Evaluating laundry automation opportunities

BY MATT POE, EDITOR

The laundry and linen services industry has been automating its processes for many years.

But with recent labor challenges and a renewed focus on quality and profitability, many operators are taking a closer look into automation options to decrease the cost of manpower and increase quality and earnings.

Harbor Results Inc., a manufacturing industry advisor, did research for the Association for Linen Management’s

(ALM) LaundryMarks benchmarking program and found some interesting details when it comes to automation.

First, automation alone will not drive profitability. In theory, automation in the finishing area will drive profitability sooner than automation in the soiled area.

Second, automation must correlate with business size. If a $10 million business and a $50 million business have the same level of automation, the $10 million laundry will likely be more profitable.

So then, how can a laundry best evaluate its automation needs and requirements, select the right vendors and equipment, and maintain operations and quality during a build or upgrade?

American Laundry News communicated with four industry insiders (three laundry operators and a consultant) to help with the automation process.

EVALUATION

For Curtis Nichols, general manager of HandCraft Linen Services in Richmond, Virginia, important factors to be considered when evaluating a laundry operation for new or updated automation include floor space, scalability and return on investment (ROI).

Other elements to consider include the quality of work, cost of maintenance and integration with existing processes.

“It’s really just a matter of applying math and simulating the process as best you can,” Nichols points out. “How many pounds or pieces do we need to do in a shift? What equipment is required to do it the labor-intensive (hard) way? What equipment is needed and what is the added upfront cost to do it the automated way? How much time and money is saved every shift doing it the automated way?

“Run the numbers and decide whether

the ROI is worth it or not. Of course, there are other factors to consider like employee morale, but the simple math is the best place to start.”

Gerard O’Neill, president/CEO/owner of American Laundry Systems, a laundry consulting business in Derry, New Hampshire, offers the following list:

1. Cost.

2. ROI.

3. Support.

4. Internal capabilities. Are you and or your staff capable of operating or using this equipment as it is intended and/or to its full potential?

5. Maintenance cost increases. The more automation, the more maintenance needs to be done.

6. Maintenance capabilities. Does your maintenance department have the necessary skills to properly maintain this level of automation?

7. Backup plan. What is the plan for when this breaks and you can’t get parts for a month or more?

“Have a grasp of your own time and motion studies and concepts,” says Patrick Garcia, president of Division Laundry & Cleaners in San Antonio. “Then bring in a third party (equipment manufacturer or consultant) to draw out a new configuration of a layout to discuss available space and benefits.

“Benefits would be lowering production hours and a more productive workflow. Also improving safety in work areas with high frequency of injuries could be a benefit.”

Regarding an existing facility, Garcia says if the objective is to improve the efficiency of soil sorting, then a discussion should take place regarding the steel

Aramark Board approves spin-off of Vestis™

PHILADELPHIA — Aramark, a provider of food, facilities management, and uniforms, reports that its Board of Directors approved the previously announced tax-free spin-off transaction of its uniforms and workplace supplies business, which will be named Vestis.

The spin-off is expected to be completed on Sept. 30 and will be effected through a pro rata distribution of the common stock of Vestis Corp.

“Our new name, Vestis, connects us to our purpose as an organization—deliver uniforms and supplies that empower people to do good work and good things for others while at work,” says Kim Scott, president and CEO of Aramark Uniform Services and appointed CEO of Vestis.

The name for the spin-off was chosen because “vestis” is the Latin word for garments and clothing and is the foundation of the words “to dress” in several languages. The name captures the uniform rental services business offering.

It also has a deeper meaning when it is used in the Latin phrase “vestis virum facit” or “clothes make the person.” Vestis will use the descriptor, “Uniforms and Workplace Supplies,” to describe the full breadth of its offering.

The Newspaper of Record for Laundry & Linen Management October 2023 • Volume 49, Number 10 www.americanlaundrynews.com

Four industry insiders share insights into evaluating, planning for and increasing automation while maintaining quality

(Image licensed by Ingram Image)

See Automation on Page 6 LATE NEWS

ImageFIRST expands in Nevada, New York

Healthcare, hospitality linen services provider acquires two more operations

KING OF PRUSSIA, Pa. —

ImageFIRST®, a national provider of linen, laundry, and safety and hygiene services to the healthcare sector, with a hospitality division serving select markets, reports it has completed its acquisition of Nevada Linen Supply and Ames Linen.

Terms of the transactions were not disclosed.

Nevada Linen Supply was founded in 1986 and provides laundry and linen, uniforms, and various other rental textiles to healthcare, hospitality, food and beverage, and special event services customers.

The company serves the greater Las Vegas and surrounding areas, such as Pahrump and Boulder City.

“When I decided to sell, I was adamant in locating an organization that shares my company’s culture relating to customers and associates, and ImageFIRST more than achieved this goal,” says founder and former owner Steve Stith Sr.

“I have no doubt that this combination will strengthen the organization and add value to our associates and customers.”

This transaction enables ImageFIRST to expand its service area in Nevada, creating more job opportunities in the region, the company says.

Existing customers of Nevada Linen Supply will now be serviced by ImageFIRST, and existing associates will be retained.

“This process was a strategic acquisition and we’re enthusiastic about bringing this extraor-

dinary company and their team into the ImageFIRST family,” says ImageFIRST President and CEO Jim Cashman.

“The way that we service our customers are very similar and this will guarantee a seamless integration into ImageFIRST.”

Ames Linen, founded in 1921, provides rental and laundry services for hospitality, food and beverage, and healthcare businesses throughout Upstate New York, serving several major markets such as Syracuse, Binghamton, Ithaca, and Utica—as well as the surrounding areas throughout the Finger Lakes region.

The company is based in

Cortland.

“I could not think of a better fit for Ames Linen,” says Johanna Ames. “As we’ve been familyowned and operated for four generations, we wanted to continue with the same emphasis on community and relationships, making ImageFIRST an ideal choice.”

This transaction enables ImageFIRST to expand its service area in New York and Pennsylvania, creating more job opportunities in these regions.

Existing customers of Ames Linen will now be serviced by ImageFIRST, and existing associates will be retained as a part of ImageFIRST.

“We’re enthusiastic about bringing this extraordinary company and their team into the ImageFIRST family,” says Cashman.

“Our companies both share a dedication to our customers and our associates, which will inevitably lead to a successful integration into ImageFIRST.”

This expansion has led to ImageFIRST becoming the largest national linen and laundry provider specializing in the healthcare industry, according to the company.

Recent acquisitions include Island Fox Inc. dba Health Ware of WNY and United Linen & Uniform Services (Oklahoma).

President Charles Thompson

Publisher

Donald Feinstein

Phone: 312-361-1682

E-Mail: dfeinstein@ ATMags.com

Editorial Director Bruce Beggs

Phone: 312-361-1683

E-Mail: bbeggs@ ATMags.com

Editor Matt Poe

Phone: 866-942-5694

E-Mail: mpoe@ ATMags.com

Production Manager Mathew Pawlak

Digital Media Director Nathan Frerichs

Phone: 312-361-1681

E-Mail: nfrerichs@ ATMags.com

Advisory Board David Barbe

Janice Ayers Davis • Nick Fertig

Deana Griffin • Cecil Lee

Edward McCauley

Jim Slatcher

Main Phone: 312-361-1700

Fax: 312-361-1685

Subscriptions 847-504-8175 ALN@Omeda.com

www.americanlaundrynews.com

2

(Photo: ImageFIRST)

