Mentoring in laundry operations

BY MATT POE, EDITOR

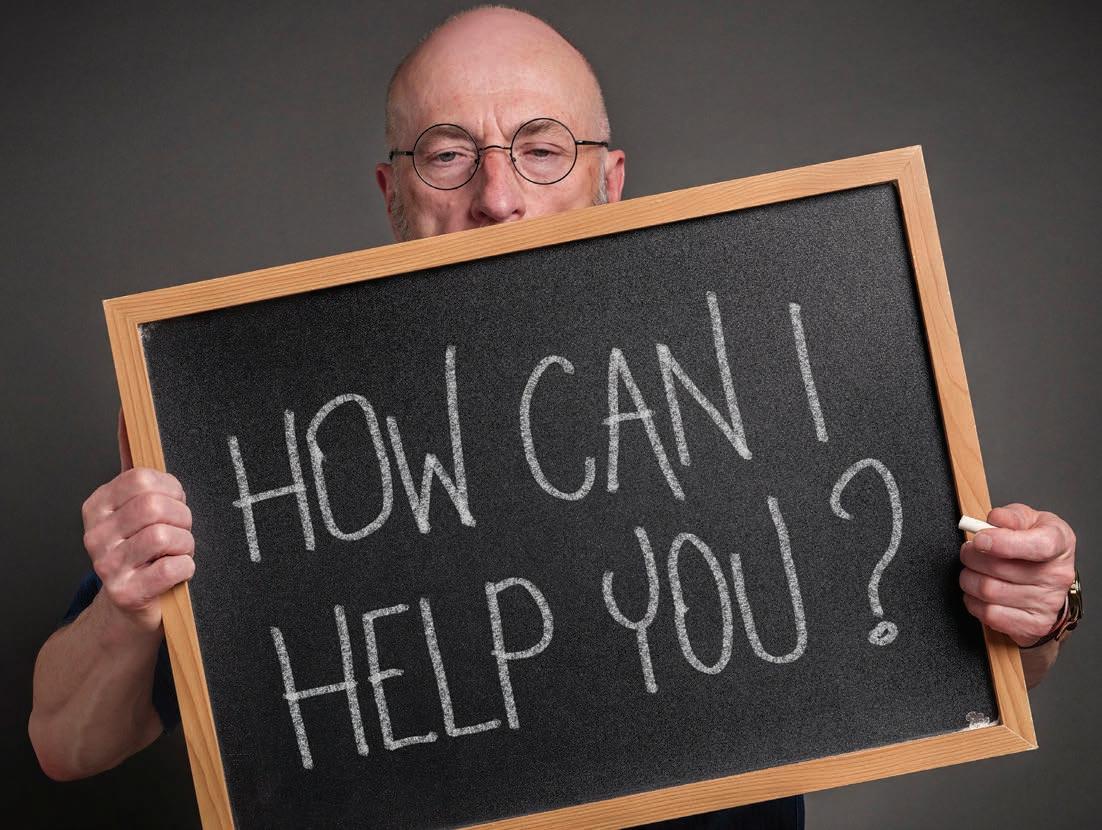

Laundry and linen services, like most businesses in general, are still struggling to find employees after the past few years.

Many strategies have been suggested and put into practice, but one that might be prime for laundry operations today is the use of mentoring programs.

Yvette Lee, an HR knowledge advisor at the Society for Human Resources Management (SHRM), says that mentoring is used to help employees learn, grow

and gain knowledge in their field.

“You see it more often when leadership wants to grow other potential leaders within the organization,” she points out.

“The leadership is seeing that somebody has high potential, and they want to have somebody mentor them so that they have a sounding board, somebody who’s had a little bit more experience in that particular position or industry, things of that nature.

“Usually that’s where you see mentoring utilized.”

Mentor programs can help laundry and linen services better train, promote and retain employees throughout the organization.

In July 2022, Prudential Overall Supply, a provider of work wear and safety uniforms, career apparel and casual wear, cleanroom garments and related services headquartered in Irvine, California, launched its Mentoring Achieves Pathways to Success (MAPS) program.

“It’s the structure that we’ve introduced,” says Michael Flores, vice president of human resources. “We launched it last year as a formal program, and we just completed our first cohort of this. Right now, we are kicking off cohort No. 2.

He says that, currently, it’s a limited program for a selection of the company’s employees.

“For the broader population, we have more of like a buddy system, and that’s pretty informal, but for any production employees, route drivers, we will give them an internal buddy for them to serve as an internal peer, who is not their manager, who will give some mentoring,” Flores points out.

“But for our formal mentoring, that’s really our MAPS program.”

MENTORING IN PRACTICE

Lee shares that there is likely more groundwork than some employers may think is necessary if they want to have a successful mentorship program.

“For example, they’re going to want to look at defining what’s the reason for the program,” she says. “Having that information can help get buy-in, especially from leadership, as opposed to saying we want to do this—explaining the why, what it’s for, what do they hope to see as a result of having a mentoring program.

“The other thing is finding the right person to be in charge of the program. You want to have somebody who’s enthusiastic about having the program and seeing a value in the program.

“If you just kind of hand it off to somebody who doesn’t really see the need for it, sometimes you can see those types of programs falter over time and it’s not as productive as employers may hope.”

Setting the goals for the program involves aligning what the objectives are for the program regarding the business, Lee says.

“Whether that be you want to see more of an influx of individuals being interested in more opportunities within the organization, that could be a goal,” she shares.

Starting small may be helpful, Lee points out. That allows for training—not just for the mentors, but also for the mentees.

And she stresses that it’s key for the success of the mentoring opportunity to find mentors who are willing to commit to the program. Mentors need to see the value of the program.

“You want to have people who are enthusiastic, and they’re going to be com-

August dates set for Clean ’25

ATLANTA, Ga. — Organizer Messe Frankfurt reports that The Clean Show 2025, North America’s largest laundering, dry cleaning and textile care exposition, will take place Aug. 23-26 at the Orange County Convention Center in Orlando.

“The Clean Show has proven to be the ideal exposition for industry leaders to find the latest innovations in textile care, ranging from industrial machinery and conveyor equipment to computer software and business systems,” says Greg Jira, show director.

“We’re excited to bring these business leaders, decision-makers, product designers and purchasers back together in 2025 to continue to drive innovation, collaboration and growth within this sector.”

The Clean Show attracts industry professionals from around the globe to see the newest and most technologically advanced products the industry has to offer, featuring networking opportunities, live demonstrations for all segments of the industry and more.

In addition to exhibits, the show offers educational seminars on the latest technology, business management, sustainability and more.

Details on exhibition space sales will be announced later this year. Organizers say returning exhibitors from Clean ’22 will have early access to secure their exhibition space.

