Late

Crown will now service dental uniforms for 42 North Group in both New York locations in addition to its 81 other locations across New England.

“We are growing and there is a lot to be proud of throughout our sales organization,” says Ed King, director of sales and marketing at Crown. “Over the last few months, not only has our team expanded, but we see that growth within our customers as well and we’re proud to have been able to hold up our standards of service.”

“We are very happy that Crown can provide the same uniform rental service to our New York dental offices,” says Cindy Feldman of 42 North Group.

“To have that same quality and service as those dental offices within our New England region is something we depend on. We trust and rely on their high-quality service while keeping us protected, and so do our patients.” ALN

BY MATT POE, EDITORAMARILLO — For years, healthcare entities in the Texas panhandle had to send out their linens to be processed.

Sometimes the goods traveled hundreds of miles.

Then, in 2013, a group in Amarillo read about the Evergreen Cooperative Laundry in Cleveland, a worker-owned co-op. That raised a question: Could such an operation could succeed in Texas?

After eight years, North Heights Linen Service (NHLS) is up and running, processing healthcare operation goods in Amarillo.

“This facility was built to provide healthcare linens to the many entities in the Texas panhandle,” says Richard Engler, general

manager of NHLS. “Previously much of this work had been sent to facilities out of state as no local option was available.”

Bowden Jones, an NHLS Board member, says that the healthcare system is vital to the success of the city.

“Being able to service this industry locally helps to bring and retain revenue for the city,” he says. “Local servicing also allows for

those organizations served to receive cost savings as well, because of the proximity of the laundry to their establishments.”

Jones adds that the laundry was started by individuals who have an interest in improving one of the underserved areas of Amarillo and, thus, improving the city of Amarillo as

BY MATT POE, EDITORCHICAGO — As businesses continue to work toward more normal operations, laundry businesses are seeing increases in the volume of goods they process.

While growth is good, sometimes a plant’s capacity can become strained. Then, it may be time for the laundry to look at adding equipment, in the space it has, to keep up with increasing pounds per hour. The question then becomes one of evaluating the laundry’s current operation and determining the best course of action as it grows.

American Laundry News spoke with representatives from two con-

Growing amounts of laundry processed could mean an operation needs to expand its equipment layout. (Image licensed by Ingram Image) Heat-Generating Equipment

See EQUIP on Page 12

Customer Service Evaluation

Two consulting firms share their thought processes for operations considering adding equipment

CHICAGO — Laundry and linen services operate on a business-tobusiness (B2B) level.

That means that unlike consumer-based businesses, their client base is smaller. They need to work hard to hold onto each and every customer they have.

To do this, laundries need to provide excellent customer service, and respondents to the most recent American Laundry News Your Views survey indicate they are serving their customers well.

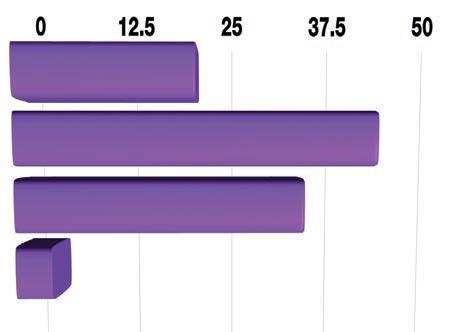

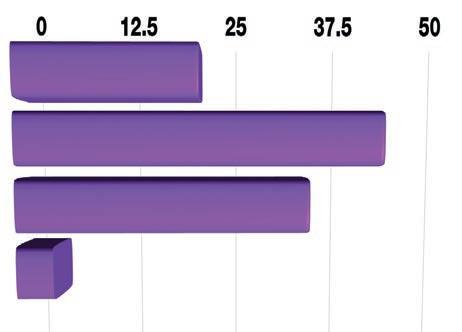

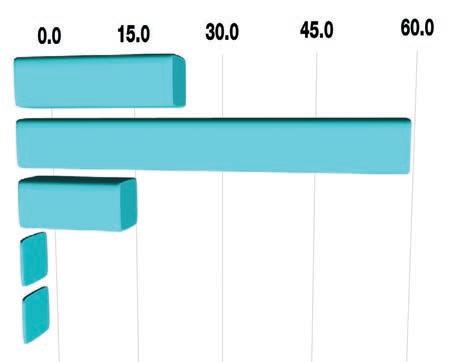

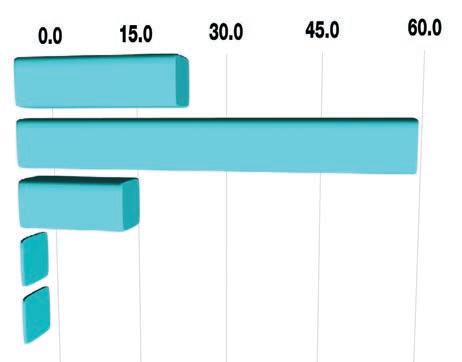

When asked, “How would you rank your operation’s level of customer service,” almost 60% of operators indicate it is “above average.” Onequarter of respondents rate their customer service as “excellent,” and almost 17% say it’s “average.”

“Customers are generally happy with the clean state of my business, they find the services rendered impressive,” one respondent writes. “Only a few customers have had issues with the level of our customer relations.”

Another writes that customer service is “most important, it’s what we deliver as an essential service.”

The majority of laundry managers (75%) who took the survey say their operation has a system in place to measure customer/end-user satisfaction in its service. The remaining respondents don’t have a system in place.

A third of those who took the survey use an informal inquiry to measure customer satisfaction, while almost 21% use a written survey. Nearly half (45.8%) use a combination of both methods.

A key part of measuring customer service satisfaction is keeping track of complaints. More than 80% of laundry managers who took the survey say their operations records and tracks service complaints. More than 12% say their laundry doesn’t, and more than 4% don’t know if their company does or not.

Overall, laundry managers indicate the pandemic improved their customers’ responses to service. Almost 70% indicate their customers are more understanding, and almost 17% say they are more positive. Almost 13% indicate their customers are less positive, and one survey taker says their customers’ attitudes are the same.

When asked, “When you receive a complaint, what is most often the cause,” respondents indicate:

• Missed or late delivery, 39.1%.

• Condition of goods, 17.4%.

• Contents of order incorrect, 17.4%.

• Reaction to increased costs, 13.0%.

• Incorrect charges or billing, 4.4%.

• Other (please specify), 8.7%

Survey takers who chose “Other” say the complaint has been “late delivery and not enough” and “combination of the above.”

“Being short-staffed makes it harder to respond and make special deliveries,” shares a respondent.

Another writes, “Supply chain is a big issue for product.” Almost 87% of respondents say they follow up immediately after a complaint is received; the remainder say they follow up within 24 hours.

When asked, “How often do you receive compliments for your customer service,” almost 21% of respondents indicate they “always” do. More than 40% “sometimes” receive compliments, while 33% “rarely” do and 4% “never” receive a compliment.

Some of the compliments survey takers have received include:

• Good turnaround time.

• Driver compliments. Professionalism, etc.

• Fast service and great results.

• Driver went above his normal job.

• Continued quality improvement.

• Fast response to meet their needs.

• Biggest compliment: Very responsive, friendly.

“We are working on our customer service right now,” a survey taker writes. “Being federal government may mean they have to use our laundry, but their satisfaction is important to me and I’m the GM, so it has to be important to my employees, too!”

While the Your Views survey presents a snapshot of readers’ viewpoints at a particular moment, it should not be considered scientific. Due to rounding, percentages may not add up to 100%.

Subscribers to American Laundry News e-mails are invited to take the industry survey anonymously online each quarter. All managers and administrators of institutional/OPL, cooperative, commercial and industrial laundries are encouraged to participate, as a greater number of responses will help to better define operator opinions and identify industry trends. ALN

Charles Thompson

Phone: 312-361-1680

E-Mail: cthompson@ ATMags.com

Donald Feinstein

Phone: 312-361-1682

E-Mail: dfeinstein@ ATMags.com

Bruce Beggs

Phone: 312-361-1683

E-Mail: bbeggs@ ATMags.com

Editor

Matt Poe

Phone: 866-942-5694

E-Mail: mpoe@ ATMags.com

Mathew Pawlak

Digital Media Director

Nathan Frerichs

Phone: 312-361-1681

E-Mail: nfrerichs@ ATMags.com

David Barbe • David Carter

Janice Ayers Davis • Nick Fertig

Deana Griffin • Steve Kallenbach Edward McCauley

Main Phone: 312-361-1700 Fax: 312-361-1685

847-504-8175 ALN@Omeda.com www.americanlaundrynews.com

American Laundry News (ISSN 1091-9201) is published monthly. Subscription prices, payment in advance: U.S. 1 year $46.00; 2 years $92.00. Foreign, 1 year $109.00; 2 years $218.00. Single copies: U.S. $9.00; Foreign $18.00.

