Hiring next-generation laundry employees

BY MATT POE, EDITOR

Hiring new employees has been difficult for the laundry and linen services industry for some time.

Even before the events of the past few years, operators were struggling to onboard key personnel such as plant employees, engineers and management.

“Like many industries, hiring remains a challenge,” says Jeff Peterson, sales manager at Spin Linen in Omaha, Nebraska. “We’ve had to re-evaluate everything from compensation to job duties, as well as get

more innovative in our job postings to attempt to stand out.

“There doesn’t appear to be a magic bullet, so we are experimenting and tweaking our approach constantly.”

Fortunately, hiring in the industry is improving.

“There seems to be a positive shift lately,” shares Frank Maresca Jr., vice president of WW Uniforms in Wallingford, Connecticut. “The traction for getting new potential employees is increasing.

“The past has been an absolute struggle—from striking interest and applying to the open job to an employee accepting an interview or the position and the person doesn’t show up at all.

“Nevertheless, in recent months there has been an increase in applications and acceptance of the said available jobs.”

“We have started to see our labor pool open up a bit over the last couple quarters,” agrees Ben Warnecke, a fourth-generation family member and general manager at Plymate Inc. in Shelbyville, Indiana.

“Incenting and promoting our employee referral program has resulted in quite a few great hires for Plymate in recent years. We are laser-focused on onboarding and employee engagement once we make a hire, so, thankfully, we don’t find ourselves with more than a couple openings very often.”

Kleen Kraft Services in Commerce, California, has also had success with employee referrals onboarding qualified, dedicated workers.

“In general, we have very little turnover,” says Marilyn McCarty, marketing manager. “Many of our staff have been here for over 10 years and some as long as 40 years. I think this speaks to the type of operation that we run, the pay and benefits offered, and the feeling of belonging.

“Most of our new hires come in as refer-

rals from current employees—drivers, sales reps, office staff—have all come in as referrals. With referrals like this, we can anticipate that the worker will be qualified and that they have a good idea of the work expected.”

While there are signs of improvement in the laundry labor market, many laundry operators still face difficulties.

“Hiring new employees remains a challenge for Paris,” says David Stern, president and CEO, Paris Companies in DuBois, Pennsylvania. “We are getting enough applications for most hires; however, the quality of the applicants has deteriorated from pre-pandemic.”

A major challenge is enticing younger employees to enter the laundry and linen services industry. Many don’t see it as a viable career option and aren’t prepared for the effort needed to succeed.

And some aren’t even aware that the laundry industry exists.

So, how can a laundry operator attract the next generation of laundry employees?

HUMAN RESOURCES PERSPECTIVE

For the textile services industry to get the attention of younger employees, it needs to better understand who the next generation is and what it is looking for in terms of employment and career opportunities.

Elissa Jessup, HR knowledge advisor for the Society for Human Resource Management (SHRM), shares that the organization has researched what younger workers are looking for in a workplace.

For Generation Z (born between 19972012), SHRM has compiled a “top 10” list of work qualities they are seeking.

“They’re looking for flexibility, peer

Healthcare Linen Services Group acquires Linen King

ST. CHARLES, Ill. — Healthcare Linen Services Group (HLSG), a provider of healthcare laundry services headquartered here, reports it has acquired Linen King, based in Tulsa, Oklahoma. A portfolio company of York Capital Management’s private equity group, HLSG provides services in the Midwest and Central United States.

As part of the transaction, Seaport Capital, a New York-based private equity firm that acquired Linen King in 2019, will receive shares in HLSG.

Terms of the transaction were not disclosed.

Founded in 1999, Linen King serves approximately 460 customers across seven facilities in five states. It processes approximately 100 million pounds of healthcare laundry annually at facilities located in Arkansas, Oklahoma, Missouri, Kansas and Tennessee.

Chris Corcoran, Linen King’s chief executive officer, will remain with the business and serve as the regional chief operating officer of HLSG.

Following this transaction, HLSG will operate 21 linen processing plants across six regional brands: Logan’s Linens, Logan’s Uniform Rental, Superior Health Linens, Textile Care Services, Reino and Linen King. These brands and facilities process approximately 350 million pounds of healthcare linen on an annual basis for nearly 1,000 customers in 19 states.

The Newspaper of Record for Laundry & Linen Management February 2023 • Volume 49, Number 02 www.americanlaundrynews.com

Experts share insights into how operators can attract, and retain, younger staff members

(Photo: © luckybusiness/Depositphotos)

See NexGen on Page 6 LATE NEWS

Cintas’ electric vehicle pilot program hits the road

CINCINNATI — Cintas Corp. reports it recently launched its electric vehicle pilot program, which to date includes almost 20 vehicles from multiple manufacturers.

Cintas operates one of the largest corporate fleets in North America with almost 14,000 commercial vehicles deployed throughout the United States and Canada, and it’s a significant source of the company’s Scope 1 (direct) greenhouse gas (GHG) emissions.

Cintas acknowledges the importance of transitioning its fleet as it continues along its Path to Net Zero.

“Our ability to remove vehicles powered by fossil fuels from our fleet and introduce vehicles that run on renewable or alternative fuels will be an important factor in our ability to achieve our Net Zero ambition and reduce our carbon emissions intensity,” says Christy Nageleisen, Cintas vice president of environment, social and governance (ESG) and chief compliance officer.

“When we meet with employee partners in the field, the EV pilot program is always near the top of their interests. There’s a lot of excitement and anticipation throughout the organization about our EV program, and we’re eager to see how these pilot vehicles perform while out in service and running our routes.”

HITTING THE ROAD

Cintas’ EV pilot program officially launched in early 2022 when the first vehicle was deployed in the Los Angeles area.

To date, 17 different vehicles from five different manufacturers are or have been included in

the pilot program with additional units in Cincinnati, Detroit, Minneapolis, Los Angeles, San Francisco, San Jose and Seattle.

EVALUATING EVS IN ACTION

The pilot program will help Cintas evaluate the performance, durability and reliability of various EVs in a variety of business, weather and road conditions.

Using the vehicles in real-world conditions is intended to help the company better understand the expectations, benefits and potential challenges of EVs in its unique route-based business.

“When we originally decided to pilot the (electric) vehicles, we wanted to test markets that were cold, hot, that had snow—that had all the different weather conditions—so that we ensured we got the right vehicle for the right industry,” says Mark Bolen, Cintas vice president of quality and engineering, whose group oversees the company’s fleet.

“Up until this point, the technology wasn’t out there to start a program like this. Over the last two or three years, they’ve really come along to where the technology’s there.”

Cintas’ fleet department works closely with various original equipment manufacturers (OEMs) to identify additional opportunities, new technologies and future use cases that can maximize the effectiveness and performance of the EVs in the pilot program.

“We are constantly talking to our vendors, meeting weekly on conference calls, sharing information, then our team—the fleet team—actually has phone calls with our operations to understand exactly what’s transpiring

throughout the week,” Bolen says.

“We’re making sure the vehicle is performing where we want it to, and then we’re constantly making that range go out a little bit further, and a little bit further, a little bit further.”

WHAT’S AHEAD

As 2023 approached, Cintas planned to procure and deploy additional EVs around its business footprint.

“We have a unique business, and our fleet has unique use cases, and we expect our fleet will continue to include different vehicle models, including various light-, medium- and heavy-duty units to meet the needs of our business,” Bolen says.

“As more options and technologies are developed, and more OEMs enter the commercial EV and alt-fuel markets, we expect to grow the pilot program in both quantity and scope.”

Additional grant funding has already been secured through different government initiatives and

the company has plans to expand the current roster of EVs with as many as 50 additional units in the next calendar year.

Cintas also plans to pursue additional opportunities to test and deploy new technologies from different manufacturers as they become available.

