Late News

Hygienically Clean ’21 program updates reviewed

ALEXANDRIA, Va. — TRSA’s Hygienically Clean (HC) Advisory Board and Users Group each reviewed a range of issues related to the Healthcare certification program on the opening day of TRSA’s Dec. 1-3 Virtual Healthcare Conference.

The Advisory Board session addressed topics including review and approval of Standard Language changes to the certification and determining that UV should be recognized as a best management practice (BMP), but information won’t be added to HC standards; and a case study review.

Other topics included realignment of Standard verbiage to meet ISO and ANSI standards; formalized and documented web-based complaint process; continuation of virtual inspection process after COVID travel restrictions are lifted (hybrid offered based on preference); and a proposal to test linen at the hospital using an ATP tester.

The Hygienically Clean Users Group discussed best practices, shared information and reviewed the outcomes of the Advisory Board meeting, including new laboratory forms and pricing in 2021. ALN

Laundry industry SWOT analysis

BY MATT POE, EDITOR

BY MATT POE, EDITOR

CHICAGO — Many businesses regularly undergo a SWOT analysis.

This process looks at the strengths, weaknesses, opportunities and threats a company faces to improve the probability of success for various projects and important decisions.

After the challenges of 2020, American Laundry News thought it would be beneficial to do a SWOT analysis of the laundry and linen services industry in the hopes of helping businesses making positive steps in 2021 and beyond.

TRSA, the association for linen, uniform and facility services, the Association for Linen Management (ALM) and the American Reusable Textiles Association (ARTA) answered the call to examine the state of the industry to help it move forward in the coming years.

STRENGTHS

Going into 2021, the laundry and linen services industry has many strengths that operations can rely on. The first is that laundry operations today provide maximum hygiene.

Capable of washing, drying and finishing at high temperatures in serving customers in all industries, linen and uniform services are superior in these respects to smaller

Laundry operation emerges from COVID-19 effects

BY MATT POE, EDITOR

LAS VEGAS — At the start of 2020, Apex Linen was riding high in Las Vegas.

What with hotels, casinos and restaurants, the city was a gold mine for a company that provides quality laundry and linen services.

Then March came, bringing with it COVID-19 and emergency shutdown orders from Nevada Gov. Steve Sisolak.

“When gaming and hotels were shut down in March due to the governor’s emergency order we were forced to close along with our customers,” says Apex Linen CEO Jared Wantoch. “That closure lead to our bankruptcy.” [9]

Columnist at Large

In this issue, Eric Frederick shares a valuable lesson about goalsetting, planning.

Laundry Equipment Financing

Q&A with industry experts on how to best make use of financing options.

Panel of Experts

Meet the laundry/linen service experts who will be answering questions in 2021.

JANUARY 2021

www.americanlaundrynews.com INSIDE [4]

The Newspaper of Record for Laundry & Linen Management

[10]

Volume 47, Number 1

Apex Linen, sold out of bankruptcy, emerges with a fresh balance sheet, new business, new attitude

See APEX on Page 7

Associations examine industry strengths, weaknesses, opportunities, threats—with strategies

(Image licensed by Ingram Image)

See SWOT on Page 6

Apex Linen in Las Vegas has the capacity to process more than 200,000 pounds of linen daily. (Photo: Apex Linen)

ATLANTA — In November, show organizer Messe Frankfurt announced that the 2021 edition of The Clean Show will be postponed due to the continued global impacts of COVID-19. The next edition will be held July 30 through Aug. 2, 2022, Saturday through Tuesday, in Atlanta.

After months of strategic conversations with Messe Frankfurt’s global leadership, partner associations and representatives from the show’s key exhibiting groups, the team decided that pushing the show and its subsequent edition is in the best interest of the industry as a whole.

The decision will affect at least the next two editions, with Clean 2023 also being moved to now take place Aug. 15-18, 2024, Thursday through Sunday.

“Although this has been a tough decision to make, we are confident that moving The Clean Show will allow us to provide the quality experience and return on investment our exhibitors and visitors have come to expect from Clean,” says Show Director Greg Jira.

The decision to move the show has been met with a positive response from around the laundry and linen services industry.

“I felt it was a good idea to postpone Clean until 2022 because I wasn’t sure that attending in 2021 was going to happen for UHS,” says Edward McCauley, president and CEO of United Hospital Services in Indianapolis.

“There were still too many unknowns, and the biggest one was the vaccine. Frankly, I couldn’t in good conscience let our people attend unless they were vaccinated.

“I also realized postponing would cause domino effects with other conferences but that had to be secondary. The safety of our employees is paramount.”

Nick Fertig, director of central laundry for Rosen Hotels and Resorts in Orlando, says that from

his perspective, the move makes absolute sense.

“Vendors have likely suspended any travel that is not absolutely essential to business operations and see this as an opportunity to eliminate the hefty expenses associated with taking part in a largescale exhibit,” he points out.

“The unfortunate reality of COVID is that the vast majority of planned capital purchases have been pushed indefinitely until the economy stabilizes and the threat of a national lockdown is not looming over all of our heads.

“Our industry, especially hospitality providers, have been devastated by this pandemic. The thought of tackling an expansion, a new build or an equipment update is completely foreign as we seek alternative revenue streams and reduced costs to simply survive and come out the other end of this

period intact.”

Reaction from laundry equipment, product and services providers has been equally positive.

“I have been very pleased with the response from Messe Frankfurt to understand the issues the exhibitors face in light of the worldchanging event of COVID-19,” says Jeff Frushtick, chairman and CEO of Leonard Automatics.

“I feel that Messe has been very open with their conversations and very understanding of the exhibitors’ issues in this very troubling time.”

“We want to thank the Clean Show. This is an industry-friendly decision to postpone, with Texcare International currently scheduled for November 2021 in Frankfurt,” says Glenn Liacouras, regional director–North America/ Australia/New Zealand for Miele Professional. “These are consistently the two most important trade shows in commercial laundry, so to separate them by a year is the right solution for our industry.

“While it’s disappointing that we won’t be together in Atlanta next summer, we appreciate the timeliness of this decision. It provides us with flexibility and clarity as we allocate resources in 2021 and 2022.

“Without the ability to meet inperson, we’re taking this opportunity to strengthen our communication with our valued distributors and business partners across all other available platforms.

“While the COVID-19 pandemic has disrupted so many parts of our lives, it is casting a spotlight on the importance of our industry. I’m confident that commercial laundry will be at the forefront

of providing critical hygiene and sanitation solutions across a growing number of vertical markets.”

“It was necessary, given what has happened over the past nine months,” adds Kasey Wahl, director of sales and marketing for WSI in Loveland, Ohio. “The industry has been greatly impacted and continues to be impacted to different extents. Hopefully, the delay will allow everyone to regroup and come together for a meaningful gathering in 2022 that can be done in a safe environment.”

Engelbert Heinz, managing director for Kannegiesser, served as an advisor during the decisionmaking process and endorsed the move to 2022.

“We have always valued our relationship with The Clean Show and are proud to have established such a prominent role in the event,” he says. “While postponing the show is regrettable, we believe it is in the industry’s best interest. Our entire company will look forward to the opportunity to meet face-to-face again in Atlanta in 2022.”

“From the Kannegiesser ETECH perspective, the Clean Show is one of the most important worldwide exhibitions and we support the show fully,” says President/CEO Phil Hart. “It is the best place for our North American customers to come and see the latest technology that we are developing, and it is a very convenient way to meet new prospective customers.

