Late

Clean ’22 booth sales open

ATLANTA — General booth sales have officially opened for the next Clean Show, taking place here at the Georgia World Congress Center, July 30-Aug. 2, 2022.

Organizer Messe Frankfurt says exhibit space will be assigned on a first-come, first-served basis. With pre-sales already underway for all 2019 Clean Show exhibitors, the floor is at almost 50% capacity.

All interested exhibitors are encouraged to act fast to secure their location on the show floor.

The next Clean Show was to have been held in June, but the ongoing COVID-19 pandemic prompted organizers to push it to 2022. Atlanta last hosted The Clean Show in 2015.

All exhibitor information can be found on The Clean Show’s website. With the online Exhibitor Prospectus, interested exhibitors can view the floorplan, select sponsorship opportunities for additional exposure, explore rules and regulations, and download the contract.

Besides vendor exhibits, the show offers educational seminars on the latest technology, business management, sustainability and more. ALN

HandCraft Services opens new facility in North Carolina

BY MATT POE, EDITOR

BY MATT POE, EDITOR

RICHMOND, Va. — HandCraft Services specializes in medical linen and apparel products and services with plants here and in High Point, North Carolina, plus linen depots in Lanham, Maryland, and Roanoke, Virginia.

The company provides healthcare linen services to medical facilities in seven states—and it’s growing.

HandCraft recently opened a new facility in Wilson, North Carolina, so American Laundry News communicated with Joe McKeown, the company’s chief operating officer, about the new plant, the company’s history and its future.

Handcraft recently worked with ARCO/ Murray to build out a laundry in Wilson, North Carolina. Why did you open this

How safe is

new facility?

We opened our new retail medical facility because we reached capacity in our Richmond-based retail medical plant.

What factors went into deciding the location, size, equipment, etc. in Wilson?

It was mostly our customers’ geography.

laundry

We wanted a location that made it easier to service our current North Carolina retail medical business and also cover the areas where we felt growth was inevitable.

We chose the equipment based on our need to produce roughly the same amount

(Part 1)

BY DONALD BOCK, ARM

SANTA MARIA, Calif. — You lie awake at night wondering whether your laundry operation is safe for your employees. So, you decide to see for yourself by inspecting your plant and fleet to verify that they are indeed safe. But where do you start?

Do you and your supervisors serve as core drivers by committing to and driving the safety process of your operation? Do your employees have ownership and participate in your safety process? Do the employees recognize that a climate of safety exists in the organization? Does safety performance get the same attention that quality, service and productivity receive?

recognize a by standards on

Is safety in your operation driven solely by complying with OSHA standards and assuming that, in doing so, your operation is safe? Or is safety dependent on the actions of your employees in observing those same standards?

Panel of Experts

In this issue, the experts share ideas for re-evaluating laundry contracts in light of COVID-19.

MAY 2021

www.americanlaundrynews.com INSIDE [4]

The Newspaper of Record for Laundry & Linen Management

[10]

Volume 47, Number 5 [12] See FACILITY on Page 6

to conduct a plant safety inspection, starting with flow, soil, boiler/compressor/shop, chemicals

How

your

operation?

News

OSHA Top 10 Violations Find out the top 10 OSHA violations at laundries, details about standards.

See SAFETY on Page 7

laundry service provider reached capacity in existing retail medical plant

Healthcare

Columnist at Large In this issue, Eric Frederick shares tricks he’s learned for selecting new employees.

HandCraft Services opened its new Wilson, North Carolina, facility in December. (Photo: HandCraft Services)

(ImagelicensedbyIngramImage)

the

Awards Dinner

ALEXANDRIA, Va. — TRSA, the association for linen, uniform and facility services, hosted its 11th Annual Legislative Conference & Industry Awards Dinner March 24-25 at The Westin Old Town Alexandria and via Zoom.

The event started with committee meetings on the first day, followed by the Industry Awards Dinner that evening. The conference wrapped up with Virtual Hill Day Meetings the following day.

COMMITTEE MEETINGS

Day One of TRSA’s Legislative Conference kicked off with a full slate of committee meetings. The meetings were held both in-person at The Westin Old Town Alexandria as well as virtually through Zoom video conference.

A meeting of TRSA’s newly formed Supplier Partner Council started the day’s agenda.

After a break for lunch, the following committees gathered for two-hour meetings:

• Diversity, Equity & Inclusion (DEI)

• Education

• Environmental

• Healthcare

• Hospitality/F&B

• Human Resources

• Industrial/Uniform/Workwear

• Marketing & Sales

• Safety

After the committee meetings wrapped up in the afternoon, the conference continued with a keynote address from political com-

INDUSTRY AWARDS

During TRSA’s Industry Awards Dinner on March 24, the association recognized 2020 honorees in 39 categories. These winners had to forgo formal acceptance of their awards last year due to the COVID19 pandemic.

Since the virus continues to be a health concern, the March 24 program was a hybrid live/online event. Several winners accepted their awards via taped video pre-

sentations.

The event began with an online message of welcome from TRSA Chair Noël Richardson, Shasta Linen Supply, Sacramento, California.

TRSA President and CEO Joseph Ricci and Vice Presidents Tom Newell and Kevin Schwalb were joined by several other association staff presenters in announcing the awards, in categories including:

• Company Community Service: Health Mats Co., Chester, Pennsylvania; Bates Troy Inc., Binghamton, New York; Rentwear Inc., North Canton, Ohio; Unitex Healthcare Laundry Services, Elmsford, New York; ARCO/ Murray, Downers Grove, Illinois.

Ed Kwasnick, director of business development for ARCO/Murray, accepted their award in person. He thanked TRSA and the company for its support of charitable activities, including a food bank in Virginia.

“I think our impact through the industry is fantastic, but the impact in our local communities is even greater,” he shares.

Other awards categories included:

• Above and Beyond Service: American Laundry Systems, Derry, New Hampshire; Alsco Inc., Salt Lake City; United Laundry Services, Honolulu; Foltex USA, Irmo, South Carolina.

• Clean Green Innovation: Arrow Linen Supply Co., Garden City, New York; PureStar Group, Las Vegas; City Laundering Co., Oelwein, Iowa.

• Diversity Recognition: Morgan Services, Buffalo, New York; PureStar Group, Las Vegas; Angelica, Oakbrook Terrace, Illinois.

• SafeTRSA Safety Excellence: Cooperative Laundry, Kearny, New Jersey; Ecolab Textile Care, St. Paul, Minnesota; Logan’s Uniform, Shelbyville, Kentucky; UniFirst Corp., Wilmington, Massachusetts; NOVO Health Services, Atlanta; Meese, Ashtabula, Ohio; Up to Date Laundry, Baltimore.

Senior Vice President/General Manager Glenn Blucher and Senior Vice President of Operations Steve Halstead for Up to Date, attended the awards program in person.

Blucher says of the SafeTRSA Award, “It’s really about the associates. Making sure they go home the way they came to work. We take it very seriously.”

J.R. Ryan, president of Meese, also accepted the award in person.

He thanked TRSA for the recognition, noting that, “We changed the whole culture there from a safety perspective. Everything we’ve done, the improvements we’ve made to keep our people safe has not only saved injuries, it’s helped with retention.”

Other awards categories included:

• Volunteer Leadership: Lynn Moreau, Hand Craft Healthcare Linen & Uniform Specialists, Richmond, Virginia.

Publisher

Charles Thompson

Phone: 312-361-1680

E-Mail: cthompson@ ATMags.com

Associate Publisher/ National Sales Director

Donald Feinstein

Phone: 312-361-1682

E-Mail: dfeinstein@ ATMags.com

Editorial Director

Bruce Beggs

Phone: 312-361-1683

E-Mail: bbeggs@ ATMags.com

Editor

Matt Poe

Phone: 866-942-5694

E-Mail: mpoe@ ATMags.com

Production Manager

Mathew Pawlak

Digital Media Director

Nathan Frerichs

Phone: 312-361-1681

E-Mail: nfrerichs@ ATMags.com

Advisory Board

David Barbe • David Carter

Janice Ayers Davis • Nick Fertig

Deana Griffin • Steve Kallenbach Edward McCauley

Main Phone: 312-361-1700 Fax: 312-361-1685

Subscriptions

847-504-8175 ALN@Omeda.com www.americanlaundrynews.com

American Laundry News (ISSN 1091-9201) is published monthly. Subscription prices, payment in advance: U.S. 1 year $46.00; 2 years $92.00. Foreign, 1 year $109.00; 2 years $218.00.

Single copies: U.S. $9.00; Foreign $18.00.

Published by American Trade Magazines LLC, 650 West Lake Street, Suite 320, Chicago, IL 60661. Periodicals postage paid at Chicago, IL, and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Laundry News, Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 47, number 5. Editorial, executive and advertising offices are at 650 West Lake Street, Suite 320, Chicago, IL 60661.

