Late

ST. CHARLES, Ill. — Healthcare Linen Services Group (HLSG) reports it has entered into an investment partnership with York Capital in New York.

HLSG says it chose York as the new partner because of its experience in both healthcare and facility services.

The partnership will allow HLSG to continue its path from “Good to Great” by bringing resources and funding for additional investments in automation, training and acquisitions that accelerate growth into new geographies.

“I am looking forward to our new partnership with York Private Equity and the growth opportunities they can provide in both capital and expertise,” says Joe LaPorta, CEO of HLSG. “HLSG will leverage this new partnership with York to solidify our footprint and enter new geographies via acquisition.

“We will continue to invest in automating our existing facilities, accelerate our growth and continue our commitment to provide the highest level of quality and service to our customers.” ALN

BY MATT POE, EDITORCOMMERCE, Calif. — The year was 1952.

Near the University of Southern California (USC), Albert Antman decided to launch a small retail laundry business—the keyword being “small.”

The site in which he began operations offered less than 2,500 square feet—only enough space for pressing and ironing of garments.

It didn’t even have its own laundering facilities.

Despite the size limitations, Kleen Kraft Services was born. Since that time, the company has moved into commercial laundering with uniform rental services and has grown into a thriving operation.

Through it all, the company has remained family owned and operated, and this year Kleen Kraft is celebrating its 70th anniversary.

CHICAGO — The effects of COVID-19 will be felt for years to come. Besides the effects on the healthcare industry, and the concerns of individuals about their health, the pandemic contributed to business interruption and soaring inflation.

One of the lasting hits on budgets all around, from individuals to laundry and linen services, has been rising fuel costs.

Then in February, Russia invaded Ukraine, which caused a quick, dramatic spike in prices.

What do these record-high fuel prices mean for laundry and linen service delivery budgets, and what can they do to cope with the high prices?

American Laundry News reached out to an oil/gas industry expert

In Eric Frederick’s penultimate column, he shares advice with young laundry professionals.

Oil/gas industry expert, laundry operation representatives share insights into situation, offer strategies

and high fuel

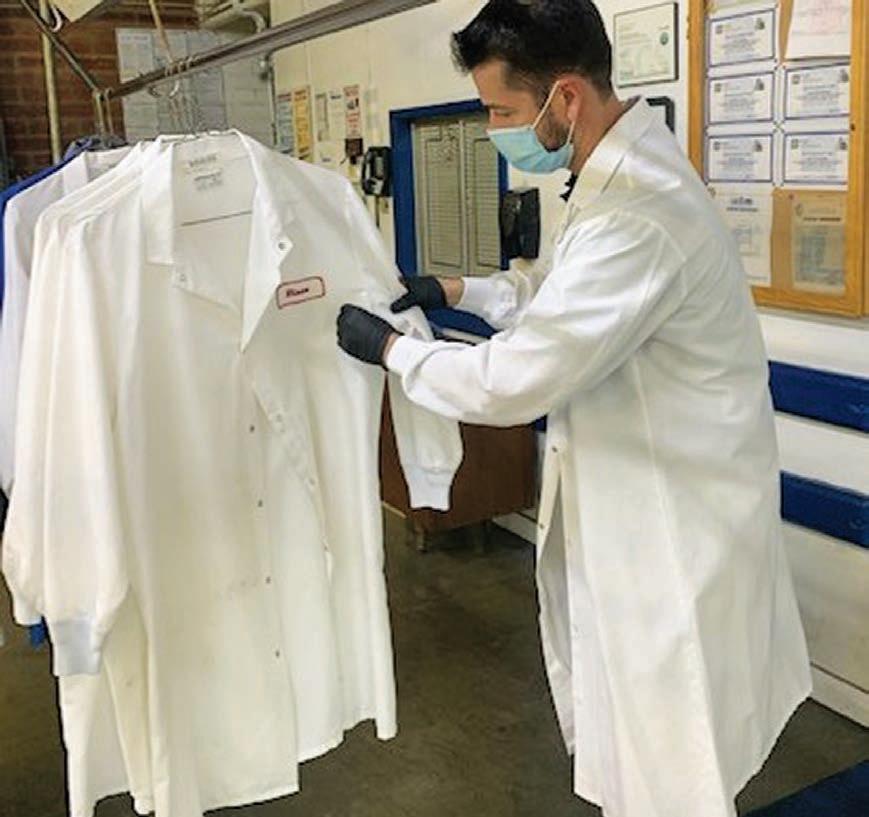

Kleen Kraft Services continues decades of evolution, growth under Antman familyKleen Kraft Services grew from a location with no laundering equipment to a plant that processes 100,000 pounds of linens a week. (Photo: Kleen Kraft Services)

WILMINGTON, Mass. —

UniFirst Corp., a provider of customized business uniform programs, facility service products, and first aid and safety services, hosted a ribbon-cutting ceremony April 7 to celebrate the grand opening of its new 66,000-squarefoot, state-of-the-art industrial laundry plant in Chattanooga, Tennessee.

Developed to accommodate a growing customer base in Chattanooga and surrounding communities, the new customerservicing plant features the latest innovations in textile services technologies and automation, according to the company.

The advanced operation and its team of 80 employees will provide local businesses with personalized service programs for uniforms and workwear, as well as facility service products like floor mats and mops, wipers and towels, and restroom products.

UniFirst says that all employees from its smaller facility in Chattanooga have transitioned to the new location, and an increase in staff by about 7% is expected over the next few years to accommodate projected growth rates.

“Our new Chattanooga facility is at the forefront of the latest advances in uniform and textile service technologies and innovation,” says UniFirst President and CEO Steven Sintros.

“The combination of the facility’s high-tech processing systems and our staff of dedicated uniforms and services experts will allow us to maximize service levels to area business customers.”

Spanning 7 acres, the company says its new facility also has an eye on the “greener” side of operations, supporting greater energy efficiencies through investments that include heat reclaiming equipment, contemporary rooftop HVAC units, latest-generation machinery that requires fewer natural resources (gas, electric, water and detergents) for the pro-

duction and hygienic laundering of garments and textiles, and ecoconscious warehouse and office lighting.

In addition, all cleaning formulas and detergents are 100% environmentally friendly, and natural light throughout the plant offers a positive employee boost to the workday while saving on energy.

“We are excited to bring this world-class operation to the Greater Chattanooga markets to serve our local customer base,” says General Manager Timothy Spencer.

“Our Chattanooga facility hous-

es the very best of all the technological advancements we’ve made over the years and serves as a model for future UniFirst servicing operations.

“It also reinforces our ongoing commitment to delivering the highest-quality uniform products and personalized service to our local customers for many years to come.”

The grand opening ceremony included representatives from the local community as well as UniFirst executives and staff. The event concluded with a tour of the new facility and a catered lunch. ALN

Publisher

Charles Thompson

Phone: 312-361-1680

E-Mail: cthompson@ ATMags.com

Donald Feinstein

Phone: 312-361-1682

E-Mail: dfeinstein@ ATMags.com

Bruce Beggs

Phone: 312-361-1683

E-Mail: bbeggs@ ATMags.com

Matt Poe

Phone: 866-942-5694

E-Mail: mpoe@ ATMags.com

Mathew Pawlak

Nathan Frerichs

Phone: 312-361-1681

E-Mail: nfrerichs@ ATMags.com

David Barbe

Janice Ayers Davis • Nick Fertig

Deana Griffin • Cecil Lee Edward McCauley Jim Slatcher

Main Phone: 312-361-1700 Fax: 312-361-1685

Subscriptions

847-504-8175 ALN@Omeda.com www.americanlaundrynews.com

American Laundry News (ISSN 1091-9201) is published monthly. Subscription prices, payment in advance: U.S. 1 year $50.00; 2 years $100.00. Foreign, 1 year $120.00; 2 years $240.00. Single copies: U.S. $10.00; Foreign $20.00. Published by American Trade Magazines LLC, 650 West Lake Street, Suite 320, Chicago, IL 60661. Periodicals postage paid at Chicago, IL, and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Laundry News, Subscription Dept., 125 Schelter Rd., #350, Lincolnshire, IL 60069-3666. Volume 48, number 5. Editorial, executive and advertising offices are at 650 West Lake Street, Suite 320, Chicago, IL 60661. Charles Thompson, President and Publisher. American Laundry News is distributed selectively to qualified laundry and linen management and distributors in the United States.