“However, given the uncertain times, until the pandemic is under control, we understand and support the decision of the Clean

Publisher

Charles Thompson

Phone: 312-361-1680

E-Mail: cthompson@ ATMags.com

Associate Publisher/ National Sales Director

Donald Feinstein

Phone: 312-361-1682

E-Mail: dfeinstein@ ATMags.com

Editorial Director

Bruce Beggs

Phone: 312-361-1683

E-Mail: bbeggs@ ATMags.com

Editor

Matt Poe

Phone: 866-942-5694

E-Mail: mpoe@ ATMags.com

Production Manager

Mathew Pawlak

Digital Media Director

Nathan Frerichs

Phone: 312-361-1681

E-Mail: nfrerichs@ ATMags.com

Advisory Board

David Barbe • David Carter

Janice Ayers Davis • Nick Fertig

Deana Griffin • Steve Kallenbach Edward McCauley

Main Phone: 312-361-1700 Fax: 312-361-1685

Subscriptions

847-504-8175 ALN@Omeda.com www.americanlaundrynews.com

American Laundry News (ISSN 1091-9201) is published monthly. Subscription prices, payment in advance: U.S. 1 year $46.00; 2 years $92.00. Foreign, 1 year $109.00; 2 years $218.00. Single copies: U.S. $9.00; Foreign $18.00.

Published by American Trade Magazines LLC, 650 West Lake Street, Suite 320, Chicago, IL 60661. Periodicals postage paid at Chicago, IL, and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Laundry News, Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 47, number 1. Editorial, executive and advertising offices are at 650 West Lake Street, Suite 320, Chicago, IL 60661. Charles Thompson, President and Publisher. American Laundry News is distributed selectively to qualified laundry and linen management and distributors in the United States.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2021. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Laundry News does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Laundry News or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

MEMBERSHIPS

2 JANUARY 2021 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

See CLEAN on Page 7 Industry reacts to Clean Show

Photo: American Trade Magazines) Next Clean Show July 30-Aug. 2, 2022, in Atlanta; 2023 edition moved to Aug. 15-18, 2024 INSIDE: January 2021 • Vol. 47 | No. 1 [8] Tools of the Trade [14] Cybercriminals Will Target Laundry Operations Joe Danaher, senior security analyst for The Ame Group shares how and why thieves get into laundry computers [17] Career Track [19] Classified Advertising [20] Source Directory [23] Trade Ticker

postponement (File

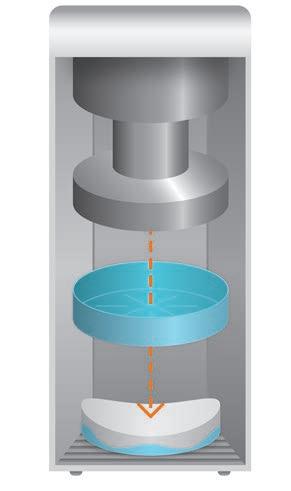

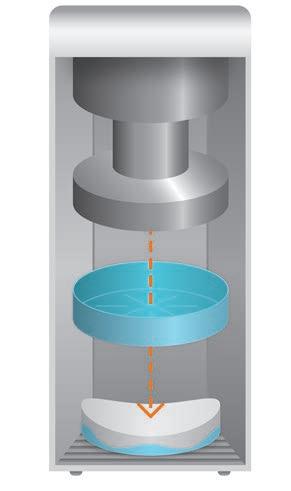

Built to combat infection.

The new Milnor MWB series washer-extractors are built to help decontaminate. Available in loading capacities of 60-200 lb. (26-90 kg), these hospital-grade machines are built with an aseptic pass-through barrier system that reduces the risk of cross contamination by separating soiled linen from clean linen. Automatic safety interlocks on two sets of doors maintain complete separation. Intuitive MilTouchTM controls offer unprecedented insight into your wash, utilizing full color graphic display and resistive touchscreen technology. Contact an authorized Milnor distributor or call 504-712-7656 to find out more.

www.Milnor.com

MWB90Z 200 lb. (90 kg) MWB70Z 155 lb. (70 kg) MWB45Z 100 lb. (45 kg)

MWB26Z 60 lb. (26 kg)

2021—Make it good

A s the clock hit midnight and the calendar flipped to January 1, I started wishing folks a Happy New Year.

It didn’t take long for me to stop doing that. Why? Because an old saying started to echo in my head, “Wish in one hand and” … well, you know the rest of it.

Wishing gets you nowhere, and after the year that was 2020, we don’t need wishing, we need to do and make things happen.

Soon, I was saying, “Make it a good year!”

And I know that we can take the hand that we’ve been dealt and make it work in 2021.

From The Editor’s Desk MATT POE

It helps to have the tools and information to create success, and I hope you’ll find some beneficial

ideas for the coming year inside.

For example, read the laundry industry SWOT analysis starting on Page 1. Representatives from three industry associations shared their insights on the strengths, weaknesses, opportunities and threats of the laundry and linen services industry.

The information from what they’ve learned from their members should help you make positive decisions in the years to come.

I hope other articles in this issue help you make the year good, and never stop working at keeping it clean, everybody! ALN

COLUMNIST AT LARGE Eric L. Frederick,

RLLD

RLLD

Setting goals for 2021

M any years ago when I was in high school, my dad taught me a very valuable lesson—the power of goal setting and planning.

I was a freshman and just an okay student. I usually did just enough to get by and hopefully that would keep both my parents and the teachers happy. But that first year I ran into an Ancient History course. The teacher was fresh out of college and was teaching the course in a lecture style.

While I found the course very entertaining, I was ill-prepared to take the detailed notes needed to get a passing grade. After an early warning note sent home after the first six weeks, my father met with the teacher and quickly diagnosed the problem.

Part of his solution was to work with me on goal setting, not only for my freshman year but my entire high school career. We discussed the grades I would need to be eligible to go to college and, more importantly, to set me up for an excellent future posthigh school. We set GPA goals for each semester, and they would require considerable improvement on my part.

ALEXANDRIA, Va. — TRSA, the association for linen, uniform and facility services, recently hosted its annual Marketing & Sales Summit for industry executives.

This year’s event, held exclusively online due to the COVID19 pandemic, saw more than 100 marketing and sales professionals attend the two-day program, says TRSA.

David Avrin, president, The Visibility Coach, kicked off the summit on Nov. 17 with a keynote address titled, “How Being Remarkably Accommodating Creates Customer Experiences that Beat the Competition.”

Avrin discussed the importance of engaging prospects and creating memorable customer experiences so that a company and brand stand out in today’s competitive business environment. He also discussed how companies must adapt to changes brought on

by the coronavirus crisis.

The first day of the summit wrapped up with an overview of TRSA’s Restaurant and Consumer Hygiene Safety Awareness Campaign presented by Charles Crowell of Milliken and Ben Fox of Alsco, before ending with facilitated breakout sessions for conference attendees to network and share valuable information.

The second and final day of the conference featured a rundown of the top videos from TRSA’s Marketing and Sales Video Contest, and the inside story on how they were created. The four videos highlighted included:

• CITY Clean and Simple, Oelwein, Iowa.

• Ecotex Healthcare Linen Service, Seattle.

• Magic Laundry Services, Montebello, California.

• Roscoe Co., Chicago. Marketing & Sales Summit

attendees voted on the videos, with the winner of the contest—Roscoe Co.—revealed at the TRSA Virtual Marketing & Sales Summit networking afterparty that was held following the Summit’s final presentation, a panel discussion featuring international marketing and sales professionals from both operator members and supplier partner companies.

Panelists included Ryan Flaherty, Aramark; Ben Fox, Alsco; Dave Katz, UniFirst; Mark Rue, Johnsons Apparelmaster; and Darryl Williams, Landau. The panel was moderated by Andy Feldman, COMPEL.

TRSA says the Summit’s interactive agenda featured breakout discussions and collaboration of current issues unique to the linen, uniform and facility services industry, as provided by Summit attendees upon registration. ALN

He then set about working with me to develop a plan to achieve those goals. My most urgent need was to learn how to take good lecture notes that could assist me in passing Ancient History. Fortunately for me my father had been an excellent note-taker all his life and showed me his outline system that he used. Each day after school my dad would review my notes from Ancient History and critique how well I was doing.

By the end of the first semester, I had a C+ in Ancient History and a life skill that would help me get through college. By the end of my four years in high school, I had met or exceeded all the goals my dad and I had set forth four years earlier.

The challenge in managing a laundry department or any other organization is working with your management team to set realistic goals for the coming year. Goals can only be met when everyone agrees and is willing to accept the goals as the direction for the organization. Goals should not be easy to reach but should also not require a miracle to be fulfilled.

