Our products and market diversity make us unique. Learn more at poseidontextilecare.com.

poseidontextilecare.com (800) 256-1073

July 2021

Vol. 88, No. 4

Whether a drycleaning business is to be passed down to a younger generation or sold as a cleaner retires, the key to a successful transfer lies in putting in the groundwork long before it’s time to make a change.

Cleaning a customer’s garments and textiles is only the start of the drycleaning process. We examine the skills and philosophy successful cleaners need when it comes to ironing, pressing and buck operation in the finishing process.

Customers expect to have a consistent, positive experience every time they come into your store and interact with your sta . How can you guarantee this will happen? Communication is the key.

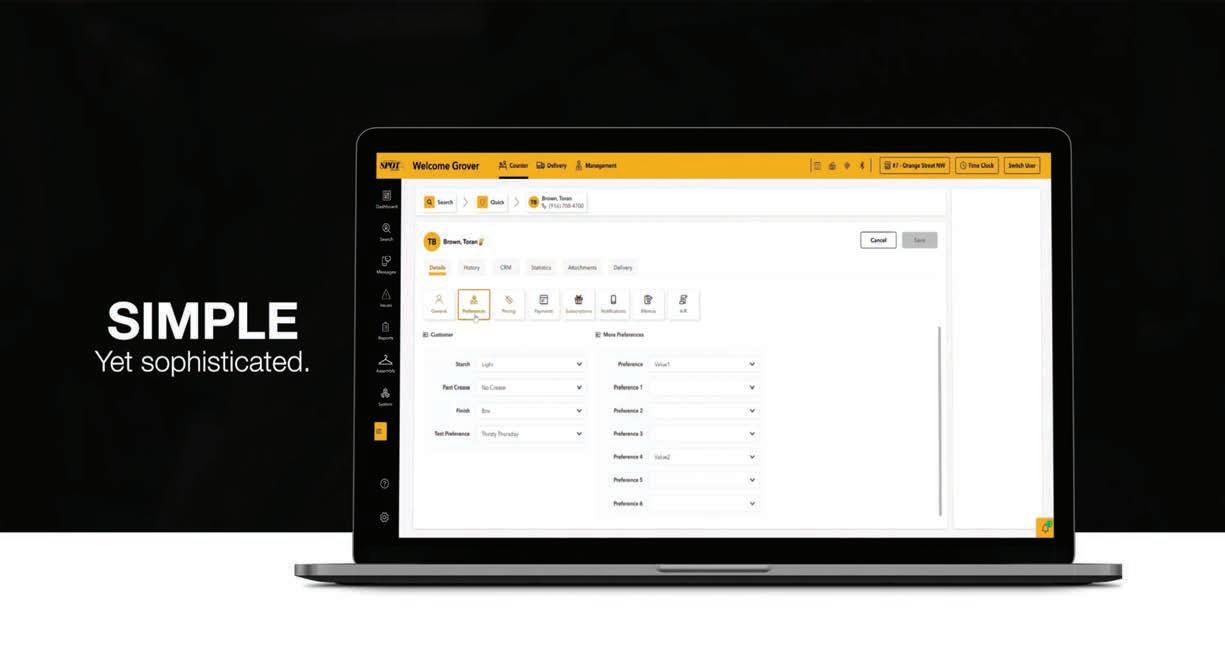

Our feature-rich software will help you run all aspects of your business more e ectively. CBS includes solutions for full service cleaners, delivery & route services, racking integrations, prepay/post pay, and two-way customer messaging; all features used across the dry-cleaning industry. Ask us about more features!

Our support team is a group of dedicated professionals based in the US that takes pride in taking care of customers without making them wait. We’ve been independently owned and operated for over 20 years, o ering you the long-term trust and support you need!

When running a drycleaning business for any length of time — especially if it has been in the family for generations — there’s a constant tension between the past and the future.

On the one hand, “the way we’ve always done it” has gotten us this far. If we — or those who came before us — hadn’t made good decisions in the past, we wouldn’t have a business to operate today. On the other hand, changing with the times is necessary to serve today’s customers, and if there’s one thing 2020 taught us, it’s that change is not optional — it’s mandatory.

Each of our features this month deals with the lessons of the past — consistency, loyalty and service — while keeping an eye on customers’ changing needs and demands.

In the first feature of this issue, “Sales & Succession Planning,” we’ll take a look at two drycleaning companies — one in its fourth generation and the other in its fifth — that have found a balance between what’s come before and what is yet to come. We’ll also examine the process that goes into handing down or selling a drycleaning company when the time comes to turn over the keys.

For our second feature, “Hot Irons,” we’re going to go back into the plant to see the role that irons, presses and bucks play in finishing during the cleaning process, and how they contribute to keeping today’s customers coming back tomorrow.

Our final feature, “What Do They Expect?” examines the role of consistency in creating customer loyalty. Cleaners who pay attention to the importance of communicating with their team will provide them with the tools they need to serve customers better — and build goodwill for the future.

Also in this issue, we’ve got the results of our latest “Your Views” survey. We’ve asked our readership how their businesses are performing at this moment, and about their outlook for the coming year and beyond as we emerge from the pandemic.

Publisher

Charles Thompson

312-361-1680 cthompson@ATMags.com

Associate Publisher/ National Sales Director

Donald Feinstein 312-361-1682 dfeinstein@ATMags.com

Editorial Director

Bruce Beggs 312-361-1683 bbeggs@ATMags.com

Editor Dave Davis 312-361-1685 ddavis@ATMags.com

Digital Media Director

312-361-1681 nfrerichs@ATMags.com

The past has its lessons, and we should heed them, but the future is where we’ll be living. By balancing both, we’ll find our way forward.

