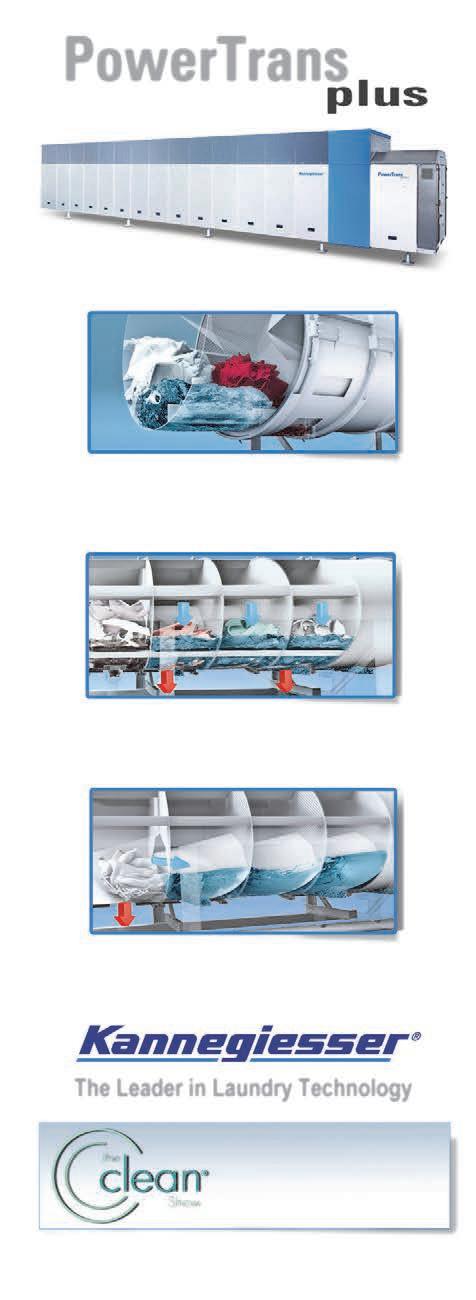

Dreher retiring; Hart is Kannegiesser USA president

DALLAS — Kannegiesser

DALLAS — Kannegiesser

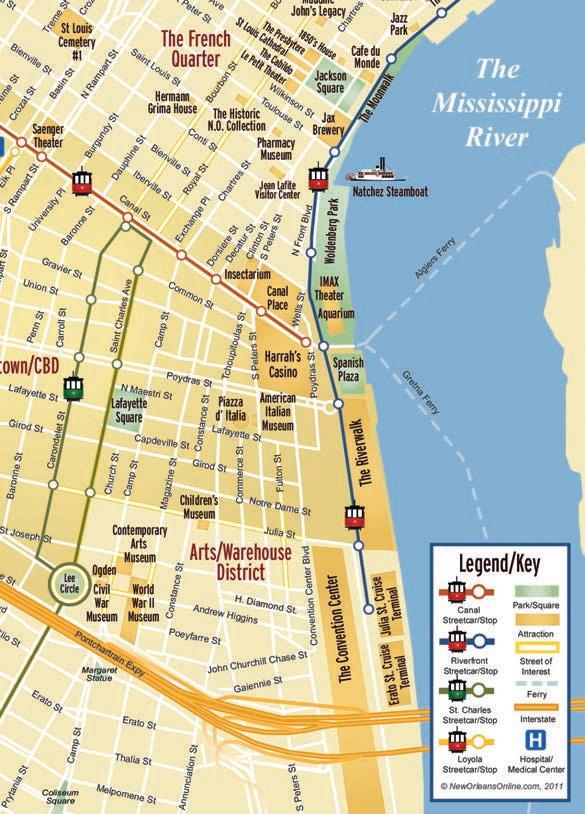

NEW ORLEANS — The Ernest N. Morial Convention Center will host the world’s premier textile care expo for a fifth time when the 2013 Clean Show—officially the World Educational Congress for Laundering and Drycleaning— arrives on Thursday, June 20, for a three-day stay through Saturday, June 22.

It will mark the first time since 1981 that the Clean Show has been scheduled for three days instead of four, reflecting a “more concise and efficient” format designed to give exhibitors and attendees alike a better value for their investment, according to the Clean Executive Committee.

Hart joined Grand Prairie, Texas-based Kannegiesser USA in 2004 as vice president of marketing, bringing with him more than a decade of industry and product experience. He was promoted to executive vice president in early 2012.

Dreher, who served as president for 13 years, will retain an advisory role that involves marketing the Kannegiesser brand in the Americas.

Kannegiesser GmbH President and CEO Martin Kannegiesser says both Dreher and Hart have demonstrated abilities in combining leadership and teamwork.

The two men thanked the staff and Kannegiesser for their support in making the U.S. market the company’s third largest behind France and Germany.

Kannegiesser USA is planning to display several products in the United States for the first time at next month’s Clean Show. ALN

The Clean Show has been convening every other year since 1977 to present new technology, educational sessions and networking opportunities to all segments of the dry cleaning, laundry and textile care industry. This year’s event is expected to draw 10,000 trade attendees, according to Riddle & Associates, the show’s longtime manager.

“I am constantly asked why

should I come to the Clean Show or why should I exhibit,” says John Riddle, president of Riddle & Associates. “There are many reasons. You will see the newest equipment, learn about new services, see working demonstrations and have access to outstanding industry education.

“In today’s world of electronic communication, it is nice to have the opportunity to communicate

with someone eye-to-eye, faceto-face and talk with them about industry issues. It’s a great chance to renew old friendships and make new ones. These are just several reasons I think making this trip is worth the time, effort and money. We encourage you to ‘Be There’ and take advantage of this opportunity.”

As this issue went to press, approximately 400 companies and organizations were scheduled

From A to Z: A list of Clean ’13 exhibitors, plus basic descriptions of their products and services.

Begins on Page 20

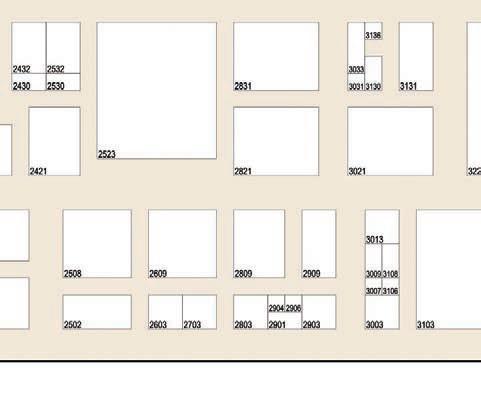

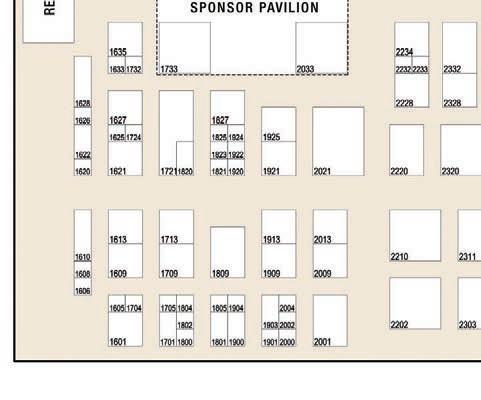

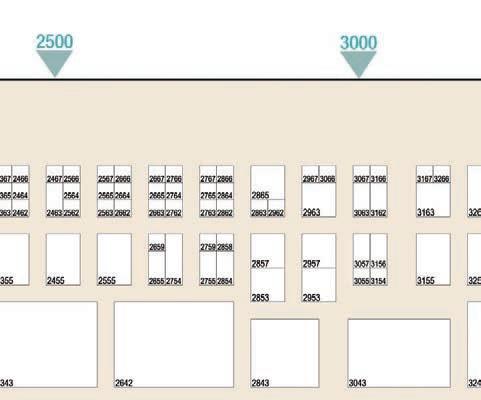

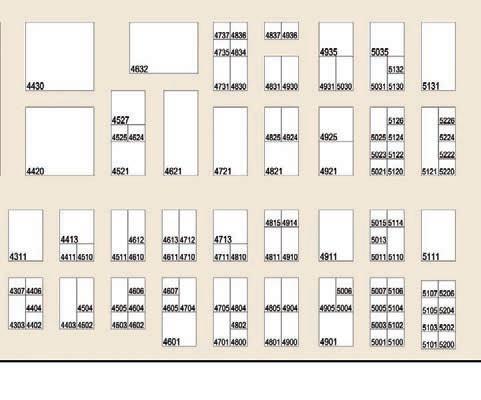

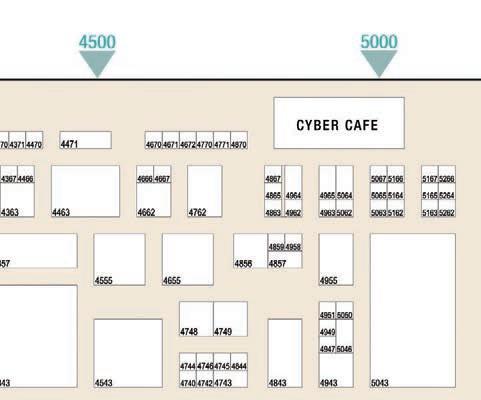

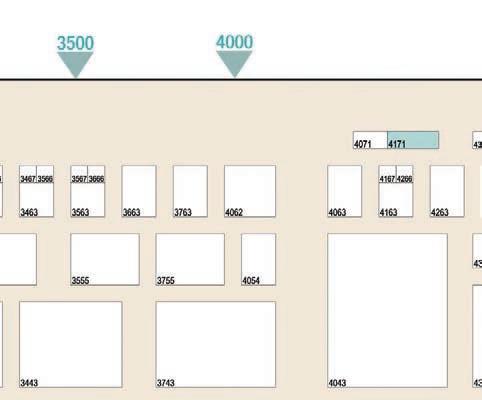

You Are Here: A map of the Ernest N. Morial Convention Center floor plan, including booth assignments. Pages 28-29

Pay Attention, Class: Descriptions of the morning and afternoon educational sessions. Pages 40-41

to be represented on the exhibit floor, covering roughly 200,000 net square feet (a full list of exhibitors, as of April 10, starts on page 20). It’s possible that more exhibitors will be added in the final weeks leading up to the event.