The Newspaper

Record

Laundry &

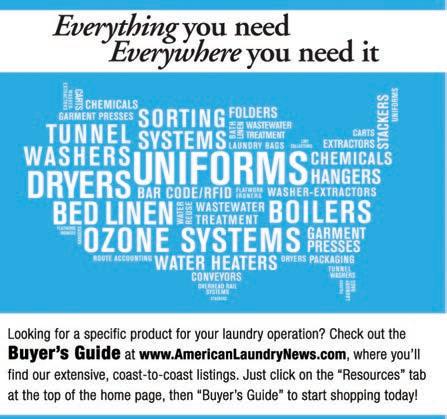

Management April 2023 • Volume 49, Number 04 www.americanlaundrynews.com

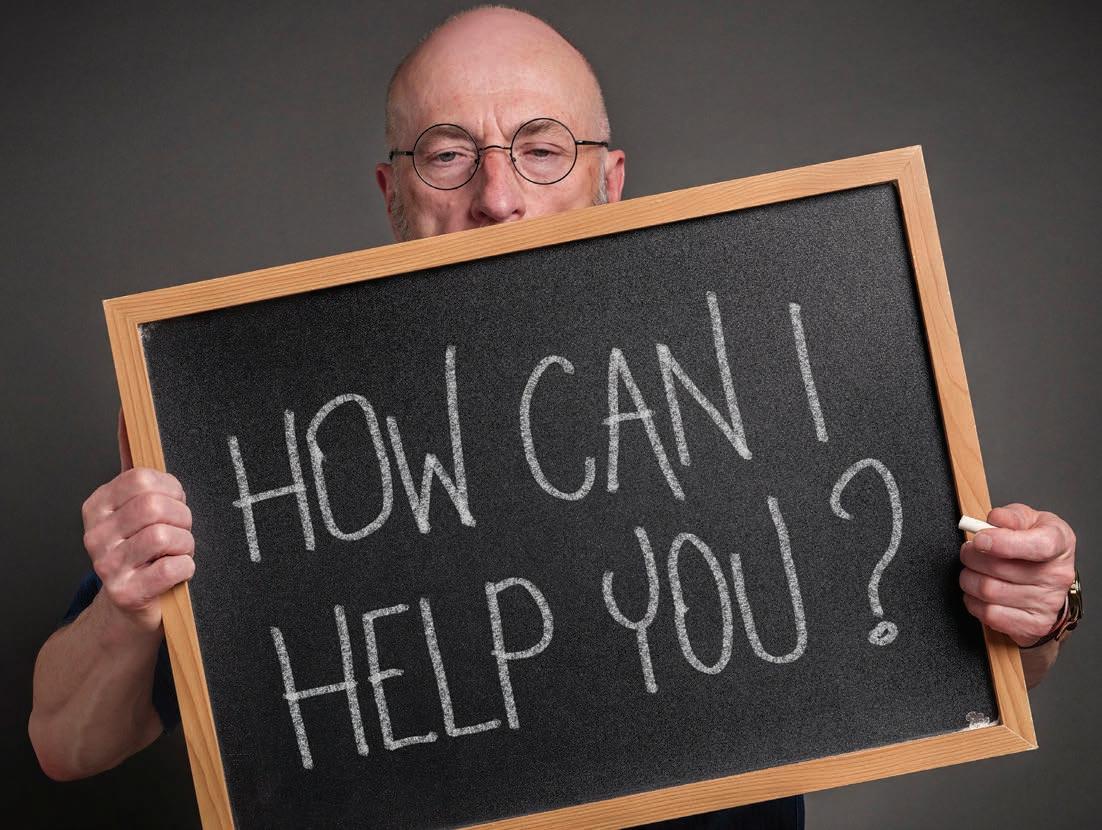

Mentor programs, done right, can be helpful for employees to learn and grow—and stay on the job

of

for

Linen

(Photo: © nastudio/Depositphotos)

See Mentor on Page 6 LATE NEWS

September show dates confirmed for TXCA & CLE 2023

Event returning to Shanghai New International Expo Centre Sept. 25-27

HONG KONG — With the Chinese and international laundry industries eager for in-person business, organizers report that Texcare Asia & China Laundry Expo (TXCA & CLE) will be held from Sept. 25–27.

TXCA & CLE is an annual event organized by the Laundry Committee of China General Chamber of Commerce and the China Light Industry Machinery Association, as well as Messe Frankfurt (Shanghai) Co Ltd and Unifair Exhibition Service Co Ltd.

The event will be returning to the Shanghai New International Expo Centre, where exhibitors will look to take advantage of the country’s gradually easing pandemic restrictions and the market’s steady growth.

Organizers say TXCA & CLE will cover around 270,000 square feet of floor space and host an estimated 300 local and overseas exhibitors and 20,000 visitors.

Despite the pandemic, the commercial laundry industry has been performing strongly, organizers say. Valued at around $72 billion in 2021, the global commercial dry-cleaning and services market is forecast to demonstrate an accelerated compound annual growth rate (CAGR) of 4.2% up to 2026.

This in turn bodes well for commercial laundry machinery suppliers, with that market predicted to demonstrate a CAGR of 6.6% and reach a size of $6.4 billion by 2027.

According to organizers, the pandemic has brought new development and breakthroughs to China’s laundry industry, in the direction of industry standardiza-

tion, increasing production scale and digitalization.

Accordingly, the number of laundry tunnels in operation in China reached 1,149 in 2021, a year-on-year increase of 23%, showing an upward trend for seven consecutive years.

Additionally, large- and medium-sized industrial laundry service providers purchased more than 520 sets of post-washing equipment (spreading machines, ironing machines, folding machines), increasing the total to over 2,000 sets.

With the Chinese market proving its potential, and the country showing signs of opening up,

the timing is favorable for both Chinese and international suppliers, say TXCA & CLE organizers.

As the leading trade fair for the laundry and textile care industry in Asia, TXCA & CLE provides business openings across the supply chain, including machinery, systems and accessories, chemicals and consumables, digital and intelligent solutions, energy saving and environmental protection technologies, leather care products, rental services and more.

Irrespective of industry strength, TXCA & CLE is a permanent fixture in many exhibitors’ yearly calendars.

Speaking at the previous edition

of the fair, Liyi Lv, president of Shanghai Weishi Machinery Co. Ltd., commented, “The visitors here are all big buyers, and our sales volume has reached its highest this year. Customers are giving us good evaluations, and this gives us great export opportunities.”

Also at the previous edition, Shixin Wu, general manager of Jiangsu Sea-Lion Machinery, explained, “We participate at TXCA & CLE every year. The fair helps the industry raise the bar when it comes to technology, and as the range of domestic products is rapidly expanding, we feel the need to increase our exposure by participating at the fair.”

Publisher

Charles Thompson

Phone: 312-361-1680

E-Mail: cthompson@ ATMags.com

Associate Publisher/ National Sales Director

Donald Feinstein

Phone: 312-361-1682

E-Mail: dfeinstein@ ATMags.com

Editorial Director Bruce Beggs

Phone: 312-361-1683

E-Mail: bbeggs@ ATMags.com

Editor Matt Poe

Phone: 866-942-5694

E-Mail: mpoe@ ATMags.com

Production Manager

Mathew Pawlak

Digital Media Director

Nathan Frerichs

Phone: 312-361-1681

E-Mail: nfrerichs@ ATMags.com

Advisory Board

David Barbe

Janice Ayers Davis • Nick Fertig

Deana Griffin • Cecil Lee

Edward McCauley

Jim Slatcher

Main Phone: 312-361-1700

Fax: 312-361-1685

Subscriptions 847-504-8175 ALN@Omeda.com

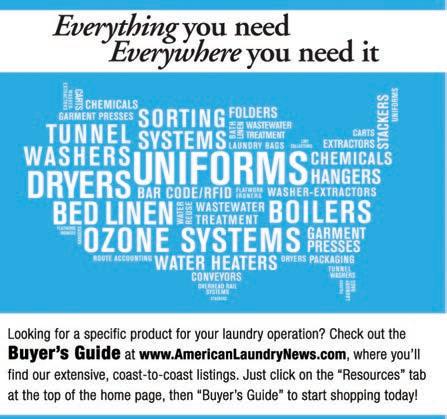

www.americanlaundrynews.com

News or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

(Photo: Messe Frankfurt (Shanghai) Co. Ltd)

2 April 2023 | American Laundry News www.americanlaundrynews.com MEMBERSHIPS American Laundry News (ISSN 1091-9201) is published monthly. Subscription prices, payment in advance: U.S. 1 year $50.00; 2 years $100.00. Single copies: U.S. $10.00. Published by American Trade Magazines LLC, 650 West Lake Street, Suite 320, Chicago, IL 60661. Periodicals postage paid at Chicago, IL, and at additional mailing offices. POSTMASTER, Send changes of address and form 3579 to American Laundry News Subscription Dept., 125 Schelter Rd., #350, Lincolnshire, IL 60069-3666. Volume 49, number 4. Editorial, executive and advertising offices are at 650 West Lake Street, Suite 320, Chicago, IL 60661. Charles Thompson, President and Publisher. American Laundry News is distributed selectively to qualified laundry and linen management and distributors in the United States. © Copyright AMERICAN TRADE MAGAZINES LLC, 2023. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Laundry News does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Laundry

01 Mentoring in Laundry Operations Mentor programs, done right, can be helpful for employees to learn and grow—and stay on the job 04 Test Created to Analyze Textile Laundering Environmental Impact New standard detects, classi es ber release, biodegradability, ecotoxicity 04 Preparing Plants to Operate in Summer Heat Columnist-at-Large David Griggs shares a checklist to prepare for coming rising temperatures 04 Most Popular 10 Human Side of Laundry How laundry work positively a ects the people involved: employees, customers, communities 12 Alternative Methods to Attract New Hires This month, the Panel looks at ways to interest employees—without raising wages 14 Product Showcase Folders 17 Blue Heron Linens Invests in Ironing, Folding Automation Company says system doubles throughput, cuts labor in half 18 Career Track 19 Classified Advertising 20 Source Directory 23 Trade Ticker 23 Calendar of Events INSIDE:

Milnor has a better solution through dilution.

When Milnor introduced PulseFlow® technology, CBW® washing was thrust into the future. The idea of balancing time, temperature, mechanical action and chemistry was missing one critical piece of the pie – DILUTION through the efficient use of water.

