Late News

JENSEN-GROUP reports revenue increase for 2021

BURGDORF, Switzerland — Laundry equipment manufacturer JENSEN-GROUP reports a revenue of $286 million U.S. for 2021, an increase of 6% compared with 2020, as well as an order intake of $380 million U.S.

“High order intake and a doubling of net profit in 2021—this success in the new normal reaffirms our strategy of having local representation in all major markets and maintaining all in-person points of sale and service with our worldwide customer base,” says Jesper Munch Jensen, CEO.

Given the overall level of activity and the difficulties the world faced in 2021 due to the COVID-19 pandemic, the Group is very satisfied with the 2021 results.

The COVID-19 limitations imposed on tourism and travel particularly affect the Group’s level of activities in the hospitality business as many customers continue to reduce or close down parts of their operations.

Most of the recovery in the healthcare and industrial laundry industries was made in Europe and North America. ALN

Personal customer service laundry access

BY MATT POE, EDITOR

BY MATT POE, EDITOR

PANGBURN, Ark. — As one of the only family-owned and operated laundry businesses in the state, the focus of HMT Industrial Laundry has and always will be on personal customer service.

“A key difference between our company and our competitors is that our customers have our personal cell numbers and are encouraged to call when they need anything—we’ve delivered on weekends, holidays, bad weather, you name it, and we’re there when you need us,” says owner Brad Watlington.

He says this type of service inspires loyalty from HMT’s customers. In the almost 20 years the company has been in business, it has experienced a remarkable less than 2% customer turnover.

“Our customers have watched our three boys grow from toddlers to teenagers; they personally know us and we know them,” shares Brad.

“Once a business becomes our customer,

they become part of our customer family and we show them how much we value them.”

HMT serves businesses that need rugs, towels, linens and uniforms, including hotels, medical facilities, restaurants, gas stations, schools, colleges and manufacturers.

“While we specialize in smaller to mid-size

Moving from customer-owned goods to rental services

BY MATT POE, EDITOR

CHICAGO — Linen rental is advantageous for both laundry services and their customers.

Healthcare providers have been moving toward rental for some time while hospitality customers still like the branding options of owning the goods. But how has the pandemic affected customers’ attitudes toward customer-owned goods (COG) and rental? And what does it mean for laundry operations?

American Laundry News reached out to the Healthcare Linen Alliance (HLA), the American Reusable Textile Association (ARTA), the Association for Linen Management (ALM), and TRSA, the association for linen, uniform and facility services, to find out what their laundry and linen service

Laundries and Distributors

Three reps share ways for laundry operators and distributors to work better together.

Panel of Experts

In this issue, the experts share strategies to handle today’s laundry labor demands.

businesses, we also service larger, Arkansasbased companies that appreciate the personal service we can provide them,” adds Brad.

APRIL 2022

HMT Industrial Laundry was started by Brad and his father, Gary, in April 2003.

www.americanlaundrynews.com INSIDE [10]

The Newspaper of Record for Laundry & Linen Management

[12]

Volume 48, Number 4 [14] See HMT on Page 6

The pandemic accelerated a healthcare shift from COG to rental goods; hospitality is a work in progress

See GOODS on Page 8

PRODUCT SHOWCASE

HMT Industrial Laundry in Arkansas prides itself on service that inspires loyalty

HMT Industrial Laundry owners Brad Watlington (left) and his father, Gary. (Photo: HMT Industrial Laundry)

(Image licensed by Ingram Image)

Tunnel Washers

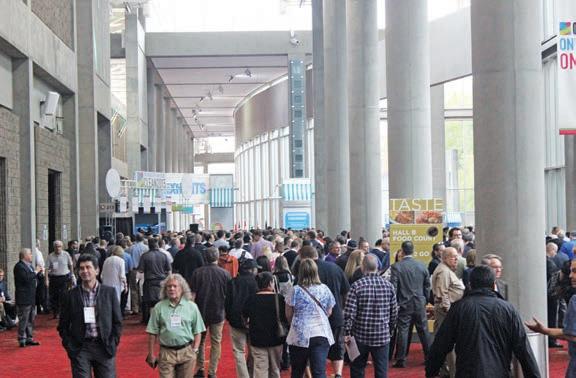

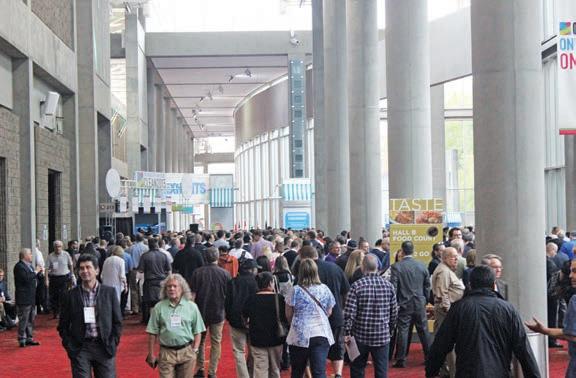

Registration open for Clean 2022

ATLANTA — Registration for The Clean Show 2022, the largest event in the United States for the laundering, dry cleaning, textile care services, supplies and equipment industry, is officially open, according to show organizer Messe Frankfurt.

The show was originally scheduled for 2021 but had to be delayed due to the pandemic.

The four-day event, held in Atlanta at the Georgia World Congress Center, July 30 to Aug. 2, will bring together thousands of industry professionals from all across the globe to conduct new business and discover the latest product developments, technology, and more.

REGISTRATION

INFORMATION

The 2022 edition will feature live demonstrations, networking opportunities and educational sessions where industry experts will share the latest technological advancements hitting the industry, trend predictions, strategies to grow and expand into new markets, and insights on how to stay ahead of the competition.

Attendee information can be found on The Clean Show’s website, along with a direct link to the registration portal. Within the Planning & Preparation section (https://theclean-show.us.messefrankfurt.com/ us/en/planning-preparation.html),

attendees can obtain detailed information about the show date and hours, venue, registration prices and deadlines, housing, and tips to explore Atlanta.

Visitor pricing is as follows:

• Member: $119 (through June 29, 2022).

• Non-member: $149 (through June 29, 2022).

• Onsite: $169 (Beginning on June 30, 2022).

EXHIBITOR OPPORTUNITIES

During The Clean Show, Messe Frankfurt says exhibitors have the unique opportunity to showcase their products and latest innovations, discover new business opportunities and establish new strategic partnerships.

The show floor features hundreds of exhibiting companies representing a diverse group of providers of products, supplies, and services to the laundering, dry cleaning, textile care services, supplies and equipment industry.

“The Clean Show has proven to be the ideal exposition for industry leaders to find the latest innovations in textile care, ranging from industrial machinery and conveyor equipment to computer software and business systems,” says Greg Jira, show director.

“The show offers a great opportunity for exhibitors and visitors to learn how the various products and services can help their businesses to thrive in today’s highly competitive market. We can’t wait to host the show this year.”

Companies can find more information on The Clean Show’s website through the Information for Exhibitors page (https://theclean-show.us.messefrankfurt. com/us/en/planning-preparation/ InformationForExhibitors.html ). They can view the floorplan and download a space application, review sponsorship opportunities for additional exposure, explore

rules and regulations, and more.

The Clean Show still has exhibition opportunities available, but space is almost sold out. Companies interested in reserving a booth should contact Jewell.Kowzan@usa. messefrankfurt.com as soon as possible.

