® MARCH 2022 © Copyright 2022 American Trade Magazines All rights reserved. ■ HIRING AND RETAINING EMPLOYEES ■ FACING ‘ONCE IN A GENERATION’ CHALLENGES Reducing Overhead for Future Growth Tips for Rooting Out Inefficiencies and Decreasing Expenses

Learn more about Connect from SPOT spotpos.com/connect Xplor the Future The most powerful dry cleaning software 801-495-1200 Spotpos.com Delivery Connect with RouteTrac Route management: anytime, anywhere. connect and SpotTrac Designed by you. Built by SPOT.

When dealing with laundry stains, your reputation rides on getting the outstanding results The Laundry Two deliver.

RiteGo® laundry spray spotter quickly penetrates to absorb collar & cuff stains, perspiration, ground-in soil and more, all without brushing. Turn to Laundry TarGo® to remove any tough oil based stains that remain behind.

Use The Laundry Two with confidence on shirts, wedding gowns... anything you're washing or wetcleaning.

Both Laundry TarGo and RiteGo are chlorinated-solvent free, biodegradable, noncombustible and California 2013 VOC and Prop-65 compliant.

Use them to deliver stain-free laundry and wetcleaning. You'll build your reputation for quality - which is what keeps customers coming back.

FROM COLLARSAND CUFFS THE LAUNDRY T WO ™ ARE RIGHT FOR YOU! TO THE REALLY TOUGH STUFF... FROM COLLARSAND CUFFS THE LAUNDRY T WO ™ ARE RIGHT FOR YOU! TO THE REALLY TOUGH STUFF... To learn more, visit ALWilson.com or call 800-526-1188 A. L. WILSON CHEMICAL CO.

a STAIN WIZARD at ALWilson.com

Become

drycleaner

March 2022

Vol. 88, No. 11

FEATURES

Reducing Overhead for Future Growth

With profit margins growing thinner for many cleaners as supply and labor costs grow, rooting out ine iciencies has never been more important. We’re o ering tips for finding areas where profitability might be leaking from your business.

Finding — and Keeping — the Right Team

It seems like the talent pool has been drying up in the past few months, making hiring a priority for many. Also, given the competition for good help, making sure your team is happy is crucial for long-term success.

Facing ‘Once in a Generation’ Challenges

The past two years have been some of the most challenging the drycleaning industry has ever seen. So, what comes next? Four industry professionals recently gave their views during a virtual workshop about the past, present and future of dry cleaning.

2 American Drycleaner, March 2022 www.americandrycleaner.com

AMERICAN AMERICAN

®

6 12 18 DEPARTMENTS Pre-Inspection 4 Feeling “Lucky”? Classified Ads / Ad Index 22-23 Wrinkle in Time 24 Perc, House Calls and Getting Steamed HUNG UP ON THE HIDDEN HANGER?

you need a little help finding this month’s hanger hidden on our cover, here’s a clue. Good luck!

(Photo:iStock.com/Atstock Productions)

If

Feeling “Lucky”?

There’s an old saying that “Luck is what happens when preparation meets opportunity.” The past couple of years has proven to business owners that there will always be elements out of their control. Those dry cleaners who are constantly aware of what’s going on in their companies, make solid plans for the future and are always ready to adapt to change, however, often find themselves the “luckiest” of all. This month’s American Drycleaner aims to help our readers work on the “preparation” part of that lucky equation. Our cover feature this month, “Reducing Overhead for Future Growth,” provides tips to dry cleaners looking to better reconcile their income with their expenses, and discover areas in their plants where inefficiencies exist. While there might not be one “black hole” in which the money disappears at your plant, several minor “leaks” here and there can become a major profitability buster when added together.

Our second feature, “Finding — and Keeping — the Right Team,” deals with one of the most signficant pain points dry cleaners are feeling today. Not only is it more difficult to find employees, but with added competition between companies, it can be harder to hang onto the team members you need the most. We’ll examine ways to find the right fits for your business and how to retain them for the long haul.

Our final feature in this issue, “Facing ‘Once in a Generation’ Challenges,” is a round-up of a presentation that was part of the WinterFest 2022 Expo, a series of online webinars in January presented by several drycleaning associations. For this particular webinar, four industry experts gathered to discuss how the industry reacted to the coronavirus pandemic and the resulting shutdowns, as well as steps dry cleaners can take to make the most of the present conditions and grow into the future.

Publisher

Charles Thompson

312-361-1680 cthompson@ATMags.com

Associate Publisher/ National Sales Director

Donald Feinstein 312-361-1682 dfeinstein@ATMags.com

Editorial Director

Bruce Beggs 312-361-1683 bbeggs@ATMags.com

Editor Dave Davis 312-361-1685 ddavis@ATMags.com

Digital Media Director

Nathan Frerichs 312-361-1681 nfrerichs@ATMags.com

Production Manager

Mathew Pawlak

Advisory Board

Jan Barlow

Mike Bleier

ADC

There are always challenges that will come up in this industry — although, hopefully, none as big as what we’ve faced recently. Those dry cleaners who are planning for the future and have a handle on their company’s activities will be “lucky” enough to take full advantage of the opportunities that come their way.

American Drycleaner (ISSN 0002-8258) is published monthly except Nov/Dec combined. Subscription prices, payment in advance: U.S., 1 year $50.00; 2 years $100.00. Foreign, 1 year $120.00; 2 years $240.00. Single copies $10.00 for U.S., $20.00 for all other countries. Published by American Trade Magazines LLC, 650 West Lake Street, Suite 320, Chicago, IL 60661. Periodicals postage paid at Chicago, IL and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Drycleaner, Subscription Dept., 125 Schelter Rd., #350, Lincolnshire, IL 60069-3666. Volume 88, number 11. Editorial, executive and advertising offices are at 650 West Lake Street, Suite 320, Chicago, IL 60661. Charles Thompson, President and Publisher. American Drycleaner is distributed selectively to: qualified dry cleaning plants and distributors in the United States. The publisher reserves the right to reject any advertising for any reason.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2022. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Drycleaner does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Drycleaner or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

John-Claude Hallak Wesley Nelson Kyle Nesbit Mike Nesbit Fred Schwarzmann Beth Shader Vic Williams

Contributing Editors

Dan Miller Diana Vollmer Martin Young

Office Information

Main: 312-361-1700

Subscriptions 847-504-8175 ADC@Omeda.com www.american drycleaner.com

4

March

www.americandrycleaner.com

American Drycleaner,

2022

Dave Davis

PRE-INSPECTION

About Iowa Techniques Iowa Techniques is a manufacturer and distributor of unique products that work in a wide variety of industries and applications, and currently focuses on helping dry cleaners make smart choices that impact the bottom line in their plant operations. When your water heater dies, DON’T replace it! Get a DynaFluid 2000 from Iowa Techniques! Getting Steamed? the (800) 727+1592 | www.iowatechniques.com With steam from your boiler and a cold water source, this little valve makes an infinite supply of hot water. It outperforms water heaters by every measure, cutting costs and increasing productivity. Call Iowa Techniques today and learn how the DynaFluid Valve will help your business! (800) 727+1592

Reducing Overhead for Future Growth

By Dave Davis, Editor

By Dave Davis, Editor

Balancing income and expenditures is always essential to running a business. Dry cleaners who saw their incomes slashed during the depths of the coro navirus pandemic, however, found that increasing the efficiencies in their plants and cutting overhead was an absolute necessity to keep their doors open.