ADC

American Drycleaner (ISSN 0002-8258) is published monthly except Nov/Dec combined. Subscription prices, payment in advance: U.S., 1 year $46.00; 2 years $92.00. Foreign, 1 year $109.00; 2 years $218.00. Single copies $9.00 for U.S., $18.00 for all other countries. Published by American Trade Magazines LLC, 650 West Lake Street, Suite 320, Chicago, IL 60661. Periodicals postage paid at Chicago, IL and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Drycleaner, Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 88, number 4. Editorial, executive and advertising offices are at 650 West Lake Street, Suite 320, Chicago, IL 60661. Charles Thompson, President and Publisher. American Drycleaner is distributed selectively to: qualified dry cleaning plants and distributors in the United States. The publisher reserves the right to reject any advertising for any reason.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2021. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Drycleaner does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Drycleaner or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

Based on the results of our latest American Drycleaner “Your Views” survey, the industry is cautiously optimistic — emphasis on the word “cautiously” — about what’s to come for the remainder of 2021 and beyond.

The prospect of people going back to work, children returning to school, recreational and societal functions returing and, yes, less competition in the drycleaning industry has our readership seeing good things in the future.

When asked how they would describe their business activity, 50% have seen “a definite uptick” in recent weeks. A little more than a third (37.5%) said they were “starting to see some old faces return,” while approximately 7% said things were remaining “as flat as they were last year.”

At the extremes, 4.5% said that “business was booming,” while 1% said business was “continuing to decline.”

Our survey also asked, “What steps have you taken to adapt your business to changing conditions in 2020-21?”

The answers included:

• “Looking for more stable revenue streams. Hospital work and Airbnb have been a huge help.”

• “Pumped up marketing — especially social media.”

• “Step up staff training, relate more with clients and reduce overhead.”

When asked if they believed their business was better positioned for the future than at the beginning of 2020, the answers were spread evenly across the board, with 20% responding “Absolutely — we’ve learned valuable lessons and put them to work,” and a third saying they have “seen what works and what doesn’t.” A little more than a quarter (26.4%) said “it’s impossible to predict the future,” and 21% felt that they were still in “survival mode.”

The outlook was rosier when our dry cleaners were asked what they were expecting in the second half of 2021 and beyond, with 45% replying that they are anticipating “increased business and a brighter 2022,” and 41.7% hoping for “slightly better days.” On the edges, 7% expected “great things,” while 2.8% each were predicting “more of the same” or “a continued slide.”

No matter what the future holds, many of our respondents are going to be taking valuable lessons with them. “Life is uncertain,” one says. “Digital is the way to go in advertising and communication.”

“It’s important to know your numbers,” another cleaner replies. “We need to market differently as the drycleaning

Businessisbooming! There’sa definiteuptick.We’restartingtosee someoldfacesreturn.Thingsremainasflat astheywerelastyear.Businessis continuingtodecline.

business is changing — we need to adapt.”

Being forced to change can sometimes be a good thing, one respondent says. “Probably the biggest advantage was having to completely restructure our business. It gave us an opportunity to change or alter processes. It also allowed us to easily raise prices without negative customer feedback.”

The “Your Views” survey offers a current snapshot of the trade audience’s views. The publication invites qualified subscribers to American Drycleaner emails to participate anonymously in the unscientific poll each quarter.

Alot of skill and expertise goes into cleaning garments, removing stains and refreshing the fabric. Just as important, however, are the finishing touches at the end of the process. Without skilled and attentive pressers and buck operators, the final product just doesn’t look finished and the customer probably won’t be satisfied.

To explore the importance of this critical process, American Drycleaner reached out to four industry professionals to get their views — Carlyn Parker, director of operations at Dependable Cleaners in Boston; David Grippi, chief operating officer of Clean Franchise Brands; Sasha Ablitt, owner of Ablitt’s Fine Cleaners in Santa Barbara, California; and Jim Desjardins, president of Daisy Cleaners in Salem, New Hampshire.

We wanted to learn how these dry cleaners approached pressing, buck operation and the finishing process in general, both from the day-to-day viewpoint and from a philosophical perspective.

Q: Describe the function of ironing and buck operations as it relates to the entire cleaning process. How important is it to the finished product?

Ablitt: That’s an interesting question because if you

As business shifted during the pandemic, the 10-foot-long Chicago® flatwork ironer at Ablitt’s Fine Cleaners in Santa Barbara, California, saw its workload increase. “They don’t make them that large anymore. The thing just runs and runs,” says owner Sasha Ablitt. “Nobody in town can match the quality of my sheets.” (Photo: Ablitt’s Fine Cleaners)

have a lot of stains on your clothes, people are not going to be happy. But finishing is kind of like the icing on the cake — without it, you really don’t have a product. I would say it’s equally important as the actual cleaning function. If your product doesn’t look good on the way out the door, you’re not going to have a return customer.

Desjardins: Well, I think that it’s as important as cleaning the garment. If you don’t give me back something that’s pressed correctly, then why bother doing the job?

Parker: We feel that stain removal and pressing are the two keys for success with our clients. If you can take all the stains out, but if you don’t press it well, they still look wrinkled. You can press it well, but if you don’t take all the stains out, the garments still look a mess because they have a stain on their garment. These are the two biggest things we do every day to get people to look their best.

Grippi: I think technology has really changed in the business. New detergents have special retexturing agents that help in the finishing process, and the way the clothes are cleaned and processed today is very different. Clothes cleaned in hydrocarbon or GreenEarth are a lot softer and easier to finish, versus the days when things

Q: How has the process changed since you first started in the drycleaning business?

were cleaned in perc. They came out very hard, rough and staticky.

Parker: Technology really hasn’t changed efficiency. It’s changed quality. For instance, now you have pants toppers that have a clamp at the bottom of the leg. It helps to steam out the pants better, so they press easier. The quality of shirts coming off the buck is better than it ever was previously.

Ablitt: The technology has gotten much better, from the auto baggers to the automated assembly and even the presses. The easiest presses now are the bucks for the shirts — because of all the technology and the programs, you can pretty much train anyone on them at this point. So that’s wonderful. It does make it a little more challenging, though, when things go wrong; it’s a lot harder to replace a computer board.

Q: How does ironing and other finishing processes change for non-clothing items? Has this process changed in recent years?

