AmeriPride Services acquires Plus Linen and Uniform Services

MINNEAPOLIS — AmeriPride Services, which supplies linen and uniform rental services in North America, has acquired PLUS Linen and Uniform Services, headquartered in Canton, N.C. The Canton production facility and its service centers in Charlotte and Greenville will now operate as a wholly owned and fully functional AmeriPride branch.

“Plus is a great fit for our company,” says AmeriPride President/CEO Bill Evans. “This acquisition expands our geographic territory in the area and supports our efforts to grow profitably. Our work over the past few years has established a solid foundation for growth, and that includes strategic acquisitions in our key markets.”

AmeriPride does not plan to make any major changes to PLUS in the foreseeable future and is keeping the branch open at full capacity under the “PLUS” name. Most employees and management have agreed to stay on board, including Kevin Lowery, who becomes the branch’s general manager.

PLUS is a fourth-generation family business that was founded in the 1920s by M.C. Sprinkle and owned and operated by the family for more than 90 years. The family considered several potential buyers before selecting AmeriPride.

“The similarities between our two companies and the personal connections we made with their management team sealed the deal for us,” Lowery says. ALN

Faultless Healthcare Linen strengthens production capacity through new facility

By Carlo Calma

ST. LOUIS — Companies face various challenges in a given year. But for Faultless Healthcare Linen, a Kansas City, Mo.-based healthcare textile laundry company, the challenge of taking on more business was considered a “good problem.”

So much so that the company’s “good problem” led to the opening of a new $12 million, 103,000-square-foot facility in St. Louis.

“We were awarded a significant amount of business from the Barnes-Jewish Christian (BJC) Healthcare System in St. Louis, and we needed to create more capacity to accommodate that business and to be able to continue to grow,” explains Faultless CEO Susan Witcher.

Located at 1615 N. 25th Street, Faultless Linen’s newest facility opened its doors last summer, and has enabled the company to process 17 million pounds of healthcare textiles annually to date,

serving 470 customer accounts, the company says.

The company reached out to Gerard O’Neill of American Laundry Systems to design the plant, after having worked with O’Neill on a previous facility.

“Having worked with Gerard

on our last plant in 2005, we found him to be an excellent resource,” says Witcher. “His involvement facilitates an efficient process through every phase of the project, from plant design, RFPs and vendor selection, infrastructure, installation, through start-up.”

“The two primary focal points in the design were energy efficiency and production efficiency,” she adds.

Though the new facility has boosted the company’s production

reversing the disposables trend

fessionals view reusable textiles.

By NaNCy JENkiNs

MISSION, Kan. — Since the 1960s, when disposable products first appeared in hospitals, the textile services industry has fought a largely losing battle against disposables for market share.

But the current focus on sustainability, combined with education, is starting to make a difference in how healthcare pro-

The American Reusable Textile Association (ARTA) recently conducted its second webinar for Practice Greenhealth—a nonprofit association dedicated to helping hospitals operate in more sustainable ways—on the benefits of reusable surgical textiles. The information from that webinar and other ARTA resources is presented here.

Making Case for Reusables

According to a survey of its 114 member hospitals, Practice Greenhealth finds that U.S. hos-

pital patients generate about 33.8 pounds of waste each day. As of 2008, there were 951,045 staffed hospital beds in the States, according to the American Hospital Association. Therefore, it can conservatively be calculated that U.S. hospitals produce nearly 6 million tons of garbage each year.

In addition, 78% of hospitals designate medical waste as infectious; 53% of medical waste is comprised of single-use disposable items1; and the biggest source of medical refuse — the operating room (OR) — churns out roughly 20-30% of a hospital’s waste.

The Association of periOperative Registered Nurses (AORN) agrees in an article featured in its journal that states, “using reusable products provides a means to decrease regulated medical waste generated in the OR by an average of 65%, as well as reduce the cost of waste disposal.”2

Cost-Effective, Safe and Sustainable

Those who have worked in healthcare for more than 30 years may remember the reusable gowns

Healthcare in 20 Years

Eric Frederick offers his predictions of healthcare in the year 2033.

FEB r uary 2013

late News

www.americanlaundrynews.com Volume 39, Number 2

The Newspaper of record for laundry & linen management

iNsidE [4] [8] Panel of Experts Methods to stem the flow of sharps returning with the soiled linen. [12] See FAULTLESS on Page 6 See REVERSING on Page 18

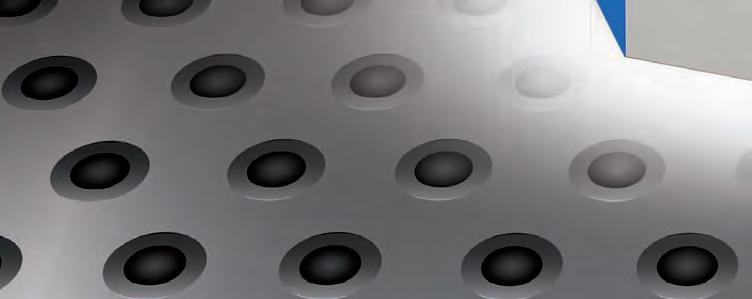

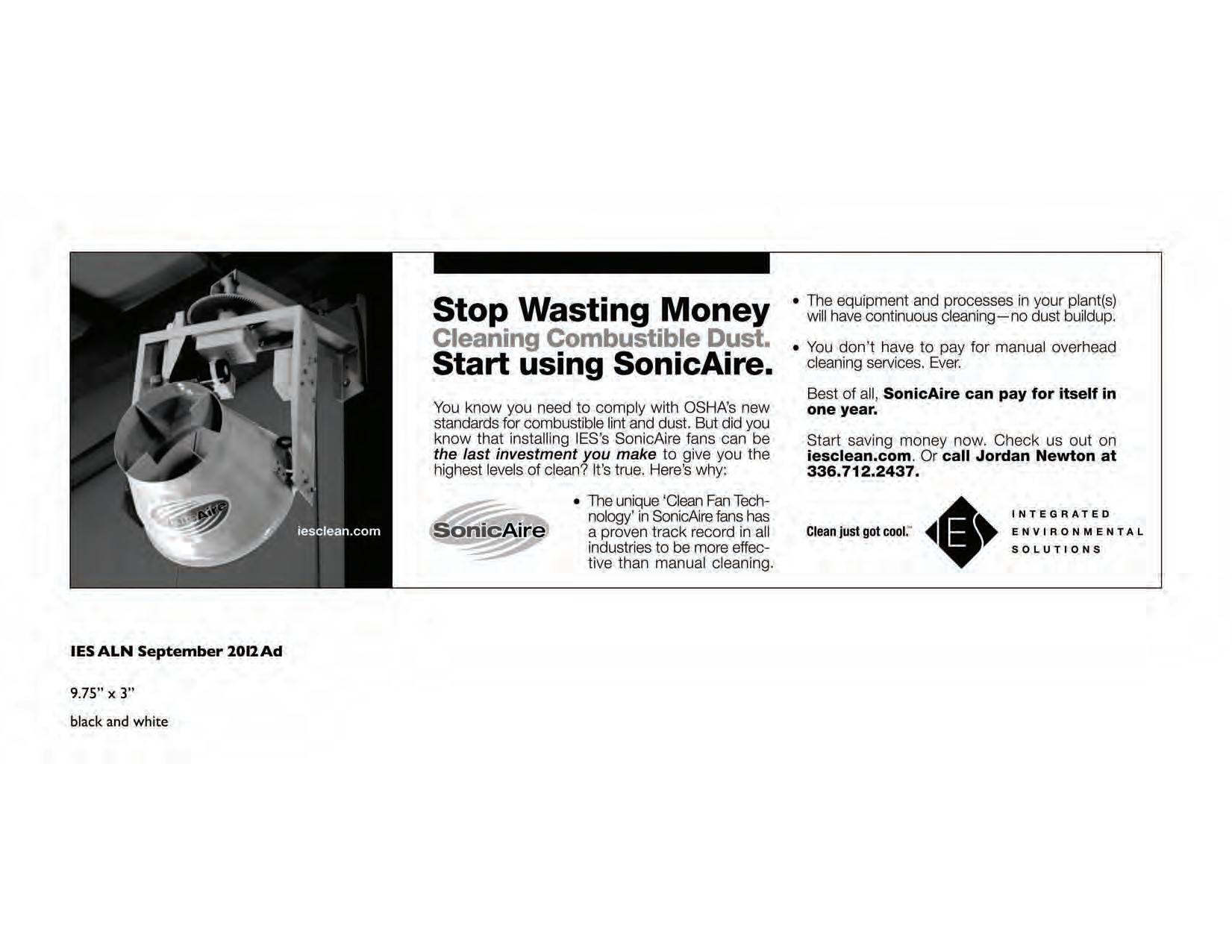

The E-Tech soil-sort area at the new Faultless Healthcare Linen plant. (Photos supplied by Faultless Healthcare Linen/American Laundry Systems)