ATLANTA, Ga. — Messe Frankfurt, organizer of The Clean Show, reports that after the 2022 edition in Atlanta, July 30-Aug. 2, the largest event in the United States for the laundering, dry cleaning, textile care services, supplies and equipment industry will shift back to odd years beginning in 2025.

The move comes in response to the unprecedented postponement and rescheduling of events and

trade fairs across the industry.

“Our goal in shifting Clean back to an odd-year cycle is to help restore balance to the international trade fair calendar as the industry recovers post-COVID,” says Greg Jira, show director. “We believe this decision is best for the global industry as a whole.”

The following edition of The

© Copyright AMERICAN TRADE MAGAZINES LLC, 2022. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Laundry News does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Laundry News or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

When Milnor introduced PulseFlow® technology, CBW® washing was thrust into the future. The idea of balancing time, temperature, mechanical action and chemistry was missing one critical piece of the pie – DILUTION through the efficient use of water.

PulseFlow combines the innovative RecircONE® fast wet down and chemical immersion in the first module with standing bath washing in every spacious process module. Thorough and efficient dilution occurs by way of intermittent high velocity counterflow rinsing and traditional True Top Transfer.

The result is hygienically clean linen using less water (as low as 0.3 gallons per pound/2.5 liters per kilogram) and less energy as proven time and again by hundreds of PulseFlow tunnels in a variety of laundry applications worldwide.

Contact an authorized Milnor distributor or call 504-712-7656 to find out more.

www.milnor.com

I n every issue of American Laundry News, we work to pro vide a variety of content to keep you informed.

Sometimes, we feature more articles that look into how other laundry and linen services operate or offer ideas for ways to increase quality and efficiency

Other times, like in this issue, there is more content focused on keeping you informed about what’s going on in the industry and other factors that affect your businesses.

The fuel price story on page 1 is a prime example.

The price of fuel has been on the rise, but then it spiked when Russia invaded Ukraine. It costs more for laundry operations to pick up and deliver goods—an unexpected outlay.

I spoke with an expert in energy markets and the oil and gas

The Editor’s Desk MATT POE

The Editor’s Desk MATT POE

industry to find out more about the rise in price and future expec tations. I also heard from three laundry operators who shared strategies for dealing with these higher fuel costs.

How about the way the pan demic changed selling and con tracting business? You can find out

how one operation is working on this in a more digital environment on page 11.

Another challenge laundries face because of the pandemic is hir ing and keeping employees, and I reached out to a laundry recruiting expert to provide an update on this on page 14.

Challenges? Yes. Insurmountable? No. By being flexible and creative, the industry will go on and thrive (and you never know who in your organiza tion might offer that creative solu tion—see page 12).

And operations with 70-year histories like Kleen Kraft Services (page 1) show that laundry and linen services overcome and endure.

No matter the challenges and hardships, you continue to keep it clean, everybody! ALN

Clean Show will take place in August 2025 at the Orange County Convention Center in Orlando for the first time since 2005.

Subsequently, Clean will return to the Las Vegas Convention Center in July 2027, Clean’s sev enth edition in this location.

“We are looking forward to returning to these cities with a history of successful Clean Shows,” Jira says. “The venues are excited to have us back, and the industry is definitely ready for the return of our regularly scheduled in-person events.”

Registration is current ly open for the next edition of The Clean Show, which will take place this summer in Atlanta, Georgia ( https://www.compu

systems.com/servlet/ar?evt_ uid=199&TrackCode=PR2).

Clean still has exhibition oppor tunities available, but space is almost sold out. Companies inter ested in reserving a booth should contact Jewell Kowzan, Jewell. Kowzan@usa.messefrankfurt.com.

The Clean Show is organized in

collaboration with five industryleading associations: Association for Linen Management (ALM), Coin Laundry Association (CLA), Dry-cleaning & Laundry Institute (DLI), Textile Care Allied Trades Association (TCATA), and TRSA, the association for linen, uniform and facility services. ALN

I was very fortunate when I stumbled into the laundry industry to work under two wonderful gentlemen—Henry Palmer and Bill Hendrix—who both had not only the knowledge of the industry, but also the vision to see its future.

I was fresh out of college and had a major in recreational land management from the Forestry Department at Utah State University. Unfortunately, I was finding it hard to find a job, so I wandered into the local hospital and hoped to find a job in the housekeeping depart ment so I could support myself until I could find a job in my major.

The hospital employment office had a different idea and sent me to the central laundry facility, which at that time was attached to the hospital. I knew nothing about the commercial laundry business and was not prepared for what I saw. But they were happy to put me to work manually loading and unloading 600-pound Washex washerextractors.

After the first day, I was ready to quit but the need to pay rent and eat kept me coming back. I soon found that I enjoyed the work and the diversity of the people I got to work with. I worked along side many people from the island of Tonga and numerous South American countries. One of my fellow workers on the wash line was the son of immigrants from Finland.

After two weeks, I was promoted to washroom supervisor and then several months later I was promoted to an assistant shift manager. My college education opened the doors to my potential laundry career.

It was at this time that I got some great advice from these two gen tlemen. Palmer explained the evolution of the industry to that point in 1972—how the commercial industry had changed with the advent of the home washing machines.

The home bundle laundry business had rapidly disappeared, which left the industry with more trained managers than jobs. This glut of managers was now rapidly reaching retirement age and there was a lack of young men in the field ready to take their place.

Hendrix took the time to explain the history of the laundry busi ness as an essential service to hospitals, hospitality and restaurants— how the industry provided critical services to support these and other industries. He shared that it was, and would be for the foreseeable future, a good and secure industry in which to work.

Based on this information, and my love of working with people, I decided to make the healthcare laundry industry my chosen field of endeavor.

Today as I look at the industry, I would like to offer a little advice to the young men and women who are just starting out in the industry.

The laundry industry has a bright future in front of it. I have seen many changes over the years in textile products, laundry chemicals, processing equipment, and the support and technology used in the business.

To be an effective laundry professional in today’s industry requires an agile mind and one that is always looking to learn new things. Top management jobs now require a Bachelor of Science degree, but edu cation without learning the hands-on skills associated with laundry production in my mind leaves a manager improperly prepared for the changes to come.

I was blessed with working my way up from the bottom, but if you did not get this opportunity, then provide it for yourself. Take off the shirt and tie and get directly involved in production in each area of your operation. What you will gain in knowledge and insight is well worth the time you will invest.

If, however, you entered the industry as a production worker and hope to become a manager one day, then make plans to take night classes and advance your education. As you gain knowledge, your ability to improve your laundry operation will also grow.

Secondly, embrace the history of your industry. The laundry industry has always been, and will always be, an entry-level position for recent immigrants. It is dependable work with skills that can be shown and taught without a solid grasp of the English language.

Reach out and cultivate opportunities to recruit the recent legal

“Our 70th anniversary is a celebration of my grandfather’s enterprise, my father’s vision and our family’s commitment to serv ing our customers with reliable, accountable uniform rental ser vices,” shares owner Fred Antman, and third generation of the family involved with Kleen Kraft.

Albert operated Kleen for four years until 1956 when his son, Seymour, joined the company after graduating from USC, shares Marilyn McCarty, marketing man ager.

Seymour moved the business into a larger building and invested in new laundry equipment. In the late 1960s, the company made a move from retail laundry to commercial laundering with linen and uniform rental service. Further growth took place after Fred, Seymour’s son, joined the business in 1975.