Parker: We’ve pivoted to finishing a lot of linen tablecloths. We used to send those out, but we now are doing them in-house. We had to get new pressing equipment that we didn’t have before. We had gotten it right before the pandemic started, so we were already headed in that direction.

Ablitt: I was blessed with an old Chicago ironer. It’s huge — about 10 feet across. They don’t make them that large anymore, and it’s built like a Mack Truck. The thing just runs and runs. It’s completely mechanical and has such a large-diameter drum; nobody in town can match the quality of my sheets.

Pressing and buck operations are crucial to the quality of the final product going out to the customer. “… finishing is kind of like the icing on the cake — without it, you really don’t have a product,” says Sasha Ablitt, owner of Ablitt’s Fine Cleaners in Santa Barbara, California. “I would say it’s equally important as the actual cleaning function.” (Photo: Ablitt’s Fine Cleaners)

The way we mark in the sheets and assemble them has changed, but that finishing piece has stayed exactly the same because that press provides me with such tremendous quality. While other technology has gone forward quite a bit, the way we press the sheets has stayed the same. I researched different ways, taking into account energy savings and gas savings, but the trade-off doesn’t seem worth it.

Q: What is your inspection process, both before the finishing process starts and after finishing? What does your staff look for, and how does the process work?

Ablitt: One of our philosophies is that everybody’s an inspector. Starting at mark-in, they sort for pre-spotting. After that, we have tall, small pant horses, where they put the stained garments on to do pre-spotting. And then, of course, the dry cleaner does the post-spotting when he hangs the clothes after cleaning. Then, the clothes go to the finishers, who all have red tape around so that if they find any stains, they can send it forward to alert the inspector. We do have a dedicated inspector who is also looking for stains.

Grippi: That’s a great question because I think sometimes we lose that inspection process, and it’s very important. With the inspection process, when you’re hanging a garment out of the drycleaning machine or the

There’s more: We’re just two members of NIE’s team of experts. NIE has been handling fabricare insurance since 1915!

Many business owners with children dream they will one day step aside and let the next generation take control. At that point, the business becomes more than just an occupation; it becomes a legacy. Dry cleaning has a rich tradition of multi-generational ownership. But, whether the business is to be handed over to family or is to be sold as the cleaner retires, the key to a successful transfer — and the company’s very survival — lies in putting in the groundwork long before it’s time to make a change.

Balfurd Dry Cleaners is a family-owned business that started serving the State College, Pennsylvania, area 94 years ago, and Monika Manter, the company’s vice president, represents its fourth generation. She officially started working for her father, Bob Fogelsanger, in 2011. “I was working as a school guidance counselor and

moved back to town, you know, ‘temporarily’ and took a position as a customer service representative,” she says. Manter worked her way up through service and marketing areas of the business. After her grandfather, Scott Fogelsanger, died in 2014, she took the position as vice president a year later.

Manter’s relationship with Balfurd goes back much further, though: “As a child, on Saturday mornings, Dad would go in and do inventory at our plant. I used to bring my roller skates, because there is no better place to skate than a drycleaning facility when nobody’s working.”

Manter didn’t see herself stepping into the business, however, having gone to graduate school to prepare for a career in guidance counseling.

“As a child growing up in a family business, you see the stress and the amount of time your family puts in that business,” she says. “And, as a dumb kid, I thought, ‘Oh, man, I want to do something easier.’”

While she enjoyed her work as a counselor, seeing the drycleaning business as an adult opened her eyes to a new reality.

“After I got married, my husband and I decided to move back to State College,” she says. “A few months into working at the store, I tagged along with my dad to a cost group meeting and heard those owners and their elevated talk about their business challenges and how they’re innovating. I just realized that this is about so much more than pressing shirts. That is what really got me hooked into wanting to be in the business permanently.”

Although she changed her career path, Manter believes her previous counseling training still serves her well.

“I’m a personality test junkie, and I want to make an effort to understand myself and everybody around me,” she says. “I want to understand the best way people take feedback. And I think great leaders are able to capitalize on things they’re good at, and then improve or outsource other areas.”

For French Cleaners in West Hartford, Connecticut, the 110-year-old business hasn’t been handed down the bloodline for the last couple of generations — it’s being passed down from son-in-law to son-in-law. Since 2016, Mark Hatch, manager of the company, has been working in the business with his father-in-law, Phil Cote, who bought the business from his own father-in-law, Mickey Gassner, in 2000.

Hatch married Cote’s daughter, Elyse, in 2012. At the time, Hatch was working in process engineering and R&D for Mars Petcare and later Mars Chocolate. “I’ve had a crazy career history,” he says. “I made M&Ms, and before that, I made pet food.” When they married and began thinking about raising a family, Hatch started to reconsider his career, which had him on the road about 50% of the time.

“I had always joked with Phil, telling him I would go into the cleaners when I retire,” he says. “But then I started thinking, ‘Well, that’s stupid — I should go work for him now.’”

Cote was receptive to Hatch’s change of heart.

“I spoke with Phil and said, ‘You should teach me everything you know. I’d rather work hard for you and help pay you and the family back rather than work for another company,’” Hatch says. “We were fishing in Florida when I floated this to him, and he said, ‘All right, sounds good. Come in on Monday.’ I told my boss at that time that I was quitting because I got an offer I can’t refuse.”

In the beginning, Hatch spent much of his time shadowing Cote, learning the business from his perspective, and then shadowing people in various departments.

“I would talk to the pressers, watching them do their job all day, just trying to get totally immersed,” he says. “This business is the polar opposite of where I came from. When you go from a 10,000-person corporation to a 20-person drycleaning company, the pace is different.”

Because Cote had lost a production manager just before Hatch joined the company, that role became a natural starting point as he started to show his son-in-law the ropes. “I focused on production — what can we do to optimize the plant? — and worked in that area early on to get the know-how and see how things operated,” he says. Hatch then started to work on the front counter and the customer-facing side of the business, and then moved to the general administration aspects.

