BY MATT POE, EDITOR

In healthcare, reusable textiles are effective for underpads, isolation gowns, surgical wrappers and surgical gowns.

That fact was most convincingly displayed during the pandemic.

“Many healthcare facilities, when faced with a shortage of disposable items (such as isolation gowns) turned to any reusable solution that they could find,” shares Jason Hartsell, vice president of operations for United Hospital Services (UHS) in Indianapolis.

Reusables vs. Disposables

“It was not so much that they wanted to move to a reusable product but more so that they had to move to something reusable. The FDA’s (U.S. Food and Drug Administration) Emergency Use Authorization (EUA) allowed companies to quickly bring isolation gowns to market during the pandemic without first obtaining FDA approval.”

Gabriel Boardman, president of the American Reusable Textile Association (ARTA) and vice president of product development for MIP Inc. in Montreal, adds, “The pandemic led to global supplychain disruption for both reusable and disposable supplies.

“As a result, reusables became the preferred and more reliable option since they can be laundered and quickly return to healthcare providers in dire need of replenishment.”

“During the pandemic, healthcare workers were offered unrestricted access to personal protective equipment (PPE) to provide a greater sense of confidence to undertake their jobs and an increased sense of personal safety,” says Bryan Bartsch, a director for ARTA and president of Ecotex Healthcare Linen Service in North America.

“Reusable PPE played a critical in meeting the demand and providing the most reliable supply of PPE.”

Scott Delin, legislative director for ARTA and vice president of healthcare sales for Superior Group of Companies/Fashion Seal Healthcare in Seminole, Florida, says laundry operators were able to guarantee delivery of contaminant-free products.

“No bacteria (hygienically clean),” he says, “and by using reusable, the contaminated disposables were no longer being tossed into the trash impacting negatively our environment.”

Laundry and linen services took steps to

try to continue reusable usage in healthcare facilities when the pandemic began to ease.

“Based on feedback from our members, some laundry/service providers took a more proactive approach than others to make the shift more permanent,” says Sarah Brobeck, executive director of the Association for Linen Management (ALM) in Richmond, Kentucky.

“Even when proactive, there were many considerations at hand and each varied by hospital. These considerations have a significant role in the long-term outcome of reusables versus disposables.

“The laundry providers with success in a permanent switch continue to be proactive in understanding the needs and concerns of their customers and providing viable solutions to address any potential barriers.

“They also provide continual data and feedback to the customers highlighting the benefits and cost savings associated with reusable products.”

“Some laundry/service providers put the necessary systems in place to continue to offer reusable linen,” Hartsell says. “This might be a tracking system such as RFID (radio-frequency identification) tags, barcodes, a QC (quality control) grid or adding the necessary additives to the wash process.”

“Laundry service providers took many steps, including educating users,” adds Rocco Romeo, treasurer for ALM and CEO of HLS Linen Service in Ottawa, Ontario.

RETURN TO DISPOSABLES

Unfortunately, the increase in reusable linen usage by healthcare facilities hasn’t continued beyond the pandemic.

“I feel that many healthcare providers

See Reusable on Page 6

Aramark announces board of directors for uniform services

PHILADELPHIA — Aramark recently announced the Board of Directors for Aramark Uniform Services, the independent public company that will be formed following the spin-off, which is expected to be completed at the end of the company’s fiscal year.

John Zillmer, Aramark’s CEO, says, “This is an important next step in our plan to create two independent companies.

“Both organizations are well positioned with an executive leadership team and Board that can focus exclusively on their respective businesses to deliver value-creating outcomes.”

Kim Scott, president and CEO of Aramark Uniform Services adds, “I am pleased to have this exceptional group of leaders on our Board that also reflect our company culture and values.

“As we seek to deliver long-term value to all of our stakeholders through the acceleration of profitable growth and the continued delivery of an exceptional service experience to our valued customers, we will benefit greatly from our directors’ deep knowledge, expertise and diverse perspectives.”

Aramark intends to appoint the following directors to its Uniform Services Board: Phillip Holloman, Chairman of the Board; Doug Pertz, Vice Chairman of the Board; Scott; Richard Burke; Tracy Jokinen; Lynn McKee; Mary Anne Whitney; and Ena Williams.

The Newspaper of Record for Laundry & Linen Management September 2023 • Volume 49, Number 09 www.americanlaundrynews.com

Laundries have tools to reinforce reusable usage in healthcare after gains during the pandemic

(Photo: © photography33/Depositphotos)

LATE NEWS

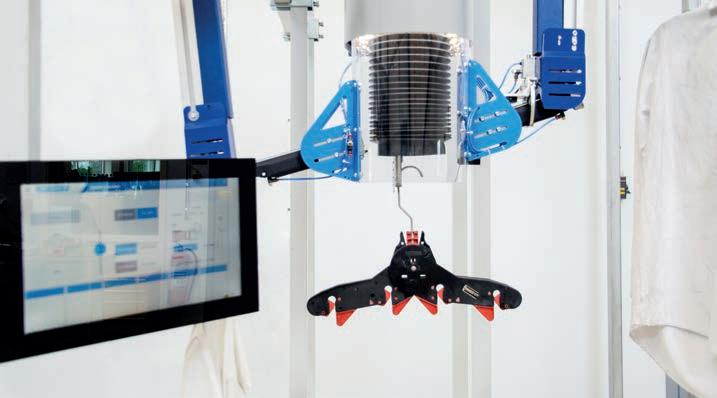

Survey: Status of automation in laundry operations

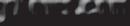

CHICAGO — Automation has been on the rise in laundry and linen services for some time, but with the effects of the past few years, some operations are taking a closer look at their operations.

In the most recent American Laundry News Your Views survey, readers were asked about current and future automation activities in their plants.

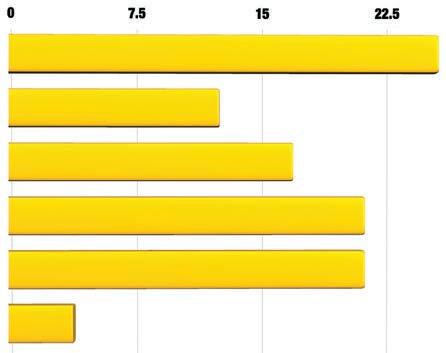

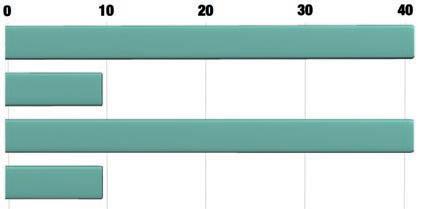

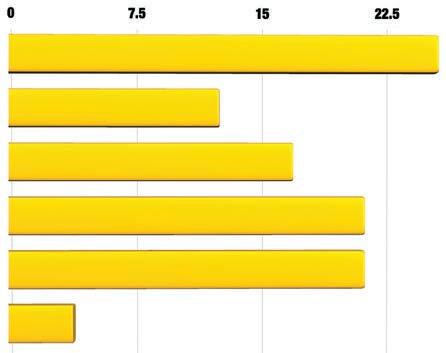

When asked how much of their operations are automated, 40% of respondents indicate 75% of their plants are automated. Those whose operations are 25% automated were also 40%. Survey takers who say half or none of their plants are automated were both 10%.

The area of facilities most automated is finishing, according to 30% of respondents. That’s followed by folding (26.7%) and wash (16.7%). Soil sort and drying were each indicated by 13.3% of those who took the survey. Ninety percent of respondents say their laundry has seriously considered automation in the past five years. And a major reason for that consideration is labor challenges.

“The more labor costs go up, it just makes sense,” a respondent writes. “We are in New York, so in addition to labor costs increasing 10-15% every year, there are many added regulations that go along with it, increasing the incentive to reduce manual labor.

“The problem being is in New York state, the population and customer base is shrinking, which ultimately shrinks the volume.”

Other reasons for considering automation include “expansion,” “to improve efficiency in the plant, and “reduce labor costs and injuries.” One respondent whose laundry isn’t looking at automation says that’s because the “cost to install a system for RFIDs on our garments is not in our budget.”

When asked “what areas of your operation would you like to automate in the future,” respondents indicate: Soil sort, 25%; Dry, 16.7%; Wash, 12.5%; Finish, 20.8%; Fold, 20.8%; and Other (total automatic cart washing and transport system), 4.2.

With the awareness and use of artificial intelligence on the rise, opinions on the progression of AI in laundry automation are mixed.

• It’s off to a good start but has a way to go.

• I would have to review it.

• Good.

• None at this time.

• I’m excited to see what our options will be.

• It’s amazing to see this technology but it is scary to think how easy it can be to replace humans in the workforce.

The most important reason for respondents’ laundries to automate is, of course, labor (60%) followed by cost savings and efficiency, both at 20%.

Not surprisingly, price is the greatest deterrent to using or increasing automation, according to 42.9% of respondents. That’s followed by “upper management moving slowly” at 21.4%.

Selecting the right equipment has slowed 14.3% of survey takers, and 7.1% are still analyzing their operations and choosing the right vendor partner. And 7.1% of respondents say their plants don’t need any further automation at this time.

Finally, one respondent cautions, “Just because it is automated doesn’t

mean it’s better.”

While the Your Views survey presents a snapshot of readers’ viewpoints at a particular moment, it should not be considered scientific. Due to rounding, percentages may not add up to 100%.

Subscribers to American Laundry News e-mails are invited to take the industry survey anonymously online each quarter. All managers and administrators of institutional/OPL, cooperative, commercial and industrial laundries are encouraged to participate, as a greater number of responses will help to better define operator opinions and identify industry trends.

Correction

Due to an editor’s error, the company name of Pellerin Milnor Corp. was misspelled in the August issue of American Laundry News on page 16 in the Product Showcase. We regret the error and any confusion it may have caused.

