New York laundry workers ratify master labor contract

NEW YORK — Industrial laundry workers who wash linen for New York City’s hotels, hospitals and restaurants voted to ratify a new master contract among 14 laundries in the metropolitan area, reports the Laundry, Distribution and Food Service Joint Board, Workers United/Service Employees International Union (SEIU).

The contract includes significant wage gains for laundry workers, a majority of whom are AfricanAmerican women and Latina immigrants, and will also grant them continued free employer-paid individual medical, dental and vision insurance and a pension, the union says.

Laundry workers will be part of one multi-employer contract, which sets the standards for a majority of laundries in the New York metro area.

Wilfredo Larancuent, regional manager of the Laundry, Distribution and Food Service Joint Board, Workers United/SEIU, says he’s proud of what the group has accomplished. “This contract makes real improvements for laundry workers and their families and continues to raise standards for the industry.”

Elected worker representatives from the laundries bargained the contract with employer representatives for more than a month. A strike vote was held at the laundries, but the contract was settled prior to the strike deadline.

hospital, hotel laundry, linen ops feel brunt of Superstorm Sandy

By RichaRd MeRli

NEW YORK — Superstorm Sandy flooded and crippled numerous hospital and hotel laundry operations when it struck the Northeast in late October.

Several laundry and linen operations were destroyed by saltwater flooding and storm surges, caused by winds of 85 to 90 miles per hour, while numerous other operations were knocked out of service for weeks by power outages, due to overhead electrical lines downed by fallen trees.

A confluence of events, combining a tropical storm, a hurricane, and a high tide, caused by a full moon—some dubbed it the Perfect Storm—created a strong storm surge of 14 feet and left an estimated 102 people dead and caused an estimated $50 billion in property damage and lost business along the East Coast.

On the east side of Manhattan, flood waters from the East River traveled 600 feet and destroyed the laundry and research facili-

ties in Hunter College’s Brookdale Health Science Center on East 25th Street. Salt water also flooded the dormitory in which 660 residents lived. Many of the campus’ programs will be relocated to Hunter College’s main campus on East 68 Street in Manhattan, according to Jennifer Raab, the college president.

The storm also shuttered the Veterans Administration (VA)

Hospital on East 23th Street, Bellevue Hospital Center on East 27th Street, and New York University Langone Medical Center on East 32nd Street, all located on First Avenue, less than 1,000 feet from the East River. Three weeks later, the hospitals were still closed.

“The East River rose and flooded the basement and first floor and knocked out our electrical

and heating systems and linen services,” says Thomas Johnson, a spokesman for the VA hospital in Manhattan. “It may be springtime before we can reopen again.”

In Somers Point, N.J., a popular Jersey shore resort town, the Pier Four luxury hotel’s laundry was flooded and destroyed by more than three feet of ocean water.

SafeTRSA data shows laundries growing safer

CHICAGO — For Toledo’s NuCentury Textile Services, 2012 began under horrible circumstances.

Published reports indicate that, on Jan. 3 last year, an employee failed to turn off and lock a folder before servicing it. His clothes got caught in the machine, and his hand and forearm were injured. He later died from complications while recovering at home.

The Occupational Safety & Health Administration (OSHA) cited NuCentury for several alleged safety violations and fined

it $40,000. NuCentury hired a safety consultant and took other steps to improve its safety program, prompting OSHA to lower the fine to $19,600.

Despite best efforts, on-thejob accidents do occur in and around textile service facilities, and employees are injured or, on rare occasions, even killed.

There are resources available to help an operator ensure his plant is being run safely, and among them is SafeTRSA, a program offered by the Textile Rental Services Association (TRSA).

It provides safety training materials to TRSA members and measures the industry’s progress in implementing enhanced practices to reduce and eliminate occupational injuries and illnesses in plants and depots, according to Ken Koepper, director of marketing and public relations for the association.

Success is quantified when TRSA administers its annual survey of its members’ occupational injury and illness data, he explains.

“Such tracking over the past several years has prompted TRSA’s

creation of industry-specific initiatives and resources to focus on the industry’s highest risk areas and those cited most frequently by OSHA.”

This has resulted in TRSA members’ adoption of proven policies and procedures for maintaining equipment (lockout/tagout), handling soiled linen (especially bloodborne pathogens) and working in confined spaces, Koepper says.

“The networking and informa-

Janua Ry 2013

ALN late n ews

www.americanlaundrynews.com Volume 39, number 1

The newspaper of Record for laundry & linen Management

inSide [4] [14] Panel of Experts Meet the illustrious group of industry experts who will tackle our questions. [10] Product showcase heatgenerating equipment See SUPERSTORM on Page 19 See SAFETY on Page 9

Value

cites four ways that a healthcare laundry can add value.

Adding

Eric Frederick

The Manhattan skyline on the second night without power due to Hurricane Sandy. (Photo: ©iStockphoto/Andrew Cribb)

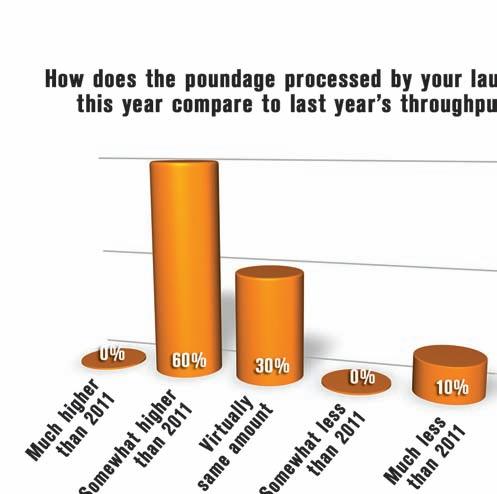

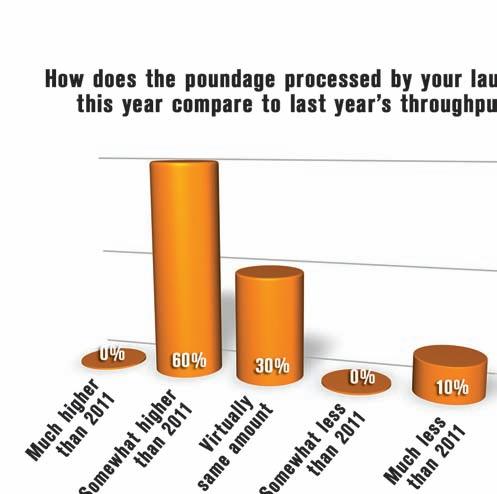

Survey: 60% of operators say 2012 throughput

CHICAGO — Sixty percent of respondents to American Laundry News’ final Wire survey for 2012 said their laundry’s poundage processed last year was “somewhat higher” in comparison to 2011 figures.

For everyone else who took the unscientific online survey, their 2012 throughput was at or below 2011 levels. Thirty percent reported processing “virtually the same amount,” and the remaining 10% lamented processing “much less.”

Total estimated production for 2012 ranged by operation from 600,000 pounds to 14 million pounds, according to these anonymous responses.

Operators whose production rose attributed it primarily to gaining institutional business or increasing total accounts (71.4%); adding, replacing or rebuilding equipment (14.3%); expanding a facility or relocating to a larger site (14.3%); and/or “other” (14.3%). (Respondents could choose any or all among several suggested factors or offer their own.)

Why did some operations fall short of annual goals or expectations in 2012? A slowing or loss of business due to the economy, staff productivity, maintenance efforts, administrative indifference or lack of support, and regulatory changes all were seen as receiving some of the blame, according to respondents.

Finally, respondents were asked how they thought their boss would grade their 2012 managerial performance. Half believed they would receive a B (50%), while 40% said they would receive an A. The less-thansunny remainder (10%) said they would receive an F.

The Wire survey presents a snapshot of readers’ viewpoints at a particular moment but should not be considered scientific.

Subscribers to Wire e-mails—distributed twice weekly—are invited to take a brief industry survey anonymously online each month.

All managers and administrators of institutional/OPL, cooperative, commercial and industrial laundries are encouraged to participate, as a greater number of responses will help to better define operator opinions and industry trends.

Linen King opens new company HQ in Oklahoma

TULSA, Okla. — Linen King, a provider of healthcare laundry services, reports that it has added a sixth location that will serve as the company’s new headquarters. Located at 1521 W. 36th Place in Tulsa, the facility provides approximately 3,300 square feet of office and conferencing space and 5,000 square feet of warehouse space.

