SETTING UP DEDICATED SPACE TO PROCESS WASHDRYFOLD

INSIDE: MAY 2023

8 STRATEGIES THAT CAN HELP SOLVE SUPPLY CHAIN ISSUES

FROM PAULIE B: DEVELOPING OTHER BUSINESS TO COEXIST WITH SELFSERVICE

WWW.AMERICANCOINOP.COM AND

Everywhere All

with special thanks to M AJERS C OIN L AUNDRY

THE OSCAR GOES TO... ‘Everything

at Once’

FlexiblePaymentOptions

Moderndaycardonlysolutions|Hybridcardandcoinsolutions EnableEMVcontactlessand EMVcontactpayments directlyonyour washersanddryers. LoyaltyPrograms Nosign-uporappdownloadrequired, aseamlesscustomerexperience Theleaderinlaundrypaymentsolutionsforover54years. sales@setomaticsystems.com|516.752.8008 www.setomaticsystems.com Allowcustomerstoautomaticallyearnfree washesordrieswithloyaltycardsortheir credit/debitcards

EMVCERTIFIED EliminateChargebacks PARTNERWITHSETOMATIC-SPYDERWASH

Credit/debitcard,cash/coin(optional),loyaltycard, NFC/MobileWallet,EMVContact&Contactless paymentsdirectlyonwashersanddryers

continentalgirbau.com • (800) 256-1073 A brand of Girbau North America GIRBAU

Magic Revealed Introducing the new Genius Washer Series. 450 G-force Extract Speeds • Shortens wash & dry cycles • Increases customer turnover per day • Decreases utility consumption New Genius Control – Best in the industry! • Switch between vended & commercial programs • Customize with your own graphics & logo • Easily change language settings • USB port for advertising screen file transfer • Bluetooth, WiFi & IoT ready • Easily integrate 3rd party systems 360 Vision Light • Light colors tell customers the machine status & availability • Machine status is visible at all times from anywhere in your laundromat Wide Door Opening • Simplifies loading & unloading • Redesigned door gasket Available in up to 80lb. capacities

Freestanding Design

Simple to install in unconventional locations • Saves thousands on installation costs Industry-Largest 10” User Interface • Scratch, impact & water resistant • User-friendly, touchscreen Discover your genius

The

Soft-Mount

•

CONTENTS

MAY 2023

VOLUME 64 ISSUE 5

AND THE OSCAR GOES TO...

A California laundromat is part of cinematic history as the setting for 2022’s “Everything Everywhere All at Once,” which earned seven Academy Awards. Owner Kenny Majers shares his experiences during shooting in 2020 and how some scenes had him drawing parallels to his own life.

INSIDE

Dedicating a specific area (or, in some cases, time periods) to WDF processing will help keep a laundry’s self-service customers happy and the separate revenue streams flowing freely.

COLUMNS

18 EIGHT STRATEGIES TO HELP SOLVE SUPPLY CHAIN ISSUES

While there is little a small-business operator can do to change the underlying factors causing supply chain issues, guest columnist Barry Victor believes there are numerous ways to navigate around shortages of parts, equipment and supplies and mitigate the impact on business.

22 POINTERS FROM PAULIE B: DEVELOPING OTHER BUSINESS TO COEXIST WITH SELFSERVICE

Drop-off wash-dry-fold service, pickup and delivery, and commercial work are income streams popular with laundry owners wanting to maximize income. But how does one manage the laundry space without interfering with bread-and-butter selfservice customers? Retired multi-store owner Paul Russo has some thoughts.

26 PLANNING YOUR LAUNDRY TO MAXIMIZE FULLSERVICE WORK

American Coin-Op releases a new podcast on a different topic of interest every other month? Give it a listen at AmericanCoinOp.com/podcasts.

Through diversification of services, laundries can better penetrate their demographic and geographical service area for added revenue and profit, writes guest columnist Tod Sorensen, but planning is essential. He offers tips for developing or renovating a laundry through design to maximize any full-service work to come.

(Credits for cover images, shown clockwise: © MidoSemsem/Depositphotos; Kenny Majers/Majers Coin Laundry; © Nicemonkey/Depositphotos; Allyson Riggs/A24)

(Credits for cover images, shown clockwise: © MidoSemsem/Depositphotos; Kenny Majers/Majers Coin Laundry; © Nicemonkey/Depositphotos; Allyson Riggs/A24)

SETTING UP DEDICATED WASHDRYFOLD SPACE

8

12

4 VIEWPOINT 31 AD INDEX 25 WEB UPDATE 32 NEWSMAKERS 30 CLASSIFIEDS

YOU

COVER STORY DEPARTMENTS

DID

KNOW...

2 AMERICAN COINOP MAY 2023 www.americancoinop.com

A PIECE OF CINEMATIC HISTORY

I had the pleasure this month to write about a laundromat rarity. In the 2022 indie film “Everything Everywhere All at Once,” we meet a family of Chinese American immigrants in danger of losing their laundromat business because of an IRS audit.

With rocky personal relationships stretched to their limits amid mounting pressures, things in the sci-fi action dramedy then shift wildly. Its lead actors jump into a crazily diverse array of alternate-universe selves. The multiverse is under attack, you see, and the matriarch is believed to be the key to stopping it. Some kick-ass martial artistry adds to the spectacle.

While this family is transported across time and space, the laundromat and, more importantly, their history there grounds the film. I won’t spoil things for you if you want to see it but the film’s message is one of acceptance, kindness and love.

The film shot its laundromat scenes on location at California’s Majers Coin Laundry, where owner Kenny Majers had a front-row seat. He was on set many hours during the six-day shoot just before the pandemic lockdown in 2020, and met and chatted with the movie’s stars.

Flash forward two-plus years and the quirky movie did well during awards season. The capper came in March when the film won seven Academy Awards

Today, besides his store’s regulars, Majers is frequently visited by “Everything Everywhere...” fans and other film buffs who snap selfies amidst the washers and dryers seen on the silver screen.

Majers is working on messaging but admits that he’s still trying to figure out how to monetize the publicity his store has received from the award-winning film.

Turn to page 12 for “And the Oscar Goes To...” to learn more about Majers Coin Laundry, now forever a piece of cinematic history.

Don’t forget the popcorn.

Bruce Beggs Editorial Director

Charles Thompson, Publisher

E-mail: cthompson@ATMags.com

Phone: 312-361-1680

Donald Feinstein, Associate Publisher/ National Sales Director

E-mail: dfeinstein@ATMags.com

Phone: 312-361-1682

Bruce Beggs, Editorial Director

E-mail: bbeggs@ATMags.com

Phone: 312-361-1683

Mathew Pawlak, Production Manager

Nathan Frerichs, Digital Media Director

E-mail: nfrerichs@ATMags.com

Phone: 312-361-1681

ADVISORY BOARD

Douglas Pratt Michael Schantz

Tony Regan Matt Simmons

Sharon Sager

OFFICE INFORMATION

Main: 312-361-1700

SUBSCRIPTIONS

847-504-8175

ACO@Omeda.com

www.AmericanCoinOp.com

American Coin-Op (ISSN 0092-2811) is published monthly. Subscription prices, payment in advance: U.S., 1 year $50.00; 2 years $100.00. Single copies $10.00 for U.S. Published by American Trade Magazines LLC, 650 West Lake Street, Suite 320, Chicago, IL 60661. Periodicals postage paid at Chicago, IL and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Coin-Op, Subscription Dept., 125 Schelter Rd., #350, Lincolnshire, IL 60069-3666. Volume 64, number 5. Editorial, executive and advertising offices are at 650 West Lake Street, Suite 320, Chicago, IL 60661. Charles Thompson, President and Publisher. American Coin-Op is distributed selectively to owners, operators and managers of chain and individually owned coin-operated laundry establishments in the United States. The publisher reserves the right to reject any advertising for any reason.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2023. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Coin-Op does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Coin-Op or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

4 AMERICAN COINOP MAY 2023 www.americancoinop.com

VIEWPOINT

Bruce Beggs

REACTION TO HIGHER UTILITY COSTS OFTEN IS RAISING VEND PRICES

Laundromats use a sizable amount of utilities to operate their washers, dryers and other equipment, so any related energy costs always figure prominently in calculating their bottom line. Natural gas prices have been particularly volatile recently. As inflation pushes costs higher, laundry owners are tasked with finding ways to stay in the black.

This quarter’s American Coin-Op Your Views survey asked the trade audience how these costs have impacted their operations, what actions they’ve taken in response, and which utility costs are of most concern.

