spirit Magazine.

Total Wine & More is the country’s largest independent retailer of fine wine, beer, and spirits. Our strength is our people. We have over 5,000 associates, who must demonstrate comprehensive beverage knowledge before they are invited to join our team. After coming on board, all of our team members undergo an extensive initial training program. We believe that an educated consumer is our best customer. We want to demystify the buying experience for our customers so they will feel confident in choosing the bottle that is perfect for them. Total Wine & More works closely with community and business leaders in each market it operates to support local causes and charitable efforts.

8 WWW. ARTISANSPIRITMAG .COM

A LETTER FROM THE EDITOR:

Where do we go from here? It’s a question I’ve found myself asking, alongside a not-insignificant portion of the distilling community. Personally, the question is predicated on recently celebrating 10 years publishing in the industry. That means reflecting on what works and what can be improved, and searching out what readers need most, now and for the next 10 years to come. For many others in the distilling industry, the question is based on having come through a global pandemic and preparing for the likelihood of a recession alongside continued economic pressures such as inflation and supply chain issues.

Honestly, it's not all roses and fresh-faced optimism like it was 10 years ago. Not every distillery will make it. That hurts to say, but it doesn't mean it's going to be all bad, or even mostly bad. It just means the industry has to adapt and do what it does best: Support our peers, share our knowledge, educate our customers, and build our communities.

I still firmly believe these are the foundational elements of what makes this industry so damn special. So, that’s what we are going to do. Share more, listen more, and keep reaching out to every distiller, vendor, and professional in this industry to keep the communication going while strengthening our ecosystem of nerds, entrepreneurs, and friends.

With that in mind, I want to again give a special thanks to our amazing writers and contributors. I’m really proud of this edition. It has some of the best hard science and technical content we have published to date, along with a strong showing of spotlights, business strategy, marketing, and industry news roundups. I’ve always joked that half the reason we run this trade publication is because I selfishly want to read these articles, and that hasn't changed yet.

To summarize in technical terms, things may suck for a while, but you are not alone. You will get through these times, and if it ever feels like you won’t, then pick up the phone or send an email to us or to other people in the industry who care. There are so many more than you think. We have your back, and we are incredibly grateful that you have ours, too.

greatest appreciation, Brian Christensen

///

10 WWW. ARTISANSPIRITMAG .COM

With

(509) 944-5919

brian@artisanspiritmag.com /// PO Box 31494, Spokane, WA 99223

QUARTERLY REPORTS

QUARTERLY GUILD & INDUSTRY REPORTS

The end of the year marks the OND sales rush, but that doesn’t mean state distilling guilds are putting off their dreams of future legislative action. From California to Oklahoma, distilling guilds are laying the groundwork for legislation to expand spirits availability in stores, make direct-to-consumer (DTC) avenues permanent, and even tackle recycling within their state. We wish the best of luck in 2023 to all the guilds and associations out there that work together to improve the industry for us all

Brian Christensen Editor, Artisan Spirit Magazine

AMERICAN CRAFT SPIRITS ASSOCIATION

The American Craft Spirits Association is looking forward to celebrating its ten-year anniversary and the first convention on the West Coast in a number of years. I look forward to connecting with many of you in February with an incredible lineup of education, networking, and mingling with our partners in the industry. Our education committee has been raising the bar on the offerings on all three tracks: technical, business, and sales and marketing to reflect the rapidly changing landscape we all operate in. Our trade show is a perfect opportunity to connect with our supplier partners, meet vendors with new offerings, and even connect with distributors. There is nowhere like the ACSA convention to really gauge the state of the

industry and connect with its key players.

In 2022, ACSA has also been investing in its ability to effectively advocate in the interest of small independent distillers. We welcomed Michael Walker to the team as our state policy advisor to help ACSA better follow and advocate in the interests of our members at the state level. Michael has an extensive background in government affairs relating to alcohol policy, and we are looking forward to being able to deploy this expertise to further state level initiatives like DtC shipping. I encourage every distiller to join their state guild if they have not already. Making progress in our ability to connect with our customers in a modern way is crucial for distilleries navigating a landscape of

UPDATES FROM GUILDS AND ASSOCIATIONS WITHIN STATES, ACROSS THE NATION, AND BEYOND!

13

increased consolidation in the wholesale and retail tiers. These changes will not come overnight and they will not be easy to gain.

As always, we encourage distillers to join ACSA if they are not already members at

www.americancraftspirits.org. We are a nonprofit trade association owned by distillers to support and advocate for small, independent distilleries. We are craft spirits.

AMERICAN DISTILLING INSTITUTE

Thank you to all that attended ADI 2022 — it was a huge success! With approximately 1,500 attendees and over 200 vendors in attendance, ADI’s annual conference was once again the largest conference of distillers in the world, for 19 years running. Highlights included a keynote by Dr. Anne Brock of Bombay Sapphire, sold-out workshops on topics ranging from corn whiskey to botanical spirits, the wonderful hospitality of St. Louis, and a casino party previewing next year’s 20th anniversary conference in Las Vegas.

Major updates from ADI include work on direct-to-consumer (DTC) sales and gearing up for our 20th anniversary celebration in 2023.

DTC Is the New FET

Over the past year, ADI has continued to work diligently to support legislative efforts towards DTC laws. The stakes could not be clearer. The permanent reduction in federal excise taxes enacted at the end of 2020 was ultimately a huge win for craft distillers, lifting bottom lines and allowing distillers to keep tens of thousands of dollars per year.

We must now get permanent DTC legislation passed. The Ship My Spirits coalition, composed of ADI, ACSA, and DISCUS, recently added the California Artisan Distillers Guild. The goal of this coalition is to support DTC legislation that follows two principles:

1) Applies to all distillers

2) Allows for shipping in and out of state

Like FET, which was originally introduced as only for craft distillers but gained momentum when it was changed to include distillers making over 100,000 proof gallons, all distillers must be part of the solution. There are numerous opponents to DTC, including beer and spirits distributors, labor unions,

and retailers. Kentucky, which currently allows DTC in-state and to 16 other states, is a valuable case study. There are many large distilleries in Kentucky, and DTC privileges have not caused a decrease in sales among craft distillers in allowed destination states.

Thirty years of Wine Institute data makes it clear who will benefit the most: small craft producers.

2022 brought many DTC setbacks, with craft distillers in multiple states losing their ability to ship as temporary COVID-related measures were allowed to lapse. To win this fight, we must engage beyond distillers and their opponents. The efforts in state capitals are a conflict between two groups of businesses. DTC is ultimately about consumer access to spirits. Consumers must contact their legislators, and that contact must be initiated in tasting rooms, where bartenders and servers can educate customers about the importance of getting legislation passed in your state. The Ship My Spirits program makes it easy for distilleries to facilitate direct consumer contact with legislators. (Visit www.shipmyspirits.org for details.)