President Charles Thompson

Publisher Donald Feinstein

Phone: 312-361-1682

E-Mail: dfeinstein@ ATMags.com

Editorial Director

Bruce Beggs

Phone: 312-361-1683

E-Mail: bbeggs@ ATMags.com

Editor Matt Poe

Phone: 866-942-5694

E-Mail: mpoe@ ATMags.com

Production Manager Mathew Pawlak

Digital Media Director Nathan Frerichs

Phone: 312-361-1681

E-Mail: nfrerichs@ ATMags.com

Advisory Board David Barbe

Janice Ayers Davis • Nick Fertig

Deana Griffin • Cecil Lee

Edward McCauley

Jim Slatcher

Main Phone: 312-361-1700

Fax: 312-361-1685

Subscriptions

847-504-8175 ALN@Omeda.com

www.americanlaundrynews.com

endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Laundry News or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

2

September 2023 | American Laundry News www.americanlaundrynews.com

01 Reusables vs. Disposables What’s the status of healthcare customers and reusable textiles a er the pandemic reusable use increase, and what’s the next battle eld/step? 02 Survey: Status of Automation in LaundryOperations 04 Increasing the Laundry Employee Candidate Pool Columnist-at-Large Richard Engler shares ways for laundries to be able to include more candidates in their hiring strategies 04 Feinstein Promoted to American Laundry News Publisher Thompson remains president of textile care B2B publications group, which includes American Coin-Op and American Drycleaner 08 Houston-area Laundry Adds Washer-Extractor Triple D Uniform & Linen Service puts in equipment to navigate market growth in Texas, where population is increasing quickly 08 ARTA Executive Director Retires, Association Management Firm to Lead Nancy Jenkins served 16 years, pursuing retirement career as a licensed professional counselor; Cra , an association management rm based in South Carolina and led by Jim Ritchie, to head 10 2023 Distributors Directory The annual listing of distributors of equipment, products and services to the laundry and linen services industry 18 Career Track 19 Classified Advertising 20 Source Directory 23 Trade Ticker 23 Calendar of Events INSIDE: What share of your laundry operation is automated, if any? About 75% About half About 25% No Automation 40% 10% 40% 10% What areas of your operation would you like to automate in the future? (Click all that apply) Soil sort Wash Dry Finish Fold Other 4.2% 0923ALN Your Views Charts.indd 1 8/8/23 2:56 PM What share of your laundry operation is automated, if any? About 75% About half About 25% No Automation 40% 10% 40% 10% What areas of your operation would you like to automate in the future? (Click all that apply) Soil sort Wash Dry Finish Fold Other 25% 12.5% 16.7% 20.8% 20.8% 4.2% 0923ALN Your Views Charts.indd 1 8/8/23 2:56 PM MEMBERSHIPS American Laundry News (ISSN 1091-9201) is published monthly. Subscription prices, payment in advance: U.S. 1 year $50.00; 2 years $100.00. Single copies: U.S. $10.00. Published by American Trade Magazines LLC, 650 West Lake Street, Suite 320, Chicago, IL 60661. Periodicals postage paid at Chicago, IL, and at additional mailing offices. POSTMASTER, Send changes of address and form 3579 to American Laundry News Subscription Dept., 125 Schelter Rd., #350, Lincolnshire, IL 60069-3666. Volume 49, number 9. Editorial, executive and advertising offices are at 650 West Lake Street, Suite 320, Chicago, IL 60661. Charles Thompson, President and Publisher. American Laundry News is distributed selectively to qualified laundry and linen management and distributors in the United States. © Copyright AMERICAN TRADE MAGAZINES LLC, 2022. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Laundry News does not

Milnor has a better solution through dilution.

When Milnor introduced PulseFlow® technology, CBW® washing was thrust into the future. The idea of balancing time, temperature, mechanical action and chemistry was missing one critical piece of the pie – DILUTION through the efficient use of water.

PulseFlow combines the innovative RecircONE® fast wet down and chemical immersion in the first module with standing bath washing in every spacious process module. Thorough and efficient dilution occurs by way of intermittent high velocity counterflow rinsing and traditional True Top Transfer.

The result is hygienically clean linen using less water (as low as 0.3 gallons per pound/2.5 liters per kilogram) and less energy as proven time and again by hundreds of PulseFlow tunnels in a variety of laundry applications worldwide.

Contact an authorized Milnor distributor or call 504-712-7656 to find out more.

www.milnor.com

*PulseFlow®, CBW® and RecircONE® are Pellerin Milnor’s registered trademarks.

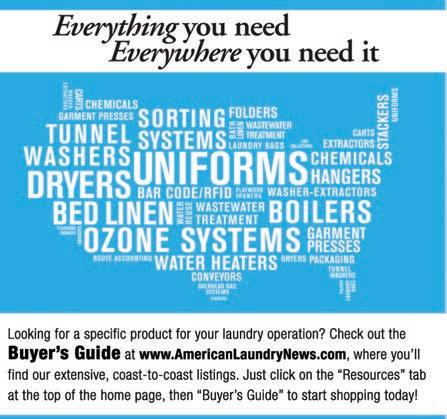

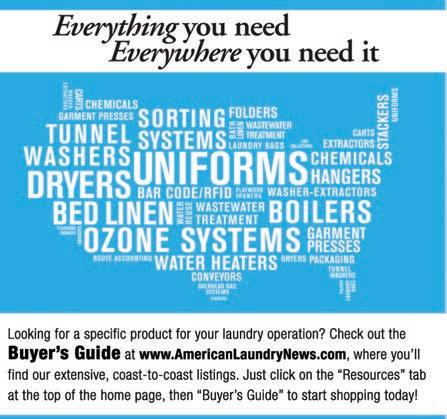

Distributing what you need

Take a moment and think, what do you need most for your laundry operation right now?

You probably need some piece of equipment or chemical or some other product or service.

Now, how are you planning to get your hands on what you need?

This issue of American Laundry News can help you with that. Every September, we provide a listing of distributors of equipment, products and services for laundry operators like yourself.

Turn to page 10 for this Distributors Directory. The companies and offices are listed by state, alphabetically by city.

We’ve done our best to bring you the most up-to-

date distributor listing available.

Also in September, we open the application/nomination portal for the Panel of Experts (https://americanlaundrynews. com/panel-of-experts/application).

From Sept. 1-30, you can apply or nominate a peer to take part in one of several categories.

Just about every month Panel members answer a question from readers like you (which you can always send my way via mpoe@atmags.com).

Those selected for the Panel will be contacted at the end of October/beginning of November. Whether you need supplies or answers to questions, we’re here to help you keep it clean, everybody!

Feinstein promoted to American Laundry News publisher

CHICAGO — American Trade Magazines LLC (ATM), the parent company of textile care B2B publications American Coin-Op, American Drycleaner and American Laundry News, announces a change in leadership.

Effective Aug. 1, Associate Publisher and National Sales Director Donald Feinstein has been promoted to publisher, assuming responsibility for the group’s editorial, production, circulation, promotions and sales operations.

Charles Thompson, the longtime head of ATM, remains company president while taking a step back from overseeing day-to-day operations.

He joined the publications group in 1989 as a regional sales manager for then-parent company Crain Communications and earned promotions to national sales manager, associate publisher and publisher.

Thompson acquired the magazines from Crain in 2011 and retained Feinstein and two other ATM

Increasing the laundry employee candidate pool

Today’s employee marketplace, in this era of nearly full employment, presents significant challenges across the entire hiring spectrum.

While this is not news, we must remain cognizant of the diminished quantity of candidates, both qualified with hard skills and less qualified with soft skills and the importance of reevaluating the past prerequisites against the current marketplace’s available talent.

The candidate count rises as the number and intensity of the prerequisite skills qualifiers decline. The cost of unfilled positions within direct labor can easily exceed the expense of training new personnel on the hard skills of a potential candidate.

Skills-based hiring has always been a preferred strategy for talent acquisition historically; the question of the amount and benefit of substituting soft skills instead of hard skills is a question to be asked as part of adapting to the market changes.

When comparing the hard, or core, skills with the soft skills that lend to successful transitions, it helps to think of these items as “must skills” and “plus skills.” These can be weighted according to the ease of time to train the missing “must skills” with consideration of the benefit of the “plus skills” assisting in the accomplishment of the training.

veterans to ensure the publications’ continuity.

“Don has led our company’s sales department for more than a decade,” Thompson says. “And, as associate publisher, he’s excelled at handling many of a publisher’s duties.

“He’s earned the opportunity to take this next step in his career and I’m excited to watch his continued growth as an executive and a leader.”

Feinstein, a graduate of Drake University, joined the ATM team in 2001 as production manager before shifting to ad sales as a regional manager in 2005.

When Thompson acquired the magazine group, Feinstein was named national sales director, then several years later added the duties of associate publisher.

“In every position I’ve held with American Trade Magazines, I’ve had the opportunity and pleasure to interact with our industry’s leading manufacturers and distributors, as well as the amazing audience of laundry and drycleaning business owners, facility administrators and managers that our magazine group serves,” he says.

“I look forward to building on those relationships and continuing ATM’s tradition of industry service that Charlie has set.”

Ideally, the desired soft skills will aid in reducing the time needed to train.

The question of compensation should also be considered as the soft-skilled candidate is not yet ready to perform the task fully or independently and this brings into play a training wage, which may further offset the expense of providing training. The risk and concern here are most likely to be compensation and compatibility of the skills with the task.

The positive impacts of this can be highly impactful to the operation. A larger pool of candidates means fewer unfilled shifts and less overtime potential.

The recruiting turn time would also be reduced and further save expense. Soft-skill hiring will allow for a better team and organizational fit. The cringy feeling of having to untrain poor task practices of experienced candidates evaporates as there are no previous experiences to draw from with this team member.

Widening the hiring net will also allow for a more diverse group to draw from and the wider array of varied experiences could potentially offer more creative problem-solving solutions.

The risks are very apparent in this approach. However, in the new hiring landscape, the only certain way to guarantee to continue to struggle is to sit and wait for the pendulum to swing back … in my experience it rarely does.

Hiring a new team member who cannot yet perform the required tasks calls for a level of preparedness on how to provide the training effectively and efficiently to accomplish the task with careful consideration of the cost of achieving this goal.

During this period, the team member will likely feel dissatisfied and uncertain if their new job is really for them. Be prepared to proactively offset their misgivings and do not let them slip into a crisis of confidence through a lack of positive feedback from several levels of leadership.

It is critical to not forget their lack of professional experience in the assignment can easily lead to second-guessing without realtime feedback or performance improvement acknowledgment. Implementing these changes is not a single-step process. The support and confidence of the leaders at all levels is imperative.

•

•

•

•

Gathering your leadership team’s consent, agreement and support of the initiative will make or break the program. Leadership must understand the skills needed by trainees and why these skills are key qualifiers, how they differ from traditional qualifications— and why this distinction matters to everyone involved.

