White Conveyors’ OAS is the perfect solution to expand your existing business, improve customer service and increase profits. Order Assembly couldn’t be easier.

The OAS significantly increasing productivity with a single operator. That means a safer workplace, helping employees observe social distancing. What’s more, order accuracy is optimized, and employee morale is improved as fatigue is virtually eliminated.

And if that were not enough, labor savings combined with increased productivity typically results in a return on investment in less than one year.*

The system can be delivered and operational the same day. As an option, it can be mounted on wheels for mobility or storage. Isn’t it time to increase productivity with less labor while increasing workplace safety? White

Easy to Use clear and easy-to-read color touch screen, plus audible instructions

Increase Productivity with Reduced Labor Force capable of assembling over 2000 garments per shift with one operator

Fast Return on Investment typical ROI in less than 1 year*

More Capacity standard 5 slots per foot have 50-80% more hanger capacity than competitors, reducing the need to split large orders

Flexible software customization is available for specialized customer’s requirements

Highly Accurate and Reliable greatly reduces the chance for human errors

Reliable, Robust and Durable Construction with average operational lifespan of 25+ years

USA Based Manufacturer for over 75 Years remote diagnostics, setting adjustments and troubleshooting assistance reduces downtime, and minimizes the need for an on-site service technician

* ROI is based on the Bureau of Labor Statistics

July 2020 Vol. 87, No. 4

Pre-Inspection 4

What’s Your Bag?!

Special Feature 18 Red, White and Blue (And You)

Special Feature 24 Green Day, Today Jeff Quail

Product News 27 Around the Industry 28

Classified Ads / Ad Index 30-31

Those bags of W-D-F, or wash-dry-fold laundry you all know it as, are not just bags of your customers garments that need to be cleaned, they’re also bags of bother and inconvenience for your customers you are taking care of, freeing them up to do other errands and things in their lives they’d rather be doing. So the bags of W-D-F laundry are also bags of garment care service that help your clients and also help you move toward better profits for your businesses. Two garment care owners share how doing W-D-F is their “bag.”

Tim Burke, Editor

Crusing along with route service can add a big block chunk of revenue to your operations. Hear from one revved-up garment care co-owner, along with his brothers, about how they build route business in many ways and keep building it constantly. Their message: If you do not add to it, it can shrink. So don’t let routes idle in neutral, always keep them revving up!

Tim Burke, EditorWrinkle in Time 32 Lost in the Marianas!

Scan this QR Code for help in finding the hidden hanger on this month’s cover. Good luck!

The smiling face on our July front cover belongs to David Poe shown working in the “bagging” area at his operation, which he co-owns with his wife Shelly, called Sun Brite Cleaners located in Portland, Oregon!

The feature, It’s In The Bag, talks with two owners, the Poe’s at Sun Brite, and also Abilene, Texas-based A-Town Cleaners’ Fran Stone all about wash-dry-fold and the added profits that can be made.

W-D-F, as you know it by, can add convenient services for your busy clients and it can add some more moolah to your own profit “bag” — if you get me!

Let It Revvv, our second feature in this issue, is all about route service at one garment care operation in the Pittsburgh area, told in a Question & Answer style to learn all we can about keeping routes thriving.

The owners relate that they have studied the dynamic of routes over the years and found that if a garment care owner isn’t adding customers to routes, then attrition can and will happen. People retire, move away, change jobs and cut back on cleaning, and attrition can be 10% or more, they note. So have weekly, monthly, and yearly goals to sign up new route customers.

This is July and that means we bring back your favorite yearly summer feature: Red, White and Blue (And You), to celebrate, in a few examples from across industry, how garment care supports our veterans and service personnel in our own patriotic way cleaning U.S. Flags, restoring flags and uniforms, and employing veterans.

Also there’s a special feature titled Green Day, Today, about what options you have when your landlord decides to go green. There are more of your favorite sections too, such as: Product News, Around The Industry and Wrinkle In Time

Enjoy the July issue and I hope your operation gets back to work safely, and I also hope you had a fun Fourth of July. I’m wishing you a summer full of renewed hopes and brighter days ahead for us all. Hope — that’s my bag! ADC

American Drycleaner (ISSN 0002-8258) is published monthly except Nov/Dec combined. Subscription prices, payment in advance: U.S., 1 year $46.00; 2 years $92.00. Foreign, 1 year $109.00; 2 years $218.00. Single copies $9.00 for U.S., $18.00 for all other countries. Published by American Trade Magazines LLC, 650 West Lake Street, Suite 320, Chicago, IL 60661. Periodicals postage paid at Chicago, IL and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Drycleaner, Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 87, number 4. Editorial, executive and advertising offices are at 650 West Lake Street, Suite 320, Chicago, IL 60661. Charles Thompson, President and Publisher. American Drycleaner is distributed selectively to: qualified dry cleaning plants and distributors in the United States. The publisher reserves the right to reject any advertising for any reason.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2020. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Drycleaner does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Drycleaner or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

American Drycleaner, July 2020

Publisher

Charles Thompson 312-361-1680 cthompson@ATMags.com

Associate Publisher/ National Sales Director

Donald Feinstein 312-361-1682 dfeinstein@ATMags.com

Editorial Director

Bruce Beggs 312-361-1683 bbeggs@ATMags.com

Editor Tim Burke 312-361-1684 tburke@ATMags.com

Digital Media

Frerichs 312-361-1681 nfrerichs@ATMags.com

Have you added wash-dry-fold service to your operation? Why not?!!!