Once goals are set, it is time to look at the skills needed to meet that goal and develop a plan that incorporates education, training, measurements and required steps to achieve what was agreed upon. Group goals require group effort or they fail.

Many years ago I was a scoutmaster in Milwaukee. In my youth I had been a member of a very large troop where everyone reached their first-class rank, a few made it to star rank and one boy made it to the life rank, but I do not remember a single Eagle Scout out of the 135 boys. We had a great activity troop but rank advancement just did not seem that important.

In Milwaukee, one of my older boys really wanted to become an Eagle Scout. He worked very hard during his 17th year and just made it to Eagle before he turned 18.

What I saw in the eyes of the boys in that troop I had never seen in the eyes of my fellow scouts in my youth. That single act of achieving the Eagle Scout rank made every other boy in the troop believe that they could reach that goal as well. Setting high goals and achieving them was possible.

A laundry that sets ambitious goals, develops its employees with the needed skills and then through properly planning achieves those goals creates an environment that cannot be beaten. It creates a workplace where people have pride in their work and are anxious to come to work every day.

Set a deadline today that in the next two weeks you and your management staff will jointly develop five goals that will improve your operation. Once they are set, determine what education is needed to achieve those goals. Finally, no more than four weeks from today, develop detailed plans that can be measured to achieve those goals.

If you will accept this challenge then 2021 can be the best year in your organization’s history and the start of an incredible journey. ALN

Eric Frederick served 44 years in laundry management before retiring and remains active in the industry as a laundry operations consultant. You can contact him by e-mail at elfrederick@cox.net, or by phone at 540-520-6288.

4 JANUARY 2021 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

Top Stories Appearing on AmericanLaundryNews.com for the 30 Days Ending December 15 (WE) = WEB EXCLUSIVE NEWS • In Memoriam: Ed Goldstein, American Laundry News ... • Lion Equity Partners Acquires T-Y Group and Harbor Linen • Mountain Electronics Acquires ALJ Electronics/ALJCO • Mission Linen Supply Promotes Pattison, French • EVI Industries Completes Merger of Yankee Equipment Systemst COLUMNISTS/FEATURES • Automation Leads to Laundry Service Evolution • Navigating Local/State Chemical Requirements • ALM Celebrates First Hybrid IMPACT Conference Success • Standing Out from the Competition • Eric Frederick: Lessons from 2020 OUR SISTER WEBSITES From AmericanDrycleaner.com: • In Memoriam: Ed Goldstein, American Drycleaner ... • Company Culture Vs. COVID From AmericanCoinOp.com: • Laundry Repair & Maintenance Tips That Cost Little or Nothing • In Memoriam: Ed Goldstein, American Coin-Op ...

holds interactive summit for marketing & sales professionals

TRSA

Besides the great relationship we already have with Norchem, what really sold us was that every product is truly fantastic. Through COVID, our partnership with Norchem allowed us to get a leg up against our competition and the Cart Washer does exactly what we ask. It efficiently and hygienically cleans our carts.

SERVING YOU IN MORE WAYS

ONE Check out our new website to learn more: WWW.NORCHEMCORP.COM info@norchemcorp.com | (800) 442-4360

THAN

ANTMAN DIRECTOR OF PLANT OPERATIONS “ ” ADVANCED TEXTILE CARE SUSTAINABLE PROFESSIONAL PROCESS SYSTEMS ENGINEERED WATER SYSTEMS CLEANING PRODUCTS NORCHEM

RICK

on-premises laundries and home washing machines, according to TRSA.

“Some 250 such services have been certified Hygienically Clean by TRSA,” says Joseph Ricci, TRSA’s president and CEO. “Their industrial-scale laundries facilitate hygiene by providing enough space to prevent cross-contamination (separating clean from soiled items) and for social distancing of workers, reducing the likelihood of a virus outbreak.”

Another strength for the industry is that reusables substitute well for disposables. TRSA says this attribute has been evident in COVID-19 regarding healthcare garments, particularly isolation gowns, as linen and uniform services have fulfilled high demand.

“An April 2020 U.K. government study determined such substitution in healthcare gowns can produce savings up to 75%,” Ricci shares. “Decreased waste disposal costs contribute to that difference. Reusable materials and products are also known to improve hygiene. They don’t need to be stockpiled.”

“The laundry industry will benefit from a renewed interest in reusable products in areas where disposables had almost become the only option (e.g., infection control gowns),” adds Gabriel Boardman, president of ARTA and vice president of Product Development for MIP Inc.

“Many of the industry’s textile suppliers have domestic resources that help them in situations where borders are closed or where certain key offshore suppliers may hoard production for selected customers/ markets.”

ALM adds that the laundryprocessing industry continues to be of high value to businesses serious about reducing their carbon footprint.

“Commercial processing’s efficiencies from water reclamation and the impact of a business utilizing reusable textiles over the disposable/single-use products makes them a highly desirable corporate partner,” shares Linda Fairbanks, ALM’s executive director.

TRSA also sees the fact that the industry is founded on competitiveness as a strength.

“While some companies anticipate reduced sales, budget cuts and cashflow and employment issues, some see competitive opportunities,” says Ricci. “They envision spending time and resources on incorporating technology and automation, building a superior work situation and investigating supplier relationships.”

Also, areas such as cleanliness are expected to grow as cultural shifts in travel, social distancing and overall sanitation take precedent.

Boardman adds, “Competitors

(whether suppliers or operators) have similar goals and there is an openness to share ideas that benefits the industry.”

Laundry and linen services are large, essential businesses as well, and TRSA says the long-term market is well-suited to improved profitability.

“In an environment characterized by increased focus on hygiene, decreased pressure from marginal competitors and an acknowledgment of company services as ‘essential,’ there is reason to believe that once linen and uniform services are able to achieve the economies of operating at or near capacity, margins can improve,” Ricci says.

Another strength is strong access to customers. Linen, uniform and facility services are among the few types of B2B suppliers that personally serve customers’ business locations by visiting them once a week or more, according to TRSA.

“Prior to COVID-19, linen and uniform service route personnel were so well recognized in these locations that, once their presence was noted, they could walk unaccompanied throughout such facilities as valued contractors,” Ricci points out. “Virus prevention has increased touch-free/outdoor deliveries but route service personnel remain highly visible.”

Laundry and linen services are also bolstered by the fact that they are long-term contract businesses.

“While operators have been flexible in payment terms and recognized customers’ hardships, these are viewed as goodwill gestures likely to be rewarded with customers’ continued loyalty as they recover,” Ricci says. “The legal standing of long-term contracts appears sound subject to usual grounds for breakage, such as bankruptcy.”

Also, the industry has flexibility in contract terms. TRSA says customers who procure laundered textiles by the pound can “pay as you go,” maintaining their connectivity to their linen suppliers through reduced orders without severing the relationship.

“In uniform rental, adds and stops are common,” Ricci points out. “Absent stipulated minimums, contracts can remain in force as minimal service continues. Conversely, if a customer is a loss leader who has been carried without reaching such a minimum, an amicable parting of ways may be likely.”

Finally, Boardman points out that laundry and linen services have many educational and support opportunities.

“The abundance of great associations (TRSA, ARTA, ALM, IAHTM, etc.) allows members to benefit from many networking events where members share common values and interests,” he points out.

WEAKNESSES

While the laundry/linen ser-

vices industry has many strengths going for it, there are weaknesses that operations have to overcome. One such weakness relates to operational infrastructure.

“With some companies experiencing major reductions in revenues, forecasting their inability to return to previous levels for up to two or three more years, lowering margins will require budget cuts and efforts to preserve cash,” Ricci says. “That can curtail spending needed to expand or economize.”

Operators will also need to think creatively about the supply chain and build relationships with other vendors, instead of relying on the international supply chain as in the past, says TRSA. Disruptions are anticipated in importing textiles, along with possible impacts from tensions in trading between the United States and China.