A fully developed training plan must be prepared and followed to ensure consistency in development. In addition, measuring suc-

See Column on Page 18

4 September 2023 | American Laundry News www.americanlaundrynews.com

From The Editor’s Desk

Top Stories Appearing on americanlaundrynews.com for the 30 Days Ending Aug. 15. NEWS • ARTA Announces Leadership Changes • Arway Linen Moving to New Facility in 2024 • Healthcare Laundry Business Compliance Platform Launches • Alliance Laundry Systems Distribution Expands West Region • Feinstein Promoted to American Laundry News Publisher COLUMNISTS/FEATURES • NY/NJ Laundry Soars to New Heights with New Equipment • Houston-area Laundry Adds WasherExtractor • Keeping Essential Laundry Equipment Parts on Hand • Strategies for Incorporating Tech Improvements, Training • Cash Family has ‘Good Rapport’ as Service Sales Representatives WE OUR SISTER WEBSITES From AmericanDrycleaner.com:

Profile: Incoming DLI President Kathy Benzinger

Professional Development for Dry Cleaning Owners From AmericanCoinOp.com:

How You Can Protect Your Laundromat from Criminals

Do You Deliver? Amazon

to Partner

You

is Looking

with

COLUMNIST AT LARGE Richard Engler

MATT POE

(WE) = WEB EXCLUSIVE

Thompson

remains president of textile care B2B publications group

FEINSTEIN

Everything. All the time. Live Inventory 24/7/365 Serving the laundry industry since 1947. monarchbrands.com (215) 482-6100 Our live inventory tracker contains every Monarch Brands item in our catalog, updated as every order is placed. If you see it, we have it in stock, and ready to ship. Visit our website or scan the QR Code to get started.

Reusable

Continued from Page 1

are returning to disposables for the same reasons they were using them in the first place: They offer convenience and less initial expense, and it’s what many healthcare providers were used to,” says Hartsell.

“The other factor that is playing into this return to disposables is that many of the products produced under the FDA’s EUA were of subpar quality. While we did not process any of the EUA isolation gowns, we did evaluate a variety of gowns that were being offered. What we found is that they were using fabric that was heavy, hot, uncomfortable and, not to mention, more difficult to launder.

“This was a complete about-face from what the reusable industry was touting in that their products were of a better quality and more comfortable to wear. If I was a healthcare provider and during the height of the pandemic, I had to wear a gown manufactured by the auto industry from Nylon 66, the same material used to make carpets and garden hoses, I would want to get back to my lightweight disposable gown.”

Brobeck says they are hearing several reasons for the return to disposables, including preference by hospital infection preventionists, logistical differences between reusable versus disposables, space constraints and consistent availability.

“Some of the return to disposables is being driven by excess disposable inventory purchased by government agencies during the pandemic,” adds Boardman. “These disposable supplies need to be used before their expiry date.”

Bartsch adds that healthcare organizations purchased an abundance of singleuse PPE during the pandemic.

“We are seeing some organizations attempt to ‘consume their single-use products,’ with an aim to decrease their carrying costs related to storage, use the product inventory that they have purchased, and consume these products before their expiration(s),” he says. “In some cases, they are also contractually committed to single-use products.”

“Old habits,” says Delin. “However, bills have been introduced in multiple states that healthcare facilities must now carry at least 50% reusable product in the event another pandemic hits and disposables are not available.

“Reusables seem like a no-brainer. They are delivered hygienically clean, not destroying our environment and reducing carbon footprint, and do not take up space in the healthcare facilities.”

EVIDENCE FOR REUSABLES

While laundry operations face challenges in convincing healthcare facilities and systems to continue using or switch to reusable products, there are solid arguments that can be employed.

“Now that we are past the pandemic, we need to get in front of the caregivers and the decision-makers inside the healthcare facilities and start touting, once again, the advantages of reusable textiles,” Hartsell says.

“We can start talking about how much better reusable products are for the environment. It’s also important that we, as an industry, make it clear that the EUA products were not representative of the type of reusable products available today.”

“Gaining buy-in from the clinical staff

and addressing any concerns through transparent communication and solution-based recommendations is key,” adds Brobeck. “Speak to your customer to understand initiatives in their healthcare facility that could support the use of reusable textiles.

“Understanding the focus of the customer and providing evidence-based case studies and/or a solid cost analysis is also important for the customer to make an informed decision.”

Romeo shares this example: 60,000 reusable isolation gowns can be stored on approximately 50 skids and represent 4.5 million disposable gowns. The same 4.5 million gowns in disposable would take up 3,750 skids of warehousing space to store representing 75 times more space for storage than reusable gowns.

“The disposable costs of 4.5 million gowns is significant compared to reusable gowns, which will be rewashed and recycled,” he says. “Laundry providers can also emphasize the environmental advantages of reusables.”

“It’s important to discuss the advantages of a reusable product as an emergency stock item,” Hartsell adds.

“If a reusable isolation gown, surgery gown, etc., can last 50-100 washes, that is much less product the healthcare organization will need to keep on hand.”

“The widespread shortages of disposables during the pandemic and environmental concerns are both raising awareness to the use of reusable textiles,” Brobeck shares.

“This is gaining the attention of lawmakers and they are taking steps to promote further examining the feasibility and potential benefits of reusable textiles in healthcare.”

ADVOCATING REUSABLE LEGISLATION

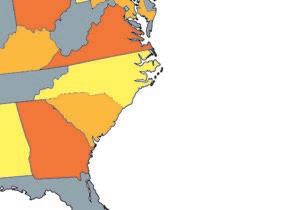

TRSA, the association for linen, uniform and facility services, shares that it recently confirmed sponsors for The Healthcare Worker Safety and Sustainability Act in New York state that requires a 50% threshold of reusable healthcare PPE in healthcare facilities.

In the state legislature, Assembly Member Amanda Septimo (D-84th District) introduced the bill (AB 6995) and Sen. Cordell Cleare (D-30th District) initiated the Senate companion measure. The legislation amends the New York public health law to require healthcare facilities to maintain this threshold of textiles as provided by a hygienically clean laundry service provider.

TRSA has been pushing for legislation to address healthcare employee safety concerns raised during the height of the pandemic as well as reduce the amount of waste health-

care facilities are sending to landfills.

“The linen, uniform and facility services industry made up for the shortfall of disposable healthcare items by stepping in to provide hygienically clean reusable products,” says Joseph Ricci, president and CEO of TRSA.

“It was a wake-up call to healthcare facilities that they need to reduce their dependence on disposable healthcare PPE. This legislation is a first step in identifying reusable healthcare PPE as a permanent solution to potential supply-chain shortages.”

“Introduction is the first step of a long legislative process; there are many initiatives that never even get drafted,” says Kevin Schwalb, TRSA’s vice president of government relations.

“Now that we have introduction, it is going to take effort from everyone in New York to move the process forward and ultimately pass the bill. This legislation is a direct result of the actions TRSA members took during our day in Albany (during TRSA’s New York Legislative Conference in April).”

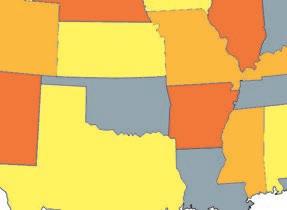

Aside from New York, TRSA is working in other states such as California and Wisconsin to introduce and ultimately pass reusable operating threshold minimums.

TRSA is also urging its members to contact their respective legislators to prompt them to add their names to a letter from members of Congress asking the Department of Health and Human Services (HHS) to examine the feasibility and potential benefits of the increased use of reusable healthcare textiles (HCTs) in hospitals and other medical facilities.

Reps. Greg Landsman (D-OH-01) and Michael Carey (R-OH-15), encouraged by TRSA, were the original authors of the letter, which asks HHS Secretary Xavier Becerra to study the issue considering reusables’ value in protecting healthcare workers, addressing the rising environmental impact of disposables, preparing for future pandemics and potentially providing cost savings.

This letter is a major step in developing federal policy to require healthcare facilities to maintain an operating stock of reusable HCTs.

“This is a huge win for the linen, uniform and facility services industry,” Schwalb says. “Secretary Becerra will be compelled to respond to a congressional Inquiry, which usually leads to a form of federal policy being either legislation or regulation.”

While securing Reps. Landsman and Carey as chief co-signers was a major step, the more names on the letter, the more impact the letter will have at HHS, Schwalb adds.

TRSA has taken advantage of the Pandemic and All-Hazards Preparedness Act (PAHPA) reauthorization process to state the case for making reusable isolation gowns and other textiles more prominent in hospital inventories.

The association has provided the House Energy and Commerce Committee with key evidence that increased use of reusable textiles will support efforts to assure the nation is better prepared, further equipped, more transparent and fully accountable when taking on future emergencies.

TRSA’s response to a Request for Information (RFI) from Reps. Richard Hudson (R-NC) and Anna Eshoo (D-CA) as part of the reauthorization process was the most recent step in the association’s effort to impact hospital inventories under PAHPA.

The pictures of healthcare workers wearing trash bags as PPE highlighted PPE shortages at the onset of COVID-19.

PAHPA covers administration of the Strategic National Stockpile (SNS), which contained about 60 million surgical gowns and coveralls in October 2022, without clear accounting of how many were reusable or disposable.

TRSA has urged Congress to ensure that the SNS contains a suitable number of reusable PPE to be prepared for supply-chain disruptions during an emergency. This could be done by requiring a specific number or percentage of reusable PPE in the SNS.

In the U.S., more than 90% of healthcare PPE and operating room textiles are single use, even though ample supplies of reusable equivalents are available, TRSA notes.

In contrast, Canada and England maintain inventories of 80% reusables. The association cites studies showing that reusable textiles are as safe—if not safer—than their disposable counterparts and pointed out that reusable PPE can be laundered and returned to healthcare facilities without stressing the supply chain during an emergency.

FINAL THOUGHTS

Hartsell stresses that laundry providers aren’t alone in their struggle to convince healthcare operators of the benefits of reusable usage.

“Rely on the manufacturer for your educational material or to assist you in your presentation,” he says. “It’s in both of your interests to convert items to reusable.

“It is also beneficial to have the manufacturers involved because with some items the healthcare facilities may ask very technical questions that you, as a laundry, may not know the answer to.”

Hartsell also stresses the importance of research when identifying potential items to switch for a healthcare provider.

“Do they have any environmental initiatives? Are they trying to reduce HAIs? Did they have supply-chain shortages with disposable isolation gowns? Are they using disposable underpads on every single bed?

“From my research, I’m going to be able to offer a reusable solution that fits their needs versus coming at them with everything all at once.