New legislation will be proposed for DTC access in 2023, and the Ship My Spirits coalition will support all legislation that meets the principles stated above. I hope all the distillers and all their customers can get on board with the coalition to make the big push to get this done.

Celebrating 20 years

Twenty-something years ago, ADI founder Bill Owens had the idea to drive around the country to visit the 24 very small craft distilleries in the U.S. After he finished that trip, he came home and founded the American Distilling Institute.

As a veteran of the brewing industry, he

Rebecca L. Harris

had a front-row seat for the explosive growth of the brewing industry and the formation of an amazing community of brewers, and he knew that the distilling industry was poised for the same growth. He organized the first ADI conference in Alameda, California, in 2003. About 60 people showed up.

Next year, ADI will host its 20th conference in Las Vegas August 23-24. ADI 2023 will be a celebration of the community of spirits lovers, artists, entrepreneurs, and visionaries that has formed over the past two decades, and of the explosive growth of craft distilling. Like all ADI conferences, we look forward to welcoming distillery founders, craftspeople, employees, media, and vendors of all types, including suppliers like Forsyth, Vendome, and Tapi who were at the original conference way back in 2003.

Our conference will have many of the same elements we have had this year, including a whiskey summit, a gin summit, the largest expo floor in the world, and the largest gathering of distillers in the world. Instead of a single keynote speaker, Distillery of the Year recipient Robert Cassell will host a panel of six distillers who were in business 20 years ago and are still operating successful distilleries today. It turned out that Bill was correct about the growth of the industry. American distilling has been forever changed by those 24 pioneers, evolving into the amazing community we have today.

Distilling Research Grant

Over $3500 was generated by the auction, and MGP donated an additional $6000 to raise a total of $9500. Thank you to all of you that donated goods and services. The next round of requests for proposals will be open Feb 1 to March 31, 2023.

Erik Owens President, American Distilling Institute

President, Head Distiller, Catoctin Creek

Secretary, Board Member, STEPUP Foundation President, American Craft Spirits Association

14 WWW. ARTISANSPIRITMAG .COM

Your Source for All ings Fermentation

Our mission is simple: to help you cra the best beverage possible.

To do that, we curate the most comprehensive and ever-expanding portfolio of ingredients and products in the industry.

But being a complete supplier means more than having the biggest catalog –we’re also a leader in innovation, technical expertise, and novel solutions for your business.

at’s why BSG is a trusted partner to distillers everywhere.

Learn more at www.BSGcra .com

CRAFT MALTSTERS GUILD

Barley harvests took place across North America over the past few months. Winter barley is typically harvested in June throughout much of the eastern United States. Spring barley is harvested in August or September across the midwest and western portions of the country. Spring barley represents a large portion of malting-quality material and 2022 helped replenish stocks after a dismal harvest in 2021. This year’s winter barley quality and yields were above average.

In September, the Guild hosted our third Craft Malt Week, designed as a celebration of the craft malt community, and we were thrilled to see companies from across the

small-grain supply chain show up digitally. Member (and some non-member) malthouses, beer and spirits producers, barley researchers, and even industry vendors posted educational information and stories about why craft malt matters on their social media accounts.

Several Craft Malt Certified breweries and distilleries used this week as an opportunity to share that commitment, with a handful of them even offering events and special beer and spirits releases. Craft maltsters across the globe leveraged Craft Malt Week to remind their audience about the essential agriculture that drives the industry. It was exciting to see

so many operations in the thick of the colorful harvest season.

We are excited to announce that Rob Arnold, author of The Terroir of Whiskey: A Distiller’s Journey Into the Flavor of Place, will be providing the keynote address at our sixth annual Craft Malt Conference in Portland, Maine this coming March 16-18, 2023. Arnold, along with a wide variety of academics, maltsters, and brewing and distilling industry professionals will present to an in-person audience for the first time since 2020. Visit www.craftmalting.com to learn more and register for the event.

DISTILLED SPIRITS COUNCIL OF THE UNITED STATES

Celebrating Bourbon Heritage Month

It was great to celebrate our nation’s native spirit during the 15th anniversary of National Bourbon Heritage Month alongside bourbon producers, consumers, and advocates throughout September! DISCUS hosted its annual Bourbon Caucus event on Capitol Hill and presented Representative John Yarmuth (D-KY) with a commemorative bottle to thank him for supporting the industry and founding the bi-partisan Bourbon Caucus in 2009. Representative Andy Barr (R-KY) joined Yarmuth, cochairs of the Bourbon Caucus, in penning an op-ed in The Hill for National Bourbon Heritage Month celebrating the pride of Kentucky and the meteoric rise of bourbon distilleries across the country. The congressmen said, “This bourbon heritage month, let’s raise a glass to this truly American spirit, and its ability to create jobs, revitalize towns and sectors, and help us make new friends — even across the aisle.” Although our month-long celebration has come to an end, it’s never too late to

visit a bourbon producer and enjoy this distinctive product of the U.S. by planning your next trip through Destination Distillery. This new initiative, powered by DISCUS, is the perfect place for spirits enthusiasts to discover distilleries and trails across the U.S.: Destinationdistillery.com.

Bringing Industry Advocates Together

Read op-ed by Reps John Yarmuth (D-KY) and Andy Barr (R-KY)

The DISCUS/American Craft Spirits Association Public Policy Conference was a great opportunity to engage with elected members on Capitol Hill. We had more than 200 distillers from 41 states participating in more than 120 virtual congressional visits. Attendees heard from senior officials from the Tax and Trade Bureau (TTB), Representative Dan Newhouse (R-WA), and Senator Gary Peters (D-MI) before splitting off into more localized meetings. Advocates discussed the importance of distilleries to their local communities and the national economy, as well as policy issues impacting the industry. It is critical that legislators see the impact their local distillers have not only on the spirits industry, but on farming, manufacturing, tourism, and so much more. This year’s conference closed with a virtual toast honoring World Central

Kitchen with the first-ever Humanitarian Spirit Award and by raising a glass with Shannon Mustipher, winner of the Tales of the Cocktail Pioneer Award. Thank you to all who joined us for a memorable two days of advocacy and we hope to see advocates in person next year.

New Report Highlights Rapid Growth of Spirits-Based RTDs

DISCUS recently issued a research report analyzing the growth of spirits-based readyto-drink (RTD) cocktails, including new poll data identifying consumer preferences driving the overall RTD market.

