3 minute read

Set for growth

Investment in a new HP Stitch means Pixalili can now add decoration to polyester fabrics on demand, while giving existing customers more choice

Pixalili, a textile printing and design studio located on the Wild Atlantic Way, typically produces short runs or one-o s of lampshades, deckchairs, table linen and cushion covers, with its own designs also available on items such as upholstery. Formerly, Pixalili was only able to o er designs printed on natural fabrics such as linen, cotton and bamboo. With growing demand for products such as velvet cushions, chi on scarves and stretch jersey for baby clothes, the business decided to look at dye-sublimation, a compatible technology for these polyester materials. After seeing a demonstration of the HP Stitch S300 at The Print Show in September 2019, the company decided to go for it.

The HP Stitch delivers fast and predictable colour matching either via transfer or direct-to-fabric methods from one single device, with a range of compatible applications including sportswear, fashion, interior decor and soft signage.

Commenting on the new purchase, James Harding, Pixalili’s R&D Director said: “We are really in love with the Stitch. We sent samples to valued customers to show

them what we can now o er and the response has been fantastic. We can see the Stitch being very, very busy.” Pixalili has customers from across the world and James says each country has its own trends and requirements. For example, customers in Iceland are looking for ethically made and eco-friendly products, while the USA and Ireland have a preference for linen and in Spain, polyester fabrics for swimwear are popular. “Thanks to the HP Stitch, we can become a one-stop-shop for existing customers and respond to demands from new buyers and markets. This is our first time using dye-sub and it opens up new avenues for us,” James added.

SALE OF FIRST SERIAL DRUPA SPECIFICATION XL 106-5+L IN THE WORLD UK company Elle Media Group has concluded the purchase of the very first serial 2020 DRUPA specification XL106-5+L in the world from Heidelberg UK. This will replace a three-year-old machine which has produced 210 million impressions since its installation in March 2017. “We had been evaluating this investment for over 12 months as we knew that with the output levels we were producing and the fixed operating costs in place, our investment cycle would need to be decreased to ensure we sustained our operating cost per sheet. This was the primary driver for the investment, combined with the increase in capacity for the same overhead due to Intellistart 3. This ensured one minute improvement on current performance which will give us another 320 hours of available press time to ensure we maximise the opportunities being presented to us,” said James Cuthbert, Managing Director at Elle Media Group.

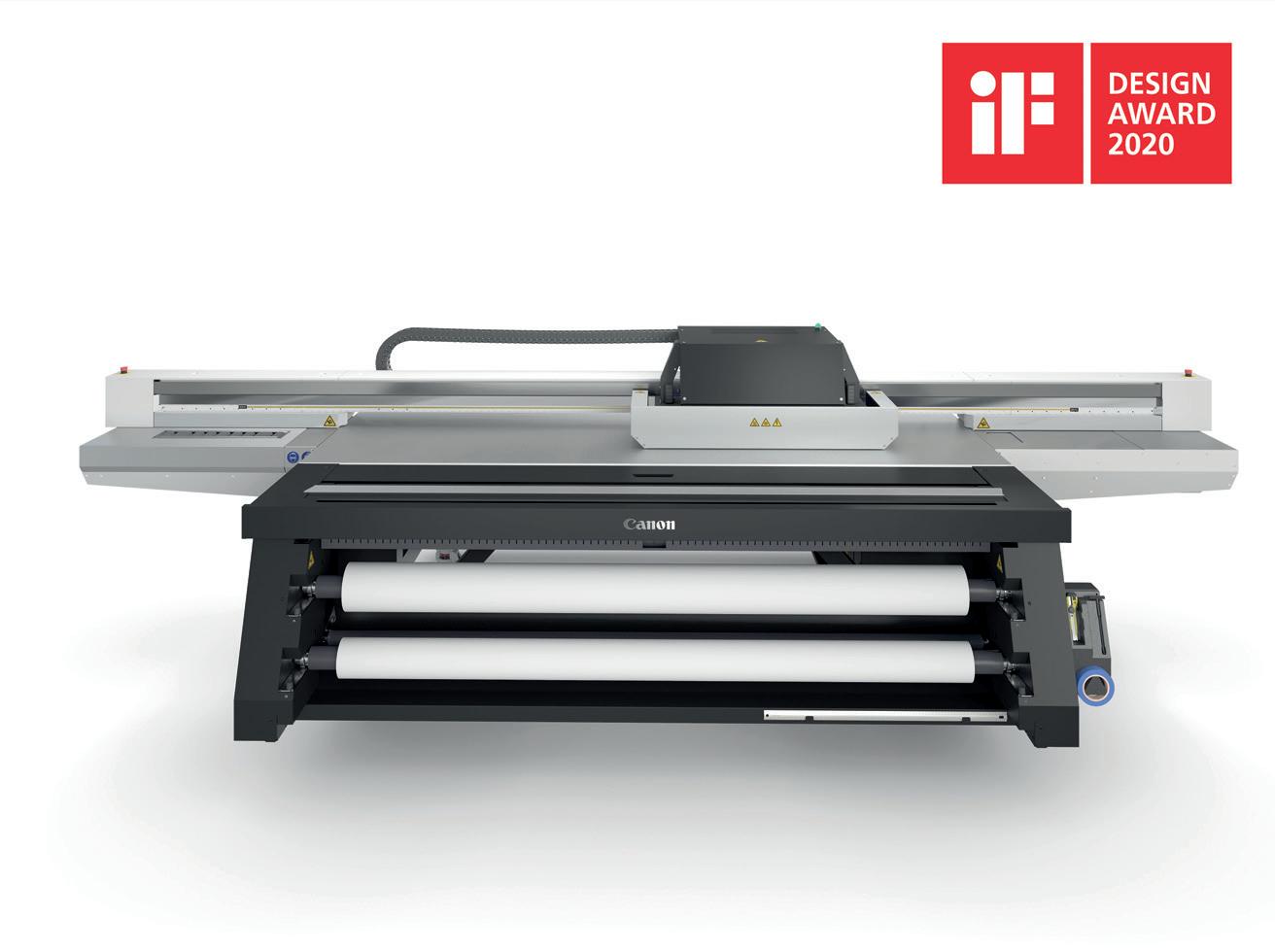

CANON TO SHOWCASE LARGE FORMAT GRAPHIC APPLICATIONS AT FESPA 2020 Canon is all set to ignite visitors’ imaginations at FESPA 2020 with its range of large format graphics applications, including indoor pointof-sale and point-of-purchase, display and packaging, interior décor including wall coverings, outdoor promotion such as banners, soft signage (backlit textile) and vehicle graphics (self-adhesive). With over 1,200 installations of the Colorado family, both the Colorado 1640 and 1650 models will be on show. Canon says that visitors will see first-hand how UVgel technology can help them handle larger production volumes with ease and give them the confidence to enter new markets such as soft signage, interior décor and vehicle graphics. For customers looking to print double-sided applications with ease, the Colorado 1640 will be in a live automated, end-to-end, print and cut workflow with the Fotoba inline cutting solution. Visitors will see in real-time how large format roll-to-roll graphics such as wallpaper can be automatically fed from the Colorado onto the Fotoba inline finishing solution, with no need for an operator to turn the media manually. The Arizona 1360 GT flatbed printer will also be in live production featuring a roll media option (RMO). It will showcase a range of interior décor output such as wood and glass, wall coverings and acoustic panels.