“In healthcare, operators envision more alignment with suppliers to manage costs, given reductions in reimbursements provided to medical facilities,” says Ricci. “Such challenges and disruptions portend the loss of reliable access to some textile items and increased costs.”

ARTA notes that the disposable industry has deep pockets.

“The production of disposable items benefits from automation that gets faster and more efficient by leaps and bounds,” Boardman points out. “Quality and availability will need to trump abundance and low cost per unit.”

Lower margins are another weakness the industry is facing.

“Capital spending will need to rise for improvements to contend with reduced labor,” Ricci points out. “Greater aggression in signing new customers will be required to increase revenue to offset those costs. This combination of higher expenses and lower revenues squeezes margins.”

Because many operators invoice

customers often, lack of payment disrupts cash flow, TRSA says. Receivables rise as customers face decreased revenues (e.g., restaurants’ limits on capacity) and higher costs to adapt to increased health and safety concerns.

“Such financial difficulties are forcing linen and uniform service management to prioritize, making balancing customer retention with customer delinquency tricky,” shares Ricci. “General managers are being asked to make decisions based on the long-term value of a customer and its financial position. Long-term contracts may become less prevalent.”

Unfortunately, services that are dependent on foodservice and hospitality will continue to suffer as COVID-19 restrictions remain.

“Linen and uniform services that specialize in these markets are deeply invested in the infrastructure and expertise to serve them,” Ricci points out.

“These customers require access to capital markets to sustain customers and expand. Their lack of such access extends to our industry as banks are very suspect to make new loans connected with travel or tourism, making it difficult to pivot from these markets to others.”

As foodservice and hospitality businesses reopen, they are likely to be cash-strapped and have a deficient customer base, prompting them to consider moving to the cheapest suppliers regardless of service or quality, shares TRSA.

ALM believes a company’s greatest weakness lies in the failure, or fear, to accurately know where they stand in comparison to other like operations.

“In a conversation with a very reputable and successful laundry operator, regarding their hesitancy in participating in an external benchmarking program, they shared it was fear that their data

would reveal they are not as good as they think they are,” Fairbanks shares.

“It has been shown that production-based companies that utilize benchmarking data in decision-making outperform their competition.

“Companies that make business decisions without accurate data are placing themselves at a distinct disadvantage. External benchmarking is a business practice that demands the time and attention of operators.”

OPPORTUNITIES

So, what opportunities are there for laundry/linen services in the coming year? One is enhanced customer relationships.

“When overall profitability is threatened, accounts difficult to serve profitably are shed,” Ricci says. “This results in more mutual support with remaining customers as relationships are strengthened through great service.

“The cycle perpetuates as operators become more strategic about selecting and acquiring prospects and think more strategically about re-evaluating their business with growth in mind. They select customers more effectively, expand or explore different markets that could generate additional sales, and increase brand awareness and marketing.”

Similar to scrutinizing customers, the value of serving different geographic areas and refocusing lines is assessed. Shifts in demand are examined and companies anticipate where future demand will lie, says TRSA. Options are likely to include:

• Reusable linen, table linen and personal protective equipment (PPE).

• Cleaning, sanitizing and jani-

6 JANUARY 2021 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

SWOT Continued from Page 1 See SWOT on Page 18

(Image licensed by Ingram Image)

Not what the company envisioned on Jan. 1, 2020.

However, with new financing and new leadership, including Wantoch and Vice President of Ops Perry Pierce, Apex Linen is a shining success story to come out of the pandemic.

“The company went through a section 363 sale, where there was strong interest from a number of parties,” shares Wantock.

He says the assets of the old business were purchased by a consortium led by Breakwater Management.

“Breakwater strongly believes in this business and has injected equity and new liquidity to position us for future growth and success,” says Wantoch. “We have right-sized the business and aligned our cost

structure with our current revenue streams. In addition, we start with a fresh balance sheet.

“The new Apex has emerged stronger than ever. Apex Linen brought in a new leadership team to not only manage the process, but strengthen the team simultaneously while preparing for the future.”

Apex Linen was founded in 2011 by seasoned individuals within the commercial laundry industry who had a belief that the market deserved better quality, service and product.

Today, Apex Linen primarily services the hotel and casino industry but has branched out into the restaurant, dry cleaning and uniform markets.

“The hotel and casino markets are a high-demand, 24-hour market that is a perfect match for a laundry of our size and capacity,” observes Wantoch.

“The rest of the business actually chose us. Our customers like to consolidate the services performed

by their critical vendors, so opening two full-service divisions for Laundry/F&B and Dry Cleaning/ Uniforms was a logical and natural progression for Apex, as well as for our customers.”

Apex Linen is a fully encompassed laundry facility with stateof-the-art equipment and technology, and it doesn’t outsource any of its product lines.

“Apex operates 24 hours a day, 365 days a year to provide our customers, and our customers’ guests, a high-quality, clean and safe product in a timely manner,” Wantoch says.

Depending on the season and the COVID-19 constraints, Apex will fluctuate between 200-plus and 400-plus employees. The facility has the capacity to process 200,000+ pounds of linen daily.

“Apex Linen employs incredible and talented production and service staff with many years of

industry knowledge,” Wantoch says proudly. “In addition, we have a full staff of highly trained engineers to keep our equipment performing at all times.

“We also use the highest quality laundry and dry cleaning chemicals, which means Apex can easily position itself as the No. 1 provider in the region.”

Wantoch says that under the new leadership, the entire Apex Linen family has become a single unit sharing the same goals.

“This strong team spirit has allowed many changes to happen quickly and embraced by all,” he says. “Changes aren’t just quick trials that are forgotten in a week. If they work, they stay and become part of the process and culture.

“Many of these changes came about from suggestions from the front line team. In this new culture, everyone is welcome to share their opinions.”

Show to postpone the Atlanta show by one year. We are doing all that we can to support our customers and the industry during these challenging times and are looking very much forward to 2022 and seeing everyone in Atlanta.”

Another key exhibitor representing the industry, Jesper Munch Jensen, CEO of JENSENGROUP, also showed his company’s support for the postponement.

“The Clean Show has traditionally been a very important platform that allows us to show-

case and demonstrate our industry’s leading automation equipment,” he says. “We appreciate Messe Frankfurt taking the global scheduling concerns of the manufacturing sector into consideration, and we stand behind Clean in their decision to move the next show to 2022.”

The JENSEN USA Team adds, “The laundry industry has experienced an unprecedented crisis since February 2020, which we expect to have a long-lasting impact on our industry and our society. Our planning for the future must consider a slow recovery, especially for the hospitality and food & beverage sectors.

“We have never experienced a global crisis of this scale that

will affect global travel habits for many years to come.

“We support the decision to move the Clean Show in Atlanta to 2022, as we do not feel the timing appropriate considering the overall state of the industry. As a team, we certainly regret not having the opportunity to

meet and greet our North American customers at an American show next year, yet we are convinced that there will be other opportunities to exchange ideas on how the future in laundry automation shall be created.”

As the show pivots to the new dates, the team will release communication around important changes and deadlines for exhibiting companies and individuals planning to attend. In addition, Jira said to “stay tuned,” as the team is working on alternative opportunities for the industry to do business until meeting in person again in 2022.

Recognized as North America’s largest exposition for laundering, dry-cleaning, textile care servic-

es, supplies, and equipment, The Clean Show attracts store owners, plant operators, technicians, institutional laundry managers, distributors, consultants, buyers and other industry professionals to see the newest and most technologically advanced products the industry has to offer. In addition to exhibits, the show offers educational seminars on the latest technology, business management, sustainability, and more.

The Clean Show is organized in collaboration with five industryleading associations: Association for Linen Management (ALM), Coin Laundry Association (CLA), Dry-cleaning & Laundry Institute (DLI), Textile Care Allied Trades Association (TCATA), and TRSA, the association for linen, uniform and facility services.

www.AmericanLaundryNews.com AMERICAN LAUNDRY NEWS | JANUARY 2021 7

ALN

Continued

Assets of the old business were purchased by a consortium, resulting in Apex Linen emerging from bankruptcy. (Photos: Apex Linen)

Apex

from Page 1

ALN

Continued

2

Clean

from Page

In the new Apex Linen culture, all employees are encouraged to share ideas and suggestions.