“What’s clear from our research is that when it comes to RTD beverages, the majority of alcohol consumers prefer those that are spirits-based,” said Robert Blizzard, partner at Public Opinion Strategies. “American consumers are increasingly prioritizing convenience, taste, variety, and quality in their choice of beverages.

Spirits-based RTDs fit squarely in this trend, so it’s no surprise these products

Read full spirits-based RTDs research report

Brent Manning Board President North American Craft Maltsters Guild

16 WWW. ARTISANSPIRITMAG .COM

Join The Fight at NASID.org AFTER 30 YEARS LEADING THE FIGHT TO ELIMINATE DRUNK DRIVING RESPONSIBILITY.ORG ESTABLISHED NASID TO CONTINUE THE FIGHT AGAINST MULTI-SUBSTANCE IMPAIRED DRIVING.

are leading the spirits category in both market growth and consumer popularity.”

The report, which is based on a recent consumer survey conducted by Public Opinion Strategies and economic data from DISCUS and IWSR Drinks Market Analysis, found that premixed cocktails, which include spirits-based RTDs, were the fastest growing spirits category in both revenue and volume in 2021. Nearly two thirds of survey respondents consider themselves to be regular or occasional consumers of RTD beverages.

Additionally, the report highlighted that adult consumers overwhelmingly want greater access to spirits-based RTDs in the marketplace, including at restaurants and bars, grocery and convenience stores, and entertainment venues like concerts and sporting events.

Success with FDA Hand Sanitizer Information Request Letters

DISCUS staff and other distilling community members met with leaders at the Food and Drug Administration (FDA) to address concerns regarding FDA letters many distillers received requesting information about hand sanitizer they produced early in the pandemic under FDA’s temporary policies. DISCUS urged the FDA to rescind these requests and accept a less onerous response, such as certification that distillers are no longer producing, distributing, or selling

sanitizer. We’re pleased to report the FDA has agreed that distillers may provide a more limited set of information in response to these letters, which may be sufficient to alleviate concerns for most distillers.

Underage Drinking at Historically Low Levels

We are glad to see underage drinking at historically low levels, but there is still work to be done to continue the progress. Together, we must continue to work to keep alcohol out of kids’ hands and drive this number even lower. You can join us in continuing to show your commitment to never serving, selling, or providing alcohol to teens or anyone below the legal drinking age by taking part in the We Don’t Serve Teens campaign dedicated to reducing underage drinking and stopping teens’ easy access to alcohol. This campaign was first launched in 2006 in a partnership with the Federal Trade Commission and other public and private sector organizations. Numerous control state agencies, state retail associations and alcohol manufacturers, distributors and wholesalers are all recommitting to the We Don’t Serve Teens campaign and getting this important message out — underage drinking is not acceptable.

In the upcoming weeks, We Don’t Serve Teens partners will be able to:

1) Order We Don’t Serve Teens materials to distribute at their places of business, to display on their cold cases or entrances, or at point-of-sale registers, kiosks, or on receipts. These materials will be available via BrandMuscle — both in their current asset portal as well as a custom We Don’t Serve Teens portal. They are also available in a Digital Toolkit.

2) A We Don’t Serve Teens webinar will have taken place on November 1, 2022, to hear the details of the campaign and how they can participate.

3) Starting on November 14, post their support on social media and educate their followers about their commitment to never provide, serve, sell or otherwise make alcohol available to teens or anyone under the legal drinking age. Social images and content are included in the Digital Toolkit as well.

4) Share the We Don’t Serve Teens campaign information to other industry partners and encourage them to participate as well.

We look forward to continuing the important work of reducing underage drinking.

R. Swonger

AMERICAN STATE GUILDS

CALIFORNIA

CALIFORNIA ARTISANAL DISTILLERS GUILD

California Artisanal Distillers Guild (CADG) has had success in 2022 with our legislation AB 920, allowing DTC shipping for craft distillers. Our previous effort, AB 620, was killed by the process at the end of August. A quick Hail Mary last minute play

was assembled that is AB 920. The CADG executive team pulled together with legislative advocate Nate Solov of Nossaman LLC. In less than a week, the new DTC shipping bill was written and passed in both the assembly and senate during the last week of the legislative session. The bill language and unanimous votes show the support small distillers have gathered in the capitol. Governor Gavin

Newsom gathered a group of bills designed to help small businesses, signing the bill and making the privilege to ship immediately available. As of September 29, 2022 until December 31, 2023, Type 74 DSPs can ship to California consumers. Countless hours and all of our budget was spent chasing this important privilege that is vital to so many of us.

Chris

President & CEO Distilled Spirits Council of the United States and Responsibility.org

18 WWW. ARTISANSPIRITMAG .COM

Learn more about the We Don’t Serve Teens campaign

INNOVATIVE SOLUTIONS since 1912

A barrel should be more than an aging vessel, it should be a partner in achieving your desired flavor profile. Using science-based research and experimentation, ISC barrel experts collaborate with world-class distillers to create innovative barrel solutions for their unique spirits.

iscbarrels.com

We are working on the permanent bill now for introduction in the 2023 legislative session. This will be a major effort and will bring CADG into a consortium with ACSA, DISCUS, ADI, various distributor industry groups and others that may include the California Family Wine Makers, The Wine Institute, California Craft Brewers Association, and other interested parties. The permanent bill will include concerns that include Granholm Compliance and the inter-state shipping issue, along with labor compliance or other industry issues. CADG also wants to represent all our members and will

work on including Type 4 & Type 7 licensee’s and out of state issues. DTC shipping is a hot-button subject in California, but also across the country.

California also will have a recycling program for wine and distilled spirits bottles. SB #1013 was signed by Governor Newsom Sept. 28, 2022 and goes into effect July 1, 2024.

Membership for 2023 will be critical to success on this major legislative push. The hope is to increase membership and unify statewide DSPs of all license types, welcome vendors and allied supporters to help. California

is a large state with many regions and CADG hopes to represent all DSPs on a statewide basis. Regional groups can play a big part in the success of CADG and we hope to work with all to continue the legislative success.

These efforts are not magic, nor do they come by somebody else doing our work.

California needs a unified voice at the state level working on all the issues important to us all. We welcome all to join and become part of the voice for California distillers.

ILLINOIS

ILLINOIS CRAFT DISTILLERS ASSOCIATION

The Illinois Craft Distillers Association (ICDA) is currently focused on enacting direct-to-consumer shipping in Illinois. To this end the ICDA has engaged a government affairs organization that previously helped Illinois distilleries achieve a legislative victory in 2019 when we successfully updated the state licensing structure to achieve greater

parity with other beverage alcohol producers.