Charles Thompson, President and Publisher. American Laundry News is distributed selectively to qualified laundry and linen management and distributors in the United States.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2021. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Laundry News does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Laundry News or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

MEMBERSHIPS

mentator and former Fox News analyst Chris Stirewalt and a Hill Day Issue Briefing hosted by TRSA Vice President Kevin Schwalb.

2 MAY 2021 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

INSIDE: May 2021 • Vol. 47 | No. 5 [8] Tools of the Trade [14] OSHA and COVID-19 in Laundry/linen Services Association for Linen Management webinar presents information on OSHA operations during the pandemic [16] Laundry Equipment Important in the Firehouse Great care must be taken in laundering gear to get it clean without damaging the life-protecting qualities of the fibers [17] Laundry in Need of Information Finds Solution Century Linen & Uniform needed help automating 50 hours a week spent collecting and inputting data into Excel sheets [18] Career Track [19] Classified Advertising [20] Source Directory [23] Trade Ticker [23] Calendar of Events TRSA hosts 11th Annual

Conference & Industry

TRSA’s Marketing & Sales Committee was one of 10 committees that held meetings at the 11th Annual Legislative Conference & Industry Awards Dinner. (Photo: TRSA) Two-day event included committee meetings, awards, virtual Hill Day See TRSA on Page 4

Legislative

Milnor has a better solution through dilution.

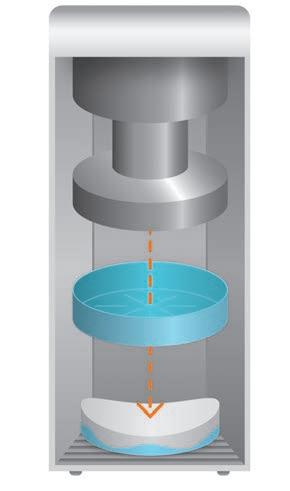

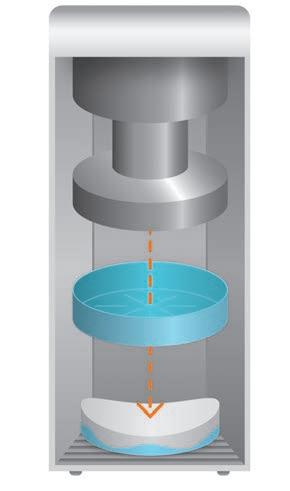

When Milnor introduced PulseFlow® technology, CBW® washing was thrust into the future. The idea of balancing time, temperature, mechanical action and chemistry was missing one critical piece of the pie – DILUTION through the efficient use of water.

PulseFlow combines the innovative RecircONE® fast wet down and chemical immersion in the first module with standing bath washing in every spacious process module. Thorough and efficient dilution occurs by way of intermittent high velocity counterflow rinsing and traditional True Top Transfer.

The result is hygienically clean linen using less water (as low as 0.3 gallons per pound/2.5 liters per kilogram) and less energy as proven time and again by hundreds of PulseFlow tunnels in a variety of laundry applications worldwide.

Contact an authorized Milnor distributor or call 504-712-7656 to find out more.

www.milnor.com

*PulseFlow®,

are

registered trademarks.

CBW® and RecircONE®

Pellerin Milnor’s

The laundry safety issue

S afety should always be a core issue to be evaluated and kept top of mind in a laundry and linen services operation.

For many operators I’ve spoken with, it is the issue—the most important consideration of plant operations, from employee safety to customer safety.

Safety is a key issue for American Laundry News. In fact, you could call this edition of the publication “the safety issue.”

Three main features in the issue exam safety in a laundry.

You probably saw the first article on page 1, “How safe is your laundry operation?” In this first of two parts, Donald Bock, ARM, principal of Seabright Safety Solutions Inc. in Santa Maria, California,

The Editor’s Desk MATT POE

shares the first steps for conducting a facility safety inspection.

A popular educational session at The Clean Show, judging by attendance, is given by Edwin G. Foulke Jr., an Atlanta-based partner with

the national labor and employment law firm Fisher Phillips. The topic? Top laundry OSHA violations.

Since Clean won’t take place until next summer, we contacted Foulke so he could share the Top 10 violations. You’ll find this year’s list on page 10.

Finally, Barry Spurlock recently conducted a webinar for the Association for Linen Management (ALM), called, “2021 OSHA Update/COVID-19 Related Safety Guidelines.” Turn to page 14 to read some of the key points he shared.

There’s more in this issue than safety articles, from contracts to a case study—plenty of information to help everybody keep it clean! ALN

Employee selection process tricks

I have always referred to finding the right replacement employee as an art form instead of a clinical process.

I have never found an exact formula that if used would always turn out with the best possible employee for a particular job, but as I traveled along my management journey, I heard of many tricks that some of my fellow managers used. These tricks seemed to work for them.

I can remember visiting with a well-known laundry manager in Indiana. She met me in the front lobby of the hospital and asked me to follow her to the laundry.

The distance from the front lobby to her department was considerable. This manager walked at a very rapid rate and I struggled to keep up with her. Once in the laundry, the manager smiled at me and said I had passed her first employment test. She then explained that when she picked up a potential employee from the employment office for an interview she would walk quickly back to the department.

If the potential employee kept up with her, that was a very good sign. If the job candidate failed to keep up or fell more than several strides behind her, then the candidate would not be considered. She wanted a potential employee who demonstrated the ability to move at a fast pace.

Because large-scale laundry work is unlike what most people are used to, I used to always start the interview process with a tour of the laundry showing the potential new employee what the laundry was all about. This always accomplished one of two things.

The first objective was to watch their reactions when exposed to the environment and culture of the laundry. The second goal was to see if any of the existing staff knew this particular individual.

VIRTUAL HILL DAY

TRSA says its Hill Day was a resounding success, with a total of 96 linen, uniform and facility services industry executives taking part in 110 meetings with members of Congress and key staff members.

TRSA staff joined members on the calls, the majority of which took place via Zoom video conference.

TRSA member executives met with congressional representatives from 27 states as well as the territory of Puerto Rico. This year’s meetings took place virtually as a result of the COVID-19 pandemic suspending in-person meetings at the U.S. Capitol building.

The executives had three key issues to discuss during the meet-

ings, including:

• FEMA Designation for Timely Restoration of Laundry Operations Issue Paper.

• Increase Healthcare Worker and Public Health & Safety (Reusable PPE) Issue Paper.

• Industrial Laundering of Scrubs Issue Paper.

“I thought that TRSA did a great job spelling out exactly what was expected of members to do in order to help push the legislative agenda in favor of our industry,” says Kelly Johnson, a regional manager at

“I would definitely be involved again and look forward to seeing if our efforts result in any substantial change.”

As a result of the meetings, TRSA says it has several action items to follow up on with legislators on behalf of the industry.

Sponsors of the two-day inperson and virtual event included Alliant Systems, Kannegiesser ETECH, JENSEN USA Inc., Lavatec Laundry Technology Inc. and Pellerin Milnor Corp. ALN

Potential employees who asked questions about the various pieces of equipment and the process passed this part of the interview. Those who looked uncomfortable during this phase would normally not want the job.

The best work references will come from members of your current staff. If the potential employee has been a good worker and was reliable at their former jobs, then the existing employees will let you know.

If, however, they were a problem employee at their former work site or had trouble getting to work, then your existing staff will not want them on your staff and, again, will let you know.

I always put good attendance high on my list of desirable traits in a new employee. Even the most productive employee cannot help if they are not at work.

I always asked a person how important they thought attendance was in being a good employee or asked them what the most important trait of a good employee would be. Those that said attendance was very important always got top marks from me.

Modern management techniques recommend using questions in a job interview that cannot be answered with a yes or a no. The more the question will elicit a lengthy response the better. The object is to have the employee share their feelings and previous work experiences with you.

Questions like “What was your favorite part of your previous job?” followed up with “Why was that your favorite part?” can help you understand your potential employee.

I can remember one day when my plant manager and customer service manager just finished interviewing a potential driver. They said they had never had a job candidate do such an excellent job at answering all their questions. They said he was simply too good to be true.

So I asked them, “Are you going to hire him?” They said yes, and I reminded them that he appeared to be too good to be true. They admitted that is how they felt but decided to ignore their feelings and hire him anyway. They came to regret that decision.

Today we have come to realize that a good long-term employee can be found when the potential employee is not only a good fit for the job, but the company is also a good fit for the employee. It is a two-way street and we must be careful to make sure we make the best possible decision. The only thing that is worse than having an open position is having the wrong person in that position.

Develop your skills in the hiring process. Know what you need in an employee and develop an interview technique that will make sure those needs are met.