October 2023 | American Laundry News www.americanlaundrynews.com MEMBERSHIPS American Laundry News (ISSN 1091-9201) is published monthly. Subscription prices, payment in advance: U.S. 1 year $50.00; 2 years $100.00. Single copies: U.S. $10.00. Published by American Trade Magazines LLC, 650 West Lake Street, Suite 320, Chicago, IL 60661. Periodicals postage paid at Chicago, IL, and at additional mailing offices. POSTMASTER, Send changes of address and form 3579 to American Laundry News Subscription Dept., 125 Schelter Rd., #350, Lincolnshire, IL 60069-3666. Volume 49, number 10. Editorial, executive and advertising offices are at 650 West Lake Street, Suite 320, Chicago, IL 60661. Charles Thompson, President and Publisher. American Laundry News is distributed selectively to qualified laundry and linen management and distributors in the United States. © Copyright AMERICAN TRADE MAGAZINES LLC, 2023. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Laundry News does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Laundry News or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

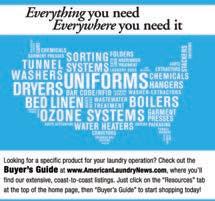

01 Evaluating Automation Opportunities Four industry insiders share insights into increasing automation while maintaining quality 04 It’s Up to the Coach to Improve the Player Columnist-at-Large David Griggs notes the similarities between laundry managers and football coaches 10 Vendor Relationships in Di cult Times It’s important for laundry operations to have both cordial and strategic associations with suppliers these days 12 Fostering Involvement, Engagement in New Team Members In this issue, the Panel of Experts examine ways for new hires to be taken seriously and grow in the industry 14 Built on Research, Challenge, Teamwork A er achieving success in B2B technology, information, Premier Linen Services’ founder shi s gears and discovers the laundry industry 17 UniFirst Celebrates Grand Opening Ribbon cutting, tours and lunch mark opening of 60,000-square-foot Minneapolis plant 18 Moving from Open-Pocket Washers to a Tunnel Insights into the timing and bene ts of moving from washer-extractors to a continuous batch washing system 19 Classified Advertising 20 Source Directory 23 Trade Ticker 23 Calendar of Events INSIDE:

Milnor has a better solution through dilution.

When Milnor introduced PulseFlow® technology, CBW® washing was thrust into the future. The idea of balancing time, temperature, mechanical action and chemistry was missing one critical piece of the pie – DILUTION through the efficient use of water.

PulseFlow combines the innovative RecircONE® fast wet down and chemical immersion in the first module with standing bath washing in every spacious process module. Thorough and efficient dilution occurs by way of intermittent high velocity counterflow rinsing and traditional True Top Transfer.

The result is hygienically clean linen using less water (as low as 0.3 gallons per pound/2.5 liters per kilogram) and less energy as proven time and again by hundreds of PulseFlow tunnels in a variety of laundry applications worldwide.

Contact an authorized Milnor distributor or call 504-712-7656 to find out more.

www.milnor.com

*PulseFlow®, CBW® and RecircONE® are Pellerin Milnor’s registered trademarks.

Automatic update

I’ve been writing about industrial laundry automation since I pulled up to the keyboard here.

And automated equipment was available in the industry well before that.

However, over the past few years, I’ve felt and heard and change in operators I communicate with. There’s a bit more intensity when it comes to automation.

In the September Your Views survey, 90% of respondents say their operations have seriously considered automation in the past five years.

Why? Labor issues. The need to save money, improve efficiency. Finding workers is still challenging and doing business costs more these days.

That’s why the cover story in this issue looks at evaluating adding/upgrading automation. Operators need to be mindful because simply adding automation isn’t a guaranteed time and money saver.

The decision needs to be made wisely, deliberately,

and that’s what our four insiders offer.

Then on page 18, Brennan Pollnow of Girbau Industrial shares his thoughts on the timing and benefits of moving from open-pocket washers to a tunnel.

However, no matter how automated laundry operations become, they will still need employees.

And employees aren’t machines; they are people, and people need maintenance—care and concern—just as much as equipment.

Maybe more. That’s why on page 12, the Panel of Experts shares ways to make new hires feel they are taken seriously while helping them grow in the industry.

There are also articles on relationships with vendors (page 10) and a profile of a laundry in Florida that started up in December 2019.

These pieces and more are in this issue, all to help everybody keep it clean!

City Uniforms and Linen acquires Knox Textiles

Uniform, linen products provider adds Ohio-based clothing rental, janitorial service

FINDLAY, Ohio — City Uniforms and Linen, a uniform and linen products provider based here, reports that it has acquired Knox Textiles.

“We are grateful for the opportunity to partner with Knox,” says Rich Kramer, president of City Uniforms and Linen.

“The Knox Brothers have a wonderful legacy in the laundry industry and we intend to honor that.”

Knox Textiles, located in Edgerton, Ohio, has been providing clothing rental services and janitorial products to Ohio, Northeast Indiana and Southern Michigan since 1936.

The company says that with this acquisition, it aims to capitalize on the unique strengths of both businesses, fostering a collaborative and innovative work environment.

To create a seamless customer experience during the transition, City Uniforms has brought on two Knox employees and will be providing its customers the same services/rental programs that they received while being Knox Textiles customers.

It’s up to the coach to improve the player

It is time for another football season.

I am not an avid football fan, but I do enjoy attending college football games. My wife and I attend several home games at our local university each year.

They are certainly not a football powerhouse, but I enjoy the atmosphere.

I spend most of my time at the game watching the coaches and the sidelines in general. You can tell the difference between the teams just based on the sidelines.

The good teams are organized, and every player or support personnel knows exactly what to do. There is no chaos going on no matter what the situation on the field.

Bad teams are unorganized with players running on or off the field late and you can generally see that everyone seems a little confused as to what to do from minute to minute.

Football coaches and laundry managers have very similar jobs. No matter what the game plan is, it can change in an instant.

A good player on the team gets hurt, and the whole game plan changes. A good laundry employee leaves your organization, and it can change the whole process.

Instead of two employees feeding the sheet ironer, it may take three now without that superstar in your ranks.

A football team gets a penalty, and it sets them back. The coaches must change their game plan to get them back where they expected to be.

A laundry machine breaks down, and it sets you back on your throughput. You must change your game plan to get to where you need to be.

FOOTBALL COACHES AND LAUNDRY MANAGERS HAVE VERY SIMILAR JOBS. NO MATTER WHAT THE GAME PLAN IS, IT CAN CHANGE IN AN INSTANT.

Really good coaches handle the issues well. They know how to make the change from “This is what we want to do” to “This is what we have to do.”

No game or day in the laundry finishes the way it was planned at the beginning of the day.

Good football coaches are good leaders, and they usually write books on their philosophies.

I read quite of few of these books by coaches who I am really impressed with. I pick up little nuggets of advice from everyone that I have read.

“With Milo and Chris staying on our team, our customers can expect the same exceptional service with a team they are used to working with,” shares Kramer.

“As a locally owned and family-operated business, City Uniforms puts customers and community first.”

My favorite coach wrote one of these books, and I try to re-read it every year. One of the stories he tells in his book is about a position coach that he had working for him.

This coach complained about every player he assigned to him. This player is too tall, this player is too short, I was hoping for a faster player, this player can’t tackle, etc.

The head coach finally told him, “Hey, this is your player, your job is to make this player successful in helping our team be successful. If you must change your system a little to fit better with this player, then do it, or you need to coach him up to fit what you expect.”

I can’t tell you how many meetings I have been in over the years that I hear this story playing in my head, especially when we are talking about maintenance.

This applicant doesn’t have enough electrical experience; this one doesn’t have enough plumbing experience. This one doesn’t have any experience in maintenance; this applicant has a ton of experience but has had too many jobs.

From AmericanDrycleaner.com:

• Tide Cleaners Opens Four Drycleaning Stores in Charlotte

• How Can Dry Cleaners Connect with Gen Z?

From AmericanCoinOp.com:

• Making the Unattended Laundromat Business Model ...

• Energy Efficiency: Getting the Most from a Store’s Utilities

I hear this about applicants in other departments as well. Every manager has in their mind what employee they are looking for, but rarely one walks through the door being exactly what they are looking for.