The exhibits will open following a brief 10 a.m. ceremony on Thursday, June 20 (distributors are

RIPON, Wis. — Alliance Laundry Systems is restaging its IPSO equipment brand for the North American market beginning at the Clean Show next month, American Laundry News has learned.

Alliance has already launched IPSO’s “Industrial by Design” platform to communicate that the equipment is engineered, tested and built for heavy-duty performance, says Gary Dixon, North American sales manager for IPSO.

“This renewed focus on North America represents the next step in IPSO’s evolution to a truly global brand,” Dixon says. “IPSO has been a premier OPL brand in Europe for more than 40 years, and is sold in 90 countries around the world; you cannot be a truly global brand though without a strong presence in the North American market.”

Alliance acquired IPSO in 2006 and has worked to incorporate key elements of its knowledge base and company identity into the IPSO operation in Belgium while also

tapping into the brand’s 40 years of manufacturing experience there.

“We have arrived at a true unity of purpose and culture, which is another reason we thought the time was right to relaunch IPSO in the North American market.”

IPSO equipment continues to utilize advanced technology developed for the European market that saves energy and reduces water consumption and detergent use, Dixon says.

Its line of 2013 washer-extractors features patented water absorption verification technology not previ-

ously available in North America.

All IPSO washer-extractors sold in North America and throughout the world are manufactured at Alliance’s plant in Wevelgem, Belgium. IPSO tumblers are made at the company’s Wisconsin plant.

Alliance is targeting the onpremise and coin laundry markets with its IPSO brand.

“The Clean Show will be the first time we highlight the restaging of IPSO from the premium European OPL brand to a truly global brand for both OPL and vend,” Dixon says. ALN

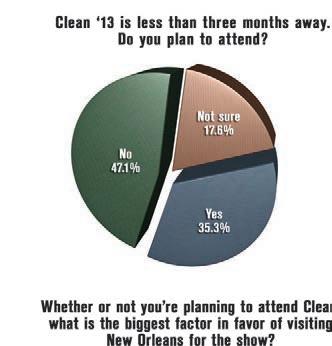

CHICAGO — More than 70% of respondents to April’s American LaundryNews.com Wire survey say they are OK with the Clean Show’s shortened three-day schedule this year, compared to the remaining 29.4% who are “indifferent about this change.”

One respondent proposed that the biennial convention be held “every five years,” but with a longer schedule. “Have mandatory attendance by all members, companies and organizations,” the respondent writes. “Have it for a full five-day week with...golf tournaments planned and social events for all in the evenings.”

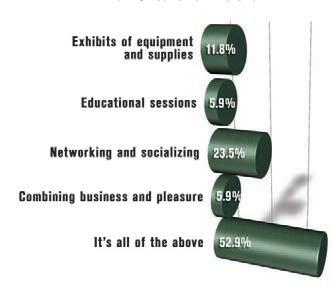

In fact, a good number of respondents answered that the biggest factor in favor of visiting New Orleans for Clean was the “networking and socializing” opportunities (23.5%), while 11.8% favored the “exhibits of equipment and supplies.” Equal shares of 5.9% pointed to “educational sessions” and “combining business and pleasure.” The most popular response, however, was “all of the above” (52.9%).

The Association for Linen Management (ALM) and the Textile Rental Services Association (TRSA) are among the organizations hosting educational sessions during the June 20-22 show. Among ALM’s scheduled offerings, Reducing the Loss of Patient Linenand Scrubs and Standards and Regulations Affecting the Healthcare Laundry and Linen Industry have drawn the most pre-show interest among respondents. As for planned TRSA sessions, Textile Services Contracts and Negotiations and TRSA Clean Green and Hygienically Clean Certification Programs: Quantifying Your Commitment to Cleanliness and Sustainability are most anticipated.

More than one-third (35.3%) of those surveyed say they are planning to attend Clean, while 17.6% remain unsure. The remaining 47% aren’t planning to attend, with cost playing an important factor for some.

Among respondents who are not attending, about 45% “can’t afford the cost,” 27.3% “can’t spare the time,” and 27.3% said they “made other plans.”

“Employers do not give the time to attend seminars or trade shows,” writes one respondent. “We have to use vacation time to attend. In the past, employers would pay for employees to attend. Now, it comes out of our own pocket.”

While American Laundry News’ Wire survey presents a snapshot of the audience’s viewpoints at a particular moment, it should not be considered scientific. Subscribers to Wire e-mails—distributed twice weekly—are invited to participate in an industry survey each month. The survey is conducted online via a partner website, and is developed so it can be completed in less than 10 minutes.

All managers and administrators of institutional/OPL, cooperative, commercial and industrial laundries are encouraged to participate, as a greater number of responses will help to better define operator opinions and industry trends.

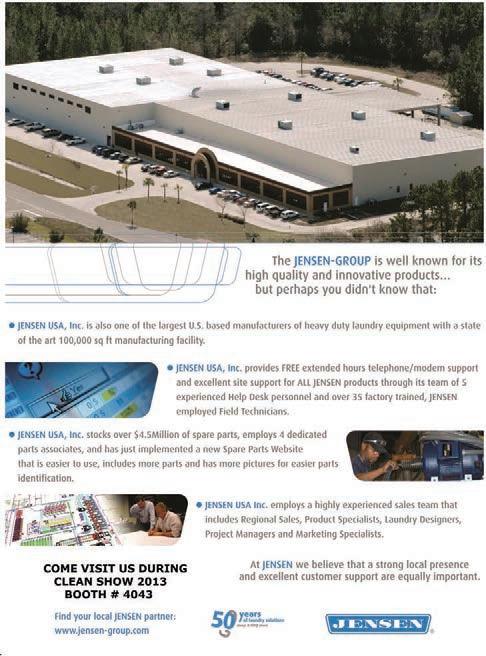

NAUGATUCK, Conn. — Lavatec Inc. has become affiliated with Belgium-based manufacturer Lapauw and is now the headquarters for Lapauw of America, according to Bruce Burmann, vice president of sales for Lavatec Inc.

Lavatec Inc. provides Lapauw with a “major hub for the sales and service of its machines in the U.S. market as well as South America, Central America and Canada,” he says.

The agreement, which was established in close cooperation with Goudkuil Laundry Machinery (it acquired Lavatec Inc. in 2011), brings Lapauw in as a “main investor,” Burmann adds.

Lavatec Inc.’s sales network will promote the complete Lapauw product range, which includes flatwork ironers, feeders, folders, washer-extractors and tunnel finishers.

Lavatec Inc.’s technicians will receive extensive training on Lapauw equipment. A local service unit will not only enable the continuance of service toward existing and new Lapauw customers, Burmann says, it will enhance it in terms of local spare parts stock and availability of engineers.

Lavatec Inc. technicians will also be called upon to start up Lapauw installations in the American market.

“With Lavatec Inc., Lapauw immediately has over 42,000 square feet of manufacturing space at their disposal, which fits in perfectly with its closeto-the-market manufacturing strategy,” Burmann says. ALN

Charles Thompson

Phone: 312-361-1680

E-Mail: cthompson@ americantrademagazines.com

Bruce Beggs

Phone: 312-361-1683

E-Mail: bbeggs@ americantrademagazines.com

Nathan Frerichs

Phone: 312-361-1681

E-Mail: nfrerichs@ americantrademagazines.com

Editorial

National Sales Director

Donald Feinstein

Phone: 312-361-1682

E-Mail: dfeinstein@ americantrademagazines.com

Office Information

Main Phone: 312-361-1700 Fax: 312-361-1685

Subscriptions 630-739-0600 www.americanlaundrynews.com

American Laundry News (ISSN 1091-9201) is published monthly. Subscription prices, payment in advance: U.S. & possessions, 1 year $39.00; 2 years $73.00. Foreign, 1 year $89.00; 2 years $166.00. Single copies: U.S. & possessions $7.00; Foreign $14.00.

Published by American Trade Magazines LLC, 566 West Lake Street, Suite 420, Chicago, IL 60661. Periodicals postage paid at Chicago, IL, and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Laundry News Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 39, number 5. Editorial, executive and advertising offices are at 566 West Lake Street, Suite 420, Chicago, IL 60661. Charles Thompson, President and Publisher. American Laundry News is distributed selectively to qualified laundry and linen management and distributors in the United States. No material appearing in American Laundry News may be reprinted without written permission. The publisher reserves the right to reject any advertising for any reason.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2013. Printed in U.S.A.

Tunnels use a minimum of 0.6 gallons of fresh water per pound of goods

Tunnels use as little as 0.3 gallons** of fresh water per pound of goods

Once again Milnor has revolutionized continuous batch washing–this time with its exclusive PulseFlow* Technology. PulseFlow tunnels combine the innovative RecircONE® pump arrangement that wets down goods quickly, with high velocity rinsing for outstanding results. PulseFlow tunnels still employ traditional True Top Transfer, but use standing bath washing, and intermittent counterflow in every process module. Dedicated rinse modules are eliminated, saving thousands of gallons of fresh water every day. Thanks to PulseFlow Technology, the water is used far more efficiently.

