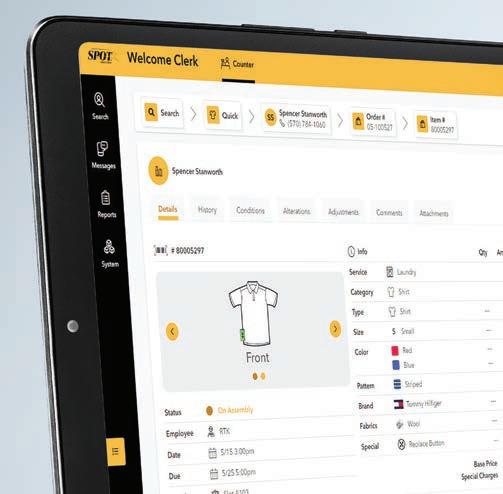

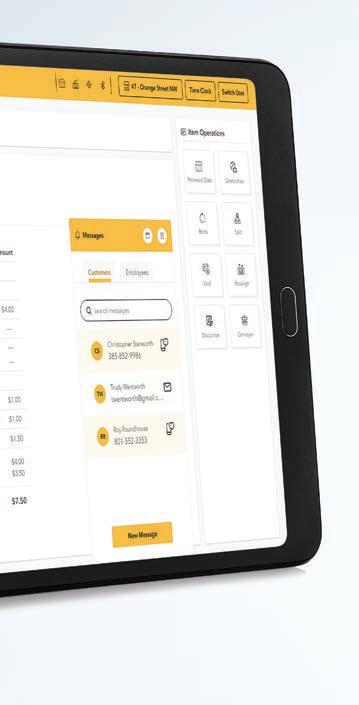

When it was originally conceived over 20 years ago, SPOT differentiated itself by being the first – a software system to simplify and improve the lives of dry cleaning operators. By delivering a new re-imagined, simple, and effective solution, SPOT continues to lead the way.

Our team of industry experts has over 80 years of experience operating dry cleaning businesses.

Our new platform is built on the latest, industryleading technologies from Microsoft, Google and Apple—technology you count on for your future.

We understand the integrations that make a difference. Metalprogetti, Twilio, BeCreative360, Zubie, Alexa and much more.

powered by

Our products and market diversity make us unique. Learn more at poseidontextilecare.com.

poseidontextilecare.com (800) 256-1073

May 2021

Vol. 88, No. 2

A new plant can mean new opportunities for your drycleaning business. We speak with two owners who decided to take the plunge into creating plants that met their current needs and will take them well into the future.

The relationship between dry cleaners and distributors can be a winning combination for both sides — if each takes the time to build that connection.

While some dry cleaners would rather avoid them altogether, online reviews are the tools that new customers use to find the services they need. By paying attention, your business can prosper with this modern word-of-mouth marketing tool.

The past few months have been difficult for everyone, but even in the darkest of times, there’s one attribute that can pull us through — hope.

Planning for the future — or even planning for a future — can allow us to see beyond our current challenges. These plans may or may not ultimately pan out, but the energy that the simple act of envisioning a brighter tomorrow generates can still see us through.

While few dry cleaners might be considering building a new facility right now, the first feature in this issue, “Starting a New Plant,” speaks to that element of generating hope. We spoke with two dry cleaners who were forced to make changes because of circumstances beyond their control, so they decided to take an active role in their own destinies. It took both of them years to make their plans, find their locations and finally make their moves. Is now the time for you to consider what your future holds for your business?

The second feature in this issue, “Getting the Most Out of Distributor Relations,” deals with one of the most crucial business relationships a dry cleaner can have. The right distributor not only helps a cleaner in the day-to-day operations of their company but can provide them with invaluable information on trends in the industry to build on for the future. Because distributors work with different cleaners, they can provide a vantage point that goes beyond a single store. When dry cleaners and distributors put in the work to build a relationship, they each can reap the rewards.

For our third feature, “Building — and Guarding — Your Online Reputation,” we examine something that many dry cleaners fear and try to avoid: online reviews and reputation management. However, by taking charge of this inescapable element of modern business, cleaners can turn something they dreaded dealing with into one of their most valuable marketing assets.

Planting seeds is one of the most hopeful activities we perform. We trust the actions we take today will provide for us in the future. In the same way, being proactive and making plans for our business’s future will set us up for better things tomorrow.

ADC

American Drycleaner (ISSN 0002-8258) is published monthly except Nov/Dec combined. Subscription prices, payment in advance: U.S., 1 year $46.00; 2 years $92.00. Foreign, 1 year $109.00; 2 years $218.00. Single copies $9.00 for U.S., $18.00 for all other countries. Published by American Trade Magazines LLC, 650 West Lake Street, Suite 320, Chicago, IL 60661. Periodicals postage paid at Chicago, IL and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Drycleaner, Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 88, number 2. Editorial, executive and advertising offices are at 650 West Lake Street, Suite 320, Chicago, IL 60661. Charles Thompson, President and Publisher. American Drycleaner is distributed selectively to: qualified dry cleaning plants and distributors in the United States. The publisher reserves the right to reject any advertising for any reason.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2021. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Drycleaner does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Drycleaner or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

American Drycleaner, May 2021

Publisher

Charles Thompson

312-361-1680 cthompson@ATMags.com

Associate Publisher/

National Sales Director

Donald Feinstein 312-361-1682 dfeinstein@ATMags.com

Editorial Director

Bruce Beggs 312-361-1683 bbeggs@ATMags.com

Editor Dave Davis 312-361-1685 ddavis@ATMags.com

Digital Media Director

Nathan Frerichs 312-361-1681 nfrerichs@ATMags.com

Production Manager

Mathew Pawlak

Advisory Board

Jan Barlow Mike Bleier

John-Claude Hallak Wesley Nelson Kyle Nesbit Mike Nesbit Fred Schwarzmann Beth Shader Vic Williams

Contributing Editors

Dan Miller

Diana Vollmer Martin Young

Office Information

Main: 312-361-1700

Subscriptions 847-504-8175 ADC@Omeda.com www.american drycleaner.com

By Dave Davis, Editor

By Dave Davis, Editor

With many dry cleaners in survival mode for the past year and then some, the idea of building new facilities at this moment, for most, might seem strange. As society rebounds, however, and cleaners adapt to what comes after the pandemic, the option should start to appeal to many looking to capitalize on new opportunities.