Fred took over the leadership of the company in 1993 and has overseen a steady expansion of the business year after year.

Kleen Kraft acquired Supreme Laundry in 1978 and Pride Uniform Rental in 2004. With the purchase of Pride Uniform, key personnel joined the business. Boris Zaidman came on board to serve as vice president and general manager. Bob Halstead currently serves as director of sales and service.

“One thing that makes Kleen Kraft special is our many longterm employees,” McCarty says. “There are several members of staff at the plant and offices that have worked for Kleen Kraft for

40 years, and most of our route service reps have worked here for five, 10 and 25 years.”

In 2020, Kleen Kraft achieved Hygienically Clean Certification in Food Safety from TRSA, the association for linen, uniform, and facility services, and is the only uniform rental company in Southern California to be certified by the state as a Small Business Enterprise (SBE).

“We are proud to be the only uniform rental company in California to be SBE certified,” shares McCarty.

Kleen Kraft Services covers the territory in Southern California designated as Greater Los Angeles, which includes L.A. County, Orange County, and portions of San Bernardino and Riverside counties.

“We provide uniform rental services, along with towels, mats, facility supplies, and related prod ucts to food processors, industrial manufacturers, automobile dealer ships, machine shops, and many other service industries where rental garments help improve safety, cleanliness, or create a more professional image for staff and field workers,” McCarty says.

She says that food processors are particularly concerned with cleanliness and sanitation and besides being certified by TRSA as Hygienically Clean for Food Safety, Kleen also offers a full HACCP (hazard analysis and critical con trol points) Program to support food processors in protecting the food supply.

“For auto dealerships and ser vice workers who call on business es, homeowners or retail clients, a professional image wear program is important to establish confi

dence and promote brand aware ness,” McCarty points out. “When we provide services to machine shops, industrial manufacturers and logistic firms, the safety of workers often comes into play.

“We work with HR or quality control directors to determine the right uniforms specified for ease of movement, flame protection, enhanced visibility and other fea tures to help workers stay safe on

the job.”

Kleen Kraft runs out of two facilities: a plant in downtown Los Angeles and an office with a ware house in Commerce. The company runs a single shift five days a week at the production plant, in the corporate office and for all route drivers, processing about 100,000 pounds of laundry per week.

“Our tag line is ‘The Accountable Uniform Company®,’ so we stand behind the quality of uniforms and the cleanliness of our gar ments after laundering,” McCarty says.

Kleen Kraft has an in-line repair system that allows the company to keep users’ garments together, eliminating shortages and missing or damaged garments.

“When our business started there were over 100 locally-owned uniform rental companies in the area,” Fred says. “Now we are the sole independent firm.”

For the customer, working with a family-run business is more direct, has less red tape and is a friendlier experience than dealing with a large, remote corporation, says McCarty.

“When we talk to prospective customers, we hear a variety of complaints about other providers, from product shortages to incom plete or missing deliveries, damaged and dirty garments, or rising prices and unexplained fees,” she says.

“However, the most frustrating complaint we hear about other uniform rental companies is that customers will sometimes go days, or even weeks, waiting for a response to their questions or complaints. A real person answers

the phones in our office!

“We are proud of our ‘60-Minute Culture,’ which means we respond to questions or concerns quickly— usually on the spot. Some requests require a bit more investigation, so we guarantee to get back to cus tomers or prospects with answers within one hour or less.”

McCarty says the company anticipates sustained growth with in its territory as it consistently improves its processes and contin ues to compete with national and non-local providers.

During the past two years, most businesses have had challenges working through the pandemic, but she says Kleen Kraft has been fortunate to have a diverse client base, most of which were desig nated as essential businesses.

“With the increasing awareness of the need for cleanliness, uniform rental and commercial laundering moved forward in the consider ation of many operations managers and human resource profession als, and the need for professionally cleaned garments, sanitized towels, and cleaning supplies became a necessity,” says McCarty.

Kleen Kraft is building on this awareness along with working into its fourth generation of fam ily ownership and management. Fred’s son, Rick Antman, has been the director of operations for many years.

“As we kick off our 70th year in business, I’m thrilled to have my son onboard to continue the family business for years to come,” Fred says.

and laundry operation representa tives to get their views on the situa tion, plus offering strategies to help deal with the costs.

Eric Smith, a professor of prac tice at the A.B. Freeman School of Business at Tulane University in New Orleans, is an expert in energy markets and the oil and gas indus try. He is the associate director of the Tulane Energy Institute and teaches in the Master of Management in Energy program and the Energy Specialization program.

Smith is also the Energy Committee chairman for the World Trade Center of New Orleans, and he says current high fuel costs, for the most part, come down to the high cost of transpor tation of the heavy crude oil used to make gasoline and diesel fuel.

And the Russia-Ukraine war is putting a squeeze on the amount of heavy crude available.

“There are certainly other fac tors going on, but essentially when you talk about gasoline and diesel, which is the fuel you would be worried about, half the cost of the fuel is the cost of the crude,” he says.

“And that’s not counting the impact of having to go in and redo the crude slate (the mix of crude grades) in the refineries to work around the lack of input of this heavy crude from Russia, which we can work around and it’ll have some effects.”

In general, Smith doesn’t think there will be a massive impact on

U.S. fuel capacity, but what the country will see is sort of a “high er-for-longer” price based on the uncertainty involved with Russia and Ukraine.

“Even if we were magically to have an armistice, a ceasefire, tomorrow, it will still take months to get everything balanced out again and get the crude flowing in the direction it was flowing before all of this happened,” Smith points out.

“But typically if, for example, we have to haul more crude down from Canada in rail, the rail freight is three times what the freight is on the pipeline,” he shares.

“And that will trace through to the delivered price of the crude to the refinery and then the refiners are going to add that onto the price of the finished product coming out the other side, most of which are diesel and gasoline.”

Smith says that if the Keystone XL Pipeline were in place, there wouldn’t be the high fuel surcharge involving rail freight to get Canadian crude into the United States.

“And we could probably do a better job on keeping prices stable than when we have to use this

more expensive transportation system,” he says.

“As I said, it’s roughly three times the cost to go by rail as it is to go by pipeline. Let’s say we were spending four dollars a barrel, and I don’t know what the exact numbers are, but let’s say it’s four dollars a barrel to use the current Keystone Pipeline, and presumably would cost about the same for the Keystone XL. Now we have to spend $10 or $12 a barrel to get it down. That’s going to trace right through.

“One of the rules of thumb is that every $10 change in the deliv ery cost of the crude is about 25 cents a gallon for the fuel that you buy at the pump.”

Smith says the crude cost itself and the refinery operating costs are going to be mostly uniform across the country, but the transportation is going to be a function of where in the country people are located.

“So, if you’re down in the Gulf Coast, where we have a lot of crude available to us and a lot of these so-called complex refineries, what you’re going to see is an uptick because the refinery needs to make adjustments to operate,” he says.

“They have to try and optimize around the constraint on the sup ply of heavy oil.

“If you’re in the middle of the country that doesn’t have com plex refiners, it runs on light sweet crude, it’s not going to make any difference at all.”

California has its own issues, according to Smith, in large part driven by factors such as the drought and the fact that the state imports a lot of the crude they use from places like Columbia and Ecuador.

“They will have to make some arrangements, and they are the more likely ones to say here’s a loan for everybody who wants to go buy an EV (electric vehicle),” he says.

“They have the highest prices in the country for gasoline. They could unilaterally reduce their state taxes. Several states are talk ing about doing that. Here in Louisiana, our state is about the same as the federal tax, about 18 and a half cents a gallon. Out in California, it’s a couple of dollars.

“Governor (Gavin) Newsom would probably like to get re-elect ed. I can see where he’s got more running room, for example, than the guys in Louisiana. They could cut it out, and it’s a rounding error. If he cuts it out it’s a dollar a gallon at the pump kind of thing.