How education is increasing use of reusable surgical textiles

Survey: Laundry managers

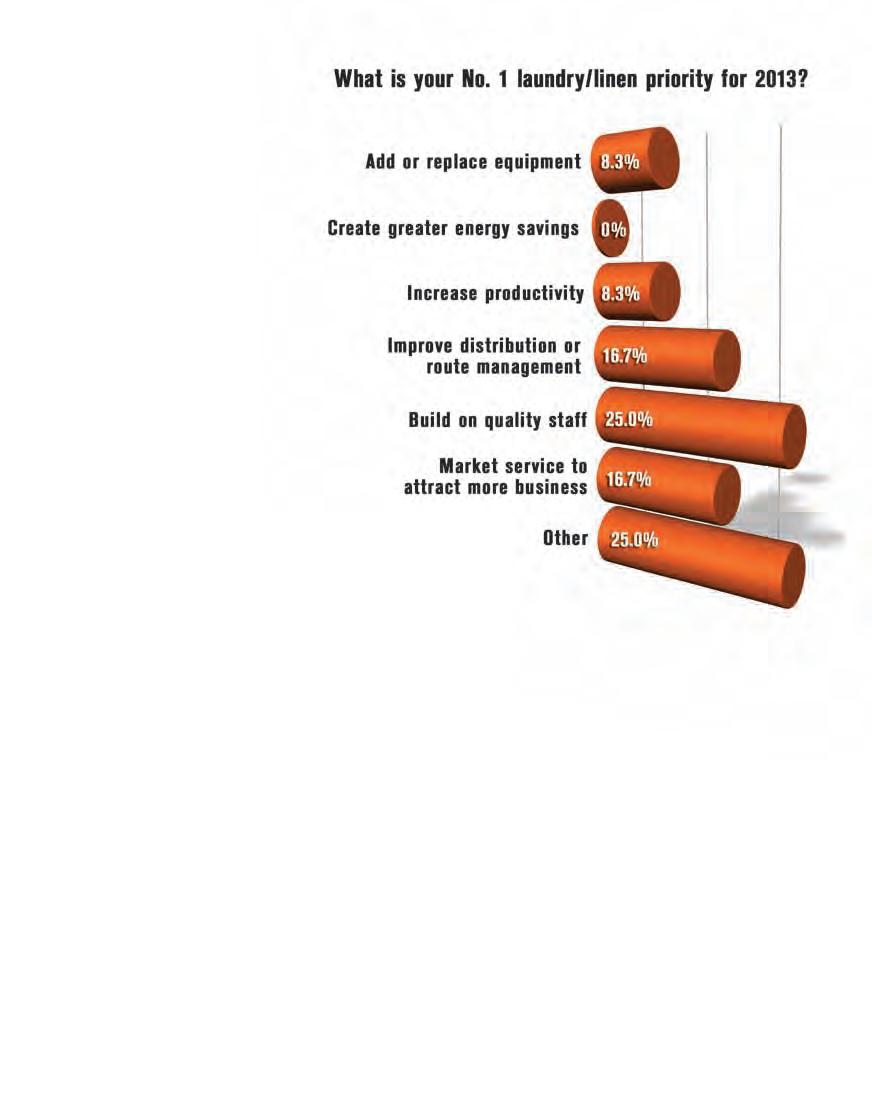

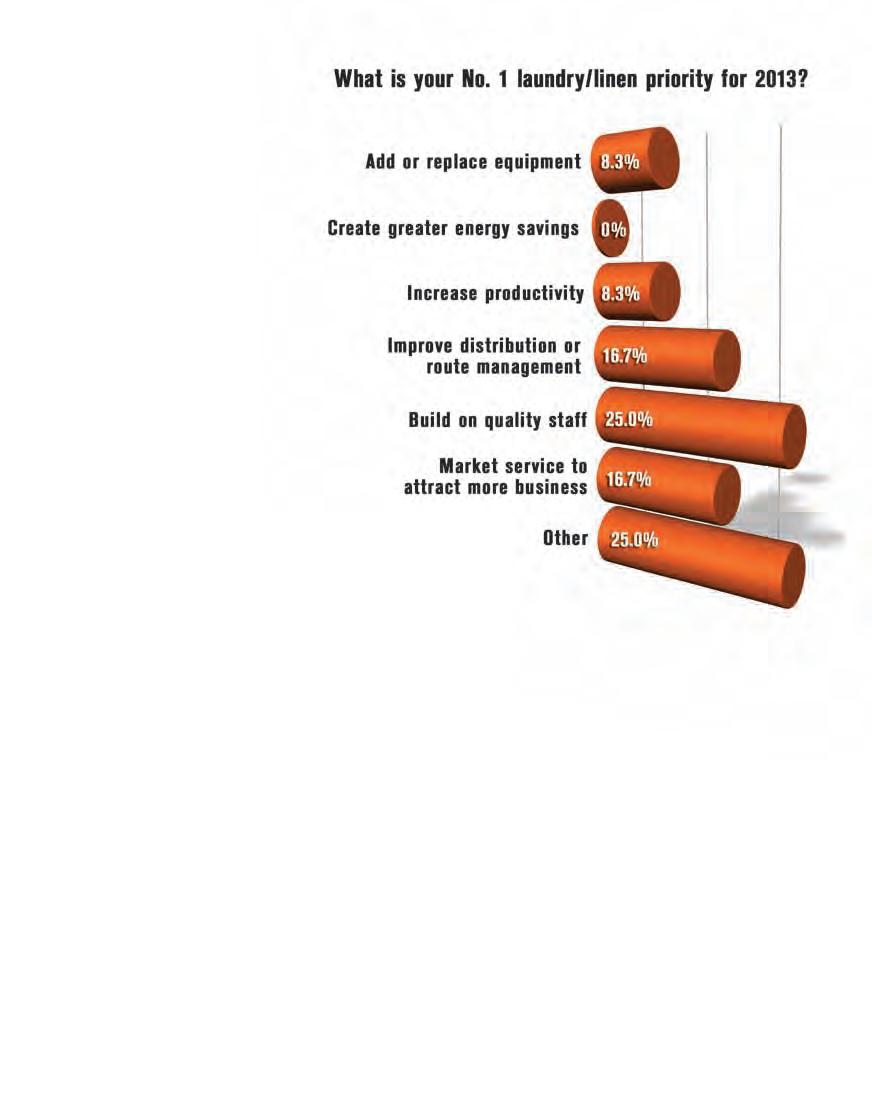

CHICAGO — For January’s AmericanLaundryNews.com respondents had the opportunity to look back at 2012 plus examine their priorities for 2013.

More than half of respondents say business was good (41.7%) or great (16.7%) last year, while another 25% say 2012 business was average. The remainder—16.7%—call it below average.

Regardless of how their individual operation fared, 75% say 2012 turned out as they expected. Approximately 17% didn’t expect last year’s business results, and 8.3% weren’t sure what to expect in 2012.

Virtually every operation polled experienced some degree of success in meeting 2012 goals, according to the survey results. More than half of operators polled (58.3%) said they met “some” of their goals last year, and 33.3% said they had met “all of our goals.” Just 8.3% reported they did not accomplish any of their goals. No one who took the survey said they didn’t set any goals last year.

Building on quality staff and “other”—most often described as creating greater production capacity—is the top laundry priority for equal shares of 25% of respondents, while equal shares of 16.7% are intent on improving distribution or route management, or marketing their service to attract more business.

The remaining shares of 8.3% see adding or replacing equipment, or increasing productivity, as their No. 1 laundry/linen priority for 2013.

Respondents are confident they will accomplish their chief task. Twentyfive percent say they will, “without a doubt.” Roughly 58% say there is a “good chance,” and the remaining 16.7% put their chances at “50-50.”

Respondents had the opportunity to share the “best” and “worst” things that happened to their operations in 2012.

Some of the “best”:

• “Finding successful candidates for chief engineer and controller.”

• “Bought some new equipment.”

• “Cotton (prices) stabilized.”

• “Opened a new plant.”

IAHTM elects officers, board members for 2013

SHAWNEE MISSION, Kan. — The International Association for Healthcare Textile Management (IAHTM) has announced its officers and board of directors for 2013. Officers include:

• President Ed McCauley, United Hospital Services, Indianapolis, Ind.

• Vice President Deborah Lark, Portland Hospital Service Corp., Portland, Ore.

• Education Officer Rocco Romeo, Ottawa Regional Hospital Linen Service Inc., Ottawa, Ontario

• Treasurer Paul Seigel, Kingston Regional Hospital Laundry Inc., Kingston, Ontario

• Past President John Sealey, London Hospital Linen Services, London, Ontario

• Past President Chas P. Olin, Virginia Hospital Laundry Inc., Richmond, Va.

The IAHTM Board of Directors includes three members from the United States and three from Canada. U.S. directors are Myles Noel, COMTEX, Columbus, Ohio; Mark Smoyer, Shared Hospital Services, Portsmouth, Va.; and Duane Houvener, Michigan Shared Hospital Services, Grand Rapid, Mich.

Canadian directors are Janice Desautels, WRHA, Winnipeg, Manitoba; Colin Lyon, Mohawk Shared Services Inc., Hamilton, Ontario; and Stephen Marois, Alberta Health Services, Red Deer, Alberta. Nancy Jenkins is executive director, based in Shawnee Mission, Kan.

IAHTM is composed of CEOs who run laundry cooperatives. The group is a buying cooperative and hosts two education meetings a year: a Spring Education Conference that provides training for staff and an Annual Membership Conference that provides education for members, as well as networking. Banff Springs Resort in Alberta, Canada, will host IAHTM’s next Annual Meeting in August.

Publisher

Charles Thompson

Phone: 312-361-1680

E-Mail: cthompson@ americantrademagazines.com

editorial director

Bruce Beggs

Phone: 312-361-1683

E-Mail: bbeggs@ americantrademagazines.com

digital media director

Nathan Frerichs

Phone: 312-361-1681

E-Mail: nfrerichs@ americantrademagazines.com

Production manager Roger Napiwocki

contributing editor

Jean Teller

editorial Assistant Carlo Calma

Advertising sales

national sales director

Donald Feinstein

Phone: 312-361-1682

E-Mail: dfeinstein@ americantrademagazines.com

Office information

Main Phone: 312-361-1700 Fax: 312-361-1685

subscriptions 630-739-0600 www.americanlaundrynews.com

American Laundry News (ISSN 1091-9201) is published monthly. Subscription prices, payment in advance: U.S. & possessions, 1 year $39.00; 2 years $73.00. Foreign, 1 year $89.00; 2 years $166.00. Single copies: U.S. & possessions $7.00; Foreign $14.00.