For some, new plants will allow them to adapt to meet both the continuing and the new demands of their customers. For others, changes in demographics or their leasing situation will require a move. Whatever the reason, relocating a plant to a new facility — or building one from scratch — is a defining moment for a drycleaning business.

And still, even if that move is years away, the homework done now can make the process easier and allow owners to reap the benefits of such an investment.

For Mark Watkins, changes to the road outside of his Alabama store ultimately meant finding a new location.

It wasn’t the first move for Watkins, owner of Mark’s Cleaners in Birmingham, Ala., but it had been a while since he pulled up stakes. Watkins started in the industry in 1981 (“I bought the business from the guy who owned ‘Ma and Pa Cleaners,’ believe it or not,” he says) and quickly outgrew the original space. In 1988, Watkins began looking for a place “over the mountain” in the more affluent area of town and settled into his next store, where he would stay until it became time for another change a few years ago.

The four-lane road in front of his store was expanded to six lanes, which completely altered the traffic flow.

“The Alabama Department of Transportation came along and changed the traffic lights I depended on,” Watkins says. “It changed the egress and ingress of

TOP: With 28-foot ceilings and almost twice the area as the prior location, Mark’s Cleaners’ new Birmingham, Ala., facility offers greater worker comfort and more options for the business. ABOVE: Mark Watkins (center) and children (from left) Sarah Watkins and Josh Watkins operate Mark’s Cleaners. When traffic changes at his old store starting hurting his business, Watkins decided it was time to relocate. “My thought was, ‘Let’s move, have some more space for growth, and diversify a little,’” he says. BELOW: When Watkins couldn’t find an existing facility when his business needed to move or expand, he decided to build a new plant. “The price was decent, and the area was fantastic,” he says. (Photos: Mark’s Cleaners)

New facilities can offer options to take your business to the next level

my business. People weren’t seeing me anymore, and they weren’t able to get to me. My front-counter business dropped like a rock, and the location became untenable.”

Besides the traffic flow situation, Watkins knew that he was starting to outgrow that location.

“We also didn’t have more than 3,400 square feet there,” he says. “Our front counter area was getting jammed up. We had also gotten into the route business, and it was growing. I decided we needed more space to accommodate that. That building never was really that conducive to a drycleaning location, although we did quite well there for a while. When the road expanded, my thought was, ‘Let’s move, have some more space for growth, and diversify a little.’”

With all these reasons in mind, Watkins began scouting for his next location. The search took longer than he thought it would. “I started searching three or four years before we actually moved,” he says. “We looked at existing buildings and properties, but nothing we were looking at seemed right.”

So, Watkins widened his scope.

“We finally found this piece of dirt here,” he says of his present location. “The price was decent, and the area was fantastic. The visibility was better than we had before, and we built 2,500 more square feet than we had at the old location.” Following construction, Mark’s Cleaners moved into the new plant in April 2019.

By building a new facility instead of moving into an existing building, Watkins was able to design the plant he wanted with no compromises.

“The new building has about 6,000 square feet, 28-foot ceilings, and the airflow is fantastic,” he says. “We airconditioned the front and the back, and it all just works a lot better. We have an automatic sliding glass door for the drive-thru and sliding glass doors inside to hold the air pressure back in the back the way it’s supposed to be.”

The new space also met Watkins’ goal of being able to expand offerings: “It’s more efficient for routes,” he says. “We’ve got two big 12-foot-tall roll-up doors in the back where the vans fans can pull up and load and unload.”

Parkway Custom Cleaning has a long history of serving the Washington, D.C., area, dating back to 1926. Its current owner, Jon Simon, explains that Parkway has been the area’s couture cleaner for decades, doing work not only for the general public but also for embassies, the White House, the Smithsonian, the Kennedy Center, and various high-end boutiques and department stores. Although counter business is important to him

(“There’s a certain percentage of the world who always wants to come in and show you the stain,” he says), routes make up about three-quarters of Parkway’s business. Since buying the business in 2001, Simon has expanded the services he offers to include the cleaning of items such as area rugs, handbags, drapery, upholstery and more. “If it’s made of fabric,” he says, “we clean it.”

So, when the area where his store was located started to become more developed, Simon saw a challenge — and an opportunity.

“We were renting our old location,” he says, “and when they rezoned it about five years ago, putting in a Metro stop and a huge town center across the street, the landlord gave me notice that he was looking for a developer.”

Simon knew he wanted to buy the next property for his business and started looking for his next location.

“I wanted to control my destiny,” he says. Because the Washington real estate market is extremely competitive, Simon had to weigh his options. In addition to price, various zoning laws made it difficult to establish a drycleaning facility.

“If you’re building a plant over 3,000 square feet, for example, you must be in an industrial zone,” he says. “You couldn’t be in a retail zone in a commercial zone, so we couldn’t be in a strip center.”

Simon patiently waited for the right property to come along, and eventually found what he needed in Rockville, Md., just north of Washington.

“It’s a 50-year-old building that’s about 20,000 square feet,” he says.

The building was portioned with a wall running down the length of it, giving him 10,000 square feet in a space that was formerly a tire company, with three automotive tenants splitting up the other half.

“They’re doing well and paying rent, and we have separate parking and entrances,” he adds.

The process wasn’t a quick one, however. “It took about a year of negotiating,” Simon says. “We had a closing date of early March 2020. And then the world changed.”

Almost a year to the day after Watkins moved Mark’s Cleaners into its new home, the bottom dropped out of the industry.