Published by American Trade Magazines LLC, 650 West Lake Street, Suite 320, Chicago, IL 60661. Periodicals postage paid at Chicago, IL, and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Laundry News, Subscription Dept., 125 Schelter Rd., #350, Lincolnshire, IL 60069-3666. Volume 47, number 12. Editorial, executive and advertising offices are at 650 West Lake Street, Suite 320, Chicago, IL 60661. Charles Thompson, President and Publisher. American Laundry News is distributed selectively to qualified laundry and linen management and distributors in the United States.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2021. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Laundry News does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Laundry News or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

When Milnor introduced PulseFlow® technology, CBW® washing was thrust into the future. The idea of balancing time, temperature, mechanical action and chemistry was missing one critical piece of the pie – DILUTION through the efficient use of water.

PulseFlow combines the innovative RecircONE® fast wet down and chemical immersion in the first module with standing bath washing in every spacious process module. Thorough and efficient dilution occurs by way of intermittent high velocity counterflow rinsing and traditional True Top Transfer.

The result is hygienically clean linen using less water (as low as 0.3 gallons per pound/2.5 liters per kilogram) and less energy as proven time and again by hundreds of PulseFlow tunnels in a variety of laundry applications worldwide.

Contact an authorized Milnor distributor or call 504-712-7656 to find out more.

www.milnor.com

I t’s that time of year when many people, and businesses, look back at the past year and look ahead to the new one.

Looking back, I think we can all agree that the further we get away from 2020, the better.

However, I hope that throughout 2021, you’ve been able to take some of the lessons learned from the previous year (lessons we had no idea were coming) and put them into practice so that 2022 can be a growth year.

Is the pandemic over? Are businesses and laundries back to where they were two years ago?

Unfortunately, no, but laundry operations and their customers can keep

The Editor’s Desk MATT POEmoving forward, growing, in 2022.

Speaking of customers, now’s a good time to look at how your laundry is performing in terms of

customer service.

Customers (even B2B customers) have changed and have more of a consumer mindset. Turn to page 8 to gain insights from customer service expert Shep Hyken about engaging your business customers like individual consumers.

Hopefully all of your efforts from 2021 heading into 2022 are leading to growth. If you need more ideas and encouragement about growing your laundry business, turn to page 14 for throughts from our Panel of Experts.

So, as we say goodbye to 2021 and move into 2022, keep on moving forward, keep on growing … and keep it clean, everybody! ALN

A s we approach the holidays and the end of the year celebration, it is time to take a moment and look back at the challenges, struggles and successes of this past year.

But most importantly, it is time to thank our employees for their efforts in making this a year worth remembering.

It is normal for managers to set goals for the upcoming year at this time. I would normally start by looking back at what our goals were at the start of the year.

I always regarded goals as guideposts and not as a defined road map. No game plan can withstand constant contact with the reality of life. Unexpected problems and opportunities arise each year that requires us to modify those goals.

A good manager adapts and changes to real-world situations. But no manager can achieve success alone. We all owe our success to the team we have put together to make the business work.

ATLANTA — Hotel reservations for The 2022 Clean Show can now be made through Connections Housing, the official housing agency for the July 30-August 2 event.

Show owner Messe Frankfurt has arranged for exclusive discounts and amenities at a variety of Atlanta hotels, some of which are located within walking distance of the Georgia World Congress Center. Reservations must be made through Connections Housing to ensure receipt of these rates and amenities (beware of fraudulent companies presenting themselves as “official partners of Clean 2022”).

Hotels included are Aloft Atlanta Downtown Hotel, Atlanta Marriott Marquis, Courtyard Atlanta Downtown, Embassy Suites Atlanta at Centennial Park, Hilton Garden Inn Atlanta Downtown, Holiday Inn Express & Suites Atlanta Downtown, Omni Hotel at CNN Center, Renaissance Atlanta Midtown and

The Westin Peachtree Plaza.

Nightly rates range from $175 to $259 and do not include local taxes.

Per-night room rates are for single or double occupancy at most hotels and may be slightly higher for three or more people in a room. Rates are based on availability, and additional room types and rates may be available at some hotels.

Some hotels are designated headquarters for each of The Clean Show’s sponsoring associations: Association for Linen Management

(ALM), Coin Laundry Association (CLA), Drycleaning & Laundry Institute (DLI), Textile Care Allied Trades Association (TCATA) and TRSA, the association for linen, uniform and facility services. However, Clean 2022 attendees are welcome to stay at any headquarter or general housing hotel.

Complimentary shuttle bus service to and from the Georgia World Congress Center is provided for headquarter hotels. All other Clean Show hotels (except those within walking distance of the venue) are within two blocks of a shuttle pickup point.

Hotel reservations may be made online via the Connections Housing website or by calling 702675-6584. Exhibitor and attendee groups requiring 10 or more rooms may choose to submit an online block request.

The housing reservation deadline is July 7, 2022. ALN

Every person in your organization is important. Every person contributes to moving the organization forward.

EVERY PERSON IN YOUR ORGANIZATION IS IMPORTANT. EVERY PERSON CONTRIBUTES TO MOVING THE ORGANIZATION FORWARD.

I believe in giving thanks more than once a year. It is important to keep everyone engaged and moving forward together. Celebrate your milestones and keep everyone focused on what the company is attempting to achieve.

But at this time of year, it is especially important to let your staff know where we succeeded together, where we might have failed and recognize the unexpected challenges we had to overcome.

The goal is to keep your staff informed, engaged and moving together toward a common goal. This of course requires a great deal of time and effort on your part in communicating directly with each employee.

You may want to reflect back on the great snowstorm that happen early in the year and how we all pulled together to meet the needs of our customers.

Perhaps there was a major piece of equipment that broke down and forced you to operate your laundry on a two-shift basis instead of just a one-shift operation.

Perhaps you introduced a new textile product to the laundry that required new handling procedures, new packaging procedures and a large amount of customer education.

Highlight these achievements, help people remember how strong teamwork helped you meet your goals.

In my laundry, we always tried to also celebrate our diversity. I had employees from over 10 different countries. Our ability to overcome language and cultural barriers to become a close working group was something we always celebrated.

We worked closely with our Muslim employees to make sure that their unique needs were met during Ramadan. We found ways to celebrate the wonderful opportunities found in our great country.

As part of our year-end celebration, we also explained our goals for the upcoming year.

We said this is what we think we need to achieve based on what we know might happen next year—but acknowledging that life happens and some of these goals will need to be changed to meet current challenges.

Thanking your employees, reflecting on the past year’s challenges and successes, and setting a roadmap for the future will result in a more dedicated, engaged and committed staff.

Eric Frederick served 44 years in laundry management before retiring and remains active in the industry as a laundry operations consultant. You can contact him by e-mail at elfrederick@cox.net, or by phone at 540-520-6288.

a whole by using the Evergreen Laundry model.

“(The Evergreen Laundry model … is one of the few, if not the only type of model, that purposes to create a viable business that employees receive the opportunity to have ownership in,” Jones says.

“Many underserved communities such as North Amarillo can be improved through ownership. This model allows that to happen.”

Puff Neigos, who is also on the NHLS Board, says the Amarillo Area Foundation initiated the operation by looking at how the anchor institutions could work together to prevent “economic leakage” in the Texas Panhandle.

“It became apparent very quickly that Amarillo did not have a laundry that was certified to adequately clean linens for medical organizations,” she says. “Each of the hospitals were sending their linens to laundries over 300 miles away.”

Once this was discovered, the foundation began researching how to keep the dollars and jobs local. Neigos says that’s when they learned about the Evergreen Cooperative Laundry, and it modeled how officials in Amarillo wanted their laundry to operate.