Wash-dry-fold can double-up and bubble-up your profits! Here’s how it works for drycleaning owners in Portland, Oregon, and Abilene, Texas, and how it can simply and easily work for you! ….What are you waiting for???

By Tim BurkeTHE SUN

Bag It!…. People enjoy having extra time to do other things instead of their laundry, and adding wash-dry-fold services has increased revenue and profit at Sun Brite Cleaners in Portland, Ore. (Photo: Sun Brite Cleaners)

eople enjoy having that extra time to do other things instead of their laundry,” say David and Shelly Poe, owners of Sun Brite Cleaners in Portland, Ore., when describing the simple allure of wash-dry-fold service.

“We normally have a large amount of wash and folds each week. We almost doubled our profit margin in the first year after taking over, and adding the service,” they point out.

Let’s hear that again: Double our profit margin.

Let say it loudly one more time, even to the point of annoying you careful readers, but just to shake up the ones who might be only doing a quick read. They said: DOUBLE OUR PROFIT MARGIN!!!

Everyone should be onboard now.

David and Shelly Poe continue: “People are always surprised to hear we offer the service. Usually if they give us a try once, they keep coming back.

“They love not having to spend the time at home or at the laundromat doing their own laundry.

“We usually offer same day service on our wash-dryfold services, so they usually run errands or go relax

somewhere while we do it for them,” they note.

Let’s review these profit-raking lessons:

LESSON 1: People don’t want to do their own laundry!

LESSON 2: People run errands while the garment care operator does it for them!

LESSON 3: People are surprised to hear dry cleaners offer wash-dry-fold service!

Three huge but simple, often overlooked or ignored, lessons to raise your profits.

Your customers don’t want to do their own laundry. You have here a captive audience, starving for you to do the work and earn the money. Your customers want extra time to run errands and do fun things instead of the doing their wash. You have an audience who is dying for convenience in their lives.

Finally, and this is really the key to everything, customers don’t know, and don’t realize, that you as the dry cleaner can do their washing-drying-and folding for them. You. The dry cleaner.

So they need to be told of your services: Wash-Dry-

Fold! Put it on signs, put it on fliers, put it on your website, put it in your emails and texts, use word of mouth, write it in the sky if you have to… but…. let them know you can do their wash-dry-fold services.

Tell them you’ll do their laundry for them. Shout it from the rooftops if you have to. All that is waiting in return is the chance to double your profit margin.

So…. Why aren’t you offering wash-dry-fold? Are you allergic to making more money? <Play laugh track.>

David and Shelly Poe: “We took over our business, Sun Brite Cleaners in Portland, Ore., six years ago. We have made a lot of changes to the business over the years, but we started with installing a 50-pound dryer.”

They continue explaining their humble beginnings: “There was only a small 18-pound washer, an old utility press, a suzy, a puff iron that didn’t work, a six-foot pipe hanging from the ceiling that was the only ‘slick rail’ here, the drycleaning machine, a spotting board, a tiny air compressor, a vacuum, and a very tiny electric boiler that didn’t work most of the time.”

It was a huge challenge for them most days to accomplish anything, they add. “We brought some hotel accounts with us and have added several more. We actually market to everyone, but we have been adding more medical accounts as well.”

And today, the Poe’s relate: “Our wash and fold business is going great and adding more all the time. It is one of the few services we offer that isn’t part of the DEQ fees — that’s the Oregon Department of Environmental Quality — and isn’t labor intensive.”

The Poe’s note that, “In Oregon, DEQ charges us ‘fees’ every year. It is based in our yearly drycleaning revenue. There is a flat fee if there was ever any perc in the location. Then there is a percentage for revenue generated for dry cleaning. We are not charged anything for laundry, and wash and fold services revenue, so that is something we are trying to build up even more.”

Sun Brite Cleaners wants to let the world know of their wash-dry-fold services. To them it’s double profits awaiting, so they tell it loudly: “We have it posted on our website, posters in the windows and signs hanging from the ceiling. However, word of mouth has been our best advertisement tool. We have had more new customers tell us: ‘That so-and-so recommended you to me.’”

W-D-F

Owners David and Shelly report that for W-D-F, “Needed supplies are pretty nominal over all, so essentially it is pure profit. Initially you have the cost of bags, detergent, fabric softener and dryer sheets if you use them. But they are usually bought in bulk so cost is pretty low. Likewise with the labor, it doesn’t take very long to wash-dry-fold a load of laundry.”

They want you to leave here with a tip: “Just like your dry cleaning, always check pockets and don’t be surprised by what you might find, and always separate your lights, darks, and colors, you never know what will bleed and create a whole new mess to clean up.”

Last: “We use our phones for our routes. Customers call, email, or text when they need a pickup and we call, text, or email back to schedule a drop-off.”

Gee, these owners really seem to like making money! They double-up — and bubble-up — profits by offering wash-dry-fold service. These owners make sure everyone knows they can do their laundry too.

Where wash-dry-fold is concerned, the profits at this cleaner, are in the bag!

In Texas, one cleaner is finding success with W-D-F cleaning garments other cleaners won’t touch.

Fran Stone was born and raised in Abilene. Texas. She owns A-Town Cleaners in her home town.

