Samuel Ginn College of Engineering

Samuel Ginn College of Engineering

While plenty of Auburn University alumni have served in the U.S. military, Maj. Gen. James E. Livingston, ’62 civil engineering, is the only one to be awarded the country’s highest military decoration, the Medal of Honor. Livingston was honored this fall as the Gameday Hero on Pat Dye Field during an Auburn football game for his service and bravery. Read more about this recent State of Alabama Engineering Hall of Fame inductee by scanning the QR code.

8 / Record-breaking research

College secures $117.7M in new awards and contracts for FY24

58 / Be the Creed Recruitment, Outreach and Scholarships director embodies the Auburn Creed

42 / Timm time

Mechanical engineering senior took over as mic-man for Auburn Athletics this fall

76 / The award goes to...

Alumni recognized by college and university for distinguished careers and service

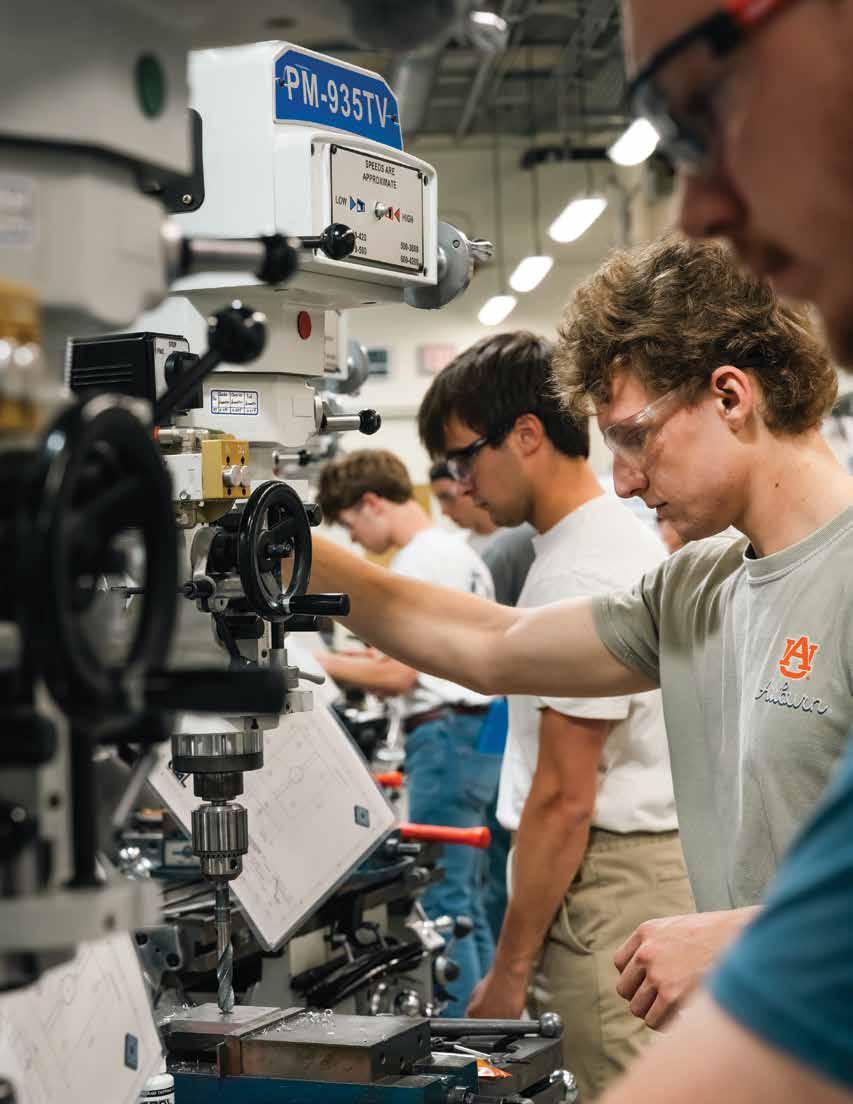

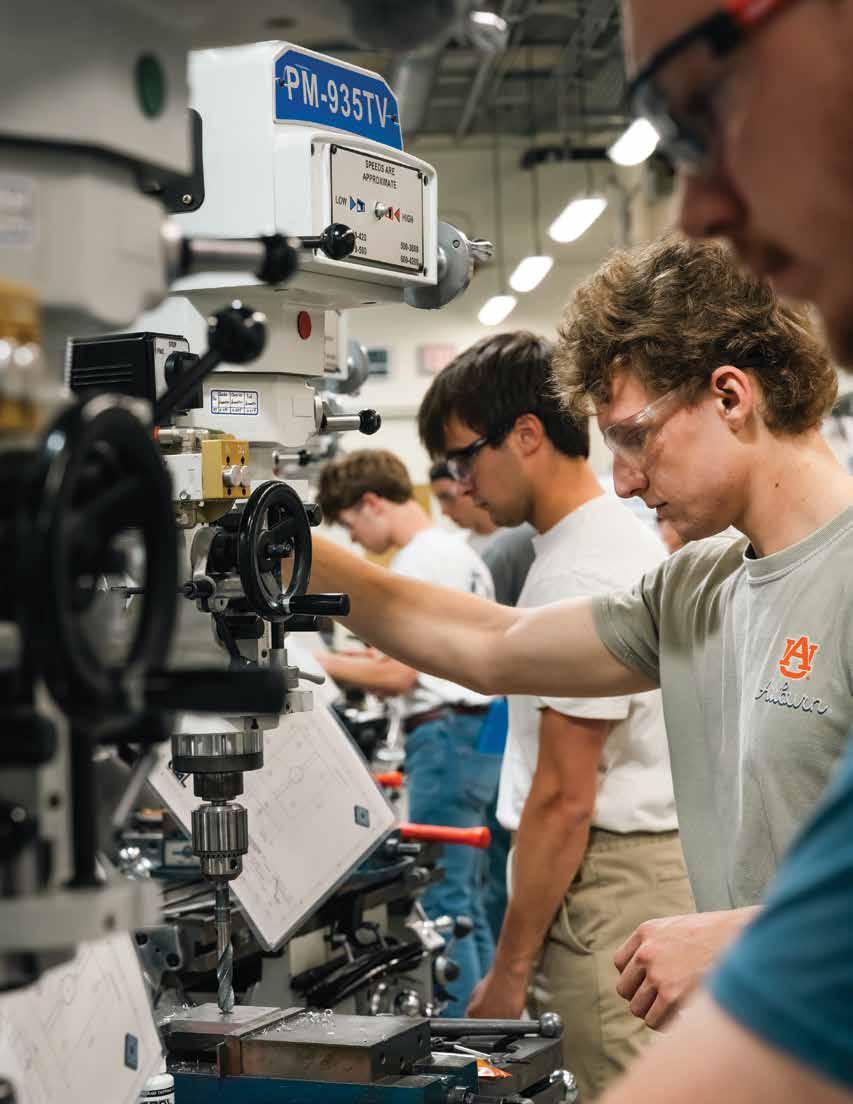

30 / Hands on

The Design and Manufacturing Laboratory — now part of the Montgomery Advanced Manufacturing Laboratories — has served as the anchor of the manufacturing laboratories in the basement of Wiggins Hall. Thanks to the Montgomery Family Foundation, it's much more advanced and serving students like never before.

36 / Engineering global

From Europe to Asia, and everywhere in between, Auburn Engineering partners with universities across the globe to provide students with the best study abroad programs in the nation.

48 / Molding the future

Armed with a $1.7 million award from the U.S. Department of Defense, the college’s Interdisciplinary Center for Advanced Manufacturing Systems plans to visit more than 28,000 sixth-grade students in Alabama throughout the next two years with the revival of the Bird Inc. program.

Thanks to a generous gift from the Montgomery Family Foundation, the Design and Manufacturing Laboratory has been completely renovated and outfitted with the latest technologies as part of the newly named Montgomery Advanced Manufacturing Laboratories

Dean

Editor & Director, Communications and Marketing

The country’s best engineering college deserves the country’s best engineering podcast.

Look for the MIC icon to identify our guests and visit eng.auburn.edu/ginning to listen to each episode.

THE MARINE / Episode 286

Follow us

@AuburnEngineering

@auburnengineers

@AuburnEngineers

@AuburnEngineers

linkedin.com/school/auburnengineering

FLICKR PHOTO GALLERY eng.auburn.edu/flickr

ONLINE MAGAZINE aub.ie/aubengmag

ENG.AUBURN.EDU

Manager, Creative Services / Graphic Design Danny Doyle

Contributor Greg Key

Website Management Tyler Patterson

Contributor Darahaas Nallagatla

Photography & Videography

Marcus Kluttz

John Sluis

Contributor

AU Photographic Services

Visit Auburn Engineer online at eng.auburn.edu/magazine for videos, photos, podcasts and more. You may also submit news items, suggestions or comments by clicking the Contact Us tab.