The Clean Show is organized in collaboration with five industryleading associations: Association for Linen Management (ALM), Coin Laundry Association (CLA), Dry-cleaning & Laundry Institute (DLI), Textile Care Allied Trades Association (TCATA), and TRSA, the association for linen, uniform and facility services. ALN

Publisher

Charles Thompson

Phone: 312-361-1680

E-Mail: cthompson@ ATMags.com

Associate Publisher/ National Sales Director

Donald Feinstein

Phone: 312-361-1682

E-Mail: dfeinstein@ ATMags.com

Editorial Director

Bruce Beggs

Phone: 312-361-1683

E-Mail: bbeggs@ ATMags.com

Editor

Matt Poe

Phone: 866-942-5694

E-Mail: mpoe@ ATMags.com

Production Manager

Mathew Pawlak

Digital Media Director

Nathan Frerichs

Phone: 312-361-1681

E-Mail: nfrerichs@ ATMags.com

Advisory Board

David

Barbe

Janice Ayers Davis • Nick Fertig

Deana Griffin • Cecil Lee Edward McCauley Jim Slatcher

Main Phone: 312-361-1700 Fax: 312-361-1685

Subscriptions

847-504-8175 ALN@Omeda.com www.americanlaundrynews.com

NORTHFIELD, Ill. — Healthcare textile provider Medline reports it has entered into a partnership with

North Heights Linen Service, a fullservice healthcare laundry processing facility in Amarillo, Texas, to

provide access to its Ready-to-Use pre-washed and pre-packaged linens to health systems across the country.

To kick off the partnership, Medline also worked directly with North Heights Linen Service to set up operations in its new healthcare laundry plant, which opened in June 2021.

Medline says its Ready-to-Use pre-laundered and pre-packaged linens undergo a rigorous sanitizing and handling process and are critical in supporting healthcare workers as a more efficient and timely solution during emergency and labor-constrained circumstances.

The pre-laundered sheets, blankets, towels, washcloths and patient gowns are ready for immediate use, skipping the processing step required for new product injections.

Being processed in the Texas Panhandle, local communities benefit tremendously, given the history of the lack of healthcare laundry processing facilities in the nearby area and the region’s susceptibility to weather-related events, in addition to health systems nationally, according to Medline.

“Medline couldn’t be more excited with the development and launch of the Ready-to-Use Linen Program,” says John Piazzi, director of product management for Medline’s textiles division.

“Healthcare linen processing is being put in an enormous bind facing volatility in labor, demand and product availability.

“North Heights Linen Service has been a fantastic partner to imple-

American Laundry News (ISSN 1091-9201) is published monthly. Subscription prices, payment in advance: U.S. 1 year $50.00; 2 years $100.00. Foreign, 1 year $120.00; 2 years $240.00. Single copies: U.S. $10.00; Foreign $20.00. Published by American Trade Magazines LLC, 650 West Lake Street, Suite 320, Chicago, IL 60661. Periodicals postage paid at Chicago, IL, and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Laundry News, Subscription Dept., 125 Schelter Rd., #350, Lincolnshire, IL 60069-3666. Volume 48, number 4. Editorial, executive and advertising offices are at 650 West Lake Street, Suite 320, Chicago, IL 60661. Charles Thompson, President and Publisher. American Laundry News is distributed selectively to qualified laundry and linen management and distributors in the United States.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2022. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Laundry News does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Laundry News or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

MEMBERSHIPS

(File photo: American Trade Magazines)

2 APRIL 2022 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

Event to take place July 30-Aug. 2 at Georgia World Conference Center after year’s delay

INSIDE: April 2022 • Vol. 48 | No. 4 [4] Strategies for Supplying Specialty Items Columnist-at-Large Eric Frederick shares how he didn’t break his budget by suggesting adjustments for specialty items [16] Laundry Achieves Higher Capacities, Efficiencies San Diego-based commercial healthcare laundry and linen service chooses machinery for capacity, energy efficiency [17] Career Track [18] Start-up Miami Laundry Enjoys Quick Growth Hospitality laundry follows phased growth approach, adding machinery, automation based on demand [19] Classified Advertising [20] Source Directory [23] Trade Ticker [23] Calendar of Events See PARTNERS on Page 4 Medline and Texas-based North Heights Linen Service enter nationwide textiles partnership Partnership allows health systems across the country to access pre-washed and pre-packaged linens The e-mail address for WSI (Washing Systems) on page 25 of the Buyer’s Guide in the March issue was incorrect. The correct address is kwahl@washingsystems.com. ALN Correction

Milnor has a better solution through dilution.

When Milnor introduced PulseFlow® technology, CBW® washing was thrust into the future. The idea of balancing time, temperature, mechanical action and chemistry was missing one critical piece of the pie – DILUTION through the efficient use of water.

PulseFlow combines the innovative RecircONE® fast wet down and chemical immersion in the first module with standing bath washing in every spacious process module. Thorough and efficient dilution occurs by way of intermittent high velocity counterflow rinsing and traditional True Top Transfer.

The result is hygienically clean linen using less water (as low as 0.3 gallons per pound/2.5 liters per kilogram) and less energy as proven time and again by hundreds of PulseFlow tunnels in a variety of laundry applications worldwide.

Contact an authorized Milnor distributor or call 504-712-7656 to find out more.

www.milnor.com

*PulseFlow®,

are

registered trademarks.

CBW® and RecircONE®

Pellerin Milnor’s

And now some good news!

Good news. It’s something in short supply these days.

Just when we seem to be turn ing a corner with COVID-19, Russia invades Ukraine.

The situation is dire for citi zens of Ukraine, and the effects here in the United States are being felt at the pump.

We’re tracking the situation and will have reports online and in print.

And the industry (both laun dries and suppliers) is still trying to figure out how to hire and retain employees.

I asked our Panel of Experts to consider the problem of laundry labor, and they offer their advice starting on on page 12.

But I mentioned good news, didn’t I?

This issue of American Laundry News is packed with it.

On page one, you probably noticed the profile of HMT Laundry. It’s a smaller operation in Arkansas, but it has tripled its

The Editor’s Desk MATT POE

customer base in the past four years.

But HMT isn’t the only laun dry in the industry generating success with customers and processing goods. Both of the laundries featured in case studies this issue are enjoying growth as well.

On page 16, read how Emerald Textiles is increasing energy efficiency and capacity with LAVATEC equipment.

Located in California, Emerald has to have high efficiency in its plants.

Then there’s SerClean, a Miami commercial laundry that started in 2020. Turn to page 18 and read how the operation has grown and added Girbau Industrial machinery and auto mation based on demand.

On page 7, you can read about the success and growth healthcare laundry operator ImageFIRST had in 2021.

And, if you hadn’t heard The Clean Show is open for business (page 2). Registration for attend ees of the Atlanta show July 30-Aug. 2 is open.

It looks like we’re finally going to get to come together as an industry, and I’m looking for ward to it.

I’m looking forward to see ing you in person, hearing your stories and sharing everything I learn to help everybody keep it clean! ALN

ment this new program with, and it is a true win-win scenario. We’re ecstatic to bring an impactful prod uct solution to our customers while providing work opportunities to the North Heights community.”

North Heights Linen Service tapped Medline in early 2021 for strategic guidance on end-user experience and laundry opera tions to help with setting up its 30,000-square-foot facility, in addi tion to leveraging the company’s laundry business solutions.

With the facility up and run ning, North Heights Linen Service is delivering essential healthcare laun dry services to linen and healthcare providers nationwide, which, now more than ever, is critical in sup porting local health systems dur ing the COVID-19 pandemic and demanding labor market.

“The North Heights Linen Service is a fantastic addition to the North Heights community,” says City of Amarillo Mayor Pro Tem Freda Powell. “The North Heights Linen Service represents historic economic progress for the community.

“The partnership with Medline enhances the potential success of this business that has been wel

comed into the North Heights com munity. This is another sign of the revitalization of North Heights and what is possible when people have a shared vision that benefits an entire community, if not the entire city.”

The significance of the partner ship to the local community dates back decades, with medical profes sionals in Amarillo having to travel miles outside of the city to seek laundry services.

The new facility has brought in 20 jobs since opening and is expected to employ around 100 by Q3 of 2022.

North Heights Linen Service also emphasizes work-life balance and an accommodating work environ ment with benefits, with the com pany being worker-owned. ALN

RLLD

Specialty item strategy

I spent my entire career working in a healthcare linen rental system.

I always wanted as many standard tex tile items as possible; however, there are times when a specialty item for a key cus tomer is just unavoidable.

