In 2017, Rusty Thompson, former President and CEO of Evans Adhesive, had a vision to create a college scholarship fund to support the next generation workforce – future formulators, chemists, and chemical engineers, marketing and sales professionals, and other career positions essential to the adhesive industry. He easily convinced the ASC Board of Directors to establish a fund and, in 2018, the first scholarships were awarded to four college students. At Rusty’s suggestion, the Scholarship Fund would be named in memory of a former co-worker, a prominent formulator, Gene Simmons, who had recently passed away but loved mentoring younger workers in the lab.

Rusty was a big believer in giving back. Before his retirement in 2022, he was a regular at ASC’s Gives Back Program, where each year members volunteer to help benefit the local community in which ASC’s Convention and EXPO is held. He had a calling to serve the industry too. He represented Evans Adhesive on the ASC Board, eventually leading the organization as Chairman. After his two-year term, Rusty continued to give back and led the creation of the Scholarship Fund.

It has been a big success. Since 2017, ASC has awarded tens of thousands of dollars to dozens of students, helping them achieve collegiate success and pursue their dreams. Some have taken up positions in the adhesive industry after graduation, and every recipient has a greater appreciation for the essential role that adhesives play in society. Furthermore, beginning this year, ASC members are asked to offer summer internships to our scholarship recipients.

Sadly, Rusty passed away earlier this year. One of my last conversations with him was in late 2021, when I asked him to serve another term on the ASC Board. Rusty said he would, but only if doing so would not take a spot away from someone “up and coming who may provide a fresh outlook.” I believe he felt that giving back also means knowing when to give others an opportunity to make a difference.

Although Rusty is no longer with us, his legacy will live on for many years through the Scholarship Fund, which is now named in his honor.

Bill Allmond, President, ASC

Please consider making a company or personal donation to the Rusty Thompson Memorial Scholarship Fund and support the industry’s next generation workforce. Visit https://www.ascouncil.org/scholarship-program for more information.

ASC is pleased to announce another 16 companies have joined our membership so far in 2024:

• Beacon Adhesives

• Brenntag Specialties, LLC

• Engineered Polymer Solutions

• Excel Color

• ExxonMobil Product Solutions

• HarperLove Adhesives

• Holland Colours Americas, Inc.

• IPS Adhesives

• Isotec International, Inc.

• Koble Sustain

• Logipack, Inc.

• Newson Gale

• Oracle NetSuite

• Re Mixers, Inc.

• Seal It Services Inc. dba Bond ItI

• Weiss USA LLC

The full ASC Membership Directory – including company overviews and contact details – can be accessed by visiting www.ascouncil.org/memberdirectory

ASC is proud to represent its membership of adhesive and sealant manufacturers, raw material and equipment suppliers, distributors, and industry consultants. Together, our members represent more than 75% of the U.S. industry, exceeding $16bn annually. For over six decades, ASC has been the mouthpiece of the industry, representing members’ interests through advocacy on Capitol Hill; offering education and training; and helping our members innovate, grow, and flourish.

Members have access to a range of resources including industry events, networking opportunities, podcasts, newsletters, directories, and reports. To find out more, visit https://www.ascouncil.org/ member-benefits

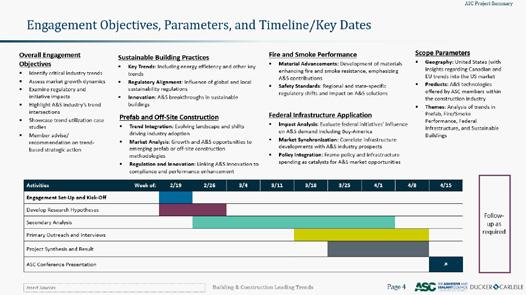

Anew study examining the latest challenges and opportunities in the construction sector is now available via the ASC website. The 2024 Building & Construction Report, produced in association with consultancy Ducker Carlisle is free for ASC members and available for non-members at only $1,950.

The study, based on in-depth interviews and discussions with ASC member experts and industry sources, provides a comprehensive exploration of the latest trends, market drivers, and opportunities in this key enduser segment. Sections include Sustainability Building Trends; Prefab and Off-Site Construction; Fire and Smoke Performance; and Federal Infrastructure application.

ASC publishes several industry reports each year with special rates available for members. Visit

the online store to find out more (www.ascouncil.org/store/ industry-reports).

To order a copy, or view a recording of a recent Building and Construction Report Preview Webinar, visit www.ascouncil.org/store/asc-building-andconstruction-report or scan the QR code.

You are invited to come and join more than 500 industry leaders at the Hyatt Regency Riverfront Hotel in Jacksonville, Florida, from April 14-16, 2025, for ASC’s Annual Convention & EXPO.

Always an unmissable event, the upcoming three-day meeting promises the usual blend of networking, education, and technical sessions focusing on business development and market trends, regulatory issues, and innovation.

Registration to the Convention also includes access to the EXPO – one of the largest expositions exclusively dedicated to the adhesive and sealant industry –which features over 90 exhibitors keen to showcase their products, services, and technologies.

The fantastic downtown venue is easily accessible and overlooks the St. Johns River with easy access to local attractions, stores, and restaurants. To book your place, visit the website at www. ascouncil.org/events/2025annual-convention-and-expo/

register or scan the QR code.

Among the many presentations, attendees can look forward to an opening keynote from Cassi Chandler, a motivational leadership expert and the Federal Bureau of Investigation’s first African American female Special Agent Assistant Director. On the second morning, we are pleased to be

Make invaluable connections and meet service providers at the EXPO, which is co-located with ASC’s Annual Convention. Registration to the Convention includes access to the ASC EXPO. Open on Tuesday, April 15, 2025 from 2-6pm, the bustling exhibition space offers attendees the chance to connect face-to-face with companies and learn about their products and services.

If you would like to view the latest floorplan to see who is exhibiting or are interested in having your own booth, visit the EXPO webpage (https://shows.mapdynamics.com/ascexpo2025/?register).

and thought

ASC still has some spaces available for speaking opportunities for April’s event.

If you are interested in hosting a presentation at the ASC Convention, you are welcome to submit an abstract based on new technology or insight relevant to

the adhesive and sealant industry. In order to be considered, submissions must be made before December 13, 2024. Visit the Events page online for more details.

Running alongside the Convention, members are also invited to attend two short courses, both lasting one and a half days from April 14-15. The Hot Melt Short Course will see expert speakers focusing on how plasticizers, tackifiers and waxes can enhance base polymers for optimized processing and properties. The second, a Waterborne course, will provide a market and applications overview as well as looking at formulation technology, polyurethane dispersions and polychloroprenes, surfactants and defoamers, rheology modifers, biocides, and more.

To find out more about the Annual Convention and to stay up-to-date with additions to the program, keep checking the ASC events page on www.ascouncil. org/events/

It has been an honor and a pleasure serving as the ASC Board Chair for the past two years. My term began in January 2023 as disruptions from COVID-19 were largely in the rearview mirror and the industry and ASC were racing forward. As my term expires at the end of the year, I am encouraged by our success

November 13, 2024

Advances in Surface Engineering: Plasma Polymerization & Laser Ablation

Giles Dillingham Ph.D., Founder & Chief Science Officer at Brighton Technologies will cover the fundamental requirements of surface engineering –including critical cleaning, surface treatment, and surface engineering via functional coatings – for bonding,

over the past two years and optimistic about the future.