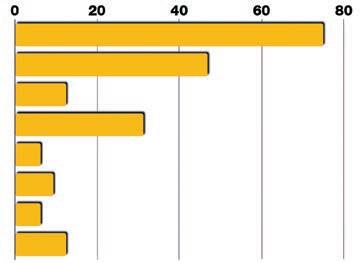

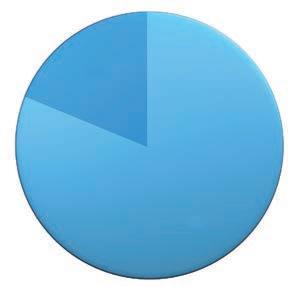

In the unscientific poll, 53.1% of respondents say higher energy costs have had a “major impact” on their operating budget. Roughly 41% described the impact as “moderate,” and the remaining share of 6.3% called it “minor.” No one taking the poll said the costs had “no impact.”

More than 81% have actively tracked their operation’s energy consumption in the last 12 months, while 18.8% have not. Comparing their usage to the prior 12 months, 50% said it was higher, 42.3% said it was about the same, and the remaining 7.7% said it was lower.

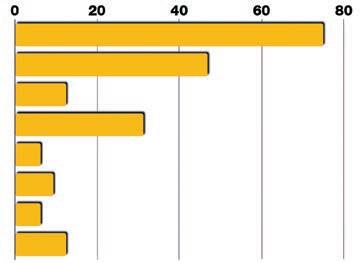

Raising vend prices on their washers (75%) or dryers (46.9%) were the actions respondents took most frequently in response to higher energy costs (they could choose any or all from eight selections). Others included upgrading to LED lighting (31.3%), investing in energy-efficient laundry equipment (12.5%), reducing hours of operation (9.4%), installing occupancy sensors (6.3%) and “other” (6.3%). About 13% reported having taken no action in response.

In many cases, technology played a role in helping respondents control their energy usage. One respondent said almost all of their store systems and controls are remote-controlled and timed to come on and shut off on schedule. Another said having a card-operated store allowed for more immediate, more precise vend price increases appropriate to changing circumstances.

Respondents were asked which utility cost—water, sewer, electricity or natural gas—was of most concern to them and why. Here are some of the responses:

• “There is a better understanding of the future increases to come in water/sewer/electricity, as they have been announced and passed by respective agencies. The natural gas increase was a totally unexpected increase, particularly in the commodity portion. Virtually no warning, and a total lack of proper management by the suppliers and distributors of natural gas.”

• “Water. We are charged for supply and handling, and then removal and treatment of water by two authorities. The combined cost of water has increased substantially over the last two years with no relief or end in sight. It alone has driven price increases and service curtailments.”

What

Upgraded

Installed

Reduced

• “Sewer rates are being used to take you to the cleaners. Insane regulations need to hit the brakes.”

• “Electric and gas (are at) most risk to go higher.”

• “Every one of the resources has an impact, mainly because I have only a 1,200-square-foot laundromat and my equipment is 40-plus years old but well-maintained. It is getting harder to find parts and the cost of new equipment will put me back in debt. I’m in my early 70s and this will probably … make me sell my business of 22 years.”

• “All of these have increased. I watch all of them equally.”

American Coin-Op’s Your Views survey presents an unscientific snapshot of the trade audience’s viewpoints. Due to rounding, percentages may not add up to 100%. Subscribers to American Coin-Op emails are invited to participate anonymously in the survey. The entire trade audience is encouraged to take part, as a greater number of responses helps to better define owner/operator opinions and industry trends.

INDUSTRY

6 AMERICAN COINOP MAY 2023 www.americancoinop.com

SURVEY

To read other Your Views survey stories, visit www.americancoinop.com/articles/data

in the last 12

YES 81.2% 12.5%

Have you actively tracked your operation’s energy consumption

months?

to higher energy costs? NO 18.8% Raised vend price(s) on washers Raised vend price(s) on dryers Invested in energy-efficient laundry equipment Upgraded to LED lighting Installed occupancy sensors Reduced hours of operation Other We’ve taken no action ACO0523 Charts.indd 2 4/7/23 10:33 AM

you actively tracked your operation’s energy consumption in the last 12 months? YES 81.2% 75.0% 46.9% 12.5% 31.3% 6.3% 9.4% 6.3% 12.5%

actions have you taken in response

Have

to higher energy costs?

NO 18.8% Raised vend price(s) on washers Raised vend price(s) on dryers Invested in energy-efficient laundry

What actions have you taken in response

(Click all that apply)

equipment

to LED lighting

occupancy sensors

hours of operation Other

taken no action ACO0523 Charts.indd 2 4/7/23 10:33 AM

We’ve

Setting Up Dedicated

Wash-Dry-Fold Space

Calls for separation from self-service, processing WDF orders after hours, or some combination

by Bruce Beggs, Editorial Director

by Bruce Beggs, Editorial Director

For the self-service laundry that also offers wash-dry-fold (WDF) service through drop-off and/or pickup and delivery, when attendants process orders at the same time self-service customers are trying to do their laundry, there’s always the risk of creating conflict, especially if both groups are vying for the same washers and dryers.

Dedicating an area (or, as you’ll read, time periods) to WDF processing will help keep a laundry’s self-service customers happy and the separate revenue streams flowing freely. Of course, laundromats can vary in service needs, store size and design, so what one business can accomplish with ease may not come so simply for another.

American Coin-Op interviewed the owners of three different laundry businesses, in three different parts of the country, to see how they have approached the concept of dedicated WDF space.

A HYBRID METHOD

Queen City Laundry has four stores on the east side of Cincinnati that offer self-service laundry, drop-off laundry and dry cleaning, and pickup and delivery laundry. Dave and Carla Menz are the owners.

“We do have a dedicated space for WDF but we don’t have dedicated equipment,” Dave Menz says. “I would describe us as kind of a hybrid, so we don’t have the stereotypical OPL equipment. We use our equipment in the store, but other than washing and drying, we have a completely separate area during the daytime hours, when our store is open to the public, where we actually … fold and package our laundry.”

Queen City’s workforce includes a general manager, two assistant GMs, four store managers, two third-shift supervisors for drop-off and pickup and delivery, plus attendants and drivers. All together, the staff

8 AMERICAN COINOP MAY 2023 www.americancoinop.com

(Photo: © Bombaert/Depositphotos)

numbers around 40.

Menz’s WDF operation started small 10 years ago and it didn’t take him long to realize that interfering with his self-service customer base would be a mistake.

“Almost immediately, we set up what we call a drop-off room. It’s just an employee room. Some would refer to it as an office, but in some of our facilities, it’s several hundred square feet. In one, it’s several thousand square feet.”

Other than its 9,000-square-foot superstore, each Queen City Laundry has a roughly 20-by-12 room where walk-in drop-off orders are processed and drop-off drycleaning orders are stored.

“We wash it in the washers, we dry it in the dryers,” Menz says. “We pull it out immediately and either lay it flat over carts and roll them in the back room or we (physically) take them in the back room and actually fold them and package them right there.”

The superstore does utilize that basic process but also employs a second-shift crew of three that processes only WDF orders. All pickup and delivery orders companywide are routed to/from the facility.

“They’re only allowed to use about one-third of our store for wash and dry,” Menz says. “We immediately pull it back into that separate processing facility. Back there, they have all the racks and folding tables. They have tons of room to work, shelving, everything they could possibly need to complete the order.”

A third-shift crew of seven to nine people (varies by volume) processes the remaining WDF work during overnights when the store is closed.

Queen City Laundry trains attendants and processors extensively on how to process WDF orders without interfering with self-service customers. They’re instructed to use only washers at the rear of the store, for

example, or the lower pockets of stack dryers, because self-service customers tend not to use them.

“There’s definitely an art to it, for sure,” Menz says. “And it’s not really as complex as it sounds. I mean, it’s a lot of, like, common sense. If your primary focus is ‘I want to do everything I can to avoid building a separate facility and paying rent,’ it’s … how can we do this without getting in our customers’ way.”

FREEING UP MACHINES

Super Suds Laundromat & Wash and Fold, located in Long Beach, California, is an 8,000-square-foot store housing 90 washers and 100 dryers. It offers self-service, dropoff, and laundry delivery service, and Aaron Simmons is business manager of the familyowned company.

Super Suds employs three managers who supervise four customer service attendants, 13 team members dedicated to wash-and-fold processing, and seven delivery drivers. The laundry utilizes five vans—three Ford Transits and two Mercedes Sprinters—for pickups and deliveries.

The laundry’s dedicated WDF space is a back room once known as the “Dryer Room,” which once was equipped with a row of stack dryers and a couple of large folding tables. “(Self-service) customers used to go dry there as it was less crowded and had the large folding tables available to use,” Simmons says.

Years ago, after self-service customers complained that Super Suds was utilizing too many machines for wash and fold, the laundry moved all WDF production to the third shift. Over time, the laundry wasn’t able to handle all production during that overnight shift.

“It began to bleed over to the morning, the afternoon, and eventually the evening,” Simmons says. To minimize the impact of the self-service business with the full service, Super Suds decided to revamp the Dryer Room.

