© Copyright 2013 American Trade Magazines All rights reserved. ® September

Pursuing site remediation without breaking the bank Contamination & Cleanup

2013

The Compassmax Delivery Assistant provides many important features. Maineline Computer Systems 800-354-2525 www.compassmax.com Point your route drivers in the right direction with Compassmax Delivery Assistant Don’t Be Led Astray.

No Brushing Required

Just spray it on and wash it out… no need to brush. You save time and labor. And because brushing causes damage, customers’ garments last longer.

You Deliver Better Quality

By delivering stain-free garments with RiteGo, you build your reputation for quality – and that’s what keeps customers coming back.

New Micro-Emulsion Technology

RiteGo penetrates quickly to absorb perspiration and collar & cuff stains, and to release ground-in soil, etc.

Environmentally Friendly

RiteGo is environmentally friendly. It’s biodegradable, non-combustible, and California 2013 VOC and Prop-65 compliant.

RiteGo. The Rite Stuff for Collars and Cuffs! To learn more, visit ALWilson.com or call 800-526-1188

A. L. WILSON CHEMICAL CO. • Kearny, NJ 07032

THE RITE STUFF

For Collars and Cuffs!

Laundry Spray Spotter Now with Micro-Emulsion Technology

RiteGo®

2 American Drycleaner, September 2013 www.americandrycleaner.com

AMERICAN AMERICAN September 2013 Vol. 80, No. 6 DEPARTMENTS Pre-Inspection 4 Talk of The Trade 6 The Numbers 10 Upcoming Events 13 Management Strategies 20 How to Make Your Stores More Profitable Diana Vollmer Industry Observations 36 The Right Way to Sell Howard Scott Spotting Tips 40 ‘Old School’ Stresses Pampering Customers Martin Young Your Money 50 Retirement Planning: It’s In Your Hands Bill Lynott Education & Training Calendar 52 Around the Industry 54 Classified Advertising 58 Advertiser Index 62 Wrinkle in Time 64 FEATURES (Cover Photo: ©iStockphoto/Tashatuvango) 14 TexCare 2013 Preview Real-world concerns drive the agenda for the National Cleaners Association’s October trade show in New Jersey 16 Contamination & Cleanup Pursuing drycleaning site remediation without breaking the bank Bruce Beggs 24 Alternative Solvents: Which is Best for You? The Drycleaning & Laundry Institute invites six solvent makers to compare, contrast for a Clean Show audience 42 Quick Fixes to Common Drycleaning Problems Expert advice on how to handle wrinkling, broken buttons, shrunken wools and more Jean Teller NEED HELP FINDING THE HIDDEN HANGER? Scan this QR Code for help in finding the hidden hanger on this month’s cover. Good luck! 16

drycleaner

“Business has never been better.”

800.406.9649 sales@cleanerbusiness.com www.cleanerbusiness.com We Speak Cleaner

inventory, orders

accounts receivable.”

“I don’t have to rely on anybody for information. I can see immediately what I have for

and

Becky Afendoulis, Owner of Afendoulis Cleaners

Pre-ins P ection

s olvents s ide by s ide

If you’ve ever wanted to put the industry’s drycleaning solvents side by side to compare and contrast, this month’s issue is for you.

As new cleaning technol ogies develop, so do the ques tions, comments and rumors, the Drycleaning & Laundry Institute says.

Bruce Beggs

So, as part of its educational programming at this summer’s Clean Show, DLI invited the makers of GenX, GreenEarth, hydrocarbon, perc, Rynex and SolvonK4 solvents to answer a set of basic pre-show questions and dispel

Publisher Charles Thompson 312-361-1680 cthompson@american trademagazines.com

Editorial Director Bruce Beggs 312-361-1683 bbeggs@american trademagazines.com

Production Manager

Roger Napiwocki

National Sales Director

Donald Feinstein 312-361-1682 dfeinstein@american trademagazines.com

Digital Media Director

Nathan Frerichs 312-361-1681 nfrerichs@american trademagazines.com Main: 312-361-1700 Fax: 312-361-1685

common misconceptions about their products, then send a representative to appear before the New Orleans audience to answer even more queries.

I found it interesting to compare the average total cycle length for a standard dark load (anywhere from 45 to 70 minutes, depending on solvent), the average cost per gallon (from $13.95 to $36), and the average solvent mileage in pounds cleaned per gallon (from 750 to 4,500).

The broadest range was in the number of machines in use in the U.S. — from 10 to 10,000-plus.

Check out our story starting on page 24 and get some answers for yourself. O

American Drycleaner (ISSN 0002-8258) is published monthly except Nov/Dec combined. Subscription prices, payment in advance: U.S. and Possessions, 1 year $39.00; 2 years $73.00. Foreign, 1 year $89.00; 2 years $166.00. Single copies $7.00 for U.S. and Possessions, $14.00 for all other countries. Published by American Trade Magazines LLC, 566 West Lake Street, Suite 420, Chicago, IL 60661. Periodicals postage paid at Chi cago, IL and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Drycleaner, Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440 Volume 80, number 6. Editorial, executive and advertising of fices are at 566 West Lake Street, Suite 420, Chicago, IL 60661. Charles Thompson, President and Publisher. American Drycleaner is distributed selectively to: qualified dry cleaning plants and distributors in the United States. No material appearing in American Drycleaner may be reprinted without written permission. The pub lisher reserves the right to reject any advertising for any reason. © Copyright AMERICAN TRADE MAGAZINES LLC, 2013. Printed in U.S.A.

American Drycleaner, September 2013 www.americandrycleaner.com

4

Contributing Editors Howard Kaschyk Carolyn Nankervis Howard Scott John Spomar Jr. Jean Teller Diana Vollmer Martin Young Editorial Assistant Carlo Calma SUBSCRIPTIONS 630-739-0600 www.american drycleaner.com

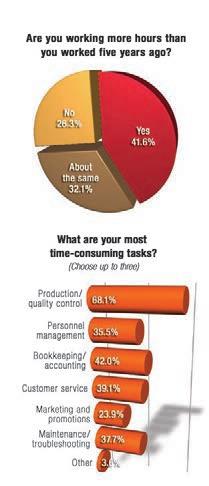

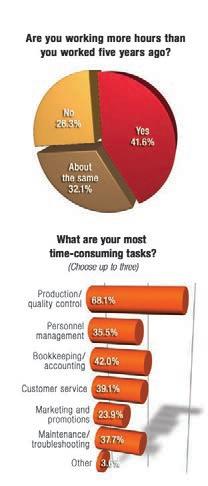

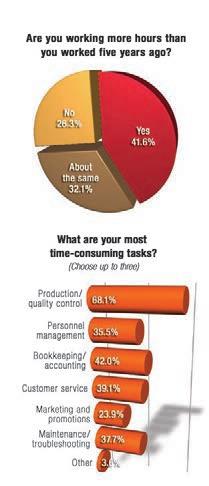

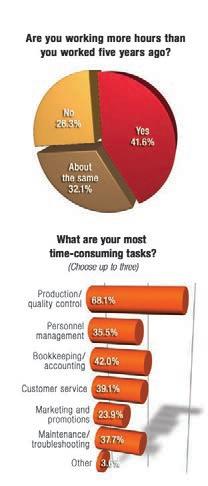

Survey: Two of five cleaners work more hours today than five years ago

Roughly 42% of dry cleaners are working more hours today than they were five years ago, according to the results of August’s American Drycleaner Your Views survey.

While 32.1% say that their schedules are “about the same,” a little more than a quarter of respondents report that they are not working more hours than they were five years ago (26.3%).

“I work fewer hours due to bringing in a future partner,” says one respondent. “I have reduced my personal compensation, thus allowing me to have [the employee] here and reduce my responsibilities.”

When asked what their most timeconsuming tasks are, the majority of respondents points to production/quality control (68.1%). Bookkeeping/ accounting (42%) and customer service (39.1%) were next. (Respondents were invited to select up to three choices from a list.)

Maintenance or troubleshooting (37.7%); personnel management (35.5%); marketing promotions (23.9%); and other tasks (3.6%), such as “covering other people’s jobs,” were among some of the other time-consuming tasks dry cleaners manage.

A sizable share of cleaners also

report they are employing fewer staff members than they were five years ago (43.0%).

“Just a few short years ago, I

6 American Drycleaner, September 2013 www.americandrycleaner.com TALK OF THE TRADE ▲

could afford to have some backup per sonnel. Now with the slow or flat sales, there is no money for backups,” says one respondent. “As a [small business owner], this puts a tremendous stress on me per sonally. I have to be there and produce at all times.”

While 34.8% of respondents say that their employee roster has remained “about the same,” 22.2% say that they have more employees than five years ago. Some dry cleaners say they man their store by them selves, while others oversee many employ ees, with one store owner saying his/her dry cleaning business has 110 employees.

“I have more employees than I ever had, yet I’m working more hours than I ever have,” says another store owner.

In terms of industry outlook, some re spondents say that reinvention is key.

“Our industry needs to rethink our role in meeting the new expectations and customer needs,” says one cleaner. “[Customer needs] have changed and most owners … do not recognize the need to change and adapt.”