Auburn Engineer is published twice yearly by the Samuel Ginn College of Engineering.

Engineering Communications and Marketing c/o Editor

Shelby Center

© 2024 Samuel Ginn College of Engineering Auburn University

Auburn University is an equal opportunity educational institution/employer.

It’s a great time to be an Auburn engineer!

The Samuel Ginn College of Engineering had a record-breaking year, eclipsing 6,700 students, securing $117.7 million in new research awards and contracts, awarding nearly $6 million in scholarships and much more.

Our undergraduate students are consistently recognized across the nation — and the globe — for their academic achievements, while our graduate student body continues to grow, produce impactful research that changes lives for the better and drives innovation and entrepreneurship.

Since 2018, our new research awards and contracts have grown more than 300% in FY24. Our faculty is relentless in pursuing opportunities for the advancement of science, submitting 544 proposals this year requesting $458 million in research funding.

To support these students, faculty and staff, our alumni and friends have continued to show their steadfast dedication to this place we all love and believe in. Our fundraising efforts once again surpassed expectations, bringing in more than $36 million to assist the college in its mission to provide the best student-centered engineering experience in America.

We are beyond grateful and humbled by the support of the thousands of Auburn engineers who donate their time, talent and treasure each year to ensure the next generation is afforded that truly unique Auburn experience.

One such alumnus, Jeff Hills, ’93 civil engineering, made a $10 million pledge that will provide more than 300 scholarships to Auburn Engineering students during the next 20 years, making it the largest single commitment to scholarships in Auburn University history. The Jeffery S. Hills Scholarship will provide financial assistance to firstgeneration students from the state of Alabama who are in financial need. The program will provide students with a scholarship covering tuition, fees, room and board for their first two years and then half of all costs for the remaining years in hopes that students will have secured co-ops or internships in their junior and senior years.

As Auburn men’s basketball head coach Bruce Pearl says, that’s just “Auburn being Auburn.”

Similarly, close friends Larry and Mary Montgomery believe in Auburn so much that the Montgomery Family Foundation has made a significant investment in the college that allowed us to completely renovate the Design and Manufacturing Laboratory and surrounding spaces and equip it with the latest and greatest technologies. As you’ll read in this magazine, the new Montgomery Advanced Manufacturing Laboratories will give our students the hands-on learning experiences they need for the future.

Indeed, it’s a great time to be an Auburn engineer, and I am eager to see what 2025 will hold.

War Eagle!

Mario R. Eden

Auburn Engineering sets research and contract award record with $117.7M in FY24

Auburn University’s Samuel Ginn College of Engineering set a college record for new research awards and contracts for a fiscal year, closing FY24 with $117 7 million

The amount is also a record for any college in Auburn University’s history

Auburn Engineering has increased its annual new research awards and contracts by more than 300% since 2018, when the college brought in $29 million

The college also set a record with engineering faculty members submitting 544 proposals requesting $458 million in research funding

“In recent years, the Samuel Ginn College of Engineering has generated record-breaking levels of funding in new research awards and contracts, alumni support and student enrollment,” said Mario Eden, dean of engineering “Our vision is to provide research that improves quality of life and fosters economic competitiveness, and that’s exactly what our dynamic faculty and students are doing as part of one of the elite public engineering institutions in the nation ”

In 2017, the college began a strategic hiring initiative that resulted in an increase of nearly 50 faculty members In turn, this has increased the number of research proposals and funding amounts for each request

“Our faculty members are not only setting a standard in the classroom, they are also doing so as part of the university’s research enterprise,” said Allan David, the college’s associate dean for research “Whether it’s related to transportation, health, advanced and additive manufacturing, cybersecurity or the environment, our faculty members are conducting cutting-edge research that is improving the quality of life, driving our economy and making us safer both here at home and across the globe ”

Funding for several high-profile research areas included:

• Transportation and Resilient Infrastructure — $32,457,000

• Advanced and Additive Manufacturing — $18,340,000

• Applied Research — $15,061,000

• Cybersecurity and Intelligent Systems — $11,100,000

• Biomedical and Health Systems Engineering — $6,900,000

• Advanced Communications and Electronics — $9,081,000

Several impactful awards and contracts included:

$50,000,000 ($22,000,000 awarded in FY24) / U.S. Army Combat Capabilities Development

Command Aviation & Missile Center

“Lightweight, Advanced Manufacturing of Metallic, Polymer and Composite Structures for Aviation and Missile Weapon Systems”

$10,000,000 / Department of Energy

“Model Regional Operations Center to Enhance Cyber Security of U S Electricity Sector”

Frank Cilluffo and James Goosby (McCrary Institute for Cyber and Critical Infrastructure Security)

$6,552,227 / Federal Transit Administration

“Low and No Emission-Component Assessment”

Christian Brodbeck (engineering administration) and Mark Hoffman (mechanical engineering)

$3,255,444 / State of Kansas

“Additive Manufacturing Material and Process Rapid Qualification for Vehicle Applications”

Nima Shamsaei and Shuai Shao (mechanical engineering)

$3,012,027 / U.S. Air Force

“Novel Timber Structures for Air Force Expeditionary Environments”

Jim Davidson, J Brian Anderson, David Roueche and Kadir Sener (civil and environmental engineering)

$1,250,000 / National Asphalt Pavement Association

“Synthesis of State of Practice and Research Needs for Airfield Asphalt Pavement Resilience”

Ben Bowers (civil and environmental engineering)

$1,099,000 / Trideum Corp.

“Missions based multi-domain operations test environment”

Steve Mills (Applied Research Institute) and Hunter Burch (electrical and computer engineering)

Allan David has been named associate dean for research for the Samuel Ginn College of Engineering

David, the John W Brown professor in the Department of Chemical Engineering, assumed the position effective June 1 He served as acting associate dean for research when former dean Chris Roberts moved on to become Auburn’s 21st president and thenassociate dean for research, Steve Taylor, became interim dean of the college

“Dr David has done a tremendous job during the past two years in his role as acting dean of research for the college, and I am thrilled to continue working with him in this permanent role moving forward,” said Mario Eden, dean of engineering

As associate dean for research, David will assist with the college’s strategic planning, budget development, facilities oversight and administration In collaboration with the dean, David will promote a vibrant research culture by working with department chairs, institute directors and center directors to improve each of their teams’ contribution to the mission of research and scholarship He will also provide leadership to ensure that processes function effectively for submission of proposals to external sponsors while mentoring, assisting and reviewing proposal development and assisting with technology commercialization activities�

David Timm has been named the chair of the Department of Civil and Environmental Engineering

Timm, whose term began July 1, has been a civil and environmental engineering faculty member since 2001, when he joined the department as an assistant professor Since then, he has held the department’s Brasfield & Gorrie Professor and associate chair of civil and environmental engineering positions

“There is a lot to be excited about in civil and environmental engineering at Auburn University,” Timm said “Our department has experienced unprecedented growth and success over the past 10-plus years under Dr Andy Nowak’s leadership, and we’re well-positioned to continue moving forward I’m honored and humbled to be the next chair to serve our outstanding students, faculty, staff and alumni ”

Timm succeeds Nowak, who returned to the department in the role of Brasfield & Gorrie Professor Timm also assumed the title of the Elton and Lois G Huff Eminent Scholar Chair

Hendrix named associate dean for undergraduate studies and program assessment

Dean Hendrix has been named associate dean for undergraduate studies and program assessment for the Samuel Ginn College of Engineering

Hendrix, who served as an associate professor and associate department chair of computer science and software engineering, assumed the position effective Aug 1 Hendrix also served as the department’s director of undergraduate programs and as the director of the college’s Engineering Global Programs

“Dr Hendrix brings a wealth of knowledge and experience, and he has demonstrated excellent leadership and great passion for supporting undergraduate students and continuous improvement in our academic programs,” said Mario Eden, dean of engineering

As associate dean for undergraduate studies and program assessment, Hendrix leads the formulation of academic policies and procedures; transmission of curricular material through the approval process; adjudication and approval of course substitution and exceptions to university academic/student affairs policies; and serves on the university’s Academic Affairs Committee and other university committees related to undergraduate education

Tamara McClain has been named the new director of Auburn University’s Center for Inspiring Engineering Excellence (CI2E) Her appointment was effective May 6

“We’re excited to welcome Dr McClain to the Samuel Ginn College of Engineering Her wealth of experience in student academic support will be a valuable asset in leading our Center for Inspiring Engineering Excellence,” said Mario Eden, dean of engineering�

McClain oversees a program that plays a vital role in serving the underrepresented population among the Auburn Engineering student body CI2E serves to recruit, retain and reward students within all engineering disciplines through graduation Serving more than 200 students annually, CI2E offers academic and professional development opportunities, mentorship and peer learning as well as collaborative study groups, workshops, programs for career readiness and financial awards

“I am thrilled to join the Auburn Family and assist with empowering engineering students to reach new heights,” McClain said “It will be an honor to contribute to their journey of self-discovery and professional growth I am eager to make a positive impact on their futures and help shape tomorrow’s leaders in engineering ”

Jon Wilson has been named senior director of development for the Samuel Ginn College of Engineering

Wilson, who previously served as senior director of athletics development for Auburn, began his new appointment in engineering July 1 In his new role, Wilson is responsible for leading the college’s development and fundraising efforts, including managing, mentoring and coaching development officers and coordinators; implementing strategic stewardship and engagement plans; and working with the dean to ensure the college’s development and fundraising goals are met Wilson will also serve as a major gift fundraiser

“We are thrilled to have Jon in the Samuel Ginn College of Engineering, now serving as senior director of development,” said Mario Eden, dean of engineering “Through his years in the college and, most recently, with Auburn Athletics, Jon has built great relationships with our alumni and understands the importance of maintaining those bonds ”

Four Auburn biosystems engineering doctoral students — Rachel Day, Noor Fatima, Raziyeh Jokar and Vivian Usha — won second place in the Bioprocessing Startup Competition at the recent American Society of Agricultural and Biological Engineers annual meeting for their alginatebased food-safe wrappers

With the idea of increasing sustainability, the four designed an alternative wrapping for food to replicate traditional unrecyclable aluminum-based films

Day said algae, known for its biocompatibility, low toxicity and

low cost, is one of the most popular wrapper replicas

The alginate film will surround the aluminum and wash off in water, making the wrapper recyclable The algae is made into a solution that will go through film casting and dry overnight by removing the salt and dissolving it The algae film would be printed onto food wrapping instead of the typical metalized film

Four Auburn Engineering junior faculty — Sathya Aakur, assistant professor in computer science and software engineering; Brendon Allen, assistant professor in mechanical engineering; Davide Guzzetti, assistant professor in aerospace engineering; and Tin Nguyen, associate professor in computer science and software engineering — were named Ginn Faculty Achievement Fellows, effective Aug 16

The Ginn Faculty Achievement Fellowship recognizes and rewards junior faculty in the Samuel Ginn College of Engineering who receive prestigious young investigator awards, including the National Science Foundation CAREER, Department of Defense, Department of Energy or National Institutes of Health

“Early career achievements in research are crucial as they lay the foundation for a lifetime of scholarly contributions and advancements,” said Mario Eden, dean of engineering “By acknowledging and celebrating these accomplishments, we are fostering a culture of excellence, encouraging our faculty to push the boundaries of knowledge and make positive impacts on industry and society ”

to

programs

The Samuel Ginn College of Engineering was again recognized as a leader in higher education, ranking among the nation’s top public institutions in U S News & World Report’s 2024 Best Graduate Schools

U S News & World Report, which ranks graduate programs nationally each spring, designated the college No 31 among public institutions when its annual list was released in June Auburn Engineering’s graduate programs continued its upward trajectory among public institutions, climbing 10 spots in the past five years

“Continued recognition by our peers in the academic community is a

Six Auburn Engineering students were named National Science Foundation (NSF) Graduate Research Fellows for 2024

Students recognized were Katie Wolfe, who graduated with bachelor’s degrees in electrical engineering and theatrical design; Marisa Kelley, senior in materials engineering; Dylan Bowen, a second-year doctoral student in chemical engineering; Ryan Pollard, mechanical engineering graduate student; Robin Weaver, who graduated with an aerospace engineering degree; and Maggie Nelson, who graduated with an aerospace engineering degree

According to the NSF, the Graduate Research Fellowship Program is “designed to help ensure the quality,

testament to the premier graduate engineering experience we offer at Auburn University,” said Maria Auad, associate dean for graduate studies and faculty development “Each year, we invest significant resources and energy into hiring renowned faculty, developing exceptional studentsupport programs, building unrivaled facilities for cutting-edge research and providing new opportunities for experiential learning ”

Auburn Engineering’s graduate programs also ranked fourth among the 13 public institutions in the Southeastern Conference and — again — No 1 in the state

vitality and diversity of the nation’s scientific and engineering workforce

A goal of the program is to broaden participation of the full spectrum of diverse talents in science, technology, engineering and mathematics ”

The fellowship, awarded to students who are either enrolled or intend to enroll in research-based graduate programs, provides three years of financial support

Auburn University’s seminal work on semiconductor packaging has new packaging of its own — the Auburn University Electronics Packaging Research Institute (EPRI)

The institute’s recent establishment marks a significant new emphasis on the semiconductor packaging research conducted through Auburn’s Center of Advanced Vehicle and Extreme Environment Electronics, or CAVE3, which was founded in 1999 through funding from the National Science Foundation and support from select companies focusing primarily on automotive electronics

Pradeep Lall, the John and Anne MacFarlane Endowed Distinguished Professor and Alumni Professor in the Department of Mechanical Engineering, has directed the center since 2008 He will continue to serve as director of EPRI

“Our need for domestic capability in manufacturing, research and development for semiconductor packaging has really entered the national conversation recently with the recent establishment of the National Advanced Packaging Manufacturing Program under the Creating Helpful Incentives to Produce Semiconductors — or CHIPS — Act,” Lall said

Four Auburn University graduate students took home top honors at the inaugural Southeastern Conference (SEC) Start Up Student-Athlete Pitch Competition this past July

David Hollinger, a doctoral student in Auburn University’s Biomechanical Engineering Lab, along with mechanical engineering master’s student David Edmondson and MBA student Allison Tanner, both former Auburn track and field athletes, make up Digital Athlete, which strives to harness the power of data-driven biomechanics to benefit athletes

Developed with guidance offered through Auburn University’s New Venture Accelerator, The Digital Athlete is a smartphone app utilizing artificial intelligence to provide quick, affordable and accessible human motion analysis

Though the technology currently focuses on running biomechanics, the team plans to expand the app to include personalized biomechanical recommendations applicable to the entire athletics spectrum

“Participating in the SEC Start Up was an incredible experience,” Hollinger said “I was blessed to have the opportunity to pitch a product that has been in my mind since I was a freshman in high school running track and cross country in Virginia ”

Doctoral student in civil and environmental engineering

Nora Lopez Rivera, a doctoral student in civil and environmental engineering, recently earned a U S Department of Energy (DOE) Office of Science Graduate Student Research award

The award allows Lopez Rivera to work for a year in a national DOE laboratory to expand her research and network with other scientists

Rivera said she will research at the Pacific Northwest National Laboratory in Richland, Washington

Her project titled “Microdiffraction Phase Mapping and In Situ Mineral Transformation Monitoring for Parametrizing Reactive Transport Models” focuses on developing a methodology with the micro XRD technique to acquire modeling data for basaltic rocks

“I specifically research geochemical reactivities between injected CO2 (carbon dioxide) and underground geological formations,” Lopez Rivera said “I do this by building reactive transport models using data from geological formations being considered for CO2 storage ”

Auburn Engineering dean and chemical engineering professor named AIChE fellows

Mario Eden, dean of engineering and McMillan Chair, and Virginia Davis, the Dr Daniel F and Josephine Breeden Professor of chemical engineering, were recently elected American Institute of Chemical Engineers (AIChE) fellows — the organization’s highest membership grade

AIChE fellow candidates are nominated by their peers and must have significant chemical engineering experience, have demonstrated longterm excellence in the profession and have held senior membership in the society for at least three years

“We are immensely proud of Drs Eden and Davis,” said Selen Cremaschi, Department of Chemical Engineering chair “This prestigious recognition is a testament to their exceptional contributions to the field of chemical engineering, their dedication to advancing research and their unwavering commitment to educating the next generation of engineers Their achievements reflect the excellence and innovation that define our university, and we are fortunate to have such distinguished faculty members leading by example ”

Auburn Engineering presented with Innovation Award for Safety Culture

For its continued efforts to incorporate safety into research and education, Auburn Engineering earned the Campus Safety, Health and Environmental Management Association’s (CSHEMA) 2024 Innovation Award for “Safety Culture for a Large School

CSHEMA’s safety culture awards recognize institutional practices of faculty, staff and students that promote a culture of safety�

“Winning the CSHEMA Innovation Award and being a semifinalist in the Green Cross Award speaks volumes about Auburn Engineering’s unwavering commitment to safety,” said Emmanuel Winful, Auburn Engineering safety manager “These accolades highlight our college’s excellence in developing and implementing effective solutions to complex safety and health challenges within our research and teaching activities They affirm that our efforts in safety, health and environmental matters are not only noteworthy but also align with national standards of excellence ”

Engineering undergraduate program ranked No. 30 among public institutions

The Samuel Ginn College of Engineering was again recognized as a national leader in higher education, ranking among the nation’s top public institutions in U S News & World Report’s 2025 Best Undergraduate Engineering Programs

The online publication, which ranks undergraduate programs nationwide each fall, ranked Auburn Engineering No 30 among public institutions for a second consecutive year

“This ranking reflects the Samuel Ginn College of Engineering’s relentless pursuit of excellence as a leader in engineering education,” said Mario Eden, dean of engineering “We take pride in providing the best studentcentered experience in America, supported by a world-class faculty dedicated to fostering innovation and academic achievement We will continue to strive for greatness and prepare the next generation of engineers to tackle the world’s most pressing challenges ”

Auburn Engineering’s undergraduate programs also ranked fourth among the 13 public institutions in the Southeastern Conference and — again — No 1 in the state

Auburn’s work on the high-tech hardware that will take people to Mars has earned some impressive hardware of its own

Researchers in Auburn University’s National Center for Additive Manufacturing Excellence (NCAME) continue to play a critical role in the Rapid Analysis and Manufacturing Propulsion Technology (RAMPT) project, specifically the project’s resulting Thrust Chamber Liner and Fabrication Method technology, which, in July, was named NASA’s 2024 Invention of the Year

“This is another in a long list of big achievements for the RAMPT team,” said John Vickers, NASA’s principal technologist for additive manufacturing for RAMPT “Along with industry partners and with support from NASA’s Game Changing Development Program, Auburn has helped create transformative manufacturing technology that will impact the nation’s space economy ”

The National Science Foundation recently tapped Brendon Allen, assistant mechanical engineering professor, for a five-year $588,408 CAREER Award aimed at increasing access to rehabilitation for individuals with movement disorders through a deep learning control framework for home-based hybrid exoskeletons

“These devices combine functional electrical stimulation with actuated robots to provide personalized therapy,” Allen said “Shifting the computational demand from individual homes to clinicians’ offices can, I believe, reduce the cost of telerehabilitation significantly ”

He also believes it can drastically decrease destabilization complications caused by communication delays between the clinician’s computer and the exoskeleton

How? By utilizing novel delay compensation and deep neural network based methods to enable the remote control of the exoskeleton

“Successful completion of this project could transform the rehabilitation industry,” Allen said�

McCrary Institute appoints two senior defense and policy executives

Auburn University’s McCrary Institute for Cyber and Critical Infrastructure Security strengthened its position as a leader among cybersecurity research and policy circles with the appointment of two veteran defense and policy executives

Craig M Whittinghill, a U S Navy veteran of 29 years, was named deputy director for applied research and services Kyle D Klein, who served on Capitol Hill in various senior policy roles for 12 years, was named deputy director for policy and partnerships

“We are thrilled to add these two executives to our senior leadership,” said Frank Cilluffo, McCrary Institute director “Craig will lead a growing team of cyber experts as we expand cybersecurity services in support of government and industry His deep experience and leadership on cyber and intelligence matters will be invaluable as we advance our efforts to better support the national security community Kyle’s leadership as a former staff director of the United States House of Representatives Committee on Homeland Security adds significant policy and legislative expertise as we further position the McCrary Institute as a hub and thought leader on all things cyber ”

Mechanical engineering professor emeritus honored for groundbreaking NSF research aboard ISS

Even in retirement, mechanical engineering professor emeritus Sushil Bhavnani’s work with vapor bubbles is rising to the top

Bhavnani, who retired from the Department of Mechanical Engineering in July 2023 after 36 years of research and instruction in thermal management, heat transfer and phase-change cooling, received the prestigious International Space Station National Lab 2024 Compelling Results Award in Physical Sciences and Material Development

He was awarded at the International Space Station Research and Development Conference held July 30 through Aug 1 in Boston

Bhavnani was selected based on the results obtained during a National Science Foundation- funded investigation, “Thermally Activated Directional Mobility of Vapor Bubbles ”

Featuring a special surface that helps move heat away from electronics without the need for fans or other moving parts, the cooling system Bhavnani’s research team conceived was successfully tested aboard the ISS The results led to an improved fundamental understanding of vapor bubble dynamics that could provide more efficient and reliable electronics for use in space, air travel, phones and laptops

Vice Chairman of the Joint Chiefs of Staff tours Auburn Engineering research centers

The Navy’s “Old Salt” — a sobriquet reserved for its longest-serving surface warfare officer on active duty — recently got a taste of new research

Adm Christopher W Grady, who, as vice chairman of the Joint Chiefs of Staff, is the nation’s second highest-ranking military officer, toured prominent Auburn University engineering research centers in May�

“It’s an immense honor to have Adm Grady take the time to get an up-close look at the next-level research happening in the Samuel Ginn College of Engineering,” said Mario Eden, dean of engineering “We take great pride in our leading role in supporting the military’s mission through our advanced manufacturing and cybersecurity capabilities ”

Grady met with Auburn University President Christopher B Roberts to discuss Auburn’s collaboration with the Department of Defense, as well as the university’s multiple space industry partnerships, including the Auburn University Research and Innovation Campus’ new status as a base of technical support operations for the Space Development Agency in Huntsville

Listen to the #GINNING podcast with Sushil Bhavnani at eng.auburn.edu/ginning

NCAT’s triennial Test Track Conference attracts asphalt industry leaders

The National Center for Asphalt Technology (NCAT) hosted its triennial Test Track Conference May 7-9 at the Auburn University Hotel and Conference Center

The event presented advancements in the design, construction, materials, maintenance and sustainability of asphalt pavements to more than 300 industry professionals

Highlighting the latest findings from the eighth cycle of accelerated pavement testing conducted at NCAT’s Test Track, situated just 20 minutes east of Auburn University, the conference offered insights into the forefront of asphalt pavement research and development

Throughout the conference, attendees explored a myriad of topics, spanning from mixture additives to innovative pavement design methodologies

Research engineers from NCAT delivered presentations on recycling agents, innovative mix additives, crack prevention interlayer strategies, high polymer binders, cold recycling, pavement preservation treatments and more

Daniela Marghitu’s reputation as an advocate for computer science education has reached the Alabama governor’s office

Marghitu, director of Auburn University’s Laboratory for Education and Assistive Technology and faculty within the Department of Computer Science and Software Engineering, was appointed on June 6 to the Governor’s Advisory Council for Computer Science Education�

In this role, she will apply 27-plus years of experience to help form strategies and policies to develop a unified state vision for computer science education The goal: offer computer science education courses in each of Alabama’s 327 public high schools

“I am incredibly honored and touched to have the opportunity to work with this council and explore innovative avenues to expose schoolchildren in the state of Alabama to computer science,” said Marghitu, whose hallmark of service includes K-12 outreach and award-winning research and curricula that provide computer science education opportunities for the underserved� “I will use my knowledge as a college professor to recommend realistic solutions and create actions that quickly and successfully implement the governor’s dream I’ll be honest and open ”

The Auburn Alumni Engineering Council inducted seven new members during its annual spring meeting in April

Each council class is active for five years Those inducted into the Class of 2029 were:

• John Floyd, ’85 electrical engineering, director of demand-side management at Florida Power & Light

• James Goosby, ’00 electrical engineering, executive in residence at Auburn University’s McCrary Institute for Cyber and Critical Infrastructure Security

• Antoria Guerrier, ’00 electrical engineering, president and founder of The Arnold Group

• Jeffrey Langhout, ’86 industrial engineering, retired director of the U S Army Combat Capabilities Development Command Aviation & Missile Center and founder of Langhout Consulting

• Nelda Lee, ’67 aerospace engineering, retired from Boeing

• Joseph Pelfrey, ’00 aerospace engineering, director of NASA’s Marshall Space Flight Center

• Emily Traylor, ’10 wireless engineering, director of data and cybersecurity at Fullsteam

Cyber Fire Puzzles, a cybersecurity challenge by the U S Department of Energy and Los Alamos National Laboratory (LANL), brought nearly 60 students to Auburn’s Brown-Kopel Center on Aug 24-25 The event honed skills in tracking hackers and analyzing malicious programs through sequences and software clues

In its sixth iteration at Auburn, Cyber Fire Puzzles was hosted by the Auburn University Ethical Hacking Club, the Auburn Cyber Research Center, and the LANL/AU Cyber Security Sciences Institute�

Through a LANL-created website, students were tasked with solving problems within 13 puzzle categories based on complicated security topics, including number sequencing and patterns, with various difficulty levels

“This is a fun event, but it’s also competitive because when you’re doing this in the real world defending the systems we all rely on There is a very competitive element to it You’re going up against the adversary,” said Daniel Tauritz, associate professor in computer and software engineering “Also, this attracts a diverse group of students who either already aspire — or will become inspired — to enter the cyber field, and we need to grow our cyber-informed workforce Plus, this can serve as a great recruiting event for LANL ”

ECE associate professor leads $600K NSF research grant

Sensitive information stored on computational devices is often eradicated before hardware is discarded However, that doesn’t mean it isn’t accessible

A 2022 study, “Beware of Discarding Used SRAMs: Information is Stored Permanently,” demonstrated that data can be recovered from static random-access memory chips, potentially enabling adversaries to recover sensitive information� Building on this research, Ujjwal Guin, the Godbold Associate Professor in the Department of Electrical and Computer Engineering, is exploring means that will identify unexpected vulnerabilities from used SRAM His colleague, Biswajit Ray from Colorado State University, will develop novel sanitization methods for permanently erasing these types of memories

Guin is principal investigator on the collaborative research proposal, “Exploring Security Risks Arising from SRAM Data Remanence and Evaluating Innovative Sanitization Techniques,” which earned a threeyear, $600,000 award for both universities from the National Science Foundation

Research emphasis will be placed on scenarios where attackers could exploit these vulnerabilities to gain access, manipulate sensitive data or launch other malicious activities

Pioneers of mobile revolution share lessons, experiences with Auburn Engineering students

Frank Canova, inventor of the first smart phone, Daniel A Henderson, inventor of photo/video messaging and Neil Papworth, who created and sent the first-ever text message, answered questions and shared experiences in a 60-minute discussion Sept 30 at the Brown-Kopel Center

“Every inventor thinks that they’re going to change to world,” said Henderson, whose 1993 picture and video messaging prototype, the Intellect, incorporated technology that is now ubiquitous in cell phones worldwide “In reality, the market, technology and society will determine what will make those changes In 100 years, none of us will be here The point why you’re innovating is to work hard and make things better when you’re not here ”

Henderson said it’s important to understand problems technology can immediately resolve, but “look beyond that curve

“Sometimes your solution is looking for a problem to resolve,” he said “Use that knowledge and bring it into what can be built today� Part of the problem and the discipline of inventions are the utilities that have the capacities to change even more ”

A group of senior mechanical engineering students has been selected to participate in the Moon to Mars eXploration Systems and Habitation (M2M X-Hab) Academic Innovation Challenge, sponsored by NASA and the National Space Grant Foundation

The challenge tasks student teams with developing innovative solutions for Artemis mission challenges Auburn was one of only three universities selected, alongside the University of Michigan and the University of Maryland, due to its strong track record in space research and faculty expertise

The Auburn team, led by Kyle Schulze, assistant professor of mechanical engineering, will focus on developing advanced mobility solutions for astronauts navigating the challenging lunar and Martian terrains

“Dr Bob Ashurst, who directs the Makerspace, sent me some information about the challenge,”

Schulze said “When I saw one of the proposal topics on the project call — Crew Mobility Modalities Inside Moon/Mars Habitats — I just thought, ‘we should be putting our hats in this ring ’”

Inspired by the gecko’s ability to climb walls, the team will explore using “synthetic setae” or artificial gecko hands and feet to allow astronauts greater freedom of movement

ECE associate professor earns NSF grant to miniaturize additive manufacturing technique

Masoud Mahjouri-Samani, the Godbold Associate Professor of Electrical and Computer Engineering, intends to push the boundaries of laser-based, powder-bed fusion additive manufacturing to micro and nanoscale, one nanoparticle at a time

Mahjouri-Samani’s proposal, “Three-Dimensional Printing of Compositionally Tunable and Hybrid Microarchitectures by Laser Nanoparticle Powder-Bed Fusion,” recently earned a three-year, $475,000 grant from the National Science Foundation

“In conventional powder-bed additive manufacturing process, microscale particles — ranging from 20 to 50 microns in diameter — are laserfused layer-by-layer forming macro architectures and parts, typically

Chemical engineering

Can young stem cells be separated from old stem cells?

Panagiotis Mistriotis, assistant professor in the Department of Chemical Engineering, believes so�

lacking functionality,” he said

“Imagine this … shrinking it down tens of thousands of times� We are developing non-equilibrium laser processes to generate, coat and fuse nanoparticles in situ and in real-time a few nanometers thick at a time, pulse-by-pulse and layer-bylayer We are creating the smallest powder bed additive manufacturing, or nanoparticle bed-fusion additive nanomanufacturing, process Now we can start integrating different materials and creating nano and microarchitectures with tunable compositions enabling functional devices,” he added

His three-year study, “Leveraging Cell Migration Dynamics to Discriminate between Senescent and Pre-senescent Human Mesenchymal Stem Cells,” not only demonstrates how but helped Mistriotis earn the honor of “2024 Young Innovator” by the scientific journal Cellular and Molecular Bioengineering

“The Department of Chemical Engineering carries a strong reputation for producing transformative bioengineering research for the healthcare industry that has the potential to produce improved patient outcomes Dr Mistriotis’ work plays a key role in this,” said Selen Cremaschi, who chairs the department “Dr Mistriotis has spent much of his career developing new tools to increase the potential of adult stem cells for cellular therapies Being recognized on the national stage is a testament to his perseverance and dedication to research ”

Transparent, accountable and evolving That’s how White House National Cyber Director Harry Coker Jr described the National Cybersecurity Strategy Implementation Plan at a special forum this past May in Washington, D C , hosted by Auburn University’s McCrary Institute for Cyber and Critical Infrastructure Security

Moderated by McCrary Institute Director Frank Cilluffo and McCrary Institute Senior Fellow Katherine Gronberg, Coker was joined in the live and online event by Nick Leiserson, White House assistant national cyber director for cyber policy and programs, Cheri Pascoe, director of the National Cybersecurity Center of Excellence at the National Institute of Standards and Technology and Valerie Cofield, chief strategy officer of the Cybersecurity and Infrastructure Security Agency

“It was a privilege to host Director Coker as he provided vital updates on our nation’s cybersecurity readiness through the lens of the National Cyber Security Implementation Plan,” Cilluffo said “While progress has been made, Director Coker underscored areas where we must continue improving our cyber defenses and resilience ”

Listen to the #GINNING podcast with Frank Cilluffo at eng.auburn.edu/ginning ↑

Cassandra Porter, assistant professor in chemical engineering, earned a three-year, $303,707 National Science Foundation grant for her proposal, “Polyamide Brush ActiveLayer Membranes for Fundamental Understanding of Structure-Function Relationships in Thin-Film Composite Reverse Osmosis Membranes ”

The object: develop a better understanding of reverse osmosis (RO) polyamide membranes and create a membrane that resists chlorine damage without minimizing performance

Porter will investigate the hypothesis that weak intermolecular interactions play key roles in the performance of polyamide RO membranes

“What we’re doing is not focusing on the entire process of desalinization

Ed Davis, associate professor of mechanical engineering, is the principal investigator for two new awards — one from the National Science Foundation (NSF), the other from the National Institute of Standards and Technologies (NIST) — aimed at educating future polymer researchers as well as recycling industry professionals on the growing importance and evolving challenges of polymer recycling

His new NSF award, a $98,000 supplement to a 2021 $2 1 million multidisciplinary NSF Emerging Frontiers in Research and Innovation project funding research into novel ways for separating the materials used in typical multilayer plastic food

but getting new membranes in my laboratory to better desalinate contaminated water that the current reverse osmosis membranes cannot handle,” Porter said� “These contaminants include organics, compounds that infiltrate current commercial reverse osmosis membranes more easily ”

The effects of crosslinking, amide, benzyl and carboxyl density will be explored by producing a highly tailorable, novel polyamide membrane built with a dense layer of brush polymers — the brush-active layer membrane

packaging, will provide experience in real-world polymer recycling research projects to 10 area high schoolers

The three-year, $500,000 NIST award aims to advance the circular polymer economy through multi-tiered workforce development in polymer metrology�

The grant will go toward a new machine that couples thermalgravimetric analysis with mass spectrometry to be housed in Auburn’s Center for Polymers and Advanced Composites

Chemical engineering associate professor earns Young Investigator Award

Tae-Sik Oh appreciates the chance to help solve real-world problems

For instance: What is the most efficient way to generate and store hydrogen?

How can levels of carbon monoxide and greenhouse gases in the atmosphere be reduced? What strategies can improve the recycling of lithium-ion batteries?