PulseFlow combines the innovative RecircONE® fast wet down and chemical immersion in the first module with standing bath washing in every spacious process module. Thorough and efficient dilution occurs by way of intermittent high velocity counterflow rinsing and traditional True Top Transfer.

The result is hygienically clean linen using less water (as low as 0.3 gallons per pound/2.5 liters per kilogram) and less energy as proven time and again by hundreds of PulseFlow tunnels in a variety of laundry applications worldwide.

Contact an authorized Milnor distributor or call 504-712-7656 to find out more.

www.milnor.com

*PulseFlow®, CBW® and RecircONE® are Pellerin Milnor’s registered trademarks.

COLUMNIST AT LARGE David Griggs

Laundry, oversimplified, is soiled goods come in, are processed and then clean goods are delivered to customers. It takes a lot of equipment to process and deliver these goods.

But sometimes a part of the equation gets lost in the work: the human factor.

While automation is increasing in the industry, people are still needed in the effort to provide clean, quality uniforms and linens to customers.

And since it’s still a challenge for laundries to locate, hire, train and retain employees, in this issue, we continue to examine ways for operators to make that human connection.

On Page 1, we look at mentorship programs as a method to help employees learn and make solid,

loyal connections in the operation.

Starting on Page 12, our Panel of Experts offers ideas on creative benefit options (beyond wage increases) to attract potential new hires.

The human connection goes beyond the laundry process, however. Operations are making worthwhile connections with employees, customers and communities,

Turn to Page 10 for a look into the human side of laundry operations.

Of course, an operation must have the right equipment, and our Product Showcase this month (14) highlights folder options.

Have questions or topics you’d like to read about? Contact me so we can share and help everybody keep it clean!

Test created to analyze textile laundering environmental impact

New standard detects, classifies fiber release, biodegradability, ecotoxicity

fibers and natural fibers.

“Biodegradability alone does not mean that pure natural fibers, for example, are completely harmless to the environment,” she says.

I

As many of us who work in non-climatecontrolled laundries know, it is also the most pleasant time to work in a laundry. You can open the doors without freezing to death or leave them closed without burning up.

It is always enjoyable to start your car in the morning without waiting for it to warm up or praying it will start. And if you can ride to work on a bike or with your windows rolled down, then you are truly blessed.

Right around the corner is to me the hardest time to run a laundry. Summertime can really heat up a facility. Your employees are not happy about working in it and neither is your machinery.

April makes for a good time to start preparing your facility for what is coming.

This month I thought I would write up a checklist of several areas I always look at to prepare for the coming season. Each laundry is a little different and they all have machines that might be affected a little differently, so this is by no means a complete list of all the areas to look at.

Below are the ones that we always like to look for.

Corral your heat generation. You can never cool an area off if you are constantly heating it up. Steam leaks and missing steam insulation are all good places to start, and they are good for your bottom line.

Venting heat out. Washers are equipped with vents that too often are left just venting into your facility. Take those vents outside and you can really cool off your washroom. The same goes for your garment finishers and flatwork ironers.

DIN SPEC 4872 combines analysis of fiber release, biodegradability and ecotoxicity.

The test method according to DIN SPEC 4872 shows how many fibers are released during textile laundering, how well these fibers degrade in wastewater and how harmful the fiber residues are to the environment.

Studies have shown that washing textiles releases microfibers into the wash water, which cannot be sufficiently retained by wastewater treatment plants. Synthetic fibers pose the greatest risk to the environment because of their longevity and inability to biodegrade.

However, Hohenstein project manager Juliane Alberts does not give the all-clear for biodegradable

“They, too, remain in ecosystems until they completely degrade and can also have a negative impact. In addition, additives, auxiliaries or finishes used in textile production can further slow the degradation process and leach into the environment.”

The new standard enables textile producers and suppliers to test, evaluate and compare products for fiber release during washing and environmental impact.

Alberts sees this systematic evaluation as an opportunity for the textile industry to take the initiative on environmental impact.

“Our reliable data can be used as a basis for more targeted product development,” she says. “This is a way to actively and consciously control further environmental pollution.”

Ironer hoods for your flatwork ironers. We prefer, when possible, to have hoods on the ironers and allow our roll vacuums to remove the heat. All new ironers use this technique to improve drying and cool off your facility.

Older ironers came with hoods that would vent the heat out of your facility. Unfortunately, many maintenance personnel remove these because it is a hassle for them. We have certainly been guilty of this as well.

The production personnel that are working right next to the hot ironers would never vote to remove them. Flatwork ironer hoods save on heating costs and provide employee comfort.

Ensure all your fans are working correctly. I can’t tell you how many times on the hottest day of the year I am finally told an exhaust fan or employee cooling fan isn’t working.

Take a walk through your plant now and ensure every device you have to help with the heat is working correctly.

What is your plan for water or other liquids for your employees? Properly placed water jugs or water fountains need to be thought about now.

Cleaning. Keeping your plant clean during the summer is vital. Motors need to be blown out daily or they will gather lint in their cooling fans and burn up.

(WE) = WEB EXCLUSIVE

OUR

From

• Dates Set for the 2025 Clean Show From AmericanCoinOp.com:

• Next Clean Show Slated for August 2025

Many of us have begun using computers on the production floor. Both the cabinet the computer resides in and the computer itself need to stay clean to avoid the dreaded crash on your busiest days.

t is finally spring! My favorite time of the year. As someone that enjoys bicycling, it is the time I can get rid of my winter riding gear and truly enjoy cycling.During the hot months, I like to leave some exhaust fans running 24 hours a day. Anyone that has been the first employee in the building can tell you it will take your breath away until you can get doors open and fans on.

More motors are ruined during the time that they are not running than when they are. A motor can burn up from its own heat if it is run all day and then locked up in a facility with no air movement.

I hope this list gives you some food for thought and enjoy your summer!

...

• Using an Attendant Training Regimen That Sticks

David Griggs serves as general manager for Superior Linen Service’s healthcare division based in Oklahoma.

4 April 2023 | American Laundry News www.americanlaundrynews.com

From The Editor’s Desk

endeavor Top Stories Appearing on americanlaundrynews.com for the 30 Days Ending March 15. NEWS • In Memoriam: Chris Duffett, TLC TriState • August Dates Set for Clean ’25 • Test Created to Analyze Textile Laundering Environmental Impact • Clean Laundry Funding Launches Financing Service • Gurtler Logistics Celebrates First Year of Service COLUMNISTS/FEATURES • Hiring Next-Generation Laundry Employees • Reinvigorating Laundry Facility Safety • Staying Ahead of the Breakdown Curve • One Woman’s Perspective: Leadership in Textile Services • Richard Engler: Reevaluating Methods, Instruments of Hourly Employee

SISTER WEBSITES

The human AmericanDrycleaner.com:

Is Your Drycleaning Business the Correct Size?

•

MATT POE

BOENNIGHEIM, Germany — Testing service provider Hohenstein reports it has worked with partners to create a new standardized test method for detecting and classifying the environmental effects of textiles during washing.

Preparing plants to operate in summer heat

Magellan 17lb Hospitality Towel Foodservice Aprons, Napkins, Table linen (215) 482-6100, scan the QR code, or visit: monarchbrands.com/inventory-tracker Hospitality Towels & Sheets Microfiber Mops & Cloths Bar Mops & Kitchen Towels Scan the QR code to browse real-time textile inventory and know we have what you need before you call. 645 Dozen Need Textile Rental Inventory? Start Here First! Makeup Removal & Bleach-Safe Salon

Mentor

Continued from Page 1

mitted and not just say, ‘Oh, I always don’t have time for this,’” Lee points out. “Those are usually not the individuals that will be great mentors.

“And you also want to look at what type of people you want to mentor. That’s another aspect of it.”

Another key, according to Lee, is to provide ongoing support.

“Mentor and mentee usually communicate about an hour a month on average, and they goal set when they meet,” she says. “What are some of the challenges you may be experiencing? How can I help you with these challenges? Do you need to talk through scenarios? Do you feel you need to get more education on some things?

“Here are some books or some articles you might want to consider. Have you thought about building your network? Those types of things to provide ongoing support.”

Communication is vital to the success of a mentor program.

“Some of the things that I have seen in the past, especially talking with other HR professionals, is don’t assume once a program is already set up that everybody knows about it,” shares Lee.

“These types of programs need to be marketed. They need to be monitored. That’s why it’s important to have a person who’s enthusiastic about having the program and being in charge of the program.

She points out that there will be some “maintenance” that goes along with having mentor programs.

