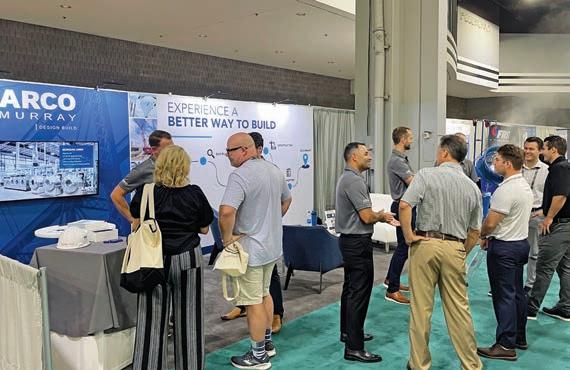

The Clean Show 2022: Industry on exhibit in Atlanta

COMPILED BY MATT POE, EDITOR

ATLANTA — Nearly 350 exhibi tors displayed their products and services on The Clean Show’s 216,000-square-foot trade show floor at the Georgia World Congress Center here July 30-Aug. 2.

And around 10,000 attendees toured the booths and exhibits over the four-day show.

While attendance was lower than previous Clean Shows (which was to be expected coming out of a global pandemic), many exhibitors were pleased with the results.

“We were anticipating a steady Saturday and Monday, with a slow er Sunday and a typical very slow Tuesday (last day of the show),” says Rick Kelly, vice president of sales and marketing for Pellerin Milnor Corp. “The show traffic met our expectations … it was a step to returning back to ‘normal.’”

Matt Conn, global director, com mercial laundry product and mar keting at Whirlpool Corporation, adds, “It was good attendance as everyone came back together for this Clean Show following three years away.

“What was more important for our team than the overall atten dance was the quality of insight, learning and time we gained from all our in-person meetings from customers all over the world.”

Joe Fleming, national sales man ager, Yamamoto North America says attendance was what the com pany expected, and even with fewer attendees than were in New Orleans its booth was the “busiest ever.”

“Our new lines, joint market ing efforts and strategic planning worked seamlessly together to make the event well worth it,” he shares.

“We have even more to introduce in Orlando and will certainly be registering as soon as it’s available. I suspect our booth size will like double.”

“As part of Sea-lion’s interna tional enterprise expansion, we see the Clean Show as an integral part of our marketing efforts and do plan to attend Orlando in 2025,”

adds Ed Kirejczyk, president, Sealion America Company.

American Laundry News presents this report describing just some of the companies and the products they exhibited in Atlanta. With so many exhibitors at the show, this article isn’t intended to be allencompassing.

Readers are encouraged to follow American Laundry News in print and online (www.americanlaundrynews. com) during the coming months for product announcements from these companies and others.

GIRBAU NORTH AMERICA

During Clean ’22, Girbau North America showcased the company’s vast product offering of commercial and industrial laundry equipment and solutions.

Drawing crowds were live dem onstrations of Girbau Industrial® ironing systems, including the Compact Pro, an all-in-one feeder, dryer, ironer, folder and stacker; a new DRC cornerless feeder and the DRE high-speed clip feeder; and the

new GI FTQ Drywork and Garment Folder.

Several end-user promotions and new and innovative custom finance options were also introduced.

A Friday evening reception and presentations for distributors and special guests kicked off the show, according to President Mike Floyd. Attendees enjoyed first glimpses of new laundry systems and the intro duction of Girbau Global Laundry Solutions’ three pillars—customer proximity, one team and innovation and sustainability.

The products showcased as part of the GI brand offering included the 140-pound capacity ST1302 Dryer with vacuum loading, which works as a stand-alone dryer or as part of a continuous batch wash ing system (tunnel), and the DRC Cornerless Feeder, which precise ly feeds a variety of items—king and queen sheets, healthcare flats and draws, and food and beverage square and rectangle tabletops— into any model corresponding ironer at industry-best throughput production rates.

Other products included the DRE High-Speed Clip Feeder, designed to precisely feed healthcare and hospi tality linens at high-speed through put production rates, and transition to feed small pieces; the new FTQ Drywork & Garment Folder, which automatically folds drywork items of different dimensions one after the other, including towels, bathmats, washcloths and blankets; and the 5-in-One Compact Pro.

MEESE

The highlight of the Meese booth at Clean was its partnership with Dura-Cast.

For more than 50 years, Meese

has offered high-quality carts and containers for the laundry industry.

The company says its partnership with Dura-Cast allows it to offer a greater selection of products to address laundry customer needs.

Meese/Dura-Cast says their col lection of carts, trucks and contain ers are rugged, yet lightweight, to ensure safe and easy transport and storage of clean and soiled linen.

ROYAL BASKET TRUCKS

Royal Basket Trucks shared its solutions for carts, trucks and con tainers at The Clean Show.

The company’s products are used in markets such as material handling, hospitality, healthcare, commercial laundry, education, recycling, ath letics, property management, retail, warehousing and distribution.

Royal Basket Trucks constructs its carts and trucks out of vinyl and canvas, molded plastics, steel, PVC and steel wire.

The company builds to order, which offers flexibility for slight modifications in dimensions, caster changes and color. Royal can also engineer fully custom cart solutions.

B&C TECHNOLOGIES

B&C Technologies says it has been providing a complete line of com mercial and industrial washers, dry ers, ironers, folders and feeders for more than 20 years, and it recently expanded its offerings with a new line of high-extract, 400 G-force hard mount washer-extractors.

The company showed off its on-premises HX Series at Clean. The series features B&C’s versatile and venerable FM7 control, which is capable of handling any custom wash program requirement.

The CARB bearings are housed in

a cast iron trunnion, with the seals physically separated from the bear ing housing, meaning that the wash solution cannot enter the bearings and cause premature failure. A sol idly welded powder-coated steel frame ably transfers extract forces to the foundation.

ROYAL BLUE INTERNATIONAL

Royal Blue International, a familyowned and -operated importer and domestic manufacturer of all types of institutional linen items, highlighted its product lines in Atlanta.

The company supplies bed ding, terry products and patient apparel through five divisions of operation: Healthcare, Hospitality, Government, Textile Rental and Athletic Clubs & Spas.

THE DECC COMPANY

The DECC Company shared with Clean attendees how it serves the commercial laundry market by applying an abrasion-resistant release coating to dryer panels.

The company says the coating drastically reduces the amount of plastic and debris that adheres to the inside of a dryer as compared to a dryer with uncoated panels.

DECC adds that the abrasionresistant qualities of the coating greatly increase durability offering extended performance.

At the show, the company shared that it has a new powder coat sys tem that gets in dryer panel holes better than before.

VENUS GROUP

In Atlanta, textiles manufacturer and distributor Venus Group shared its industrial linen solutions with attendees.

The company says its wide assort ment of in-stock products and madeto-order U.S. capabilities enable it to meet the on-demand needs of customers, including restaurants, healthcare facilities, hotels and more.

Venus adds that its industrialquality products are designed for durability and comfort.

Products include its range of Milliken Signature® table linens and Venus proprietary Diplomat® napery, Performance Twill® sheets and Linea Roma® linens, which the company says are engineered for superior quality, strength and ease of cleaning.

KANNEGIESSER ETECH

Kannegiesser ETECH says the theme for its exhibit at The Clean Show was the keys to the future of hygienic textile processing: “Logistics and Automation, Robotization, Employee Ergonomics, Productivity and Sustainability.”

The more than 10,500-squarefoot booth featured:

• The washing area with

8 OCTOBER 2022 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

Nearly 350 exhibitors were on hand on The Clean Show’s 216,000-square-foot trade show floor in Atlanta for almost 10,000 attendees to explore at the end of July and beginning of August. ( Photo: The Clean Show)

A sampling of what some exhibitors shared at the largest textile care trade show in North America

Girbau shared lots of new equipment across its brands in Atlanta. (Photo: Girbau North America)

PowerTrans, PowerPress, PowerDry and PowerSwing.

• The flatwork area with the company’s entire range of feeding and folding machines for large and small items as well as for hospitality and healthcare.

• As special highlights in the flatwork area, Kannegiesser ETECH presented the new SynchroPro series and the fully automatic quality assur ance with Quantex.

• The dry work area with a fully automatic small pieces line, consisting of CSP sup ply, RFT Robofeed and XFM Speedline, and an additional XFM in manual operation.

• The garments area with a complete circuit made up of FA-X and Transline.