“Our specialty is cleaning garments that others can’t or won’t clean. Sometimes you have to be creative when you clean certain items to meet the challenge. Generally

Wash-Dry-Fold, known as WDF, can increase revenue for dry cleaners,” she notes.

She was in the fire and water restoration business for 16 years prior to purchasing an existing dry cleaners in 2008.

“Our WDF service is okay. I feel we could do better at how we do it and market it. It is a good service to fill slow days and can create chaos on busy days if you have an order that is last-minute must-have,” Stone says, further noting that it would be great if she had a dedicated employee for just the WDF. She says they haven’t had enough to keep an 8-hour employee busy doing only WDF every day. But some days they do.

“I have been operating this plant for 12 years. We have one cleaning plant, two drop stores and route service to hotels, homes and offices. We were named SBA Small Business of the Year in 2018. We employ 23-25 employees. Customers consist of bankers, lawyers, cowboys, and teachers. We market to the age group of 26-65,” she points out.

“I have been blessed with two sons and a daughter. All are married and have children. I’m Gigi to five fun grand boys,” she says.

Gigi has served on several boards in her community; cleaned for the Jackets for Joy campaign; cleaned for Night to Shine; and she’s a member of the Abilene Cham ber of Commerce and Abilene Better Business Bureau.

She says that some of the best associations to be a member of is the Drycleaning & Laundry Institute, and the Southwest Drycleaners Association, of which she is a board member.

“We have had the best success with hotels and workers traveling. For getting the message to customers we use our website and CSR offers at the counter. There are lots of other ways: Billboards, radio, TV, but they are much more costly,” Gigi notes.

WDF has increased their profit level. When asked spe cifically about that, Gigi responds: “Yes, I would say it in creased by at least 5%. Our average ticket is around $40.”

Gigi provides a specific story as example of her WDF success: “I have a customer that lost her nanny, she works full time outside the home and she asked if we could do her laundry.

“I told her absolutely, get each child a bag to put their laundry in and we could wash-dry-fold it and the children could put it away. She was so excited and came back the next week with personalized bags for all six children and herself. She said we made her life so much better and gave her more time with her family.”

WDF can most of all make life easier — better — for your clients and that is the message from these two garment care owners. WDF service puts profits, and a better life, in the bag!

This drycleaning co-owner and his four brothers built a going route service within their operation and it’s intake is a big-block chunk of revenue. Find out how they ramped it up, and plan to keep it cruising, because adding new route clients is the ignition to cranking up a thriving route biz. Now revvv up!

By Tim Burke

By Tim Burke

It’s time to talk all things routes. Let’s get your motor revved and runnin’ with a straight-up, both hands on the wheel, supercharged Q&A with Dan LaCarte, president of Model Cleaners.

Q: First off, tell our readers about your business, Model Cleaners.

Dan: “Model Cleaners started in 1986 from one small location in Charleroi, Pa., with five employees. Today, the operation has grown in Western Pa. to 15 locations and 11 pickup and delivery routes that service more

The Poseidon system offers innovative programmability for complete control over every conditional aspect of the wet cleaning, drying and ironing process. Customers are thrilled when even their most delicate garments including tailored wool suits, cashmere sweaters and silks come back with a cleaner smell, better odor removal and an overall superior clean.

“ We’re excited to be leaders in the industry by making the switch to wet cleaning and happy to do our part in minimizing our environmental footprint. ”

— Miriam Choi, daughter of Hyeon-Dong & Young-Sook Choi Owners, University Cleaners

than 100 local Western Pa., and Morgantown, W.V., communities.

“Model Cleaners has diversified into three other distinct divisions, specializing in Uniform Rental services, called Model Uniforms; apparel, embroidery, screen-printing and company uniform fulfillment services, called Model Apparel, and in addition, the company runs a beer company which is called Stoney’s Beer,” he explains.

“The operation has grown from five employees in 1986 to a total of 225 employees in 2020. Five LaCarte brothers: John, Mike, Dave, Joe and Dan, operate and run Model on a daily basis.”

Q: Generally speaking, can an owner increase business significantly by adding route services?

Dan: “Absolutely! Adding route services to your operation can significantly increase your business.

“A route customer generally spends 30% more in business than a customer going to a store. With the added convenience of the route service, we generally see more pieces turned in, and see an increase in frequency of use from the route customer,” he relates.

“Also, an interesting dynamic: We have seen with a route customer vs. a store customer that the route customer is less price sensitive, uses coupons less, and has less quality related issues than a store customer. The convenience of the route service trumps everything.”

Q: Specifically for your operation, how is your route business doing?

Dan: “Honestly, if we did not get into the route business, I am not sure Model Cleaners would still be here today. When I joined Model and the family business in 2004 we had one route and did close to $250k per year, since then we currently have 11 routes doing close to $3 million a year in the route business and we have between 4-10% in yearly growth with the routes. Routes have been a core focus of ours throughout our entire drycleaning organization.”

Q: Routes are a game of volume. Can you explain more about the volume needed to be successful?

Dan: “If you do not add to routes it can shrink. Routes are like a pile of sand, and when you don’t add to the sand pile that sand pile can shrink.

“We have studied this dynamic over the years, if you do not add any customers to routes, then attrition can happen. People retire, move, change jobs or just cut back on cleaning. Yearly attrition on the routes can be between 10-13%, so you must add new route customers to the list every week,” he says.