The large folding tables were removed and five large OPL washers,

www.americancoinop.com MAY 2023 AMERICAN COINOP 9 ▼

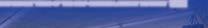

At each of Queen City Laundry’s four stores in the Cincinnati area, there is a “drop-off room” where employees are instructed to take freshly laundered and dried wash-dry-fold orders for folding and packaging. (Photos courtesy Queen City Laundry)

When Super Suds found it couldn’t handle all WDF processing during the overnight shifts, it decided to revamp the “Dryer Room” used by self-service customers and limit its use only to WDF employees. (Photo: Super Suds Laundromat & Wash and Fold)

including two with direct chemical injection, were added. The door to the room was marked “Employees Only,” and Super Suds doesn’t publicize what lies beyond it.

“We added more racks for additional storage and four folding tables so we could have stations set up for our launderers,” Simmons says. “We still use the self-service area in conjunction with the WDF processing area during the days and nights.”

Early on, Super Suds took some heat for making the change.

“Some vocal customers were unhappy about losing the Dryer Room, as they enjoyed the area being quieter to work in with the large folding area,” Simmons says. “We explained how we were doing that in order to free up more machines for them to use and the objections quickly went away.”

The dedicated WDF space minimizes impact on self-service customers visiting the store during the day.

“At nighttime, our team takes over the entire laundromat, including the WDF Employees Only area,” Simmons says. “The space isn’t large enough to handle all of our processing, and we do appreciate that we can use all of our equipment with the third shift and keep those machines turning 24/7.”

If considering setting up dedicated WDF space in your laundry, he has a suggestion.

“Think about the customers/commercial accounts you have and think about the ones you would like to have,” Simmons says. “Do you need space for large OPL (equipment)? Do you need an iron? You never have enough storage space for the orders being dropped off and the orders being delivered. If you have the option to go bigger, do it.”

WAREHOUSING CONNECTION

The Folde is a laundry pickup and delivery service that relies on laundromats it owns in Houston and Austin, Texas, as processing hubs. Mark Vlaskamp is co-owner and managing partner.

“When looking for a store, we look for size as the No. 1 criteria — knowing that we can fill them up with WDF,” Vlaskamp says. He describes his company’s two stores as “monsters.”

“(We’re at) 7,500 square feet in Austin and 10,000 square feet in Houston,” he says. “Both have separate space for WDF and PUD while still offering self-service to our retail laundromat customers. In these stores, we have about 70 employees … broken into drivers, loaders, folders and attendants” supervised by six managers (four in Austin, two in Houston).

Warehousing is The Folde’s main reason for the separate WDF/PUD space, he explains.

“The warehouses are connected but separate from the retail laundromat,” Vlaskamp says. “These ‘Employees Only’ spaces are similar to the back of house at a restaurant. They’re warehouses to store, organize and stage either 1) clean laundry that is set to be delivered to the customer or 2) dirty laundry that is set to go into our production process.”

Each store has about 2,000 square feet of connected warehouse space.

“We process 150 to 200 orders per day. So the need for separate space is simple to warehouse these orders,” he says. “Typical laundromats are not built with storage in mind. So, we turned the units next door to the laundromats into a private warehouse and connected (them) … with a set of double doors.”

No processing is done in the warehouse spaces, where doors are labeled “Employees Only.” Instead, all processing is done on the laundromat floor but mostly after hours. The warehouses help the business to get organized and properly rack/store orders.

“As PUD and WDF gets more popular, I am excited to see how laundromat layouts change to accommodate the space needed to scale (them),” Vlaskamp says.

10 AMERICAN COINOP MAY 2023 www.americancoinop.com

While this room at Super Suds is restricted to WDF processing, the laundry must also use its self-service area at times for that work. (Photo: Super Suds Laundromat & Wash and Fold)

Relying on its two laundromats as WDF processing hubs, The Folde acquired units next door to each of them to store, organize and stage either clean or soiled laundry flowing through its system. (Photos: The Folde)

‘Everything Everywhere All at Once’ with special thanks to

MAJERS COIN LAUNDRY

12 AMERICAN COINOP MAY 2023 www.americancoinop.com

AND THE OSCAR GOES TO...

(Above) Inside the Majers Coin Laundry. (Photo: Kenny Majers)

(Below) IRS inspector Deirdre Beaubeirdre (Jamie Lee Curtis, left) and laundry owner Evelyn Wang (Michelle Yeoh) share a personal moment outside in ‘Everything Everywhere All at Once.’ (Photo by Allyson Riggs/A24)

by Bruce Beggs, Editorial Director

For six days in March 2020, a large cast and crew occupied Majers Coin Laundry in San Fernando, California, to film scenes for a motion picture featuring a family of Chinese American immigrants whose laundromat was being audited by the IRS.

The family-owned business serves to ground directors Daniel Kwan and Daniel Scheinert’s indie sci-fi action dramedy “Everything Everywhere All at Once,” which sees its lead actors jump into a crazily diverse array of alternate-universe selves as they attempt to save (or—spoiler alert destroy) the multiverse.

Shutting down Majers Coin Laundry for nearly a week to host the motion picture production grabbed the local neighborhood’s attention at the time. But now that the 2022 film did well during awards season and won seven Academy Awards (including Best Picture, Best Director, Best Actress and both Best Supporting categories) in March, the store has become a destination for “Everything Everywhere...” fans and other film buffs.

Owner Kenny Majers remembers the filming experience positively but admits that he’s still trying to figure out how to monetize his store’s newfound popularity born from the film’s success: “The tourists aren’t bringing their laundry. Well, maybe a few are.”

LOCATION SCOUTING

Majers’ grandfather built the laundromat in 1983. When he died in 1997, Majers’ father inherited it and was looking to sell the business that had fallen into disrepair. But it was Majers’ dream to own his own business and he was able to talk his dad out of selling. Instead, he leased it from him until his death and now owns it outright.

“It’s a freestanding laundromat, as you’ve seen in the movie,” Majers says. “It doesn’t have an apartment … on the roof; that was CGI’d.”

The self-service-only store covers approximately 2,800 square feet and offers 18 top loaders, 25 front loaders ranging from 35 to 80 pounds, and 58 dryer pockets: “It’s three different brands of equipment I have. Over the years, I’ve decided to go with certain equipment that I was comfortable with.”

Majers employs two attendants to assist him in running the laundromat. His wife, Irene, used to help out but she’s since graduated from nursing school and now works full-time as an RN, he says.

He decided against offering drop-off service, saying it’s “not my thing,” plus the area’s demographics don’t really call for it. The laundry opens at 5 or 5:30 a.m. depending on the day, with “last wash” at 9 p.m.

It was just another washday when Majers was approached by a woman who said she was scouting locations for a new movie.

“She said she liked the way the laundromat was freestanding,” he says. “She said she went to five different laundromats to get ideas, and they really liked the way my laundromat was freestanding, by itself, and not in a strip mall. A lot of the laundromats here in LA are in strip malls.”

Once he verified her identity and studio affiliation, they started negotiating. His primary concern was possibly losing customers and impacting his business long-term.

“I told them, ‘You’ve got to make it worth my while, because to close down and lose one customer … the way I look at it, if I lose one customer, and that customer goes to another laundromat and they spend 10 bucks a week, that’s close to a thousand dollars a year. … If I lose 10 customers, that’s $10,000 a year. That’s the way I was thinking about it.”

Ultimately, he told them that if they paid him enough to put in a

parking lot—the subject of a lawsuit he was facing at the time—he’d go along with it. The cost to do that was close to $20,000. “I need the ▼

www.americancoinop.com MAY 2023 AMERICAN COINOP 13

new

(Top) Today’s view of the store from outside. When a location scout approached him about shooting parts of an indie movie there, owner Kenny Majers sought guarantees that it wouldn’t inconvenience his regulars for too long and that it would earn him enough so he could pay to redo his parking lot. (Photo: Kenny Majers)

(Above, left) Majers gets his hands dirty while removing a motor from a 35-pound front loader. The motor needed to be rebuilt when the bearings went bad. (Photo courtesy Majers Coin Laundry)

(Above, right) The psychedelic artwork on this “Everything Everywhere All at Once” movie poster gives one just a taste of the movie’s wild imagery. (Photo: A24)

(Below) Kenny and Irene Majers pose near the customer counter inside the laundromat. (Photo courtesy Majers Coin Laundry)

parking lot put in, and I don’t have the money for it (myself), so I have to risk taking the loss,” Majers says now.

The deal was straightforward, he recalls, and he signed a written agreement without involving an attorney.

“They told me when I signed the contract, ‘You cannot change anything because we like it just the way it is.’”

QUIET ON SET, PLEASE

Trucks started rolling in a few days before production was scheduled to begin.

“They had strike days. They had days where I was allowed to remain open while they were setting up,” Majers says. “They paid me for partial days. They paid me half their rate, then on days I had to close, they paid me full rate.”