“We were making more money than we had made before working at the other place,” Watkins says. “The volume was up. Everything was up. And then, when COVID hit, we were down that first month in April 55%, with a building to pay for.”

He was alarmed but didn’t panic. Remaining positive is not an issue for Watkins. “We’ll get through it,” he says. “I promise you. It’s not a matter of ‘if’ — I will

Parkway Custom Cleaning’s new plant covers 10,000 square feet. Besides increased space for services, the new location offers better lighting, more air movement and better overall comfort for Simon’s team. “This all bears on your employees’ quality of life, which speaks to employee retention and productivity.” (Photo: Parkway Custom Cleaning)

No question about it.”

Watkins says that many around him questioned the decision to construct a new building at his age (73) but he knew that it was something that he had to do.

“I should be retiring,” he says. “I’m at that point and age where it’s been long enough. I’ve got a young son, Josh, who’s going to take it over, and I think he’s going to do well. I had people, all peers, asking me what the hell I was doing. Why was I doing this at this stage of my life? And I told them: This was the next step. It’s not just about building the business for my son; it was just the next step.”

In fact, Watkins wrote down his “business purpose,” a piece of self-talk he uses to keep driving toward success. “‘You said you had to move, and you have done the best you can,’” he says, reading the note. “‘Now attack it, and make it work.’ That’s all we can do. Just have the confidence that you’ve done the right thing. Keep the naysayers away from you and tell them to shut up. That’s what I do.

“If you’re going to do this, you’ve got to steel your mind away from doubt,” he says, “and do as much research, legwork and deep diving as possible. Ask all the pertinent questions to people who you think will give you good advice — not just anybody’s advice — and then tell people to leave you alone. They’ll scare you to death if you let them.”

As for Simon, when the pandemic lockdown started, he knew he had a choice to make: “I could have given up and walked away from a $200,000 deposit because I saw the writing on the wall, but I had a long-term vision.”

At the time, he never thought the pandemic would last as long as it has, but he has no regrets.

“Even if I had a crystal ball, I probably would have still done this because there’s nothing like owning, and I could control my own destiny.” Because the building is in a desirable area of town, he knew that, if the worst happened and he had to close his doors, he could still rent the property and be its landlord or sell it off.

Once Simon made his final decision and closed on the building, the real work began. “It was a complete gut job,” he says. “We had 20- to 30-year-old electrical, plumbing that was kind of a mess and no HVAC air handling.” Stripping things back to the cement block walls, Simon hired an architect and started the process.

One of the major benefits of newer, updated facilities is that they allow dry cleaners to think bigger, says Stuart Ilkowitz, president of Mamaroneck, N.Y.-based Trevil America. His company helps dry cleaners design, build and equip cleaning plants.

“Let’s say someone is limited on space, and they’ve maxed out their capacity,” he says. “Because of that, they don’t go after new business opportunities. They don’t advertise. Or, say you have a cleaner who doesn’t have his own shirt unit, and they send their work out to a wholesaler. If they have a new plant, and they put in their own equipment, they control the process. They control the volume. It might give them opportunities to go out and expand their business.”

For Watkins, newer, more efficient surroundings opened Mark’s Cleaners up to new possibilities.

“If you have enough space, you can diversify,” he says. “Depending on where you put your location, it can actually present different opportunities than you would have normally had.”

One of the first decisions that went into Watkins’ plant was its location.

“I tried to put myself in a situation where I’m dealing with people who are going to have their clothes cleaned,” he says. “It made sense to me to locate near hotels, nicer apartments and condos, and so on. We’ve got hospitals around here that we didn’t have before, with doctors’ offices around them. You want to put yourself in the best area you can afford.”

As more of a specialized cleaner, Simon knew that, in his case, Parkway Custom Cleaning needed to stay close to its existing customer base. “Nobody is coming to

When the building he rented became rezoned, Jon Simon knew he had a choice to make. He decided to buy a building for his business, Parkway Custom Cleaning. “I wanted to control my destiny,” he says. (Photo: Parkway Custom Cleaning)

me for price. Zero,” he says. “We are, no question, the most expensive in town.”

Although the new store is technically in a different city — he moved from Chevy Chase to Rockville — it’s still located about five miles from his old location.

“Customers might drive a few miles,” Simon says, “but if you’re putting yourself outside of a 15-minute drive, you’re going to potentially be in trouble because there are probably several cleaners between your new location and your old one.”

Other factors, such as population density, convenience, traffic flow, ease of access and more also need to be weighed before making a final decision.

Parkway’s new facility gives Simon and his team options that they never had at the old location, as well as simply being a better place to work.

“There’s better light and much better air movement here,” he says. “We also have more room to store things — we’ve built out a climate control system for furs and off-season and restoration storage. I had to outsource that before, so now I’m not paying that fee. It’s also not as noisy because I now have a much more isolated boiler room and compressor area. This all bears on your employees’ quality of life, which speaks to employee retention and productivity.”

Renovating an existing building or erecting a new structure can be expensive: Simon estimates his remodeling cost in the neighborhood of $750,000, while Watkins said his new building cost “north of $1 million.” There are other economic factors to consider, though. The economics of the move, including creating a much more efficient facility, made sense to Simon.

“You have to look at your carry,” he says. “When I factored in rent and utilities, I did the math, and I saw I was going to save thousands of dollars a month, so that ROI alone was going to be something. You’re also building equity, and you can depreciate the building as well as your equipment on your taxes.”

Besides savings in utilities, Ilkowitz believes there are other ways new equipment can bring a quick ROI.

