7 minute read

Can we expect a forward leap in automation?

GRAEME RICHARDSONLOCKE, TECHNICAL SUPPORT MANAGER AT FESPA, TALKS ABOUT RECOGNISING THE OPPORTUNITIES IN AUTOMATION AND WHAT VISITORS TO THIS YEAR’S SHOW SHOULD EXPECT

tanding on the brink of a new decade, a predictable host of articles are flooding the business media, assessing the tech trends likely to reshape our ways of working. One topic that surfaces wherever I look is automation. Research company Gartner even goes as far as putting “hyperautomation” in first place in its Top 10 Strategic Technology Trends for 2020 analysis, saying that “hyperautomation refers not only to the breadth of the pallet of tools, but also to all the steps of automation itself (discover, analyse, design, automate, measure, monitor and reassess).”

Automation isn’t new. The print sector has been harnessing process automation enthusiastically over the last 20 years, with clear benefits for productivity and reduced time-tomarket. But speciality printers served by FESPA have arguably been slower to embrace the potential.

Maybe that’s because our roots are often in more craftbased techniques like screen printing and it’s only with the rise of digital wide format printing that we’ve become a more tech-driven industry. Perhaps it’s linked to the diversity of print stock we handle, which makes standardisation more challenging than printing on paper alone. Is it down to the typical size of the businesses in our sector and their propensity to invest? Or are we just affected by a tendency to focus on product quality and client service at the expense of manufacturing efficiency?

FOLLOW THE AUTOMATION PIONEERS Whatever has challenged progress so far, the truth is inescapable. For most speciality print businesses, buying patterns are changing, run volumes continue to reduce and we need to manage increasing quantities of small and individualised orders, together with escalating customer expectations of lightning-fast 24-hour turnaround. That means challenging every received wisdom about how we work and building new processes for the economics of an evolving work mix.

There are many inspiring speciality printers who have recognised the opportunity in automation and used it to turn their business model on its head, for example with streamlined online ordering enabled by web-to-print solutions. I blogged about three remarkable UK examples earlier in 2019. Where these automation pioneers have led, I believe that our sector as a whole will quickly follow, or suffer the commercial consequences. It is worth bearing in mind that your business may be in a position to match the pricing of a web-to-print competitor by reducing margin. However, getting fast processing of online proofing and ordering without the laborious tasks of going through estimating, prepress and booking in of suppliers can present a great benefit only achievable with automation. Looking ahead to FESPA Global Print Expo 2020 and beyond, it wouldn’t be out of place to suggest we’re on the cusp of a forward leap in automation.

