6 minute read

Built to Perform, Engineered to Last

James Croll investigates how the installation of playing surfaces is just as critical as the choice of the surface itself when it comes to ensuring high quality playing performance and safety

In 2009 following a surge in demand for higher quality playing surfaces, world football governing body FIFA launched its FIFA Preferred Provider (FPP) initiative. The objectives of the initiative were twofold. In the first instance, it was launched to address the need for higher quality surfaces, not just in the product itself but in the installation process. It also however aimed to protect the interests of the consumers when

Advertisement

Tuff Turf installation at Nicolls School. purchasing pitches to ensure they met ambitious standards when it came to performance and safety. The initiative was well received by venues across all levels, from community through to elite level, due to the growing demand among consumers for the best possible surfaces.

One of the first turf suppliers to become FPP accredited was CCGrass. Based in Vietnam, the company owns the largest synthetic turf factory in the world and has been providing artificial grass for both sports and landscape purposes for more than 20 years. It produces more football fields than any other global artificial grass manufacturer. In fact, its daily production equals four full-size artificial football turf fields.

Since it became FPP accredited the company has seen its reputation grow significantly with its surfaces being adopted by the likes of Chelsea FC, Olympiacos CFP, and by a number of international tournaments, such as the FIFA U-15 World Cup, FIFA U-17 World Cup, FIFA U-20 World Cup, 2015 Summer Universiade (Gwangju), 2017 Summer Universiade (Taipei), and the Homeless World Cup. The company is one of only a select number of manufacturers worldwide that is a preferred producer for all FIFA surfaces and for that matter FIH and IRB surfaces.

WORLD CLASS SURFACES

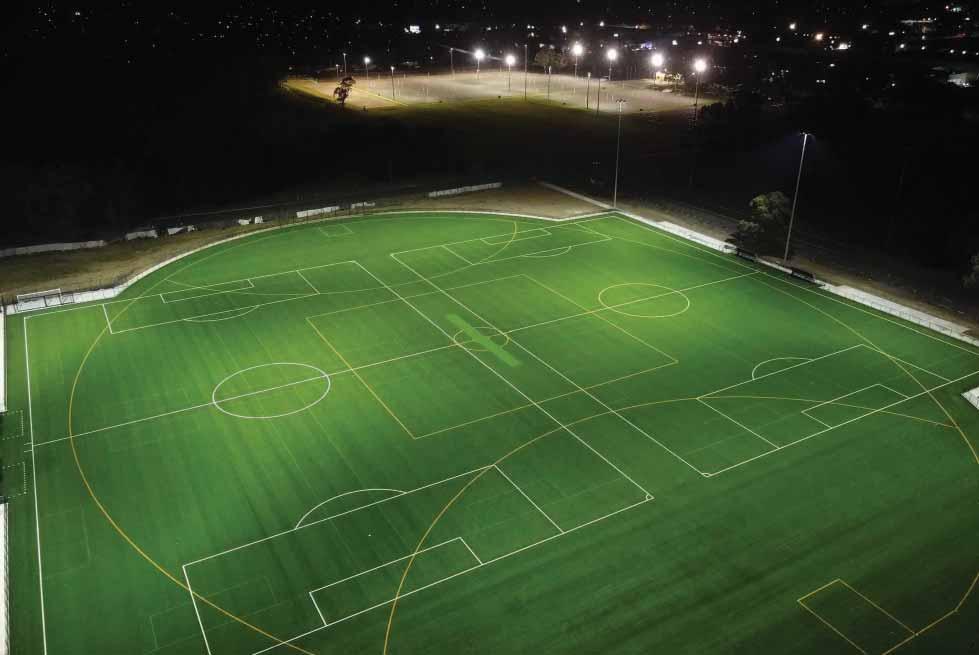

Tuff Turf installation at Melbourne’s Veneto Club.

The exclusive Australian supplier of CCGrass is Melbourne based Tuff Group. Since it was founded over a decade ago, Tuff Group has grown to become a significant player in the industry. Its success is due to its structure with the company having developed specialised divisions for the design, construction, management, and maintenance of sporting facilities.

Tuff Group Commercial Operations Manager, Travis Knight explains “as a team, we are driven to serve the community and this sees us collaborating with a variety of stakeholders, from State Government to local sporting clubs.