• The variety of its logistic solu tions with Vectura and with eVue, which the company says is designed to be the most modern and advanced laundry logistic system in the world.

FASHION SEAL HEALTHCARE

Fashion Seal Healthcare, a sig nature brand of Superior Uniform Group, highlighted its collabo ration with WonderWink® for scrubs in Atlanta.

The company says it has com bined WonderWink® fashion, fit and fabric with its industrial apparel manufacturing experi ence to launch the WonderWink® INDY line of scrubs.

Fashion Seal Healthcare says INDY scrubs are designed with fit, finish and designs that flatter all body types. Wrinkle-resistant, softfeel fabrics stretch for maximum all-day comfort.

The company says the line is loaded with additional features and is available in both unisex and women’s styling.

VEGA SYSTEMS GROUP

VEGA systems Group specializes in the design, development, manu facturing and implementation of industrial laundry equipment, and the company shared its many prod uct offerings with Clean attendees.

VEGA shared that its equipment for washing ranges from batch washers to extraction presses. Its flatwork products include feeders, folders, full-dry folders and ironers.

The company’s garment tech nology offerings include tunnel finishers and garment folder and transport options. Finally, material handling equipment includes sheet separators, conveyors and rail sys tems.

In the United States, laundry operators can learn more about the company’s product and service offerings through VEGA Systems USA.

SEA-LION AMERICA

As part of Sea-lion’s interna tional enterprise expansion, the company says it sees The Clean Show as an integral part of its mar keting efforts and plans to attend

Orlando in 2025.

Sea-lion says most significant in Atlanta was a virtual meeting con ducted with the factory, including Sea-lion’s Chairman Hong Chen and the owner of its pilot laun dry project in North America. The meeting included the presentation of a “ruyi” commemorating our partnership.

This month Sea-lion shipping the machines from the factory and will be doing the installation in Boston in October. The laun dry, which is designed to produce 32,000 pounds per shift, includes Sea-lion’s first tunnel washing sys tem (the “Laundry Dragon”) in

North America along with standalone washers and dryers, a finish ing line and folders.

New at the show was one of Sealion’s washer-extractors featuring its patented Water Droplet Drum design. This feature is designed to improve cleaning power while creating a super smooth washing surface.

Sea-lion also introduced the world’s first intelligent and efficient mattress cleaning machine. SCXH series’ intelligent and efficient mat tress cleaning and drying line per forms mattress cleaning, steriliza tion and drying automatically.

The company says the process

improves cross-contamination problems in the fields of medical care mattress washing and greatly improves the quality of life, health safety protection and living envi ronment.

Also on display were a barrier washer for medical laundries and clean rooms and an automatic towel folder.

CLEAN CYCLE SYSTEMS

Clean Cycle Systems highlighted its lint filtering systems for com mercial and industrial laundry/ textile processors in Atlanta.

The company says its Dry Lint Filter (DLF) or “SlimLine” models

represent a design concept requir ing minimum space to install while providing large area filtration. All models are tall, slim, and compact, often referred to as “inline” mod els. The DFL-500 Series filters are all-weather construction and may be mounted inside or outside, even in extreme conditions.

The OPL 200 and 300 Series Lint Filters are especially designed for properties with dryers in the 30 to 170-pound range. Multiple dryers may be vented separately or into a common duct to the filter.

•

•

•

•

•

www.AmericanLaundryNews.com AMERICAN LAUNDRY NEWS | OCTOBER 2022 9

31 31 PRODUCTIVITY : Productivity 31 Pro 31 PRODUCTIVITY NEW ISO 9001 CERTIFIED ISO 9001:2015 Certified | Made in USA Scan for more information

Braun’s PrimeDry easily processes three loads per hour! Others process only 1 load per hour. It takes 3 competitor dryers to match the efficiency of one PrimeDry! (While processing up to 175 lb. loads.)

Modulating gas valve for precise temperature control.

Installation costs are lower, one PrimeDry dryer vs. three of our competitors. This also saves floor space!

Disassembly

to fit

feature – top is removable

through a standard commercial double doorway.

Touch

information on features and product performance data

at

or visit our web site at www.gabraun.com (125 – 200 LBS. Cƒpƒcity) ® ® ® ➢ Page 10

screen control For more

contact Braun

800/432-7286

Finally, Clean Cycle Systems says its System 700 was the industry’s first “inline” style “wet lint filter”— tall, slender and representing a design concept requiring mini mum space to install while provid ing a large area filtration system

TECNI-QUIP CARTS

Tecni-Quip Carts shared its laundry cart options with attend ees at The Clean Show.

The company manufactures and markets material handling carts to healthcare facilities throughout the United States and Canada. All manufacturing, design and sales are done at its factory and main location located in Seguin, Texas.

Tecni-Quip Carts says all of its products are made in the United States, and it can custom design any of its products to fit specific needs.

MAXIMOVERS/ CHEMTAINER

Chem-Tainer Industries, which provides material handling prob lems solutions, shared its MaxiMover line of trucks and contain ers for the laundry industry with attendees.

The company manufactures Bulk Delivery Trucks, Shelved Exchange Trucks, Tilt Trucks, along with Utility and Bushel Carts.

In 1972, Chem-Tainer says it introduced the nation’s first line of plastic transportation solutions to the material handling and textile processing industries.

More durable than the canvas units and less costly than the metal or fiberglass options available at the time, the company says MaxiMovers and its globally licensed plastics manufacturing technologies spawned a new industry and revolu tionized the industries they served.

JP EQUIPMENT INC.

In Atlanta, JPE highlighted the Olma OBIFOLD Premium folding machines with attendees.

The company shares that the folder is designed to fold thick or thin items and cotton, poly or bar rier material because of its elastic, captured crossfold.

JPE says presorting isn’t neces sary because the folder is designed to automatically sort based on the length or width measurement taken as each item enters the pri mary fold table.

Representatives shared that the folder also has color sorting capa bilities.

The delivery/rising conveyor can be configured for sorting to discharge on the left or right side of the machine.

NORCHEM CORP.

Norchem Corp. says The Clean Show is always a great place to reconnect with longtime partners, old friends, see what’s new in the market space and show off all the hard work that the company does year-round.

Front-and-center on display, the hot-commodity that always draws the crowds, The UltraPure® Wastewater Reclamation System

was a popular conversation over the weekend as regulations across the nation begin to tighten among the industry, says Norchem.

Also on display were the Norflow-WIN® Automated Chemical Injection System and the NorQuest™ Washer and Dryer Controllers. Each display featured a simulated but interactive display to showcase just how the system would look inside an operation.

MAXI-PRESS

MAXI-PRESS introduced Clean attendees to its latest development: the ANTI-BACT water extraction membrane.

The company says the hightech innovation from Germany is a certified product and has all the well-known advantages and areas of application of MAXI-PRESS. It is designed to contribute to a significant reduction of germs in the laundry.

In addition to testing by the German Hohenstein Institute, MAXI-PRESS says customers con firm the advantages of the mem brane. The mode of action actively prevents the formation of germs on the membrane surface.

ANTI-BACT membranes are particularly suitable for use in hos pitals and care facilities.

TJERNLUND PRODUCTS

Tjernlund Products, which manufactures solutions for exhaust, ventilation and heating/ cooling problems, highlighted its dryer duct boosters in Atlanta.

The boosters are designed to solve the problems of inadequate exhaust velocities, including exces sive lint build-up, extended drying times and inflated utility bills due to the longer drying times.

The company says its COPSeries controllers measure pres sure within the duct and modulate commercial dryer duct booster fans to match exhaust volume changes.

LATTNER BOILER COMPANY

Lattner Boiler celebrated its 104th anniversary at The Clean Show.

Established in 1918, the com pany manufactures both fuel-fired and electric boilers for a variety of industrial applications, including

laundries.

In addition to vertical tubeless boilers, horizontal firetube boilers, low-NOx boilers and steam boil ers, Lattner manufactures conden sate return, feedwater and blow down systems.

AMERICAN DAWN

In Atlanta, American Dawn shined a spotlight on its workwear/ healthcare apparel products.

The company manufactures, imports and distributes textiles for hospitality, food and beverage, healthcare, industrial, home, and salon markets worldwide.

ADI says its standing inventory allows same-day shipping with next-day delivery to most major cities.