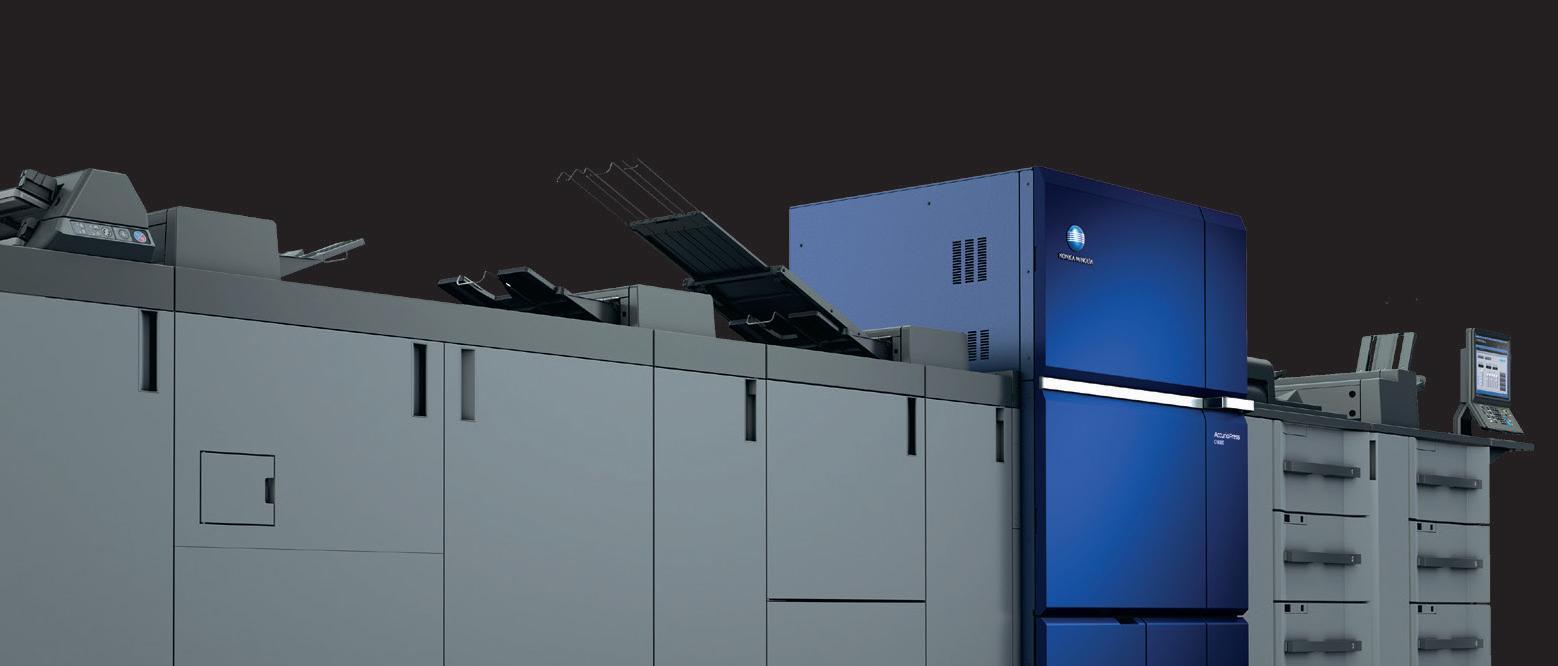

From my perspective there are two strands to this – production automation using hardware and software automation to link the ‘islands’ in a production workflow, either using individual software tools or with an end-to-end production ecosystem from a single vendor.

The “pallet of tools” described by Gartner certainly exists for speciality printers today, from planning and estimating, through pre-flighting, file preparation and colour management, to load balancing and job nesting and so on. The solutions are available now to automate and streamline virtually every stage of production from ordering to dispatch and I see more evidence of this at every successive FESPA exhibition.

MODEST CHANGES, MEASURABLE BENEFITS While hardware upgrades are often front of mind for printers when visiting a major technology exhibition like FESPA Global Print Expo, visitors to Madrid should keep a close eye on the innovations happening in software and carve out time to seek these out.

It’s often a neglected area in a printer’s overall investment planning, but a good rule of thumb would be to think in terms of allocating 10% on top of your capital expenditure budget to achieve production efficiencies through a more streamlined overall workflow.

It may seem daunting if you’ve yet to explore the automation potential for your business, but you can make modest changes and still see measurable benefits on the road to more comprehensive process automation. If a task is repetitive and a logic can be identified, it can be automated, so your starting point is to look for those opportunities.

A word of caution, though. Making a success of automation is not all about the products. While many of the tools are pretty intuitive to use, integrating them does require a mindset shift. And for printers steeped in the craft of print, new levels of process automation can feel a bit overwhelming. It can certainly feel like a whole load of “new”.

But there’s plenty of guidance available from vendors too and from organisations like FESPA and our national associations. At FESPA 2020, the Trend Theatre will run regular free seminar sessions on automation hosted by independent experts from Keypoint Intelligence and if your focus is on boosting your colour management practices, book your free guided tour of Colour L*A*B*. For garment printers, Print Make Wear is the place to explore the latest in automated workflow and manufacturing.

My advice is – don’t be intimidated by automation, embrace it. The printers that have done so are already counting the commercial gains that come from faster production, better use of capacity and staff resource, reduction of errors and waste and improved overall consistency. Isn’t it time for you to join them and unlock your full potential?

For free entry to FESPA Global Print Expo 2020, use code FESM210 when registering your attendance at www.fespaglobalprintexpo.com

Bond Over Le erpress!