Published by American Trade Magazines LLC, 566 West Lake Street, Suite 420, Chicago, IL 60661. Periodicals postage paid at Chicago, IL, and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Laundry News Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 39, number 2. Editorial, executive and advertising offices are at 566 West Lake Street, Suite 420, Chicago, IL 60661. Charles Thompson, President and Publisher. American Laundry News is distributed selectively to qualified laundry and linen management and distributors in the United States. No material appearing in American Laundry News may be reprinted without written permission. The publisher reserves the right to reject any advertising for any reason.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2013. Printed in U.S.A.

memberships

2 FebrUA rY 2013 | AmericAn LAUndrY news www.AmericanLaundryNews.com

Association for Linen Management

inside: [4] Healthcare in the Year 2033? Longtime columnist Eric Frederick peers into his crystal ball and predicts what healthcare will look like in 20 years [8] Panel of Experts: Watch Out for Sharps Measures you can take to stem the flow of sharps— hypodermic needles, cutlery, etc.—returning to your facility [10] Product Showcase: Small-Capacity Washer-Extractors [17] OPL 101: Infection Control & Equipment Proper laundry equipment selection and processing protocols can minimize the risk of textiles posing as a source of infection to patients and healthcare workers January 2013 • Vol. 39 | No. 2

split

on top priority for 2013

ALN

The 2013 IAHTM Officers and Board of Directors: (front row, from left) Past President Chas Olin, Education Officer Rocco Romeo, President Ed McCauley, Vice President Deborah Lark, Treasurer Paul Seigel; (back row, from left) Canadian Director Colin Lyon, Past President John Sealey, U.S. Director Mark Smoyer, U.S. Director Myles Noel, Canadian Director Stephen Marois and U.S. Director Duane Houvener. (Photo: IAHTM)

Celebrating the First

PulseFlow® Tunnels Sold

EaCh Saving UnprECEdEntEd aMoUntS of WatEr, EnErgy, Labor and tiME.

Milnor is proud to announce the sale of over one hundred PBWTM (PulseFlow Batch Washers) tunnels worldwide. You might call it our Centunnel Celebration Since 2009, Milnor has revolutionized batch washing with True Top transfer and RecircONE® pump arrangements. And now, our PulseFlow Technology has changed the laundry industry again.

In the last year alone, PulseFlow® tunnels have saved our customers over 325,000,000 gallons (1.5 billion liters) of fresh water with actual improvement in their wash quality. It’s hard to imagine numbers this big. Imagine a fresh water lake. Saved. Every year. It is groundbreaking.

We want to thank all of the PBWTM pioneers...they took a chance on a radical approach to tunnel washing and are enjoying unprecedented savings. We are proud of the first 100, but are excited about the next 100 PBWs.

Now, imagine what your laundry could save with a Milnor PBWTM Contact an authorized Milnor distributor or call 504-712-7656 to find out more.

www.milnor.com/pulseflow_technology / pellerinmilnor To see how a PBWTM works, scan this code.

Here’s what’s up, Doc

With our healthcare system being tasked with caring for a country full of weezing, sniffling, achy patients, I think it’s the perfect time to take a closer look at the healthcare segment of the laundry industry.

From The Director’s Chair

BRucE BEggs

as of this writing, I have been fortunate enough to avoid falling victim to the flu epidemic that has swept the nation. But I’m sure it’s only a matter of time before I join the majority.

This month, Carlo Calma, our new editorial assistant here at American Laundry News, takes a look at Faultless Healthcare Linen and its newest plant in St. Louis. According to his cover story, the company recently invested $12 million in building the facility to accommodate new business received from a local healthcare system.

In our other main cover story, Nancy Jenkins examines how healthcare professionals are chang-

ing their view of reusable surgical textiles and the like thanks to education and a renewed focus on sustainability. Are reusables making headway against disposables?

Right next door on this page, 40-year laundry veteran Eric Frederick dusts off his crystal ball and predicts what healthcare laundry will look like in 20 years. Anyone for a network of government-run laundries?

On page 8, our Panel of Experts offers methods for stemming the flow of sharps—such as hypodermic needles and surgical instruments—that are sometimes found in your soiled linen.

Yep, we’ve got our fingers on the pulse of the industry. ALN

In Memoriam: William K. ‘Bill’ Steiner, 82, Steiner-Atlantic and Dryclean USA

AVENTURA, Fla. — William Kalman “Bill” Steiner, founder of Steiner-Atlantic Corp. and Dryclean USA, died Dec. 27 after a three-year struggle with pancreatic cancer. He was 82.

The Chicago-born Steiner worked hard his entire life, beginning as a newsboy at age 9. He held part-time jobs throughout high school and worked his way through Baltimore Business College to earn his accounting degree.

While working as an accountant, a client asked Steiner to help him book rock ’n’ roll shows around Baltimore. Show business soon enthralled him, and he booked prominent 1950s stars

such as Screamin’ Jay Hawkins and the Kingston Trio at concerts around the country.

But he tired of the constant travel and moved in 1959 to Miami, where he met his future wife, Sheila. They married in 1961.

He founded SteinerAtlantic Corp., a distributor of commercial laundry and dry cleaning equipment, boilers, parts and service, in 1959. Son Michael Steiner took over the reins in 1987.

After building and selling several of his own dry cleaning plants, Bill Steiner co-founded Dryclean USA, a dry cleaning business franchisor, in 1977. It also continues through this day under

Michael’s leadership.

Bill and Sheila Steiner have been members of Aventura’s Beth Torah Congregation for many years. They provided the educational center there in memory of son Jim, who died in 1989.

They were also generous in their community. In honor of their support, the Jackson Memorial Hospital Foundation renamed a part of the hospital the Bill and Sheila Steiner Family North Lobby.

Surviving Steiner are his wife, Sheila; four sons, Robert, Richard, Michael and David; a brother, Tom; and four grandchildren.

Donations in Steiner’s memory may be made to the Beth Torah Congregation, Jackson Memorial Hospital, or the Greater Miami Jewish Federation. ALN

Healthcare in the year 2033?

ihave been employed in the healthcare laundry market for more than 40 years, starting as a washman in a healthcare laundry in Salt Lake City, Utah, in June 1972. I have often marveled at the changes in the laundry industry over the past four decades. The industry has been unpredictable at times, but I have always found my work enjoyable and interesting.

In this month’s column, I project what the laundry industry will be like in 20 years. Now, I know my crystal ball is not perfect, and I claim no special ability to predict the future, but a little common sense can go a long way in predicting what might happen.

My expertise is in the area of healthcare textiles, so I will deal only with this segment of the business. There are four main areas that will affect our industry: national healthcare, environmental concerns, energy, and textiles.

National Healthcare Effects

In the year 2033, the U.S. healthcare laundry market will look very much like the Canadian laundry market does today. The majority of U.S. healthcare will be controlled by the government through its single provider network. Because government is the major source of all revenue, it will be actively involved in helping to control costs on all levels.

Administrators have for years looked at linen service in a healthcare facility as an unavoidable cost. They have continually looked at ways to reduce the costs associated with this service by outsourcing to lower-cost providers, using contract management companies, limiting the number of items in the linen inventory, and re-introducing cost-effective reusable products.

just LikE canada, tHE u.s. govERnmEnt wiLL EstaBLisH a nEtwoRk oF HEaLtHcaRE autHoRity LaundRiEs tHat wiLL pRovidE pREdictaBLE-quaLity LinEn sERvicE to aLL HEaLtHcaRE FaciLitiEs.

Sometime between now and 2033, the politicians will focus on commercial laundries that want to make a profit off of sick people, and the inefficient in-house laundries, and make the decision government always makes: they can do it better. Just like Canada, the U.S. government will establish a network of healthcare authority laundries that will provide predictable-quality linen service to all healthcare facilities.

This move will probably happen at or near the point when the brain trust in Washington similarly takes over the food service programs at hospitals, moving the majority of food preparation to regional, off-site central kitchens.

The commercial laundry industry will, of course, fight this development, but in the end it will lose.

This development of government-operated central laundries will also eliminate all contract management business in the healthcare laundry market. A number of provider companies will find themselves in a position to sell their facility to the government or face owning a facility that has no customers.

Environmental Concerns

•

•

•

•

•

•

•

•

•

•

•

•

The need to lessen our collective impact on the environment will continue to be heralded over the next 20 years. It will reach the point that all laundries will need to treat their wastewater and reuse it. (We currently reuse a little more than 50% of our water used in processing linen.) Over the next 20 years, substantial researchand-development dollars will be spent in all industries to make it possible for them to clean and reuse water. Once the technology is available, all laundries will be required to use it.

4 FEBRua Ry 2013 | amERican LaundRy nEws www.AmericanLaundryNews.com Top Stories Appearing on AmericanLaundryNews.com for the 30 Days Ending Jan. 15 (WE) = Web exclusive news

IAHTM Announces Officers and Board Members for 2013

McCauley Named ARTA President; New Board Announced

Admits New Equipment to Rightsize OPL

Shriners Hospitals

Steiner,

In Memoriam: William K. “Bill”

Steiner-Atlantic...