FINDING EFFICIENCY

“I know many owners have made a lot of sacrifices in order just to survive, and many of us have learned to do more work with fewer people,” says John Rothrock, president and CEO of Yale Cleaners in Tulsa, Oklahoma. “Lots of people are short on staff — we’re short on staff. That’s necessitated owners themselves stepping into roles such as pressing clothes or working the counter on a regular basis, and I think that’s opened a lot of eyes.”

Rothrock believes this new perspective, while painful at the time, could

rooting

inefficiencies and decreasing expenses

Tips for

out

6 American Drycleaner, March 2022 www.americandrycleaner.com

(Photo: © Rawpixel/Depositphotos)

Wt:1\!Jt to replt1ce perc1 C7lt1rVv1e\!Jts t1re et1sy to press[ VV\t1c\11i\!Jes lt1st for dect1desl ,_ ORV CLEAN OHLV ·Wt:1\!Jt to vtpt3rt1de tec\11\!Jolot3y1 liket1 \!Jew vl\!Jio\lJ. Exte\!Jds life of t3t1rVv1e\!Jtsl No specit:11 Co\!Jditio\!Jersl New vl\!Jio\lJ dry clet1\!Ji\!Jt3 Vv1t1CV1i\!Jes v1tili0e wt1ter St1Vi\!Jt3 tec\11\!Jiojvtes. to\!Jserve wt1ter, every drop covt\!Jts. IGREENEARTH ClfANING 1-800-433-9401 www.uniondc.com 5lmerica's 13estSe{[ing 13randof'Dry C{eaning .Machines S::I Finduson ._. Facebook • Follow uson lnstagram

provide owners with valuable information — if they’re paying attention.

“We have the opportunity to identify things that can be minimized or reduced,” he says. “The smart owners who were forced into those roles looked at that and asked, ‘What can we do to make this more streamlined and reduce some waste?’ Many cleaners are much more efficient than they were 24 months ago.”

Part of this efficiency comes from cutting some of the excesses that formed during less challenging times, says Kermit Engh, owner of Fashion Cleaners, Omaha, Nebraska, and managing partner of the drycleaning consulting group Methods for Management.

“What I’ve found working with people through our group is that the majority of them have right-sized their busi nesses,” he says. “They’ve closed marginal stores, they’ve reduced staff, and they’re measuring PPOH (pieces per op erator hour) and their productivity closer. They’ve adjusted store hours and, in some cases, the days they are open.”

Hard times make for hard choices, Engh says, but it’s necessary: “They’ve made decisions they would not normally have made when things were kind of fat and happy. They are more efficient, and I would assume that they are also more profitable because of it.”

While learning from the past is an essential part of running a business, hanging onto those lessons into the future can be a challenge, says Christopher White, executive director of the certification and consulting agency America’s Best Cleaners.

“I think the challenge that, historically, our industry has always faced is sticking with those efficiencies,” White says. “That’s one of the things we are coaching our affiliates on right now. This has been a ‘Great Reset,’ and you realize that you can get a lot more value out of your employees than you’ve ever had before. Are you going to be able to continue to maintain getting that value? What systems are you putting into place to make sure you don’t slip back?”

White says this cycle has played out in recent memory: “In the 2008 recession, everyone got lean. And then, by 2014, all of a sudden they were top-heavy in management, and their labor was a little bloated.”

He believes, though, that cleaners who pay attention to their pain now will be able to maintain their efficiency.

“Those who have good systems in place to measure, manage and coach their people to stay on track are going to be successful,” White says. “They’ll stick with it.”

THE HIDDEN AREAS OF WASTE

A key part of creating and maintaining efficiencies and keeping overhead as low as possible is taking an honest look at your facilities and identifying areas that could be

operated more effectively.

“A whole lot of little things can really add up once you start putting them together,” Engh says. He’s identified several areas for dry cleaners to examine for inefficiencies that are wasting money.

•Utilities — This can include leaving lights on or starting equipment early in the day that’s not yet needed. “Electric bills can be hugely impacted by how you start your plant each morning,” Engh says.

•Employee Performance — Engh says his business tracks CSR (customer service representative) dollars per hour. “It’s a key performance indicator (KPI) on how productive a CSR is in checking in or detailing garments.”

•Marketing — “If you can’t measure it, stop wasting the money,” Engh says. “How many new customers are you bringing into your system on a weekly and monthly basis? How many customers are you retaining on a monthly basis? What is your turnover on customers?”

• Vehicle Expenses — Engh has found that unneces sary trips have a huge impact on your profitability: “This is where your point of sale system, if you’re do ing home and office delivery, can help by providing opt-in or opt-out functionality, so you’re not driving to customers who have nothing to pick up or deliver.”

•Insurance — A regular audit of your insurance poli cies, Engh believes, can be worth a cleaner’s time. “How many people have adjusted their insurance coverage to their new, right-sized business? You might have too much coverage because your business isn’t the same as it was two years ago,” he says.

•Supplies — Because supply chain problems have driven up prices and made some materials harder to get, even seemingly small steps can make a difference in profitability. “Are cleaners measuring the soap that goes into their drycleaning loads and their laundry loads every time to make sure there’s no waste?” Engh asks.

• Credit Card Fees — “This is a hot button for a lot of people,” Engh says. “How many actually calculate their rates to process credit cards on a weekly or monthly basis, and are they seeing their rate trending up?” he asks. “If so, they can call their card processor and have a rate review.”

•Postage — This can be a “how we’ve always done it” area that Engh believes needs to be reviewed. “How many statements are you still mailing out to people that could have been converted to either a credit card on file or by email?” he asks.