“All of the complaining in the world is not going to alter the economy or the rapidly changing consumer,” says another respondent. “We need to stay lean, adapt quickly and keep having fun at it.”

While the Your Views survey presents a snapshot of the trade audience’s view points at a particular moment, it should not be considered scientific. Subscribers to American Drycleaner e-mails are invited to participate in a brief industry survey they can complete anonymously.

The entire American Drycleaner au dience is encouraged to participate, as a greater number of responses will help to better define owner/operator opinions and industry trends. O

American Drycleaner,

Top stories @ AmericanDrycleaner.com for the 30 days ending Aug. 15 Top News sTories

1. National Dry Cleaning Brand Announces First Franchisees

2. OneClick Cleaners Signs California Territory Development Deal

3. Anton’s Cleaners Raises $210,000 at Hearts Warmed Charity Event

4. French Cleaners Aids TV Show ‘Hotel Hell’ with Inn Makeover

5. NARD Members Convene at Texas Event, Interview Prospects

Top columNs & feATures

1. A Dozen Ways to Stay Out of Court

2. Making the Case for Pre-Spotting 3. Take the One-and-Done Approach

4. Get Happy: Positive Attitudes Boost Dry Cleaning Profits

Top sTories @ our sisTer siTes

Americancoinop.com:

1. A Dozen Ways to Stay Out of Court 2. Attendant Training: How to Mold and Manage Employees

3. Your Coin-Op Attendant as Teacher

AmericanlaundryNews.com:

1. Winona ORC Opens New Healthcare Laundry

2. An Industry Veteran’s Reflections on Clean Show ’13 3. ARAMARK Plans New Plant in Florida

4. Rikers Island Laundry Upgrade Pays Dividends for NYC

2013 www.americandrycleaner.com

8

September

888.249.5142 fabricaremanager.com Fast, Easy, Secure POS Built for Touch Drycleaning Management at Your Fingertips Fabricare Manager

THE NUMBERS

SEVERAL ECONOMIC FACTORS showed some gains in July, and the unemployment rate decreased slightly to 7.4%, with better jobs numbers in retail trade, food services, financial sectors and wholesale trade.

Job openings were static, with about 3.9 million openings reported at the end of June, basically the same number as in May, according to the U.S. Bureau of Labor Statistics. And the U.S. Department of Labor reported that as of Aug. 3, seasonally adjusted unemployment insurance claims stood at 333,000, up 5,000 from the previous week.

THE HOUSING INDUSTRY reported strong numbers in second-quarter 2013, with median home prices continuing to rise in most metropolitan areas. The national price of a single-family home increased 87%, the strongest year-to-year gain in almost eight years, according to the National Association of Realtors.

Lawrence Yun, NAR chief economist, says tight

inventory is continuing to drive home prices. “There continue to be more buyers than sellers, and that is placing pressure on home prices, with multiple bids common in some areas of the country,” he says. “Higher interest rates are now causing sales to level out, but the tight supply conditions look to be with us for the balance of the year in most of the country.” Delinquent mortgage rates were down 6.96% at the end of the second quarter, another figure that was at its best level since 2008, reports the Mortgage Bankers Association. RealtyTrac data shows foreclosures were down 5.43% in May, and new foreclosures were down in June by 13.69%.

THE FEDERAL RESERVE DISTRICTS indicate an increase in overall economic growth, with the 12 districts reporting modest to moderate growth, according to the Board of Governors of the Federal Reserve System. Most districts showed expanding manufacturing

figures, an overall increase in consumer spending as well as auto sales, and transportation was stable or increased in several districts. Weather affected tourism numbers slightly, though most districts reported strong numbers.

THE INTERNATIONAL COUNCIL OF SHOPPING Centers reports a net income increase for the second quarter that was the strongest gain since 2008. U.S. shopping centers saw income up 7.5% from the same time frame last year. The industry has shown increases for five consecutive quarters.

CONSUMER CONFIDENCE AGAIN WAS UP in July, according to the Surveys of Consumers from Thomson Reuters and the University of Michigan. It marked the third straight month of high confidence. Levels are higher than at any time since July 2007, and bodes well for continued increases in consumer spending in the future. O

—Jean Teller

10

www.americandrycleaner.com

American Drycleaner, September 2013

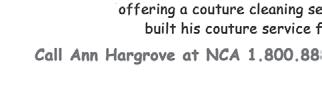

Our new generation of Point Of Sale system is designed for both small and larger cleaner stores. DryClean PRO Enterprise (DCPe) is even simpler to use than before. With user friendly screens and menus, DCPe will make your life easy. We offer, promise, and guarantee the best after sales support to our end users. Our excellent service commitment to you does not end with your purchase. We are always there to help you whenever you need us. Just pick up the phone and call us on our Technical Support line.

Call us about our new version of Uniform Tracker

Computer Systems (888) 325-4763 www.dajisoft.com

THINK OUTSIDE YOUR SYSTEM WITH Free cordless scanner with our Garment Verification System Contact us TODAY! LIMITED TIME OFFER Ask us about our DCPe RENTAL

Visit us at TexCare Booth #317

Upcoming Ev E nts

dli , nca ready to head south for Fives tar Brainstorming

The Drycleaning & Laundry Institute (DLI) and the National Cleaners Association (NCA) is preparing for their annual Five-Star Brainstorming event Jan. 16-19 at the Now Jade Riviera Cancun Resort.

Christophe Morin, the co-author of Neuromarketing: Understanding the Buy Buttons in Your Customer’s Brain, will be the headline speaker. Morin will help attendees understand how the decision-making part of the brain works, leading them to deliver more convincing sales pre sentations, close more deals, create more effective marketing strategies, and radically improve their ability to influence others, the groups say.

Morin will introduce attendees to the importance of marketing to customers’ emotions. He will help attendees identify customers’ pain and show how to identify solutions and promote a response that will resonate with customers on an emo tional level.

The all-inclusive resort offers many interesting attractions, the groups say. For more information, call 800-638-2627 (DLI) or 800888-1622 (NCA). O

www.americandrycleaner.com

c al E ndar

Sept. 17 Wisconsin Fabricare Institute Fall Golf Outing and General Membership Meet ing. To be held in Slinger, Wis. Call 414529-4707 for more information.

Sept. 20 North American Restoration Dry Cleaners Annual General Meeting. To be held in Kansas City, Mo. Call 877-630-6273 for more information.

Sept. 22-24 Textile Rental Services As sociation Annual Conference. To be held in Sonoma, Calif. Call 703-519-0029 for more information.

Sept. 27-28 GreenEarth Cleaning Fall Workshop. To be held in To be held in Kan sas City, Mo. Call 816-926-0895 for more information.

Oct. 11-14 JET Expo 2013. To be held in Paris, France. Visit jet-expo.com for more information.

Oct. 19-20 National Cleaners Association TexCare Trade Show & Exhibit. To be held in Secaucus, N.J. Call 212-967-3002.

Nov. 19-21 Texcare Asia. To be held in Shanghai, China. Visit texcare-asia.com

Jan. 16-19, 2014 Drycleaning & Laundry Institute and National Cleaners Association Five-Star Brainstorming winter conference. To be held in Cancun, Mexico. Call 800638-2627 (DLI) or 800-888-1622 (NCA).

April 25-27, 2014 Southwest Dryclean ers Association Cleaners Showcase Trade Show. To be held in Fort Worth, Texas. Call 512-873-8195.

June 20-22, 2014 South Eastern Fabri care Association Southern Drycleaners and Launderers Show. To be held in Jackson ville, Fla. Call 877-707-7332. O

Post notices of your organization’s events on AmericanDrycleaner.com

American Drycleaner, September 2013 13

Real-World Concerns Drive TexCare 2013 Agenda

The National Cleaners Association’s (NCA) biennial trade show and exhibit called TexCare will return to the Meadowlands Expo Center, Secaucus, N.J., just outside New York City, in October.

Ann Hargrove, NCA’s director of special projects, says the Oct. 19-20 show will be bigger and better than ever.

“Free admission and free parking are not the only reasons TexCare has such a great drycleaner turnout, we also have just about every industry manufacturer or supplier a dry cleaner could ever need on the show floor,” she says. “It’s a great opportunity for cleaners to find new vendors and ideas, or simply cement bonds with existing suppliers.”

In addition to live demonstrations and product/service exhibitions, the NCA has planned a strong, relevant educational program, according to Hargrove. This year, NCA members’ interests and real-world problems and

concerns they’ve been facing in their businesses are driving TexCare’s educational program.

The seminars, which are free to NCA members, will be focused on Obamacare, employee problems, attracting new customers, making more money, and problem garments.

“Although pundits say the economy is coming back, cleaners are still faced with the problems associated with actually making money and then protecting the money they’ve made, so that’s where the seminar topics are designed to help them,” says NCA Board of Directors President Bob (Sultan) Sneed.

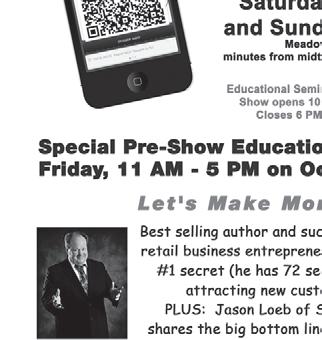

The pre-show event, an all-day educational seminar on Friday, Oct. 18, is also generating a lot of excitement, organizers say. The association is featuring small-business owner and consultant Claude Whitacre, CEO of Local Profit Geyser (LPG).