7th Mission Linen Supply Plant Receives HLAC Accreditation

Hospital, Hotel Laundry/Linen Operations Feel Brunt of Superstorm...

Columnists/Features •

Gudenburr: Proving the Need for Capital Improvement in the Laundry

Career Track: Companies Announce Personnel Moves

Frederick: Deliver Value to Your Laundry’s Owners, Customers and Employees our sister websites From AmericanDrycleaner.com:

The Structuring of Dry Cleaning Pricing

Plant Design Awards—Grand Prize: Rainbow Cleaners From AmericanCoinOp.com:

IRS Raises Standard Mileage Rates for

e)

2013 (W

StatShot: November Sales Largely Positive... (We)

Columnist At lArge Eric L. Frederick, RLLD

See YEAR 2033 on Page 19

Steiner

Faultless

capacity, the road getting there was not easily traveled.

“When we got all of this new business from BJC, we actually had to take on that business before we got the new plant opened up,” Witcher says.

The company had to employ double shifts at its 45,000-squarefoot facility in the Soulard area of St. Louis to accommodate the business acquired from BJC. Once Faultless opened its new facility roughly four miles to the north, it was able to shut down a separate 18,000-square-foot plant in Soulard, and split the BJC business 50-50 between the remaining Soulard plant and the new laundry.

The new plant employs the use of various industry-familiar systems, and bears the same layout as Faultless’ existing facilities, according to Witcher. “In terms of the general design of the workflow, it’s very similar to our other plants. A lot of the systems that we’ve used in our other big plants in St. Louis, we designed into this one.”

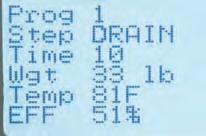

For example, the facility utilizes an E-Tech monorail system for sort soiling; Milnor PulseFlow® tunnel (eight 250-pound modules); Chicago Dryer Co. finishing system that includes ironers, feeders and folders; Softrol garment sorting system; and Kemco process

water system.

Considering the new facility’s technology and capacity, it’s brought a sense of ease for the staff—there are 110 full-time employees—regarding the overall production, Witcher says.

“From a quality-of-life perspective, everybody’s in a much better place because we’re running both plants seven days a week (through) 10-hour days, so everybody’s back on a normal schedule and (has) more room to move.”

The larger facility has an annual capacity of 43 million pounds but only 40% is currently being utilized.

To fill its unused capacity, the company’s sales force is continually scoping out prospective clients, Witcher says, and even hosted an open house in early November to ensure that the company acquires new business to be able to take full advantage of its facility.

In addition to energy and production efficiency, one other priority for the company was to ensure the new plant met standards established by the Healthcare Laundry Accreditation Council (HLAC), which examined the facility in early January.

Because Faultless Linen’s other facilities are already HLACcertified, the company has a “very clear understanding of the processes that are required, and the documentation that’s required,” Witcher says.

Much like the Soulard plant, a wall divides the new facility in two, where one side strictly processes

soiled linen, while the other handles clean linen to be shipped out. Soiled linen is sorted into slings by type and washed hygienically with the proper pH. Once properly cleaned, linen is stacked onto clean delivery carts that have been sanitized through an automatic cart washer.

Meeting standards like these, in addition to training employees on proper procedures, are just some of the ways the company is ensuring it meets HLAC’s criteria, according to Witcher.

Achieving the HLAC accreditation is “entirely voluntary,” she notes, but represents an important “stamp of approval.”

“I think it speaks to our customers, and our potential customers, that we are committed to doing things the right way. … From an infection control standpoint, it is becoming increasingly important,” says Witcher, adding that the Association for periOperative Registered Nurses (AORN) recommends the practice of laundering surgical attire in an accredited facility.

With the new facility up and running, the company still has many goals in mind, according to Witcher.

In addition to awaiting HLAC certification, the company is also pursuing the Hygienically Clean

certification from the Textile Rental Services Association (TRSA).

With room for the business to grow, Witcher says she feels “excellent” about the facility going into the new year.

“While we’re not at peak productivity and energy efficiency at this point, over the next several months we would expect nothing but continued improvement in the performance of the operation,” she says. ALN

Carlo Calma is editorial assistant for American Laundry News. He can be reached by e-mail at ccalma@ americantrademagazines.com.

6 FEBRuaRy 2013 | amERican LaundRy nEws www.AmericanLaundryNews.com

continued from Page 1

Cutline...

tunnel washer in use has eight 250-pound modules.

Faultless’ sales force is continually scoping out prospective clients to utilize more of the new plant’s 43-million-pound annual capacity. The

Milnor PulseFlow

Under construction.

garments ... and lots of them.

Full sling bags staged in the overhead rail system. Sorting

The Pulse Flow Technology logo is a registered trademark of Pellerin Milnor Corporation.

The Pulse Flow Technology logo is a registered trademark of Pellerin Milnor Corporation.

PanEL oF ExPERts

Sharps pose constant threat to soil sorters

Although my laundry processes hospitality linens, we observe universal precautions when detecting and handling sharps. Sharps, in our case, consist of cutlery and broken glass sent down the laundry chute in error by our enduser, the room attendants.

that lists the date and location of the incident as well as the type of sharp.

place to minimize the safety hazard should these mistakes continue to occur.

in an efficient, productive and timely manner.

Finding foreign objects in linens is not an uncommon occurrence. Trash, glass, dishes and cutlery are sometimes mistakenly and carelessly mixed in with the soiled linens by the end-users when gathering the linen for reprocessing. Healthcare linen poses the additional threat of bacterial and viral contamination from needles and scalpels.

All incidents are documented, and the appropriate people are notified. All soil sorters wear proper protective equipment, including masks and punctureresistant gloves. Broken glass is picked up with tongs or brush and dustpan and placed in a medically approved sharps container. This container is disposed of when three-quarters full.

The laundry maintains a log according to OSHA guidelines

We have weekly meetings with the room attendants to provide details of the prior week’s foreign objects found in the linen. We seek to educate them on the danger that sharp objects pose to their co-workers.

We also seek feedback from the housekeeping team on ways to reduce the instances of foreign objects, particularly glasses, dishes and cutlery, which pose a safety hazard.

In the end, we stress regular communications to achieve buyin from our end-users to reduce the problem with sharps. At the same time, the processes are in

Turn-Key Industrial Engineering Services Charlottesville, Va.

y

ALN_Jr_half 10/4/12 2:30 PM Page 1

ou owe a duty to your employees to ensure a safe work environment and to minimize or eliminate exposure to hazards on the job. At the same time, you have a duty to your customers to ensure their textiles are processed

Most people think of healthcare linen as the primary sharps concern because of the serious health issues that can arise from laundry workers being stuck by needles or cut by other sharp medical devices, but those of you who operate non-healthcare laundries should also be concerned with how the intrusion of these items can present a danger and affect the smooth flow of production through your plant.

Do all that you can to eliminate the intrusion of sharps into soiled linen before that linen reaches your loading dock. Your sales

american laundry news / 4.75x6.75 For laundry done on time and on budget, there’s no better choice than IPSO. Forty years of European ingenuity, rugged industrial construction, and our intuitive Cygnus controls all add up to help you achieve your ultimate goal — maximum throughput at a minimized cost. Learn more about how IPSO helps you get the job done at IPSO.com/industrial INDUSTRIAL BY DESIGN Work with your IPSO finance expert to learn about customized financial solutions for your business. IPSO USA 1.800.USA.IPSO IPSO.com/industrial INDUSTRIAL BY DESIGN. Optimal Efficiency. Maximized Throughput. 3758_IPSO OPL_jrhalfPgHoriz amerlaundnews v12a.indd 1 1/9/13 2:30 PM ALN_Jr_half.indd 1 1/10/13 11:10 AM 8 FEBRuaRy 2013 | amERican LaundRy nEws www.AmericanLaundryNews.com

See EXPERTS on Page 10

Hotel/motel/ Resort Laundry Charles Loelius

The Pierre New York New York, N.Y.

What measures can a professional laundry manager implement to stem the flow of sharp objects in soiled linen— such as hypodermic needles, surgical instruments, cutlery, etc.—before it reaches the laundry service?

consulting services

David Bernstein

With over 50 years strong on the job, we know there are no small parts when it comes to delivering big dependability. In fact, we use all we’ve learned to build durable, longer-lasting machines. Machines you can trust with the tough chore of keeping your operation up and running even as they handle the largest of loads. And no matter who’s operating the equipment, our user-friendly controls always keep it easy, shift after shift. Visit mclaundry.com for digital brochures, or for more information, visit our website at maytagcommerciallaundry.com or call 800-662-3587.

maytagcommerciallaundry.com for warranty details.

We don’t overlook a single belt, bearing or bolt when it comes to reliably easier-to-do laundry.

® /™ ©2013 Maytag. All rights

FINANCING as low as 0%† † Limited time offer. Low fixed financing rates. Terms to 96 months. Subject to credit approval and individual’s credit worthiness. Contact your distributor for details.

*Visit

reserved. *

and service teams need to partner with customers to provide education for their management and employees so that they can put the proper controls in place.

In the healthcare realm, work with your customers’ infection control and/or environmental departments to ensure that they are using safer medical devices with the latest engineering controls (e.g. sharps containers, needleless systems, self-sheathing needles, etc.). Some customers may initially resist adopting some of these devices based on cost, but having a frank conversation with them about the cost of each exposure may help them to come around.

Those of you processing industrial and non-healthcare linen may need to approach the topic from an economic perspective. Explain how a sharp knife can injure a production worker, how a fork can puncture the diaphragm of a press extractor and shut down your production, how a screwdriver can damage a washerextractor or dryer, etc.