My specialty items normally came from a renowned surgeon or equally wellknown doctors involved in caring for premature infants in the newborn ICU unit. These doctors had enough pull to get whatever they wanted.

I learned over the years that it was pointless to say no or try and talk them out of the item they wanted. I learned it was easiest to say “of course we can do that but there is an extra cost to deliver ing such an item that will require an adjustment in the contract or an adjustment to my reimbursement from the facility.”

I would then detail out how much additional labor was involved in tracking, washing, finishing and delivering a specialty linen item back to this area.

The higher-than-normal inventory cost to ensure a constant supply and the higher risk associated with that inventory was because it was for just their use.

If the doctor happened to work at a contract hospital, I would present them with the additional costs and a modification to the contract that said should the doctor leave the facility or decided to stop using said product that the facility would buy all serviceable product cur rently in the system at 50% on the invoice cost for used inventory and the entire new inventory held in back up at 100% of the purchase price.

This buy-out provision also took effect in the event the hospital decided to change linen rental vendors.

I LEARNED OVER THE YEARS THAT IT WAS POINTLESS TO SAY NO OR TRY AND TALK THEM OUT OF THE ITEM THEY WANTED. I LEARNED IT WAS EASIEST TO SAY ‘OF COURSE WE CAN DO THAT BUT THERE IS AN EXTRA COST TO DELIVER ING SUCH AN ITEM THAT WILL REQUIRE AN ADJUSTMENT IN THE CONTRACT OR AN ADJUST MENT TO MY REIMBURSEMENT FROM THE FACILITY.’

By doing this I protected the laundry from possible loss caused by inventory that was no longer in demand and from the higher operating cost associated with that inventory.

Small specialty items can present a challenge, but some hospitals, based on recommendations from an interior design consultant, want a special color of thermal spread to be used in their facilities.

If the customer was large enough, there might not be an upcharge for an item that got lots of usage per day, but the inven tory risk is the same and I made sure to get that covered in the agreement.

There is a substantial benefit of not having to be the one to say no. When presented with the cost and the associated buy-out agreement, some items suddenly became less essential.

The final decision as to whether to implement the new item rests with the financial people in the hospital.

If I say no, then I am not being cooperative or understanding. I can be accused of standing in the way of a best patient practice. If, how ever, I say yes and ask for a reasonable adjustment to the contract or my budget, then the final decision is moved on to someone else.

Often my competitors would try and compete on price alone and would not even consider such a request.

By both considering and making a reasonable response I appear to be more than a healthcare vendor, but a healthcare partner interested in working with the facility to improve patient care.

The more you can distinguish yourself in a positive way from the competition the better it is for your laundry. ALN

Eric Frederick served 44 years in laundry management before retir ing and remains active in the industry as a laundry operations con sultant. You can contact him by e-mail at elfrederick@cox.net, or by phone at 540-520-6288.

4 APRIL 2022 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

From

COLUMNIST AT LARGE Eric L. Frederick,

Top Stories Appearing on AmericanLaundryNews.com for the 30 Days Ending March 15 (WE) = WEB EXCLUSIVE NEWS • EVI Industries Completes Merger with CLE • Faultless Healthcare Linen, An ImageFIRST Company, Rebrands • Division Laundry & Cleaners Expands to Dallas, Houston • TCATA 2022 Conference to ‘Move Forward Together’ • Registration Open for Clean 2022 COLUMNISTS/FEATURES • Current Inflation and Laundry Operations • Working with Laundry Suppliers as Prices Rise • Giving Back to the Community: Paris Companies • Eric Frederick: Hard Things Are Worth Doing! • Effective Laundry Chemistry Solutions OUR SISTER WEBSITES From AmericanDrycleaner.com: • American Express Offers $5K Grants for Small-Business ... • Surveying the Economic Landscape of 2022 From AmericanCoinOp.com: • Maximizing Your Signs’ Effectiveness • Shopping Center Developer Invests in Vended Laundries Partners Continued from Page 2

When dealing with laundry stains, your reputation rides on getting the outstanding results The Laundry Two deliver. RiteGo® laundry spray spotter quickly penetrates to absorb collar & cuff stains, perspiration, ground-in soil and more, all without brushing. Turn to Laundry TarGo® to remove any tough oil based stains that remain behind.

Use The Laundry Two with confidence on shirts, wedding gowns... anything you're washing or wetcleaning.

Both Laundry TarGo and RiteGo are chlorinated-solvent free, biodegradable, noncombustible and California 2013 VOC and Prop-65 compliant.

Use them to deliver stain-free laundry and wetcleaning. You'll build your reputation for quality - which is what keeps customers coming back.

FROM COLLARSAND CUFFS THE LAUNDRY T WO ™ ARE RIGHT FOR YOU! TO THE REALLY TOUGH STUFF... FROM COLLARSAND CUFFS THE LAUNDRY T WO ™ ARE RIGHT FOR YOU! TO THE REALLY TOUGH STUFF... To learn more, visit ALWilson.com or call 800-526-1188 A. L. WILSON CHEMICAL CO.

a STAIN WIZARD at ALWilson.com

Become

Gary, who has been in the indus trial laundry business for 49 years, started his career at a locally owned company as a driver and eventually moved into management.

“When that company was bought out by a much larger competitor and changed the way they were doing business, he started considering branching out on his own,” Brad shares.

“He recognized the need for personal, relationship-based cus tomer service in the industry, and all he needed was a partner—that’s where I come into the picture.”

As a child, Brad rode on the route with his father whenever he could.

“You could say I grew up in the laundry business,” he says. “When I finished college, dad proposed we open our own company. We started HMT Industrial Laundry in April of 2003 with one van running all of our services out of our 1,200-square-foot garage.”

Brad says that Gary “literally found our original 50-pound washer-extractor sitting in a field and talked a friend of his into repairing it for us.”

HMT used the washer for two years until it could purchase another.

In 2009, Brad’s mother, Gail, retired from her career in the public school system to manage the wash floor, allowing Gary and Brad to focus on selling and run ning routes.

“Her leadership on the wash room floor was instrumental to the success of the company,” Brad points out.

While Gary and Gail are semiretired as of 2017, Brad says they still play a crucial role in opera tions, and the couple gives their son credit for the company’s

growth over the last five years.

“We’re so proud of where Brad’s leadership has taken the company,” Gary says. “His pro fessionalism, honesty, and dedi cation to growing the business show in the rapid increase in customers we’ve experienced.

“I also want to thank all of our employees who believe in our com mitment to customer service and bring that to the job every day. We consider them part of our family.”

Today the HMT family includes 11 employees that work 10-hour shifts Monday through Thursday in the company’s 7,000-squarefoot facility.

HMT moved into the facility in 2008, and today it uses washerextractors ranging from 110 to 275 pounds with four 175-pound dryers to process 11,000 pounds of laundry every week for its cus tomers.

And Brad says each team/fam ily member “owns” the respon sibility of ensuring quality and timeliness for HMT’s customers.

“We’re all invested in making sure our customer deliveries are on-time, accurate and meet all quality expectations,” he shares.

“We inspect each delivery four times before it leaves our facil ity, beginning with the washroom employee who fills the order, con tinuing to the washroom manager who checks it, leading to our plant manager who does another inspec tion and ending with our driver who is responsible for final signoff before they leave the facility.”

Another way HMT remains on task is by using Friday of each week as a catch-up day if needed.

“For example, we recently had an ice storm that shut us down half of Wednesday and Thursday,” Brad relates. “Our team pivoted

to Friday and business continued on track and on schedule for the following week.”

HMT is good at “pivoting” to maintain its business.

“We weathered the economic downturn in 2008 with persever ance and customer loyalty,” Brad says. “A fire in 2015 destroyed 70% of our facility and all of our sup plies. For weeks, we washed prod uct with retail washers and dryers, cleaning rugs with soap and water hoses in our yards and garages.