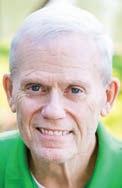

Eric Frederick served 44 years in laundry management before retiring and remains active in the industry as a laundry operations consultant. You can contact him by e-mail at elfrederick@cox.net, or by phone at 540-520-6288.

4 MAY 2021 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

• Best Plants of the Year: Ecotex Healthcare Linen Services, Kelowna, British Columbia, Canada; Textile Care Services, Rochester, Minnesota.

Alsco Inc. based in Phoenix.

From

COLUMNIST AT LARGE Eric L. Frederick, RLLD

ALN

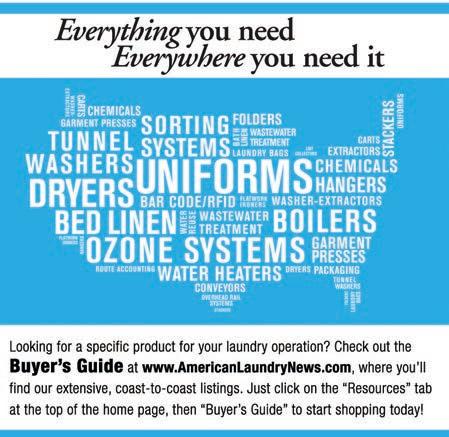

Top Stories Appearing on AmericanLaundryNews.com for the 30 Days Ending April 15 (WE) = WEB EXCLUSIVE NEWS • Crown Health Care Laundry Services Majority Interest ... • Gurtler Hires Two Market Development Managers • Westport Linen Services Locating Healthcare Laundry in Greenville • Pellerin Milnor Names New Applications Engineering Manager • American Laundry News Launches Free Jobs Board COLUMNISTS/FEATURES • Keeping Corrections’ Laundry Operating Correctly • COVID-19: Global Research Shows Wash-Process Effectiveness • Future Vision: Increasing Production with Predictive Technology • Eric Frederick: Understanding Healthcare Linen Hoarding • Texcare 2021: Stay Healthy, Stay Hopeful OUR SISTER WEBSITES From AmericanDrycleaner.com: • Restoring Items to Their Former Glory • DLI Presents April Webinar Series From AmericanCoinOp.com: • Can a Laundry’s Name Make a Difference? • Economics of a Laundromat Retool TRSA Continued from Page 2

uniform

facility services

their

Linen,

and

industry executives held Zoom meetings with legislators and

staff during TRSA’s Virtual Hill Day. (Photo: TRSA)

See how you can improve and save throughout your entire facility by visting: WWW.NORCHEMCORP.COM (800) 442-4360 ADVANCED TEXTILE CARE SUSTAINABLE PROFESSIONAL PROCESS SYSTEMS ENGINEERED WATER SYSTEMS CLEANING PRODUCTS WE’RE A FAMILY WHO INNOVATES WITH PROVEN CUSTOMER TRUST AND RELIABILITY NORCHEM

of weekly volume on one shift as we do in our Richmond retail medical plant.

When did the new facility “open for business”? How will it affect Handcraft’s services?

We were open for business in December 2020. The new facility gives us a state-of-the-art presence in both bulk hospital and retail medical spaces.

We feel we have the ultimate competitive edge, as we serve each space out of plants specifically designed for that market.

Describe the operation of the new facility in terms of employees, shifts, equipment, pounds processed, etc.

Our plant operates one shift, five days per week, from 6 a.m. to 2:30 p.m. We currently have about 50 employees.

The plant is equipped with one 110-kilogram, 17-chamber continuous batch washer with eight dryers, along with one open pocket 110-kilogram machine and one 65-pound washer.

On the finishing side, we have an automated garment system designed to sort 3,000 scrubs per hour, along with 10 hanger stations and two garment tunnels producing 1,500 pieces each per hour.

The plant also has two largepiece ironers, along with one small-piece ironer. Additionally, the plant includes a blanket system and six small-piece folders for gowns, towels, knit sheets, underpads, washcloths, etc.

Finally, we have an automated pack-out system specifically designed for our RFID (radio fre-

quency identification) linen inventory and management system.

The plant is equipped with one 200 horsepower boiler, a wastewater heat reclamation system, along with 60- and 25-horsepower air compressors and air dryer.

The soil and clean linens are routed through the plant with an automated rail system.

Can you share a bit more detail on the company’s founding in 1970? What spurred its founding and early growth?

We are a family-owned and -operated business that still values superior customer service and integrity, which is apparent in our soft-touch, proactive customer service.

HandCraft Services was found-

ed by John A. Nichols in 1970. He built a small drycleaning business on the philosophy of always going the extra mile, one customer at a time. HandCraft continues to live out that philosophy today and our family business continues to grow as John’s sons, Keith, Jay, and Jeff, carry the torch forward.

All of our products and services comply with or exceed Occupational Safety and Health Administration (OSHA), The Joint Commission (TJC), Centers for Disease Control and Prevention (CDC), Environmental Protection Agency (EPA), and state standards and regulations.

We stay on the leading edge of new technology and set the pace for our industry.

Also, our family-run business

is environmentally conscious and community-oriented. In addition to our industry-leading green initiatives, HandCraft supports our community, health systems, numerous charities and much more every year.

You can feel great about the high-tech, soft-touch company you’re working with and what we’re doing globally and locally.

Why does Handcraft service the healthcare market? How does the laundry service such a wide area?

We feel laundries are best suited focusing on one niche. For us, it’s healthcare linen.

Operationally speaking, our plants are very efficient. As a result, we are able to allocate

many man-hours to keeping our plants clean and our equipment maintained. This allows us to service more customers at the best price.

However, our focus on customer service is what really allows us to successfully provide what our customers need, as we have a team of 20 customer relations specialists and district managers throughout our territory.

Do you have any certifications? How do you ensure timeliness and quality?

We are in the process of applying for the TRSA Hygienically Clean certification.

Each plant, including the new Wilson facility, employs a team of quality control personnel.

Operating one shift per plant allows us to meticulously plan our transportation efforts. We put a heavy emphasis on delivering the customer everything they need on time, every time.

What challenges has the company faced in recent years, and how have you overcome them?

A major challenge has been growth. We promote from within, hire good people and grow our service team to meet this challenge.

What have been some of the company’s greatest successes? How were those achieved?

Building the two North Carolina plants has been a great success.

We’re relentless in our pursuit to becoming the industry’s lowcost provider—without sacrificing quality or service.

What’s in the future for the company?

We plan on opening a fifth and sixth plant in the future. ALN

6 MAY 2021 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

Continued from Page 1

Facility

wash aisle also includes an open pocket 110-kilogram

a 65-pound

The workhorse of HandCraft’s new plant is a 17-chamber continuous batch washer with eight dryers (shown). (Photos: HandCraft Services) The

machine and

washer.

The Wilson plant has 10 garment hanger stations.

The truth is that operational safety is a combination of the two. Establishing and implementing programs that comply with and adhere to OSHA standards are the first steps in building employee safety into your operation.

OSHA standards are designed to protect workers from serious injury and are effective when being followed. Secondly, and more importantly, how closely do your employees and supervisors adhere to those standards?

Typically, safety performance is measured against the Illness and Injury data provided by the Bureau of Labor Statistics called DART Rate or TRIR (Total Recordable Incident Rate). DART Rate and TRIR for Linen and Uniform are 3.6 and 4.9 respectively, meaning that roughly five of every 100 employees are injured seriously enough that the injury is recorded on the OSHA 300 log.

Often an operation is considered safe because its metrics are equal to or less than the benchmark for laundries. But how much better would it be if the operation could actually improve

its safety metrics to exceed BLS data?

Injury and Illness data are lagging indicators that tell you where you’ve been, much like looking in the rearview mirror. We need to develop leading indicators that can improve metrics and allow us to measure that improvement more often than once annually.

One of the leading indicator tools to be used is the facility or plant inspection.

This article is going to walk you through the process of inspecting your own operation to determine where the opportunities for improvement exist and how you can make those improvements.

It will also provide a guide to

identify at-risk behavior that may be overlooked during normal operations. At-risk behaviors are the most prevalent cause of injury, so to be able to identify and correct those behaviors is integral to continuous improvement in safety performance.

Risk is defined as the potential for an outcome, good or bad, but

the key components of risk are frequency (how often we do the task), likelihood (how likely is a bad outcome) and severity (how bad will it be).

It then behooves you to observe employees performing their tasks and focus on those jobs that are performed most often. The three leading loss drivers are “sprains and strains” from lifting and carrying, “slips and falls” and being “struck by.” Clearly, these losses are more closely tied to behavior than machinery failure.