• Free Cleaning for Employees — While free clean ing is a benefit many cleaners provide to their team,

8

www.americandrycleaner.com

American Drycleaner, March 2022

Our Automation Systems will help you do more - with less! Are you short-handed? ReliableAffordableAvailable Simple design along with great customer service. Keep it simple! Provides the best return on investment. Made in the USA. Delivery available in as little as 2 weeks. 501-420-1682 garmentmanagement.com 247 EXPRESS Dry Clean at Your Convenience

“Look at

put them on a list to eliminate,” he says. “When you gather that list, focus on the ones that are the most complicated to produce — you’re putting a lot of time and energy into something that’s not generating a profit, and you’re wise to eliminate it.” (Photo: Yale Cleaners)

least-profitable

Engh says that this can be a mistake. “I believe that, if a benefit is free, it gets abused and is not appreci ated,” he says. “Employees should get a discount on cleaning, but there shouldn’t be any free cleaning.”

•Miscellaneous — “This is the ultimate catch-all bucket,” Engh says. “Whatever the cost is, identify it and get it categorized properly.”

“The bottom line is to measure your EBITAL percent on a monthly basis — earnings before interest, taxes, amortization and leasing,” Engh says. “That’s how businesses are valued. If you’re not paying attention to that, what you really have is a glorified job, rather than a business that has value.”

PAYING RENT OR BUYING PROPERTY?

One of the biggest overhead expenses for many dry cleaners is paying rent for their locations. Rothrock’s business examined this area years ago and made a decision that would have long-term benefits.

“Our company owns every single one of our facilities,” he says. “We have 11 locations or purpose-built freestanding buildings, and we own them. That’s not always been the case — we started out renting. Our focus in the 1990s was to own all of our buildings, and it took us 20 years to get there.”

So, when does it make more sense to rent property versus buying a piece of real estate to set up a business?

“When you’re first starting out, I think it makes a lot of sense to rent,” Rothrock says. “Dry cleaning already has a high barrier to entry if you’re opening up a plant and doing the work yourself. The cost of capital and la-

bor are big numbers to overcome, and owning your facility is just one more hurdle that makes it prohibitive to get into the industry.”

The decision to buy, he believes, comes with a cleaner’s experience at that location.

“If you think you’ve identified a strong market but aren’t 100% certain, it makes sense to rent,” he says. “If it does really well and outperforms your expectations, then you can transition and look for the right opportunity to purchase instead of renting.”

While it might entail more risk, Rothrock believes the benefits of owning the right property are worth it.

“Obviously, purchasing is preferred because when you rent, the building owner controls the property, and dry cleaners are hard on facilities,” he says. “When you own, you don’t have to fight those battles — you have complete control over the facility, and you can set it up to be the most successful. It also starts building wealth for you. Instead of paying rent to someone else, you can diversify your income stream, allowing you to be a stronger company.”

STRAIGHTENING OUT THE CHAIN

Another recent obstacle to profitability has been problems in the supply chain. Many cleaners are finding that, even when they can get the materials they need to operate, the rising costs are impacting their budget.

White has witnessed online discussions between dry cleaners who can’t seem to get supplies and others who have been able to stay fairly well-stocked through the supply chain disruption. He says the difference comes down to relationships.

10 American Drycleaner, March 2022 www.americandrycleaner.com

John Rothrock, president and CEO of Yale Cleaners in Tulsa, Oklahoma, believes in streamlining his business to maximize profitability.

your

services and

“If you really dig and start asking some ‘how and why’ questions, you find that those people who are having supplies delivered on a regular basis — while it’s still challenging and prices have gone up — are those who have traditionally valued their partnership with their supply houses and have always had a two-way communicative process,” he says.

“Unfortunately, a lot of people in our industry look at the supplier as just the guy who brings hangers and the guy they have to beat up when the bill goes up 5%. That’s not a partnership. That’s not going to get you through tough times.”

White believes that maintaining this type of relationship works on both the business level and from the standpoint of basic human nature.

“At the end of the day, it’s a good, sound business decision for any distributor to ask themselves who are the people who have paid on time, have been great business partners with them, who have given them good feedback and given them great recommendations,” he says. “I don’t know of any supplier out there right now saying, ‘I don’t want to sell hangers to anyone because of XYZ reason.’ They’re saying, ‘I have to make a smart business decision and take care of the people who have always taken care of me.’”

LOWERING THE COST OF LABOR

Labor can be another massive component of a dry cleaner’s budget. Investing in the right type of equipment, Engh believes, can help dry cleaners increase efficiency and decrease overhead.

“Automation is used to replace labor,” he says, “and if there was ever a time that labor has become a massive issue, it’s right now, with the hourly rates accelerating and the lack of people who want to work. It can also help reduce mistakes and allow tracking of an item throughout your entire process. It can give you a garment’s history and, in some cases, lets you take a photo of each garment, so you have documentation.”

Rothrock believes that barcoding is perhaps the best place for cleaners to begin automating processes.

“I know there are still dry cleaners out there writing tickets, thinking that they’re too small to invest in barcode technology,” he says, “but it’s absolutely astounding how much labor you can save and how many activities in the building you can eliminate by transitioning to a barcode identification system. No company is too small to do it. It will cost more time while you transition, but once you do, it will pay dividends that last forever.”

“After you start barcoding, the biggest bang for the buck is an auto bagger,” Engh says. “That literally eliminates a full person, and the baggers are very efficient

and save on poly. The next step would be in assembly — either auto assembly or semi-auto assembly. That cuts down on mistakes and cuts steps.”

ARE SOME SERVICES WORTH IT?

For his business, Rothrock has found that not every service makes cost-effectiveness sense.

“Look at your least-profitable services and put them on a list to eliminate,” he says. “When you gather that list, focus on the ones that are the most complicated to produce — you’re putting a lot of time and energy into something that’s not generating a profit, and you’re wise to eliminate it.

“When you do that, it will enable you to focus on those services that are profitable, and you will start improving on them, making them better and even probably higher quality. Your sales are going to increase on those activities, and it’ll be an easier company to run.”

Rothrock and his team have pared Yale’s offerings down for maximum profitability: “We focus on what people wear every single day. We do wedding dresses and a couple of other things, but everyday clothes are 90% of our business. That’s where you can make your money, and you can get efficient.”

CLEARING A PATH TO THE FUTURE

While auditing your business to root out inefficiency may seem like a never-ending quest, White advises cleaners not to forget about their most valuable assets.

“Don’t be afraid to empower your people,” he says. “As an owner, if you’re feeling overwhelmed, it’s probably because you decided you needed to step in and take on some of these extra tasks. But if you have good communication with your staff and can let them know what you need them to do, and then empower them to do it, people will do amazing things for you.”

And that includes the younger generation, he adds.

“I think many people write them off because ‘they’re all attached to their phones’ or things like that. Maybe they do things differently than the way we historically have done it, but people will do amazing things if you are clear on what you want.”

Also, the quest to minimize inefficiency in your business isn’t a “one-time” effort, Rothrock says. It can, in fact, be boiled down to a simple idea.