“During the entire time, we kept service running and our cus tomers stayed with us until we got everything back up and running.”

COVID-19 has been another setback for HMT as the company sadly watched customers it has had for years go out of business.

“We’ve had some positive turns in new industries that’s helped us pick up new business, but we’ve

absolutely felt the impact,” says Brad.

Despite the pandemic, he shares that HMT has tripled its customer base over the past four years.

“If we keep growing at our cur rent rate, we’ll be expanding our facility and adding personnel to support our increasing customer base,” Brad points out. “We’ve increased our customer base pure ly through word of mouth, refer rals and feet on the pavement.”

The company is in the pro cess of obtaining certification from the Healthcare Laundry Accreditation Council (HLAC), and he says exceptional cus tomer service, loyal customers, great vendors/suppliers and “an awesome home team” help with attracting new customers.

“Potential customers call us based on talking with our other customers,” Brad says. “We’re referred to new customers from established customers, and our sales team and drivers are con stantly reaching out to prospects and leaving business cards.

“With the growth of our busi ness, we’ve been blessed to be able to add several outstanding employees to our work fam ily who understand our focus on customer service and are com mitted to supporting that goal.”

He reiterates that the HMT team is always willing to do what it takes to exceed customers’ expectations whether that means being available via phone 24/7, 365 days a year, working on a normal day off, or making an extra trip to a customer that ran out of planned supplies.

“HMT Industrial Laundry is the best place I’ve worked and the people I work with are amaz ing,” says Amber Cole, wash floor manager. “We are a team where everyone is treated the like family. We make memories and still get the job done!”

6 APRIL 2022 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

ALN HMT Continued from Page 1

HMT’s dedicated wash floor staff (from left): Trent Adams, Gail Watlington, Angela Glenn, Amber Cole, Casey Cramer and Jon Prine. (Photos: HMT Industrial Laundry)

Matthew Justice delivers the goods to one of HMT’s loyal customers.

ImageFIRST reports record-breaking year in national growth

2021,

KING OF PRUSSIA, Pa. —

ImageFIRST, a national provider of linen and laundry services for the healthcare industry, reports that it achieved record-breaking growth in 2021.

The textile provider added more than 10 facilities through acquisitions in 2021, stretching across the nation from Maine to Seattle.

To support its growth, ImageFIRST expanded its national account division to enhance its capabilities to support more multiregional accounts.

The healthcare linen provider entered multiple new states and regions in 2021, including South Texas, Maine, Minnesota and Utah.

Additionally, ImageFIRST increased its processing capac ity in several geographies, such as Lakeland, Florida; San Diego; Elmsford, New York; and Seattle, to support its growing customer base.

“2021 was another record-set ting year for us and this growth expands our already industryleading service footprint,” says Jim Cashman, president and CEO of ImageFIRST.

“Even as the pandemic head winds grew stronger as the year progressed, our progress in 2021 gives us tremendous momen tum for the future and I sin cerely appreciate the efforts of our team.

“We look forward to bring ing our world-class service to even more healthcare facilities in 2022.”

Rick Taft, previous owner of Textile Care Services (TCS) in Utah, is looking forward to his future with ImageFIRST after his business was acquired in December 2021.

“All TCS employees, including myself, are excited to join the ImageFIRST team,” he says. “It has been a positive experience throughout the integration peri od, and it has been great to have the opportunity to work with such a superb group of people.

“Our employees have always been a main focus for us, so it is great to join a company with the same values.”

With the addition of these new locations for laundering textiles for the medical indus try, ImageFIRST says it has pri oritized growing its national account division.

By expanding its footprint in current and new markets, ImageFIRST’s strengthened national coverage supports its capabilities to service more mul tiregional accounts.

“As we grow nationally, we recognize that other laundry providers can’t guarantee con sistent service across their loca tions. Our service model allows us to certify all plants are adher ing to the same standards in terms of quality, pricing, prod

ucts, processing and infection prevention standards.”

Key leadership additions occurred across several depart ments, including human resources, operations, business development and marketing.

ImageFIRST says the combi

nation of adding new locations as well as growing relationships with national accounts will provide it with greater oppor tunities to increase processing capacities, add new job oppor tunities and enhance service capabilities nationally.

ALN

www.AmericanLaundryNews.com AMERICAN LAUNDRY NEWS | APRIL 2022 7

“ImageFIRST is unique in that not only do we exclusively service the medical industry, but we also pride ourselves in our ability to offer consisten cy across locations,” says Brian Peterson, director of national accounts.

textile provider continues rapid expansion in

grows national account division ! Braun High Production Finishing Systems. Solid, Proven Performance. See us at Clean 2022 Booth #2908 gabraun.com ISO 9001:2015 Certified

Healthcare

members are experiencing regarding COG vs. rental.

HEALTHCARE GOODS

“The pandemic just continued to accelerate the existing move to rental linens from customer-owned linens (COG), a trend that has been underway for several years now,” says Rick Gaffney, who heads business development and partnerships for HLA, which is made up of seven healthcare laundries offering services to hospitals and medical facilities across North America.

“Members … have seen a sig nificant swing toward rental textiles, a trend we believe is most likely permanent.”

Gaffney says that even before the pandemic, most of the business of its members was heavily skewed toward rental textiles while acknowledging a good amount of COG volumes remain in some geographies.

Gary Fuller at Century Linen in upstate New York, part of HLA, reports that his rental-to-COG ratio was about 95% to 5% before the pandemic and remains at that rela tive ratio today.

Century Linen picked up some added COG business when hospitals added customer-owned isolation gowns and other customer-owned personal protective equipment (PPE) cover garments, including scrubs and lab coats. Most of this PPE surge happened when the pan demic started.

Fuller says he has seen supply chains slowing and textile prices increasing for hospital customers that still buy and supply their own linens. Hospitals are starting to find it a lot more difficult to source the linens they need.

He adds that with the purchas ing power of Century Linen, as an Alliance member, his company’s rental programs give his hospital customers many more options and assurance of supply. This is critical to hospitals in this ongoing pandemic environment.

Randy Bartsch, the CEO of Ecotex Healthcare Linen Service, part of HLA and a member of ARTA com ments that he hasn’t seen a change in his business mix either. He says that almost 100% of the linen Ecotex supplies to its Canadian hospital cli ents is on a full-service, rental basis.

Ecotex, which also operates sev eral healthcare laundries supporting hospitals in the U.S. Midwest, serves a relatively small volume of COG products for hospitals but shares that this has been slowly declining.

“Hospitals today are looking for full-service solutions and an assur ance that we can supply their com plete linen needs,” Bartsch says. “Our linen rental programs provide the best control for our customers, where we take on and manage the risk of linen shortages.”

Continued consolidation of hos pitals and health systems, as well

as consolidation on the healthcare laundry supply side of the business, have both driven this macro trend toward rental textiles.

The largest laundry operators in the country, including groups like HLA, that are processing more than 750 million pounds of linen a year have strong purchasing power. This makes rental programs much more price competitive compared to smaller, single-plant laundries that may not have the pricing leverage with textile and other suppliers and rely on their hospital customers to purchase the linen inventory they need.

Bartsch says another contribut ing factor to this trend is staffing at hospitals. Staffing issues, includ ing front-line labor shortages and departmental supervision, when combined with the lack of experi ence with linen due to turnover and training, make conversions to linen rental programs an easy decision for hospital administrations to make, allowing them to focus on their core business: patient care.

Another Alliance member, Mark Carter of Up To Date Laundry in Baltimore, also reports his hospi tal customers are looking for rental solutions due to the many staffing issues caused by the pandemic.

Hospitals feel that they can save money and have more control with a well-run rental program. They are looking for a laundry supplier that will partner with them and help with linen utilization and identify sources of loss.

Rental programs have come up in customer conversations when dis cussing money-saving alternatives.

Transportation costs have increased during the pandemic and costs sav ings can come with those rental conversions by potentially making fewer trips to the customer increas ing efficiencies.