He recalls set decorators wallpapering the columns inside and installing signage to augment his own. Workers applied a “rust” paint to age the folding tables, “like a ’70s laundromat.”

While curious, those living in the neighborhood, and the laundry’s regulars, respected the production.

“They had a lot of security. I didn’t think they had any issues. I’m pretty well known in the community. If the crew, if someone, had come to me and said something … all the neighbors, some were looking in from a distance. It was pretty safe.”

By choice, either Majers or one of his attendants was always on set, just in case.

“I told the location manager that I need to be here at all times, or my attendant needs to be here at all times, because ‘A broken water hose can mean a disaster for you guys in a matter of minutes. Who’s going to be quickest to turn it off, with all this electrical and power lines you’ve got coming in through here?’”

He once mistakenly sat in the wrong chair on set and a production assistant asked if he wouldn’t mind leaving the store and they’d call if they needed him. He said he’d get out of the chair but he wasn’t leaving.

“Either me or my attendant was on at all hours while the crew was there,” he says. “Sometimes they were walking on top of the machines to hang things from the ceiling, and I’m, like, ‘No, guys, you cannot walk

in the center of the machine. If you’re going to get up there, you have to stand on the corner, the edge.”

But destruction was the goal when filming an actor shattering one of the large windows at the front of the store.

“I guess they call it sugar glass,” Majers says. “They took out my old window and then put this glass in. … When they replaced it (with a new window), I said, ‘Can you break all the windows? Can you replace them all?”

Everyone with the production knew they were working on a tight schedule, according to Majers.

“You could tell, they were on a time constraint,” he says. “It was a welloiled machine, the way they worked, the production, the staff, the crew. They were on the ball. A few minutes here or there costs a lot of money.”

For one shot, the crew wanted a dryer to be running but it was making a noise like it was out of balance. “‘I can fix it, it’ll take me about five minutes.’ They said, ‘Are you sure it’ll only take five minutes?’ I said, ‘This is what I do.’ I had it done in five minutes and then it was running smoothly.”

All of the main cast—Michelle Yeoh, Ke Huy Quan, Jamie Lee Curtis, Stephanie Hsu and James Hong—had scenes in the laundromat at one point or another, Majers says: “I met them all. I talked to them all.”

He remembers sharing with Yeoh a video of his daughter playing violin, and asking Curtis to say hello to his family while he was FaceTiming with them on his phone. But his biggest thrill was meeting Quan, who got started in Hollywood as a child actor in the 1980s in “Indiana Jones and the Temple of Doom” and “The Goonies.”

“When Ke was there, I insisted I get a picture with him: ‘You don’t understand how big an impact ‘Goonies’ had on my life. You can’t say no.’ I don’t think I would have let him say no.”

At least one powerful scene filmed had Majers drawing parallels to his own family.

“A lot of the (flashback) scenes, they had a little daughter running around the laundromat. Another scene, Stephanie was fighting with her mom (Yeoh) and she was running out to her car. I think all the cast and crew were outside; they were filming her running out of the laundromat. Then she’d come back in, all emotional, and they’d do another take.

“She saw me crying, like, getting emotional. I said, ‘That triggered a lot, of 26 years of being here raising my daughter in this laundromat. You triggered something,’ and she just nodded her head yes.”

Majers Coin Laundry receives roughly 24 minutes of screen time in the 139-minute spectacle. Majers would do it all again given the chance, he says, but probably charge more: “If there’s a sequel, I can have more demands,” he quips.

“It’s probably the most famous laundromat in the world now.”

“Everything Everywhere All at Once,” rated R, is available from various streaming outlets or can be purchased on DVD or Blu-ray.

14 AMERICAN COINOP MAY 2023 www.americancoinop.com

(Above, left) In “Everything Everywhere All at Once,” Joy Wang (Stephanie Hsu, right) pauses by the dryers while contemplating how she’s finally going to tell her parents that “friend” Becky Sregor (Tallie Medel) is actually her girlfriend. (Photo by Allyson Riggs/A24)

(Above, center) Ke Huy Quan (holding the laundry bag), who plays husband/father Waymond Wang, waits off camera while a scene is shot. (Photo: Kenny Majers)

(Above, right) The “Everything, Everywhere...” cast and crew gather outside the laundry for a group photo to commemorate that shooting had wrapped there. (Photo: Kenny Majers)

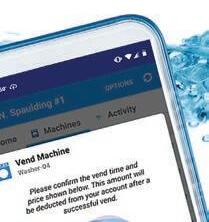

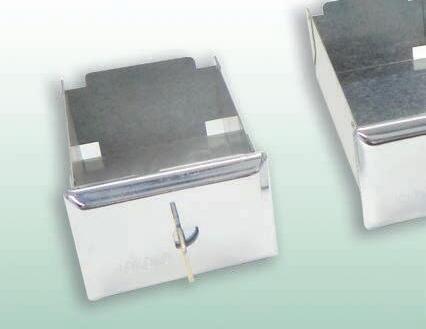

Before investing tens of thousands of dollars into a retool, upgrade your existing machines to accept modern, mobile payment. All you need is a BluKeyTM for each machine to give your store a boost. You can install them yourself, and then accept payment from virtually any source through the PayRange app. Plus, add loyalty features, discounts and convenience. Enable your customers to pay as they please on your existing machines with PayRange. Join the 3,500+ laundromats already using PayRange.

Don’t Retool, Retrofit! Upgrade your existing machines with PayRange PayRange BluKey™ for Laundry GIFT CARDS Only $49.95* per device. Get started at: shop.payrange.com *Service Bundle Fee applied to all devices. Pricing and fees subject to change. Terms and conditions apply. PayRange is a trademark of PayRange Inc. Patent 8856045 and other Patents Issued and Pending. © 2023 PayRange Inc.

Contact Your ESD® Distributor Phone: 215-628-0860 • Mobile Phone App Fast and Flexible Laundry Payment System Edge A10 Combo • Credit card adds • Cash adds value • MyLaundryLinkTM • On-site refund capabilities CyclePay Mobile App Trident Reader Edge Contactless Payment Center Use Cash Contactless © ESD Inc. All Rights Reserved

Cash

or

Credit

Card to add value to your

Contactless Laundry Card or CyclePay Phone App

Edge A10

• Credit card adds value to contactless cards

(EMV, Swipe and Tap)

• MyLaundryLinkTM management system

• On-site refund capabilities

• No card dispensing

Cloud Connected

Contactless Payments

value to contactless cards (EMV, Swipe and Tap) to contactless cards (EMV, Swipe and Tap)

management system

capabilities

• Card dispensing

Distributor or email us at: sales@esdcard.com

Fax: 215-643-4623

• www.esdcard.com

Edge A10+

• Credit card adds value

to contactless cards

(EMV, Swipe and Tap)

• MyLaundryLinkTM management system

• On-site refund capabilities

• Card dispensing

Edge Contactless Reader

EIGHT STRATEGIES TO HELP SOLVE SUPPLY CHAIN ISSUES

Most experts agree that the supply chain issues we have been facing since the COVID-19 pandemic began will be with us well into 2023. As a small-business operator, you have no doubt experienced shortages of supplies, equipment and parts necessary to run your business. While there is little a small-business operator can do to change the underlying factors causing supply chain issues, there are numerous ways to navigate around these shortages and minimize the impact on your business.

In this column, I will share eight strategies to consider for finding replacement parts to keep your machinery in operation. The focus is on parts, but many of these methods can also be used in other areas.

1. OPTIMIZE YOUR SUPPLIER NETWORK

You no doubt have formed relationships with many suppliers over the years and have come to trust them as a source for items required to run your laundry business. They can also be a source of creative ideas and market information. They have their own network of suppliers and likely a vast knowledge of potential sources of supply. They are also faced daily with the same issues you have from their customers, and should be able to provide helpful guidance. If your current supplier is not providing guidance, consider taking the time to find new suppliers who can help you navigate these issues.

One of the best ways you can mitigate shortages and reduce your costs is by planning ahead and stocking maintenance

18 AMERICAN COINOP MAY 2023 www.americancoinop.com

(Photo: © iqoncept/Depositphotos)

▼

Barry Victor

items that are frequently required. If you have been working with the same supplier for many years, they should be able to review their records of past purchases and suggest items that you have ordered multiple times. You probably already have a spare parts inventory, so make sure to take the time to review stock levels and order before the machine malfunctions. Planning ahead will not only give you peace of mind, it will save you money by eliminating the need for expensive air shipments.

If you do find yourself needing an item that you do not have in your spare parts inventory and multiple suppliers have told you it is not readily available, you will need to consider other options. The options you have will depend somewhat on the type of part that has malfunctioned or deteriorated.

2. REWIND, REPAIR, RESURFACE

While it may not be a less expensive or long-term solution, rewinding a motor can allow you to put the motor back into service, if not permanently, then at least temporarily until the new replacement motor is available. Computer boards and other electronics can often be repaired as well and usually come with a short warranty.