“Every single day, we look to be better than we were yes terday,” he says. “You have to create that in the culture. It starts with the person at the top and goes down from there. You have to build those relationships with your team so that everyone gets on board and buys into this idea.

“Create a culture of continuous improvement and get buy-in from the entire team to help you reach that goal. You’ll be amazed at what you can achieve.”

www.americandrycleaner.com American Drycleaner, March 2022 11

ADC

Finding — and Keeping — the Right Team

Tips for hiring and retaining employees in a tight labor market

By Dave Davis, Editor

By Dave Davis, Editor

One development that many dry cleaners weren’t prepared for last year was their inability to find labor after the lockdowns eased and society reopened. When the work came back in, there were fewer hands to do it — and this has become a pain point for many in the industry. What’s more, with good employees in seemingly short supply, the competition for them has heated up over the past few months.

THEY ARE OUT THERE

“It’s

because of different factors,” says Jennifer Whitmarsh, a member of The Route Pros, a drycleaning consulting firm. One of Whitmarsh’s roles is to help dry cleaners develop and follow best hiring and retention practices.

“We had COVID, and we had so many people retire last year and the year before,” she says. “Maybe we haven’t trained our staff well enough to go up to the next level. Now, we’re looking to raise others to fill the gaps.”

12 American Drycleaner, March 2022 www.americandrycleaner.com

tough

The fact that the very nature of work has changed for many is also directly affecting the pool of applicants available to dry cleaners.

“More people are seeking remote work and, obviously, there are very few dry cleaners that can offer remote employment,” says Amy Wischmann, who oversees hiring at Benzinger’s Clothing Care, a drycleaning business with five locations and 40 employees in the Buffalo, New York, area. “You’ve got people still nervous to return to the workplace or who just can’t because of child care or other reasons. I think people are seeking different kinds of work now.”

“It’s tight,” Whitmarsh says, “but it’s not impossible. It’s like digging for gold. They are out there, but we just have to be a little more proactive than we used to be.”

FINDING GOOD FITS

Part of this proactivity is increasing the search for new employees from “as needed” to a constant basis.

“If you want to have a team of dedicated employees, you can’t always do what you’ve always done,” Whitmarsh says. “I would strongly urge people to revisit and examine their processes. Even 10 years ago, hiring was easy, so to speak. Now, it’s practically a full-time job trying to hire. But you have to invest that time so you can find these great employees who are going to add to your team and not ultimately waste your time and take you away from the important things you need to do.”

“Cleaners have to stay on top of the hiring process, and I believe they have to have someone who does it every single day,” Wischmann says. “It might take an hour a day, but it has to be a priority.”

The days of newspaper want ads are over, Wischmann believes, and cleaners who want to attract today’s employees need to be where their applicants are.

“It’s important for people in dry cleaning to take the time to learn some kind of online hiring platform, whatever that may be,” she says. “That is the way that

most people are seeking work these days. Waiting for people to come in and use a paper application is not what people are currently doing, especially younger people. If you don’t have an online presence, you’re definitely at a disadvantage from the start.”

However, employers who might be intimidated by starting job searches online shouldn’t worry, Wischmann says.

“As long as they have someone at their business who is computer-savvy, it’s not going to be that hard for them,” she says. “Most platforms make it very userfriendly. That’s the business they’re in, so they’re going to make it as easy as possible for both applicants and employers.”

ASKING THE RIGHT QUESTIONS

Being prepared for interviews makes the process easier for both employers and applicants, Whitmarsh says. Part of this preparation is not reinventing the wheel for each interview.

“At one point, I felt that I needed to be asking different questions every time,” she says. “You’re interviewing different people, so it didn’t make sense to do that. I now have a good group of questions, including behavioral questions. You don’t have to make it harder on yourself.”

Behavioral questions are essential, she says, because they tap into the applicant’s actual experiences. Instead of asking them what they would do in a certain situation, Whitmarsh prefers to ask them what they have done in past situations. This gives a truer sense of the person, she says.

Wischmann has also found that internal referrals have been a valuable method for hiring: “We’ve had good luck finding drivers that way. Someone will say, ‘Hey, I do know someone who has retired and is looking for some extra cash.’”

The hours of the position to be filled can also be a factor, Wischmann says.

“We get the most applicants when we post jobs that are in the evening,” she says. “The people who really seem to be seeking employment are those who are already working elsewhere, and they’re looking for additional money. We have some evening sorter positions, for instance, and when we post those jobs, we get twice the number of applicants as for positions during the day. So, if there’s any work that can be shifted to the evening, that might be worth exploring.”

While some people still set up interviews as a requirement of their unemployment benefits and never show up, Wischmann has found that particular point of aggravation has eased considerably.

“We’re still seeing that to some degree, but I do think that if they’re searching, they’re serious about searching now,” she says.

14 American

March 2022 www.americandrycleaner.com

Drycleaner,

Wischmann

Whitmarsh

There’s more: We’re just two members of NIE’s team of experts. NIE has been handling fabricare insurance since 1915!

EXPANDING THE SEARCH

Whitmarsh believes that having a smaller pool of potential applicants means that dry cleaners should be prepared to throw out a bigger net and look in places that they might not have considered in easier hiring times.

“You have to be creative,” she says. “When you’re out and about at the grocery store, the restaurant, the dog groomer, or wherever, notice when you are interacting with somebody who is giving you exceptional customer service. You don’t know what’s going on in that person’s world, so have a simple conversation: ‘Hey, I love the way that you work with me every time I’m here. If you’re ever looking to get out of this field, please give me a call.’”

This effort costs nothing and might gain a cleaner his or her next best employee.

“Give them your card or give them your number — you never know,” Whitmarsh says. “Not every waiter or waitress wants to stay in that field forever, and it’s not always about money. Maybe they really don’t love it. They’re just doing it until something else comes around. So, ask when you’re out.”

HIRING MISTAKES, AND HOW TO AVOID THEM

Time is often against dry cleaners looking to fill positions, Wischmann says — whether they realize it or not.

“One big mistake when it comes to hiring is letting too much time pass after receiving an application and not having a sense of urgency about it,” she says. “You can’t let off the gas. You have to be quick in responding. I have responses for (job site) Indeed come right to my phone, so if I see someone we really should speak with, I can immediately reach out to them.”

Because of the law of supply and demand, there is increased competition for a smaller labor pool, and cleaners need to consider this.

“The shorter you can make that time interval between when they apply and when you reach out to them, the better,” Wischmann says. “Applicants have their lines in the water everywhere. Whoever gets them in the door the quickest obviously has a huge advantage.”

One of the benefits of having an ongoing hiring strategy is that it helps owners avoid costly mistakes.

“Don’t hire out of desperation,” Whitmarsh says. “We’ve all been guilty of that at some point, when we feel like we just need a warm body, and we end up hiring someone and trying to make them fit. Ultimately, three

months down the road, it doesn’t work. Now we’re back to square one, and we’ve wasted all that time.”