“Sometimes a mentor has to say, ‘This is a great relationship; however, I’ve taken on XYZ roles, so now I’m not going to have as much of an opportunity to dedicate myself to this. Maybe it’s best we start looking at somebody else,’” Lee shares as an example.

“Or during the conversations with the mentee, they ascertain that maybe an individual has different aspirations within the organization and there may be somebody better suited to be that person’s mentor.”

Finally, she says it’s important for a business to have realistic expectations for its mentor program.

“Because, again, it’s not one person’s full-time job,” says Lee. “The mentor and the mentee still have their own jobs that they’re going to do. So, saying to somebody, you’ve got to meet every week, depending upon the situation, could become cumbersome.

“The idea is that you want people to have the opportunity to learn from one another because mentors have learned a lot, too, from having these types of programs.

“They’ve been able to reflect when I was in this type of position, what did I do? Would I have done it differently back then? It gives them an opportunity to grow as well.”

STARTING A PROGRAM

Flores says that for Prudential to start its mentor program, the company had to come up with a concept and what it thought it would ultimately look like.

“As we did that, we went through a number of steps,” he says. “The first one was we wanted to get the company involved and make sure that the business

had participation, and so we took a group of primarily general managers and asked them to help us construct this.

“And so we had this mentoring advisory council and we met, I think, every other week and we would get their input. We would go back, and we build a little bit more. Come back in the next session. Run it by everybody, get their thoughts and opinions. Go back, build some more and so on.”

Once the concept and structure were set by the mentoring advisory council, Flores says the next step was to roll out initial communication.

“We let the organization know, ‘This is what we’re working on, stay tuned,’ because the organization will then be asked for mentor nominations,” he shares.

“And that was step number three. We wanted folks to nominate people who they work with internally who could serve as mentors for others.”

The mentor applications were then reviewed by a regional director, Flores says, who would then determine if the nominee made sense to be involved as a mentor. Then they would be approved.

“Then we went out and we did the same thing but on the mentee side,” he says. “And for our mentees, we went through a mentee nomination process, and then ultimately we had a mentor-mentee matching process.”

“When you’re talking about selecting mentors, again, a lot of that is going to go back to what’s the reason for the program? What is the organization looking to get out of it?” Lee says.

“And when you’re looking at selecting mentors, you want people who are going to be enthusiastic but also have enough knowledge that they can, for lack of better phrasing, impart that on to someone else.

“You also want to look at individuals

who are open-minded to hearing concerns from others or even being a cheerleader, if you will. Just like not every person can be a manager, not every person wants or can be a mentor.”

She cautions that it does take time to look at who in the organization could be a mentor. What are their skill sets? Can they be helpful in this process?

“When you’re looking at mentees, usually, you’re looking for individuals who are hungry for knowledge,” Lee says. “Usually, you’re looking at individuals who have really shown a desire to grow within an organization or even in their field, if you will. And usually, you’re looking at individuals that are willing to accept advice and absorb.”

EVALUATING, IMPROVING PROGRAMS

For mentoring programs to be beneficial, they need to be monitored, evaluated for success and to determine areas for improvement.

“Without knowing what the program already has in place, they may want to evaluate if the mentors and the mentees are communicating on a regular basis,” Lee shares. “If they’re not communicating on a regular basis, that could be why the program is not thriving because people aren’t committed.

“Could it be that the mentors and the mentees need more support in terms of making that connection? Sometimes it takes time to build relationships. So, having events that are specific to the mentors and mentees, maybe having somebody come in and be a guest speaker to give them tips on how we can improve this mentor-mentee relationship.”

Another key factor she points out is determining whether or not leadership is supportive of the program.

“Because if leadership isn’t supportive of

the program, then those who are mentors may not see it as a priority, and that can also hurt a program,” Lee points out.

“It’s very similar to a lot of programs in that it has to come from the top down. If leadership is constantly saying put that to the side, then the mentors are going to say, ‘Okay, I’m going to put that to the side,’ and it doesn’t really foster success.

“But if leadership is saying, ‘I know we have this project that’s due next week, make sure that you’re still making time for your mentee, maybe move up the conversation or push back the conversation by a week,’ those types of things can be helpful so that mentors don’t feel like it’s not being understood what’s needed.

“And not only that but sometimes it’s great to hear from leadership that this program can work, again that cheerleader, this program really can work. We can definitely cultivate individuals in our organization.”

Lee says she’s even seen some leaders who will make the mentor program part of a regularly scheduled meeting.

“They have that as part of their monthly meetings, asking how the program going,” she shares. “Do you need anything from us? Do you see any tweaks that may be needed? Things of that nature can help.”

Flores says that after cohort No. 1, the company gathered testimonials from some of the mentors and mentees, and “they were all positive.”

One mentee wrote, “My mentor taught me very much about Prudential and becoming a successful employee. I have since been promoted. The MAPS program is a great way to help develop skills and knowledge on getting prepared for that next step in my career.”

And a mentor wrote, “To be honest, I

See Mentor on Page 8

6 April 2023 | American Laundry News www.americanlaundrynews.com

(Image licensed by Ingram Image)

FROM COLLARSAND CUFFS

TO THE REALLY TOUGH STUFF... FROM COLLARSAND CUFFS

When dealing with laundry stains, your reputation rides on getting the outstanding results The Laundry Two deliver. RiteGo® laundry spray spotter quickly penetrates to absorb collar & cuff stains, perspiration, ground-in soil and more, all without brushing. Turn to Laundry TarGo® to remove any tough oil based stains that remain behind. Use The Laundry Two with confidence on shirts, wedding gowns... anything you're washing or wetcleaning.

™

Both Laundry TarGo and RiteGo are chlorinated-solvent free, biodegradable, noncombustible and California 2013 VOC and Prop-65 compliant.

Use them to deliver stain-free laundry and wetcleaning. You'll build your reputation for quality - which is what keeps customers coming back.

THE LAUNDRY T WO

ARE RIGHT FOR YOU!

THE LAUNDRY T WO

ARE RIGHT FOR YOU!

To learn more, visit ALWilson.com or call 800-526-1188 A. L. WILSON CHEMICAL CO. Become a STAIN WIZARD at ALWilson.com

™

TO THE REALLY TOUGH STUFF...

Mentor

Continued from Page 6

was very nervous to do this. I wasn’t sure if I was actually qualified to be a mentor. I thought it took many years of experience, but I’m very glad that I accepted. These past few weeks, I’ve been working with my mentee and that’s really been rewarding.”

“We just graduated our first cohort, and I think we had 15 mentee-mentor relationships,” shares Flores.

“We celebrated that by building recognition certificates. We distributed those out to our different locations. And for those people who actually completed this program, it had my signature and I think the signature of their regional director.

“We asked that that be done very publicly so that we could kind of build momentum for the program. And heading into cohort No. 2, we would hope that we would be even more successful.”

Flores says the company is conducting more in-depth surveys to determine the success of the program and any needed changes.

“The measurement will have to come from surveys to find out,” he says. “This being our first, this will be our baseline to see exactly what kind of feedback we get. We’ll be asking those questions in terms of numerical values, ‘rate the following.’

“We’ll see on a one to five scale, did we measure in key areas at a 2.5 or 3 or 3.23 or whatever it is, but that is still in the works.”

MENTOR PROGRAM EFFECTIVENESS

“If they’re done right and they’re nurtured, I have definitely seen in my experience where (mentor programs) have worked well and people have flourished,” Lee says.

“It gives mentees an opportunity to learn from somebody who has more experience, not necessarily older but more experienced in the area.

“And that’s the key. Because sometimes you do see that there are people of a different generation who are mentoring oth-

ers. For example, with IT issues, if somebody has a desire to go into IT but they don’t have that expertise, that could be a good place to start with mentoring.

“But I have seen them flourish where individuals appreciate the opportunity to learn and have some one-on-one time with somebody more experienced.”

On the mentor side, Lee says mentors can gain a feeling of self-gratification that they’re helping somebody along, that they can give back and the organization sees value in them spending time with somebody who’s not as experienced.

“So, I have seen them flourish. I have seen a couple of instances where they did not work as well, and I’ll be honest with you there, because they weren’t nurtured, and that seems to be the key,” she points out.

“Once you start, it’s got to be a gradual progression. And that’s why one of the things, starting off small with kind of a pilot program, may be the way to kind of see how things can go. Work out some of the kinks before expanding a program like that.

“In the past, when I’ve seen employer’s programs not do as well, it’s because they were all in at once, but then they didn’t monitor the program. They didn’t, again, nurture it, cultivate it. They didn’t encourage for it to continue, and people just didn’t see the value in it because it was more sporadic.

