8 minute read

Modifier Performs from Lab to Field

AAn innovative asphalt binder modification additive from BASF, Wyandotte, Michigan, has completed its preliminary field-testing stages with promising results.

IN THE FIELD

BASF recently finished preliminary field testing of its new additive, B2Last®, a low-viscosity liquid asphalt modification additive used to improve adhesion perfor mance of an asphalt mix. The field tests were performed on job sites across Ken tucky where B2Last modifier was added to the standard asphalt binder. All other components—gradation, asphalt content, placement—remained the same. Blanken ship Asphalt Tech and Training (BATT), a consulting engineering company in Rich mond, Kentucky, was on site to monitor and sample the demo projects. Participants had some positive things to say about working with the new material.

One of the first real tests of a new mix, ac cording to Phil Blankenship, owner/founder of BATT, is what it does when the truck bed is raised.

“It is important with any new material to pave well and stick together,” Blanken ship said. “So, when I watch the first truck raise its bed and dump the mix, I watch for these indicators: does it release well from the bed, flow through the paver, set up un der the screed, workable with tools, and finally compact well. I even like to grab a sample immediately and place on the side of the road to let cool. I then observe the mix as it cools to understand what we are dealing with concerning adhesion and workability.”

Another interesting characteristic of the B2Last additive is that it did not initially per form like a traditional polymer when placed on the road during the field testing. Blan kenship reported that the mix came out of the truck smoothly with no sticking issues at 320 degrees F.

Blankenship added, “We were working around 320 degrees F.” He said he could not tell that there was any modifier in the mix, but when the mix cooled and set up, he was impressed with the adhesion aspect of the mix. The B2Last modifier added something that he referred to as “toughness.”

“I could not feel any stickiness until the mix began to cool after rolling,” he said. “I then went back to the pile that I had made on the roadside. While you can normally pick off aggregates from a typical mix, I could not get a stone to move. B2Last is extremely ad hesive tough.”

Zack McKay, laboratory operations man ager for BATT, was also on site and had several observations.

“Some of the immediate feedback I re ceived was that it didn’t have that traditional asphalt smell,” McKay said. “It removed the odor of the asphalt.”

During the field-testing stage, paving crews worked with a B2Last-modified mix and a non-modified mix for comparison pur poses. The paving crew found a significant handling difference between the two as well.

“When we transitioned to the B2Last binder, the paver operator to the crew work ing the back of the screed and the roller operator, all commented there was a noticeable difference,” McKay said. “All said it was a more workable mix to handle than the non-modified mix that we had started with.”

IN THE LAB

Working with B2Last, similar results were seen in the lab. McKay tested materials sam pled from the Kentucky field trials that compared the B2Last-modified mixes to the non-modified mixes.

“While working with mixture in the lab, we saw that samples required less gyratory com pactive effort than its non-modified counterpart [standard mix],” he said. “The repeatability we have seen in this trend may indicate that B2Last enhances compactibility.”

Further studies into compactibility of the B2Last mixture are on the horizon at the BATT lab by analyzing the laboratory-pre One of the first real tests of a new mix, according to Phil Blankenship, owner/founder of BATT, is what it does when the truck bed is raised. Blankenship reported that the B2Lastmodified mix came out of the truck smoothly with no sticking issues at 320 degrees F.

pared and plant-produced mixtures with non-modified mixtures.

The IDEAL-CT (ASTM 8225) test ing also showed positive results with the B2Last-modified mixes.

“When we compared the Kentucky non-modified mixture to the modified mix ture, we saw an improvement on the resistance to cracking,” McKay said. “B2Last test mix provided a higher CT index value, and those higher values are an indicator of bet ter cracking resistance. This indicates a reduction in cracking pavement over time [as compared to the standard mix].”

Further study at the BATT lab included evaluating a standard mix and comparing it to a B2Last-modified mix with the same job mix formula (JMF).

Blankenship commented, “It is exciting to see how new materials perform in the lab. While materials can do well in the field, our testing is not always robust enough to pick up on performance characteristics of new mate rials. This means we have to keep our lab-eyes wide open and not just ‘run the test.’”

“We conducted testing on formulations of B2Last with SBS polymer modified binders and compared it to a KY standard [3/8-inch NMAS surface] control mixture,” McKay said.

Figure 1. IDEAL-CT cracking testing on lab mix at 25 degrees C (77 degrees F)

Figure 2. Hamburg Wheel Track rutting/stripping testing on lab mix at 50 degrees C (122 degrees F) and wet

“When B2Last was modified with SBS polymer, we saw a synergistic effect occur where laboratory resistance to cracking improved by 46 percent over control and SBS binders.” (See Figure 1)

B2Last also showed the potential to im prove rutting issues on some projects. The BATT lab ran the Hamburg Wheel Track test wet and at 50 degrees C on the B2Last mix.

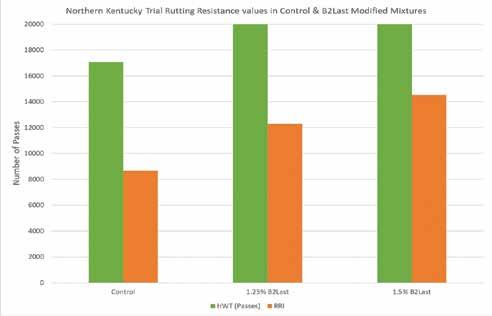

“On one of the trial projects in Kentucky, we were able to conduct a small study on dosing,” McKay explained. “The trial in cluded B2Last modification at two dosages along with the non-modified mixture. We tested the three mixtures in a Hamburg Wheel Tracker and found that after increas ing B2Last dosage, the rutting resistance index (RRI) 1 of the mixture increased.” (See Figure 2)

MULTIPLE APPLICATIONS FOR ADDITIVE

Although B2Last is a new player in the asphalt industry, the chemical modifier has been used for a variety of applications in manufacturing worldwide.