“So that would be the sort of thing I would expect to see coming out of California: adjustments in their temporary adjustments and their environmental laws.”

Part of federal and state gov ernments’ fuel price strategies will likely be influenced by 2022 being a mid-term election year.

“I think that (President Joe Biden) would certainly like to see the prices come down,” Smith points out. “He’s trying to get people re-elected in the midterm elections, and all of this is not

good for them. Typically whoever’s in charge when you have a price spike in fuel loses representation in Congress, so that’s what he’s worried about.

“And he’s not worried about long-term effects. What he’s wor ried about is how can he show that he’s doing something to ame liorate the high prices, and that can include unsustainable releases of crude oil from the Strategic Petroleum Reserve. He’s already got a couple of those in the works.

“Originally, he was just trying to save money on the budget, but now if we could, for argument’s sake, flood the Gulf Coast states with oil that the government would sell cheaply out of the reserve, that would tend to dampen or reduce those prices going into these com plex, refineries.”

Smith says that sort of strat egy on the part of President Biden would only have a short-term effect. It wouldn’t be sustainable, but it would possibly get the presi dent and his party through the elections.

Another option would be for the president to push legislation through Congress that would enact price controls, he says.

“We did that a couple of times in the past, reacting like in ’73 when we reacted to the Arab Oil Embargo,” Smith says. “That was one of the times when we put some price controls on.

“More recently, we did it with the natural gas and it took us 20 years to sort it all out. We had prices for new gas and old gas and gas that was redeveloped from old wells and all this sort of thing.

“He could do this with execu tive action. He could very well be proved wrong, but while we were

If you attend one industry event this year, The Clean Show should be it! Discover new products, exciting technology, and ground-breaking research in commercial laundering, drycleaning, and the textile service industry as exhibitors from around the world showcase their latest innovations. Registration is now open. Start making your plans to attend!

www.cleanshow.com

sorting it out in the courts, it might take a couple of years, it would at least get him through the election.

“He could put some price caps on refined products. Again, not sustainable, pretty inefficient eco nomically, but it would serve the purpose of getting a few congress men elected.”

Smith says the long-term effects, those factors that will take the lon gest to normalize, are the things that involve severed trading rela tionships with Russia, like the dis ruption of trade routes and financ ing solutions due to sanctions being imposed on the country by governments around the world.

“A lot of the world gets its crude from Russia,” he points out. “When Russia’s running flat out, it’s like the No. 3 supplier of crude. We don’t buy a lot, but other people do, particularly the Europeans buy a lot of it. For us, it’s 3% of our crude supply. For the Europeans, it’s like 30%.

“Not only are the trade routes being disrupted but the banking financing those movements is shut down. The so-called SWIFT (Society for Worldwide Interbank Financial Telecommunications) system is out of whack at the moment, which is the banking sys tem that allows the central banks to clear the loans and the letters credit and all that sort of thing. They just simply aren’t happening now.”

Smith offers two ways busi nesses can deal with increased fuel costs (besides enacting transporta tion surcharges). The first is to limit delivery trips.

“If they were making two deliv eries a week to my house, now they’re making one,” he says as an example. “That’s certainly was happening with my laundry and everybody else’s.

“And I think some of that is the fact that they can save a lit tle money on the drivers and the mileage on the trucks, assuming the trucks have the capacity to handle the extra load. I would think they’ll make those kinds of adjustments almost immediately.”

Smith’s second recommenda tion is to “shop around” for the best fuel prices.

“If the crude’s coming in by ship and the refined products are coming in by ship, which certainly happens up in the New York area, you will end up with very little effect other than the cost on the crude itself, but the transportation won’t change because they don’t use rail,” he says.

For laundry and linen servic es, the immediate effect of the dramatic spike in fuel prices has been the unexpected, unplanned increase in their fuel costs.

“We’ve definitely been impacted by the rising cost of fuel,” says Brad Watlington, owner of HMT Industrial Laundry in Pangburn, Arkansas, which specializes in serving smaller to mid-sized busi nesses. “It’s increased our fuel charges by 35%.”

Jason Hartsell, vice president of operations for United Hospital Services LLC, a cooperative health care laundry in Indianapolis, says his company has also experienced an increase in fuel expenses due to the unplanned increase in the cost of fuel.

“It’s also had the impact in that we now must take another look at some of the day-to-day habits that contribute to increased fuel usage such as idle time and route efficiencies,” he says.

David Potack, president of Unitex, a medical uniform and linen rental company in Elmsford, New York, says that high fuel costs are causing all companies to evalu ate routing strategies and look for efficiencies, no matter how small.

“To reduce costs, we’ve stream lined our driver routes to ensure we’re not backtracking or covering the same areas multiple times,” shares Watlington.

“Using these steps, we’ve been able to absorb those costs without having to pass them on to the cus tomer as a fuel surcharge.”

Hartsell believes that fuel price should not affect the service pro vided, but businesses should be taking a look at what ancillary non-revenue generating runs are taking place, such as extra pickups or deliveries that are off of rota tion.

“It will also lead to many com panies examining the profitabil ity of long-distance runs,” he says. “I’m sure that many businesses will add or increase their fuel surcharg es or look to shed the unprofitable runs.”

“Our view is that a cost shock like the current fuel price spike cannot and should not impact

customer experience in any way,” Potack agrees. “We need to perse vere through this challenge, but cus tomer service is non-negotiable.”

“If prices continue to rise, I’m not sure how we’ll avoid shar ing those costs with the customer,” Watlington says.

Hartsell thinks that in the long term, there will be some hesitancy for operations to set their fuel bud gets.

“I think a lot of us have become complacent in the fuel market and what the long-term fore cast looks like,” he says. “We uti lize the U.S. Energy Information Administration’s (EIA) forecasts as one of the primary sources for budget purposes, but the cur rent situation has shown that an unplanned global crisis can turn an entire market upside down very quickly.”

Besides the increased fuel costs, Hartsell says there is going to be a “trickle-down” cost increase in all aspects of doing business.

“We will see fuel surcharges on everything from linen and chemi cal deliveries to lawn care,” he says.

“When these surcharges first started being added on a dozen years ago, the thought was that these were temporary but as diesel prices started to level off and then decrease they never really went away.

“I incorrectly thought that busi nesses would move the fuel costs from a separate line item into the price of goods, but it has remained a separate fee and will probably remain that way.

“When we couple the ship ping issues that we experienced in 2021 with the fuel prices in 2022, it’s more expensive and there is a higher level of difficulty to conduct day-to-day operations.”

Hartsell shares that the EIA is forecasting stabilization in Q2 with a decrease in the second half of 2022, but there is a great deal of uncertainty due to the war in Ukraine.

“We will probably see increased domestic production of oil and natural gas, which should help for the next few years but increasing some sustainability through elec tric or alternative fuels will leave us in a better position,” he shares.

“I’ve not seen a lot of people talking about what natural gas will do in Q3 and Q4 but that is a con cern. Already in Europe, they have seen an all-time high on March 7; it’s presently up over 90% over last year.

“The U.S. in 2021 was the largest exporter of liquefied natural gas to Europe with Russia accounting for 20%. I’m certain that as the U.S. and other countries fill in the gap created by the ban on Russian imports, we will see increased prices domestically for natural gas. This will also most likely have some impact on the cost of goods from European manufacturers.”

One positive Hartsell notes is that the transportation market may start to see some headway made in electric, plug-in hybrids (PHEV) or alternative fuels.

“When the price of fuel climbed in 2008, we started to see some options start to come to the mar ket such as compressed natural gas (CNG), but they never seemed to gain widespread traction,” he points out. “I feel that our market is in the right place for electric or PHEV delivery vehicles.

“One of the downfalls of large electric trucks powered with bat teries is the weight of the batteries. As an industry, we do not typically underutilize the weight capacity of our delivery vehicles, and battery packs would have minimal impact on our load capacity.”

The other advantage Hartsell sees with this type of option is the ability to recharge vehicles on-site.