“I’m also going to be willing to offer them a trial in a certain department. It’s important that if I trial an item, I get feedback from the caregivers in this department.”

Finally, Hartsell says a laundry must be uncompromising in its system if it has an item that is inspected or has cycle recording.

“The end-user has to have complete trust in your laundry, the products you offer and the process you have in place,” he concludes.

6 September 2023 | American Laundry News www.americanlaundrynews.com

(Photo: © SimpleFoto/Depositphotos)

The Power of Three

Leave behind the limitations of manual handling and embrace the power of automation with DR Series Feeders. Our advanced technology ensures precise large and small piece feeding — eliminating the risk of jams or misfeeds, reducing rework and saving valuable time. DR Feeders seamlessly integrate with any ironer in the market. Pair it with a PC Series Ironer and FR Series Folder and you’ve got the ultimate powerhouse. Together, they’ll take your laundry to a new level in productivity, programmability, versatility and quality.

Join the ranks of smart, e cient laundry operators who have upgraded their laundry game with Girbau Industrial.

Industry-Leading Warranties Flexible Financing Options Processing Versatility

INDUSTRIAL

girbauindustrial.com • 800-256-1073

PC Ironers

DR Feeders

FR Folders

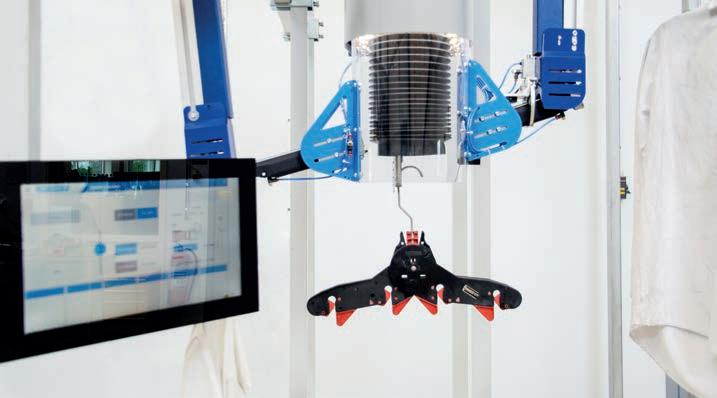

Houston-area laundry adds washer-extractor

Triple D Uniform & Linen Service installs new equipment to navigate market growth

BEACON FALLS, Conn. — The old axiom that everything is bigger in Texas is alive and well. The state’s population is among the fastest growing in the United States, and well-run businesses like Triple D Uniform & Linen Service are responding to the challenge.

A local staple in Houston for over 50 years, they recently expanded service to markets in central Texas and turned again to LAVATEC to help handle the new demand.

“We recently purchased a LAVATEC LX460 washer-extractor to join the two smaller washers from them that we’ve had in service for 16 years,” says Jacy Henderson, Triple D’s vice president.

“These are workhorse machines and suit our needs perfectly. The newest machine has proven to be just as solid as the other two.”

LOCAL LEADER WITH LARGER GAME PLAN

Triple D is a third-generation-owned company that originally began as a uniform rental organization when it was run by Wayne McCullough.

The business has been operated by Doug McCullough and his wife, Cindy, since 2005. Its automated facility located on the northwest side of Houston now provides customers with state-of-the-art laundering, corporate apparel, custom embroidery and servicing technology.

The decision to expand comes after an unprecedented population boom.

According to statistics compiled by the U.S. Census Bureau, Texas showed a 43% increase from 2020 to 2022, making it the fourth largest growing state. The largest of the 48 contiguous states, it is now home to more than 30 million residents.

During the same period, Triple D has shown steady progression.

After processing 5.4 million pounds of linen in 2021, it ramped up to 6.9 million pounds last year and currently is averaging 150,000 pounds per week.

Henderson anticipates the company will

deliver about 7.8 million pounds by the end of the year.

“We are now servicing clients in Austin and San Antonio. That is in large part the reason for our increase,” says Henderson, who began working at Triple D as a route relief driver in 2007 after graduating from Texas A&M University.

“It was supposed to be a part-time gig, but 16 years later here I am. I ran the production floor for eight years before moving into my current role.”

Henderson manages the three uniform rental service programs Triple D makes available to its customers.

It includes the industrial side for healthcare and food service uniforms, restaurant services for chef wear that includes aprons, coats, pants and chef hats, and healthcare rental that covers lab coats, scrubs, isolation gowns and footwear.

He says healthcare clients account for 20% of the work—with industrial and hospitality evenly splitting the remainder—but

ARTA executive director

hospitality has been the fastest growth segment since the COVID-19 pandemic first arrived in 2020.

“We currently employ about 70 people and work a four-days-a-week schedule, Monday through Thursday,” Henderson says.

“Most of our accounts get serviced once a week, but some of the larger organizations require service two or three times per week.”

TRUSTED PARTNERSHIP WITH RESOLUTE EQUIPMENT, SERVICE

Henderson explains that it’s important to have trusted equipment to avoid downtime.

“We chose LAVATEC for their cost effectiveness and their reliability,” he says of the two older LX445 washer-extractors and the new LX460.

The LX445s have a 450-pound capacity compared to the larger LX460, which can accommodate up to 600 pounds.

All three are employee-friendly, frontloading machines.

“We are using the larger LX460 main-

ly to process our bar towels and mats,” Henderson shares. “We loved the idea of having the larger capacity.

“At the same time, we benefitted from the fact it didn’t take up much more floor space. I do believe the front loaders are more beneficial at reaching a higher extract speed with a full load of mats than some of the competitor models I have seen.”

When the inevitable does happen with a service interruption, Henderson knows that downtime will be limited.

“Occasionally there are the typical breakdowns, but the LAVATEC service team is very responsive,” he points out. “That’s reassuring because our customers know that we take care of business and deliver on our promise to provide a superior quality product.

“LAVATEC is always willing to spend the time needed to troubleshoot. With help from the service and parts teams, they get our needs taken care of and keep our machines up and running.”

retires,

association management firm

MISSION, Kan. — The executive director for the American Reusable Textile Association (ARTA) has retired and a South Carolinabased association management firm has been selected to lead the association.

After serving 16 years, Nancy Jenkins is leaving the association to launch her retirement career as a licensed professional counselor.

ARTA’s Board of Directors chose Craft, an association management firm based in South Carolina and led by Jim Ritchie, to

lead ARTA beginning Aug. 1.

Jenkins will help with the transfer before officially departing at the end of September.

“Nancy has been instrumental in helping grow ARTA’s education conferences, coordinate peer-reviewed LCA research and develop a robust website,” says ARTA President Gabriel Boardman. “And we wish her the best as she begins her next adventure.”

Jenkins joined ARTA in 2003 as editor of its bimonthly newsletter. In 2007, with the retirement of Bill Carroll, she stepped into the executive director role.

The ARTA Board of Directors began its search for new leadership late last year.

Based on its goals for the future, the Board believed that Craft was best positioned to help ARTA meet its growth objectives.

“Craft has the bandwidth to provide the

services our members need and want,” says Boardman. “And personally, we believe Craft and its staff are a good cultural fit for ARTA and the textile services industry.”

Craft opened its doors in Columbia, South Carolina, in 2017. It defines itself as a firm delivering realized value through difference-making strategies crafted with clear vision.

“We help our clients craft a roadmap to success,” says CEO Ritchie. “We do this by developing strategies built on strengthen-

to

lead Jenkins served 16 years, pursuing retirement career as a licensed professional counselor

ing member connectivity and improving the association’s impact.

“When our clients see tangible wins in their business from their membership investment, that drives the association forward and affects the greater good.”

Ritchie brings 30 years of legal and public policy experience to Craft, where his work focuses on association leadership, government relations and strategic planning for its clients.

Founded in 1982 by Nathan Belkin, Ph.D., ARTA’s mission is to create greater appreciation and demand for reusable textiles. Membership is open to all in the textile services industry, and its members include allied associates, suppliers, manufacturers, and commercial, institutional and cooperative laundry operators.

8 September 2023 | American Laundry News www.americanlaundrynews.com

Keeping the washers and other equipment performing at Triple D Uniform & Linen Service is the responsibility of, from left to right, Vice President Jacy Henderson, Production Manager Myriam Caceres and Chief Engineer David Lobos. (Photo: LAVATEC)

JENKINS RITCHIE

Central Laundry Plant in NY has Closed

• Milnor 8 Module Pulse Flow CBW/Press with Monorail with slings

• (5) 64/58 up to 320 Lb Gas System Dryers (July 2015)

• (4) Chicago Century 2 Roll 52” Steam Ironer (2019), Various years

• Edge Maxx (2019) (4) Edge, Various years

• Chicago Skyline 1 Lane (2019)

• Skyline 4 Lane, (2) Skyline 1 Lane, Various years

• (3) Air Chicago XXL Blanket, Towel & Gown Folder, Various years

• (2) Braun Towel & Gown Folders

• (3) Milnor Soft Mount Open Pocket 140 LB Washers (2015)

• (2) Milnor M202 Gas Fire Dryers (20015)

• (2) 500 HP York Shipley Gas Boilers

• Colmac Connie Lab Coat Presser

• (3) Quincy Air Compressors

• Voss 75 Pound Tunnel Washer (1984)

• Multiple Linen Carts (350)

• Scissor Dock Lift

• Portable Scissor Dock Riding Lift FROM WELL MAINTAINED LINEN PLANT EQUIPMENT:

• 4- Roll American Super Sylon 110”

• 8- Roll American Sylon 120”

• (5) 8- Roll American Super Sylon 120”

• Jensen Olympic 3 Lane Folder

• Jensen 5 lane Napkin/3 lane for Apron

• Lavatec 5 Lane Napkin Folder

• (2) BB&D 3 Lane (2/1)

• Lavatec 3 Lane (2/1)

• Chicago Dryer Towel Folder

• Colmac Finishing Steam Tunel

• Gardner Denver Air Compressor

• Sullivan / Pallatek Air Compressor

• Hankison Air Dryer

• Puro Midi Oil Water Separator

• Air Tank

• Cleaver Brooks Boiler 500 HP

• Cleaver Brook DA Tank

• Cleaver Brook Hawk Control

• (2) Milnor Centrifugal Extractor

• (2) Norman 400 Gas Dryer

Please make an appointment to see equipment as it won’t last! EXCELLENT OPERATING EQUIPMENT. • Call Ron Hirsch • 516-938-4300

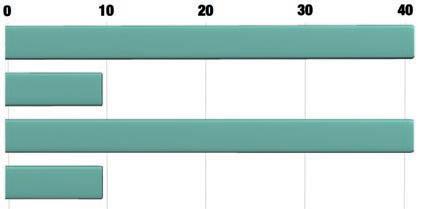

These distributors and suppliers responded to American Laundry News’ invitation to be listed. They provide laundry equipment, textiles, chemicals, parts, services, and/or other products or supplies, and are listed alphabetically by city and state.