I know I have evolved into the manager who just has two main rules: if you show up every day and don’t lie to me, I will figure out what you can do to help the organization.

I work with folks every day who are rock stars in our organiza-

See Column on Page 17

4 October 2023 | American Laundry News www.americanlaundrynews.com

From The Editor’s Desk

Top Stories Appearing on americanlaundrynews.com for the 30 Days Ending Sept. 15. NEWS • Aramark Announces Board of Directors for Uniform Services ... • ImageFIRST Expands in Nevada, New York • Honda’s Recycled Cintas Uniforms in New Vehicles WE • Intermountain Health Says Upgrades Save Millions of ... WE • Prudential Constructs First Solar Project at Cleanroom Laundry WE COLUMNISTS/FEATURES • Staffing Success Stories • Study Finds Employers Should Allow Workers to Break the Rules ... WE • Laundry Operation Security Risk Assessment • Richard Engler: Increasing the Laundry Employee Candidate Pool • Improving Laundry Customer Retention

OUR SISTER WEBSITES

COLUMNIST AT LARGE David Griggs

MATT POE

(WE) = WEB EXCLUSIVE

(Photo: City Uniform and Linen)

45 Gram 16” x 16” Microfiber CLOTHS Just 30 ¢ Yup. Believe It! NEW POP SALE OPPORTUNITY 16” x 16” 45 Gram 16” x 16” 35 Gram 30 ¢ 25 ¢ FOODSERVICE AUTOMOTIVE HEALTHCARE OFFICE & RETAIL EDUCATION facilitIES Profit from the best of both worlds. New 16” x 16” seamless microfiber cloths increase truck routes POP sales and hold up to the rigors of the commercial laundry wash-cycle! MOQs apply. 16” x 16” SmartRags are now available. Call (215) 461-3720 or visit monarchbrands.com

Automation

Continued from Page 1

structure.

“It would be prudent to hire a company that specializes in coming in to torque all the bolts in the entire structure, especially in the area where the sling system will be installed,” he says.

Then a structural engineer should be hired to come do the math calculations regarding the goal. What is the brand of system to be installed with specs and weights?

“It is almost imminent that the structure will need support, and you should be prepared to reinforce the steel structure and you would do the same thing on the clean side of the plant if you have intentions to install a sling system there as well,” says Garcia.

Regarding the finishing side, which he says would entail small-piece folding and the flatwork, examine the current layout to look at how the operation would perhaps rearrange the equipment in place and possibly add equipment.

“The next important step in preparing for more automation would be how to deliver the products that are discharged from the folding equipment,” says Garcia.

“This will give an opportunity to redo the layout and where you utilize conveyors and re-distribute the products coming out of all the folding equipment to a centralized packaging area.”

Mario Stagliano, managing partner of Arway Linen & Uniform Rental Service in Philadelphia, which is in the process of building a new plant, says his first question is, “Can I do more with less? Meaning, will this allow me to increase volume with less hands, ultimately?

“The analogy is, I’m going to run two tunnel washers with one person versus 11 conventional washers with six or seven people. I’ll be able to wash double the amount of volume in the same eight-hour

shift as I do with my conventionals.

“That’s ultimately how we are. Evaluating what makes sense for us. More with less.”

Stagliano says that on the food and beverage side, there are many different calculations used to help understand the financial picture.

“A lot of people use pounds per operator hour revenues, per pound, that kind of thing,” he says. “These pieces of equipment are insanely expensive, and there’s not many small independent laundries that can write a half-million dollar or a million-dollar check for a new piece of

“IN THE EVENT WE FINANCE OUR EQUIPMENT, WE SAY, WHAT’S THIS GOING TO COST US PER MONTH, BASED ON THE FINANCING TERMS WE’RE GOING TO GET? WILL THIS INCREASE OUR POUNDS PER OPERATOR HOUR, AND IF SO, WHAT’S OUR NEW MARGIN VERSUS THE OLD MARGIN?”

equipment.

“So, in the event we finance our equipment, we say, what’s this going to cost us per month, based on the financing terms we’re going to get? Will this increase our pounds per operator hour, and if so, what’s our new margin versus the old margin?

“I think to answer the question specific to ROI is a calculation of will it increase pounds per operator hour and, in turn, will it increase your throughput so maybe you can absorb some more volume because of it?”

AREAS FOR AUTOMATION TODAY

So, what areas of laundry operations are “most popular” and gaining industry interest for automation these days?

“After a piece is sorted in soil, getting it washed, dried and to the feeder—as long as the laundry is willing to make the investment, the available equipment makes it easy to automate this process,” says Nichols.

“Laundries are recognizing the cost savings and reduction in physical labor. It’s an easy choice. I would say garment sortation systems have come a long way, and linen pack-out systems are gaining momentum and improving, specifically in the nonacute space.”

O’Neill says that laundries are automating many areas of their operations, including material handling (soil side and clean side), garment sortation, washrooms, automated garment finishing and automated linen finishing, route makeup, and stockrooms.

“Because in order of the above, these are the best bang for the buck with the best return on investment,” he shares.

“Soil sort automation is now becoming more popular as vendors work out the ‘kinks.’ We are not quite there, yet, but I can see a ‘hands-free’ laundry in the notso-distant future.”

“I believe automation of your linen distribution routing to your packaging department is most popular, especially

if you have a COG (customer-owned goods) plant with a mix of rental,” Garcia observes.

He says that folded and stacked linen bundles are best routed off production equipment to a centralized conveyor line long enough to capture fluff-dried and ironed linen bundles to be able to capture a large COG account’s product to get all the products at the same time every day.

“It has to work like a clockwork,” Garcia points out. “For rental, you route all your loaded carts to a staging/shipping area with dedicated staff building individual account orders.

“Maintaining an efficient flow is highly important as you can streamline your operations.”

Speaking from the food and beverage side of laundry, Stagliano says that possibly in a few years the industry will see automatic napkin feeding.

“Napkins are our biggest rented item,” he points out. “When you look at, per piece, what we rent on a weekly basis right now, we do a million pieces a week and more than half of that is napkins, that’s your biggest labor item.

“We touch a napkin 11, 12 times before it gets out the door. So, if you can figure out how to automate getting a napkin out the door, that’s the next automated area where we really see an ROI from.”

VENDOR PARTNER SELECTION

Key to adding new automation or upgrading equipment is for an operator to work with the right vendor/supplier partner or partners.

“I would choose partners that have experience in the laundry industry,” says Nichols. “That said, I think it’s also good to look ‘outside’ the industry for ideas as well.

“As far as selecting a vendor, I think it’s important to visit other projects they have completed and do your due diligence.”

6 October 2023 | American Laundry News www.americanlaundrynews.com

(Image

See Automation on Page 8

licensed by Ingram Image)

(Image licensed by Ingram Image)

FROM COLLARSAND CUFFS

TO THE REALLY TOUGH STUFF... FROM COLLARSAND CUFFS

When dealing with laundry stains, your reputation rides on getting the outstanding results The Laundry Two deliver. RiteGo® laundry spray spotter quickly penetrates to absorb collar & cuff stains, perspiration, ground-in soil and more, all without brushing. Turn to Laundry TarGo® to remove any tough oil based stains that remain behind. Use The Laundry Two with confidence on shirts, wedding gowns... anything you're washing or wetcleaning.

™

Both Laundry TarGo and RiteGo are chlorinated-solvent free, biodegradable, noncombustible and California 2013 VOC and Prop-65 compliant.

Use them to deliver stain-free laundry and wetcleaning. You'll build your reputation for quality - which is what keeps customers coming back.

THE LAUNDRY T WO

ARE RIGHT FOR YOU!

THE LAUNDRY T WO

ARE RIGHT FOR YOU!

To learn more, visit ALWilson.com or call 800-526-1188 A. L. WILSON CHEMICAL CO. Become a STAIN WIZARD at ALWilson.com

™

TO THE REALLY TOUGH STUFF...