How do you get your goods cleaner, faster using half as much water? Using less. Cleaning more. The only answer is the PulseFlow Technology tunnel–only available from Milnor.

Contact an authorized Milnor distributor or call 504-712-7656 to find out more.

*Patent applied for. **Light soil.

To see how PulseFlow CBW Tunnels work, scan this code.

www.milnor.com/pulseflow_technology

n my experience, time is always at a premium when attending the Clean Show.

i

And time management during Clean will never be more important than it is this year, when next month’s show in New Orleans lasts just three days compared to the usual four.

Clean Show veterans know the importance of having a plan once they enter the Ernest N. Morial Convention Center. This year, you can’t afford to be without one.

Aside from our show cover preview, you’ll find inside a list of the 400 or so companies and organizations that have reserved exhibit space as of April 10, plus basic descriptions of their products

granted exclusive access from 8 to 10). Exhibits will open at 9 a.m. on subsequent days, and they will close each show day at 5 p.m.

Some of the Clean 2013 sponsors, as well as several other industry associations, will offer approximately 40 hours of education over the show’s three-day schedule. Most of the seminars will occur in on-site meeting rooms between 8 and 10 a.m. daily, but in a change this year, some sessions have been scheduled for each afternoon on the exhibit floor itself (a full schedule, along with brief descriptions of each session, is on pages 40-41).

The Clean Show has released a new, free mobile app for Apple iOS- and Android-based smartphones that offers features such as locating exhibitors, planning a personalized show itinerary, and connecting with others via social media. The free app can be downloaded from an individual’s device

The Director’s Chairand/or services and their booth numbers, as well as details on the 40 hours of educational sessions that are scheduled. (Did you know that some sessions will be staged on the show floor itself?)

And don’t you dare forget

about our show floor map, which adorns this issue’s center spread.

If you’re not sure how to go about preparing for Clean, read Phil Perry’s take on getting the most from your trade show investment.

We’ve done what we can to provide you with the tools necessary to create your own plan.

A couple of my staff members will be attending Clean for the first time, and I’m sure this issue will be dog-eared by the time their three-day whirlwind adventure ends.

We’ll have extra copies at our booth—4171. I hope you’ll take just a moment to stop by, introduce yourself, and let us know how we can best serve you. ALN

in the App Store or Market, and is fully integrated with the Clean Show website, and with LinkedIn and Twitter.

“In the age of technology, offering a smartphone app just makes sense,” says John Riddle. “We want our attendees and exhibitors to be able to stay connected before, during, and after the show and be able to do it while on the go.”

Attendees who do not have a smartphone can still maximize their time at the show by using CleanShow.com’s “My Itinerary” feature. Visitors can store in a personalized “Briefcase” their schedule of educational sessions and booths they wish to visit, as well as print out their “Itinerary” to bring with them.

Another show change is the relaxation of certain rules regarding the convening of affiliate groups during trade show hours. In the past, meetings were restricted to hours outside education and exhibit hours, but now exhibitors and industry associations can schedule their sales, distributor or group meetings during educational

sessions or between the hours of noon and 2 p.m.

Attendees can easily register for the Clean Show online at its website for the discounted rate of $99 a person through May 31 (on-site registration will be $149 per person).

Registration hours at the convention center will be 1-5 p.m. June 19, 7 a.m. to 4:30 p.m. June 20, 7:30 a.m. to 4:30 p.m. June 21, and 7:30 a.m. to 4 p.m. June 22.

Reservations for official Clean Show hotels can be made on the show’s website until May 17 (special show rates are available only through the Clean Show Housing Bureau).

Complimentary shuttle buses will transport attendees between official hotels and the convention center mornings and afternoons during the show.

The Clean Show is sponsored by the Association for Linen Management, Coin Laundry Association, Drycleaning & Laundry Institute, Textile Care Allied Trades Association, and the Textile Rental Services Association of America. ALN

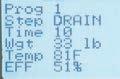

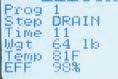

This month’s column addresses finetuning a tunnel washer system to get maximum productivity. I have never seen a tunnel washer system that had enough dryers to prevent the tunnel from going into hold while it waits for an available dryer. I have seen many a tunnel washer operation that, with proper scheduling of the work, can eliminate the need for the tunnel going into a hold cycle.

The key to maximizing tunnel washer productivity is in knowing how to schedule work through the machine.

To begin, gather this information:

1. Number of loads to be washed per day of each type of linen

2. Drying time for each type of load

3. Hourly requirement of the production side for each item

4. Inventory level for each type of load (to ascertain need to push loads through in case of low inventory)

5. The number of available dryers

6. Cycle time for the tunnel washer

In my laundry, I have broken my loads down into three categories: No-dry loads (sheets sent directly to the ironers), short-dry loads (patient gowns, pillowcases, bath towels, bath blankets, washcloths), and long-dry loads (thermal blankets, incontinent pads). By developing a scheduling system that follows a set pattern, I can keep all the workstations busy and maximize use of the tunnel washer capacity.

To start improving your tunnel washer capacity, you need a good starting point. Before making any changes, accurately determine, over the course of at least one week, how many loads per hour you are getting through your washer. Compare that figure to the theoretical capacity. For example, a tunnel washer operating on a 2minute cycle can produce up to 30 loads per hour. A tunnel washer operating on a 21/2 minute cycle can produce 24 loads per hour. Chances are, yours is not operating at its theoretical capacity.

A quick review of the problems causing you to not meet maximum capacity will most likely confirm that the problem is lack of dryer capacity. If other problems are discovered—tunnel going into hold for low temperature, or a low water level—these should be corrected before you move forward with a productivity improvement program.

To improve your tunnel productivity, you need to be able to pick and choose which linen items are going into the machine. This may require that your soil-sort area start work 30 to 60 minutes before your tunnel washer. Based on your original research into the types of loads you are washing, and their respective dry times, make a first attempt at developing a tunnel loading schedule. Use this schedule for several days and compare the results with your baseline productivity. Expect to make some changes as you learn what mix of linen works well and what mix of linen does not.

In my plant, I can easily maximize my tunnel output for an hour or two by running a majority of sheets through the tunnel that bypass the dryers and go directly to the ironers. But by doing so, dryers are not utilized and various areas of the laundry run out of linen. My goal is to maximize dryer use and tunnel washer output. Each laundry operates with different equipment and a different linen mix so there is no universal loading system that works for all occasions or circumstances.

•

•

•

•

•

•

•

•

•

•

•

•

By monitoring the loads per hour in your tunnel, and tracking the utilization of your dryers, you should be able to develop a highly workable loading system within a month. The improvements made from this effort, even if small, will have a major impact on your operation over the course of a year.

•

Having received numerous requests for newly revised information on this subject, I have reviewed the volumes of information obtained from both healthcare and hospitality laundry operations worldwide for 2010-2011.

I did my best to convert foreign cost to U.S. cost—both were changing rapidly as of December 2011—and discovered that our foreign counterparts were, in most segments, slightly more cost-efficient and, due to exchange rates, getting more production for the money simply due to the value of certain currencies, lower fringe benefit cost and higher degrees of automation. (I am pleased to report that this gap is closing rapidly.)

There could be numerous explanations, of course, but the primary reason was the vast difference in labor and fringe benefit cost in our country vis-à-vis other foreign locations, primarily those in Europe, Russia and the Far East.

The basis for this analysis was to determine benchmark alignments once various currencies were adjusted to match the U.S. dollar. Both higher and lower extremes in costing for each element were evaluated for accuracy. A group of independent accounting specialists who volunteered its time was utilized to draw the various conclusions reached in the report. Foreign laundry experts assisted in the translation of some information.

Throughout the process of validating accuracy of the data provided and drawing comparisons, the identity of each facility remained confidential. Each facility was simply referred to as a number or letter, depending on the type of operation: healthcare or hospitality. For those with a combination of tasks, every effort was made to categorize each element.

Every facility that supplied information has done so every year since this periodic review began.

As consultants and various levels of internal management continue to overly complicate laundry operational cost scenarios, as well as depicting systems that may not prove costeffective, it is apparent that laundry and facility managers, as well as top executives with a renewed interest, require a cost benchmarking rule of thumb that will assist them in selling their operations, i.e. justifying new systems or a new facility, obtaining new customers and, probably most important, comparing variable cost that should influence decisions to continue in-house operations or examine outsourced management, operations, linen rental, transportation, etc.

I remain amazed that folks who seem to be knowledgeable simply complicate data in such a form that it becomes extremely difficult if not impossible to interpret. The same situation applies when reviewing opportunities to automate and modernize operations. It is apparent in some cases that new operations with new systems are not as cost-effective as planned, mostly due to a misunderstanding of previous cost and the industry’s promises to improve on the status quo.

Institutions, general contractors and A/E’s that hire consultants to review laundry facility operations should also continue to rely on internal expertise and experience, I believe. The institutions should also ensure that the consultants and experts selected are experienced in reviewing all applicable operational elements. A consultant with expertise in energy management, for example, may not be qualified to review laundry production or linen distribution.

It is quite apparent that large laundry and linen-rental consortiums that deal specifically with healthcare markets are becoming more competitive. As business tends to escalate, and based on recent information, cost seems to be leveling out to some degree, with the exception of the impact of

high cotton cost and, most recently, fuel cost.

My previous forecast that total cost of operations may reach $1.10 per pound processed/delivered by 2013 seems right on target. The rising cost of healthcare insurance benefits enacted as a result of healthcare reform could dramatically increase the cost of operations and associated product and equipment purchases in 2014.