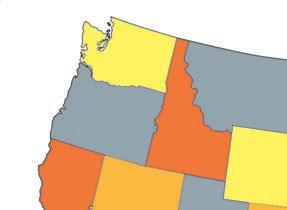

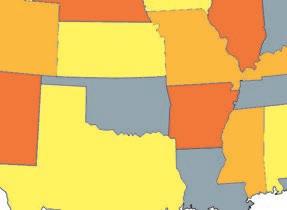

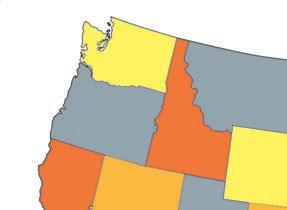

Contact distributors to determine their coverage area—local, regional or national. The map below indicates on which page a given state’s listings begin. No distributor information was received from states that have no listings. The Distributors Directory runs through page 17.

Compiled by Matt Poe, Editor

ALABAMA

FabriClean Supply C O of Birmingham

1200 2nd Ave. N. Birmingham, AL 35203

☎ 205-251-7272 or 800-626-8428

W www.fabricleansupply.com

☞ Steve Taylor @ info@fabricleansupply.com

Wholesale Commercial E P s O

Laundry Equipment Co. SE 2950 Highway 77 Southside, AL 35907

☎ 256-312-4761 or 866-544-7228

W www.alaundryman.com

☞ Russ Arbuckle @ thelaundryman1@gmail.com

ALASKA

Automated Laundry E C P s Systems & Supply 360 E. 100th Ave. Anchorage, AK 99515

☎ 907-561-1752

W www.autolaundrysystems.com @ sales@autolaundrysystems.com

ARIZONA

Pierce Machinery E P.O. Box 2110 Chandler, AZ 85244

☎ 602-538-5081

W www.piercemachinery.com @ plaundmach@aol.com

Astro Distributing E P s O & Leasing 4322 E. Winslow Ave. Phoenix, AZ 85040

☎ 602-267-7072

W www.astrodistributing.com @ admin@astrodistributing.com

C-PEC E P s 3120 W. Weldon Ave. Phoenix, AZ 85017

☎ 602-248-0808 or 877-835-5866 W www.cpec-laundry.com @ sales@cpec-laundry.com

Laundry & Cleaners E P s Equipment Co. 320 S. 25th St. Phoenix, AZ 85034

☎ 602-244-0800

W www.laundryandcleaners.com

☞ Tim Eckenrode @ teckenrode@laundryand cleaners.com

Southwest Laundry E P s Equipment LLC 2430 S. 11th Ave. Phoenix, AZ 85007

☎ 206-517-5463 or 602-253-9687

W www.azsle.com

☞ Neil Lind @ neil@lindindustries.com

Wardlaw Equipment E P s Consultants Phoenix, AZ 85014

☎ 520-791-2804 or 877-927-3529

W www.wardlawequipment consultants.com

☞ Kevin Wardlaw @ wardequip@aol.com

CG West E P s O 500 S. 52nd St., Ste. 302 Tempe, AZ 85281

☎ 623-937-0125 or 800-789-6412 W www.cg-west.com @ info@cg-west.com

C-PEC E P s 3202 S. Richey Ave.

Tucson, AZ 85713

☎ 520-790-7377 or 877-835-5867

W www.cpec-laundry.com

☞ Greg Svancara @ greg@cpec-laundry.com

ARKANSAS

FabriClean Supply C O of Arkansas 6600 Allied Way Little Rock, AR 72209

☎ 501-565-5288 or 800-442-7021

W www.fabricleansupply.com

☞ Omeed Esfandi @ info@fabricleansupply.com

Justin Laundry Systems E P s

5310 Baseline Rd. Little Rock, AR 72209

☎ 501-551-8600 or 888-403-9600

W www.justinlaundry.com

☞ Mark DeJesus @ mark@justinlaundry.com

Central Laundry E P s O Equipment

P.O. Box 324 Ward, AR 72176

☎ 501-843-3194 or 800-467-3194

W www.centrallaundryequipment.com

☞ Jeff Craig @ jeff@centrallaundryequipment.com

CALIFORNIA

Washex Machinery E P s of California 101 E. Santa Anita Ave. Burbank, CA 91502

☎ 818-840-8900

W www.washexcalifornia.com

☞ Mark Sanders @ mark@washexcalifornia.com

Western State Design E P s

17000 Marquardt Ave. Cerritos, CA 90703

☎ 800-633-7153

W www.westernstatedesign.com @ info@westernstatedesign.com

Consolidated E P s

3804 Main St., Ste. 1 Chula Vista, CA 91911

☎ 866-632-2298

W www.cicus.com @ sales@cicus.com

ATS/California Textiles T

P.O. Box 77306 Corona, CA 92877

☎ 951-272-1200

☞ Lenore Law @ catex1@att.net

Western State Design E P s O 2331 Tripaldi Way Hayward, CA 94545 ☎ 800-633-7153 W www.westernstatedesign.com @ info@westernstatedesign.com

Automated Laundry E P s O Systems 3626 S. San Pedro St. Los Angeles, CA 90011

☎ 818-556-6432 or 800-423-8045

W www.automated-laundry.com @ info@automated-laundry.com

United Fabricare Supply C O P.O. Box 01796 Los Angeles, CA 90001 ☎ 310-537-2096 W www.unitedfabricaresupply.com @ info@unitedfabricaresupply.com

Continental Girbau West E P s O 9830 Alburtis Ave. Santa Fe Springs, CA 90670

☎ 562-205-0140 or 866-950-2449 W www.cg-west.com @ info@cg-west.com

TheLaundryList.com Inc. E P s O 5010 Parkway Calabasas, Ste. 2020 Calabasas, CA 91302

☎ 818-789-8045

W www.thelaundrylist.com

☞ Brian Cohen @ sales@thelaundrylist.com

10 September 2023 | American Laundry News www.americanlaundrynews.com

KEY ☎ Phone W

☞ Contact @ E-Mail e Equipment C Chemicals T Textiles P Parts S Service o Other Products or Supplies

Website

Distributors Directory

WA 17 OR 14 CA 10 NV 14 UT 16 WY — MT 14 ND SD 16 NE 14 KS 12 AK 10 VT 17 DE NH 14 MA 13 RI 15 CT 11 NJ 14 MD 13 HI 12 PUERTO RICO 17 MN 13 IA 12 MO 13 AR 10 LA 12 MS 13 AL 10 GA 12 FL 11 TN16 SC 15 NC 14 KY 12 IL 12 WI 17 MI 13 IN 12 OH 14 WV 17 VA 17 PA 15 NY 14 ME — AZ 10 NM 14 TX 14 OK 15 CO 11 ID 12 2023

Alliance Laundry Systems E P s

DistributionWest Region Pittsburg Office

162 Harbor Ct Pittsburg, CA 94565

☎ 800-464-6866

W distribution.alliancelaundry.com/west

☞ Courtney Satterlee @ Courtney.Satterlee@alliancels.com

Alliance Laundry Systems E P s

DistributionWest Region San Diego Office 4876 El Cajon Blvd., Ste. B San Diego, CA 92115

☎ 858-560-6969

W distribution.alliancelaundry.com/west

☞ Courtney Satterlee @ Courtney.Satterlee@alliancels.com

Alliance Laundry Systems E P s

DistributionWest Region South Gate Office 12020 Garfield Ave. South Gate, CA 90280

☎ 323-721-8832

W distribution.alliancelaundry.com/west

☞ Courtney Satterlee @ Courtney.Satterlee@alliancels.com

Alliance Laundry Systems E P s

DistributionWest Region San Francisco Office 161 Starlite St., Ste. B South San Francisco, CA 94080

☎ 650-871-0300

W distribution.alliancelaundry.com/west

☞ Courtney Satterlee @ Courtney.Satterlee@alliancels.com

WASH E P s

2200 W. 195th St. Torrence, CA 90501

☎ 800-421-6897

W www.wash.com

ACE Commercial E P s O

Laundry Equipment 14404 Hoover St. Westminster, CA 92683

☎ 800-583-3203

W www.acelaundry.com @ acelaundry@gmail.com

COLORADO

Cowell Sales Co. E P s 2220 Downing St. Denver, CO 80205

☎ 303-861-8826 @ cowellsales@aol.com

Katzson Brothers E C T P s O 960 Vallejo St. Denver, CO 80204

☎ 303-893-3535 or 800-332-2417

W www.katzson.com

☞ Richard H. Right @ sales@katzson.com

Martin-Ray E P s O

Laundry Systems

2050 W. 9th Ave. Denver, CO 80204

☎ 720-359-8000 or 800-279-6622

W www.martinray.com

☞ Timm Mullen @ timm@martinray.com

Commercial Laundry E C P s O Systems of the Rockies

P.O. Box 974 Johnstown, CO 80534

☎ 970-587-2727 or 800-270-8539

W www.clsrockies.com

☞ Brenda Maetzold @ brenda@clsrockies.com

Clean Designs E P s 2800 S. Oak St. Lakewood, CO 80227

☎ 303-969-8288

W www.cleandesigns.com

☞ Tim Stoklosa @ tim@cleandesigns.com

CONNECTICUT

Lavatec Laundry E P s Technology 49 Lancaster Dr. Beacon Falls, CT 06403

☎ 203-632-8777

W www.lavatec.com

☞ Mark Thrasher @ m.thrasher@lavatec.com

Connecticut Laundry E P s O Equipment Co. P.O. Box 399 Fairfield, CT 06824

☎ 203-763-9163

☞ Steven Olmanni

@ ctlaundryequip@aol.com

MAXI-PRESS P s O Elastomeric Inc. 80 Turnpike Dr., Ste. 4 Middlebury, CT 06762 ☎ 203-527-5800 or 844-447-5559