Whitacre’s story is unique in that he developed a second business (LPG) in order to share the marketing ideas,

14 American Drycleaner, September 2013 www.americandrycleaner.com

TRADE SHOW PREVIEW

strategies and tactics he used to build his retail vacuum store called The Sweeper.

The other featured presenter, returning to TexCare, is Jason Loeb of Sudsies.com, Miami. In addition to building his momand-pop Laundromat/drycleaning business into a multimillion-dollar operation, Loeb has adopted some “revolutionary” marketing strategies and service enhancements, namely his couture cleaning service, according to the NCA.

Getting existing customers to spend more money is one of the few ways to grow sales, and Loeb has capitalized on that notion with his premium-priced service niche. The who, what, when, where, why and how big a difference it’s made to his bottom line will all be laid out in his usual tell-all style.

Besides the programming, the New York area location also has an appeal for many cleaners from around the country.

“Autumn in New York is a great time,” says NCA Executive Director Nora Nealis, “which makes this the perfect opportunity for cleaners from other parts of the country to combine a great investment in their business by attending TexCare with a New York City holiday courtesy of that business.”

For out-of-towners, the Meadowlands location is easily accessible from all of New York City’s major airports (including JFK, LaGuardia and Newark), as well as NYC Penn Station (Amtrak). The special convention rates available at the Embassy Suites and Holiday Inn (located across the street from the convention center) make the weekend especially affordable, the NCA says.

To learn more about the upcoming show, call Hargrove at 800-888-1622 or visit the NCA website at nca-i.com. O

www.americandrycleaner.com

Exhibitors as of Aug. 5

A.L. Wilson Chemical Co. 426

Air Essentials 422

Air World Pads & Covers ................................433

Albatross USA 628

Caled Chemical..............................................420

Church & Dwight Co. 233

Columbia Boiler Co. 324

Columbia/ILSA Machines Corp. .......................415

Compassmax/Maineline Computers 333 Computer Connection .....................................317

Dfh Environmental Services TBA Dry Cleaning Computer Systems (DCCS) .............................................728

Drycleaning & Laundry Institute (DLI) 334 Easy Plus.......................................................521

European Finishing Equipment (Hi-Steam) 611

EzProducts International .................................624

Fabricare Management Systems 533

Fulton Boiler Works ........................................525

The Green Garmento 402-404 InnoClean Corp. 617

Itsumi USA.....................................................601

Liberty Computer Systems 529 MBH Enterprises ............................................629

Machine World Depot (A+Plus) 117 Maruso USA 527

Metropolitan Laundry Machinery .....................517 Minda Supply Co. 417

Multimatic Corp. ............................................215

National Cleaners Association 421, 431

—NCA E-mail Marketing Program

—NCA Endorsed Insurance Broker

—NCA Health Benefits Plan

—NCA Worker’s Compensation Group

New York Machinery 501

NIE Insurance 325

Pariser Industries ...........................................303

Phoenix Manufacturing 315 Sankosha USA ...............................................201

Tatch Technical Services TBA

TCF Equipment Finance 301

Union Drycleaning Products ............................401 Unipress Corp. 621

American Drycleaner, September 2013 15

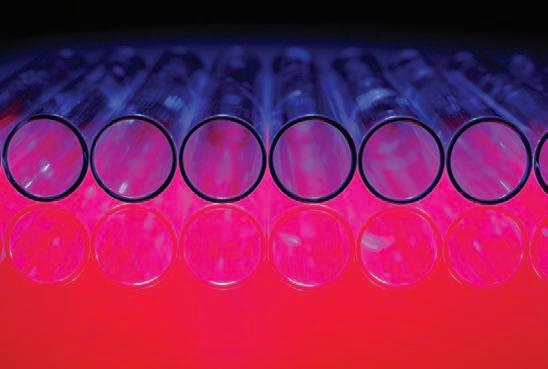

Contamination & Cleanup

By Bruce Beggs, Editorial Director

Many dry cleaners produce hazardous waste that is strictly regulated by federal and state authorities. Modern equipment and better operational measures have served to prevent or curtail site or groundwater contamination from drycleaning-related discharges in recent years, but even the most conscientious operator can run into a problem now and then.

While there are alternative solvents in use in the industry, perchloroethylene, or perc, has been the “solvent of choice since the 1960s,” according to the State Coalition for Remediation of Drycleaners (SCRD). Approximately 28,000 U.S. dry cleaners use perc today, says the

U.S. Environmental Protection Agency.

Last year, the EPA officially characterized perc as a “likely human carcinogen.” The agency has taken several significant actions to reduce exposure, including clean air standards for dry cleaners that use perc, as well as limits on the amount of perc allowed in drinking water.

Hydrogeologist Steve Henshaw, P.G., is president and CEO of EnviroForensics, an Indianapolis-based company that specializes in representing dry cleaners in environmental investigation and remediation matters.

He estimates that more than 95% of dry cleaners, often through no fault of their own, have some amount of soil or groundwater contamination if they’ve used perc. This is because enforcement levels are so low—he equates them to a thimble full of liquid in an Olympic-size swimming pool.

“Even under the best of circumstances, dry cleaners can have unexpected and unintended accidents, spills, boil-overs, that can cause the release to get into the surrounding groundwater,” he says.

When contamination is feared, a dry cleaner could be on the hook to pay for ▲

16 American Drycleaner, September 2013 www.americandrycleaner.com

Pursuing drycleaning site remediation without breaking the bank

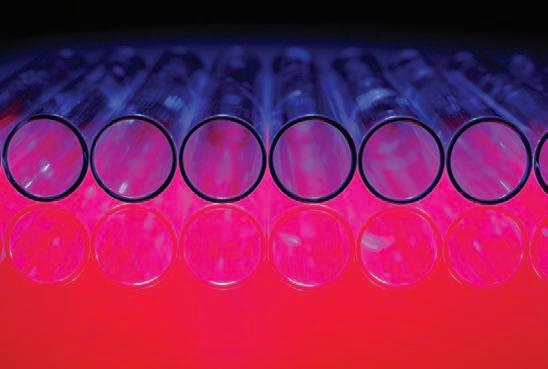

(Photo: ©iStockphoto/Tashatuvango)

site assessments and possibly remediation involving excavation and soil removal.

Unless an obvious problem of some kind is independently reported or detected, it’s of ten the pending sale or refinancing of a prop erty that houses or once housed a dry cleaner that prompts the need to check the site for possible contamination, Henshaw says.

ASSESSMENT AND REMEDIATION. David O’Dea is president of Chicago-based Environmental Consulting Group, which provides consult ing, testing and remediation services to a host of clients, including dry cleaners.

“When someone is buying a shopping center, or selling one, or wants to investigate their dry cleaner, they contact us and we do a Phase I environmental site assessment to see if there are potential problems,” he says. “Ninety-nine percent of the time, it’s going to go to Phase II.”

Phase I is a “non-intrusive study involv ing site research, historical research, a site visit and inspection,” he describes. “A report is generated saying everything is OK or, alternatively, we see potential problems and recommend a Phase II.”

Phase II assessments generally involve

By Adam Weber

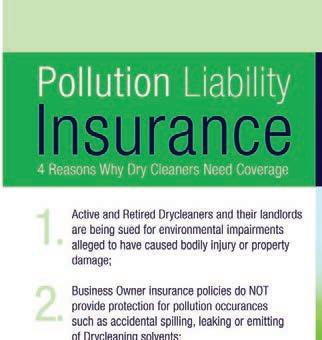

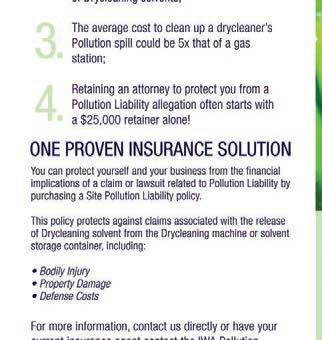

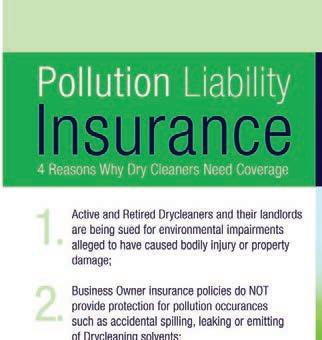

Pollution insurance wasn’t always a significant issue, but close to 30 years have passed since business insurance policies stopped including pollution liability coverage.

In the early 1980s, with exces sive numbers of pollution lawsuits appearing, insurance companies removed any reference to pollution liability from their standard policies. In fact, in most cases, policies include absolute pollution exclu sions.

Today, since standard busi ness insurance policies do not offer the coverage, a separate pollution policy is needed. Most business owners and landlords aren’t aware that the average cost for cleaning a spill from a contaminated drycleaning site can easily be in excess of $50,000, while the average cleanup from a gasoline station is estimated at only $10,000. (These figures are based on a known accident; they don’t include the legal expense associated with the spill, nor do they contemplate if ground con tamination has occurred over a long period of time.)