A review of approximately 473 healthcare and hospitality laundry facilities located in the United States and 23 foreign countries with operations that process a combined 276 million pounds annually with varying degrees of efficiency reveal the following benchmark costs (in U.S. dollars) that should be deemed most efficient on the average, even though most every facility demonstrated opportunities to reduce cost, especially in labor-sensitive areas.

Most important to note in this analysis were the plans to reduce labor and utilities cost related to washing, drying, conveyance, and flatwork feeding and finishing. These facilities also reported that major efforts were under way to reduce textile-replacement cost through standardization efforts and by examining best value over lowest cost for an item. It’s unfortunate that the federal government seems to continue to focus on lowest cost rather than the impact of overall cost.

Other major components under review seem to drive at lowering chemical cost by conducting actual comparisons and focusing on the customer service element that is so critical to this facet of the operation.

The variables between healthcare and hospitality cost were certainly interesting. Hospitality was higher on the average, which was expected, with the average variance

costs were running at 24-32% of actual salary cost (in other words, add that percentage to base salary cost).

— 3-5 cents per pound processed and delivered

Maintenance and Repair Cost: Labor cost and materials associated with routine maintenance of applicable systems, including processing and ancillary support equipment, carts, etc.

— 7-11 cents per pound processed and delivered

Equipment Depreciation: Divide equipment value by 15 years.

— 4-6 cents per pound processed

Depreciation of Property and Applicable Property Taxes: Divide aggregate cost of land and building plus annual taxes by 75 years.

— 3-5 cents per pound processed and delivered

General Supply Cost: Includes leasing of office equipment, office supplies, covers, pads, hangers, thread, wax, patches, buttons, etc.

— 2-4 cents per pound processed

Chemical Supply Cost: Laundry chemicals, water treatment, etc.

— 3-5 cents per pound processed

Utility Cost: Electrical, steam, gas, water, oil, sewer, refuse removal, and solar.

— 8-10 cents per pound processed

SUBTOTAL: For a most efficient operation, Production Cost should be 48-69 cents per pound processed

Textile Distribution & Replacement Cost Benchmarks

Textile Distribution and Return Cost: Includes drivers, fees, tolls, leasing, fuel, vehicle maintenance/repair, linen room distribution (from cart assembly to end-user locations) labor and benefits, seamstress/repair/marking, uniform distribution, cart depreciation and replacement, and transportation to external customers.

—13-15 cents per pound processed (within this component, fuel cost was 4-5 cents per pound)

Textile Cost: Surgical, uniforms, general textiles, drapes and other textiles based on a seven-par maintenance value for healthcare or hospitality.

—17-21 cents per pound processed

SUBTOTAL: Textile Distribution and Replacement Costs should be 30-36 cents per pound processed and delivered.

The overall operational cost benchmark ranged in 20102011 from 78 cents to $1.05 per pound processed and delivered.

While the overall variance in cost ranges is certainly widespread, a manager must carefully and accurately calculate all costs associated with the actual operation—all are different.

A major failing on management’s part is the inability to calculate fringe-benefit cost and include it as part of the outcome. Calculating production cost while forgetting other costs simply raises additional questions. All costs depicted in this exercise are considered equally important; one without another would have painted an inaccurate picture.

being between 6 and 7 cents per pound processed. This was mostly attributed to the higher quality/cost of textiles acquired, which is significant.

Processing Cost: Direct labor costs, including fringe benefits (health insurance, retirement, etc.), which are applicable to the receipt, sorting, washing, drying, ironing, conveying and preparing of textiles for delivery within a laundry processing facility.

— 18-23 cents per pound processed

Administrative Cost: Covers personnel in laundry and textile product management, secretarial, contracting administration, general foreman and nonproduction employees/ housekeeping (includes fringe benefit costs, such as union dues, health insurance, etc.). On average, fringe benefit

If, for some reason, you think your costs are lower than the benchmark’s lowest range, I encourage you to re-examine and recalculate your numbers. More importantly, make sure you have included all costs so they parallel those listed in this report.

As mentioned in my previous analysis (published in 2011), textile replacement cost and transportation cost for 2010-2011 did reflect marginal increases. ALN

Ken Tyler is vice president of government operations for Encompass LLC. He managed the entire textile and laundry operations for the U.S. Department of Veterans Affairs for 23 years, retiring in 2000.

Talley Machinery Corp. offers inverter drive cabinets that meet Underwriters Laboratories testing requirements as an option to help support the safe operation of flatwork ironers.

To be shown at Clean ’13 in New Orleans, the inverter drive cabinet earned UL-certification under UL 508A, the Standard for Safety of Industrial Control Panels, enabling laundry operators to meet an increasing number of state mandates requiring electrical installations to meet UL standards, according to the company.

The UL listing documents a high level of quality and instills confidence in workers operating and maintaining the laundry machinery, Talley Machinery says.

Installed to date on a variety of Hypro, Sylon, Super

Electrolux Professional recently introduced SmartDosing, a new system that automatically adjusts the quantity of detergents to the actual load size in the washer. It works in combination with Electrolux’s Automatic Water Savings system (AWS), which weighs the actual load size and adjusts water for that load.

The human error of underloading washers allows for wasted water and laundry chemicals. While traditional systems work on the assumption the washer is always loaded to full capacity, with SmartDosing, the laundry chemical controller is “smart” enough to adjust chemicals in relation to water. If a washer is loaded to 50% capacity, the water and chemical savings could be up to 30% per load, Electrolux says.

SmartDosing is simple to install and easy to use, according to the company. Operators do not need to select anything — the process is automatic. An integrated USB port completes the system, allowing pro-

Ecolab introduces the Performance™ Industrial Program, which addresses the high-performance cleaning needs of industrial laundries while helping to minimize environmental impact.

To improve operational sustainability and align with EPA efforts to promote alternative ingredients, many healthcare and hospitality laundries have reduced or eliminated the use of formulations with ingredients such as nonylphenol and nonylphenol ethoxylates (NPEs). Given their extraordinary cleaning challenges, industrial laundries have found it challenging to find effective, NPE-free alternatives, Ecolab says.

The Performance Industrial Program is a threeproduct system that uses patented NPE-free chemistry to effectively remove the heaviest industrial soil. Mike Johannsen, Ecolab’s senior vice president and general manager of Global Textile Care, says the

Sylon and Streamline flatwork ironer models from American Laundry Machinery, and on several Troy Laundry Machinery flatwork ironers, the UL-certified inverter cabinet serves as the foundation of the company’s soft-start inverter drive system.

The ironer system gradually increases the speed at startup over a period of several seconds to eliminate parts wear while reducing energy consumption and cutting electric bills, Talley Machinery says.

The UL-listed inverter cabinet may be retrofit onto ironers while in plant or added to ironers during remanufacture at Talley’s facility.

talleymachinery.com 800-222-9954

The Pillow Factory Division of Encompass Group introduces Stellar® Positioning Products, designed to find the perfect balance between the function healthcare providers require and the comfort patients deserve.

The positioners can be used to elevate, prop and support patients. The powder blue color is attractive and ideal for both inpatient and outpatient use, Encompass says.

Technologically advanced Comfort Care™ fabric provides an ultra-soft and breathable surface that easily wipes clean (the positioners are not launderable). Its cloth-like surface combines with a cool, dry feel and recycled polyester fiberfill to create a unique option for patient positioning. Unlike tradi-

tional foam positioners, which can lead to moisture and heat buildup, Comfort Care™ fabric promotes healthy skin care, Encompass says.

The positioners are anti-microbial-treated, resist fluids and staining, and can be easily disinfected for reuse, the company adds.

Stellar Positioning Products are available in a variety of styles. encompassgroup.net 800-245-4636

gramming data to be uploaded or reports to be downloaded. The controller is able to manage from two to six pumps, and works seamlessly with Electrolux Compass Control washers equipped with AWS. The proper dosing ratio allows for a finished product that has been thoroughly rinsed and is comfortable for use. Controlling chemicals and water also has a positive environmental impact, the company adds.

“It’s not just about machines,” exclaims Kim Shady, senior vice president of OPL at Laundrylux, which distributes Electrolux products in North America. “Electrolux solutions create added value for your business. … Every innovation is designed by experts to best meet your needs and exceed your expectations — and SmartDosing definitely exceeded my expectations.”

laundrylux.com/electrolux 800-645-2205

Tingue, Brown & Co. will unveil its new Black Knight laundry machine belting during the Clean Show in New Orleans, the company reports. Black Knight features a proprietary, high-density weave to deliver strength, wear resistance and long life exceeding that of other premium-quality belts, the company claims.

To be unveiled in booth 2903, the Black Knight belting was developed for installation on flatwork ironers, folders and other laundry equipment where non-stop productivity is required, downtime is to be avoided and cost savings are desired, the company says.

Made exclusively in the United States, the Black Knight laundry belt is available in 1-inch, 11/2-inch, 2-inch, 21/2-inch, 23/4-inch and 3-inch widths, and in 375-foot rolls with a choice of lacing styles. Glued ends or sewn endless are offered as options.

A spec sheet is available free as a PDF on the company’s website.

tinguebrownco.com 800-829-3864

program “redefines industrial-strength cleaning for today’s efficiency-driven, sustainability-minded era.”

The program’s distinctive blend of surfactants, conditioner and soil suspension agents effectively removes petroleum, oil and grease, and delivers an exceptional level of whiteness, Ecolab says.

Currently in use by multiple industrial laundries, the Performance Industrial Program delivers soil removal and whiteness results comparable to detergents using NPE chemistry, the company adds.

Besides providing cleaning and sustainability benefits, the Performance Industrial Program delivers operational savings to industrial laundries through first-pass cleaning and easier rinsing; shortening wash cycles; reducing rinse steps; and helping customers to conserve water and energy, Ecolab says. ecolab.com 800-553-8683

The HF-25 ozone system from WET-TECH, The Ozone People, represents an innovative approach to commercial and industrial ozone washing, the company says.