The new headquarters is centrally located between Linen King’s five Midwest plants, including facilities in Oklahoma, Arkansas, Missouri and Kansas. The company processes more than 50 million pounds of textiles annually for hospitals and medical facilities, and revenue is expected to grow by 20% in 2013.

“Our investment in a new headquarters in Tulsa supports our strategy that focuses on both organic growth and acquisitions,” says Leonard McCullough, CEO of Linen King. “Our goal is to become one of the nation’s leaders in healthcare laundry service. This involves maximizing the capacity in our current markets and also expanding in ways that provide backup for our existing facilities.” ALN

Alliance appoints Washburn

RIPON, Wis. — Alliance Laundry Systems has officially appointed Washburn Machinery, headquartered in Elk Grove Village, Ill., as its new UniMac distributor for northwestern Indiana.

The longtime distributor already represents UniMac’s on-premise laundry equipment in northern and central Illinois and east-central and southern Wisconsin, according to its website.

To learn more about Washburn Machinery and its relationship with Alliance Laundry Systems, visit washburnmachinery.com.

Publisher

Charles Thompson

Phone: 312-361-1680

E-Mail: cthompson@ americantrademagazines.com

Editorial Director

Bruce Beggs

Phone: 312-361-1683

E-Mail: bbeggs@ americantrademagazines.com

Digital Media Director

Nathan Frerichs

Phone: 312-361-1681

E-Mail: nfrerichs@ americantrademagazines.com

Production Manager

Roger

Napiwocki

Contributing Editor Jean Teller

Advertising Sales

National Sales Director

Donald Feinstein

Phone: 312-361-1682 E-Mail: dfeinstein@ americantrademagazines.com

Office Information

Main Phone: 312-361-1700 Fax: 312-361-1685

Subscriptions

630-739-0600 www.americanlaundrynews.com

American Laundry News (ISSN 1091-9201) is published monthly. Subscription prices, payment in advance: U.S. & possessions, 1 year $39.00; 2 years $73.00. Foreign, 1 year $89.00; 2 years $166.00. Single copies: U.S. & possessions $7.00; Foreign $14.00. Published by American Trade Magazines LLC, 566 West Lake Street, Suite 420, Chicago, IL 60661. Periodicals postage paid at Chicago, IL, and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Laundry News Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 39, number 1. Editorial, executive and advertising offices are at 566 West Lake Street, Suite 420, Chicago, IL 60661. Charles Thompson, President and Publisher. American Laundry News is distributed selectively to qualified laundry and linen management and distributors in the United States. No material appearing in American Laundry News may be reprinted without written permission. The publisher reserves the right to reject any advertising for any reason.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2013. Printed in U.S.A.

MEMBERSHIPS

2 JANUARY 2013 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

Association for Linen Management

INSIDE: [6] Industry Laments Lower IHMRS Turnout Laundry/linen-related exhibitors encounter belowaverage attendance in the wake of Hurricane Sandy [8] Tools of the Trade [10] Panel of Experts Introductions Meet the newest members from across the industry who will answer our laundry management questions in 2013 [13] Career Track [14] Product Showcase: Heat-Generating Equipment [16] Trade Ticker [18] OPL 101: Long-Term Care Laundry Solutions Residents and their family members are becoming increasingly discerning about the level of services provided January 2013 • Vol. 39 | No. 1

ALN

higher

than previous year’s

ALN

Sandy Hook and security

who were gunned down by a troubled young man is the least that I could do to honor their memory.

freedom and security. We live in the land of the free, after all, but that comes with a price.

The Director’s Chair Bruce Beggs

s I was in the midst of writing this, I paused, along with many others in our nation, for a moment of silence to honor the victims of a mass shooting at a Connecticut elementary school. Taking a moment to remember the young children and educators

Each weekday, I commute from the Chicago suburbs into the city, traveling to an office building with a secure entrance. I’m vigilant during my six-block walk from the train station because, after all, I am in Chicago, but once I’ve buzzed myself in and reached my office, I feel safe and can get to the business at hand.

That’s probably how the Sandy Hook Elementary students felt on Dec. 14— secure about their surroundings and ready to learn. But then unspeakable evil burst in without warning and snuffed out their innocence.

My thoughts today are not on gun control, but about how best we can strike a balance between

Take a moment to review your facility and its security measures. How easy is it for people to come and go? Are you and your employees truly safe there?

“That could never happen here,” we think. But then it does, and we’re changed forever.

• • • • •

Lastly, a reminder for you manufacturers, exclusive distributors, or unique service providers about our March Buyer’s Guide issue. You should have received an e-mail invitation instructing you how to update your information on our website. If you didn’t receive one, or have any questions, e-mail me at bbeggs@american trademagazines.com. ALN

Design-build firm relocates mechanical room, adds on to loading dock for Alsco

SAN DIEGO — ARCO/Murray

National Construction Co. recently completed a mechanical room relocation and canopy building addition here for Alsco.

In November 2011, a boiler malfunction caused the textile rental company to shut down its mechanical room and rent a temporary boiler. Alsco hired ARCO/Murray to relocate the mechanical room and install new mechanical-room equipment. The firm was able to complete the project by early April, limiting the amount of money spent to utilize a temporary boiler.

The mechanical-room relocation included demolition of a two-story storage and office area to make room for the new system, which included a 400-horsepower boiler,

a water softener package, and a brand-new water system with a stack economizer. ADA-compliant bathrooms were also constructed.

ARCO/Murray was responsible for the demolition and reconstruction as well as all power and process piping tie-ins to the equipment within the mechanical room and out to the existing wash floor and wastewater systems.

While the expedited mechanical-room project was under construction, ARCO/Murray was also hired to design and permit a 5,000-square-foot loading dock addition. Through careful coordination with the City of San Diego and Alsco, ARCO/Murray was able to complete the project with limited interruption of Alsco’s opera-

tions and minor disruption of the city’s traffic flow, the company reports.

Along with the canopy, ARCO/ Murray was responsible for demolishing and replacing approximately 300 linear feet of sidewalk. The new dock canopy is able to hold six step vans and one box truck, increasing loading capacity and allowing Alsco to load completely within its property lines.

Project executive Elliot Mata and project manager Patrick Hidder represented ARCO/Murray. Bob Stephens served as Alsco’s corporate engineer, and Shane Harrison, the San Diego plant’s general manager, served a vital role in coordinating between Alsco and ARCO/ Murray during construction. ALN

deliver value to owners, customers and employees

•

•

•

•

•

•

•

•

•

•

w

hat is the primary focus of a good manager? I think too often, as managers, we get lost in the weeds of everyday life and fail to focus on the really important things.

A good manager should focus on delivering value to his organization or ownership, his customers, and his employees. During the past several years, there have been ample opportunities for managers increase value to all three groups. Let’s quickly review some of them:

Add a microfilament mop program to your laundry.

These types of mops are designed to be easier to use, provide better cleaning and disinfecting in the healthcare environment, and protects a critical portion of your business.

Add reusable isolation gowns to your product mix.

This product is a cost-effective way to lessen the environmental impact of the healthcare industry. They are more comfortable for the end-users to wear, and provide better protection for the healthcare worker. The additional volume is a nice addition to any laundry facility.

Develop a cubicle curtain-cleaning program.

Cubicle curtains have been identified as a possible source of contamination in a patient’s room. More frequent cleaning is being recommended, and the need to develop a quick, effective cleaning program is becoming essential.

The days of curtains hanging in a room for months or years are gone.

a good manager shouLd focus on deLivering vaLue to his organization or ownership, his customers, and his empLoyees.

Many hospitals have been sending their curtains out to local cleaners to get them processed, and many are paying by the square inch for this service. Developing a cost-effective cubicle curtain program requires minimal research on the part of the manager. The healthcare facility benefits by reducing the cost and improving the turnaround, the patient benefits from a cleaner curtain, and the laundry benefits from having the additional volume.

Develop a microfiber cleaning cloth program.

Effective environmental cleaning in the hospital is the first line of defense. Patients are carefully watching the work of their housekeepers. Lately, there has been an increase in the number of complaints concerning using the same cloth to clean the bathroom and the bedside table. Patients are looking for a readily identifiable change in procedure.