Automation

Continued from Page 6

O’Neill says it’s important for laundry to “do its homework” when it comes to vendors.

“Hire a professional who can write the specs and develop an RFP (request for proposal) so that you can evaluate all the vendors that can supply this equipment,” he says. “Check the service capabilities, including spare parts and service techs.

“Do a SWOT analysis (strengths, weaknesses, opportunities, threats) or similar type of analysis and stay neutral, keeping opinions out of your analysis.”

Garcia recommends making use of all the tools available to laundry operators for choosing vendors, including by word of mouth, visiting other laundries, going to The Clean Show, reading laundry periodicals and reaching out to organized laundry associations.

“There are a lot of companies out there, so it’s just the service and the support that you’re going to get while you’re getting open,” Stagliano says.

“I think it’s mostly the support that we feel like we’ll get on our level and with the amount of money that we’re spending.

“I think maybe a JENSEN or a Kannegiesser can, maybe one or two other companies, are companies that can do a complete laundry and that are the farthest ahead with automation.”

OVERLOOKED FACTORS

Unfortunately, automating laundry operations sometimes isn’t as smooth or easy as it sounds. Sometimes unconsidered factors make processes more difficult.

“I think sometimes laundries assume automating a process will make things easier, but that’s not always the case,” Nichols points out. “There are some processes that are better, and more cost-effective, done by hand.

“Additionally, I think it’s important not to overcomplicate it. Apply the appropriate

amount of automation. Too much automation can work against you.

“We’ve made that mistake before and have been careful since then to not overthink it.”

O’Neill uses the analogy of buying a brand-new Formula 1 race car for a laundry when management and staff have been used to driving, operating and maintaining a pickup truck.

“Do you know how to drive this new racecar to the best of its capabilities, and can you maintain it enough so that it is on the racetrack and not in the shop waiting to be fixed?” he asks.

“In other words, learn how to use this machine and maintain it or don’t bother buying it. What’s the point of owning an F1 racecar if you only drive it at 60 mph like your pickup truck?”

“I THINK SOMETIMES LAUNDRIES ASSUME AUTOMATING A PROCESS WILL MAKE THINGS EASIER, BUT THAT’S NOT ALWAYS THE CASE. THERE ARE SOME PROCESSES THAT ARE BETTER, AND MORE COST-EFFECTIVE, DONE BY HAND. ADDITIONALLY, I THINK IT’S IMPORTANT NOT TO OVERCOMPLICATE IT. APPLY THE APPROPRIATE AMOUNT OF AUTOMATION.”

Garcia says it’s crucial to have a qualified maintenance staff to sustain the maximum efficiencies of the new automation in the new equipment. Sometimes operations don’t ensure that staff is in place.

Also, some laundries haven’t ensured ample space to avoid overcrowding everything into a confined space, jeopardizing access to maintain each piece of equipment.

“I talked to a laundry owner up in Rhode Island, and when he moved his plant, he said, ‘Hey, I went and I tried to automate as much as I can and I didn’t see as much of a return as I thought,’” Stagliano shares.

“I said, ‘Did you come from tunnel washers? Did you come from a rail system? Did you already have these things in place that I don’t?’ He said they had all that. Maybe the ROI on that additional automation that you invested in was not going to give you what you need because you were already kind of halfway there with what’s available in the industry for us.”

In his plant, Stagliano says they didn’t realize how big soil sort automation would be.

“Right now, I have 19 people sorting, and we figured we’re going to have additional space and we’ll have a little more updated of a soil sort system,” he shares. “But the way it’s been designed with what they knew they had available, I can sort the same volume with eight people as I can now with 19.

“Food and beverage specific, I think we initially overlooked the power of a solid sorting system to really reduce full-time employees (FTE). That saves you money.”

Stagliano also says it’s important to not overlook the flow of the operation when planning.

“You can’t overlook the flow of the product because that can set you back,” he says. “I wouldn’t maybe put that in the automation category, but flow is really big.”

MAINTAINING QUALITY, SERVICE

Once the evaluations and selections are complete, it’s time for a laundry to upgrade equipment on site or create a new operation at a different location.

Still, during the upgrade and changeover, goods must be processed and current customers satisfied.

“Pretty much all of the automation we’ve implemented has been a new buildout,” shares Nichols. “I would say careful planning and leadership would be the keys to adding automation to a plant while it is operational.”

Options O’Neill suggests include buying new inventory of stock so that customers can be served while the equipment is not available or not working yet, extending working hours, or outsourcing temporarily.

“Find a hole—really—find a place or make space or build an extension to house the equipment that is being installed so that there’s as little impact on production as possible,” he says.

Garcia recommends getting a memo of understanding from all vendors that they will have to work after the plant has completed production.

“That means after hours,” he says. “You can’t compromise your employees’ safety at any time. You need all oars in the water during your normal operations so you’re not sacrificing quality and service.”

Stagliano says his company will be operating at its current plant until the new operation is set.

“Until we transition in, one of the things during our syncing process, when all this new equipment is up and running, it’s trial and error,” he says.

“Just because we have a plan for when all this equipment arrives and we plug it in and say we designed this with the intention of it going this way, maybe it’s not going that way and we have to figure something out on the fly. I think all those things will affect quality.

“It takes an army. We have consultants. We have manufacturers. We have chemical companies. We have our entire team. Everybody’s going to have to lend a hand to make sure this thing goes as smooth as possible.

“When I say smooth, I don’t just mean the equipment brought in reducing FTEs, we want to have a better-quality product than we do now.

“I think it’s just going to take that army of people to work together, to get our heads together and make sure that we are where we need to be.”

8 October 2023 | American Laundry News www.americanlaundrynews.com

(Image licensed by Ingram Image)

(Image licensed by Ingram Image)

The Power of Three

Leave behind the limitations of manual handling and embrace the power of automation with DR Series Feeders. Our advanced technology ensures precise large and small piece feeding — eliminating the risk of jams or misfeeds, reducing rework and saving valuable time. DR Feeders seamlessly integrate with any ironer in the market. Pair it with a PC Series Ironer and FR Series Folder and you’ve got the ultimate powerhouse. Together, they’ll take your laundry to a new level in productivity, programmability, versatility and quality.

Join the ranks of smart, e cient laundry operators who have upgraded their laundry game with Girbau Industrial.

Industry-Leading Warranties Flexible Financing Options Processing Versatility

INDUSTRIAL

girbauindustrial.com • 800-256-1073

PC Ironers

DR Feeders

FR Folders

Vendor relationships in difficult times

BY JEFF LANDRY

BY JEFF LANDRY

The last three years have been ones of trauma and turbulence in which global supply chains went from an unprecedented stoppage of production to a massive production increase in the face of unbelievable demand in a short period.

Understandably, your relationships with your favorite vendors were stretched to the limit. Their inability to deliver products at the old cost became impossible.

The laundry industry had been in a state of unvarying cost. Since the economic crash of 2008 and the cotton crisis of 2011, the cost of the products has been very steady.

Most vendors proposed and implement-

ed very few cost increases over that period. Gains in efficiency and minor price adjustments were enough to accommodate the low inflation rate and the steady cotton prices, making it a very passive environment for vendors not to have difficult discussions about availability or price.

The world enjoyed nine years of very dependable supply chains. Factories could schedule out production, secure an adequate supply of raw materials and be guaranteed very reliable freight—over the ocean and on land.

The steady world we lived in all came crashing down with the COVID-19 pandemic, highly impacting 2020 to 2022.

Laundries started having to cancel orders and return products with an unknown future. These were difficult conversations.

10 October 2023 | American Laundry News www.americanlaundrynews.com

Author says it’s important to have both cordial and strategic associations with suppliers these days

(Images licensed by Ingram Image)

The boomerang impact late in 2021 and through 2022 caused the reverse. There were no inventories, no goods on the water, no cotton in spinning and no yarns on the loom.