Carter’s rental business has increased by 19% during the pan demic, much of it as a result of new rental conversions. He feels these changes will be permanent because of their flexibility with textile pur chases offering a better assurance of supply versus a hospital sometimes being locked into long-term supply chain decisions.

Karl Fillip II, CEO of Atlantabased NOVO Health Services, reports that 98% of its business is rental. He says the synergies created through better purchasing power as a result of rental programs are better for them and their customers since they don’t have to allocate resources toward ordering, receiving, main taining inventories and issuing pur chase orders for textile goods.

Productivity and efficiency in a rental plant are on average 50% better than in a COG plant. These savings ultimately go back to the customer as NOVO uses its lower costs to win new business.

“This is a big deal when the healthcare laundries are facing pan demic-related staffing issues of their own,” Fillip says.

He also feels that the trend toward rental linen is permanent and feels that the issues that would drive a

customer back to COG in the future will not be the result of a pandemic but a laundry operator issue like poor order fulfillment rates, late deliveries or insufficient finances, which ultimately result in poor qual ity and declining service.

“What hospital administrator would want to authorize a couple of million dollars to buy linen inven tory and invest in additional staff ing if they are in a rental program today?” he says. “Better to find a good healthcare rental laundry and linen supplier to manage the whole program.”

Andy Kratky, president of Emerald Textiles LLC in California, responds that the customer base in their market is and remains pre dominately rental, both pre- and post-pandemic.

There are certain customers in California that continue with COG programs; however, these customers have begun to review the impact of moving to a rental program as well.

Emerald’s perspective is that managing linen is not their cus tomer’s core competency and, in their experience, customers on COG programs experience increased costs related to linen procurement.

The company has not experienced any dramatic changes in the way customers view its linen programs. Mixing COG in with rental can affect laundry operations that create a higher level of inefficiency, which in turn increase costs. Emerald says it is fortunate to have a single, dedi cated laundry plant in the Northern California region that can process most of its COG customers.

The pandemic has not affected the storage or delivery of the rental or COG linens, but customers have expressed concerns about linen replacement costs increasing and having sufficient inventory to sup port the healthcare system.

Emerald works with its custom ers on linen management and how to mitigate increased replacement costs. They assure their customers that there will be sufficient inventory to support their health system needs, and ultimately the patient.

Kratky believes COG custom

ers will continue to migrate toward rental because they can better use their capital in areas of their business other than to purchase linens.

The pandemic has changed the business in many ways, but the remaining COG healthcare laundry business is slowly and steadily mov ing towards linen rental programs, Gaffney shares.

COG programs can be run most efficiently if there is a partnership with laundries accepting and storing customer-owned linens onsite and helping the hospitals with control ling weekly linen inventory injec tions.

A monthly inventory would then be taken and given to the hospital so they can reorder their linens in a timely manner to assure supply.

Linda Fairbanks, executive direc tor of ALM, spoke with about 10 of its members and also found that healthcare textiles products continue to be mostly rental and a shift to COG isn’t likely.

“Typical COG for specialty items such as patient slings, cubical cur tains, etc., continues but not the standard hospital textile products,” she says. “They continue to be rental goods.

“Most members indicated that while there may have been initial concerns over isolation gowns and/ or scrubs that this has settled back into pre-COVID patterns.

“Most hospitals seem to have ben efited from good relationships and communication with their laundry providers, and if there were substan tial increases needed for products, they reached out to their laundry processor to have them secure great er volume and avoided the need to purchase COG.”

Fairbanks adds that some health care facilities may have used COG as a stopgap measure to supply short ages, but they have already returned to rental goods.

“Hospitals that have purchased reusable COG for backup and emer gency preparedness measures will want to be sure to monitor the stor age situation so that those emer gency goods are fit for use when needed,” she says.

HOSPITALITY GOODS

On the food and beverage/hos pitality side of the industry, Ken Koepper, director of member and industry relations for TRSA, says that its F&B/Hospitality Committee has identified shifting hotel work from COG to rental as a priority.

Dan French, vice president and general manager of TRSA member Gold Coast Linen Services in West Palm Beach, Florida, which provides a mix of food and beverage/hos pitality and healthcare textiles, tells Koepper that COG wash is a com plicated process that demands as much or more attention to tracking and historical detail than washing rental goods.

“COG garments need to be segre gated on first arrival,” he says. “They need to be tagged, chipped and entered into route accounting sys tems. These processes are best done on the clean side so coordinated pickup and preparation is best. Once chipped and tagged, COG items will sort and deliver through normal processes.”

French points out that not all gar ments are suitable for COG wash ing—many can’t tolerate the indus trial laundry wash process.

“Replacing worn garments is the customer’s responsibility,” he says. “Communication needs to be flaw less. Pricing is critical. COG must be priced higher. There is no under wash in COG. You need to build it into your pricing models.”

Koepper shares that TRSA mem ber People’s Linen Service of Keene, New Hampshire, has 90% of its hotel volume in rental as opposed to COG. The company’s rental success is the antithesis of the vast majority of TRSA members who specialize in this market.

Mike Benik, People’s Linen CFO, indicates to Koepper that when both hoteliers and linen services back off their traditional stances, even if just a bit at first, rental can prevail because both parties are better served.

For example, in a “hybrid” pro gram, the linen service buys the branded linen the hotel wants and rents it to this customer. Contract terms indicate that should the part nership end before the service agree ment expires, the hotel will buy the linens from the service.

“It’s not the most desirable for us, but we still control the amount of inventory and the amount pur chased, they get their brand, and we still rent it to them,” Benik says.

This doesn’t have to apply to all items the hotel uses. A customer may like the complete range of rental items except a particular a top sheet, for example, so People’s will buy it and charge a premium for its rental.

Either party may retreat com pletely from its industry’s traditional stance. A hotel in a chain operation whose properties typically adhere to its linen brand standard can break ranks, choosing to benefit from rental’s lower cost. People’s may be attracted to a COG deal with a larger resort (at least 150 to 200 rooms)

8 APRIL 2022 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

See GOODS on Page 11 Goods Continued from Page 1

(Image licensed by Ingram Image)

July 30 – August 2, 2022

World Congress Center

THE CLEAN SHOW IS THE #1 PLACE TO BE NEXT SUMMER!

the Floorplan

Georgia

Atlanta, Georgia USA If you attend one industry event in 2022, The Clean Show should be it! Discover new products, exciting technology, and groundbreaking research in commercial laundering, dry-cleaning, and the textile service industry as exhibitors from around the world showcase their latest innovations. Registration opens this winter. Start making your plans to attend!

Explore

www.cleanshow.com

Laundries and distributors: Improving the working relationship

BY MATT POE, EDITOR

CHICAGO — A laundry can’t operate without the right equip ment.

That’s why it’s key for opera tions to have solid relationships with distributors.

How do these relationships work today? How should they work? How can they be improved?

American Laundry News reached out and heard from three distributor representatives about these questions and more: Mike Fox, sales manager for Alliance Laundry Systems Distribution in Chicago; Jocelyn Maldonado, product marketing specialist for Laundry Solutions Company in Springfield, Missouri; and Tom Marks, president of Western State Design in Cerritos, California.

How does the laundry/distrib utor relationship usually work, in your experience?

FOX: Unfortunately, I think laundry managers often con fuse dealers with distributors. As a result, they are a bit skeptical because they had a bad experi ence with a dealer who offers no service and support for the equip ment they sell.

How it should work is a bond of trust between distributor and customer—having a trustworthy partner invested in their success, with the staff, expertise and ser vices to deliver a next-level cus tomer experience.

MALDONADO: At our com pany, our laundry/distributor relationship is mutually beneficial. Customers call us when they need certain parts shipped to them for their machines, or they let us know when they need a service request. We try to be as quick as we can when we send parts or create ser

vice requests since we understand these things happen unexpectedly.

MARKS: As with any relation ship, each party should define expectations. To achieve the most favorable outcome, the distributor should “fill the gaps” between the experience and resources of the operator and the requirements of the task/project assigned.