The reason that a dry cleaner’s cleanup cost is so high is simple. The most commonly used dry

cleaning solvent has been classi fied as environmentally hazardous, meaning that once it’s released to the environment, it is complicated to trace as well as difficult and costly to clean up.

Generally speaking, most dry cleaners are small, family-run businesses lacking the financial resources to protect themselves from a potential claim due to an alleged release of the cleaning solvents they use on a daily basis. This can involve property damage and/or bodily injury. Many owners think their business is too small to worry about purchasing pol lution insurance, but think again. All dry cleaners using, storing and disposing of various solvents are at risk for a pollution liability claim whether actual or alleged, as are their landlords.

For this reason, many landlords today require that a drycleaner tenant purchase pollution liability coverage that names the land lord as an additional insured. But just because a cleaner’s landlord doesn’t require the cover age doesn’t mean said cleaner shouldn’t give it consideration. The fact is, if a cleaner operates a plant location, it should consider the coverage (which may vary based on the primary solvent in use).

Cost of the coverage, which can range from $2,000 to $4,000 per year, may seem high ini tially. But when weighed against a claim’s or lawsuit’s potential cost of tens or hundreds of thousands of dollars, which could destroy a business by eliminating any equity developed over the years, the easily acquired insurance can be seen as a necessary drycleaning business expense. The nominal monthly expense not only provides for cleanup costs but also legal defense.

Drycleaning business owners should take the time to review their current business insurance and discuss their coverage with their insurance broker. Dry clean ers who own the building in which their drycleaning business is housed should also consider their exposure as a property owner.

Take the necessary steps to protect your drycleaning business and livelihood from the exposure of an environmental claim, which can come in many forms.

Adam Weber is president of IWA — Irving Weber Associates, which has been providing insurance services since 1946. He can be reached at 800-243-1811, ext. 8201, or aweber@iwains.com.

18 American Drycleaner, September 2013 www.americandrycleaner.com

P O llu TION lIA b I l IT y C O v ERA g E P ROTECTS Ag AINST C ONTAMINATION Cl AIMS

soil and groundwater testing. The company takes soil borings inside and outside the facility, then tests the soil for dryclean ing contaminants, particularly perc and its “breakdown products.”

“If all samples come back clean or below a certain level, then that’s where it ends, usu ally. … Alternatively, samples come back contaminated, show contamination above the criteria.”

Determining the extent of contamination leads to deciding the course for remediation.

In the past, O’Dea says, on sites that were found to be contaminated, soil classified as hazardous waste was removed, “which could be a very expensive process.”

In some instances, companies like O’Dea’s are able to remediate sans soil removal by utilizing an in-situ process. “Cer tain benign chemicals are injected into soils at fairly high pressure. They get distributed through the soil and groundwater, and they react with perchloroethylene and the break down products, and basically transform them [into substances that are not considered to be contaminants].”

A dry cleaner can maintain operations while the in-situ process is ongoing. The time it takes will depend on the extent and severity of contamination. “A typical dry cleaner site in a strip mall could be cleaned up within a year’s time,” O’Dea says.

In Illinois, the ultimate goal for seller or buyer is to obtain a “No Further Remediation (NFR)” letter, O’Dea says. This written con firmation from an environmental oversight board confirms that any contaminants there have been properly addressed.

PAYING THE BILL. An average Phase I assess ment will cost a dry cleaner $2,000, while a Phase II price tag averages $15,000 to

www.americandrycleaner.com

$20,000, O’Dea says. Beyond assessment costs, an in-situ cleanup could cost the aver age dry cleaner as much as $120,000, he adds.

“I don’t want to alarm people,” Henshaw says. “The vapor and immediate threat can be mitigated for anywhere between $5,000 and $30,000. … Soil and groundwater re mediations, unfortunately, can be anywhere from half a million to a million dollars.”

In addition to state-led drycleaner reme diation funds, voluntary programs and insur ance are helping spread the cost for cleanups.

According to the SCRD, 14 states have established programs to fund remediation of drycleaner sites: Alabama, Connecticut, Florida, Illinois, Kansas, Minnesota, Mis souri, North Carolina, Oregon, South Caro lina, Tennessee, Texas and Wisconsin. They are supported by various membership fees and taxes, although their capacity to fund projects can be limited. Several other states don’t have formal programs but are active in remediation under other authorities.

Henshaw’s firm has a sister company that specializes in “insurance archaeology,” or lo cating historical insurance policies that cov ered individuals and businesses. Old policies, particularly comprehensive general liability policies written prior to the mid-1980s, may be used to pay for costs associated with site investigation, remediation and cleanup.

Industry experts remind dry cleaners that any costs surrounding remediation will con tinue to rise as time passes.

“If they don’t address this, they’re just putting their head in the sand,” O’Dea says. “When they sell their property, when they re tire, when they sell the business, this is going to be a big bugaboo. … The more proactive they are about it, the better things will be for them.” O

American Drycleaner, September

19

2013

ANAGE m ENT STRATEGIES

How to m ake Your Stores m ore Profitable

Do you have the most stores in town? Are they all profitable? Is your staffing expense high because the store(s) sales are too low to support even minimum coverage for all the hours the store is open?

Did a store used to be great, but the sales have slacked off? Do you believe that a location should be doing much more than it actually is?

These are some of the challenges of running stores. The fabricare business is complicated with all of the issues a business can address:

• Manufacturing without the luxury of consistent raw materials but rather a different product with each order that must be made to look like new

• Logistics of getting everything through the system and back to where it needs to be when it was promised

• Financial issues of every kind

• Personnel management

• Site selection

• Fleet management

• Sales and marketing … and it goes on and on.

All of these contribute to the challenge of improving store profitability,

To find past Management Strategies columns or share this month’s with your friends, visit AmericanDrycleaner.com.

but let’s concentrate on the most direct impact items. For the purposes of this discussion, we will assume that the following basics are in place: 1) on-time delivery, and 2) consistent, appropriate quality for the pricing structure.

From there, you can create a “Store Profitability Impact Checklist” that includes the following:

SITE SELECTION. This is absolutely critical to the success of a store. Not only does the location need to be “good,” it needs much more:

• High traffic counts of potential drycleaning customers. Research the demographics and psychographics of the people who drive by. High traffic on the way to the financial and retail district is much more important than extremely high traffic on the way to a manufacturing plant.

• Easy access from the street is also critical. Are there enough convenient curb cuts into your parking lot? Are they easy to see?

• High visibility, both up close and from a distance, and both from a vehicle and on foot.

ATTENTION-GRABBING SIGNAGE. It should immediately grab one’s attention and convey a clear message, i.e. your name/logo and “Fine Cleaners” or

American Drycleaner, September 2013 www.americandrycleaner.com

20

m

Diana Vollmer

“Cleaners”; “Drive-Thru”; “24/7 DropOff”; or “24/7 Service.”

STAFF THAT IS FRIENDLY, HELPFUL, KNOWLEDGEABLE AND SALES-ORIENTED. Hire for friendliness, sales inclination and service attitude, as all are essential to the success of a store. Also, train for subtle selling technique and for fabricare and process knowledge.

SCHEDULING OF STAFF AT APPROPRIATE TIMES. Schedule staff and open hours appropriately in concert with customer demand and need for interaction—when and where the customers want to do their cleaning errands.

Track and review your “feet on the floor” customer counts by day and by hour. (Note: this is different than your mark-in timing and is a good reason to

provide quick receipts to customers.) Combining the quick receipts and the pick-ups will give you a fairly clear customer count, with the exception of the 24/7 drop-off customers who are already happy to drop off when the store is unattended.

Study these traffic counts to get clear direction for staffing. If your stores are typical, you will see the lowest customer

Hire for friendliness, sales inclination and service attitude, as all are essential to the success

of a store.

traffic when your most experienced (and most highly paid) staff is scheduled, and highest per-hour customer counts when the least experienced (and least supervised)

Go With The Flow!

The latest ARO® pump innovation packs our 80-year reputation for reliability and efficiency into a non-metallic, compact, ¼” dosing pump with:

• Consistent flow

• Clog-free operation

• Corrosion-resistant construction

• *360º mounting versatility

At sizes from ¼” to 3”, ARO diaphragm pumps give you the power to go with the flow and keep your business running efficiently and productively, no matter what’s flowing.

Discover the latest from ARO www.ingersollrandproducts.com/AROlatest

Compact diaphragm pumps, electronic interface pumps, EXP Series 2:1 pumps and one-piece diaphragm kits

*with optional flex checks

September 2013 21

www.americandrycleaner.com American Drycleaner,

▲

people are scheduled.

Look closely at the last hour of the day. There is a good reason that the question that phone-in customers ask most frequently is “When do you close?” The predominance of this question indicates that hours are not convenient to customers and that they don’t think they can get there in time without an extraordinary effort.

Look closely at the weekend hours. Despite the controversy of Sunday hours, for the cleaners that are open, Sunday is often

Air-conditioned stores are now the norm. No other service business expects customers to conduct business in a sauna.

the highest volume per hour of the week, especially at “going to” and leaving church times. When deciding your Saturday hours, consider what other errands cannot be done after your closing hours on Saturday. Should you be the only inconvenient service in your town?