“As a worker-owned co-op, not only could the jobs and profits stay, but we could make a transformational difference for some of our neighbors by providing an opportunity to develop wealth,” she says.

“Our company is unique in the fact that it was created as a co-op, which will give the workers the ability to have ownership and input into the decisions that are made by the company,” agrees Jones.

“Bringing the jobs back to Amarillo was an important consideration in the decision to build NHLS,” adds Engler.

Leonard Cantly, production manager 1 for NHLS, says the company is unique in the laundry business because of its location.

“We are the only healthcaredesigned laundry in the area,” he says. “We have also spearheaded a culture change by hiring the hard to hire. Those who have only heard ‘no,’ we are saying, ‘yes.’”

Jones points out that another company could have set up a laundry, providing jobs for the community, but the profits would be funneled out somewhere else.

“This company will allow a significant amount of those profits to remain in the community and ideally help to create growth, build wealth and allow for the citizens of the community to have a hand up to change their lives for the better,” he shares.

“There are also a number of normally hard to employ individuals that our company will welcome in order to give them an opportunity to change their circumstance and get on the path to success.”

Neigos shares that Ted Howard with the Democracy Collaborative and the people at Evergreen were instrumental in helping North Heights Linen Service establish the laundry, providing valuable information that helped them avoid serious errors.

In addition to the opportunity for ownership, NHLS has added a classroom to the building for GED classes and college courses that will assist its employees going forward.

“Our partnership with Amarillo College and having a classroom within our facility for employee education is the first that I have seen in the industry and highlights our commitment to our coworkers’ growth and opportunity enhancement,” Engler says.

“One of the greatest benefits of this project has been how our community has pulled together to make this a successful endeavor,” Neigos shares. “All of our major community banks have joined to provide funding.

“In addition, our community foundation has chosen to invest

in the project along with the Amarillo Economic Development Corporation. The City of Amarillo sold NHLS the land at a reasonable price and gave favorable terms on an installment note.

“Finally, our higher education institutions, Amarillo College and West Texas A&M University, will be providing our classroom experiences. This is truly a communitybased collaboration that benefits the North Heights neighborhood, the local hospitals, the City of Amarillo and the people who live and work in the Texas Panhandle.”

North Heights Linen Service is housed in a 30,000-square-foot,

purpose-built facility, shares Art Jordan, plant manager.

It’s configured with a 10-module, 130-pound tunnel feeding three dryers, two 450-pound passthrough washers and two small conventional machines feeding four more dryers. The clean linen is discharged to two high-speed ironer lines, a blanket folder, a mini folder and two small-piece folders.

“This setup will produce up to 25,000 pounds of clean linen per eight-hour shift,” shares Jordan.

“On a five days a week, one shift schedule, we can process over 6 million pounds a year. This is all accomplished with our 20-25 laundry techs daily.”

Takeaway conveyors transport goods to a central packing and shipping area.

“The design of the facility allows for a second tunnel and dryer line, a fourth dryer on the existing line, another pass-through 450, clean and soiled rail, a third ironer, and additional small-piece folders,” Engler says. “The building can be expanded by a third on the existing property when needed.”

He adds that NHLS will apply for Healthcare Laundry Accreditation Council (HLAC) certification as well as the TRSA Hygienically Clean certification.

“We have experienced the normal challenges that any startup would face in terms of gaining additional clients,” says Jones. “Hiring the right people, specifically the right person to lead the laundry has been critical and that gives us confidence that success is imminent.”

Engler adds that overcoming the

obstacles of building and starting up during the pandemic was a greater challenge than expected.

“As everyone has experienced, many supply and logistics concerns arose while in process and underway,” he shares. “Adapting to extended delays and juggling of schedules to accommodate these continuing changes was the biggest success of the startup efforts.”

Cantly says that a great success of North Heights Linen Service is that during Amarillo’s 100-year existence, this is the first company on the north side of town that is geared for the workers needing workable hours for single parents, along with the local community college providing the training center within the facility that teaches finance courses and GED.

Jordan adds that another success has been the outpouring of support in the form of the overwhelming number of applicants at a time where most companies are struggling to find employees.

“This was achieved through our Board members’ tireless efforts in getting the word out about the laundry and ushering applicants to the website and the plant directly,” he says.

“I think that for the future, the company is going to experience significant growth that will ultimately force us to add additional space and equipment to service clients efficiently,” Jones says.

“I also believe that the success of the company is a preview to what is going to happen with the community and that within itself creates a sense of pride and accomplishment.”

Jeff Gardner, aka “The Laundry Doctor,” shut down his vended laundry of 19 years in order to expand commercial laundry services. Without interrupting service to existing wash/dry/fold and commercial customers, Gardner re-purposed the 3,500-square-foot building with Girbau Industrial laundry equipment, including a Compact+ 5-in-One Ironer. The Compact+ install allowed expansion into new markets. On the commercial side, The Laundry Doctor specializes in processing customer-owned goods for boutique hotels, vacation rentals, bars and restaurants. Meanwhile a small, linen-rental business serves clients including acupuncturists and massage therapists. “We cater to small business needs and alter our processes to benefit them,” said Gardner. “We take on the small guys that big commercial laundries just don’t service well.”

•

•

•

CHICAGO — As laundry and linen services look to move on from the effects of the pandemic, to grow their businesses, they are examining every process in their companies.

That includes their customer service processes.

Without excellent customer service, a laundry would struggle to survive, let alone thrive.

How can an operation evaluate its customer service experience, its overall customer service culture, to improve and grow?

American Laundry News spoke with Shep Hyken, a customer service and experience expert about how customer service has changed and what laundry and linen services can do to evaluate and improve their customer service cultures.

Hyken founded Shepard Presentations in 1983 and has worked with hundreds of clients ranging from Fortune 100-size organizations to companies with less than 50 employees. His articles have been read in hundreds of publications, and he is a New York Times and Wall Street Journal bestselling author.

What does excellent customer service in a business-to-business (B2B) setting look like to you?

I believe that the B2B customer has a mindset of a consumer. They are comparing experiences in the B2B world with the best experience they had from any company, and that’s typically going to be a business-to-consumer (B2C) experience.

Your B2B customers are now

comparing their experiences to what they get at Amazon. They love the speed of delivery. They love the information that Amazon continues to feed to them throughout the process, and they love the experience. If something goes wrong, how it gets fixed. And that’s what the standard is today.

Not long ago I was working with a healthcare organization, and they ordered a half a million dollar piece of X-ray or imaging equipment. They had to build out a specific room that had a certain size and a certain amount of electricity. There was a checklist of things they had to do to put this equipment in there, and the equipment showed up about two weeks early.

Normally people would be ecstatic to have their orders show up early, but when you’re building something out, it’s important to coordinate.

What the executive said to me

was fascinating. He said, “You know, I ordered toilet paper from Amazon, and they e-mailed to tell me it’s on its way. Why didn’t this company give us a heads up that piece of equipment was going to show up?”

I thought to myself, he’s just compared a half a million dollar X-ray machine to toilet paper.

That goes into my next question on how customer service has changed over the past few years.

What’s happened over the years is customers, in general, have become smarter and smarter about what great customer service looks like and feels like. Companies are advertising and saying they have great service. They’re going to give you the best experience, and that’s part of what the value proposition is.

What B2B vendors want to try to create is, instead of a vendor

relationship, they want to move into more of a partner relationship where they can help contribute to your success, where they’re tied to you emotionally the same as a consumer is tied to a brand for a number of reasons.

What’s happening is the perception of the importance of service has come up to the top, and customers are recognizing that more and more. I don’t care where I go. I can go to a high-end luxury store, or I can walk into a local drugstore, and both will tell me that they have great customer service.

So now we get to the big question: How can a laundry operation evaluate its customer service in terms of its customers, its employees, its vendors. How can it evaluate how it’s doing in terms of its customer service?

There are a number of measurements we want to look at,

these are the

net

The lifetime value of a customer is very, very important. I also want to look at the behavior of the customer. What is the cadence of a regular customer?

I realize in the B2B world, we have an advantage and a disadvantage, which is many times we have a finite number of customers that’s easy to manage versus a large company or brand in the consumer world.