Once cleaners make their hire, getting started on the right foot is key to building this new relationship.

“Make sure you have a strong onboarding process, so you don’t lose them quickly,” Wischmann says. “Have someone there who’s dedicated that first day to just making sure that person is greeted and has someone to follow around and to introduce them to everybody. It’s great to make them feel welcome that very first day.”

PHONE SKILLS

One of the best interviewing tools in an employer’s tool kit is the telephone, Wischmann says.

“We always screen with the phone and do phone interviews first,” she says. “It saves you a ton of time. I’d much rather have someone not show up for a phone interview than not show for an in-person interview.”

Part of effectively using the phone in hiring is understanding what to look for — another reason Wischmann says it’s good to have one person at the company responsible for this stage of the process.

“You can get a good sense when you hear someone’s voice and listen to how they respond to questions,” she says. “I describe very clearly for them exactly what the job entails, and then ask if they are interested in pursuing this. It will cut one way or the other. They’ll either tell you that, yes, it’s something they’re interested in, or, if they waver at all after hearing what the job is like, I typically won’t pursue an in-person interview with them.”

KEEPING THEM AFTER THE HIRE

Again, with businesses competing for employees, it can be challenging to keep good employees on the team for the long term. While pay hikes are always appreciated, there are other ways owners can make sure their employees feel valued.

“A simple ‘thank you’ can go a long way to let your team members know that they’re valued,” Whitmarsh says. “Dollars are nice, but in a month, individuals can forget about that pay rate.”

Just as creativity is necessary for today’s hiring market, Whitmarsh believes it’s needed in retention efforts, as well.

“Your team members will also remember the bottle of wine and the gift card that you gave them so they can have a nice date night with their spouse, over the 50-cent raise you gave them,” she says. “You can give them an added vacation day. All these things individually might not shoot your culture through the roof, but a combination of a few of these will make team members feel appreciated.”

Benzinger’s has similar methods of appreciating their employees, Wischmann says.

16 American Drycleaner, March 2022 www.americandrycleaner.com

“When we hire people, we find out what they like,” she says. “We ask people specifically, ‘What’s your favorite coffee shop? What’s your favorite restaurant? Do you have a pet?’ So, when we do little things, little recognitions, even just a $5 or $10 gift card, it’s targeted.”

Letting their peers know they’re doing a great job is also a valuable method of respect that costs nothing.

“We have an internal newsletter, and we publish people’s accomplishments,” Wischmann says. “It means a lot to people to be recognized by their managers or the owner in front of their peers.”

Perhaps even more fundamental is making sure the employee has the tools necessary to do his or her job.

“Training is an ongoing process,” Whitmarsh says. “One-on-one training might end after four weeks, but training never ends. No matter if you own the company or it’s your first day on the job, you’re always learning something. I think if you continue to have conversations about that, you’ll find out which team members are really satisfied with their job and which ones might not be.”

“I interview a lot of people who say they left their last job because they felt they were thrown into the position,” Wischmann says. “Younger people are especially not used to that — they want to feel comfortable before being left to their own devices.”

It’s important for an owner or manager to get to know their employees as people rather than positions — it not only makes for a healthier workplace but can give leaders essential clues when an employee is becoming unhappy.

“I think one of the first things you’ll see is that they start to shut down,” Wischmann says. “They aren’t commu nicating as much. They’re calling off work more. People who were very consistent and reliable suddenly aren’t as reliable anymore. It’s important to address these issues face to face as soon as possible. That way, you can find out what’s changed or if there’s an issue they’re dealing with. They might be having a childcare problem and need some time off. That’s a way of building loyalty.”

Whitmarsh says communicaiton is key, so you’ll know what they are saying —and what they are not saying.

“Have these monthly or quarterly check-ins and ask them questions. ‘How are you liking your job? Where do you see yourself in a year? In five years?’ What’s going on in that person’s life? If one of your CSRs is graduating, or they’re going on to their next degree, see how you can continue to work with them instead of talking about it the day after they graduate.

“Once you learn and understand who they are outside of work, it can help you to determine how you can make sure you continue to fit into their life.” ADC

www.americandrycleaner.com American

March 2022 17

Drycleaner,

Facing

‘Once in a Generation’ Challenges

Workshop examines past trials of the industry — and future opportunities

By Dave Davis, Editor

By Dave Davis, Editor

Now into 2022, the previous two years have cast a long shadow over the drycleaning industry, and part of knowing how to proceed to brighter days ahead is to make sure we learn from the past.

That was the theme of a webinar that gathered four industry experts together to discuss “The Industry’s Response to ‘Once in a Generation Challenges.’” The event was part of the three-day WinterFest Expo, a series of virtual workshops staged in January. It was co-sponsored by the Northeast Fabricare Association (NEFA), the Pennsylvania and Delaware Cleaners Association (PDCA) and the South Eastern Fabricare Association (SEFA) in cooperation with the Drycleaning & Laundry Institute (DLI).

BY THE NUMBERS

The first part of the presentation discussed sales trends of the past three years to better see how much the pandemic cost the industry and where areas of growth might be found going forward. Toran Brown, vice president of product management for SPOT by Xplor, a point-of-sale and computer system provider for the drycleaning industry, led the discussion. Brown is also a third-generation dry cleaner and owns Rytina Fine Cleaners in Sacramento, California.

Brown presented data from 2019 through the beginning of 2022 aggregated from the actual sales data from SPOT customers. He offered data that showed the pandemic’s massive hit on the industry in mid-March 2020 and how sales started to slowly climb again, starting in summer 2020 and continuing to the present.

Still, while Brown says things are trending up, the numbers have not recovered from where they were in pre-pandemic times: “We still remain down from sales on a 20% average.”

Brown’s data also shows that the number of customer visits — counted as both customers coming into the store for drop-off and pickup, as well as delivery routes — were relatively consistent with the sales numbers. What was surprising, he says, is that the piece counts customers brought in during 2021 and the beginning of 2022 are not showing the same amount of recovery as sales and visits.

“So what it tells us is that we still have a number of customers coming to us — they’re just bringing in fewer pieces,” Brown says, “and we are charging more for them to try and make up for that sales volume loss.”

SPOT’s data shows that cleaners, on average, were charging around $6.35 per piece at the beginning of 2021. That had increased to nearly $7 per piece at the end of the year.

18 American Drycleaner, March 2022 www.americandrycleaner.com (Photo: © SergeyNivens/Depositphotos)

Brown found that during the early days of the pandemic in 2020, the demand for route pickup and delivery outpaced retail sales for revenue per piece, especially when it came to items not regularly brought to dry cleaners before.