Valves can often be repaired in place with repair kits, saving the and effort of removing the complete valve from the piping. Air cylinders and other pneumatic components can also be repaired — usually at a far lower cost than replacing the entire component. Dryer wheels are an item that can be resurfaced with a new wear material, much like changing the tires on your car, and can be a viable and less expensive alternative to replacing with new wheels.

3. USE ALTERNATE COMPONENT BRANDS

Many manufacturers design and build components that have the same or similar specifications. One laundry machinery manufacturer may choose one brand and another may choose a different brand. The important principle to keep in mind when replacing a component with a component of a different brand is the engineering terms of “form,” “fit” and “function.”

Form typically refers to the size, shape, and other visually descriptive terms. Fit refers to the ability to interface with the surrounding machinery without modification. Function refers to the ability for the component to

function in the application. Most parts supply companies should be able to help you navigate these criteria and offer you a suitable replacement that has not been affected by supply chain issues.

4. USE ALTERNATE OEM BRANDS

As described, manufacturers of laundry machinery often choose different component brands, but in some cases, they use the exact component as many other manufacturers. A supplier that has the data and tools to know when this is the case can offer you the exact part you need for your brand by sourcing it from a different OEM brand. While the price of the component may be different, the availability of the component could be better from the alternate OEM brand.

sidered carefully with the help of your parts professional. In some cases, substituting a component of a different horsepower—a pump, for example—could be a valid option if the exact pump needed is not available. Machine operation could be impacted by this sort of substitution but it can occasionally be a valid option during supply chain disruptions.

7.

TRY SUBSTITUTE MATERIALS

5. LOOK AT GENERIC VS. OEM

Similar to the alternate brands I’ve already described, generic parts are often manufactured for high-volume components. While I would generally advise sticking with OEM parts to be confident in their ability to function successfully over long periods of time, generic parts can be a valid option if the OEM parts are not available. Your parts professional should be able to guide you to suitable generic replacements. Some components that are typically available in generic equivalents are drive belts, ironer ribbons, drain valves, pads and covers, bearings, blower wheels and lint filters.

6. SEARCH FOR ALTERNATE SIZES

This type of substitution should be con-

During the design of most machinery, decisions are made regarding the materials used in components based on price, longevity and a host of other parameters. If the component you are searching for is not available in the exact material used in the original component, you may be able to substitute a different material. Substitutions of this type could impact the longevity of the component, with longer life usually linked to higher cost and shorter life to lower cost. Gaskets would be an example of a component that can usually be supplied in alternate materials.

to lower cost. Gaskets would be an example of

8. CONSIDER USED VS. NEW

If all else fails and you are desperate to get your machinery back in operation, you can consider trying to find a used component to make the repairs. Many equipment distributors who take used machinery in trade often keep the machinery in order to salvage parts from it. As parts removed from used machinery do not generally have part numbers on them, making sure the part is the exact part you require can be a challenge. If the part being salvaged has been in operation for many years, it may not function properly or its life expectancy could be limited, but it could be worth a try if all other options have been exhausted.

Supply chain issues have been hard on all of us. Hopefully, we see an end coming. In the meantime, let’s continue to find new ways of doing things and, possibly, find efficiencies and discoveries that we may not have seen before.

Barry Victor helped found PROS Parts, which supplies replacement parts and supplies for laundry and drycleaning equipment, in 1988. In its early years, PROS manufactured drycleaning machinery before evolving into an industrial and commercial laundry equipment and drycleaning operations parts supplier. Victor can be reached at barryv@prosparts.com, 763-231-7379.

20 AMERICAN COINOP MAY 2023 www.americancoinop.com

time

(800) 845-3903

May, most orders received by 3pm CST will be shipped same day. Phone orders only. Up to 20 lbs. Does not include oversized items.

During

WWW.LCPARTS.COM

EXPIRES 05/31/23 M A Y KEYPAD COIN TL BELT & IDLER KIT SOLENOID 120V P/N F200270500 P/N 959P3 E ELECTRODE SPARK K PKG P/N 44328701P P/N F300124P DOOR GASKET EH020 $9 94.99 Each.

call for pricing. List Price $147.96 SHOCK ABSORBER $3 33.99 Each. List Price $49.85 BRASS WATER VALVE $169.99 Each. List Price $240.25 SHOCK ABSORBER $15.99 Each. List Price $25.51 TEMP PROBE $14 99 Each. List Price $19.62 P/N 323238 P/N 333708 P/N 193912 P/N 352161 P/N 193862 P/N 70359801P P/N F0231582-17P 2" DRAIN VALVE L1018 & L1030 $99.99 Each. List Price $129.24 P/N 251835 List Price $23.79 List Price $361.71 40%OFF LIST PRICE DEXTER $11.99 Each. List Price $40.24 STACK TRUNNION OEM $18 85.99 Each. List Price $121.58 WATER VALVE 120V $18.99 Each. List Price $84.95 P/N 9379-183-001G P/N 9732-126-001G P/N 9568-011-001 LINT SCREEN REPLACEMENT $12 49 Each. List Price $13.58 P/N 9555-057-002 COIN COUNT SWITCH $57.99 Each. List Price $90.00 NO FREE SHIPPING Aftermarket P/N 9857-116-002G I IGNITION N CONTROL Aftermarket LC WASHER/DRYER ID NUMBERS Sale Price $12.99 Each. Per Sheet WE SELL PARTS FOR : HUEBSCH, SPEED QUEEN, CONTINENTAL, DEXTER, ALLIANCE, WASCOMAT, GE, UNIMAC, MAYTAG AND MORE Call Us At 1-800-845-3903 | These Prices Are Also Available At Our Web Store www.lcparts.com | Open Monday - Friday 8am to 5pm | Sales price cannot be combined with any other o er *Free shipping excludes baskets, trunnions, some motors and oversized packages. Please call for details (Some sale items limited to quantities on hand) *Prices subject to change without notice, Offer valid until May31st SE HABLA ESPANOL All Orders Over $250 RECEIVE FREE DELIVERY UP TO 20 LBS*

M

Please

POINTERS FROM PAULIE B

DEVELOPING OTHER BUSINESS TO COEXIST WITH SELFSERVICE

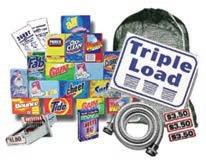

If you want to maximize your mat’s income, drop-off wash-dry-fold (WDF) service, pickup and delivery (PUD), and commercial work (smoke removal, restaurant linens, hair salon towels, etc.) are the popular income streams many owners use.

You can pull in thousands of pounds a week, but how do you manage your space and not interfere with your bread-and-butter self-service customers? How do you not compete with them for machines, folding tables and carts?

Some mats I’ve seen have no choice but to do PUD or commercial work due to heavy competition for self-service. There simply aren’t enough self-service customers to support their mat.

If your self-service volume is hopelessly slow after you’ve tried boosting it by installing new equipment, cleaning up your mat’s appearance, and securing adequate customer parking, you’re left with doing some kind of service work. The good part is that you don’t have many customers to bump carts with, so to speak.

Alternately, if your store is typically full of customers, doing service work there can be more daunting. When customers routinely see most of the machines occupied with other service work, they will go somewhere else. Your crew will have to wait to use some machines that are occupied by customers, but time is money. If they have work that must get out quickly, they will be forced to use the wrong machines for the job. So what can be done to lessen that impact?

I have a couple solutions to share. Mostly common-sense things that you may have thought of already. Some have been hinted at in previous columns. Not all of these solutions are palatable, so you need to figure out how much sacrifice you’ll need to make in the name of gaining more income.

AUTHOR’S FAVORITE SOLUTIONS

Use a Graveyard Crew — This is the best solution. You also get the best bang for the buck as far as maximizing your occupancy costs. (Why pay the rent with only daytime business?)

Some mats close their doors to the public after a certain hour and simply have a crew overnight to process laundry. It’s the easiest, most efficient way for your staff to get the work done.

Since I was located in New York City—“The City That Never Sleeps”—I chose to allow selfservice customers in on a 24/7 basis. The overnight hours were much slower though, allowing us to get a lot of work out smoothly. For security reasons, we would lock the doors from midnight to 6 a.m. but customers could use the store if they showed their laundry. We simply buzzed them in, and the door locked behind them. The quietest time was 1 to 5.

I wasn’t comfortable leaving just one employee in the mat overnight. If your service work is plentiful enough, you can afford to staff two or more crew members during this shift, despite the fact that you may have to pay higher night rates. Keep your mat well-lit, and your windows clean and unobstructed; use a “buzz-in” system plus silent alarm buttons; and install a high-quality surveillance system.

Schedule the Work to Your Benefit — Write up your service work so you have time to spare. I believe this is the next best solution to keeping a night crew.