With company-owned distribu tion centers in Los Angeles, Chicago, Houston, Atlanta, and Philadelphia, ADI says it is logistically positioned to serve more than 85% of the U.S. laundry market with same-day shipping and next-day delivery.

The company says that to the industrial and commercial linen laundry market, it is the largest provider of rentable textiles.

American Dawn also supplies towels, bed linens, table linens and other related products to laundry customers throughout the United States and Canada.

LEONARD AUTOMATICS

Laundry equipment manufac turer Leonard Automatics high lighted the fact that its tunnel fin isher has a new burner for better finishing and efficiency.

Also, the company’s folders/ crossfolders/feeders attracted attendees in Atlanta.

Leonard also shared its many other products and services for the laundry industry, including press ing equipment, steam cabinets and conveyor systems.

The company says that it pro vides automated finishing systems that can improve an operation’s quality and reduce pressing labor.

UNX-CHRISTEYNS

The recent merger that formed UNX-Christeyns, finalized on July 1, was front and center at The Clean Show in Atlanta. When attendees visited the booth, they saw how a

wide selection of innovative and proprietary chemical solutions, combined with real-time analytics and exemplary customer service, benefits all-size commercial laundry operators, drycleaners and textile service providers.

In addition to the many timetested solutions offered by UNXChristeyns, the company shared how its Compact Max (for tunnel washers) and Compact One (for conventional washers) solutions can help any healthcare and hospitality operator tackle operating challenges and bring their plant operations up to the highest efficiency standards in the U.S. laundry market.

The company also showcased three precise dosing systems, demonstrating the small-format MiniTron™ dispenser. Recognized for its ability to dispense up to six chemicals to three different washers, MiniTron measures the amount of a chemical by its weight and vol ume to verify “Truth in Delivery” in detailed production reports, accord ing to the company.

Complete with a compact foot print and touchscreen controls, UNX-Christeyns says the dispens ing unit is capable of delivering up to 20 wash formulas. Since it offers Wi-Fi connectivity, customers can monitor and receive laundry reports remotely.

Also on display were the FluxCompact, Flux-Multi and Flux-Star systems. Flux-Compact is a wallmounted central dosing system for OPLs and small shirt laundries. Flux-Multi is a central dosing sys tem for conventional washrooms with up to 15 washers. Flux-Star is designed for medium and large laundries.

G.A. BRAUN

G.A. Braun introduced three new products at Clean ’22: the TopLine® Air Folder, the PrimeDry® dryer and an open pocket water reclamation system.

The company says its Precision Series TopLine Air Folder® is designed to process all sizes of tow els, blankets, pillowcases, industrial and medical garments.

Features include, but are not limited to:

• Can process unfolded items that are within 48 by 74 inches.

• French folds—finished items between 6 and 16 inches.

• Touchscreen ability to show user proper way to feed a gar ment depending on desired presentation and fold type.

• Jog forward and reverse fea ture in cross fold to easily remove any possible jam with an EZ-Out system in place to efficiently remove a jam.

• “Manual Send” mode allows the operator to start/stop the infeed table and prefold items while going into the machine.

The PrimeDry® 125-200 pound capacity dryer, is industrial grade, feature rich and compact, accord ing to the company.

Features include, but are not limited to:

• 3:1 productivity—this dryer

easily processes three-plus loads per hour (while process ing up to 175-pound loads).

• Side-by-side dryer design construction and through put capabilities significantly reduces floor space

• Disassembly feature—the top is removable to fit the dryer through a standard commer cial double doorway

Line burner technology— uniform heat distribution.

• Modulating gas valve for pre cise temperature control.

Finally, Braun says its open pock et water reclamation system tank recovers 173 gallons of water (450pound open pocket washer-extrac tor). The water typically comes from the final rinse of the previous load, which is then added to the initial fill cycle of the next load.

Features include, but are not limited to:

• Minimal footprint—only 4.5 inches deeper than the exist ing yellow fence/guarding.

• Can be retrofitted on any touchscreen-controlled open pocket washer.

• Environmentally friendly with a compelling ROI.

Quick disconnect fittings (hose and electrical cables), and caster wheels for easy access to the washer for rou tine maintenance.

PELLERIN MILNOR CORP.

With the conclusion of the 2022 Clean Show in Atlanta, Rick Kelly, Pellerin Milnor Corp.’s vice presi dent of sales and marketing, said visitor traffic in the Milnor booth met the company’s expectations.

“It was a pleasure to visit with many of our valued customers and our dealer network attendees dur ing Clean,” he says. “Our machin ery lineup on display, including our new E-P Plus® rigid mount machines, expansion of our MWFSeries soft-mount washer line, and Fundamental Software for our MilRail® monorail systems, was well received.”

This year’s Clean show celebrat ed Milnor’s 75th anniversary as an industrial laundry equipment manufacturer.

The company says it showcased a wide variety of equipment that has helped Milnor become synon ymous with industry-leading stateof-the-art equipment throughout its history, including a PulseFlow® technology tunnel, single-stage press, and pass-through dryer.

The company also ran its PulseFlow demonstration unit so that customers could once again get a firsthand look at how the technology works.

MIURA

Miura featured its LX-Series Low NOx 50 HP steam boiler in its Clean Show booth.

The company says attendees were really drawn to the following features of the boiler:

• Compact size—This way operators could add additional steam capacity in their current

10 OCTOBER 2022 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

Pictured from left in the Norchem Corp. booth: Jonathan Bohorquez, Jaime Gastelum, Chad Folkerts, Lorina Minissian, Houri Minissian, Karineh Minissian, Maddie Schneider, Leonardo Gastelum, Vaughn Minissian. (Photo: Norchem Corp.)

boiler rooms or redo their boil er rooms with more output.

• Five-minute start up— With this feature, laundries wouldn’t have to have employ ees come in two hours early to start the boiler, and the boiler could fire when needed instead of being left on all the time reducing energy usage and emissions creation

Easy-to-use interface—It’s a simple boiler designed to start with the push of a button.

LAVATEC LAUNDRY TECHNOLOGY

LAVATEC says commercial and industrial laundry operators look ing for answers to energy and effi ciency needs found them with new equipment solutions in its booth at The Clean Show.

The LAVACascade drying sys tem made its tradeshow debut alongside the LAVAPress ULTRA 597S 60-bar extraction press.

The company says its LAVAPress ULTRA is designed to speed work flow and conserve resources. With the ability to handle 265-pound loads using up to 60-bars of pres sure, it processes more linen from a tunnel washer and compresses the time spent on each load before moving to a dryer.

LAVACascade, which debuted a year ago, uses a three-tiered sys tem. The first module introduces

recirculated heat to the laundry load by using the exhaust air of the second dryer. Recirculation can be programmed easily, and when the first phase is completed, the dryer tilts for unloading.

The load next travels by a con veyor belt to the second dryer. When it is loaded directly into the machine, heat loss is reduced during the transfer and the dryer remains hot so no energy is wasted to heat it again. The third dryer is the cooling stage, and each phase takes only a few minutes to complete.

LAVATEC’s booth housed a LavaDry TT-756 batch dryer, an LX445 washer extractor and an LT60 10-compartment bottom transfer tunnel washer.

LAPAUW USA

Lapauw USA and TOTO Folder partnered up for Clean Show 2022. The booth showcased the new TOTO 2 Station Blanket Folder (BFS-2-30) with the Vision System (TOTO VMS-GL700M); the TOTO TB-100F-WK, a three sort/stack Towel Folder; and the Lapauw IronMAX Duo Ironer.

The company says the two-sta tion blanket folder processes 1,100 blankets per hour with exceptional quality and features like cornerless feeding in two stations and a stack er provide maximum efficiency.

The Vision System inspects the linens in expanded condition

between the ironer and the folder.

Lapauw USA says with the multi-function towel folder/stack er/conveyor, pre-sorting hand tow els, bath towels and bath mats is unnecessary. Towels, knitted fitted sheets, scrubs, spa uniforms and more can be folded and stacked.

Finally, the Lapauw IronMAX has features like a new chest design and a parallel oil flow pattern for increased productivity and effi ciency.

RENNCO

Rennco, a ProMach brand, dis played its new ProPick Laundry Bagging Equipment, which conveys linen items to the bagging system

where packages of linen items are produced.

The customer’s sling dispenses clean items into a stainless-steel hopper area. The items are then transported up the vertical con veyor onto a horizontal belt scale conveyor.