Tools f the Trade

Next-generation patient warming introduced

UHF RFID tag launched

Fujitsu Frontech North America Inc. reports it has developed a new UHF RFID (radio-frequency identification) garment tag that allows garment, uniform and workwear rental companies to enable sophisticated garment tracking and asset management while continuing to use their existing bar code equipment at depots and customer locations.

The company says that unlike other UHF RFID washable tags, the new garment tag is only 0.6mm thick and virtually transparent. It can be easily attached to garments with standard heat-seal labels and be virtually unnoticeable.

The tag is designed for typical garment industrial laundry and dry-cleaning equipment and processes.

Fujitsu says that like its linen tag, the garment tag uses advanced antenna technology that allows for reading hundreds of items while reducing mis-reads of nearby tags.

The company says its washable UHF RFID tags are widely used for garment and linen asset manage-

ment in a wide variety of markets throughout the world, including hospital and medical institutions, food and beverage, hotels, manufacturing, linen supply services, transportation, entertainment and amusement venues, and more.

Fujitsu Frontech and its subsidiary, Positek RFID Inc., provide a wide variety of asset tracking and linen management solutions throughout North America and the world.

The new garment tags have an adhesive backing allowing the tag to be placed directly on the heat seal label before being attached to the garment. The company says this eliminates mis-attaching labels and costly rework.

Users can continue to use their existing heat seal label equipment and labels. For ease of use, tags are attached on an easy-to-use release-paper roll to simplify operator handling.

www.fujitsufrontechna.com 877-766-7545

The ironing surface includes both steam-heated roll and upper and lower press plates. A serpentine flow path regulated by a variable-speed drive allows for ironing on both sides of the linen with the rotation of the roll by up to 510 degrees of contact. This unique design results in a substantially smaller machine footprint, Sea-lion says.

Encompass Group LLC, a manufacturer and marketer of reusable textiles, professional apparel and disposable and single-use medical products, has introduced NovaTM, which the company says warms patients without air movement, reducing infection risks associated with forced air.

With no moving parts, Encompass says the Nova system is silent, creating no additional noise in the operating room (OR). The Nova blanket is easy to apply and to keep on the patient, and the controller unit is intuitive and simple to operate.

The company says Nova banks a patient’s heat before surgery and maintains normothermia throughout the surgical process. The Nova blanket doesn’t emit excess heat, so patients stay warm while clinicians remain cool during surgery.

Encompass says Nova was designed with both the caregiver and patient in mind. Upper and lower body products are available.

www.encompassgroup.com 800-284-4540

First antibacterial membranes for water extraction presses introduced

MAXI-PRESS reports that it introduced the first antibacterial membrane for all common water extraction presses in laundries at the beginning of the year.

Jiangsu Sea-lion Machinery Co. Ltd. has introduced a new dual chest plate, single-roll ironer for high-output laundry operations.

The CYZ3400IIC-1300 features a single 51-inch diameter roll that is 134 inches wide and can process flatwork linens up to 164 feet per minute, the company says.

The machine is fitted with a touchscreen control that is fully programmable and can be networked with several choices of spreader-feeders and folders to create a fully automated finishing line of the highest quality output, the company says.

www.sealionamerica.com 860-316-5563

Thermopatch, which specializes in supplying garment/textile identification labeling systems, has introduced an ergonomically designed heat-seal table with high efficiency in mind for stockrooms.

The heat-seal table can be purchased 48 inches wide by 36 inches deep or 60 inches wide by 36 inches deep with an operator cutout.

The second option available to consider when purchasing is adjustable or non-adjustable height, Thermopatch shares. The adjustable has a manual crank to raise and lower the height of the table, making it ergonomically designed for various size employees and to help improve productivity.

The non-adjustable table can be set to a 30- to

36-inch height by adjusting the locking bolts in place. Both options come standard with a Formica top, steel insert pan that fits an Easy Seal or Thermoset III heat-seal, lockable table wheels, and two hanger bars.

www.thermopatch.com 800-252-6555

The manufacturer of water extraction membranes says it developed the new ANTI-BACT membranes to permanently reduce the risk of bacterial contamination in laundries. TheANTIBACT membranes are made of an antibacterial material—tested by the German Hohenstein Institute—which actively prevents the formation of bacteria on the membrane surface.

MAXI-PRESS says ANTI-BACT membranes ensure more hygienic linen. The linen is protected during the pressing process from possible bacterial contamination originating from the membrane surface, preparing it for further processing.

ANTI-BACT actively prevents the formation of organic deposits on the membrane and is designed to give strong effectiveness against bacteria forming. This is especially significant for laundries that offer textile services for markets with strict standards, the company says.

MAXI-PRESS goes on to say that working with ANTI-BACT membranes will significantly lower the maintenance effort required to meet any strict hygiene standards. The new ANTI-BACT products combine the germ-reducing properties with all known advantages of the previous EASYFIX membranes from MAXI-PRESS and are given the suffix “AB.”

The antibacterial effect of the new ANTI-BACT membranes is unlimited, according to the company, and it’s available in the EASYFIX membrane design with built-in fixing ring for all common water extraction presses.

www.maxi-press.us 844-447-5559

Manufacturers: Have you introduced a new product? Revamped your system? Released a new catalog? E-mail your product news, along with a high-resolution image, to mpoe@atmags.com and we’ll consider publishing your news free in Tools of the Trade.

8 JANUARY 2021 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

Low-cost, washable

Dual chest plate, single-roll ironer for high-output laundry operations released with smaller machine footprint

Ergonomic, highly efficient heat-seal table designed for stockrooms

Laundry equipment financing in unprecedented times

Q&A with experts to show how management can best make use of capital improvement financing options

BY MATT POE, EDITOR

CHICAGO — In a world where many businesses are simply trying to hold on, it may seem strange to think about financing new equipment for a laundry and linen service.

However, life, and business, must go on, and for many operations that means buying machines necessary to process goods in a timely matter and exceeding quality expectations. And financing is a way to keep cash on hand with manageable payments.

But how can a laundry best navigate capital financing today?

American Laundry News heard from four experts for this article: Scott Hawkins, president and CEO of Commercial Industrial Finance in St. Louis, Missouri; Amy Bartol, consumer finance associate, Girbau North America, Oshkosh, Wisconsin; Mark Thrasher, president and CEO of Lavatec Laundry Technology Inc. in Beacon Falls, Connecticut; and Jeff Harvey, manager, U.S. Underwriting North America for Alliance Laundry Systems in Ripon, Wisconsin.

First, let’s acknowledge the elephant in the room: COVID-19. How has the pandemic (and other events of 2020) changed financing in general? How about laundry equipment financing?

HAWKINS: The pandemic triggered a hard stop for many businesses, large and small. From a lender’s standpoint, it has also altered credit underwriting for the unforeseeable future.

The initial response from most lenders was to offer their borrowers payment deferrals from three to six months buying time until their business get back on track.

The first round of PPP (paycheck protection program) loans were utilized by most of our clients. For some, although no fault of the operator, it very well might not be enough to endure winter through to spring, regardless of a second round of PPP or vaccines.

From our perspective, our medical and industrial laundry operators are faring well. Service, travel, hospitality and event rental are now considered cautionary industries until positive signs or reversal of pandemic effect.

BARTOL: Historically, customers tend to shy away from making major financial decisions in an election year. When you factor in the uncertainty of the COVID pandemic, customers have become even

more cautious.

Not knowing what level of business (and subsequent cash flow) they may have, customers have been apprehensive to invest in assets for their company. To their advantage, however, is the fact that many companies are offering financing promotions to help customers out.

THRASHER: The pandemic has caused many operators to even more closely evaluate capital equipment purchases and, at the same time, has caused many lenders to even more closely evaluate potential borrowers. However, what is different now versus 2008, for example, is that lenders are still lending and doing so at historically low interest rates.