“At this time, we were hearing a lot about comforters and other household items, when people were taking the opportunity to do some housecleaning and early spring cleaning,” he says. The data showed that revenue per piece hit a high of about $6.75 in May 2020 before falling back to about $6.25 at the end of the year.

Routes were a great way to conduct business during the depths of the pandemic, but SPOT’s numbers show that the increase in route sales was not a permanent change for its clients.

At the beginning of 2019, route sales made up about 39% of the average SPOT client’s total sales. When the pandemic lockdowns hit in March 2020, that number shot up to around 55%. Then, beginning around summer 2020, the number decreased.

“Over the last eight or nine months, it’s begun to trail off and return to the 35-40% range,” Brown says.

When asked if he believes cleaners will move toward charging fees for providing pickup and delivery services, Brown believes there are a couple ways the industry might go.

“It really comes in two forms,” he says. “One is a minimum order, and the other is a per-delivery fee. There are some cleaners who charge a monthly fee to be on a route service, but I don’t think the jury’s quite in on the success of that yet. Gas prices can clearly play a role in this area. I also believe that other industries setting some precedent would make that easier for us. But in a declining industry where we’re down 20%, I think we have to be very careful that we don’t create barriers to having people avail themselves of our services.”

PAST AND PRESENT PERFORMANCE

Brian Fish of Pier Cleaners in Rhode Island has a simple answer to why it’s crucial for owners to measure their company’s key performance indicators (KPIs): “Because what gets measured gets done.”

Fish says he finds that key performance indicators provide a focus for strategic and operational improvements. They also create an analytical base for decision-making and allow his team to remain focused on the areas that matter most for the profitability of his business.

“We want to make sure we’re measuring our company’s success versus our targets, objectives and industry standards,” Fish says, noting that this valuable data allows him to see how his company’s performance has changed over time. “We want to make sure that we’re judging ourselves versus what we’ve done in the past, not just versus the industry.”

KPIs also provide a solid base for performance reviews, Fish says: “These reviews become less opinion-based and more measured, which is crucial, especially as our labor costs are increasing. We want to make sure that when we’re talking with our staff, we know exactly what they’re doing.”

Fish detailed some of the data he measures at Pier Cleaners, including incoming sales, piece counts, washdry-fold sales, and pieces per operator hour (PPOH).

Another critical KPI for Fish is customer flow.

“I want to make sure we’re not overstaffed at times because our customer flow was down,” he says. He found it was important to look at this set of data, because customer habits have changed since the pandemic. “Customer flow used to increase in the middle of the day,” he says, but the data shows that behavior has dropped off. “We saw some changes that indicated that we would be able to adjust our labor because of different trends we saw in 2020 and 2021.”

www.americandrycleaner.com American Drycleaner, March 2022 19

Using KPIs, Fish can check his company’s progress and compare it to previous years. This gives him actionable data, as well as a handle on what his costs actually have been at any given time — crucial information for setting prices.

“Having the information I need to make sure I’m pricing properly, and that I’m scheduling properly, are probably the biggest things that you can take away from any of these numbers,” he says.

The ability to track a team member’s productivity provides Fish with insight into where more training — or personnel changes — might be necessary.

“With it being so hard to find people right now, we don’t want to get rid of somebody just because they’re pressing 35 shirts an hour instead of 40 shirts an hour,” he says. “If that person is showing up every single day, and they’re doing a quality job, and there aren’t a ton of touchups, we can work with that person to get them to 40 shirts an hour.

“But if I’m tracking this properly, and I know that the person isn’t there half the time and they’re only doing 32 shirts an hour, then I need to be out looking for people.”

While tracking important KPIs takes some time and effort, Fish says that this task can become a simple — yet powerful — part of a manager’s day if it’s done regularly.

“I’ll take 15 minutes every day and input some data, but I’ll look into it a lot more once a week,” he says. “I’ll take a couple of hours, typically on a Monday morning or afternoon, and put together the numbers for the previous week into a report to give all the managers. Then, we’ll spend a couple of minutes on it at our weekly managers’ meeting so that everyone knows exactly where they stand and are able to use those numbers to forecast for scheduling for the next week.”

ONGOING SUPPLY CHAIN CHALLENGES

While the supply chain woes continue to affect the drycleaning industry, a cleaner’s location can lessen or worsen their impact, says Mike Ross, president of the New England division of Minda-Aristocraft Supply.

“I think a lot of it depends on where you are in the country,” Ross says. “If you are inland, not on the West Coast or the East Coast, it is much more difficult to get hangers because of inland transportation. There are a lot of people still having struggles that those of us on the coasts aren’t having as much of.”

Other significant shortages hitting the drycleaning industry have included plastic shoulder guards, comforter bags, and chemicals, including detergent.

“We were out of Tide, believe it or not, for two

months because Procter & Gamble couldn’t get the boxes to package it in,” he says. “It really depends on the particular day what the issue can be.”

One of the major problems is with overseas shipping. This has become so severe that some companies are “reshoring,” or producing products once offshored to other countries back in the United States. Unfortunately, Ross says, this isn’t an option for many types of drycleaning supplies.

“One of the problems we face as an industry is that we’re not big enough to cause a push for reshoring,” he says. “For hangers, in particular, there are only two domestic manufacturers, and they can’t keep up with production, and nobody else is opening up. That’s the case with most of the products that we’re importing.”

As is the case with most suppliers, Minda-Aristocraft has been attempting to widen their own supply lines to get materials into the hands of their clients, says Ross, but at the moment, it’s an uphill battle.

“We’re trying to find substitutable items that will allow our customers to continue to operate the business in the way that they want to, but it’s a challenge every day, and I don’t see it getting better anytime soon,” he says. Container space is as difficult, if not more difficult, to get today than it was three months ago. “I thought container costs had peaked at around $20,000 to $23,000, but now I’m being quoted $28,000 for a container of hangers.”

The key to dry cleaners riding out this challenge, according to Ross, is keeping the lines of communication open with their distributors and staying flexible.

“Work with your distributor,” he says. “Talk to them. It’s critical to communicate, and it’s critical to be open to some changes. If a black shirt hanger shows up one day instead of a white one, understand that it’s because black shirt hangers are what your distributor had that day. Try to work with them to help get through this together.

“There’s absolutely no way we’re all going to get through this if we just stick to what we’ve been doing for the last 10 years. That’s the advice I’d like to give to the cleaners and distributors out there — just communicate and work together to fight through this mess.”

A CLEANER’S MOST VALUABLE ASSET

Part of James Peuster’s duties at The Route Pros, a drycleaning consulting firm, is to speak with cleaners and help them increase the profitability of their business. As a result, he’s seen some of the challenges owners face around the country.