They may have hundreds of thousands of customers, and all they can look at is general averages and look at trends they can spot a lot, and they can dissect it a number of ways. But with B2B, I could probably take a look at a list of my customers, and it’s not a

InkGo has been reformulated to remove its odor… and to improve its performance.

InkGo is still the environmentally friendly,* safe way to remove ink stains from all types of fabric. It’s still great at removing autoclave tape and adhesives. And since it’s odor-free, InkGo is more pleasant to work with.

Does odor really matter? As more drycleaners position themselves as good environmental stewards, keeping chemical odors in the plant to a minimum can help them differentiate from their competition. And odor-free is a real plus if you’re working on ink for an extended period of time.

Now that’s worth noticing!

*InkGo is Biodegradable and is California Prop-65 and California VOC Compliant.

Become a STAIN WIZARD at ALWilson.com

To learn more, visit ALWilson.com or call 800-526-1188 A. L. WILSON CHEMICAL CO.

daunting task. So, I think that’s a tremendous advantage.

And what we need to do is the same evaluation of how we’ve been doing. Are you happy with the service we provide; are we doing what we’re supposed to?

Two, are we staying in touch with you enough? If there’s a problem, are we responding quickly enough and resolving the issue to your complete and total satisfaction the gives you the confidence to want to keep doing business with us?

I want to know all of those metrics, but every one of those is a history lesson—it’s not what’s happening right now and going into the future. It will help me design what I need to give in the future, but it doesn’t tell me what’s really happening with my customer. What I need to also be looking at is the actual behavior.

The best way of looking at it is, I want to use the word “cadence.” What is the cadence of a repeat customer in my business? You need to start the renewal process before the contract is ever signed in the first place.

We want them to love us going into it, and we want them to keep loving us so they’ll never want to consider anyone else because they realize the risk they would put themselves at if they were to switch to a different vendor and not be happy. Because they are so happy now, that makes price a little less relevant when you can deliver the value.

So, what we want to do is look at the behavior of what a typical customer looks like. I’m going to give you an example that’s completely unrelated but I think is relatable. A CEO of a major organization shared this with me. His

business was hair salons, and I was hired to speak to thousands of managers and owners of hair salons across the U.S., and what I realized is he was recognizing the cadence of a repeat customer.

A person with a certain head of hair might come in once every four weeks where somebody who’s got curly, long hair and gets it colored comes in every three weeks, and somebody else may come in every six weeks.

Once you segment your customers and you understand what the routine of the repeat customer is, you can start to spot whether you have a true repeat customer or you have somebody that’s falling off, that’s not as consistent with their buying pattern, so you’ve got to go in fix that by

building the relationship, talking them about what you can do, etc.

You’ll also notice opportunities to grow that relationship and build trust with that relationship. That’s what you’re attempting to do.

Now, do not confuse this repeat pattern with loyalty. Loyalty is a different level of repeat business. You want the repeat business, and there’s nothing wrong with that. Don’t think I’m knocking repeat business. What I’m saying is that there’s a higher level and that is where your customer views you as a partner versus just the vendor that they’re buying from.

And so when you have a customer that is buying from you over and over in the cadence that you would consider a good repeat customer, don’t say that they’re a

loyal customer unless you know, are 100% sure that they’re loyal.

You need to understand the why behind their buying pattern, and once you do that, you’ll say, okay, they like us because we deliver quickly. They like us because our price is always the lowest. Well, that’s great—until somebody comes along and delivers faster and drops the price lower.

But if somebody says, I love them because their sales rep gets in and understands our business and they’ve been able to do all that we’ve done before, but we save money because of an idea they offered, now we’re getting into this partnership concept versus just being a vendor.

You’ll start to know you’re doing a good job when you start

to look at your metrics and you start to look at the behavior combined.

How about after you’ve evaluated your customer service and find it’s lacking? What kind of training do you recommend? How do you improve the customer service culture?

You just said the exact perfect word, “culture.” When you started the question, I thought you were going to ask how to train the people who are on the front line or dealing with vendors.

It’s not about just the front line. It’s about the culture of a company. You know, if everybody in the front line is amazing, but people inside aren’t okay, it’s eventually going to erode the overall experience.

I say customer service is not a department; it’s a philosophy to be embraced by everybody within an organization from the CEO all the way to the most recently hired, lowest-level type of employee that you have. Everybody’s got to be on board.

There are two ways to go about this. No. 1, when you bring on a brand-new employee, get them right into what your culture is. You’ve got to train them to that culture.

There’s some onboarding, but it takes more than that. No. 2, it takes a sustainability program. You’re going to bring it up again and again. Sometimes it’s weekly. Sometimes in some businesses, it’s daily, but it’s an ongoing reminder about service and experience, and we can put customer experience in that same category as well.

It’s philosophical, and the person behind the scenes who thinks that they don’t impact the customer needs to be shown how

they impact the customer.

My example is if you work for an airline and you work in the baggage department down underneath the airport. You see the bag come down the conveyor belt. You put it on a cart and it gets out to the airplane. If that customer, that passenger never sees their bag when they end up at the baggage carousel at their destination, I failed the customer.

I also failed an internal customer—the person who the passenger who’s upset, who can’t find their luggage, has to go and see in the baggage office. And nobody walks into that baggage office happy, right? And that person behind the baggage counter is going, “Why could the people just do their job and put the bag on the right plane?”

Everybody supports somebody internally, or part of a process, internally. They all have to be properly trained. I’m going to share with you a six-step process for creating a customer-focused culture, and it’s very simple. Simple doesn’t mean easy, but it’s simple to understand.

No. 1 is you have to define what customer experience, customer service, looks like to your organization. I suggest doing it in one sentence or less. Because if you do it right, and it’s that simple, everybody can remember it and it’s easy.

I’ll give you a great example. The Ritz Carlton has nine words: “We are ladies and gentlemen serving ladies and gentlemen.” They have 24 gold standards that drive that line, and when you come to work at the Ritz, part of your initial training are those 24 standards.

No. 2, communicate it over and over again all the time. Put it in front of everyone.

What the Ritz does for sustainability is every day, one of those gold standards is highlighted in their pre-shift meetings, meaning every shift, and that’s easy to do with the hotel industry, because it’s very shift focused. And the manager meets with the team and goes over one of those gold standards, and then everybody goes off to work, 24 days in a row.

At the end of the 24 days, they start over again. And at the end of the year, they estimate that the average employee at the Ritz will have heard this gold standard message, probably about nine to 10 times, which is really important for the sustainability and keeping that message right in front of them.

No. 3, everyone’s trained to it. No. 4, leadership has to be a role model. In other words, they have to treat the people they work with the way customers need to be treated or should be treated. They can’t be incongruent with their behavior.

No. 5 is leadership, management, supervisors, etc., need to be the ones who defend that culture. If they see someone or a department going out of alignment with

what that defining statement is that you do in step one, they need to get those people to move back into that alignment.

And, finally, No. 6, celebrate it when it works. If people are doing a good job, let them know they’re doing a good job. If the company overall is trying to create a better experience and you can measure this and say our net promoter score is 45 and we need to get it to 50. If we get it to 50, we’re going to have a pizza party, or whatever, and you hit that number, let everybody know. They’re all on the same team working for the

same goal.

Those are the six steps: Define it, communicate it, train to it, be the role model, defend it and celebrate it.

Do you have any final thoughts on customer service for the readers?

We need to unmake our B2B leadership mindset, understand that it’s not much different than B2C anymore. It used to be, but not anymore.

Something I’d like to add is if there’s one thing to remember is that in the B2B world if you lose a

customer, it’s not like a customer who walks into the mall. They could walk into the mall 12 times a year and there’s a hundred stores in there and they’re going to buy a T-shirt. They can go to your store, and if you don’t have the right size or what they are looking for in the right color, they just go to another store.

But that doesn’t mean they’re never going to come back to you. The next time they walk in the mall, they’ll probably stop by if they need the same thing and see if you have what it is that they want.

In the B2B world when you

lose a customer, it could be a long time. It could be an entire generation before you have a chance to go in and resell that customer that you lost. So, I think it’s really important to understand there’s a generational mistake that costs a company a fortune in the B2B world.

And when it comes to the choices that customers have in the B2B world, oftentimes it’s a much smaller group to choose from and once that customer chooses a company to work with, it’s a little bit harder than in the retail world to steal them away. ALN

sulting firms who shared their expertise on laundry equipment expansion.