Cintas leaders are also monitoring innovations and developments in other types of alternate-fuel vehicles.

Along with its ambition to achieve Net Zero GHG emissions by 2050, the commercial vehicle industry will also continue to evolve with new technologies and capabilities.

Bolen notes that Cintas remains open-minded about the types of vehicles the company will choose for its fleet over the long term and that the company is anxious to evaluate new renewable and alternate-fuel vehicles when they’re available.

“Who knows what the new technology will be in the next 5, 10, 15 years?”

Publisher Charles Thompson

Phone: 312-361-1680

E-Mail: cthompson@ ATMags.com

Associate Publisher/ National Sales Director

Donald Feinstein

Phone: 312-361-1682

E-Mail: dfeinstein@ ATMags.com

Editorial Director Bruce Beggs

Phone: 312-361-1683

E-Mail: bbeggs@ ATMags.com

Editor Matt Poe

Phone: 866-942-5694

E-Mail: mpoe@ ATMags.com

Production Manager

Mathew Pawlak

Digital Media Director Nathan Frerichs

Phone: 312-361-1681

E-Mail: nfrerichs@ ATMags.com

Advisory Board David Barbe

Janice Ayers Davis • Nick Fertig Deana Griffin • Cecil Lee Edward McCauley Jim Slatcher

Main Phone: 312-361-1700

Fax: 312-361-1685

Subscriptions 847-504-8175 ALN@Omeda.com

www.americanlaundrynews.com

2

FEBRUARY 2023 | American Laundry News www.americanlaundrynews.com MEMBERSHIPS American Laundry News (ISSN 1091-9201) is published monthly. Subscription prices, payment in advance: U.S. 1 year $50.00; 2 years $100.00. Single copies: U.S. $10.00. Published by American Trade Magazines LLC, 650 West Lake Street, Suite 320, Chicago, IL 60661. Periodicals postage paid at Chicago, IL, and at additional mailing offices. POSTMASTER, Send changes of address and form 3579 to American Laundry News Subscription Dept., 125 Schelter Rd., #350, Lincolnshire, IL 60069-3666. Volume 49, number 2. Editorial, executive and advertising offices are at 650 West Lake Street, Suite 320, Chicago, IL 60661. Charles Thompson, President and Publisher. American Laundry News is distributed selectively to qualified laundry and linen management and distributors in the United States. © Copyright AMERICAN TRADE MAGAZINES LLC, 2022. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Laundry News does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Laundry News or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication,

editors, publishers

agents

accept responsibility for damages

injury which may arise therefrom.

(Photo: Cintas Corp)

neither the

nor its

can

or

01 Hiring Next-Generation Laundry Employees Experts share insights into how operators can attract, and retain, younger sta members 04 Mitigating Rising Energy Costs Columnist-at-Large Tommy Cocanougher shares options to help contain energy usage levels in laundry plants 10 Staying Ahead of the Breakdown Curve Preventive maintenance laundry operations can do with the plant running and with minimal downtime impact or parts costs 12 Reinvigorating Laundry Facility Safety In this issue, the Panel of Experts answers a question about how to re-emphasize safety in operations 14 Supplier Experience, Relationship Strengthens Customer Value Rental Uniform Service touts partnership with UNX-Christeyns to create customer-pleasing wash formulas 16 Product Showcase Small-capacity washer-extractors 19 Classified Advertising 20 Source Directory 23 Trade Ticker 23 Calendar of Events INSIDE:

Milnor has a better solution through dilution.

When Milnor introduced PulseFlow® technology, CBW® washing was thrust into the future. The idea of balancing time, temperature, mechanical action and chemistry was missing one critical piece of the pie – DILUTION through the efficient use of water.

PulseFlow combines the innovative RecircONE® fast wet down and chemical immersion in the first module with standing bath washing in every spacious process module. Thorough and efficient dilution occurs by way of intermittent high velocity counterflow rinsing and traditional True Top Transfer.

The result is hygienically clean linen using less water (as low as 0.3 gallons per pound/2.5 liters per kilogram) and less energy as proven time and again by hundreds of PulseFlow tunnels in a variety of laundry applications worldwide.

Contact an authorized Milnor distributor or call 504-712-7656 to find out more.

www.milnor.com

*PulseFlow®, CBW® and RecircONE® are Pellerin Milnor’s registered trademarks.

Finding new employees

There was a time in my career, about 15 years ago, when I was involved in hiring (and firing) employees. It was not a favorite part of the job for me.

First off, when you advertise that your publication is looking for a writer or editor, the floodgates open on resumes.

It seemed like anyone who had even looked at the alphabet applied. Not that they knew how to use it for how many misspelled words I read on cover letters and resumes.

And I can’t begin to tell you how many were “imaginative,” “creative,” “artistic” and “could write about anything.”

After sifting through the piles and selecting a few I hoped might work, it was time for interviews.

One person spent the time chewing gum like a cow, staring at their shoes and giving one-word answers.

Another tried to wow me with their knowledge of the trade industry of the publication (travel)—they weren’t even in the right zip code.

Yet another kept asking about the possibility of publishing poetry—in a trade magazine.

I can’t imagine what you as a laundry operator are going through these days, especially when it comes to hiring and working with younger employees.

Fifteen years ago, their attitudes toward work baffled me.

But without younger employees, the industry is going to have an uncertain future.

That’s why this issue’s cover story is about hiring the next generation of laundry employees. I spoke with human resources and laundry operation experts to gather information to help with your search.

To help you keep operating, the second feature (page 10) is about preventive maintenance. There’s also a Product Showcase on page 16 that highlights small-capacity washer-extractors.

All this and much more is in the pages of this issue to help everybody keep it clean!

Alsco orders 30 batteryelectric step vans from Xos

LOS ANGELES — Xos Inc., which provides fleet services, software solutions and manufactures Class 5 through Class 8 battery-electric commercial vehicles, reports it has secured a purchase order for 30 of its 100% battery-electric step vans from global uniform and linen rental services company Alsco Uniforms.

The 30 vehicles will be split and deployed across several of Alsco’s California laundry processing facilities as follows: nine vehicles to Santa Rosa, nine vehicles to San Jose, seven vehicles to San Francisco, three vehicles to Concord and two vehicles to Los Angeles.

“We’re thrilled to add Alsco to the Xos ecosystem and expand our footprint within the uniform and linen services industry,” says Jose Castañeda, vice president of business development at Xos.

Mitigating rising energy costs

While we have always had fluctuating energy costs in our businesses, it seems lately there is a whole new level of price escalation.

No matter what we do to contain costs, the industrial and commercial laundry industry is seeing dramatic impacts on profitability like rarely before. Mark it up to general inflationary pressures, polar vortexes, aging infrastructure, increased governmental regulation or some other cause, it just seems to be getting out of control.

There are limited options to control per-unit costs—these are often regulated by local entities that control services like water and sewer, or perhaps markets where fuel oil and natural gas are impacted by weather events.

There are more options available to us to contain usage levels in our plants, and these can impact your P&L (profit and loss statement) positively. Let’s unpack some of these key areas where we can make a difference in the bottom line.

PER-UNIT COST CONTROL

Check with each utility supplier and assure your business is on the correct rate schedule. Getting on an alternate rate schedule can impact your per-unit cost in a big way.

In its most recent sustainability report, Alsco Uniforms outlined its latest efforts and results in building a more sustainable business, including a reduction of water use by 50% over the last 10 years, the elimination of paper waste by implementing an online account management system and investment in American-made fabrics with life cycles of up to 80% longer than imported linens.

“We are thrilled to add the Xos step vans to our nationwide fleet,” says Tim Stuewer, director of operations support at Alsco. “The move to fleet electrification is an important pillar of our ESG initiative.