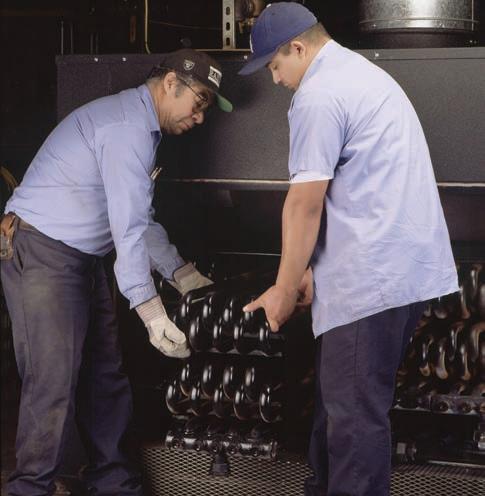

“I think the single biggest issue with older plants with older equipment is that this industry is highly laborintensive,” he says, “especially when you look at increases in minimum wages and other factors. There have always been issues with labor in this industry. Ten years ago, people used to complain about the cost of labor, and then two or three years ago, they started complaining about the availability of labor.”

New technology can help cleaners ease this stress and even out their workload.

“With new, user-friendly equipment, you can hire good employees who show up for work every day and cross-train them to work on every piece of equipment,” Ilkowitz says. “With the currently reduced volumes in the industry, it’s hard to find enough hours for everybody. Now, if you have a good employee who can do a little of this and a little of that, you can give them regular hours, and they can get all the work done.

“If you’re going to get into a new plant, that’s kind of the direction that would give you the best opportunity of being able to do something efficiently and make some money.”

When building a new facility, the decision of what to take from the old one and what to buy new is one that owners must consider.

“If you’re going into this and building a new plant, you don’t want to cut every corner and bring a whole bunch of old, used, inefficient equipment,” Ilkowitz says. “In general, if you’re going to build new, you’re building new because you want to make everything efficient. That means that you need a good installer, and that means you’ve got to have good suppliers who are supplying you with the right piece of equipment that fits your expected needs.”

While Parkway moved some of its equipment from its old location to the new, Simon saw this as an opportunity to evaluate what he had and see if it could be better.

“I had a couple of old presses,” he says, “and I had to pay to get them ripped out. Why not put the cost of re-installing them at the new place into installing a new piece of equipment? You’ve got to weigh the ROI.”

Simon estimates that he moved 80% of Parkway’s his equipment into the new space. Even so, the more

You might be surprised at what the right company can bring to the table

By Dave Davis, EditorIf you think about the drycleaning industry as the human body, distributors are not only part of the circulation system but could also be considered connective tissue.

Not only do they get much-needed supplies and equipment to stores so they can continue their daily efforts of serving their own customers, but distributors also bring a lot more with them. By working with several clients spread over a geographic area, distributors can provide their customers with a vantage point of the industry that is impossible to see from just a single storefront.

The relationship a dry cleaner has with his or her distributor is one of the most valuable connections he or she can have with the industry as a whole. However, making the most of this association requires effort from both sides, and choosing the right distributor can be critical for maximizing a cleaner’s success.

Like any long-term relationship, certain factors must be there from the beginning to keep the connection between dry cleaners and distributors alive, while other elements will develop over time.

“It’s kind of like a friendship,” says Ann Hargrove, director of events and special projects at the National Cleaners Association (NCA). “You want to know that, when you talk with your distributor, they’re

If

you are having trouble maintaining profits, 24/7 Express can help you gain more revenue without increasing your opera�ng costs. Customers can drop off or pick up at any hour at a secure 24/7 Express kiosk.

telling you the truth and that you can always call on them for advice. After the sale, you want to know that, if you have a problem, you can pick up the phone and they’ll answer you. It takes time to build a relationship — it’s a gradual thing. I have a few who I call automatically if I have a question about a piece of equipment or anything because I know I’m going to hear the truth. They have no agenda.”

John Silverman, president of Tschopp Supply Co., based in New York state, agrees: “It’s treating your customers as friends, and all the things that go with it — integrity, honesty and being willing to work with customers when things don’t go right,” he says. “If they need a little extra time to pay, for example, you extend some credit.”

“We focus on being honest with our customers and try to put ourselves in their shoes,” says Andrew Dubinski of Texas-based Mustang Enterprises. “We make recommendations based on what we would want for our own drycleaning plant, if we owned one.”

ers that we communicate. That’s what we owe them.”

“The key to maintaining good relationships,” says Larry Lieberman, president of North Carolina’s B&G Lieberman Co., “is doing what you say! This includes communicating, being fair with pricing and helping solve customer problems.”

“We do our best to update our customers on new equipment and innovations in the industry,” Dubinski says. “We also have insight into which brands have proven the most reliable. We push products that we have had the least amount of trouble with.”

Some of the tools dry cleaners use can last for decades. It’s important to know that the company they depend on for parts, supplies and servicing will be there for the duration of their equipment’s life span.

“A dry cleaner should look for a distributor who can deliver superior-quality drycleaning equipment, genuine parts, technical service and excellent customer support,” says Marc Katzman, president of Metropolitan Laundry Machinery Sales, headquartered in the borough of Queens in New York City. “They should also find a company that has been in business for many years and has a good reputation in the market of doing right by their customers.”

At the NCA-sponsored biennial TexCare Dry Cleaning & Laundry Show, Hargrove sees this longevity in action.

“Every year, you see the same people, but you also see about 10 or 15 new people,” she says. “And, when I do the show again, in two years, some of those new ones won’t be there. Now, what happens when you buy something from them?”

When researching distributors, the experiences of others can provide invaluable information when it comes to making the final choice. Great suppliers have great word-of-mouth recommendations.

Another essential element in forging a lasting relationship is maintaining open lines of communication. Because of the pandemic, keeping the supply chain intact has been especially difficult during the past year.

Because of this, Silverman believes that clear communications can ease — or remove — the pain involved.

“There have been a lot of chemicals that haven’t been available,” he says. “Rather than just sending nothing, we call the customer and explain that product XYZ has been in backorder for three weeks, but we have another product and ask if they would be willing to try it. A lot of distributors just send the other product, but we call the customer to notify them that day and explain the substitution. It’s important to our relationship with our custom-

American Drycleaner, May 2021

“I like to encourage our potential customers to contact our existing clients about our services and the products we sell,” Dubinski says. “We are fortunate to have strong relationships.”