“Today, we are a bigger route operation than in the past so we have to aspire to sign up more new route customers than before. Our weekly goals are to sign up between 25-40 new route customers.”

Q: When you got into routes did you know how much volume you needed to be profitable?

Dan: “Back in 2004, we just knew we needed to add new route customers each week to help us be successful. I remember then we would be happy to sign up 10 new route customers per week. As you grow goals tend to change.

“For the past 15 years we have been successful with routes, having a dedicated route sales person knocking on doors and talking with prospective customers. We would have a crew of three dedicated sales reps talking to over 450 people per week about our services.

“Lately, we have seen technology enhancements change the way we actively sell our route services. With privacy concerns and an app out there like the Ring app, which lets a person monitor their home from their smart phone, it is becoming harder to just have a crew of route sales reps knocking on doors. We have to be more refined in our approach than ever before,” he relates.

“Today, we do not have as many sale reps as we used to, but we do have a focused sales rep to call on new homeowners, new apartments and trendy businesses.

“We spend a tremendous amount on Google AdWords, and testing and refining our website to get more route customers to signup via our website. We also use our social

CRDN, as a network, has grown every year since its inception in 2001, including through tough economic times in the US and Canada, including the events of 9/11 and the recession of 2008 and 2009. There is no offperiod for residential and commercial insurance claims and, as such, we believe there will always be a need for insurance restoration services.

media platforms to enhance our route services as well.

(Ed. Note: AdWords is described by Google as it’s advertising system in which advertisers bid on certain keywords for their clickable ads to appear in a search.)

“In addition,” he says, “the best thing you can do is continue to make your trucks look great out there on the road, no better marketing dollar can be spent on ensuring that your trucks look great all the time.”

LaCarte continues: “In 2004, we were lucky to get 3-5 customers a month to sign up for route services, today we get over 50-60 customers per month signing up for our route services which is good news. We continue to sell route service in our stores and on our website. Our goal is for routes to be 60% of our total revenue.

“Another thing that we have studied over the years is that a route customer spends on average $814 per year with us and stays as a customer with us for 7.51 years, whereas a store customer spends on average $112 per year and stays as a customer with us for 1.81 years.”

Q: Share a memorable story from your routes?

Dan: “With the harsh winter weather we experience in Pittsburgh, we have a lot of adventures on the roads in helping take care of our route customers,” he regales.

“I remember a time when a route customer absolutely needed their garments to go on a trip the next morning and our area declared a local state of emergency due to the icy conditions. Of course we kept the customer needs number one, so I remember getting into our Model truck and turning what would have been a 35 minute trip into a three hour adventure to ensure that this customer’s

garments were back to them. It was a fun trip, I got pulled over by the police and was issued an $85 fine but managed to arrive at my destination,” he says.

“That one trip we made for that customer proved priceless as that customer happened to be an owner of a large business, and we were able to sign up his business onto our uniform rental services. That customer now spends over $1,800 a week with our uniform rental company. He remembered what we did for him that time and was appreciative on how our company goes above and beyond for its customers. It was worth the $85 fine.”

Q: Can you share a tip for readers who are thinking of adding routes?

Dan: “Stay focused with routes. Let route service be something you lead with on your website, your trucks and in your stores. If you do not focus on routes and make it a half-half thing you will not get the most from it.”

Q: How do apps and emails play a part today in route business?

Dan: “Apps certainly play a huge role for our customers. It’s more convenient for them to stay engaged with our brand, request pickups, see their invoices, and use coupons at their convenience. Having an app, I believe is critical in customer retention and keeping them as route customers.

“Emailing is a huge way to keep your route customers engaged in remembering their days of service. Most customers alway forget their days of service for some reason so emailing, and now texting, helps to remind them of their service days. Including a ‘days of service’ magnet reminder in the new customer welcome kit can be a good idea too.”

Q: As an owner, is it hard to manage your route business on top of your other responsibilities?

Dan: “It is a part of the process. To me, route service is essential for a dry cleaner to survive and to stay relevant, so managing the routes is a fun thing for my team and I to stay focused on.

“Route service is a different business than the stores. You must ensure your drivers are practicing strong driving safety habits. You must always make sure your team of drivers are doing their part to take care of route customers on a daily basis in the most professional way possible,” he concludes.

Keep adding new route clients, that’s the message! Let’s call it additives to your operation’s engine! You’ve idled long enough now at this starting line. Revvv it up and punch it on outta here!

By Tim Burke

By Tim Burke

Let’s celebrate once again at this time of year in our own way with shared stories from you of a patriotic nature from the fabricare industry. So many of you do things for our service personnel and veterans, including flags, uniforms, and much more. Here are just a few stories that help represent all that you do. Enjoy these, and have a fun, patriotic and safe 4th!

This is a photo of two of my employees who are veterans, says Linda Mitchell, owner of Trinity Dry Cleaners located in Lawrenceburg, Ind.

“Dale Schroeder, on the left, has been an employee for one year as a delivery driver. Dale also helps out in customer service and production,” Mitchell notes.

“He is 71 years old and is a U.S. Navy veteran, serving domestically and internationally from 1968-1972, including one tour serving on an aircraft carrier in the Mediterranean.”

Tom Patton, on the right, has been an employee at Trinity for four years as a delivery driver, customer service rep, and production assistant, Mitchell explains.