“As a measure to manage and control the quality of our projects, Tuff Group have invested significantly in our team to ensure we can provide in-house, end-to-end boutique project solutions. This means we have specialised sports facility designers and engineers, experienced and qualified project managers, some of the most experienced synthetic surfacing installers in the industry, and a dedicated in-house maintenance division.”

“As a company, we aim to create spaces that engage and uplift the communities in which they reside, and in doing so, Tuff Group are responsible for some of the highest quality FIFA, AFL, and FIH fields in Australia.

“Our exclusive arrangement with CCGrass and being one of the very few specialists able to provide FPP accredited surfaces has been crucial to this as it cements our reputation for delivering elite sports surface construction.”

Tuff Group recently celebrated the completion of their 25th certified FIFA Quality football field, a milestone achievement by any standard.

As a FIFA Preferred Provider (FPP), CCGrass’s artificial football turf systems excel in all FIFA tests, such as ball roll (48m), vertical ball rebound (0.6-0.85m), shock absorption (62%68%) and skin friction (0.35-0.75). To date, over 180 CCGrass artificial football turf systems have been tested and recognized to comply with FIFA standards while over 200 CCGrass football turf pitches have been received FIFA Quality Pro and FIFA Quality certifications. This rigorous testing is key to maintaining the high standards of quality and performance control that the initiative was set up to achieve.

An excellent example of these high standards is the recently completed Tuff Group synthetic FIFA field at Veneto Club in Bulleen, Victoria. The venue services both the local club, and the Melbourne Victory Women’s Team as a training field. The project provides a typical case study since, like all installation projects involving CCGrass, the most challenging stage was not laying the surface itself but constructing the base the turf was placed on. No matter what the quality of the surface itself, it fails if the base is not perfectly engineered and prepared.

Knight states “the installation stage generally takes up 20 to 25% of the cost and timeframe of a typical project.

“However, it is the most visible and highly scrutinised part of any job. CCGrass stands up to the highest scrutiny and correct and diligent installation ensures that surfaces not only look good but perform as expected under time and duress. Rushing the installation stage will quickly cause problems.”

The Veneto Club project was supported by the Victorian Government through the Northeast Link Project and Tuff Group were engaged as subcontractors through Mainbrace Construction. The company was tasked to provide the full package including earthworks, fencing, lighting, and surrounding landscape works.

Knight adds “the chosen product; Vmax50 combines two hard wearing yarns together.

“Through the resilient ‘V shape’ monofilament, excellent ball roll is achieved, while the split, fibrillated yarn holds the infill in place and as a result offers great performance characteristics. The combined yarns are densely tufted and show exceptional wear; over 150,000 cycles on the Lisport tester, remaining upright for longer than other turf systems.”

The extensive Lisport testing is interesting and key to the quality of the product. Lisport is a new generation of wear simulation machine which replicates realistic wear simulation of sport fields after years of usage. The wear pattern is characterised by the compressive stress of football studs (cleats) and the abrasive wear caused by flat-soled sports shoes. The testing is a major step forward in excellence, and it is already adopted by the industry as the most state of the art means of producing realistic simulated patterns.

Since completion the Vmax50 surface at Veneto has been so well received that the venue has seen a surge in participation, complemented by a significant rise in performance and safety with the local community engaging with the new world class facility. The surface has enabled the tier two Victorian Premier League Bulleen Lions, and all ages of football players to play on a daily basis for over 60 hours a week.

Tuff Group recently gained ISO9001 certification for Quality Management in all aspects of their operations in the design, construction, and maintenance, of elite sporting facilities. The certification completes a trilogy of ISO Certificates. This, along with a reputation for delivering quality projects as well as an increasing demand internationally for FFP accredited surfaces, has seen Tuff Group called on to install CCGrass turf internationally. To date, the company have completed FIFAgrade installations in five countries.

Knight concludes “we know that one of the things that sets us apart is that we have the internal resources to help our clients with everything from the concept phase, right through to installation and ongoing maintenance.

“The CCGrass product now enjoys a reputation that is second to none but correct installation is vital. Because of our experience, expertise, and unique structure with specialists in all key areas, we can help clients work out exactly what they need from a FIFA-grade surface and the best way to achieve it within budget.” James Croll manages client and partner relations for Australasian Leisure Management.

ENROL NOW