This guild is also very excited to be planning the first public tasting event since 2018, where member distilleries will showcase the breadth of spirits from across the state of Illinois. In order to achieve the highest turnout, ‘Distillinois’ will be held in June 2023 to coincide with the DISCUS conference in Chicago.

In the first three quarters of this year, our guild has been able to increase distillery participation rate as well as supplier membership.

In order to build on this, ICDA membership voted during its third quarterly meeting for the Board to spend the coming months gaining input from other distillery trade organizations to better understand the potential to create a broader membership and governance structure.

Please contact us at President@ IllinoisDistillers.org if you would like to join our community as a distillery member or industry sponsor, or otherwise connect.

MARYLAND

MARYLAND DISTILLERS GUILD

Maryland now boasts nearly 50 distilleries, with more in the licensing process. The vast majority are members of the Maryland Distillers Guild (MDG), and a number are joining together to create “Spirits of Collaboration,” unique collaborations that are donated to the guild to raise funds to support its efforts. The first two spirits are:

> VOLUME 1 – GIN : Gray Wolf Craft Spirits

and McClintock Distilling Company. This Spirit unites eastern and western Maryland distillers. The flavor profile of this gin is vapor infused with 23 different botanicals and is inspired by Maryland’s native flavors.

> VOLUME 1 – RUM : Lyon Rum and Puerto Rico Distillery. Tamarind Honey Flavored Rum (almost sold out!)

MDG and its members joined the ACSA/ DISCUS Policy Conference to help support

the push for USPS Shipping Equity Act as well as a few other agenda items relative to our industry. In quarter four, we’re finalizing our plans as a guild to address a few legislative items we need to help our business advance forward, including pursuing extensions of emergency provisions afforded the industry during the pandemic.

Finally, November was Maryland Spirits Month, and various restaurant and retail accounts highlighted locally-produced spirits through promotions and events.

Brian Treacy Co-Founder & President, Sagamore Spirit

Cris Steller

Executive Director, California Artisanal Distillers Guild

Ari Klafter President, Illinois Craft Distillers Association Head Distiller, Thornton Distilling Company

20 WWW. ARTISANSPIRITMAG .COM

WHEN GLASS IS A TASTE EXPERIENCE. BY YOUR

Vetroelite Inc T: +1 646 559 0674 T: +1

984 3178 www.vetroelite.com ORIGIN LINES - VETROELITE ∧ SELF PROMOTION

SIDE, SINCE 1994.

(518)

NEW YORK

NEW YORK STATE DISTILLERS GUILD

A broad broad swath of the New York State Distillers Guild’s more than 100 members gathered virtually in October to share information, experiences, and ideas on public policy, marketing, and industry developments.

The guild is closely monitoring legislative elections in New York State, which will shape our efforts to regain the ability to ship DTC, a privilege the industry had temporarily during the COVID-19 emergency. The guild is also building on a significant legislative win in 2022 that brought parity with other beverage manufacturers on several fronts under the state’s Alcoholic Beverage Production Credit. The guild is closely monitoring the actions of a new Commission to Study Reform of the Alcoholic Beverage Control Law and is keeping our members abreast of developments

and weighing in to the greatest degree possible. The guild is also monitoring enhanced producer licensing legislation and recycling proposals in New York and in other states.

Our public policy efforts benefit strongly from collaboration with New York’s other craft beverage manufacturing trade associations, as well representatives of the agricultural sector. We recommend that other guilds reach out to form similar alliances wherever possible. Across the 50 states opponents of our public policy goals have long-standing influence and relationships with public policymakers, so collaboration and cooperation will be key to victories on major issues like DTC and parity. The guild also enjoys strong ties with our national spirits trade association partners, which provide infrastructure to help catalyze consumer contacts with their elected representatives on DTC.

The guild is as strong as it has ever been, with a robust membership and a sponsorship program that brings benefits to our membership as well as our related industry partners. We have completed a major initiative to increase representation of our membership on our consumer-facing website, NYDistilled. com. The site shows the strength and diversity of our membership — highlighting a wide variety of products produced in every region of the state and in big cities, small towns, and on farms and in orchards.

The Guild’s membership is looking forward to gathering in person in the first quarter of 2023 in the Empire State’s capital region. The meeting, which will take place near the capitol during the legislative session will provide excellent opportunities to engage with elected officials and executive branch regulators and economic development officials.

NORTH

CAROLINA

DISTILLERS ASSOCIATION OF NORTH CAROLINA

The Distillers Association of North Carolina (DANC) held its fall meeting on September 29 at Mystic Farm and Distillery in Durham, North Carolina. The meeting was well attended, including representatives from 25 distilleries and 12 vendors who showcased their services and products for distillers.

Chairman Hank Bauer of the North Carolina ABC Commission provided an update on how the commission is modernizing its operations including improving their website, offering online permitting, and updating their pricing system. The commission has also begun planning for a new state

warehouse building.

Bruce Tyler, DANC vice resident and owner of Weldon Mills Distillery, presented a proposal on how DANC can market North Carolina’s growing distilling industry that builds on the state’s long history of producing spirits prior to Prohibition. The proposal was well-received by DANC members, and the association will continue to focus on promoting our industry to North Carolinians and out-ofstate visitors.

In October, DANC sponsored the Spirited Pie Competition at the North Carolina State Fair, which offered cash prizes for the best pies made using a DANC member’s spirits as a pie ingredient. The pie event received 34 entries — the most entries of all the state fair cooking

competitions. The judges were very busy tasting and comparing so many pies! DANC’s state fair sponsorship included the opportunity for distilleries to offer free tastings of their products on the same day as the pie competition. Ten DANC distillery members poured free samples for state fair attendees during the event, which was the first time that legal spirits were served at the North Carolina State Fair. The state fair also invited Broadslab Distillery, the state’s first farm distillery and a DANC member, to exhibit and demonstrate distilling throughout the ten-day State Fair. DANC appreciates our partnership with the North Carolina Department of Agriculture and Consumer Services and the opportunity to promote our industry at the fair.

OKLAHOMA

OKLAHOMA DISTILLERS GUILD

Back in 2016, the passage of Oklahoma Senate Bill 424 (allowing full-strength beer

to be sold at breweries) and Oklahoma State Question 792 (allowing wine and all beer to be sold at grocery and convenience stores and enabling liquor stores to sell cold beer) were among the hallmarks in Oklahoma alcohol

reform. Originally the lobbyists hired by private companies had wanted to go after liquor in grocery as well, but had decided to wait until a later date in hopes of just getting ‘something’ through. It seems as though the time

Teresa Casey Executive Director, New York State Distillers Guild

Leah Howard President, Distillers Association of North Carolina, CEO, Cultivated Cocktails

22 WWW. ARTISANSPIRITMAG .COM

The soul is in the details.