“He is 60 years old and is a U.S. Army veteran, serving as a military police officer and combat engineer both domestically and internationally from 1980-2004, including two tours in Germany and one tour in Iraq.”

Proud of our U.S. veterans, and of being able to clean and repair uniforms and flags.

All Star Dry Cleaners in Las Vegas, Nev. Cleans and repairs uniforms like these two (right) and presses flags for a nearby military base. (Photos: All Star Dry Cleaners)

“Hi! We are All Star Dry Cleaners located in Las Vegas, Nev.,” say Randy and Audry Barnett, owners.

“We are very patriotic and love our military. We clean and repair uniforms from the nearby military base as well as our local metro police department, fire department, etc.,” they note.

“The photos show two of the uniforms we have done and show a special flag that we recently cleaned,” the Barnett’s point out.

“It is an antique flag from 1942. It had to be cleaned entirely by hand, and we cleaned it for free! We clean all American flags at no charge,” they note.

Alan and Rhonda Wernick, owners of Oakwood Cleaners in Nashville relate that: “Every now and then we get the opportunity to work on very special items whether it be an heirloom wedding gown or christening gown, vintage items with sentimental value or in this case an historical United States Flag.

“We were approached by Michael Korak, facility manager at the Downtown Presbyterian Church in Nashville, to clean and restore a flag from the 1930s,” she notes.

“When he first wrote in, there was no question in my mind that we would want to take on this project and even though it was a vintage item that would require extra attention we would do it at no charge.

“Oakwood Cleaners looks for ways to help our community and this is a perfect example. It not only allows us to restore a found relic but allows us to show our patriotism for our wonderful country,” Wernick relates.

Forenta says it is currently building an order of presses for the U.S. Marine base in Okinawa, Japan.

These presses will be installed at Camp Kinser later this summer. What makes this particular order special for Rusty Smith, president of Forenta, is the fact that his youngest brother served in the Marine Corps and was stationed at this same base in Okinawa many years ago.

In addition, Rusty’s oldest brother, who has worked for Forenta for 38 years, is actually doing most of the Q.C. inspection for this order of presses. It’s safe to say that this shipment of presses will be very personal for the Smith brothers and Forenta.

The Morristown, Tenn.-based firm has a rich history of supplying equipment to the U.S. military, it notes. The Forse Corporation, its forerunner, first began building laundry presses for the U.S. Navy in the early 1940s during the height of World War II.

As our world comes together to win the race against adversity,

As our world comes together to win the race against adversity, We cheer the hundreds of thousands of courageous first responders caring for those who are affected.

We cheer the hundreds of thousands of courageous first responders caring for those who are affected.

We cheer, too, for our entire professional garment care industry supporting those who are running the race. We are proud to be associated with GreenEarth Affiliates around the globe as they join our entire industry in delivering sanitized garment care in their communities.

We cheer, too, for our entire professional garment care industry supporting those who are running the race. We are proud to be associated with GreenEarth Affiliates around the globe as they join our entire industry in delivering sanitized garment care in their communities. Thank you all for the essential services you are providing!

Thank you all for the essential services you are providing!

www.greenearthcleaning.com

www.greenearthcleaning.com

Almost every week we do something for veterans, says Clementina Yazdani, co-owner with Vahid, of Executive Cleaners in Connecticut. “Our staff recently did pressing on four extra-large flags at no charge of course!”

Rhonda Eysel, CEO of Columbus, Ga.-based Master Kleen Dry Cleaners, a 3rd generation drycleaning and laundry business with four locations, says, “One of our locations is a five-minute drive from U.S. Army Fort Benning and the Maneuver Center of Excellence.” Fort Benning is home to one of five U.S. Army Basic Combat Training facilities.

Eysel relates: “We are contracted to process bulk unit orders of ASUs (Army Service Uniforms) that have been issued to soldiers in training who are in BCT (Basic Combat Training) units here at Ft. Benning.

“The purpose for cleaning/pressing their uniforms during BCT is 1) for individual uniform inspection, and 2) to wear during their “Turning Blue” ceremony and/or graduation. We’re honored to serve our local military heroes by taking great care of their dress uniforms,” she says.

Those are just a few examples, out of so many across your garment care industry, to help celebrate the Fourth of July! ADC

(Left) Team member at Executive Cleaners, Milford, Conn., cleans one of four large U.S. Flags for a local American Legion. The cleaners received a certificate of appreciation from the Legion. (Photo: Executive Cleaners)

(Below) Rhonda Eysel, CEO of Columbus, Ga.based Master Kleen Dry Cleaners stands with all the Dress Blues they clean for the nearby military training base. (Photo: Master Kleen Dry Cleaners)

Many of our associates come from different backgrounds. Therefore, we have had the opportunity to learn about each other’s culture and experience new ways of understanding and communication. We are so lucky because our customer base is also very diverse. We are truly committed to helping our customers with their business and we are thankful for each and every one of them.

understand

one

1901 Landmeier Rd., Elk Grove Village, IL 60007

TOLL FREE: (888) 427-9120 • TEL: (847) 427-9120 • FAX: (847) 427-9634 http://www.sankosha-inc.com

of the most sincere forms of respect is actually listening to what another has to say together we will always succeed

....Often times, this is because of misleading information based on the drycleaning practices and machinery from 20 years ago. The truth of the matter is that today’s alternative solvents and machinery leave little impact on the environment and public health.