So, for operators interested in upgrading their equipment, desirable financing terms are available.

HARVEY: As with many industries, the financing industry was becoming more digital prior to 2020, but the pandemic accelerated that trend. This shift has the benefit of making the financing process easier for customers.

There has been a shift to leveraging technology to meet virtually with customers. What may have been done in-person in 2019, is being done with a variety of web tools today.

As with any recession, banks tend to become more stringent with their underwriting standards.

Laundry equipment financing is following the finance industry trends of becoming more digital.

Additionally, there has been a focus in 2020 on providing customers solutions with deferred or reduced payments at the beginning of the loan to allow customers to make capital improvements while pushing back payments as businesses recover from being closed and/or substantial reductions in business due to the pandemic.

Manufacturer-based finance companies typically have more consistent underwriting standards with a focus on the economic situation within their specific industry, and regardless of the more macroeconomic environment. This helps ensure capital continues to be available for equipment purchases.

If you’ve heard from operations that they prefer to use cash for equipment, what reasons have they given?

HAWKINS: In the past, preCOVID, small and larger businesses have had different reasons. Broadly speaking, some smaller businesses just didn’t like the fact of having a loan. Financing for some is generally utilized in a break-and-replace event.

Larger operators budget for replacement generally years in advance and set aside capital for

those purchases in the coming years.

BARTOL: Many companies are offering attractive financing programs to allow customers to better cope with uncertainty. Deferred payments, interest-only payments and low interest rates are ways to ease financial obligations during these uncertain times.

THRASHER: Typically, companies that have traditionally paid cash for their equipment purchases have not wanted to pay interest. However, in general, and especially in the current economic environment, conserving cash and/or cash flow is the name of the game. And with current interest rates at historic lows, this is a great time for companies to take advantage of financing their equipment.

With current interest rates being so low, financing is more desirable than ever. Many of our customers also look at the longer terms of financing deals for spreading out the cost of large capital purchases.

HARVEY: We’ve actually seen more customers looking to take advantage of the great financing promotions that have been available in 2020 and hold onto cash. This has been driven by attractive financing rates and the preference to preserve capital in the uncertain times we’re living in.

Customers who elect to self-fund equipment purchases typically do so to avoid the interest expense and they already have it allocated in their capital budget.

How about those who use financing?

HAWKINS: Financing is a smart strategy; conservation of cash is the play here.

Nearly one-third of all equipment acquisitions globally are financed. Businesses large and small, for-profit, nonprofit, municipalities, utilize alternate financing as a busi-

ness strategy. Rates are at historic lows, and securing the loan from a reputable finance company is generally easier than requesting the same from the operator’s bank.

THRASHER: The majority of companies will finance or lease something for their businesses. Companies prefer to conserve their cash and cash flow, so many of our customers will ask for financing as we offer it for purchases of $10,000plus.

HARVEY: We are seeing greater utilization of financing in 2020. This has been driven by aggressive financing rates offered through manufacturer promotions and the preference to preserve capital in the uncertain times we’re living in.

What are the differences between financing and leasing?

HAWKINS: Rates are at historic lows. Well-positioned borrowers can negotiate favorable rates and terms from local banks and national non-bank lenders. Leasing has faded as a desirable offering due to the loss of any tax benefits as operating expenses.

There are new and attractive hybrid offerings, like full-service rentals, where all costs, including general maintenance and repair, are included in the monthly payment.

BARTOL: A lease is handled through a financing source and is very similar to a traditional loan, except the title transfers to the lessee at the end of the term. The sales tax is also handled differently and, depending on the state, is added to the monthly payment. A lease is handled differently on the accounting side, as well.

With an equipment finance agreement/promissory note, the customer holds title to the equipment throughout the loan. Sales tax can be included in the finance amount. The customer sends a

monthly payment to the financing company.

THRASHER: The most notable difference between financing and leasing, as it is commonly seen in the auto industry, is the end-of-term structure. With leasing, the lessor owns the equipment and there is typically an end-of-term residual amount, whereby the customer has the option to extend the term, purchase the equipment for the residual amount, or return the equipment.

With financing, which is the structure most commonly selected by customers, the customer owns the equipment and there is no endof-term residual amount. Given the long, useful lives of our equipment, it is rare for the customer to return the equipment.

HARVEY: There are several differences between financing and leasing. Financing provides ownership of the asset while leasing you are paying to use the asset for a fixed period of time. Typically at the end of the lease you have the option to return it or buy it.

Another major difference is that the two products are taxed differently.

If your experience, what are the benefits of a laundry operation using financing for upgrades and purchases?

HAWKINS: This current market speaks directly to the value of having operating capital in reserves. Negotiate good loan terms, and

www.AmericanLaundryNews.com AMERICAN LAUNDRY NEWS | JANUARY 2021 9

See FINANCE on Page 16

(Image licensed by Ingram Image)

Thrasher

Hawkins

PANEL OF EXPERTS

Meet the Panel of Experts for 2021

speak on the differences of both environments.

My staff consists of housekeepers, laundry personnel, floor techs and lobby personnel. The community at Vi has 90 beds in our Care Center, and 260 apartments and casitas in our Independent Living section.

My name is Monique C. Walker, and I have been the director at Vi at Grayhawk since September 2002. Vi at Grayhawk is a luxury senior living community that offers amazing amenities and four different levels of care. Our community is considered a CCRC (Continuing Care Retirement Community).

We have different levels of care, which start off with Independent Living and, should the need arise, you have the other venues available to you such as Assisted Living, Skilled Nursing and our Al heimer’s unit (Memory Support).

In the time I have been with Vi at Grayhawk, I have been fortunate to partake in many learning opportunities. The Breakthrough Leadership course that Harvard developed for Vi helped me with self-reflection, skill-building and commitment to my personal leadership development.

I completed the CHHE (Certified Hospitality Housekeeping Executive) course, which helped me with training and education in the hospitality side of things in senior living. I completed the CMIP (Certificate of Mastery in Infection Prevention) course, which helped me further my knowledge in principles of disinfection, emerging pathogens and environmental services practices.

Most recently I completed the training for Certified Disinfection Specialist through Spartan, which focuses on preventing the spread of infection in a healthcare setting. Of course, the issue that presents me with challenges in our community right now is the coronavirus pandemic, and postpandemic.

Before I worked in senior living, I worked in hotels from 1997-2002. With the combined experience from hotels and senior living, I feel I have a unique advantage to be able to

In 2020 we were named to Ranking Ari ona’s Top Ari ona Businesses. This is the 19th consecutive year the community has received top honors from the publication. In 2019, Vi was recognized by Great Place to Work and Fortune as one of the Best Workplaces for Aging Services.

And the “Best in ellness” Beacon award is an acknowledgment by ICAA (International Council on Active Aging) that Vi is leading the way in the wellness sphere.

It’s uite an honor and privilege to serve on this distinguished panel. It is my sincere hope to share with you the benefit of my over 30 years of professional experience.

I’ve been in the commercial laundry equipment industry as a contracting officer for the VA since 2012. I am responsible for purchasing all the laundry equipment for the A’s laundry plant facilities located throughout the United States. These laundries range in size from 7 to million pounds annually and have an average age of 36 years.

I have a wealth of experience in large-equipment contracting for the federal government going back to , with my most recent experience being in the High Tech Medical Equipment (HTME) arena.

In a previous professional services lifetime, I worked as a management consultant for the Big Accounting Firms and as a licensed attorney admitted to practice before the U.S. Supreme

Court.

I joined the VA Office of Acquisition and Logistics National Ac uisition enter’s (NAC) National Contact Service as Chief/Assistant Director in 2009. I am responsible for negotiations, contract awards and administration of multiyear, multi-million-dollar contracts for HTME and industrial laundry equipment along with related support services for all VA Medical Centers in the Veterans Health Administration HA —a . billion program.

In 2012, I was placed in charge of national contracts for the VA Environmental Program Services Laundry Equipment Program. I work closely with the Defense Logistics Agency (DLA) Troop Support in the joint administration of many of these contracts. I am proud to serve the High Tech Medical and Laundry Facilities E uipment needs of our nation’s veterans and their families.