He believes the changing business conditions that started in 2020 have caused a lot of people to rethink

20 American

March 2022 www.americandrycleaner.com

Drycleaner,

how business is done, and this can pose a danger if not handled correctly. He notes that the labor shortage is a major driver of this type of re-evaluation.

“I think a lot of it is this perception that we’re no longer the boss,” Peuster says, “that your employees run the business, not you. And I think it’s a challenge that we have to overcome.”

Part of keeping everything in the correct focus is to make sure hiring and retaining good employees is part of the owner’s everyday activities, not something considered only when a labor shortage becomes an emergency, impacting business profitability.

“We talk about customer retention all the time,” he says, “but do we ever talk about employee retention? What are we doing to ensure that our best employees stay? Sometimes they’re forgotten, and sometimes we just take them for granted, but the strong leaders are adapting to recognizing who they want to keep and how they can keep them.”

As knowledgeable and talented as a business owner might be, successful businesses are generally not operated by only one person. While cleaners may have gotten used to running their business short-staffed because of cost-cut-

ting efforts, Peuster says, that can go on for only so long.

“I think the past two years, leaders have felt like they’ve worked harder,” he says, “and so now you’ve got to develop systems to allow you to work smarter. You’ve got to make some adjustments.”

Getting the right team in place is one of the best ways to accomplish this.

“Always be interviewing, and always be hiring,” Peuster says. “That goes hand in hand with employee retention.”

While many cleaners say they might not have the time to spend 30 minutes a day, for instance, going through résumés, posting on job boards or other hiring activities, Peuster advises them to reassess their schedule because this activity will pay off.

“The reason why you don’t have time for that is that you’re stuck,” he says. “So, you’ve got to make that time; you’ve got to be proactive.

“There are two types of owners. The successful ones are the ones who say, ‘I cannot afford not to have somebody on board who can help me run my business,’ while the not-successful leaders are the ones who are doing it themselves, and they’re the ones who continue to get buried and lose focus.”

www.americandrycleaner.com American Drycleaner, March 2022 21

Hot-Topic Trio: Increasing Profitability, Building Teams, and Your Online Image! Cleaners, Raise Your Prices! Cleaners are often reluctant to raise their rates, even as their own costs are on the rise. Methods for Management’s Kermit Engh discusses the myths surrounding pricing increases and their impact on profitability. Building a Cohesive Staff Jeff Jordan of Fabritec International shares ways he’s found to form a team atmosphere in a business. We discuss the role of management in fostering this feeling in a drycleaning plant, and how to avoid common morale killers. Building Up Your Online Reputation Dave Coyle of Maverick Drycleaners joins us to explore online reputation management — what it is, why it’s important and what dry cleaners can do to make sure they are putting their best foot forward online to attract and keep customers. Every FREE episode... offers engaging, industry-specific conversation with an expert, including business-building tips you won’t find anywhere else. And you can listen anytime, either online or download for later! Give us a try! Listen in at: americandrycleaner.com/podcasts

ADC

22 American Drycleaner, March 2022 www.americandrycleaner.com COMPUTERSYSTEMS CARTS,

PANDEMIC TIME! $1000.00 > > > $750.00/Refurbished, $1250.00 > > > $950.00/HP All In One, Ref $2000.00 > > > $1450.00/New System Includes Computer, Touch Monitor, Invoice Printer. All Name Brands & One Year Warranty! www.westerndccomputer.com 773-878-0150, westernk@msn.com 2022 RATES: One- to five-time rate: $2.20 per word, boldface $2.30 per word. Minimum charge: $25.00 per ad. Call or write for our three- and 11-time rates. If box number is used, add

credit cards

PAYMENT

Paying too much for spotters? Buy 3 Get 1 Free! Buy online and save. DryCleanerSoap.com CHEMICALS www.AmericanDrycleaner.com 000+ Annual Visitors Advertise Today Contact Don Feinstein • 312-361-1682 GARMENT LABELING HEAT SEAL PRESSES from EzProducts International Inc. Toll Free 877.906.1818 www.ezpi.us You Deserve the Best! The Ultimate Heat Seal Machine Proudly made in the U.S.A. Built to OSHA standards 2 YEAR WARRANTY 3 models, 7 different interchangeable lower platens and single or dual heated platens Partnership Equity Partner (in- training) Ehrenreich & Associates is looking for Retired Business Owner or B to B Sales Pro to join E & A as an Equity Partner (in-training) while you learn the Business Merger, Brokerage, Expert Witness & Consulting professions. Reply with your history, location, Contact Info & availability: Ehrenassoc@gmail.com WWW.AMERICANDRYCLEANER.COM www.AMERICANDRYCLEANER.com For more classifieds, visit:

TRUCKS & BASKETS

cost of 5 words. Display classified rates are available on request. All major

are accepted. DEADLINE: Ads must be received by the 1st of the preceding month. For example, for a September ad, the closing date is August 1st.

FOR CLASSIFIED ADS: Must accompany order.

POSITIONS

PARISER INDUSTRIES

A National Manufacturer of Dry Cleaning and Laundry Chemicals is looking to hire a Chicago based, regional sales and service representative.

Candidates will possess good technical and people skills, along with three years related industry experience preferred.

Candidates must have basic computer skills (Microsoft Word & Excel, etc.) and be capable of performing field chemical tests, programming washing equipment microprocessors, and be able to install and maintain electronic dispensing systems. Salary commensurate with experience, Health Benefits, Auto Allowance and full expense reimbursement.

Send Resume to: HR@pariser.net

Luetzow

Newhouse

Parker

Patriot Business Advisors . . . . . . . . .23

Realstar . . . . . . . . . . . . . . . . . . . . . . .13

Royal Basket Trucks . . . . . . . . . . . . .22

Sankosha USA. . . . . . . . . . . . . . . . .BC

SPOT Business Systems . . . . . . . . IFC

Union Drycleaning Products . . . . . . . .7

2022 RATES: One- to five-time rate: $2.20 per word, boldface $2.30 per word. Minimum charge: $25.00 per ad. Call or write for our three- and 11-time rates. If box number is used, add cost of 5 words. Display classified rates are available on request. All major credit cards are accepted.

Ads must be received by the 1st of the preceding month. For example, for a June ad, the closing date is May 1st.