Wet cleaning using water, or systems using steam under vacuum, of course, leave none. So, when your landlord pressures you to change, first try to reeducate him or her. If that fails, explore your “green” drycleaning options.

Historically, perchloroethylene (perc) was the dryclean ing solvent of choice. Although efficient at degreasing and deodorizing textiles, perc is a carcinogen and classified as a Toxic Air Contaminant by the Environment Protection Agency (EPA). That’s why the 2008 National Perchloro ethylene Air Emission Standards for Dry Cleaning Facili ties requires a phase-out of perc machines co-located with residential buildings by December 2020.

The rule also requires all dry cleaners to implement controls on perc emissions.

So, if you’re still running with perc, the EPA is not on your side even when you use a closed-loop machine. Your landlord isn’t either. But, if you use an alternativesolvent drycleaning machine with or without wet clean-

ing, you can attempt to reeducate your landlord so your business can stay put.

When your landlord won’t budge, evaluate the options because for better or worse perc is on its way out.

It used to be that dry cleaners resisted alternative solvents because they did not clean as well as perc. But, that has changed over the years. Today’s most popular solvent categories, with examples, listed below, can produce excellent results without the environmental or health hazards of perc.

Hydrocarbon (DF-200 — EcoSolv — HC Boost): Low-odor, petroleum-based combustible solvents with a flash point greater than 140 F.

This technology is the most widely used alternative to perc dry cleaning. It works very well on delicate items, and when heated, it becomes a much more aggressive solvent. This alternative requires longer cycles and proper machine maintenance.

Modified alcohol solvents (Intense — Sensene — Lift): Based on modified alcohol formulations that are biodegradable and have low aquatic toxicity.

These solvents can be used in hydrocarbon and some

multi solvent machines. They work well for cleaning normal and delicate items, require short cycle times and involve minimal spotting. These solvents are on the high side, but excel at keeping colors bright.

Acetal (SolvonK4): Halogen-free solvent introduced in 2010. This technology is quickly increasing market share.

It’s biodegradable and non-toxic. This alternative has the closest cleaning action to perc so there is very little spotting needed. As with perc, care must be taken with beading, ap pliques and other decorations glued on to the garments.

Water (Poseidon): Uses highly programmable wetclean ing machines and new-technology dryers, along with bio degradable detergents and specialized finishing equipment to process delicate garments that would otherwise be dry cleaned. Effective, eco-friendly and non-toxic.

Wet cleaning is probably the most cost effective and thor ough way to process textiles, but there is a learning curve and there are proper techniques and procedures that must be followed before, during and after the cleaning process.

When compared apples to apples, the costs for new alter native solvent machinery is much greater than that of new wetcleaning equipment. Many times, dry cleaners choose to purchase a small-capacity alternative solvent drycleaning

machine, or a system that uses steam under vacuum, for use in combination with large capacity wetcleaning equipment. Others choose to exclusively wet clean.

Before you purchase any new equipment, check to see if there are state, county or city grant dollars or tax credits available for changing to alternative solvents or water. California and Washington, for example, both have grant dollars available ranging from $10,000-$20,000.

Moving away from perc is inevitable. But, you understand your drycleaning business best. So make new equipment decisions based on your operation’s clientele, staff and profit potential. And, don’t forget to factor in any federal, state AND city regulatory requirements and landlord ultimatums.

My advice? Contact your equipment distributor to help you sort through the pros and cons. ADC

Jeff Quail, co-owner of Poseidon Textile Care Sys tems®, has more than 30 years of hands-on industry operations experience in dry cleaning and wet clean ing. E-mail: jquail@poseidonwetcleaning.com.

CITRAZYME One-shot, powdered laundry detergent containing enzymes, oxygen bleach, and citrus degreaser.

NAPTHOL-T Powdered laundry detergent formulated to clean dark-colored shirts in cold water temperatures.

MEGA BRYTE One-shot, powdered laundry detergent that contains non-phosphate water conditioners.

CITRASOL Concentrated citrus-based liquid degreaser additive for oil and grease stain removal.

STAND UP Advanced synthetic liquid starch for shirts and denim designed to provide significant body and rigidity.

AQUA VELVET Eco-friendly one-shot wet-cleaning detergent with stain removers and conditioners. This product is EPA Safer Choice certified.

SHOT-SPOT Versatile, all-purpose stain remover.

ACTIVATE Color-safe oxygen bleaching agent blend containing a lowtemperature catalyst.

HYDROCON Eco-friendly fabric conditioner and retexturizing agent with optical brightener. This product is EPA Safer Choice certified.

LS-100 Synthetic liquid sizing and natural corn starch blend.

Luetzow Industries manufactures gussetless, but also biodegradable, poly. If you are familiar with the Metalprogetti and Sankosha auto baggers, they use this type of poly because it is easier to tear on the perforations as well as much easier to open up when sliding over a garment, the company notes. It’s a poly at 25, 27 or 28 inches wide with no pleats/gussets. “It’s not revolutionary, but I always keep my eye open for any way I can improve my customers’ efficiency and experience when using the poly I manufacture,” says owner Ryan Luetzow. www.luetzowind.com | 800-558-6055

Cleaner’s Supply wants to keep you safe and looking professional while we all continue to battle the coronavirus, the firm notes. The company is selling custom printed face masks, made of 100% cotton, fully washable, reusable. “Provide these branded masks to your employees so they can work with confidence, and floor decals promote your brand or services you offer. Wearing a face mask is recommended by the CDC, and required in many states,” the firm says.

www.cleanersupply.com | 800-568-7768

As efforts to contain the spread of COVID-19 by restricting travel rippled across the country, Methods for Management (MfM) based in Omaha, Neb., the international consulting group, says it opted to move meetings online as an alternative to canceling them.