CHECKLIST

The first step in setting up your inspection is to develop a checklist to which you can refer as you complete your inspection. The checklist serves two purposes: it guides you through your facility in a standardized manner and also ensures that you inspect all areas of the plant by reminding you that places, tasks or objects may have been missed should you be interrupted or have to resume the inspection at a later time.

Your checklist must include the standard OSHA requirements to ensure that your operation is compliant and you reduce the risk of life-threatening injury or illness.

www.AmericanLaundryNews.com AMERICAN LAUNDRY NEWS | MAY 2021 7

Continued from Page 1 See SAFETY on Page 9 ORDER NOW! WORLD FIRST: ANTI-BACT BY MAXI-PRESS Active germ reduction Hohenstein certified incl. all MAXI-PRESS advantages The antibacterial membrane for water extraction presses of all common manufacturers. MAXI-PRESS.US INFO@MAXI-PRESS.US / CALL (844) 447-5559 MAXI-PRESS membranes for use in water extraction presses from Kannegiesser, Jensen, Passat, Lavatec etc. WATER EXTRACTION PRESS Tested as per ISO 22196. More information:

(Image licensed by Ingram Image)

Safety

Tools f the Trade

Laundry software management update released

sentative (RSR)/driver.

The Route Assistant now contains the picture capturing of stop locations. This enables the RSR/driver to capture specific drop-off locations (like the red door) or even maps of the customer’s location showing the physical mat/washroom locations.

The Contact Manager supports the recording of communication with customers. Contacts/calls with messages or attachments can be entered in ABSSolute and the Route Assistant App.

Standard Textile, which offers products in the hospitality and healthcare textile markets, reports it has released a new solution for hoteliers and hospitality designers.

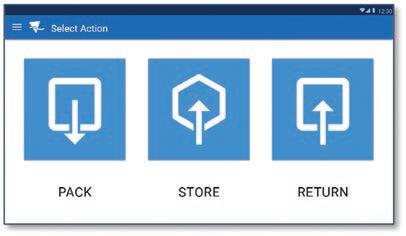

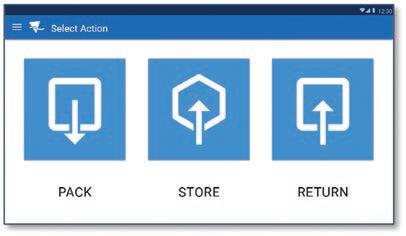

Based on feedback and input from all of its customers, ABS Laundry Business Solutions reports it has again invested in the development of new features for its ABSSolute 9.05 core software release.

Last year with the 9.04 core release, ABS released the Dynamic Mat Storage and the mobile app Bulk Packing Assistant. The company says these have proven to increase the efficiency at the route packing departments.

Now extensions have been made for supporting the internal and external logistics with so-called Mat Carry Units. This is again supported by mobile apps such as the Bulk Packing Assistant and the Route Assistant.

The logging of the GPS coordinates for the stops is visible within ABSSolute as well. The distance of the real customer location and where the truck stopped for servicing the customer(s) is shown.

ABS says this will be a good basis for optimization of the route and stop sequences. This in combination with the use of the Route Check-In meeting can be a valuable discussion point with the route service repre-

Calls can be created automatically via Alert options such as “customer stock norms are too high” or “check required on too low volume load” of containers. The new Contact Monitor gives an overview of all contacts.

ABS adds that the update includes new mobile solutions. The My Uniform Assistant app brings a company’s services to the real end-user: the wearer.

With the app, a customer can check where his/her inventory of garments is, check his/her replacements on the way, request attention for repairs and register a “lost and found” notice, like “I lost my keys/wallet/ phone” in my garment.

Instead of using printed packing documents, ABS says the Packing Assistant app will present the packing instructions to the packing employee in the correct sequence. In case of shortages, the containers can be “parked.”

Finally, the Truck Load Assistant app helps load trucks based on the correct and complete load, load sequence and route deadline. Alerts can be sent to the RSR that the truck load is completed.

www.abslbs.com 877-380-9527

Fully sustainable linen packaging material, system available

As a pioneer and market leader in the field of packaging systems, company hawo, based in Germany, has been placing a special focus on sustainability in the development of its products for many years.

Managing Director Christian Wolf is highly committed to reducing the use of plastics: “Responsibility is one of our natural resources. This also includes the conscious use of valuable raw materials. At hawo, we try to implement this in our daily activities, both in our own company and in the development of our products.”

The company says the result is an innovative, holistic concept for textile packaging: the new ORGANIXtex system.

The most important component of this new system is the sustainable ORGANIXtex packaging material, hawo says. Like traditional plastic covers, it reliably protects the cleaned clothing from all kinds of wind and weather and also to a certain extent from germs, especially during the current pandemic.

With the new ORGANIXtex packaging material by hawo, consumers now have an easy way to make a conscious decision to use less plastic in their everyday lives. The new packaging material is made from plasticizerfree, thermoplastic BIO granules and is therefore 100% plastic-free.

Neither forests are cleared nor monocultures cultivated for its production. Only natural raw materials are used that are left as a waste product elsewhere, mak-

ing ORGANIXtex 100% home compostable, the company says. Energy from fossil fuels is completely avoided and the production is almost exclusively done with solar energy (additionally required electricity is 100% ecological). This means that the production of ORGANIXtex is CO2 neutral.

The ORGANIXtex system is completed by the ORGANIX 630 KST sealing device adapted to the new material. With this stand-alone unit, the length of the packaging can be adapted exactly to the garment to be packaged. Packaging that is too long or too short is, therefore, a thing of the past—another important contribution to the conscious use of packaging in the textile industry, says hawo.

In addition, the ORGANIXtex packaging material is compatible with many fully- and semi-automatic packaging machines of leading manufacturers.

The company shares that the ORGANIXtex concept was nominated for the German Innovation Award 2021 only two months after its market launch.

“The nomination of ORGANIXtex for the German Innovation Award 2021 is a very positive surprise for us because we launched the product only in November of last year,” Wolf says. “This proves to us that we are on the right track with our principle of combining sustainability and innovation.”

www.organix.eco 312-585-8329

The company says its Encircle™ box spring cover allows for easy covering of a box spring in a matter of minutes, without having to remove the mattress or take on the heavy lifting of the box spring to put the cover in place.

Standard Textile says additional features and benefits of Encircle™ include:

• Accommodating various heights of box springs, ranging in heights from 5 inches up to 14 inches, and allows for a 2-inch tolerance for length and width, for a smooth, snug fit on nearly any box spring.

• Easy and quick removal for laundering and its durable construction holds up to the

rigors of industrial processing.

• Ability to be custom printed. Customer can supply their art or work with a design team to create the desired expression for the environment.

• Stock covers are available in two colors (magnesium and sand) with a basket weave pattern, which can also be custom colored to match the room. Available sizes include king, hotel king, queen and full.

www.standardtextile.com 800-999-0400

fying the enclosed materials.

“The COVID-19 pandemic has made workplace safety a priority in all industries,” says Mark McElhinny, president and CEO of Justrite Safety Group. “Our poly bags help companies establish clear protocols for waste—especially waste that can cause great harm to public health.

Justrite Safety Group, a provider of industrial safety products, reports it has launched a line of poly waste container bags that are designed to easily identify biohazard and infectious linen waste for their appropriate handling and disposal.

The bags are available in two colors: Red for biohazard material handling and yellow for infectious linen. Specially made to fit a range of Justrite Biohazard Cans and Eagle Poly Drums, the bags come in three sizes: 15, 33 and 60 gallons.

To make waste disposal even more secure, the safety warnings on each bag are in English, Spanish, and French and include internationally recognized symbols identi-

“Any company that is truly invested in the safety of its workers, the environment and their surrounding community need these bags.”

The bags are leak-proof and meet or exceed ASTM D1709 and ASTM D1922 impact resistance standards, the company says. Their durability means they will avoid sudden punctures and tears, which further protects workers and their environments. Both bags are sold in quantities of 100.

“We have taken great strides in our design and labeling to make sure our bags are the best on the market for ensuring the safe transport and disposal of dangerous waste,” adds McElhinny.

www.justrite.com 800-798-9250

Manufacturers: Have you introduced a new product? Revamped your system? Released a new catalog? E-mail your product news, along with a high-resolution image, to mpoe@atmags.com and we’ll consider publishing your news free in Tools of the Trade.

8 MAY 2021 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

Biohazard/infection linen waste bag line launched for easy identification

Stretch knitted bedding solution designed to quickly and easily cover box springs

FOLLOW THE FLOW

The best way to establish the checklist is to follow the flow of textiles as they are processed through your facility. As you enter the facility to begin the inspection, verify that all aisles are kept clear and unblocked by carts or other items. Aisles must be at least 36 inches wide to enable employees to exit the building quickly in the event of an emergency.