To celebrate letterpress being added to the National Inventory for Intangible Cultural Heritage, the National Print Musuem is running a series of team-building, letterpress workshops

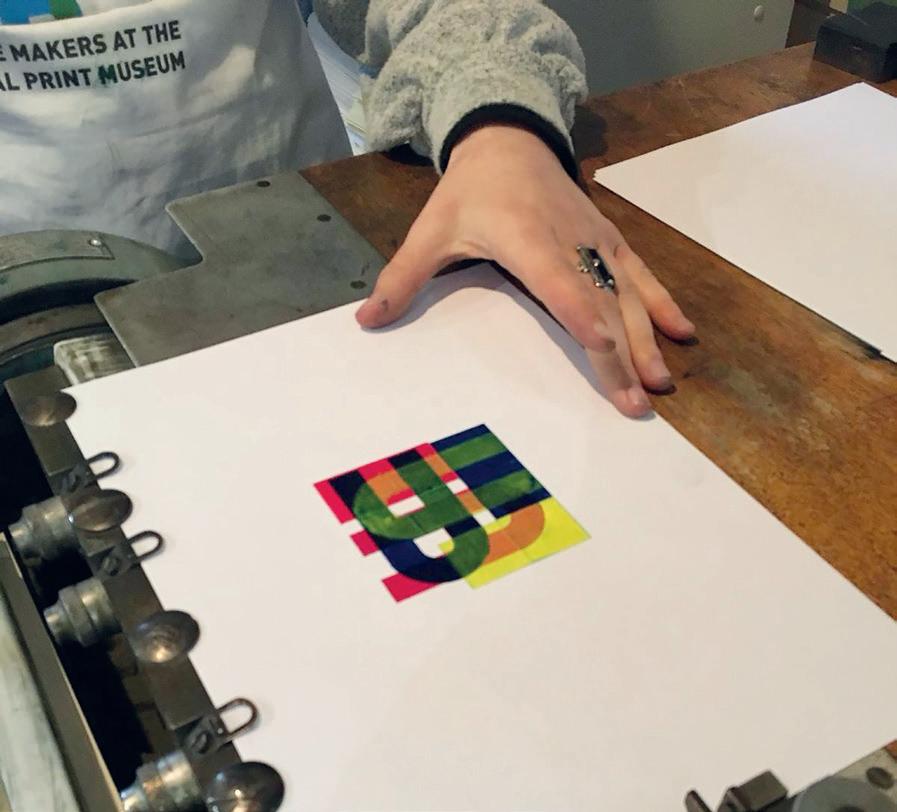

The National Print Museum’s collection is largely made up of letterpress printing equipment and stands as an example of a working collection organised like a traditional 1960’s printshop. According to the Museum, the past few years have seen an international revival in letterpress as a craft form, with a growing appreciation for tactile involvement in design and craft.

To recognise and celebrate letterpress being added to the National Inventory for Intangible Cultural Heritage, the museum has organised a series of team-building workshops where participants can collaborate with letterpress designers to produce posters for their o ce space and/or gift to their families, friends or clients.

The Museum has created three letterpress workshop options to suit either half-day or full day workshops for smaller or larger teams. The P22 Blox Workshop is a halfday event for six participants who will work together to design and typeset abstract letterpress posters using P22 Blox and the Museum’s flatbed proofing press. P22 Blox are modular letterpress printing blocks which can be assembled in a number of ways to create letters and beautiful geometric patterns. The Woodtype Workshop is another full-day workshop for six participants, focusing on the Museum’s rare collection of large wooden type as well as the flatbed proofing press. Beautiful results can

be achieved by playing with the layout, ink e ects and the texture of the wood type. All stages, including the inking, will be done by hand. Finally, the Introduction to Letterpress Workshop is a full-day workshop designed to cater for larger teams of 10-12 participants. The team will set their type, pull their prints using the printing presses and experiment with wooden type printing techniques. This workshop also includes an interactive tour of the Museum. All workshops will cover the fundamentals of letterpress printing techniques, as well as the history and background of this traditional craft.

With plans in place for the National Print Museum to move on from its current location at the old Garrison Chapel in Beggars Bush Barracks, Haddington Road by November 2021, the Museum is calling on the industry to keep an eye out for a suitable premises. “We’re looking for buildings at the moment and would be particularly interested in derelict premises that may have once been a printing house or a newspaper. We think it would be really nice to be in a building with a rich printing industry,” said Carla Marrinan Funder, CEO at the National Print Museum.

For more on the letterpress workshops or to suggest a new home for the Museum, contact Carla at carlamarrinan@nationalprintmuseum.ie or call +353(0)1 6603770

WE ARE POP SUPERSTARS The experts in innovative, attractive point of purchase engineering, design and print MAKING IDEAS HAPPEN