“Using video conferencing platforms like Zoom, members can connect to their scheduled meetings from any location and interact with one another in the same way a person-to-person meeting would work,” says MfM.

“The agenda and format of the meeting,” the group adds, “can remain relatively the same as a typical onlocation meeting would work.”

In addition to the Q2 scheduled meetings, the group reports, it is also having weekly all-member Zoom meetings, where concerns and strategies regarding navigating through COVID-19 can be discussed and shared between members.

“To date,” MfM shares, “eight group meetings have successfully been completed, with a fantastic number of members participating.”

The group relates that it will continue to, “Remain in close contact with our members and will seek out more creative ways to stay connected, informed, and up-todate daily.”

This group, facilitated by Kermit Engh, says it will, “Provide membership to elite dry cleaners who wish to further their expertise and improve their business through shared industry knowledge, local community action, higher productivity, efficiency, and training for excel in garment care and customer service.”

Engh has been an owner/operator in the drycleaning

industry for over 28 years, a member of MfM for more than 24 years, and the president of the Association of Wedding Gown Specialists for 17 years, among other achievements, the group notes.

Union Drycleaning Products selected Gulf States Laundry Machinery as its 2019 Dealer of the Year. In photo from left: Sunil Parmar and Harish Parmar of Gulf States, Matt A. Lipman from Union, and Pravin Parmar of Gulf States. Photo was taken earlier this year. (Photo: Union Drycleaning Products)

McDonough, Ga.-based Union Drycleaning Products company named Gulf States Laundry Machinery it’s 2019 Dealer of the Year, the firm relates.

Sunil Parmar, Harish Parmar, and Pravin Parmar of Gulf States received the award from Matt A. Lipman of Union earlier this year.

“Union’s over 30-year relationship with Gulf States has been an incredibly valued one. Gulf States is an honest company that prides itself in a dedicated, hardworking team. It is an honor to have them in the Union family,” says Jack Burnett, president of Union Drycleaning Products.

“At Gulf States we pride ourselves in selling the very best equipment that is available in the market place. We have been selling Union machines for the last 30 years and have countless numbers of very satisfied and happy customers,” says Harish Parmar, partner in Gulf States.

“Without a doubt Union makes the best drycleaning machine in the world. Their commitment to providing unparalleled service and support is second to none in our industry,” adds Parmar.

Headquartered just south of Atlanta, Ga., Union describes itself as offering the drycleaning industry a full line of machines that utilize any of the solvents now in the U.S. Union adds that its machines are noted for their innovative designs, cutting edge technology, safety of operation, highest quality control, and full compliance with Federal, state, and local regulations.

Gulf States Laundry Machinery describes itself as the largest distributor of commercial/industrial drycleaning and laundry equipment in the United States, and says it has two offices, one in Houston, and one in Atlanta.

Texcare International, held every four years in Frankfurt, Germany, will be postponed this year, Messe Frankfurt re ports, and will take place in Frankfurt Nov. 27-Dec.1, 2021.

“Due to the economic situation caused by the pandemic,” Messe writes, “and the travel restrictions which are to be expected, Messe Frankfurt has decided this jointly with the German Textile Cleaning Association and the

VDMA Textile Care, Fabric and Leather Technologies.”

Wolfgang Marzin, president and CEO of Messe Frankfurt says: “We want to do full justice to the expectations which the industry brings to a leading trade fair such as Texcare International. The current regulations governing major events, the continuing restrictions on global travel, and the critical economic situation, however, are calling this aim into question.”

Marzin says: “At the same time, in the interests of exhibi tors and visitors, we want to avoid unnecessary costs at an early stage. None of us took this decision lightly, but we are now directing our energies to supporting the economic re covery at the right moment through the event in 2021.”

As a result of COVID-19, it had already been necessary at short notice to postpone Texcare International, originally scheduled for June 2020, to October 2020, Messe relates. How far the travel restrictions will already have been lifted this autumn is yet unclear, it adds.

Moreover, Messe notes, both the international textilecleaning industry and the laundries are suffering from the economic consequences of the pandemic, particular ly in the tourism, food-service and professional-cloth ing sectors.

Equipment is all operational and can be viewed in Montreal, Quebec. Listed below is just a sampling of what we have to sell.