Colored microfiber cleaning cloths are ideal for use, because they do not lint and can be purchased in the preferred 12x12 size. One color can be used for the bathroom and a different color for the patient’s room. This product replaces the use of washcloths as cleaning cloths, increases the effectiveness of cleaning, provides greater patient satisfaction, and is easily processed by the laundry.

In all four of these cases, the laundry manager has increased value at all levels of his or her operation. By increasing the value, the manager increases customer satisfaction and employee job security.

Based on what is happening in our country, with high levels of unemployment, I take my responsibility to provide good working conditions and stable employment to my employees seriously. By focusing on adding value to my operation through improving existing products, adding new products or improving production, I meet this goal.

4 january 2013 | american Laundry news www.AmericanLaundryNews.com

Top Stories Appearing on AmericanLaundryNews.com for the 30 Days Ending Dec. 15 (WE) = Web exclusive news

Design-Build Firm Relocates Mechanical Room, Adds On...

New Consulting Firm Aims at Improving People, Processes...

Columnist At lArge Eric L. Frederick, RLLD

•

•

AmeriPride Plant in Idaho Earns First TRSA Hygienically Clean...

Washing Systems Honored for Green Chemistry...

Laundry Labor Union Elects Taylor President

Columnists/Features

Survey: Many Thankful Because Their Laundry Operations are Performing Well (We)

Panel of Experts: Seek Balance Along with New Business

•

Retrofit Project Enables Spin Linen to Add Healthcare Service to Portfolio

Purchasing Laundry Equipment: Buying New or Used? our sister websites From AmericanDrycleaner.com:

StatShot: Dry Cleaning Sales Rise Across the Board (We)

Pre-Spotting Step Toward Better Cleaning

From AmericanCoinOp.com:

Sales School Arms Attendees with Tools to Compete

Maytag

Girbau

Garners...

e)

Belson Co./Continental

Open House

(W

From

a

ALN

Eric Frederick is director of laundry services for Carilion Laundry Service, Roanoke, Va., and a past president and manager of the year of the Association for Linen Management. You can reach him by e-mail at efrederick@carilion.com.

Laundry industry laments lower turnout for IHMRS

BY RichARd meRLi

NEW YORK — Manufacturers of laundry machinery, reusable textiles, and laundry chemicals encountered below-average attendance at the annual International Hotel, Motel + Restaurant Show (IHMRS) here Nov. 10-13, in the wake of Hurricane Sandy, which had battered the East Coast Oct. 29. But the dark clouds carried within them a silver lining: Many exhibitors suggested the storm damage to laundries may drive demand for replacement machinery, textiles and chemicals well into 2013.

“Some laundries were able to function with generators, but other laundries were completely devastated,” says John Smith, regional sales manager for Speed Queen. “In the hospitality industry, it’s still too early to make an accurate assessment of the damages to laundries. But equipment replacement orders may lag into the spring. This storm could have an ongoing effect into the next year.”

Total trade attendance at the show this year was unchanged from 2011 at 23,953. But the number of industry buyers totaled 15,082, down from 17,955 in 2011, according to Melissa Gray, a spokeswoman for the show’s management. “The hurricane definitely had an impact,” she adds.

However, among the hotel owners and operators who attended the show, there was strong interest in increasing efficiency in laundry operations to help hotels and motels become more profitable by reducing energy costs, according to Smith. For example, hotels can increase energy efficiency by reducing gas usage, beginning in the wash process. Using a washer-extractor equipped with a 200 G-force extraction speed can ensure optimal water removal from linens, which leads to reduced drying times, he says. In addition, using a tumble dryer equipped to prevent over-drying further decreases gas costs.

Hotel owners and operators demonstrated strong interest in laundry controls capable of providing reports on productivity, according to Bill Brooks, North American sales manager for UniMac. The first day of the show produced little floor traffic, according to Brooks. But then the company experienced rising interest from small, independent hotel owners and representatives of larger chains, who are increasingly cost-conscious.

“Owners and operators understand that

if you can measure your consumption, you can improve your utility, chemical and labor costs,” says Brooks.

He predicted that Hurricane Sandy will have “a big impact” on equipment replacement orders from hotels in 2013, because many laundries on the East Coast were flooded with salt water. Many of those laundries were located on lower floors or in basements, Brooks noted.

“When hotels re-open for business, one of the first things they need is clean laundry,” he says. “They have to do laundry, whether they salvage their equipment or replace it.”

Pellerin Milnor Corp., which shared a booth with Chicago Dryer Co., enjoyed “quality traffic” and generated “strong leads” at the show, according to John Rasimas, regional sales manager for Milnor.

Milnor exhibited a washer-extractor and washer, both with 60-pound capacities, while Chicago® exhibited its new maximumspeed version of its Air Chicago Express high-production small-piece folder. The new folder featuring a continuously running high-speed conveyor is designed to provide faster throughput in a narrower footprint.

“The first day of the show, Sunday, was very slow, but Monday produced some quality leads for us,” says Steve Hietpas, national sales manager for Maytag Commercial Laundry. “There was good interest from owner-operators of smaller hotel facilities of 100 rooms or less, both from the East Coast and the Caribbean.”

Cuddledown, a manufacturer of institutional bedding, pillows and comforters, came to the show “expecting it to be dead – the worst ever – because of Hurricane Sandy,” according to Ryan Scott, a hospitality sales associate for the company. “But it turned out to be much better than expected. We were very pleased, because hospitality represents the fastest-growing segment of our business these days.”

Greg Eubanks, group vice president of Hospitality Sales and Marketing for Standard Textile, echoed that experience. “We expected the show to be really slow,” he says. “But it’s turned out to be a pleasant surprise. It was much better than expected.”

Standard Textile exhibited its Todd-Avery Lenahan Collection of sheets, which are now in use in more than 40 J.W. Marriott hotel properties worldwide, according to Eubanks. The microfilament interior of the sheets provides durability, while the cotton surface

provides comfort. The sheets are laundered with Tide products and delivered clean, fresh and ready-to-use out of the box.

Cintas Corp. teamed with fashion designer Jay Godfrey to present its Fashionable New Apparel Collection, according to Dan Ambrosio, vice president of Global Lodging and Cruise for Cintas. The purpose of the partnership was to create a new line of stylish, distinctive and durable suiting for hotels.

Godfrey collaborated with Cintas to create a distinctively contemporary black suiting collection for men and women. The collection consists of slim-fitting silhouettes with narrow lapels, high-notch collars, shell buttons wrapped in stainless steel and signature jacquard dot-lining with magenta piping.

W Hotels Worldwide debuted the new wardrobe in 28 North American properties and plans to expand it globally. Although the collection is now exclusive to W Hotels, it will become available to all hospitality organizations in early 2013, according to Ambrosio.

The Textile Rental Services Association (TRSA) exhibited to demonstrate how the services of TRSA members can reduce the carbon footprint and increase the profitability of hotel, motel and restaurant operations.

The association emphasized its new Clean Green certification, which provides third-

party verification that the linens, napkins, tablecloths, garments and other reusable textiles obtained from TRSA-certified members are laundered in an environmentally friendly manner.

TRSA gathered market data to help drive future programming. For instance, attendees were asked for feedback on their experiences with contracting for linen services. Many smaller hotel and motel operators appeared to be unfamiliar with the outsourcing option, according to TRSA, and were directed to the association’s website to find a textile services provider.

Proctor & Gamble, the maker of Tide, had a busy second day at the show and enjoyed strong interest in its color-safe products, according to Greg Elmore, an account executive for the company.

Ecolab generated interest with its Aquanomic laundry products, designed for low-temperature washing to achieve energy savings of 30-40%, says Bob Makely, associate district manager.

The IHMRS will convene again in New York in November. ALN

Richard Merli, who resides in Brooklyn, N.Y., is a former editor of American Laundry News.