The horizontal conveyor advanc es gradually until the correct weight is achieved and then advances at full speed to load the correct weight of items into the film. The package is produced and then discharged for transport to the end user.

Previous weigh bagging systems required operators to load items into a scale and press a palm button to start the cycling operation. With

the ProPick System, Rennco says it is committed to providing more value for its customers with this fully automated option, effectively eliminating costly operator involve ment.

Features and benefits of the ProPick bagging solution include:

• Easy-to-operate Allen Bradley PLC with intuitive HMI design for diverse workforce. Variable bag lengths based on products.

• Produces two to four packages per minute (depending on single or dual arrangement).

• Bag sizing up to 24 inches wide by 27 inches tall.

• No ties to a film contract.

• Designed to retrofit to existing bagging units.

A1 AMERICAN

A1 American says it was proud to participate in The Clean Show 2022, North America’s largest laundries exposition to network, educate, and exchange info on trending technol ogies within the industry.

With roots dating back to 1911, A1 American says it has been a lead ing global manufacturer, distributor and single supply source for prod ucts within the hospitality, vacation rental, healthcare, commercial laun dry and fitness markets.

With its vertically integrated

www.AmericanLaundryNews.com AMERICAN LAUNDRY NEWS | OCTOBER 2022 11

➢ Page 12 Miele_BMAd_4.75x6.75in_PrtOL.indd 1 4/22/21 8:41 AM

Rennco displayed its new ProPick Laundry Bagging Equipment. (Photo: Rennco, a ProMach brand)

manufacturing supply-chain pro cess, the company says it is uniquely positioned in the marketplace to serve top-tier products with com petitive pricing and the highest of customer satisfaction to clientele, including custom-branded prod ucts.

The company’s product line includes towels, sheets, decorative bed coverings, bulk and bottled amenities, small appliances, paper products, draperies, furniture case goods and more.

R&B WIRE PRODUCTS

R&B Wire Products highlighted its recently introduced CartCop™, an anti-tamper device that allows laundry owners to secure an Apple AirTag™ to their R&B Wire laun dry carts for theft deterrence and loss prevention.

CartCop™ is made of high-den sity thermoplastic with a tamperresistant design to keep the AirTag secured to the cart.

CartCop™ is compatible with all new and existing 100, 200 and 201 series carts by R&B Wire Products. The product is sold as a four-pack with all mounting hardware and one special anti-tamper wrench.

The AirTag is not included but can be purchased from Apple or an authorized Apple reseller.

HAMILTON ENGINEERING

Hamilton Engineering says it uses patented technology to engineer hot water systems and hydronic boilers that are efficient and provide high performance.

The company points to the EVO line as an example, which has operating efficiencies up to 99.8%.

At The Clean Show, Hamilton showed attendees its new EVO XL with a larger design.

Hamilton says it custom designs and manufactures every system to match each customer’s exact specs and hot water needs—no matter the size and scale of an industrial laundry operation.

For on-premises laundries, the company says it has the capabil ity to analyze the hot water needs of an entire operation and infra structure to determine if necessary capacities exist and if modifica tions can be made to upgrade the current system to accommodate operational needs.

ENERGENICS CORP.

Energenics says it supplies prod ucts that offer solutions in the commercial laundry industry to remove lint and dust, resolve air flow issues and attack the bacteria generated by healthcare textiles.

The company partners with equipment manufacturers and knowledgeable distribution rep resentatives to maximize market coverage and service availability.

Energenics says it manufactures more than 50 Lint Filters for both the OPL and larger commercial dryer application markets.

The company also offers UV (ultraviolet) products such as:

UV Max Belt, which continu ously treats conveyors as they

run, mitigating the buildup and proliferation of crosscontaminating organisms.

• UV-Max Truck Disinfection, which treats empty tractor trailers between linen loads to the customer. More con sistent than chemical applica tions, the UV Max truck uses hospital-level disinfection to meet industry accreditation standards.

• UV MAX Room Air Disinfector, which re-circu lates the air past both filtra tion and UV-C light energy to kill 99.9996% of airborne pathogens.

• And in Atlanta, the company debuted its new single-cart, no-touch UV cleaner.

TINGUE

Tingue reminded Clean ’22 attendees that it is a global organi zation encompassing manufactur ing, distribution, installation, and marketing of hundreds of practi cal, innovative products for com mercial laundries and a wide range of other markets.

The company’s operations include plastics molding, metal fabrication and machining, textile converting, product design and development, and other services.

WASHING SYSTEMS

In Atlanta, WSI showed how the future of commercial laundry is here with TRUpath™, a patent-pending wash process.

Washing free of alkali, the com pany says its process extends textile life by more than 25%, saves 30-40 hours of machine time per week and produces hygienically clean textiles.

WSI says a gentler wash process removes concerns of alkaline hydro lysis and produces whiter whites and brighter brights. Further, the com pany says its patent-pending pro cess is proven to dramatically reduce merchandise costs for operators.

WSI also showcased its solutions to ensure laundry wastewater is ready for reuse or release. Its newly formed WSI Water team of highly trained wastewater technical experts is poised to provide support in solv ing any technical issues that may arise in an operation’s wastewater treatment system.

DEXTER LAUNDRY

Dexter Laundry says it was espe cially impressed with the level of interest from well-qualified, wellinformed new investors at The Clean Show in Atlanta.

The company says its O-Series line has expanded to include Express Plus washers with extract speeds up to 400 G-force. Including the T-675, T-975 and T-1475 mod els, the company says the powerful high-extract machines offer total control over laundry operations, creating a better laundry operation with labor and utility savings, and they help reduce linen wear.

Dexter also shares that its O-Series line of Express dryers also continues to expand with the recently launched T-170, its largest

dryer to date, offering the choice of O-Series or 6-Cycle controls. It’s designed for easy and flex ible installation with a removable upper compartment and extralarge reversible loading door.

Finally, the company shares that it will launch its all-new, made in the USA, Express Plus Line of softmount washers in March 2023. This line includes Dexter’s S-975 (60 pound) model and is available in 400 G-force.

Dexter adds that it offers a full line of on-premises washers and dryers that are designed and built in the USA.

MONARCH BRANDS

Monarch Brands shares that two items drew attention of visitors to its Clean Show booth: Cabana & Pool Towels and SmartRags & Smart Pads.

The company says that this year more than any other, hotels and large property management com panies were drawn to its selection of cabana & pool towels.

Monarch carries everything from a budget blue-stripe 6-pound 22- by 44-inch towel up to an over sized 25-pound 35- by 70-inch lux ury cabana towel. Most, however, had particular interest in the over sized (30 by 70 inches) California Cabana towel or large Cali Cabana Towel (30 by 60 inches).

Available in popular colors (blue, green, yellow) and alternate colors (beige, grey, black), the tow els also come in a combination of alternate color stripes (the Cabo Cabana collection).

SmartRags & Smart Pads contin ue to gain traction with healthcare facility programs as well as food and beverage point of purchase opportunity sales, Monarch says.

The dispenser box design is terrific for storage, keeps mops and cloths free from contamina tion, and is priced to be disposable (however can be washed), accord ing to the company.

SPARTAN CHEMICALS

The main message from Spartan Chemicals at The Clean Show was, “We’re here.”

Whether attendees were with a facility with an on-premises laundry or a large-scale laundry operation, Spartan shared that it has a Clothesline Fresh program

designed to help control costs and improve sustainability, all while reducing fabric loss and improv ing customer satisfaction.

The company says its Clothesline Fresh system incorporates the lat est technology in linen care com bined with high-accuracy dispens ing solutions.

Spartan Chemicals adds that it markets exclusively through local distributors.

MOUNTAIN ELECTRONICS

Mountain Electronics, a laun dry circuit board repair company, exhibited at The Clean Show for the first time in Atlanta. The com pany says it had high hopes about the number of customers it would connect with, but expectations were exceeded by far.

The company says many longtime customers expressed their appreciation for its services over the years. It also connected with poten tial customers, educating them about the company’s services and website for free shipping, seeing what control boards it repairs and what refur bished and new parts are in stock.

COLMAC INDUSTRIES

Colmac, which offers many laundry finishing products, high lighted its CFS 90 “MICRO” reduced-height steam tunnel fin isher in Atlanta.

The finisher is just 73 inches in overall height, meaning it can fit in shorter spaces.

Colmac says the CFS 90 “MICRO” steam tunnel finisher features:

• Automatic garment loading/ unloading.

• Steam heat.