With drop-offs, it seems some customers have to have it back right away, yet they often don’t

22 AMERICAN COINOP MAY 2023 www.americancoinop.com

Paul Russo

Author Paul Russo installed this walk-up window for drop-off and pickup service, manned here by employee Jay, in one of his New York City stores in 2008. (Photos courtesy Paul Russo)

show up for a week after the date they had to have it! Very frustrating when you don’t have the room or time.

So, train your customers. Many of them are flexible, but you have to know how to write up their ticket.

If you ask, “So when do you want your laundry back?”, many customers will instinctively say that night or the next day, which puts pressure on the system. I overheard more than one employee promise to have the laundry ready later that day or that evening, trying to impress the customer in hopes they’d receive a tip.

If you spoil every customer into expecting their laundry back right away, you won’t have any wiggle room for the real emergency customers. You’ll have to bring in more help to get the work out in a rush, and the store will get needlessly jammed up, aggravating your self-service customers.

What’s worse, if you get customers used to expecting quick service, they’ll start showing up at the last minute to drop off. If we were jammed up and couldn’t do it for them, they freaked out.

So, I told my crew to ask a customer who was dropping off on a Monday if a Wednesday or Thursday return would be OK. Half the time, they said it was fine. Then, there was no rush, and we had room for the real rush jobs.

STORAGE ISSUES AND OPTIONS

Storage Alternatives — When on-site storage is an issue, what are the alternatives? Your basement? An off-site solution? Using an adjacent store’s extra space, such as its basement?

If an empty store space becomes available next to yours, consider grabbing it for storage, even if you don’t put any equipment in it. You could

also use it as your primary service area with counter space and folding tables to service drop-off customers, and to store the laundry leaving your original mat. Just break through some openings between the two stores. It’s simple and cheap. Don’t forget to install cameras and mirrors.

The Joy of “Prepaids” — Customers who prepay tend to pick up much sooner. We gave a dollar off any drop-off order that was prepaid. It helped! And if the customer didn’t have the cash, we had an ATM right next to the counter. We posted signs at the counter asking to please pick up within 5 days, but the prepaids were more reliable than that with their timely pickups.

Contact the Slowpokes — Some people simply forget they have finished laundry to be picked up. We routinely called our customers with a friendly reminder about their laundry. Today, it could be an email or a text.

Raise Prices — Should your mat reach the point of bursting at the seams, with no way to expand, you could raise prices on both your selfservice and drop-off work to make room. It would not be my first choice, but according to the law of supply and demand, whenever there is a shortage of goods or services, prices rise.

I was forced to do this quite a few times due to New York City retail space being so tight. I managed to expand two mats over the years, but it took a long time of waiting.

Keep in mind that all these tactics used for drop-off customers can also be used for pickup and delivery, and for writing up commercial work. When we were doing smoke removal, we routinely received 600 to 1,000 pounds at a time but we arranged to have a week to get the work done. Eventually, I had to give this work up because it took up too much space. We stored it downstairs, which did help greatly, but carrying it up and down those stairs was a pain.

HOT-TOPIC TRIO: Finding the Right Candidate, Livin’

Large, and Reasonable Accommodations

Hiring in a Tough Labor Market

In a truly competitive job market, a laundromat owner’s ability to hire well has never been more vital. Multi-store owners Jim Radovic and Tim Gill share their approaches to hiring and retaining good workers in this episode.

Bigger Capacity Can Deliver Bigger Results

Alliance Laundry Systems’ Mike Hand describes how o ering large-capacity equipment can help decrease turnover plus attract customers eager to clean bulky items their home equipment can’t handle.

Complying with the Americans with Disabilities Act New York City attorney Eric Sarver describes the ADA, identi es store areas most deserving of ownership attention, and warns of the problems that noncompliance could bring.

Every FREE episode...

offers engaging, industry-specific conversation with an expert, including business-building tips you won’t find anywhere else. And you can listen anytime, either online or download for later!

Give us a try!

www.americancoinop.com MAY 2023 AMERICAN COINOP 23

▼

Listen in at: americancoinop.com/podcasts 0523aco_Podcast_half_horz.indd 1 4/11/23 7:47 PM

SMOOTH OUT THE PEAKS AND VALLEYS

If you can smooth out the peaks and valleys in your front lobby on the “dreaded” weekends, you’ll lower the odds of competition for machines. And this applies not only to crew members vs. customers but also to customers vs. customers.

I believe the best strategies involve shunting customers from busy times to slow times, and can apply to both service and self-service business.

Senior Day — Retirees can usually come any day of the week. Why not give them a discount to show up on your slowest day(s)? You could extend this to other groups—first responders, students—as well.

Post Your Busy and Slow Hours — If you don’t tell your customers the best times for them to come, how will they know?

The 20% Discount — This is a strategy that worked well for me over the years. It’s bad enough to have customers competing with each other on a Saturday or Sunday. Add a lot of service work that requires your crew members to take any available machines and tempers will flare!

Our drop-off business got so busy, we ran out of storage room at times. The workload was often overwhelming. A nice problem to have, yes, but headaches abounded. These nuisances were primarily on the weekends because customers would drop off their laundry on Saturday morning and expect their clean clothes back by that night so they go out partying wearing their best threads.

To make things worse, Saturdays and Sundays are “washdays” for self-service customers who don’t work on weekends. This convergence of self-service customers and heavy drop-off demand service became too much to bear.

So, I decided it was time to increase prices, but in a different way. I began raising washer prices group by group. We lost some customers, but there were still plenty remaining who were willing to pay the increases that offset the loss of volume.

However, that was far from enough to balance the mat. I had to do more, so I increased the drop-off prices by 10% on weekends, and discounted the price by 10% on weekdays.

This started a small shift of weekend dropoff customers to weekdays when we could handle the work more easily. Unfortunately, it wasn’t enough. They simply showed up on Friday, demanding their laundry back that night or on Saturday. It was still a burden, plus many drop-off customers didn’t care about paying 10% less Monday through Friday.

I eventually landed on the right solution for my mat: 20% off Monday through Thursday.

Those four days then became our heaviest drop-off days, but they were much easier to handle because the lobby wasn’t quite as busy. Plus, it was also much easier to bring in extra workers on those days. Drop-off customers looking for a deal were happy to visit then.

Those who still wanted quick service simply paid the extra 20%; I was always amazed at how many people didn’t care about the price!

One thing about pricing service work: Drop-off customers are different than self-service customers. They often make a good living. They want quality, and are willing to pay for it. So service success rests more heavily on giving them high-quality work; fast, friendly service; and professionalism.

Never forget, you are handling their property. And their clothing are a reflection of who they are, so they often care a great deal about them. It’s an ego thing.

It’s also an ego thing when they tell their friends that they leave their laundry with the “best, most expensive” laundry service in town. It’s a boast, sure, but also a recommendation for your service.

On a final note, keep in mind that my suggestions this month can be applied to most any other service. I wish you well in your efforts to develop services that complement your self-service operation without compromising it.

Paul Russo owned and operated multiple laundromats in New York City for more than 40 years before retiring in 2018. You’re welcome to direct any questions or comments for Russo to Editor Bruce Beggs at bbeggs@atmags.com.

24 AMERICAN COINOP MAY 2023 www.americancoinop.com

POINTERS FROM PAULIE B

Note the circled signs in one of Russo’s laundries that directed drop-off wash-dry-fold customers to pick up their orders within five days.

• AllianceLaundrySystems Acquires California Distributor

• R&BWireProductsNames GrantRawlinsPresident

• WashingBeddingAmongTopSpring CleaningPriorities:ACISurvey (WE)

• HappyNestContinuestoAdd LaundromatPartners (WE)

• FloridaStoresPreparefor... (WE)

COLUMNISTS/FEATURES

• 2022-23StateoftheIndustrySurvey

• FleetManagementforLaundry PickupandDelivery (WE)

• LeveragingShippingCostEfficiencies

OUR

From

• QuestionsaboutHealthcare LaundryHandling

• Success=Innovative,Intentional Thinking,Planning

From AmericanDrycleaner.com:

• BuyingOuttheCompetition

• TuchmanAdvisoryGroupTours, CritiquesLocalCleaner (WE)

www.americancoinop.com MAY 2023 AMERICAN COINOP 25 WEB UPDATE Most popular stories from AmericanCoinOp.com for the 30 days ending April 10 — (WE) denotes Web Exclusive

TOP FIVE NEWS STORIES

SISTER WEBSITES

AmericanLaundryNews.com:

PLANNING YOUR LAUNDRY TO MAXIMIZE FULLSERVICE WORK

Agrowing number of vended laundries offer full-service wash-dry-fold and/or residential/commercial laundry services. And for good reason. Through this diversification of services, laundries can better penetrate their demographic and geographical service area for additional revenue and profit!

But, to do it well, planning is essential. So, if your goal is to develop or renovate a vended laundry — and design it to maximize full-service work — peruse the following planning tips before jumping in:

Evaluate the Lease — If you’re leasing a space for your laundry, consult people in the business to negotiate your lease. Get several legal opinions before signing. Be certain a competitive laundry cannot move in next door in the same strip mall, for example, because this happens and could be detrimental to your business, even if it performs well.