One of my priorities as Chair has been to sell the value of what ASC has to offer. By working with the ASC Board and staff, we have had meaningful growth in several core programs and services. First, membership has grown between 2022-2024 to 112 member companies, a reversal from membership declines in 2021. Second, the number of company subscribers to ASC’s Training Academy Certificate Program continues to rise as do our total graduates, which is approaching 800. Third, attendance at ASC’s Convention and EXPO has returned, and exceeded, pre-pandemic levels since 2023. Furthermore, attendee satisfaction has risen; for the past two years, satisfaction has been over 90%.

ASC has also been more

coating and sealing in critical applications.

November 15, 2024

Boost Formulation Performance with New toughening Technologies In this free webinar, Jose Fanjul, Senior Global Strategic Marketing Manager for Industrial Segments at Huntsman Advanced Materials is joined by Dr. Alex Duréault,

active on the advocacy front. The Regulatory Affairs Committee and staff have voiced strong objections to numerous proposed federal and state regulations. Altogether, 14 separate public comments have been submitted since June 2023 – the most in years. From bans and restrictions on adhesive and sealant uses by the U.S. Environmental Protection Agency to burdensome and unnecessary changes to product warning labels by California’s Proposition 65, ASC has gone on record to represent our industry’s concerns.

However, I believe ASC’s value isn’t always measured in numbers. It is also measured in the take home value after attending an ASC event. It is measured in new customer or supplier relationships we make through our participation. And it is measured by access to tools

and resources available to us as members.

I want to recognize the support given to ASC by the outstanding volunteer leaders serving with me on the ASC Board. They, with our fantastic staff, are strongly committed to ASC’s mission that, together, we accelerate the adoption of adhesives and sealants to strengthen our member businesses.

Lastly, thank you for being a member of ASC. Your company’s membership enables ASC to deliver essential programs, services, and events that are not possible without your dues investment. Moving forward, I am more optimistic than ever about our future growth and organizational value.

Technology Manager, Head of Technical Support Europe, to explore how Huntsman Reactive Liquid Polymer (RLP) tougheners improve formulation performance and reduce brittleness.

December 11, 2024

Adhesion for Circularity: Debonding Substrates OnDemand In this webinar, two basic

mechanisms: cohesive and adhesive failure, and the general strategies through polymer modification and additive approaches to achieve “Adhesion-on-Demand” are examined by Grace Wan, Ph.D., Core R&D Fellow and Wayne Zhang Core R&D Fellow at The Dow Chemical Company.

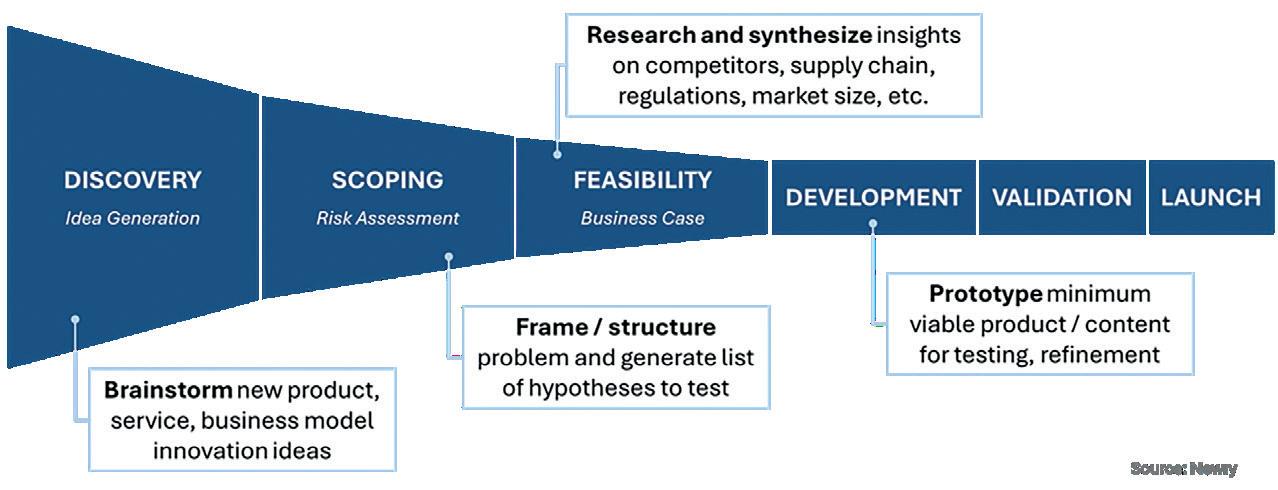

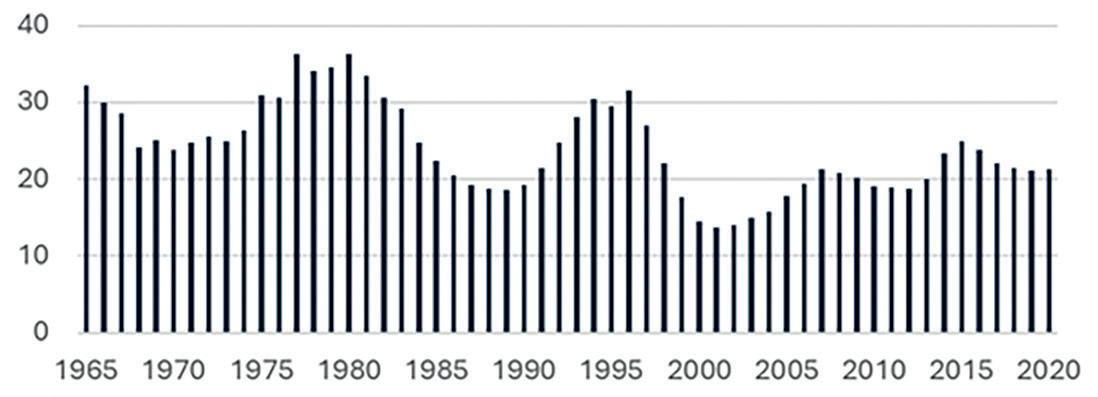

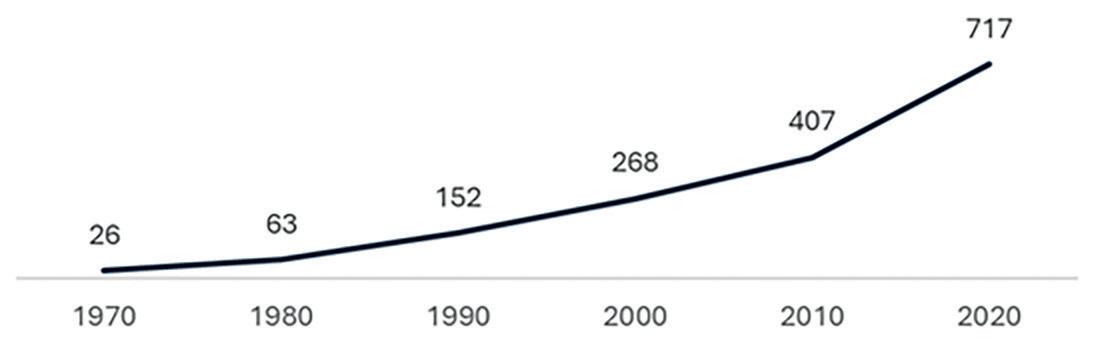

Company lifespans are declining. R&D expenditures are rising. Markets are being disrupted. Your organization’s survival depends on its ability to innovate fast to deliver growth, says Kasey Correnti, Vice President at Newry

With a finite amount of investment dollars and growing pressure to maintain a competitive edge, companies must identify, vet, and scale new product, service, and business model opportunities rapidly. Any concepts with low growth potential need to be killed off early to “fail fast”, so that resources can be reallocated to fast-track and scale winning projects.