“We have relationships with customers that stretch back 50 years,” Silverman says, “so our customers often find customers for us, believe it or not, and there are industry reps (who) also find customers for us. A machine rep or a soap rep might call and say, ‘You know, I have a nursing home over here. Would you guys be able to supply them?’ That’s how we get a lot of our business. When you’re doing things right, word-of-mouth pays off.”

“I like to look at how long they’ve been around and listen to feedback from other people who have used them,” Hargrove says of distributors. “You want the good ones who you know are going to be around.”

Something all quality distributors display is caring about their clients after the sale is made. In fact, Hargrove believes that, ideally, the sale is only the first step in a much longer relationship.

“Say you’re building a plant,” she says. “You’re going to tell your distributor what you’re looking for, and they’re going to tell you what you absolutely need. But then, they’ll also tell you, ‘You could also have this and this,’ and then they’re going to give you a price.”

And, while the initial cost is important, Hargrove believes there are other factors to examine.

“Some people will shop only for price, but you have to look at the long term. You’re going to be in that store for years and years and years, and you want to walk in that store and know when you turn that machine on, it starts. You want to know that the boiler will start, and the presses aren’t spitting.”

And when something isn’t working correctly?

“You want to know exactly who to call,” she says. “And you’ll get a feeling about them early on. How many times do you call them, and do they call you right back? The good ones, you’ll know immediately. Again, it’s almost like a friendship because they have to be there for you when you need them. And then, you go back to them every time you need a new boiler, a new compressor or a new press. You give them a shot. It’s an aspect of loyalty.”

“Being a good distributor is about giving people advice and making sure that, when they need a product, it’s there,” Silverman says. “Did they run out of something before their supply run? Can your salesman drive it to them? Can you UPS it? Making sure you supply the customer in a very consistent way is a vital part of being a distributor.”

“After-sale support, honesty and integrity are key to building and maintaining a good relationship,” Katzman says. “It’s important to be there for your customers. The conversation about equipment and the services you provide should be fluid and ongoing.”

“Look at what services the distributor is offering beyond the product — specifically the follow-up service, such as programming of equipment, troubleshooting issues down the road, etc.,” Dubinski says. “A dry cleaner needs support, not if, but when a machine has a breakdown.”

“A good distributor brings knowledge, experience and quick service at a fair price,” says Lieberman. “There must be an ease of communication and ordering, with a large selection of products and innovations.”

And, because of their connective nature, distributors often can help a dry cleaner in ways the cleaner might not know they can — it never hurts to ask.

“We often find used equipment for people when one dry cleaner isn’t using a piece of equipment that another dry

cleaner needs,” Silverman says. “If one cleaner needs a special drapery machine, for instance, and there’s one just sitting an hour away in another cleaner’s plant, we go and find it for them and help them out. There are just so many things we do for people that go beyond making a sale.”

As piece counts dropped when the pandemic lockdowns took effect, the shock wave hit the cleaning industry’s distribution sector immediately after it struck dry cleaners. Not only did the need for supplies drop, but distributors had a heartbreaking front-row seat as their clients fought for their financial lives.

“The coronavirus has had an impact on an already vulnerable industry,” Katzman says. “With dry cleaners struggling before the pandemic, we have seen fewer stores who are able to keep their doors open. If the coronavirus has shown us anything, it is that we must look out for one another’s safety.”

“The pandemic has been extremely harsh for us and the entire industry,” says Dubinski. “The calls have slowed now, but for about six months, we got a call two or three times a week about a dry cleaner closing and needing to liquidate their equipment.”

“The pandemic has affected our business by causing most of our customers to have to reduce staff or close,” Lieberman says. “Sales of supplies are down, but we hope that in the next six months, as stores return to normal, that our supply side will improve, as well.”

While orders fell, Katzman believes that dry cleaners earned their “essential business” status and were particularly well-prepared from a health perspective during this challenging time.

“Dry cleaners have always practiced safety and cleanliness within their stores,” he says, “so, when the pandemic hit, they were ready to rise even higher when it came to the safety of their employees and customers. I see distributors, as well as dry cleaners, maintaining their loyalty and keeping their customers safe by continuing to provide an essential service to their communities.”

For those dry cleaners who survive, Dubinski says, there is the potential to gather business from the companies that were forced to shut their doors.

“A lot of our customers have picked up laundry contracts with bed-and-breakfasts, Amazon warehouse wear, insurance fire/flood claims, and so on,” he says. “We all have been forced to diversify and change our business model. As weddings and events come back, religious services reopen, and people return to their offices, we are optimistic that our industry will thrive.”

Besides offering their advice and observations about the industry, Silverman believes that one of the most

valuable things a distributor can do for clients is simply to let them know that they are there for them.

“We’ve become obsessive about communicating with our customers through our newsletter, and our sales staff have doubled down on calling on their people,” he says. “For us, the pandemic has put customer service at the forefront of what we do.”

This effort, Silverman believes, has given his customers a much-needed boost through the dark times: “A lot of people thought that, with the pandemic, customers might not need as much service. We think that people need our services now more now than ever. We think in-person customer service is very important.”

“All of us have really learned what’s truly important in our lives,” says Mark Towery, vice president of Tschopp. “We have spent thousands of hours on the phone and in person speaking with our customers. They are truly our friends before, during and after the pandemic. Some of these conversations were heartbreaking, but I believe we helped them, just as they’ve helped us. This pandemic isn’t forever, and we’ll get through it. Friends first, sales second.”

Having the right relationship with a distributor can help a dry cleaner in good times or bad. It’s a collaboration that boosts both parties — but the relationship needs to be built and maintained from both sides.

“If customers are not feeling connected to their distributor,” Silverman says, “they should seek out the distributor principal, give them a call and talk to them. A lot of us are out there, willing to talk to people and help them with business problems in general. I think that it’s important to stay in touch, even if you’re just calling to say, ‘Hey, how are you doing? How are things going there?’”