“I’m still picking up things every day, and learning a lot,” he says.

While Hatch was new to the drycleaning business, some experiences from his youth came in handy: “I was raised on an orchard in Ohio, so I grew up in a family business. A lot of this stuff feels natural to me.”

Hatch also brought some of the skills he learned from the corporate world with him.

“I worked in an R&D role, trialing new products, and a lot of my job was generating buy-in from the plant to let us do new things,” he says. “I was always convincing operators who had been there 20 years to try crazy stuff on their machines. So, I gained a lot of influencing skills in my old role, and that’s been monumental. It’s hard to gain trust and generate rapport with people who have been here forever and might see me as an outsider, so that’s definitely helped.”

The path to succession has been gradual for Manter, which she believes benefits everyone involved.

“We still haven’t completely transitioned over,” she says. “Over the last few years, we’ve been transferring ownership. My dad is still slightly the majority owner of the company, but he’s only involved on a very high level. We do have a succession plan in place, with that happening in the next few years.”

Manter says she’s in no hurry to speed the transition because the path they’re on will only make better leaders.

“This slow transition has helped both me and my husband, Dave, who also is involved in the business as our director of operations,” she says. “We’ve been able to make progressively bigger and bigger decisions, really build our confidence and it’s allowed us to make mistakes and figure things out. It’s been helpful that it wasn’t just a flip of a switch.”

Things are similar at French Cleaners. While the transition is underway, Cote still plays an active role in the

company. “He’s involved in the day-to-day operations,” Hatch says. “He’s just gradually doing less. We talk each day, and we share an office. We network, check on things together and teach each other things.”

Both Hatch and Manter are anomalies when it comes to multi-generational businesses.

A 2010 study done by Bloomberg Businessweek found that the average life span for a U.S. family-owned business is 24 years. The study went on to find that approximately 40% of such businesses transition to the second generation, about 13% are successfully passed to the third and only 3% go on to the fourth generation and beyond.

For a family business to survive when the next generation takes the reins, Richard Ehrenreich, principal drycleaning consultant and business broker for Washington, D.C.-based Ehrenreich & Associates LLC, suggests making an honest evaluation.

“You’ve got to make sure that they just don’t feel entitled,” he says. “They’re going to need to do the work — to do what they need to do to run the business and stay focused.”

Ehrenreich, who specializes in drycleaner exit strategies and succession planning, recommends introducing children to the family business at an early age. Even if they don’t go into it directly out of high school or college, it’s still a good investment of time and effort.

“They can get out in the world, make their mistakes somewhere else, and then you bring them back,” he says. “They’ll have more ability to manage, and you can retrain them on the business.”

When selling or passing down a business, Ehrenreich recommends building a team to get the best value for everyone involved.

French Cleaners, located in West Hartford, Connecticut, is a rare instance of a familyowned company being passed through five generations — and possibly beyond.

Pictured from front left is Roz Gassner, wife of the late third-generation owner Mickey Gassner; Susan Cote, daughter of Mickey and Roz Gassner and wife of fourthgeneration owner Phil Cote, at right. On the back row, left, is Elyse Hatch, daughter of Phil and Susan Cote, and wife of fifth-generation manager Mark Hatch. Their sons, Camden, center, and Trey (not pictured) could one day form the company’s sixth generation. (Photo: French Cleaners)

“You need a broker — one who knows about dry cleaning — who’s going to be the team leader,” he says. “The broker will work with a CPA tax attorney; an accountant; a business accountant who knows how the state’s laws work, knows how to properly do documentation and possibly has some environmental experience; an environmental consultant; your lender and perhaps a commercial real estate agent. Also, obviously, the seller. The broker is going to be the orchestra leader, with all these people playing their own instrument.”

Ehrenreich also believes that selecting the right broker is one of the most important decisions a dry cleaner can make when selling his or her business.

“So many business brokers work quantity rather than quality,” he says. “They take 30 or more listings, throw them at the sky, and whatever sticks, they jump on. You want someone with a small number of clients, and who has a good reputation among those clients.”

It’s essential, Ehrenreich says, to find multiple potential buyers for a business if selling outside of the family.

“If you’ve only got one buyer, you don’t have anything,” he says. “There will be no negotiation because they’ve got a chokehold on you. You need to have other buyers or at least the perception of other buyers.”

Getting a proper valuation of the business can sometimes be difficult, because the owner’s emotions can quickly become entangled in the discussion. After all, the business has usually been a big part of their life and the lives of their family. Still, while it can be difficult to put a price tag on a business, it’s a step that needs to be taken.

Another difficulty Ehrenreich has often run into is that, for tax purposes, many small-business owners often want to minimize the profit they show during the year. He

calls this practice “living out of your business.” This creative accounting can come back to haunt the owner when it comes time to sell.

“(During the evaluation), we take what the CPA comes up with at the end of the year as the profit, and we build upon that,” he says. “We have to have the confidence of the owner to be able to sit down with them and find out where all those little perks are. Maybe all of his kids have cell phones and cars, for instance. It all comes back to the bottom line.”

Also, when contemplating selling a business, Ehrenreich believes that things should be on a “need to know” basis in the beginning to avoid rumors and worries becoming real problems.

“You don’t want your landlord to know, and you don’t want your big accounts to know,” he says. “That can really hurt you.”

When it comes to the team, Ehrenreich has seen that fear can become a self-fulfilling prophecy if the owner is not careful.

“You want to be honest with your employees, but selling a business is complicated enough,” he says. “You don’t want 30 employees being part of the plan, asking questions and getting scared. They might start looking for other jobs, and if enough of them jump ship, you

won’t have a ship to sail. Don’t make it more complicated than it already is.”

There’s a distinct advantage when it comes to passing down a drycleaning business rather than putting it out on the open market — especially given the state of the economy in the past few years.

“You’re dealing with someone you know,” Ehrenreich says. “When you go out to sell your business, you are competing with every other business in your town and region. You’re looking for someone who is going to invest their money, and you’ve got to be able to present yourself better than every other business.”