So, the ever-pressing question remains: how can we accelerate innovation to sustain long-term growth?

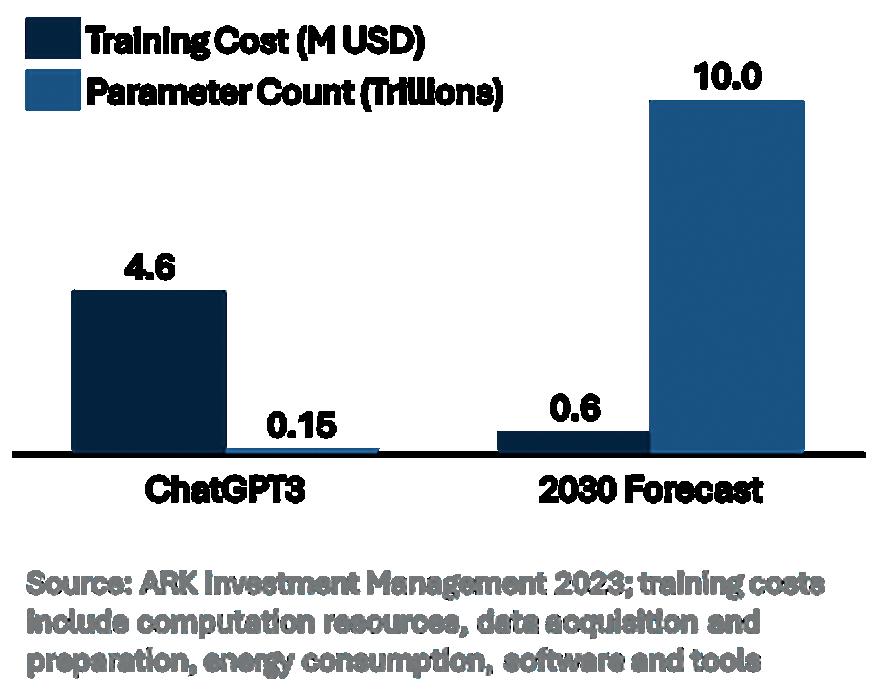

You have probably heard a lot about large language models (LLMs) already. ChatGPT, Perplexity, Gemini are all generative Artificial Intelligence (AI) systems designed to understand prompts and create output as human-like text. They can answer complex questions, summarize vast amounts of information, provide insights, and support creative processes.

With continued investment in LLMs –which is growing at 74% CAGR according to McKinsey – the next few years will bring along unimaginable new and improved capabilities. However, LLMs already have the potential to drive significant productivity gains across various workstreams, including B2B market research and innovation.

For example, LLMs can brainstorm new products, services, and business model innovation concepts that tie to an organization’s technical and commercial capabilities and target markets. This can be applied for multiple positions in the value chain, be it additive suppliers, equipment OEMs, or end-product adhesive and sealant manufacturers. In addition, they can structure problems and frame hypotheses around “what must be true” for a given innovation to succeed.

Their capabilities also extend to researching and synthesizing large data sets to develop insights around market attractiveness, growth, competitive dynamics, technological trends, disruptions, regulatory changes, and other factors. When it comes to refining and testing new product and service concepts, they can draft and prototype content, including

marketing and pitch materials.

“In our experience, LLMs have been extremely useful for helping with ideation,” says David Wylie, Vice President of Newry. “For more than a decade, we’ve leveraged automated techniques to surface unmet needs in big data sets that have allowed us to identify opportunities that drive growth in adjacent markets and applications.”

“We’ve adapted our process to supercharge the way Fortune 500 and PE-backed portfolio companies within the B2B space, including adhesives and sealants players, approach growth strategy,” he says. “Our tools have evolved over the years but with recent LLM advancements, we’ve found that the approach all starts with prompt engineering.”

Prompt engineering skills enable rapid ideation and allow users to gain a variety of concepts that overcome some of the pre-LLM innovation follies of relying solely on market pull or tech push. Strictly using “market pull” ideation often leads to focusing on meeting existing customer needs that result

in incremental innovation, reacting to and overemphasizing current trends, and staying within familiar territories. While on the other hand, “tech push” ideation is often misaligned with market needs, comes at higher cost, and risks developing cutting-edge solutions that do not resonate with consumers.

LLMs can help you sidestep these pitfalls by considering multiple perspectives, bridging market needs with technology, processing technological trends and predicting market shifts, and serving as a cost-effective way to iterate and explore difference concepts to accelerate ideation. With appropriate prompt engineering techniques, organizations can mitigate the reactive nature of market pull, reduce the risk of tech push misalignment, and improve the overall innovation process with data-driven insights.

“There are several ways to get the appropriate coverage with prompt engineering, but the three techniques I use most often are market-/megatrendled prompts, capability-led prompts, and

Approach Example Prompt Example Output

Market- / Megatrend-led

Capability-led

Imagine you are looking for problems to solve as they relate to dispersions in the adhesive and sealants industry. A key trend you are interested in is the growth of battery electric vehicles. Brainstorm one application.

Imagine you have a new dispersion tech that enables production of extremely stable aqueous dispersions – i.e., sub-micron particle sizes, high stability, and no agglomeration. Brainstorm one application in adhesives and sealants.

Thermal management adhesives for EV batteries

High-performance water-based adhesives for flexible packaging, including multi-layer films

Entrepreneur Innovative, risk-taker, visionary, tendency for market disruption

Technical Expert Detail-oriented, conservative, focus on tech feasibility, practicality

Student Curious, open-minded, creative but less practical

Customer Advocate Empathetic, focused on user needs and experience

Source: Newry examples, generated by ChatGPT

persona-based prompts,” Wylie says.

Market-/megatrend-led prompts focus the tool on markets or megatrends of interest to ensure ideas are aligned with strategic growth areas. Capability-led prompts require inputting detailed capability statements describing technical product specifications for the tool to brainstorm adjacent uses. Finally, persona-based prompts assign the tool a persona to center its brainstorming around, which of course will yield different results and advantages depending on that role’s traits.

“For example, imagine a company with unique technologies that enhance and stabilize the dispersion of different additives used in coatings, adhesives, sealants, and elastomers (CASE) formulations,” adds Wylie. “A megatrend-led approach may focus the tool on the growth of battery electric vehicles in the automotive space, whereas a capabilityled approach might focus on an application with problems to solve – in this case, aqueous dispersions for flexible packaging with agglomeration issues.”