“Distributor relations are critical to the success of the drycleaning industry since the pipeline cannot be filled by just one company,” Lieberman says. “Relationships are still the best way to do business — not by price alone. Customers know that many factors affect the price; quality is very important and knowledgeable servicepeople are not free.”

“We are here to see our customers succeed and here to support the drycleaning industry,” Dubinski says. “Without our strong and loyal customers, we have nothing.” ADC

Online reviews can be one of the most valuable marketing tools a dry cleaner can have, but many cleaners both hate and fear the concept, mainly because it’s an element outside of their control. “One disgruntled customer,” the thinking goes, “can singlehandedly ruin my business.”

While it’s true that online reviews and reputation aren’t entirely in the control of the business owner, there are things they can do to influence the system — not only to limit negative reviews but to encourage positive ones as well, says Yash Patel of BeCreative360. Patel recently presented his views in a Drycleaning & Laundry Institute (DLI) webinar, “The Power of Reputation Management.”

Perhaps the most surprising point Patel shared is that most of the actions business owners need to do to build and protect their online reputation don’t require a financial budget — they simply require the owner’s attention.

“The biggest question most cleaners have is, ‘How do I get new customers?’” Patel says. “Everybody wants new customers, especially during this time when your competitors are closing their doors. You want to grab those customers. You want to make sure that you are the one they find when looking for a new cleaner.”

The quickest, most efficient way to introduce your business and your services to these customers is to have a strong online presence. This, however, is where many dry cleaners fail because they don’t want to deal with the online element of running their businesses. Cleaners who ignore this facet do so at their peril, Patel says, providing the following statistics:

• 93% of customers search for a business online.

• 90% choose a company on Page 1 of the Google results.

• There has been a 500% growth in recent years of “near me” searches (“dry cleaners near me,” for instance).

“Google yourself.”

This piece of advice from Patel is, on the surface, simple, but it will reveal a great deal of information about how customers see your business. How easy is it for a potential — or current — customer to find you online?

“How high are you ranked?” Patel asks. “Are you at the top of the page? Are you on Page 1? Or are you on Page 2 or 3? Generally, people won’t look anywhere past the first page. The first step to online visibility is to make sure you Google yourself regularly to see where you stand.”

Of course, one way to increase your visibility is to have a business website. “It’s very important that you get even a basic website,” Patel says. “Having a website helps your customers and can answer some of the questions they have.”

The website should be updated regularly with new information and images, Patel says, and store hours should always be updated and available. Building a site that allows reviews to flow to it automatically is a simple yet effective method of increasing Google rankings and, therefore, visibility. This constant updating shows Google that your site is active and helps boost your search rankings.

Another easy — and free — activity is to make sure you claim your “My Business” page on Google.

“It’s very easy to do,” Patel says. “Just Google, ‘Google My Business’ and claim your business. It will take you about 10 minutes.” When you do this step, he says, Google knows to serve up your company’s information when someone does a search relevant to your business.

Patel also advises business owners to turn on notifications on platforms like Facebook, Yelp!, Google My Business and other forums where people might leave comments or reviews.

“It’s very important that you turn on notifications on your phone, on your email and anywhere else you can be notified,” he says. “Response time is crucial. And you may not think that it’s important because you believe your customers may not care about it, but how fast you’re responding to all of this goes a very long way.”

When a customer leaves a negative online review, it’s not necessarily a bad thing.

The important thing is to respond correctly to it. “You want to keep it short and simple,” Patel says, “even if it’s the customer’s fault. Some business owners will write long novels going back and forth, arguing with the customer. The best thing you can do is say, ‘Hey, Chris, we’re sorry you had a 1-star experience. Someone from the team is going to reach out right away.’”

If the customer is new and not in your database, Patel suggests leaving a number in the response where the customer can contact you. Not only does it give the angry customer an option, but it shows others who are reading the review that you care.

“A new review reader is going to think, ‘OK, this business owner is doing everything they can to make sure that customer who left a 1-star review is able to get the problem fixed or get a refund or whatever it needs to be.’ It’s very important to do that.”

Patel believes that dry cleaners shouldn’t fear bad reviews because they can serve a bigger purpose: “You can’t impress everyone,” he says. “A balance of reviews makes your business look legitimate.” If there’s a nega-

tive or lukewarm review every now and again, he adds, it makes the reviewing process look more honest than if a cleaner’s reviews were uniformly — and unrealistically — raving.

Patel urges dry cleaners to respond to both negative and positive reviews.

“A lot of people say, ‘Hey, I’ve received a 5-star review — I don’t need to respond back to it,’” he says. “Respond ing to reviews is so important, and it’s simple. ‘Hi, Chris, thank you for the 5-star review! We really appreciate your great feedback.’ It takes 20 seconds to write that out, and it goes a long way as a business owner.”

Besides being the courteous thing to do — showing a re viewer that you took the time to read what they wrote — it also has an impact on the overall visibility of your business.

“Google sees this response as fresh content,” Patel says. “It’s just data that you’re pushing online. Every review that comes in is data, but every response is also data. So, wheth er it’s a 1-, 2-, 3-, 4- or 5-star review, respond to it. Just a few words. Use the customer’s name, use the date they ar rived, and maybe the (name of the) CSR who assisted them. All of this is important because those are keywords that are going to help your business build its reputation.”

efficient gear that made up the other 20%, along with modifications to the building itself, is starting to show a return. “My operating costs from a gas and electric standpoint alone are about 10% to 15% lower,” Simon says.

In his plant, Watkins bought a more efficient boiler and new holding conveyors, as well as updated his computer system. Screw conveyors were installed to make moving the clothes around the plant more efficient. The very shape of the new building also helps with the workflow; the previous location was L-shaped, where the new area is a rectangle and offers more options.

One strategy that Watkins says helped him in the process was getting equipment ahead of time: “I didn’t buy a ton of new stuff, but what I did was buy it ahead of time, before we even built the building. It was sitting, waiting for me, and I got that part of it out of the way.”