“The communication became more sporadic and the relationships with mentoring didn’t work out as well.”

FINAL THOUGHTS

Lee concludes that having buy-in from the top down is essential, making sure that once the employer starts with the program, if they really want it to flourish, they need to put some work into it.

“One piece that was critical for us that I’m still trying to digest, and I’m not sure if we got it right or if we got it wrong, but we really tried to make the mentor-mentee relationship equal in terms of job level,” shares Flores.

“For example, if we had a service manager who had raised their hand as a mentee, what we tried to do is we tried to match them up with another mentor who was also a service manager.

“If the mentee was new in the role, maybe had been a service manager for six months, a year, two years, we would try and match them up with a current service

manager who had been with us for 10 years, 15 years, 20 years.

“The reason that we did that is because if we matched them up with, say, a general manager, it could complicate that mentormentee relationship because if they were learning things through this mentor, another general manager, and how they run their location, while we have company policies and procedures, it might cloud their current relationship with their local general manager.

“The mentee might say that through his or her mentor they learned that they do it differently over in Tucson vs. here in Fresno. Why is that, and why don’t we do it the way that they do it? Now you’ve got two general managers who are questioning one another, and we just didn’t feel that that was appropriate.”

Flores goes on to say that Prudential also learned that both mentors and mentees needed more structure.

“What we did early on is we brought everyone together and we said, ‘Listen, this is our training session for this, pay attention because this is going to this is going to make your mentor-mentee experience more valuable.’

“But what we learned is we need some kind of curriculum or guide that they can actually hold in their hands that they can use as a reference guide or reference material. And so, we are completing that as we speak for cohort No 2.

Finally, as Lee previously mentioned, Flores says the company learned its MAPS program needed more executive sponsorship.

“And so, our CEO will be part of that, will play a larger role in the kickoff for cohort No. 2,” he shares.

“So, those three things, those were learning pieces from the first cohort into where we’re headed now.”

8 April 2023 | American Laundry News www.americanlaundrynews.com

(Image licensed by Ingram Image)

(Image licensed by Ingram Image)

The Girbau Industrial Compact Pro 5-in-One easily processes your most complicated pieces from fitted sheets to table rounds. Plus, it takes only a single operator to feed, iron, fold, stack and deliver. One operator can feed 240+ sheets per hour! The all-in-one system is also configurable for two lane ironing and folding with delivery options to front, optional rear table, accumulator or stacker.

Solve customers’ challenges by fitting their unique needs and expand into new markets with Compact Pro.

A GIRBAU NORTH AMERICA BRAND girbauindustrial.com

INDUSTRIAL Industry-Leading Factory Warranties and Flexible Financing Options. In stock & ready to ship!

in size. Big on performance. COMPACT PRO

800-256-1073

Small

Human Side of Laundry

BY MATT POE, EDITOR

The laundry and linen services industry is made up of businesses that take in soiled goods, process them and then return clean, hygienic goods to customers.

At first glance, it may seem like the only human engagement the industry has is the touch and feel of clean goods customers enjoy, possibly some interaction with sales and route service representatives. But there is so much more to the industry.

Laundry and linen services touch lives beyond the laundry in many ways, from the employees to customers to communi-

ties, from offering needed assistance to offering job satisfaction.

American Laundry News columnistsat-large Tommy Cocanougher and David Griggs volunteered and dove into the topic, recording observations about the human side of laundry from their respective experiences and operations.

First Cocanougher, director-operations engineering solutions for Cintas Corp. Western North America, shares about how laundry operations are caring for employees, the community and their customers.

Then Griggs, director of operations development for Superior Linen Service, writes about the many opportunities

10 April 2023 | American Laundry News www.americanlaundrynews.com

How laundry work positively affects the people involved: employees, customers, communities

(Image licensed by Ingram Image)

available in the laundry industry to build employees’ lives.

CARING LAUNDRY COMMUNITY

Laundry business employees across many companies in the United States truly engage at every level to help one another, and the communities in which they live, all the while enjoying a secure employment picture. Since this business cannot be outsourced overseas, it provides a secure role with a steady income and good benefits in most cases.

The employees in our industry care deeply for each other. There are numerous stories where an employee had a family medical emergency, in one case a grandson was ill and in the hospital.

The entire production team held a fundraiser for the family to help them through the difficult time. They made homemade foods and sold plate lunches at the facility with all proceeds donated to the family in need.

Working in our industry also allows us to help the community. Laundry services are routinely provided free of charge in many cases to nonprofit organizations.

In one case, a location of one of the industry’s larger operators provides laundry services for homeless bedding and provides garments to various rescue missions.

In two instances recently, companies have provided surplus and slow-moving garment stock to homeless shelters in Tulsa and Las Vegas.

Not only do the communities benefit from these products and services, but the employees at the locations also feel good about the effort and about their company as they get to participate in the gathering and distribution of these garments to those less fortunate.

Employees also have experienced multiple opportunities to help with food drives and clothing drives, furthering their engagement in a team event at the location and often out in the community.

Our industry is very customer driven. One operator had a customer who had a fire over the weekend.

The operations team was able to help them by picking up all their garments and linen on Monday and washing it the same day to get it back to them so they could re-open for business.

EMPLOYEE LIFE CHANGES

There are probably few industries that offer more opportunities to be promoted than the laundry industry. We have long been an industry where if you are willing to work hard and use a little common sense, then you can pretty much go anywhere you want to go.

I know I have personally been able to move from the morning maintenance person to the general manager just by working hard and trying to keep the company’s best interest in mind with any decision I have made.

I know several other team members in our company who have made similar career moves. That may be a reflection of the company we have been fortunate to work for; however, I see this same occurrence in other laundries.

I have had the opportunity to work with countless immigrants

who, when they started for us, could barely speak any English. Those same employees come to me proudly a few years later requesting a day off so that they can be sworn in as American citizens.

Their children often go on to college. That is truly the American dream in action—with the first steps being helped along by our industry.

We are also an industry that forgives past mistakes and helps people rebuild their lives. It seems like in the past we were an entry-level industry.

That means many folks went to work in a laundry as their first job out of school and then maybe they would move on to something else. We have noticed that we seem to get more applicants that life may have run them aground and are looking for a restart. These humbled people are just looking for a chance to start over, and a laundry seems to be the perfect starting point.

To be fair we are a demanding industry. By and large, we don’t have many work-from-home jobs. We are more of a hands-on

industry.

Since we are an addictive industry that doesn’t seem to be an issue. I know I have spent close to 40 years working in a laundry and can’t remember one day that I left and thought “we were perfect today.”

There are always improvements to be made both with efficiencies and quality, which is also something I enjoy about our industry. You are never “there.”

The road to improvement is always taking a new turn that keeps you engaged and excited to come to work.

Productivity

• Braun’s PrimeDry easily processes three loads per hour! Others process only 1 load per hour. It takes 3 competitor dryers to match the efficiency of one PrimeDry! (While processing up to 175 lb. loads.)

• Modulating gas valve for precise temperature control.

• Installation costs are lower, one PrimeDry dryer vs. three of our competitors. This also saves floor space!

• Disassembly feature – top is removable to fit through a standard commercial double doorway.

• Exceptional airflow

• Touch screen control

• Environmentally friendly with a compelling ROI!

For more information on features and product performance data contact G.A. Braun.

|

11 American Laundry News | April 2023 www.americanlaundrynews.com 31 31

PRODUCTIVITY :

31 31 PRO ISO 9001 CERTIFIED ISO 9001:2015 Certified | Made in USA Scan for more information

(125 – 200 LBS. Cƒpƒcity) ® ® ® 800.432.7286

gabraun.com

PANEL of EXPERTS

Alternative methods to attract new hires

In a competitive job market, companies need to offer alternative creative benefits to attract and retain talent beyond just offering higher wages.

There are a variety of ways to differentiate yourself in the market, including professional development opportunities, health and wellness benefits, and unique perks. Professional development opportunities can be appealing to potential hires and can aid in retaining engaged employees. This can include access to training, conferences, ride-alongs, job sharing or continuing education.

Providing opportunities for employees to develop new skills or advance in their careers in laundry can be a valuable benefit and help to retain top talent for years to come.

Health and wellness benefits can also be significant draws for job seekers. Offering comprehensive health insurance plans, employee assistance and other wellness programs can help employees maintain a healthy work-life balance, reduce stress and promote overall well-being.

Simple perks can also be a low-cost and effective way to attract and retain employees. These can include things like free snacks or coffee or company outings or events.

