3 minute read

NEW YORK CITY TESTS MACREBUR PRODUCTION

Recycled plastic waste uses temps of 330 degrees on Staten Island

BY ASPHALTPRO STAFF

Editor’s Note: All stats and figures are courtesy of Rutgers Center for Advanced Infrastructure and Transportation via MacRebur’s “August 2022 NYCDOT Trial Road MacRebur MR8” document.

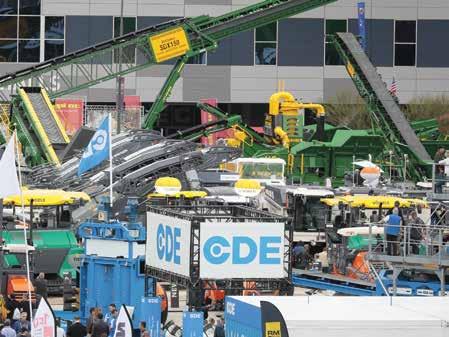

SStaten Island became home to roads surfaced with recycled waste plastic mix design at the end of August 2022, offering a chance at recycled production for the team of the New York City Department of Transportation (NYC DOT); MacRebur, Lockerbie, Scotland; and City Asphalt LLC, Staten Island. Here’s what the team executed.

NYC DOT looked at four dosage rates of MacRebur MR8 product into asphalt mix with 40% recycled asphalt pavement (RAP) from City Asphalt’s fractionated stockpiles. The foundation mix had a nominal maximum aggregate size of 12.5 mm and PG64S-22 binder. The dosage rates tested were 0, 6, 10 and 12% by weight of virgin binder and 0, 3.8, 5.5 and 6.5% by weight of total binder. The MacRebur MR8 product was added by fiber feeder at the RAP collar of City

Asphalt’s Gencor Drum Mix Ultraplant, rated at 400 tons per hour, which was put into service March 2020 on Staten Island.

Plant production in late August 2022 was around 250 TPH to produce 2,200 tons of HMA, 1,800 tons of which contained 10,395 pounds of MacRebur MR8. The production temperature for the control mix was around 315°F. The production temperature ranged from around 320 to 330°F for the mixes dosed with recycled plastic waste. The mixes were allowed a 2-hour silo storage time and saw a 40- to 60-minute haul time. The two pavements are located on Rice Avenue and Royal Oak Road.

The team reported the amount of recycled waste plastic used was 10,395 pounds and the amount of virgin asphalt cement binder reduced, by weight, was also 10,395 pounds, which would suggest a 1:1 ratio. The team also reported the carbon savings as 7,331 kilograms of carbon dioxide equivalent (CO2e).

Testing took place Aug. 29, Aug. 30, Aug. 31 and Sept. 1, with dosages of MacRebur MR8 at 0, 6%, 10% and 12% respectively. The actual percent passing are listed for each of the sieves with the targets and limits for the job mix formula (JMF) listed to the right of the actuals. Table courtesy of MacRebur

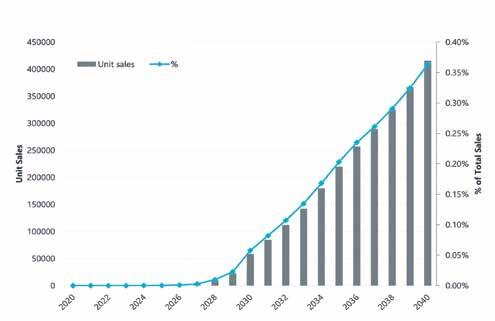

One of the graphs available from Rutgers and NYC DOT shows fatigue cracking results for the control and the different dosage rates of the recycled waste plastic. Additional graphs with more cracking performance data are available from MacRebur. Reach out to their marketing group via charlotte.dixon@pacecomms.co.uk and let them know you saw this request for data in AsphaltPro Magazine.

A spokesperson for MacRebur told AsphaltPro that the team at City Asphalt was able to run at its usual temperatures. “There were no changes to their production process or the paving process,” the spokesperson shared. “The initial results showed that our product met all the required QC measures and specifications with City Asphalt and NYC DOT.”

Matthew Cruz, general manager at City Asphalt, stated, “When NYC DOT advised us of the trial using waste plastic in asphalt, we were initially reluctant as we hadn’t had much experience with the introduction of new products into our new Gencor plant.

“However, as we researched the product and had the opportunity to discuss with other asphalt plant operators, our reluctance turned to curiosity and excitement. The opportunity to address a major environmental concern seemed too good to be true.”

Hit Goal

The stated goal of NYC DOT was to “not worsen” the existing pavement performance by adding the recycled waste plastic product. To ensure they hit their goal, they tested in the lab and the field. See the table and graph included with this article for examples of data gathered so far. The trial sections will now be tested and monitored to measure performance against traditional asphalt by Thomas Bennert, Ph.D., at Rutgers University.

The agency also looked to improving environmental sustainability. While the NYC DOT is reported to produce and lay 1.1 million tons of asphalt each year, it is also reported as one of the United States’ leaders in using RAP, typically putting 40% RAP in its mixes. Now the project in Staten Island has diverted the equivalent weight of 214,534 single-use plastic bottles from landfill, according to the team at MacRebur.

“Having worked with the team at NYC DOT for just over a year, it’s refreshing to see such enthusiasm about new technology and products for use in asphalt,” Roddy McEwen said. He’s the international business officer at MacRebur. “Whilst trial sections such as these typically take up to three years from start to finish, we have worked together to begin trials within just four months—with a long-term goal of utilizing local waste for local roads.”

“We are excited to partner with MacRebur on this promising pilot and look forward to monitoring how its asphalt mix performs in New York City weather,” NYC DOT Commissioner Ydanis Rodriguez said.

For more information, visit www.macrebur.com/us.