When passing the business to the next generation, Ehrenreich says this transaction can be more personal.

“When you’re going into a succession, hopefully, you’re training somebody from a young age,” he says, “and you’re going to be able to keep your corporate culture and continuity, which is important for your staff and your customers.”

When it comes to being a multi-generational business, Manter believes there is a clear benefit: The process of transferring control isn’t an alien concept.

“Being a fourth-generation business, my dad and my grandfather have always done a great job with think-

ing about succession,” she says. “What that looks like, what they’ll need and how to make sure it doesn’t negatively affect the business.”

Having that succession plan in place is crucial to multi-generational success, Manter says — even if it might make for some difficult decisions.

“Our family has an unpopular belief that you need to choose one child to be the boss,” she says, “and I know that’s hard for businesses that have multiple kids involved. My grandfather had seven kids, though, and he left 100% of the business to my dad. He had seen other businesses implode when siblings were partners.”

Fortunately, that choice didn’t come into play when it was Manter’s turn to step up.

“I have an older sister who worked for a short time in the business and decided that it wasn’t for her,” she says. “She has a different career now.”

Manter believes the only way a business survives long enough to be passed to a fourth generation and beyond is if it is flexible and can adapt to changing conditions.

“I’m in a fortunate position that all three of the generations before me were forward thinkers,” she says. “Our business started in the 1920s as a small tailoring and pressing shop, and each generation continued to add services, and the business evolved based on our customers’ needs and wants.”

Manter’s father and grandfather added a linen rental service — which now makes up the bulk of Balfurd’s business — after seeing a home drycleaning machine at a trade show in the 1960s. While the machine never made a dent in the industry, that willingness to change the business model was baked into the company’s DNA.

“They brainstormed and came up with the linen service division because they wanted to stay in business — even if that business was different from what they were doing at the time,” Manter says.

Manter found that the mindset of trying new things was a gift when the pandemic hit.

“We always say that we’re going to try some things, and we’ll hit some homers, and we’ll have some strikeouts,” she says. “We follow the philosophy of ‘creative destruction,’ where you can’t be so emotionally tied to how you do business today, or your business will be obsolete. Once you stop providing value, that’s the end of your business.”

Ehrenreich shares the opinion that it’s also not enough to just keep doing what the prior generation did.

“A good family business is like an airplane,” he says. “If you don’t keep flying, you’re going to crash. Businesses have to keep growing, looking for different markets and finding ways to do things in a more productive manner.”

American Drycleaner, July 2021

Part of the evolution at Balfurd is that, as the company grew — it now has about 130 employees — the role of leadership had to change.

“My grandfather, up to the time he passed, was working 80 hours a week,” Manter says. “He just loved being at work. As he came up, we were a much smaller company, so he had to be involved with everything because we didn’t have a lot of managers.”

As Manter’s father took his place, he found that “hands-on” management had its limits.

“Dad saw the importance of surrounding himself with strong managers,” she says. “I started very hands-on, but in the last few years, I’ve tried to remove myself from the day-to-day things. Our company has just gotten too big, and I would be putting out fires all day long. That’s just not a great use of my time.”

To fight the temptation to get involved in every facet of the business, Manter moved her office out of Balfurd’s main facility and into a drop store.

“That allowed me to remove myself,” she says. “It’s given me a lot of freedom to work on strategy and special projects, and think how we can make some big changes to our business.”

In order to successfully lead a company across the decades and generations, its leadership has to learn the lessons of the past while keeping an eye on the future.

Hatch is grateful for the latitude his father-in-law has allowed him to have as he learns the business — even if the learning curve is sometimes painful.

“For me, one of the biggest things that Phil has done was to give me a lot of freedom in my decisions — even at times where he’s probably been through the same process, made a decision, made the mistake and then found a way through it. It’s easy for an owner to restrict movement and the decision-making process, so Phil has been great and kind of let me live through that.”

Hatch appreciates that there’s still a safety net, though. “Obviously, he’ll protect me if I’m going to make a catastrophic decision,” he says, “but for small stuff, like how you approach specific activities, how you schedule something or where you want to spend your money on marketing, I’m able to make decisions. We always talk about it.”

Hatch believes that, since Cote was once “the new guy,” he understands what his son-in-law is experiencing.

“He’s been through the same process, and so he empathizes,” he says. “I think he’s made a conscious decision to just give me freedom. And it’s been helpful. I think I’m learning faster because I have that freedom.”

Manter agrees with the idea that taking a step back gives the next generation room to grow.

“Don’t micromanage their every move,” she says. “Let that next generation make some mistakes. Give them small projects at first to build their confidence.”

While the work is hard and the hours are long, Hatch and Manter appreciate the opportunity they’ve been given to join — and eventually lead — the family business, as well as the choices their predecessors made.

“I’m thankful for the time and effort that Phil and the past generations put into this place,” Hatch says. “I’m grateful for their entrepreneurial mindset. The last 110 years that French has been around, people have been brazen enough to do the right thing.”

He’s not the only one who has a multi-generational perspective when it comes to French Cleaners, he adds.

“The customers who come in love this place,” he says. “Their grandparents came in and got their wedding gown done here. Then, their daughter got their wedding gown done here. I’m grateful for what they’ve done and those relationships they’ve made. They built a great business.”

Manter shares that gratitude for the generations that came before.

“I am so grateful that my father and grandfather diversified the business,” she says. “Like everybody else, we

were hit hard by the pandemic, but having such a diversified business, I think we’re coming out of this in a much better position than most people. I look at my dad and my grandfather, and they took some big risks. I appreciate they had the courage and vision to expand our business, and it has paid off.”

Both Manter and Hatch have children, so there is the potential for fifth- and sixth-generational leadership at their respective companies.

“I have three small kids,” Manter says, “and, if it’s something they want to do, that’s great. And if not, that’s OK, too. You know, for me, it just needs to be something that fits into what they love, or else the stress of running won’t be worth it. So, it needs to be something they’re passionate about doing.”