Ken Arnopole, owner of Arnopole & Associates, a professional laundry design and consulting service specializing in the West Coast and Hawaii since 1979, shares about what a laundry needs to consider before even thinking about new equipment.

Then, Ted Barry, senior project manager for John Barry & Associates, founded in 1954, which has designed hundreds of square feet of small, medium and large laundry operations worldwide, looks at his firm’s steps toward maximizing productivity in the space available.

When it comes to determining the need to add laundry equipment and expand, information is key.

“First of all, it’s going to depend a little bit about is it linen supply? Is it garments? What kind of plant?”

Arnopole says. “Second of all, from a management point of view, it’s important that the plant itself know what it’s currently doing for the best optimization of what they have.

“And by that, I mean, a lot of the plants I go review, they don’t know how many pieces per hour each department does. They don’t have an objective point of view.”

As an example, he shares one instance where the son of the owner of a plant in Los Angles wanted a new building.

“He drove the BMW with

the personalized license plates,” Arnopole shares. “Dad started the company with one route at a time.

The young kid that wants to build the laundry that his dad doesn’t want to spend the money, but the kid wants the fancy place. Their focuses were different.”

As he worked on designing a new plant, going over square footage based on the company’s production needs, frustration set in.

The operation didn’t need a new facility; it needed to remodel its current plant, which could have doubled production.

“I believe an operator needs to have, first of all, the full knowledge of what their costs are,” says Arnopole. “What their space currently is using and why.

“There are a lot of things that should be looked at to make sure that they’re currently operating efficiently before buying another shirt press just get more shirts out or add another washing machine to the line.”

He says that’s one of the first questions he asks: Does the laundry really need new equipment, or is there something else that needs to be adjusted in the plant?

For example, say a laundry has five 200-pound washers in line, and the operation needs to increase from processing 1,000 pounds per hour to 1500 pounds per hour.

“Do you buy one 400-pound washer or get a little bit more out of one or two of what you have?”

Arnopole points out. “There are a lot of decisions that have to be made based on what your needs are.

“But now, if I do more wash, where do I put it when it comes out? Do I have the space on the floor to hold it prior to the next production step? And if I wash

more, am I going to be able to press more? Are my ironers going to be able to handle the extra production, or my folding machines, or my presses?

“So, it isn’t just a matter of how many pounds you put through the washroom. It’s how many pounds you put through the entire plant.”

Another factor to consider with equipment expansion is return on investment (ROI), Arnopole shares.

“You don’t want to spend $70,000 on a 400-pound tilting washing machine when you might be able to run your existing washroom for two more hours until the payback’s there,” he says. “It’s so

dependent on the actual operation.

“There are so many things to look at when it comes to increasing production within the facility. And No. 1, obviously, is make sure you’re producing enough and you’re at the limit before you spend your money.”

Arnopole recommends that laundry operations conduct a regular audit of its facilities, equipment and processes.

“Every five years or so, go through the plant; do an audit of everything,” he says. “Look at all the systems, all of them in an overall sense. What’s the age of the equipment? Do you need to replace it or not? How much water do you use? All of those factors work into production audits.”

Arnopole suggests using an outside, independent source to help with an audit and planning equipment expansion and then partnering with equipment suppliers, chemical providers, etc., to create the expansion solutions needed for the specific laundry operation.

“Get some good honest answers and get some good feedback,” he recommends. “That’s when they’re even considering expanding their equipment.”

Like Arnopole & Associates, John Barry & Associates puts in a solid effort increasing productivity of space, process, procedures, methods and overall throughput in the laundry operations it works with.

“When the JBA team looks at a laundry facility, we are looking at maximizing productivity within the square footage available,” Barry says. “When looking at advancing your laundry operation you might look at a ‘blank sheet of paper’ and think about how you would design your laundry facility in your ideal fashion.”

He says that the reality is that some laundry equipment can be costly to move, and JBA calls those “monuments”—equipment that likely won’t or can’t be moved.

“Much of the additional equipment has greater flexibility in placement and sequence,” Barry points out. “By starting with a ‘blank sheet of paper,’ you can define your ideal layout and reengineer your space to be close to your ideal layout while keeping in mind the ‘monuments.’”

The next step, he says, is to look at all of a laundry’s equipment and identify the current condition of each piece.

“In this case, look at which equipment has excessive maintenance requirement,” says Barry. “Some may be difficult to replace parts, and some that may no longer have knowledgeable personnel maintenance people available.”

The following step is to look at the equipment’s productivity and volume.

“In many cases, these may be newer equipment that’s faster and more efficient to operate and run,” says Barry. “In all cases, you want to look at replacement cost and return on investment as well as space requirements.”

In the overall analysis, he says laundry operations need to look at their volume by laundry type for effectively evaluating the layout, equipment and ideal processes.

“Look to the future and evaluate the volume by laundry type that you expect to provide over next three to five years,” Barry recommends.

“As you know, some of your equipment that was built well can be in operation for 25-35 years or more and still produce a high quality and efficient product.

“The key is to look carefully at the volume required by laundry item and adjust your equipment layout and process to meet your changing needs.”

WASHINGTON — The U.S. Department of Labor’s Occupational Safety and Health Administration (OSHA) reports it has issued a new emergency temporary standard (ETS) designed to protect workers from contracting COVID-19 on the job.

Under this standard, certain employers must develop, implement and enforce a mandatory COVID-19 vaccination policy, unless they adopt a policy requiring employees to choose to either be vaccinated or undergo regular COVID-19 testing and wear a face covering at work.

Employers must comply with most requirements by Dec. 4 and with testing requirements by Jan. 3, 2022.

The ETS covers employers with 100 or more employees—either at the firm or companywide—and provides options for compliance. It also requires employers to provide paid time to workers to get vaccinated and to allow for paid leave to recover from any side effects.

The ETS is estimated to cover more than 84 million workers in the United States—about twothirds of the nation’s private-sector workforce.

“COVID-19 has had a devastating impact on workers, and we continue to see dangerous levels of cases,” says U.S. Labor Secretary Marty Walsh. “We must take action to implement this emergency temporary standard to contain the virus and protect people in the workplace against the grave danger of COVID-19.

“Many businesses understand the benefits of having their workers vaccinated against COVID-19, and we expect many will be pleased to see this OSHA rule go into effect.”

The ETS requires companies with 100 or more employees to: Determine the vaccination status of each employee, obtain acceptable proof of vaccination status from vaccinated employees, and maintain records and a roster of each employee’s vaccination status.

• Require employees to provide prompt notice when they test positive for COVID-19 or receive a COVID-19 diagnosis. Employers must then remove the employee from the workplace, regardless of vaccination status; employers must not allow them to return to work until they meet required criteria.

• Ensure each worker who is not fully vaccinated is tested for COVID-19 at least weekly (if the worker is in the workplace at least once a week) or within seven days before returning to work (if the worker is away from the workplace for a week

or longer).

Ensure that, in most circumstances, each employee who has not been fully vaccinated wears a face covering when indoors or when occupying a vehicle with another person for work purposes.

OSHA notes that this ETS does not require employers to pay for

testing, although employers may be required to pay for testing to comply with other laws, regulations, collective bargaining agreements or other collectively negotiated agreements. Employers are also not required to pay for face coverings.

“While vaccination remains the most effective and efficient defense against COVID-19, this emergency

temporary standard will protect all workers, including those who remain unvaccinated, by requiring regular testing and the use of face coverings by unvaccinated workers to prevent the spread of the virus,” says Jim Frederick, deputy assistant secretary of Labor for Occupational Safety and Health.

For more information about

the ETS and compliance assistance available to businesses, OSHA has posted a webinar (https://www.youtube.com/watch?v=ixxkn3Y8z6g), along with compliance materials (https://www.osha.gov/coronavirus/ets2) and a directory of frequently asked questions (https:// www.osha.gov/coronavirus/ets2/ faqs). ALN

•

•

•

•

•

•

•

The past two years have been very hard on businesses, employees, and owners.

If you are reading this article, I certainly don’t have to tell you that. Laundries in all segments from rental to OPL to healthcare were affected in some way.