For his continued research contributions, Oh has received the Korean Institute of Chemical Engineers (KIChE) President Young Investigator Award for 2024

The KIChE President Young Investigator Award honors Korean and Korean American scientists and engineers who, while early in their research careers, demonstrate exceptional potential for leadership at the frontiers of chemical and related engineering fields

“It’s important that we, as researchers, explore ways to make a positive impact on society,” said Oh, an associate professor in the Department of Chemical Engineering, whose research interests include heterogeneous catalysis, CO2 capture and utilization, membrane reactors, electrochemical cells and filtration membranes “Energy storage is a big part of my research, but I would also like to contribute to filtering small particles from the air ”

Auburn University continues to take steps to address needs in Alabama and beyond

Its latest endeavor involves extending its support for the state’s capabilities in advanced manufacturing: the use of innovative techniques and technology to improve the productivity and efficiency of manufacturing

The Samuel Ginn College of Engineering will create an Analytical, Innovation and Manufacturing Laboratory to specifically foster workforce development, interdisciplinary collaboration and industry-relevant research and innovation aimed broadly at advanced manufacturing

The Auburn University Board of Trustees accepted the project’s initiation at its June 7 meeting, which will be funded by the state legislature with FY23 supplemental appropriations Facilities Management will now search for an architect to renovate 16,000 square feet beneath the Gavin Garden

“Auburn University stands as a premier institution in the country for advanced manufacturing due to its cutting-edge research, state-of-the-art facilities and unwavering commitment to advancing the field,” said Allan David, associate dean for research in the College of Engineering

John Stephen “Steve” Newton, ’75 civil engineering and ’76 environmental engineering, has been inducted into the Alabama Sports Officials Foundation Hall of Fame Class of 2024

Newton, 71, officiated football games for 46 years at various levels before retiring in 2021 After retiring, he joined the Fox 6 Sideline Show in Birmingham, where he provided a segment on high school rules He was also a referee state camp instructor with the Alabama High School Athletic Association (AHSAA)

Newton refereed several AHSAA state championship games and contests televised on ESPN He also officiated at the collegiate level in the Gulf South and Southland conferences In 2001, he served as a replacement official for the National Football League

Segun Osibodu, a doctoral student in the Department of Civil and Environmental Engineering, has been awarded a 2024-25 fellowship from the American Concrete Institute (ACI)

Osibodu will receive the Nicholas F Malloof Jr Georgia Chapter Fellowship, awarded to a graduate or undergraduate student pursuing an advanced degree in the concrete industry focusing on construction or building material sciences

According to Anton Schindler, director of the Highway Research Center (HRC), Osibodu is researching an HRC project for ALDOT to develop cost-effective, ultra-high-performance concrete for the transportation industry

Osibodu will receive $10,000 as a fellowship awardee for tuition, residence, books and materials

He will also be recognized in Concrete International magazine, the ACI Foundation website and receive

travel expenses and attendance fees to attend the ACI Concrete Conventions in Philadelphia in November and Toronto in April 2025

Osibodu will additionally receive assistance finding an industry mentor

“Segun is a hard-working student who is always willing to help and learn,” Schindler said

“This is a prestigious fellowship because students from all over the world apply, and awardees were selected after in-person interviews in New Orleans This fellowship is thus a testament to Segun’s exceptional technical and communication skills,” he added

In 2020, Emma Signor was making one of the most important decisions of her young life about where to attend college

She didn’t know much about Auburn University besides the men’s basketball team’s thrilling trip to the Final Four the previous year and its renowned aerospace engineering department, known for its cuttingedge research, distinguished faculty and outstanding academic facilities All it took was one visit to the Plains,

Aerospace

Matthew Hooks, a master’s student in the Department of Aerospace Engineering, was recently awarded a National Defense Science and Engineering Graduate (NDSEG) Fellowship sponsored by the Department of Defense

His fellowship proposal investigates how birds use surface textures on their feathers to improve aerodynamic performance during flapping flight

“Birds use their wings to make midflight adjustments effortlessly,” he said

and she was hooked Fast-forward to 2024, and Signor has cemented herself in the Auburn Family and earned hardware to relfect on her time at Auburn

She won:

• First place in the Southeastern Regional Student Conference hosted by the American Institute of Aeronautics and Astronautics (AIAA) for the Region II undergraduate category

• The Undergraduate of the Year award from the AIAA Greater Huntsville Section

• The Mark A Spencer Creative Mentorship Award from the Samuel

“However, we’re trying to understand if the surface texture on the wings improves aerodynamic performance ”

Hooks’ academic mentor, Vrishank Raghav, associate professor in aerospace engineering, handpicked the NDSEG scholar after learning of his academic aspirations in a personal

Emma Signor

Ginn College of Engineering along with her faculty advisor Joe Majdalani, the Hugh and Loeda Francis Chair of Excellence in the Department of Aerospace Engineering

statement to Auburn Hooks said he was interested in investigating birds’ flight patterns and developing software solutions for physical problems

“Matthew has demonstrated that he is passionate about bird flight and has previously conducted research in physics,” Raghav said

“As such, we explored avenues for him to get involved with fluid physics and aerodynamics of bird flight by using resources available at Auburn University The NDSEG fellowship is a testament to his perseverance and hard work I look forward to working with him on this exciting project,” he added

Students’ research ideas celebrated at college’s AUSome Science in 60 Seconds

Can waste materials be used to produce sustainable 3D-printed housing? Can sustainable fuel trim aircraft emissions in the fight against climate change and end our dependence on aviation petroleum? Can Auburn engineering students examine such research projects, then explain them on video in just 60 seconds?

Of course they can�

AUSome Science in 60 Seconds, a research-based competition in its second year presented by the Council of Engineering Graduate Students, tasked students to create videos and explain their respective projects in a minute or less

Winners were announced during an awards ceremony in April

Lucila Carias, a second-year graduate student in polymer and fiber engineering in the Department of Chemical Engineering, and Ayden Kemp, a senior double-majoring in aerospace engineering and biosystems engineering, earned highest marks among faculty judges — winning top honors in graduate student and undergraduate student categories

Listen to the #GINNING podcasts with Lucila Carias, Ayden Kemp and Michael Perez at eng.auburn.edu/ginning ↑ ↗

NCAT doctoral student awarded Asphalt Institute Foundation Kirk Scholarship

Anthony Brenes-Calderon, a doctoral student working with Auburn University’s National Center for Asphalt Technology (NCAT), is driving sustainable asphalt innovation forward with help from the Bill and Shireen Kirk Scholarship

The Kirk Scholarship, administered by the Asphalt Institute Foundation, is awarded annually to third or fourth-year undergraduate, graduate or doctoral students pursuing degrees in civil engineering, construction management or related programs

“Anthony is exceptionally well-organized, always prepared and very proactive,” said Adriana Vargas-Nordcbeck, associate research professor at NCAT and Brenes-Calderon’s advisor “He takes on every challenge with a positive attitude and has a genuine desire to produce something useful to our industry Anthony’s exceptional qualifications make him highly deserving of this scholarship

Auburn University’s Stormwater Research Facility (AU-SRF) has been tasked with creating design guidelines for erosion and sediment control practices used on highway construction sites to minimize stormwater pollution

Michael Perez, director of the AU-SRF and Brasfield & Gorrie associate professor in civil and environmental engineering, is the principal investigator on the three-year, $750,000 grant from the National Academy of Sciences’ National Cooperative Highway Research Program

He said the erosion and sediment control industry is currently driven by generally accepted but not scientifically evaluated design guidelines The resiliency or the

risk of failure of these practices is not defined clearly or is difficult to quantify with current design methods

“That’s the unique thing about our lab — we’re taking practices that have been used for a long time that nobody’s had the opportunity to actually investigate through controlled research experiments,” Perez said “We’re putting science behind it and trying to really understand how they perform and also provide improved designs with consideration to resiliency and risk of failure ”

Biosystems engineering dominates at ASABE International Meeting

Auburn University’s Department of Biosystems Engineering was hard to miss at the 2024 American Society of Agricultural and Biological Engineers Annual International Meeting held in Anaheim, California

Associate professor Brendan Higgins received the New Holland Young Researcher Award and Outstanding Associate Editor

Associate professor Simer Virk was recognized as an Outstanding Manuscript Reviewer

Kritika Maholtra, who recently earned both a master’s and doctorate from Auburn and her advisor, associate professor Jasmeet Lamba, received a Superior Paper Award in the Natural Resources and Environmental Systems division Lamba also earned first place in the Boyd-Scott Graduate Research Award along with recent master’s graduate Preetika Kaur