Look closely at morning opening hours. Ask yourself why you open at that time. How many customers are actually coming into the store to interact with staff in the first hour or two? Can your early customers be served with a drop box? Is your store the only one open in your center at 7 a.m.? How many cars are in the center parking lot?

Revise the staffing schedule to provide knowledgeable employees when the customers have time to discuss their issues, which is usually not when they are rushing to work in the morning. Some cleaners have been successful meeting this

matching challenge through flex staffing wherein the most experienced people work a variation of four 10-hour days or three 12-hour days per week. Having a three- or four-day “vacation” every week is appealing to them and rejuvenates them for the workdays. It also allows your store to have expertise and supervision (if more than one person is scheduled during high-traffic times) every hour it is open.

Review the “lunch” coverage. If two people are being scheduled so one can take lunch during a high-traffic time, shift the lunch schedule. It is easily possible to schedule so meals are taken before or after the shift. Remember, it is the customer’s convenience you are providing, not the staff’s.

CLEAN, WELCOMING INTERIORS. If “clean” is in the name, it is only appropriate to look the part. Everything should be spotless and newly painted, conveying the message of meticulous attention to detail. Store visits should literally pass the “white glove test.”

Stores should be remodeled at a minimum of every five years to maintain a fresh, current look. It is easy to think that “store was just remodeled” five or even seven years later. Look at it with fresh eyes or ask a fastidious friend for a constructive critique.

Air-conditioned stores are now the norm. No other service business expects customers to conduct business in a sauna.

CONVERSION FROM “ORDER TAKER” TO “SALES CULTURE.” Create displays that prompt customers to think about other services they can use, and provide the tools your sales staff needs to succeed.

Simple name tags make it easy for the

American Drycleaner, September 2013 www.americandrycleaner.com

22

customers to converse with staff and for the staff to build a relationship with the customers. Require professional uniforms (no shorts, jeans, sneakers or flip-flops).

Rotate physical displays of services. More alterations and repairs will be sold with a mannequin and a tape measure in the lobby than without one. Offering alterations also distinguishes you from your competitors.

A beautiful table display will sell household linen services. A portable “door” display with a route delivery order hanging on it will sell route service (where the same customer will spend more than they spend in the store).

Professionally created displays (courtesy of your retailer partners) will sell services better than amateur displays done in-house.

Have your sales staff ask each customer a question that could lead to a sale. Each month, provide a new list of five appropriate questions from which they can choose so it doesn’t sound scripted. Samples for the fall season are:

• Is your tablecloth ready for the upcoming holidays?

• Do you need your comforter cleaned before the weather gets cooler?

• Is your fall wardrobe ready for use yet?

• Would you like us to pick up your doormats for cleaning?

• Would you like us to freshen your sweaters for the cool weather?

FLATSCREEN TVS FOR MESSAGE DELIVERY. Placing TVs at customer eye level behind the counter can be extremely effective. Use a rotating loop of service types and messages. This is especially effective for con-

www.americandrycleaner.com

verting store customers to routes, because often staff will “protect their customers” from being moved to the route. It is also ensures a consistent, professional message.

EXPENSES THAT ARE APPROPRIATE TO SALES VOLUME. When is the last time you renegotiated the rent? Over the last few years, landlords are surprised if you haven’t approached them for a rent reduction and they are praying that you won’t wake up to the possibility.

Have you taken advantage of the provid er-paid energy-saving lights, etc.? Leaving the interior lights on at night for visibility is important and the energy-saving type will reduce the cost of doing so.

How many times per day is the shuttle stopping at this store? How long is the driver staying to chat? Is the shuttle being run during rush hour? Does it make more sense to run the shuttle at night? Is the entire shuttle schedule efficient and necessary?

ALLOCATION OF ALL RELEVANT EXPENSES TO A STORE. Do not use the “incremental revenue” argument to keep an underperforming store open. It takes more effort and diversion to help an underperforming store stay open than it does to find a new store that will thrive.

These are a few of the key issues to consider to improve your store profitability. Think of your habits as a consumer and the logic will become more clear. O

Diana Vollmer is managing director at Methods for Management (MFM) Inc., which has served the dry cleaning and laundry industries with afford able management expertise for improved profitabil ity since 1953. For assistance with improving store profitability, Vollmer can be reached at dvollmer@ mfmi.com, 415-577-6544.

American Drycleaner, September 2013

23

Which is Best for You? Alternative Solvents:

As new cleaning technologies develop, so do the questions, comments and rumors. Thus, the Drycleaning & Laundry Institute (DLI) invited several solvent manufacturers to answer some of these questions and dispel common misconceptions.

The result was a well-attended Clean Show educational session that compared and contrasted six solvents in use in the dry cleaning industry today.

Panelists for the Alternative Solvents: Which is Best for You? session were:

• Jack Belluscio, president of Caled, representing GenX

• Tim Maxwell, president of GreenEarth Cleaning, representing GreenEarth

• Robert Blacker, director of technical services for RR Street & Co., representing hydrocarbon

• Sherry Emmrich, technical manager for Dow Chemical Co., representing Dowper perchloroethylene (perc)

• Greg Rinehardt, national sales manager for Adco, representing Rynex

• Dr. Manfred Seiter, technical director for Kreussler’s Textile Chemistry division, representing SolvonK4

Each panelist was given several minutes to comment on their company’s solvent, then the floor was opened to questions. Some dealt with decomposition, the potential costs of converting from one solvent to another, and if the solvents being discussed were considered “organic.” ▲

24 American Drycleaner, September 2013 www.americandrycleaner.com

(Image licensed by Ingram Publishing)

Clean Show attendees fill seminar room to hear solvent comparisons

DRYCLEANINGCOMPUTERSYSTEMS– designbyMarkman–Since1973–1210StanbridgeStreet,Norristown,PA19401fax610-275-9703610-275-6090www.dccs.com Wedon’tchangethewayyoudobusiness… Wehelpyoudoitbetter!

TheWayYouOperate. MakeDCCSyourchoice! DCCSnowofferstwotypesofpreprintedBar CodeHeatSeallabelstopermanentlymark garments.Theselabelsarethemostpopular, costeffectiveandefficientwaytointegrate with industrysortingconveyors. BarCodedHeatSeals • AvailableformostPoint-of-Salesystems • Leastexpensivesource • Quickturn-around • Interleaved2of5orcode93 • 8charactertextoptionaboveBarCode • Aslittleas $14perthousand

Fromaccurateandconsistentpricingtoinventory controlandrobustcustomerdatacapture,the designofDCCSsoftwarehasalwaysbeen SIMPLICITY.Thissimplicitytranslatesintoless waitingtimeforyourcustomers,quickerandmore efficientmarkinginofordersandfasteraccessto criticalowner/managerinformation…Ourstaff ofprofessionalsbringsanunmatchedlevelof industryexpertiseandknowledgethatwillhelpyou identifyyourspecificneeds,offersolutionstoyour problemsandhelpyouachieveyourbusinessgoals. Wemakethispromiseandcommitment…wewill tailorfitaDCCSsystemthatispractical,efficient andcosteffective…AllThisWithoutChanging

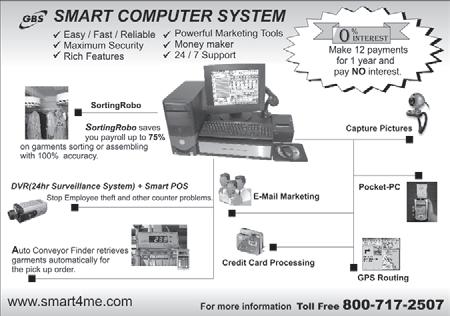

Each of the companies had submitted answers to a prepared list of questions, which touched on cycle lengths, average costs, average solvent mileage, the number of machines using their solvent, disposal recommendations, and rumors or misconceptions about their solvent, among others. Their responses follow:

Q: What is the average total cycle length for a standard dark load?

GenX – Caled: 45-55 minutes.

GreenEarth – GreenEarth Cleaning: 60 minutes.

Hydrocarbon – R.R. Street & Co.: Single Bath program – 50 to 60 minutes depending on configuration of machine; Double Bath program – 55 to 65 minutes depending on configuration of machine.

Perc – Dow Chemical Co.: There will be some variation, based on the machine capabilities and features, but the average total cycle length for a typical load, using perchloroethylene solvent, is about 45 minutes.

Rynex – Adco: 74 minutes.

SolvonK4 – Kreussler Inc.: Two Bath: 70 minutes, One Bath: 62 minutes.

Q: How much of that is the wash time?

GenX – Caled: 4-8 minutes.

GreenEarth – GreenEarth Cleaning: 17 minutes.

Hydrocarbon – R.R. Street & Co.: 18-20 minutes.

Perc – Dow Chemical Co.: The wash time during a typical cycle may be on average 15-20 minutes, depending on the soil or size of the load.

Rynex – Adco: 7.5 minutes.

SolvonK4 – Kreussler Inc.: Two Bath – 3-minute prewash/6-7-minute main

wash; One Bath – 7 minutes main wash.

Q: How much of that is the drying time?

GenX – Caled: 25-30 minutes.