Of course, any of you who process food and beverage linen have also seen silverware and cooking tools end up in these facilities, and I would suggest that you explain how much money is being wasted on items that end up in your soil room rather than in their dishwashers.

Cultivate an attitude of zero tolerance. It has become common practice in healthcare laundries to, as a part of a written exposure plan, log the appearance of sharps and other foreign objects in soiled laundry and provide a monthly report to your customers. I would argue that you should take this practice further.

Work with your team and your customers’ risk management and infection control departments to develop a list of priority items that, if found among your linen, trigger an immediate call to the customer and an investigation

into how the item got into your soil room.

Some laundries charge customers for each foreign item found among their soil, with higher amounts charged for more dangerous items. This type of negative reinforcement can turn a customer off of your service, so I recommend taking a more positive approach. Reward employees who find, report and properly handle sharps, and consider an annual award to those customers who eliminate or reduce the number of sharps and other foreign items sent to your laundry.

implemented in the facility.

There are circumstances (emergency “Code Blue” resuscitations, for example) that, due to their chaotic nature, increase the likelihood of sharps being lost in linens. Provide education/training to your laundry personnel in the proper shaking-out and separation of soiled linens. And be sure to include techniques on how to pick up sharps and dispose of them properly.

commercial Laundry

Richard Warren

Laundries don’t put the sharps into the linen stream, and we can’t keep them out.

Equipment manufacturing

needles in bulk linen. You would think that most instruments would be coming primarily from ambulances, emergency rooms and surgical units, but that’s not the case. They simply come from everywhere in a facility.

Professional laundry managers can do two things to help stem the flow of objects found in dirtied linens: an employee training program and, where applicable, conveniently placed containers for depositing razor-sharp objects.

By educating healthcare staff, the flow of sharps will significantly decrease. Most on the patient care units have been eliminated or at least reduced by using tubing and needles with safety devices. Re-educating the infection control nurse at each property on a quarterly basis seems to work best.

To help stem the flow of these items, and to keep the communication lines open with clinical staff, the laundry manager should meet regularly (at least quarterly) with nurse managers, surgery, emergency services, ambulance, etc., to help determine the root causes. This cooperative effort helps establish rapport with clinical staff while addressing legitimate concerns.

Most healthcare organizations have a PI (Performance Improvement) team and/or safety committee that looks at the various OSHA violations (both recordables and non-recordables). The laundry manager should volunteer to participate on this type of team so that these concerns can be voiced to the appropriate people and so that he/she can remain abreast of the efforts being made to address them.

Champion the use of safety devices and engineering controls designed to decrease the risk of employee exposure. Assist with the research and promotion of these efforts by utilizing resources (other laundry managers, industry standards, guidelines, etc.) to determine “best practice” policies and procedures that could be

I find that infection control staffs at hospitals are embarrassed about the issue, so we need to be sensitive in our approach. I find them quite willing to work with a laundry that maintains a professional attitude toward what they perceive as their own problem. We certainly can’t be heavy-handed when we discuss this issue.

We contact the infection control people, our point of contact in the linen department, and the linen committee to talk about how to keep the sharps out. They need to know where the offending item came from, so we help by taking a picture of the item; sometimes it’s identifiable. If the discovery is made in the sorting department, we make note of the specific carts we are working with at the time. We e-mail all this information to personnel at the hospital so they have something to work with. Calling them to complain just keeps the adversarial relationship alive.

Not all hospitals recognize the urgency of the situation, but those that do have shown a dramatic decrease in incidents. We apply the same procedure to all manner of rogue hospital items, some of obvious value. Any customer would appreciate that attention.

In healthcare settings, a number of pointed objects—hypodermic needles, for example—are used on a regular basis. These needles, if left in soiled linens, are dangerous to professionals processing the laundry. By incorporating collection receptacles in or near every patient’s room, it makes disposing of these items properly more convenient and more likely. Coupled with a program to train staff of the importance of sharps disposal, laundry processing is much safer for all parties involved.

In the food and beverage industry, training again plays an integral role in reducing the amount of cutlery found within soiled linens. The awareness gleaned from training helps to protect those processing the linens and ensures the vast majority of utensils are available for patrons.

Equipment/ supply distribution

Ireached out to a few of my customers who are professional healthcare laundry managers and have decades of experience. They all shared that this problem never goes away. There are procedures in place to control exposure to sharps, but it is extremely difficult to eliminate them.

Metal detectors are too expensive and will not detect small

Most healthcare laundry facilities operating under pool linen or COG programs monitor each facility’s goods upon receipt for control of linen shortages, damage, etc., so anything more intensive than that wouldn’t be cost-effective.

Numerous types of sicknesses can be contracted due to encounters with needles, surgical instruments, or cutlery. Proactive communication between the laundry and healthcare facility is key to avoiding them.

Every time a laundry discovers sharps in the soiled linen, the occurrence should be documented and reported immediately to the healthcare facility. Prepare and present an incident report to the appropriate department. By physically showing the sharps that came back in the soiled linen, it might be possible to identify the specific department from where they came and prevent future occurrences.

Schedule ongoing educational sessions with individual departments as needed. In an effort to ensure that facilities properly dispose of sharps, laundries should provide them with collection containers and proper signage at all collection points. ALN

10 FEBRua Ry 2013 | amERIcaN LauNdRy NEws www.AmericanLaundryNews.com

Experts continued from Page 8

Steve Hietpas

Maytag® Commercial Laundry St. Joseph, Mich.

uniforms/ workwear manufacturing

Scott Delin

Superior Uniform Group Seminole, Fla.

Linen King Conway, Ark.

Healthcare Laundry

Judy Murphy, RN, BSN, CLLM, RLLD

North Mississippi Medical Center (NMMC) Tupelo, Miss.

Bill Bell

Steiner-Atlantic Corp. Miami, Fla.

Electrolux smart washers will forever change the way you do laundry.

Imagine a washer smart enough to weigh the load size and add precisely the correct amount of water. Imagine a laundry chemical controller smart enough to adjust dosing for accurate water ratio each time.

Electrolux Professional washers do all that

Underloading washers is a common problem in many laundries, wasting water, chemicals, and energy. That’s why Electrolux developed AWSTM, a UNIQUE feature that automatically matches water consumption to load size. Combine that with SmartDosingTM which adjusts laundry chemicals to water ratio, and you will see immediate savings and superior wash results – every time, automatically.

Electrolux’s SmartDosingTM controller automatically dispenses the correct amount of chemicals for the weight load.

world. Special financing available. Call to learn more.

To learn more visit www.laundrylux.com

– the

selling on-premise laundry brand

the

Laundrylux® (800)381-7222 info@laundrylux.com Electrolux washers adjust water and chemicals to correctly match the weight of the load. Laundry Chemicals Dispenser Control FuLL Loa Load 60-65 LBS PLeaSe doSe detergent Load 30-33 LBS PLeaSe doSe detergent

Experience the Electrolux difference

#1

in

Product showcase

UniMac

From UniMac comes the UW65, a 65-pound hard-mount washerextractor that includes innovative features to help increase throughput. It is designed to handle double the spinning force of commercial washer-extractors, as well as the largest and most outof-balance loads, resulting in less downtime, the company says.

The new larger capacity allows laundry operators to increase their load size, which helps improve employee and work efficiencies, UniMac says.

The UW65’s new drive shaft assembly with cylindrical front and spherical rear bearings is designed to handle heavier loads and have a longer life, and the larger shaft diameter is built to be 200% stronger than cabinet hard-mount shafts, according to the company.

A taller frame with a 28-inch cart clearance and elevated drain height offers improved ergonomics for end-users, UniMac says. The new dimensions also offers ease of use for employees and eliminates the need for an elevated base.

The machine features a 400 G-force extraction speed for maximum water removal. And with a proprietary designed inverter drive, the machine is able to offer smooth, reliable power for optimal wash and extraction performance.

Additional features include: A spray rinse that UniMac says fills 200% faster than other machines, allowing users to do more in less time; a standardized door that opens from the right and is paired with a roll pin/cam lock system

to ensure smooth opening and closing while eliminating the door unlock control button; and ease of installation due to the 34.24inch width of the machine, which allows it to easily fit through a 36-inch commercial doorway.

The UniLinc™ control also available on the UW65 features maintenance reminders and monitoring of error codes and idle time. The programmable delayedstart feature allows laundry to be given a 30-minute head start before employees arrive, saving labor costs.

unimac.com 800-587-5458

Maytag coMMercial laUndry

Maytag® Commercial SoftMount, High-Speed WasherExtractors provide the right size and useful features for any on-premise launderer, according to the company. Available in 25-, 35-, 55-, 80- and 100-pound models, each size offers a large cleaning capacity and installation flexibility.

options for chemical suppliers.

Maytag washer-extractors have several features to help with easy operation. There are 15 pre-programmed cycles, plus the capability to create additional unique cycles. Multilingual readouts make the controls easy for everyone to operate. The External Chemical Injection System features easy-access connections on the outside of the machine to eliminate the need to open up the washer on routine service visits and cut down service time.

The heavy-duty latch, strut suspension, and tough cabinet and frame add to the machine’s durability, the company says. maytagcommerciallaundry.com 800-662-3587

continental girbaU

Continental Girbau’s E-Series™ Washer-Extractors offer a softmount design, available in 20- to 90-pound capacities. They deliver energy efficiency, simple installation and programmability, according to the company.

The programmable Intelligent (Inteli) Control delivers 20 preprogrammed cycles and up to 79 owner-programmable cycles. It is suited for laundries requiring high-level control over cleaning specific types of fabric.

iPSo

IPSO now provides on-premise laundries with the new IH040, a 40-pound washer-extractor.