Designed to meet the needs of highvolume production facilities dealing with heavy-soil classifications, the system independently supplies controlled levels of ozone to multiwash machines, including tunnel washers or continuous batch washers.

Controlled ozone applications can help improve wash quality and reduce operating costs while assisting in meeting regulatory stan-

dards, the company says. Ozone, which is infused in a gaseous state, provides improved wash performance without leaving a chemical residue on fabrics, it adds.

Producing from 25 to 100 pounds per day at 5% concentration, the HF-25 system impacts washer operation by breaking down washwater contamination for improved wastewater treatment.

Its booster feed supply with compressed air flushdown ensures complete, positive ozone feed to each wash machine. wet-tech.com 508-831-4229

UL-certified inverter drive cabinet designed to support safe flatwork ironer operation

Dosing system automatically adjusts quantity of detergents to actual washer load sizes

Machine belting features high-density weave to deliver strength, resist wear

New chemistry program formulated to address industrial laundries’ high-performance cleaning needs

System independently supplies controlled levels of ozone to multi-wash machines

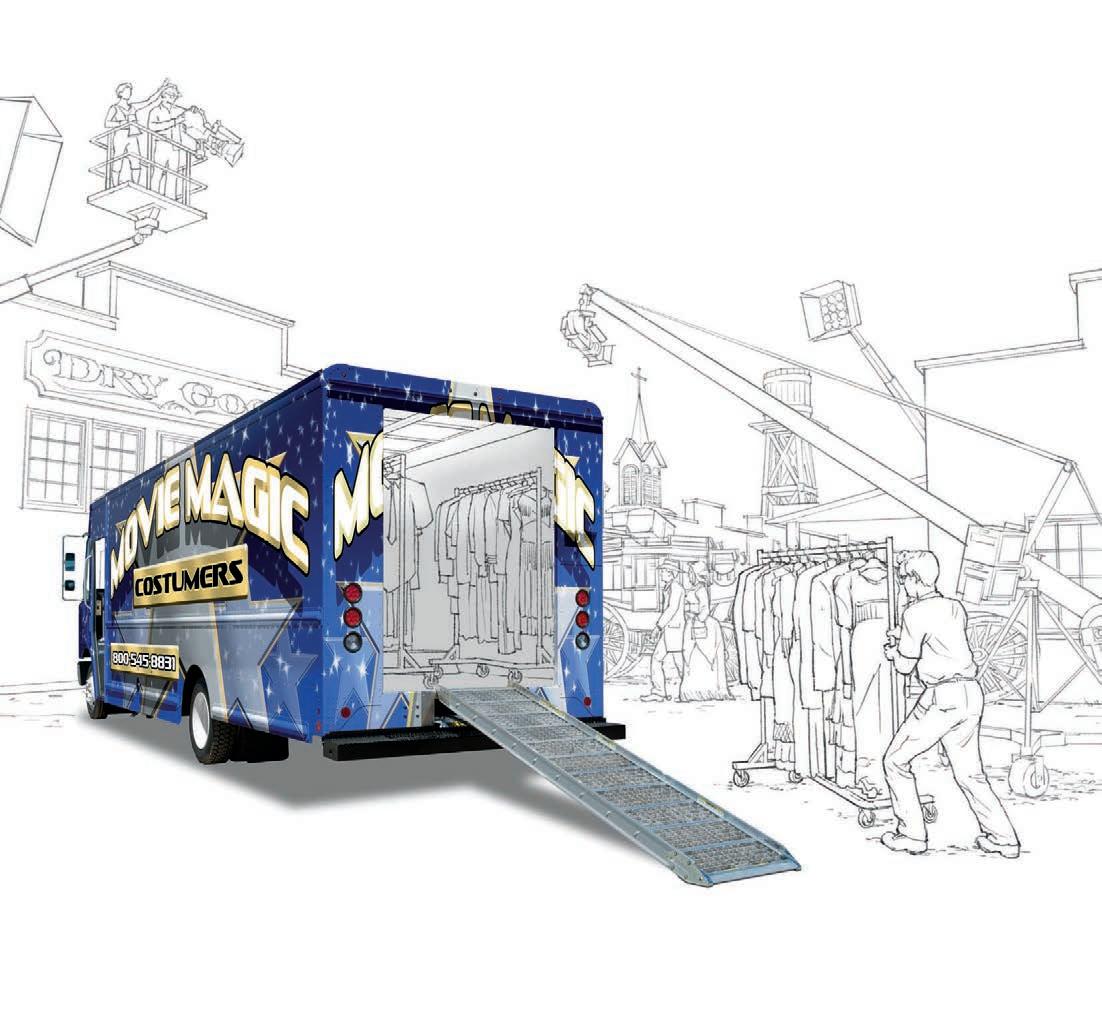

Out-think the box.

As a small business owner, we understand you’re always looking for ways to improve efficiencies and increase profits. An FCCC walk-in van is just the vehicle to get you there with proven reliability, superior performance, efficiency and durability that deliver maximum return on your investment. Affordable in diesel- or gas-powered models, FCCC walk-in vans offer easy entry and exit for fast and convenient deliveries.

Outfitting your business for success has never been so easy. Let us show you at www.freightlinerchassis.com or call (800) 545-8831.

With the state of the economy in question, many are looking at used and rebuilt equipment for their laundries. But like purchasing a used car, the buyer must perform the due diligence to ensure the savings they seek.

There are three types of “used” equipment categories one may consider when looking at deciding on a piece of equipment not purchased new from the original equipment manufacturer (OEM). There are the truly “used” equipment items that are typically purchased “as is.” Second, there is the equipment purchased from a third party and then “rebuilt.” Last, there is the equipment purchased from the OEM that is rebuilt to OEM specifications.

Using the analogy of purchasing a used car, buying an “as is” piece of equipment equates to purchasing that car from another car owner. This presents the most risk, and requires the most diligence on the buyer’s part.

Here are some important questions a buyer in this situation should try to answer:

How many hours of actual runtime does the machine have and/

or what year was it manufactured?

If the machine has more than 30,000-50,000 hours, it is generally approaching the end of its useful life without going through a complete rebuild.

Was the machine purchased new, and why is it being sold?

This is why a thorough inspection is important. Structural issues, evidence of poor maintenance or functional problems present “buyer beware” signals.

Is the machine running now, and can it be inspected?

If the machine isn’t running or the seller declines to allow a prospective buyer to inspect it, there’s cause for concern.

Has the machine been maintained during its life, and are there records to support this?

No record of preventive maintenance presents a red flag.

Are parts still available for the machine from the OEM or another source?

An inability to source replacement parts, especially control parts for upgrade or retrofit, is another red flag.

Does the machine carry any certifications (i.e., UL, CSA, ETL) and

will they still be valid if the machine is purchased and relocated?

Depending on the machine type, certifications may be mandated by the local municipality in order to run the machine. Most certifications end when the machine is moved to a new location, and obtaining new certification may be impossible.

When looking at a third-party rebuild, here are some questions to ask:

Does the rebuilder have references on other like equipment that one can check on?

No references could mean poor workmanship, and the machine may have been repainted but not rebuilt.

Does the rebuilder tear the machine down completely and inspect for and replace/repair structural damage?

If the answer is no, or one gets a “yes” but no proof, buyer beware.

Are components and controls upgraded to the latest available?

If not, can one obtain parts for what the rebuilder is selling on the machine? If not, buyer beware.

Does the rebuilder provide a warranty on the rebuilt machine and

the components?

No warranty puts a prospective buyer back in the “as is” scenario. If the rebuilder does offer a warranty, qualify what is covered.

What certifications will a buyer need to allow for operation in his/ her plant/municipality?

According to CSA and ETL certifying agencies, no rebuilder other than the OEM can recertify a machine to CSA, UL, ETL or similar standards.

Finally, when considering purchasing a rebuilt machine from the OEM, here are some questions to ask:

Does the OEM have references on other like equipment?

If the OEM can’t provide references on similar-type rebuilds, this presents a red flag.

Was the machine completely torn down and inspected for structural issues and repaired as necessary? Does the OEM provide a warranty on the rebuilt machine?

If it was not completely torn down and repaired as necessary, then there is a good chance that the warranty, if any, will be limited. Were all the components and controls upgraded to the latest available?

If the component and controls weren’t upgraded, is there a path through either the OEM or another party to obtain replacement parts in the future? If not, there’s cause for concern.

What certifications does a buyer need to allow for operation in their plant/municipality? Does the OEM recertify the rebuilt machine to the latest standards?

Again, according to CSA and ETL, OEMs are the only ones that can recertify a machine to the latest standards. To do so, however, means replacing all components and controls so the machine meets standards. If it doesn’t come with certifications, what’s the reason?

Which purchasing scenario is best comes down to the buyer’s budget.

Typically, a machine rebuilt by third party or OEM is going to cost more than one bought from an owner. Also, buying a truly rebuilt machine as opposed to an “as is” machine may lend more confidence to depreciating the asset as one would a new machine.

Take the time to do the homework and make sure a bargain is truly a bargain. ALN

The

Everyone in the Healthcare Laundry field has experienced the skin sanitizer stain that won’t go away. Now you can prevent those stains in one washing cycle with the new patent pending Magi-ClensTM chemical laundry product from Gurtler Industries. Plus you can eliminate the costly changes you made to avoid the dreaded permanent stains from Hibiclens® or similar Chlorhexidene Gluconate (CHG) products that your healthcare partners use.