GreenEarth – GreenEarth Cleaning: 35 minutes.

Hydrocarbon – R.R. Street & Co.: 28 minutes – average.

Perc – Dow Chemical Co.: The extraction/drying time during the cycle is about 30-35 minutes.

Rynex – Adco: 60 minutes.

SolvonK4 – Kreussler Inc.: 48 minutes drying and cool down.

Q: Is a specific drycleaning machine required to use the solvent?

GenX – Caled: Any Class IIIA machine.

GreenEarth – GreenEarth Cleaning: Most Class IIIA machines have been approved for use.

Hydrocarbon – R.R. Street & Co.: Class IIIA machine.

Perc – Dow Chemical Co.: Perc drycleaning machines do not require special components for optimum performance. A fourth-generation or newer machine provides the technology to remove vapors prior to opening the machine, which enhances worker safety. New models of perc machines may offer enhanced features to improve programming flexibility, maintenance, and/or energy savings.

Rynex – Adco: Yes, K Series machine.

SolvonK4 – Kreussler Inc.: Class IIIA machine with vacuum distillation, preferably one that is designed and optimized for SystemK4 to include efficient drying and stronger cooling capacities.

Q: Are there fees/licenses required to ▲

American Drycleaner, September 2013 www.americandrycleaner.com

26

R. J. Kool 234 W 12th Avenue N Kansas City, MO 64116 Phone: 816-474-9274 Fax: 816-474-2141

use the solvent?

GenX – Caled: No fees. All consumer advertising tools are free.

GreenEarth – GreenEarth Cleaning: Yes, there is a standard Affiliation Fee of $2,500 to license the intellectual property (patents, systems, technical information, marks, brands, and marketing materials) associated with the GreenEarth Cleaning System.

Hydrocarbon – R.R. Street & Co.: No.

Perc – Dow Chemical Co.: Dow is not aware of special licenses or franchise fees required by perc manufacturers or perc machine manufacturers in order to use this solvent for dry cleaning.

Rynex – Adco: No. SolvonK4 – Kreussler Inc.: No.

Q: Are any proprietary products or supplies required?

GenX – Caled: No, but Caled products use half the amount.

GreenEarth – GreenEarth Cleaning: GreenEarth has approved a number of products manufactured by a variety of vendor partners representing the top brands in the textile cleaning industry. All are readily available through typical drycleaning distribution channels.

Hydrocarbon – R.R. Street & Co.: (No response)

Perc – Dow Chemical Co.: No, there

is not a need for specific or proprietary supplies. DOWPER™ Dry Cleaning Solvent already contains a stabilizer to help maintain the solvent. Dry cleaners are free to use a variety of pre-spotters and detergents of their choice to enhance the removal of difficult soils.

Rynex – Adco: Booster and sizing. SolvonK4 – Kreussler Inc.: Yes, only Kreussler products designed for SolvonK4 are allowed: ClipK4 (detergent), PrenettK4 (pre-spotter), Peramon (still additive).

Q: What is the average cost of the solvent per gallon?

GenX – Caled: $29.41 per gallon in 55 pack.

GreenEarth – GreenEarth Cleaning: $21-24 per gallon.

Hydrocarbon – R.R. Street & Co.: $13.95 per gallon (55-gallon drum).

Perc – Dow Chemical Co.: Virgin drycleaning grade perc typically costs around $25 per gallon. Additional taxes may be applied and vary by region.

Rynex – Adco: $36.

SolvonK4 – Kreussler Inc.: Suggested

28 American Drycleaner, September 2013 www.americandrycleaner.com

Caled’s Jack Belluscio discusses his company’s solvent while GreenEarth Cleaning’s Tim Maxwell (seated, left) and R.R. Street & Co.’s Robert Blacker wait for their turn at the podium. (Photos: Bruce Beggs)

list price is $30.70 per gallon.

Q: What is the average solvent mileage? (Pounds of clothes cleaned per gallon consumed)

GenX – Caled: It depends on the machine. We are seeing as high as 1,400 pounds per gallon and as low as 800 pounds per gallon. On an average, with a new machine, the dry cleaner can expect 1,100 pounds per gallon.

GreenEarth – GreenEarth Cleaning: Usage rates vary depending on factor such as maintenance and configuration of equipment being used. Our best estimate from reports by Affiliates would be approximately 1,500 pounds per gallon.

Hydrocarbon – R.R. Street & Co.: 1,500 to 1,800 lb./gal. - standard Class IIIA machine; 4,000+ lb./gal. - K Series Class IIIA machine.

Perc – Dow Chemical Co.: Dry cleaners using perc can probably expect solvent mileage levels between 750 to more than 1,000 pounds (of) clothes cleaned per gallon of perc, with the highest values likely achieved using the latest machine technology and solvent management principals. Solvent mileage can be greatly affected by the size of the loads, the types of clothes cleaned, size and type of machine technology used, and the cleaner’s practices to purify and recycle their solvent. DOWPER™ solvent is engineered to accommodate extremely high levels of recycle and reuse.

Rynex – Adco: 3,000 plus.

SolvonK4 – Kreussler

www.americandrycleaner.com

Inc.: 4,500 pounds per gallon, minimum of .5% weight of the load.

Q: What is recommended for waste disposal?

GenX – Caled: Non-hazardous municipal waste.

GreenEarth – GreenEarth Cleaning: GreenEarth recommends that Affiliates adhere to municipal, state and local regulations. The silicone product licensed for use in the GreenEarth System is not regulated by the U.S. EPA. Many Affiliates have reported receiving dispensation from local and state regulators for solid residue from the system to be treated as standard refuse. Where that dispensation has not been granted, GreenEarth’s recommendation is to have waste removed by a licensed waste disposal company.

Hydrocarbon – R.R. Street & Co.: Process waste disposal must be in accordance with federal, state and local regulations through an appropriate licensed waste hauler. In any event, DO NOT dispose in sewers.

Perc – Dow Chemical Co.: The waste removed from perchloroethylene

29

American Drycleaner, September 2013

▲

From left, Sherry Emmrich, Dow Chemical Co.; Greg Rinehardt, Adco; and Dr. Manfred Seiter, Kreussler, listen to another panelist.

drycleaning machines must be handled and disposed of as a hazardous waste in compliance with all federal, state and local regulations. Licensed hazardous waste-handling companies are available to provide this service to perc users.

Rynex – Adco: Regular waste hauler.

SolvonK4 – Kreussler Inc.: Waste collection by a licensed hauler.

Q: How many machines are currently using the solvent in the U.S.?

GenX – Caled: 800-1,000.

GreenEarth – GreenEarth Cleaning: There are more than 900 machines operating in the United States. There are approximately 1,700 GreenEarth machines licensed in 44 countries around the world.

Hydrocarbon – R.R. Street & Co.: 10,000-plus machines in over 8,000 plants in the United States.

Perc – Dow Chemical Co.: The commercial drycleaning industry in the United States consists of approximately 36,000 shops. Approximately 85% of drycleaning shops in the U.S. use perchloroethylene as their primary solvent. (Source: NIOSH)

Rynex – Adco: Ten in USA, three in Canada plus Europe.

SolvonK4 – Kreussler Inc.: 200 U.S., 450 global.

Q: What are some of the major legitimate issues concerning the use of the solvent?

GenX – Caled: GenX is combustible, rated as a Class IIIA fluid.

GreenEarth – GreenEarth Cleaning: There are no major issues associated with the use of GreenEarth Cleaning System. GreenEarth silicone has no odor, and is not regulated by the U.S. EPA. It is not a HAP, TAC, or VOC. It has the highest

flash point (170 F/76 C) of the Class IIIA solvent options and can be used in colocations.

Hydrocarbon – R.R. Street & Co.: While not considered “major” issues, there are items that must be addressed with respect to using high flash hydrocarbon solvents:

• Fire Codes — Over the last several years, the standard for Class IIIA drycleaning plants, both NFPA 32 and IFC, have been relaxed due to improvements in Class IIA drycleaning machines and the safety technologies involved.

• Permits — The “authority having jurisdiction” i.e. fire marshal must approve the construction and/or operation of a hydrocarbon drycleaning facility in most areas. Note this is true for all drycleaning plants. Air emission permits may be required in certain locations.

• Safety Handling Practices — Safe handling practices must be employed and adhered to, specific to the solvent in use. Note this is true for any chemical.

Perc – Dow Chemical Co.: Since perc has been studied extensively, the potential issues associated with perc in dry cleaning are well understood. These may include restrictions on location (which may vary depending on your state and local areas), and special reporting or permitting. Due to the inherent toxicological properties of the solvent, proper handling and disposal are essential. Employees should be trained on the proper use, operation and maintenance of the equipment.

Rynex – Adco: After drying, the solvent leaves a residual solvent signature.