“We have a 3-year-old son, Camden, and a 1-year-old son, Trey,” Hatch says, “and I always joke that we have a pants presser and a tailor coming up the ranks. They’re young, obviously, but they’re going to be working here during school, for sure. We’ll see how their development progresses and what they’ll want to do. I know I have no control over that, but I’m planning on it being available to them if someday they’d be interested.” ADC

dryer, you want to make sure that the clothes are hung on the hanger correctly. Make sure that the pockets are put back in place if they’re out of place, for instance, because when it gets to the presser, it makes it easier for them to finish. If you’re folding the garment over a hanger — or throwing them on a hanger — they’re just sitting there getting squished and the wrinkles get stuck.

After the garments have finished, you want to look at each piece, and especially the ones that really stand out. On suit coats, for example, the lapels should be nice and rolled. Always check pants to make sure you have only one crease and they’re not double-creased. And make sure you’re checking for loose threads for loose buttons. That’s all part of the finishing process.

Parker: Both processes are pretty much the same. On the first inspection, you’re looking for any stains, rips, tears or anything on the piece that doesn’t look right. And then post-pressing, the finishing inspection is all about making it look perfect for your clients. So, it’s looking for those same things, but also looking at the quality of the pressing.

Q:

Grippi: One of the things that we try to train the new operators on is how the equipment works, and what each piece and each activity of the press does — what the bottom steam does, what the top steam does, how the vacuum works, and so on. We also give them some background training so that the pressers know the difference between finishing a cotton garment, a linen, something that has acetate or something with a pile fabric, like wool or an angora sweater.

Parker: It’s one-on-one training with another presser, and they get on to the press by the end of the day. They do only a few garments during the first couple days, but they’re doing it. And then, within 30 days or so, they’re up to just about the minimum pieces that we want them to do — the minimum efficiencies. Since we pay by the piece, they’re incentivized because the faster they get up to quality and piecework, the more they can make.

Ablitt: Typically, the manager will do the safety training on the equipment first, and then the basic training. We always start people on the simplest equipment. Usually, new finishers are going to start on the shirt buck because, as I mentioned, that’s the easiest one for people to learn, and it gives them a good feel for what it’s like to work in the plant — it’s really like a factory in the back of the cleaners.

Once they get the hang of production flow, speed, and just general equipment usage and safety, we have a mentor for them — I like to train all my people in leadership

skills, and I want them to think of themselves as coaches. We have about a two-month process, which may seem a little long, but I feel like giving them a good period of time really helps.

Q: Do you cross-train your staff to work different machines in the process?

Parker: We cross-train a lot of people in inspection and pressing. They’ll learn to press first, and then, if they have some downtime waiting for work to come in, they can do wash-dry-fold, or fold up the comforters and put them in the bags or inspect clothes — those types of things. We also like to have training on pressing different kinds of garments; if you can press silks, we’d like you to be able to press pants and vice versa. That was a key during the pandemic. At the very beginning, we called in more people who could do multiple jobs because we didn’t have enough work to have somebody just press pants for three hours.

Ablitt: Our staff is completely cross-trained so everyone is constantly learning how to press everything. After shirts, we move them to sweaters and pants, and go all the way through to silks and linens. Linens can take a long time if someone doesn’t have the right training. We want everyone to learn everything.

Grippi: Cross-training is more important than ever before. Finding an experienced presser is more difficult today than it was five years ago. It’s important to crosstrain everyone on not only your presses but having your inspection people be able to press different garments. It makes your plant more flexible, helps cover for days off, and allows you to cover if you lose someone.

Q: What are some skills that a good finisher has? What can be taught, and what characteristics should the person innately possess?

Desjardins: You need someone who’s detail-oriented. I like to look at the car they’re driving; if they’re driving something filthy, they’re likely not going to make a good presser.

Grippi: Good hand-eye coordination is something that we look for — someone who can move things quickly from one point to the next. We also want someone who has attention to detail because we want to make sure we’re finishing these garments correctly and that they’re not rushing to the process. We want people with a good work ethic, and who don’t mind being on their feet for a long period of time. They should be able to work in an environment that can sometimes be hot, and I look for someone who is upbeat and friendly.

Parker: Attention to detail and hand-eye coordination are crucial. They also need to like routine and have a good focus. They’re systematic, and they should under-

What kind of training do you give to someone new to ironing and buck operations?

stand a little bit about the mechanics of how the press works, and how they can use that to their favor.

Ablitt: We tend to hire people who haven’t worked in production at other cleaners because we find they come in with bad habits. We also hire for attitude. Are they going to show up to work? Are they going to show up on time? Are they going to communicate with us? You can train for that a little bit, but a lot of it is innate. But the No. 1 thing I’ve found is that the naturally detail-oriented person makes for a much better presser.

Q: Describe your philosophy of finishing — what part does it play in overall customer satisfaction?

Grippi: I think that pressing is one of those lost arts, and it’s something that I enjoy training people how to do. I want team members to understand what finishing is about. It’s about finishing that garment for it to be ready to wear for that customer. It all goes to the overall satisfaction of the customer. Once you have a presser who comes to enjoy the process, you know, then they can really finish those garments. I think that’s the big thing — it’s finishing, not just pressing.

Parker: It means a lot. We are a higher-price dry cleaner, and I think the quality of our stain removal and pressing has to be one of our top goals. If we didn’t have

the quality, people wouldn’t pay our prices. We want our clients to look the best they can every day, whether they’re going to work or going to a party or getting married.

Ablitt: I always imagine that I’ve got friends and family who are going to be wearing the clothes we clean. So, I look at it from the perspective of how I’m going to feel when these clothes go out. When the customer sees it, am I going to be proud of it? That’s the same thing I encourage my operators to think about.

We provide cleaning for our employees, so when they see their own clothes, they think like a customer. It’s fun when I see them acting like a customer instead of the presser. It’s the idea of being proud of your work, and really understanding the effect you have on the final product — and on the bottom line of the cleaners.