Factories had also pushed back on their vendors the purchasing of chemicals and other supplies needed to make products.

There also came along a oncein-a-generation need for medical supplies: isolation gowns, scrubs, etc. These products were nowhere to be found and took some specialized manufacturing to produce, taking away resources from other products.

It is at this point that having not only a cordial relationship with your vendor base is important but also a strategic relationship.

There is a level of trust that was enacted when the vendor sales rep showed up at the door with price increases and inventory shortages.

Were you able to sit down and receive accurate, factual data on the direct causes of these increases and how long they would last? Would the product be available? At what price?

How did that go?

The successful strategic alliances relied on long-term relationships—those that, over time, had cultivated a level of trust on both sides to help ride out the storm.

If you did not have this, you found yourself in a sea of many vendors that may or may not be able to execute a plan to keep your business running. It was not a time to start testing new relationships.

Communication with trust became a must. You had to have open communication with a trusted source, one where the information on product availability and cost were upfront, accurate and you could communicate down to your customer base with accuracy.

The ability to work with a supplier to come up with creative solutions was also key. Were you able to have a paradigm shift away from products you thought were irreplaceable to alternate products that were similar and available? Could you use a nostripe bar mop vs. a yellow stripe?

Having product is the most important thing to keep the plant and business running. With no product there is no business.

These problem-solving ideas could only occur in an open communication relationship that focuses on a strategic alliance between the supplier and yourself.

These uncertain times also generate the temptation to move your business and try new vendors that have been knocking on your door for years. Maybe they would have the secret sauce to deliver products that were not readily available.

This did work in some situations and pointed out the need

to diversify some of your supply chain needs, but those could be short-lived.

You needed to rely on your long-term relationships to guarantee future supply. They had a forecast and a plan to deliver, but some secondary suppliers did not.

It was essential to fully understand the constraints of conducting regular business. These constraints impacted all suppliers equally.

The shortage of raw materials, chemicals, production capacity and transportation were not unique to one supplier. It affect-

ed all of them.

The world we live in has permanently changed. There are inflationary cost increases that have been enacted that will not be reversed.

It will imperative that your future vendor relationships be strategic. The keys to success with your suppliers should include:

•Open communication, regularly.

•Forecast planning.

•Inventory visibility.

•Supply chain and cost updates.

•Innovative and alternate product solutions.

•Creative ideas to purchase better, packaging and delivery methods.

Remember that the way you handle difficult times with your vendors can have a lasting impact on your relationship beyond the immediate crisis.

By working together, being understanding and finding mutually beneficial solutions, you can emerge from challenging situations with even stronger vendor relationships.

There may not be another

worldwide crisis soon, but there continue to be other threats to business locally and regionally.

Shortages of labor and some raw material could cause smaller, but still impactful, delays to delivery.

Be vigilant. Be strategic. Be aware.

Jeff Landry is executive director of CSCNetwork in Franklin, Tennessee, which offers both purchasing power and advanced training to independently owned and operated industrial and linen rental companies.

11

American Laundry News | October 2023 www.americanlaundrynews.com ALN_Jr Page.indd 1 6/2/23 10:28 AM

PANEL of EXPERTS

Fostering involvement, engagement in new

the business are just some of the ways to accomplish this.

Ultimately someone being taken seriously at work and growing in the industry is a two-way street. They must want to get there, and we, in turn, need to show them that we are sincerely there to help show them the way.

Our industry is unique. On the one hand, there is a ton of opportunity for anyone willing to come in and learn. It is not overly complex, which allows people to become experts in many different areas.

However, it is also not the most glamorous, and although extremely important, it is not something the average person thinks about daily.

With that said, with anyone who is a new hire, and especially those coming from outside the industry, it is important to take a very strategic approach to ensure they are successful.

For example, when they start, take time to explain their onboarding process. Don’t simply tell them what they will be doing but take time to explain why they are doing it.

For example, on my second day of employment (after I went through proper day-one orientation), my boss told me that I would be working all day in the plant. I was to arrive at 5:45 a.m. and spend a half hour in each section of the process for the entire day.

The reason why I was doing this was also explained.

One, begin to learn the production process. Two, learn the different jobs involved and how they are done. Three, get to know the members of the production team. Fourth, begin to build trust with them … you get the point.

At the end of the day, he sat down to see what I had learned, and by connecting the what with the why, my boss signaled that he was taking both me and my development seriously.

If I was simply told to go work in the plant on day two with little explanation or follow-up, at around noon, I probably would have questioned if I had made the right career choice.

I have always taken my second day in the industry to heart, and there are simple lessons everyone can implement right away.

The first is to take the time to build trust. This can be done in many ways, but ultimately, the person should feel as if the company and their supervisor have their best interest at heart.

Once trust is established, the next step is to take a vested interest in their training and development.

Again, there are many ways this can be accomplished. Like my first boss did for me, taking the time to walk the person through and explaining the onboarding process, regular check-ins and involving them in

No matter the position that someone is in at your organization, whether it is a laundry or at a place like ours that services the industry, you always must respect your good employees and allow them to grow.

There is no negative in doing so as it only helps to elevate their wanting to be a major piece to your successful puzzle.

With a new employee, I feel that it is very important to make sure that their fellow veteran workers help to engage with them, and you need to also have your management team at the laundry continually check with them on how they are liking their jobs and have conversations with them to get their feelings on how things are progressing for them and allow them to have open conversations with management and yourself.

You can never discount a new hire’s opinion just because they are new. As they say, everyone has to start somewhere. And lo and behold, they may have ideas that could change everything for your company.

Of course, you can’t afford to stay on top of the new hires every moment of the day. You want to have people working for you in the laundry who can do what is required of them without constant supervision.

Once you see that your new hire is doing everything that is required of them, then it is a matter of allowing them the opportunity to grow within your firm.

At our company, we have always respected our employees, no matter how long they have been with us. We are always excited when we have a new hire and will do whatever is possible to make them successful and grow within our company.

Again, that benefits all parties involved.

For all the years that I personally have been a part of the laundry industry, I cannot tell you how thrilled I am to hear of so many of my contacts who have gotten promotions within their companies.

I know so many who have started folding or ironing and then lo and behold, before you know it, they have become plant managers, operations managers, general managers, etc.

Working with these same companies for

years, I know how much they continually engage in a positive way with their new and old employees and in turn, those same people not only grow at their respective laundries because of what the owners and management did, but those same workers now are helping those same laundries to grow as they work with their respective current and potential customers.

As I was traveling over the last couple of weeks to see numerous customers of ours, I consistently met with people who I had first met years ago in different positions who are now running their own plants. And the interesting thing is, every one of those laundries are ones who have seen significant growth since those same people moved into their new jobs.

So, because of those situations, I cannot think of a better reason why a laundry should not help stimulate, engage and push their new workers and help them feel like they are a part of their team.

With the right employee and the right situation, it could end up being a match that benefits all parties involved.

5.Use the inverted pyramid approach to employee engagement. This provides opportunities and works to control top-down communication and provide a more powerful employee value proposition and a flexible and dynamic work environment.

The late Dr. W. Edwards Deming stated in his final years that 90% of the problems were due to poorly designed processes, and management is responsible for processes.

Remember you are the manager in title, but we work for our staff. It is our job to provide them with the resources, equipment, materials, training and processes that allow them to be successful.

The only thing each company has that the competition likely doesn’t have is their employees. This can be the competitive advantage each company is always looking to obtain and maintain.

“A leader’s main job is to grow employees, and when he or she does that, it is amazing what people will do and how productive they will become.” — A.S.

Migs Damiani

First and foremost, we need to view this situation with a sense of urgency. Are we glad they brought this to our attention, or do they see annoyance on our faces? We should be glad they care enough to bring their feelings to our attention.