Space Needs — Plan for extra space inside your vended laundry, or near your store, to house the right equipment and to store linens before and after processing. If you plan to launch commercial laundry processing for clients like vacation rentals, spas, hair salons, small hotels, catering companies and restaurants, a flatwork ironer is also critical. You’ll need to dedicate about 200 square feet to the installation and operation of a 13-inch ironer. An additional 100 to 200 square feet of shelving for storage is recommended.

Consider Investing in a Point-Of-Sale (POS) System — If you really want to grow your business efficiently, a POS for full-service work is an absolute necessity. One that includes a website for your business would make online orders and tracking simple. A good website is essential for marketing and managing full-service offerings. A POS not only allows customers to schedule and pay for wash-dry-fold services online, or via

26 AMERICAN COINOP MAY 2023 www.americancoinop.com

Tod Sorensen

their phones, it simplifies management and tracks payments, laundry processing, scheduling and deliveries.

Equipment Needs — If you only want to offer residential wash-dry-fold, you can get away with using basic vended washers and dryers. Just be sure you have plenty of them. But, if your intent is to process both residential and commercial laundry, commercial washer programmability and automatic chemical injection are essential to generate consistent, high-quality results. So is a flatwork ironer for ironing flat goods.

Washer Capabilities — Choose highly programmable washers with automatic chemicalinjection capabilities and programmable water temperatures. Getting consistent, quality results using preprogrammed vended cycles can be difficult. Body oil, lotions and food stains are hard to remove using the one- or two-rinse cycles typical of vended programming. The good news? There are vended washers on the market that do double duty, including Continental’s ExpressWash® and Genius Series®.

Consider Investing in a Flatwork Ironer — An ironer quickly and automatically irons bedsheets, pillowcases and table linens, allowing your laundry to service bigger accounts that require high-quality linen finishing. Look for a compact

model that is simple to operate with a waxless design. For example, Continental Express Ironers properly finish linens without the need for dryer conditioning or messy wax application and removal. They automatically iron linens straight from the washer — eliminating any dryer time — using two operators. Bypassing the dryer step also boosts laundry productivity and reduces gas and electricity consumption.

Maximum Efficiency — The cost of natural gas reached its highest point last year since 2008, according to the U.S. Energy Information Administration (EIA). In Southern California, gas prices just jumped 315%, making it the biggest increase yet. So, it remains imperative to plan for maximizing efficiency.

Ozonation — One way to do this is through ozone. Ozone is a gas that, when injected ▼

www.americancoinop.com MAY 2023 AMERICAN COINOP 27

CALL US TODAY! 800.362.1900 77 Streamwhistle Dr., Ivyland, PA 18974 E: Info@acpowerco.com www.acpowerco.com THE BEST EQUIPMENT AVAILABLE AT THE BEST PRICES! The #1 Regional Distributor of Commercial Laundry Equipment, proudly serving businesses throughout Pennsylvania, New Jersey, Delaware, and Maryland for over 48-years! We are experts in Commercial Laundry Solutions. NOW HIRING FOR ALL POSTIONS! Contact us today.

The customer service counter at a laundry center offering wash-dry-fold services. (Photos: Girbau North America)

into the wash cycle, sanitizes laundry; activates wash chemistry; relaxes fibers for improved removal of dirt, stains and grease; and works best in cool water. It reduces fabric wear and lowers utility costs. While ozone cuts gas bills and provides sanitization, it can also damage certain types of washers. So, be sure the equipment you choose is ozone-compatible.

High-Speed Washers — A second way to reduce gas costs is by choosing high-speed, soft-mount washers that produce extract speeds between 350 and 450 G-force. High-speed extraction can cut resulting drying time by up to 50% or more. And, since dryers consume loads of natural gas, high-speed washers also drastically cut natural gas costs. A side benefit? Customers complete their laundry faster.

The Impact of Pickup And Delivery —

Determine if your services will include pickup and delivery based on your demographic. This service is a fast-growing trend sparked by dualincome households and the recent pandemic. It also helps protect you in the event there’s another pandemic and the self-service side of your business gets shut down. Analyze your service area

and keep it relatively tight to start to ensure gas and labor costs don’t eat away profit. You’ll need trained employees and a delivery vehicle. Start with a few customers or key commercial accounts and improve processes as you grow. Your POS system should help you manage and track orders.

Consult Your Equipment Distributor

Early On — Good equipment distributors are familiar with their local vended laundry market and can lead you through the laundry planning process. Be sure to discuss your goals related to

full-service work well ahead of time and visit laundries that do it well.

Tod Sorensen is a regional business manager at Girbau North America and vice president of Continental Girbau West, a full-service distributorship serving the Southern California vended, on-premise and industrial laundry markets. He has more than 20 years of vended laundry development and market analysis experience. He can be reached at tsorensen@gnalaundry.com or 866-950-2449.

28 AMERICAN COINOP MAY 2023 www.americancoinop.com

www.LaundryParts.com 800-640-7772 Your One Stop Laundry Distributor Since 1959 www.sudsy.com 24-7 PARTS ORDERING Vending Products • Fluff n Fold Paper Products • Attendant Items 60% UP TO OFF PARTS LIST PRICES

At this laundromat, a customer can easily drive up and either drop off their dirty laundry or pick up their clean clothes from an attendant.

The independent voice of the self-service laundry industry Find what you’re looking for wherever you are. Stay on top of the latest industry news and updates on your tablet, phone or in your mailbox. www.americancoinop.com SETTING UP DEDICATED SPACE TO PROCESS WASHDRYFOLD 8 STRATEGIES THAT CAN HELP SOLVE SUPPLY CHAIN ISSUES FROM PAULIE B: DEVELOPING OTHER BUSINESS TO COEXIST WITH SELFSERVICE INSIDE: MAY 2023 WWW.AMERICANCOINOP.COM AND THE OSCAR GOES TO... ‘Everything Everywhere All at Once’ with special thanks to M AJERS C OIN L AUNDRY 0523aco_p0C1-Cover-FINAL.indd 1 4/12/23 9:53 AM

2023 RATES: One- to five-time rate: $3.00 per word, boldface $3.05 per word. Minimum charge: $50.00 per ad. Call or write for our six- and 12-time rates. If box number is used, add cost of 5 words.

Display classified rates are available on request. All major credit cards are accepted.

DEADLINE: Ads must be received by the 1st of the preceding month. For

example, for a July ad, the closing date is May 1st.

order.

CLASSIFIEDS 30 AMERICAN COINOP MAY 2023 www.americancoinop.com

PAYMENT FOR CLASSIFIED ADS: Must accompany

BUSINESSOPPORTUNITIES

pro t to your

by vending your

CARTS, TRUCKS & BASKETS DRYER BOOSTER & EXHAUST FANS EQUIPMENT FOR SALE (800) 446-2719 imonex.com COIN DROP for a Buck & a Quarter EQUIPMENT FOR SALE Check Out More Listings ONLINE www.AmericanCoinOp.com ELECTRONICREPAIRS Professional Laundry Scales from Summit Measurement NTEP Digital Bench, Portable, Commercial Floor and Coin Counting Scales The Single Best Place to Buy Laundry Scales Online! (818) 561-3636 www.summitmeasurement.net ON SALENOW! * Pillar Optional COIN LAUNDRY FOR SALE LAUNDRY SCALES LAUNDRY SCALES NTEP DIGITAL LAUNDRY SCALE APM-60 Bench Scale Capacity 150 lbs. Legal For Trade Summitmeasurement.net 818-561-2626 Summit APM Laundry Scale Ad for May/Sept 2019 855-972-2537 LAUNDRY SCALES LAUNDROMAT & BUILDING FOR SALE AMARILLO, TX 43 WASHERS • 24 DRYERS CALL 806-364-2617 E-MAIL 2KEEDO@GMAIL.COM LAUNDROMAT FOR SALE Reach + Coin Laundries Advertise Today Contact Don Feinstein • 312-361-1682

18 Select Laundry Center Vending Machine Sales 515-480-4613 www.vendingmachinesales.com Add

establishment

patron’s favorite laundry goods.