“It has uses in the auto industry, glues, everyday products that you touch,” Blankenship said. “Now we’re finding out that it does some unique things in asphalt. This is an adhesive that we need.

“Think of it like a polymer and asphalt—a two-part system but no separation issues, you blend it in,” he continued. “This liquid goes in and becomes one with the asphalt, it’s com pletely reactive. So, the stability, the compatibility, the usability, becomes very easy.”

While contractors should typically add B2Last to their asphalt binder upstream, Blan kenship said they can also add it at a local hot mix plant binder tank, where permitted to do so by existing DOT and other regulators. No sig nificant retrofitting is required to add B2Last to a mix at an asphalt plant. The only possible ad dition would be an injection port, but, in many cases, those are already installed at the plant.

“It’s a big advantage from the point of sell and point of usability,” Blankenship said. “It puts the tool in the hands of the contractor.”

From improved workability and compact ibility of the mix to reduced rutting and odors and localized usability, B2Last is showing ad vantages for contractors in its initial field testing. Road building professionals can expect more test results to see how this additive can improve their operations in the near future.

– BY BERNIE MALONSON

Bernie Malonson is the marketing and business development manager for asphalt initiatives in the chemical monomers di vision of BASF Corporation, Wyandotte, Michigan. Malonson joined BASF in 2016 as an innovation specialist and project manager. He is on four published and pending asphalt-related patent applications. Prior to joining BASF, Malonson held various market ing, business development, product and project management positions in the telecommunications industry and in the automotive industry. He received his MBA from INSEAD in Fontainebleau, France. He also holds a MS in business analytics from Michigan State Uni versity, and a BA in history from Harvard College. For more information, contact BASF at (734) 324-6697 or visit www.basf.com.

1.RRI is an index value that combines the number of passes to failure and the rut depth into a single, more relatable value. RRI = the number of HWT passes X (1 – rut depth in inches).

INSPECTION SERVICES ULTRA-PORTABLE ASPHALT PLANTS

PARTS

AND WE DO THIS... ULTRA-PORTABLE ASPHALT PLANTS PARTS INSPECTION SERVICES

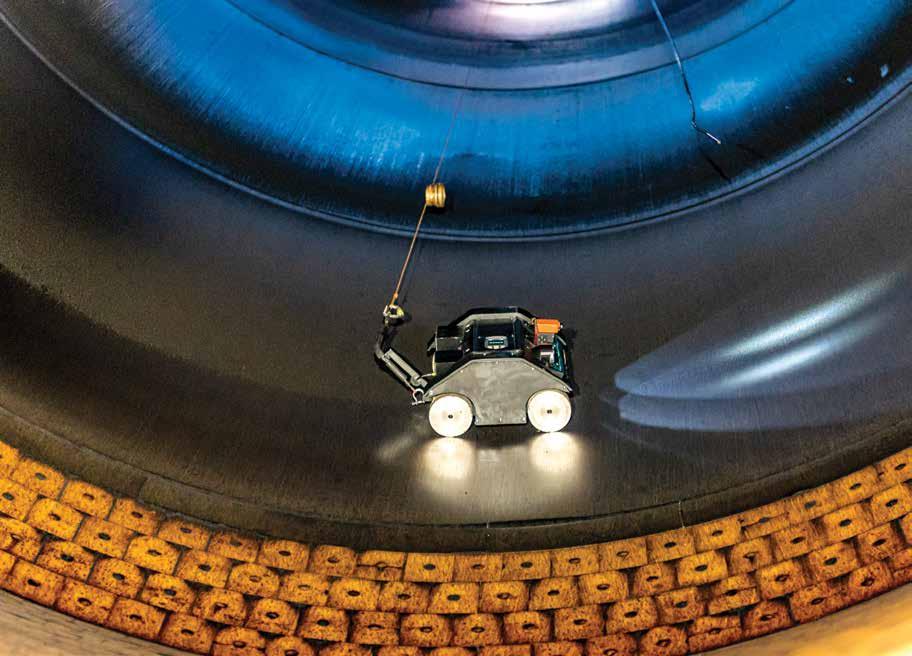

SILOBOT SM INSPECTION SERVICE

ULTRA-PORTABLE ASPHALT PLANTS PARTS INSPECTION SERVICES Traditional silo inspections are costly, time-consuming and risky, but failure to regularly inspect silo interiors could result in costly repairs or even catastrophic failure. With regular inspections, you can perform preventative maintenance that extends silo life.

ULTRA-PORTABLE ASPHALT PLANTS PARTS INSPECTION SERVICES An Astec SiloBot SM inspection takes less than two hours to fully inspect the entire silo. A traditional inspection takes much longer and only inspects the bottom third.

To schedule a Silo Inspection call 423.356.4791

A unique approach to asphalt silo inspection.

SAFER

Technician stays safely outside of the silo during inspection

CONVENIENT

No scaffolding needed

FASTER & LESS DOWNTIME

Full inspection in less than two hours per silo

COST EFFECTIVE

Less cost than a traditional inspection