Second, do we realize this is an organizational issue and not just this new employee’s issue?

Lastly, if we do not have a program in place to keep these situations to an absolute minimum, we need to build one immediately.

Let’s discuss an approach that has worked for me to nearly eliminate this scenario. We start this in the interview process by discussing with them their interest in being in the laundry profession.

Then we:

1.Assign a mentor (pay extra and pick someone who has the culture you want to promote).

2.Train and cross train until they are a capable trainer and mentor themselves. Your team is your most valuable asset!

3.Schedule regular team meetings. Regularity is much more important than the length of each meeting.

4.Show respect by sharing articles and quotes that helped you and others you know who have been successful. Ask them to share a couple with you.

Having employees express their desire to be taken seriously is a positive sign for any organization. It demonstrates their genuine interest and commitment to the company.

However, it can be challenging to understand what exactly they mean when they say they want to be “taken seriously.”

In my experience, the meaning behind the phrase can vary greatly from person to person. It could imply the need for more responsibilities, recognition or even a desire to be heard.

Regardless of what employees mean by wanting to be taken seriously, it is an excellent problem to have. It provides an opportunity for the organization to foster employee involvement and engagement.

Employees who feel involved are more likely to go above and beyond their job responsibilities, feel more connected to the organization and are more likely to stay with the company. This is especially important in the current job market where retaining top talent is essential.

In our industry, being part of something bigger may mean different things to different employees. It could be as simple as having a uniform they feel comfortable in or as complex as being given more responsibilities or being promoted.

The more involved employees are, the more opportunities they will have to grow

12 October 2023 | American Laundry News www.americanlaundrynews.com

“Recently, a new hire said they felt they weren’t being taken seriously. How can I reassure this person and help them grow in the industry?”

team members

Hotel/Motel/Resort Laundry Rodrigo Patron Lace House Linen, Petaluma, Calif.

Consulting Services

Cliff Beiser Champions Touch, Kissimmee, Fla.

Equipment/Supply Distribution

Ross Sanders Streamline Solutions, Orlando, Fla.

Healthcare Laundry Jay Juffre ImageFIRST, King of Prussia, Pa.

and the quicker the growth will occur.

It is vital for organizations to recognize the value of employee involvement and offer opportunities for employees to have a voice in the decision-making process.

When employees feel that their voice is being heard, it can have a significant impact on their motivation and job satisfaction. They are more likely to be engaged and committed to their work, which has a positive impact on the overall health of the organization.

Being taken seriously plays a vital role in both factors, ultimately benefiting the employees and the organization as a whole.

said, make their day better, not worse. Nearly all day-to-day good or bad things are within the manager’s control.

Get to know your team, find out what makes them happy, what bothers them. If you listen, write down their ideas to show you are listening, ask knowledgeable questions, offer insightful suggestions, trust will be gained.

Some questions to ask include “What’s the single most important thing I can do to make it better?”

“Can I count on you to come to me directly if you feel that way again?” “What are you learning?”

“What would you like to do?”

All basic questions and simple to ask.

Gallup tells us that a full 50% of employees who seek other jobs do so because of their managers! The only thing they can’t easily replace at another work location is their leader or, let’s say, first-line supervisor.

When employees seek support regarding recognition, development, scheduling, stress, pay, they can’t work with someone or any other daily employee needs, their supervisor is their go-to source.

The “boss” must be seen as

being trustworthy by their team. Reassuring new hires and assisting them to grow in our formidable industry is paramount to our companies. Make it a priority for you, your supervisors, everyone in the company, to engage new hires from the very first interview.

If you (and the company) are seen as trustworthy from the outset of someone’s employment, they will contribute ten-fold of what they are being paid.

At the end of the day, taking all employees seriously is simply good business!

Last fall while sitting out on our deck in our backyard, my lovely bride of 38 years boldly brought to my attention the wear and tear our deck has taken over

on Page 15

New hires are an opportunity!

They allow a company to revisit employment engagement standards.

The textile rental industry has a wide variety of team members: plant laborers, route representatives, sales representatives, service and office staff, management and chief operating officers, among others.

Our companies must be cognizant of the fact that our policy of employee engagement is diverse and taken seriously by all team members.

According to Deloitte, we spend $1.53 billion per year to fix employee engagement. The time to act is the first day of a new hire’s engagement!

If a new hire is not taken seriously, it shows a lack of trust. They do not trust the company or their supervisor. Employees, what they want most, more than more pay, more than time off, more than working from home, is a boss they can trust.

I began my journey over 45 years ago as a plant worker (Wagg’s Linen & Uniform in north Toronto) and have worked in every possible job position in this industry to learn the business.

I was not taken seriously at first by my supervisors. I had many ideas that were ignored or disregarded with comments such as, “We tried that many years ago, and it doesn’t work.”

At times it was frustrating. It wasn’t until I was in a management position that I gained trust, trust in the company and trust in my team members, and I learned we must listen and that we must make our employees’ workdays—each one of them—as good as we can.

Later in my career, I made it a point to look everyone in the eye as they left to go home and thank them for their efforts. Quite a simple, yet powerful statement—it gained trust!

How do you build trust? As I

13

American Laundry News | October 2023 www.americanlaundrynews.com

Textile/Uniform Rental

W. Kirby Wagg Performance Matters, Sarasota, Fla.

Uniforms/ Workwear Manufacturing Scott Delin Fashion Seal Healthcare, Seminole, Fla. See Panel

Built on research, challenge, teamwork

BY MATT POE, EDITOR

FORT MYERS, Fla. — Jason Mitchell didn’t set out to start a laundry and linen service.

In fact, the Southwest Florida native started his career in finance working for large banks.

In the early 2000s, Mitchell and his wife, Brooke, started a B2B technology and information company, servicing some of the largest insurance companies in the world.

“We grew very quickly, and it was an incredible learning experience because our company had to constantly adapt to handle the growth, and we had to learn how to scale and retain a great team,” he says.

In 2014, a large private equity group acquired the business.

“I found myself essentially retired at 35,” Mitchell shares. “Brooke became a stay-athome mom, so life was great. I spent the next few years buying and selling commercial real estate, but this left me feeling very unfulfilled.

“I really missed the camaraderie of building a great and cohesive team and the affirmation that comes from your clients when you do great work.”

His desire to be part of an operating company led him to research dozens, possibly hundreds, of different industries.

That’s where the laundry and linen services industry enters the story.

NO ROOM FOR ERROR

Today, Mitchell is CEO of the couple’s operation: Premier Linen Services.

The business focuses solely on processing linens for hotels, but the couple didn’t even have industrial laundry on their radar when the search for a new business began.

“We were specifically looking for (an industry) that we felt we could bring some transformative value to,” says Mitchell.

“In our former company, there was very little room for error. Our customers relied on our accuracy, and we had virtually no

competition.

“What attracted us to COG (customerowned goods) hospitality laundry, aside from the huge challenge of building a brand new, state-of-the-art plant, was that same feeling of ‘no room for error.’

“I love that laundry keeps you on our toes every day.”

He points out that if the laundry misses a delivery, a hotel customer might not be able to sell a room.

“As a team, we all feel that pressure every day to perform,” shares Mitchell.

He also enjoys the partnerships the company has with its customers.

“In a way, we feel much as a part of the hospitality industry as we do the laundry industry,” Mitchell says. “There’s no better feeling than when you walk into a customer’s hotel, like I recently did with the Ritz Carlton in Sarasota, and the GM greets you with a smile and thanks you for all you do.

“That’s the affirmation we were missing. The kind that puts a smile on our faces, and that reminds us why we do what we do.”

CHALLENGING STARTUP

After researching the industry for about four months, the Mitchells opened their first facility in December 2019.

Three months later the pandemic reared its ugly head.

“I remember those early days having a lot of extra time to think about what our company should look like. I had a lot of time because we had very little laundry to do,” Mitchell says.