We’re a branding and design agency built to show brave brands a way forward. We deliver strategy, storytelling and package designs that move products off shelves as fast as they’re stocked.

See more examples of our branding and label design work

creaturetheory.com

Photography: Andrew Welch

has come and this next legislative session is where the new liquor bill will be presented to congress. The bill will likely begin as a push for liquor sales in all grocery and convenience stores, but it could very well end in

an agreement for liquor and spiritous RTDs in grocery stores with an allowance for spiritous RTDs of only 17 percent ABV or less in convenience stores.

We don’t have much else to share at this

time, though that piece of legislation will obviously be a massive change to our culture here in Oklahoma.

SOUTH CAROLINA SOUTH CAROLINA CRAFT DISTILLERS GUILD

Since partnering with its association management partner, Sweatman Strategies, this year, the South Carolina Craft Distillers Guild (SCCDG) has seen tremendous growth and organization come to the guild.

As part of its new initiatives, the SCCDG has been busy planning and preparing for its first ever Meeting and Trade Show on November 10, 2022, at

High Wire Distilling in Charleston, SC. This event, a landmark for the South Carolina guild, will bring together more than 15 members and over 10 new affiliate members for a day of networking, industry education and association operations updates. Due to overwhelming participation, this not only be the first fundraising event for the guild but also its most successful event.

The SCCDG is excited for the many upcoming events this year,

as well as the 2023 legislative session and continued growth.

IS YOUR

Share your latest victories, recruit supporters, request suggestions to solve your latest challenges, and inspire fellow groups. EMAIL BRIAN@ARTISANSPIRITMAG.COM TO GET INVOLVED!

GUILD OR ASSOCIATION

MISSING? Don’t miss out on this opportunity to reach a national audience of distillers and suppliers!

Jeffrey Alan Cole Spirits Director/Distiller, WanderFolk Spirits

24 WWW. ARTISANSPIRITMAG .COM

Campbell Mims Association Manager, South Carolina Craft Distillers Guild

The

ClearSource is a premier supplier of high-purity alcohol products specializing in grain neutral spirits made from New York corn.

Distilled seven times through nearly 600 feet of distillation, our world-class distillation system produces alcohol products that contain virtually no impurities and no detectable organoleptic characteristics.

Request A Sample

Clear Choice for Your Grain Neutral Spirit Needs clearsourceus.com Medina, New York sales@clearsourceus.com 585.798.6695

WHY WORKING WITH A BRANDING EXPERT MATTERS

When new customers encounter your brand, they meet your packaging before anything else — after all, we drink with our eyes first.

You’ve spent so much time and money to start your brand and your heart and soul are in every sip. While it may be a bargain at first glance, hiring an amateur is risky and will likely cost you far more time, money, and lost sales in the long run. Experts never seem expensive once you’ve paid amateurs.

Experts don’t exist by accident either. Years, often decades, of experience separate experts from the rest. But experience doesn’t always equal expertise — experts will not only have deep and broad industry knowledge but an abundance of focused creativity paired with deep market insights on what will sell.

Here’s how to identify experts in the alcohol beverage industry:

> First and foremost, the alcohol beverage industry is highly regulated — an expert will be fluent in TTB regulations. They will be able to deliver final files that are legally compliant, and if issues or questions arise, they’ll navigate these alongside you to solve them.

> Experts ask the crucial questions up front, setting clear aesthetic and strategic goals at project kickoff. They will make sure they understand key objectives and budget restrictions, and their creative and strategic questions are answered

before starting work, to save budget and time. They will work with you to understand your business plan, tiering structure, and sales objectives.

> An industry expert understands supply chain challenges. They can help you navigate this complex landscape and will have best-in-class vendor relationships that you will be able to leverage to get the best materials and thus, the best packaging results possible.

> Experts will help manage the production process, gather bids, and negotiate the best possible pricing. Once vendors are chosen, they will conduct meetings to avoid pitfalls and leverage cost savings.

> An expert will have a high level of technical knowledge on bottling, canning, and other downstream production processes to ensure your design produces seamlessly.

> They are experts in materials and sourcing — they will recommend paper, print methods, and other packaging solutions that make sense within your budget.

BRAND BUZZ

BY

WWW. ARTISANSPIRITMAG .COM 27

WRITTEN

DAVID SCHUEMANN

> Industry experts will have numerous in-category examples to share. They will have a defined process and case studies that prove their work’s return on investment.

Measure twice, cut once. It’s always worth it to engage an alcohol beverage brand expert to get your story, logo, and packaging done right the first time. Expertise may come with a higher price tag, but avoiding costly missteps and developing the proper horsepower behind your branding will more than cover extra fees.

Potential red flags when vetting a branding partner

> They are not subject matter experts in alcohol.

> Fee structure is time and materials with a low hourly rate but are not clear about timing or total fees to complete your project. (Surprise invoices forthcoming?)

> Few or no pertinent client testimonials or case studies outlining their agency’s ROI/increased sales created by their work.

> Unsure of TTB regulations and the nuances of label requirements.

> Doesn’t ask the proper questions to set parameters of your project, doesn’t have a formal written briefing process or benchmarks for you to judge their project work.

> Willingness to provide a strategic or design solution up front to win business before they even have been engaged and fully immersed in your project’s challenges.

> No examples of how they have built brand systems that allow for brands to grow and expand clearly into additional products.

> Weak or nonexistent relationships with vendors, little or no knowledge of materials and production treatments/ requirements.

> Does not guide production or the actual execution of your project. This means they’ll likely deliver your design and say goodbye, leaving you to figure out production and cost of goods challenges.

28 WWW. ARTISANSPIRITMAG .COM

YOUR COCKTAILS DESERVE A PREMIUM PACKAGE to be enjoyed from home, no extra glass needed! glass-catalog.com #chooseglass #drinktainer

CONTRACT DISTILLING NEW FILLS CUSTOM MASHBILLS BARREL STORAGE CRAFTING YOUR VISION www.corsairdistillery.com/bulk 615-351-9442

THERMAL OIL DISTILLATION VS STEAM DISTILLATION

There are many factors that influence the character of single malt whiskey. Barley varietal and malting style, mashing and fermentation factors, water, still type, cut points, and maturation are just a few. One often overlooked and critical factor is the heating and temperature of the still when distilling. Beginning in the early 1500s, distilled spirits made in Scotland were traditionally produced on stills heated by open fire. This method of heating was used for hundreds of years until the late 20th century, when many of the Scotch distilleries converted their heat sources to steam. There are many advantages to using steam for heating distillation. The efficiency of heat recovery and regeneration is maximized, and the explosive concerns of using open fire to heat ethanol is mitigated. The majority of steam boilers being used have a maximum temperature of 135 degrees Celsius. This temperature is more than sufficient to boil wort for distilling, making it an obvious draw, but there is much more to distillation than merely boiling wort.