• Five models that offer pro duction rates from 60 to 600 garments per hour.

• A standard two-year parts warranty.

PARKER BOILER

Parker Boiler reminded Clean attendees in Atlanta why its boilers dependably furnish steam and hot water for the laundry and linen services industry.

Customers can choose from gas, oil or combination gas/oil firing models. Low NOx is available on all models.

Representatives shared that a superior boiler can cut steam or hot water generating costs. Also,

they say clients will be surprised at the low initial costs.

CHICAGO DRYER COMPANY

Chicago showcased its lat est innovations in flatwork tech nology at Clean 2022 in Atlanta. Show attendees were treated to live demonstrations by local laundry operators to show the equipment’s production capacity.

The company featured the next generation of tried-and-true cus tomer favorites such as the Air Chicago 360 modular French fold er; King Edge Maxx high-produc tion, cornerless sheet feeder; and Carousell small-piece accumula tor now available with large piece bypass option.

Chicago also showcased new models such as the TruFeed pre cision two-lane three-station clip feeder and SoloFeed built-in lowprofile spreader/feeder.

The company says it received the most buzz on the show floor with the debut of its fully auto mated hands-free towel processing line that uses A.I., vision technol ogy, and robotics to save labor and automate towel processing from start to finish.

This system includes a Sort-All that separates washcloths from mixed items and delivers them to an ATM mini, which then picks, stacks and neatly sends them to a master conveyor.

Sort-All then automatically delivers mixed towels into the Genesis ATM automatic feeder, which automatically picks, cor rectly orients and feeds towels into either a built-in folder or a sorting folder such as Air Chicago Quattro.

AC Quattro then folds and sorts towels into neat stacks that are then pushed to the CHI intelligent con veyor system, delivering them any where they need to go in the laundry.

ELLIS CORP.

Equipment manufacturer Ellis Corp. shared its Uptime® Intelligent Machine Manager at Clean ’22.

Offered as an option on all Ellis products, the company says Uptime® Intelligent Machine Manager is a simple but smart control and reporting system.

Operated from a touchscreen panel mounted on its machines, this user-friendly virtual engineer allows laundry operators to:

• Receive alerts when it’s time to perform preventative maintenance that will main tain assets and document that the work was performed.

• Cut troubleshooting time to just minutes because the sys tem diagnoses the machine, pinpoints problems and instructs what to do.

• Tap into experts who can remotely access the system and quickly tell what’s going on with the machines—and what actions are required to get machines operating at their best.

Identify and order any needed parts in less time.

12 OCTOBER 2022 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

Clean Show attendees check out the King Edge Maxx high-production, cornerless sheet feeder in the Chicago Dryer Company booth. (Photo: Chicago Dryer Company)

UNIMAC

UniMac, a brand in the onpremises laundry market and part of Alliance Laundry Systems’ com mercial laundry equipment, featured its recently released next-generation control platform during Clean.

UniLinc Touch builds on the advantages of its wildly popular UniLinc control and puts them in a touchscreen.

UniLinc Touch’s touchscreen not only uses real words to make it simple to operate, but also offers 34 languages to ensure all staff members can use it. This removes any ambigu ity, shortens training time and helps ensure correct cycles are used to pro tect finished quality, according to the company.

UniLinc Touch is offered on both washer-extractors and tumble dryers, ensuring continuity in the operation.

Other features of UniLinc Touch the company shares include:

• Bright, capacitive touchscreen with clear cycle navigation.

• Easy-to-read main screen cycle countdown timer, compli mented by a count-up timer upon completion of the cycle to streamline throughput.

• Delayed start allows maximum efficiency with the option to prep a load and set it to run before staff arrives for the day.

• Simplified set-up, program ming and troubleshooting with easy-to-understand notifica tions.

• Diagnostics and machine audit data to identify and resolve errors faster, reducing down time and service costs.

• The new control is now avail able, and UniMac says it has some of the lowest lead times in the industry. So, on-prem ises laundries can have new machines installed quickly to begin making an immediate impact.

A.L. WILSON CHEMICAL CO.

A.L. Wilson once again dazzled Clean Show attendees with the effectiveness of its product lines.

The company says it continues to manufacture high-performance stain removers that contribute to the success of the cleaners and launderers who use them, valuable tools that let operators deliver the quality stain removal that their customers desire.

A.L. Wilson says its products pair high levels of effectiveness with equally high levels of safety for material color and tensile strength so that operators can remove more stains completely and safely.

The company says its newly developed products are also designed to be safer for workers and the environment.

YAMAMOTO NORTH AMERICA

Yamamoto North America dis played a new towel folder line dur ing The Clean Show in Atlanta.

First was a live demonstration of the company’s recently updated FUT10BT Multipiece towel folder, which features several differences that Yamamoto says help it achieve increased throughput and sharper folds than several other options in this field.

The live demo allowed visitors to see how simple the machine is to operate. Since the unit auto matically identifies and sorts each sized towel, they didn’t have to toggle through countless program options to prep the machine or pre-sort the towels before folding.

Yamamoto says it was excited to see the show bring visitors from all over the United States who came from different backgrounds (established buyers, new buyers, small/large processors, old/new distributors, etc.), receiving inter

est on this line from each type.

LG COMMERCIAL LAUNDRY

LG highlighted its Smart Solution at The Clean Show in Atlanta.

Smart Solution is a cloud service designed to connect businesses and machines to everyone from business owners to customers.

The company says Streamline Maintenance can monitor condi tions and detect errors anytime and anywhere and is designed for operators to adjust settings and control individual locations and even specific machines.

LG also showed off its selfsanitizing washers. The system is designed to sanitize washers before, during and after each load.

HYDRO SYSTEMS

Dispensing system provider Hydro Systems displayed several products at its booth in Atlanta.

The LM200 dispenser system is a compact, low-cost, easy-to-use dispenser for on-premises laundry applications, the company says. It includes a washer-mounted con troller, a super isolated machine interface and a wall-mounted pump module. It can handle up to six laundry chemicals and up to 20 different formulas.

EvoClean is the world’s first venturi-based, water-powered laundry dispenser, according to Hydro Systems. It is compatible with the Total Eclipse Controller and includes an integrated flush manifold.

The system is available in four, six and eight product configurations with either low or high chemical flow rate. This covers a full range of product configurations and washer sizes used in OPL accounts.

Designed to manage chemical dispensing for on-premises laundry sites, the company says its Multi-

Washer 3000 Series with EvoClean offers cost-saving potential and cutting-edge reporting. The MultiWasher 3000 Series with EvoClean provides reliable and accurate dos ing that can support up to three washers and dose up to eight prod ucts within a single system.

Designed to manage chemical dispensing for commercial/indus trial laundries, the Multi-Washer 10000 Series offers reliable dosing that can support up to 10 washers and dose up to 10 products within a single system.

Flexible and easy to configure, the Multi-Washer 10000 Series uti lizes an accurate flowmeter for pre cise control to reduce rewash and prevent costly overdosing, Hydro Systems says.

LUETZOW INDUSTRIES

Luetzow Industries was in Atlanta to share its poly laundry packaging options with attendees. The company says its direct sell ing, coupled with total automation, produces consistent plastic polyeth ylene garment and laundry bags.

Luetzow also produces cart lin ers and pallet covers.

MIELE

Miele Professional, a provider of commercial-grade appliances, pre sented a series of in-booth demon strations illustrating the advantages of the Miele WetCare® system at The Clean Show in Atlanta.

Miele Professional, America’s

www.AmericanLaundryNews.com AMERICAN LAUNDRY NEWS | OCTOBER 2022 13

Laundry Wrappers ▪ Parts ▪ Wrap Wrap! Seal! Protect! Minimize Contamination and Loss Simplify Content Identification Enhance Appearance and Delivery Presentation Fully wrapped and sealed bundles... Keep Finished Laundry Clean and Protected As Seen At Clean Show ‘22 BOOTH 3705 DP Exclusives: Burn Guard, Height Adjust, Thermostat Guard, Easy Loading, Great Service! Quality... ...fortheLongHaul. Formoreinformation: G.S.M.LinenHandlingSystems 1-800-363-CART(2278) www.gsm-cart.com Precisionbuilt,allwelded,anodizedaluminumcarts, specifically engineeredfortheextremesofloading, handling,cartwashand off-sitetransportinyourbusy laundry.Availableinawiderange ofmodelsandsizes, andalwaystoyourcustomrequirements. GSM_haul_mp july_aug.pdf 1 2/20/2014 7:42 AM ALN_3rd Page.indd 1 4/6/15 11:08 AM 0317aln_GSM Clean Show.indd 1 7/17/17 2:05 PM ➢ Page 14 Miele highlighted its wetcleaning process at its booth in Atlanta. (Photo: Miele Professional)

Best Cleaners, Kruessler and highend professional finishing equip ment companies partnered to highlight their businesses’ impor tant role in providing fast produc tion, high-quality washing, drying and finishing of hard-to-clean tex tiles and fabrics.