I have a bachelor’s degree from the State University of New York at Buffalo and a Juris Doctor

degree from the University of Toledo, ollege of aw. I’m also a graduate of the VA Acquisition Academy Senior Acquisition Leadership Training (SALT) Program.

I have a diverse and varied treasure trove of professional experience. I look forward to providing you with my unique perspective on laundry equipment purchasing in a government healthcare environment.

dry owner/operator.

Lace House Laundry and Linen Supply Inc. was established in in Petaluma, alifornia, about miles north of San Francisco). I operate the business with my brother-in-law and sister, and our father still comes in every day to collect mail and deposit checks.

We are proud to operate our business in the community where we live, and we are also proud to be involved in and support many local organizations and charitable causes. Lace House maintains the same foundation today that it was originally founded upon: integrity, personal service, reliability and responding to our customer needs.

Iam thrilled to be included on the Panel of Experts! I am looking forward to engaging, learning and sharing some of my experiences as a fourth-generation, family-owned commercial laun-

We have many employees who have worked for us for more than 20 years and many customers who we have served for more than 20 years. We are truly a family business, including our employees, customers and our community.

As we all sort through the COVID-19 effects on our indus-

10 JANUARY 2021 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

Learn about our new panelists as they introduce themselves and their operations while sharing accomplishments and discussing the challenges of their industry segments.

Commercial Laundry Phoebe Ellis Lace

Petaluma,

House Linen,

Calif.

Long-Term Care Laundry Monique C. Walker

Vi at Grayhawk, Scottsdale, Ariz. Other Institution Laundry Frank Zacchigna U.S. Department of Veterans Affairs, Hines, Ill.

(Image licensed by Ingram Image)

try, we are looking for the “silver linings” in our businesses. At ace House, we have been able to focus on our production and route efficiencies, employee metrics and accountability, as well as customer and vendor contract terms.

Though in March of our business was down close to , we have been able to rebound back to of pre- I sales volume. e are fortunate and at times spinning our wheels that we operate a truly mixed plant

American Laundry News Thanks Members of the 2020 Panel of Experts for Their Contributions

avid Bernstein, Propeller Solutions Group Bob Fesmire, Ellis orp.

avid Griggs, Superior inen Service auren Hunker, Ecolab Phil ones, Hotelier inen Service

Alexis Miller ettis, Regent Apparel

Brian Polatsek, EcoBrite inen Timothy oit, Thomaston Mills yle abrin, E uipment International

ing and communicating with our customers, vendors and other operators so that we all remain essential, relevant and vital.

e are looking forward to when business travel, celebrations and in-person meetings will hopefully resume and we can all gather to share stories, laughs and experiences. Please feel free to e-mail phoebe lacehouselinen.com —I love to meet new people.

sentative and managed the laundry e uipment sales in ouisiana for eight years. In , I became sales manager for Pellerin and I am now vice president of Sales. I will celebrate my th anniversary with Pellerin in as our company celebrates its th year of service to our industry.

American Laundry News is still seeking Panel of Experts candidates to represent hotel motel resort laundry, linen supply, textile uniform rental and uniforms workwear manufacturing segments. If you think you would be a good fit, or can suggest someone who is, please contact Matt Poe, editor, at mpoe atmags.com, - - .

you think you would be a good fit, or can suggest someone who is,

including hospitality, food beverage, industrial, food manufacturing and uniforms.

e are very proud of our long-term customer relationships, and we have worked very closely with them as they struggle to stay open and comply with guidelines. e believe that our flexibility and open communication has helped us retain and sign new customers during this time as customers are continually changing orders to comply with guidelines.

e also have used this downtime to focus on our e uipment maintenance program, including regular cleaning and updating maintenance logs on each piece of e uipment.

As we plan for the next months, we recogni e that restaurants and hotels will be some of the last businesses to fully recover, so we are continuing to build our grocery store, food manufacturing and uniform customer base.

e are focused on collaborat-

Equipment/ Supply Distribution

Scott McClure

Pellerin Laundry Machinery, Kenner, La.

Iam vice president of Sales for Pellerin aundry Machinery Sales ompany Inc., located in enner, ouisiana. I have a bachelor’s degree in Industrial Technology, and I began my career at Pellerin as their inhouse Auto A engineer and pro ect manager.

In , I became Pellerin’s ouisiana Territory sales repre-

Pellerin aundry Machinery is one of the largest and most experienced full-service laundry e uipment distributors in North America. ur Sales and Service teams are located throughout our seven-state territory—Texas, ouisiana, Arkansas, Mississippi, Alabama, estern Tennessee and the Florida Panhandle.

e take a consultative approach with our customers and in doing so we provide the most valuable and efficient solutions to meet their laundry e uipment and service needs.

Pellerin aundry has been providing successful laundry solutions to multiple laundry markets in the South- entral nited States since the s. ur company is in its fourth generation of continuous management by the Pellerin family.

Some of the markets we service include hospitals, hotels, cooperative laundries, uniform rental, industrial, nursing homes, coin-

www.AmericanLaundryNews.com AMERICAN LAUNDRY NEWS | JANUARY 2021 11

10% DISCOUNT* WORLD FIRST: ANTI-BACT BY MAXI-PRESS Active germ reduction Hohenstein certified incl. all MAXI-PRESS advantages The antibacterial membrane for water extraction presses of all common manufacturers. MAXI-PRESS.US INFO@MAXI-PRESS.US / CALL (844) 447-5559 MAXI-PRESS membranes for use in water extraction presses from Kannegiesser, Jensen, Passat, Lavatec etc. WATER EXTRACTION PRESS Order now and secure your discount: *Offer valid one time for end users until 01-31-2021 Tested as per ISO 22196. More information:

and personal residents task, fact hours per dering linens residents— that’s per year!” Unconnected connectivity Late News HandCraft open new North plant Va. — HandCraft Linen Specialists plans to system that continuously Senior living community reaches ‘moonshot’ laundry goal Fundraiser helps nonprofit keep laundry processing on-premises Christian Village Late News Weed in the workplace Employers struggle with growing marijuana use and

BY MATT AG — vice presi- operations, and Garcia una, vice administration, aundry Antonio, which commercial laundry and believe that the laundry services industry presents challenges. sisters also believe opportuni- ties. “Some challenges face are gender that we are or too bossy,’” ur perspective are passionate leadership skills. continue fight stereotypes.” Avery, general Munson Record for Management www.americanlaundrynews.com INSIDE AT Messe Frankfurt preparing for scheduled une pandemic preventactivities placeonsite lean will likely again until to organi ers. irector updated Textile Trades Association members on the during recent and trade associations—Association Management aundry A rycleaning Institute TRSA, the association uniform and services—sold the to Messe Frankfurt Messe retained show manager Associates to event in New now has fully reins for lean Georgia orld enter. Your SurveyViews this issue, survey share laundry/ linen changes due to the pandemic. Volume 17 on Postponement not option if coronavirus/COVID-19 restrictions prevent gathering in June Prepping Clean 2021 amid pandemic uncertainty Late News IMPACT Conference both virtual RICHMOND, Ky. Linen Management (ALM) reports its 2020 ALM Educational IMPACT, both Springs and 2-4. The association says recogniz- because COVID-19 pandemic, people comfortable with traveling others or unwilling ALM says that current and recommendations the experience, with tional safety for comfort. association create virtual attendees from their home Registration online who hadn’t previously. says will current update their attendance Details will be they the website www.ALMnet.org/ IMPACT. Spotlight on women in laundry CLEAN First in two-part series highlights four women who excelled in laundry/linen services Sisters (left), VP Theresa have excelled Laundry Cleaners, laundry/linen service Antonio. (Photo: Cleaners) Finance Questions for America’s presents questionsfive to ask. 0920aln_p01-02,04,06-FINAL.indd

operated facilities, dry cleaners, schools and fire departments.