“We’ve been impressed by the vehicles that Xos has built and we’re looking forward to using them to make uniform, linen, floor mat, first aid and restroom supply deliveries to our many customers in California.”

ARE YOU RECLAIMING ALL THE WASTE HEAT YOU CAN? BOILER STACK ECONOMIZERS, WASTEWATER HEAT RECLAIMERS AND MAKE-UP TANK VENT CONDENSERS CAN HELP RECLAIM HEAT. MAKE SURE THEY ARE CLEAN AND WORKING PROPERLY.

Assure you are auditing your bills for each utility supplier each month and are checking their billed usage levels against your daily meter readings (more on that later). There is no substitute for understanding your billing and rates.

Consider utilizing the services of an energy management firm. They will usually offer services including bill auditing, payment processing and negotiation of new utility contracts that can help you keep costs in check.

They’ll also educate you on how the utility system works, and that is important to understand.

IN-HOUSE USAGE CONTROL

Use the usually complimentary services of your utility suppliers to audit your site and offer ideas to reduce energy consumption. Ask about rebates for work that you do based on their recommendations.

Turn the lights off! How often do you walk into your plant on a weekend, when it is quiet and no work is in play, and the night shift left on all the lights? Train your employees to keep the lights off when not needed and when they leave. Consider timers, motion detection actuation and LED lighting retrofits to help contain lighting costs.

As mentioned above, be sure your team is taking daily meter readings and doing the math to catch any spikes in usage. This may be particularly noticeable in water meter readings where it can give you early notice of a leak in the line or a leaking drain on a washer.

It gives you the data to assure that the utility billing office is charging you for the correct amounts used.

• David Griggs: New Year, New Goals, New Challenges

OUR SISTER WEBSITES

From AmericanDrycleaner.com:

• Dry Cleaners’ Predictions for 2023

• Counting Down 2022’s Top 10 Stories WE

From AmericanCoinOp.com:

• Entrepreneur Pursues Opportunity with Love ...

• Girbau Group Appoints Joris as Oasis Laundromat Owners ...

Are you reclaiming all the waste heat you can? Boiler stack economizers, wastewater heat reclaimers and make-up tank vent condensers can help reclaim heat. Make sure they are clean and working properly.

Water reuse systems come in handy when you have the space to place the tanks and pumps. Planning for these systems should include installing a split trench and washers that have two drains so you can direct the flow of potential re-use gallons. Treated water from your DAF (dissolved air floatation) may also be redirected to re-use.

See Column on Page 18

4 FEBRUARY 2023 | American Laundry News www.americanlaundrynews.com

From The Editor’s Desk

January 15. NEWS • Alliance Laundry Systems Distribution Relocates Texas Office • Maxon Completes Construction on Second Manufacturing Plant

CITY Laundering Acquires Lake Superior Laundry

In Memoriam: Lee Ekola, Kannegiesser ETECH

Huebsch Services Receives Award for Sustainable Practices

to Laundry/Linen Services Longevity

on

Update, Strategies

Top Stories Appearing on americanlaundrynews.com for the 30 Days Ending

•

•

•

COLUMNISTS/FEATURES • Secrets

• Reflecting

2022, Looking Toward 2023 • Laundry Operation Supply Chain

COLUMNIST AT LARGE Tommy Cocanougher

MATT POE

(WE) = WEB EXCLUSIVE

Visit www.monarchbrands.com or scan the QR code to access our live inventory 24/7/365 2022 Home Textiles Today 2022 Reader Rankings Award Winner Best Table Linens Best Kitchen Textiles Jeff has been looking for bistro napkins for 3 hours... Jeff is getting upset. Don’t be like Jeff. 1. Browse our textile inventory in real time on monarchbrands.com. 2. Get your order shipped the next business day. 3. Put the phone down.

coaching, teamwork, diversity, work-life balance, development, growth, social awareness, mentorships and job rotation,” Jessup says.

She says younger millennials (born between 1981-1996) are looking more for performance-based compensation, flexible schedules and a flexible location—whether that’s remote or maybe a hybrid-type situation flexibility.

“Also being able to have marketable skills, so training,” Jessup continues. “Having access to decision makers regardless of what type of level or position they may be in. They want to be able to build those relationships with management and higher leaders in an organization.

“They also want to have a clear area of responsibilities in their job and then a chance to be creative as possible

“And there was something that I thought was interesting, its Gallup survey data, but there were three things that the young millennials and Gen Z both agreed on what they wanted: an organization that cares about their well-being, organizations and leadership that is ethical, and an organization that is diverse and inclusive of all people.

“And the last one wasn’t just an employer having a program saying that they value diversity, but they can actually see those results—you can see the difference in those organizations that do that.”

From Jessup’s experience and studies about the younger generations and how they work, she has found that they want their position to matter. They want it to be part of something bigger than themselves.

“So, if an employer can relate their job to a bigger emphasis and being a part of something bigger than themselves, they want to do that,” she points out. “As opposed to the older generation, where they stayed with the same employer most of their career and were mostly looking at financial stability, things like that.

“The younger generation is a bit more different in that they want to feel passionate about what they’re doing. If an employer can connect what they’re doing and they can feel passionate about that, I think that would make a big difference in what they’re doing.”

This also means that younger employees will likely not remain with an employer for their entire career.

“I believe the data on the younger generation is three to five years with the same employer versus the older generation, which is obviously a lot longer than that with an employer,” Jessup says.

“It is looking that way with our research and especially given how many employers don’t have pension plans anymore. Employees can take their 401k and move that anywhere. They see the value in not only promotion opportunities elsewhere but raising their salary elsewhere.

“There’s not so much that commitment to one organization.”

That’s not to say that all young employees are going to stay with an employer for three to five years, but Jessup suggests that employers need to consider building career paths for younger workers.

“If they can see where their career path is going with a certain organization, they may be more likely to stay with that

employer longer,” she points out.

“If an employer creates mentorship opportunities, connecting with someone who is in the direct career field they want to be in, or if there is a different career field within the same organization where they can learn from, having those robust types of training and or leadership programs can often help combat that shorterterm commitment from the younger employees in the laundry operation.”

When it comes to attracting younger employees to either management-level positions or plant operations, Jessup says it depends on the education level of the workers.

“This is more anecdotal, but someone with a college degree isn’t going to want to work in a plant but it can help an employer in general, I would say, to target high school career fairs or maybe even community colleges if maybe they aren’t sure if the four-year degree is for them,” she says.

“Kind of target the right job based off the education level that an employer is looking at.”

But still, even in a plant setting, younger workers will be looking at advancement, being more a part of the team and understanding the whole of what’s going on.

“I think another thing to consider is focusing on well-being,” Jessup shares. “Whether that’s providing an employee resource or just the overall well-being of employees, they want to feel like their organization cares for them.

“I think also having a healthy work-life balance is important. That can be challenging, depending on the type of industry, of course, but integrating work and life and being able to manage that is important to the younger employees as well.”

Ultimately, she says it’s vital for younger workers to have managers who not only provide feedback but also inform them of what’s going on within the organization.

“We have some data for employees, and 61% of millennial workers are engaged when their manager, or supervisor, informs them of what’s going on in their organization,” says Jessup.

“Just keeping employees in the loop, and, again, connecting how their role impacts the organization overall, can help with that engagement.”

The initial challenge, though, is attracting the attention of the younger generations to consider employment in the laundry and linen services industry.

Jessup says employers need to update their recruiting methods for younger workers.

“One idea in recruiting methods is updating the technology,” she says. “Text alerts for job openings. Creating videos for a day in the life of working for either a specific job or a specific company to give an idea of what it’s actually like to work there.

“Make sure the job advertisements are interesting. That they grab the reader’s attention. More likely than not, if the younger applicant is reading something and it’s not engaging right away, they’ll probably move on.

Jessup says that many online job descriptions use a lot of copy-and-paste from job descriptions on file.