These perks may not have a direct impact on an employee’s paycheck, but they can contribute to a positive workplace culture and make employees feel valued and appreciated.

Most importantly, if you want to build community within your business, the leadership must be present, available and approachable.

Retention is about much more than just dollars and cents. Helping your team feel a sense of community, loyalty and job satisfaction begins with the leaders and their commitment to their employees.

employee of the month or a simple posting of a job well done.

Wellness programs could also help to reduce absenteeism caused by illness.

Frequent one-on-ones by your front-line managers can also help keep your employees engaged. And keep you apprised of what is important to your people.

Other ideas include:

•Free meals.

•Leadership opportunities.

• More autonomy.

•Parties. Celebrations.

Finally, ask your employees. Maybe they have an idea you have not thought of yet.

attract and retain employees is by offering comprehensive benefits packages. This includes healthcare, paid time off (PTO), and matching 401k contributions. By providing these benefits, we are showing our employees that we value their well-being and want to invest in their future.

Healthcare can be a particularly important benefit for employees in the commercial laundry industry, as it often involves physical labor that can lead to injuries. By providing healthcare, we are helping our employees take care of themselves and their families.

PTO is also a valuable benefit, as it allows employees to take time off for personal and family needs without sacrificing their paychecks. Matching 401k contributions are another way we show our employees that we are invested in their long-term financial success.

Culture. Another way we have been able to retain employees is by creating a positive workplace culture. This includes employee recognition, lunches, parties and creating an overall fun workplace.

sional team-building activities.

One anecdotal story that highlights the importance of a positive workplace culture comes to mind. We had an employee who had been with us for several years and was a reliable and hardworking member of our team. However, she left for a job that offered a dollar more per hour.

Within a month, she returned to our company, citing that the new job was not what she had expected. Despite the higher pay rate, she found the workplace culture to be toxic and management to be unsupportive.

She missed the positive and uplifting atmosphere that we had created at our company and realized that it was worth more to her than a dollar increase.

This story illustrates that wages are not the only factor that determines employee satisfaction and retention. A positive workplace culture, recognition and employee engagement are equally important.

We believe that investing in our employees’ well-being and creating a fun and supportive workplace is key to attracting and retaining top talent in the commercial laundry industry.

In conclusion, dealing with rising wages can be a challenge for commercial laundries, but it’s important to look at other opportunities to attract and retain employees.

By investing in comprehensive benefits packages and creating a positive workplace culture, businesses can show their employees that they value their contributions and want to invest in their future.

Hotel/Motel/Resort

Laundry

Rodrigo Patron

Lace House Linen, Petaluma, Calif.

First off, you can offer flexible work hours. This can be very important to folks juggling family or other obligations.

Recognition can also be very important to the folks who work with you, such as

F

or every business owner or manager, there comes a point where you may feel like you have reached your ceiling on wages and cannot sustain higher wage rates. This can is particularly challenging for our industry. Commercial laundries often have large workforces and rely heavily on manual labor.

However, it’s important to look at other opportunities to be able to keep and attract new employees.

At EcoBrite Linen, we have faced these challenges head-on and have found success in two key areas: benefits and culture. We have invested in our employees’ wellbeing and created a workplace culture that values and recognizes their contributions.

Benefits. One way we have been able to

We believe that employees who feel valued and recognized are more likely to stay with the company long-term.

Employee recognition can come in many forms, such as employee of the month awards, bonuses for good performance or even just a simple thank-you note. We also hold employee appreciation events, such as lunches and parties, to show our employees that we value their contributions and want to celebrate their successes.

Creating a fun workplace can also help to reduce employee turnover. We have found that employees who enjoy coming to work are more likely to stay with the company long-term. This can be achieved through simple things like playing music, decorating the break room or having occa-

Even though we get walk-in applications almost daily, the quality of the applicants is not always optimal, and we have realized that the best-qualified applicants are usually relatives or acquaintances of people that already work for us.

We have found that our employees are our best headhunters, and the reason is pretty simple: our employees actually enjoy working here, and it’s not because working at an industrial laundry it’s easy (anybody that knows a little bit about the laundry knows that there are not easy jobs in this industry). The reason is that we treat our employees like people, and we listen to their concerns and needs.

Now, this doesn’t mean that we have ping pong tables, bean bag chairs, vegan menus and free chai lattes on Tuesdays, but it does mean that we try to focus on

12 April 2023 | American Laundry News www.americanlaundrynews.com

“My laundry’s hourly wages are starting to reach upper limits. What other forms of compensation are companies offering, like alternative creative benefits, instead of higher starting wages to entice new hires?”

Commercial Laundry Brian Polatsek EcoBrite Linen, Chicago, Ill.

Equipment Manufacturing Tom Vanden Heuvel Kemco Systems, Clearwater, Fla.

Chemicals Supply John Schafer

Diversey, Fort Mill, SC

(Image licensed by Ingram Image)

the small things that we all take for granted when we are outside of the workplace, things like having a clean, well-lit facility, clean bathrooms, a clean kitchen, clean common areas, and keeping the plant like that every day.

This is not only when we have a tour or a visitor but also doing it for our employees and showing them that we care for their well-being, which is a crucial step to establishing a good employer-employee relationship.

It’s that relationship that allows us to establish performance goals and quality and quantity expectancies in a kind of quid pro quo situation where our employees know what we expect from them, and they know what to expect from us in a process that usually allows us to do more with less because everyone is working for a common goal.

And, of course, we still go through the whole hiring process with all the new candidates. We do offer competitive pay, and not all of the people that we hire come recommended by current employees. However, it has been our experience that word of mouth from happy, involved employees that have clear goals and work in a clean plant is a lot more effective than an ad in the local paper or a “Now Hiring—Great Benefits” sign.

So, next time you need to use the restroom at your plant don’t use the “office restrooms” and instead dare to venture into the “production restrooms” and ask yourself: Is this representative of a place where I would like to work?

Consulting Services

The best practice answer to this question is to increase revenue either by adding additional wash-and-fold business or going after some commercial laundry business (Vrbo, Airbnb, hotels, spas, etc.). By utilizing all the machines to a fuller extent and increasing revenue, your compensation can increase due to these avenues being lucrative on both the revenue and profit side.

If your laundry is super busy currently and you are having compensation issues, then perhaps consider a pay-for-performance model of rewarding top employees while motivating both new and underperformers.

Lastly, one of my favorite business books of all time is 1001 Ways to Reward Employees by Bob Nelson. So many of the ideas involve non-direct pay compensation.

One of my favorites was a special meal and/or gift card for a star or a group achievement. The technology sector has used these methods to recruit, retain and grow their companies.

In conclusion, a quote from Jon C. Mondana comes to mind that fits this question: “Nothing stops an organization faster than people who believe that the way you worked yesterday is the best way to work tomorrow.”

Equipment/Supply Distribution

This is a bit of a difficult question to answer for someone who does not own a laundry as the compensation for a sales company is certainly going to be much different than what is being done at a laundry.

But even with that being the case, everyone is struggling in hiring and then keeping employees happy financially. For our company, we have been very lucky in being able to not only hire but keep new employees and sales representatives.

The need to be creative is certainly a need in today’s world.

For us, we have been able to entice people to come on board knowing that they will have the opportunity to get involved in many additional projects and jobs that will not only help them to use their minds but also allow them to gain additional income opportunities when that new project is successful or if they can move into a new higher paid position soon afterward.

Streamline Solutions has allowed our people to use their skills to help the company grow, which, in turn, means that they are rewarded financially because of the great job they did along with being able to earn extra money when that translates into more sales for the company.

In other words, a bonus would be paid

as we always feel, whether veterans of our company or new hires, that it is important to “share the wealth” with the entire team when we are successful.

We have found that doing things like this allows us to compensate our workers fairly even if it may be initially tougher to pay some of the higher wages that our competition may be offering.

It also helps to keep everyone on the same “team” mentality no matter what job they may be doing for the company.

Over the past year, I have discussed all aspects of the textile rental business with industry leaders from production to sales to route service reps, to management to cost recovery to labor issues (new hires and current roster) with all departments including hourly employees.

Let’s look first at what they have told me about how they are enticing new hires, attracting them, and keeping them engaged in the laundry industry.

“We now pay 100% (from 80%) of healthcare as of mid-last year, and it went

See Experts on Page 15

13

American Laundry News | April 2023 www.americanlaundrynews.com

Textile/Uniform Rental

W. Kirby Wagg Performance Matters, Orillia, Ontario

Cliff Beiser Champions Touch, Kissimmee, Fla.