There are many complex reactions that occur simultaneously with distillation. For the first distillation, wort containing significant

amounts of unfermented sugars is heated in a pot still. When sugars are heated, caramelization and Maillard reactions take place. Maillard reactions happen when an amino acid and a reducing sugar combine in the presence of heat to form a wide variety of non-enzymatic browning reaction products. These reactions are responsible for non-enzymatic browning, which is why a seared steak is brown, or a cookie fresh out of the oven is darker. Some of the classes of compounds that are created from Maillard reactions are pyrazines, pyrans, and furans. These compounds have nutty, coffee, roasted, and caramel aromas and flavors associated with them. Maillard reactions require a minimum temperature of 140 degrees Celsius. Caramelization reactions produce similar compounds (furans) via the oxidation of sugars that are present in the wort. Different sugars undergo caramelization reactions at different temperatures. Above 110 degrees Celsius, fructose begins to caramelize, while glucose and galactose require 160 degrees Celsius and maltose not until 180 degrees Celsius. The products of Maillard and caramelization reactions are a sign of quality and complexity

In a thermal oil system, thermal oil is heated and run through an external calandria heat exchanger to heat the wash for distillation.

in the single malt market. If Maillard reactions don’t begin until 140 degrees, and most of the caramelization happens above 160 degrees Celsius, does this mean the future of Scotch whisky is going to be devoid of these complex and delicious characters?

To combat this problem, a thermal oil heating system was designed and built, by Briggs of Burton Engineering Firm, for Bently Heritage. Instead of using steam or direct fire for the heating of the stills, a thermal oil system was implemented. In this system, thermal oil is heated and run through an external

GOOD GUY DISTILLERS

PHOTOGRAPHED BY DAVID LETTENEY

WRITTEN AND

WWW. ARTISANSPIRITMAG .COM 31

FIGURE 1:

RESEARCH FINDINGS

calandria heat exchanger to heat the wash for distillation. The temperature and flow rate of the thermal oil, as well as surface area contact in the calandria, can be controlled to fine tune the exact amount of energy that is being introduced to the system. The thermal oil can be heated from a minimum of 135 degrees Celsius (the same temperature as steam heating) all the way up to 190 degrees Celsius. Although the thermal oil cannot obtain temperatures as hot as direct fire stills, which have hot spots that exceed 200 degrees Celsius, the thermal oil is able to heat into the Maillard and caramelization reaction range, which is often of higher importance for achieving a particular type of character in single malt whiskey. It had been theorized that the conversion of many Scotch whisky distilleries to steam heating would have a major quality shift because of the lack of the Maillard and caramelization reactions present in the wash still. This is a shift that would not be felt for years because of the minimum aging requirements. Furthermore, it was hypothesized that the thermal oil system would combine the high quality of spirits with

maximized efficiency of heat recovery and safety required for modern distillation. Tom Barnett of Briggs of Burton flew to Minden, Nevada, to work alongside the team to design and implement a testing protocol.

To begin the testing protocol, the same batch of malt was used for all testing, to minimize the variation of sensory characteristics not due to wash still heating temperature differences. In addition, mashing profiles and fermentation parameters were consistent for the four test batches. Each batch was mashed to a final sugar concentration between 15 and 15.5 brix, and then fermented for 92 hours which resulted in a final ABV of 6.1 to 6.6 percent ABV. Increasing wash still temperatures were tested from 140 degrees Celsius to 180 degrees Celsius (namely 140 degrees, 155 degrees, 170 degrees, and 180 degrees) in four different runs. No cuts were made on the wash still. Cut points for the first and second cut on the spirit still were 69.88 and 69.98

percent and 59.09 to 59.81 percent ABV respectively. Once distillations commenced samples were taken and analyzed for chemical profiles using gas chromatography mass spectrometry (GCMS) by Barry Harrison of the Scotch Whisky Research Institute. Sixtythree compounds of interest were tracked, and two components were identified for use in Principal Component Analysis (PCA). In addition, sensory profiles were analyzed using a trained sensory panel.

The use of GCMS and PCA analysis yielded significant differences between Scotch whisky new make samples obtained from the market and new make samples obtained from Bently. The 63 compounds of interest were investigated including key congeners such as esters, aldehydes, acids, ketones, phenols, and furals. PCA is a statistical method which summarizes large data sets using “summary indices'' to make the larger data sets easier to interpret and plot. For the analysis, component one depicts the difference between our new make and the new make of the Scottish distilleries, and component two indicates the effect of heating profiles on the new make samples. Figure 1 shows the correlation of our samples being very similar in component one, which is to be expected because the samples were distilled from the same batch of malt, as well as similar mashing and fermentation profiles. In addition, the figure shows

PC2

-8

6

PC1 (43.1%)

(20.5%)

-6 -4 -2 0 2 4 6

8 2 4 -2 0 -4

Direct Fired 200+°C

Thermal Oil 180°C Thermal Oil 170°C Thermal Oil 155°C Thermal Oil 140°C Steam 135°C Steam (HEX) 135°C TVR (HEX) 107°C

Principal Component Analysis of Bently Heritage Single Malt and Scotch Whisky new make.

32 WWW. ARTISANSPIRITMAG .COM

It had been theorized that the conversion of many Scotch whisky distilleries to steam heating would have a major quality shift because of the lack of the Maillard and caramelization reactions present in the wash still.

2:

BRIGGS TRIALS SENSORY FLAVOR COMPARISON

Radar Plot of Sensory

the increasing amount of component two with increased wash still temperature for the Bently samples. This data verifies that component two is strongly correlated with wash still temperatures. The circular cluster of Scottish new make samples indicates that there is insufficient data to correlate them for component one (because of their difference in production methods), but it does show that the Bently samples are unique compared to the Scottish samples. Finally, the similar levels of component two in both the direct fire sample and the high-temperature thermal oil sample from Bently implies the thermal oil system is capable of catalyzing the caramelization and Maillard reactions desired.