“The key point to keep in mind is that a job ad should not just be a copy-paste job description,” she says. “People lose interest very quickly.

“What you could do is the first paragraph, try to make it more interesting in terms of describing maybe the team environment or what they would be doing. Asking questions like, do you want to be part of an innovative team working on X, Y or Z; do one, two or three; do these things appeal to you?

“Thinking outside of the box of how you can engage a reader in seeing this isn’t

just any job ad. They’re trying to describe what this position is doing.”

Finally, Jessup says it’s important to streamline the overall recruitment process to reach younger employees.

“Younger workers are more likely to apply to a job with their phone versus a desktop like older generations,” she says. “So, it’s important to make the process easy, efficient.

“Specifically, no one wants to upload their resume and then have to fill out the exact same information on an application. That’s probably the biggest complaint that I’ve heard.

“That’s an area that I think employers could benefit from in at least the recruitment-type process.”

LAUNDRY OPERATOR INSIGHTS

Laundry operators agree with the insights Jessup shares about younger workers, in general, when it comes to laundry and linen services attracting nextgeneration employees.

“In today’s environment, we must effectively convey the full package/opportunity to younger candidates when recruiting,” Warnecke points out.

“With an expectation of immediate gratification and plenty of options, we need to be able to map out a plan for possible upward mobility, promote the strong work-life balance we can offer, and focus on effective engagement and recognition once we have them onboarded to get the most out of each one.”

Maresca says, “The younger generation looks deeper into your company, not so much for what you offer on paper but for what others think of you—for scalability, company culture and opportunity for their resume.

6 FEBRUARY 2023 | American Laundry News www.americanlaundrynews.com

Continued from Page 1 ➢ Page 8

NexGen

Mentorship opportunities and robust training can help next-generation employees see the value and longevity of a career in laundry. (Image licensed by Ingram Image)

YellowGo® removes unwanted dye from fabric.

Results on whites are excellent. On colors, you have nothing more to lose and everything to gain by trying YellowGo. YellowGo may take out color you want to keep. But if it removes the unwanted dye without damaging the underlying color, you win! You won’t have to pay for the dye-stained garments and you won’t disappoint your customers.

So use YellowGo to keep your customers happy and keep them coming back.

For more information visit AlWilson.com or call us at 800-526-1188 or 201-997-3300

NexGen

“The work that our industry provides is not glamorous and requires leg work, lifting and early hours. Some of the major points we use are our involvement in green sustainability, community enrichment, four-day work weeks, great benefits, company outings, a relaxed family atmosphere, we have been in business for 99 years, and, of course, very competitive pay.”

“Younger folks have lived through some tribulations when it comes to the jobs,” Peterson shares. “They’re naturally not as inclined to trust employers, who they have seen treat people close to them as expendable. So, they’re a bit more jaded and cynical—perhaps rightfully so.

“Given that, you’ve really got to make an emotional appeal to them that they’ll be valued, treated with respect and part of a team. They like to belong to things that give them purpose, so appealing to the big picture and explaining the ‘why’ beyond simply telling them what their job duties are is one way to accomplish that.”

Stern agrees, “Younger employees’ expectations are different than past generations. They want upward mobility quicker without having to prove themselves.

“They have never seen a market where the employer has the leverage, so they know they have many alternatives, so a bird in the hand is not worth two in the bush.”

There are elements of the laundry industry that appeal to millennials and Gen Z, according to operators, along with methods to make a career in laundry more appealing.

“They like the technology piece, and most want interaction and recognition with and from other departments,” Warnecke shares.

“Cross-training is more important than ever not just to optimize our front-line labor but also to keep folks engaged and curious about other roles within our organization.”

“It seems that younger generations feel any position early on is more of a stepping stone until the next opportunity comes along,” says Maresca. “Older generations look for long-term positions, loyalty, ben-

efits and the laundry’s long-term outlook.”

“The laundry industry isn’t as glamorous as many of the alternatives young people are exposed to,” Stern shares.

“However, we noticed that young people are engaged in the fast pace and the different challenges that arise on a monthly basis and like the challenges of serving the customer on a just-in-time basis.”

Still, increasing the next generation’s interest in laundry operations will remain a challenge.

“By and large, they’re not getting into the laundry industry,” Peterson points out. “We need a talent infusion in a big way.

“As for the ones that are, I believe that they’re not inherently loyal, and sometimes that catches established, generational organizations (of which are very prevalent in this business) off-guard. Then, when they don’t stick around for 30

years, younger folks tend to get demonized for looking for greener pastures in more theoretically lucrative or more glamorous industries.

“Instead of treating such instances as a time for self-reflection, they’re made out to be scapegoats. And that becomes a vicious cycle because we need fresh perspectives.”

“Younger employees consider this a place to work just for the paycheck, not because they like this industry,” adds Rick Antman, director of operations for Kleen Kraft Services.

“They have more options than ever,” reminds Warnecke. “Some can find a structure where they aren’t expected to be ‘at work’ for the entire week and that’s what many of them want.”

Also, Maresca shares, it’s hard, dirty work on the floor.

“It’s early shifts and a lot of hard work,” Antman agrees. “Young people need a job where they can work and hold onto their cell phone with their other hand.”

Stern reiterates, “They don’t see the industry as glamorous, and, therefore, they don’t see the opportunities for themselves and their family.”

“It’s a systemic problem caused by a lot of ‘we’ve always done it this way’ coupled with an industry that, fundamentally, is actual rigorous, blue-collar traditional work,” adds Peterson. “The processing of textiles, the picking up of dirty laundry, etc., is not inherently sexy.

“But, on the flip side, a lot of young people who have come up staring at screens for years are looking for something ‘real’ and to get some dirt on their hands. Those are the ones we have to recruit and develop. There is a profile of talent that this industry can appeal to; it just needs to be presented correctly.”

And that means having a better understanding of how to reach younger employees, speaking to what they are looking for in a workplace.

Ed Heilman CEO of Ace Imagewear in Houston says the next generation is look-

ing for purpose.

“I think as a society (in the United States), we’ve climbed the pyramid of Maslow’s hierarchy of needs and the current generation is looking for more than security (at least until they go hungry),” he shares. “They need to feel that their work is purpose-driven and has a good worklife balance.”

Warnecke adds that younger generations want interaction and recognition, balance and “fun.”

“Communication is key, and if there is upward mobility potential, creating a plan/ roadmap for them early on can help keep them engaged and motivated,” he says.

“(They want) a community that values them as individuals but also assimilates them into a team framework with a communal purpose—a partnership,” says Peterson. “They’re not stupid.

“If they’re being exploited or taken advantage of, their opportunity for other careers is almost infinite in this labor climate. They know that and pretending otherwise as an employer is a dangerous game of chicken. Don’t assume that loyalty is a one-way street; these employees realize they don’t have to work for an employer that they don’t value.”

Stern adds, “Young people want quick advancement, shorter work weeks and like to work for a cause they believe in.”

Antman concludes, “They are looking for better pay with less manual labor.”

BENEFITS OF A CAREER IN LAUNDRY

All of this begs the question: How can operations better share with younger generations that the laundry industry is a beneficial career?

“Sell the service as a marketing/branding opportunity (branded work apparel) within a green industry,” says Heilman.

“What we do is sustainable. We re-use clothing, provide a centralized, highly efficient processing system that uses the smallest amount of natural resources and cleans the water before returning it to the

8 FEBRUARY 2023 | American Laundry News www.americanlaundrynews.com

from Page 6

Continued

Younger employees are more attracted to employers that show interest in their well being, offering work-life balance. (Image licensed by Ingram Image)

(Image licensed by Ingram Image)

local municipalities.”

Antman says, “The benefit that I share with younger employees at the plant is that we are a business-to-business company. We don’t have to deal with unruly customers coming into our business.”