But the good news is there is light at the end of the tunnel. The world is slowly “returning to normal” and during some recent trips, I had the chance to speak with several people within our industry and got a sense of excitement from them about what lies ahead.

As more establishments open, it creates more and more opportunities. In order to take advantage of the everchanging business environment, here are a few suggestions that might just help energize your business for growth.

Consider completing a digital transformation strategy by removing old, antiquated processes, like paper invoicing, filing, etc., and help your employees do more, more efficiently.

Businesses of all types were transitioning to the cloud before 2020, but the pandemic seemed to have slowed that trend. For most of the past year, developments like the rise of working remotely and virtual communication have been at the center of most companies’ business strategies. The future is all but certain to be one that is online.

Examine your laundry systems, washers, dispensing equipment, and controls. A move to more automated systems can help your business become much more efficient and profitable by saving you on costly expenses in the long run.

Equipment manufacturers of all types are producing IoT (Internet of Things) connected and enabled devices that provide proactive alerts, reminders and updates. Many of these solutions also provide valuable data and analytics related to your operation and organization.

This information can help with

items like employee performance, turn times, inventory control, and chemical spend, just to name a few. The information should be used to improve efficiencies; save on resources like water, gas and labor; and prevent wasteful spending.

And finally, think about adding additional products and services to existing routes and making them available on your business website.

Often, daily route operators will service customers at businesses who need cleaning supplies and tools, bottles, buckets, chemicals, dispensers, etc. These businesses also use hand soaps, sanitizers, paper goods, carryout containers and utensils, rubber gloves, etc.

If you are already stopping there, consider offering some of these items to improve route profitability. Keep in mind that there could be some safety measures to consider when handling certain chemical products, but overall, getting creative about what you offer on routes can provide additional revenue sources and build customer loyalty.

Creating a business strategy around technology upgrades, cloud-based programs, automated tools and increased service offerings can improve the outlook of strong growth for companies competing in the commercial

laundry industry in 2022.

Good luck and I wish everyone a wonderful Holiday Season and a terrific start to the New Year!

121 all-inclusive. We really didn’t need 165.

This is a demonstration of how knowledgeable employees can allow you to do more with less.

Additionally, fully trained and experienced employees train and influence new employees. Also during COVID it has been more important than ever to explain that the work employees are doing is saving lives. Their work is important to all the work that is going on in the healthcare systems they and their families use.

From 2019-2021, laundry services have experienced some challenges and obstacles, but during this time, we have become acutely aware of key issues that require attention.

We have always been aware of potential risks in laundry because of so many pathogens that are infectious. The fact that the coronavirus made us look at risk a little bit more in-depth and through a different lens was frightening but provided some opportunity to look at safety practices. It helps us maintain safety and security amongst staff, patients, guests and residents, which is a priority and goal in hospitals, healthcare settings and hotels.

I believe the focus should be on two things: retention of current employees and planning of product needs in your supply chain.

Turnover and loss of employees truly raised its ugly head during the COVID-19 pandemic. We as a world and industry went from laying employees off to begging them to come back. Nevertheless, many employers kept their employees at risk to their longterm existence.

In the end, it has come back to keeping employees. I recently attended the TRSA Annual Conference and I was hit by a presentation by Dick Finnegan talking about turnover and retention.

My worst experience with turnover was when I did a startup of a healthcare laundry in 2006. At one point we had more than 165 employees only to settle in at

Regarding product needs, I am repeating myself from past articles when I say forecast, forecast, forecast. Working for Standard Textile, I can’t tell you enough how forecasting assists us in serving customers well regardless of the times.

After 18 months of COVID, I believe all of us should be forecast proponents. And it is not just textile needs but parts for equipment. Lead times for all goods have increased.

You must be ready when the new business avails itself. If you are not taking care of the customer business you currently have, how will you be able to bring on more business properly and successfully?

We are not a minimalist business; we are in the service industry. Thus, we are not just trying to get by, we are trying to excel! Thus, I believe it is about being

Awareness will be a key area of focus for the laundry team in 2022 as well as re-establishing the operational aspect of service that is provided to our patients, guests and residents.

Incorporating additional training that is focused on best practices in the industry is another area of focus and an opportunity to follow industry standards. Now that we know what new pathogens are present and the risk of other potential pathogens in the future, we are positioned to enhance our training efforts to address these risks.

There are many programs that offer certifications in laundry to strengthen your team. The Association for Linen Management (ALM) has many great courses on linen management, infection prevention, and many webinars and e-Learning opportunities for continued education for all laundry staff.

TRSA has a Hygienically Clean

“The past two years have, basically, been about survival. What should my laundry focus on to move beyond survival and help achieve growth in 2022?”

ready and being ready means committing yourself to taking care of the employees you have and committing your efforts to increased planning for all your laundry needs. It is fundamental and necessary. Take care!Long-Term Care Laundry Monique C. Walker Vi at Grayhawk, Scottsdale, Ariz. Textiles Cecil B. Lee Standard Textile, Cincinnati, Ohio Chemicals Supply Campbell Dodson Lavo Solutions LLC, Cincinnati, Ohio (Image licensed by Ingram Publishing)

Healthcare certification. TRSA can help you in maintaining hygienically clean healthcare standards, accreditation and TRSA Hygienically Clean certification.

The certification is an affirmation that your organization is dedicated to infection prevention, compliant with industry standards and the processing of healthcare textiles with best management practices.

These courses and certifications will help the laundry staff to be prepared for current and future challenges in laundry and achieve growth in 2022.

of the year, recovery will be difficult, and you might make some very bad decisions due to stress, particularly on the sales/income/ revenue side of the business and then everything is uphill from there. Specifically:

Search for Free Rental Revenue—Do you have billing errors? How many times have I seen a $3.00 mat being charged out at $.30? This $2.70 “misbilling” equals $140.40 in annualized billing.

I recommend that you do this by printing a separate set of invoices and doing a scan of every line looking for inconsistencies. Incentivize the people reviewing the invoices. A $50 gift certificate for every $50 found in errors gives you a return of $2,550 when annualized.

profile in your route accounting system.

Maybe you are simply afraid to enforce the terms of the agreement as this guy might quit. People who lose, damage or abuse merchandise are the anchors that weigh on your profits. Why rake someone over the coals with loss charges to offset the non-paying customer?

The bottom line is you will maintain the non-paying customer and ultimately lose the over-paying customer. This is a recipe for disaster.

Managing Expenses, Not Cutting Expenses—Do you have a professionally calculated budget? If no, develop one.

excluded).

Google “ROI” and there will be many examples of how to perform this function or reach out to me.

Capital expenses can run up to six figures, and not having a process in place to find the best deal, with the best returns, by the best vendors is squandering at best.

same square footage of my laundry without sacrificing quality?”

Happy late autumn ALN readers!

Let me start by saying that you cannot let the holidays lull you to sleep. Enjoy the family and festivities, but, especially those of you starting fiscal 2022 come January 1, you must get your business off to a strong start.

If you falter at the beginning

If something looks “way off,” then go to the current service agreement and do the math. I have had audits in large operations that have generated $2,800 in additional justifiable revenue. Doing the math once again, you have just generated $145,600 with no associated merchandise, labor, or utility cost. I should just say no associated cost.

Search for Free Loss/Damage/ Abuse Charge Revenue—Are you not billing losses for a customer? It could be as simple as a missing check box in your customer’s

To take last year’s numbers and lower expenses by 5% and raise sales by 5% is not budgeting. You must analyze the market and your vendors. It is a waste of time and will lead to frustration on your team.

This is a top-down approach and never ultimately works. Think bottom-up and empower your teammates to contribute. They, believe it or not, know more about their processes than you do, or I do.

Capital Expenses—Include your team in your capital expense (Capex) planning. You must perform a return on investment (ROI) on each capital project (government mandates probably

In closing, you may note that I focused more on sales/income/ revenue than expenses in this article. The reason is simple: All success starts with a growing top line! Growth and expenses are somewhat easy to manage and will lead to greater profits and give you, the valued leadership team, more money to reinvest in people, processes and performance.

Merry Christmas and Happy New Year!

Automating some of the production areas of your laundry may be the answer for growth by increasing the production capability of your facility and the efficiency of your operators. There are several areas in the laundry to consider automating:

1. Washing and drying. If your laundry is needing to produce over 1,000 pounds per hour and uses conventional-style washers and dryers, it may be feasible to look at automating this process with a small CBW™ Tunnel System or Automated Washer/ Dryer and Shuttle System.