This is a good opportunity to observe whether carts are left in aisles where they obstruct egress. Establish an expectation that the aisles be kept clear. Check the emergency lighting equipment to again confirm safe operation in an emergency evacuation.

SOIL DEPARTMENT

As you visit the soil department, verify that your personnel are properly wearing their assigned personal protective equipment (PPE) and handling the soiled product carefully.

Are there sharps containers located in the soil room? Is there an adequate number of containers? Do your workers know your procedure when a sharp is found? Is there sig-

nage warning others of the presence of potentially hazardous material?

Does the conveyor belt have an emergency stop system accessible by all working along it? Are the rollers at the end of the conveyor covered to prevent pinches? Do your employees walk on the conveyor?

If you use cart dumpers, is there a barrier to prevent personnel from walking under the elevated cart?

Is there at least one eyewash station nearby so that workers can reach it within 10 seconds with their

eyes closed? Is the eyewash pressure checked at least weekly? Do you have handwashing facilities nearby the soil sort area so that employees can wash their hands immediately after sorting soil before eating?

Do you prohibit food and beverage consumption or storage in the soil department?

BOILER ROOM, COMPRESSOR, SHOP

The next stops in your inspection are the boiler room, compressor

and shop areas. You should inspect posted procedures for starting and shutting down this integral equipment safely. Verify that the persons tasked with operating this equipment have been properly trained and are familiar with the process.

Again, confirm that the eyewash/drench shower is properly operational and tested weekly.

Are ladders properly secured to the wall or lying down? Inspect ladders for damage and ensure that they are constructed of a material that does not conduct electricity.

Inspect any extension cords to be used in temporary situations for damage. Check bench grinders for proper guarding.

Do the maintenance staff personnel have lockout/tagout equipment assigned to each of them?

CHEMICAL STORAGE

Next up, in the chemical storage area you

should verify that all chemical containers are properly labeled with the contents with a “Right To Know” station nearby the area to ensure that workers have ready access in the event of a spill or release.

Does your facility have secondary containment for all chemicals? Secondary containment can be in the form of a concrete berm, double-walled containers or secondary containment pallets.

Is there an eyewash/drench shower within the requisite 10-second access? Will the eyewash continue to function if the shower is actuated? Do workers wear the proper PPE when transferring chemicals from one container to another? Have you found a “spill kit” capable of cleaning up a small spill in the area?

This ends the first installment of the facility inspection. The second installment next month will continue the inspection in the wash aisle, finishing area, delivery vehicles and offices, as well as suggestions for engaging employees in the safety process. ALN

www.AmericanLaundryNews.com AMERICAN LAUNDRY NEWS | MAY 2021 9

Donald Bock is principal of Seabright Safety Solutions Inc. in Santa Maria, California.

SafetyContinued from Page 7

Bock

(Image licensed by Ingram Image)

Laundry industry: Avoid these top 10 OSHA violations

Author says with the Biden

BY EDWIN G. FOULKE JR.

ATLANTA — Now that the Biden administration has taken over power in Washington, it is anticipated that the Occupational Safety and Health Administration (OSHA) will take on a much stronger enforcement-driven focus.

This is particularly true in light of the strong union influence that is going to be found at the Department of Labor with the addition of Marty Walsh as Secretary of Labor, Jim Frederick as Deputy Assistant Secretary for OSHA and Joseph Hughes as Deputy Assistant Secretary for pandemic at OSHA.

These three individuals all have strong ties to the international labor movement. As a result, it will be prudent of all employers, especially those in the industrial laundry industry, to be prepared for enhanced enforcement inspections by OSHA over the next four years.

This article outlines the top 10 violations cited by OSHA during inspections at laundry service facilities (NAICS Code Number 812320) and examines the primary requirements of each of the cited standards.

The top 10 most frequently cited violations are as follows.

1. 1910.37 – MAINTENANCE

administration, OSHA will take on a stronger enforcement-driven focus

systems, alarm systems, fire doors and exit lighting must be in proper working order at all times.

2. 1910.147 – CONTROL OF HAZARDOUS ENERGY (LOCKOUT/TAGOUT)

Under this standard, employers are required to protect all authorized employees performing service and maintenance on machines or equipment from the unexpected energization of machines or equipment or release of stored energy.

Employers are required to have a lockout/ tagout energy control plan program that includes the development of energy control procedures for each piece of equipment or machinery that service or maintenance is performed on. The employer is required to train all authorized and affected employees as to the requirements of the energy control plan program and provide the necessary lockout tags and/or locks used to de-energize the equipment.

Finally, employers are required to conduct periodic inspections of the energy control procedures, at least annually, to ensure that the lockout/tagout procedures are being followed by both authorized and affected employees.

ed tripping devices and electronic safety devices.

4. 1910.219 – MECHANICAL POWER TRANSMISSION APPARATUS

This statute covers all types and shapes of power transmission belts, as well as flywheels, belts, ropes, train drives, and chains and sprockets.

Employers are also required to guard all exposed horizontal shafting 7 feet or less from the floor or working platform as well as any pulleys, horizontal belts and ropes, overhead horizontal belts vertical and inclined belts.

Vertical and inclined belts, pulley belts as well as gears, sprockets and chains all less than 7 feet above the floor or platform are required to be guarded.

5. 1910.303 – ELECTRICAL ISSUES

Under this standard, employers are required to ensure that electrical equipment is free from recognized hazards that are likely to cause death or serious physical harm to the employee. Listed or labeled equipment is required to be installed and used following instructions provided by the manufacturer.

tion and maintenance of such equipment.

In addition, training requirements are spelled out as to how frequently employees who face the risk of electrical shock that is not reduced to a safe level by electrical insulation requirements need to be trained. Employers are required to train all employees to be familiar with all safety-related work practices when dealing with electricity.

6. 1910.335 – ELECTRICAL SAFEGUARDS FOR PERSONAL PROTECTION

Under this standard, employers are required to provide and require the use of electrical protective equipment that is appropriate for the specific part of the body to be protected for the work being performed. Protective equipment has to be maintained in a safe, reliable condition and shall be periodically inspected or tested as required.

The employer is also required to ensure that when working near exposed energized conductors or circuit parts, each employee is utilizing insulated tools or handling equipment if the tools or handling equipment may come in contact with such conductors or parts.

SAFEGUARDS,

OPERATIONS FOR EXIT ROUTES

Under this standard, employers are required to keep exit routes free from obstructions of material or equipment on either a permanent or temporary basis within the exit route. The exit must have adequate lighting and each exit must be clearly visible and marked with a sign that the word “exit.”

Emergency safeguards such as sprinkler

3.

1910.212 – GENERAL MACHINE GUARDING REQUIREMENTS

Under this standard, employers are required to provide one or more methods of machine guarding that protects operators and other employees in the machine area from hazards, such as those created by points of operation, and ingoing nip points, rotating parts, flying chips and sparks.

Examples identified include guarding methods such as barrier guards, two-hand-

All electrical equipment is required to be installed in a neat and workmanlike manner and all unused openings in any type of box or cabinet shall be closed to protect from any electrical exposure. All disconnecting means and circuits are required to be legibly marked for their purpose unless the purpose is evident.

Also, sufficient space is required to be provided and maintained about electrical equipment to permit ready and safe opera-

Also, employers are required to provide protective equipment for the eyes or face when there is a danger of injury to the eyes or face from electrical arcs, flashes or flying objects.

Finally, protective shields or protective barriers, as well as insulating material, are required to protect employees from shocks, burns or other electrically related injuries when the employees are working near exposed energized parts that might be accidentally contacted or where dangers of electrical heating or arcing may occur.

7. 1904.39

– RECORDKEEPING AND REPORTING

Under this standard, all employers who have at least one employee must report to OSHA within eight hours after the death of any employee as a result of a work-related incident.

In addition, all employers must notify OSHA within 24 hours after the in-patient hospitalization of one or more employees or an employee’s amputation or an employee’s loss of an eye as a result of a work-related incident.

For to reporting a fatality, the employer only needs to report the fatality if the fatality occurs within 30 days of the work-related incident. Concerning reporting in-patient hospitalization, amputation or loss of an eye, it is only required to be reported those that occurred within 24 hours of the workrelated incident.

8. 1910.22

– WALKING-WORKING SURFACES GENERAL REQUIREMENTS

Under this standard, all employers are required to keep all places of employment, passageways, storerooms, service rooms and walking-working surfaces in a clean, orderly and sanitary condition.

Also, all floors and any walking-working surfaces must be maintained in a clean, and

10 MAY 2021 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

licensed

Image)

(Image

by Ingram

to the extent feasible, dry condition. In addition, all employers must ensure that each walking-working surface can support the maximum intended load for that surface.

All employers are required to provide and ensure for each employee’s use, a safe means of access and egress to and from walking-working surfaces. To that end, the standard requires that all walking-working surfaces be inspected regularly as necessary and maintained in a safe condition.