The machine is engineered, tested and built for heavy-duty performance and to provide high reliability. The IH040 is industrial by design, and is built to extend linen life as well as reduce water usage and utility costs. It features contemporary aesthetics and offers intelligent technology, durability and efficiency, the company says.

The IH040 was designed for easy installation and maintenance, with a strong frame and proprietary inverter technology that provides users a more efficient cycle, IPSO says. Other characteristics include a soap dispenser with four compartments, a dispenser lid with four compartment symbols, and a door lock mechanism with a reed switch for extra safety.

laptop. Cygnus also provides a full spectrum of service features, from scheduling maintenance at designated times to recording valuable information such as the number of completed cycles and service warnings.

ipso.com 800-872-4776

Built with an all 304-grade stainless steel top, front and sides, the line is able to withstand any level of use and is gentle enough for operating in centuries-old buildings. The soft-mount suspension system reduces the need for machine bolt-down, so many wooden-floor installations are possible. With an inverter drive system, users will notice a decrease in the wear and tear of washer components, such as the shaft, bearing, seals and belts, Maytag says.

High-speed extraction of up to 350 G-force cuts drying time and energy usage. Programmable water levels provide flexible cycle

All E-Series models offer a reduction in water, gas and electricity usage, Continental Girbau says, allowing laundries to embrace energy-efficient ‘green’ benefits, lower utilities and labor, and improve productivity. Featuring a soft-mount design, the E-Series also provides a highspeed alternative to hard-mount machines – consuming less water and offering high-speed extract speeds up to 387 G-force. This can cut the time to dry a load by as much as 50%, the company says.

E-Series washers can be installed without bolts and special reinforced concrete foundations.

continentalgirbau.com 800-256-1073

The washer-extractor’s design offers SmartWAVe technology to help with minimum consumption and maximum performance. The technology uses sensors to measure a fabric’s absorption capacity and dispense the ideal amount of water in the cylinder.

The IH040 features IPSO’s Cygnus control systems available in two tiers: Ultra (Premium) and Select (Commercial). Cygnus Assist software allows a laundry owner to modify every parameter, including the wash cycle, from the convenience of a computer or

SPeed QUeen

Speed Queen offers on-premise laundries the SC60, a 60-pound washer-extractor equipped with Quantum™ controls to help increase efficiency and throughput. The machine is ideal for OPLs because it can wash extralarge loads and large items, such as king-size comforters, rugs and quilts, the company says.

Equipped with technology to help reduce operating expenses, the SC60 uses 33% less electrical energy and 11% less water, according to the company.

The washer-extractor has extraction options up to 200 G-force, which leads to shorter dry times and lower dryer energy costs, Speed Queen says. To further increase efficiency, the machine offers a cylinder design that provides low water consumption by minimizing “nonwash” water with smaller sumps. Additionally, it comes equipped with patented Water Guardian technology, which detects drainand fill-valve leaks.

The SC60 has an intuitive chemical dispenser that enables staff to add up to four laundry chemicals at the beginning of the cycle, and it easily integrates with automatic supply injection systems. It also features alternate rotating wash action that produces excel-

12 FEBRua Ry 2013 | amERican LaundRy nEws www.AmericanLaundryNews.com

cOmPiLEd By JEan TELLER, cOnTRiBuTinG EdiTOR

[IPso]

[Maytag commercial Laundry]

[UniMac]

[continental Girbau]

➢

[speed Queen]

Clean. Safe. Protected.

What she can’t see — like healthcare acquired infections — can hurt her. Partner with Ecolab and ensure the cleanliness of your linens and facility:

• Protect your environment with a wide array of EPA-Registered sanitizing and disinfecting products to help make your facility clean and safe.

• Provide disinfection against HAIs with AdvaCare™ Disinfectant; an EPA-Registered laundry disinfectant that kills: Protect your patients when they’re most vulnerable. Partner with Ecolab.

Staphylococcus and Listeria monocytogenes. (EPA Reg. No. 1677-193) aureus, MRSA, E. Coli, Pseudomonas aeruginosa, Acinetobacter

baumannii

For more information about AdvaCare™ Disinfectant, or other Ecolab disinfection solutions, visit Ecolab.com or call 800 553 8683.

©2013 Ecolab USA Inc. All rights

reserved.

lent wash quality without damaging delicate fabrics, according to the company.

When equipped with the Quantum Gold control, laundry managers can program the washer-extractor and receive information on laundry operations, including audit data.

Management can customize up to 30 water levels and cycles.

speedqueen.com 800-590-8872

HuebscH

Huebsch offers the HX75, a 75-pound soft-mount washerextractor that the company says helps reduce utility expenses.

Installation costs are kept low because the washer-extractor has a heavy-duty suspension system and does not require special

foundations, the company says. This feature also offers flexibility in machine placement.

Programmable wash speeds help ensure the best in linen care, while high-speed extracts of 475 G-force maximize water extraction. Higher extraction speeds remove more water in the wash cycle, leading to significantly shorter dry times and lower dryer energy costs, Huebsch says.

There is a four-compartment soap dispenser positioned in front for easy access. The compartment permits the use of both powder and liquid detergents. The inlet valves also fill the soap compartments for complete flushing.

An additional water valve offers faster filling time, while a 3-inch drain provides fast draining to improve cycle times. The large stainless steel door makes loading and unloading the washerextractor easier for employees. Each door has the improved door lock and ergonomic door handle for increased safety and smooth opening/closing, Huebsch says.

The machine comes with a programmable microprocessor control with 39 pre-programmed cycles and room for 99 total programs. Temperature-controlled fills and a thermal cool-down support the washer’s performance.

huebsch.com 800-553-5120

Dexter

Dexter’s V-Series washers are designed to be energy-efficient and to help on-premise laundry owners and managers choose sizes, extraction speed, and cycle programming options that match their needs, the company says.

Dexter 200G-force Express washers are available in 20-, 30-, 50-, 60- and 90-pound capacities, and the non-Express 100G-force washers are available in 20-, 30-, 40-, 60- and 80-pound capacities.

The entire line includes userfriendly features such as extralarge loading doors. High-speed extraction reduces energy costs by reducing drying time, and the use of variable-frequency technology delivers up to a 60% reduction in electrical power consumption, according to the company.

To minimize water usage, Dexter washers feature a “sumpfree” outer tub design, and large doors to ensure that customers

still see adequate water in the machine.

dexterlaundry.com 800-524-2954

Wascomat

Wascomat offers a full range of energy- and water-saving washers, including the 65- and 80-pound EXSM-model 300 and 220 G-force washers designed to be maintenance-free, handle large loads, and offer high-speed spins for fast drying, lower energy costs and increased productivity, says distributor Laundrylux.

The company’s 20- to 77-pound W-model 100 G-force washer offers programmability, includes single-phase electrical for low installation costs, and Compass Control to create programs for specific needs. It also displays two languages at one time.

Wascomat’s EX soft-mount washers – in 45-, 60- and 75-

pound capacities – offer up to 350 G-force extractions for fast drying. And for guest laundries, the 22-pound-plus Crossover by Wascomat is a small-chassis washer engineered for commercial use. It stays in balance and will not over-suds, Laundrylux says, and it is built to last 15,000-plus cycles. laundrylux.com 800-645-2205

eDro

The EDRO DynaWash®openpocket, soft-mount CSL60 washer-extractor features high-speed extraction speeds of more than 300 G-force through an efficient inverter with a single motor drive setup, the

14 FEBRuaRy 2013 | amERican LaundRy nEws www.AmericanLaundryNews.com

Wehavenowstrategicallypartneredwith HBDConstruction, whoiscommittedtodeliveringqualityandintegrityonevery constructionproject,fromconceptiontocompletionand FVConsulting,Inc. theefficiencyspecialistforyourlean processimprovements.Wearenowtheoneandonlylaundry servicecompanyinNorthAmericatoofferfullservicesfrom buildingconstructionthroughtoplantoperationsandsupport. BuildingSmarterLaundriesforSmarterOperators. www.eomech.com Or call 978.373.1883 Allofthepieces areinplace. Thebestjustgotevenbetter. GerardO’Neill President/CEO DavidMertens Senior VPOperations

ALN_Tab_half 10/8/12 2:31 PM Page 1 [Huebsch]

[Dexter] ➢

FredericVeau StrategicPartner

[Wascomat]

15,000 POUNDS OF LAUNDRY. 400 CUSTOMERS. 1 WISE INVESTMENT. Serious about laundr y. In a commercial laundry, you don’t just purchase equipment. You invest in it. UniMac is the leader in reliable, energy-efficient commercial laundry equipment. The industry-leading controls and superior performance of our machines allow for increased throughput while reducing labor costs and utility expenses. Optimal productivity and the lowest cost of ownership in the market –now that’s a wise investment. Fo r more information, visit UniMac.com or call us at 1-800-587-545 8. © 2013, Alliance Laundry Systems, LLC. specificallyCustomizedfinancingdesigned foron-premiseslaundry.

company says. The CSL60 also features state-of-the-art DynaTrol Human Machine Interface (HMi) Touch Screen Control V2.0 with isolated electronic enclosure, DynaMount shock-and-spring suspension mounting, a stainless steel basket and wash tub, and a stainless steel cabinet.

The machines can be installed in laundries where the structure is able to support the static weight of a fully loaded machine.