“When we originally researched a CNG option, there was a very large capital expenditure associated with putting in the necessary infra structure to refuel the vehicles,” he shares. “The barrier to entry for

electric would be much lower.

“When we figure in the time savings by recharging on-premises, fuel savings, potentially reduced maintenance costs, etc., we could be in a situation where a 25-40% premium for electric or PHEV could be worthwhile.

“The primary issue right now is a somewhat restrictive range of 100-200 on Class 6 (GVWR of 19,501-26,000 pounds) and Class 7 (GVWR 26,001-33,000 pounds). Some well-known manufacturers are close to releasing Class 6 and 7 trucks with a range of 230 miles which would be able to accommo date roughly 90% of my straight truck runs.”

“Some companies with smaller delivery vehicles may look at alter natives in terms of electric, LNG (liquefied natural gas) or a power source alternative to gas or diesel fuel,” agrees Potack. “That’s difficult for companies with larger trucks to do this in 2022 as the infrastructure really doesn’t exist, yet.”

Potack thinks that elevated fuel costs will last for some time; however, he does think they will begin to moderate to some degree between now and July.

“I think that cost of service will increase as the industry is not immune to inflation, which I also think is not at all transitory,” he says.

“A new cost floor has been set and will likely never revert back to pre-pandemic levels.”

Hartsell points out that laun dry operations can’t control the price of fuel, but they can conserve wherever possible.

“It may be worth looking at aero add-ons to trucks and trailers to squeeze a little more mpg,” he says. “We also can do simple things like reducing idling and driving at more efficient speeds while on the roads. If it’s possible to avoid traf fic by conducting off-hour runs it would make sense to do this. We can also examine our routes and make sure that we are being effi cient and not adding unnecessary miles to the route.

“Some of these things will require driver training to change habits. Some drivers may have got ten in the habit of driving miles off route to go to their favorite lunch stop, with increased fuel prices this 5-10 mile detour now has added considerable expense to the daily fuel costs.”

“Conduct a holistic review of current delivery models and rout ing and see where the opportu nities present themselves,” Potack suggests. “Invariably, some of these opportunities come with tradeoffs or negatives, but it’s important to really review in detail to see what mitigation steps, if any, can be implemented.”

Potack believes that any chal lenge like current high fuel prices should lead to long-term improve ment for the companies that are most engaged in their business.

“Fuel prices are cyclical but this elevated cycle feels like it will last for some time,” he shares. ALN

CHICAGO — The COVID-19 pandemic caused many changes in the business environment. One of the most drastic changes? Forcing B2B businesses to buy and sell online.

A study by McKinsey says that only about 20% of B2B buyers hope to return to in-person sales, and these customers have found digital service to be effective.

The Harvard Business Review says that the pandemic has placed new emphasis on relationships, provid ing solutions, not products—and the appropriate digital technology is part of these relationships and solutions.

So, what are laundry and linen services doing in this new sales and marketing paradigm to effectively reach and serve their customers?

American Laundry News com municated with Emerald Textiles, a provider of healthcare linen and laundry services headquartered in San Diego, about how it has han dled the online business shift.

Robert Hines, vice president of sales, points out that, traditionally, sales and new business for health

care linen service providers have been conducted in person.

“Over the last two years, espe cially with hospitals and healthcare offices ceasing in-person meetings during COVID-19, everyone has had to adapt to virtual communi cation (Zoom, phone or e-mail),” he says.

“This switch varied dependent on the level of relationship since it was easy with customers and known contacts; on the contrary, with new contacts, it was a format that every one had to get used to, almost over night.

“Now looking into the future, I see virtual meetings becoming more important as an alternative to con duct efficient, time-sensitive meet ing planning.”

However, Hines says virtual com munication will never replace the high value of face-to-face customer relationship building for Emerald.

Online meetings were always con sidered impersonal, and he points out that healthcare is a very per sonal, close partnership type of environment.

“That’s something Emerald still prides ourselves in, delivering inperson, dependable 24/7 service and

ensuring customers know exactly who their Emerald team is and that starts with building the foundation with our leadership team and inperson sales meetings,” he says.

Egbert Dugall, vice president of customer relations, says that as Emerald has transitioned into a virtual world of communication, it’s been important to have account managers properly trained with var ious platforms (e.g., Zoom, Teams, etc.) to effectively communicate with customers.

“We find that a proactive approach with any/all communica tion channels must always remain open to assure a successful partner ship,” he says.

“Availability is instrumental to maintaining a happy customer, and Emerald’s account managers are easily accessible through multiple sources of communication.

“This group is responsible for being the key liaison between cus tomers and appropriate Emerald departments to answer questions or fix any concerns. Emerald is about delivering exceptional service through, and even greater expecta tion of, good communication, so we make sure that our account man

agers are always following proper phone and e-mail etiquettes.”

While Emerald has worked to maintain face-to-face contact with its customers as the pandemic winds down, Hines says that the digital contract has become an effective tool.

“The majority of all contracts signed in the last year plus have been completed digitally through DocuSign,” he shares. “I find it to be a very effective and fast way to get contracts completed once all terms have been negotiated.

“Digital contract tracking also improves on readability, tracking changes and levels of review and approvals across organizations. Digital contract quality is much better than the days of multiple scans, back and forth, pulling physi cal contract files and overnighting for multiple signatures to get fully executed.”

Whatever percentage of in-per son and online sales and marketing a laundry and linen service uses, customers “need effective service support that is easy … yet effective in controlling costs through a prop er linen management program,” says Hines.

“Our sales team and our custom er experience team work together to ensure the goals of the customer, from initial meeting and contract phase, are being met all the way down the account manager and Emerald service team.”

Dugall says that a smooth transi tion of responsibility to the account manager from the sales team is vital to meeting all customer expecta tions.

“Having a sync relationship between sales and service is felt by the customer in where they’re not over promised and under delivered by service,” he says.

Hines agrees that overall relation ships and proven service are key drivers in the industry.

“The linen industry is at a point where companies are sinking or swimming and those that are swim ming have shown a keen interest in supporting their healthcare partners while continuing to re-invest into their business,” he points out.

“This ties directly into our high renewal success rate with our cus tomers. Emerald firmly believes partnership between both parties is critical to the success of a linen and laundry service program.” ALN

department.

The best way to encourage employee creativity is to com municate with them about any issues that need solutions.

It is also a great idea to let them know that if they have an issue, they can communicate it and then solicit solutions from them.

I have been in this situation before and my approach was to let my people know what was going on—what was needed and what my ideas were to make it happen.

Then, I would let them know that if they had any ideas, I would be willing to listen and if something sounded like it would work, then we would try it.

It was also important to make sure that people have a stake in the outcome. Otherwise, why would they want to bother with input?

To train supervisors to lis ten better, I point out that all employees have a starting point.

Managers and supervisors typically have more experience and training. However, some subordinate-level employees may have training and experience you are not aware of. Most certainly people have different ideas about how to accomplish the same thing.

So, it is a good idea to ask people how they would do this or that since life should be a con tinuous learning and improve ment process. It is important to listen without thinking of a response before the person is fin ished talking. That is a skill that most people need to work on to do effectively.

One of the most important aspects of listening that I have discovered is to be honest with people and communicate with them what is expected, what is going on and why things are happening the way they are.

If higher management says you need to do such and such,

tell your employees that upper management says this is what we need to do. Then ask, “Do you have any ideas on how we can do better?”

They are thin since they are shallow and see-through, lacking substance. These thin companies are also unremarkable and leave no memory on customers or for mer employees.

Thick organizations make an impression that lasts and share collective rituals, origin stories, ideals, language and a common goal.

“Thick institutions have a dif ferent moral ecology,” Brooks writes. “People tend to like the version of themselves that is called forth by such places.”

Transparency in the culture impacts the entire organization and produces highly engaged employees and it is easy to default to transparency. Instead of asking yourself, “Is it abso lutely necessary to share this?” ask instead, “Is it absolutely nec essary to conceal this?”