9. 1910.23 – LADDERS

Under this standard, employers are required to ensure the ladder surfaces are free from punctures and laceration hazards and that they are used for the purpose for which they were designed.

Also, employers must ensure that ladders are inspected before initial use in each work shift and more frequently as necessary to identify any visible defects that could cause injury to an employee.

Employers are required to immediately tag any ladder with structural or any other defects with “Dangerous – Do Not Use” and remove it from service until repaired.

Portable ladders are not to be loaded beyond the maximum intended load, and they must be used only on stable and level surfaces unless they are secured or stabilized to prevent accidental displacement. Also, portable ladders used to gain access to upper landing surfaces must have side rails extended at least three feet above the upper landing surface.

10. 1910.178 – POWERED INDUSTRIAL TRUCKS

Under this standard, employers are not allowed to modify or make additions that affect the capacity of safe operations of the powered industrial truck without the manufacturer’s prior written approval.

Battery-charging installations shall be located in areas designated for that specific purpose. Also, the employer is required to ensure that the charging facilities have provided for necessary flushing and neutralizing spilled electrolytes, as well as fire protection and protecting the charging apparatus from damage by trucks. When charging the battery, acid shall be poured into the water, but water cannot be poured into acid.

Additionally, brakes of highway trucks

shall be set and wheel chocks placed under the rear wheel to prevent the truck from rolling while they are boarded by a powered industrial truck.

The standard details specific operator training, which includes safe operations before an employee is permitted to operate a powered industrial truck. Powered industrial truck operator training shall consist of both classroom training and on-the-job observation by a qualified individual.

Trainees cannot operate powered industrial trucks unless under the direct supervision of a person who has knowledge, training and experience to train operators and evaluate their competency. Refresher training, including an evaluation of the effectiveness of training, must be provided to ensure that the operator has the knowledge and skill needed to operate the powered industrial truck safely.

Retraining must be provided when an employer observes an operator operating the vehicle in an unsafe manner, is involved in an accident or near-miss incident, or when the evaluation reveals the operator is not operating the truck safely.

Evaluations of each powered industrial truck operator shall be conducted at least once every three years under the standard. The employer is required to certify that each operator has been trained and evaluated and the certificate must include the name of the operator, the date of the training, dates of evaluation and the name of the person performing the training evaluation.

In addition to the above-identified most frequently cited OSHA violations in the laundry service industry, employers in this industry should be also aware that there is a specific OSHA standard dealing with laundry machinery and operation (1910.264).

This standard applies to moving parts of equipment used in laundry and to other conditions peculiar to this industry. Specifically, it requires that each washing machine shall be provided a means of holding open the door that covers the inner and outer cylinders or shells while being loaded or unloaded.

Also, each dryer shall be provided means for holding open the door or cover of the inner and outer cylinders or shells while being loaded or unloaded. The same requirement is also required for each shaker

or clothes tumbler of the double-cylinder type.

These requirements do not apply if the linens are loaded into an open-end of the revolving cylinder and are automatically discharged at the opposite end.

In addition, this standard requires that all steam pipes that are located within 7 feet of the floor or working platforms and which

an employee may come in contact shall be insulated, covered with heat resistant material or otherwise properly guarded.

This standard requires that the employer shall ensure that their employees are properly instructed as to the hazards of their work and be instructed in safe practices by either bulletins, printed rules or verbal instructions.

Finally, the standard requires that no safeguards, safety applications or other devices shall be removed or made ineffective except to make immediate repairs or adjustments.

As the Biden administration begins, it is critically important that all employers in the laundry industry be fully compliant with the safety requirements cited above.

Being prepared to handle an OSHA inspection and knowing all of your rights provided under the Act can protect employers from receiving a significant number of citations and penalties from a most likely enforcement-driven OSHA. ALN

Edwin G. Foulke Jr. is an Atlanta-based partner with the national labor and employment law firm Fisher Phillips. He was the assistant secretary of Labor for OSHA in the Bush 43 administration and chairman of the Occupational Safety and Health Review Commission in the Bush 41 and Clinton administrations.

www.AmericanLaundryNews.com AMERICAN LAUNDRY NEWS | MAY 2021 11

Miele_BMAd_4.75x6.75in_PrtOL.indd 1 3/12/21 11:20 AM

(Image licensed by Ingram Image)

Foulke

PANEL OF EXPERTS

Evaluating laundry customer contracts

requiring customers to notify your service employees of linens that have been exposed to the virus, requiring them to place the linens in biohazard containers or bags, or requiring them to be placed in specific areas for pickup.

Contracts of any type can be confusing and even daunting at times, especially regarding specifics around language, clauses, addendums, etc.

In my experience, reviewing contracts regularly, with professional legal counsel, can prevent mistakes and other challenges that can cost you wasted time and money. And, when you also consider the complexities of the COVID-19 pandemic over the past year and a half, now would be the perfect time to review your business’ contract language to ensure they are up-to-date.

During this extended time of uncertainty, some businesses are changing how they approach and accomplish reviewing contracts. There are many things to consider, and some include:

• Keeping clear and accurate records of all contract deadlines.

• Reporting on contract details and updates with a review team at least once per year.

• Fully understanding and communicating any renewal provisions.

• Keeping records of all communications with the other party.

• To reduce the possibility of a disagreement, acting clearly and promptly.

• Considering remote access to contracts.

In addition to the list above, many companies have said they are concerned now more than ever with managing and reducing organizational risk and are addressing safety concerns for any future contract renewals.

For example, some companies have revised contracts to included “Exposure Clauses” specific to COVID-19. These clauses can be written to help protect service employees, plant employees and customers alike from possible exposure to COVID-19 and other harmful pathogens.

Considerations could include

Adding this type of specific language to contracts could help reduce exposure and the spread of unwanted pathogens to employees.

Finally, some companies are also considering a remote or cloudbased service with 100% digital access to agreements and other sensitive business information.

With more and more employees working remotely, these services can help teams review contracts safely and securely, without being in the office. These kinds of services offer peace of mind that your information is safe, secure and accessible 24/7, which improves accountability, centralized control and increases productivity.

When reviewing your contracts, you and your review team should be mindful that there are many things to take into account to help protect your business, your employees, and your customers.

Consider current market conditions, environmental regulations, labor law changes, and, where appropriate, seek legal counsel to aid you in your review process.

two years that are triggered by a date like 12 months before the contract end date if not noted otherwise. A general rule is the longer the contract, the better.

One concept that thoroughly stood out to me as I was leaving managing operations was “legal outs.” I am never in favor of an out clause without cause, especially with a short timeframe.

For cause, out clauses within 60-90 days are reasonable. If a customer decides to leave and I need to alter my full-time employees (FTE), I need an appropriate time to notify my employees who may be affected by the departure.

Contractually, laundries want the ability and time to correct a problem a customer might have. Many times, these are called “cure periods” and can be set at 30-90 days to correct issues.

the relationship/contract term. A schedule outlining early termination should be set up.

As you review your contracts, I would stress the importance of backup laundries to be used in the case of an emergency. Additionally, I would get copies of those reciprocal agreements and use those as exhibits in your contract. This is even more important due to COVID-19 and other natural disasters like floods, electrical outages, tornadoes, hurricanes, etc.

Of course, there are normal and long-standing regulatory requirements to adhere to. Additionally, there may be a requirement for the laundry to be accredited or certified and the contract would document that.

Textile, writing about contracts makes me think of linen contract specials. Special products can be a good thing and can satisfy your customer. The product is made exactly to customer specifications and there is a commitment from the manufacturer to stock and a commitment from the laundry to purchase. This is a clear, concise and satisfying relationship.

In the end, the contract is to provide a stable platform for the buyer and the seller regarding laundry and linen services. Each time it’s negotiated, you have the opportunity to fine-tune.

Thanks to Johanna Ames at Ames Linen in Courtland, New York, for her input.

When the time comes to renew a laundry contract, it is always the opportunity to correct or improve on the things you like and do not like. Sometimes issues swing too much to one side’s favor. These issues generally stand out to you. Contracts should be mutually respectful.

It is prudent to work toward re-signing a customer as much as a year before the current contract expires. You cannot run a laundry without planning, and customers need the ability to plan as well.

Contracts can be written with automatic extensions of one to

During the COVID-19 epidemic, reusable personal protective equipment (PPE)—isolation gowns for example—became a new opportunity for many laundries, as strange as it may seem.

If the laundry is to invest in additional products or new products like PPE, the customer needs to commit to using these items for at least 12 months. The same goes for investments in carts and other capital equipment.