The distribution relationship fails when there are unmet, unspo ken or over-promised results. As with any relationship, personal character and effort are the pri mary factors toward success.

Since distributors offer vari ous types of equipment from dif ferent manufacturers, how does a distributor work with manu facturers to order to offer the best for its laundry customers?

FOX: Truly high-quality dis tributors will align themselves with truly high-quality manu facturers. With a foundation of representing highly reliable and efficient equipment, distributors can then work closely with laun dry managers to identify the best solution for their unique needs.

MALDONADO: Our salesmen have a one-on-one conversation with all of our customers to deter mine what type of brand they can suggest and the different models that brand offers. We tend to assign certain salesmen based on location so they can dedicate more local time going to locations and helping each customer when needed.

MARKS: The first step is to define the problem. Most solu tions involve adding machinery to upgrade the laundry with capacity, technology or replace the obsolete. Frequently, however, the solution can be found outside the laundry room, such as linen storage or upgrades to the physical plant.

Distribution works with man ufacturing to provide the most cost-effective and elegant solu tion that integrates manufac turing, installation, the physical space and laundry operations. Distribution’s role is to coordi nate these interests resulting in a successful project.

Is a distributor’s relationship with a laundry ongoing? How often do a laundry and a distrib utor work together? Why?

FOX: Again, this is where a dis tributor and a dealer are different. A dealer’s relationship pretty much ends at the sale. However, distribu tors should always have an ongoing relationship with a laundry.

From ongoing training and access to service and parts to being a partner in quality, the contact can be as regular as the laundry manager requires. At its highest level, the laundry-dis tributor relationship should be a long-term bond.

MALDONADO: Our distribu tor relationship with a majority of our laundry clients is ongoing. Customers call us when they have a machine down at their business, and they tend to want service as soon as possible so they can be up and running again.

As long as they are continu

ously running their business and using their machines on a regular basis, they call us for any of their laundry distributor needs.

MARKS: Trusted distribu tion can be a resource for space planning, budgets, maintenance, safety, repair, parts and health regulations in laundry processing such as recommendations from the CDC, OSHA and TJC. These tasks require a focused expert. A trusted relationship with a dis tributor will keep problems from becoming a distraction.

Your distribution representa tive should be an ally in providing solutions or connecting the laun dry with those who have the expe rience. Many representatives meet regularly with clients throughout the year to be proactive.

What are some things a laun dry operator might not know that a distributor offers or can do for them to help with their operations?

FOX: Anything from a laun dry operating cost analysis, where they review current utility, labor, and equipment costs to identify possible efficiencies, to equipment sizing and laundry room layout/ design to streamline operations.

Distributors often offer ser vice and maintenance training for laundry staff, so they can do minor projects without the need for a service call.

MALDONADO: We lease equipment! If you are interested in starting a laundry but can not afford to buy new equipment right away, know that we offer leasing options for your business. Our leasing salesmen will go over a basic leasing contract with the terms and details.

MARKS: Some distributors offer the following:

1. Preventative maintenance contracts.

2. A list of spare parts to keep in inventory.

3. CAD-assisted space plan ning and growth planning. 4. Linen distribution assis tance. 5. Productivity software.

6. Emergency backup resourc es.

7. Labor productivity aver ages.

8. Utility measuring devices.

9. Ergonomic solutions.

10. Rigging and installation.

11. Training in operations.

12. On-site maintenance train ing and service schools.

If a laundry is working with a distributor for the first time, what are some basic elements they can expect as they develop and grow a relationship?

FOX: I think it’s just about expecting more. If they are used to working with a dealer that sells them a machine and walks away, the distributor experience can be a bit surprising. They can expect to have someone who asks questions to better understand their unique needs rather than just presenting them with equipment solutions.

MALDONADO: We appreciate each and every one of our cus tomers and we keep your account information confidential. We require an account to be created with us for our system and we can save your preferred payment method information for future invoices. We offer discounts if you pay for your parts order with a credit card.

MARKS: The laundry should seek to determine the scope of experience represented by the dis tributor. Not all distribution is equal in experience or breadth. The laundry operation should determine if their needs match the distributor’s experience. Interview distribution as you would a trusted advisor and make sure they are a culture fit.

What can a laundry manager do to improve his/her working relationship with a distributor?

FOX: It’s obviously about trust and sharing information. So, the better laundry managers are at providing insight into laundry needs and challenges, while also trusting that they have a partner dedicated to helping, versus push ing services and equipment, the better the relationship will be.

MALDONADO: A laundry manager can improve the rela tionship with their distributor by attending our annual trade show event where we showcase the newest technology we have to offer and the distributors we work with.

Customers get to meet us as a whole company and ask us ques tions during the event. The event tends to last a couple of days in a hotel, casino or convention center, each year is different.

MARKS: Clearly define the goals for the laundry and opera tions with the expectation that the distributor will communicate their experience and offer a plan to achieve your goals.

10 APRIL 2022 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

ALN

representatives answer questions about how operators

better

(Images licensed by Ingram Image)

Three

and distributors can work

together

because it represents enough rev enue for the laundry.

“We try to tell them why COG is contentious,” Benik explains.

COG arrangements, more often than rental, are vulnerable to linen shortfalls. Supervisors responsible for ensuring rooms are properly made up are likely to have difficulty prompting their management to spend enough to maintain proper inventory.

People’s makes it clear to COG customers they will not receive sev en-day-a-week service. Special week end runs may be needed, prompted by an unexpected rise in demand from a hotel or a production snafu in the laundry. But a request for seven-day service is similar to asking an outsourced laundry to prema turely wear linen out from too much laundering.

Again there’s potential for com promise. The service agreement can provide for the substitution of rental linen when a COG shortfall is expected. People’s has luxury, midscale and economy linen lines.

“Our stock can match their brand,” Benik says. When this occurs often enough, customers can become accustomed to rental linen and shift to all-rental.

“They realize they don’t have to manage the linen purchase anymore and they convert.”

Another way to prompt selection of rental over COG is to compare the durability and comfort of rent al linen to the brands customers think they want. Such prospects who believe they have found items that will distinguish them are likely to be short-lived.

When People’s evaluated samples of one hotel’s planned buy, they appeared attractive, but would likely stiffen and have only half the life of an equivalent rental product. The laundry’s acceptance of such work was a trap—if the linen were used, the customer would almost certainly blame the laundry for causing the problems.

Instead, People’s noted that its rental linen doesn’t suffer from these issues and highlighted the impor tance to hotels of recognizing that because items are commercially laun dered, durability must be considered as well as attractiveness and branding.

Evidence that rental is the bet ter alternative was around before the pandemic, but COVID-19’s impact on labor and supply chains has accentuated the difference. These two issues converge when a hotel doesn’t buy enough linen and requires repeated servicing of the same linen.

The hotel’s merchandise costs increase and so do the linen ser

vice’s (especially route labor and fuel, both more expensive post-COVID). Hoteliers ultimately bear these COG service costs, further increasing the pricing edge of rental, which is also less stressful on them.

Hotels’ inability to procure linen due to supply chain difficulties also favors rental. Lately, they are ask ing linen services for inventory and appreciating the simplicity of del egating purchasing and laundering so they can dedicate whatever labor they can get to make up rooms.

Existing rental customers are indi cating more flexibility. A customer who usually uses mid-scale products and suddenly requires a lot more hand towels, for example, is happy to take the economy equivalent to fulfill inventory needs.

“It’s not common,” Benik says, “but when customers are really busy, they are very happy to get what they can get.”

The same can apply to a single COG item such as a pillowcase. When this occurs, People’s advises them they still need to buy more, but the available rental stock will tie them over.

To maintain rental’s stock-keeping edge, People’s pre-orders inventory and asks suppliers to store it earlier than People’s needs it. While shortages of certain products have been a prob lem, shipping cost (which has grown dramatically) is more of a concern.