6 JANUARY 2013 | AmeRicAN LAUNdRY News www.AmericanLaundryNews.com

While attendance at the 2012 International Hotel, Motel + Restaurant Show was reportedly down, exhibitors familiar with the laundry industry say damage from Hurricane Sandy could drive increased demand for replacement equipment and more well into 2013. (Photo: Richard Merli)

Pellerin Milnor Corp. and Chicago Dryer Co. displayed new equipment in a shared booth. (Photo: Richard Merli)

Cintas Corp. teamed with fashion designer Jay Godfrey to present a new line of stylish, distinctive and durable suiting for hotel staff. (Photo: Richard Merli)

SLINGS

PLASTIC

HAMPERS BASKETS

NETS

CARTS FILM COMMERCIAL INSTITUTIONAL

Tools f the Trade

New dual hazard knits protect against arc flash, flash fire

Workrite Uniform Co. has introduced a line of knits with new styling featuring a dual hazard fabric called TenCate Tecasafe® Plus.

The knits protect against both arc flash and flash fire, the company says, and are geared toward both industrial and fire service customers. Workrite is working to have the knits certified to both NFPA 2112 and NFPA 1975, and further report that they meet Hazard Risk Category 2 for NFPA 70E. The line represents a more modern fit and incorporates features such as longer tails, raglan sleeves on the T-shirts and high-low hems on the polos. The dual hazard knit shirts retain their strength,

Sunburst Chemicals has introduced a new line of solid laundry products that are composed of EPAapproved ingredients. Called the Conserv Energy System (CES), the line of products is adaptable to specific laundry needs, uses less water, and can deliver hot-water results with cold-water use to reduce water, heating and electric utility costs, the company says.

The lineup includes the Conserv SG65 laundry detergent, which is formulated to remove heavy grease and particulate soils; Conserv SG55 color-safe oxygen bleach, which whitens and brightens fabrics in hard, soft, warm or cold water; Conserv SG80 fabric softener, which speeds extraction and drying time while reducing wrinkling and static cling; and Conserv SG84 iron removing sour, which reduces staining problems by controlling metals in the water.

The make-up of the chemicals not only include EPA-approved ingredients, but also a detergent exclusive to their brand, according to Patrick Laughlin, vice

Speed Queen reports that it has upgraded some of its tumble dryers with Over-dry Protection Technology (OPT), and some with reversing technology.

The OPL stack 30- and 45-pound tumble dryers are now available with OPT, while its single-cylinder 25and 55-pound OPL tumble dryers, as well as its 50- and 75-pound vended tumble dryers, are now available with reversing technology.

OPT controls the level of dryness to help sustain the integrity of materials, the company says, reducing fiber loss by as much as 31%. Baffles are used

shape and color after repeated launderings, the company says.

“With the ability to be industrially laundered, they are perfect for all our customers, regardless of what type of [flame-resist] program they are in,” says Charlotte McGee, director of marketing.

The line is protected by a one-year guarantee, and comes in long- and short-sleeved polos in navy blue and a long-sleeved T-shirt in heather gray.

workrite.com/knits 805-981-6502

Plexus Industries, in collaboration with Admiral Linen & Uniform Services, reports that it has developed a new closure system for route bags, with no draw cord–or strings–attached.

Called the Buckle Bag, the product design eliminates the issues that can come with draw cords—knots that can’t be untied, cords being cut, bags without cords–and utilizes two side-release buckles made of ballistic plastic, Plexus Industries says.

When placed on a stand and filled with product, the Buckle Bag is closed by locking the opposing color-coded buckles, ensuring that the product stays in place during transport, the company adds. Once the bag arrives at a sorting

station, the buckles are released with a finger pinch and the product is removed. The buckles can also be released when full bags are hanging upside-down.

The company is offering the buckle feature on all of its bags, from the PVC-coated mesh to the woven polyethylene.

plexusindustries.com 619-888-7173

president of sales and marketing. “The foundation of CES is Sunburst’s patented COMPASS solid laundry detergent, an EPA Design for the Environmentapproved product that most often requires no additional chemicals in the washing process.”

sunburstchemicals.com 800-899-7627

Penn Emblem Co. is releasing a new flame-resistant transfer application combining safety and identity that the company says is safe for use on FR fabrics.

The company says it has obtained certification that meets standards for transfer applications on all FR fabrics.

Launderers that allow Penn to sample a customer’s logo will see that small details are clearly visible and that colors on the transfers are vibrant, the company says.

Product samples and application directions are available from Penn by calling or e-mailing.

pennemblem.com 800-793-7366

as sensors and provide pinpoint moisture readings throughout the entire load.

When the tumbler has reached its preset level of dryness, it shuts off automatically, Speed Queen says.

Reversing technology allows the dryer cylinder to alternate directions, preventing large items such as sheets or tablecloths from becoming knotted and twisted, providing a consistent and even dry, the company explains.

Both OPT and reversing technologies on the company’s tumble dryers are available through its Quantum controls. speedqueen.com 800-590-8872

manufacturers: Have you introduced a new product? Revamped your system? Released a new catalog? E-mail your product news, along with a high-resolution image, to news@ americantrademagazines.com and we’ll consider publishing your news free in Tools of the Trade.

Talley Machinery Corp. is introducing an automated laundry lift table that replaces manual handling and transfer of clean linens with a system that eliminates heavy lifting, speeds work flow and boosts efficiency, the company says.

For use in commercial, industrial and institutional laundries, the table corrals clean, dried linens in a companion laundry truck, which then raises and dumps the linen onto a work surface for folding. The entire process moves automatically through the use of compressed air, Talley says.

Originally developed by Norman Control, the automated lift tables are offered in a choice of four standard

models with wire trucks, and may be customized to suit various laundries’ production requirements and floor plans.

Talley also manufactures and stocks replacement parts and provides repair services for units in the field.

talleymachinery.com 800-222-9954

8 january 2013 | american Laundry news www.AmericanLaundryNews.com

Solid laundry chemicals formulated to be adaptable to specific needs, use less water

Newly designed route bag comes with ‘no strings attached’

Flame-resistant transfers combine safety and identity

Equipment maker upgrades tumble dryers with over-dry protection, reversing technology

Automated lift table safely removes linens from carts to eliminate manual transfer

tion-sharing between members on such matters has generated new programming for educational institutes and conferences as well as publications, online resources, videos and more.

Membership-wide safety statistics enable TRSA companies to easily compare their improvements to the industry norm and foster further gains.

Data from 2011, reported in 2012, will be released by TRSA shortly.

“Our survey from 2010 covered 59 textile services companies operating 720 processing facilities and depots,” Koepper says. “It showed that in the prior four years, the industry experienced across-theboard reductions in its injury and illness rates. TRSA calculates separate TRIR and DART rates for plants and depots.

“The new report will reflect further reductions. Also, participation in the survey increased in 2012, to 66 companies operating 792 facilities.”

TRIR stands for Total Recordable Incidence Rate. DART is short for Day Aways, Restricted or Transferred.

From 2006 to 2010, TRSA respondents reduced their total number of recordable injuries and illnesses per 100 employees (TRIR Rate) from 9.5 to 5.5, Koepper says. Injuries and illnesses per 100 employees resulting in days away from work, job restrictions and/or job transfers (DART Rate) dropped from 5.8 to 3.9.

TRSA also calculates separate figures for the industrial and linen segments. The new report will cross-reference these with the federal Bureau of Labor Statistics’ (BLS) industry-wide figures, according to Koepper.

In 2011, at TRSA’s request, for the first time in roughly a decade, BLS published separate TRIR and DART rates for textile services (industrial and linen) as opposed to the agency’s prior practice of only consolidating them with all other types of commercial laundry (mostly dry cleaning and coin laundry).

Koepper says TRSA requested this reporting enhancement as a means for tracking future industry-wide improvements.

“Although TRSA and BLS results show that the industry is still short of achieving its ultimate objective—eliminating occupational injuries and illnesses in its facilities—these reports also demonstrate dramatic progress towards achieving that goal,” he says.

TRSA hosted a Safety Summit last year that focused on enhancing safety cultures across the industry.

“It had been four years since the industry conducted a single-subject meeting on safety,” Koepper

says. “Although it was a seminar topic in conferences and educational institutes, too much time had passed since an event dedicated to the subject was held.”

Audiences for prior safetyfocused meetings had consisted mostly of hands-on safety professionals. The Summit concept involved the highest levels of textile services management, elevating TRSA’s involvement in guiding operators in increasing the prominence of safety in their corporate cultures.

“The Summit went beyond day-to-day injury prevention tactics,” Koepper says. “It examined

options the industry could exercise collectively to hire the proper expertise, immediately assess the greatest risks and devise near-term action plans for developing standards and communicating them to operators.”