Users can further tailor how LLMs approach ideation by assigning a specific persona. The tools will take on different perspectives to

Expansion joint sealants for bridges, roads, and large concrete structures

High-performance pressure-sensitive adhesives (PSAs) used in medical, automotive, and electronics industries

Curtain wall and glazing sealants for highrise buildings

Water-based adhesives for subfloor installation

Newry is a Cleveland-based growth strategy firm that partners with Fortune 500 companies and PE-backed portfolio companies to help them grow in adjacent markets. Contact Kasey Correnti, kcorrenti@newrycorp.com, or visit www.newrycorp.com, to learn how Newry can help you generate revenue, make confident investments, and save time.

ideate from, and these different roles will offer unique traits and advantages that allow for a more diverse set of ideas to consider.

“We’ve found using LLMs accelerated the market research for many relevant activities our clients needed to explore within numerous areas of interest, including market landscaping and sizing.” However, Wylie cautions that there are limitations to LLMs. “It’s not a silver-bullet solution. Users will still struggle with getting the tool to provide relevant ideas, and it still requires vetting concepts against criteria. There’s no way around it. Regardless, LLMs, if harnessed effectively, can accelerate innovation and serve as an amplifying tool.”

LLMs are not a substitute for human expertise and judgment, but as they continue evolving at an impressive rate, our ability to unlock their potential is dependent upon continuously upskilling our teams and methodologies. “To accelerate how we innovate with LLMs to deliver growth, we must continue to be fast – experimenting, failing, learning, iterating, collaborating – to define best practices.”

Companies united on September 29 for International Adhesive and Sealant Day to acknowledge the

important role played by our industry

Now in its second year, International Adhesive and Sealant Day provides a unique opportunity to mark the enormous impact and positive effect adhesives and sealants have on our everyday lives.

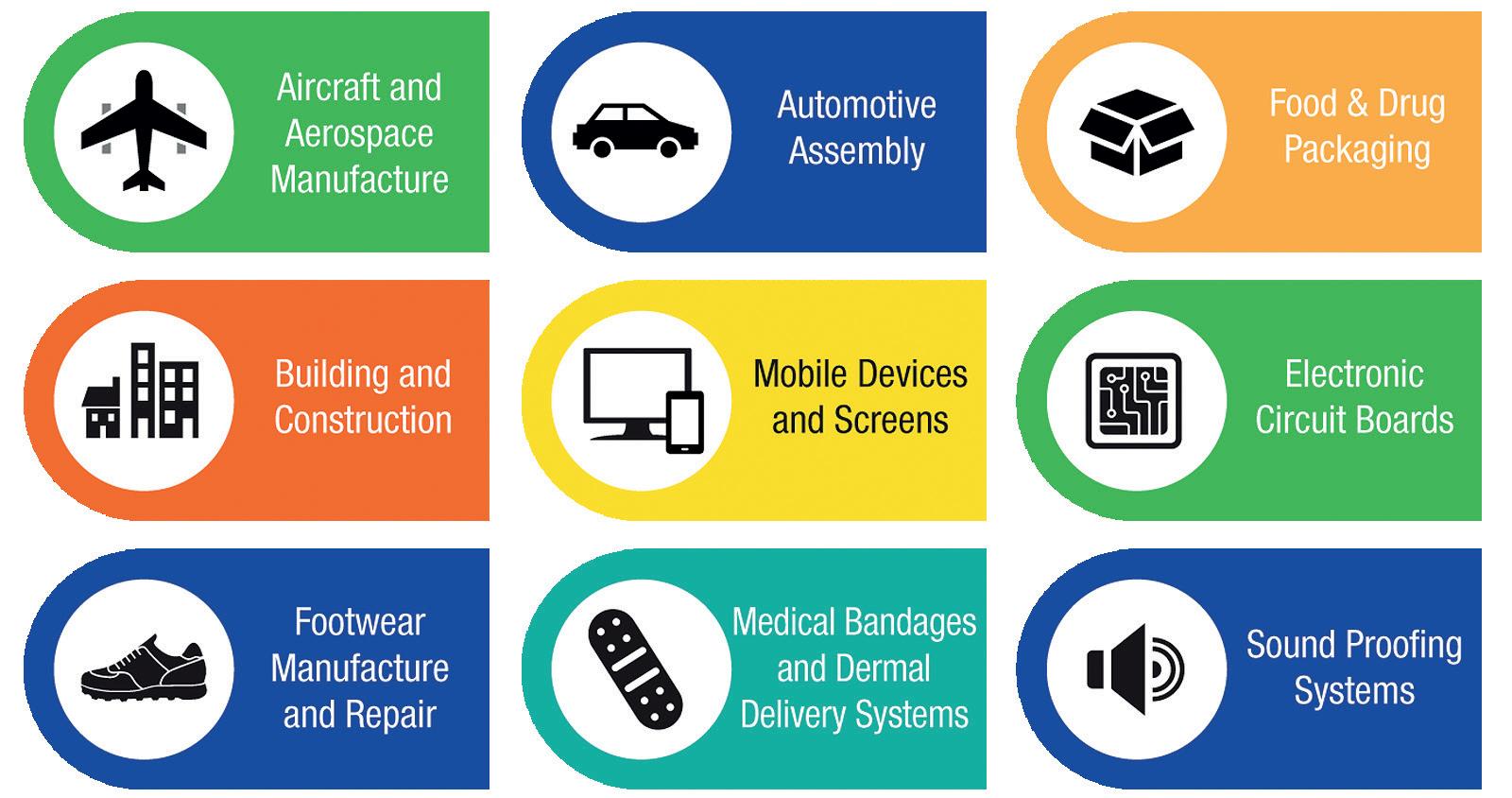

Glue has origins dating back more than 200,000 years to the Paleolithic era – but gone are the days when it was solely used for rudimentary toolmaking and repairs. Adhesives and sealants are now ubiquitous, arguably making it impossible to go through a day without encountering something that relies on these increasingly complex formulations.

Buildings, vehicles, electronics… you name it, most of what we use on a day-to-day basis is touched by the innovative technologies produced by ASC member companies.

In North America alone, more than 10bn pounds of adhesive and sealants are produced each year, in a market valued at more than $22bn. That equates to a staggering 30,000 manufacturing jobs and a total payroll that exceeds $1bn.

Given the enormous reach and impact of adhesives and sealants, it therefore seemed

fitting that there should be time set aside each year for the entire world to mark the incredible achievements of the industry and showcase these intrinsically important products.

While attending the 2022 World Adhesive and Sealant Conference (WAC 2022) in Chicago, IL, Mr. Murakami, the Chairman of the International Committee of the Japan Adhesive Industry Association (JAIA),

suggested that day should be September 29. The proposed date would correspond with school terms everywhere, thereby encouraging even more young people to participate in the celebrations.

The idea was welcomed and unanimously approved by the various international adhesive and sealant associations, including ASC; the European association, Fédération Européenne des Industries de Colles et Adhésifs (FEICA); and the Asia Regional Adhesive Council (ARAC). Last year marked the launch of what has now become a key date on the calendar.

“It is hugely important we recognize the many contributions of our global industry to making everyday life not only possible but better,” says Bill Allmond, ASC President.

JAIA had already been observing the impact of adhesives and sealants through an art competition among students. The European and North American associations, meanwhile, decided to instead focus on highlighting the role of the industry's products in contributing to sustainable goals.