W www.maxi-press.us

☞ Reiner Schmelcher @ r.schmelcher@maxi-press.us

FLORIDA

Commercial Laundry E P s Equipment 2054 Sprint Blvd. Apopka, FL 32703

☎ 407-886-1722 or 800-226-9449

W www.commerciallaundry.net

Alliance Laundry Systems E P s O DistributionSouth Region Gulf Breeze Office 1626 Tradewinds Dr. Gulf Breeze, FL 32563 ☎ 800-366-4168

Wdistribution.alliancelaundry.com/south

☞ Sam Husain @ sam.husain@alliancels.com

FabriClean Supply C O of Florida 11705 Industry Dr. Jacksonville, FL 32218 ☎

904-696-7685 or 800-442-7021 W www.fabricleansupply.com ☞ Dave LaPorte @ info@fabricleansupply.com OEM Laundry Parts LLC E P s 4020 University Blvd. Ct. Jacksonville, FL 32217 ☎ 904-240-0211 W www.oemlaundryparts.com ☞ Rebecca Sharpe @ parts@oemlaundryparts.com Davis Packaging E P s O 1002 N. Palmway Lake Worth, FL 33460 Miele-OPL-Benchmark-Coming Soon-7.75x10-Jun23-E.indd 1 7/6/23 9:01 AM ALN_Jr Page.indd 1 7/9/23 2:46 PM 11 American Laundry News | September 2023 www.americanlaundrynews.com Page 12

(Images: Background Image licensed by Ingram Image)

W www.pellerinlaundry.com @ sales@pellerinlaundry.com

Pierce Commercial E P s O

Laundry Distributors 22258 Marshall Rd. Mandeville, LA 70471

B 800-254-9274

W www.piercecommercial.com @ gpierce@piercecommercial.com

MARYLAND

Alliance Laundry Systems E P s O

DistributionEast Region Hagerstown Office 13015 Salem Ave. Hagerstown, MD 21740

☎ 800-866-6905

W distribution.alliancelaundry.com/east

☞ Andy Bingham @ Andy.Bingham@alliancels.com

Laundry Equipment Repair P s Service 3241 Lucky Dr. Street, MD 21154

☎ 410-452-5260

W www.laundryequipment repairservice.com

☞ Charlie Fitzpatrick @ lersco@gmail.com

Express Parts and Services P s 6908 Spring Hill Dr. Sykesville, MD 21784

☎ 410-563-9000 or 800-977-7278

W www.epslaundry.com @ service@calleps.com

Hynes & Waller E P s 16000 Trade Zone Ave., Bldg. 403 & 404 Upper Marlboro, MD 20774

☎ 301-249-9421 or 800-776-9424

W www.hynesandwaller.com @ sales@hynesandwaller.com

MASSACHUSETTS

National Conveyor

& Machine

16 Scenna Rd. Beverly, MA 01915

☎ 978-927-1281

W www.ncm1.com

☞ Bob Baker @ ncmtextile@aol.com

ERC Wiping Products O

19 Bennett St. Lynn, MA 01905

☎ 781-593-4000 or 800-225-9473

W www.ercwipe.com

☞ Valerie Sweeney @ erc@ercwipe.com

Garment Machinery Co. P s

10 Kearney Rd., Ste. 308 Needham, MA 02494

☎ 781-559-4077

W www.garmentmachinery.com @ info@garmentmachinery.com

Eastern Laundry Systems E

s 705 Myles Standish Blvd. Taunton, MA 02780

☎ 508-828-9274

W www.elsequip.com @ sales@elsequip.com

W www.enequipment.com

☞ Steve Casalou @l steve@enequipment.com

Eagle Star Equipment E P s 2329 Alger Dr. Troy, MI 48083

☎ 248-457-1140 or 800-482-3400

W www.eaglestarequipment.com @ general@eaglestarequipment.com

Universal Laundry E P s Machinery

38700 Webb Dr. Westland, MI 48185

☎ 734-727-0478 or 800-825-7787

W www.univlaundry.com

☞ Ryan Hubbard @ rhubbard@univlaundry.com

MINNESOTA

W www.kannegiesser-etech.com @ sales@kannegiesser-etech.com

Bobco Systems E P s O

12713 320th Ave. Princeton, MN 55371

☎ 763-389-3625

W www.bobcosystems.com @ tia@bobcosystems.com

BDS Laundry Systems E P s

2430 Enterprise Dr. St. Paul, MN 55120

☎ 651-688-8000 or 800-688-0020

W www.bdslaundry.com

☞ Karen Ganter @ sales@bdslaundry.com

MISSISSIPPI

Dongieux E P s

Kansas City, MO 64161

☎ 913-384-5200 or 800-383-9274

W www.laundrysolutionscompany.com

☞ Richard Gaar @ rgaar@laundrysolutions company.com

Loomis Bros. E P s O Equipment Co. 6110 Deramus Ave., Ste. B Kansas City, MO 64120

☎ 816-452-4115 or 800-783-6665

W www.loomisbros.com

☞ Drew Hoselton @ sales@loomisbros.com

Sav-A-Day E P s Laundry Machinery 55 Millwell Ct. Maryland Heights, MO 63043 ☎ 314-291-1910 or 800-489-9274

Aldrich Clean-Tech E

s Equipment 59 Webster Place Worcester, MA 01603

☎ 888462-2832

W www.aldrichcleantech.com @ info@aldrichcleantech.com

MICHIGAN

Allied Eagle Supply Co. E O 1801 Howard St. Detroit, MI 48216

☎ 313-230-0770 or 800-211-6244 W www.alliedeagle.com @ info@alliedeagle.com

Curtis Equipment Co. E P s 1410 W. Main (P.O.Box 209) Lowell, MI 49331

☎ 616-897-9810

W www.curtisequipmentco.com

☞ John Curtis @ john@curtisequipmentco.com

A&B Equipment Co. E P s 635 Wellington St. Saginaw, MI 48604

☎ 989-753-4764 or 800-369-4764

W www.ab-equipment.com

☞ Scott Clark @ sales@ab-equipment.com

E&N Equipment Co. E P s 6492 Malvern Dr. Troy, MI 48098

☎ 248-866-5500

The Minnesota E P s Chemical Co.

3750 Dunlap St. N. Arden Hills, MN 55112

☎ 651-646-7521 or 800-328-5689

W www.minnesotachemical.com

☞ Information Desk @ info@minnesotachemical.com

PROSParts P s 1630 91st Ave. N.E., Ste. 107 Blaine, MN 55449

☎ 800-359-0628

W www.prosparts.com

☞ Barry Victor @ barryv@prosparts.com

Darling’s Sales E P s O & Service Co. 10007 Baltimore St. N.E. Minneapolis, MN 55449

☎ 763-786-1803

W www.darlingsales.com

☞ Brad Darling @ bdar@darlingsales.com

E. Weinberg Supply Co. E C P s 7434 W. 27th St. Minneapolis, MN 55426

☎ 952-920-0888 or 800-279-0888

W www.weinbergsupply.com @ david@weinbergsupply.com

Kannegiesser ETECH E P s 2090 Elm St., S.E. Minneapolis, MN 55414

☎ 612-722-1366 or 800-344-0403

P.O. Box 9386 Jackson, MS 39286-9386

☎ 601-366-2636 or 800-844-3664

W www.dongieuxs.com

☞ John R. Schemmel @ dongieuxs@bellsouth.net

Ideal Chemical C O

106 Ware St. Jackson, MS 39208

☎ 601-932-4920 or 800-824-0356

W www.idealchemical.com

☞ Sam Block Jr. @ sblock@idealchem.com

Laundry South E P s O Systems & Repair

185 Country Place Hwy. Pearl, MS 39208

☎ 601-420-9414

W www.laundrysouth.com

☞ Robert Harris @ robert@laundrysouth.com

MISSOURI

Loomis Bros. E P s O Equipment Co.

409 Biltmore Dr. Fenton, MO 63026

☎ 636-343-8888 or 800-783-6665

W www.loomisbros.com

☞ Matt Lamons @ sales@loomisbros.com

Laundry Solutions Co. E P s O

3509 N. Kimball Dr.

W www.sav-a-day.com @ sales@sav-a-day.com

RJ Kool Co. E C P s 234 W. 12th Ave. North Kansas City, MO 64116 ☎ 816-474-9274 W www.rjkool.com @ info@rjkool.com

Phoenix Textile Corp. T 21 Commerce Dr. O’Fallon, MO 63366 ☎ 314-291-2151 or 800-325-1440 W www.phoenixtextile.com