The TRSA Safety Committee is working on those plans, and a second Safety Summit has been scheduled for May 22 in Indianapolis.

Koepper says he’s seen the industry make great strides in automation in recent decades.

Automated material handling reduces the “manual labor requirement for this purpose. Soil bags are hoisted and carried on rails auto-

matically to washers. Computing drives clean-side garment sorting. To prevent hazardous discharge of energy, smart systems are limiting access to areas where electricity must be controlled to ensure machines don’t start unexpectedly.”

But automation isn’t likely to ever completely eliminate all the different types of human movement required to provide textile services.

“Route service, for example, will always involve an individual walking from a truck to a customer’s receiving area,” Koepper says.

“To reduce exposure, the industry

has increased its proficiency in safer lifting, carrying and pushing. More individuals are cross-trained to perform different jobs in the course of a day to curtail redundant motion.”

TRSA is guiding members in their quest to convince every employee that safety comes first and productivity second.

While it is still a huge job to get to zero incidents in an industry so heavily dependent on athleticism and individual workers’ judgment, Koepper says TRSA is pleased with the gains of recent years and believes more improvement lies ahead.

www.AmericanLaundryNews.com AmericAn LAundry news | JAnuAry 2013 9 continued from Page 1

ALN

safety

2013

Since graduating from the University of Wisconsin with a bachelor’s degree in business administration and marketing, I’ve spent the majority of my career—more than 15 years—in the commercial laundry industry, with a focus on the on-premise laundry segment.

Currently a senior sales manager, I joined the Maytag® Commercial Laundry team in October 2007. To date, I have managed OPL sales throughout the Midwest, Mid-Atlantic and Canadian markets, and I work directly with distributors to ensure our products meet the needs of their customers. Previously, I was a regional sales manager for another commercial laundry equipment manufacturer covering a similar territory. My background also includes working with national accounts that purchase equipment directly for their own use, as well as selling to franchisees.

Maytag® Commercial Laundry offers a full range of commercial washers and dryers to the OPL market through an international network of distributors. Our company is dedicated to developing energy-efficient solutions and dependable products for the commercial laundry market. And in 2008, Maytag® Commercial Laundry celebrated the 50-year anniversary of its entry into the commercial laundry business.

As the industry continues to evolve, so does commercial laundry equipment. From a manufacturer’s perspective, this can create challenges. An excellent example of this is the ongoing objectives to increase the energy and/or water efficiency of equipment, while decreasing the amount of time it takes to do laundry—therefore decreasing labor costs—and providing exceptional cleanability.

2012 was a busy and successful one for Maytag® Commercial Laundry. We introduced an industrial line of soft-mount

PaneL oF exPertS

ready to answer industry questions

washer-extractors available in 180-, 230- and 275-pound models. We also enjoyed continued growth within the OPL market segment and are continuing to work on new product introductions for 2013 and beyond.

Textile Association (ARTA), where I serve on the board of directors, and am a member of the Healthcare Laundry Accreditation Council (HLAC) advisory board. I hold a bachelor of science degree in textile and apparel management from Philadelphia University.

in laundry, dry cleaning and linen management.

Ihave expertise in image apparel and uniform program management, specializing in healthcare laundries. With more than a decade of supplier sales experience, and another 15 years in a mixed-plant linen supply company, I believe my hands-on knowledge base is unparalleled.

I, alongside my father, grew up operating a women’s apparel cutand-sew operation. I am passionate about sharing my knowledge with others and helping them build successful partnerships.

The company I work for, Superior Uniform Group, was founded in 1920 as Superior Surgical Manufacturing. By 1926, its Fashion Seal Uniforms brand was created. After acquiring several other manufacturers over the years, Superior Surgical officially changed its name to Superior Uniform Group in 1998 to better reflect its greatly expanded clientele base.

Superior Uniform produces more than a dozen catalogs, outfitting employees from various industries that include healthcare, restaurant/food service and governmental/public safety. The company has also created a call center division called The Office Gurus, and a digital apparel division called everyBody Media, which were launched in 2008 and 2011, respectively.

I am a board member for the Textile Rental Services Association (TRSA), where I develop and present in-house training programs that can be used in laundries as they seek new, innovative approaches to selling uniforms to the healthcare industry. I am also active in the American Reusable

A couple issues that will present challenges in the new year include market changes and how our healthcare customer base is looking for a new type of uniform look, with new kinds of user-friendly fabrics. I’ll also be thinking about more employee purchase programs as hospital and healthcare budgets continue to be cut.

As director of Laundry Services for The Pierre New York, I am responsible for the day-to-day service, production, distribution, maintenance and procurement for this Five Diamond hotel’s laundry and dry cleaning operations.

During 2012, the laundry processed 2.5 million pieces of rooms and food-and-beverage linen, which represented a 23% increase over 2011. Additionally, it processed more than 350,000 pounds of garments during 2012, representing a year-to-year increase of 11%. Increases in productivity were achieved without any increase in expenses.

The biggest challenges I face at the Pierre today are similar to the challenges faced by the entire industry: providing the best possible products and services at the lowest possible cost.

tion systems, marketing and sales meetings, as well as maintaining many long-term customers in my own Philadelphia area territory.

At Metro-Chem, we manufacture more than 100 laundryspecific products for all laundry needs. We provide innovative, top-quality chemistry to all segments of the industry, but we believe that you can only be as good as your ongoing commitment to service in the field. It is this combination of effective products and a true consultative approach to technical service that I believe helps fuel our sales growth and delivers the greatest good to our individual customers’ businesses.

First, it is an honor to be once again selected for this Panel, and I hope to continue to share the benefit of my experience with the readership of American Laundry News

I have been in the commercial laundry industry for 30 years, having operated healthcare, hospitality and uniform plants throughout the United States. The laundries have ranged in size from 10 million to 40 million pounds annually, and have operated in both union and non-union environments.

I have a wealth of experience in production, distribution and service management, as well as budget preparation and financial analysis—skills honed during my seven years on Wall Street.

During the past nine years, I have concentrated on the hospitality side of laundry management, presently operating an OPL for Taj Hotels at the Pierre New York, as well as serving as a consultant for our sister property, Taj Boston.

I have served on the faculty of NYU, teaching laundry and dry cleaning operations as part of NYU’s Hospitality Management program. I also maintain several industry-recognized certifications

Hello, my name is Phil Bodner, and I am a “soap-man.” I get to wear many hats and mean many things to the customers I serve. I’m pleased to be a part of American Laundry News’ continuing effort to bring new ideas and beneficial information to our industry. I hope to contribute to the conversation and provide whatever insights that my experience will allow.

I live in South Jersey with my wife, Penny. My likes include family, golf, history, politics, current events and dining out with our friends. For the past 28 years, I have worked as a sales representative and sales manager for Metro-Chem Inc., and my expertise in laundry technology extends from shirt laundering, hospitality and institutional, to linen supply and industrial uniform plants.

My responsibilities have included new product ideas and testing, hiring and training field technicians, procurement and engineering of automated injec-

As a company, we stay abreast of everything from local water conditions and water restrictions, to wastewater regulations and new types of textiles and garments. As such, we’ve been busy in 2012 developing a new activated chemistry to help perform well in lower temperatures, lower pH, and with fewer oxidizers required. This concept is moving us toward shorter wash formulas with importance placed on less water consumed per load.

We have also done our due diligence and created several new non-NPE surfactant-based detergents with exciting results. These formulations are more readily biodegradable for those that desire, or are required to take, a greener path toward laundry production.

I would like to wish everyone a Happy New Year, and I hope that 2013 will provide opportunity, renewed prosperity and happiness to all in our industry and our country.

10 january 2013 | amerIcan Laundry newS www.AmericanLaundryNews.com

Iwork for Linen King, which owns laundries in several states. We provide COG (customerowned goods) service, as well as linen rental to hospitals. I am the general manager of the facility in

commercial Laundry

Richard Warren

Linen King Conway, Ark.

Hotel/motel/ resort Laundry Charles Loelius The Pierre New York New York, N.Y.

This year’s contributors introduce themselves, describe their operations, identify challenges, and list their accomplishments for 2012

uniforms/ workwear manufacturing

Superior Uniform Group

Fla.

Metro-Chem

Panel

equipment manufacturing Steve

Hietpas

Maytag® Commercial Laundry St. Joseph, Mich.