“At ASC, we're really excited about the International Adhesive and Sealant Day – a day

Thank you to all who helped make International Adhesive and Sealants Day so memorable by sharing their successes, achievements, and contributions on their social media channels. Here are just a few of your stories:

H.B. Fuller

Happy International Adhesive and Sealant Day! International Adhesive and Sealant Day was established at the 2022 World Adhesive and Sealant Conference (WAC 2022) by the heads of the three global adhesive and sealants associations (FEICA ARAC and The Adhesive and Sealant Council, Inc).

Today, H.B. Fuller celebrates the incredible innovations and advancements in the adhesives and sealants industry that bond our world together. At H.B. Fuller, we are proud to be connecting what matters by creating solutions that not only enhance

product performance but also drive sustainability and efficiency across diverse industries.

From automotive and construction to electronics and packaging, our products play a vital role in everyday life, ensuring safety, durability and functionality. Join us today in celebrating the art and science of adhesives and sealants! To learn more about International Adhesive and Sealant day, visit: https://ow.ly/e2qA50Txx7k

Catalynt

Celebrate International #Adhesive & #Sealant Day with Team Catalynt The Adhesive and

Sealant Council, Inc on September 29th #InternationalAdhesiveandSealantDay Did you know Catalynt offers Contract Manufacturing services for the Adhesive and sealant industry? Visit our Industry and Manufacturing pages for more details. https:// lnkd.in/eBYg6dMT

ChemPoint Happy #InternationalAdhesiveandSealantDay!

ChemPoint offers a broad portfolio of resins and performance additives designed to improve the performance and processing economy your adhesive and sealant systems. Contact us to celebrate or chat with one of

every year when our global industry comes together to celebrate the many ways in which our products improve lives,” continues Allmond.

“On September 29, we join with the other associations to collectively raise awareness

about how we rely upon adhesives and sealants in many of the products we use every single day; that they’re invisible but everywhere.”

Information hub

as many examples of how they helping to produce specific consumer products like electronics or vehicles.”

“On September 29, we joined with the other associations to collectively raise awareness about how we rely upon adhesives and sealants in many of the products we use every single day; that they’re invisible but everywhere”

Bill Allmond, ASC President

our technical experts who share your passion for formulation. Explore our portfolio here: https://lnkd.in/gb6yctyh

Beacon Adhesives

Today is International Adhesive & Sealant Day! Without the hard work and dedication of everyone in the adhesive and sealant community, we wouldn’t be where we are today. We’re proud to be part of this dynamic industry for the past 98 years. Our team is passionate about creating solutions that not only meet the highest standards but also push the boundaries of what’s possible.

Clariant

It’s #InternationalAdhesiveandSealantDay! Our innovative solutions for stronger bonds provide:

• Enhanced adhesion & cohesion

ASC has created a dedicated website to provide details about the day itself, www. internationaladhesivesealantday.com, explaining the history and key applications of adhesives and sealants, and highlighting statistics about their economic impact and huge significance of the sector. This resource also includes videos, statistics, and links to reports that feature the sustainable and environmental benefits of adhesives and sealants.

“ASC is also encouraging its members to mark the day by talking about their products, how they’re innovating, and what they’re doing in terms of sustainability,” says Allmond. “We’ve seen companies talking about their contributions to sustainability and referring people to their Sustainability Reports, as well

• Increased durability

• Improved compatibility

• Exceptional thermal stability

From #construction to #automotive, we deliver high-performing solutions like specialty polymers, waxes, flame retardants, and stabilizers across various applications to stick, seal, and stabilize for a brighter future!

With our global footprint and R&D labs located worldwide, we provide localized #adhesives and #sealants expertise. Stay tuned in the coming weeks to learn more from our experts! #Greaterchemistry

More details here: https://lnkd.in/ejZErmhT

Tremco Commercial Sealants & Waterproofing

Happy #InternationalAdhesiveandSealantDay from Tremco! We’re proud to be part of an industry that always sticks together

“Last year, International Adhesive and Sealant Day received a lot of social media activity with our members talking about their products and the great work done by their companies. I'm really pleased that we’ve again seen a number of posts on our members’ LinkedIn, Facebook, and X – formerly known as Twitter, and Instagram pages.”

On September 29, the adhesive and sealant industry was joined together by a common bond – using this special day to talk about our commitment to the environment and sustainability, showcase innovation and product development, and raise awareness about the essential contributions we make to everyone’s lives. Thank you for your support, commitment, and dedication!

Andy Brice

Franklin Adhesives & Polymers

On #InternationalAdhesiveAndSealantDay, we celebrate the transformative impact of adhesives and sealants through generations of innovation.

Since 1935, Franklin Adhesives & Polymers has been a catalyst for the industry, providing trusted solutions that drive efficiency and unmatched performance for manufacturers and end-users alike. Today, our research and development work is essential in expanding technologies and pushing boundaries as as we continue our efforts to advance key industrial manufacturing sectors.

Today and every day, we proudly join the global community in recognizing the significance of these often unseen yet essential technologies. Celebrate with us — click below to learn more about the adhesives & sealants industry.

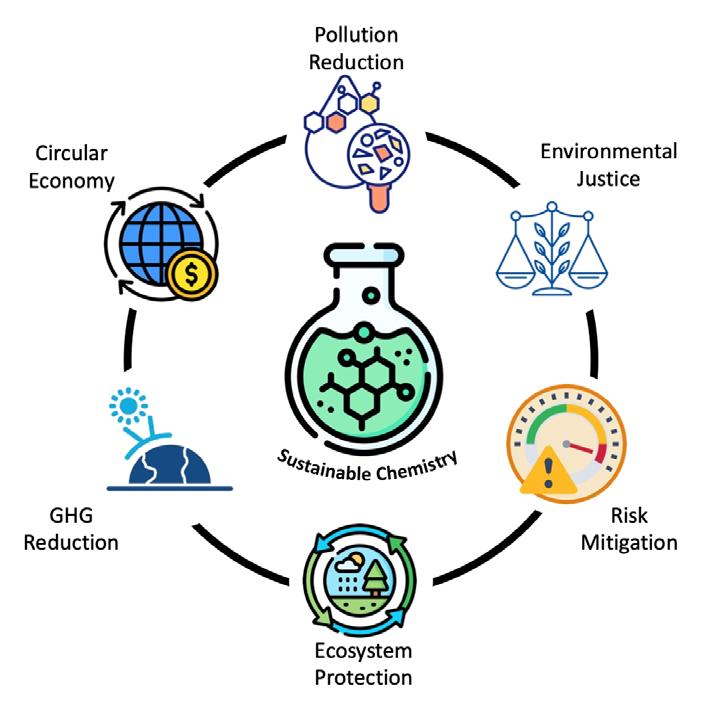

For us to achieve our sustainability goals, the manufacturing value-chains that provide our goods and services must be underscored by sustainable chemistry, says Rui Resendes, Director of Partnerships & Business Development at Change Chemistry

Our economy and way of life is enabled by a myriad of consumer goods and services made possible by the over 350,000 commercially available chemicals and materials. With over 1,000 new chemicals being introduced each year, the boundaries of our technological capabilities continue to expand. While the dawn of the modern chemical industry inaugurated an era of unprecedented innovation and prosperity; this has come at significant cost.