Rental deliveries to hotels are larg

er, and for a hotel that converts from COG, more storage space is needed because drop-off and pickup are less frequent.

Linen loss becomes more of an issue in rental with the customer’s delegation of inventory control responsibility. When they rent, they pay not to worry about counts. They don’t observe as closely all the places linen can go out of service and may exaggerate losses.

It’s up to the linen service to determine how to cover the cost of anticipated losses; building it into the base charge for service can help avoid arguments, although separate charges can work, too.

While flatwork generally isn’t vul nerable to guest theft, high-quality terry can be.

“It’s a lot less enticing to steal if it’s not a luxury brand,” Benik quips.

Loss can also be caused by multiunit hotel owners shifting linen inventory from one property to another.

Factors such as these make charg ing and educating hoteliers crucial. Linen services can pinpoint losses by evaluating each customer’s linen replacement rate and recognizing where deliveries exceed pickups.

“Losses are, without a doubt, manageable,” Benik says. “We get very consumed with linen loss and rightfully so. It’s important.”

But labor remains the highest cost, is far more difficult to control and

could do more bottom-line damage.

Fortunately, customers can relate to laundries’ supply and labor shortages. If a laundry can’t pro vide enough bags for soiled laundry, housekeepers can inadvertently dis card reusable linen in black plastic garbage bags.

If a laundry doesn’t have enough staff to complete its luxury linen work for the day, affected rental customers may have to use midscale or economy equivalents. These pressure laundry margins but when hotels are very busy, they are less concerned about the consistency of their linen items.

Prospects for converting from COG to rental still can be hesitant, though. After all, if they rent and there’s a sud den falling-out with a linen service, they won’t have any linen.

“There’s some truth to that,” Benik admits. “It’s one of the obstacles you have to get over.”

Service agreement clauses protect them and they grow confident in a laundry that continues to demon strate trustworthiness.

Despite the details that need to be worked out for conversion, People’s remains bullish on rental and could grow closer to 100%. Processing is so much easier when accounts are commingled, instead of having to track each customer’s goods.

“It’s the best way to service the industry from a lot of different per spectives,” Benik concludes. ALN

www.AmericanLaundryNews.com AMERICAN LAUNDRY NEWS | APRIL 2022 11

Goods Continued from Page 8 The Newspaper of Record for Laundry & Linen Management It’s not just print anymore. Whenever. Wherever. American Laundry News can now be viewed on your mobile devices. Stay on top of the latest industry news and updates. www.american laundrynews.com INSIDE shift from COG to rental goods; hospitality work progress Moving from customer-owned goods to rental services Late News Personal customer service laundry access HMT Industrial Laundry in Arkansas prides itself on service that inspires loyalty PRODUCT Tunnel Washers Miele_BMAd_4.75x6.75in_PrtOL.indd 1 4/22/21 8:41 AM

PANEL OF EXPERTS

Dealing with laundry labor demands

Since labor costs are one of the largest expenses when run ning any business, it makes the most sense to treat your employ ees as the assets that they are.

People, in general, wish to be challenged, respected, given responsibility and trusted. Of course, pay is part of the equa tion, but it is much easier and less expensive to retain an excel lent employee than it is to find and train a replacement.

Make your workplace great and word of mouth will get you great employees through recom mendations from your current employees.

How can you make your workplace great? Try the basics:

1. Treat your employees like humans. We are all a part of the human experience and no one is any better than anyone else. Realizing this and treating others the way you would like to be treated creates trust. No one goes above and beyond for some one they can’t trust.

2. Pay them well. We’re all working because we have goals in life and at this time, solid hard-working employ ees find themselves more valuable than ever. Reward your employees for their hard work in growing your business. Keep in mind that buying lunch is nice, but money pays the rent. If you’re underpaying compared to your competition, no amount of pizza parties will keep your employees happy.

3. Listen to their concerns and act on those concerns. No matter the business, there is always room for improve ment. Listening to ideas from the people who are actually doing the work and then act ing on those ideas builds trust (there’s that word again) in the relationship. If you’re truly interested in creating a work environment where people want to stay, trust is key.

4.Let them know they are doing a good job both verbally and monetarily. Compliments are free and should be handed out when appropriate and it’s always appropriate to compli ment a job well done. Dealing with a difficult customer in a great way? Compliment! Did something nice unexpect edly? Compliment! If you have a hard time with this, just try simply saying thank you as it really goes a long way when the boss gives you a compliment. Handing out performance bonuses (again, money, not gift cards and the like) regularly is also an excel lent way to literally put your money where your mouth is and show appreciation for your hard-working staff. We’re all on this journey together, and we as humans have the unique power and capabil ity to improve each other’s lives. It’s well past time that we should treat each other with kindness and understanding in order to create a better world for our selves, our children and future generations. We can make the choice to start right now.

Look outside your normal recruiting avenues. Don’t exclude potential candidates based on criminal records. I had great success when running a restau rant hiring folks from a halfway house. They are required to work and if they don’t or get fired they typically are sent back to prison.

Be cautious and diligent in your interview process but I would not exclude these folks from my recruiting efforts.

Other ideas:

• Contact your local unem ployment office.

• Advertise online.

• Network with other facili ties. Perhaps you have a schedule that is more attrac tive to their employee or perhaps they have a sched ule that is more attractive to one of yours; don’t be afraid to trade labor back and forth. Or perhaps someone is willing to work two jobs.

• Consider temp agencies.

• Contact former employees to see if they might want to come back to work for you (assuming they left on a positive note).

few suggestions:

• First and foremost, have consistency and fairness in the workplace.

• Managers need to be sup portive leaders. The objective of supportive leadership is team members who can work autonomously but who feel comfortable seeking sup port when they need it.

• Provide quality tools and equipment to do their job.

• Provide them with a more than adequate quantity of supplies to perform their job. It can be humiliating to staff to not have the supplies they need to perform their job.

• Flexible schedules—when possible, try to work togeth er with your staff.

• Offer a sign-on bonus pay able after 90 days of perfect attendance.

• Relax company dress code a little—if possible, allow staff to wear jeans. Offer payroll deduction for work clothing and shoes.

• Adjust your absentee policy.

• Offer free or discounted meals.

• Make the work environment more comfortable.

• Use social media and recruiting sites like indeed and your local newspaper.

• Cross-train current employees.

and even overpaying, to get them on board. Those are the most untroubled candidates.

Many of the applicants that so many see now are troubled peo ple with checkered employment and background history.

This reminds me of 2005. If you had a good employee who showed up late every day, you were grateful they showed up every day.

This is cyclical. In 2009, I had people begging for work. I don’t think we will see an economic downturn of those proportions again, but I do think it will level off.

I think for the present time we must be cognizant of what keeps our current employees feeling appreciated and willing to come back tomorrow. It also means being more patient with people who have come on board because of a satisfied employee suggesting they give us a shot.

We’ve all read the articles telling us how much more a millennial wants recognition and a pat on the back, rather than a raise. I’ve pro moted guys out of the washroom to engineering. I started doing this when I found it hard to compete with offers for already qualified technicians and engineers.

Others in the plant recognize advancement can happen through hard work and reliability, and it shows them this isn’t a dead end.

The labor market is especially tight now, more so for hourly employees than others. These employees have more choices and are demanding higher wages.

Working in a laundry is harder work than many of the other positions they could possibly choose. You will need to create a positive work environment that focuses on your employees.

First, make sure your exist ing employees are happy. Ask them what else you could do for them—besides a wage increase— flexible schedules, better com munication, advancement.

Also, ask them if they know of anyone looking for a job. Offer incentives for referrals.

Make sure your management team is treating your existing employees with respect.

abor shortages and demands for higher wages were happening to companies prior to COVID-19.

L

One thing that increased these challenges we are facing was the recipients of state unemployment benefits were provided an addi tional $600 in weekly benefits by the federal government on top of their standard unemployment.

Most of these recipients made more money while unemployed than they made while they were working. This made it exceed ingly difficult for a lot of us to fill open positions.