☞ Mike Hayes @ mhayes@phoenixtextile.com

Centraz Industries C 4051 Bingham Ave. St. Louis, MO 63116

☎ 314-752-7627 or 800-695-7627 W www.centraz.com @ centrazind@centraz.com

Komro Supply Co. C O 2600 S. 2nd St. St. Louis, MO 63118

☎ 314-772-4360 or 800-264-6535 W www.komrosupplycompany.com

☞ Gary Thuro @ gary@komrosupply.com

John Morris Equipment E P s Company 2023 S. Glenstone Page 14

13 American Laundry News | September 2023 www.americanlaundrynews.com

E P s O

P

P

Distributors Directory 2023

@ info@tplaundry.com

R.W. Martin Company E P O 4675 Mogadore Rd. Kent, OH 44240

☎ 330-673-8712 or 800-635-4363

W www.rwmartin.com

☞ Jeff McLain @ info@rwmartin.com

Moore Services E P s 29500 Aurora Rd., Ste. 4 Solon, OH 44139

☎ 440-498-0200 or 800-941-MORE

W www.mooreservices.info

☞ Jerry Moore @ mooreservices@aol.com

OKLAHOMA

Laundry Solutions Co. E 713 S. 8th St. Broken Arrow, OK 74012

☎ 918-251-0800

W www.laundrysolutionscompany.com

☞ Nick Luzecky @ nluzecky@laundrysolutions company.com

Arrow Machinery Co. E 1121 N. Martin Luther King Ave. Oklahoma City, OK 73117

☎ 405-424-4318

W www.arrowmachinery.org @ arrow@arrowmachinery.org

Elite Equipment Co. E P s O 4400 S.W. 134th St. Oklahoma City, OK 73173

☎ 405-692-4800 or 800-335-3600

W www.eliteequipment.com

☞ Marty Jackson @ marty@eliteequipment.com

FabriClean Supply E P s O of Oklahoma 201 N. Ann Arbor Oklahoma City, OK 73127

☎ 405-232-9289 or 800-442-7021

W www.fabricleansupply.com

☞ Kenny Dillon @ info@fabricleansupply.com

AAdvantage Laundry E Systems

7626 E. 46th Pl. Tulsa, OK 74145

☎ 918-627-2138 or 800-880-2138

W www.aadvantagelaundry.com

☞ Daniel Kramer @ dkramer@aadvantagelaundry.com

OREGON

True Color Fabric Dyeing T 2305C Ashland St., #281 Ashland, OR 97520

☎ 541-488-5911

W www.fabricdyeing.com

☞ Sherry Smilo @ info@fabricdyeing.com

Peterson Equipment Co. E P s 151 N. Front St. Woodburn, OR 97071

☎ 503-981-4032

W www.peterson-equipment.com

☞ Russell Peterson @ russell@peterson-eq.com

PENNSYLVANIA

Olek Belts P s O

445B Mill Rd. Bensalem, PA 19020

☎ 215-638-4550 or 800-869-2683

W www.olekbelts.com

@ sales@olekbelts.com

Butler Staple Co. E P s O

241 North Rd. Butler, PA 16001

☎ 724-287-6980 or 800-821-8842

W www.butlerstaple.com @ ray@butlerstaple.com

Alliance Laundry Systems E P s O

DistributionEast Region Camp Hill Office

1440 W. State St., Ste. B Camp Hill, PA 17011

☎ 800-866-6905

W distribution.alliancelaundry.com/east

☞ Andy Bingham @ Andy.Bingham@alliancels.com

PAC Industries E P s O 950 River Rd. Croydon, PA 19021

☎ 215-638-1000 or 800-972-2292

W www.pacindustries.com @ info@pacindustries.com

Professional Laundry E P s Systems

950 River Rd. Croydon, PA 19021

☎ 215-354-0111 or 888-637-0600

W www.plslaundry.com @ info@plslaundry.com

M.C.H. Equipment E P s 421-A Philmont Ave. Feasterville, PA 19053

☎ 215-355-3778 or 800-399-5237

W www.mchequipment.com

☞ Bob Feldman @ info@mchequipment.com

PAC Industries E P s 5341 Jaycee Ave. Harrisburg, PA 17112

☎ 717-657-0407 or 800-692-6214

W www.pacindustries.com @ info@pacindustries.com

AC Power Co. E P s

77 Steamwhistle Dr. Ivyland, PA 18974

☎ 215-364-3430 or 800-362-1900

W www.acpowerco.com @ info@acpowerco.com

CILS E P s C O

36 N. 16th St. Lebanon, PA 17042

☎ 717-274-2693 or 888-820-2457

W www.cils-inc.com

☞ Tony Mohl or John Noss @ info@cils-inc.com

CILS Inc. North E P s C O 555 High St. New Berlin PA 17855

☎ 570-884-4644 or 888-978-4799

W www.cils-inc.com

☞ Tony Mohl or John Noss @ info@cils-inc.com

Alco Washer Center E P s O

1243 W. State St. New Castle, PA 16101

☎ 724-658-8808

W www.alcowasher.com @ alco.washer@verizon.net

Frankford Machinery E P s O 4500 Torresdale Ave. Philadelphia, PA 19124

☎ 215-289-3434

W www.frankfordonline.com

☞ Nick Kashkashian @ info@frankfordonline.com

Pittsburgh Laundry Systems E 7500 Washington Ave.

Pittsburgh, PA 15218 ☎ 412-351-4500

W www.pittsburghlaundry.com

☞ Sonny Rogalla @ sonny@pittsburghlaundry.com

Sea Isle Corporation T 5447 Guarino Rd. Pittsburgh, PA 15217

☎ 800-722-0429

W www.seaislecorp.com

☞ Bill Halpern @ bill@seaislandcorp.com

Central Pennsylvania E P s Laundry Equipment 231 Rear E. Main St. Shiremanstown, PA 17011 ☎ 717-761-3617 or 800-242-5520 W www.centralpalaundry.com

☞ Andy Priest @ centralpalaundry2@gmail.com

RHODE ISLAND

Norton Supply Co. E C O 4972 S. County Trl. Charlestown, RI 02813 ☎ 401-454-8380 or 800-869-7664 W www.nortonsupply.com

☞ Bill Mark @ sales@nortonsupply.com

SOUTH CAROLINA

Texchine Inc. E P

s 207 Beaufort St. Chapin, SC 29036 ☎ 803-345-5171 or 800-768-8205 W www.texchine.com Page 16 15 American Laundry News | September 2023 www.americanlaundrynews.com The Newspaper of Record for Laundry & Linen Management Find what you’re looking for wherever you are. Stay on top of the latest industry news and updates on your tablet, phone or in your mailbox. www.american laundrynews.com Laundries have tools to reinforce reusable usage in healthcare after gains during the pandemic www.americanlaundrynews.com Reusables vs. Disposables LATE NEWS 0923aln_ALN Digital Edition_Jr Half.indd 1 8/14/23 10:53 AM ALN_Jr Half.indd 1 8/2/23 8:53 AM Distributors Directory 2023

☞ Jay Dixon @ jaydixon@texchine.com

Consolidated Laundry E P s

Equipment

127 Overland Dr., #B Columbia, SC 29209

☎ 800-766-0926

W www.consolidatedlaundry.comm

☞ Gary Palmer @ gpalmer@consolidatedlaundry.com

FabriClean Supply C O of Carolina

1200 1st Street South Ext. Columbia, SC 29209

☎ 803-776-7988 or 800-442-7021

W www.fabricleansupply.com

☞ Debra Wilson @ info@fabricleansupply.com

Universal Unilink T C O

P.O. Box 2628

Greer, SC 29652

☎ 888-830-7872

W www.universal-unilink.com

☞ Sherryl Stoner @ sherrylstoner@universalpa.com

SOUTH DAKOTA

Horwath Laundry E P s Equipment

1880 Center St. Rapid City, SD 57703

☎ 605-343-3507

W www.aahorwath.com

☞ Jim Horwath @ origin@rushmore.com

Richard-Ewing E C P s O Equipment Co.

27121 S. Parklane Dr. Sioux Falls, SD 57106

☎ 605-368-2528 or 800-658-3368

W www.richardewingequipment.com

☞ Al Christianson @ al@richard-ewingequipment.com

Ryco Conveyors E P 1512 E. 17th St. Sioux Falls, SD 57104

☎ 605-610-4026

W www.rycoconveyors.com

☞ Todd Ramsey @ todd@ryco92.com

TENNESSEE

Cates Laundry Equipment E

s 1846 Vanderhorn Dr. Memphis, TN 38134

☎ 800-489-0023

W www.cateslaundry.com @ info@cateslaundry.com

Ideal Chemical C

4025 Air Park St. Memphis, TN 38118

☎ 901-363-7720 or 800-232-6776

W www.idealchemical.com

☞ Sam Block Jr. @ sblock@idealchem.com

Larry & Mike’s E P s O Laundry Services 6376 Winchester Rd. Memphis, TN 38115

☎ 901-546-8151 or 866-328-5173

W www.lmlaundryservices.com

☞ Mike Leake @ laundryservices@comcast.net

Allied Boiler &Supply E P s 419 S. Front St. Murfreesboro, TN 37129

☎ 615-890-6607 or 800-858-0484 W www.alliedboiler.com @ info@alliedboiler.com

FabriClean Supply C O of Tennessee 741 Massman Dr. Nashville, TN 37210

☎ 615-254-5192 or 800-442-7021

W www.fabricleansupply.com

☞ John Holt @ info@fabricleansupply.com

Star Distributing E P s 3729 Charlotte Ave. Nashville, TN 37209

☎ 615-298-5547 or 800-897-7570

W www.stardistributing.com @ info@stardistributing.com

Laundry Systems E P s C of Tennessee 1506 W. Meadow Ct. Sevierville, TN 37862

☎ 888-427-5743 W www.tnlaundry.com @ jeff@laundrysystems.com

TEXAS

FabriClean Supply C O of Amarillo

3412 W. Amarillo Blvd. Amarillo, TX 79106

☎ 806-374-2851 or 800-442-7021

W www.fabricleansupply.com

☞ Gary Mohon @ info@fabricleansupply.com

RAMCO Laundry E P s

Machinery 301 E. Stephens St., Ste. 100 Arlington, TX 76018

☎ 817-640-5100 or 800-878-5578

W www.ramcolaundry.com

☞ Ralph A. McMillan @ sales@ramcolaundry.com

FabriClean Supply C O of Austin/San Antonio

2089 Main St. Buda, TX 78610

☎ 512-295-5550 or 800-442-7021

W www.fabricleansupply.com

☞ Russ Massey @ info@fabricleansupply.com

Alliance Laundry Systems E P s O DistributionSouth Region Dallas Office 631 Southwestern Blvd., Ste. 140 Coppell, TX 75019

☎ 833-288-5700

Wdistribution.alliancelaundry.com/south

☞ Sam Husain @ sam.husain@alliancels.com

Ed Brown Distributors E P s 3236 Irving Blvd. Dallas, TX 75247

☎ 214-352-9494 or 800-929-5520

W www.edbrowndistributors.com

☞ Eric Arthur @ eric@edbrowndistributors.com

FabriClean Supply C O of Dallas

8301 Ambassador Row Dallas, TX 75247

☎ 214-826-4161 or 800-442-7021

W www.fabricleansupply.com

☞ Trevor Hericks @ info@fabricleansupply.com

AAdvantage Laundry P s

Systems

2510 National Dr. Garland, TX 75041

☎ 972-278-2138 or 800-880-2138

W www.aadvantagelaundry.com

☞ Marcela Veloz @ mveloz@aadvantagelaundry.com

Intex Distributing Co. C

1173 109th St. Grand Prairie, TX 75050

☎ 972-660-1900 or 877-649-9904

W www.intexdistco.com

☞ Ben Henke @ intexdallas@intexdistco.com

FabriClean Supply C O of Houston

9770 Wingfoot Houston, TX 77041

☎ 713-864-6373 or 800-442-7021

W www.fabricleansupply.com

☞ Trevor Hericks @ info@fabricleansupply.com

Professional Laundry E P s Solutions

2500 Wilcrest Dr., Ste. 300 Houston, TX 77042

☎ 210-272-9300

W www.prolaundrysolutions.com @ info@prolaundrysolutions.com

Scott Equipment E P s

5612 Mitchelldale Houston, TX 77092

☎ 713-686-7268 or 800-321-7268

W www.scott-equipment.com @ sales@scott-equipment.com

Skyline Equipment LLC E P s

5612A Michelldale St. Houston, TX 77092

☎ 281-445-9907 or 800-444-1227

W www.skylineequipmentco.com @ info@skylineequipmentco.com

Best Wash E P s

15012 Eddie Dr. Humble, TX 77396

☎ 281-441-2465 or 800-456-2378

W www.bestwashinc.com

☞ James West @ sales@bestwashinc.com

Brim Laundry Machinery Co. E P s

302 Nichols Dr. Hutchins, TX 75141

☎ 214-630-4517 or 800-527-5886

W www.brimldry.com @ website@brimldry.com

Intex Distributing Co. C 411 Tradesmens Park Dr. Hutto, TX 78634

☎ 512-474-6075 or 800-322-7131

W www.intexdistco.com

☞ Cliff Fitch

@ cliff.intex@gmail.com

Alliance Laundry Systems E P s O

Distribution -

South Region Houston Office 603 E. Sam Houston Pky. S., Ste. 100 Pasadena, TX 77503