Scott Delin

Seminole,

chemicals Supply Philip L. Bodner

Kearny, N.J.

Conway, Ark. I have been here since Linen King acquired the facility from my previous employer in 2007, and am honored they kept me. I have worked at this facility since 1994.

Upon high school graduation, I had no idea what to do. Some said I had no clue. The first real job I had was in a shirt laundry. They must have liked me, because I was promoted to washman. It seemed like wherever I went, there was always a laundry that needed help, and I was fortunate to be able to provide that for them.

I got involved with an industrial laundry and learned a lot during the years I was with it. My production experience started in an industrial laundry. For several years, I owned a small group of leather and fur cleaning stores. For many years now, I have been in the healthcare laundry service, both OPL and commercial.

From time to time, I talk to people about careers in laundry. It certainly doesn’t sound like a sexy career, but it is a good industry, and is generally more stable than many other industries. There are also many companies that supply our industry with textiles, machinery and chemistry, so being involved with a laundry can be rewarding.

Our workers really enjoy coming to work, and reducing the big pile of unfinished linen. An hour or so later, that pile is ironed, folded, and looks, feels and smells nice, with the workers ready for another load. Frankly, it takes a while to learn the rhythm, but when it starts to work, it is fun.

best practices, develop utilization programs, develop linen awareness/use and misuse recommendations, and implement staff development programs. In 2012, we implemented a successful linen-reject program that utilizes the end-user to help improve quality by removing unacceptable linen items at the point of use.

I’ve researched staining concerns, as well as ozone applications in laundry (NMMC was one of the first U.S. facilities to place an ozone system on a CBW®); provided education on topics that include bed bugs, safety, infection

control, etc., at a local and national level; and have written articles for NMMC’s bimonthly Check-up magazine.

I was asked to take on the role of laundry director in February 2008. To become better informed, I turned to the American Laundry and Linen College (ALLC) in Richmond, Ky.

I received my CLLM certification from the Association for Linen Management (ALM) in July 2008 and my RLLD certification in March 2012. I serve as president of the association’s Tri-State Chapter, administrative secretary

on its national Board of Directors, member of its Scholarship and Membership committees, ALLC facilitator for fall 2012, and as a member of a variety of focus groups on a wide range of projects.

Challenges abound in the linen industry. Though it’s truly a manufacturing process, this industry has its own niche.

One universal challenge has been the implementation of the latest Association of Perioperative Registered Nurses (AORN) recommendations regarding reprocessing scrub apparel. NMMC

had been successfully home laundering for years. Processing the scrubs added more than 17 hours of labor to our work day but we received no additional FTEs. Implementing lean processing concepts, learning how other laundry plants were succeeding, and networking with many industry experts has allowed us to adjust and conquer. We’re now researching anti-wrinkling technology and automated scrub-processing equipment.

Another challenge is having to

My background is in education, nursing and quality. I started working for North Mississippi Medical Center (NMMC) in the Education department in February 1988. Via scholarship, I received my associate degree in nursing from Itawamba Community College in June 1991, and my bachelor of science degree in nursing from the Mississippi University for Women in May 1996. During this time, I worked full-time as a staff nurse, charge nurse and in administration.

NMMC has been instrumental in helping me achieve my educational goals and to grow within the organization.

In 1997, I became a clinical liaison for Materiel Management and served as a clinical resource for purchasing, sterile processing, laundry, nursing, surgery, etc. I worked with nursing to develop linen specifications, determine

www.AmericanLaundryNews.com AMericAn LAundry news | jA n u A ry 2013 11 ELLISCORP.COM To receive the complete test data document simply scan here. Or contact Ellis Corporation at: info@elliscorp.com / call 630-250-9222 FASTEST, QUIETEST, MOST EFFICIENT GUARANTEED! Introducing the New Ellis Here’s the Proof: :: New terry towels, nominal 450 lb. weights Averaged 21.76 Minutes at 1651 BTU’s Per pound of water removed. :: New terry towels, nominal 250 lb. weights Averaged 15.23 Minutes at 1910 BTU’S Per pound of water removed. 123098_ELLIS Whisper ALN Ad.indd 1 12/4/12 2:24 PM ALN_Jr Page.indd 1 12/4/12 3:25 PM See EXPERTS on Page 12 Healthcare Laundry Judy Murphy, RN, BSN, CLLM, RLLD North Mississippi Medical Center (NMMC) Tupelo, Miss.

process 6-7 million pounds per year using older, poorly maintained laundry equipment in an older, poorly designed facility.

Fortunately, I work for a company that focuses on quality and customer service (currently the only two-time healthcare winner of the Malcolm Baldrige National Quality Award, in 2006 and 2012) and understands the need for an educated, well-trained staff, stateof-the-art equipment and lean processing concepts.

We’ve been able to slowly replace outdated equipment, and are planning a modern, state-ofthe-art, energy-efficient (possibly LEED-certified) facility with pack room and sterilization capabilities. Our goal is to efficiently process 15 to 20 million pounds of linen per year, with plans to begin operations within the next 18 to 24 months.

In an uncertain future, survival will depend upon our ability to continue to develop and implement best practices, forward “out-of-the-box” thinking, and lean concepts in an effort to become a truly lean, green washing machine.

independent laundry with six routes serving the San Francisco Bay area. Like most laundry companies, there is a real challenge in finding and establishing long-term employees. However, by creating procedures designed to empower employees, Golden West has created a strong retention program.

The last few years of economic belt-tightening has had a profound effect on our industry.

Adapting to an ever-changing economy requires reviewing and modifying policies, procedures and practices.

While identifying key areas for profit and setting practical costcutting measures in 2012, Golden West experienced one of its most successful years for growth and profit. I am excited about the opportunities in 2013, and enter into the new year with the understanding that change is more than a mindset.

out the need for added expense or equipment.

As the fourth generation of my family in this industry, I have a lifetime of experience and more than two decades of professional work in laundries, starting with my tenure as vice president and, later, president of Consolidated Laundry Machinery Co. I worked in all aspects of CLM’s manufacturing, sales and marketing of laundry machinery, and helped our customers with specification, layout, upgrades and improvements to their plants.

Iam the operations manager for an independent industrial laundry located in the San Francisco Bay area. Starting in 1980, delivering linens and mats to the mining industry of northern Minnesota, I have held management positions in sales, service, production and administration. The position of operations manager suits me well, as it affords me an opportunity to interact and direct all departments while drawing on a vast wealth of experience.

Golden West is a family-owned,

Iam senior vice president of Turn-Key Industrial Engineering Services, a consulting firm that has been serving the laundry, healthcare and hospitality industries for nearly 15 years. We are an industrial engineering firm that designs, builds, retrofits and improves the processes and profitability of laundry facilities throughout the world, using professional design, lean manufacturing and project management techniques.

As our name implies, we perform these services “turn-key,” which means we can deliver a multitude of services, including facility design, RFP development, project management, process improvement and Lean Six Sigma implementation. Our team of certified engineers and consultants have extensive experience in the industry, and have helped our clients save money, labor and increase throughput, often with-

Scott Beaton, Kaiser Permanente Northern California

Steve Clark, Laundry Equipment Services

David Dersheimer, formerly with SITEX Corp.

Ronald Evans, RJ Evans & Associates

Tom Gildred, Emerald Textiles

Steve Kallenbach, American Dawn

Tom Langdon, Encompass Group

Steve Marcq, General Linen Service Co.

JR Norris, Delta Uniform & Linen

Kim Shady, Laundrylux Corp.

Douglas Story, Swisher Hygiene

Marlene Williams, Anderson Chemical Co.

I moved into industry advocacy and education as the director of Plant Operations, Customer Service and Information Technology for the Uniform and Textile Service Association (UTSA). The industry was under close scrutiny by OSHA, Congress and safety regulators at that time, and I led the effort to create an industry-wide health and safety program that reached more than 65,000 employees in more than 1,000 plants nationwide, produced an industry-specific safety training DVD, and created a stronger, more positive relationship with OSHA and Congress for the industry.

Following UTSA’s merger with TRSA, I spent more than three years as the chief operating officer at F-MATIC, where I helped lead the development of several new sanitary supply products and product lines, improved and diversified the company’s international supply chain, reduced operating expenses and increased revenues.