Historically, new chemicals and materials were designed with two primary objectives in mind – cost and performance. While safety and, to a lesser extent, sustainability were also considered, it is only over the past 20 years that they have been elevated to similar levels of importance. As a result, we are now confronted with unprecedented chemical and material pollution challenges that threaten our very quality of life. But there is a solution. Notwithstanding the growing body of evidence that links chemical pollution to specific products of the chemical industry, it is the chemical industry that will ultimately usher in the next generation of products based on sustainable chemistry that will address these challenges.

Sustainable chemistry is the development and application of chemical processes and products that benefit current and future generations without harmful impacts to humans or ecosystems.

In essence, it is chemistry that is both sustainable and safe. Sustainable Chemistry is a critical enabler of sustainability. “Sustainability” is a broad term that encompasses several dimensions such as pollution reduction, circularity, greenhouse gas reduction, ecosystem protection, risk mitigation, and environmental justice. It is only by transitioning manufacturing valuechains to sustainable chemistry can we achieve our objectives for most dimensions of sustainability.

The circular economy: The circular economy shifts away from the linear takemake-use-waste model, focusing on waste reduction, prolonged product use, and natural system regeneration. Transitioning to a circular economy requires implementing sustainable chemistry technologies across all consumer products.

As circularity requires products to stay in use longer, the chemistry that underpins those products must be intrinsically safe and sustainable. Transitioning manufacturing toward biomass feedstocks, enhancing recycling, and enabling remanufacturing will require new sustainable chemicals and materials that are amenable to and maximize material recovery and reuse and limit recirculation of toxic materials.

To ensure continued availability of sustainable sources of renewable feedstocks, we must create new materials that can safely

and easily be returned to nature at the end of their useful life.

Pollution prevention and ecosystem protection: These are two highly interdependent dimensions of sustainability. In addition to the acute and chronic human health risks associated with certain chemicals of concern, these same chemicals also threaten ecosystem health and biodiversity.

Given the complexity of modern manufacturing value-chains, harmful chemicals can enter the environment at each stage of a product’s lifecycle. These include fugitive emissions of reagents, products and byproducts from chemical manufacturing, emissions and effluents associated with consumer goods manufacturing, and soil and water contamination resulting from improper disposal of products at the end of their useful life.

In addressing these challenges, there are two paths to be taken. The first involves mitigation, abatement and remediation of waste streams related to manufacturing and waste management. On this front, tremendous progress has been made in developed economies, but we need to do better. To do so, we need to transition away from managing exposure risks to eliminating those risks by adopting new chemistries that are intrinsically safe and maximize circularity while improving toxics and waste reduction strategies. Only then will we be able to minimize pollution and preserve the integrity and diversity of our ecosystems.

Greenhouse gas reduction: According to a 2022 U.S. Department of Energy report, bulk chemical manufacturing accounts for 24% of all industrial energy use and 20% of industrial carbon emissions. In fact, the industrial production of ammonia alone – a key base chemical – through the Haber-Bosche process consumes about 1% of world energy.

The transition to green renewable sources

of energy that will ultimately enable the electrification of chemical manufacturing will address this challenge, but that will take time – time we do not have. To accelerate energy deintensification of chemical manufacturing, we will need new sustainable chemistries. These new chemistries will more closely mimic biochemical pathways that use water as the “solvent” and are based on catalyst-assisted sequential cascade reaction pathways that obviate the need to isolate and purify reaction intermediates.

Even the most sophisticated industrial chemical processes pale in comparison to the versatility, selectivity, and efficiency of the chemistry taking place in unicellular organisms. We have already made significant progress on this front with more and more biomaterials and biologically synthesized traditional materials starting to displace petrochemically-derived incumbents.

Environmental justice: Environmental justice focuses, in part, on people who are regularly and disproportionately exposed to harmful waste streams and byproducts associated with the nature of and their proximity to large scale manufacturing sites. One of the main tenets of environmental justice is that everyone has the right to clean water, air, and soil. Sustainable chemistry has the potential to significantly contribute to overcoming environmental justice challenges by enabling the re-invention of chemical and consumer goods manufacturing.

Sustainable chemistry will enable new platform and tunable chemistries and manufacturing processes that produce less waste, use safer chemicals, and avoid the production of harmful intermediates or

byproducts. The products resulting from these new manufacturing processes will be intrinsically safe and will minimally contribute to end-of-life pollution by being readily recycled, remanufactured, or safely returned to nature.

The chemical industry is capital intensive with global manufacturing assets representing trillions of dollars of investment. Unfortunately, most existing infrastructure is incompatible with emerging sustainable chemistry platforms and would either need to be retired, completely overhauled, or rebuilt. This will require trillions of dollars of investment. This, and the fact that incumbent technologies have been optimized over decades for both price and performance and can be supplied reliably, at scale and cost, around the world makes it difficult for emerging sustainable chemistry technologies to compete with and displace them. This begs the question; can we afford to undergo this transition? The better questions is, can we afford not to?

The World Health Organization estimates that two million lives and 53m years of life were lost, in 2019 alone, due to premature death, illness, and incapacitation linked to harmful chemical exposure. Researchers have found that health care costs linked to plastics alone to be nearly $250bn. A Reuter’s report estimates that settlements for damages linked to Per- and polyfluoroalkyl substances (PFAS) currently exceed $11.5bn and with some expecting that settlements will go on to eclipse the $200bn paid by “Big Tobacco” in the 1990s. Liability tied to PFAS will also impact downstream users. In fact, a recent

report by UBS estimates the total market capitalization of companies impacted by PFAS will reach $30 trillion.

To mobilize the necessary capital to shift manufacturing to sustainable chemistry will require incentivizing policies to complement existing, and necessary, restrictive policies, new economic incentives (e.g., procurement subsidies to encourage market uptake of sustainable chemistry alternatives) to create both clear demand signals and grow supply and re-distribution of current subsidies. For example, the International Monetary Fund estimates global subsidies for the fossil fuel sector at $1.3 trillion per year – $7 trillion if external climate change costs are factored. In direct subsidies alone, this translates into over $3.5bn per day. We could be building about four world-scale sustainable chemical manufacturing plants, per day, every year.

The good news is there is increasing demand for products (particularly consumer products) that are safer and healthier for consumers, workers, and ecosystems. Large retailers and brands, purchasers, and investors are seeing both the benefits of sustainable chemistry investments and the risks of not adopting them. Change Chemistry research shows that products of sustainable chemistry are growing significantly in the marketplace compared to incumbents in the same product category. Consumers are willing to pay more for products that help protect their families.

Even though the money needed to build the manufacturing plants for this transition is there, it takes more than manufacturing capacity to mobilize sustainable chemistry. Collaboration along manufacturing valuechains and across industry verticals is needed to ensure that we are avoiding regrettable substitutions, meeting performance requirements, and preserving economic performance, including finding ways to address the increased costs of sustainable chemistry innovations.

As a community, we need to improve chemical transparency across value-chains and define objective global standards and metrics through which safety and sustainability can be quantified. Finally, globally harmonized incentivizing policy frameworks are needed to catalyze market uptake of emerging sustainable chemistries and mobilize investment capital to support capacity increase.

*Note: the opinions expressed in guest editorials are the author’s own and do not represent ASC policy or position.

Congratulations to all the ASC Scholarship recipients. Here, some of them share how it has helped them with their studies.