An automated tunnel system will streamline your plant’s production, reduce labor and utility costs, and allow your laundry to grow by increasing your production capacity. In many cases, an automated system uses less floor space than a conventional system.

2. Soil Linen Sorting and Rail System. These areas are often overlooked to reduce production costs and increase throughput. An automated sort on rail system can increase the production of your soil sorting operators by 30-50% and allow your laundry to sort

A key question in considering growth is, “How can I efficiently produce more linen in the

PHILADELPHIA — Aramark CEO John Zillmer reports that Kim Scott has been named as president and CEO of Aramark Uniform Services, effective immediately.

In her new role, Scott will become a member of the company’s Executive Leadership Team, reporting directly to Zillmer, and will oversee the company’s nearly 20,000 employees who serve approximately 400,000 customers providing uniform, laundry and allied services.

Brad Drummond, who announced his retirement from the company at the end of the year, will serve as an executive advisor during his transition.

“Kim is a growth-oriented executive with extensive commercial experience closely related to our business model,” Zillmer says. “Her pragmatic leadership and strategic thinking will help accelerate our profitable growth while enhancing our employee and customer experience.

“As we focus on growth and better alignment within the industries we serve, we are confident that under Kim’s leadership the business will reach new heights of performance success.”

“I am excited about the opportunity to lead this team of dedicated associates,” Scott says. “Together we will drive profitable growth in the business, creating opportunities for our people and delivering exceptional service for our customers.

“Building on our strong track record of success, our innovative thinking and our deep consumer insights, Aramark Uniform Services will be well-positioned for future success.”

The company says Scott brings more than 26 years of experience to her new role. A graduate of Auburn University, she has an extensive commercial background leading large, dispersed workforces in route-based distribution businesses.

She brings deep experience in strategic and plant operations, logistics, engineering, procurement and M&A. Before her most recent role as chief operating officer of Terminix Global Holdings Inc., Scott held key leadership roles including president of Rubicon Global Holdings.

During her 11-year career

at Brambles Limited, she rose through the ranks from manager, strategic operations, CHEP USA, to president, CHEP North America.

Her early career was spent with the United States Steel Corp. and the General Electric Co., where she held positions in environmental engineering, procurement, and health and safety.

INDIANAPOLIS — Edward McCauley, president and CEO of United Hospital Services (UHS), located here, reports that he has promoted Jason Hartsell to vice president of operations and Lifang Zhu to vice president of finance.

“As UHS continues to grow, we are happy to have such capable people to fill the roles of these two important positions,” he says.

Hartsell has worked at UHS for more than 17 years and in nearly every department. He has worked in maintenance, IT, customer service and most recently as director of operations.

He also served in the Army and retired after 14 years with the rank of captain.

Hartsell graduated from Indiana University with a bachelor’s degree in political science and Indiana Wesleyan University with an MBA.

He is also active in the industry serving on the Board of Directors as treasurer for the Association for Linen Management (ALM).

Zhu has been the controller at UHS for the past 14 years. She emigrated from Hangzhou, China, where she was an office director for many years. Zhu has the Chinese equivalent of a bachelor’s degree in archival services and a master’s degree in financial and economic management from Hangzhou University.

manufacturer G.A. Braun, reports that Dave Clark, vice president of aftermarket operations/ customer

service has retired after 24 years of dedicated service to the company.

Clark’s successor, Sandro Bortoloni, has been promoted to the position of director of aftermarket operations.

Also, Gary Ostrum, executive vice president of global sales and marketing shares that Ray Burke has been promoted to vice president of sales, U.S. and Canada.

Throughout his career with Braun, Clark successfully led his team of field service technicians, service support help desk and replacement parts programs to the highest levels in the industry, the company says. He was also instrumental in the development of Braun’s Certified Remanufactured Equipment Program.

“We wish Dave much welldeserved relaxation and time with his family as he embarks on the next chapter of his life and thank him for 24 years of dedication to team Braun,” says Werner. “We also congratulate Sandro on his promotion and are extremely confident that with his leadership he will complement our strategic business pursuits well into the future.”

Bortoloni joined G. A. Braun in 1996. Through the years due to his hard work and dedication, the company says he was promoted to many positions with his last being field service manager.

Bortoloni holds a Bachelor of

Science in operations management and obtained a Six Sigma Black Belt Certification, as well as many other certifications.

Burke has been in the laundry industry for 42 years and is actively involved in several laundry industry associations. For the past 15 years, he held the position of West Coast regional sales manager.

Canadian markets.

“Ray is a respected industry veteran and has a strong background in laundry facility management, strategic sales planning and business analysis,” Ostrum says.

“In his new role, we are confident Ray will help to further strengthen our commitment to our U.S. and Canadian client base by providing exceptional customer support.”

OSHKOSH, Wis. — Girbau North America (GNA) recently welcomed Melissa Kuhn as digital marketing manager.

Kuhn, of Stockbridge, Wisconsin, brings more than nine years of marketing and digital marketing experience to the company. In her new role, she plans and executes GNA’s digital marketing and advertising strategies and social media campaigns.

“GNA has grown considerably over the years in terms of its brands, products and staff,” says Director of Marketing Communications Tari Albright. “This is the company’s first dedicated digital marketing management position and we are happy Melissa is at its helm. Her highlevel skills and positive attitude perfectly fit our productive company culture.”

Prior to joining GNA, Kuhn served four years as marketing manager for Optima Machinery Corp., in Green Bay, where she managed marketing strategy, budget and communications; created and led advertising, public relations and digital marketing campaigns; and worked closely with a diverse sales team.

Prior to that, she served five years as marketing associate for The Boldt Co., in Appleton, Wis. A 2011 graduate of University of Wisconsin Oshkosh, Kuhn holds a bachelor’s degree in English/ journalism.

campaigns, among other digital marketing efforts,” Kuhn says. “I have a passion for digital marketing and am looking forward to putting my experience to good use in my new role.”

MINNEAPOLIS — Kannegiesser ETECH reports that Larry Erickson is joining its executive leadership team as chief technology officer.

“As our industry progresses further in the path of increasing automation, it is critical to have the vision of where technology is going at the leadership level,” says Phil Hart, president and CEO.

“That is why we are incredibly fortunate to have Larry join our leadership team at Kannegiesser ETECH. His experience in developing both new technologies and building successful teams to implement these technologies will be a welcome voice as we plan for the near term as well as long term future.”

Erickson started his laundry career in 2004 with ETECH as a programmer and since has grown into a strong manager, coach and leader, the company says. He has most recently been leading the eVue Software and Controls Team.

He has also been integral to the success in many other areas such as IT, customer support, projects, sales, and global integrations with many teams within Kannegiesser.

“Utilizing technology to advance the laundry industry forward and improve our internal operations has been a passion of mine for the last 17 years,” says Erickson. “Being a part of the leadership team will help me gain a new understanding of the business so that I can help create our long-term technology vision and strategy.”

SYRACUSE, N.Y. — J.B. Werner, CEO and Chairman of the Board for laundry equipment

The company says Burke’s dedication to the industry, vast knowledge of plant operations and strategic planning will enhance its customer support in the U.S. and

“I am excited to really shape the digital marketing strategy for GNA and will be focusing on growing our social media following, targeted e-mail marketing, and digital inbound marketing

COLUMBIA, S.C. — Folder, feeder, stacker manufacturer Foltex reports that Mark Simoneau has joined its team as director of technical support.

“Mark’s background in indus-

Clark retires from G.A. Braun, two promoted

more linen using fewer operators.

Automatically loading washerextractors or tunnel systems will increase your equipment’s production while reducing labor requirements. Overhead rail systems can also increase the capacity of your facility by utilizing the entire horizontal and vertical footprints of your laundry.

3. Clean Linen Processing. There are several equipment solutions that can be used to enhance the production efficiencies of your clean linen processing.

Automated/Sorting Small Piece Folders; Automated Sheet Separating Systems; Corner-less Automatic Spreader Feeders for processing sheets, table linen and blankets; clean sling rail delivery systems; clean accumulation conveyors; and Self-Contained Thermal Ironing Systems are a few solutions that may be right for your laundry. All these products can enhance your production capabilities allowing your laundry to produce more linen with fewer employees.