“Marketing it as a fun and rewarding, stable industry,” says Warnecke. “Offering job trials and creative scheduling when possible.”

“Longevity, the need for our services, technology,” says Maresca. “The industry is a strong service to many different companies and industries.

“You will be able to meet and interact with so many different types of companies and industries. You can, as a driver/salesperson, be almost your own boss on the road.”

“Many of our team leaders and managers came from the rank and file,” Stern points out. “Having these leaders spend time with applicants and share their story is useful.”

“I believe that strides are being made,” Peterson says. “The appeals of this industry are in stability, growth, personal development, and opportunity and the ability to see the results of your work in a tangible way—every single day. And compensation.

“It’s about marketing at this point and getting innovative on how to appeal to the value that we absolutely do possess to potential candidates of all ages.”

How are laundry operators working to reach younger candidates for jobs in the washroom?

“We get young employees at the plant because we have an aunt/uncle or a parent that refer them here to work because they are usually sitting at home on their phone doing nothing,” Antman shares.

“Partnering with local schools, setting up an open house, job trial or glimpse into the operation to allow young candidates to see what it all looks like behind the scenes,” Warnecke says.

“Good pay, employee interaction, employee welfare outings and overall camaraderie between top management to productive workers,” shares Maresca.

“Did I say company culture? Excite them with the technology that is used to handle all the garments, explaining this is not a laundromat, but rather a sophisticated washing process that is a steward in green sustainability and ecological concerns.”

Peterson says, “By accentuating the communal and team aspects of the work and by making the goals and directives very transparent and clear.

“Make them feel like they’re a part of something and then hold them accountable. It can’t be marketed as assembly line work; it has to be framed as the nerve center.”

“I think sometimes the stigma of the laundry operation is in the

basement with sweatshop image,” Stern says. “Our industry is far from that and highly automated.

“Job shadowing helps prospective employees see good working conditions and interact with employees that are positive about working in the plant”

Heilman adds, “Make it fun.”

To attract the next generation of management to the industry, Peterson says, “With young professionals, it’s vital to give them a roadmap with a clear trajectory of what their career path will be.

“The work we do is critical to many industries, and we

really do make an impact with real results every day. There are many industries with vague or nebulous outcomes, and this is very much not one of them. That’s cool!

“Also, this is an industry with aging leadership, and it’s very important to accentuate that we are looking to cultivate the next generation to take their place.”

Stern adds, “Working through universities, trade schools and business colleges are good sources to attract young admin and management candidates.”

Once a laundry and linen

service has recruited and hired a next-generation employee, what can an operator do to keep them engaged in a position, encouraging them to make the industry a long-term career?

“Consistent communication and recognition from the top,” Warnecke says. “Key leaders from within the organization should all play a role in the development and ongoing engagement of younger new hires to help them see and understand we are willing to invest time, training and resources into their long-term success.”

“This one is simple: Articulate the ‘why’ to them over and over again,” says Peterson. “Make them be a part of something— both from a team perspective and also turning tasks and duties into missions and goals.

“Ask their opinion. Young workers are creative and resourceful. Utilizing those talents will improve an organization and make them feel valued.”

“Like any generation, good training and constant feedback around expectations are what keeps employees engaged,” Stern concludes.

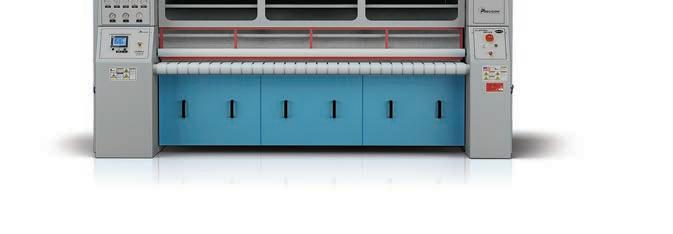

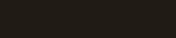

Precision Series® Ironers

Deep Chest Ironing

Performance

• Torsion Bar suspension distributes pressure evenly along each roll, assuring uniform drying and travel of flatwork through the ironer with a minimum of padding wear

• Floating Chest self-centers to the ironing roll during operation, optimizing the contact area under pressure

• Adjustable Ribbon Tensioner prevents ironer ribbon from creating uneven surfaces, lines and wet spots on sheets

Efficiency

• Deep Chest Ironers continue to have the largest heat sink and remain the most energy-efficient

• Full insulated chest, canopies, and insulated stainless heat shields contain up to 96% of heat radiation

• Inverted bucket traps ensure condensation purge without remaining open (steam ironers)

• Direct Controllable Speed

• Gearmotor Drive ensures reliability and low maintenance

Safety

• Auto-stop infeed safety gate to prevent hands or items from going into chest

• Solid heat shields along the ironing box keep side frame covers temperatures cool to the touch

• Enclosed canopies prevent foreign items from getting into ironer rolls, chest, and pad

• Roll raise lockout prevents lowering rolls if air pressure has been disconnected

• Safety switches on all doors and e-stops on all four corners

9 American Laundry News | FEBRUARY 2023 www.americanlaundrynews.com Made in the USA | ISO 9001:2015 Certified | gabraun.com

A Superb Flatwork Finish!

Moisture Content Pressure Time Temperature Ironing Pie® 25%25% 25% 25%

Staying ahead of the

curve

BY LEE BALDAUF

Keeping ahead of mechanical failure is like chasing a virtual carrot—if you were a horse.

You never catch the carrot, and it is a repetitive situation. It’s good for engineers—it keeps us employed.

Preventive maintenance is the little things we do, repeatedly, hoping to prevent or delay the inevitable breakdown.

Every plant is going to have different needs in this arena, as well as varying levels of cooperation with owners, plant managers and hours of operation.

For this article, I’m defining “preventive maintenance” as the things we can do with the plant running with minimal downtime impact or parts costs.

I wish the real world was as easy as the “scheduled on paper” world, but it isn’t, and sometimes we change the oil on our car a little later than prescribed.

The beauty of having a schedule for greasing, blowdowns, control panel vacuuming and such is that you can keep the pace a little tighter than it needs to be so that on the occasion a service interval is delayed, you have built in a safety of time.

GREASING—AND DOING IT PROPERLY

Every plant has grease guns and guys rolling around hitting zerk (grease) fittings, but there is more to it than that. Lubrication, when done right, prevents so many problems.

Grease less, but more often. This is critical.

Obviously, if you are trying to stop a squeak, you have waited too long, or you have a failure already.

Bearing seals can be pushed out with too much grease, especially with today’s cordless guns. Unsealed bushings, like on roll blocks on a sylon, are just wasting

grease and potentially creating a mess.

Too often we take the newest, leastexperienced technician and throw the grease gun at them with no training. “Hit the zerks on this at the end of each shift” type of stuff.

A couple pumps a day, consistently, on your dailies, or whatever the interval, should see the seal maybe weep a bit of grease without the seal failing. Once the seal is gone, you will have to over-grease constantly to push out moisture and contaminants. This is already a failure but one you could live with temporarily until you have time to change the bearing and/or seal.

If you grease at the recommended intervals and do it right, you can get away with the occasionally missed interval that has been caused by “scheduled breakdown.”

INSPECTING DURING SERVICE

So many shafts fail because set screws have backed out or keyways have slid out. This creates a situation where the shaft will rotate at a different speed than the collar, causing shaft and race wear in a hurry. Pointing these things out to your team and getting them to check for this can pay great dividends. Nearly every shaft failure I have seen has been caused by this, rather than breaks.

AUTO OILERS

Some of our industry uses auto oiling systems for bearings, generally triggered by a drain valve cycle or some other pneumatic means. These can be easy to overlook.

Be sure to periodically test these systems, and verify the oil is getting delivered to its target.