As with any big project, there are going to be surprises. While neither Simon nor Watkins expected a full-blown pandemic to strike just as they were getting started, they were prepared for the usual snags that go along with the process and have managed to ride out the rest.

“The biggest surprise was probably the overall cost of having things done, although I think we did it about as well as we could have,” Watkins says. “We saved everywhere you can save, and we still have a nice, pretty building to show for it.”

Making sure the zoning laws are in your favor is crucial, he says.

“You need to read the fine print and make sure where you’re moving can accept the business you have,” Watkins says, “and that you can do it the way you want to.”

Getting inspections can sometimes push a schedule back unexpectedly, as can supply shortages and other factors outside of your control.

“Expect that you’re going to have delays,” Simon says. “Also, if you’re renting now, you’d better build in some flexibility with your landlord into going month to month on your lease once you give notice you’re moving. If something gets delayed, you could be in a lot of trouble.”

Because of the nature of construction — the drywall team can’t come in until the plumbing is complete, for example — a schedule can get out of control quickly if the building owner or general manager of the project isn’t on top of things.

“It’s like a giant jigsaw puzzle,” Simon says, “only you have to put the pieces together in a particular order. You have to put down pieces 43 and 44 before you can put down piece 45.”

Watkins believes that the old construction adage that “everything will take twice as long and cost twice as much” is something those who are building a new facility should take to heart.

When taking on a project like building a plant, having a financial cushion can save you from disaster.

“If you’re contemplating it, I’d make sure I had a bunch of money in my back pocket,” Watkins says. “I was in a decent spot where I made sure I had the funds that I needed so I wouldn’t have to get a second mortgage on my house. Make sure you’re lined up with good creditors and that they can give you some parameters on how lenient they can be or how much space they can give you.

“Let’s say you need to add a different boiler or you need a little more equipment. You need to be able to talk with your lender and make sure that, if something comes up unexpectedly, they will be able to help you out.”

Ilkowitz offers some guidance for those who are seeing the light at the end of the tunnel and want to capitalize on what comes next.

“Give yourself a good understanding of what it is you are hoping to achieve,” he says, “instead of buying things here and there, and then opening the doors and see what happens. You must be prepared for a lot of hard work, but there’s a lot of opportunities.”

Above all, Ilkowitz advises, pay attention to trends.

“If you’re going to build a new plant today, you’ve got to plan for what this generation is going to expect, not what has been happening from 2010 to 2020. You want to build a plant that is going to operate from 2025 through 2050, so try to figure out what that’s going to look like.”

But, while a negative review here and there won’t hurt a business, no dry cleaner wants a customer to leave his or her store angry — and eager to publicly vent about it. One way to avoid this is to offer some sort of messaging system, where customers with issues can let you know about it more privately.

“Use a service that allows your customers to message you and let you know about negative experiences,” Patel says. “A messaging tool is important because this way, it’s not going out online and that you, as a business owner, have the ability to fix an issue before it becomes a problem.”

There are three assets that online reviews can provide to a dry cleaner, Patel says, and those who do not take an active role in gathering reviews risk losing them. They are: Visibility — “You do all these different things,” Patel says. “You Google yourself to check the results. You make sure you’re listed online and that your hours are correct. You have a Google My Business page, a Yelp! page and a Facebook page. When you do all this, you’re

building visibility. In many cases, reviews for a business become visible to consumers before they ever click a link. You show up when someone searches ‘dry cleaners near me.’”

Credibility — Customers like to choose companies with numerous reviews, even if they’re not all 5-star en tries, rather than companies with only a handful to display. “The ability to read real-life experiences about a service will naturally provide a customer with second-hand expe rience, and that gives them valuable insights,” Patel says. He also reminds cleaners that a “perfect” score is not the goal. “Nobody is a perfect cleaner,” he says. “You’re go ing to get negative feedback, and you should embrace it.” While people read negative reviews, they’ll also see if the cleaner responded to them and tried to make things right.

Accessibility — Because online reviews are now incred ibly easy to find, thanks to search engines, mobile apps and review features on platforms such as Facebook, customers looking for information about dry cleaners around them will be able to find you through reviews. “You can’t stop someone from leaving a review on random websites,” Patel says. “It’s going to happen, positive and negative. So, embrace it and accept those reviews. Turn on notifica tions and, when a new review comes in, respond. That’s it. You’re building your reputation.” ADC

• Topics of specific interest to dry cleaners like you

• Engaging industry-specific conversation with an expert

• Business-building tips you won’t find anywhere else

• Convenience of listening anytime, either online or downloading for later

• Information and insight to get a leg up on competitors – give us a listen!

Brian Butler, president of Dublin Cleaners, joins us to discuss how to deal with customer complaints, including ways to train your staff to deal with customer claims, methods to avoid conflict with customers, what to do when conflict is unavoidable, and more.

Jennifer Marquardt, a partner in Arthur’s Executive Cleaners, shares her experiences of adding young adults to her client base — including what they’re looking for, what they expect and what they might not know a cleaner can do.

Tom Zengeler, president of Zengeler Cleaners, discusses the value of charity drives — how to start them, how to operate them and what they can mean for both your community and your cleaning business.

Listen in at: americandrycleaner.com/podcasts

2021 RATES: One- to five-time rate: $2.20 per word, boldface $2.30 per word. Minimum charge: $25.00 per ad. Call or write for our three- and 11-time rates. If box number is used,

add cost of 5 words. Display classified rates are available on request. All major credit cards are accepted. DEADLINE: Ads must be received by the 1st of the preceding month.

For example, for a September ad, the closing date is August 1st.

ADS: Must accompany order.