In addition to the use of automation for growth, you should also consider ways to reduce your operating cost to maintain your competitive edge.

The mechanical room presents great opportunities for capturing savings. Wastewater reuse and heat reclamation systems, boiler stack economizers, condensate return vent condensers are a few examples of ways to reuse your laundry’s energy to produce heated water for your facility.

One of my favorite quotes is, “The only way to grow is to accept change.” Exploring opportunities to efficiently increase production while reducing operating costs is a great way to achieve growth and increase profits.

production/customer needs as we entered Q4. We have been receiving outstanding linen orders as well which has helped with our inventories.

We have used the time to perform preventative maintenance on much of our equipment. We have cleaned up and eliminated items offered so that we can better manage our production schedule. We are almost fully staffed, and 98% of our employees are vaccinated.

With all of this in mind, we are excited to think about growth in 2022.

are excited about the prospects for the new year and feel ready to grow effectively and efficiently.

It is hard to believe that this article is for the December publication; what a year it has been. I have enjoyed the opportunity to participate in this panel, and I hope that I have provided some insights. I know that I have gained much knowledge from the other panelists and the entire industry.

Cheers to all—wishing loads of growth for our industry as we move into 2022!

the normal 2-3% cost-of-living adjustment (COLA).

Pay extra attention to capital purchase return on investment (ROI) for equipment that can give you additional capacity and save you labor dollars. Ask for ROIs from anyone you anticipate purchasing equipment from and put that burden on them. A good salesperson can, and will, jump right in and show you the value of their equipment.

Finally, don’t overlook the sales budget:

Laundries are now beginning to have a moment to pay attention to its quality of linen, which is of great concern to all customers. It’s time to invest again with customers for feedback on linen initiatives.

I’m hoping laundries will now also have some time to value the hard work of their employees as well. Over this two-year period, all businesses suffered shortages. This required extra attention from the remaining staff.

Thank you for letting me share this year.

When we think back to 2019 sales volume and customer demands, we get a bit anxious and overwhelmed. In order to support those large dollar amounts and demands, we were working seven days a week and had over 100 employees.

In March 2020, we were forced to downsize dramatically, and we have been very strategic and creative with re-building our business during the past six months. We are focused on services and customers who we can take care of and who are solid partners. We know now what we do well and how much laundry we can handle and how much laundry we want to handle!

Looking toward growth, we will focus on specific service areas where we can build our current routes and offer a limited line of specialty napkins that we know that we can wash and process.

And we have learned that is okay to say “no” to potential business for valid reasons.

I love this question, and it is such a timely topic as 2021 is winding down. We finally feel as if we have settled into our sales/

We are encouraged by new restaurants opening in our region and old customers re-opening with increased linen orders. We

1. Find out what capacity you have available in your plant production and …

2. Contact anyone and everyone in your market and find out who’s looking and get their details.

3. Review and then categorize these into three columns: Must Have, May Take and Pass.

ongratulations! If you’re reading this article and planning for 2022, then take a moment to appreciate that you’ve survived a challenge and are ready to look forward.

Moving forward will not be easy; however, there are some things you can do to ensure continued success and future growth.

The competition has, in most cases, been thinned out. The strong have survived, and it’s time to feed and recuperate.

This year more than most, I’d make sure that budget is tight, labor is realistic to include overtime you may be incurring due to staffing shortages, and leave something extra in utilities and transportation, as these costs seem to be increasing beyond

4. Get as many of your Must Have’s before moving on to the May Take and avoid the Pass altogether … now is not the time for more risk.

If you fill the plant with your Must Haves, then stop for now. If you go to the May Take column, remember that they’re in there for a reason … you can still pass if have any doubts. You’ve been steadfast and wise to survive the past few years, so trust your instincts and you’ll do fine.

Finally, it has been my pleasure to share some of the experience I’ve gained from operating plants and selling equipment for nearly 20 years for Paris Companies and G.A. Braun Inc. The year 2022 can be a growth year for you, and I look forward to seeing your successes when I’m out there on the road!

ALN

ALN

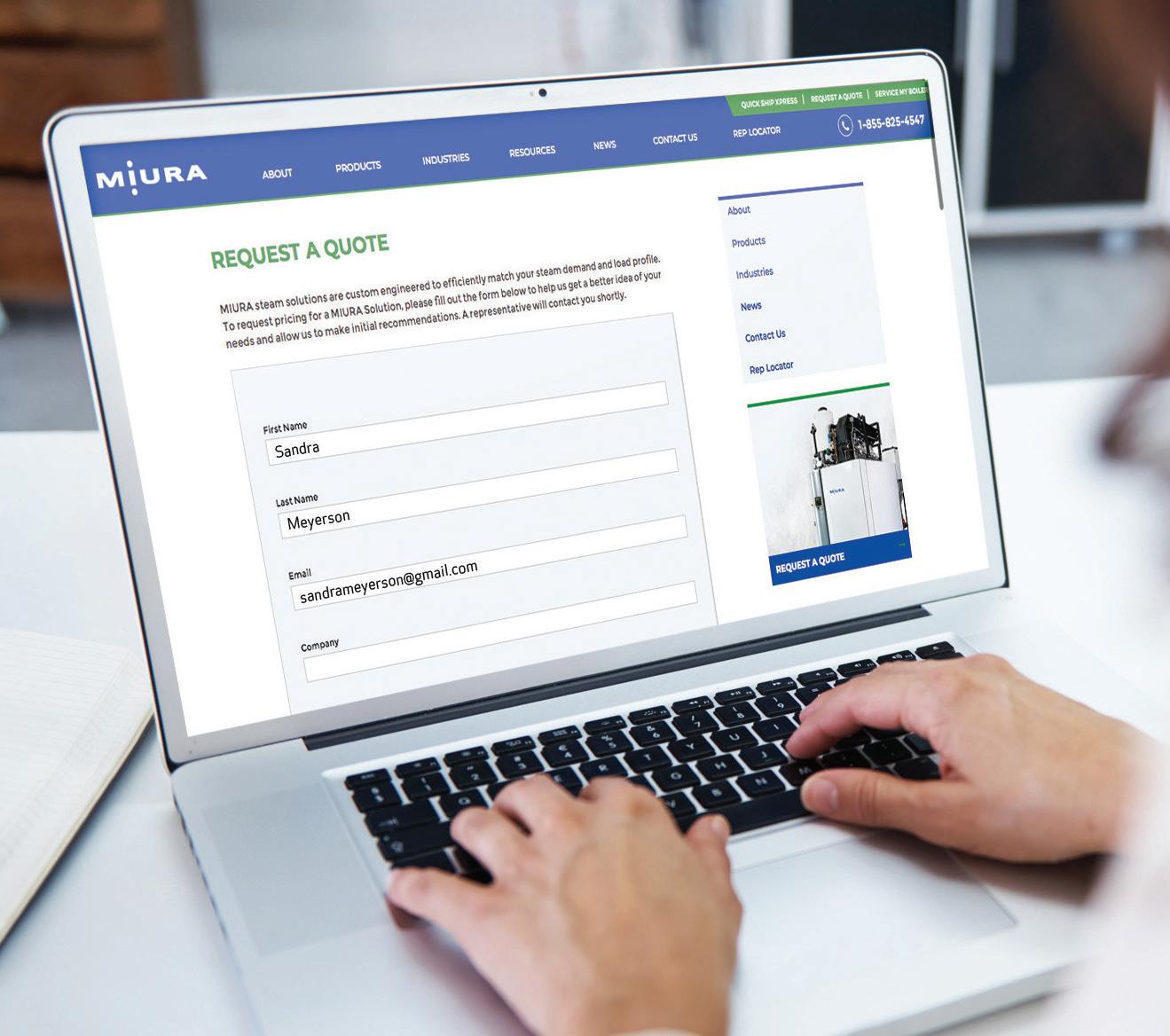

Miura, which designs and manufactures modular, on-demand steam solutions made in America, says it has taken monitoring connected equipment to the next level with Miura Connect.

The company says its new real-time, remote view web-based portal puts system health tracking, scheduled report generation and optimal system reliability scheduling in the hands and pockets of boiler room operators.