I am a past chairman of the UTSA Plant Operations Committee, a former member of the Western Textile Services Association board of directors, a long-time instructor at the industry’s Production Management Institute (PMI) and Maintenance Management Institute (MMI), and a recent addition to the faculty of the American Laundry and Linen College (ALLC). I am also honored to be among an elite group of industry leaders to have been named to the Plant Operations Hall of Fame.

I hold a bachelor’s degree from the University of California, San Diego, and live in Park City, Utah, with my wife and two daughters. I am an avid cyclist, skier, sailor and private pilot. What challenged our clients in 2012 was the continuing difficult economy and the need to find ways to adapt. Laundries in all segments of our industry fought to increase productivity and safety, while dealing with ever-increasing costs of doing business, challenges from unions, and increased regulation. These challenges will no doubt continue in 2013 and beyond, and I expect my colleagues and I, both at Turn-Key and on the esteemed Panel of Experts, will increasingly be called upon to assist the industry with meeting them head-on.

Among Turn-Key’s accomplishments in 2012 were designing and breaking ground on a new healthcare laundry for a client in Florida, designing a new state-of-the-art hospitality laundry for a major international resort and entertainment firm, and helping numerous operators (both large and small) reap the financial and productivity benefits resulting from the implementation of process improvement and the application of Lean Six Sigma methodologies.

in business. I reside in Orlando, Fla., with my wife, Lisa, and our daughters Taylor and Jordan.

As regional vice president for Steiner-Atlantic Corp., I am responsible for sales and service in the central Florida market. Steiner-Atlantic, founded in 1959 by William Steiner, is a large laundry, boiler and dry cleaning equipment, parts and service distributor, with its core business in Florida and the Caribbean.

Upon graduating from college, I set out on my path to a successful sales career by working for Controlled Motion, a small company selling power transmission to equipment OEMs and endusers. My mentor, Tony Harris, taught me the importance of listening and recognizing what my customers needed. I owe much of my success to him.

After working for him for five years, my journey shifted to selling textile sock dyeing and packaging equipment. This move led to my start in the laundry business, when David Carter hired me to cover the central Florida territory for Wink Davis Equipment Co. in 2001. Upon completing my training, I relocated from Charlotte to Orlando. In 2004, when Wink Davis closed its doors, another door opened for me with Steiner-Atlantic.

equipment/ supply distribution

Mike Steiner, our president and CEO, brought me on board to continue servicing our central Florida market. At SteinerAtlantic, we provide customers with turn-key solutions from design-build to equipment sales, installation, start-up and training, with continued parts and service.

Igrew up in Charlotte, N.C., with two loving parents. I have an older sister and a twin brother, and our parents instilled in us the value of hard work, education and moral character, which shaped the adults we are today.

I get my competitive spirit from playing sports throughout my early years. I graduated from Mars Hill (N.C.) College in 1993 with a bachelor’s degree

I am honored to have received many sales accolades, including Chicago Dryer Co.’s “Rising Star” and “Heavy Hitter” awards, and multiple Pellerin Milnor “Key Man” awards. This past year, I also received our local Association for Linen Management chapter’s Allied Tradesman of the Year award.

I look forward to the challenges of 2013, and hope that you will find some of the articles that I participate in to be informative and helpful.

ALN 12 january 2013 | amerIcan Laundry news www.AmericanLaundryNews.com

experts continued from Page 11

Bill Bell Steiner-Atlantic Corp. Miami, Fla.

Textile/uniform rental

Tom Peplinski Golden West Oakland, Calif.

consulting services

David Bernstein Turn-Key Industrial Engineering Services Charlottesville, Va.

american Laundry news wishes to thank the members of the 2012 Panel of experts for their service:

(Photo: ©iStockphoto/Ivelin Radkov)

Alliance Laundry promotes Bittner, honors Brothers

RIPON, Wis. — Alliance Laundry Systems has promoted Bill Bittner to vice president of North American sales. He succeeds Jeff Brothers Sr., senior vice president, who is retiring after 35 years of service.

Track Career

leadership roles in sales, manufacturing, and genuine parts. He most recently served as vice president of Customer One, the global company initiative focused on customer service.

For 35 years, Brothers has served as an important and respected leader in the commercial laundry industry, having made “significant contributions that have helped the company achieve the market success that it continues to build upon today,” Alliance Laundry says. He participated in three major acquisitions and the integration of those companies, resulting in “significant market share, sales and profit growth.”

Bittner is responsible for managing Alliance’s brands, which include Speed Queen, UniMac, Huebsch, IPSO, and Cissell, through a team of national sales managers and their respective regional sales managers. Additionally, he will oversee pricing, budgets, forecasts, sales promotional activity and distributor development.

During his 15-year tenure at Alliance, Bittner has held a wide variety of positions that include

“I want to thank Jeff for his years of service and dedication to Alliance Laundry Systems, and wish him the very best in his retirement,” CEO Mike Schoeb says. “While he will be deeply missed, he has earned the opportunity to enjoy more time for his leisure interests and his family.”

O’FALLON, Mo. — Phoenix Textile Corp. has appointed Geoff Mayo to the newly created posi-

tion of director of key accounts and commercial laundries.

In his new role, Mayo brings with him more than 25 years of industry experience, and will represent the company to large-scale commercial laundries across the nation.

“His experience and knowledge of the industry will support Phoenix’s mission to serve the needs of its customers,” says Scott Rodgers, vice president of sales.

A graduate of the Carlson School of Management at the University of Minnesota, he previously served as senior vice president of operations and partner with Lintex Corp.

He was also executive vice president of the Extended Care Division for Encompass Group and division director of healthcare for American Dawn.

Kemco hires Borden as exec VP of global sales and marketing

CLEARWATER, Fla. — Kemco Systems recently hired Don Borden Jr. as its executive vice president of global sales and marketing.

Borden has spent his professional career as an operating executive in general manufacturing and high technology industries. A majority of his experience is in the fluid handling industry, primarily in the water and wastewater arena.

Prior to joining Kemco, Borden served as president of Crane Environmental and as international vice president at GAITronics, with a record of implementing Six Sigma and LEAN Manufacturing.

Borden holds a bachelor of science degree in water resource engineering from Pennsylvania State University, and a master’s degree from the University of Pennsylvania.

Kannegiesser USA adds Tannert to sales team

GRAND PRAIRIE, Texas — Dave Tannert has joined the sales team for Kannegiesser USA, where he will serve as a regional sales manager in Huntington Beach, Calif.

He holds a bachelor of science degree in manufacturing technology, and has experience in OEM sales to the aerospace, heavy equipment and durable consumer goods sectors.

His responsibilities have included business development and account management.

Leybelman joins Penn Emblem staff

PHILADELPHIA — Rita Leybelman has joined the Penn Emblem Co. marketing department, serving as its Internet marketing coordinator. She will oversee and develop social media initiatives and work to increase the company’s Internet presence. ALN

Phoenix Textile appoints Mayo to new position

www.AmericanLaundryNews.com AmericAn LAundry news | JAnuAry 2013 13 For over 50 years U.N.X. INCORPORATED has been involved in the development of products that not only solve quality problems that exist at the moment, but also provide long term benefits to the customer and the environment in which we live. U.N.X. was built on the foundation of improving the industry in which we participate. U.N.X. prides itself on being an industry leader with state-of-the-art products and dispensing equipment, and our plans for the future are extraordinary. With a Research and Development team second to none, U.N.X. is in a position to provide the industry with the most technologically advanced products and dispensers as possible. U.N.X. INCORPORATED 707EArlingtonBlvd Greenville,NC27858 (252)756 8616 www.unxinc.com ALN_Tab_half 10/9/12 2:40 PM Page 1

Brothers Bittner

Tannert

Borden

Mayo

PRODUCT SHOWCASE HEATGENERATING EQUIPMENT

PICK HEATERS

The Pick Constant Flow Direct Steam Injection Heater offers a constant flow of heated liquid at a precisely controlled temperature. The heater delivers a compact system, including all piping, valves and controls that can be easily customized to meet customer specifications.