If a customer signs on and you have significant expenses, the customer needs to repay for some of these costs if they exit early in

There should be a loss clause and it should be thoroughly understood by both sides. Deliveries should be realistic, and you could put a delivery window in your contract so that both you and the customer know when to expect the shipment of the linen within a one- or two-hour window. Sometimes penalty clauses for missed timeframes assist with keeping deliveries on schedule.

Dock times and space are limited so this may be a critical part of your contract. If you plan on a delivery lasting 24 hours (until the next day) and your delivery does not come for four to six hours, you may have some real shortages on the floors.

As a representative of Standard

First, you should consider if the contract you have in place is still meeting your needs. Have your requirements changed? Have your needs increased?

Do you need to specifically address enhanced cleaning standards due to COVID? Are you considering requiring vaccinations

12 MAY 2021 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

“With all that’s gone on over the past year, I want to be sure my contracts are up-todate. How should I evaluate my contract language? What should I be looking for?”

Textiles

Cecil B. Lee Standard Textile, Cincinnati, Ohio

Chemicals Supply

Campbell Dodson

Lavo Solutions LLC, Cincinnati, Ohio

(Image licensed by Ingram Image)

Other Institution

Laundry

Frank Zacchigna

U.S. Department of Veterans Affairs, Hines, Ill.

for all laundry plant staff?

All these issues can be addressed in your contract. Any changes in contract terms and conditions can have far-reaching consequences, so be careful what you wish for.

Second, please consider how new/changing requirements will impact your costs. Higher operating costs will generally result in having to raise prices for your service.

Are there other parts of your operation that can be operated more efficiently to offset your increased costs? Do you need new equipment? Does your service maintenance need to be updated due to COVID?

Lastly, the full implications of the pandemic on laundry plant operations will be seen for years to come, so this is all a work in progress. The only constant is change, and you need to anticipate what you want your laundry operations to accomplish in the future based on changing conditions.

Contracts are a good way to address these changing conditions and need to evolve as your operations require.

properly extended.

6. Great opportunity to conduct a needs analysis and provide current customers with the entire product offering. We now see the “whats” and “whys”; now the “hows”:

1. Assess the quality of verbiage in the current service agreement. Understand what your competitors have written into their service agreement language so you differentiate yourself, where needed, from that competition. Your service agreement verbiage can help you minimize potential

liabilities.

2. Set length of agreement of renewal/extension parameters.

3. Define an expired (out-ofdate and not enforceable) and an exposed (current agreement set to expire in the next 12 or 18 months) service agreement.

4. Reconcile, if needed, all current paper agreements to route-accounting software for accuracy and determine percent expired and exposed.

5. Define an authorized signature.

6. Prioritize expired and exposed accounts in the order that you wish to attack.

7. Assign person/persons to execute agreement extensions.

8. Contemplate a reward system for renewal execution (capped payouts or not capped).

9. Make results visible by posting and creating a competitive environment to excel.

10. Always consult with your attorney for proper verbiage and liability when making any changes to your service agreement.

Ideas on compensations to those involved:

1. Five-year agreements/extensions. Minimum two years.

2. Account must have 24 months or less remaining on the term when extending.

3. No price decreases.

4. No reissue of garments/no new specialty linen to achieve an extension.

5. Authorized signature— imperative.

Service agreements are the

Happy spring to all ALN readers!

I would first like to say that we need to re-evaluate the word “contract.” Contracts have 1) a negative connotation, and 2) we assume there is a negotiation that needs to occur to “hammer out” terms to move forward.

Also, let us remove the word “renewal” from our lexicon. Renew intimates something new. Let us think about the word “extension” instead. Extension connotes the “continuation of an existing relationship,” which is what this is all about! The language is not only softer, but it allows us to move forward rather than stopping and hemming and hawing.

Why are service agreements and extensions so vital? Six reasons:

1. A client’s commitment (signed extension) allows you to invest in that client with a more assured return.

2. A client’s written commitment allows you to plan and budget with assured volume that is “committed” for years.

3. A client under agreement adds exponentially to the value of the organization (up to 30 to 1 perhaps).

4. Negotiating with an existing service agreement allows you to be in the driver’s seat.

5. Lost business and price decreases should be practically nil when agreements are

www.AmericanLaundryNews.com AMERICAN LAUNDRY NEWS | MAY 2021 13

It’s not just print anymore. Whenever. Wherever. American Laundry News can now be viewed on your mobile devices. Stay on top of the latest industry news and updates. www.american laundrynews.com BY MATT POE, EDITOR and in High Point, North Carolina, plus linen depots in Lanham, Maryland, and states—and it’s growing. HandCraft recently opened new facilofficer, about the new plant, the company’s history and its future. Murray to build out laundry in Wilson, North Carolina. Why did you open this ity because we reached capacity in our Richmond-based retail medical plant. location, size, equipment, etc. in Wilson? was mostly our customers’ geography. where we felt growth was inevitable. The Newspaper Record for Laundry Linen Management INSIDE 4 SANTA MARIA, Calif. — You lie awake night wondering whether your Do you and your supervisors serve as core drivers by committing to and driving the safety process of your operation? Do your employees have ownerattention that quality, service and productivity receive? safety your operation driven solely by complying with OSHA standards and assuming that, in doing so, your operation is safe? Or is safety dependent on the actions of 10 Experts In this issue, the experts ating laundry contracts in light of COVID-19. on Page How to conduct a plant safety inspection, starting with flow, soil, boiler/compressor/shop, chemicals How safe is your laundry operation? (Part 1) Late News Clean ’22 booth sales open ATLANTA General booth sales have officially opened for the next Clean Show, taking place here Organizer Messe Frankfurt says exhibit space will be assigned on tors, the floor is at almost 50% capacity. to 2022. Atlanta last hosted The Prospectus, interested exhibitors can view the floorplan, select sponsorship opportunities for additional Besides vendor exhibits, the OSHA Top 10 Find out the top 10 at laundries, details HandCraft Services opens new facility in North Carolina SAFETY Healthcare laundry service provider reached capacity in existing retail medical plant HandCraft Services opened its new Wilson, North Carolina, facility December. (Photo: HandCraft Services) Columnist at Large In this issue, Eric Frederick shares tricks ing new employees. (Imagelicensed IngramImage) The Newspaper of Record for Laundry & Linen Management See EXPERTS on Page 15 Consulting Services David Graham Performance Matters, Fort Mill, S.C.

OSHA and COVID-19 in laundry/linen services

What laundries need to know about

BY MATT POE, EDITOR

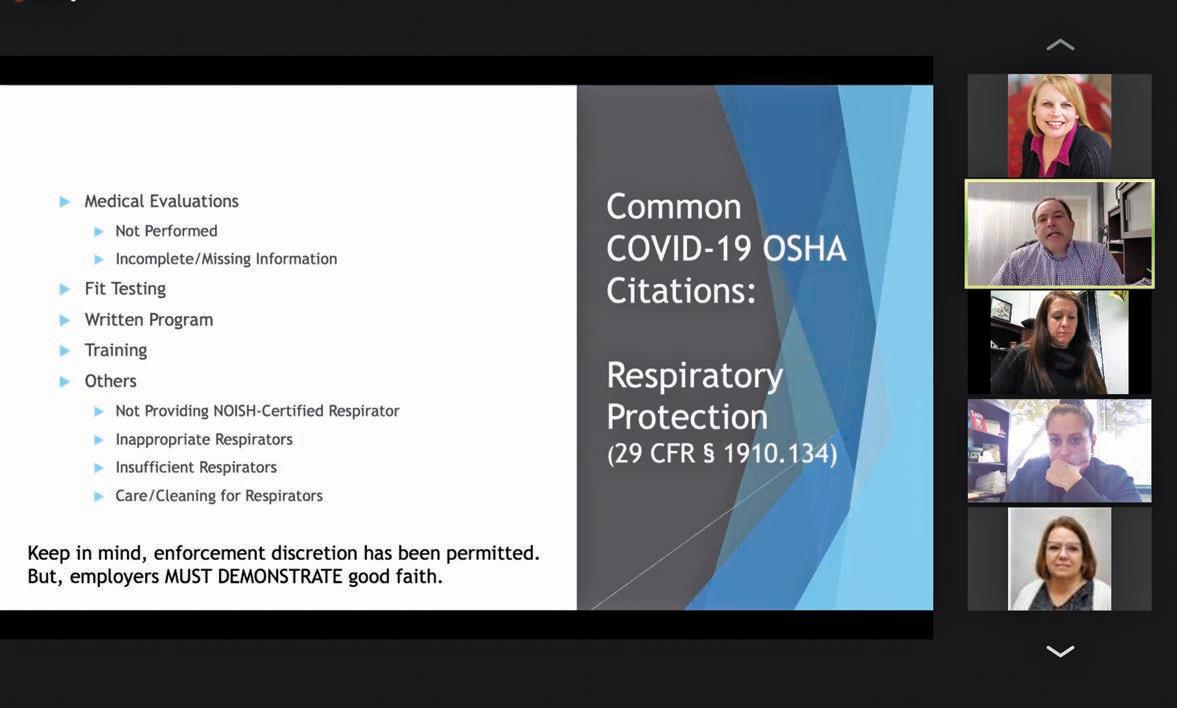

RICHMOND, Ky. — The Association for Linen Management (ALM) shares that as of November 2020, nearly $2.5 million in fines have been issued for COVID-19 safety violations.