Gabrielle Gravel, a sophomore at the University of Florida says that beyond the financial support provided by ASC’s Scholarship Program, it has also opened her eyes into future career opportunities. “I am incredibly grateful to be a recipient of the ASC Scholarship. As a student majoring in Applied Physiology and Kinesiology, the additional lab and class fees can be a financial challenge, and this scholarship will help me cover those costs,” she says. “This program has provided me with invaluable insight into career paths I hadn’t originally considered. It has broadened my perspective and motivated me to explore opportunities within my field.”

Kalina Gravel, a sophomore at the University of New Hampshire, was also delighted to receive the financial assistance. “I am very grateful to have received the ASC Scholarship. Not only did the scholarship broaden my career possibilities in Marine Biology, but it also provided financial aid that will lessen the burden of my university costs. The Scholarship has allowed me to continue to fully concentrate on my studies and focus on my academic success.”

“The Rusty Thompson Memorial Scholarship will help me finish my last year studying at the University of Nebraska-Lincoln,” adds another of this year’s recipients, Spencer Godina, Junior, University of Nebraska-Lincoln. “It will allow me to continue developing my computer science and mathematics skills to progress toward my goal of having a career in the adhesives and sealants industry.”

“I am so grateful to be a recipient of the Rusty Thompson Memorial Scholarship,” continues Sarah Sheldon, Sophomore, Ohio Northern University.

“Due to my heavy course load, I work only a few hours each week. This scholarship will help lessen the financial gap. Not only did I discover a new path that I could take my career on in the future with this scholarship, but I also greatly appreciate the financial assistance it has brought me.”

In August, prior to the fall 2024 semester, ASC revealed the latest cohort to be named as the recipients its 2024 ASC Scholarship Program. Each received a financial contribution towards their studies.

Those lucky few this year were: Gwenyth Lowery, a sophomore at Loyola University Maryland (pursuing a degree in Biochemistry and Business); Gabrielle Gravel, sophomore, University of Florida (degree in Kinesiology and Physiology); Benjamin Zhuang, sophomore, Carnegie Mellon University (degree in Chemical Engineering); Sarah Sheldon, sophomore, Ohio Northern University (degree in Forensic Biology with a minor in Psychology); Kalina Gravel, sophomore, University of New Hampshire (degree in Marine, Estuarine, and Freshwater Biology); Spencer Godina, junior, University of NebraskaLincoln (degree in Computer Science and Mathematics with a focus on Data Science and

Statistics and minoring in Business).

ASC wishes them success in the remainder of their studies and thanks the member companies that so kindly contributed funding to this important initiative.

The Scholarship Program has proven a resounding success since it was originally launched in 2017 in memory of Gene Simmons, a hugely respected pressure sensitive adhesive formulator. It was renamed in 2024 to pay respects to the late Rusty Thompson, a dear friend of ASC and former member of the Board of Directors, who is greatly missed by the adhesive and sealant industry. This year, Thompson’s legacy was honored with his inclusion into the ASC Hall of Fame (see the article on page 20).

Among his many contributions was his unwavering commitment to establishing the ASC Scholarship Program seven years ago, resulting in many thousands of dollars being

ASC’s landmark Scholarship Program supports talented young people with their studies, so they can play their part in shaping the future of the industry

contributed to scholarships for dozens of students pursuing business and chemistryrelated degrees.

“Rusty Thompson, the former President of Evans Adhesive and ASC Treasurer and Board Chair, felt strongly that ASC should have a Scholarship Program to help students who could potentially be the next adhesive formulator or a future global business manager in our industry,” says Bill Allmond, ASC President.

“In addition, he felt that creating a program

like this would help create some muchneeded visibility among college students of the important role the adhesive and sealant industry plays in society and how it could be a lucrative career choice for them,” continues Allmond. “The science of adhesion may not be particularly attractive to some young people, but it really is a fantastic industry to work in.”

Such has been the success of Thompson’s vision, that it has encouraged many young people to consider taking roles in the sector, many of whom have already made a very real

impact on the future of the industry since graduating.

“ASC is proud that tens of thousands of dollars have been awarded to date,” says Allmond. “Ever since the program’s inception, ASC has awarded five to seven scholarships each year to college students aged 18-21 years old across the U.S.”

These checks are mailed directly to the financial aid offices of the recipients’ colleges or universities to go towards their tuition. Amounts vary between $2,000-3,000 each, depending on available funding, he says.

To be eligible for consideration, ASC asks that applicants are a full-time freshman, sophomore, or junior studying chemistry or a business-related degree at an accredited college, university, or community college.

Applicants no longer need to be related to someone working at an ASC member company, adds Allmond. “Starting this year, we removed that as a prerequisite to cast the net even wider and make the Scholarship Fund available to more students,” he says.

Although there is no formal application form, those wishing to be considered for scholarship funds are invited to submit a 750-1,500 word statement describing their career goals; how their current studies relate to, or possibly could relate to, a career in the adhesive and sealants industry; and explain some of their academic and extracurricular achievements or activities – whether that is volunteering in their local community or participating in clubs or organizations outside of their studies. The information they provide paints a picture of not just what they are doing academically, but about who they are and their interests and passions.

ASC’s dedicated Scholarship Committee of six judges then review all the submissions. Based on a scoring process that considers criteria including their course, future career aspirations, and achievements, they determine who rises to the top and should receive funding.

An exciting new addition to the program this year will also see these successful applicants given the chance to take part in an internship in the summer of 2025 with a participating ASC member company, where positions are available. This fantastic opportunity provides those selected to experience first-hand what it is like to work in the adhesive and sealant industry and leave with some key takeaways and contacts that will help them on their future career path.

Applications for ASC’s Scholarship Program for the Fall 2025 Semester will open March 1, 2025.

Andy Brice

Each fall, the ASC community comes together to welcome the latest inductees to the Hall of Fame and celebrate the achievements of key contributors to the adhesives and sealant sector

All attendees at the Executive Leadership Conference are invited to the ASC Chair’s Reception and Dinner on the second evening of the event for a special ceremony to honor some of the “giants” of the industry chosen to enter the ASC Hall of Fame.

This year, ASC is delighted to announce that the Class of 2024 comprises three new, very deserved, inductees: Traci Jensen, Bill Arendt, and the late Rusty Thompson.

“Each of them is what we refer to as an ‘industry giant’ and is very deserving of entry into our Hall of Fame because of their significant, lasting contributions,” says Bill Allmond, ASC President.

“Rusty was a former ASC Board Member, Treasurer, and Chairman who created the ASC Scholarship Program and the Gives Back Program that we run for the local communities where we hold our Annual Convention,” he says. “Even though he came from a small company, his influence was really wide, and he created many lasting projects and programs that have been meaningful to our industry.”

Thanks to Thompson’s influence, countless community service projects have been assisted by ASC members in many cities across the U.S. The Scholarship Program, recently renamed in his honor, has seen many thousands of dollars awarded in grants that

To find out more about the ASC Hall of Fame and how to nominate individuals for inclusion next year, visit https://www.ascouncil.org/asc-hall-of-fame Information...

Where it all began… the launch of the Hall of Fame in 2022 honored Jim Owens (center)

have supported dozens of students in their pursuit of business and chemistry-related degrees. Some of these recipients have gone on to take positions in the adhesive and sealant industry since graduating. Thompson was also responsible for reinstating the Executive Leadership Conference as an annual event.