www.americancoinop.com MAY 2023 AMERICAN COINOP 31 WASCO GEN 5 DOOR LOCKS & TIMERS REBUILT Door Lock $85 • Gen 6 Door Lock $99 Gen 5 & 6 Timer $85 WASCO Gen 4 Timer $85 Continental Timer $115 DRYER COMPUTER BOARDS ADC Stack $75 • Single $60 Huebsch SQ Board $45 Huebsch Old Style Board $80 Stack Dexter/Continental $80 Dexter Coin Board $65 Huebsch MDC/EDC Computer Board $60 Washer Coin Boards $65 Some prices may vary!!!! JECON INC. 18415 140th Avenue Springfield Gardens, NY 11413 One-Year Warranty on All Parts Send Core Unit with S&H Fees Call Toll Free: 1-888-532-6677 (888-JECON77) Local: 718-525-3733 • Fax: 212-656-1913 718-525-2266 Visit: JECONINC.COM We Now Accept All Major Credit Cards Why haven’t laundry owners added credit card acceptance on their washers and dryers? • They Say It’s Unaffordable • They Think There Are Too Many Choices • They Heard It’s Difficult to Install and Use CryptoPay answers ALL of these concerns. To see how, give us a call! 719-822-0294 www.getcryptopay.com/laundry.php EVERYDAY LOW PRICES 800-568-7768 CLEANERSUPPLY.COM VENDING MACHINE PRODUCTS WASH N’ FOLD BAGS PLASTIC COIN-OP BAGS WIRE CARTS PAYMENT SYSTEMS TIMERS REBUILT REECO TC, Inc. — IPSO main & reverse, Dexter, Primus, Speed Queen, Maytag & Continental Girbau, Wascomat Generation 4, 5 and 6. WE’VE MOVED 811 W. Jericho Turnpike., Ste 104W Smithtown, NY 11787 631-498-6999 www.reecotimers.com SERVICES AND SUPPLIES SERVICES AND SUPPLIES SAVE 30% WF PLASTIC BAGS We Manufacture and Deliver Reduce Waste • Cut out the Middle Man • Build Profit Wash Fold Bags Comforter Bags Blanket Bags Factory Direct Plastic Made in Wisconsin Family Owned & Operated www. LuetzowInd.com 800-558-6055 Your Ad Should Be Here AC Power 27 American Switch 26, 31 Card Concepts ..................................................3 Cleaner’s Supply 31 Continental Girbau...........................................1 CryptoPay 31 ESD Inc. 16-17, BC Gold Coin Laundry Equipment......................19 Imonex Services 30 KioSoft 11 Laundry Concepts 21 LaundryParts.com 28 LG Electronics ............................................. IBC Luetzow Industries 31 Maytag Commercial Laundry 7 Monarch Coin & Security ..............................25 Mountain Electronics 30 PayRange 15 Royal Basket Trucks 30 Setomatic Systems IFC Sudsy Vending Supplies ..................................28 Tjernlund Products 30 Vend-Rite 5 Vending Machine Sales 30 WASH Commercial Laundry 30 Advertiser PageAdvertiser Page ADVERTISERS’ INDEX www.AmericanCoinOp.com 000+ Annual Visitors Advertise Today Contact Don Feinstein • 312-361-1682

R&B WIRE PRODUCTS NAMES GRANT RAWLINS PRESIDENT

R&B Wire Products, a manufacturer of industrial material-handling products, including laundry carts, has promoted Grant Rawlins to president, the company reports.

Rawlins, the third generation in his family to lead the business, has been with R&B Wire since graduating from Pepperdine University in 2016.

During his time at the company, Rawlins has held various leadership positions to learn all aspects of the business. Most recently, he led an 18-month process of evaluating, testing and implementing a new ERP (Enterprise Resource Planning) system to modernize and streamline the operational aspects of the business.

“Grant is an exceptional leader who has developed a deep understanding of our business, from the day-to-day operations to the long-term goals and overall strategy,” says CEO Rick Rawlins, Grant’s father.

“I am honored and excited to take on this new role as president,” says Grant Rawlins. “What motivates me every day is my responsibility to continuously improve all aspects of our business — from our team and culture to our products, infrastructure and processes. This is all made possible with our team’s dedication and hard work.”

His grandfather, Rea Rawlins, purchased the company in the mid1960s, and his father, Rick, joined R&B Wire in the mid-1970s.

ALLIANCE LAUNDRY SYSTEMS ACQUIRES CALIFORNIA DISTRIBUTOR

Commercial laundry equipment manufacturer Alliance Laundry Systems reports it has acquired the distribution assets of Pittsburg, Californiabased Taylor Houseman. Terms were not announced.

The distributor has more than two decades of experience providing commercial laundry solutions in Northern California.

“This acquisition further solidifies our capacity to provide exceptional services in the significant California market,” says Craig Dakauskas, senior vice president, Americas Commercial, Alliance Laundry Systems. “Taylor Houseman’s reputation for taking care of customers at a high level matches our values and focus perfectly.”

Taylor Houseman will become part of the Alliance Laundry Systems Distribution West Region, while maintaining its Pittsburg office.

For more than 25 years, the team at Taylor Houseman has delivered high-quality commercial laundry products, services, and support for on-premises laundry, drycleaning, laundromat, and industrial laundry customers, Alliance says. It is a full-service distributor, offering technical service and replacement parts.

“I am thrilled to be able to offer our customers a whole new level of service through this sale,” says Randy Houseman, president of Taylor Houseman. “We have incredibly loyal customers, so it’s exciting to transition them to the global leader in commercial laundry.”

INTEGRATION DEEPENS FOR CARD CONCEPTS, WASHDRYFOLD POS

Card Concepts Inc. (CCI), which provides automated payments for the self-service laundry industry, reports there has been a deeper integration of its LaundryCard and FasCard products with Wash-Dry-Fold POS, which markets a drop-off laundry POS system.

Through this update, features previously only available at the CCI X-Changer/Kiosk are now available at the point-of-sale register.

“We are excited that WDF POS is taking full advantage of our API and making improvements to better support our mutual customers,” says CCI President Steve Marcionetti. “It’s great to see the CCI products working in harmony with WDF POS. Ultimately, this integration results in happier customers and a more profitable business.”

Wash-Dry-Fold POS has new features that allow attendants to easily add loyalty card value or issue refunds to the customer right at the POS register. The updates simplify the process and make it more convenient for both laundromat customer and business.

“These new integrated features allow laundromats to offer more extensive customer service at the register,” says Brian Henderson, WashDry-Fold POS founder. “The LaundryCard and FasCard integrations are 100% functional and in regular use by many of our customers.”

IN MEMORIAM: WILLIAM ‘BILL’ LUSE, FORMER TCATA PRESIDENT

William W. “Bill” Luse, a former president of the Textile Care Allied Trades Association (TCATA), died Feb. 24 at his Marion, Ohio, home at the age of 95. Luse served on the TCATA Board of Directors in the late 1960s and was association president in the early 1970s.

He once owned and operated Half Hour Laundry, Marion County’s first laundromat. Luse and his father ran the family business, Marlyn Chemical Co., manufacturing and selling commercial drycleaning and laundry supplies throughout the United States and Canada.

Surviving Luse are his companion, Judy Roberts; his children, William C. Luse, Barry Luse, Bunny Britton and Brian Luse; eight grandchildren; and 14 great-grandchildren.

He was preceded in death by his father, William K. Luse; mother, Mary Patterson; wife of 56 years, Donna Ruth Luse; and a granddaughter, Sarah J. Luse.

Donations in Luse’s memory may be made to the Sarah Jean Luse Foundation, c/o Sandusky County Communities Foundation, 1245 Napoleon St., Fremont, OH 43420.

WHIRLPOOL CORP. AMONG FORTUNE’S MOST ADMIRED COMPANIES

Whirlpool Corp., parent company of Maytag Commercial Laundry and ADC, has been recognized by Fortune Magazine as one of the “World’s Most Admired Companies” for the 13th consecutive year. The list includes respected and reputable companies around the world, as ranked by peers within their respective industries.

“We feel incredibly honored to once again be recognized by Fortune as one of the most admired companies,” says Marc Bitzer, Whirlpool’s chairman and CEO. “This recognition is only possible due to hard work and collaboration by our people and their commitment to improving life at home for consumers around the world.”

Fortune partnered with Korn Ferry on its survey of corporate reputation as the basis for the annual list. The survey began with 1,500 candidates: the 1,000 largest U.S. companies ranked by revenue, along with non-U.S. companies in Fortune’s Global 500 database that have revenues of $10 billion or more.

Survey respondents—including executives, directors and analysts— were asked to rate enterprises in their own industry on nine criteria, from investment value and quality of management and products to social responsibility and ability to attract talent.

NEWSMAKERS 32 AMERICAN COINOP MAY 2023 www.americancoinop.com

Grant Rawlins

Luse

Do a lot at once with LG TITAN

Customers favor the large capacity of LG Commercial Laundry machines because they can finish their laundry in one load. Bigger capacity means more customer rotations for your business.

• 35lbs capacity in a very small space

• Soft-mount design with low noise and less vibration

• Premium powder coating helps resist scratches and contamination

• High performance with less water consumption

• Durable and reliable with extended operation life

• Available in single and stack washer and dryer

• Auto-dosing ready

• Powerful and cost-saving

• Efficient system and easy maintenance

• Increase revenue and customer satisfaction

LG Titan, A Smarter Machine. gnalaundry.com/lg