And you will be able to address those infection control issues you have faced. We specialize in laundry chemical product technology...it’s our main focus. That’s why we have developed some of the most advanced and trusted laundry chemical products in use today. New Magi-Clens is only available from Gurtler Industries.

Contact your local Gurtler sales consultant today for a free magical demonstration!

Magi-Clens™...eliminates skin sanitizer stains like magic!

CHARLOTTESVILLE, Va. — Running a business can be a daunting responsibility, and perhaps at the core of this duty is strategizing the company’s move toward growth.

David Bernstein, senior vice president at Turn-Key Industrial Engineering Services, recently presented an Association for Linen Management (ALM) webinar titled Growing Your Business, during which he laid out key strategies and considerations for business owners ready to develop and grow their company.

Bernstein’s strategy first calls for owners to think of “SMART” goal setting: to be specific about their company’s goals; set measurable, attainable and relevant goals; and create a time frame for accomplishing those goals.

“If you say [you] want to increase [your] business, you need to start thinking about what business is it that [you] want to increase,” says Bernstein. “What is it exactly that you want to do [and] what do you want to accomplish? And then make it measurable.”

Think of establishing key performance indicators that will not only enable owners to track the company’s progress, but also in an objective manner. Goals should ultimately be attainable by the company.

“A lot of times [owners] will really shoot very far into the stratosphere,” he says. “When you challenge your team […] are you giving them a goal that is attainable or have you given them a stretch goal? Make sure that you’re realistic with them about it.”

“Everyone thinks that they can do many things and add a lot to their plate,” he added. “But at a certain point, you start adding so much that you’re not doing anything very well.”

Another factor is determining whether a company has the physical means to sustain growth.

A clear understanding of the company’s production model, staffing requirements and equipment purchase projections are the key factors Bernstein pointed out when owners take stock of their capacity analysis.

“Make sure that you can […]

live up to the promises that you’ve made to your customers […] while making sure that you’ve got the right amount of people [and] equipment [and that] you’re still caring for the equipment and the people in the way that they need to be.”

Regarding acquiring new equipment to boost capacity, Bernstein advises laundry owners to consider the various industries that many laundries service, and whether their company has the means to provide that service.

For example, if a hospitality laundry owner wants to start processing food and beverage goods, Bernstein suggests that they might look into purchasing a sorting and counting system to process smaller garments.

“If you’re strictly one or the other, moving to the one that you’re not can be quite an adjustment on your people and your process,” he says.

Taking on more accounts is one strategy to take to grow business. Another avenue Bernstein spoke about was the possibility of starting a direct sales/ancillary services

department.

He cites several industrial, food and beverage, hospitality and healthcare laundries selling restroom services and cleaning supplies as part of their product line to existing customers.

“If you’re not offering these kinds of services, your competitors will,” he advises.

What strategies can owners take to develop and form new relationships with prospective customers?

Bernstein admits that making cold calls can be a frightening ordeal, but there are other approaches owners can take.

A former customer, for example, may have become dissatisfied with your service. Consider calling them and addressing how your company has improved upon that specific service or product.

He also suggests using referrals, which allows barriers to come down because of the familiarity between contacts.

In addition to working with colleagues in scouting for new business, Bernstein suggests partnering with others in the industry who sell complementary products.

But no matter what approach business owners take, Bernstein

recommends owners go out themselves and “make periodic visits” to customers.

“Remind them why they bought from you […] Remind them what you promised and that you delivered,” he says.

“It never hurts to ask them, ‘What could we do better?’ You may learn something,” he adds.

Bernstein suggests investing in services such as a customer relationship management (CRM) system—Zoho and Salesforce. com are examples—that will help employees organize, manage and automate a company’s business.

He also suggests the use of marketing automation software like Marketo.com or Constant Contact to keep in touch with customers on a digital scope, as well as prospect research tools like Hoovers and Manta to help owners learn more about prospective customers in their market.

With this foundation in place, according to Bernstein, business owners can begin to reach their growth objectives.

“These are the things that you need to be doing if you’re looking at growing your business and improving your sales.” ALN

For over 50 years U.N.X. INCORPORATED has been involved in the development of products that not only solve quality problems that exist at the moment, but also provide long term benefits to the customer and the environment in which we live. U.N.X. was built on the foundation of improving the industry in which we participate. U.N.X. prides itself on being an industry leader with state-of-the-art products and dispensing equipment, and our plans for the future are extraordinary.

By mark e. BattersBy

By mark e. BattersBy

ARDMORE, Pa. — The socalled “fiscal cliff” tax package recently signed into law renewed more than 50 temporary tax breaks through 2013, saving individuals and businesses an estimated $76 billion. For the owners and operators of small- and medium-sized laundry businesses, there is good news and bad news.

First, the good news: greater certainty in taxes. The owners and operators of laundry businesses have grown used to many longstanding tax breaks but they also have had to get used to the uncertainty of whether they will be renewed each year.

On the downside, in addition to a 3.8% Net Investment Income (NII) tax and a 0.9% Additional Medicare tax that, thanks to the Health Care and Education Reconciliation Act of 2010, began in 2013, many business owners discovered they are subject to new taxes. Single individuals with incomes above $400,000 and married couples with income higher than $450,000 will pay more in taxes in 2013.

The American Taxpayer Relief Act extended through 2013 the Tax Code’s Section 179 first-year expensing write-off for equipment and business property purchases. Now, the higher expensing limits in effect in 2011 have been reinstated for 2012 and extended for expenditures made before Dec. 31, 2013. Thus, a laundry business can expense or immediately deduct up to $500,000 of expenditures in 2012 and 2013, subject to a phaseout if total capital expenditures exceed $2 million.

The election to expense off-theshelf computer software under Section 179 has also been extended and applies to expenditures made before Dec. 31, 2013.

The tax break that allows profitable laundry businesses to write off large capital expenditures immediately—rather than over time— has long been used as an economic stimulus by our lawmakers. While 100% “bonus” depreciation expired at the end of 2011, today the new law allows 50% bonus depreciation for property placed in service through 2013.

Some transportation and longer-lived property are even eligible

for bonus depreciation through 2014. If bonus depreciation had not been extended, the 2012 tax year would have been the final year in which substantial first-year write-offs for buyers of business automobiles and light trucks were available.

To be eligible for bonus depreciation, property must be depreciable under the standard MACRS (Modified Accelerated Cost Recovery System) and have a recovery period of less than 20 years. Section 179 first-year

expensing remains a viable alternative, especially for small businesses.

Property qualifying for the Section 179 write-off may be either used or new, in contrast to the bonus depreciation requirement that the taxpayer be the “first to use.”

Leasehold improvements and building improvements generally must be depreciated over 39 years. The tax law provides a special 15-year, straight-line depreciation break for qualified leasehold improvements, restaurant property, and retail improvements.

Naturally, there are quite a few restrictions, such as the lease must between unrelated parties.

Qualified leasehold improvements also qualify for the 50% bonus depreciation. In fact, qualified leasehold improvements, restaurant property, and retail improvements up to $250,000 may qualify for Section 179 expensing. Best of all, these provisions have been extended for property placed in service before Jan. 1, 2014.

[on your employees and your budgets]

The patented Vacuum Loading system on Girbau Industrial’s ST-1300 dryer allows operators to quickly load items into the dryer without a conveyor. A powerful suction pulls items inward with minimal effort and no risk or hazard to attendants. In less than one minute, attendants can fully load up to 140 pounds of laundry into the dryer. From the same area, items are then automatically unloaded—increasing productivity, reducing labor and boosting profits for your laundry.

Visit www.girbauindustrial.com to see Girbau Industrial’s complete range of products for industrial laundries.

Contact Girbau Industrial today to see how the ST-1300 can reduce labor costs in your laundry! (800) 256-1073 • www.girbauindustrial.com

The Work Opportunity Tax Credit (WOTC), which rewards employers that hire individuals from certain target groups, has extended to Dec. 31, 2013, and applies to individuals who begin work for the employer after Dec. 31, 2011. Under the revised WOTC, laundry businesses hiring an individual from within a target group are eligible for a credit generally equal to 40% of first-year wages up to $6,000.

An S corporation is a passthrough entity and not usually subject to income taxes. It is, however, liable for the tax imposed on builtin gains or capital gains. The tax on built-in gains is a corporate-level tax on S corporations that dispose of assets that appreciated in value during the years when the operation was a regular C corporation.

The new law extends a relaxed version of the provision limiting the “recognition period” to five years, but only for “built-in gains” recognized in 2012 and 2013. Thus, if a laundry business elected S corporation status beginning Jan. 1, 2007, it will be able to sell appreciated assets it held on that

date without being subject to a hefty tax bill.

As mentioned, single individuals with incomes above the $400,000 level and married couples with income higher than $450,000 will pay more in taxes in 2013 because of a higher 39.6% income tax rate and a 20% maximum capital gains tax. Of course, for other individuals, the alternative minimum tax (AMT) has finally been indexed for inflation.

Ironically, the AMT was created to ensure that wealthy individuals, not middle-income households, would pay some kind of income tax. The new law increases the 2012 exemption amounts to $50,600 for unmarried individuals and $78,750 for couples filing jointly. For 2013, the AMT exemption amounts are predicted to be $80,750 for married couples filing jointly and $51,900 for single individuals.

Always of significant interest to family-owned businesses, the estate tax has long been a bit of a mixed bag. The $5 million-perperson exemption was kept in place (and indexed for inflation). The top rate was increased, however, to 40% effective Jan. 1, 2013. This change is expected to increase

government revenues from 2012 levels by $19 billion. Other good news for estate planning: portability is kept in place and estate and gift taxes remain unified, i.e., the $5 million stays in place for gift-tax purposes as well as estates. And, best of all, it is all permanent.