Typical installations include the on-premise laundries of hospitality and healthcare establishments, prisons and correctional facilities, dry cleaning, wet cleaning, and pony machines in industrial and uniform rental laundries.

edrodynawash.com 800-628-6434

size. Combine that with Smart Dosing, the ability to adjust laundry chemicals to water ratio, and a laundry owner will see savings and superior wash results, the company says.

Models include:

• H-model soft-mounts with 18-pound and higher capacities, with up to 350 G-force for ultra-fast drying, and easy installation over basements and on upper levels;

• X-model 220-350G models in 65- and 80-pound capacities feature high-speed performance, and heavyduty construction; and

• S-model 200G washers in 20- to 77-pound capacities that easily install on regular concrete pads or steel bases with bolts.

laundrylux.com 800-381-7222

out-of-balance conditions.

The system also helps produce consistent, repeatable high-speed extracts of 300 G-force. Six speeds allow a variety of fabrics to be processed. The 36026 X8J uses an inverter drive that provides all speeds from just one single-speed motor. The cylinder’s larger perforated area offers higher wash quality, better rinsing and better extraction, the company says. Cylinder ribs are high and provide excellent lifting.

Preprogrammed wash formulas are easy to select through userfriendly controls. The E-P Plus® control also allows for formula modification.

milnor.com 504-712-7656

process, including pre-washing, washing, rinsing, bleaching and extracting, is automatic. Operators can optionally switch between automatic and manual by selecting easy-to read icons such as wash cycle, rinse time, and water level control.

All RAMCO machines are single-motor with variable speed drives. The front seal on the HWE60 and SWE60 washerextractors is a water seal, and the back is an oil seal to provide extra protection. In addition, the cylinder, stainless steel drum and panels are corrosion-resistant, according to the company.

ramcolaundry.com 800-878-5578

and controls water inlets, drain, wash speeds, temperature and water levels to achieve optimum wash result at the lowest possible cost, B&C says.

The HP series of professional hard-mount washer-extractors is available in 60-pound capacity. This model features hard-mount construction, 300-G extraction, inverter drive, and an advanced EL6 microprocessor control.

The SP series, available in 40-, 60- and 100-pound capacities, is a breakthrough for suspended, freestanding washer-extractors, B&C says, with many advanced technological features.

The 350-G extraction brings moisture retention to levels that save significant amounts of energy and time, B&C says. Installation cost is minimal, because there is no need for concrete foundations, waiting for curing, grouting or hole drilling.

SP models use the highly flexible and powerful EL6 microprocessor, and are equipped with SKF CARB toroidal bearings, according to B&C. The SP’s inverter drive controls all aspects of wash operation, resulting in lower maintenance costs and long life, the company adds.

ElEctrolux

Electrolux Professional smart washers, distributed by Laundrylux, weigh a load size and add the needed amount of water, plus feature a laundry chemical controller that adjusts dosing for accurate water ratio each time.

Under-loading washers is a common problem in many laundries, wasting water, chemicals and energy. Electrolux developed AWS (Automatic Water Savings) to match water to load

Milnor

Pellerin Milnor Corp.’s 36026 X8J suspended washer-extractor helps boost washroom production, save overtime costs, and conserve floor space because fewer machines are needed, the company says. The 36026 X8J, like all X-Series models, increases productivity through larger cylinders, and offers a twopoint inverted suspension system to help control vibrations and

rAMco

RAMCO hard-mount and softmount washer-extractors begin at 60 pounds in capacity and include easy-to-follow controls, low noise and movement, 240 G-force (over 300 G-force for SWE models)— which the company says reduces drying time and saves energy— easy installation and operation, and a large door for easy loading and unloading.

The fully auto microprocessor on the HWE60 and SWE60 models are readable and easy to use, RAMCO says. The washing

[RAMCO]

B&c tEchnologiEs

B&C Technologies offers an array of washer-extractors with capacities between 30 and 100 pounds.

The HE series of hard-mount machines is available in 30-, 40-, 60- and 80-pound capacities. All models feature single-motor inverter drive with 200-G-force extraction and simple microprocessor control. All parts in contact with the wash solution are made of 304-grade stainless steel. The controller provides four chemical signals for external liquid supplies,

bandctech.com 850-249-2222

16 FEBRuaRy 2013 | amERican LaundRy nEws www.AmericanLaundryNews.com

[EDRO]

[Electrolux]

[Milnor]

[B&C Technologies]

Equipment choice can lessen infection risk, utility costs

By AdAm coLAizzi

By AdAm coLAizzi

LAKEWOOD, Colo. — Every year, hospitals and other healthcare facilities produce more than 5 billion pounds of soiled linens. Laundry managers are consistently updating protocols and procedures to ensure linens are thoroughly cleaned and free of bacteria and other viruses. Various types of bacteria can survive up to 90 days on linens, according to published reports.

According to the U.S. Centers for Disease Control & Prevention (CDC), there are multiple methods to hygienically clean textiles. But each requires an equipment mix designed to incorporate the various processes.

In addition, with a large volume of laundry being processed each year, it’s also important for healthcare organizations to ensure they are being as efficient as possible to keep operation costs low.

With proper laundry equipment and processing protocols, the risk of textiles posing as a source of infection to patients and employees can be greatly minimized, as well as reduce utility costs.

In Hot Water

Experts say that in order to kill bacteria and other viruses on linen, laundry should be washed with detergent and bleach for

25 minutes in water that is heated to 160 F. Studies have shown that bacteria, viruses and even bed bugs cannot survive this water temperature or chemical mix.

If your facility has chosen to use this method, it must be able to test water to make sure it’s reaching the 160-degree requirement, in case the operation is ever audited.

Advanced controls are able to show the exact water temperature inside the washing machine. They also allow users to program fill, wash and rinse water temperatures. Also, the controls – either networked or wireless – can send data to a computer, which allows managers to print reports to ensure protocols are being properly followed in the wash. This option also enables supervisors to provide documentation that its washing procedures meet federal requirements.

If a facility is concerned about water usage, some advanced controls allow users to select from as many as 30 different water levels. Programs such as these will help contribute to a reduction in water costs because employees can select the appropriate water level based on load capacity.

High Extraction Speed

It’s equally critical to make sure machines have high G-force extraction speeds.

This extraction helps maximize water removal from linens in the spin cycle. The

higher the G-force, the more water removed from linens. Newer machines offer top speeds of 400 G-force, the highest in the industry. When maximum water is removed in the wash, dry times are greatly reduced.

The Drying Process

Since textiles are already put through a rigorous washing process, it’s important to use tumble dryer programs that will help linens last longer and avoid expensive replacement costs. The dryer should work as a system with the washer-extractor, using the same control platform to ensure ease of use and optimal efficiency.

When selecting a dryer, look for a balance between drying temperature, airflow pattern and usable cylinder space for maximum energy efficiency.

Some equipment on the market offers over-dry prevention technology, which automatically turns a dryer off once the linens inside have reached the optimal dryness level. Over-drying wastes gas and can damage linens and garments, causing replacement costs to rise each year.

More on Advanced Controls

Advanced controls help laundry managers identify expenses within their operations and pinpoint specific areas where they can increase efficiency and reduce costs associ-

ated with labor, linen replacement, utilities and maintenance. With nearly 50% of costs associated with labor, up to 25% for linen replacement and roughly 13% on utilities, it benefits managers to be able to easily identify inefficiencies or potential problems and correct them fast.

Features such as delayed start allow employees to load washers before the end of their shift and have the first load completed by the beginning of the next day.

The real-time clock feature lets managers see what time each cycle was started and stopped, and the idle-time feature monitors the length of time between the starting and stopping of cycles.

Reduce Risk, Lower Utilities

Healthcare facilities can benefit from taking a hard look at their on-premise laundry operation and working with suppliers and manufacturers to pinpoint areas where they can increase efficiency and reduce costs, and, most importantly, achieve the best results for their patients. ALN

Adam Colaizzi is a sales manager for Clean Designs Inc., a distributor of UniMac commercial laundry equipment in the Rocky Mountain region. He has more than six years of industry experience. He can be reached at 800-4444580, adam@cleandesigns.com.

Lavatec Inc.

300 Great Hill Road Naugatuck CT 06770 - USA

Toll Free: 1 800 255 2515 Tel: 203 723 1122 Fax: 203 729 4977

Email: info@lavatec.com www.lavatec.com

Service: Lavatec, Passat, Washex, Challenge Cook MADE IN USA Lavatec Feeders & Folders Remanufactured Equipment Dealer Inquiries Welcome Master Eclipse Two machines in one Towel Folder Master Fold Spare Parts Ironers U.S. DISTRIBUT0R OF LP571 LX445 Master Eclipse Master Fold

3/9/12 3:34 PM Page 1 www.AmericanLaundryNews.com AmericAn LAundry news | F e B r uAry 2013 17

ALN_Tab_half

OPL 101

and drapes used before disposables were introduced. But today’s reusable healthcare linens, gowns and drapes are superior to those used in the 1960s. Consider the facts:

Reusable surgical textiles meet or exceed AMMI standards. Indeed, reusable gowns and drapes meet or exceed AMMI3 barrier protection standards required in the healthcare environment for Level 1 to Level 4 gowns. And reusable gowns and drapes often offer a more comfortable alternative to single-use disposable gowns and drapes.

LCAs prove reusables have a smaller carbon footprint. In addition, several life-cycle analyses (LCA) have confirmed that reusable surgical gowns and drapes are environmental preferable over single-use disposable products.

The 2009 life-cycle assessment study conducted by the University of Minnesota Technical Assistance Program (MnTAP) examined three areas: cost, environmental impact and infection prevention.