More than 30 years ago, Miele and Kruessler partnered to create the WetCare® system. Since then, it has become a sustainable and profitable option for the professional cleaning of hard-to-clean and delicate textiles like wool, cashmere and silk.

Michael Erstad, production management and mechanical con sultant at America’s Best Cleaners demonstrated the capabilities of the machines and the actual pro cess of wetcleaning, and Kruessler illustrated the use of chemicals and cleaning solutions, showcasing the resulting finished product profes sionals in the industry can expect.

ECOLAB

Ecolab highlighted its ability to create seamless laundry operations at The Clean Show.

The company says that sustain able, high-performing chemistry and reliable and accurate dispensing are key to cleaning right the first time, offering quality wash products and programs that consistently deliver clean, bright and stain-free linen.

Ecolab shares it also keeps a sharp focus on maximizing operational efficiencies and helps improve plant performance to steer businesses to success.

The company’s data manage ment technology, enVision™, is designed specifically for commer cial laundry operations to provide laundry managers with real-time visibility and actionable insights to deliver consistent quality, improve efficiency and reduce costs.

Finally, Ecolab says it will col laborate and integrate its expertise with laundry operations. It says this comprehensive approach allows it to deliver exceptional results at the lowest total cost of operation.

Experienced teams are avail able in the areas of R&D, support and applications, lab and technical service, customer support, waste, water and energy, and dispensing.

MAYTAG COMMERCIAL LAUNDRY

Visitors to the Maytag

Commercial Laundry booth in Atlanta were able to gather infor mation on the offerings of singleload and multi-load machines, OPL offerings, as well as ADC dryers.

The Whirlpool Corporation Commercial Laundry leadership team says the company achieved all of its strategic objectives: reconnect ing with customers from all over the world, recognizing top-performing customers and leveraging The Clean Show to portray its brand value and demonstrate its quality machines and solutions to the broader com mercial laundry industry.

The company says attendance was good, but more important was the quality of insight, learning and time gained from the in-person meetings. The company had three conference rooms at the booth, and they were filled every half hour.

R.W. MARTIN COMPANY

R.W. Martin Company chose Clean 2022 to formally announce its partnership with ABG Systems, based in Milan, Italy.

ABG, which also exhibited at Clean, is a world leader in using RFID technology to provide automated textile management solutions across industries. R.W. Martin is now an authorized dis tributor to the U.S. market for ABG, focusing primarily on medi cal scrub management for the healthcare industry.

The industry-wide exposure allowed each company to dem onstrate the usage and capabili ties of ABG’s equipment and soft ware solutions, according to R.W. Martin.

Clean Show attendees were able to interact with ABG’s textile management systems directly and get their questions answered in person. The interest in automat ed scrub management solutions exceeded the expectations that both R.W. Martin and ABG had before the show began.

Actual face-to-face time with customers is invaluable and was sorely missed during the pandemic. R.W. Martin is looking forward to attending Clean 2025 in Orlando.

CONSOLIDATED LAUNDRY MACHINERY

At The Clean Show, CLM rein troduced attendees to its dryers and mat rollers.

CLM industrial tumble dryers can be configured with one or two doors for pass-through processing. They can tilt back or forward.

The three main configura tions are one door with tilt back for loading and tilt forward for unloading (two-way tilt), two doors with tilt back only (one-way tilt) or the two-door, two-way tilt that provides the ability to load or unload from either side.

CLM says its mat rollers com pletely automate the mat-rolling process. The operator simply plac es a mat (up to 4 feet wide on the MTR-1, up to 5 feet wide on the MTR-2) onto the feedboard and the machine automatically takes up the mat, rolls it and drops it into a waiting cart.

This leaves the operator free to pick up the next mat, thereby increasing efficiency and overall production.

AQUAWING OZONE LAUNDRY SYSTEMS

Aquawing Ozone highlighted its San-O3-wash in Atlanta. The system is designed to use the right amount of ozone in every wash cycle, giving operators peace of mind knowing that washers have been completely sanitized.

Adding ozone to the wash allows the use of lower-temperature water (if desired) in a hot cycle, which the company says will substantially lower utility bills, reduce the car bon footprint of the operation and reduce the wear on fabrics.

BRIM LAUNDRY

MACHINERY

Brim put the spotlight on its Challenge Pacesetter dryer with the new and improved model 165, which features more advanced tech nology and improved efficiency.

The company says its new Challenge Pacesetter retains its commendable qualities including component wear resistance and superb efficiency, with the bonus of lower emissions.

Brim also shared information on its other products, including washer-extractors and conveyors, touchscreen controls and auto mated systems, used and rebuilt machinery, and allied equipment.

JENSEN

Laundry equipment manufac turer JENSEN highlighted several new technologies in Atlanta.

First was the brand-new THOR robot engineered by its partner Inwatec. THOR automatically sep arates all soiled articles, including T-shirts, uniforms, towels and flat linen. Depending on the article size, THOR can handle up to 1,500 pieces per hour.

At the JENSEN booth, visitors experienced a live demonstra tion of THOR combined with a Futurail loop that bulk loads the soiled system to increase laundry capacity and free up floor space. This new hybrid sorting solution allows complete automation with a hands-free operation and allows for operator-assisted sorting to

help increase volume.

The new XR dryer will pro cess big cakes with a diameter of 51 inches, the company says. The wider opening also allows faster unloading, with savings of 10-20 seconds per batch.

In the finishing section, JENSEN says the new Express Pro feeder will double PPOH in operations pro cessing laundry from the healthcare, hospitality, and food and beverage sectors. It’s a cornerless feeding sys tem that excels at high speeds.

A simplified version is offered with the new KliQ feeder that fea tures a new generation of feeding clamps. This simple and spacesaving solution is available with a Concorde-shaped nose for direct feeding, eliminating the need for an inlet table on the ironer. Both feeders stand for high and uniform finishing quality and high produc tivity, JENSEN says.

At the booth, the KliQ and Express Pro feeders were com bined with the new Kando folder, which incorporates fully adjust able air blast pressure in the lat eral folding section and reversing conveyors in the cross fold section, ensuring optimum folding quality for all types of flatwork.

Premium folding quality at high speed can also be discovered in the new Fox 1200 garment folder, JENSEN says. Using a new servodrive motor at the hanger release and a new conveyor at the first cross-fold, the Fox 1200 processes up to 1,200 garments per hour in mixed production.

The company says the Metricon handling and sorting system for garments is presented in the new MetriQ loading station. Featuring the unique “buttons-to-the-front” option for garments of all types can be loaded without any time loss by moving to the opposite side.

A further highlight at the booth was the new GeniusFlow solution that “ties the laundry together” and gives proof of how smart technolo gies boost productivity: The sorting robot communicates the recorded data from the soiled side to the gar ment sorting area in real time.

Further exhibits included high ly productive solutions for the washroom and finishing section of all types of linen. The exhibi tion area was rounded off with an information stand demonstrating

JENSEN’s services offering.

GURTLER INDUSTRIES

Gurtler Industries celebrated its 40th anniversary at Clean 2022. Booth visitors received special edi tion souvenir Gurtler 40th anni versary socks.

The company also featured its Work*Clean Team of specialty laundry chemicals, a team of three products formulated for the heavy soils in the uniform and F&B laun dry markets. The company says the low-alkaline products use an inno vative blend of surfactants that deep clean, delivering top-quality results while reducing wash times, water, and energy use.

Also featured were Gurtler’s Vis-Tex laundry chemical injec tion systems. Gurtler says Vis-Tex Systems provide the fastest, most accurate, and most reliable injec tion capabilities for both tunnel washers and washer-extractors.

KEMCO SYSTEMS

Kemco Systems, a provider of water and wastewater treatment in the laundry industry, highlighted its recently announced award of pat ent for its KLEENWATER™ system at The Clean Show.