SolvonK4 – Kreussler Inc.: There are no major issues with using SystemK4. It is a Class IIIA solvent and local and federal ▲

American Drycleaner, September 2013 www.americandrycleaner.com

30

Multimatic 30-lb. SL-30 $18,500* Forenta Dry Cleaning Topper (used) $3,600* Form Finisher $2,850* Spotting Board $2,195* Huebsch 75-lb. Steam Dryer $3,700* Lattner 20hp Boiler $11,900* Milnor 60-lb. Washer $6,450* Bowe 40 Hydrocarbon Machine $28,500* New & Used Equipment for Drycleaning & Laundry 86 6 - 73 4 - 364 4 Monthly Specials Online: MustangEnterprises.com Huge Selection of Parts! Prices valid until October 1, 2013 | *Freight Not Included MUSTANG enterprises 1/2” Steam Traps $35 each, 5 trap minimum

codes must be followed for use. Q: What are the biggest rumors or misconceptions about the solvent?

GenX – Caled: Rumor: “GenX cleans so good it doesn’t need detergent.”

GreenEarth – GreenEarth Cleaning: Rumor: GreenEarth doesn’t clean.

Despite the fact that more than 1,700 machines are in operation with dry cleaners around the world, there remain operators of other solvent systems who maintain that GreenEarth doesn’t clean due to the relatively low KB Value of the silicone fluid used in the GreenEarth Cleaning System. The scientific data supporting the role of low surface tension in relation to excellent cleaning performance (as reported in the 2002 IFI Fellowship) seems, at times, to fall on deaf ears.

Rumor: Canada is going to ban GreenEarth.

Canada is definitely not going to ban the GreenEarth silicone fluid. As a matter of fact, Environment Canada announced over a year ago that “D5 silicone does not pose a danger to the environment or its biological diversity” and furthermore, that “the projected future use of Siloxane D5 will not pose a danger.”

Hydrocarbon – R.R. Street & Co.: The biggest misconception surrounding high flash hydrocarbon solvents is that they do not clean garments as effectively as other solvents in the marketplace.

This misconception is directly related to insufficient wash times and little to no use of additives (detergent). For the record, this is true of all the drycleaning solvents in use today. Without sufficient wash time and proper use of additives, none of the solvents, including water, will clean garments effectively. High flash hydrocarbon

solvents have proven to be as effective, and in some cases more effective, than other solvents in use in the industry today when run properly: 18 to 20 minutes of wash time, and the proper use of additives.

The recent use of heated high flash hydrocarbons (110 F/43 C maximum) has demonstrated even better cleaning performance.

Perc – Dow Chemical Co.: Rumor 1: “Perc will be banned for use in dry cleaning.”

The use of modern equipment and safe handling and disposal practices have shown that this solvent can be used safely and successfully for the long term. We encourage perc users to join with industry alliances to educate and advocate for its continued use at the local and state level.

Rumor 2: “Perc will no longer be produced for dry cleaning.”

U.S. perchloroethylene suppliers have publicly stated their commitments to providing long-term supply and support to the drycleaning industry, as long as there is a market for perc into dry cleaning. They will also continue to work with the HSIA (Halogenated Solvents Industry Association) to promote the safe use, handling and disposal of perchloroethylene.

More than 800 million pounds per year of perc are produced and consumed on a global basis. The vast majority of that perc is used as a “feedstock” to make refrigerants that are used in homes, cars, etc. How ever, perc is also used around the world for numerous “solvent” uses, and one of the main solvent uses is in dry cleaning.

Rumor 3: “The stabilizer in perc disappears when it gets distilled.”

Perc products are differentiated by their stabilizer packages. We can only comment

American Drycleaner, September 2013 www.americandrycleaner.com

32

on the product we manufacture, which is DOWPER™ Solvent. Dow has chosen a stabilizer package that distills along with the solvent and remains with the product in either liquid or vapor form to maintain the alkalinity of the solvent. This same stabilizer is included in perchloroethylene products for metal cleaning/vapor degreasing applications, which are typically much harsher on the solvent than drycleaning applications.

Rynex – Adco: None that we know of.

SolvonK4 – Kreussler Inc.: Rumor: The odor of the solvent will be a problem for the staff and clients.

No one using SystemK4 has found the odor of the solvent to be a problem for their staff or clients. The cleaned garments, after unloading, have a very faint smell and after finishing the textiles have a neutral

smell. Kreussler GmbH installed air quality control measuring in our own plant and in several production plants operating with SystemK4. The concentration of SolvonK4 as a non-hazardous solvent was measured within an eight-hour shift concentration with less than 5 mg/m3 in the air.

Q: What are the top three benefits of using the solvent?

GenX – Caled: 1. Better – Perfor mance for oil and water stain removal. 2. Cheaper – Spotting labor and chemical additive cost. 3. Faster – Cleaning with no harsh smell, with cycle times under 55 minutes.

GreenEarth – GreenEarth Cleaning: 1. Favorable Regulatory Profile – Interna tional regulators (including Canada and the UK) have conducted recent exhaustive

www.americandrycleaner.com

September 2013 33 ▲

American Drycleaner,

scientific studies and have concluded that the GreenEarth silicone solvent is environ mentally non-toxic. 2. Garment Manu facturers’ Recommendations – Given its low aggressivity, garment manufacturers recognize that a wide range of garments (including sequins, beads, vinyl, trims, etc.) can be cleaned safely, with no odor, a soft hand, and easy finishing. Care labels recommending GreenEarth are sewn into garments on retail racks around the world. 3. Landlord-Specified Locations – Given its safety and elimination of environmental liability, more and more landlords are insist ing that the GreenEarth Cleaning System be used by their drycleaning tenants.

Hydrocarbon – R.R. Street & Co.: 1. Cost-effective. 2. Virtually odorless cleaning. 3. Ease of transition and ongoing operation.

Perc – Dow Chemical Co.: 1. Safety – Perc is not flammable or combustible, and has no flash point or flammability limits. There are little to no emissions with modern equipment and safe handling practices. 2. Proven performance – Efficient cleaning for multiple soils and fabrics. 3. Economical – Easily separated from water and recyclable. Delivers high performance at a reasonable cost.

Rynex – Adco: 1. Testing done in Europe shows Rynex cleans better than perc in some areas and is second to perc in all the rest. 2. Less reruns. 3. Great solvent mileage. 4. Removes grease and oils better than some of the other alternative solvents.

SolvonK4 – Kreussler Inc.: 1. Exceptional cleaning performance. 2. Unmatched solvent mileage. 3. Environmental and occupational safety for the clients, staff, landlords and, last but not least, the dry cleaners themselves. O

GenX Caled

Cycle Length 55-60 min.

Wash Time 4-8 min. Dry Time 25-30 min.

Is a Specific Class IIIA Machine Required?

Fees/Licenses No

Proprietary Products No Required?

Average Cost Per Gallon $29.41

Average Solvent Mileage 800 to 1,100 (Lbs. Cleaned Per Gallon)

Recommended Waste Non-hazardous Disposal municipal waste

Number of Machines 800 U.S. in U.S. 1,000 global

Any Major Issues? None

Rumors or Doesn’t need Misconceptions detergent

(Source: Responses to DLI Questionnaire)

34 American Drycleaner, September 2013 www.americandrycleaner.com

GreenEarth Hydrocarbon Perc Rynex SolvonK4 GreenEarth R.R. Street & Co. Dow Adco Kreussler Cleaning

60 min. 2 Bath 55-65 min. 45 min. 74 min. 2 Bath 70 min. 1 Bath 50-60 min. 1 Bath 62 min.

17 min. 18-20 min. 15-20 min. 7.5 min. 7-10 min. 35 min. 28 min. 30-35 min. 60 min. 48 min. w/cool-down

Class IIIA Class IIIA Class IV K Series Class IIIA Class IIIA vacuum still

$2,500 - Annual No No No No

Many approved No No Booster Yes, Kreussler products available. Sizing products Top brands $21-$24 $13.95 $25 $36 $30.70 1,500 1,500 to 1,800 750 to 1,000 3,000+ 4,500 Standard Class IIIA minimum of .5% 4,000 weight of load K Series Class IIIA Licensed waste Appropriate waste Licensed waste Regular waste Licensed waste hauler hauler hauler hauler hauler 900+ U.S. 10,000+ U.S. 36,000 U.S. 10 U.S. 200 U.S. 1,700 global 13 global 450 global

None None Proper handling Residual None and disposal; solvent restrictions signature on location; after special reporting drying and permitting

Does not clean; Does not clean Banned; None Odor of banned in Canada unavailable; the solvent stabilizer disasppears will be a when distilled problem

www.americandrycleaner.com American Drycleaner, September 2013 35

INDUSTRY OBSER v ATIONS

The Right Way to Sell

At one time or another, most dry cleaners think about selling their businesses. They’ve been working for many years, the challenge is no longer as exciting as it used to be, and their income needs, what with the children grown and retirement income kicking in, are less.

But there are pitfalls. If the negotiation goes poorly, the results could be disastrous. Either the prospect pulls out at the last minute, the full payment is not received, or there’s a lawsuit involving deception. All are things you don’t want to experience. Here are several ways to avoid a disaster:

HIRE A BROKER. Why, you ask? You built the business completely on your own, so why should you seek advice from a so-called “business broker”?

You’re in uncharted waters here. First, where are you going to get your qualified buyer? The key word is ‘qualified.’ Second, you’re dealing with a lot of money, and people feel strongly about shelling out hardearned savings. There’s an aura of distrust around the transaction. The buyer thinks, “Is he/she giving me what is stated? Am I overpaying? Am I making a mistake? Will I be able to run the

business?” This means that you must manage the transaction carefully.