Sensory analysis was conducted on site at the distillery using the distilling, quality assurance, and production staff as summarized in figure two. Each sample was given to the sensory panel and rated for seven aroma attributes and 10 taste attributes. Not all attributes were shown to have a step increase in each of the categories associated with the caramelization and Maillard reactions. All distillations were conducted above 135 degrees Celsius, which would account for this lack of correlation (e.g. all distillations had caramelization and Maillard reaction products present). The attributes that showed a marked increase correlating to the increase in temperature of the wash still were toast and finish. The toast component most likely corresponds to the pyrazines and furans that were produced at higher levels due to the caramelization reactions of glucose, galactose, and maltose. Panelists were asked to provide descriptors for each of the samples provided. For the lower-temperature runs (140 degrees and 155 degrees), the most common descriptors were malt, apple, floral, and lavender. For the higher-temperature runs (170 degrees and 180 degrees), the most common descriptors were nutty, caramel, toast, toffee, and almonds. These descriptors show a key difference in the sensory of the new make

Finish Viscosity

Harsh-Smooth

3.00 2.00 1.00 0.00

Oily Floral

Fruity

spirit. In order to conduct a more exhaustive exploration into the sensory characteristics and differences at varying wash still temperatures more trials need to be performed with a larger sensory panel size to validate or nullify this data.

New make single malt whiskey is a minuscule market compared to that of aged products, because of its generally harsh and unpleasant characteristics. Because of this, care and attention are placed on the full scope of maturation. There are many factors that influence maturation, such as barrel size, type of wood, toast or char level, and environment in which the barrels lie. Single malt whiskey is a longer aged product (Scotch has a minimum requirement of three years) as compared to its American counterparts (straight bourbon has a minimum requirement of two years). Many distilleries choose to age Scotch whisky for 10 years or more. One requirement of American bourbon is the use of new, charred oak barrels. The use of used bourbon barrels in single malt whiskey allows the aging spirit to mellow and esterify over a much longer period without over-extracting oak, which can be seen in bourbon with similar age statements. At Bently Heritage, the use of a climate controlled rickhouse, which mimics the temperature and humidity of Scotland, allows the single malt to age as if it were in a rickhouse in Scotland. This should lead to

Toast

Roasted

Nutty

Carmelization

very similar barrel maturation as that of the Scottish distilleries.

Using the thermal oil heating system we were able to test this article's introductory hypothesis by increasing temperatures used for heating the wash still. Using GCMS and PCA, correlation was seen between the increase in wash still heating temperatures and the component related to the associated reaction products. Sensory analysis was also conducted and a small correlation was seen with the wash still temperature and the amount of “toast” tasted in each sample. The sensory descriptors given by the panel indicated that the presence of congeners associated with the Maillard and caramelization reactions was increasing with a corresponding increase in wash still temperature.

Because of the nature of single malt whiskey, time is needed to see how these differences in reaction products and congener loads develop over maturation. Will the products from Scotch whisky be markedly different on the market over time because of the conversion to steam heating? Only time will tell, but the implementation of a thermal oil system yields energy efficiency paired with the positive flavor attributes that are characteristic of a great glass of single malt.

David Letteney is quality assurance technician at Bently Heritage Estate Distillery.

FIGURE

data acquired at Bently Heritage on single malt new make with varying wash still temperature.

140C 155C 170C 180C 4.00 3.00 2.00 1.00 0.00 WWW. ARTISANSPIRITMAG .COM 33

ETHANOLIC ODDITIES

Three Obscure Spirits from Around the World

It’s that time again! Those of you that are familiar with my articles will know that I like to do deep dives into strange and obscure spirits. Typically, my articles only cover one spirit; however, in my research and reading I sometimes come across spirits that have so little documentation that it is difficult to confirm they even exist, much less write a whole article about them. Once I have collected enough of these ethanolic oddities, I like to write a single article that gives what little information I have been able to find on each. My hope is that by just informing readers about each spirit’s existence, they will be given a glimpse into how interesting and vibrant the distilling world truly is.

BÄRENFANG

Bärenfang is a type of spiced honey liqueur. Honey is a common addition to many liqueurs, such as Polish Krupnik, and indeed, it can be difficult to tell the differences between many honey liqueurs. Nevertheless, Bärenfang is uniquely German and any visitor to the country would be hard pressed to find a house without a bottle tucked away somewhere.

The first records of Bärenfang production date back to the 15th century in Eastern Prussia, where many peasants made versions for at-home consumption. In German,

Bärenfang means bear trap, and it has been said that bear hunters, or in German, Bärenjägers, used the honey liqueur to lure out their prey. Each hunter had his own specific recipe, and it was common for the drink to vary wildly between producers. Tuecke & Koenig introduced the first commercial brand of Bärenfang, named Bärenjäger, in the 18th century and rapidly found success in the market. They were quickly joined by many other brands that each built up regional followings.

The process of making Bärenfang is relatively straightforward, though it does require careful attention to detail. The first step is to select the honey that will be used to flavor the drink. Different kinds of honey can have wildly different tastes, so it is important that the honey used be clean in flavor with no hint of bitterness. Once the honey is selected the base spirit must be chosen. Customarily, Bärenfang uses neutral spirit as a base, though other spirits can be used. Finally, the spices are chosen. Each producer uses their own unique blend of spices to produce Bärenfang, with vanilla, cinnamon, clove, and gentian being some of the most common. All these ingredients are then mixed together and allowed to marry for a set amount of time. The resulting beverage is normally between 30 percent and 45 percent ABV and should taste sweet but have enough spice to keep it from being cloying.

Today, most Americans’ only experience with Bärenfang comes from a chance encounter with Tuecke & Koenig’s original Bärenjaäger. Indeed, the brand, which was

taken over by spirits powerhouse Schwarze & Schlichte, is the top-selling Bärenfang brand in the world and the only one regularly imported to the states. However, there are still plenty of small regional producers in Germany — and even more home producers. If you get the chance to pick up one of these bottles, you won’t be disappointed.

PASITA

If you have never heard of Pasita, that’s not surprising. Of all the strange spirits that I have covered over the years, Pasita is probably the most obscure; however, it is also one of the most fascinating. In short, Pasita is a raisin liqueur whose production and consumption is isolated to a single bar in Puebla, Mexico. Despite this inauspicious description, Pasita is world famous, and it plays a central role in the life of many a citizen of Puebla.

raisin liqueur

The story of how Pasita came to be created is confused at best. What is known is that at some point in the last century a man named Emilio Contreras Aicardo started a small grocery store called El Gallo de Oro in the neighborhood of Los Sapos. (I have seen a number of different dates put forward about when this supposedly happened.) Among the items that Aicardo offered at the store was a range of homemade liquors, specifically one that he

spiced

fro m

N Y A TYPE O F

Written by READE A. HUDDLESTON, MSC.

honey liqueur

GERMA

fr o m MEXIC O A TYPE O F WWW. ARTISANSPIRITMAG .COM 35

named Pasita, or little raisin in English. The popularity of his Pasita grew so quickly that eventually he decided to do away with the grocery part of the store and turn the business into a bar/liquor store. Taking the moniker La Pasita, after the popular drink, the bar has become a staple of Puebla, and Pasita consumers come from miles around to sip the beverage and sometimes take a bottle home.