Ross Sanders Streamline Solutions, Orlando, Fla.

PRODUCT SHOWCASE Folders

GIRBAU INDUSTRIAL

Girbau Industrial offers two highvolume flatwork folders that it says work seamlessly with any model ironer—the FRB and the FR+.

Each folder features one, two or four folding lanes and the ability to automatically perform two to three primary folds and up to three cross-folds.

The company says the folders are ideal for the automated and high-quality folding of small and large items alike.

The folders are also equipped with a laundry-feeding belt with a multi-position design, making it adaptable to any ironer on the market no matter the manufacturer, roll diameter or ironing working width, according to Girbau Industrial.

While the FRB delivers high-volume production and quality folding, the FR+ offers more options than its counterpart and premium quality folding consistent with the needs of the hospitality and food and beverages markets.

Both models are equipped with the Inteli control system, a full-color touchscreen control offering 99 program options; a series of graphic menus to eliminate operator language barriers; and management capabilities, including reporting on item/program counts and overall operating time.

The FRB and FR+ can also be used on

any number of lanes—required at any moment—to make folds that adjust to varying items and dimensions. Moreover, the company says the design of the primary folder and the adjustable speed control with inverter makes the FR Folders capable of processing up to 164 feet per minute to match specific ironing speeds and production requirements.

Finally, both folders can be used in sync with up to three drop stackers to assist with sorting needs.

www.girbauindustrial.com

800-256-1073

G.A. BRAUN

G.A. Braun says its Precision Series® Folder/Cross-Folder delivers hand-folded quality with Braun reliability.

The automatic folding sequence makes two or three primary folds in flatwork as large as 130 by 120 inches or as small as 12 inches square. Then the folder makes up to three cross-folds, keeping selvage edges neatly folded inside.

The company says the folder is programmed to determine whether an item should get two or three cross-folds on the fly. This feature allows for different-sized goods to be processed without changing programs. This includes queen-size, king, and full-size sheets, one after the other.

The Folder/Cross-Folder can be specified for left- or right-side discharge to suit the needs of the facility and is available with one- to four-lane primary fold capability and one- or two-lane cross-fold capability, shares G.A. Braun.

An option available is flatwork sorting stackers. Sorting stackers save labor and maintain fold quality as they automatically sort, separate and stack flatwork from a continuous flow of differently-sized items.

On the line, the stackers sit side-by-side, accepting flatwork items or passing them on until each piece reaches the stacker programmed for its size. Up to four stackers can be arranged in this manner and are easily field retrofitted to an existing Braun Folder/Cross-Folder.

The company says small-piece accumulators and a 90-degree swivel conveyor are also available.

www.gabraun.com

800-432-7286

JENSEN USA

JENSEN says it offers a variety of largepiece folders and cross-folders.

The Classic series offers one- or twolane lateral folds with up to three lateral folds, depending upon the design, and two or three cross-folds. The series has outboard stackers.

Introduced in 2022, the Kando series is based upon the Classic series with one-lane lateral folds but with up to two inboard stackers, the company shares.

Additional outboard stackers can be added increasing its sorting capabilities. JENSEN says this makes for a very nice spacesaving design.

Finally, the Katana series features up to six inboard stackers. The series is also available with one- or two-lane lateral folds with up to three lateral folds depending upon the design.

The company says all are available in working widths of 118, 120, 130, 138, 142, 157 and 165 inches.

www.jensen-group.com

850-271-5959

increased production.

With models capable of folding 14 towels per minute, B&C Technologies says the folder’s speed is only limited by the operator.

The PF-3 can further increase throughput by eliminating time-consuming presorting due to the ability to sort based on width, length, or both and then placing the pieces neatly into sorted stacks, according to the company.

B&C Technologies adds that not only does it fold, sort and stack the goods, but it also offers versatile folding through custom programming with several different folding options to allow for easier storing or showcasing logos.

www.bandctech.com

850-249-2222

SEA-LION AMERICA

Sea-lion says its intelligent small-piece folder features a programmable control system with a large, multi-lingual touchscreen display.

Key folding features include optical photo sensors that automatically detect the size of the item and adjust the width accordingly. A lateral fold is done with a folding plate.

An encoder installed on the shaft measures the length of the item and then selects the appropriate folding method.

The first cross-fold is done via a positive-reverse run and air blow. An autostretch device is installed for discharge to transfer stacked items to the next conveyor belt for collection.

Established in 1969, Sea-lion says it manufactures industrial laundry machines with a focus on intelligent automation, efficient washing and professional finishing.

www.sealionamerica.com

860-316-5563

B&C TECHNOLOGIES

By adding a PF-3 Small Piece Folder to a laundry, B&C Technologies says operators can expect to save money, save time, increase production, eliminate sorting, create customized folds and achieve consistent results.

The company says a small-piece folder saves labor costs by reducing the personnel needed to fold laundry. Not only do small-piece folders work with a single operator, but they can also process linens faster than folding by hand, allowing

FORENTA

When it comes to folding shirts, Forenta says it has many years of experience under its belt. With two models to choose from—manual or semi-automatic—the company says its folders provide a consistent fold on every shirt, every time.

Forenta says that for laundries that need a compact, cost-effective folder, the manual model (10MF) is simple and easily maneuvered into smaller spaces.

Laundries that have a higher folding volume needing a place to store cardboard and poly bags will benefit from the semi-automatic model (20MF), which is air-assisted

14 April 2023 | American Laundry News www.americanlaundrynews.com

FORENTA

G.A. BRAUN JENSEN USA

SEA-LION AMERICA

B&C TECHNOLOGIES

16

See Showcase on Page

GIRBAU INDUSTRIAL

Experts

over very well.”

Continued from Page 13

“We are giving membership to warehouse stores (Costco, Sam’s), health clubs and tickets to events.”

“We track our production, and it has helped tremendously. Employees are working 30-32 hours per week, but they receive pay for 35 hours if they meet some criteria.”

“We just introduced an additional three vacation days: Christmas Eve and the day after Thanksgiving. Also, a floating holiday that the employee can, at their discretion, use for a special day.”

“In addition to a $13/hour start wage we contribute to retirement, 100% of healthcare, offer overtime, which is every Saturday, and a day or two during the week we run longer.”

“We offer longevity bonuses, vacation days, bereavement bonus and referral bonuses.”

All these benefits are a must in the workplace today, but I believe we must look deeper.

My over 45 years of experience in this industry (many of my employees worked 20-30 years and, yes, over 45 years for me!) has taught me that the key to enticing new hires and achieving remarkable results is by offering your current employees at every level specific kinds of help and encouragement to build trust.

A company can only become the best version of itself if its employees become the best version of themselves. You must have collaboration between management and employees and work together to achieve company objectives and personal dreams.

A favorite quote comes to mind from Walt Disney, “All our dreams can come true, if we have the courage to pursue them.”

Supervisors who build trust and an engaging workplace will improve retention more than the above ideas like pay and

benefits. Sounds simple, too intangible, but true. If you build trust, the relationship will steadily grow from there.

The best perks are the environment you create. We judge people on how we feel about them versus what they do for us.

Another term is “stay interviews,” during which personal dreams can be revealed and company objectives can collaborate. Schedule a meeting with each employee at least three times a year, listen to them, ask them about their personal goals and help them strive toward them.

Watch how “enticing new hires” will no longer be a challenge for your company as they will flock to your company because your current team members will now be your voice. They will be your recruitment team!

paycheck from their place of employment right out of the gate. The days of starting at a low rate and working yourself up to a higher rate seem to be outdated and no longer acceptable.

Between the national push for raising the minimum wage and an unusually low available workforce, to attract and keep employees many laundries/companies are offering higher than usual starting salaries.

Sad to say, however, if another local company is offering a higher starting hourly wage accompanied by a signing bonus, this employee, plus others previously employed, is gone in a heartbeat.

With the push for those loyal competent employees, many companies are searching or exploring ways to attract staff to keep our businesses running without staffing hiccups.

Having grown up in the cut-and-sew environment and then jumping into the laundry arena, I feel I can honestly say working in these settings is not always as glamorous as it seems. However, with a hard work ethic and proper training, there are many ways for one to excel and be successful while providing a nice life for their family.

are, this is a great incentive to offer. Couple this by offering managerial and educational courses—such as Dale Carnegie or other behavioral modification classes on-site for your employees to take advantage of—is another way to attract good staff.

Looking for that next supervisor, manager, sales director or more, why not look within? Making sure we let our employees know that we practice promoting from within for higher-paying positions is another way to attract and maintain a good workforce.