Finally, ensure that you are recognizing and rewarding these valuable contributions. Recognition is incredibly impor tant to a company’s culture and leads directly to lower turnover rates and higher productivity.

To engage your employees in any meaningful way requires a strong company culture of trust.

Most businesses singularly focus on business strategy and provide little focus on the cul ture of the company. Culture change is a tremendous enabler of improvements in general because it gives the employees what they want: a feeling of belonging.

David Brooks wrote in The New York Times about what he termed “thin” and “thick” cul tures, where thin cultures take advantage of people’s strengths and treat those people as resources to be marshaled.

When people like this version of themselves that is called forth, they will work hard for it and bond with others who also work there. Cultures like this attract talent, and without it, talent flounders.

Developing a strong company culture requires a believable and achievable mission statement as well as top-tier transparent com munication.

The desire of an employee to make the most of their talent represents a huge opportunity for organizations. Allowing them to develop and engage their natural talents sets the stage for leaps in productivity and cus tomer engagement.

When you add inspiration to the mix, productivity skyrockets.

The Harvard Business Review reports that if satisfied employ ees are productive at an index of 100, then engaged employees produce at 144, almost half again as much.

But then comes the real kicker: inspired employees score 225 on this scale. In other words, it takes 2.25 satisfied employees to generate the same output as one inspired employee.

Richard Branson has it right: “Take care of your employees and they’ll take care of your business. It’s as simple as that. Healthy, engaged employees are your top competitive advantage.”

F

irst, communicate with your supervisors your desire to have employee input on issues. Make sure they understand that you are encouraging their input. Make sure your supervisors are supportive and promote employ ee feedback.

Second, communicate with your employees your desire to gain their input. Give details of some of the issues you are facing and ask for their solutions.

Make sure they understand that you want all their ideas— however crazy they might be. Brainstorming works best if there are no restraints.

Make it a contest. Have rewards. Reward people for input—not just implemented ideas.

Make gaining their input easy—a suggestion box or an e-mail to gather their ideas.

Periodically communicate the ideas, even if not implemented, that the employees have shared.

Have recognition for those employee ideas that were imple mented.

Employee engagement is important regardless of indus try or job function, but especially so considering the many labor challenges we all face in our workplaces today.

As the frontline worker, the employee sees the many chal lenges that we face in our opera tions firsthand, and if you walk about and look closely, you might even find some question able, albeit ingenious, fixes with

“We’ve had a few ‘insurmountable’ problems solved by employee creativity— no matter the

How can we encourage our employees to share creative ideas and train supervisors to listen better?”Healthcare Laundry William Muse United Hospital Services, Indianapolis, Ind. Hotel/Motel/ Resort Laundry Kelly Reynolds Sea Island Acquisitions, Sea Island, Ga. Chemicals Supply John Schafer Diversey, Fort Mill, S.C. Equipment Manufacturing Al Adcock B&C Technologies, Panama City, Fla. (Image licensed by Ingram Image)

in their work environments.

That said, often some of the most basic conversations such as “How is your day going?” can lead to conversations that pro vide a new solution or create that “aha!” moment that can lead to positive change within the work place.

We should never forget that ingenuity comes from the many challenges we all experience within the course of completing even the simplest of tasks. Your employees just want to do their job and do it well.

If we take the time to truly lis ten, we can often learn quite a lot from them!

Supervisors can certainly be challenging when attempting to foster the desired active listening skills as many supervisors have been in the industry for quite some time.

That said, as with any initia tive, a top-down approach has been proven time and again to show great success.

If we as leaders take the time to show what active listening looks like, we can foster an envi ronment in which supervisors not only have the skills and tools necessary to do so, but they see

the value in these conversations and the value that can be gained from our team members regard less of job function or level.

pany as well as you do. They are the ones who are completing the day-to-day tasks, and they can see some things that could be improved upon.

So, what can we do to encour age employee creativity and for them to share those creative ideas and problem-solving solu tions with the company?

Nor can you allow yourself to get bored and lose focus on what the other person is saying.

Regardless of how big or small a company may be, we are always looking for ways to improve by being more costeffective and improving employ ee retention and customer satis faction.

To accomplish those things, we should use our greatest asset: our employees.

Employees are an invaluable resource of ideas and in helping to solve problems. We should always remember that a fresh perspective could provide that breakthrough you need to help solve a chronic problem you’ve been struggling with.

Most of them know the com

I would say step one is to be an ACTIVE LISTENER. Listening is one of the most important skills you can have. We should teach active listen ing to all employees so we all can understand what people are really saying in conversations and meetings.

Most of us are truly not good listeners. If we were, we would have already solved several problems. We have to make a conscious effort to hear not only the words that another person is saying but, more importantly, understand the complete message the person is communicating.

You must pay attention to the other person very carefully. You cannot allow yourself to become distracted by whatever else may be going on around you, or by men tally preparing a rebuttal while the other person is still speaking.

We want to welcome ideas from all levels and all depart ments of our organization. You know great ideas and solutions can sometimes come from an unexpected source. That one employee who generally keeps to themselves could have the solu tion to the problem.

Some employees may feel intimidated and have a fear of embarrassment or anxiety. So, let’s remove any communication barriers so employees can have the ability to share. Tell them they can drop off a note, e-mail you, leave you a voicemail or mention the idea in a meeting.

We all need to remember that there are no “bad” ideas. So, avoid criticizing any ideas. When someone gives you an idea, you should acknowledge and respond effectively.

I would start giving employees more independence. This lets employees know that we trust and value them.

When that employee hired on it was to do a job, so we need to let them do the job. This can sometimes lead to an employee

making mistakes or decisions you would not have approved of, but it isn’t the end of the world. I for one have learned and grown from mistakes I have made over the years.

We need to remember as long as the work is being done, deadlines are being met and the company is seeing an increase in profit, there’s no need to con stantly look over the shoulder of your employees.

Give employees more flexibil ity to try an idea. If the idea fails, discuss what went wrong or why the idea was not really feasible. Failure can be a learning experi ence that can lead to the next idea that just might pan out.

Over the years I would say a highly creative and fun way to get employees “brainstorming” and engaging in the workplace is white butcher paper.

You can take large sheets of butcher paper and hang some up on the wall by the time clock and in the employee breakroom. You put some butcher paper sheets on the breakroom tables.

Wherever you put the butcher

CHICAGO — The current job market in the United States is one of the most unusual the country has experienced.

Job openings remain high while worker shortages continue since many people are hesitant to return to work after isolating during the COVID-19 pandemic.

Almost every industry is fac ing a lack of workers to fill jobs, including the laundry and linen services industry.

American Laundry News communicated with Deana Griffin, president of The Griffin Group, a specialist in recruiting employees for uniform and linen/textile, food, healthcare, and service industries for 23 years, about the state of hiring and retaining employees in the industry.

What’s the current state of hiring/training/retention in the laundry industry?

Several things are taking place regarding this job mar ket. Companies are experiencing a candidate job market vs. an employer-driven market across the board for all industries. “Leading the market” compensa tion packages are being offered in order to attract talent. Workers are fleeing the urban areas to rural areas and are slow to migrate back. There is an increased volume of job opportunities for all positions within the industry. Laundries are cross-training employees for mul tiple positions.

Retaining employees is harder than ever due to a plethora of job opportunities. If an employee isn’t happy, they will immediately start the search process for new opportunities. They are switching industries more so than ever and the “Great Resignation” is here. The nation’s “quit rate” reached a 20-year high in November due to the COVID-19 pandemic.

Working remotely remains a top factor when considering new job opportunities in 2022.

Pay increases are failing to keep up pace with the inflation rate of 6.8% reported in November. Benefits and other perks are being evaluated post pandemic in order to attract talent. Finding a new career opportunity is easier today vs. prior to the pandemic.

What is affecting labor most (fear, wages, etc.) at this time?