A third party is needed to respond to both the buyer’s needs and the seller’s needs. The business broker finds and evaluates the buyer, works through the negotiation, and sees that all the T’s are crossed and I’s dotted. The broker might charge 5-6% of the sale price, but you can split the fee with the buyer.

Consider these scenarios. You come up with a price. The buyer agrees. Then the buyer finds some of the equipment not up to snuff. He checks the books and finds some information incorrect. He wonders if your figures are fuzzy. There is distrust all around. He wants to take another look at the selling price, but you are adamant that the price is justified. This negotiation is heading for trouble.

CONSULT AN OUTSIDE PARTY. If you have a buyer who agreed to your price, you can handle the transaction yourself, right? Wrong. At least consult a trusted adviser during the negotiations. This might be your accountant, your lawyer, or a friend who has had experience with buying and selling businesses. The adviser is a sounding board for you as well as a person who can see the other person’s side and provide a big-picture viewpoint.

36 American Drycleaner, September 2013 www.americandrycleaner.com

Howard Scott

The adviser assists the seller in resolving any issues and acts as an intermediary in disputes.

For example, the buyer is worried about aging equipment. The adviser suggests bringing in a mechanic to look over the equipment and report his findings. If the mechanic thinks some of the machines have a useful life of less than two years, some negotiation is in order. If the mechanic thinks the machines can be used beyond two years, then the agreed-on price remains. The adviser can do such finetuning, not the seller.

PAY ATTENTION TO TIMING. Unfortunately, timing is a critical part of the transaction. Not paying attention to timing could cost you a lot of money.

Take, for instance, Florida real estate. Seven years ago, a nice condo would have sold for $150,000. That same condo goes for $40,000 today. The reason: overbuilding, foreclosure, real estate downturn, and fear that property isn’t worth as much.

Perception changes everything. It’s the same in business. There are periods of optimism when, it seems, businesses can’t fail. Then there are periods when the economy is in the doldrums and every business worries about its survival.

It’s the same business, and the sales and profit figures might be the same, but the different time period colors the facts. To generalize, you could probably get 30% more for your business during an upswing than a downturn. The goodwill factor simply adjusts up or down.

It might be a good idea to time your sale during an upswing. Postpone your current plans for a few years and hope for a changed economy. Even the beginning

www.americandrycleaner.com

of an upswing creates confidence, which you can channel into a higher price. You say, “We’ve had a tough couple of years, but now things are beginning to look up. Customers are loosening their purses because they can sense good times coming, and they’re tired of being down. As a new owner, you will be there to capitalize on the boom. You’ll be able to double my figures, and then consider where you will be.” Such an argument works.

To use another real estate analogy, it is like the period, not too many years ago, when buyers would bid above the asking price to secure the property. Perception means money in the bank.

USE FORMULAS TO CREATE A SELLING PRICE. Many dry cleaners argue that you just figure what you need and that’s the selling price. That’s a poor strategy. Using a formula helps you arrive at a figure and determine what your business is really worth. It’s the structure around which you dicker.

There are several formulas to determine selling price. Most of them work on some version of a multiple of net profit over the last three years, giving more preference for recent years. This profitability factor translates to what the business is worth, and is used to assess the 15% to 30% rate of return a buyer wants to achieve. So, if a buyer wants to achieve a 15% rate of return, and the business churns out a $30,000 net profit per year, the buyer will not pay more than $200,000 for the business (because a $200,000 investment will return exactly a 15% return of $30,000, which is the current profitability).

With this formula, buyer and seller have figures to help make the negotiation specific. For example, there can be

American Drycleaner, September 2013 37

▲

discussions about the definition of real profit, the number of years considered, asset value, and demanded rate of return. By breaking down these elements, the parties can build a working agreement from the bottom up. A business broker is your specialist in valuing companies.

TAKE YOUR MONEY UP FRONT. Some operators disagree with this point because of the significantly higher tax liability. Better to take payment over time, they say. No way. An “over-time” payout is a recipe for disaster, because most result in the seller not getting his full sale price.

I can add my personal experience here. I have sold two businesses, one with an “over-time” payout. I chose that method because the tax burden would have resulted in a 20% savings over five years. Moreover, the buyer had owned a $4 million business, and he had enormous financial resources. I thought he was a sure choice. However, what actually happened was my business and the buyer clashed. He had a breakdown of sorts and the money flowing to me stopped. My choice was to take over the business, as it was, or to take a lump-sum payment that was $200,000 below my expectation. I chose the latter, because the business was in such reduced condition that I didn’t want to return to it. I was smarter my second time around and demanded and received full payment up front.

To me, there are no conditions that would make “over-time” payouts acceptable. Too many things can go wrong. Yes, raising the necessary money is always an issue. But, a buyer has options. He can borrow from family and friends, remortgage his home, take on a financial backer,

or negotiate with a bank. A going business always attracts capital.

BE WILLING TO COMPROMISE. Too many dry cleaners say, “This is the price. Take it or leave it.” That’s why many transactions break down. Compromise is the order of the day.

You must be flexible. You need to look at the transaction from the point of view of the buyer. Each party stands to gain: you get out of running your business and get paid for it, and the buyer gets a business to run. Therefore, each person will need to compromise. Both parties need to realize that nothing is written in stone.

Having said that, you want to be sure, before the negotiation begins, that you come out satisfied. If your business is going downhill, maybe what will make you happy is coming out with $75,000 after paying off bills. To arrive at such a realization, you should have in mind what’s next.

If your price is $500,000 and that amount is barely enough to do what you want to do next, then even a $30,000 compromise will pain you. Set up a price that gives you wiggle room, so that the compromise price will leave you satisfied. Otherwise, you’ll be dickering in a poisonous atmosphere. If you can’t come up with a reasonable figure, then maybe it’s best to postpone the sale.

Pay attention to these guidelines. They may save you thousands when you actually decide to sell. O

Howard Scott is a longtime industry writer and dry cleaning consultant, and an H&R Block tax prepar er specializing in small businesses. He welcomes questions and comments, and can be reached by writing Howard Scott, Dancing Hill, Pembroke, MA 02359, by calling 781-293-9027 or via e-mail at dancinghill@gmail.com.

American Drycleaner, September 2013 www.americandrycleaner.com

38

‘old School’ Stresses pampering Customers

Icame away from New Orleans with “a burr under my saddle.” As I networked with my brother cleaners in and around the Clean Show, I was chastised for being “old school.” I am old school, because I was trained in a business model that stressed pampering the customer.

I have had the benefit of having as my friends and influences people like Norman Oehlke, Stan Caplan, Bill Seitz, and my dad. All of them have stressed the necessity of supplemental stain removal and the “bizarre” idea that exceeding expectations will lead to longevity.

According to a few people, stain removal has become passé, a luxury, not worth the effort. Stain removal was once the staple of the industry and the major reason for customers using our service. Today, a number of cleaners are relying solely on the drycleaning machine for their garment care. With this attitude has come a consumer that has been conditioned to expect “Sorry” tags instead of results.

However, this is a good thing for some cleaners/spotters. Spotters armed with the attitude that each spot can and will be removed, and with the knowledge gained from continuing education

in fibers, fabrics, dyes and techniques, are safely removing stains and enhancing their reputations.

Good word of mouth is one of the most effective ways to promote your garment service. Removing the last traces of blood and mustard simply requires knowledge and effort. As my dad had a habit of telling me, “While you are hitched up and headed that way, get the rest of it.” While you have the garment, give the customer a job that will have them talking to their friends about you rather than ranting at you.

This subject was brought into focus by a series of e-mails I happened to read. The idea being presented was an advertised policy of “Guaranteed Stain Removal.” Never lose sight of the fact that time is money. Effort should be compensated, successful or not. The most common business model addresses this by doing little or no supplemental stain removal and processing garments quickly and at a reduced cost.

The road less traveled—yet highly profitable—is the one of supplemental stain removal as standard policy. The price point for this service varies from the first business model and may even involve a “time and materials” charge for stained areas that are established as excessive. These particular stains

40 American Drycleaner, September 2013 www.americandrycleaner.com

Spotting t ip S

Martin Young

must be returned to the customer or must be dealt with at a profit. They may require additional time for repeated steam spotting, the use of chemicals to soften and remove the stain, or even a soaking bath. More time and extra chemical usage means additional business profit.

I have always believed that supplemental stain removal is a part of the drycleaning process. I never want to feel hesitant to face a customer because I failed to use everything in my arsenal to produce the best results possible. On one occasion, I had a customer admit to me that the old stain that I had removed from her dress had been her key to getting free cleaning at other cleaners.

Being an Award of Excellence/Seal of Approval cleaner immediately raises a customer’s expectations. Meeting and exceeding those expectations has been the basis of prosperity for 32 years.

Do a great job and your customer will tell his/her friends about your fine service and how to find you.

Using “Guaranteed Stain Removal” as a marketing tool could have advantages. It will attract garments that are not easily discarded due to their high value. Once you receive them, you will need to restore them safely or risk a disappointed customer. You can market the sizzle, but eventually you must serve the steak.