LUBRICATION

Lubrication is probably the simplest, easiest form of preventive maintenance.

10 FEBRUARY 2023 | American Laundry News www.americanlaundrynews.com

breakdown

Preventive maintenance laundry operations can do with the plant running and with minimal downtime impact or parts costs

(Photo: © Photoerick/Depositphotos)

(Photo: © DmitryPoch/Depositphotos)

It is also widely misunderstood. Consult your manual or reach out to the service department for the specific machine in question.

Be sure you understand the manufacturer’s needs. They love selling parts, but they love a solid and reliable reputation even more.

In maintaining proper lubrication, you reduce wear on many systems beyond shafts, bearings and gears.

Less friction equals less load on motors, drives, belts, etc. This will build extended life into those systems, reduce utility costs, and lighten your load and stress in doing so.

CART SAFETY

I do not like carts (and that’s putting it mildly). Other than caster maintenance and cart repairs in general, carts seem to be the most destructive force known on the planet.

It’s definitely the most destructive force in a laundry. More destructive than apron strings even!

Seriously, though, fabricating and installing bollards and curbs and guards to protect equipment from carts seems to be an endless task at laundries.

Beating the cart to the touch-screen controller and E-stops is a constant challenge. Always be looking!

FREQUENCY DRIVES

These are becoming less easy to source and often can be time-consuming and painful to program on replacement.

We like to use a vacuum to pull lint

and dust out a couple of times a month or every other week.

This is something that should be done every time you vacuum a control cabinet. I say vacuum because air tends to push debris deep into the drive or contactors. This, however, is not enough—at least in my world.

Dust, and especially lint, will tightly compact itself into the heatsink fins and your frequency drive will begin to overheat. This absolutely reduces the life of these drives.

When you can power down these units for at least an hour (they have capacitors that hold stored energy in many cases), do this. Then, you can strip the drive in segments and use air in conjunction with the vacuum to remove all of this life-robbing debris.

If you have multiple repeats of the same frequency drive (I have a ton of F7 drives in my plant), then build a cheat sheet for setting parameters and keep a spare on hand.

Newer equipment tends to have integrated mini drives in the cabinet, so keeping them as dust- and lint-free as possible is very important.

WEATHER CONSIDERATIONS

As I write this, winter is here. It hit us, and much of the country a little harder

and earlier than we expected.

Winter demands an entire set of preparedness and prevention. Water lines and potential freezing/bursting are obvious, and you probably already have dealt with this and have built-in countermeasures in place.

What about your fire suppression? Our sprinkler contractor comes in every September for a “low point drain” of our system.

In many municipalities, such as ours, the annual inspections and maintenance must be done by a third party that is certified. This is expensive but so worth it.

A dry system, even if it has not tripped, will build up condensation inside simply by being pressurized by compressed air and subjected to wildly varying temperatures, like what you would expect in an ironing room.

I have dealt with a couple of failures of these systems. One was annoying; the other was quite painful.

I will say that I have seen how quickly a well-serviced suppression system can quickly arrest what would otherwise be a devastating fire.

Another winter frustration is frozen air lines and actuators. Most of us have air dryers and oilers on our equipment.

You see water stacking up in the bowl,

and you drain it, and the world is good, right? Well, that water was delivered to that bowl from somewhere.

We have a relatively new and well-sized air dryer immediately after our plant compressor. We live in the Northwest, so our air is wet. We extract about 4 gallons of water a day at this point.

Many of you (and us, previously) do not have an air dryer. That moisture is going to your accumulation tanks, and even if you are diligent about draining those, your supply lines will carry some moisture.

Even with the air dryer, we still drain the tanks, and we still get some moisture in our lines.

Winter exacerbates the problems of moisture in your system, but moisture is a problem year-round. Pneumatic cylinders and actuators will suffer a premature demise from the moisture ruining piston seals and clogging ports.

Alcohol can be used to help dry these systems, but if your subsystems are not using lubrication at the separator, this can accelerate the drying out of all the rubber seals associated with pneumatic systems.

I like to replace poly lines every couple of years, sometimes pulling the lines apart at lower points to push built up moisture out by charging the system. This has helped me.

I also have begun installing “dirt lines” on new systems. Essentially this is just a drop like you would see on a gas line or a

11 American Laundry News | FEBRUARY 2023 www.americanlaundrynews.com

The Newspaper of Record for Laundry & Linen Management Find what you’re looking for wherever you are. Stay on top of the latest industry news and updates on your tablet, phone or in your mailbox. www.american laundrynews.com Experts share insights into how operators can attract, and retain, younger staff members Group acquires Linen King H Hiring next-generation laundry employees LATE NEWS 0223aln_ALN Digital Edition_Jr Half.indd 1 1/13/23 11:02 AM See Maintain on Page 18

EVERY PLANT IS GOING TO HAVE DIFFERENT NEEDS IN THIS ARENA, AS WELL AS VARYING LEVELS OF COOPERATION WITH OWNERS, PLANT MANAGERS AND HOURS OF OPERATION.

PANEL of EXPERTS

Reinvigorating laundry facility safety

All accidents and fires will result in a poor financial situation for laundries.

OSHA compliances, workers’ compensation costs, lost time, retraining costs, equipment damages and delays to production—all these issues affect the laundry, its customers and the team members (employees).

All leaders should be aware that the safety of their team members is a top priority, period. Communication of safety concerns improves morale and develops a cohesive team!

After over 45 years in the textile rental industry, I have seen my share of laundry fires and accidents; none of them are fun.

To reinvigorate safety efforts for both employees and customers, it must start with leadership.

Safety permeates an organization, and it spreads throughout the company when managers and supervisors are engaged and responsive.

As Arnold Glasow said, “One of the tests of leadership is to recognize a problem before it becomes an emergency.”

This is so true when it relates to safety in the workplace; leaders must be initiative-taking.

To help reinvigorate safety efforts within a company, a safety committee must be active daily, recognizing safety concerns before they become a catastrophe.

At least weekly walkarounds should happen with the committee members identifying potential hazards, noting injury rates, the severity of injuries and the workers’ compensation costs are all lagging indicators.

Leading indicators are the number of team members completing safety training, timeliness of reporting, number of nearmisses and timeliness of corrective actions. Route service reps, office staff—all departments must not be forgotten.

There must be representation on the committee from the service team as they are integral in recognizing hazards at customers’ locations. The local fire department is a reliable resource as well as safety consultants to round out your safety team.

During my time at Wagg’s Linen & Uniform, we experienced two significant fires.

One was laundry bags dried at the end of the day and automatically dumped into a cart. During the night, they ignited and caught fire, burning a conveyor belt. We later learned that the “cool-down” on the

dryer was not sufficient to cool the laundry bags.

The other fire was caused by soiled shop towels stored in an overhead sling over the weekend, and spontaneous combustion caused them to catch fire.

We rectified that by washing the shop towels (and leaving them in the washer) before leaving for the day to avoid that hazard. Thankfully, we had a sprinkler system that nullified the damage in both instances.

Again, leaders must take responsibility for everything that happens in the company, and safety is no exception. Safety must not take a back seat, or you will not be in business.

lish a clear vision and set of values that prioritize safety. This includes identifying the specific behaviors and practices that are necessary to ensure the safety of everyone, every day.

Communicate your safety vision. It is important to communicate your safety vision to all employees and stakeholders. This can be done through regular meetings, training sessions and other forms of communication. Just like writing down a new year’s resolution helps you keep it (longer), so, too, does purposefully communicating your safety vision.

Lead by example. Management and leadership must model safe behaviors and practices and hold themselves and others accountable for following safety protocols.

tion. This can be done through various methods, such as safety awards or recognition programs.