He can laugh about the situation now, but at the time, he says it was very challenging because many of their prospective customers were caught off guard, dealing with what seemed like daily updates from corporate on best practices for social distancing, sanitization, etc.

“And because we had no brand recognition, it was not easy to get a meeting in those days,” Mitchell points out.

Despite losing what felt like most of Premier’s first year, he says 2021 “took off

with a bang.”

“Within two years, we had outgrown our first plant,” shares Mitchell. “Fortunately, we had already begun the process of working with consultants and designing our new fully automated, state-of-the-art plant.”

That’s when the Mitchells faced their next challenge: the building industry.

Mitchell says Premier Linen Services was in a position to grow, and the company wanted to expand. Several properties wanted to work with the laundry, but it couldn’t take on any more work.

“We had decided to build our new plant in one of the most challenging environments in the history of construction,” he points out.

“Florida was experiencing huge growth, and on top of that, we all were dealing with the supply chain, etc. As a result, our origi-

See Premier on Page 16

14

Premier Linen Services, located in Fort Myers, Florida, focuses solely on processing linens for hotels. (Photos: Premier Linen Services)

After achieving success in B2B technology, information, Premier Linen Services’ founder shifts gears and discovers the laundry industry

October 2023 | American Laundry News www.americanlaundrynews.com

Sheets are run through Premier Linen Services’ finishing equipment.

Clean linen bags await the next step of the process at Premier Linen Services.

“IN A WAY, WE FEEL MUCH AS A PART OF THE HOSPITALITY INDUSTRY AS WE DO THE LAUNDRY INDUSTRY. THERE’S NO BETTER FEELING THAN WHEN YOU WALK INTO A CUSTOMER’S HOTEL ... AND THE GM GREETS YOU WITH A SMILE AND THANKS YOU FOR ALL YOU DO.”

Panel

Continued from Page 13

the years and proclaimed, “It is time for a long overdue deck makeover.”

She hated the deck and told me to make the call and get someone in here to redesign a new fresh look for our deck. We could not put it off any longer.

Therefore, to design a fresh look, we arranged to bring in a contractor and discuss our dream deck, complete with an extended bump out for our grill and a place for our firewood for the fireplace. We also wanted to have an octagon extension for outdoor dining.

Being a diligent husband who listens to everything my wife tells me, I made the call and arranged a meeting. We went over our ideas and plans with our contractor, and he then prepared renderings of our dream deck and presented them to us for approval.

Once approved, demolition and new construction were underway.

As our son was looking at the final approved plans, he told us our octagon was too small and we would not like it. Being a typical parent and not taking his comments and feedback seriously, I told him he did not know what he was talking about and not to worry about it as the original design would be just fine.

He then immediately shot back at me and suggested I ask the contractor to build a larger template and place it against the original design in the yard for us to see what a larger octagon would look like and how it would enhance our new deck.

Again, being the fantastic father that I am, I agreed to his suggestion, as I wanted him to feel his input meant something.

This situation made me think about work and how much better we as laundry operators would be if we would just listen more to our employees as they are on the front lines of production day in and day out.

We need to let our new hires and exiting staff know and feel comfortable that if they have suggestions on how to increase productivity and improve quality, and even save dollars, we as owner-operators are willing to listen.

While not all their suggestions may be doable or realistic, we are willing to take them seriously and listen. You never know, as it takes just one or two ideas to change the work environment around us.

Several ways we can assure our employees new and old we take them seriously is to form committees within the workspace and have them serve as members of different committees. Such committees could be:

• Safety.

• Quality control.

• Productivity.

• Employee appreciation.

By getting our employees involved and meeting every week, we empower our staff to feel that they are not just everyday employees coming to work but their involvement is really making a difference in the work culture that surrounds them daily and also affecting the success of our businesses.

Another way to make our staff feel as though their suggestions make a difference is to award, monthly, a gift certificate of some

kind or a prize/award to the team or employee that has any of their ideas put into place.

We all know how hard it is to get and keep a strong workforce. Doing little things to recognize input from our staff makes for a stronger more powerful team and maintains employee retention.

It also shows the rest of the staff that we as owner/operator listen to what they have to say and no idea is silly or stupid.

We need to show them that we take all ideas as great ideas.

When they cannot be into action or implemented, we need

to take time and explain why the ideas may or may not work at this time. Is it how our plants are laid out/designed? Is it we are just not equipped to do so at this time?

Maybe down the road in the future we can use their ideas. One never knows.

By listening, explaining and, most of all, rewarding our employees, we assure them that there is a place for growth within our organizations.

We also may want to send some employees to offsite seminars or give them the opportunity to attend classes to further their

education. The stronger they are mentally, the better it is for our survival and success in today’s challenging market.

As for my son, well, he was right in suggesting the larger design as it was definitely the way to go. We are so happy we listened to him.

His reward was to christen the new deck with his father by enjoying the first of many cigars and glasses of aged scotch around the fire pit.

What we thought was silly actually worked out to our advantage. Thanks for the suggestion, Ben!

15

American Laundry News | October 2023 www.americanlaundrynews.com Setting a new standard for on-premise laundry. Coming this fall. There’s only one Miele clean. mieleusa.com/professional Miele-OPL-Benchmark-Coming Soon-7.75x10-Jun23-A.indd 1 8/31/23 4:16 PM ALN_Jr Page.indd 1 9/6/23 9:45 AM

Continued from Page 14

nal estimate of getting into the new facility by January 2022 was missed by more than 10 months.”

Premier’s third challenge came right as it was moving into its new facility in September 2022: Hurricane Ian.

“We designed our new building to withstand these types of events,” Mitchell shares. “It’s even engineered with a concrete roof; however, we had also committed to bring on two new large customers, and a large hotel in Naples needed us for emergency processing—all while we were moving into our new facility.”

He says several of his team members were displaced, and the general morale of the community was total shock.

“A lot of our customers had to get back up and running very quickly to house all of the FEMA and Red Cross people that came into our area,” says Mitchell. “We never shut down, but those were some very long days for our team.

“Fast forward to today, and we are 100% up and running. We have been dialing our team in on all the new technology that was embedded into our plant.

“It’s exciting times, and we are very grateful for our customers and team members that stuck it out during the transition.

“There are many people that Brooke and I are indebted to for their tireless long hours and commitment to our customers.”

OPERATIONS

Premier Linen Services’ facility is designed to process up to 150,000 pounds in 24 hours.

The facility operates seven days a week, 365 days a year, and averages about 70 employees at any given time.

“Currently, our largest days are around 55,000-60,000 pounds,” says Mitchell.

“Our engineering team is very experienced, and we work very closely with our

chemical provider to ensure the proper formulation and that the look, smell and feel of the linen is the best possible quality available.”

Mitchell says he can talk about how great the company’s equipment and technology are, but, ultimately, success comes down to assembling a great team.

“WE HAVE STARTED BUILDING GREAT FRIENDSHIPS IN THIS INDUSTRY, AND I’M ALWAYS AMAZED THAT THERE ARE INDIVIDUALS LIKE MYSELF THAT CAME FROM OUTSIDE OF LAUNDRY BUT ARE STILL HERE 30 OR 40 YEARS LATER—AND STILL LOVING WHAT THEY DO. THERE IS A STRANGE ATTRACTION, ALMOST AN ADDICTION, TO WHAT WE DO, BUT THIS BUSINESS CAN BE VERY REWARDING AND WILL TEST YOU IF YOU ARE NOT PREPARED.”

“I believe this is our major differentiator,” he shares. “Our approach is to provide better quality and service, and our customers see that.

“We want them to have that ‘wow’ experience, just like they do for their guests. I love onboarding new accounts. That first delivery to the housekeeping team, they are like ‘Wow!’”

From the very beginning, Mitchell and Premier Linen Services have aimed to ‘wow’ customers.