The majority of laundry businesses operate as pass-through entities, such as partnerships and S corporations. Profits are passed through to their individual owners and therefore are taxed at individual income tax rates. Some business owners might be considering switching to a regular C corporation with its top rate of 35% rather than doing business through an S corporation, LLC, etc., subject to a top rate of 39.6% on the passthrough income.

But it’s important to look much deeper than the tax rates. With a pass-through entity, the shareholders are taxed only once on the income. With a regular C corporation, distributions would first be taxed at the corporate level and once again at the shareholder’s level for an additional 15-20%, plus the 3.8% net investment income tax.

That double taxation becomes even more significant on the sale of the laundry business. Although there are provisions in the tax law

that allow all or a portion of the gain on the sale of a business to be excluded or ignored, they are limited.

Another consideration, particularly for small businesses, is that any expenses disallowed by an IRS auditor will only result in increased income to the passthrough entity. When doing business as a regular corporation, disallowed personal expenses increase the income of the corporation and are taxed as constructive dividends to the shareholders. The same is true for unreasonable compensation of shareholder/officers.

Keep in mind that if a switch from an S corporation to a regular C corporation is made, a switch back to an S corporation can’t be made for five years—unless permission is received from the IRS. If an LLC or partnership is incorporated, there can be expenses and potential tax consequences.

The increase in the top tax rates, the AMT relief provided for the 2012 tax year, and the hidden taxes all combine to make it possible for many small- and medium-sized businesses ineligible for business credits thanks to AMT limitations in 2011 to potentially be able to take advantage of these dozens of credits. It is, in essence, a backdoor opportunity, similar to when Congress expanded eligibility for credits for 2010.

Although it is not the grand bargain as envisioned by lawmakers, many popular but temporary tax extenders relating to businesses were included in the American Taxpayer Relief Act: the Code Section 179 small-business expensing, bonus depreciation, and the Work Opportunity Tax Credit. Unfortunately, the new law is effectively a stopgap measure designed expressly to prevent the onus of the expiration of the Bushera tax cuts from falling on middle-income taxpayers. Congress must still address spending cuts and may even tackle tax “reform.”

The time is now for every laundry business owner, operator and manager to consult with their accountants and/or tax professionals to focus on the potential savings offered by these newly revised, extended and expanded business credits, deductions and tax write-offs. ALN

Information in this article is provided for educational and reference purposes only. It is not intended to provide specific advice or individual recommendations. Consult a financial adviser for advice regarding your particular situation.

Mark E. Battersby is a freelance writer who has specialized in taxes and finance for more than 25 years. He is based in Ardmore, Pa.

Lavatec Inc. 300 Great Hill Road Naugatuck CT 06770 - USA

Lavatec Inc. 300 Great Hill Road Naugatuck CT 06770 - USA

Toll Free: 1 800 255 2515 Tel: 203 723 1122 Fax: 203 729 4977 Email: info@lavatec.com www.lavatec.com

Toll Free: 1 800 255 2515 Tel: 203 723 1122 Fax: 203 729 4977 Email: info@lavatec.com www.lavatec.com

Contra Costa Water District.

CONCORD, Calif. — When one thinks about the highlights of a hotel property, they’ll mention amenities, restaurants, and overall service. The on-premise laundry likely doesn’t figure into even the top 100 features.

But if your business is efficiency and turning a property into the pinnacle of green lodging, the laundry room certainly might warrant top billing.

That’s the case here at the Hilton Concord. The 329-room Interstate Hotels & Resorts Worldwide property recently completed a $10 million dollar upgrade that focused heavily on sustainability. And the result is a hotel transformed into the standard for efficiency.

Lead consultant on the project, Charles Smith, CEO of Hotel Sustainability Solutions Inc. (HSSI), says that from the start, the charge was to place the property in a leadership position in terms of sustainability.

“This hotel is light years ahead of the competition,” says Smith,

adding that the outcome is the culmination of extraordinary integration, collaboration and cooperation.

Make no mistake, this was an extensive effort, one that involved addressing all facets of the facility.

It included incentives and rebates from utility provider Pacific Gas and Electric (PG&E), Smart Lights and Lodging Savers, as well as the

Taking a leadership position included implementing 33 sustainability initiatives, such as replacing all 6,400 light bulbs with LEDs, adding motion sensors, swapping shower heads with new low-flow heads, adding window film to reduce energy use, a pillow restoration unit, food scrap digester, and much more, even addressing landscaping and exterior lighting that utilizes LEDs and motion-sensing technology.

But whenever peers or Interstate

personnel want to learn about the property, the laundry makeover gets top billing.

“The laundry really is one of the highlights whenever anyone wants to see the property,” Smith says.

Ahmet Ibrahim, owner of Roseville, Calif.-based A2Z Laundry Systems, spearheaded the installation of cutting-edge Electrolux laundry equipment at the hotel. He views this facility as the new green lodging standard as well. “This is our model for efficiency.”

As the hospitality market began to tick upward, finding a sustainability solution became ever more critical.

Becoming the model of efficiency, however, would take some work. The current state of the laundry was rough. Equipment was dated and repairs were mounting, when parts actually could be found to make the fixes. One dryer even had been taken out of service. Still, laundry loads were being processed daily, but the true cost of this dated equipment soon would be uncovered.

As HSSI began the task of evaluating options, key factors con-

sidered were the efficiency of the equipment, availability of rebates or incentives, distributor/manufacturer service and support, and the ability to upgrade equipment in the future.

Though Smith looked at a variety of laundry equipment manufacturers, the goal of creating the model of efficiency guided selection. That meant choosing a brand that delivered on its efficiency claims and had the numbers to prove it, according to Smith.

“Electrolux played a key part in the technology,” he says. “They stood out in the selection of technology available...their prominence caught our attention.”

Electrolux’s global leadership is evident in it being named to the Dow Jones Sustainability World Index in 2012. This places it in the top 10% of the 2,500 companies in the Dow Jones Global Indexes with regard to long-term economic, environmental and social performance.

The Hilton Concord had been using soft-mount washers in the laundry and Smith was committed to staying with this product type because of its high G-force extrac-

Hilton Concord revamps OPL with new washers, ozone system, dryers(Photo: Laundrylux)

tion speed versus hard mounts. Soft mounts also were preferable because they don’t require an additional concrete foundation. However, lower installation costs and high G-force extraction would not be enough. Water conservation, utility consumption, and operational efficiency were equally important.

Oddly enough, water savings started at the drain. The Electrolux soft-mount units (two with 145 pounds capacity and one with 60 pounds capacity) that Ibrahim recommended featured a unique pancake drain that helps reduce water consumption during fills. The hotel’s existing units can waste as much as 2 gallons of water per fill because they include a large sump and drain hose in the fill.

Considering a standard of five to six fills per cycle, savings total 10-12 gallons per cycle. Overall, the Hilton Concord is saving 192,960 gallons of water annually in the laundry. When added to the savings realized through guestroom improvements such as low-flow shower heads and toilets as well as other conservation efforts at the property, water savings total more than 525,000 gallons per year.

Savings grew with the addition of an ozone system. Ozone, when injected into the wash cylinder, is reported to increase the effectiveness of laundry chemicals, thus requiring smaller dosages and

eliminating the need for hot water.

The majority of the ozone system’s cost was offset through rebates from PG&E and the Contra Costa Water District.

On the drying side, an agreement was reached on five 83-pound-capacity Electrolux dryers to replace two 150-pound and two 110-pound units. Though drying capacity went down, the speed and efficiency of the new dryers combined with the high-extract G-force of the washers enable the laundry to process more loads per day: 9.78 loads versus 7.81.

“The overall result of the higher extraction rate allowed us to go with smaller dryers and really spread out the loads,” Smith says, adding that the additional capacity contributed to greater operating efficiency, making staff more productive.

Moisture-sensing technology, which enables the units to dry to a set moisture-retention level and then shut off the heat, further boosted efficiency.

With much of a laundry’s gas consumption coming on the drying side, this is where the Hilton Concord saw a huge reduction in utility usage and costs. Combined with the 90% reduction in hot water usage, the laundry is consuming almost half as many Btus as before.

“There is a dramatic drop...Btus are so much lower and there’s a huge amount of savings,” Ibrahim says, adding that the laundry will see roughly $8,400 in gas savings annually.

He pointed out that the dryers derive their efficiency advantage from a unique horizontal airflow pattern as well as their reversing cylinder — a standard feature on 120volt units, an industry exclusive.

Linens benefit from reduced drying times. With more water being spun out in the washer and ozone injection opening linen fibers, only short dry cycles (or conditioning cycles before linens are ironed) are used. Table linens even go directly from the washer to the ironer, with no drying necessary.

The laundry is using about onethird the electricity it did before the retooling. Savings such as these, however, are only part of the green story. Because of the involvement of water and utility entities, $135,360 in rebates and incentives have helped offset purchase and installation of new laundry equipment and other efficient products, systems and technologies.

While the new equipment takes much of the risk of operator error out of the equation, retraining staff is integral to maintain efficiency, Smith says. “The biggest challenge

was re-educating people. We had to break some bad habits.”

Part of that retraining includes weighing loads to make sure employees always utilize full machine capacity. Underloaded washers and dryers waste utilities, cutting into operational efficiency. In addition, staff also was taught that linen could be slightly moist; it doesn’t need to be bone-dry.

Manivone Khangsensing, the property’s executive housekeeper, says the staff has responded favorably to the retraining and to the ease of operating the new laundry equipment.

“People liked that we lightened their burden,” Khangsensing says of ridding the laundry of manual overrides and training employees to trust the advanced software technology. “It provides for ease of operations; there’s nothing complicated about it.”