Jensen’s place in the Hall of Fame, meanwhile, marks her years of commitment and service to the association. She served on the Board of Directors and ensured ASC made it through a particularly tough period when it lost its President and had to search for a successor. She was also instrumental

in implementing various strategic changes, which are attributed to helping ASC become what it is today.

“Traci was a former ASC Board Member and Chair of the Board who, when my predecessor left, navigated the association through that transition to find a new President eight years ago,” continues Allmond. “She really stepped in and did a lot of the day-today management until I came on board. She was also instrumental in championing the ASC Training Academy as an outcome of the first strategy session.”

Arendt’s stellar career has seen him push the boundaries of adhesive and sealant technology

To date, seven industry veterans have been accepted into ASC’s Hall of Fame

and innovation for over four decades, and he is widely recognized as an influential and inspirational leader. He holds numerous patents, including a range of formulations that improve the compatibility and functionality of plasticizers in various polymer systems. His work has often focused on achieving lower viscosity, better solvating properties, and enhanced environmental profiles.

“Bill’s career has been more on the technical side than the others,” says Allmond, “and his role behind the scenes working at several companies saw the development of new technologies and innovations for plasticizers and other polymer additives. He has been pivotal in driving substantial advancements in product performance and sustainability.”

All inductees receive a complimentary lifetime registration to ASC’s annual Executive Leadership Conference, as well as a commemorative crystal trophy to mark their inspirational and unerring contribution to the

adhesive and sealants sector.

During the presentation at the Chair’s Reception, they are also invited to provide a short acceptance speech, reflecting on their careers and how others have influenced their direction and success.

“Over the years, our recipients have told us how humbled they’ve felt winning this award and being mentioned in the same breath as some of these other industry greats,” says Allmond. “They’re excited, surprised, and thankful that their peers have recognized them in such a way.”

Memorializing accomplishments

Nominations for new inductees are invited from the ASC membership and must be co-signed by two people in addition to the nominator, with an outline of their contributions – whether that has been while working in a leadership position in their companies, on the technical and the development side, or with the ASC itself. Each

year, one to three people are selected for entry into the Hall of Fame.

Anyone who was currently working, retired, or deceased could be considered – as long as they were employed by an adhesive and sealant manufacturer or supplier in North America and had made impactful and positive contributions to the association and wider industry.

The submissions received by the May deadline are subsequently reviewed and assessed by the ASC Hall of Fame Committee and then the Board of Directors, who pass a vote on the winners.

The total number of inductees since the launch of the Hall of Fame in 2022 now totals seven, with Jensen, Arendt, and Thompson joining Theodore (Ted) Clark; Dr. Selim Yalvac; and David Nick from the Class of 2023, as well as Jim Owens who was the first to be honored in 2022.

Elevate your brand with ASC and reach thousands of key decision makers.

The ASC’s Adhesive and Sealant Showcase is a print and digital publication with outstanding reach and readership.

Get in touch to discuss our range of advertising opportunities to showcase your products and services and rise above the crowd.

What is the value of being a member of the ASC? It’s hard to put a specific number on it… says Brian Peters, Director, Membership and Industry Programs

The Adhesive & Sealant Council (ASC) was founded in 1958 as a 501 (c) (3) nonprofit trade association. Today, it serves as the voice of the North American adhesive and sealant value chain and represents more than 75% of the U.S. industry.

Thanks to our dedicated seven-strong team, ASC oversees programs, events, reports, and resources that are accessible to all our 112 main member companies –which include manufacturers, raw material and equipment suppliers, distributors, and industry consultants.

We are governed by 22 industry experts and leaders on our Board of Directors, have seven working committees, and two Task Forces that are constantly looking to help drive the industry forward and represent our members’ needs.

We maintain roughly 3,400 user profiles in our database and attract over 800+ industry thought leaders to our ASC Events. Of the three main industry meetings we host each year, the largest is our Annual Convention & EXPO, which takes place every April and attracts hundreds of attendees eager to hear about the latest and most pressing issues affecting the adhesive and sealant sector. The three-day meeting is packed with presentations and keynote speakers and regularly features close to 90 exhibitors keen to showcase their products and services.

After an eight-year hiatus, we relaunched our Sustainability Summit in 2022, and this has become a must-attend event every

September, highlighting one of the most talked-about and topical issues in the industry. It is closely followed a month later by the Executive Leadership Conference, which brings senior leaders and executives together for high-level commentary and analysis.

If that was not enough, our popular Training Academy boasts 772 graduates and 400 active learners, while ASC also runs around 20 feature-packed webinars throughout the year too!

Our Innovation Awards – now in its ninth year – has received hundreds of submissions since its inception and celebrates the amazing advances made by our membership for the betterment of the industry.

And let us not forget our coveted Hall of Fame that marks the “giants” of our industry. We are delighted to have recently welcomed another three outstanding inductees to join

the four who have already been included since its launch in 2022.

But it is not all about the facts and figures. Of course, we recognize it is you, our members, that also bring so much value to the association – and we cannot do all this without you.

On my travels across the country, I often hear our members refer to ASC as a community, a hub, a network. They say the association is about connections, that we are the voice of the industry, and your trusted partner. You tell us that ASC is a platform, a forum, and even the living, breathing “organ” of adhesives and sealants.

Since joining the ASC team as Director of Membership and Industry Programs over two and a half years ago, I like to explain who we are, not only to those who are not yet members and may be exploring ASC

membership, but to my children, my family, my neighbors, and friends. Put simply, I tell them that ASC is a family.

Every day, our purpose is to work for our members. We are constantly asking ourselves how we can get even better, and whether a new program or offering could benefit you. We try and stretch our thinking, and really challenge ourselves to identify ways we can better serve our industry.

I often reflect on our ASC Vision Statement, Innovators Secure the Future with Adhesive & Sealants and how the

Strategic Pillars outlined by our Long Range Plan help our members stay nimble and adapt for the future.

We are in the process of rolling out a new Net Promotor Scote (NPS) feature via our association management software platform. This will be administered to ASC supporting members only. We seek your participation and honest feedback. When you see an email from us, please do not delete it but take time to complete it. Your input will help us better serve you.

Whether you are a long-standing ASC member or new to the association, we welcome your involvement and ask you to get involved and share your voice. We would love you to let us know how you feel about your ASC membership, membership programs, or whether there are areas you feel we could focus on and improve. You can reach out to me directly; ASC’s President, Bill Allmond; or any member of the ASC team. ASC is always looking for member testimonials. Whether you are happy

To contact Brian Peters, Director of Membership & Industry Programs, by email, use brian.peters@ascouncil.org or by phone, (314) 283-1842. Get in touch...

to write a short testimonial or take part in a short video interview online we would love to hear from you. You can see some of these on a dedicated page our website called the Voice of the Member (https://www. ascouncil.org/voice-of-the-member).

Next year, we are looking to run a series of podcasts, entitled From the Field. These will focus on end users and look at their likes, dislikes, and provide some insight into their operations. Again, if you would like to get involved or have any ideas or suggestions about subjects that you would like covered, please do get in touch, and thank you for your team’s commitment to the ASC and that of the industry.