“I think one of our greatest successes came from our very first account,” he shares. “It took several months just to get a first meeting, and it was the Crystal Shores Marriott on Marco Island.

“I convinced them to let us start with

just their pool towels. Less than six months later, they called us and offered us the entire account.

“It was spring break and peak season, and it was our first real contract. We wanted to execute this perfectly, but it was short notice and we had less than a week to get ready.

“It was very exciting, but also an all-handson-deck experience that I will never forget.”

PREMIER’S FUTURE

Make no mistake, Mitchell and his crew are still excited and looking to grow and

‘wow’ hotel customers.

And this growth isn’t limited to the immediate future.

“We have started building great friendships in this industry, and I’m always amazed that there are individuals like myself that came from outside of laundry but are still here 30 or 40 years later—and still loving what they do,” he shares.

“There is a strange attraction, almost an addiction, to what we do, but this business can be very rewarding and will test you if you are not prepared.”

IRONER SOLUTIONS

Premier

16 October 2023 | American Laundry News www.americanlaundrynews.com 092722 KE 4.75x4.75 JR_OL.pdf 1 9/28/22 11:16 AM Joseph Amaral • 224-627-8638 Joseph@LapauwUSA.com www.LapauwUSA.com 401-317-9510

FIND YOUR SOLUTION TODAY BEYOND INNOVATION Innovative Touchscreen Allows user to make all necessary adjustments via the touchscreen No Guide Tapes On all single roll ironers Lapauw Individual Springs Versus traditional springpress, Lapauw Springs provide 5x more suction Flex Chest Technology Most ironing surface under pressure Parallel Flow Technology Maximum energy savings with consistent temp through chest IronPRO IronMAX Classic Accelerated Lead Times

Premier Linen Services’ towel folders create perfect folds to please guests.

UniFirst celebrates grand opening of Minneapolis facility

Ribbon cutting marks opening of 60,000-square-foot plant to serve Minnesota, beyond

MINNEAPOLIS — UniFirst Corp., a North American provider of customized business uniform programs, facility service products, and first aid and safety services, celebrated the grand opening of its state-ofthe-art uniform service and processing facility in Eagan, Minnesota, on Sept. 12.

“Our new Minneapolis facility is part of our long-term growth plans focused on delivering customer service excellence and product quality to local communities throughout North America,” says UniFirst President and CEO Steven Sintros.

“Through the combination of our on-site uniform experts and the facility’s high-tech processing systems, we are well positioned to deliver top-notch services for many years to come.”

A ribbon cutting opened the 60,000-square-foot facility that the company says is designed to deliver exceptional customer service, top-notch product quality and eco-friendly laundry solutions to businesses in Minneapolis, the state of Minnesota and beyond.

The new customer-servicing plant is a direct response to the growing demand for

UniFirst’s services throughout Minnesota, according to the company.

The facility will house 60-plus dedicated employees, providing local businesses with personalized service programs for uniforms and workwear, as well as the delivery and rental of facility service products such as floor mats and mops, wipers and towels, and restroom products. UniFirst plans to increase its workforce by approximately 20% in the coming years to accommodate the anticipated growth.

Spanning over five acres, the new facility also prioritizes sustainability, the company shares. The facility utilizes energy-efficient equipment, such as heat reclaimers, contemporary HVAC units, latest-generation machinery for the production and hygienic

laundering of garments and textiles, as well as LED lighting for greater energy efficiency.

All cleaning formulas and detergents are 100% environmentally friendly, and natural light throughout the plant enhances the work environment while saving energy.

“We are excited to expand to the Greater Minneapolis market and help local businesses find solutions to their uniform and facility needs,” says General Manager Brett

Grandmont.

“This advanced service facility reinforces our ongoing commitment to serving local customers and their hard workers.”

The grand opening ceremony included representatives from the local business community as well as UniFirst executives and staff.

The event concluded with a tour of the new facility and a catered lunch.

Continued from Page 4

tion. Very few of them are working in the position we hired them for, and every one of them at one time or another had a supervisor who thought they were not going to make it and we should move on from them.

Leadership is leadership no matter what industry or sport they are in.

I would suggest reading any books by leaders who have excelled in their field. You will always pick up good insights into how you can improve your team. They all seem to universally say that it is up to the coach to improve the player.

17

American Laundry News | October 2023 www.americanlaundrynews.com Column

ALN_Tab_half.indd 1 9/10/23 1:39 PM

David Griggs serves as general manager for Superior Linen Service’s healthcare division based in Oklahoma.

(Photo: UniFirst Corp)

Moving from open-pocket washers to a tunnel

Author shares insights into the timing and benefits (including production and cost savings) of moving from washer-extractors to a continuous batch washing system

BY BRENNAN POLLNOW

BY BRENNAN POLLNOW

OSHKOSH, Wis. — When and why should a laundry transition from open-pocket washers and dryers to an automated continuous batch washer system?

In this article, we’ll offer some timing guidelines for moving into a tunnel system that directly relate to laundry poundage; the benefits a tunnel brings, including amped productivity and savings in labor and utilities; and its anticipated return on investment (ROI).

TUNNEL AUTOMATION DESCRIBED

First, it’s important to know how a tunnel works. A tunnel system—or continuous batch washing system—includes a loading conveyor, batch tunnel washer, water extraction press, shuttle lifting conveyors, pass-through dryers and a master control. The equipment is automated but simple to use and operate.

One operator places laundry loads onto a loading conveyor, which automatically feeds the tunnel washer. The goods travel through each tunnel module, where linens are prewashed, washed and rinsed according to how the modules are programmed.

The loads are then run through a press where the majority of the water retained is removed.

At this point, the laundry resembles a “cake,” which is then automatically shuttled into an open dryer.

From there, loads are automatically unloaded for folding or ironing, depending on what’s being washed and dried.

Through this entire process, the master control tracks and displays load locations, customer names, product categories, weights, etc.

The space required depends on the size of the tunnel washer and the number of modules you select. Girbau Industrial offers tunnels in five to 14 modules in 110-pound capacities.

A five-module tunnel system that processes 2,000 laundry pounds per hour might occupy a space as small as 25 by 50 feet.

WHEN TO INVEST IN A TUNNEL

A tunnel is a big investment, but even laundries processing just 1,000 laundry pounds per hour can benefit in terms of labor, efficiency and productivity.

It’s important to know that not all batch tunnel washers are configured for high-volume productivity. For example, we can configure five-module tunnels with all the features and

efficiencies of larger batch tunnels.

These tunnels offer double-drum flexibility and programmability by module. Plus, you can continue to modify them once they are installed for capabilities including water reuse, filtration, heat reclamation and ozone sanitization.

Brightwater Laundry, in Sevierville, Tennessee, launched operations with openpocket washers and dryers but quickly ramped up to 1,000 pounds of laundry per hour.

They added an eight-module tunnel and immediately saw huge labor and water savings.

At the end of the day, Brightwater Laundry eliminated an eight-hour shift and improved production potential to 2,400 pounds per hour—leaving room to take on new business.

TUNNEL CAPABILITIES— PROGRAMMABILITY

The programmability of today’s tunnels allows for great flexibility of various wash loads with superior results (napkins, table linens, bathmats, rugs, blankets, duvets, hospital gowns, scrubs and sheets).

The key is choosing a tunnel where every module is programmable—offering multiple inputs for water, reused water, chemicals, steam, ozone, and drain valves and control over water temperature and mechanical action.

Programs can be established based on item type. The operator enters a program based on the first module’s item type and all the modules in the system automatically adjust to that program.

This is a great option for laundries processing customer-owned goods (COG).

Ser-Clean in Miami completes COG laundry with a 12-module tunnel.

Like many laundries, it started out using open-pocket machines. A few years later, it added the tunnel and now processes 3,200 laundry pounds with that system.

The modular configuration of the tunnel allows for precise programmability to meet the specific needs of any operation.