Kemco has been recognized with the SafeTRSA award for its safety leadership because of programmatically developing our safety culture. By following these steps, you, too, can build an effective safety culture that promotes the well-being and safety of all employees and stakeholders. A strong safety culture not only helps to prevent accidents and injuries but also fosters a positive work environment and enhances productivity and performance.

Building an effective safety culture requires the commitment and collaboration of all employees, from management to front-line workers.

A strong safety culture is characterized by a shared set of values and behaviors that prioritize safety in all aspects of work.

Define your safety vision. The first step in building a safety culture is to estab-

Involve employees in safety decisionmaking. Encourage employees to participate in safety committees and to speak up about any safety concerns they may have. This not only helps to identify and address potential hazards, but it also fosters a sense of ownership and commitment to safety among employees.

Provide ongoing training and education. Include both formal training programs and informal opportunities for employees to learn about safety practices and procedures.

Recognize and reward safe behaviors. Actively reinforce, recognize and reward the importance of safety in the organiza-

Isn’t it quite interesting that no matter what side of this industry we are all in, whether it is a laundry or a distributor/ manufacturer like us, in times like this where we are all looking to save money whenever we can, you sometimes wonder where you might be sacrificing certain things to make sure that you are a profitable company?

When I say, “isn’t it interesting,” that doesn’t necessarily mean it’s a good thing.

12 FEBRUARY 2023 | American Laundry News www.americanlaundrynews.com

“I’ve been seeing more news reports on laundry fires and accidents, and I am concerned safety has taken a backseat to staying in business. How can I reinvigorate our safety efforts for both employees and customers?”

Textile/Uniform Rental

W. Kirby Wagg Performance Matters, Orillia, Ontario

Equipment Manufacturing

Tom Vanden Heuvel Kemco Systems, Clearwater, Fla.

Equipment/Supply Distribution

Ross Sanders Streamline Solutions, Orlando, Fla.

(Image licensed by Ingram Image)

Sorry to say but sometimes we all look at certain things within our business and then fail to look at others the way that we should.

Yes, we have heard about the fires and the other issues that have occurred at our laundry customers’ plants. When we hear and read about them, we certainly feel their pain as they have spent so much time and energy over what has been many generations to have terrible situations occur at their plants.

What also makes it tougher in today’s world where there has been a good amount of turnover (and it’s harder to find employees, let alone, high-quality ones), it sometimes means that your current and new employees must constantly be trained on all aspects of their jobs, including safety. This would be the case at laundries, at their respective customer facilities as well as at companies like ours.

As a company, we will always remind our employees of what needs to be done to make sure that all angles are covered in regard to safety, whether that means for fire, potential flooding issues or individual employee safety.

All required notifications will always be posted as well as others that we as a company feel are beneficial to keep everything up to date and interesting.

We feel that as a “close-knit” company, employee-wise, we always try to look out for each other’s best interests. We also know and continue to remind each other that whatever we do to help each other out, it always benefits the company and all parties involved.

That’s not to say that we have not had issues through the years, but we quickly implement any needed changes and requirements to hopefully avoid any safety issues that may occur down the road.

Regarding our customers, we have an extremely tight relationship with many of them and because of that, we can be honest with each other if and when we see potential issues arise. We discuss them with each other.

One of the first things that I personally notice, and always will, is how clean a laundry looks. Not that a clean laundry guarantees anything, but it is certainly a good starting point for making sure that a clean laundry is a safe one.

Also, as a company that recycles plastic bags at many of our customers’ plants, we always try to stay in contact with them to make sure that our recycling equipment is safe and in working order.

We require them to have yearly maintenance done to our balers to make sure that everything is working correctly and, of course, to verify that all safety requirements are met.

As I mentioned earlier, in times when there are many changes in employees who handle this part of the business for the laundries, we feel that this is a key part of making sure that all employees are kept safe when working with a large piece of equipment that they normally would not have experience in using.

In conclusion, no matter how things are going financially at your respective businesses, none of us can afford to sacrifice the safety side of things. It would only be detrimental to your business and your employees.

All safety bases must always be covered!

Uniforms/Workwear Manufacturing

Baby it’s cold outside! That was the battle cry this most recent Christmas holiday week when our daughter was home for the holiday visiting from Florida.

For those of you who were not impacted by this unusual polar vortex, temperatures here in Northeast Pennsylvania with wind chill were at a balmy -25 F.

Unbelievably, we even had ice forming

on the inside of our windows. With those abnormal temperatures, our daughter with her blood having thinned out by living in Florida began her search in our house for the space heater we had in storage to help add some warmth to her bedroom.

Once her search was complete, without removing the dust collected from not being used over the years since she relocated to the land of sun and warm weather, she happily plugged the rarely used space heater into the electrical socket.

Soon after the magical warming unit was plugged in, sparks started to fly as the dust balls gathered on and inside the filters caught fire.

On seeing sparks and smelling smoke, I started to think about what are we, as laundry operators, doing to prevent fires and small stupid electrical incidents in our plants?

What are we as laundry operators doing to keep our employees warm and safe during these cold winters while at work or even at their homes?

What are we as laundry operators doing to educate our service team and our customers on proper storage of product so as to not place it in areas that may cause unexpected fires?

Every laundry must have a safety team in place with a checklist that is given its utmost attention to detail. The safety team should set a schedule for when to meet to discuss all items of concern that are dealt with and corrected on a timely basis.

To avoid fires in the plants, it is the responsibility of our safety and top-notch maintenance teams to make sure the air filters are changed and replaced regularly.

That we have in place procedures that require blowing down and removing all dust and lint that tends to build up on machinery, overhead pipes, and even in some cases, inventory in our storage areas.

Also, let us not forget the roofs on top of our buildings. We need to make sure any possible lint buildup is removed as well, as we have seen fires start on rooftops from

gathered lint never removed.

By checking these few little steps off our checklist, we are taking the possibility of any lint fires out of the equation.

Also, being a realist, some laundry operators have cold spots in their plants, and employees have been known to plug in space heaters to keep them warm at work during the cold months.

In these cases, we need to make sure there is no lint gathered on the heaters and also that these heaters are not close to anything considered to be a combustible item that can cause a spark that can turn into a fire.

Is there any way heat or steam being vented out of our buildings be recycled back into the building? If so, we should do so. Not only will this help keep the temperatures at a comfortable working level, but it will also add to a more environmentally friendly workplace.

What about our fleet of trucks? If parked inside the building, do they need to be plugged into wall sockets so engine blocks do not freeze during the cold weather? If so, we need to make sure wires are all properly grounded so there is no chance of any possible sparks that can also be the culprit of an unsolicited electrical fire.

Let us not forget about our employees and our customers. We also need to educate them on ways to keep warm at home by changing air filters and if they are using space heaters, not to place them near curtains or anything that can catch fire easily.

If they have wood-burning fireplaces in their homes or places of work, make sure they have proper ventilation and make sure there is no chance of any sparks being emitted from the fireplace that can cause a fire. A little education goes a long way to preventing fires.

We should also consider empowering our employees to report all fire and safety hazards every week to the safety committee so they can be dealt with immediately.

13

American Laundry News | FEBRUARY 2023 www.americanlaundrynews.com

Scott Delin Fashion Seal Healthcare, Seminole, Fla.

See Experts on Page 15

Supplier experience, relationship strengthens customer value

Rental Uniform Service touts partnership with UNX-Christeyns to create customer-pleasing wash formulas

GREENVILLE, N.C. — Longevity is an admired hallmark of a successful business. Now in its 74th year of operation, Rental Uniform Service has reached this point by making deft and correct decisions time after time.

One of its recent pivotal moves was selecting UNX-Christeyns to return as its washroom chemistry partner, a decision that has produced significant benefits in a short window of time.

“We began a review of our wash chemistry situation in late 2021, did extensive research and narrowed it down to two companies that we met with personally,” recalls Danny Lawrence, longtime CEO of Rental Uniform Service.