SPECIAL SALE IN DIFFICULT TIME! $1000.00 > > > $750.00/Refurbished, $2000.00 > > > $1450.00/New System Includes Computer, Touch Monitor, Invoice Printer, Cash Drawer. All Name Brands & One Year Warranty! www.westerndccomputer.com 773-878-0150, westernk@msn.com

WEAVERS — More than 60 years’ experience. We are the experts in silks, knits, French weav ing and piece weaving. Reasonable prices. Send garments for estimate to: 3344 W. Bryn Mawr, Chicago, IL 60659; 800-475-4922; www.withoutatrace.com.

LEATHER-RICH INC.

• High-quality cleaning, refinishing & repair Leather, Suede and Fur; • Free Inbound Shipping in USA FOR MORE INFORMATION: www.leatherrich.com E-mail: leatherrich@att.net Call 800-236-6996 Route Service in Upper Midwest

2021 RATES: One- to five-time rate: $2.20 per word, boldface $2.30 per word. Minimum charge: $25.00 per ad. Call or write for our three- and 11-time rates. If box number is used, add cost of 5 words. Display classified rates are available on request. All major credit cards are accepted. DEADLINE: Ads must be received by the 1st of the preceding month. For example, for a June ad, the closing date is May 1st.

10 YEARS AGO. Slow to Recover —

Although indicators showed that the U.S. economy was growing again in 2009 after the recession of the previous year, many dry cleaners were unconvinced, according to an American Drycleaner survey. Asked whether they thought a generalized economic recovery had begun, almost half (47.3%) said “No.” About 29% answered “Yes” and 24.2% reported that they weren’t sure. When asked if dry cleaning is experiencing or will soon experience renewed demand, 45.1% said “No,” 31.9% said “Not sure,” and only 23.1% answered “Yes.” “About 95% of clothing on the market is wash-andwear,” one operator said. “I see a very dim future for the industry due to this fact.”

25 YEARS AGO. The Olympic Spirit Cleaners across the country provided drycleaning and laundry services to the 150 staff members along the 15,000-mile route of the 1996 Olympic Torch Relay as it made its way to Atlanta. The IFI coordinated the volunteer effort for the 84-day event. “This donated service is just another way to show the world the dedication of IFI and its members to the community, the state and the international spirit of the Olympic Games,” said Bill Fisher, IFI’s executive vice president.

50 YEARS

The 62nd annual National Institute of Drycleaning (NID)/American Institute of Laundering (AIL) Interna-

tional Convention welcomed recordbreaking, standing-room-only crowds, with 11,386 dry cleaners and laundry professionals registering for the Las Vegas event. Among other activities were four diversification workshops: “Career Apparel for Uniform Rental,” “Drapery Selling-Leasing-Cleaning,” “Coinop Cleaning & Laundry” and “Upholstery and on-location Carpet Cleaning.” The “See the Sun in ’71” convention offered “refreshing optimism,” the description read, “pervading the drycleaner-conventioneers as they flooded the mammoth exhibition hall, and many were in a buying mood.”

85 YEARS AGO. Ad of the Month — American Drycleaner awarded five plants membership into its “Ad of the Month” Club in May 1936, with Blair’s of Youngstown, Ohio, taking the top spot (pictured above). “The layout achieves a new high in mechanical perfection,” said the ad description. “The headings are as bold as headings on a poster, but are refined sufficiently against a background that gives the impression of being ‘texturized.’” Blair’s had also taken the top ad prize two months earlier.

—Compiled by Dave Davis, Editor

—Compiled by Dave Davis, Editor

Productshaveproventolastupto10timeslongerthansimilarproductioninthisindustryandapplications.

Wehavemanyinstallationswithsteamboilersthathave beeninserviceforover50-years,10hoursperday.

Thematerialsusedincurrentproductsarebetterthanthe materialsused50yearsago.Forexample,inthe80’s,steam drumwentfrom3/8”thickto1/2”thick.

Ourheatingsurfaceoramountofsteelabsorbingenergy hasalwaysbeen2to3timesthatofotherunits(upto6sf ofheatingsurfaceperboilerhorsepower,whichsomeunits arecloserto2sfofsteelperhp,andsomeeven1sf).

Wehavethebestdistributedflameormostevensurface areaevenlydistributedundertheentirepressurevessel.It isalsoamodulardesign,soitcanberepairedeasily.

TubeswentfromSeamlessratedpipetoseamlessrated tubingwhichisnowannealedwhichgivesthemateriala millscalecoatingforlongerlastingandless corrosionresistance.

Thicknesswentfrom.133pipewith10percentunderto.12 with10%over,andisalways.133walltubing.

Maximized Sustainability.

Maximized Sustainability.

TESTED AND PROVEN

TESTED AND PROVEN

GreenEarth formed in 1999 to assist an environmentally challenged industry in moving forward

GreenEarth formed in 1999 to assist an environmentally challenged industry in moving forward

During our first 12 years, several perc alternatives made unsupported environmental claims

During our first 12 years, several perc alternatives made unsupported environmental claims

In 2011, the Canadian Minister of the Environment published an 83 page report

In 2011, the Canadian Minister of the Environment published an 83 page report

Its conclusion: GreenEarth is “non-toxic to the environment and its biodiversity”

Its conclusion: GreenEarth is “non-toxic to the environment and its biodiversity”

Since the 2011 report, cleaners, property owners, retailers, and financial institutions have relied on GreenEarth as the unquestioned leader in meeting corporate environmental, safety, and governance (ESG) goals.

Since the 2011 report, cleaners, property owners, retailers, and financial institutions have relied on GreenEarth as the unquestioned leader in meeting corporate environmental, safety, and governance (ESG) goals.

CANADIAN ENVIRONMENTAL PROTECTION ACT, 1999 REPORT OF THE BOARD OF REVIEW FOR DECAMETHYLCYCLOPENTASILOXANE (SILOXANE D5)

CANADIAN ENVIRONMENTAL PROTECTION ACT, 1999 REPORT OF THE BOARD OF REVIEW FOR DECAMETHYLCYCLOPENTASILOXANE (SILOXANE D5)

www.greenearthcleaning.com/CAN-Study

www.greenearthcleaning.com/CAN-Study