The company calculates a 16% steam savings through its Energy Savings Comparison Program. This energy and cost savings existed even after considering the added cost of treating boiler feed make-up water resulting from condensate no longer being returned to the boiler, Pick says.

pickheaters.com 262-338-1191

KEMCO SYSTEMS

Kemco Systems offers a 97%-efficient TE-100 direct contact water heater, which, according to the company, reduces water heating costs by 35% to 40%, as well as provides instant, continuous hot water with temperatures of up to 190 F. USDAapproved, the stainless steel TE-100 offers a small footprint and easy operation.

Kemco’s stainless steel Boiler Stack Economizer helps to recover up to 100% of the heat going up a stack, providing continuous hot water by using the latest in energy-efficient heat-transfer technology.

kemcosystems.com 800-633-7055

REIMERS ELECTRA STEAM

Reimers Electra Steam manufactures electric steam boilers and associated equipment specialized for the dry cleaning and garment industries.

The company says it offers compact boilers that fit under a utility press and can be installed without a condensate tank when using Reimers PC-20 piping package.

The boilers meet the codes within the United States and Canada, are manufactured and designed to the A.S.M.E. Boiler Code, and have a U.L. Listing, Reimers says.

reimersinc.com 540-662-3811

NATIONAL COMBUSTION CO. (NATCO)

National Combustion Co.’s (NATCO) Fire Coil 85 is a midefficiency (85%), direct-vent, gasfired water heater. It combines the reliability and ease of maintenance of the original NATCO Fire Coil with environmentally responsible low-NOx emissions and venting flexibility, the company says.

In commercial laundry facilities, fresh air for combustion can be a serious problem—atmospheric heaters that depend on passive fresh-air inlets can run unreliably when other equipment draws fresh air, NATCO explains. A fan-assisted, sealed combustion water heater like the Fire Coil 85 maintains its efficiency by drawing its combustion air directly from outside. This also helps ensure good indoor-air quality, as the products of combustion are never open to the inside space, the company says.

Fire Coil 85 water heaters

circulate to a storage tank, and can maintain water temperatures of up to 165 F without a booster heater. nationalcombustion.com 888-OK-NATCO

CLAYTON INDUSTRIES

Clayton Industries’ new 1,500-horsepower boiler was designed to meet and exceed the laundry industry’s growing demands for energyefficient heat-generating equipment, while reducing an environmental footprint, the company says.

The boilers offer a quick startup and shut-down, generating clean steam in only 10 minutes, according to Clayton. They need only to be turned on for production, and turned off immediately afterward, which offers laundries an opportunity to lower operating savings.

All Clayton boilers, including its Sigma-Fire™ Signature Series, are 100% explosive-proof, the company says. claytonindustries.com 800-423-4585

PARKER BOILER CO.

The Parker Boiler Indirect Fired Water Heaters are heavy-duty, packaged boilers used to heat water for laundries, coinoperated laundries and industrial laundry applications, the company says.

The WH Series boilers are available from 300,000 to 3,000,000 Btu input. They can heat water in the low-temperature, 60-degree to 100-degree range without flue gas condensation, and up to 190 degrees without burning out the heat transfer coil.

Boilers are available in natural gas, propane and low-NOx firing, and the company also offers 316 stainless steel heat exchangers or copper/nickel heat exchangers as an option.

The company now offers the TC Series of condensing hot water boilers available in sizes from 399,000 to 5,443,000 Btu input

14 JANUARY 2013 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

[Reimers Inc.]

Hot water is necessary for traditional laundering processes, but laundries also need steam for presses, continuous batch washers and other equipment. That means that commercial boilers and water heaters are virtually indispensable to nearly any laundry operation. Here, some of the major manufacturers and suppliers of heat-generating equipment share their newest and most popular product offerings.

[National Combustion Co.]

[Pick Heaters]

[Parker Boiler Co.]

[Clayton Industries]

[Kemco Systems]

COMPILED BY JEAN TELLER, CONTRIBUTING EDITOR

with stainless steel construction for resistance to corrosion at low operating temperatures.

The units are available with conventional gas burners or low-NOx power-type burners.

parkerboiler.com 323-727-9800

Raypak

Raypak recently introduced its VERSA IC™ fully integrated boiler control. The new system improves on the Raypak control platform developed 20 years ago.

The new modulating or stage fire VERSA IC™ integrates temperature control, ignition, safety and individual fault monitoring,

and it is field-upgradable.

Raypak’s Cold Water Protection control function is now built in; laundry owners can simply add an appropriate 3-way valve or variable-speed pump. A Modbus communications port is standard for continuous monitoring, trending, and troubleshooting.

The VERSA IC™ control platform is now incorporated into Raypak’s XFyre modulating condensing, hydronic, and domestic hot water boilers. raypak.com 805-278-5300

LudeLL ManufactuRing co.

The Direct Contact Water Heater (DCWH) from Ludell Manufacturing Co. is designed for energy efficiency, heating by a method different from that of a conventional boiler. Efficiencies up to 99% can be achieved and hot water provided instantaneously with this technology, the company claims.

The Ludell high-efficiency Direct Contact Water Heater design simplifies the energy-heat transfer by placing the process water with the combustion

boiler inspections; no tubes to rodout or replace; no need to chemically treat or deaerate feed water; stainless steel construction for equipment longevity; having hot water when needed; a quick return on investment (with 30% water-heater fuel saving being typical); and minimal equipment maintenance, says Ludell, a division of Ellis Corp. ludellmanufacturing.com 800-558-0800

BHP, and up to 300 psig. The furnace is corrugated to maximize efficiency while also minimizing thermal stress. The FBS boiler has a liberal steam-release area, making it an ideal choice for lowpressure steam applications, the company says.

Fulton horizontal firetube boilers are used in a variety of applications throughout many industries. Large-scale laundry operations utilize Fulton horizontal boilers to provide a steady supply of steam for ironers and presses, and steam injection for washers and tunnels.

source. That is, the process water is heated directly by the combustion exhaust of the natural- or propane-gas-fired burner.

Ludell says it can maximize profits by supplying a stainless steel system with a compact footprint and easy-to-assemble pre-piped and pre-wired, match-marked pump-and-valve assemblies. The complete system concept greatly reduces installation time and on-site set-up, the company adds.

Some benefits include no required special pressure vessel permits; no required certified

Disinfect with AdvaCare

fuLton

The Fulton FBS boiler product line includes a variety of models ranging in size from 60 to 800

A full range of ancillary equipment also is available.

[Fulton] [Ludell Manufacturing Co.]

fulton.com 315-298-5121

Healthcare linens need to be disinfected, anything less is not clean enough.

The EPA is THE regulatory body with authority over products claiming to have antimicrobial activity.

AdvaCare™ Disinfectant is an EPA-Registered laundry disinfectant that kills:

Staphylococcus aureus, MRSA, E. Coli, Pseudomonas aeruginosa, Acinetobacter baumannii Listeria monocytogenes. (EPA Reg. No. 1677-193) and

www.AmericanLaundryNews.com AmericAn LAundry news | jA n u A ry 2013 15

™ ©2013 Ecolab USA Inc. All rights reserved. 800 553 8683 laundry@ecolab.com

“Clean enough” isn’t an option anymore. Choose AdvaCare™ Disinfectant and step up to a disinfection level of clean. ALN_Tab_half.indd 1 12/5/12 4:07 PM

[Raypak]

AmeriPride plant earns first TRSA Hygienically Clean Healthcare nod

ALEXANDRIA, Va. — AmeriPride Services’ Twin Falls, Idaho, commercial laundry is the first ever to earn TRSA’s Hygienically Clean Healthcare designation, recognizing the plant’s commitment to cleanliness measured through thirdparty, quantified biological testing and inspection.

The certification process utilized by the Textile Rental Services Association maximizes objectivity in verifying that textiles cleaned in a laundry meet hygiene standards appropriate for medical facilities. The designation is a variation of the association’s standard Hygienically Clean seal, which is suitable to any type of business that uses garments, linens, towels, floor mats, mops and other professionally laundered items.

Hygienically Clean Healthcare inspection protocols emphasize scrutiny of techniques for compliance with OSHA’s bloodborne pathogens standard. To attain either designation, a laundry must deploy best management practices (BMPs) and pass bacteriological testing and facility inspections.

A laundry is not required to use particular processes, chemicals or BMPs to achieve certification—whatever tactics management feels are necessary can be used to achieve TRSA’s Minimum Performance Specifications as measured by bacteriological testing. But BMPs must be documented in a written quality-control manual.