Desjardins: The first thing the customer is going to see is the pressing. You only have one opportunity to make a good impression with your customers. I remember going to drycleaning school in 1983, and the teacher said, “If you’re going to do a bad job, do a bad job all the time. You’re going to do a good job, do a good job all the time, but don’t screw your customer and do a good job one time and a bad job the next.” I’m big on consistency and providing quality products the customer can expect each time they come in.

• Topics of specific

When building customer loyalty, it’s not enough to occasionally give good service, or even great service. People who come into your drycleaning store want to have a consistent, positive experience every time.

This was the message that Jennifer Marquardt, customer service expert for The Route Pros, gave during her presentation, “Consistency Leads to Customer Service Excellence.” Marquardt spoke at the recent SpringFest Expo, an online series of virtual learning courses sponsored by the North East Fabricare Association (NEFA), the South Eastern Fabricare Association (SEFA), the Pennsylvania & Delaware Cleaners Association (PDCA) and the Drycleaning & Laundry Institute (DLI).

Marquardt’s main point during her presentation is that consistency doesn’t happen in a vacuum — it requires constant planning, training and communication with all team members. “If you do not have a consistent process, you are going to have inconsistent results,” she says.

Fortunately, building consistent processes doesn’t require a lot of money, or even time; Marquart believes it simply requires discipline and paying attention to how your staff interacts with each other and with customers.

A team cannot build a culture of consistency without ongoing, regular communications, Marquardt says. Checking in with your team or telling them what you expect is not something to do when “convenient”; build it into the schedule.

• Daily — When your front-counter shift changes, for example, have them check in with each other. “If the only interaction they’re having is a couple of minutes of chatter, they have no idea if there were any issues that need to be addressed,” she says.

• Weekly — “Communicate with your production staff weekly to let them know what’s expected, what’s working and what could be working better,” she says.

• Monthly — While it can be challenging to get the entire staff together on a monthly basis, technology like Zoom can be helpful in this regard. “You can go over

By Dave Davis, Editor

By Dave Davis, Editor

what we did this month, what we expect next month, and if we achieved our goals,” Marquardt says.

• Quarterly/Annually — Marquardt believes that town hall meetings are crucial to long-term planning and improvement. “You can’t get done what you want for the upcoming year without giving a road map to your team,” she says.

One of the areas where Marquardt focused was on the front counter, where customers often have their primary interaction with your company. She asked three questions: • Script or No Script? — It’s inevitable that a customer is going to come in unhappy from time to time. Marquart has found that training the front counter staff to expect and communicate with them effectively can quickly diffuse the situation. “The first thing you should say to an upset customer is, ‘I can see you’re upset. I understand completely. Don’t worry; we’ll take care of this,’” she says. A little training on how to consistently handle common situations can go a long way into turning an angry customer into a satisfied one.

• Who’s Doing the Training? — “How many people are training?” Marquardt asks. “Is it a manager one day, Suzy on Monday and Tabitha on Tuesday?” Without having a structured training program, dry cleaners can’t expect consistent results from their staff. “Teach one person to train your staff the way you want them to be trained,” she says. “Then, if you want to grow, start teaching someone else.”

• Who Owns the Problem? — “Whoever takes the phone call or greets an upset customer, they should own it, in the sense that they’re responsible for checking in and making sure things get done,” Marquardt says. While that front-counter person might not have the authority to make it right — although she urges owners to empower their team to be able to handle common complaints — a customer who feels neglected because a busy manager forgot to call them back will soon take their business elsewhere.

2021 RATES: One- to five-time rate: $2.20 per word, boldface $2.30 per word. Minimum charge: $25.00 per ad. Call or write for our three- and 11-time rates. If box number is used,

add cost of 5 words. Display classified rates are available on request. All major credit cards are accepted. DEADLINE: Ads must be received by the 1st of the preceding month.

Dominant Rural Chain Retiring, but will Train

• $1,800,000 2019 Retail Sales

• Strong Brand in Compact Market

• Family owns all Biz Real estate

• Profitable, Mature, growing Biz

For example, for a September ad, the closing date is August 1st.

PAYMENT FOR CLASSIFIED ADS: Must accompany order.

• Upcoming Eastern Ohio City

• Huge Facilities Reinvestments

• Modern Fully automated Plant

• 2021 Sales Returning to 2019 Levels

• Contant Profit - Stable Growth

• Financing Avail for Strong Buyer

• 25%+Production Capacity Avail

• Buyer Finder’s Fee Paid on Sale!

Contact Richard Ehrenreich, F-CBI Ehrenreich & Associates, LLC Richard@Ehrenassoc.com 301-924-9247

WWW.AMERICANDRYCLEANER.COM

Dominant Coastal Maine Drycleaner + Laundromat

• $1,000,000 Av. Retail Sales last 5-years

• Strong Brand in Compact Market

• Seller owns Production Facilities

• Profitable, Mature, Growing Biz

• Owner is 2nd Generation of Family

• Only Regional Drycleaner, no Discounters

• 2021 Sales at pre-Covid 2019 level

• Close to Ski & Ocean Water Sports

• Experienced Staff in Place

• Constant Profit – Stable Growth

• Flexible Financing for Qualified Buyer

• 25% Excess Capacity for Growth

• Great Family Lifestyle, Low Living Cost

For further information: Please contact the Exclusive Agent: Richard Ehrenreich, F-CBI, CED, SBA Ehrenreich & Associates, LLC Richard@Ehrenassoc.com 301-924-9247

Richard Ehrenreich’s PowerPoint Lecture covering Succession or Sale to the Outside Buyer World will be sent by email upon your emailed request. This program was given at a NC Cleaners Assoc. event. Along with this PP program, we will offer a limited amount of Exit Strategy Coaching without any obligation or cost. Ehrenreich & Associates, LLC has the unique experience of hands-on Drycleaner Operations, Cleaner Brokerage & Mgmt. Consulting to HELP YOU toward your deserved Retirement!