The patented process employs the combination of Kemco’s ceram ic membrane filtration system and specialized reverse osmosis tech nology which conserves water and thermal energy.

Kemco says it is the only com pany in the industry with the ability to combine these treatment systems while maintaining thermal energy.

The KLEENWATER™ system presents a cost-effective means of combating rising water, sewer and energy costs by removing emul sified, suspended and dissolved contaminants including PFAS and microplastics from wastewater without utilizing high volumes of chemicals, according to Kemco.

The well-established process has demonstrated consistent reuse of 75 to 85% of a plant’s water and thermal energy in the same process, all while reducing its consumption of wash aisle chemistry, the compa ny shares. The process reuses water and significantly reduces green house gas emissions by lowering the plant’s heating load.

The core of the KLEENWATER™ system is the combination of

14 OCTOBER 2022 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

Gurtler Industries handed out commemorative socks in honor of its 40th anniversary at Clean. (Photo: Gurtler Industries)

Maytag had plenty of traffic in its booth during The Clean Show. (Photo: Maytag Commercial Laundry)

Kemco’s ceramic membrane filtra tion and reverse osmosis technol ogy:

• Kemco’s ceramic membrane process is based on highvelocity crossflow filtration with wastewater being filtered through ceramic ultrafiltra tion elements. The result is a filtrate free of oils, greases, sus pended solids, viruses, bacteria and microplastics.

• The high-temperature reverse osmosis process uses spe cially designed and purposebuilt membranes to remove remaining dissolved constit uents, color and PFAS from the filtrate. This innovative approach allows laundry facil ities to return the highest qual ity water to their wash aisle, reducing chemical usage and ultimately delivering softer goods and whiter whites.

Kemco says the award of this water recycling process patent is the validation of its commitment to transforming how the industry protects its vital water resources while achieving system ROI and achieving sustainability goals.

ENCOMPASS GROUP

Encompass Group showcased reusable Synergy and Essentials institutional apparel and its UltraLinks blankets at The Clean Show in Atlanta.

The company says Synergy and Essentials scrubs offer minimal shrinkage, and they’re constructed for durability and institutional processing.

They’re available in a compre hensive collection of fashionable and functional styles, including V-Necks and long-sleeve modesty tops, elastic and drawstring waist pants, and warmup jackets. Sizes range from XS to 5XL.

Encompass Group says its UltraLinks® blankets provide superior performance with stainresistant properties that reduce relaundering and rag-outs. The 100% polyester fabric reduces lint build-up during processing, helps the blanket to maintain its origi nal weight longer and dries faster compared to a cotton blend.

The UltraLinks line offers a vari ety of colors and two standard sizes: 66 by 96 for 36-inch mat tresses, and 74 by 102 for 42-inch mattresses. Encompass says all UltraLinks blankets offer hemmed edges and a soft, smooth weave that delivers next-generation warmth and comfort.

SPINDLE

Spindle showcased its new iOS and Android app at The Clean Show.

The company launched the app because it knows that operators aren’t always near a computer to check the health of the plant.

All customers can now experi ence the power of Spindle direct ly from the palm of their hand, according to the company.

Operators can visualize plant performance, view recommended

actions, log coaching moments and much more directly from their phones.

ABS LAUNDRY BUSINESS SOLUTIONS

ABS shared new developments in Atlanta such as:

• Mobile apps: truckload assis tant, bulk load assistant, lock er verification and others.

Facility services, including truck inventory and route assistant order/delivery.

• Mat logistics: full-cycle track ing from laundry to depot/ service center and customer.

• Container management sys tem, including new billing options.

• UHF RFID: full support for all business lines.

CRM contact manager exten sions.

ABS also shared that it provides Application Hosting (ABSSolute) solutions on all continents.

Benefits include:

• Uptime and availability guar anteed via the ABS (private) Cloud.

• Maximum safety: profession als looking after security and updating the backend.

• Back-up of data and system. Scalable to the future: grow ing business is seamlessly sup ported.

To assist in the global effort toward reducing emissions, ABS says it also continues to develop software that enables customers to maximize the reusability of exist ing inventory. Recycling ragged products is also an important aspect, which is supported by the ABSSolute system.

FIBERTECH PLASTICS

Fibertech Plastics used The Clean Show to show off its line of laundry carts and share how the company can help laundry operations.

The company says its laundry trucks feature the latest in dura bility design. The laundry cart on wheels is rotationally molded with polyethylene using a one-piece design with a nominal .250 wall that resists dents, scratches, stains and rust. They also feature a pow der-coated metal base that adds strength and gives support to the cart when carrying heavy loads.

Fibertech says the linen carts

can hold 48 cubic feet and have smooth interiors with rounded corners to help eliminate collec tion points.

It adds that its commercial laun dry carts are rust-proof and non corrosive and offer industrial laun dry trucks that will work whether the operation serves hospitals, schools, prisons or hotels.

1CONCIER

In Atlanta, 1Concier highlight ed its Reigel Linen colorGUARD techology™.

Specifically, the company highlighted the savings a client achieved in laundry and staffing costs over 12 months using col orGUARD products ($48,000 on napkins alone).

1Concier says the proprietary manufacturing process is per formed before fabrics are formed so the colors become part of the “DNA of the fabric.”

The process is designed to

secure the color and ensure stabil ity throughout multiple wash and dry cycles.

LAVO SOLUTIONS

At The Clean Show, Lavo Solutions presented new, smart, data-driven technology from its position as the exclusive North American distributor for CM2W connected solutions that provide the ability to remotely monitor and control a wide range of hardware equipment uniformly.

Clean was also the first large, pub lic venue where the company was able to introduce the new relation ship between Lavo Solutions and Lafferty Equipment Manufacturing.

Lavo says it introduced how, together, they are already push ing forward into the market place innovations that combine Lafferty’s highly recognized ventu ri technology expertise and Lavo’s advanced connectivity and control technology.

MILLIKEN & CO.

Clean Show 2022 was a suc cessful show for textile provider Milliken & Co.

The company says that, overall, the traffic was steady and many of its laundry end users were in attendance.

Milliken says the more promi nent laundry equipment manufac turers attend the show with large booths, and their presence helps boost floor traffic.

While laundries are at the show to explore new technology and equipment, they also visit other suppliers, and Milliken says Clean Show was worthwhile, adding that it’s always delightful to see and interact with its direct customers and laundry end-users.

Milliken says it is already excit ed to exhibit at the next show in Orlando.

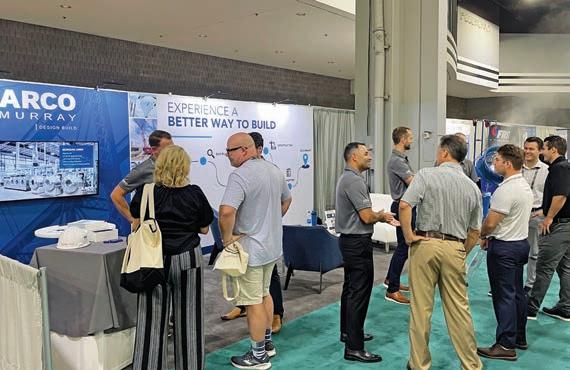

ARCO/MURRAY

ARCO says that laundry con struction activity has been very strong since the last Clean Show (New Orleans 2019).

Over the past three years, ARCO/ Murray shares that it delivered 41 total laundry projects across the United States, Canada and the Caribbean. This includes projects in the healthcare, hospitality, F&B, industrial and cleanroom sectors for clients like ALSCO, Aramark, Cooperative Laundry, Loews Hotels, Montana Linen and UniFirst.

The company says this year’s Clean Show was a great opportu nity for it to reconnect with past clients, meet with current custom ers, and network to discover future opportunities.

Overall, ARCO/Murray says it was a great show, and it is excited about the outcome—and it looks forward to 2025.

BECK’S CLASSIC MFG. INC.

Textile provider Beck’s Classic introduced its new product line, Arid Care Impressions, at The Clean Show.

The company says the collection is designed to contribute to the athome environment patients crave.