Employers are faced with increased wages/salaries in order to attract top talent. Employees can demand a higher salary that is

aligned with their skill set due to the lack of supply of talent.

Ghosting from companies and candidates is happening more. Today, the ability to have a frank and direct conversation is a dying art. Ghosting, either from an employer or candidate, is poor business acumen and betrays a lack of empathy when it comes to appreciating the amount of effort that goes into the job hunting and hiring processes.

With today’s technology and communication tools available to all of us, ghosting should never be a factor. A simple communication can be the difference between a good or bad employer and a consumer brand.

This statement also implies the same mean ing when it comes to a candidate—the dif ference between a good and a bad candidate. Candidates ghost employers out of “fear’ and “ego.”

Clients “ghost” because of better candidates and lack of decisiveness of whether to hire or not to hire.

The labor shortage is still a major concern. The rental uniform and linen/textile industry is one of the hardest industries to work in and attracting top talent is more challenging. This isn’t a glamorous industry and one that most indi viduals don’t consider when decid ing on a new career opportunity.

The old adage applies here, “You get more flies with honey.” Employers need to “sell” the poten tial candidate on why they should join their organization during the interviewing process. Employers need to communicate the pros to why it would be beneficial for can didates to make a transition.

Hiring decisions need to be shortened due to a plethora of other career opportunities. If you snooze, you will lose a top talent ed candidate, which has a trickledown effect within the organiza tion. Top talented individuals and job seekers are receiving multiple contacts for great opportunities per day, which has increased due to the labor shortage we are expe riencing today.

Employees are handling more job responsibilities today within their job descriptions due to labor short ages, which causes burnout, employ ees seeking new career opportu nities, low employee morale, lack of effective communication, work ethic challenges and increased hours without increased wages.

How are laundry operations dealing with fewer employees?

This issue causes employers to examine their entire business

model. Companies are:

• Looking for ways to out source, automate (robots).

• Addressing issues of longer cycle times for sales, service, product and overall opera tions.

• Hiring temporary workers in the interim and, hopefully, they can become full-time employees.

Transferring talent to loca tions where there are labor shortages if they have mul tiple locations (looking for talent in-house).

• Forced to create and offer more perks/incentives for their employees.

• Making retaining employees a priority because a record number of employees are quitting now—the “Great Resignation.”

• Being flexible with employ ees’ schedules—working remotely.

• Hiring better talent in order to fill two or three positions vs. one.

• Considering an intern or creat ing apprenticeship programs.

Also, temporary foreign workers are possible candidates. According to the press release from Homeland Security, the Department of Labor (DOL) made more visas available for the first half of the fiscal year— 20,000 H-2B visas.

Are you seeing any indications that workers will return to the industry or that new employees will start taking positions?

Several indicators are apparent, starting with operations offering “leading the market” compensa tion plans.

Inflation has increased the cost of living, along with increased house prices and rental increases. And the $400 weekly unemploy ment benefits expired and stimu lus checks have ceased. There is now a child care tax credit when employees hire a nanny or other child care provider.

Business demand has cre ated more career opportunities, and there are a lower number of COVID-19 and variant infections. Finding a new job could mean less of a commute for employees due to the cost of gasoline.

It’s also a time of business clo sures and start-ups, and business es now have available workspaces with the right tools and informa tion for the job.

What methods for attracting new employees are working?

Many methods are available and working, such as:

• Hiring an industry recruiter.

• Implementing a simple and

fast hiring plan.

• Employee referrals with incentives.

• Networking.

• Social media.

• Advertising in trade maga zines, newsletters, banner ads.

• Job boards (expect to pay more because with each click/view the employer incurs a cost).

• Internship, apprenticeship programs.

• Recruiting from the military and veterans talent pool.

• Jobs posted on the company website—with a video.

• Staying in touch with passive candidates for future career opportunities.

• Visas are available.

• Beating the competitor com pensation package. Market test your current pay struc ture and increase accordingly to attract top talent.

What strategies for retaining employees are working?

Again, there are many ways the rental uniform and linen/ textile industry can better retain employees, including: Flexibility, which increases productivity.

• Re-evaluating current com pensation plans and adding perks, offering wage increas es where warranted, annual reviews evaluated every six months vs. annually.

• Investing in ongoing training options for employees.

• Communication is key among all departments in order to keep everyone informed.

• Perks including after-work get-togethers, gym member ship, bonus trips, outings/ events that involve the family, etc.

• Investing in the hiring pro cess and hiring the right peo ple. Hiring a recruiter to “vet” the candidate for the position and company culture. Respecting the employee— making them feel appreci ated and valued.

• Listening and receiving feed back from staff can be effec tive.

• Fostering a favorable work place.

How much does training/edu cation affect hiring and retaining employees?

Further training and education involves the employee—shows that the employer is investing in the employee. It makes the employee feel part of something bigger than just having a title, and the employ ee feels appreciated and valued.

If a company is willing to invest in training and education for its employees, it resonates with growth, the bigger picture mindset, suc cession planning, upward mobil ity, company stability and a positive team atmosphere, to name a few.

What do you think will happen with the laundry labor market in the next two years? Further out?

According to a recent Baird sur vey, the linen and uniform rental segment will have positive growth over the next 12 months, which will have an increased number of posi tions to be filled. This will be ongo ing depending on positive growth.

Acquisitions and mergers have increased in the industry and this will continue in the future as the industry consolidates. This will also have an impact on the num ber of employees hired and avail able job opportunities.

The “Great Resignation”— three out of four full-time employees plan to quit their jobs over the next year and compensa tion is the major reason.

Any final thoughts to share with the readers?

Healthcare costs are rising and companies are evaluating exist ing and new plans. Some compa nies are reducing coverage, which doesn’t align with better plans from the competition.

Cannabis usage—companies need to implement policies that pertain to this subject.

Companies have the thought process of “doing more with less,” especially with small profit mar gins in this particular industry. With this being the case, we need to perfect the hiring processes with KPIs (key performance indi cators) in place.

Addressing the costs to hire, train, educate, retain and crosstrain will be offset by how well you align your company to the business plan and economic factors.

paper make sure to scatter a variety of writing utensils for them to use on the paper. This will give employees a place to scribble down their idea when unprompted.

This could also create a spon taneous “brainstorming” session. Brainstorming can help to get people to think out of the box.

I hope that my contribution has provided you with some ideas. I wish all of you success.

on making improvements or addressing issues.

As a software vendor, we have a “Feedback” link for users logged onto our online customer portal. We try to gather thoughts that arise while people are active ly working with our solution.

Schedule brainstorming ses sions. Put a “Problem Solving” or “Innovation” session on the agenda for regular team meet ings and create a habit out of it. If people know there will be an opportunity to share, then their creativity may come out.

Do so at all levels. By getting supervisors accustomed to mak ing suggestions at higher-level meetings, they might open up to listening for ideas in plant floor huddles or one-on-one interac tions.

Committee” has become some what ubiquitous, but consider others, such as an “Operations Committee,” a “Quality Improvement Committee” or a “Process Flow Committee.” Any of these might recognize an opportunity to improve a procedure, potentially reducing operating costs.

Install a Suggestion Box. Your team members might be shy about presenting ideas in a group setting, but one of them could have the silver bullet in mind for improving a process. Create a separate committee that reviews items submitted in this manner.

employees to get creative is to enact one of their ideas. It might take some time to solicit that first solution and put it into place, but seeing the vision from a coworker come to fruition could inspire others to become problem-solvers themselves.

will ever be fast enough.

One thing I noticed about owners in this industry, right away, is their willingness to hear a suggestion from anyone, and they suggest trying it if it sounds like it may streamline production or eliminate an issue.

I try to remind my crew to always be considerate when hear ing complaints, but I also remind them, often, we can do a lot of immediate troubleshooting with a brief conversation with the person running the machine.