Now in 2022, things have improved slightly. We have increased wages to be more com petitive with other companies. We are not only focused on hir ing new staff but also on retain ing what staff we do have. With all that said, here are a

I hope that my contribution has provided you with some ideas that will help with this ongoing challenge we all face. I wish all of you success.

I don’t know any magic tricks. People don’t grow up saying they want to work in laundry. The only magic bullet I have is let ting others outside of our field know that even I was able to find a career here, and that means there is opportunity in laundry for anyone.

Laundry

These are trying times, in many ways. Laundries, and the engi neering side of it for sure, have always been underserved with a good pool of labor.

Let’s face it, many of us are saying no to potential new accounts simply because finding the bodies to process the work is near impossible.

If someone wants a job right now, they have people begging,

L

abor availability

Healthcare Laundry

and pricing

is a hot topic in today’s work ing environment. That said, as a laundry and linen provider, we don’t work in an attractive industry and as such we must constantly think of ways to attract new talent while retaining the talent we already have.

12 APRIL 2022 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

“Like many laundries, I’m still dealing with labor shortages and demands for higher wages. What suggestions do you have for finding and retaining employees?”

Chemicals

Diversey, Fort Mill, S.C.

William Muse United Hospital Services, Indianapolis, Ind.

Supply John Schafer

Long-Term Care Laundry

Wood-Lawn

Ark.

Juli Reding

Inc., Batesville,

Equipment Manufacturing

B&C

Commercial

Lee Baldauf Superior Linen Service, Tacoma, Wash.

Al Adcock

Technologies, Panama City, Fla.

Across all industries and jobs, we are seeing an increase in pay rates that breaks the delicate bal ance of pay across industries and job functions.

That said, one task that most companies should be undertak ing if they haven’t already is a job analysis or job study to iden tify what you are asking of your employees while comparing the duties of said job to comparative jobs in the area.

This can help you identify if there truly is a pay gap that is making your recruitment more difficult.

Most companies will complete these every couple of years, but with the rate at which the labor market and pay rates are chang ing, I would recommend doing this as often as every six-12 months or as needed.

When looking at ways to retain existing talent, allow your employees to have a voice and an opinion, offer them oppor tunities for growth, treat your employees with respect and appreciate their contributions to your overall success.

Without your employees, you would likely have a hard time completing the work necessary to satisfy your customers!

always fought against other job opportunities for potential and current employees.

If it is possible to raise wages, there’s your “silver bullet.”

Otherwise, the following are some strategies that might help.

Regarding finding employees, one of the best ways that my customers have recommended is internal referral programs.

Provide a benefit to your employees for bringing family and friends on board.

Your employees can best describe their work environment and can probably identify people who will be able to keep up with the pace of working in a laundry, which should increase your suc cess rate with new employees.

An interesting point that I recently read about internal referral programs is the sugges tion to increase the compensa tion for delivering a successful hire. Recruiters can receive up to 40% or more for supplying executive candidates.

An increase from a few hun dred dollars to a larger percent age of the wage for a production position could improve the quality of referrals, and it might encourage employees to help you work on retention—the referrer won’t want to lose the “refer-ee” and miss out on their payday.

a good job, get a bonus, enjoy your work and improve your life, keep doing a good job—it’s a self-sustaining cycle.

Health benefits and other perks are often highlighted as a difference between other jobs and our laundry positions, but the dollars themselves often speak louder. Just as with the referrals above, there must be minimum requirements to get a bonus (an employee must be on time and have good attendance) if not (regardless of how well they work when they are on the job), an incentive bonus won’t payout.

It goes without saying that a good work environment is key for all of this to be successful and to keep people happy and com ing back to the job each day.

Coming full circle, incentive plans might also help in recruit ing. A customer recently men tioned to me that they changed their tactic from “Earn $X per hour” to “Earn up to $X+ per hour” after seeing a similar sign in a convenience store window. He spoke with the clerk, who explained that he could be happy with the base pay, or he could agree to work nights and week ends or do other “grunt work” to get the higher wage.

Hiring and retaining quality employees is a crucial facet of running a successful company.

Whether it is a small “mom and pop” operation or a large corporation, knowledgeable and dependable employees really are the heartbeat. Each person is a piece of the puzzle that creates the culture of a company.

I have been in a position to search for, hire and retain employees for over 15 years and have seen both the great as well as the ugly. I have learned count less lessons in that time.

Job recruiting websites can be a good place to start; however, the initial high volume of appli cants will dwindle as the hiring process moves forward. E-mails, phone calls, scheduling and conducting interviews, all these things require valuable time and will lead to frustration when candidates don’t respect that.

somebody else may be the per fect fit for you.

Sometimes, I will contact local colleges to find new graduates. Another good resource is our chamber of commerce, which we have been active in for years. Surprisingly, it is quite often that someone knows someone who would be a great candidate.

At our company, STN Laundry Systems, we are continually look ing for quality people to join our team and become part of our family. If the right person is available, then there is always a role they can excel in.

Once the right employee has been selected, the next challenge is retaining them, which is especially crucial in roles that require high levels of training. Getting employ ees to make long-term commit ments can be achieved by striking a balance between our needs and theirs. A reasonable salary, paid time off and benefits are require ments for most people today.

Employees know what they’re worth and what their salary should be for their position. Keep it simple and make it stan dard for everyone on your team.

This is a question every employ er is facing. It’s obvious that recent government programs have affected our labor pool, but regardless, our industry has

Of course, certain terms must be met for the referral bonus (e.g., new hires must meet atten dance requirements, remain employed for a minimum peri od, achieve productivity targets, etc.). The time spent on develop ing a program and training staff could have a significant return on investment.

To retain employees, one of the best practices that we recom mend to our customers is to pro vide productivity incentives. Do

An incentive and/or night, weekend and tougher jobs should be presented as options for candidates to make more money.

I wish you luck in the battle for employees. I’m sure we all see “Help Wanted” signs everywhere we go these days, so we know that competition is out there.

Creating the right plan to recruit and retain staff will put you in a position to bring in can didates and to run as profitably as you can.

Hiring a placeholder for an open position is often the easy and quick response; however, it’s hardly ever a long-term solution and often increases difficulties for us in the long run.

How do we find candidates? My preference is word of mouth. I let everyone I know—current employ ees, friends and even family—what position we need to fill and exactly what we are looking for.

Networking with other busi ness owners has also been one of the best avenues for quality hires. What may not be a right fit for

Beyond fulfilling basic needs, another key factor in employee retention is the opportunity for advancement and long-term growth throughout your compa ny. A clear, comprehensive plan needs to be laid out early upon hiring and kept track of on a regular basis with the employee.

Quality employees will not remain underpaid at a dead-end job; they will constantly move on until they find an occupation that gives them a sense of accomplishment, as well as being part of a team.

As employers, we have the responsibility to our employees to have purpose and fulfillment in their jobs.

www.AmericanLaundryNews.com AMERICAN LAUNDRY NEWS | APRIL 2022 13

ALN

Equipment/ Supply Distribution

Armand Lemieux STN Laundry Systems LLC, Hamden, Conn.

Consulting Services

Jon Witschy Spindle, Woodridge, Ill.

JENSEN USA

With more than 3,200 tunnels in operation, JENSEN says it offers unique concepts such as the Universal tunnel washer with FlexWash and FlexRinse Technology, which features total batch integrity; the patented Universal Mediline, which features no enclosed process tanks on the tunnel; and the “TopDrain” style extraction press with no external tanks for maximum hygiene level.

In addition, JENSEN offers options such as QuickSoak and UVClean. With QuickSoak, the company says goods that tend to “float” on top of the water (such as barrier gowns or Gore-Tex items) are forced underwater due to the very efficient, precise and faster soaking in the first compartment, higher mechanical action, faster soil removal

PRODUCT SHOWCASE

Tunnel Washers

and improved distribution of chemicals.

No extra maintenance or utilities are required—high wash quality with high productivity.