DEADLINE:

PAYMENT FOR CLASSIFIED ADS: Must accompany order. www.americandrycleaner.com American

March 2022 23 Poly Made for: Sankosha Metalprogetti Unipress Save 30% on Poly! Heat Seal Poly Reliable & Affordable Reduce Waste - Cut out the Middle Man - Build Profit Any Size or Gauge, Clear or Branded 10 Roll SPECIAL - 32 Roll Pallet Discount - 56 Roll Best Value SUEDE & LEATHER SERVICE LEATHER-RICH INC. • High-quality cleaning, refinishing & repair Leather, Suede and Fur; • Free Inbound Shipping in USA FOR MORE INFORMATION: www.leatherrich.com E-mail: leatherrich@att.net Call 800-236-6996 Route Service in Upper Midwest SUPPLIES SUPPLIES 800-568-7768 CLEANERSUPPLY.COM OVER 20,000 PRODUCTS IN-STOCK American Dry Cleaner.indd 2 8/25/20 1:11 PM SUPPLIES A.L. Wilson Chemical Co. . . . . . . . . .1 Cleaner Business Systems . . . . . . . . . .3 Cleaner’s Supply . . . . . . . . . . . . . . . .23 Cleantie . . . . . . . . . . . . . . . . . . . . . . .17 EzProducts International . . . . . . . . . .22 Garment Management Systems. . . . . .9 Iowa Techniques . . . . . . .

Drycleaner,

. . . . . . . . . .5

Industries. . . . . . . . . . . . . . .23

Maverick Drycleaners . . . . . . . . . . . .19

Specialty Co. . . . . . . . . . .23

NIE Insurance . . . . . . . . . . . . . . . . . .15

Boiler Co.. . . . . . . . . . . . . . IBC

AVAILABLE

PLANTS FOR SALE Patriot Business Advisors Specializing in Selling Drycleaners in NJ, PA, DE & MD. Sell or Buy Drycleaners. WE HAVE BUYERS!!! Call Liliane at 267-391-7642 www.AmericanDrycleaner.com To Place Your Ad Call Don Feinstein @ 312-361-1682

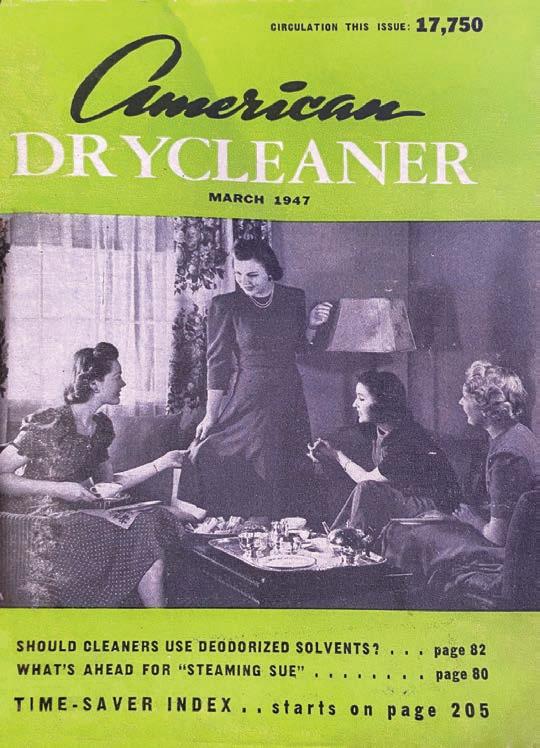

Perc, House Calls and Getting Steamed

10 YEARS AGO. The Word on Perc

The U.S. Environmental Protection Agency (EPA) officially characterized tetrachloroethylene — also known as perchloroethylene (perc) — as a “likely human carcinogen,” but the agency did not believe that wearing clothing dry cleaned with perc posed a health risk. The agency had already taken several significant actions to reduce exposure to perc. Among other steps, it had set clean air standards for dry cleaners who used perc, including requirements that would phase out the chemical’s use in residential buildings by 2020.

25 YEARS AGO. Insurance Strategies

According to ECS Underwriting, a provider of environmental insurance, dry cleaners were leading a trend among commercial businesses and managing their environmental exposures with innovative risk management strategies, said Scott Britt, managing underwriter of ECS’ Industrial and Commercial Facilities Customer Business Unit. In light of the health risk reports that were showing up in media, “dry cleaners nationwide are actively managing their environmental risks with innovative programs including specialized pollution insurance coverage to protect their profitability,” Britt said.

50 YEARS AGO. Curtain House Calls

— Hugh Landes and Paul Bender, partners in Mobile Drapery Cleaners in Hawaii, reported that they were having success in performing curbside cleaning of draperies for both homeowners and business establishments. Their entire operation, which took place in a 22-foot long mobile home that was converted into a cleaning plant, took one hour from start to finish. “Service and speed are what (customers) like most about our mobile setup,” Landes said.

found that more than a third of the nation’s dry cleaners were using steam and air form finishers for silk and wool finishing. The survey also found that 5,800 cleaners were planning to buy this type of finishing equipment and, of this number, about 25% were reordering this equipment. The popularity of steam and air form finishers led to a decline in the demand for silk finishing presses, with cleaners saying they expected to buy fewer than 2,000 pieces of this equipment. ADC

YEARS AGO. Getting Steamed — A survey by American Drycleaner

75

— Compiled by Dave Davis, Editor

24

www.americandrycleaner.com

American Drycleaner, March 2022

WRINKLE IN TIME

Productshaveproventolastupto10timeslongerthan similarproductioninthisindustryandapplications.

Wehavemanyinstallationswithsteamboilersthathave beeninserviceforover50-years,10hoursperday.

Thematerialsusedincurrentproductsarebetterthanthe materialsused50yearsago.Forexample,inthe80’s, steam drumwentfrom3/8”thickto1/2”thick.

Ourheatingsurfaceoramountofsteelabsorbingenergy has alwaysbeen2to3timesthatofotherunits(upto6sf ofheatingsurface per boilerhorsepower,whichsomeunits arecloserto2sfofsteel per hp,andsomeeven1sf).

Wehavethebestdistributedflameormostevensurface areaevenlydistributedundertheentirepressurevessel. It isalsoamodulardesign,so it canberepairedeasily.

Tube materials were upgraded from seamlessrated pipe to seamlessrated tubing. Material is not only thicker, ends up .133 wall, but is annealed which give the surface on both sides a mill scale coating that is more resistant to corrosion and is long lasting from testing.

LowestCostofOwnership?

COMPROMISE FOR QUALITY OR SAFETY

www.parkerboiler.com

NEVERA

5930 Bandini Blvd. Los Angeles, CA 90040 Tel: 323-727-9800

lowestinitialcost,but wehavelowestcostofownershipbecause:

Wemayneverbethe

H app y St. Patrick ’s Day ! Whetheryoupurchaseapieceofourneworused equipment,youbecomeapartoftheSankoshafamily. Andyougetthehigheststandardofserviceplus PeaceofMind SankoshaUSAInc. TOLLFREE:(888)427-9120•TEL:(847)427-9120 http://www.sankosha-inc.com

By Dave Davis, Editor

By Dave Davis, Editor

By Dave Davis, Editor

By Dave Davis, Editor

By Dave Davis, Editor

By Dave Davis, Editor