You can do everything without us after reading our material or engage us as a Coach, Consultant and/or Broker to work with your transition!

Contact Richard at 301-924-9247 or Richard@EhrenAssoc.com

2021 RATES: One- to five-time rate: $2.20 per word, boldface $2.30 per word. Minimum charge: $25.00 per ad. Call or write for our three- and 11-time rates. If box number is used, add cost of 5 words. Display classified rates are available on request. All major credit cards are accepted. DEADLINE: Ads must be received by the 1st of the preceding month. For example, for a June ad, the closing date is May 1st.

10 YEARS AGO. New Company, Same Tradition — The July 2011 issue of American Drycleaner was the first to be produced by American Trade Magazines after Charles Thompson bought it and its sister magazines from Crain Communications. Thompson, president and publisher of ATM, acquired American Drycleaner, along with American CoinOp and American Laundry News, in June 2011. “In this new environment,” Thompson said, “we will be better able to react more quickly to our markets’ wants and needs. We have a great team in place to take American Trade Magazines to a new level.”

25 YEARS AGO. Environmental Insurance Becoming More Popular According to ECS Underwriting, more U.S. dry cleaners were managing their day-to-day environmental risks by utilizing insurance to protect their bottom line. The company projected a 280% increase for the 1996 fiscal year in submissions from dry cleaners nationwide seeking this type of insurance. “Most dry cleaners are small businesses,” said Scott Britt, managing underwriter for the company. “A single pollution incident can put an establishment out of business.”

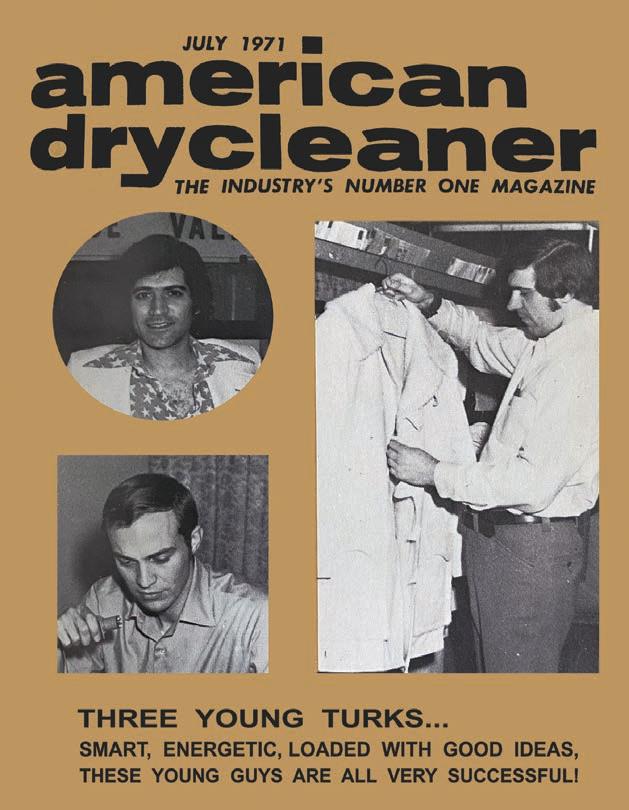

50 YEARS AGO. Customer Hangups — Denver-based Dependable

American Drycleaner, July 2021

Drycleaners decided to help their customers get rid of some of their hang-ups. In this case, the hang-ups were metal coat hangers that seemed to mysteriously multiply in closets, garages and other places around the home and were more difficult to get rid of than often thought. Dependable offered by pay customers a half-cent for each returned hanger brought to one of their stores with a cleaning order. What couldn’t be reused in the store was sent off to recycling. Jack Bugdanowitz, the president of Dependable, pointed out that the program was ecologically beneficial and that the response of the general public to the offer was

nothing short of “overwhelming.”

85 YEARS AGO. Depression Recovery — The last vestiges of the Great Depression were being swept out, American Drycleaner reported, with business surging throughout the industry across the country. “Unit volume has risen to 1929 peaks in many localities,” the report stated. “In some places, plant owners are handling more garments than ever before in their history. In many others, plant production has fallen behind volume. Machines and men are strained to the limit.” ADC

—Compiled by Dave Davis, Editor

—Compiled by Dave Davis, Editor

Products have proven to last up to 10 times longer than similar production in this industry and applications.

We have many installations with steam boilers that have been in service for over 50-years, 10 hours per day.

The materials used in current products are better than the materials used 50 years ago. For example, in the 80’s, steam drum went from 3/8” thick to 1/2” thick.

Our heating surface or amount of steel absorbing energy has always been 2 to 3 times that of other units (up to 6 sf of heating surface per boiler horsepower, which some units are closer to 2 sf of steel per hp, and some even 1 sf).

We have the best distributed flame or most even surface area evenly distributed under the entire pressure vessel. It is also a modular design, so it can be repaired easily.

Tube materials were upgraded from seamless rated pipe to seamless rated tubing. Material is not only thicker, ends up .133 wall, but is annealed which give the surface on both sides a mill scale coating that is more resistant to corrosion and is long lasting from testing.

Maximized Sustainability.

Maximized Sustainability.

Our newest technology—a programming change to our standard GreenEarth Cleaning process that enables deep vapor cleansing.

Our newest technology—a programming change to our standard GreenEarth Cleaning process that enables deep vapor cleansing.

Developed and independently laboratory tested as a dry cleaning response to the Covid pandemic.

Developed and independently laboratory tested as a dry cleaning response to the Covid pandemic. Our new deep vapor process is patent pending for use against the lipid envelope structure of all current coronaviruses and future mutations.

Our new deep vapor process is patent pending for use against the lipid envelope structure of all current coronaviruses and future mutations.

No chemical additives required. Environmentally non-toxic.

No chemical additives required. Environmentally non-toxic. Safe for people, fabrics, and our planet.

Safe for people, fabrics, and our planet.

www.greenearthcleaning.com

www.greenearthcleaning.com