Processing is much improved with the speed, efficiency and reliability of the Electrolux models, which eliminates worker stress. Plus, the work environment has been improved with LED lighting strategically installed where equipment is located.

For hoteliers pondering similar projects to increase sustainability, Smith stresses taking time upfront to focus on planning. He recommends carefully analyzing the

property to determine where the greatest efficiency may be gained. Then, it’s a matter of investigating the potential to offset upgrades through rebates and incentives.

“Sometimes you wouldn’t move forward without a rebate. It’s an integral part.”

When it comes to the laundry, equipment that reduces water/utility consumption is the key focus, but Smith also cautions against taking efficiency boasts at face value. Review and analyze numbers.

In today’s technological revolution, it’s important to select products and systems that can be upgraded within the expected life cycles of ownership. It was Electrolux’s commitment to those upgrades that garnered the hotel’s attention.

Lastly, Smith advises that a strong equipment warranty and continued backing from the equipment manufacturer and distributor are important in the pursuit of sustainability.

“The retrofitting of the laundry room was a much-needed and important part of our sustainability platform,” says Jack Hlavak, the Hilton Concord’s general manager. “Uptrending in the hospitality market necessitated a higher commitment to the guest experience... we are now delivering the pinnacle of linen quality and that is showing in our improved guest-satisfaction ratings.” ALN

NEW ORLEANS — The following companies and organizations have reserved exhibit space in the Ernest N. Morial Convention Center for Clean ’13 as of April 10, according to show manager Riddle & Associates.

The list totals approximately 400 exhibitors at press time; it’s possible that more exhibitors will be added in the final weeks leading up to the June 20-22 event. Check www.cleanshow.com for any late additions or changes.

Riddle & Associates estimates exhibit space will total approximately 200,000 net square feet.

Where available, the descriptions of products and/or services provided here are general in nature and should not be considered all-inclusive.

Listings are subject to change without notice.

under the Cissell®, Huebsch®, IPSO®, Speed Queen® and UniMac® brand names.

❏ Alliant Systems 1962 Irving, Texas Route accounting software for the textile service industry.

❏ A.L. Wilson 3406 Chemical Co. Kearny, N.J. Stain removers and other chemicals for professional dry cleaning and laundry use.

❏ A-1 Textiles 5003 Chatsworth, Calif.

Bed, bath and table linens for the hospitality industry.

❏

Ameresco 4800 Framingham, Mass.

Renewable-energy, energyefficiency and energymanagement solutions.

A❏

❏ A&B Wiper 5220 Supply Inc. Philadelphia, Pa.

Wholesale towels, microfiber cloths and cleaning rags.

❏ ABS Laundry 2155 Business Solutions Tucker, Ga.

Route accounting, garment tracking and linen management software and systems.

❏ Adco Products 4856 Albany, Ga.

Alternative dry cleaning solvents.

❏ Air Quality Labs 3154 Seattle, Wash.

Wastewater equipment for dry cleaning systems.

❏ Air World Inc. 4900 Mahwah, N.J.

Pads, covers, mesh net bags and other supplies for dry cleaners and laundries.

❏

Ajax Boiler Inc. 4466 Santa Ana, Calif.

Boilers and commercial water-heating products.

❏

Albatross 4936 USA Inc.

Long Island City, N.Y.

Dry cleaning chemicals and detergents; compressed air equipment; spotting boards and kits; steam generators.

❏

Time Session Title Sponsor

and administrators of institutional/on-premise laundries and textile rental companies (commercial, industrial and linen supply).

❏

American 4607 Laundry Products

North Augusta, S.C.

Textile products for laundry and dry cleaning, including flatwork ironer pads and covers; specially woven fabrics; and feed and folder ribbons.

❏

American 4821 Laundry Systems

Haverhill, Mass.

Mechanical engineering company specializing in commercial laundry consulting, plant layout/design, process mechanical systems, and equipment installations.

American 5120 Associated Companies Inc. Fayetteville, Ga.

Sheets, towels, table linen, healthcare garments, laundry bags and aprons for the linen rental industry.

❏ American Changer 1856 Fort Lauderdale, Fla.

Bill changers, bill breakers, token dispensers, ticket dispensers and card dispensers.

❏ American 4171 Coin-Op Chicago, Ill.

Trade magazine and website for self-service laundry owners.

❏ American 2609 Dawn Inc. Compton, Calif.

Textile products for wholesale, commercial and retail markets.

❏ American 4171 Drycleaner Chicago, Ill.

Trade magazine and website for dry cleaning businesses and suppliers.

❏ American 2831 Dryer Corp. Fall River, Mass. Dryers for on-premise, coin-operated and industrial laundry facilities.

❏ American Reusable1655 Textile Association Mission, Kan.

Trade association promoting awareness of and appreciation for reusable textiles.

❏

American Textile 5222 Systems Cerritos, Calif.

Bed linen and pillows; terry towels and bath products; sheeting; and miscellaneous textiles and toilet paper.

❏

American 4171 Trade Magazines Chicago, Ill.

Publisher of American Laundry News, American CoinOp and American Drycleaner.

❏

AMS Products/ 4742 Object Design Wharton, N.J. Nylon, cotton, mesh, polyester, biohazard and barrier laundry bags.

❏

Angeline 1825 Group Ltd. Shin Juang City, Taipei, Taiwan Healthcare and hospitality textiles and other products.

❏

AquaPhoenix 2254 Scientific Hanover, Pa. Quality-control testing supplies and equipment.

❏

Alliance Laundry 3621 Systems

Ripon, Wis.

Commercial laundry equipment and services

Thursday, June 20

8-8:30 a.m. Meritorious Service Awards DLI

Honoring individuals or firms who “have given so much to [the] industry” 8-9 a.m. Coin Laundry Trends for 2013 CLA

Learn where the coin laundry industry is going in 2013 8-9 a.m. Regulatory and Legislative Update TRSA

Gain a competitive insight into regulatory initiatives impacting textile services 8-9:30 a.m. Reducing the Loss of Patient Linen and Scrubs ALM

Get a handle on preventable linen loss and put new strategies in place 8-10 a.m. Efficient Laundry Processing ETSA

Techniques in the European Market

European supplier firms will discuss efficiency and sustainability in laundry 8:45- How to Build a Great Yelp Presence DLI 10 a.m. Learn about Yelp and how to manage your organization’s online reputation 9-10 a.m. Internet Marketing Success Stories of Coin Laundries CLA Strategies for Internet marketing and social media

9-10 a.m. Textile Services Contracts and Negotiations TRSA

Examine important aspects and best practices of the contracting process

2:30- Implementing Best Practices ALM

3:30 p.m. How to use your organization’s best practices to bolster your marketing position

3:30- Social Media: Which Tools Laundries Should Embrace CLA 4:30 p.m. Learn the must-do’s and best practices of social media for laundries

8-9 a.m.

Best Practices for Wash, Dry, Fold and CLA

Commercial Accounts

Discover best practices of marketing, sales operation, and production for wash, dry, fold and commercial accounts

8-9 a.m. International Textile Services Market Panel TRSA (ETSA, TSA-UK and Intex)

Gain insight from global organizations representing the largest textile services operators and associates 8-10 a.m. Alternative Solvents: Which is Best for You? DLI Experts discuss the benefits and drawbacks of various solvent choices 8-10 a.m. Demystifying Healthcare Terminology CLATA

Review industry trends, topics and terminology related to healthcare textiles 8-10 a.m. Standards and Regulations Affecting the ALM Healthcare Laundry and Linen Industry

Examine the standards set by CMS, Joint Commission, CDC and OSHA 9-9:30 a.m. Today’s and Tomorrow’s Consumer Needs in TRSA Emerging International Markets (CINET)

Learn about textile services opportunities based on extensive global research 9-10 a.m. Advanced Laundry Lease Analysis CLA Examine the fine print and learn how to secure one that works in your best interest

9-10 a.m. Winning Strategies to Control Linen Loss and Abuse ARTA Panel of experts will present proven strategies for keeping linen in your system 9:30- Future International Textile Services Market Demand TRSA 10 a.m. Gain insight into developing partners, supply chains and customers to establish long-term business growth

2:30- Quick Fixes to Common Problems DLI

3:30 p.m. Discover practical, easy-to-implement solutions to problems plaguing dry cleaners

3:30- TRSA Clean Green and Hygienically Clean Certification TRSA 4:30 p.m. Programs: Quantifying Your Commitment to Cleanliness and Sustainability

Learn how to meet rigorous standards and quantifiable measurements

8-9 a.m. Disposables vs. Reusables: Research that Quantifies TRSA the Sustainability Advantages of Napkins, Shop Towels and Barrier Gowns

Obtain life-cycle assessment (LCA) figures that quantify the sustainability of reusable textiles

8-9 a.m. Goin’ Green DLI

Find out how some cleaners are using “green” to bring in more customers

8-9:30 a.m. ALM Fireside Chat ALM

Eavesdrop on this discussion among allied trade partners

8-10 a.m. The ABC’s for Potential Laundry Owners CLA

Take an in-depth look at key numbers, reports, lease info and more 8-10 a.m. The Future’s So Bright, I Gotta Wear Shades! CLATA

Analyzing the state of the dry cleaning and laundry industry

8-10 a.m. The Keys to Successful Multiple Store Management CLA

Learn what it takes to grow a chain of laundries

❏ American 4171 Laundry News Chicago, Ill.

Trade magazine and website for managers

❏

AquaRecycle 2953 Marietta, Ga.

Laundry wastewater recycling systems and dryer heat recycling system.

ArbelSoft Inc. 2603 Fort Lee, N.J.