The exact recipe for Pasita is a closely guarded secret, known only to the Aicardo family, which continues on production of Pasita and operations at the bar, and the employees of La Pasita. That said, there are numerous recipes online that claim to mimic the exact taste. The majority of these recipes agree that Pasita is a mixture of brandy, raisins, and sugar; though few agree on the exact measurements of each, and it is recommended that you mix each batch to your preferred tastes.

What really makes Pasita unique is

the way it is consumed. Traditionally Pasita is consumed in a tequila shot glass called a caballito and it is garnished with a raisin and a piece of goat cheese. The salt from the cheese and the sweetness from the liqueur mix to create a unique experience that often leaves the consumer wanting more. This has sparked a long standing challenge by La Pasita’s owners that if anyone can drink 100 Pasitas in a single sitting they will have their bar tab covered (it should be noted that only one person has been said to ever have accomplished this and he allegedly died shortly after).

Although Pasita is not distributed in the traditional way and the only way to get a bottle is from the bar that created it, this does not diminish its importance. Booze is all about stories, and Pasita has that in spades. If you ever get a chance to visit Puebla, Mexico, I recommend you head to La Pasita and have a drink or two, but probably not 100.

EUCALITTINO

Finally, we head to Italy for our last spirit on this list: Eucalittino. Eucalittino is a type of Italian amaro produced by members of the Trappists order of monks that live and work at the Tre Fontane Abbey in Rome. Although Italy is famous for its dozens, if not hundreds, of unique amaros, Eucalittino stands out as one of the most unique.

amaro

The Tre Fontane Abbey sits on the believed site of St. Paul’s beheading at the hands of the Emperor Nero. Supposedly, Paul’s head bounced three times after being cut off, creating three natural springs that still flow today and give the name to the abbey. The original abbey was supposedly founded in the seventh century, but it was slowly abandoned and, for many years, lay vacant. In the late 1800s, the Cistercian Order of the Strict Observances, today known as the Trappists, purchased the land from the Italian government on the condition that they improve the land. One of the required

TYPE O F 36 WWW. ARTISANSPIRITMAG .COM

Italian

f r om ITALY A

improvements was that the monks had to plant eucalyptus trees on the property to improve drainage and help fight off malaria. The venture was a success, and the land quickly became some of the most fertile in the region. Eventually, the monks realized that the eucalyptus trees could be useful in other ways, and they began mixing the leaves of the tree into their homemade liqueurs, birthing the first Eucalittino. Since then, the abbey has been producing and selling Eucalittino to the public.

The process for making Eucalittino is exceedingly easy, yet a bit laborious. First, eucalyptus leaves are picked and crushed by hand. They are then macerated with neutral grain alcohol and sugar and are allowed to infuse for several weeks before being filtered out. Unlike other Amaros, no other spices are traditionally used by Tre Fontane, though some other recipes include cinnamon and mint. Nevertheless, the resulting drink is sweet and minty — a perfect digestif after a large meal.

Although Eucalittino does not have a large following outside of Italy, it can still sometimes

be found at various liquor stores in the U.S. If you ever get the chance to purchase a bottle, I highly recommend it. It is excellent served either neat or poured over ice.

Hopefully this article has opened your eyes to some new spirits. The alcohol industry is ever-changing, with new products being created and old products rediscovered each day. Sometimes, all it takes is a brief trip down to the corner bar or local liquor store to find a spirit that you have never heard of before. Happy hunting.

REFERENCES

*Final note: Some will note the absence of formal citation in this article, as I mentioned previously the proper documentation of these drinks is shaky at best. I have included below what little written reference I have found to help anyone interested in exploring further.

1. Graham, C., 2022. What is Bärenjäger Honey Liqueur. Available from <https://www.thespruceeats.com/barenjagerhoney-liqueur-760264> [October 10, 2022]

2. Drink Secrets, 2022. Bärenfang Honey Liqueur. Available from <http://www.drinksecrets.com/ingredient/barenfang-honeyliqueur--/i1113c6> [October 11, 2022]

3. Bärenjäger., 2022. Bärenjäger Honey Liqueur. Available from <https://barenjagerhoney.com> [October 10, 2022]

4. Chavez-Busch, L., 2022. Pasita. Available from <https://www. atlasobscura.com/foods/pasita> [October 11, 2022]

5. Zoldos, M., 2018. La Pasita: The Most famous bar in Puebla, Mexico. Available from <https://theculturetrip.com/northamerica/mexico/articles/la-pasita-the-most-famous-bar-inpuebla-mexico> [October 11, 2022]

6. Gerson, F. 2010. My Sweet Mexico. Ten Speed Press. Berkley, California.

7. Global Beer Network, 2022. Tre Fontane. Available from <https://www.globalbeer.com/breweries/tre-fontanetrappist-tripel> [October 15, 2022]

Reade A. Huddleston, MSc. in Brewing and Distilling, is a beverage industry consultant based in Tampa, Florida. He is fascinated with all things drinkable and is always searching for strange and forgotten spirits. If you would like to contact him about said spirits, or anything else, please email him at ReadeHuddleston@gmail.com.

8. Sala, L., 1931. Il Liquorista Practico. Casa Editrice Bietti. Milano, Italy.

9. Van Allen, S., 2022. Eucalittino. Available from <https://www.atlasobscura.com/ foods/eucalittino-eucalyptusliqueur-tre-fontane> [October 15, 2022]

1 8 6 25 6 2 7 0 0 + 9 0 + V I S I

T M O O N S H I N E U N I V E R S I T Y . C O M

WWW. ARTISANSPIRITMAG .COM 37

•

•

•

•

• Biology/microbiology

•

•

•

•

•

•

•

•

THE

SPECIAL THANKS TO

SPONSORS MAKING THIS POSSIBLE Peer-reviewed, original scientific papers

Reporting significant research

Technical reports

Applicable analytical techniques and methods

Reviews Scientific and technical disciplines applied to the distilling of high-quality, potable alcoholic beverages

Chemistry/ biochemistry

Molecular biology

Physics and engineering International board members, contributors, and audience

Universities and colleges

Research institutes and industrial laboratories

Distilleries

Raw materials producers

Allied industries supporting the testing and quality control functions of distilling operations

SIGN UP TODAY for access to the digital and print versions of the publication visit www.journaldistilling.com The FIRST EDITION of the peer-reviewed Journal of Distilling Science has arrived.

A GENUINE NEVADA PARADISE