☎ 800-888-0074

Wdistribution.alliancelaundry.com/south

☞ Sam Husain @ sam.husain@alliancels.com

Mustang Enterprises E 1238 W. Laurel San Antonio, TX 78201

☎ 210-734-3644 or 866-734-3644

W www.mustangenterprises.com @ info@mustangenterprises.com

Datamars O 1110 Industrial Blvd. Temple, TX 76504

☎ 254-598-3440

W www.textile-id.com

☞ Kevin Makowski @ kevin.makowski@datamars.com

UTAH

Mendenhall Equipment Co. E P s 880 W. 100 N. North Salt Lake, UT 84054

☎ 801-298-1133 or 800-537-0438 W www.mendenhallcle.com @ sales@mendenhallcle.com

Reliable XeVision P s 4245 Airport Rd. Ogden, UT 84405-3301 ☎ 801-622-7000 W www.xevision.com

☞ Dan Blumel @ dblumel@xevision.com

Reliable Commercial P s Laundry 269 N. Bluff St. St. George, UT 84770 ☎ 435-652-1330 W www.reliablecl.net @ reliablecl@infowest.com

Evans Commercial E P s Laundry Sales 3463 W. 1987 S. Salt Lake City, UT 84104 ☎ 801-972-6580 or 800-433-6859 W www.evanslaundryequipment.com

☞ Aaron Burningham

P

O

16 September 2023 | American Laundry News www.americanlaundrynews.com @AmericanLaundryNews facebook/americanlaundrynews www.americanlaundrynews.com FOLLOW US on Facebook & Twitter Share Our Content Tell Us What’s on Your Mind Distributors Directory 2023

@ aaron@evanslaundry.com

Katzson Brothers E T C P s O

3493 W. 1500 S. Salt Lake City, UT 84104

☎ 801-322-5757 or 877-534-4565

W www.katzson.com @ sales@katzson.com

VERMONT

Big Bill Work Wear T

294 Crawford Rd. Newport, VT 05855

☎ 800-992-6338

W www.bigbill.com @ service@bigbill.com

Foley Distributing C P s O

280 Seward Rd. (P.O. Box 99) Rutland, VT 05702

☎ 802-773-3738 or 800-950-3738

W www.foleydistributing.com @ info@foleydistributing.com

VIRGINIA

Consolidated Laundry E P s Equipment

209 Research Dr., #102 Chesapeake, VA 23320

☎ 800-227-6149

W www.consolidatedlaundry.com @ consolidatedlaundry1@gmail.com

Valley Washers E P O

18 W. Johnson St. Harrisonburg, VA 22803

☎ 540-434-8086 or 800-433-0506

W www.valleywashers.com @ valleywasher@ntelos.net

FabriClean Supply C O of the Mid Atlantic

4311 November Ave. Henrico, VA 23231

☎ 804-232-6703 or 800-442-7021

W www.fabricleansupply.com

☞ Dwayne Gwaltney @ info@fabricleansupply.com

Caldwell & Gregory E 129 Broad St. Rd., Ste. A Manakin-Sabot, VA 23103

☎ 877-784-6100

W www.caldwellandgregory.com @ info@caldwellandgregory.com

Virginia Dry Cleaning E P s O & Laundry Equipment

1565 Oakbridge Dr., Ste. H Powhatan, VA 23139

☎ 804-271-4401 or 800-767-1946

W www.vadrycleaning.com @ sales@vadrycleaning.com

Commercial Laundry E P s Equipment Co.

2507 Jefferson Davis Hwy. Richmond, VA 23234

☎ 804-231-9668 or 800-543-3499

W www.commlaundry.com @ office@commlaundry.com

Richclean C O 2810 Ackley Ave. Richmond, VA 23228

☎ 804-262-7433 or 800-237-5825

W www.richclean.com @ supplies@richclean.com

WASHINGTON

Washington Automated E P s 5801 23rd Dr. West, Ste. 103 Everett, WA 98203

☎ 425-743-7388 or 800-422-0380

W www.washingtonautomated.com

@ sales@washingtonautomated.com

Alliance Laundry Systems E P s

DistributionWest Region Pacific Northwest Office 12910 NE 125th Way B-3 Kirkland, WA 98034

☎ 800-595-0253

W distribution.alliancelaundry.com/west

☞ Courtney Satterlee @ Courtney.Satterlee@alliancels.com

Northwest Laundry Supply P s 624 N. Francher Rd. Spokane Valley, WA 99212

☎ 509-487-4800 or 800-487-4814

W www.northwestlaundrysupply.com

☞ Craig Moore @ craigm@northwestlaundry.com

WEST VIRGINIA

Char-Ann Equipment Co. E P s

2505 Elizabeth Pike Mineral Wells, WV 26150

☎ 304-489-9355 or 800-679-9350 W www.charannequipment.com

☞ Ed Boice @ charann@wirefire.com

WISCONSIN

Herb Fitzgerald Co. E P s O

13150 W. Glendale Ave. Butler, WI 53007-0465

☎ 262-783-5808 or 800-686-3489

W www.herbfitzgerald.com @ info@herbfitzgerald.com

Wausau Chemical C

13137 W. Glendale Ave. Butler, WI 53007

☎ 262-783-4500 or 800-236-2200

W www.wausauchemical.com @ support@wausauchemical.com

Belson Co. E P s C

730 Lambeau St. Green Bay, WI 54307

☎ 920-499-1451

W www.belsonprolaundry.com

☞ Jake Paider @ jpaider@belsonco.com

Commercial Laundry E P s O Sales

1130 Elizabeth St. Green Bay, WI 54302

☎ 920-437-0947 or 800-662-8356

W www.claundrysales.com

☞ Wayne Kuhn @ sales@claundrysales.com

The Minnesota E C P s O

Chemical Co.

N57W13250 Carmen Ave., Unit 4

Menomonee Falls, WI 53051

☎ 262-781-8630 or 800-328-5689

W www.minnesotachemical.com

☞ Dan Baker @ dan.baker@minnesotachemical.com

Badger Laundry Machinery E P s

3680 S. 60th St. Milwaukee, WI 53220

☎ 414-321-3636

W www.badgerlaundrymachinery.com

☞ Brad Brown @ badgerlaundry@gmail.com

Laundry Systems E P s C of Wisconsin

7276 Commerce Plaza Dr., Unit B Neenah, WI 54956

☎ 920-383-8200

W www.wisconsinlaundrysystems..com @ seth@laundrysystems.com

Haiges Machinery E P s 131 E. Wisconsin Ave. Pewaukee, WI 53072

☎ 800-542-2828

W www.haigesmachinery.com @ info@haigesmachinery.com

Wausau Chemical C 9919 Inovation Way Wausau, WI 54403 ☎ 715-842-2285 or 800-950-6656

W www.wausauchemical.com @ support@wausauchemical.com

Montequin Distributors E Calle 13 S.O. #903 Caparra, PR 00921 ☎ 787-781-6390 W www.montequin.com ☞ Felix Montequin @ office@montequin.com Universal Equipment E Sales & Service Corp. 1405 Ave. Fernandez San Juan, PR 00909 ☎ 787-724-2448 W www.universalequipmentpr.com @ info@universalequipmentpr.com 17 American Laundry News | September 2023 www.americanlaundrynews.com MISSED GETTING YOUR COMPANY LISTED? E-mail Digital Media Director Nathan Frerichs (nfrerichs@ atmags.com) to learn how your distributorship can be added to our free online Distributors Directory at AmericanLaundryNews. com and to next year’s print edition! -Laundry Wrappers ▪ Parts ▪ Wrap Wrap! Seal! Protect! Minimize Contamination and Loss Simplify Content Identification Enhance Appearance and Delivery Presentation Fully wrapped and sealed bundles... Keep Finished Laundry Clean and Protected Davis Wrapper Exclusives: Burn Guard, Height Adjust, Thermostat Guard, Easy Loading, Great Service! NEED PARTS? Davis, Felrap, HeatSeal in Stock! ALN_JR 3rd Page.indd 1 8/2/23 8:55 AM 092722 KE 4.75x4.75 JR_OL.pdf 1 9/28/22 11:16 AM Distributors Directory 2023

PUERTO RICO

Track Career

1Concier appoints Smith CEO

FORT LAUDERDALE, Fla.—1Concier, a provider of linen products formed through the merger of Riegel Linen, T-Y Group, and Harbor Linen, reports that Tony R. Smith has been appointed the company’s chief executive officer.

Smith succeeds outgoing CEO Chris Nelson, who has decided to step down to focus on his family.

Nelson was responsible for leading the integration of Riegel Linen, T-Y Group and Harbor Linen and rebranding them into 1Concier.

“Tony is a seasoned leader with an outstanding track record of accomplishments and success,” says Travis Dziubla, principal at Lion Equity Partners.

“With over 30 years of experience in the bedding and durable goods industry, he has held senior executive positions at Sealy Corporation, International Bedding Corporation, Simmons Bedding, and Serta Simmons Bedding, including CEO, COO and president.”

Smith comes to 1Concier from MITY Incorporated where he served as its CEO for the last four years. MITY Incorporated is a global supplier of furniture, fixtures, and mobility products serving many markets, including hospitality, senior living, restaurant and e-commerce.

“As we enter this new chapter, my vision for our company is to embrace transparency, collaboration, and accountability as the cornerstones of our culture,” Smith says. “By doing so, we aim to attract top talent, exceed customer expectations and foster sustainable growth.