Custom patterns are an inte grated part of creating a soothing experience with the high-wicking, fast-drying features from Arid Care Underpads.

www.AmericanLaundryNews.com AMERICAN LAUNDRY NEWS | OCTOBER 2022 15

Pictured from left at the Milliken & Co. booth: Annika Dahlgren, David Hassen, LeAnne Flack, Heath Maughon, Allen Greer, Steve Burgess, Lee Huston. (Photo Milliken)

Campbell Dodson (right) explains the benefits of a CM2W connected panel for laundry opera tions at the Lavo Solutions booth. (Photo: Lavo Solutions)

Attendees talk construction with the folks from ARCO/Murray at The Clean Show in Atlanta. (Photo: ARCO/Murray)

Laundry operation preventive maintenance plan

Atypical time-study evaluation for developing a production standard includes a PFD fac tor, which stands for “Personal, Fatigue and Delay.”

The “Delay” component refers to unscheduled maintenance and other issues that interrupt processing. I have a couple of time-study examples where that number is 4%, so the expected production output should be reduced by 4% for downtime. We might consider that to be the “industry standard.”

I recall working with a few tex tile manufacturers who ran their plants on multiple shifts yearround, except for the week of July 4 and the week between Christmas and New Year. They had the luxu ry of not having to make pick-ups and deliveries during these busy periods. They would then per form major overhauls on systems throughout the plant.

Coincidentally (or probably not), those two weeks account for roughly the same 4% of a year: two weeks/52 weeks = 3.85%. Of course, other main tenance was completed between shutdowns, and there are a lot more machine hours to include in a detailed calculation, but it’s interesting how these general numbers compare.

The answer to the second part of this month’s question provides the opportunity for a challenge. The goal for downtime during operating hours should be 0%: a facility should “plan to conduct preventive maintenance” outside of production time.

This means planning tune-ups and regular service on a second shift, performing quick routine activities when the equipment is offline while employees are at break or lunch, completing a major part replacement over a weekend, when the equipment is not required for production, etc.

Create a calendar and/or uti lize a CMMS tool so that you can coordinate with and schedule the

work with production needs and maintenance personnel availabil ity in mind.

I have another service-related story. I took my car in for an oil change several years ago, and the service manager was almost giddy to show me something. She had a picture on her phone of the odometer from another 2012 Kia Sedona that showed over 300,000 miles at about four years old.

The other car was used for deliveries throughout Georgia, Alabama, and Tennessee and racked up more than 1,500 miles each week. Its owner aimed for 0% downtime during “produc tion” (i.e., while driving hundreds of miles from home) by schedul ing service every two weeks.

He was ahead of the recom mended service interval, but the results speak for themselves. Taking his car to the shop for a few hours every two working weeks is again close to that 4% target. I’m sure many of you can relate to this with your delivery vehicles.

Best of luck! I know we have all experienced downtime that interrupts processing, but we shouldn’t accept it as a normal part of operations. Your goal for accidents should be “0,” and your target for breakdowns should be the same.

This is a great question and one that every successful plant should be asking when planning their preventative maintenance team and schedule. That said, I don’t know that there are any one-size-fits-all answers as every plant is different, and, more importantly, the machinery in each plant is varied.

One way to go about set ting a preventative maintenance schedule is to understand your machinery and the recommended manufacturer’s PM schedule set forth within the user manuals.

Additionally, it’s important to consider any modifications that have been made to the machin ery since being delivered by the manufacturer as well as the age of your machinery.

Over time as machines age, they generally need more pre ventative maintenance to ensure machine downtimes do not neg atively impact your production

capacity during operating hours.

In my experience, utilizing a CMMS (computerized mainte nance management software) will allow you to enter and track all your maintenance intervals for your machinery and deliver work orders that can be complet ed by your maintenance staff.

The most challenging aspect then becomes when do you schedule your maintenance. For a single-shift plant, you have plenty of time after hours to complete your PM work. For those plants with multiple shifts though, you either have to condense your PM work into a shorter window with more maintenance staff or choose to bring down pieces of machinery strategically during operating hours to complete the necessary work.

ing, and even opposing, opin ions and solutions. I will throw a mostly kind of approach-ish answer, and it may, or may not, be what I actually do.

All plants being so different in their hours, product, staffing needs and age of equipment, I think there exist a few constants. You are going to have to break the plant off into segments: soil, washroom, flatwork, etc. Once you have done this, it is sub-seg ments: ironers, feeders, folders, steam system, etc.

Much of the maintenance can be performed with minimal impact on the plant, like basic greasing or speed control adjustments.

This is relatively easy, if gremlins aren’t beating the heck out of your crew during their shift (which is almost always caused because something last week prevented all of the PMs from being done) and you start thinking about those DARE commercials from the ’80s, so you can work more, so you can make more money, so you can buy more … grease?

Post-COVID, many plants are doing everything they can to get back to 2019 numbers, but staff ing issues mean less opportunity for as thorough a preventive program as we would like, and certainly predictive projects sit in cue longer than we like.

Our plant, being a stand-alone, means no diverting work to the facility cross county. I try to rotate basic greasing-type respon sibilities, so I increase my chances of issues being caught before they are failures. Some people hear better than others see.

On the predictive … now, we have supply issues to think about. An OEM board or slot card maybe not something eas ily found for overnight delivery. Having these parts on hand may be easy, especially if you have multiple machines that use the same part. You might have to eBay for a used part at an inflated cost.

Is a motor making ugly sounds? Probably should do your best to source the replacement now and have it for what you know is inevitable—the failure.

W

OW! This topic deserves an encyclopedia-sized response. One that would have many vary

I absolutely despise “scheduled breakdowns,” but it seems to be something that has reared its ugly head in my world more than I would like these last few years.

16 OCTOBER 2022 | AMERICAN LAUNDRY NEWS www.AmericanLaundryNews.com

“Is there an industry standard on what percentage of time a well-maintained laundry operation should expect to be down for service? How can I best plan to conduct preventive maintenance?”

Healthcare Laundry

William Muse

United Hospital Services, Indianapolis, Ind.

Consulting Services

Jon Witschy Spindle, Woodridge, Ill.

Commercial Laundry

Lee Baldauf

Superior Linen Service, Tacoma, Wash.

(Image licensed by Ingram Image)

Don’t forget the value of a network of vendors, and other laundries, that you have built. I have mentioned this before, but just the other day I borrowed from a competing plant, as they have from me.

All of that said, I do not know if there exists a realistic standard for downtime for maintenance. I do know that a “well main tained” facility will most likely experience greater uptime, but Lean Six Sigma, time travel and amicable divorces are mathemat ical impossibilities, as far as I am concerned, but don’t think for a moment that I am not hoping for someone else’s opinion on this topic to be a grand epiphany for me!

be if you don’t have one in place), here are some guidelines for getting your PM program off of the ground:

1. Schedule maintenance according to equipment usage. Although some machines prompt the operator to perform certain maintenance tasks, wait ing until this happens can inter fere with production. If tasks are scheduled in advance, they’re less likely to be postponed and then forgotten in the interest of meet ing a production deadline.

The more you use a machine,

the more abuse it takes, so plan machine maintenance frequen cies accordingly.

If you run a small washer eight hours a day, a maintenance schedule of once every three months is probably adequate for that machine. But if you’re running three shifts on the same machine, you might need to perform maintenance tasks on it once every month or even more frequently if you don’t have a qualified maintenance crew.

2. Make employees account able for maintenance. Once

you’ve identified what preventive maintenance activities need to be performed and when they should be done, assign follow-through responsibility to a maintenance coordinator, machine operator or other appropriate personnel.

Have these designated employ ees sign off on maintenance activities on a sheet attached to each machine, through a soft ware program, or through daily, weekly, and monthly cards sub mitted to supervisors.

Whatever method you decide on for tracking, consistently fol

low the preventive maintenance schedule that you’ve devised.

3. Ensure that the preven tive maintenance tasks being performed are beneficial to the equipment. Use the operating manuals for the machines to determine the maintenance tasks that need to be performed. Each piece of equipment is different and will have different mainte nance requirements. Trying to use a catch-all technique will likely cause more problems.

The best answer to this question is no, there is no standard for what percentage of time a wellmaintained laundry operation should expect to be down for service.

Your best plan to conduct pre ventive maintenance is to follow the guidelines given to you by the manufacturer of the equipment you purchased. They should give you good guidance on what needs to be done when as far as preven tive maintenance goes.

Don’t take shortcuts. Don’t not do the maintenance and your equipment should perform well for years and years.

Performing routine mainte nance on the commercial laundry equipment that you rely on to produce clean goods and meet your customers’ tight dead lines may not sound exciting but it may well make the difference between meeting and missing a delivery date.