In summary, the research conducted at the University of Minnesota Medical Center4 (2,000 beds and 20,000 surgical procedures a year) found that reusable medical textiles (chemo, isolation and surgical gowns) provided cost savings of $360,000 per year, reduced waste by 254,000 pounds per year, produced CO2 emissions three times less than disposables, and produced carcinogenic emissions 16 times less than disposables (i.e. arsenic, chromium, lead) while offering the same infection prevention attributes.

Case studies build credibility among healthcare profession-

als. A study in the Journal of the American Medical Association reports that about 80% of surgical drapes and gowns now used in hospitals are disposable. It estimates that by using reusable linen products and recycling other items as able, hospitals can reduce surgical waste by 73% in weight and 93% in volume.5

A study in The American Surgeon compared costs incurred by two similar hospitals — one used disposable gowns and the other reusable gowns. Annual expenditures were $66,000 and $25,000 respectively.6

Conversion or Increasing Use

For a supplier or an operator of an on-premise or commercial laundry or laundry cooperative, sharing the facts can warm healthcare clients to the pitch to convert to, or increase the use of, reusable surgical textiles. But they may need hands-on help in getting a surgical textile program started.

They could be looking for assistance with product selection, budgeting, storage layout and inventory levels. Touring a laundry that processes reusable surgical textiles might be beneficial. Their ability to gather information and build support may be the key.

What are some ways to increase use of surgical textiles in the OR?

Reusable Surgical Towels — Offering reusable surgical towels for the OR can be an easy, logical “foot in the door.” Some suppliers now tout a disposable surgical towel that can be reused. Yes, these products can survive a wash or two, but they cannot be compared to a woven, reusable surgical towel for effectiveness, sustainability and durability.

Reusable Surgical Gowns and Drapes — Today’s surgical textiles provide comfort, flexibility,

breathability, safety, fluid barrier performance, strength and durability, and low rates of particle release (linting). Upfront costs for switching to or increasing use of reusable gowns and drapes can seem expensive, but case studies show a well-managed program is actually more cost-effective than using disposables.

For example, the University of Maryland Medical Center moved to reusable textiles in the OR more than 15 years ago, and utilizes a vendor to provide clean, sterilized textiles. In 2010, the Medical Center avoided creating 138,748 pounds of waste as a result of using reusable textiles in the OR, which correlates to estimated cost savings of nearly $39,000 in disposal costs and an estimated $39,000 in returned instruments.7

Custom Surgical Packs and Hybrid Packs — For clients using disposable surgical packs and throwing lots of items in the trash, custom packs (sterile or non sterile) or hybrid packs (including key disposable items with reusables) could be an alternative.

While hybrid surgical packs and increasing recycling of items is helpful, even reprocessed disposables must eventually be thrown away. According to Dr. Rafael Andrade, a general thoracic surgeon at the University of Minnesota Medical Center, Fairview, the larger goal is to resume the old practice of relying on permanently reusable equipment.

“We’re just trying to undo a lot of the damage we’ve done,” he says. To that end, Andrade and a nurse, Lynn Thelen, started an OR Green Team at Fairview. With input from colleagues, they reviewed 38 types of OR packs, identified which supplies were never used (such as plastic basins, catheters, syringes and dressings),

and asked their medical product vendor to remove them. One kit for implanting an intravenous port in chemotherapy patients contained 44 items, but the Green Team downsized it to 27 items and switched disposable gowns and linens for reusable ones. This effort eliminated a pound of trash and $50 in supply costs per procedure. In the first year, the various kit reformulations eliminated almost 8,000 pounds of waste and saved $104,658.8

Quality Assurance — One of the biggest objections to reusable surgical textiles is the belief that they are not as hygienic as disposable items. Stains sometimes don’t come out of textiles, but that doesn’t mean they aren’t clean or their performance is lessened. Education is critical in this area.

According to Barb Fordyce, surgical textiles manager, Healthcare Systems Cooperative Laundry (HSCL) in St. Paul, Minn., once clients are aware of quality control measures followed by a laundry, they are more amenable to using surgical gowns, drapes and packs.

Change is Hard

Healthcare professionals generally have been well trained to use disposable items. For the most part, single-use items are all they have ever known in the OR and many other areas of the hospital.

“Any change is hard for people,” says Ed McCauley, CEO of United Hospital Services in Indianapolis. “But once clients have made the switch to reusable textiles, they are typically happy with the change.”

“Inertia can be a problem,” says Fordyce. “I had a nurse convinced that reusables were the best choice, but she backed out because she didn’t want to do the work the conversion would require. You really need an internal champion on the

client side to push for reusables.” While any change in hospital protocol is a challenge, those suppliers and operators willing to provide training, textile management support and hands-on service can succeed in selling reusable surgical textiles to healthcare organizations. And perhaps the industry can begin to reverse the disposables trend. ALN

Nancy Jenkins is executive director of the American Reusable Textile Association (ARTA), whose mission is to create greater awareness and appreciation for reusable textiles. She can be reached at 863-6605350, njenkins@arta1.com.

Footnotes

1) Tieszen ME, Gruenberg JC, A quantitative, qualitative and critical assessment of surgical waste. JAMA 1992;267:2765-8.

2) Association for Perio-Operating Room Nurses Journal, “Reducing Medical Waste,” June 2010 Vol. 91, No. 6, page 711.

3) Association for the Advancement of Medical Instrumentation. 2005, P. 957-958. Selection and use of protective apparel and surgical drapes in healthcare facilities. Arlington, Va.

4) University of Minnesota Technical Assistance Program (MnTAP), Catherine Zimmer and A.J. van den Berghe, 2009.

5) Tieszen ME, Gruenberg JC, A quantitative, qualitative and critical assessment of surgical waste. JAMA 1992;267:2765-8.

6) Cost Containment in the Operating Room, TAS, Oct. 1992.

7) Reusable Textiles in the OR, The University of Maryland Medical Center, Baltimore, MD, Case Study, Guidance Documents, Greening the OR, Practice Greenhealth, 2011.

8) Dr. Rafael Andrade, surgeon, University of Minnesota Medical Center, Fairview, speaking at CleanMed 2010, organized by Practice Greenhealth, quoted in New York Times, June 5, 2010, issue, reporter Ingfei Chen.

18 FEBRUARY 2013 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

Continued from Page 1 Reversing DON’T MISS OUT HERE’S WHAT’S COMING UP IN AMERICAN LAUNDRY NEWS... Want to send a press release or submit a story? Contact Bruce Beggs, editorial director, today! Phone: 312-361-1683 E-mail: bbeggs@americantrademagazines. com MARCH Feature: Buyer’s Guide Arguably the most complete, widely circulated guide of manufacturers and unique suppliers serving the laundry and linen industry today. Editorial Submission Deadline — January 15 APRIL Feature: Do You Know Where Your Textiles Are? Those who manage laundry/linen services or textile rental firms find that counting and tracking the goods streaming in and out of their plants improves productivity and inventory control. Showcase: Flatwork Separators/Spreader-Feeders Editorial Submission Deadline — February 15 MAY Feature: Clean 2013 Show Guide Complete listings of the exhibitors, educational sessions and events that make Clean the industry’s can’t-miss show. Plus, our famous show floor map! Editorial Submission Deadline — March 15 JUNE Feature: Running the Route Route operations is an important function of any successful rental or commercial laundry and requires constant attention. Editorial Submission Deadline — April 15

Similar improvements will be found in boilers, dryers and ironers, reducing our use of energy but forcing the industry to quickly utilize the newest technologies.

Government planners will mandate the use of reusable linen surgical packs and other items. Government-run laundries will make and sterilize surgical packs for use in the operating rooms. They will provide reusable underpads and isolation gowns. Every effort will be made to lessen the amount of trash that needs to go into a landfill. New fabrics will be developed that are easier to wash but present additional challenges in the finishing area. Some of these products may eliminate the need for ironers altogether (more on that later).

Washroom chemicals will need to be developed based on their ability to clean and their effect on the environment. All products will have to be biologically safe and have a minimal effect on the environment. This will require our universities to train a new breed of enviro-chemist. These chemists will understand how various chemical properties will affect the environment. Over the years, they will greatly expand our knowledge in this area, as we learn from our mistakes and get better at predicting the unintended consequences of our actions.

Energy

Environmental consequences will be the driving force behind our energy policies. The internal combustion engine will continue to be Public Enemy No. 1.

To effectively reduce pollution from automobiles and trucks, the government will continue to allow oil prices to increase. The steady increase in fuel processing, which will create higher gasoline and diesel prices, will cause consumers and companies to reduce their use of these products. This reduction will be heralded as a major achievement for the environment.

Some companies will switch their vehicles over to natural gas, and this will help for a while. But the current excess supply of natural gas will quickly disappear and the government will move to limit fracking as an environmentally hazardous way to get this energy source.

This energy policy will affect the number and location of government-run central healthcare laundries. These plants will be designed to provide services to healthcare facilities in a welldefined geographic area. Gone will be the days of operating a depot in a far-off city! Distance and weather-related problems will determine the location of healthcare laundries. Gone will be the days of several laundries competing to serve the same geographic

area. Each area will be carefully planned, and healthcare providers will find themselves assigned to the government-run laundry in their area. The government will do away with the VA laundry system.

Nursing homes and other non-acute care healthcare facilities will also be directed by the government into one of these government-controlled laundries. The power of the U.S. government will be based on the control it can exert as a single payer.

Textiles

It does not take a lot of imagi-

nation to see the development of a new line of products that will enhance the healing process and decrease bed sores. The current reimbursement system will penalize facilities for skin care problems that develop during a patient’s stay in a facility.