Graduate students Rachel Day, Noor Fatima, Vivian Usha and Raziyeh Jokar won second place in the Bioprocess startup competition

Master’s student Ayden Kemp, who recently earned a bachelor’s degree from Auburn in biosystems engineering, won first place in the K K Barnes Student Paper Award for undergraduate students

CSSE assistant professor part of cyber workforce development program

Akond Rahman, assistant professor in computer science and software engineering and an affiliated faculty member of the Auburn Cyber Research Center, is part of a multiinstitution workforce development program designed to provide students with extra cybersecurity training to prepare for Department of Defense (DOD)-related careers

The project, “A Virtual Institute for Cyber Research and Experiential Education,” will focus on meeting the cyber workforce needs of the U S Armed Services, DOD and Defense Industrial Base partners

Auburn University was awarded more than $120,000 for the first year of this two-year grant, funded via North Carolina A&T

“There is a tremendous gap in the cyber workforce,” Rahman said “This gap is not only within industry, but also in the government and federal sector We need to develop students to become professionals who have the necessary cybersecurity knowledge to defend and mitigate cyber attacks constantly coming from enemy states This project directly responds to the call of strengthening the nation’s cyber workforce strategy mentioned in the National Cybersecurity Strategy ”

Assistant professor in chemical engineering to explore frozen polymer solutions’ impact on oil pipelines

Polymer solutions are injected into petroleum products to enhance viscosity and increase oil recovery

However, polymer solutions are also subject to freezing upon extraction in bitterly cold environments, potentially bursting pipelines The result: disruptions and costly repairs

Jean-François Louf, assistant professor in chemical engineering, hopes to solve the problem

His study, “Freezing of polymer solution droplets,” will leverage a very well-defined geometry, a droplet, to develop a fundamental understanding of polymer solutions freezing He hopes to establish new guidelines for designing resilient polymer solutions – potentially preventing pipeline damage in sub-freezing climates

The project was awarded a two-year, $110,000 grant from the American Chemical Society Petroleum Research Fund

“Upon freezing, so many things can happen to a polymer chain; it can be trapped, pushed, stretched, etc�, which can alter the shape and volume of the final frozen object,” Louf said “You can do so many things with polymers and ice, so we started looking at freezing in a very simple geometry: the freezing of polymer solution droplets ”

Aleksandr Vinel, associate professor of industrial and systems engineering, has been awarded a Fulbright U S Scholar Program grant� Vinel will spend the spring 2025 semester teaching and collaborating at Bilkent University in Turkey

Fulbright U S Scholars are esteemed faculty, researchers, administrators and professionals who engage in teaching and research at institutions around the globe These scholars often participate in cutting-edge research, expand their professional networks and establish international collaborations that benefit their home institutions

“I already know several researchers in Turkey, but spending a semester there will allow me to build direct collaborations and travel throughout the country,” Vinel said “I believe this experience will not only advance my own professional and personal goals but also benefit Auburn University by bringing back valuable insights to share with students and colleagues

Stormwater Research Facility to develop portable stormwater treatment device

The Auburn University Stormwater Research Facility (AU-SRF) is partnering with Fagan Consulting LLC to design a portable, self-contained stormwater treatment device to treat stormwater runoff and protect the waters of Alabama and the U S

Fagan Consulting of Prattville is owned by Tracey and Barry Fagan, both ‘94 Auburn civil engineering graduates Barry Fagan, the project’s principal investigator, has worked closely with the Samuel Ginn College of Engineering for more than 20 years and was involved in developing the stormwater research facility in 2008

Michael Perez, director of the AU-SRF and Brasfield & Gorrie associate professor in the Department of Civil and Environmental Engineering, said the project is funded through a Small Business Innovation Research (SBIR) contract with the U S Department

of Transportation (USDOT) and Innovate Alabama, a public-private partnership that fosters new technologies and creates jobs

Auburn and Fagan have partnered through Phase I of the SBIR contract to develop a working prototype, nicknamed the “Tiger Shark,” that successfully removes pollutants from stormwater runoff Fagan and Auburn have recently been awarded a Phase II contract with the USDOT along with another supplemental grant from Innovate Alabama This phase involves developing a market-ready product within the next two years

Through August, the team has received awards totaling $975,000

HL Mando America Corp. recognized for support of Auburn mechanical engineering

HL Mando America Corp was recognized for its support of Auburn University, the Samuel Ginn College of Engineering and the Department of Mechanical Engineering

HL Mando’s commitment of $200,000 will support up to four graduate students participating in the accelerated bachelor’s and master’s degree program in mechanical engineering at Auburn with a special interest in automotive technologies

Based in Seoul, South Korea, HL Mando is an electric vehicle and autonomous driving solutions company specializing in core components key to vehicle safety It is a global leader in key enabling technologies for future mobility including redundancy concept and bywire technology and is strengthening eco-friendly vehicle solutions such as e-Drive and hydrogen fuel cell converters HL Mando America is HL Mando’s U S -based subsidiary with manufacturing operations in Opelika and Hogansville, Georgia

HL Mando America produces brake calipers, electric steering systems and suspension systems

HL Mando America executives, including CEO Bruce Kim and Head of Americas Region Yun Lee, presented a ceremonial check to Mario Eden, dean of engineering, in August during a reception

Professor emeritus in electrical and computer engineering earns IEEE award

Victor Nelson, professor emeritus in the Department of Electrical and Computer Engineering (ECE), was presented with the Institute of Electrical and Electronics Engineers

Educational Activities Board

Meritorious Achievement Award in Accreditation Activities at its annual conference in November

This award recognizes efforts to foster the maintenance and improvement of education through accreditation of engineering, engineering technology, computer science and applied science programs

Nelson began his tenure at Auburn in 1978 as an assistant professor in ECE and made his home on the Plains for 41 years before retiring in 2019 Even in retirement, the classroom remains a familiar place for Nelson as he continues to live in Auburn and serves as a visiting lecturer

“I literally haven’t been out of school since kindergarten,” Nelson said “I am currently, as my wife says, flunking retirement

“I love teaching� It’s been my favorite part about the whole thing, and that’s why I’ve continued to offer to help Since retiring, I’ve taught courses for electrical and computer engineering, but also taught in the computer science online program for a couple of years ”

CSSE assistant professor develops software used to identify leukemia cells

Haynes Heaton, an assistant professor in the Department of Computer Science and Software Engineering, has developed software which likely will change the standard of care for leukemia patients undergoing bone marrow transplants

By using his software, Heaton and fellow researchers hope to replace current diagnostics for post-bone marrow transplant relapse monitoring with a new technology, singlecell RNA sequencing Heaton and collaborators at the Fred Hutchinson Cancer Center at the University of Washington were awarded a $3 5 million grant from the National Institutes of Health for their project, “A Compass for Those With Relapsed Leukemia After Transplants

Single-cell RNA sequencing, created by biotechnology company 10x Genomics, is the new technology that has revolutionized how biology is studied in the modern era

This sequences the RNA from each cell — attaching a barcode of DNA on each sequence to indicate its origin

Using a beta-binomial iterative anomaly detection system, the software distinguishes donor bone marrow cells from user bone marrow cells among transplant recipients to within 05% Heaton said previous methods struggled to distinguish these cells to within 2%

CEE assistant professor researching temperature change’s impact on permafrost

How are changes in climate temperatures affecting permafrost and potentially infrastructure in Arctic and sub-Arctic regions?

Ali Khosravi, an assistant professor in the Department of Civil and Environmental Engineering, aims to answer this question through his recent National Science Foundation collaborative project with his twin brother, Mohammad Khosravi, an associate professor at Montana State University

Bart Prorok, a materials engineering program chair, and Paul Bartley, an assistant professor in horticulture at Auburn University, are co-PIs

Khosravi, who specializes in geotechnical engineering, seeks to improve understanding of how climate change impacts permafrost, enhancing predictions about permafrost thaw and its effects on infrastructure in Arctic and sub-Arctic regions

“When permafrost starts to thaw and becomes thinner due to changing climates, that’s going to cause more settlement within the soil, and any structures on top of that soil will begin to settle as well It could also affect the stability of coastal bluffs, leading to increased erosion rates and potential hazards for nearby communities and infrastructure,” he said

Researcher in ECE earns $307K grant to explore how helicopters can land after engine failure

Turbine helicopter engines fail once every 375,000 flight hours, according to the Federal Aviation Administration

Which control sequences and flight conditions make it possible for trained pilots to land in the event of engine failure? Which conditions do not?

Matthew Kirchner, assistant professor in electrical and computer engineering, will soon find out

Sponsored by the Office of Naval Research, his three-year, $307,000

Professor to explore microgravitational printing of semiconductors through NASA-supported parabolic flights

Can a small, laser ablation and sintering enabled (LASED) multi-material printer operate in microgravity?