This is a great comment and question. It makes sense to go to the people who work every day with the equipment and processes in your plant for ideas

An occasional company-wide meeting, which brings together departments that don’t normally work together, could become a great idea-generator since person nel can identify potential cause and effect (e.g., “When goods are delivered to our department in this manner, we have to take these extra steps…”).

Form committees. The “Safety

Incentivize idea generation. For something that is success fully implemented in the plant, offer a small award (or a big one, if it ends up saving the organiza tion a lot of money).

Alternatively, hold contests with prizes. I recall a nationwide chain that put on a competition with local, regional and then national winners, ultimately resulting in improved operations across the country.

Whatever approach is taken, your best bet for encouraging

Itry never to view a problem as “insurmountable.” Some are, such as the cost of fuel, inflation, textile and parts avail ability. These things can even be addressed and accounted for, but the production and service chal lenges are always subject to one good idea, usually something simple, that can cure an issue. Being the maintenance guy, I have to satisfy as many people as I can. I don’t always get it right on the first try, and I doubt it

I am blown away watching an equipment operator who is learning English as a second lan guage navigate their way through an interphase to switch from a certain formula or function to another.

Some of the operators at our company have three decades here. For me to discount their input would be foolish on my part.

To keep this relationship with them is as simple as being respectful and appreciative. They want to be heard. We just need to be ready and willing to listen.

Sure, some ideas aren’t the best, but oftentimes those are mine! ALN

UniMac says its 200-pound capacity tumble dryer equipped with the UniLinc control delivers the perfect balance of capacity, speed and efficiency to help medium and high-volume laundries manage their loads.

Efficiency is driven by an enclosed heat system that uses radiant heat from the stove top to preheat intake air before it enters the combustion chamber.

The efficiency story gets even better, according to the company, with UniMac’s OPtidry system, which eliminates costly over drying by drying to a set moisture level and stopping. Many operations unknowingly suffer the effects of over drying, which are inefficient in both utilities and labor.

The UniMac UT200 also comes with peace of mind through a three-year warranty that ensures exceptional worryfree performance, the company shares.

www.unimac.com 800-587-5458

Brim Laundry Machinery says its Pacesetter large batch tumbler dryers are built for optimum performance in high-volume

laundry operations.

Better designed and better built, these dryers have long been the benchmark for efficient, dependable operation, according to the company, and equally important, they provide more production for the investment.

Pacesetter CPG Gas Heated Dryers feature:

• Large drying chambers (155 to 210 cu. ft.).

• 400- to 700-pound dry weight capacities.

• Standard two-door, one-way tilt pass-through design.

• Unique double-shell geyseric gas-heated burner.

• Axial airflow directs heat to center of load.

• Variable-speed friction basket drive.

• Swing out exhaust blower.

• Operator-friendly touchscreen color microprocessor controls.

• Proportional gas train.

• Insulated body and doors to retain heat.

• High capacity in a smaller footprint.

• Use for standalone applications or as part of an automated system.

Brim says its Pacesetter Dryers blend the right combination of technology and common sense with the most rugged industrial machine design available anywhere in the world.

www.brimldry.com 214-630-4517

JENSEN offers a full spectrum of dryers, ranging from its JTD series with capacities of 45 to 250 pounds, to the DTX series in 450- and 800-pound capacities, to the DT series batch system dryers in 130- to 520-pound capacities, and, finally, to the WR series batch system dryers in 120-240 pound capacities.

JENSEN says its dryers can have features such as direct-drive technology, frequency-controlled basket speed, a modulating gas valve on the burner system, mirror-image design, a high basket volume, extremely well insulated and sealed basket housing, and built-in lint collection, all depending upon the series.

The company says its combination of heat generation, air conduction, basket geometry and insulation results in optimal heat distribution in the basket and the best possible airflow through the linen while maintaining low radiant heat and noise levels.

www.jensen-group.com 850-248-5264

The company says they are installed as standalone machines or in open pocket washer-extractor systems and batch tunnel washer systems.

Braun’s PT Dryers are also available with an optional rollup door for low ceiling clearance installations and patent-pending chute load configurations. In this system, a shuttle transfer of goods is eliminated allowing for great flexibility with respect to washroom layouts.

Braun says standard features include, but are not limited to:

• 42-inch direct ignition modulating line burner ensuring uniform distribution throughout the basket.

• Automated Blowdown Internal Lint Collection System—no need for regular manual cleaning between loads.

• Dual panel control box separates high voltage from low voltage components— exceptional safety feature.

• Largest door opening in its class.

• Automatic or manual load and unload.

• Insulated shell for heat and noise.

• Plug-and-play components.

• Robust and rugged industrial construction.

• Non-clogging main blower.

Optional features include:

• Certifiable low NOx emissions.

• Sling load, cake load, chute load.

• External lint collection.

• Non-stick basket perf coatings.

• Inlet and exhaust duct configuration.

• Gas usage monitoring.

• Coated baskets.

• Steam.

• Single door.

ADC

www.gabraun.com 800-432-7286

riencing state-of-the-art drying with exceptional technology and industry-leading advancement.

ADC says standard features include:

• Variable drum speed.

• Pre-heat system.

• Trans-axial airflow.

• Fully insulated cabinet.

• Double-pane door glass.

• Self-cleaning lint screen.

• Direct spark ignition.

• Two-point roller support.

• IMC® intuitive micro control with auto-dry system.

• S.A.F.E. (Sensor Activated Fire Extinguishing System).

• Reversing basket.

• Stainless-steel basket and fronts.

• Simplified inverter drive system.

• Fitting through standard 48-inch door.

• Availablity in gas, steam and electric.

ADC says that through innovative design, i-Series dryers achieve higher performance, efficiency, shorter dry times and safer, more reliable operation. Owners save money on utilities, payroll and maintenance.

Braun’s PT (Pass Thru) Series Dryers are available in natural gas and optional steam-heated machines in processing capacities of 300-400, 500-600, and 700800 pounds clean dry weight.

ADC says its AD-120i is more aggressive, more eye-catching and more innovative than any other 120-pound dryer in the marketplace today—all backed by an unconditional five-year warranty.

The company says that owning an Intelligent Dryer means expe-

The company says it designed the i-Series with years of reliable operation as an absolute design necessity. A sturdy steel welded cabinet, fewer moving parts and top-quality components are the foundation of the line, cutting down on costly repairs and unwanted downtime.

Finally, ADC says the IMC is an intelligent and simple-to-use control system that provides

one-touch program selection. By creating a fully integrated dry ing system, ADC utilizes IMC to control all aspects of the drying process to minimize user error and maximize drying speed and efficiency.

www.adclaundry.com 269-923-3000

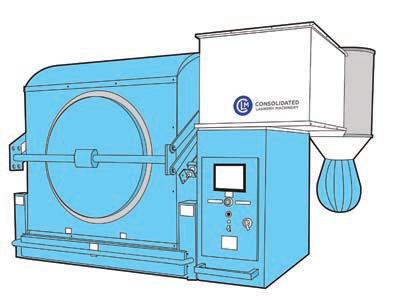

performing dryers and updated them with features that further enhance efficiency and ease of use. Able to handle any stand alone or automated application, as well as communicate with a current data-management sys tem, CLM says its powerful dryer control includes three heat-cycle termination methods to help reduce dry times.

CLM says its dryers are built to provide decades of productive and efficient operation. Either steam heated or gas fired, CLM’s six industrial sizes from 200 to 1,200 pounds are used in many industries including healthcare, hospitality, industrial, institu tional and apparel.

The company says it took the best attributes from its high-

With features such as cross-axis airflow, large door openings, selfcleaning blower, superior fuel modu lation and CLM’s unique door-to-bas ket design that pro tects your products, the company says its dryers deliver pro ductivity and effi ciency while being very simple to operate and maintain.

These improvements increase productivity, “green” efficiency and overall safety while uphold ing the CLM “workhorse” indus try reputation.

www.clmco.com 323-232-2417

B&C Technologies says its dryer line is built to meet the