“It was remarkable that cost-wise, there was not much difference between the two. But it was evident from the beginning the UNX-Christeyns folks genuinely wanted our business, and they had the technology and service we were looking for.”

Rental Uniform Service has an intriguing history.

The North Carolina-based, family-owned company began as a small operation in Bluefield, Virginia, with a 2,000-square-foot building and one truck in 1949.

James E. Waggoner and his brothers sold many of their possessions to fund their startup and steadily grew their business with persistence and a sincere dedication to their customers.

Today, Waggoner’s legacy lives on. His four daughters serve as the company’s board of directors and other family members hold vital roles.

CEO grandson Lawrence is married to Paula, the company’s controller. Robert King, the director of corporate development, is the husband of Waggoner’s granddaughter, Susan-Hager-King.

And Holly Benfield, the director of human resources, is Waggoner’s greatgranddaughter.

When Benfield joined the company out of college in 2007, she became the first fourth-generation family member to serve on the management team at Rental Uniform

Service. That is an impressive accomplishment few companies can claim.

According to Harvard Business Review statistics, a staggering 70% of family-owned enterprises either fail or are sold before the second generation becomes involved.

Lawrence emphasizes that having family members learn the business from the ground up is one of the keys to why Rental Uniform Service has been successful for so long.

“I’ve been in the linen and uniforms industry my entire life,” he says. “I became a full-time employee here in 1978 after working in the plant for my apprenticeship.

“I was promoted to assistant plant manager in 1981 and promoted to general manager at our Sunshine Rental Uniform Service facility in Gastonia in 1988.”

Lawrence has guided the company as its CEO since 2000.

About the time he was elevated to assistant plant manager in 1981, UNX-Christeyns first became a Rental Uniform Service supplier. Known then as UNX—which merged with and became UNX-Christeyns in July 2022—it became involved during a growth spurt.

“I was heavily involved in the washing technology operations at that point,” acknowledges Lawrence. “It became apparent their service was always quality oriented and their pricing was fair. The relationships we had at that time were second to none.”

Those moments were remembered during the recent selection process.

Rental Uniform Service is now a more diversified organization with 145 employees. It utilizes 200,000 square feet of space between its headquarters in Statesville, North Carolina, a processing facility in Gastonia, North Carolina, and distribution centers in Mills River, North Carolina, and Florence, South Carolina, putting it in favorable proximity to an expansive client base.

Management also operates an employeefriendly schedule, running 10-hour shifts four days a week.

Rental Uniform Service also understands that working with the food, healthcare, hospitality and manufacturing industries, as

well as government, municipalities and others, requires different and specialized wash formulas for each.

“We provide the highest quality product for our customers,” explains King. “That involves utilizing good modern chemistry with natural soap.”

After working for General Electric, he joined Rental Uniform Service in 1999, first in sales before switching to marketing and then as the general manager in Gastonia.

King has been instrumental in growing the company’s sales and technology efforts in his current position.

“We wanted the highest quality product possible, so the goal was to create advanced wash formulas that were unique to each of our customer segments,” he continues.

“For example, we partnered with UNXChristeyns to develop a low pH dispensing formula. In simple terms, since the wash cycle environment is less harsh, the goods are going to be brighter, they will last longer and they are going to wear better.

“We have always been known for the quality and comfort of our garments. Now, with skilled input from UNX-Christeyns, we have been able to achieve an even higher level of comfort and appearance for our customers. This innovative treatment environment makes it better, and we didn’t have that process prior to working with them.”

King acknowledges that working with an experienced, technically proficient UNXChristeyns staff generates better results.

“They have a smart group of laundry industry professionals. People like Graham Skinner (vice president of field engineering) and others who have actually worked in our industry and know what they’re doing,” he says.

“Their area supervisor, Nicholas Vangelakos, visits our plants regularly, and we consider him like family. He’s developed a trusted work relationship with our facility managers.”

King adds, “UNX-Christeyns was able to provide significant efficiencies by reducing the number of steps in our wash formula processes from the beginning to the end.

They’re making sure we are being trained properly on their equipment and making any necessary adjustments.

“They also just finished constructing a unique rack system for the chemical dispensers, which provides efficient product injection while reducing mechanical components. The end result is we have a better looking and cleaner product, in addition to the tangible benefits of using less energy, natural gas, electricity and water.”

Those benefits include improved effluent (wastewater), which is always an important goal for industrial laundries. They have provided real-time, in-house reporting capability that tracks pertinent management data, such as determining the cost-per-load and other vital daily production numbers.

King says that looking at the big picture, it’s better chemistry with UNX-Christeyns that ultimately benefits its customers.

“You can get a uniform from anybody, but what our customers get from us and our vendor partners is better service and quality that can’t be found elsewhere,” he points out.

“Our customer’s expectation is they want a clean and comfortable product, not one that was run through a solvent process.

“We invest more money than most of our competitors because we require our wash process to deliver the highest quality product for our customers. They know we have an experienced service team that is providing the best care in the industry.

“We treat our employees and partners like family, and that’s why many of them have been with us for three decades. That is what truly impacts the relationship with our customers, not just numbers on a page.

King concludes, “Some of our most loyal customers are those who have previously used our competition. Once they experience our superior quality level, the dramatic differences become apparent, and we never lose them.

“Thus, we are pleased that we have found a solid partnership with UNX-Christeyns. They get it. They have the same goals and with their support, we make happier customers.”

14

UNX-Christeyns Area Supervisor Nicholas Vangelakos (center) visits Rental Uniform Service’s plants regularly. (Photos: UNX-Christeyns)

FEBRUARY 2023 | American Laundry News www.americanlaundrynews.com

Rental Uniform Service says its wash cycle environment is less harsh, goods are going to be brighter and will last longer, and they are going to wear better.

Experts

Continued from Page 13

Those who take part in this process should have their names entered into a weekly lottery to possibly win a prize or even a small bonus. By doing this we create a safer workplace, increase morale and have many eyes keeping watch to prevent unwarranted fires.

Oh, and by the way, right after the Christmas holiday our daughter was back in her car driving back to the land of sun and fun. She did arrive safely and the last time we spoke, she was hanging out at her pool sipping a cold drink. I am so jealous. As a wise bear once said, only you can prevent fires!

•Make sure your dryers are maintained properly.

• If the linen smells of grease or oil after washing—do not dry—wash again. Doing these things will show your employees your commitment to safety and communicate why the buildup of lint can cause fires and linen left in carts can spontaneously combust.

Discuss safety at employee meetings. Provide updates on where you are with safety. Solicit feedback and suggestions from your employees on how to be safer. Invite experts to talk about safety and give training. Chemical use is one—your vendor can provide proper chemical use training and explain SDS sheets.

Ensure your employees have proper attire and PPE for the jobs they are doing. Again, with chemicals use, your chemical vendor can assist with this.

Remember a safe business is good for business.

Extra signage, safety shoes, rags, and mops at the ready, and daily inspections for any machine leakage, should be “top of mind.”

We need to show how much we care for our staff and customers by training them and protecting them. It is to the business’ advantage in a financial sense as well due to the large claims that are paid out annually and, on the back end, larger insurance bills due to the accident.

In addition, create a positive attitude by putting safety in a primary position of importance with a program with employees. Contests with simple rewards work very well.

I have seen some have a “safety wall” and saw one large laundromat with a PPE (personal protection equipment) vending machine for both employees and customers.

Of course, making sure that all communication is in the language(s) of both our employees and customers is vital. You might even have a trusted employee give a short presentation on how being safe has impacted them.

they had their employee smoking area outside the laundry with a table and ashtrays set up right next to the dryer vents!

The overriding point is that fire and standing water safety in and around the laundry is a constant item for concern, inspection and action.