4 minute read

Back to the future – detail on NAPIT’s latest publication dedicated to inspection and testing of electrical installations

from ECN March 2021

BACK TO THE FUTURE

NAPIT’s Technical Development Engineer, Richard Townsend, provides detail on NAPIT’s latest publication dedicated to initial and periodic inspection and testing of electrical installations.

Advertisement

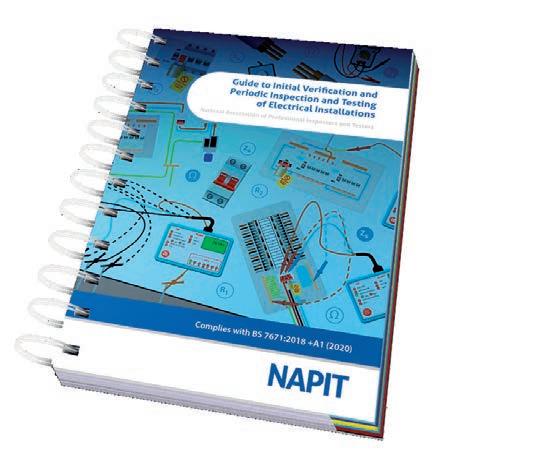

The new Guide to Initial Verification and Periodic Inspection and Testing of Electrical installations The National Association of Professional Inspectors and Testers (NAPIT) started over 28 years ago, in 1992. With the recent addition of a publications department at NAPIT, it was high time all the experience, knowledge, and understanding of its senior technical team was put to good use and gave back to the industry some solid advice and guidance.

Until now, all NAPIT’s publications have centred around its core business – that being site-based guidance for electricians (On-site Solutions), periodic inspections (EICR Codebreakers and Landlords Private Rented Sector Guide), and understanding risk assessments (Risk Management Code of Practice). The one book missing from this list, and enforcing what NAPIT stands for, is a definitive, purpose-written publication covering how to inspect and test an installation, either from an initial verification or periodic perspective.

NAPIT’s technical authors have put together its latest publication, Guide to Initial Verification and Periodic Inspection and Testing of Electrical Installations, which covers everything you need to know on how to carry out an initial or periodic inspection and test a circuit.

Back to basics

The book goes into detail to explain all the separate pieces of test equipment we use. Often taken for granted is a multifunction tester - we mustn’t forget that individual test equipment was where it all started and is still of great value now.

Many electricians that are new to inspection and testing find it difficult to understand the different tests and instruments that give the required measurements. The best way to deal with this is to break down each piece of test equipment and the tests they’re used for and explain them in detail. NAPIT’s latest publication does exactly this; in easy to read steps.

What are the tests?

After the test equipment, the most daunting part of the testing process is understanding the different tests, when to apply them, and how to do them. NAPIT’s new guide gives an in-depth explanation of all the individual pieces of test equipment required to comply with BS 7671, plus a few extras that are important to have, or at least know how to use.

Along with individual pieces of test equipment, NAPIT also covers the more familiar multifunction installation testers (MFTs) that are most common in the industry today. There are also many different test types required by BS 7671, and the organisation explains what all these are, how to carry out each one, and when to use them.

Time to inspect

After explaining all of the different tests and their respective pieces of test equipment, the different inspections need to be looked at. Although we technically inspect before we test, we need to know what the tests are before we start, which is why NAPIT explains them first.

There are essentially two inspections to carry out before any testing takes place:

1. Initial verification inspection 2. Periodic inspection Different inspection schedules cover the two inspections, and although mostly similar, some distinct differences need to be understood. All these differences and schedules are dealt with in detail to give the user an in-depth understanding of the two inspection types and how to carry them out.

The book explains all of the different test equipment, what they’re used for, and how to carry out all of the required BS 7671 tests

Before you start

Before any inspection or testing is carried out, there are a few things that need to be confirmed for either initial or periodic inspections.

Initial verification is a very different process to periodic, and so are the outcomes and the certificates or reports that are produced on completion. NAPIT explains all these differences and the legislation that needs to be taken into account before any work starts. Especially where periodic inspection is concerned, the work that needs to take place before the inspection and any testing starts is very important and can’t be skipped; which is also covered in the publication.

Who is it for?

As we all never stop learning, NAPIT’s new guide has been written to support those just starting off in inspection and testing, those undergoing any training courses which are specifically for inspection and testing, or for the experienced inspector or tester. It complies fully with BS 7671:2018 + Amd 1 and is a must-have toolbox book for any electrician.

NAPIT, napit.org.uk

GTC 400 C PROFESSIONAL THERMAL CAMERA

Your precise, reliable and efficient helper ▶ Ensure high quality of work ▶ Ensure efficiency by evaluating the situation on site ▶ Provide increased transparency and easy documentation for your client