5 minute read

DUSTROL COMPLETES HIR FOR BUTLER COUNTY

BButler County, Iowa, is moving toward hot in-place recycling (HIR) to leave a legacy of restored rural roads benefiting taxpayers, agriculture and light industry. To this end, in early summer 2022, just west of Cedar Falls, subcontractor Dustrol Inc., used the method on the surface of County Road T47 (Sinclair Ave.) from Iowa 57 north 12 miles to Iowa 3.

BUTLER COUNTY’S CHALLENGE

Like many Iowa counties, Butler County is square in shape. It’s bisected by one state trunk highway north/south, and another east/ west. “The secondary road system branches off them, to all communities, generally on a three-mile grid,” said John Riherd, P.E., P.L.S., Butler County engineer.

The county is responsible for approximately 400 lane miles of secondary roads, including drainage structures and bridges. Unpaved (gravel) roads total another 1,600 lane miles. “We have one section of Portland cement concrete that’s 1,100 feet long, otherwise everything else is asphalt,” said Tom Hoodjer, PLS, assistant engineer.

Other than funding, the county engineers say fighting cracks in pavement is their biggest challenge. “Keeping the surface crack-free so it drains well is most important,” Riherd said. “Cracks will kill your road more than anything else. One of the first things we do is fill the cracks. We try to either fill or eliminate the cracks so water’s not getting into the base and we’re holding that surface together.”

Heritage Of Engineers

That the county roads aren’t plagued with potholes isn’t just a testament to staff keeping cracks filled, but to preceding civil engineers who knew how to build long-lived roads.

“The one thing we don’t generally have is a lot of potholes,” Hoodjer said. “The engineers before us spent a lot of time working on that base. The road system in Iowa was developed over time, and they had the foresight to make sure that they had constructed a good base before they paved it. They knew what they were looking to do.

“Also, another good thing for us is the availability of good limestone rock,” he added. “There have been quarries in all parts of the county and we still have most of them.” Indeed, one of Butler’s townships is named Shell Rock.

A typical road cross section in Butler is 6 inches of rolled, or compacted, stone, topped with 3/4-inch of seal coats, and later, 2 inches of hot-mix asphalt (HMA). Eight to 10 years later another inch or two of HMA would be placed and there would be 3 to 5 inches of asphalt on top of the base course.

“Around the early- to mid-1990s we began doing a lot of cold in-place recycling [CIR] in the county,” Hoodjer said. “At that point most asphalt pavement had 5 to 6 inches of asphalt and bituminous seal coat. At this time approximately 90% of the county roads have been cold in-place recycled.”

MOVE TO HOT IN-PLACE

Over the years the layers of cold in-place recycled (CIR) asphalt rose higher and higher, and Butler County began to look at alternatives such as HIR.

Riherd said 2021 saw the county’s first trial of HIR. “We had a cold in-place program but started to get to a point where we asked, how much is too much cold-recycled pavement? We had some roads which were cold in-place-recycled in the 90s, and hit ’em again, cold in-place-recycling the either 2- or 3-inch cap that was on that, and into the old cold-recycle. At that point we were getting to 6, 7 inches of a cold- recycled mix, and then a 3-inch cap of asphalt on top. We didn’t know if that was really a good thing to continue to build these pavements up.”

Staff also began to see the function of the cold-recycled layer in a different light.

“We saw that cold recycle as a stress relief layer, a crack prevention layer, not necessarily a load-carrying layer,” Hoodjer said. “And we became concerned about having too much of the ‘softer’ mix in the middle of this pavement. We saw industry promoting hot in-place and thought that would be a good way to deal with that.

“That is, we’re planning to leave that CIR layer alone, essentially, but work with that 3-inch cap because that’s where the wear is. The cold inplace layer still is doing its job under there, but now we’re seeing some cracking in that cap. That’s what we saw with Sinclair Ave.”

Due perhaps to loads of stone headed to a different project on Sinclair Ave. from a local quarry, rutting began to appear shortly after it was resurfaced. “We felt it saw a lot of abuse in its first year or two of life and rutted because of that,” Riherd said. “We like to restore the cross-section before we in-place recycle, so we milled a nominal 3/4-inch to 1-inch to create a cross-slope again, and to generate RAP for a new cap and give the recyclers a good chance for a uniform surface.”

On Sinclair Ave., cores taken earlier were analyzed by consultant Road Science, a division of Arkema, which came up with the recycle mix design. The surface was recycled with HIR to a depth of 2 inches. This included preparing the surface by milling, softening the surface via uniform heating, and mixing with a rejuvenating agent, and spreading, leveling, and compacting the mixture for surfacing.

The rejuvenating agent was composed of a polymer modified asphalt emulsion, containing 3% styrene-butadiene solution polymer.

The final recycled course was compacted by a Hamm double-drum HD+ 140i high-frequency roller in breakdown position, followed by a Hamm double-drum HD+ 140i VO finish roller in oscillation mode, compacted to minimum 95% density.

The prime contractor, Heartland Asphalt Inc., of Mason City, Iowa, would then place a 3-inch HMA friction course in two 1.5inch lifts.

Unique Hir System

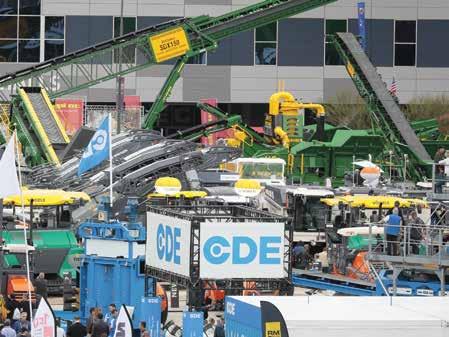

Dustrol’s eight-unit HIR train has four units pulled by tractor cabs, and four pushed by the heater mill units. “Each of the eight heaters and heater mills have an operator, who does not drive the truck, but operates the equipment,” said Ron Wilson, vice president for Dustrol.

Dustrol’s MARS process, which stands for Mobile Asphalt Recycling System, is the contractor’s current method of hot in-place recycling asphalt 2 inches or more. The process begins with one custom-made, propane-fueled preheater. The next heater in the train is equipped with grade-controlled milling drums, which windrow the top 1/2 to 3/4 inch of softened material. The milling heads are capable of cutting 16 feet wide.

Tunnel heaters follow, heating the underlying pavement while maintaining the temperature of the windrow in the tunnel. The surface again is milled and heated by up to three more milling heaters alternating with tunnel heaters, depending on material and depth. The last milling heater in the process has an oil metering system that injects and mixes the rejuvenating agent into the milled asphalt and aggregate.

“We don’t have a direct flame going down to heat,” Wilson said. “Instead, the flames heat fire brick within the unit’s ‘oven.’ It helps us retain heat and is better than insulation only. It’s a gentle heat above 200 degrees F that is not very long on the surface, as we are trying to go 20, 30 or 40 fpm; we are not exposing it deeply to very hot temperatures.”

This protects the recycled material from premature aging caused by excessive production temperatures. “Yet, there is a degree of