That begs the question, what Occupational Safety and Health Administration (OSHA) regulations are being applied to issue these fines and what changes have been made on a federal and state level?

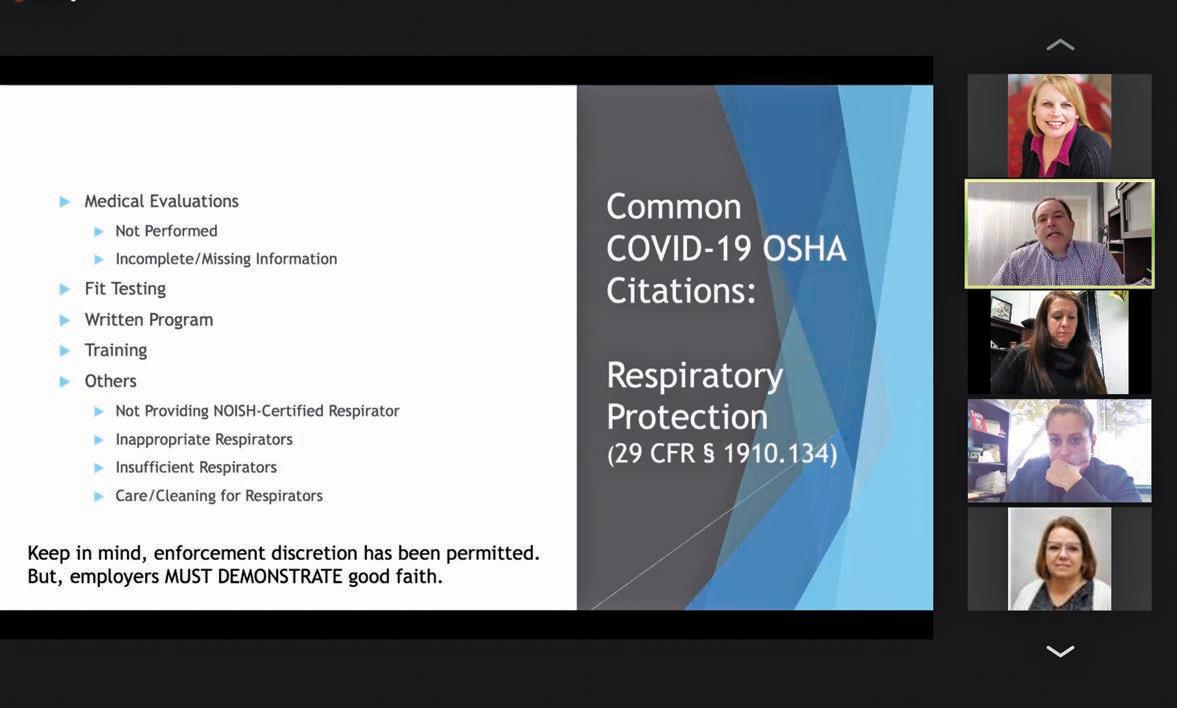

Barry Spurlock, an attorney and an associate professor at the School of Safety, Security and Emergency Management at Eastern Kentucky University in Richmond, provided some guidance on OSHA and COVID-19 during the recent ALM webinar “2021 OSHA Update/COVID-19 Related Safety Guidelines.”

“I think many people through the COVID struggles and challenges seem to think that they get the special treatment with OSHA,” he says.

“There are there are some specific guidelines to specific things that OSHA is doing, but in the world of inspections and violations and penalties, OSHA still has that framework that it has to work in for COVID, just like it would for lockout/tagout or confined space entry or some other OSHA standard.”

INSPECTION TRIGGERS

What triggers an OSHA inspection during the current pandemic?

“This is still the same report of imminent danger; that always takes top priority,” says Spurlock. “If there’s a report of imminent danger, then behind that is a fatality inspection. They want to look to see what can we do to prevent a fatality from happening.”

He goes on to say that imminent danger almost takes priority over a fatality. The next level is complaint referrals.

“I will tell you most of the COVID-related inspections and COVID-related citations have come as a result of complaints or referrals,” shares Spurlock. “In some states, maybe it was a public health official who made some kind of a referral and then the programmed inspections is the trigger or the priority behind that.”

OSHA is conducting on-site inspections in some cases, he says, practicing social distancing and other safety precautions. Another option has been for employers to mail in documentation, such as photos.

“If it is a COVID-related complaint, OSHA might actually come

OSHA guidelines, inspections, citations

out to see us observe social distancing, mask usage, those kinds of things,” Spurlock says. “It’s kind of been a mixed bag with OSHA coming out, and pretty much the programmed inspections are still occurring out there.

“So, don’t think just because COVID is going on that they’re not going to come out on a complaint or referral inspection, even for something that’s not related to COVID.”

So, what have been the primary COVID triggers for OSHA inspections?

“It’s been complaints, complaint inspections overwhelmingly,” Spurlock says. “Did the company

violate a standard? That’s their big question.

“So if they come out and they’re doing an inspection, whether it’s COVID or whether it’s something else, they still have the burden of proving a violation that has always been there.

“In a lot of states, like Kentucky, there is a deputized member of the Department of Public Health, and they have a whole different standard you’re dealing with, so you have to look at that.

“But from a federal perspective, coming out on the COVID-related complaint, a standard has to apply to the condition. There are guidelines, and the general duty clause might come into play, but it is a recognized standard.”

These standards include recognized hazards, respiratory protection, record-keeping, personal protective equipment (PPE), signage, etc., he says as examples. Was there non-compliance and the employer knew or should have known? Have there been willful, repeat citations?

“You should try your best to avoid any kind of willful repeat citations,” Spurlock points out. “A general duty can be a willful citation, but they also have to show intentional knowing or voluntary disregard and indifference by the employer—employees reported the situation and OSHA can show that that the employer just chose to ignore it.”

What does OSHA have to do to fulfill its procedural obligations? It has to be in writing, he says. It has

to be signed by the area director or the state equivalent. It has to describe the violation with particularity, and it has to be timely.

COMMON COVID CITATIONS

Spurlock then shared some of the more common COVID-related OSHA citations that have been given over the past year.

“Probably the most cited standard related to COVID-19 has been respiratory protection,” he says.

Different elements of the respiratory protection standard that have been used to issue citations include medical evaluations either not being performed or are incomplete or missing information.

“If an employer requires an employee to wear a respirator, then they have to comply with medical evaluations, fit testing, training— some of those elements have to be required,” Spurlock says.

Other citations include not having a written respiratory protection program, not giving training and providing a non-certified respirator for people who need it for their job.

“There are a lot of COVID-19 OSHA citations related to respiratory protection,” he points out. “That’s probably the one we’ve seen the most, certainly the most variety of citations.”

OSHA citations issued relative to PPE have mainly been about training on usage—in both the healthcare and non-healthcare sectors, Spurlock shares.

“The catch-all when there is no

14 MAY 2021 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

Barry Spurlock (highlighted) shares OSHA COVID-19 updates with Association for Linen Management members. (Photo: Matt Poe)

(Image licensed by Ingram Image)

pandemic-related

standard, OSHA can use the general duty clause to issue a citation, and that might be where employers are failing to maintain social distancing, put up barriers, do what they need to do to protect workers from COVID exposures,” he says.

The next area of common COVID citations regards recordkeeping and reporting.

“A lot of folks have thought about COVID as this novel thing relative to record-keeping and reporting, and OSHA has sent out a lot of guidance, and the recordkeeping standard hasn’t been changed because of COVID,” says Spurlock.

“The record-keeping standard already took into account pandemics and illnesses beyond the common cold and flu. The big thing is determining whether or not the COVID-19 was a workrelated exposure, and that can be difficult.”

A work-related case will trigger reporting obligations, if an employee contracting COVID results in any of the recordable triggers such as a fatality, medical care that is not first aid, etc.

Spurlock shares that he has had questions about training in regards to COVID regulations when in-person or hands-on training is required.

“If you’re going to get some discretion because COVID has hampered the resources, the ability to put people together, you have to show some good faith,” he says.

“Something like forklift training, I think that’s going to be a really big burden for the employer to show good faith as to why they didn’t do hands-on training when you know social distancing,

wearing masks and those other things that you could do.”

RECENT OSHA COVID GUIDANCE