We sell and service all our customer’s e uipment needs, including mechanical room e uipment, washing drying e uipment, linen finishing e uipment, heat and water recycling e uipment, and miscellaneous items like storage shelving and delivery carts.

We find our customers desire to purchase more complete solutions from fewer ualified vendors. This allows us to be more involved with the total design and construction of state-of-the-art laundries. Our project responsibilities include layout design and MEP drawings, mechanical, electrical, construction, demolition, rigging/assembly, ducting, trenching and comprehensive training services.

The founder of our company, .A. Pellerin, once said, “Every decision made for a laundry should reflect an improvement— both production-wise and profitwise. More revenue per s uare foot of floor space, smoother workflow, greater profits—these we offer through complete laundry analysis, efficient layouts and the proper cost-cutting e uipment to do the right ob.”

ur team’s ob ective today is to provide the best possible value to our customers. We recognize that providing value is the basis for continuing our success.

It is an honor to be a member of this year’s Panel. I look forward to sharing our company’s successful solutions and innovative ideas this coming year with the subscribers of American Laundry News.

linen and significant change, as well as the trust of my peers, at every facility I have had the pleasure of working with.

The challenges I encounter daily are always controlling linen loss and overall conformity to changes implemented. This includes EVS staff, clinical staff, as well as hospital staff in general.

HHS has a great leadership team that I attribute my growth to, as well as my experiences in the journey.

Massachusetts with a Bachelor of Science in Health and Physical Education. The economy was in malaise, but I was able to start in 1979 in Worcester, Massachusetts, as an assistant service manager and had a great mentor in John Sarafian Jr.

I mention this as we all need a mentor somewhere along the line (see Troy above). Five years of progress with Coyne led to six great years with Aramark, where I ran three different New England locations as a general manager.

our company is assisting our valued clients in merchandise control, zero-based budgeting and accounts receivable/payables. But having been a general manager for so long, I also feel I possess expertise that can help the valued readers of American Laundry News in just about any area.

I am honored to have been asked to join the group, and I look forward to assisting everyone in reaching down further to create wealth and processes for your company. It is my rule that we have fun while learning!

Rossetti, Tom Walsh, Joe Liparulo and many others, I was educated in our industry and I was introduced to even more great mentors like those I work with today at Braun, another ISO-certified company.

I’ve had the opportunity to live, learn and have successes and failures in an industry that 20 years ago was completely unknown to me.

I was a general manager for 10 years at Paris Healthcare (now NOVO Healthcare) in Dubois, Pennsylvania, where I was able to help build a ground-up 1 million pounds per week commercial healthcare laundry, and with Tom Walsh, and engineers from a few Canadian trailer manufacturers, design and build an industry-first double-deck 53-foot delivery trailer capable of carrying 55-plus full-size, standard-height hospital linen carts directly to our customers.

I like to compare the days at Paris to riding the tip of a rocket for about seven years. ur growth curve taught me to rely on words of wisdom from my father, a carpenter measure twice and cut once.

Today I work as a regional sales manager at G. A Braun Inc., where we manufacture a full line of laundry e uipment, and for over 75 years have been privately owned and head uartered out of Syracuse, New York.

G

Iam a linen utilization manager for HHS, a career I’ve had for the past five years. I am currently assisting two sister facilities in Virginia: Danville Regional Hospital and Martinsville Memorial Hospital.

I began in a small facility of 80 beds in Florida. I then relocated to Naples to two sister hospitals for three years. I do not come from a long background of linen knowledge; I have however gained a tremendous amount of insight into linen utilization and use over the past five years.

I play a role in best patient practice use of linen as well as utilizing linen properly to save cost to the facilities. I work closely with the linen supplier, making sure the hospital receives the best uality of linen.

I have accomplished savings, best patient practice, uality

ood day to all American Laundry News readers.

My name is Dave Graham and I have been a senior consultant at Performance Matters, a leader in the uniform/linen/healthcare/ medical consulting industry for the last 12 years. Before I tell you about me, I feel compelled to tell you about Performance Matters.

Performance Matters was started in 2006 by our leader/ CEO/president Troy Lovins. A cool twist is that Troy worked as my plant manager in 19901991 at a well-respected regional company—Mechanics aundry & Supply of Indiana. He showed grit and determination, and it was a given that I would take him under my wing and tutor him.

Now we gainfully employ 11 stars with both industry and non-industry experience. Check us out at Performance-Matters. com.

ell about me. I have been in this industry for 42 years and, yes I love it. I graduated in 1976 from the University of

As you may know, a boss often determines how we excel or falter. They create an environment where we turn on our juices, or they can extinguish our flame. I had two great bosses at Aramark then, well a realignment in the company put me in an untenable situation, so I picked up the phone and spent the next eight years with Mechanics Laundry & Supply.

With Mechanics, I attained the level of regional vice president, covering Northern Indiana and Michigan. This is where I sharpened my garment utilization skills, and I will be forever grateful for that time.

After eight great years, we merged with Cintas and it became time to move on. I was lucky to land in Wilson, North Carolina, with RUS/OMNI and spent four wonderful years with some of the finest people in the industry. I was promoted from Wilson to Rock Hill, South Carolina, to run the second-largest facility serving six locations until they sold to Cintas in 2002.

I stuck it out as general manager in Clinton, North Carolina, and had six great years honing my stockroom skills and my financial skills.

Performance Matters then reared its beautiful head, and at the age of 67, I cannot be more pleased. My main area of focus at

It’s an honor to be selected to participate on this panel, and I hope that I can help some of you the way so many others have helped me.

Coming out of Penn State University in 1992 with a degree in communications, I would have never dreamed that I would work the bulk of my career in the laundry business. I was prepared to work hard, but I had no idea how much I still had to learn.

On the heels of NAFTA in the early 2000s, and having just lost my management job at an ISO-certified injection molding operation, I wanted something I could put my hands on something real that couldn’t be shipped overseas.

Laundry was all new to me, but fortunately I had stumbled into one of the best laundry opportunities in the country at Paris Companies in Dubois, Pennsylvania. Thanks to Dave Stern, Chris Corcoran, Randy

Much like my father’s advice, being a salesperson, GM, production manager, etc. in our industry re uires you to make some hard, and often expensive, decisions. Those decisions are validated when you analyze your return on investment (measure) and make the purchase (cut) on uality e uipment or plans that help you grow your business and/or make it more profitable.

et’s face it, the Iworld has made mostly a negative impact on labor costs and our top-line revenues. Despite the challenges of a COVID-19 world, we must be able to offset these and keep our paths tracking toward greater safety, productivity and efficiencies, while reducing our carbon footprint in an industry that relies heavily on our natural resources.

This coming year, I look to help you find more ways to be successful in those endeavors.

12 JANUARY 2021 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

My name is Cecil Lee and I am director of the healthcare laundry marketplace for Standard Textile. I have the wonderful

(Image licensed by Ingram Image)

Textiles

Cecil B. Lee Standard Textile, Cincinnati, Ohio

Equipment Manufacturing Charles Spencer G.A. Braun Inc., Syracuse, N.Y.

Consulting Services

David Graham Performance Matters, Fort Mill, S.C.

Healthcare Laundry

Tammy Barrett HHS Environmental Services, Bonita Springs, Fla.

opportunity to participate as a laundry industry writer for the second time in five years. I have been working in the industry since 1981 when I started working for a cooperative healthcare laundry in Saginaw, Michigan, after college.

I have gone on to spend 33 years managing central, cooperative and commercial healthcare laundries in several cities in Michigan, New York and Ohio. Twenty-five of those years were with Sodexo, which afforded me the opportunity to work with many industry greats who are still working in the healthcare laundry business. Liz Remillong, Phil Foussard, Tim Montague, Ron Seaman and Emeka Okeani are a few among them.

My formal training consists of a bachelor’s degree in Political Science from the University of Michigan and a master’s degree from Central Michigan University in Administration.

I attended the Association for inen Management’s A M Laundry & Linen College in Canada for Part 1 at the University of Guelph. My mentor at the time the late ick Starkey was insistent on me having a solid foundation, and because of him, I have a strong technical background in the business.