Did someone say food? How about offering your staff on-site meals? If you have the space, maybe set up a cafeteria where you can offer your staff lunch at no charge to them.

Yes, this can be costly, but it also would go a long way in keeping your staff happy about where they work knowing their employer cares about their well-being.

Couple this with a wellness program, you will soon find your staff telling their friends what a great place they work at and could possibly attract new talent.

Recently, a friend of mine who was paying his staff $18 per hour as a medical scribe lost what he considered a loyal employee to Chick-fil-A.

She left her job to start a new one at Chick-fil-A at a starting rate of $21 an hour to say, “Excuse me, sir, would you like waffle fries with your sandwich?” Hard to believe, $21 per hour from day one.

Help Wanted! Looking for a job, we are Hiring! Need Work? Look No More! These are just a few examples of signage we are now seeing as ways many companies are trying to entice people to come work for us.

This type of direct advertising—job postings in stores, billboard postings, radio ads and media ads (both social and non-social)—is the new warfare being used to attract and find more employees to fill the empty spots in our businesses. Unfortunately, today’s employee is looking for instant gratification and that big

As we all know, today’s potential workforce wants to excel faster and at a higher pay scale.

As owners/operators deal with this ongoing labor shortage, we need to look for alternative ways to address this dilemma. What other methods can we use to entice, attract and keep a solid loyal workforce to keep our businesses successful and running smoothly?

Come work for us and receive a signing bonus. In addition to signing bonuses, some laundries are offering referral bonuses. Refer a friend and if they remain employed for a set period, you are awarded a monetary bonus.

Another incentive to attract staff would be to offer an education bonus. Any employee, should they wish to further their education, would be offered that opportunity to do so with a tuition bonus for going back to school to further their education.

Granted, not everyone is looking to climb that corporate ladder, but for those who

As the mantra of doing more with less seems to be the norm these days, maybe offer a four-day workweek to those who wish to take advantage of it. Maybe offer the four-day work with two options: Option 1, work four days for 10 hours a day, or Option 2, work 4 days for 12 hours a day and offer overtime for the eight extra hours worked.

Obviously, the five-day workweek remains intact for those who wish to continue working five days per week.

We are faced with many obstacles these days with our younger workforce. Yes, it is challenging, but we do have options to attract and maintain good reliable employees. We just need to think outside the box and get creative.

What used to appeal to us when we first entered the workforce may not apply and be attractive to today’s future employees. They want more, faster.

So, I leave you with this, the next time you go thru Chick-fil-A and asked if you want waffle fries with your chicken sandwich, go for the milkshake. They are awesome!

15

American Laundry News | April 2023 www.americanlaundrynews.com 092722 KE 4.75x4.75 JR_OL.pdf 1 9/28/22 11:16 AM

Uniforms/Workwear

Manufacturing Scott Delin Fashion Seal Healthcare, Seminole, Fla.

Showcase

Continued from Page 14

and is surrounded by an integrated storage cabinet, according to the company.

Forenta says that from its beginning in 1937, it has been a leader in the design and manufacturing of a wide range of garment care products: laundry presses, drycleaning presses, form finishers, steamvacuum boards, shirt-pressing equipment, spotting boards, garment conveyors and water chillers.

www.forentausa.com

423-586-5370

operating with zero stackers.

The company says the VEGAFOLD-S saves floor space, maximizes production per square foot, and automatically sorts and stacks up to four different flatwork sizes.

According to VEGA Systems USA, the VEGAFOLD-S can replace most any folder on an existing ironer line and includes the latest technology and design features for fully automated flatwork systems.

www.vegasystems-group.com

855-834-2797

R.W. MARTIN COMPANY

work.

CLM says its sophisticated PLC control features a vivid touch-screen display that is easy to program and operate.

Items are automatically measured, French folded and stacked to a pre-determined quantity and desired fold width.

Since 1983, CLM says it has focused on building high-quality durable dryers and other outstanding wash aisle equipment known for heavy-duty, high-efficiency and high-productivity output.

www.clmco.com

323-232-2417

JB INDUSTRIES INC.

For more than 24 years, JB Industries says it has been manufacturing the JBX Folder/Crossfolder and Stackers along with the latest addition of Self-Contained Ironers.

The JBI Folder/Crossfolder is available

The machine comes with two or three primary folds and is equipped with a userfriendly Siemens PLC interface uploaded with automated troubleshooting, alarm logs, PM schedule and runtime history. It is engineered and built in the United States. www.leonardautomatics.com

704-483-9316

CMV SHARPER FINISH

In addition to buying and selling preowned large- and small-piece folders, R.W. Martin Company says it also reconditions folders from virtually every major manufacturer.

KANNEGIESSER ETECH

From bath sheets to hand towels, thick or thin fabrics, the range of dry work applications is becoming increasingly varied while customers demand ever-higher quality standards, observes Kannegiesser ETECH.

The challenge for textile service providers is to meet these demands while keeping costs down. And to do that, they need to increase productivity, and the company says Speedline offers the perfect solution: a fast, reliable dry work folding machine with outstanding performance.

With its high-performance non-stop folding, Kannegiesser ETECH says the Speedline guarantees maximum precision and item throughput, allowing operators to save time and get the highest quality folding results.

Automatically identify and process a wide variety of articles and stack them quickly and reliably for maximum output, the company says, adding that operators experience maximum comfort and convenience with its ergonomic work area and easy access to all functions.

www.kannegiesser-etech.com

612-722-1366

The company says its reconditioning process provides a reliable folder with a one-year warranty at half the cost of investing in a new machine.

The reconditioning process involves disassembling and rebuilding folders using a combination of new and reconditioned components.

R.W. Martin says it not only demonstrates its commitment to partnership by providing reliable equipment with a one-year warranty but also through installation, on-site start-up and preventive maintenance services.

In addition, thanks to its extensive network of industry partners, R.W. Martin says it can provide replacement parts from nearly any OEM (original equipment manufacturer).

R.W. Martin says by partnering with it, a customer will experience an exceptional pre-owned equipment experience coupled with a superior return on investment.

www.rwmartin.com

800-635-4363

CONSOLIDATED LAUNDRY MACHINERY

Intended for high-speed folding and occupying minimal floor space, Consolidated Laundry Machinery (CLM) says its SPF-1 Towel Folder is ideal for high-output plants.

According to the company, the CLM SPF-1 design is simple and silent when compared to competitive products. It uses mechanical and pinch-roll folding techniques to French-fold faster than operators can feed.

VEGA SYSTEMS USA

VEGA Systems USA says its VEGAFOLD-S flatwork folder’s design allows it to process flatwork in both single and two lanes and includes up to four large-piece stackers integrated within the main frame of the machine. The result is a flatwork folder that uses approximately the same floor space as a traditional single or two-lane folder

To install the advanced CLM SPF-1 towel folder, simply wheel it into the plant on its heavy-duty locking casters, hook it up to electrical and air supplies and it is immediately ready to be put to

in one, two, four or six lanes with widths of 120, 130 and 144 inches.

The sheet stacker is offered as a primary, dual or triple-sort unit. The two models available are the JBP—a primary folder only—and the JBX, which offers two primary folds and three cross-folds.

Both models are inverter-driven with microprocessor control. The control is operator friendly, fully programmable and has a self-diagnostic program for ease of maintenance.

Manufactured in the United States, JB Industries says its machines contain readily available “off the shelf” parts.

www.jbilaundryfolder.com

561-863-9696

CMV Sharper Finish says its all-in-one IFCS machine is a great way to provide an upscale experience to the consumer by ironing linens while optimizing time and labor in the laundry.

The company says the machine takes linens directly from the washer and irons, folds, cross-folds and stacks them. This helps save on drying time and folding time as the user can skip the dryer on these flatwork linens and the machine will save on labor as the operators do not have to fold and stack the sheets.

There is an optional feeder add-on that helps spread and feed these linens so that one person can operate the entire machine.

CMV Sharper Finish adds that there is an optional multi-lane capability to allow for fast ironing and folding of small linens or pillowcases.

The machine is available in multiple cylinder sizes and widths based on the needs of the laundry and will provide a comprehensive solution to finish all flatwork linens, providing a crisp experience for the consumer, according to the company.

www.cmvsharperfinish.com

800-247-4766

LAPAUW USA

Lapauw USA says that its partnership with Toto folder machinery in North America has allowed it to supply quality solutions in flatwork finishing.

The Toto Folder Manufacturing line offers numerous folding solutions with accumulators and stacking devices. This has allowed Lapauw USA to provide solutions for almost any application.