Masoud Mahjouri-Samani, the Goldbold Associate Professor in the Department of Electrical and Computer Engineering, will find out next spring through a series of NASA-supported parabolic flights

The purpose: to prove the space functionality of a specially designed LASED multi-material printer capable of printing various materials, including semiconductors, metals and insulators that can be used to make electronics and semiconductor devices in gravity-challenged environments

“When it comes to space manufacturing, we need sustainable technology that is compatible

study, “Safe Flight Envelope Characterization and Emergency Landing with Reachability,” will create height-velocity diagrams for various helicopter models — guides for pilots to handle emergency landings and investigate reliable engine failure detection techniques

“It’s rewarding to have the opportunity to provide the Navy with

with the space environment,” said Mahjouri-Samani, founder of NanoPrintek, Inc , an Auburn-based startup that creates disruptive LASED multi-material printing technology for electronics, energy, biomedical and sensing applications “With printed electronics, the entire industry has been based on wet ink, but ink and liquids are not compatible with space or microgravity environments

“Our dry LASED multi-material printer also does not require postprocessing, a procedure that typically necessitates the use of ovens and/ or heaters, which have their own challenges in the space environment This supply chain-resilient and sustainable technology is an energy-

important information that could reduce the number of potential accidents and keep our pilots safe,” Kirchner said

Kirchner’s research will distinguish “safe regions” from “unsafe regions” when pilots undergo emergency landings

Safe regions are flight conditions where a control sequence can land the helicopter safety

Unsafe regions are conditions where no such control sequence is available, and a safe landing is impossible

Listen to the #GINNING podcasts with Matthew Kirchner and Brian Anderson at eng.auburn.edu/ginning

efficient and environmentally friendly process that will open a new realm of manufacturing in space I am proud that this technology was invented in my lab and doesn’t exist anywhere else worldwide,” he added

The project, “In Space Dry Printing Electronics and Semiconductor Devices,” recently received a $870,000 grant from NASA to pursue new manufacturing frontiers

The technology uses in-situ laser ablation to generate pure and dry nanoparticles from solid materials

Next, the nanoparticles are flown out of the printer nozzle and laser sintered in real time to print various multi-material electronics and semiconductor devices

Aerospace engineering

assistant professor to study flow-induced vibrations of 3D

Nek Sharan, assistant professor in the Department of Aerospace Engineering, seeks to understand how 3D geometries vibrate when exposed to fluid flows

Through his $300,000 National Science Foundation project titled “Three-dimensional Geometry Effects on Flow-induced Vibrations,” Sharan will conduct novel simulations to investigate 3D structural vibrations in fluid flows, establish links between specific shapes and vibration

CEE professor, two graduate students, receive Graduate School recognition

The Department of Civil and Environmental Engineering was well represented at the Auburn University Graduate School’s annual awards ceremony held April 26�

J Brian Anderson, professor, graduate program officer and associate chair for research, received an Auburn University Outstanding Graduate Mentor Award

Geotechnical graduate student Anthony Matthews received a Merriwether Fellowship from the Auburn University Graduate School for 2024-25 Geotechnical graduate student Mengwei Xuan received an Outstanding Doctoral Student Award

behaviors and develop methods to modify shapes for controlling those vibrations

“There is a lot of interest in drones delivering packages in urban communities, and those environments tend to be more chaotic because of buildings, cars and other disturbances,” Sharan said “These

Huaguo Zhou, the Elton Z and Lois G Huff Professor in the Department of Civil and Environmental Engineering, was recently awarded for his research on intoxicated drivers and engineering countermeasures to prevent wrong-way driving

Zhou, along with Chris Correia, professor and chair of the Department of Psychological Sciences in the College of Liberal Arts, received the supplemental category of the high-value research award from the California Department of Transportation for their study, “Developing Engineering Countermeasures for Wrong-Way Driving ”

“This recognition highlights the quality and significance of our study, which examined the cognitive abilities of severely intoxicated drivers and assessed various engineering countermeasures to prevent wrongway entry onto freeways,” Zhou said

The study involved 30 participants

aerial vehicles should be able to withstand severe winds and gusts So, what geometric modifications can be implemented to enhance their stability and robustness?”

Sharan’s research can improve the design of various structures that are susceptible to vibration during heavy winds/precipitation, such as buildings, bridges and construction cranes Additionally, the findings can be used to improve the design of energy harvesting technologies, which thrive on unstable vibrations to produce electricity from ocean waves

in a driving simulator, and each participant had three sessions: one for training, one while sober and one while intoxicated with a blood alcohol level of 0 12%

“Through a detailed analysis of driving inputs and eye-tracking data during sober and intoxicated sessions, we identified the most effective wrong-way warning methods and provided practical implementation guidance for state DOTs,” Zhou said

Zhou noted that while wrong-way crashes are rare, they often result in severe injuries or fatalities, with alcohol being a major factor The study found that impaired drivers accounted for almost 60% of all wrong-way driving crashes and nearly 77% of fatal wrong-way crashes

One of the nation’s leading experts in multiaxial fatigue and fracture mechanics has made the move to Auburn

Reza Molaei, new assistant professor of mechanical engineering and former director of the Metal Additive Manufacturing Lab at the University of Memphis, will continue his research into the relationship between process parameters, material structure and the mechanical properties of additively manufactured materials for Auburn University’s National Center for Manufacturing Excellence (NCAME)

“Dr Molaei is a brings a wealth of expertise in additive manufacturing (AM) related to enhancing the structural integrity and fatigue life of AM components,” said NCAME director Nima Shamsaei, the PhilpottWestPoint Stevens Distinguished Professor of mechanical engineering “He’s a very valuable addition to NCAME’s research team At the University of Memphis, he was involved in numerous projects that solidified his reputation in the field His reputation precedes him ”

The feeling, Molaei says, is mutual�

“I was drawn to Auburn in part due to Dr Shamsaei’s pioneering contributions to the understanding of fatigue, fracture and structural integrity of AM components, which are particularly inspiring,” he said

Jeff LaMondia, a professor in the Department of Civil and Environmental Engineering, is once again helping Alabama communities address distinctive local active transportation needs

LaMondia, in collaboration with Auburn University Extension, has worked with community members in Eutaw to install new crosswalks and restripe parking spots near Eutaw Primary School in Greene County

Through the Live Well Alabama Thriving Communities program, LaMondia teams with Katie Funderburk, Ruth Brock and Mitch Carter

Live Well Alabama Thriving Communities is supported by a five-year, $4 4 million grant from the Centers for Disease Control and Prevention to improve opportunities for safe and accessible physical activity by empowering community coalitions across the state to lead the charge for change

In Eutaw, LaMondia has been working with the community coalition for several months on a community active transportation action plan for short-, medium- and long-term improvements to help promote safe walking and bicycling within its city limits

The kudos for materials engineering doctoral student Vladislav Korostelev keep coming

Korostelev was named Auburn University’s 2023-24 Outstanding Doctoral Student for the Department of Materials Engineering He received the Graduate Research Scholars Program award for his work in ensuring the safe and widespread use of hydrogen as a clean energy alternative

“Hydrogen is essential for various applications from rockets to cars, but it’s colorless, odorless and highly flammable,” Korostelev said “That poses significant safety challenges Accurate hydrogen detection is essential to prevent disasters in everything from aerospace applications to everyday hydrogen-operated vehicles My research focuses on developing advanced hydrogen sensors by examining how hydrogen interacts with different materials ”

Awarded through the Alabama Established Program to Stimulate Competitive Research, a consortium of the state’s eight doctoral granting institutions, the Alabama Department of Commerce, the Alabama Commission on Higher Education and business leaders; the GRSP award provides Korostelev valuable resources to support his research

Listen to the #GINNING podcasts with Jeff LaMondia and Chris Roberts at eng.auburn.edu/ginning ↖ ↑

National defense applications in space are heating up� That’s good news in a certain sense, not so good in another

“There’s obviously no air in space, no standard means of venting heat from electronics like you might normally envision,” said Dan Harris, associate professor of mechanical engineering “We have to find new ways to dissipate that heat because as weapons systems in space, and even terrestrial and airborne environments, grow more sophisticated, traditional waste heat management scenarios are becoming obsolete That’s what this project aims to address ”

Harris is speaking of his recent $593,886 grant from defense and

Nearly 30 engineering graduate students were recognized at the annual Auburn University Graduate School awards ceremony in April in the Melton Student Center Ballroom

technology contractor L3-Harris, which will go toward research into mitigating the challenges of short duration bursts of high-power dissipation rates on emerging defense systems designs