• Sysmetic (formerly HMC) ADAC Automatic Dry-cleaning Assembly Conveyor System(service contract available)

• Polypack Type 22A Auto Garment Bagger (service available from U.S. based technician)

• Hoffman New Yorker Utility Presses 42”,45”

• Hoffman New Yorker Drapery/Flatwork Presses 24”x60”,24”x96”

• Unipress NT2 Double Buck Shirt Press with two PCZ Cuff & Collar Presses

• Unipress all-in-one VASY3P Shirt Unit

• Unipress Tensioning Utility Finisher (TUF)

• Sankosha Pant Topper & Double Legger

• Continental & Cissell Steam dryers –75-100lbs

• Continental 55lb, Unimac 60lb, Milnor 135lb Washers

• Air Compressors 5HP,40HP

• Vacuum with reservoir 5HP

• Rema Vacuum Double Tank RPD50

• Cissell Puff Irons, Spotting Tables & Hand Finishing Tables

• Sleevers - Cissell Horizontal, Kriete & Cindy Lou Vertical • Iowa Techniques Helping Hand Sheet Folder • Automatic Twist Tie Machine

• Harris Pillow-Vac • Ozone Machines

• Conveyor Systems-Retail,Screw & Trolley Type

www.AmericanDrycleaner.com

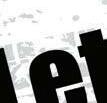

CleanCloud-Tailor Made London . . . .17

Cleaner Business Systems . . . . . . . . . .3

Cleaner’s Supply . . . . . . . . . . . . . . . .31

Continental Girbau. . . . . . . . . . . . . . .13

EzProducts International . . . . . . . . . .30

Fabricare Systems, LLC. . . . . . . . . . . .9

GreenEarth Cleaning . . . . . . . . . . . . .21

iDryclean . . . . . . . . . . . . . . . . . . . . . .27

Iowa Techniques . . . . . . . . . . . . . . . . .7

Luetzow Industries. . . . . . . . . . . . . . .31

Newhouse Specialty Co. . . . . . . . . . .31

NIE Insurance . . . . . . . . . . . . . . . . . .11

Pariser Industries . . . . . . . . . . . . . . . .26

Parker Boiler Co.. . . . . . . . . . . . . . IBC

Realstar . . . . . . . . . . . . . . . . . . . . . . . .5

Redstone Payment Solutions . . . . . . .29

Royal Basket Trucks . . . . . . . . . . . . .25

Sankosha USA. . . . . . . . . . . . . . . . . .23

SPOT Business Systems . . . . . . . . IFC

The Huntington Group. . . . . . . . . . . .15

Transworld Business Advisors . . . . .30

Union Drycleaning Products . . . . . .BC

White Conveyors. . . . . . . . . . . . . . . . .1

2020 RATES: One- to five-time rate: $2.20 per word, boldface $2.30 per word. Minimum charge: $25.00 per ad. Call or write for our three- and 12-time rates. If box number is used, add cost of 5 words. Display classified rates are available on request. All major credit cards are accepted. DEADLINE: Ads must be received by the 1st of the preceding month. For example, for a June ad, the closing date is May 1st.

10 YEARS AGO. Home Sales Rose to a five-month high in April ahead of the expiration of an $8,000 federal tax credit to first-time buyers. Sales rose 7.6% from the previous month to an annual rate of 5.77 million units, according to the National Association of Realtors (NAR).

35 YEARS AGO. EPA Proposes Stricter Regulation of Dry Cleaners. In the matter of air pollution, the EPA is proposing stricter federal regulation of dry cleaners, service stations, wood burning stoves, home heaters and industrial heaters, while leaving chemical plant supervision largely up to state regulation.

50 YEARS AGO. Pants Problem: Pocket Protection…. Wear-resistant plastic film is being used by several clothing manufacturers. It’s bonded to the inside bottom three inches of the pants pockets in men’s slacks to prevent the small holes that usually turn up there. B.F. Goodrich, maker of the new film, says that the product has also been utilized as reinforcement for knee sections of 45 million pairs of boys’ pants.

75 YEARS AGO. Lost in the Marianas!

From a letter in the July 1945 issue of American Drycleaner: “Dear Ed., The other day I had the rare good fortune of finding a copy of your American on this out-of-the-way and war-torn South Pacific island. Your advertisers will doubtless be thrilled to learn they are receiving such widespread circulation. The copy was in bad condition, lacking

American Drycleaner, July 2020

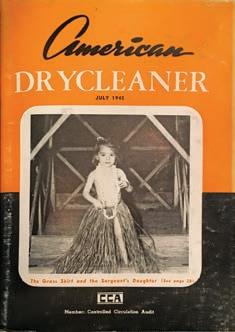

The July 1945 front cover of American Drycleaner’s headline is The Grass Skirt and the Sergeant’s Daughter and references the article inside the issue. It was a tongue-in-cheek piece about the possibility of cleaning grass skirts since allied forces, it mentions, had taken the island of Okinawa in the Pacific.

both covers, but it served the purpose of making your address known to me. I am by profession a dry cleaner, having worked and managed several plants in the Middle West. Before enlisting in the Army, I received your American Drycleaner for a number of years. I created a reference library of them, filing them in monthly order, and typed an index to certain articles describing new materials,

methods of spotting, etc. I found this arrangement handy and almost indispensable in my daily work.

You can readily see, then, why I am lost without the little book (it was digest size then) and would like to know if I can subscribe to American Drycleaner and receive it over here. Please hurry that first copy!” ADC

Editor

The Parker Boiler tube bundle is extremely flexible and offers a long life with a 25 year warranty against thermal shock.

Each unit is Factory Assembled & Fire Tested. 4 years of Field Testing.

Extra heavy boiler tubes 1-5/16” OD. minimum 0.12” (11GA) heavy thickness steel, built for long term service life.

5:1 Burner Turndown Ratio. Digital Pressure Control. Boilers require access on two sides only. Reflex Prismatic Sight Glass. Up to 4” of insulation and 1/2” thick steam drum.